Page 1

ONIX8 and ONIX10

Installation Guide

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Install the Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Install the Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Route the Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect the Transducer Cable . . . . . . . . . . . . . . . . . . . . . . . . 17

Install Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connect the Control Head Power Cable . . . . . . . . . . . . . . . . 19

Test and Finish the Installation . . . . . . . . . . . . . . . . . . . . . . . 20

Power On the Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setup Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Set Up the Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Manage Your Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

NMEA Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Side Imaging Transducer Mounting Template . . . . . . . . . . . 41

Contact Humminbird . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

532187-1_A

Page 2

THANK YOU!

Thank you for choosing Humminbird®, the #1 name in marine electronics. Humminbird has built its reputation by designing and

anufacturing top-quality, thoroughly reliable marine equipment. Your Humminbird is designed for trouble-free use in even the harshest

m

marine environment. In the unlikely event that your Humminbird does require repairs, we offer an exclusive Service Policy. For complete

details, see the separate warranty card included with your unit. We encourage you to read this operations manual carefully in order to get

full benefit from all the features and applications of your Humminbird product.

Contact Humminbird Customer Service at 1-800-633-1468 or visit our Web site at humminbird.com.

WARNING! This device should not be used as a navigational aid to

prevent collision, grounding, boat damage, orpersonal injury. When

the boat is moving, water depth may change too quickly to allow

time for you to react. Always operate the boat at very slow speeds

if you suspect shallow water or submerged objects.

WARNING! The electronic chartin your Humminbird unit is an aid to

navigation designed to facilitate the use of authorized government

charts, not to replace them. Only official government charts and

notices to mariners contain all of the current information needed

for the safety of navigation, and the captain is responsible for their

prudent use.

WARNING! Compass Safe Distance: The control head must be

installed at least 4 feet (1.2 meters) from the compass or other

magnetic equipment on the boat. Also, see your compass

installation guide for details.

WARNING! Humminbird is not responsible for the loss of data files

(waypoints, routes, tracks, groups, recordings, etc.) that may occur

due to direct or indirect damageto the unit’s hardware or software.

It is important to back up your control head’s data files periodically.

Data files shouldalso be saved to your PC before restoring theunit’s

defaults or updating the software. See your Humminbird online

account at humminbird.com and the operations manual on your

Humminbird Manual CD for details.

NOTE: Some features discussed in this manual require a separate

purchase, and some features are only available on international

models. Every effort has been made to clearly identify those

features. Please read the manual carefully in order to understand

the full capabilities of your model.

NOTE: The illustrations in this manual may not look the same as

your product, but your unit will function in the same way.

NOTE: To purchase accessories or any additional equipment for

your control headconfiguration,go to humminbird.com or contact

Customer Service at 1-800-633-1468.

NOTE: The procedures and features described in this manual are

subject to change without notice. This manual was written in

English and may have been translated to another language.

Humminbird is not responsible for incorrect translations or

discrepancies between documents.

WARNING! Disassembly and repair of this electronic unit should

only be performed by authorized service personnel. Any

modification of the serial number or attempt to repair the original

equipment or accessories by unauthorized individuals will void the

warranty.

WARNING! This product contains chemicals known to the State of

California to cause cancer and/or reproductive harm.

WARNING! Do nottravel at high speed with the unit cover installed.

Remove the unit cover before traveling at speeds above 20 mph.

Page 3

Environmental Compliance Statement: It is the intention of Johnson

Outdoors Marine Electronics, Inc. to be a responsible corporate citizen,

operating in compliance with known and applicable environmental

regulations, and a good neighbor in the communities where we make or

sell our products.

WEEE Directive: EU Directive 2002/96/EC “Waste of Electrical and

Electronic Equipment Directive (WEEE)” impacts most distributors,sellers,

and manufacturers of consumer electronics in the European Union. The

WEEE Directive requires the producer of consumer electronics to take

responsibility for the management of waste from theirproducts to achieve

nvironmentally responsible disposal during the product life cycle.

e

WEEE compliance may not be required in your location for electrical &

electronic equipment (EEE), nor may it be required for EEE designed and

intended as fixed or temporary installation in transportationvehicles such

as automobiles, aircraft, and boats. In some European Union member

states, these vehicles are considered outside of the scope of the Directive,

and EEEfor those applications can be considered excluded fromthe WEEE

Directive requirement.

This symbol (WEEE wheelie bin) on product indicates the product

must not be disposed of with other household refuse. It must be

disposed of and collected for recycling and recovery of waste EEE.

Johnson Outdoors Marine Electronics, Inc. will mark all EEE

products inaccordance with the WEEE Directive.It is ourgoal to complyin

the collection, treatment, recovery, and environmentally sound disposal

of those products; however, these requirements do vary within European

Union member states. For more information about where you should

dispose of your waste equipment for recycling and recovery and/or your

European Union member state requirements, please contact your dealer

or distributor from which your product was purchased.

ATTENTION INTERNATIONAL CUSTOMERS: Products sold in the U.S.

are not intended for use in the international market. Humminbird

nternational units provide international features and are designed

i

to meet country and regional regulations. Languages, maps, time

zones, units of measurement, and warranty are examples of

features that are customized for Humminbird international units

urchased through our authorized international distributors.

p

To obtain a list of authorized international distributors, please visit

our Web site at humminbird.com or contact Customer Service at

(334) 687-6613.

ROHS Statement: Product designed and intended as a fixed installation

or part of a system in a vessel may be considered beyond the scope of

Directive 2002/95/EC of the European Parliament and of the Council of 27

January 2003 on the restriction of the use of certain hazardous

substances in electrical and electronic equipment.

360 Imaging™, Cross Touch™, Down Imaging®, DualBeam PLUS™, Humminbird®, i-Pilot®, ONIX™, and Side Imaging® are trademarked by or registered trademarks of

Johnson Outdoors Marine Electronics, Inc.

Adobe, Acrobat, Adobe PDF, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Navionics® Gold and Navionics® Classic Charts are trademarked by or registered trademarks of Navionics®.

C-MAP® by Jeppesen is a registered trademark of Jeppesen Marine, Inc.

NMEA 2000® is a registered trademark of the National Marine Electronics Association.

© 2013 Johnson Outdoors Marine Electronics, Inc. All rights reserved.

Page 4

Page 5

INTRODUCTION

This manual will guide you through the following installation requirements:

• Installing the Control Head

Installing the Transducer

•

• Connecting Cables to the Control Head

• Connecting the Control Head to Power

• Powering On the Control Head

• Configuring the Control Head and Basic System Setup

PREPARATION

Before you start the installation, please take a moment to familiarize yourself with the parts

list and supplies list. We also encourage you to read the instructions beforehand so that you

may understand the installation requirements.

NOTE: Product supplies and features are subject to change without notice.

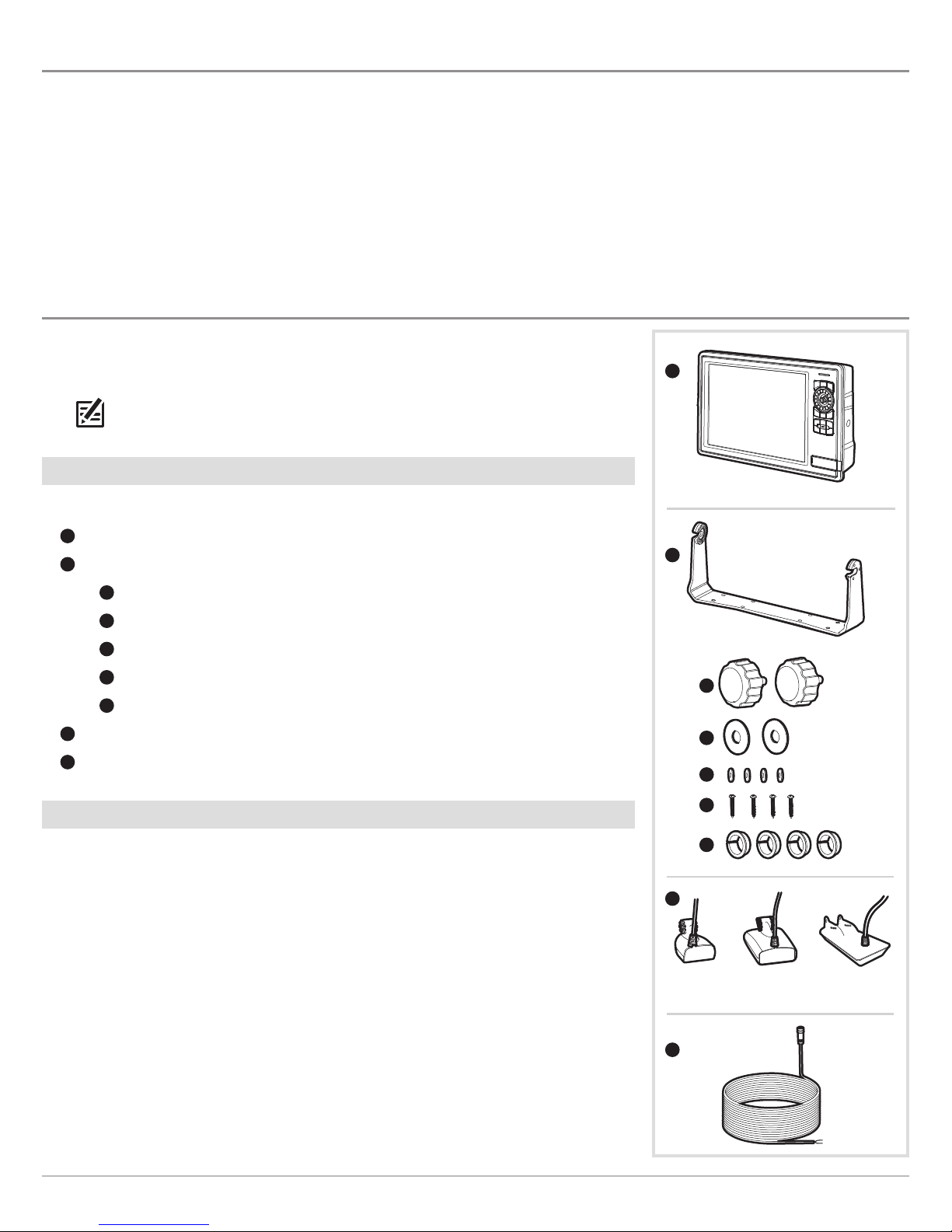

Parts

Your ONIX includes the following items:

A

A

ONIX control head with cover

B

gimbal mounting bracket with gimbal mounting hardware

C

(2) gimbal knobs

D

(2) urethane washers

E

(4) flat washers

F

(4) 1" - #10 wood screws

G

(4) 1" - split ring cable grommets

H

(1) transducer with transducer mounting hardware

I

power cable

Supplies

In addition to the parts supplied with your installation kit, you will need the following items:

• powered drill with various drill bits

• various hand tools, including

a socket wrench or flat blade screwdriver

ruler, straightedge, or measuring tape

level

12" plumb line (weighted string or monofilament line)

B

C

D

E

F

G

H

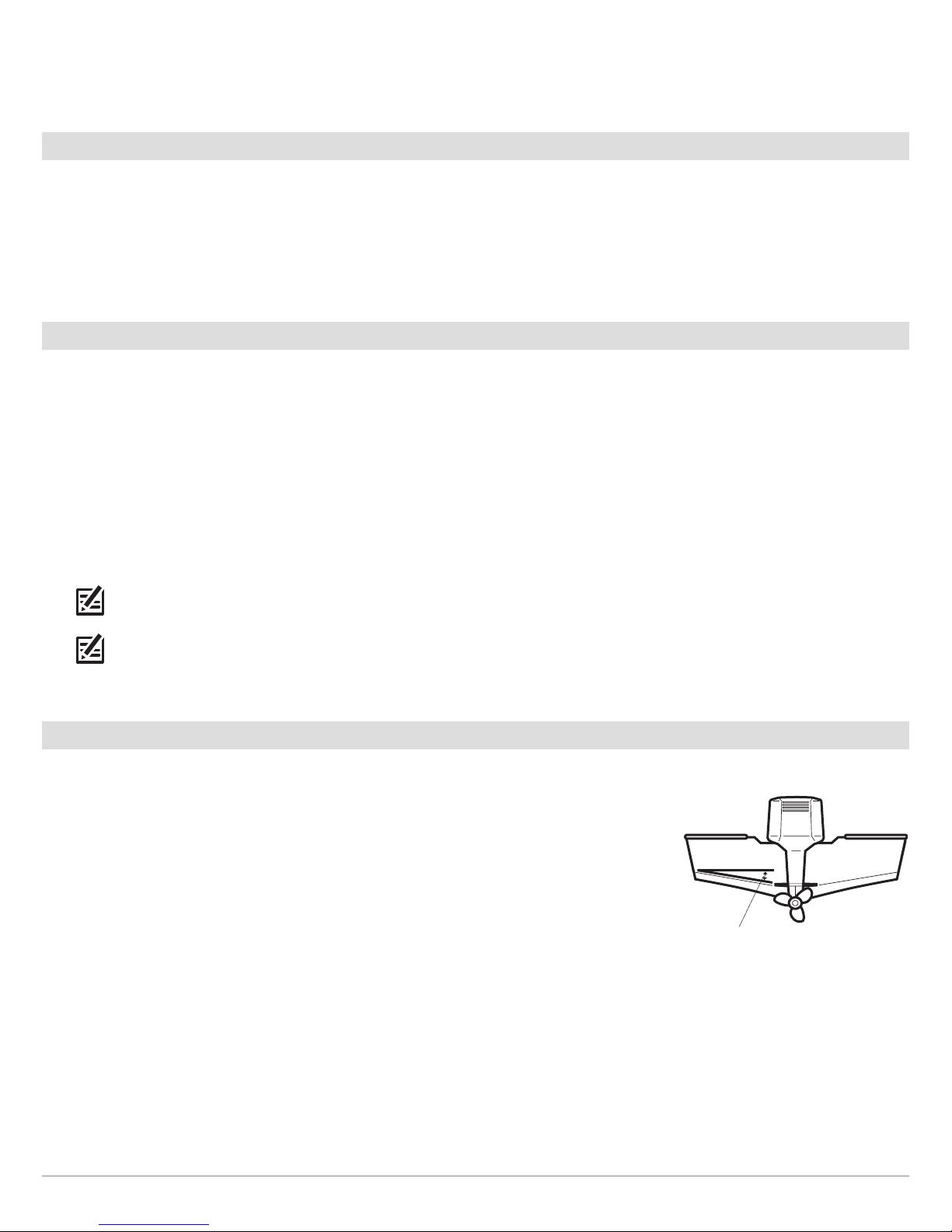

OR OR

DualBeam PLUS

transducers

Side Imaging

transducer

• marker or pencil

• safety glasses

• dust mask

• marine-grade silicone sealant

• dielectric grease (optional)

I

1

Introduction

Page 6

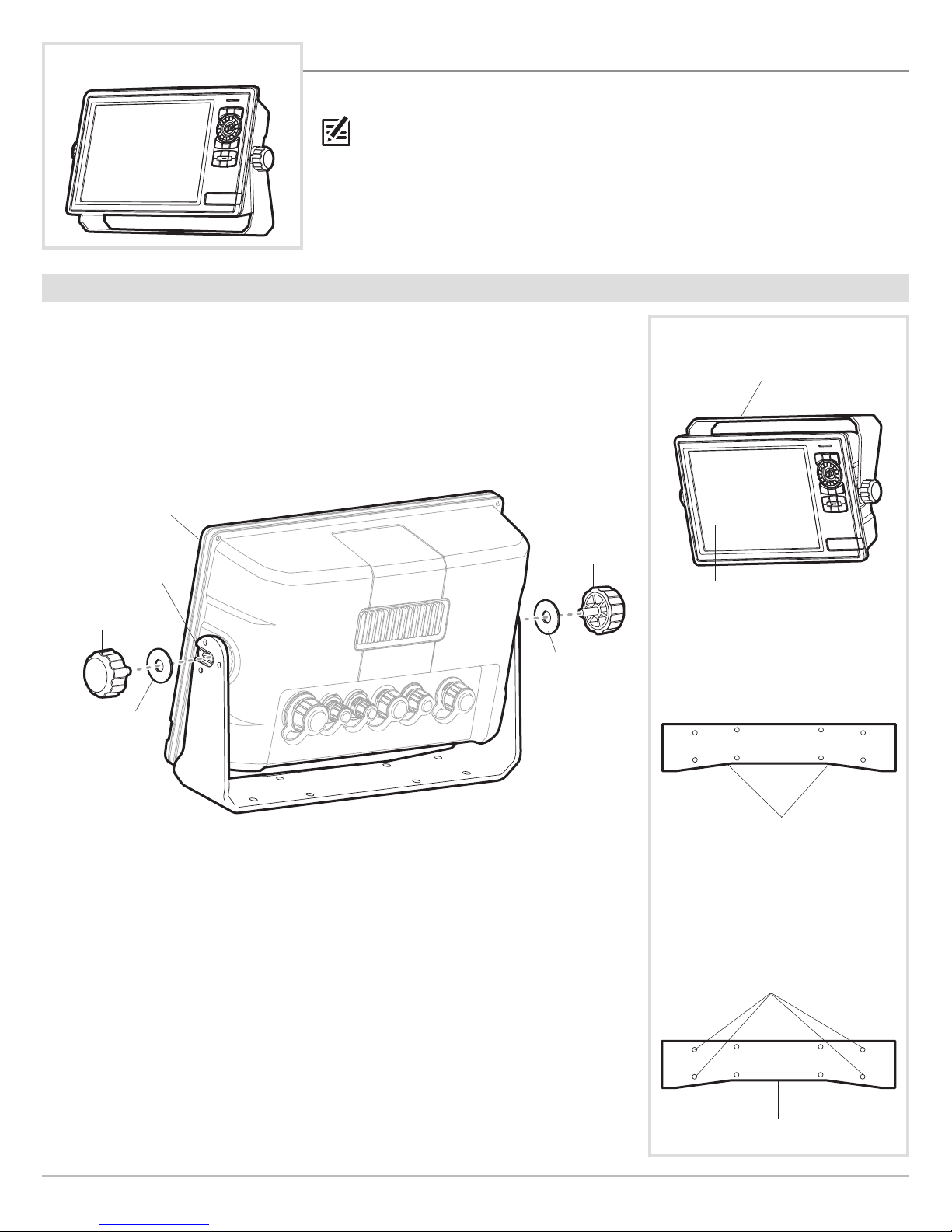

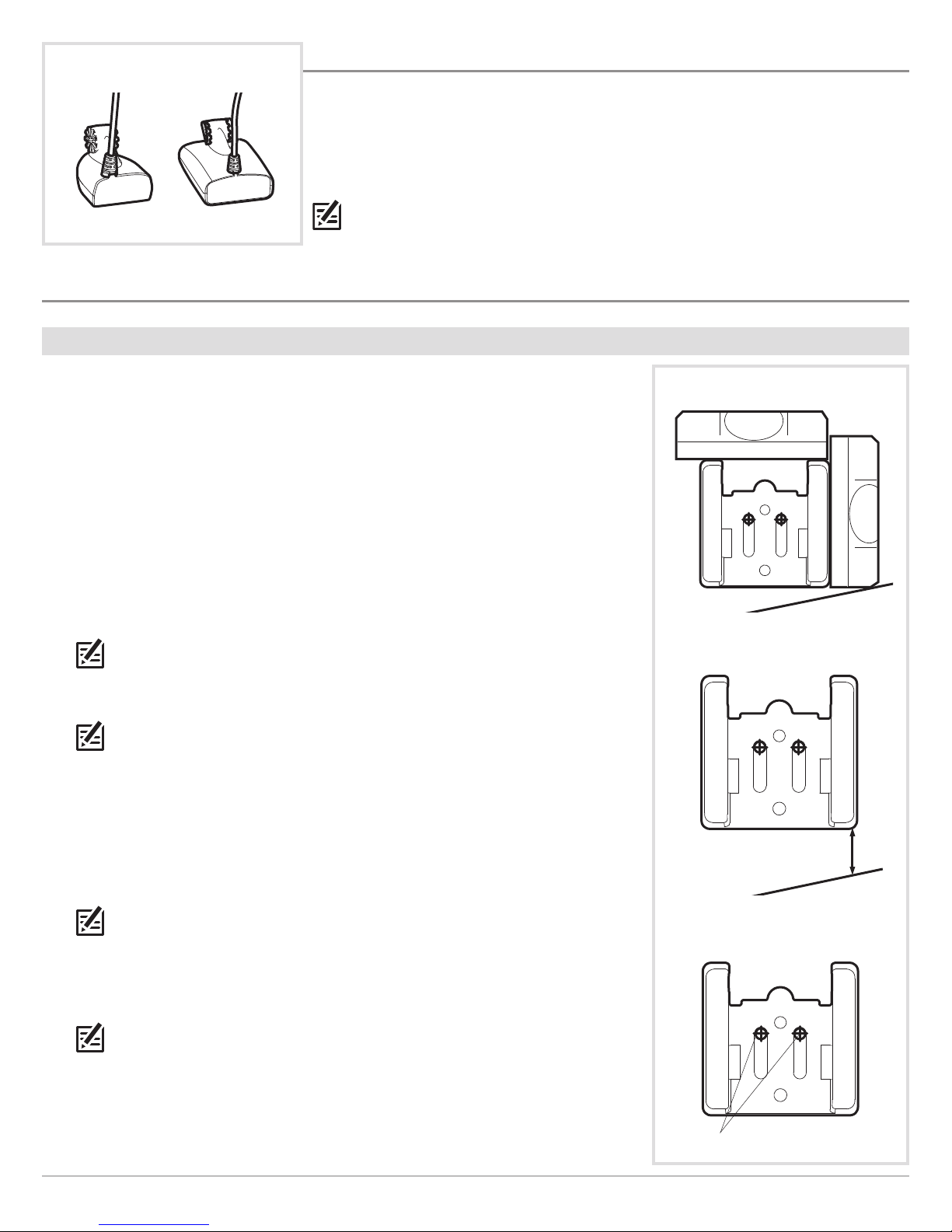

Traditional Gimbal Mount

INSTALL THE CONTROL HEAD

Use the instructions in the following section to gimbal mount the control head on your boat.

NOTE: If you prefer to mount theHumminbird control head overhead, follow theinstructions

in thissection and install the gimbal bracketabove the control head (see Install the Gimbal

Bracket: Overhead Mount). Overhead and/or thin panels may require additional hardware

(separate purchase required) to securely mount the control head.

|

1

Determine the Mounting Location

Pre-assemble the control head to plan the best mounting location.

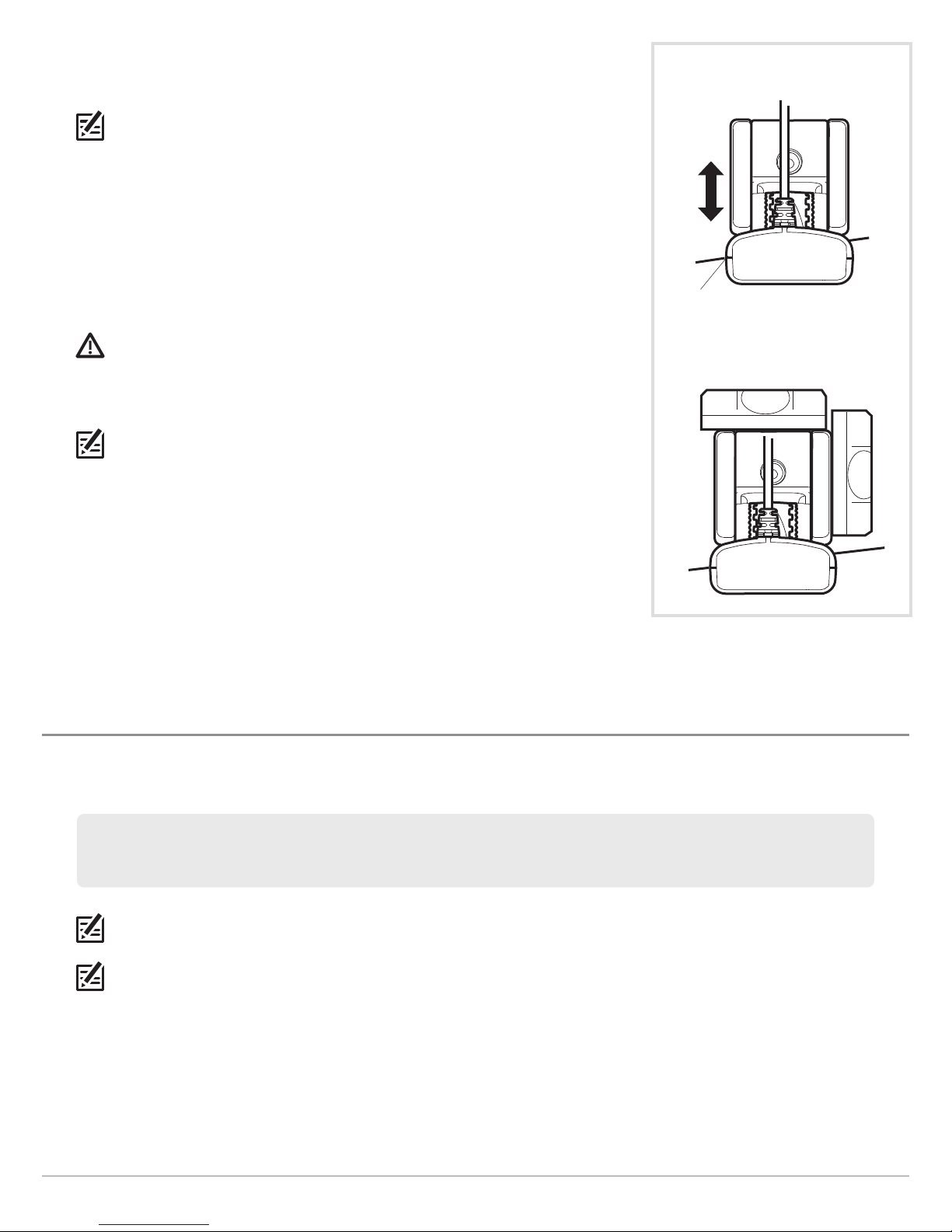

1. Place one urethane washer on one of the gimbal knobs. Thread the gimbal knob and

washer into the control head housing and tighten using 2-3 rotations. This will allow the

knob to stay in place while leaving adequate space to install the control head into the

bracket in the proceeding steps. See the illustration Assembling the Control Head.

2. Repeat step 1 for the other side of the control head.

Assembling the Control Head

front of

control head

Optional Gimbal Mount: Overhead

Flip bracket to the top

of the control head.

opening on

bracket arm

gimbal knob

urethane

washer

gimbal knob

urethane

washer

3. Install the control head into the arms of the bracket mount. Confirm the front of the

gimbal bracket is aligned with the front of the control head (see the illustration Gimbal

Bracket).

4. Hand-tighten the gimbal knobs to secure the control head to the gimbal bracket.

5. Place the assembled control head in various locations to determine the best mounting

location.

Consider the following when choosing a mounting location:

front of control head

Gimbal Bracket

Angled corners indicate

the front of the bracket.

Gimbal Bracket: Mounting Holes

outer screw holes

(recommended)

• The mounting area should allow sufficient room (approximately 2 to 4 inches [50.8

to 101.6 mm]) behind the chosen location to drill up to four 1-inch (25.4 mm) holes

for the cables to pass through.

• The mounting surface should be stable enough to protect the control head from

excessive wave shock and vibration.

• The mounting area should allow sufficient room so the control head can pivot

through its full tilt range.

Install the Control Head

front of bracket

2

Page 7

• The mounting location should allow for visibility during

operation, as well as easy installation and removal.

• You must have access, either above or below the

ounting surface, to pass the cables through to the

m

control head.

6. Test route the appropriate cables (power, accessory, etc.) to

the control head mounting location. If the cables are too

short for your application, extension cables are available.

Contact Customer Service for information.

|

3

Install the Gimbal Bracket

Refer to the section that applies to your installation and perform

he procedures to install the gimbal bracket.

t

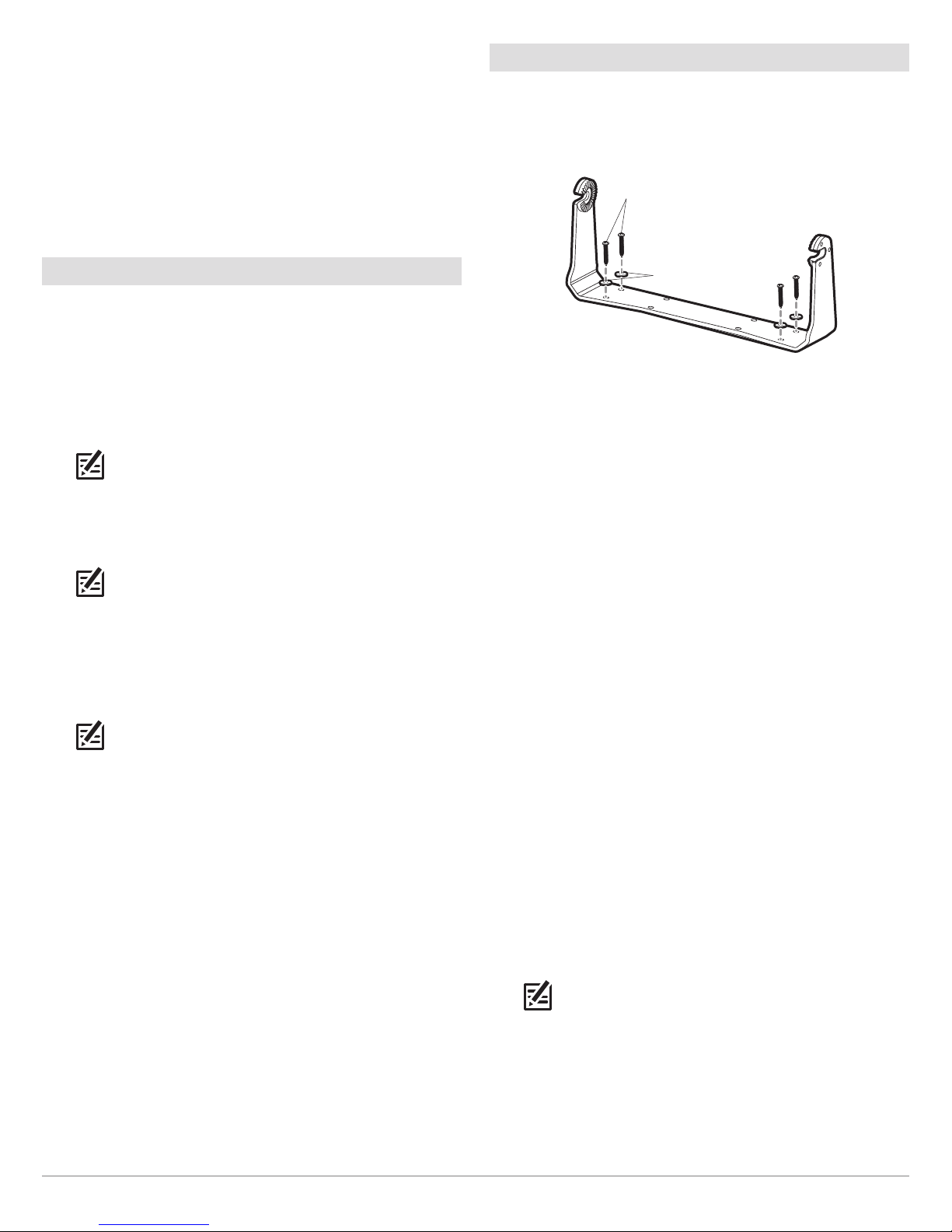

Installing the Gimbal Bracket

wood screws

|

2

Drill the Mounting Holes

1. Loosen the gimbal knobs and remove the control head from

the gimbal bracket.

2. Place the gimbal bracket in the chosen position on the

mounting surface and mark the four outer screw locations

using a pencil or center punch (see the illustration Gimbal

Bracket: Mounting Holes). Confirm the front of the bracket is

facing forward.

NOTE: The outer mounting holes are recommended.

You may use the interior mounting holes if necessary.

3. Set the gimbal bracket aside. Select an appropriately sized

drill bit for the #10 wood screws and drill four pilot screw

holes.

NOTE: When drilling holes in fiberglass, start with a

smaller bit and use progressively larger drill bits to

reduce the chance of chipping the outer coating.

4. Mark and drill a 1-inch (25.4 mm) diameter hole that will

allow you to run the cables close to the mounting bracket.

This hole should be centered approximately 2 to 4 inches

(50.8 to 101.6 mm) from the back of the control head.

NOTE: Your installation may require additional cable

holes. Mark and drill up to four holes according to the

instructions in step 4.

5. Insert the plastic cable grommets (included) to smooth the

hole edges and prevent damage to the cables.

flat washers

Traditional Mount

1. Place the bracket on the mounting surface aligned with the

drilled holes and fill the holes with marine-grade silicone

sealant.

2. Place one flat washer on each wood screw and install the

wood screws into the four mounting holes (see the

illustration Installing the Gimbal Bracket).

3. After all four screws are in place, tighten each screw until

secure.

4. Place the control head back onto the gimbal bracket (see

Determine the Mounting Location for details). Adjust the

control head viewing angle as needed and tighten the gimbal

knobs until the assembly is secured.

Overhead Mount

1. Place the bracket on the mounting surface aligned with the

drilled holes. Fill one hole with marine-grade silicone

sealant.

2. Place one flat washer on a wood screw and install the wood

screw into the hole (see the illustration Installing the Gimbal

Bracket). Repeat for the remaining three holes.

3. Tighten each screw until it is secure.

4. Place the control head back onto the gimbal bracket (see

Determine the Mounting Location for details). Adjust the

control head viewing angle as needed and tighten the gimbal

knobs until the assembly is secured.

NOTE: Overhead and/or thin panels may require

additional hardware (separate purchase required) to

securely mount the control head.

3

Install the Control Head

Page 8

INSTALL THE TRANSDUCER

Review the transducer installation options and the transducer mounting requirements in the following sections. Then proceed to the

nstallation section for your transducer type as follows:

i

• DualBeam PLUS Transducer

• Side Imaging Transducer

NOTE: If the included transducer will not work for your application, you can exchange it, NEW and UNASSEMBLED, with the transducer

mounting hardware included, for a transducer appropriate for your application. This offer applies to the DualBeam PLUS transducer only.

Visit humminbird.com for more information or call Customer Service at 1-800-633-1468.

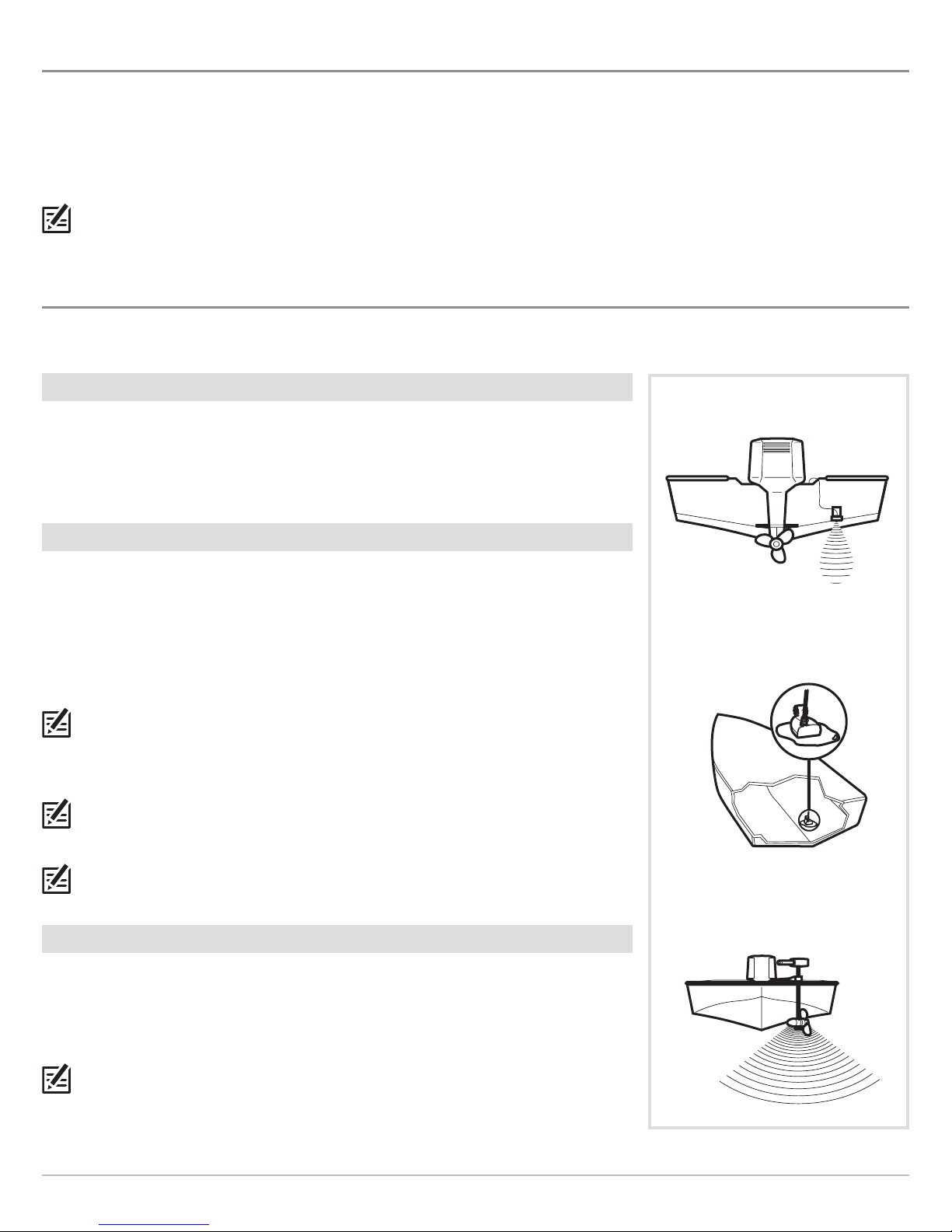

TRANSDUCER INSTALLATION OPTIONS

Your ONIX control head includes either a DualBeam PLUS transducer or a Side Imaging transducer. Depending on your transducer type,

there are different options available for mounting the transducer on the boat. Review the transducer installation options below.

Transom Transducer Installation

Available for the DualBeam PLUS transducer and the Side Imaging transducer.

Your transducer includes the transom mounting hardware. See Transom Transducer

Installation for additional information.

In-Hull Transducer Installation

Available for the DualBeam PLUS transducer only.

In-hull mounting generally produces good results in single thickness, fiberglass-hulled boats.

See DualBeam PLUS Inside the Hull Installation for installation instructions.

Humminbird cannot guarantee depth performance when transmitting and receiving through

the hull of the boat, since some signal loss occurs. The amount of loss depends on hull

construction and thickness, as well as the installation position and process.

NOTE: This installation requires slow-cure two-part epoxy. Do not use silicone or any other

soft adhesive to install the transducer, as this material reduces the sensitivity of the unit. Do

not use five-minute epoxy, as it has a tendency to cure before all the air bubbles can be

purged, thus reducing signal strength.

NOTE: The integral temperature probe will not work with in-hull mounting, so you may want

to consider purchasing a Temperature/Speed accessory, a Temp Sensor, or obtaining a

different transducer.

Transom Transducer Installation

In-Hull Transducer Installation

NOTE: In-hull mounting requires an installed and operational control head.

Trolling Motor Transducer Installation

Available for the DualBeam PLUS transducer and the Side Imaging transducer.

You can purchase a Trolling Motor Adapter kit that will allow you to mount the transducer on

the trolling motor. If you already have a trolling motor bracket, refer to the separate installation

instructions that are included with the bracket.

NOTE: Visit our Web site at humminbird.com for more information, or call Customer Service

at 1-800-633-1468 for details and pricing.

Install the Transducer

4

Trolling Motor Transducer Installation

Page 9

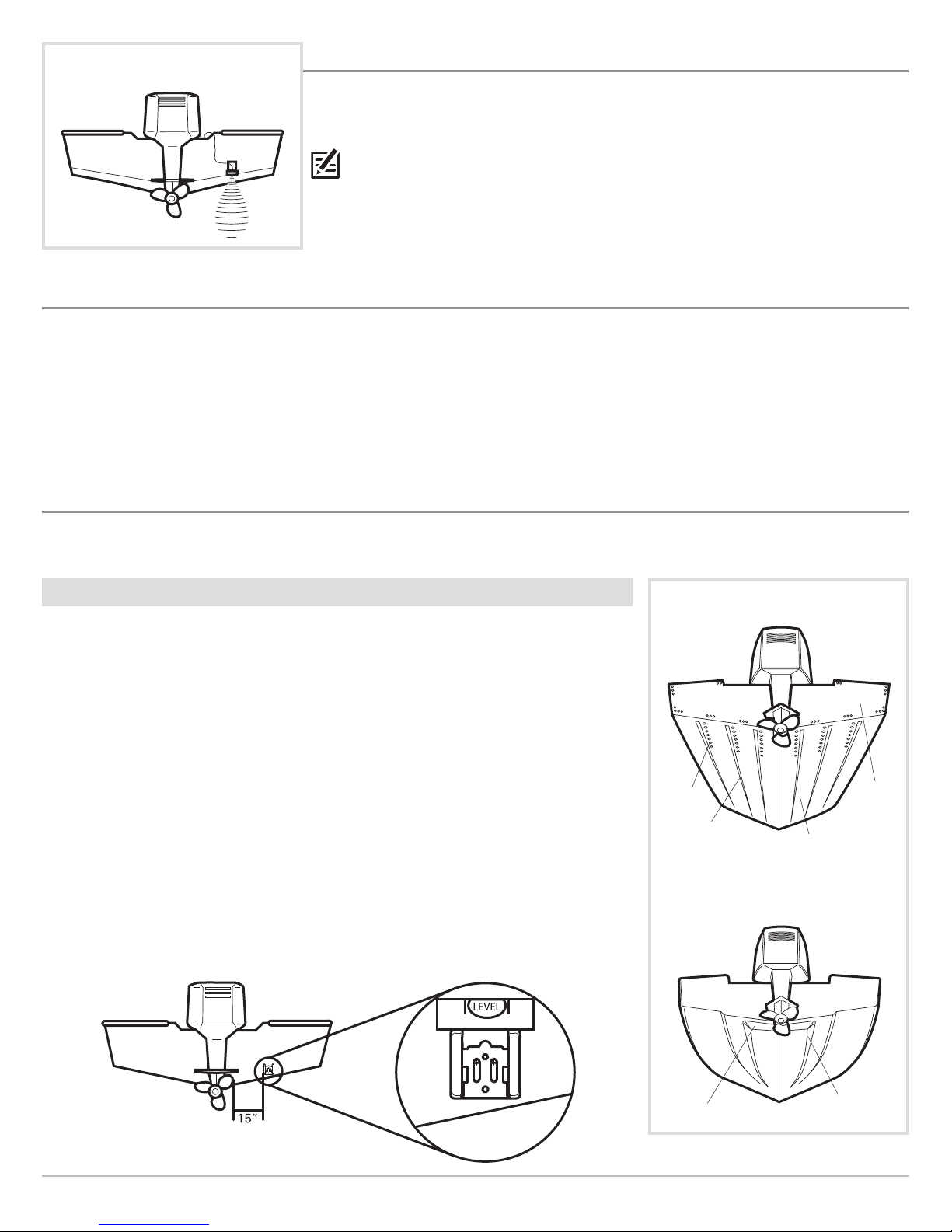

Installing theTransom Mount Transducer

TRANSOM TRANSDUCER INSTALLATION

Your ONIX control head includes transom mounting hardware for your DualBeam PLUS or

ide Imaging transducer. Review the mounting requirements in this section, and then proceed

S

to the section for your transducer type to begin the installation.

NOTE: Due to the wide variety of hulls, only general instructions are presented in this

installation guide. Each boat hull represents a unique set of requirements that should be

evaluated prior to installation. It is important to read the instructions completely and

understand the mounting guidelines before beginning installation.

INSTALLATION OVERVIEW

The transom mount installation provides the following:

• Least loss of signal since the transducer is mounted outside the hull.

• Allows adjustment of both running angle and depth after the transducer is mounted, which enables you to tune the installation

for best results.

• The mounting hardware is designed to pivot the transducer body out of the way should the boat strike debris in the water, or when

trailering.

TRANSOM TRANSDUCER MOUNTING REQUIREMENTS

You must first determine the best location on the transom to install the DualBeam PLUS or Side Imaging transducer. Review the

following information to help you identify the best mounting location.

Turbulence

It is very important to locate the transducer in an area that is relatively free of turbulent

water. Consider the following to find the best location with the least amount of turbulence:

Turbulence: As the boat moves through the water, turbulence is generated by the weight of

the boat and the thrust of the propeller(s) - either clockwise or counterclockwise. This turbulent water is normally confined to areas immediately aft of

ribs, strakes, or rows of rivets on the bottom of the boat, and in the immediate

area of the propeller(s).

Propellers: Clockwise propellers create more turbulence on the port side. On outboard or

inboard/outboard boats, it may be best to locate the transducer at least 15" to

the side of the propeller(s). The Side Imaging transducer has additional

mounting requirements. See the section Side Imaging Transducer Mounting

Requirements.

If the transom is behind the propeller(s), it may be impossible to find an area

clear from turbulence, and a different mounting technique or transducer type

should be considered.

Find a turbulence-free location that is not in line with trailer bunks or rollers.

Areas of Possible Turbulence

rivets

strakes

Stepped Hull

transom

hull

step

5

Transom Transducer Installation

rib

Page 10

Observation: The best way to locate turbulence-free water is to view the transom while the boat is moving. This method is

recommended if maximum high-speed operation is a high priority. If this is not possible, select a location on the

transom where the hull forward of this location is smooth, flat, and free of protrusions or ribs.

Boat Characteristics

Stepped Hulls: On boats with stepped hulls, it may be possible to mount the transducer on the step. Do not mount the transducer on

he transom behind a step to avoid popping the transducer out of the water at higher speeds. The transducer must

t

remain in the water for the control head to maintain the sonar signal.

Trailering: If you plan to trailer your boat, do not mount the transducer too close to trailer bunks or rollers to avoid moving or

damaging the transducer during loading and unloading of the boat.

High-Speed Operation

DualBeam PLUS Transducer

Traveling over 65 mph with the transducer in the water is not recommended for the 200/50 kHz DualBeam PLUS transom mount

transducer (XNT 14 74 T), as damage might occur. If high-speed operation is critical, you may want to consider using an inside the hull

transducer instead of this transom mount transducer (see DualBeam PLUS Inside the Hull Installation).

Side Imaging Transducer

Side Imaging sonar is best performed at boat speeds from 2 to 6 mph, and is not recommended for high-speed operation as gaps

between strips of information can appear. However, the transducer can support traditional 2D sonar and Down Imaging sonar at higher

speeds (up to 65 mph).

NOTE: The Side Imaging transducer has additional mounting requirements. See the section Side Imaging Transducer Mounting

Requirements.

NOTE: If you require a high-speed application (above 65 mph) and cannot find a transom mount location that will work for your

boat hull, a different mounting technique or transducer type should be considered. See the FAQ (Frequently Asked Questions)

section of our Web site at humminbird.com or call Customer Service at 1-800-633-1468.

Deadrise

DualBeam PLUS Transducer

The hydrodynamic shape of your transducer allows the beam elements to point straight down

without deadrise adjustment.

Side Imaging Transducer

In order for the side beams to be displayed accurately, the transducer must be mounted parallel

with the waterline. This positioning allows the beam elements to point straight down without

deadrise adjustment.

Deadrise

deadrise angle

Transom Transducer Installation

6

Page 11

ualBeam PLUS Transducers

D

INSTALL THE DUALBEAM PLUS TRANSDUCER

Use the procedures in the following sections to install the DualBeam PLUS transducer on

our boat. Your installation choices are as follows:

y

• Transom Mount

• Inside the Hull Mount

200/83 kHz

200/50 kHz

NOTE: Your transducer might not look exactly like the illustrations in this guide, but it will

mount in the same way.

DUALBEAM PLUS TRANSOM MOUNT INSTALLATION

|

1

Prepare the Mounting Location

In this procedure, you will determine the mounting location and drill two mounting holes,

using the transducer mounting bracket as a guide.

1. Confirm you have read the transducer mounting requirements under Transom

Transducer Mounting Requirements.

2. Make sure that the boat is level on the trailer, both from port to starboard and from

bow to stern, by placing your level on the deck of the boat, first in one direction, then in

the other.

3. Hold the mounting bracket against the transom of the boat in the location you have

selected. Align the bracket horizontally using the level. Make sure that the lower corner

of the bracket does not protrude past the bottom of the hull, and there is at least 1/4"

clearance between the bottom of the bracket and the bottom of the transom for

fiberglass boats, and 1/8" clearance for aluminum boats.

NOTE: If you have a flat-bottomed aluminum boat, some additional adjustment may be

needed to accommodate the rivets on the bottom of the boat (in other words, the gap

may need to be a little smaller than 1/8"). This will help you to avoid excessive turbulence

at high speeds.

Positioning the Mounting Bracket

Level

Level

Boat Hull Types Require

Different Mounting Positions

NOTE: If your propeller moves clockwise as the boat moves forward (as you're facing the

stern of the boat from behind), mount the transducer on the starboard side, and align

the bottom right corner of the mounting bracket with the bottom of the boat. If your

propeller moves counterclockwise as the boat moves forward (as you're facing the stern

of the boat from behind), mount the transducer on the port side, and align the bottom

left corner of the mounting bracket with the bottom of the boat.

4. Continue to hold the bracket on the transom of the boat, and use a pencil or marker to

mark where to drill the two mounting holes. Mark the drill holes near the top of each slot,

making sure that your mark is centered in the slot, as shown in the illustration.

NOTE: The third hole should not be drilled until the angle and height of the transducer is

finalized, which you will not do until a later procedure.

5. Make sure that the drill bit is perpendicular to the actual surface of the transom, NOT

parallel to the ground, before you drill. Using a 5/32" bit, drill the two holes only to a

depth of approximately 1".

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flaking the outer coating.

1/8" for aluminum

1/4" for fiberglass

Using the Mounting Bracket

to Mark the Initial Drill Holes

mark initial drill holes

7

Install the DualBeam PLUS Transducer

Page 12

|

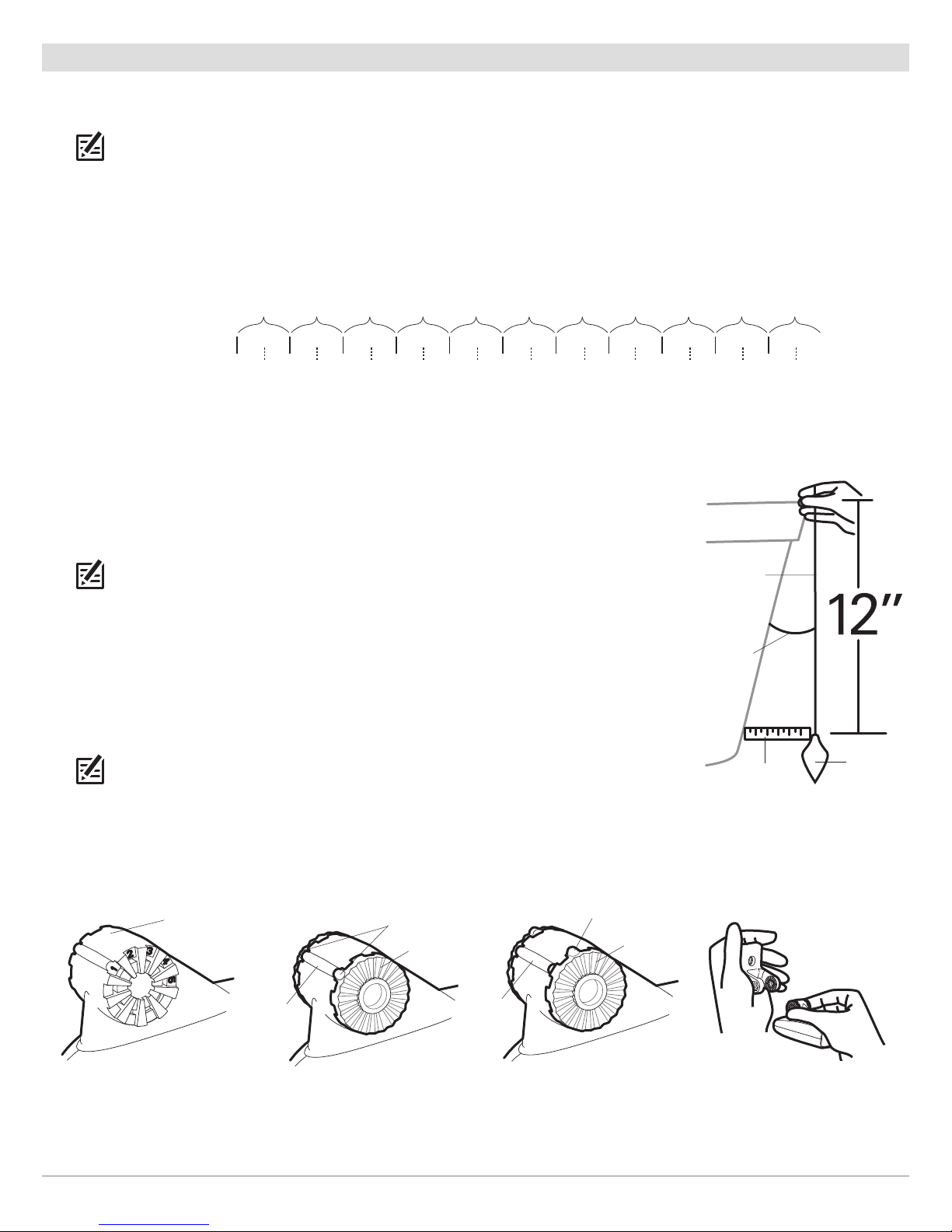

-

2 -1 012345678910 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Transom Angle (°)

Bead Alignment

Number

142531425

2

5 26 27

3

2

8 29 30

1

Measured Distance (x)

1

.1cm

1

/2“

0

.0 cm

0

“

2

.5 cm

1

“

4

.3 cm

1

5/8“

5

.9 cm

2

3/8“

7

.6 cm

3

“

9

.3cm

3

5/8“

1

1.1cm

4

3/8“

1

2.9cm

5

“

1

4.9cm

5

7/8“

1

6.9cm

6

5/8“

2

Assemble the Transducer and Initial Mounting

In this procedure, you will assemble the transducer using the hardware provided, then mount it and make adjustments to its position

ithout locking it in place.

w

NOTE: You will initially assemble the transducer and the pivot arm by matching the two ratchets to a numbered position on the

transducer knuckle. Further adjustments may be necessary.

Determine Your Transom Angle

1a. If you already know your transom angle, refer to the chart below for the initial position to use to set the ratchets. If your transom

is angled at 14 degrees (a common transom angle for many boats) use position 1 for the ratchets. In either case, go to step 2.

or...

1b. If you do not know your transom angle, measure it using a plumb line (weighted nylon string

or monofilament line) exactly 12 inches long. Hold the top of the plumb line against the top

of the transom with your finger, and wait until the line hangs straight down. Using a ruler,

measure the distance from the bottom of the plumb line to the back of the transom, then

use the chart. Refer to the illustration, Measuring the Transom Angle, for more information.

NOTE: It is important to take your measurement in the location shown in the Measuring the

Transom Angle illustration, from exactly 12 inches down from the top of the transom.

Assemble the Transducer

2. Place the two ratchets, one on either side of the transducer knuckle, so that the beads on

each ratchet line up with the desired position number on the knuckle. If you are setting the

ratchets at position 1, the beads on each ratchet will line up with the rib on the transducer

knuckle to form one continuous line on the assembly.

NOTE: The ratchets are keyed. Make sure that the square teeth on each ratchet face the square

teeth on the transducer knuckle, and the triangular teeth face outward.

3. Hold the ratchets on the transducer knuckle with one hand and fit the pivot arm over them

until it snaps into place with the other hand. Refer to the illustrations below.

Transducer Knuckle Positions

knuckle

Ratchets Placed in Position 1

beads

ratchet

Ratchets Placed in Position 2 Fitting the Mounting

bead

ratchet

Measuring the Transom Angle

plumb line

transom

angle in

degrees (°)

measured

distance (X)

weight

Bracket Over the Ratchet

rib at

position 1

Install the DualBeam PLUS Transducer

rib

8

Page 13

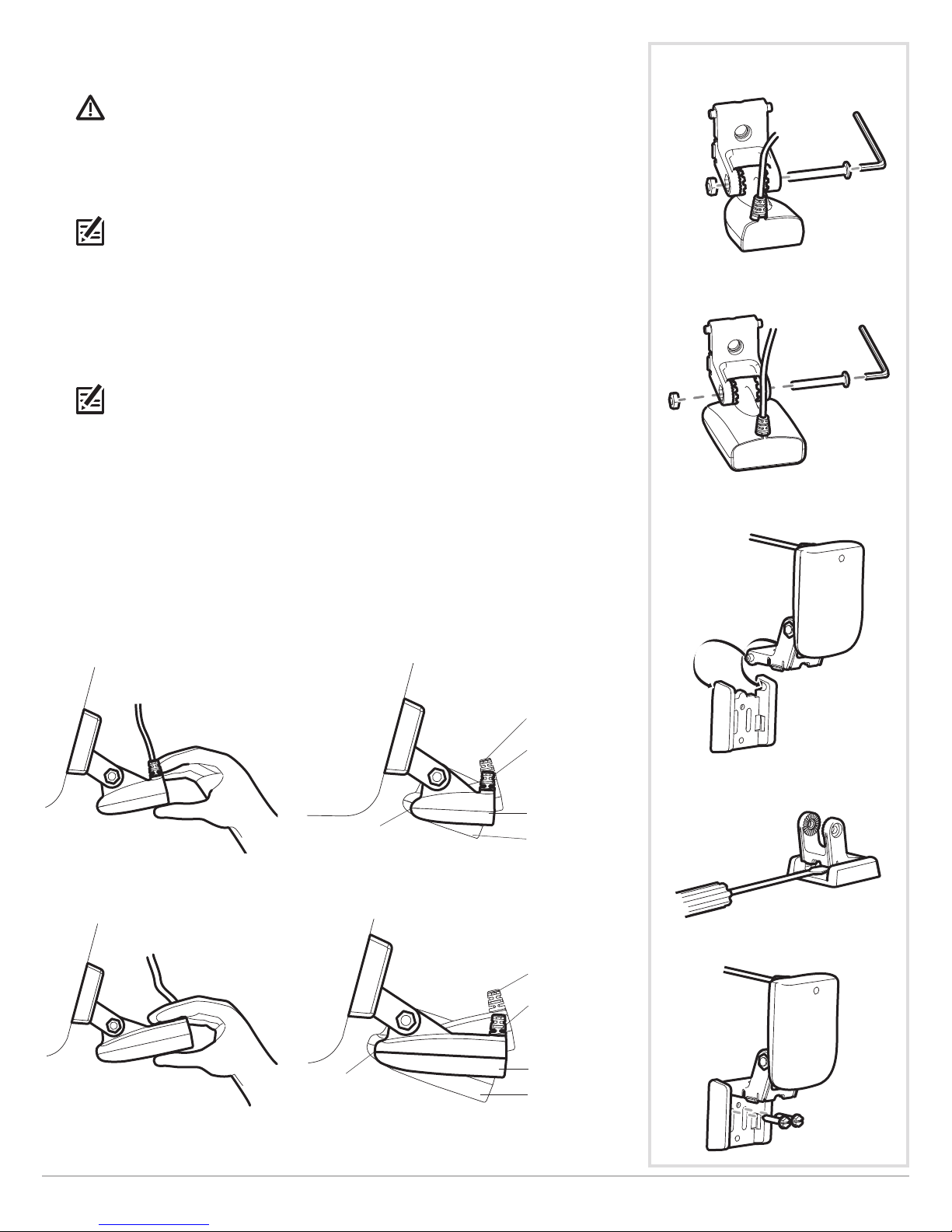

4. Put the pivot bolt through the assembly to hold it in position and loosely install the nut,

but do NOT tighten the nut at this time.

CAUTION! Do not use a high speed driver on this combination of fasteners. Hand-tighten

nly.

o

5. Insert the pivot arm assembly into the mounting bracket as shown in the illustration.

Do NOTsnapthe assemblyclosed,as you willneedto access the mountingbracketin the next

step.

NOTE: If the pivot assembly is snapped closed over the mounting bracket, use a flathead

screwdriver or similar tool to gently pry the assembly away from the mounting bracket.

Mount the Transducer

6. Align the mounting bracket transducer assembly with the drilled holes in the transom.

With a 5/16" socket driver, mount the assembly to the transom using the two #10 - 1"

long screws (provided). Hand-tighten only!

NOTE: Make sure that the mounting screws are snug, but do not fully tighten the

mounting screws at this time to allow the transducer assembly to slide for adjustment

purposes.

7. Snap the pivot arm down into place.

nserting the Pivot Bolt -

I

200/83 kHz Transducer

nserting the Pivot Bolt -

I

200/50 kHz Transducer

Make Adjustments to the Transducer Mounting Position

8. Adjust the initial angle of the transducer from back to front by rotating the transducer

until the side seam on the transducer is almost parallel with the bottom of the boat, one

click at a time in either direction. See the illustration Adjusting the Initial Transducer

Angle.

Adjusting the Initial Transducer Angle - 200/83 kHz Transducer

one click too high

correctly aligned

(transducer side

seam is aligned

with boat bottom)

trailing edge

leading edge

Adjusting the Initial Transducer Angle - 200/50 kHz Transducer

one click too low

Inserting the Pivot Arm Assembly

into the Mounting Bracket

Prying the Assembly Away from

the Mounting Bracket

Mounting the Assembly to the Transom

leading edge

one click too high

correctly aligned

(transducer side

seam is aligned

with boat bottom)

trailing edge

one click too low

9

Install the DualBeam PLUS Transducer

Page 14

9. Adjust the transducer assembly vertically, until the seam on the leading edge of the

transducer (the edge closest to the transom of the boat) is level and just slightly

below the hull.

NOTE: The transducer has a natural downward slant of 4 to 5 degrees from leading edge

(closest to the boat transom) to trailing edge (farthest away from the boat). Looking at

he back of the transducer, the seam should be slightly below the bottom of the hull.

t

10. Continue to adjust the transducer assembly until the bracket is also level from port to

starboard (horizontally level as you look at the transducer from behind the boat).

11. Mark the correct position on the transom by tracing the silhouette of the transducer

mounting bracket with a pencil or marker.

Adjusting the Transducer

Mounting Position

12. Tighten the pivot bolt, using the pivot screw and nut to lock the assembly. Hand-tighten

only!

CAUTION! Do not use a high speed driver on this combination of fasteners. Hand-tighten

only.

13. Snap open the assembly and hand-tighten the two mounting screws, then snap the

assembly closed.

NOTE: You will drill the third mounting hole and finalize the installation after you route

the cable and test and finish the installation in the following procedures.

Proceed to the section Route the Cables.

DUALBEAM PLUS INSIDE THE HULL INSTALLATION

seam aligned

with boat hull

Leveling the Mounting

Assembly Horizontally

Level

Level

In-hull mounting generally produces good results in single thickness, fiberglass-hulled boats. Humminbird cannot guarantee depth

performance when transmitting and receiving through the hull of the boat, since some signal loss occurs. The amount of loss depends

on hull construction and thickness, as well as the installation position and process.

This installation requires slow-cure two-part epoxy. Do not use silicone or any other soft adhesive to install the transducer, as this

material reduces the sensitivity of the unit. Do not use five-minute epoxy, as it has a tendency to cure before all the air bubbles

can be purged, thus reducing signal strength.

NOTE: The integral temperature probe will not work with in-hull mounting, so you may want to consider purchasing a

Temperature/Speed accessory, a Temp Sensor, or obtaining a different transducer.

NOTE: In-hull mounting requires an installed and operational control head.

Install the DualBeam PLUS Transducer

10

Page 15

|

1

Determine the Transducer Mounting Location

Decide where to install the transducer on the inside of the hull. Consider the following to find

the best location:

• Observe the outside of the boat hull to find the areas that are mostly free from turbulent

ater. Avoid ribs, strakes, and other protrusions, as these create turbulence (see Areas

w

of Possible Turbulence).

• As a general rule, the faster the boat can travel, the further aft and closer to the centerline

of the hull the transducer has to be located in order to remain in contact with the water

at high speeds (see Preferred Mounting Area).

Areas of Possible Turbulence

rivets

transom

|

Trial Installation

2

You will not be able to adjust the mounting after an inside the hull transducer is installed. It is

best, therefore, to perform a trial installation first that includes running the boat at various

speeds, in order to determine the best mounting area before permanently mounting the

transducer.

1. Plug the transducer into the control head, then power up the control head. If the unit

does not power-up, confirm that the cable connectors are properly connected and that

power is available.

2. Setup Guide: See the section Setup Guide for initial start up instructions. You must

complete the steps indicated in the Setup Guide before starting normal operation.

NOTE: After completing the Setup Guide, the control head will automatically enter normal

operation.

3. Press the HOME key .

4. Select a sonar view from the Favorites bar to display on-screen.

NOTE: See your control head operations manual for more information about selecting

views.

5. View the sonar signal at its best by holding the transducer over the side, immersed in the

water, so that it is pointing straight down over a known flat bottom. Use the display to

benchmark against the sonar signal that will be detected once the transducer is placed

in the hull.

strakes

Preferred Mounting Area

In-Hull Transducer Installation -

200/83 kHz Transducer

hull

6. Place the transducer body face down at the identified mounting location inside the hull,

with the pointed end towards the bow (see In-Hull Transducer Installation).

7. Fill the hull with enough water to submerge the transducer body. Use a sand-filled bag or

other heavy object to hold the transducer in position. The transducer cannot transmit

through air, and the water purges any air from between the transducer and the hull, and

fills any voids in the coarse fiberglass surface.

8. View the sonar signal on the display and compare against what was observed in Step 5,

making sure that the boat is in the same location as it was during your observations in

Step 5. If the results are comparable, move on to Step 9. Otherwise, locate a new position

in the hull and repeat Steps 6 through 8.

9. Run the boat at various speeds and water depths while observing the screen on the

control head. If depth performance is required, test the transducer in water at the desired

depth. If the performance is acceptable, move on to Step 10. If the performance is not

acceptable, repeat Steps 6 through 9.

10. Once you have determined the best mounting location using the above steps, mark the

position of the transducer.

In-Hull Transducer Installation -

200/50 kHz Transducer

11

Install the DualBeam PLUS Transducer

Page 16

|

3

Route the Cable

1. Once the mounting location is determined and you have marked the position of the

transducer, route the cable from the transducer to the control head.

|

Permanently Mount the Transducer

4

. Make sure the position of the transducer is marked.

1

2. You may have to disconnect the cable to the control head and reconnect it at the end of

this procedure.

3. Remove the water from inside the hull and thoroughly dry the mounting surface. If the

surface is excessively rough, it may be necessary to sand the area to provide a smooth

mounting surface.

4. Mix an ample quantity of two-part slow cure epoxy slowly and thoroughly. Avoid trapping

air bubbles.

5. Coat the face of the transducer and the inside of the hull with epoxy (see In-Hull

Transducer Installation and Applying Epoxy to the Transducer).

6. Press the transducer into place with a slight twisting motion to purge any trapped air

from underneath, keeping the pointed end of the transducer body pointed forward,

towards the bow (see Installing the Transducer).

NOTE: Proper operation requires the pointed end of the transducer body to face towards

the bow.

Applying Epoxy to the

200/83 kHz Transducer

Applying Epoxy to the

200/50 kHz Transducer

7. Weight the transducer so that it will not move while the epoxy is curing.

NOTE: When the epoxy cures, no water is necessary inside the hull.

NOTE: Neither water, spilled gasoline, nor oil will affect the performance of the

transducer.

Proceed to the section Connect the Transducer Cable.

Installing the 200/83 kHz Transducer

Installing the 200/50 kHz Transducer

Install the DualBeam PLUS Transducer

12

Page 17

Side Imaging Transducer

INSTALL THE SIDE IMAGING TRANSDUCER

Use the procedures in this section to install the Side Imaging transducer on your boat. The

ransducer mounting template is provided at the end of this manual (see Side Imaging

t

Transducer Mounting Template).

OTE: See the Transom Transducer Mounting Requirements before beginning the

N

installation.

SIDE IMAGING TRANSDUCER MOUNTING REQUIREMENTS

Side Imaging Requirements

In addition to the requirements shown in the Transom Transducer

Mounting Requirements section, the Side Imaging transducer has

some special requirements because of its side viewing

capabilities:

• The Side Imaging transducer must NOT have anything

obstructing the ‘view’ of the side looking beams. For

example, nothing can be in the line of sight of these beams

(not a hull, motor, additional transducer, etc.). See the

illustrations below.

NOTE: You may need to tilt the motor up and out of

the way when using the side looking beams.

Transducer Mount Position: Unobstructed View

The jack plate gives the transducer safe distance from the motor

and turbulence. The SideImaging beams havea clear view side-to-side.

Multiple Transducer Installation (optional)

If you have installed or are planning to install a second transducer

in addition to this Side Imaging transducer, you must determine

which transducer will be used as the primary source for traditional

2D sonar when operating the boat at high speeds (up to 65 mph).

There are special mounting requirements for the Side Imaging

transducer depending on if it will be in the water or out of the water

during high-speed operation.

Primary Source - Side Imaging Transducer

If you plan to use the Side Imaging transducer as the primary

source for traditional 2D sonar and Down Imaging sonar during

high-speed operation (up to 65 mph), mount the transducer at

least 15" from the center of the engine with an unobstructed view

on both sides of the transducer (see Side Imaging Requirements

and the illustration Transducer Mount Position: Unobstructed

View).

Primary Source - Secondary Transducer

If you plan to use a second transducer as the primary source for

traditional 2D sonar only during high-speed operation (up to 65

mph), mount the Side Imaging transducer where it will not be in

direct water flow. For this installation, you may install the

transducer less than 15" from the center of the engine. Review

the following mounting alternatives:

Transducer Mount Position: Obstructed View

The transducer is tooclose to motor turbulence,and the Side Imaging view

is blocked by the motor. The view cannot extend from side-to-side.

• The Side Imaging transducer can be mounted on or near the

centerline of the boat and higher on the transom to prevent

direct contact with water flow under the boat at high speeds.

Confirm that the transducer is low enough on the transom to

be submerged in the water at low speeds. It should not come

into contact with the motor when it is raised or lowered.

NOTE: Mounting the Side Imaging transducer higher

on the transom should not create turbulence that

affects the engine’s water intakes. Contact your

dealer to verify your individual boat setup.

• The Side Imaging transducer can be mounted to the jack

plate. Contact your dealer for more information about the

brands of jack plates that will accommodate this type of

installation.

NOTE: A Y-cable or transducer switch may be required

to connect the Side Imaging transducer to the second

transducer. The Y-cable and transducer switch require

separate purchases.

13

Install the Side Imaging Transducer

Page 18

Deadrise

In order for the side beams to be displayed accurately, the transducer must be mounted

•

parallel with the waterline. This positioning allows the beam elements to point straight

own without deadrise adjustment (see the illustration Deadrise).

d

NOTE: Rough seas, high speed, and air bubbles can also affect the reading of the Side

Imaging transducer.

eadrise

D

|

1

Mount the Transducer Bracket

In this procedure you will mount the bracket, using the mounting template provided as a

guide. This template allows you to mark where the mounting holes should be drilled. See

Side Imaging Transducer Mounting Template at the end of this manual.

1. Confirm you have read the transducer mounting requirements under Transom

Transducer Mounting Requirements and Side Imaging Transducer Mounting

Requirements.

2. Cut out the transducer mounting template from the back of this manual (see Side

Imaging Transducer Mounting Template). Match the mounting bracket screw slots to

the template screw slots.

3. Hold the template on the transom of the boat in the location you have selected. Align

the template vertically, matching the lower edge of the transom with the bottom corner

of the template.

NOTE: If your propeller moves clockwise as the boat moves forward (as you're facing

the stern of the boat from behind), mount the transducer on the starboard side, and

use the bottom left corner of the template. If your propeller moves counter-clockwise

as the boat moves forward (as you're facing the stern of the boat from behind), mount

the transducer on the port side, and use the bottom right corner of the template.

4. Continue to hold the template on the transom of the boat, and use a pencil or punch

to mark where to drill the three mounting holes shown on the template.

5. Using a 5/32" bit, drill the three holes only to a depth of approximately 1".

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flaking the outer coating.

deadrise angle

Attaching the Bracket

Inserting the Square Nuts

square

nuts

6. Use a marine-grade silicone sealant to fill the drilled holes, especially if the holes

penetrated the transom wall.

7. Align the metal mounting bracket with the mounting holes. The center slot of your

mounting bracket should be above the two outer slots. Insert the three 1" flat head

wood screws into the drilled holes, but do not completely tighten.

NOTE: The mounting bracket and all other hardware supplied is top quality stainless

steel for maximum strength and corrosion protection.

|

2

Assemble the Transducer

In this procedure you will attach the pivot to the transducer using the hardware provided.

1. Attach the pivot to the transducer body as shown in the illustrations using the square

nuts, toothed washers, and two 1/4–20 x 5/8" machine screws. The square nuts will be

prevented from rotating by the pocket in the back of the pivot. The toothed washers

must fit on the inside of the transducer ears, between the pivot and the ears.

NOTE: An Allen wrench is provided which fits all of the 1/4–20 screws, but do not fully

tighten the screws at this time.

Install the Side Imaging Transducer

14

toothed

washer

transducer

ear

Attaching the Pivot

pivot

machine

screw

Page 19

|

3

Attach the Transducer to the Bracket

1. Slide the assembled transducer into the metal bracket from the bottom, aligning the

large hole at the top of the bracket with the hole in the pivot.

2. Insert the headed pin through the pivot holes in the bracket and pivot. The headed pin

can be inserted from either side of the bracket.

3. Place the nylon washer over the opposite end of the headed pin. Place the stainless

washer over the 1/4–20 x 5/8" screw threads, then insert into the opposite end of the

headed pin and finger tighten only. The screw has a thread locking compound on the

threads to prevent loosening, and should NOT be fully tightened until all adjustments

are made.

|

4

Adjust the Running Position

The running position of the transducer is now completely adjustable. Subsequent adjustment

may be necessary to tweak the installation after high speed testing. The mounting bracket

allows height and tilt adjustment; the machine screws allow angle adjustment.

NOTE: Side Imaging is best performed at boat speeds from 2 to 6 mph. If the boat is

stationary, the same information is displayed over and over. If the boat is moving too

quickly, there will be gaps between the strips of information. The best boat speed to use

will depend on the side range selected. Slower speeds are good for longer ranges, while

faster speeds can be used at shorter ranges.

1. Adjust the angle of the transducer body first, so it is parallel with the hull of the boat.

Fully tighten the two machine screws using the supplied Allen wrench. Access the

machine screws through the lower holes in the side of the mounting bracket.

Attaching the Transducer

to the Bracket

allen wrench

nylon washer

(fits over headedpin)

screw

stainless washer

(fits over screwthreads)

Tightening the Machine Screws

allen wrench

metal bracket

headed pin

pivot

2. Next, adjust the height of the assembly so the face of the transducer is 1/8" to 1/4"

beneath the bottom of the transom, and fully tighten the three mounting screws. To

access the mounting screws, pivot the transducer assembly up into the bracket as

shown in the illustration Tightening the Mounting Screws.

CAUTION! Be careful not to alter the running angle, as some force is necessary to pivot

the assembly.

3. If access to the top mounting hole is not possible due to the selected height of the

transducer, fully tighten the two lower screws. Remove the headed pivot pin and the

transducer assembly, tighten the top screw, and then reassemble.

4. Confirm that the pivot angle has not changed and that all mounting screws are fully

tightened.

Proceed to the section Route the Cables.

machine screw holes

Tightening the Mounting Screws

Pivot the

transducer

assembly up

to tighten the

mounting

screws.

15

Install the Side Imaging Transducer

Page 20

Routing the Cables

ROUTE THE CABLES

Use the procedures in the following section to route and connect all cables to the control

ead.

h

CAUTION! Do NOT mount the cables where the connectors could be submerged in water

or flooded. If cables are installed in a splash-prone area, it may be helpful to apply

dielectric grease to the inside of the connectors to prevent corrosion. Dielectric grease

can be purchased separately from a general hardware or automotive store.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the cable

insulation. Route the cable as far as possible from any VHF radio antenna cables or

achometer cables to reduce the possibility of interference. If the cable is too short,

t

extension cables are available to extend the transducer cable up to a total of 50'. For

assistance, contact Customer Service at humminbird.com or call 1-800-633-1468

for more information.

Route the Transducer Cable

The transducer cable has a low profile connector, which must be routed to the point where the

control head is mounted. There are several ways to route the transducer cable to the area

where the control head is installed. The most common procedure routes the cable through

the transom into the boat.

NOTE: Your boat may have a pre-existing wiring channel or conduit that you can use for

the transducer cable.

1. Unplug the other end of the transducer cable from the control head. Make sure that the

cable is long enough to accommodate the planned route by running the cable over the

transom.

NOTE: The transducer can pivot up to 90 degrees in the bracket. Allow enough slack in

the cable for this movement. It is best to route the cable to the side of the transducer

so the transducer will not damage the cable during movement.

2a. If you are routing the cable over the transom of the boat, secure the cable by attaching

the cable clamp to the transom, drilling 9/64" diameter holes for the #8 x 5/8" wood

screw(s), then skip directly to Connect the Transducer Cable.

or...

2b. If you are routing the cable through a hole in the transom, drill a 1 1/8" diameter hole

above the waterline. Route the cable through this hole, then fill the hole with marinegrade silicone sealant and proceed to the next step immediately.

3. Place the escutcheon plate over the cable hole and use it as a guide to mark the two

escutcheon plate mounting holes. Remove the plate, drill two 9/64" diameter x 5/8" deep

holes, and then fill both holes with marine-grade silicone sealant. Place

the escutcheon plate over the cable hole and attach with two #8 x 5/8" wood screws.

Hand-tighten only!

4. Route and secure the cable by attaching the cable clamp to the transom. Drill one 9/64"

diameter x 5/8" deep hole, then fill hole with marine-grade silicone sealant, then attach

the cable clamp using a #8 x 5/8" screw. Hand-tighten only!

Routing the Cable: 200/50 kHz

DualBeam PLUS Transducer

escutcheon

plate

1 1/8"

hole

cable clamp

Routing the Cable:

Side Imaging Transducer

escutcheon

plate

1 1/8"

hole

cable

clamp

NOTE: If there is excess cable that needs to be

gathered at one location (as shown in the

illustration), dress the cable routed from both

directions so that a single loop is left extending

from the storage location. Doubling the cable

up from this point, form the cable into a coil.

Storing excess cable using this method can

reduce electronic interference.

Route the Cables

Storing Excess Cable

16

Page 21

Connecting the Transducer Cable

CONNECT THE TRANSDUCER CABLE

1. Connect the transducer cable connector to the proper port on the control head or black

ox sonar (depending on your system configuration). The ports are labeled and the cable

b

connectors are keyed to prevent incorrect installation, so be careful not to force the

connector into the wrong port.

2. Hand-tighten the screw nut on the cable to secure the connection.

CAUTION! Do NOT mount the cables where the connectors could be submerged in

water or flooded. If cables are installed in a splash-prone area, it may be helpful to

apply dielectric grease to the inside of the connectors to prevent corrosion.

Dielectric grease can be purchased separately from a general hardware or

utomotive store.

a

Installing Accessories

Routing the Cables

INSTALL ACCESSORIES

If you have purchased additional accessories for your control head configuration, see the

installation guide provided with each accessory for installation instructions. See the Network

Configuration illustration for an example of possible network connections.

Ethernet: Your unit has a built-in ethernet connector so that you can network advanced

accessories and multiple Humminbird units. The Ethernet cable requires a separate purchase.

See the Ethernet Installation Guide for details.

Adapter Cables: Your installation may require adapter cables to connect accessories to the

control head.

NOTE: To review the latest compatible accessories for your control head, and to

purchase cables or other equipment, go to humminbird.com or contact Customer

Service at 1-800-633-1468.

Route and Connect Accessory Cables

1. See the installation guides included with each accessory for installation instructions.

2. Route the cables to the control head.

3. Pass the cables through the drilled hole(s), and connect them to the appropriate ports

on the control head. The ports are labeled, and the connectors are keyed to prevent

incorrect installation.

dashboard

(partial view)

port cover

route cables

to control head

Securing the Cables

(magnified view)

screw nut

cable label

(optional)

cable hole

NOTE: When the cables connect to the control head through the hole, leave enough

cable slack to allow for the control head to pivot through its full tilt range. Extra cable

slack will also help when connecting or disconnecting the cables.

4. Hand-tighten the screw nut on each cable to secure the connection. Any unused ports

should be covered with the port covers to prevent potential damage.

5. Apply labels to the cables (optional). Use nylon cable ties (not included) to secure the

cables and create a clean assembly.

Proceed to the section Test and Finish the Installation.

17

Connect the Transducer Cable - Install Accessories

Page 22

Power/Speed/Temp

Sonar/Temp

Video Out

Ethernet

NMEA 2000

NMEA 0183 (1-2)

Radar

AS 360

Gigabit Ethernet Switch

TV

Engine Monitor

Compass/GPS

Power

Speed and Temp

Sonar with Temp

Network Configuration

NOTE: To view more examples of network configurations, visit our Web site at humminbird.com.

Install Accessories

18

Page 23

Connecting the Power Cable

CONNECT THE CONTROL HEAD POWER CABLE

A 6 ft (2 m) power cable is included to connect power to the control head. You may shorten

r lengthen the cable using 18 gauge multi-stranded copper wire.

o

CAUTION! Some boats have 24 or 36 Volt electric systems, but the control head MUST

be connected to a 12 VDC power supply.

WARNING! Humminbird is not responsible for over-voltage or over-current failures.

The control head must have adequate protection through the proper selection

nd installation of a 5 Amp fuse (recommended fuse type: slow-blow, time-delay, or

a

time-lag).

Fuse Terminal Connection

Power

Cable

Black Wire (–) Ground

Red Wire (+) 12 VDC

Battery Switch Connection

Fuse Terminal or

Battery Switch

Connect to Power

The power cable can be connected to a fuse panel (usually located near the console) or to

a battery switch.

1. Make sure that the power cable is disconnected from the control head.

Fuse Terminal Connection

2a. Use crimp-on type electrical connectors (not included) that match the terminal on the

fuse panel. Attach the black wire to ground (–), and the red wire to positive (+)12 VDC

power. Install a 5 Amp fuse (not included) for protection of the unit.

OR

Battery Switch Connection

2b. Install the battery switch (not included) using the instructions provided with it. You will

also need to install an inline fuse holder and a 5 Amp fuse (not included) for protection

of the unit. Attach the black wire to (–) ground, and the red wire to (+)12 VDC power.

NOTE: In order to minimize the potential for interference with other marine

electronics, a separate power source (such as a second battery) may be necessary.

3. Route the power cable to the Humminbird control head, and insert the connector into

the POWER-SPEED-TEMP port. The ports are labeled, and the connectors are keyed to

prevent incorrect installation. Hand-tighten the screw nut to secure the cable

connection.

Connecting the Power Cable

to the Power-Speed-Temp Port

(magnified view)

screw nut

cable label

(optional)

port cover

Proceed to the section Test and Finish the Installation.

CAUTION! Do NOT mount the cables where the connectors could be submerged in

water or flooded. If cables are installed in a splash-prone area, it may be helpful to

apply dielectric grease to the inside of the connectors to prevent corrosion.

Dielectric grease can be purchased separately from a general hardware or

automotive store.

19

Connect the Control Head Power Cable

Page 24

Test the Installation

|

1

Confirm Sonar Signal on the Control Head

1. Power on the control head (see the section Power On the Control Head). If the unit does not power-up, confirm that the cable

connectors are properly connected and that power is available.

2. Setup Guide: See the section Setup Guide for initial start up instructions. You must complete the steps indicated in the Setup Guide

before starting normal operation.

NOTE: After completing the Setup Guide, the control head will automatically enter normal operation.

3. Press the HOME key .

4. Select a sonar view from the Favorites bar to display on-screen.

TEST AND FINISH THE INSTALLATION

Once you have installed both the control head and the transducer, and have routed all the

ables, you must perform a final test before locking the transducer in place. Testing should

c

be performed with the boat in the water.

NOTE: See your control head operations manual for more information about selecting views.

5. If the bottom is visible on-screen with a digital depth readout, the unit is working properly. Make sure that the boat is in water

greater than 2' but less than the depth capability of the unit, and that the transducer is fully submerged, since the sonar signal

cannot pass through air.

NOTE: The transducer must be submerged in water for reliable transducer detection.

6. If the unit is working properly, gradually increase the boat speed to test high-speed performance. If the unit functions well at low

speeds, but begins to skip or miss the bottom at higher speeds, the transducer requires adjustment.

|

2

Make Adjustments

NOTE: It is often necessary to make several incremental transducer adjustments before optimum high-speed performance is

achieved. Due to the wide variety of boat hulls, however, it is not always possible to obtain high speed depth readings.

NOTE: The deeper the transducer is in the water, the more likely that a rooster tail of spray will be generated at high speeds, so

make sure that the transducer is as high as it can be and still be submerged in the water.

DualBeam PLUS Transducer

1. If you have the correct angle set on the transducer, yet lose a bottom reading at high speed, adjust the height and the running angle

in small increments to give you the ideal transducer position for your boat. First, adjust the height in small increments (see DualBeam

PLUS Transom Mount Installation: Assemble the Transducer and Initial Mounting).

If you are still not getting good high-speed readings, you may need to disassemble the transducer mounting assembly and

re-position the ratchets, using the illustrations showing the transducer knuckle positions in the section DualBeam PLUS Transom

Mount Installation: Assemble the Transducer and Initial Mounting. If you do change the transducer position, re-trace the position

of the mounting bracket before proceeding.

Side Imaging Transducer

1. If you have the correct angle set on the transducer, yet lose a bottom reading at high speed, adjust the transducer to a lower depth

in the water. If you reach the top of the screw slots and continue to lack high-speed performance, increase the angle of the

transducer by lowering the back of the transducer in increments of 1/8".

Test and Finish the Installation

20

Page 25

|

3

Finalize the Transducer Installation

Once you have reached a consistently good sonar signal at the desired speeds, you are ready

to lock down the transducer settings.

DualBeam PLUS Transducer

. Force the pivot to the Up position to gain access to the mounting screws, then re-align

1

the mounting bracket against the transom of the boat to match the traced silhouette.

Check the bracket position with the level again to make sure it is still level, then mark

the third mounting hole using a pencil or marker. Unscrew and remove the mounting

screws and the transducer assembly and set aside.

2. Drill the third mounting hole, using a 5/32" drill bit. Use a marine-grade silicone sealant

to fill all three drilled mounting holes, especially if the holes penetrated the transom

wall.

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flaking the outer coating.

3. Re-position the transducer assembly against the transom of the boat, then handinstall all three screws. Make sure that the transducer location and the pivot angle have

not changed, then fully tighten all three mounting screws. Hand-tighten only!

4. Snap the pivot back down. If you have performed the preceding procedures correctly,

the transducer should be level and at the right height for optimal operation.

Drilling the Third Mounting Hole

4th mounting hole

3rd mounting hole

Fully Tightening All Three

Mounting Screws

Lock Down the DualBeam PLUS Transducer (optional)

The following procedures are for the DualBeam PLUS transom mount transducer only.

NOTE: You have the option to lock down the Two Piece Kick-Up bracket if you do not

want the transducer to kick up. Be aware, however, that the transducer can be damaged

if it is locked down and it strikes debris in the water.

1. To lock down the transducer, trace the position of the mounting bracket. Force the pivot

to the Up position to gain access to the mounting screws, then re-align the mounting

bracket against the transom of the boat to match the traced silhouette. Check the

bracket position with the level again to make sure it is still level, then mark the fourth

mounting hole using a pencil or marker. Unscrew and remove the mounting screws and

the transducer assembly and set aside.

2. Drill the fourth mounting hole, using a 9/64" drill bit. Use a marine-grade silicone

sealant to fill all four drilled mounting holes, especially if the holes penetrate the

transom wall.

3. Re-position the transducer assembly against the transom of the boat, then hand install

the first three screws (two on the outside edges and one in the 3rd mounting hole).

Make sure that the transducer location and the pivot angle have not changed, then

fully tighten all three mounting screws. Hand-tighten only!

4. Snap the pivot back down. Install the #8 x 1" wood screw into the 4th hole to lock down

the pivot arm. Hand-tighten only!

Locking Down the 200/83 kHz

Transducer (optional)

Locking Down the 200/50 kHz

Transducer (optional)

Side Imaging Transducer

1. Once you have reached a consistently good sonar signal at the desired speeds, fully

tighten your assembly to lock it into place.

21

Test and Finish the Installation

Page 26

POWER ON THE CONTROL HEAD

Use the procedures in this section to power on and power off the control head.

Power On

1. Press and hold the POWER key .

irst Power On: On the first power on after installation, the

F

Welcome Menu displays on the screen.

2a. Select Start Normal Mode.

2b. International Units only: Select Language to select the language

displayed on the control head.

3. Selecting Start Normal Mode launches the Setup Guide. Proceed

to the section Setup Guide for instructions.

Cross Touch: The Cross Touch feature allows you to use the touch screen

or press the control head keys to select menus and start actions on the

control head. See the Quick Start Guide for more information.

Power Off

1. Press and hold the POWER key .

Welcome Menu

OR

tap to select select open

+

SETUP GUIDE

The Setup Guide is a first time setup tool to help you configure basic system preferences, such as the sonar source and map

source. The following sections provide basic instructions for each step of the Setup Guide.

See the Quick Start Guide and your control head operations manual for more information about the menu system.

NOTE: All settings are automatically saved.

NOTE: The Setup Guide settings can be changed at any time. See each menu option in the menu system for details. See your

control head operations manual for more information.

First-Time Setup

1. Select Begin Manual Setup to manually select the settings.

Selecting Begin Manual Setup will automatically open the first

menu dialog box.

|

Begin Manual Setup

currently selected menu optionmenu name

Power On the Control Head - Setup Guide

22

Page 27

General Settings

|

Select Time and Date Format, and Units of Measurement

elect Units of Measurement

S

1. Select Units and open the submenu.

2. Select a menu option and open the submenu.

3. Select a setting and press the CHECK key to confirm the

selection.

. Tap the back arrow on-screen or press the EXIT key to return

4

to the submenu.

5. Repeat steps 2 through 4 to change another setting.

6. Tap the back arrow on-screen or press the EXIT key to return

to the main menu.

7. Select additional settings as needed. Tap the right arrow on-screen

or press the RIGHT ARROW key on the keypad to proceed to the

next menu dialog box.

menu options

current menu option setting

current menu option setting submenu

current menu option setting

submenu

back

Sonar

The control head will default to the transducer that was included with your unit and automatically select sonar settings based on the

transducer’s capabilities. If your control head is compatible with an accessory transducer, and it is connected to the control head, use

Transducer Setup to select the accessory transducer. Use the following instructions to confirm transducer setup and set the depth offset.

Confirm Transducer Setup

1. Select Transducer Setup and open the submenu.

2. Review the current menu settings.

3. Tap the back arrow on-screen or press the EXIT key to return

Set the Depth Offset

1. Select Depth Offset and open the submenu.

2. Drag the slider, or use the Rotary Dial, to adjust the setting.

3. Tap the back arrow on-screen or press the EXIT key to return

|

Confirm Transducer Setup and Set the Depth Offset

To make changes: Select a setting and press the CHECK key to

confirm the selection. If your transducer supports multiple sonar

beams (Side Imaging, Down Imaging, and 2D Sonar), select each

one you plan to use.

to the main menu.

to the main menu.

4. Select additional settings as needed. Tap the right arrow on-screen

or press the RIGHT ARROW key on the keypad to proceed to the

next menu dialog box.

23

Setup Guide

Page 28

Chart

Humminbird is the built-in map source for your control head. You can also select Navionics or C-MAP by Jeppesen as your map source. If

ou install an SD card with additional maps, set the map source to match the SD card type.

y

From this menu, you can also set the Water Level Offset (Humminbird charts only). Water Level Offset allows you to change the level of

the water being read from the control head. For example, if the lake is down 5 feet, set the Water Level Offset setting to -5. The displayed

numbers on the Contour Lines will adjust from the Water Level Offset setting. See your control head operations manual for more

nformation.

i

|

Select the Map Source and Water Level Offset

NOTE: If you trailer the boat to a new location, the Water Level Offset must be reset according to the current environment.

Select a Map Source

1. Select a map source and press the CHECK key to confirm the

selection.

Set the Water Level Offset

1. Drag the slider, or use the Rotary Dial, to adjust the setting.

2. Tap the right arrow on-screen or press the RIGHT ARROW key

on the keypad to proceed to the next menu dialog box.

My Vessel

Use the following instructions to select the NMEA 2000 engines and/or tanks and the vessel dimensions of your boat.

Select Engines and Tanks with NMEA 2000 Sensors

If you have a NMEA 2000 network on your boat that is connected to the

engines and/or fuel tanks, select your current configuration to receive

NMEA 2000 data on your control head.

|

Select NMEA 2000 Engines/Tanks and Vessel Dimensions

current menu option setting

slider

NOTE: See NMEA Input/Output for a complete list of compatible

NMEA sentences.

1. Select Engines/Tanks and open the submenu.

2. Select a setting and press the CHECK key to confirm the

selection.

3. Tap the back arrow on-screen or press the EXIT key to return

to the main menu.

4. Select additional settings as needed.

Setup Guide

24

Page 29

Set Vessel Dimensions

It is important to set the height, width, and depth allowances required for

your vessel as that information affects the accuracy of auto route

calculations during navigation.

. Select Vessel Dimensions and open the submenu.

1

2. Select a setting. Drag the slider, or use the Rotary Dial, to adjust the

setting.

3. Select additional settings as needed.

4. Tap the back arrow on-screen or press the EXIT key to return

to the main menu.

5. Select Confirm to confirm the selected settings.

The unit will automatically enter normal operation.

25

Setup Guide

Page 30

Home Screen

Start Radar Transmission

SET UP THE CONTROL HEAD

After completing the Setup Guide, use the following sections to configure basic system settings

and confirm operation.

NOT E: See the Quick Start Guide and the control head operations manual that was

provided with your unit for additional information.

If you have a radar connected to the control head system, use the

following instructions to start radar transmission.

WARN IN G! The radar must be configured before it can be used

for on-the-water operations. See the operations manual for

configuration instructions.

Start Radar Transmission

1. Confirm the radar power source is turned on (breaker or switch).

2. Press the HOME key .

3. Tap the Radar View on the Favorites Bar, or use the Joystick to

select it and press the CHECK key to open.