Humbaur 10000, HTK 195024 Operating Instructions Manual

OPERATING INSTRUCTIONS

MACHT’S MÖGLICH

HTK

Three way tipper (195024)

10000 SERIES EN

xx

humbaur.com

Humbaur GmbH

Mercedesring 1

86368 Gersthofen

Germany

Tel. + 49 821 24929-0 l info@humbaur.com

Fax + 49 821 249-100 l www.humbaur.com

Your trailer:

Model __________________________________________________

Type (abbreviation) _______________________________________________

Registration number ______________________________________________

►►

WHD

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

VIN number

Trailer data:

Date of first registration ______________________

Gross weight ________________________________

Load capacity ________________________________

Keep this instruction manual readily available in the towing vehicle!

Pass on the complete documentation to the new owner if you sell the trailer.

Trailer components

Axle(s)

(Type / manufacturer) ____________________________________________

Brake system

(Type / manufacturer) ____________________________________________

Support device ___________________________________________________

(Type / manufacturer)

Electronic system __________________________________________________

(installed components)

This operating instruction manual must

be carefully read, understood and

complied with in full by anyone who is

responsible for the Humbaur GmbH

vehicle and its modules.

Humbaur GmbH accepts no liability for

damage or failures which arise through

disregard of this manual!

Read and observe the operating

instruction manual with all the

instructions, warnings and notes

before driving for the first time!

Please note that all illustrations are

representative and may differ from the

actual appearance / equipment.

Also read and observe the

instruction manuals for

components such as axles,

support devices, etc.!

The complete technical documentation is

part of the product and should be kept in

the driver's cab of the traction unit for

reference at all times.

Key details for the handling, operation

and the requisite care and maintenance

work of the trailer are referred to in this

operating instruction manual, and errors

can only be avoided and trouble-free

operation guaranteed if you are familiar

with them.

Errors excepted. The manufacturer:

Humbaur GmbH

Mercedesring 1

89368 Gersthofen (Germany)

reserves the right make technical

changes to the design, equipment and

accessories with respect to the

information and illustrations in the

operating instruction manual.

As a result, no claims whatsoever can be

derived from the information, illustrations

and descriptions.

Obligations of the operator

The trailer may only be operated in

perfect condition.

Ensure that the operating instruction

manual is included with the trailer e.g. if it

is sold.

Only utilise trained or instructed

personnel.

Ensure that the operating

instruction manual is complied

with in all life cycle phases of the

trailer and that the prescribed

personal protective equipment

(see “Personal protective

equipment / rules prohibitions”

on page 24) is worn.

Provide the requisite operating and

auxiliary materials.

1

Contents

Identification

Dimensions, weights and performance

data can be found in the approval documents of the respective trailer.

Vehicle type: Model

Three-way tipper, tandem (gross weight 19 t) HTK 195024

The applicable trailer should be marked with a cross upon delivery.

2

Keyword index

Use the keyword index from page 5 to

search for specific topics.

1 Safety

You will find safety information for the

correct handling of the trailer in the

"Safety" chapter from page 9.

Read this chapter before driving for the

first time.

2 General information

You will find details on vehicle

identification in the "General information"

chapter from page 27.

3 Operation

You will find information on loading and

unloading, correct load distribution and

coupling and uncoupling the trailer in the

chapter on "Operation" from page 37.

4 Operating the chassis

You will find valuable information on the

operating elements of the chassis, such

as the lifting / lowering system, support

devices and information on the safe

loading and unloading, in the chapter on

"Operating the chassis" from page 59.

5 Body

You will find information on how to

operate the body correctly, e.g. folding

down the drop sides, securing loading

ramps, and also on the equipment you

can use to secure the load in the chapter

on the "Body" from page 101.

6 Electrical system

You will find information on the lights,

plug connections and connector

assignments in the chapter on the

"Electrical system" from page 143.

Contents

7 Testing, care and maintenance

You will find out more about the work

required to maintain operational safety

and the value of your vehicle in the

chapter on "Testing, care and

maintenance" from page 157.

8 Troubleshooting

You will find information on

troubleshooting and important service

addresses in the "Troubleshooting

guide" from page 217.

3

Contents

4

Keywords

A

Accumulator parking brake . . . . . 66

Action

in the event of faults. . . . . . . . 218

in the event of fire . . . . . . . . . 218

Address

Manufacturer. . . . . . . . . . . . . . 1

Adjusting the central locking mecha-

. . . . . . . . . . . . . . . . . . . 182

nism

Adjusting the tubular drawbar . . 180

Aluminium surfaces. . . . . . . . . 212

Automatic lowering system . . . . . 72

Inductive sensor . . . . . . . . . . 153

Axle lifting system . . . . . . . . . . . 96

B

Body . . . . . . . . . . . . . . . . . . 101

Brake name plate . . . . . . . . . . 191

C

Care. . . . . . . . . . . . . . . . . . . 157

CE conformity statement . . . . . . 36

Centre of gravity. . . . . . . . . . . . 46

Changing the wheels. . . . . . . . 187

Chapter

Electrical system. . . . . . . . . . 143

General information

Operating the body . . . . . . . . 101

. . . . . . . . . 27

Operating the chassis

Operation

Safety. . . . . . . . . . . . . . . . . . 9

Testing, care and maintenance . . 157

Troubleshooting guide

Chassis

Operating. . . . . . . . . . . . . . . 59

Check when parking . . . . . . . . . 57

Cleaning

Aluminium disc wheels . . . . . . . 209

Cleaning the Duo-Matic coupling . 196

Climbing aids. . . . . . . . . . . . . . 126

Climbing the tipping box. . . . . . . 129

Compressed air container . . . . . 67

Connecting element . . . . . . . . . 48

Connecting the electric system . . 146

Coupling. . . . . . . . . . . . . . . . . 51

Hydraulic line . . . . . . . . . . . . 75

Coupling / uncoupling of the supply

. . . . . . . . . . . . . . . . . . . . 63

lines

. . . . . . . . . . . . . . . 37

. . . . . . . 59

. . . . . . . 217

D

Danger area . . . . . . . . . . . . . . 40

Departure check. . . . . . . . . . . . 57

Disposal

Batteries . . . . . . . . . . . . . . . 215

. . . . . . . . . . . . . . . . . 215

Tyres

Waste oil / lubricants . . . . . . . . 215

Disposing of operating materials . 215

Documentation

Maintenance of axles / wheels . . 159

Maintenance of support device

Proof of the HU/SP . . . . . . . . . 159

Draining the compressed air container

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

. . 159

E

EBS plug connection

7-pin (ISO 7638) . . . . . . . . . . 148

Electrical system . . . . . . . . . . . 143

maintenance. . . . . . . . . . . . . 199

Emergency release device

Brake. . . . . . . . . . . . . . . . . 197

Environmental pollution

Poisonous substances . . . . . . . 215

Environmental protection measures. .

208

Exchanging lights. . . . . . . . . . . 201

F

Fasteners, cable clamps . . . . . . 190

Fastening torque values

for screw connections . . . . . . . 163

for wheel nuts . . . . . . . . . . . . 163

Faulty wheel . . . . . . . . . . . . . . 189

Friction coefficients for material pairs .

123

5

Keywords

G

Galvanised steel surfaces. . . . . 211

General information. . . . . . . . . . 27

H

High-pressure cleaner . . . . . . . 209

Hydraulic connections . . . . . . . 175

Hydraulic pump

- switch off . . . . . . . . . . . . . 119

- switch on . . . . . . . . . . . . . 118

I

Identification . . . . . . . . . . . . . . . 2

Intelligent trailer access point (iTAP) .

155

L

Lettering work . . . . . . . . . . . . 206

Lifting axle. . . . . . . . . . . . . . . . 96

Lighting system . . . . . . . . . . . 144

Lights

Allocation plan . . . . . . . . . . . 199

Light bulbs . . . . . . . . . . . . . 200

Marker light

Position lamp. . . . . . . . . . . . 200

Power / type . . . . . . . . . . . . 200

Side light

Load securing . . . . . . . . . . . . 122

. . . . . . . . . . . . . 200

. . . . . . . . . . . . . . 200

Basic principles

Tie-down points

Loading . . . . . . . . . . . . . . . . . 42

Lubrication

Aluminium disc wheels . . . . . . . 190

Central locking for drop sides . . . 170

Central locking mechanism, front

Drop side mounting . . . . . . . . . 168

Implementation instructions . . . . 164

Spindle support

Tailgate mounting . . . . . . . . . . 171

Telescopic cylinder . . . . . . . . . 176

Tilting bearing

Towing ring. . . . . . . . . . . . . . 165

Underride protection lock. . . . . . 174

. . . . . . . . . . . 122

. . . . . . . . . . . 125

. 182

. . . . . . . . . . . 167

. . . . . . . . . . . . 173

M

Maintenance . . . . . . . . . . . . . . 157

Adjusting / maintaining the brake linings

. . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Brake lining exchange . . . . . . . 193

Cleaning the compressed air filter

Cleaning the coupling heads . . . 195

Compressed air system . . . . . . 194

Drop side lifting spring

Electric systems. . . . . . . . . . . 199

Greases

Hydraulic system . . . . . . . . . . 175

Licence plate light "LED". . . . . . 204

Licence plate light "Standard

Operating brake system . . . . . . 191

. . . . . . . . . . . . . . . 164

. . . . . . . 181

193

. . . 204

Position / marker lights. . . . . . . 205

Side light standard 24 V

Side marker lights. . . . . . . . . . 205

Tail light "24 V - standard". . . . . 201

Tail light "LED"

Tailgate locking / unlocking mechanics

184

Tailgate tension spring

Underride protection lock . . . . . 174

Maintenance brace. . . . . . . . . . 176

Maintenance intervals

Once-off maintenance work . . . . 160

Regular maintenance work

Marker lights . . . . . . . . . . . . . . 151

. . . . . . . . . . . 203

. . . . . . 202

. . . . . . . 183

. . . . 161

N

Number plate light . . . . . . . . . . 152

O

Operating

Body . . . . . . . . . . . . . . . . . 101

Chassis

Operating brake

use . . . . . . . . . . . . . . . . . . . 65

Operation. . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . 59

P

Painted and powder-coated steel sur-

. . . . . . . . . . . . . . . . . . . 211

faces

Parking warning signs. . . . . . . . 100

6

Keywords

Permitted weights / load distribution .

46

Personal protective equipment. . . 24

Physical foundations

Friction force . . . . . . . . . . . . 123

Plug connection

15-pin (ISO 12098-24V) . . . . . 147

7-pin (ISO 7638 - EBS) . . . . . . 148

ABS/EBS . . . . . . . . . . . . . . . 61

Plug connections (standard) . . . 145

Plug socket terminals

15-pin (ISO 12098-24V) . . . . . 147

7-pin (ISO 7638 - EBS) . . . . . . 148

Position lamps . . . . . . . . . . . . 151

Positioning the lifting device . . . 188

Product description

Three-way tipper HTK 19 t . . . . . 28

Versions / accessories

Prohibitory signs / symbols . . . . . 25

. . . . . . . 31

Q

Quick coupling

Duo-Matic. . . . . . . . . . . . . . . 64

R

Rear drop side

- lock . . . . . . . . . . . . . . . . 120

unlocked . . . . . . . . . . . . . . 117

Reversing / operating lights. . . . 152

Roll-up tarpaulin . . . . . . . . . . . 131

CRAMARO

Horizontal version

Rubber hoses . . . . . . . . . . . . . 212

. . . . . . . . . . . . . . 138

. . . . . . . . . . 132

S

Safety . . . . . . . . . . . . . . . . . . . 9

Safety during tipping . . . . . . . . . 39

Safety instructions . . . . . . . . . . 22

Securing the cargo bed

Tilting bearings . . . . . . . . . . . 78

Securing the trailer . . . . . . . . . . 66

Service addresses . . . . . . . . . . 219

Side light . . . . . . . . . . . . . . . . 202

Signal words . . . . . . . . . . . . . . 22

Sources of danger . . . . . . . . 16, 17

Spare wheel . . . . . . . . . . . . . . 189

Specifications for HTK 19 t - three-way

. . . . . . . . . . . . . . . . . . . 30

tipper

Spindle support identification . . . 35

Staff qualification . . . . . . . . . . . 16

Start of the journey . . . . . . . . . . 17

Steam jet . . . . . . . . . . . . . . . . 209

Steps

Pedestal with banister and folding lad-

. . . . . . . . . . . . . . . . . . . 128

der

Pedestal with climbing steps. . . . 127

Stichwörter . . . . . . . . . . . . . . . . 5

Switch-off / securing mechanisms

Lift limitation . . . . . . . . . . . . . 179

T

Tail light

LED with side light . . . . . . . . . 150

Standard with side light 24 V . . . 149

Testing . . . . . . . . . . . . . . . . . 157

Tilting positional stability . . . . . . . 39

Toolbox . . . . . . . . . . . . . . . . . . 99

Traffic signs regarding height . . . . 25

Trailer

decommissioning . . . . . . . . . . 216

disposal

securing . . . . . . . . . . . . . . . 188

Trailer information module (TIM) . 154

Trailer materials. . . . . . . . . . . . 210

Troubleshooting. . . . . . . . . . . . 217

Axles

Braking system

Electrical system . . . . . . . . . . 224

Loading / road handling . . . . . . 220

Rear drop side / side drop sides

Troubleshooting guide. . . . . . . . 217

Tyre pressure / wheel profile. . . . 186

Tyre types . . . . . . . . . . . . . . . 185

. . . . . . . . . . . . . . . 216

. . . . . . . . . . . . . . . . . 225

. . . . . . . . . . . 222

. 227

U

Uncoupling . . . . . . . . . . . . . . . . 55

Unloading. . . . . . . . . . . . . . . . . 42

Use

Foreseeable misuse . . . . . . . . . 11

7

Keywords

Intended use . . . . . . . . . . . . . 10

V

Vehicle combination brake balancing

12

Vehicle identification number. . . . 34

VIN . . . . . . . . . . . . . . . . . . . . 34

W

Warning signs . . . . . . . . . . . . . 23

Warranty. . . . . . . . . . . . . . . . . 14

Waste plate (A-plate). . . . . . . . . 98

Wheel chocks

in front. . . . . . . . . . . . . . . . . 93

Retaining pin . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . 92

Use

Wheel nuts . . . . . . . . . . . . . . 186

Zugösen-Verbindung 235

8

1

Safety

9

Use

1

Intended use

HUMBAUR vehicles and bodies are built

according to the acknowledged rules of

technology and safety engineering.

However, inappropriate use may result in

risks for life and limb of the user or third

parties and damage to the HUMBAUR

vehicles and other goods.

HUMBAUR vehicles and bodies are

exclusively made for appropriate

transportation according to the transport

regulations.

Appropriate use also includes adherence

to the regulations, descriptions and

recommendations in these instructions

and the operating and maintenance

instructions of the sub-suppliers.

Inquire at Humbaur GmbH or at a

HUMBAUR contract workshop if you are

planning additional changes to your

HUMBAUR vehicle or body.

Only have accessories attached to your

HUMBAUR vehicle or body after

discussion with Humbaur GmbH or a

HUMBAUR contract workshop.

The following are permitted:

– Transport of bulk goods

– Operation only within the framework

of the permissible gross weight

– Only operate with appropriate towing

vehicle

– Only operate in a technically flawless

condition

– Ensure an even weight distribution for

the goods

– Only drive with appropriately secured

goods

– Adhere to the legally prescribed and

permitted max. driving speed and

adapt the speed when driving on bad

roads or in bad weather conditions

– Loading and unloading is only

permitted in secured areas or on

public roads after additional securing

measures

– Use additional safeguards against

rolling off when switching off / parking

the trailer

The regular presentation of the trailer for

the main inspection and the safety tests

by the specialist staff as well as its

documentation is a requirement for

participating in road traffic.

The operator / user of the trailer is

responsible for regular servicing /

cleaning and maintenance.

HUMBAUR vehicle bodies are

provided with a VIN (Vehicle

Identification Number) - see

Page 34.

It is essential to specify the VIN when

making enquiries and ordering

spare parts!

10

Safety

Reasonably foreseeable misuse

Any use extending beyond the

prescribed transport applications is

regarded as other than intended.

In particular, this includes:

– Person / animal transports

– Transports of goods for which special

regulations apply and / or special

vehicle versions are required (e.g.

chemical substances, food stuff,

dangerous goods)

– Exceeding the load capacity

– Exceeding the max. permitted axle /

support / trailer load

– Transporting hot / liquid materials

(e.g. tar)

– Driving with badly secured or

unsecured goods

– Driving with a tipped cargo bed

– Driving with bad load distribution

(load one-sided or in one point)

– Structural changes to the trailer that

were not approved by the

manufacturer or were arbitrary

– Use of unapproved spare parts or

accessories

– Driving with a faulty light or electric

system

– Driving with a dirty trailer on which the

number plate, lights, markings are

unrecognisable or hard to recognise

– Driving when the underride protection

is not in driving position

– Driving with support devices not

moved up

– Arbitrary performance of

maintenance / repair of safety-related

components that may only be

maintained or repaired by specialist

personnel

– Driving at an excessive /

inappropriate speed in bad weather

conditions or on a bad road

– Parking the trailer without sufficient

safety precautions against rolling off

– Operating the trailer in a damaged

state and when parts are visibly worn

or safety-related components are

broken

Use

– Operating a trailer without

appropriate brake adjustment

involving the towing machine or with

the wrong oil pressure

– Tilting / lowering the loading bridge

while persons remain within the

danger zone

– Remaining on the cargo bed when

bulk goods are being tipped or when

the loading bridge is lowered

– Tilting the loading bridge on steep

slopes and soft ground

– Tilting the loading bridge with uneven

tyre pressure

The manufacturer:

Humbaur GmbH

Mercedesring 1

86368 Gersthofen (Germany)

rejects any damage which arises through

disregard of this manual – the risks are

borne solely by the user.

1

Safety

11

Use

WARNUNG

WARNING

nach

Überlastung der Bremsen!

Verminderte Bremswirkung durch überhitzte Bremsen / starker Bremsenverschleiß.

XBremskraft-Zugabstimmung

2000 - 5000 km und nach jedem

Zugmaschinenwechsel durchführen.

after 2000 - 5000 km and

Overloading of the brakes!

Reduced braking effect caused by overheated brakes / strong brake wear.

X

Perform Tractor / Trailer synchro-

nisation

after each exchange of tractor.

620.00127

1

Vehicle combination brake balancing

Vehicle combination brake balancing is

part of appropriate use.

Even when there is only 1 vehicle without

EBS in a vehicle combination, the

combination has to be balanced after

approx. 5,000 km.

When different brake systems, i.e. disk

brakes and drum brakes, are present in a

vehicle combination, the brakes of the

entire vehicle combination must be

balanced.

Towing vehicles without EBS always

require vehicle combination brake

balancing.

Unlike drum brakes, disk brakes do not

indicate overload to the driver by

noticeable deterioration of the braking

effect.

This overload may cause the brakes of

the towing vehicle or the trailer to

overheat. Overloaded brakes may result

in decreasing brake force, higher brake

lining and / or brake disk wear as well as

damage to the wheel bearings or axles.

Optimal distribution of the brake force in

the entire vehicle combination requires

the brakes of the vehicle combination to

be balanced with loaded vehicles

according to 71/320/EC or ECE R13 by a

neutral brake service after a short run-in

time of 2000-5000 km or within 14 days

after acceptance of the vehicle and after

every exchange of the towing vehicle.

When the towing vehicle and the trailer

are equipped with EBS, optimal brake

force distribution requires a balancing

examination and possible correction of

the EBS parameters of the towing

vehicle and possibly also the trailer.

Checks, settings and corrections of EBS

parameters may only be performed by

vehicle manufacturers!

Abb. 1 Warning sign on the trailer

Warranty claims against

Humbaur GmbH become void

when this instruction is not

adhered to or documentation of

the result of the vehicle

combination brake balancing is

missing.

12

Safety

Disclaimer

Any liability of the manufacturer

becomes null and void if:

Any risks and liability exclusions

resulting from this also exist if:

Use

1

– the trailer and its components were

altered without authorisation.

– The original parts or conversion parts

/ accessories approved by Humbaur

GmbH are replaced by other

components.

– subsequent changes were made to

the trailer

(e.g. new drill holes in the frame,

tubular drawbar or widening of

existing drill holes in the frame). This

is considered by Humbaur GmbH to

be a structural change, and the type

approval therefore becomes null and

void.

– Non-approved accessories or third-

party spare / component parts which

are not original HUMBAUR parts are

attached or installed. The type

approval of the trailer, possibly even

the insurance cover, becomes null

and void.

– care and maintenance intervals

prescribed by the manufacturer are

not complied with.

– Acceptance inspections have been

carried out by inspectors / authorised

experts of the technical inspection

authorities or officially recognised

organisations.

– Official approvals are available.

Safety

13

Service and warranty claims

1

The warranty includes the following:

Defects that occur during proper use of the trailer

as specified, or which are design-related or can

be attributed to material faults.

Repairs carried out during the guarantee period

do not extend it.

As the contracting party, the dealer is responsible for the warranty.

Requirements

Original replacement parts must be used for

repairs.

Repairs must be carried out by a specialist

workshop.

The maintenance instructions and regulations of

the manufacturer as listed in this operating

manual must be observed.

Defects must not be attributable to

Non-compliance with the technical and legal

regulations listed in this operating manual.

Improper use of the trailer or lack of experience

on the part of the user.

Unauthorised alterations to the trailer and the

use of fittings not approved by Humbaur GmbH

invalidate the warranty. Non-compliance with the

relevant statutory regulations.

The following are not defects

Each trailer is a hand-made product. Despite the

greatest of care, minor superficial scratches

which have no effect on the intended use can

occur during assembly.

Tension cracks in the surface (hair cracks) are

inherent in the production method and cannot be

avoided. These hair cracks have no impact on

the stability or use of the trailer.

Gaps between the drop side and the loading

bridge.

Furthermore, polyester components are not

100% colour-fast. Here, too, UV and weather

effects can cause fading.

It should also be noted that rubber parts generally age as a result of UV exposure and the

formation of cracks and fading of the surface is

possible.

Parts coated with the cathodic dip-painting

process (KTL) are not colour-fast. They can fade

as a result of UV irradiation.

Galvanised parts are not normally shiny, as they

lose their bright finish after a short time. This is

not a defect but rather a desired effect, as full

protection against rusting of the metal is only

guaranteed after oxidation. Wood is a natural

material. Despite the most diverse types of

processing and coating, it is therefore subject to

natural, weather-dependent expansion and

shrinkage, which can result in warping. Natural

wood grain and irregularities are normal for this

natural material and can appear on the surface.

Fading is also possible as a result of UV irradiation and weathering effects. A manufacturing

tolerance is specified for the thickness of the

wooden components used. Claims will not be

accepted for deviations within the tolerance.

As the trailers are not generally insulated,

temperature fluctuations can result in the formation of condensation under tarpaulins and polyester covers. In this case, adequate ventilation

should be provided to prevent mould growth.

Furthermore, the trailers are not 100% watertight. Water ingress at the doors, flaps and

windows is still possible, even with extremely

careful workmanship and the use of rubber

seals.

14

Safety

Service and warranty claims

1

The warranty will expire

If the regulations for operation, maintenance,

cleaning and inspection are not observed.

In the event of engineering alterations to the

trailer.

In the event of independently added fittings and

superstructures which have not been approved

by Humbaur.

In the event of the overloading and improper use

of the trailer.

If non-original Humbaur replacement parts are

used.

If the safety instructions provided on the trailer

are not observed.

If the service intervals are not adhered to, even

when the parts concerned, e.g. axle, brake,

drawbar, hydraulic systems etc. were fitted by

Humbaur.

In the event of incorrect surface treatment of the

materials used.

In the event of continued use of the trailer even

though defects have already been detected and

reported and the use has been prohibited by the

manufacturer until repairs have been carried out.

In the event of continued use of the trailer with

known defects where repair is not possible or is

time-consuming or is only possible with significant additional expense and reduced function.

The warranty does not include

Expenditure for ongoing maintenance.

Costs that can be attributed to normal wear or

even because the trailer has not been used for a

long time.

Faults that can be attributed to not treating the

trailer as specified.

Defects that can be attributed to the use of nonoriginal Humbaur replacement parts.

Defects that can be attributed as a consequence

of a repair not carried out by a specialist workshop.

Defects that can be attributed to structural alterations or assembly work on the vehicle.

Damage which can be traced back to snow and

water loads on tarpaulin, plywood or polyester

bodies.

The manufacturer reserves the right to make

design changes.

Safety

15

Staff qualification

1

HUMBAUR vehicles and bodies as well

as their operating components may only

be used and maintained by personnel

who are aware of:

– this operating instruction manual.

– the trailer and the associated traction

unit.

– the operating and maintenance

instructions of the suppliers.

– the German Road Traffic Act (StVO)

and German Road Traffic Licensing

Regulations (StVZO).

– All the respective health and safety /

accident prevention regulations as

well as other safety, occupational

health and road traffic regulations.

– the basic requirements of goods

transport.

– the risks of handling dump trucks

(see Brochure BGI -5064 "AVOID

TIPPING OVER")

16

Safety

Sources of danger

Take note of the following points without

fail:

– Coupling and uncoupling a trailer:

Standing in the danger area is

prohibited.

– Driving with unsecured support

devices.

– Driving with an unlocked tailgate.

– Driving when the underride protection

is not in the driving position.

– Inappropriate operation of the drop

sides.

– Clearance heights on the route, while

loading and unloading.

– Driving with a tipped loading bridge -

not permitted by law.

– Exceeding the permissible gross

weight or one-sided overloading

through incorrect loading.

– Poorly secured or unsecured goods

and / or body components.

– Reversing - keep an eye on the rear

area.

– Excessive twisting while

manoeuvring.

Check, adjust and secure before each journey

– Overloading of the trailer, axles and

brakes.

– Overstressing caused by fitting

incorrect wheel and tyre sizes.

– Use of wheels with incorrect offsets,

one-sided run-out or centrifugal

imbalance.

– Overstressing as a result of reckless

and inappropriate driving or handling.

– Impact and shock stress of the axles.

– Speed inappropriate for the road

conditions and the loading status of

the trailer, especially in bends.

– The parked trailer can tilt or sink in on

soft uneven ground.

– Tilting the loading bridge too close to

a slope or excavation.

– Driving on severe inclines.

– Loading / unloading of the trailer in an

area with a steep gradient.

– Standing on a tipped / moving loading

bridge.

– Driving under a raised loading bridge.

– Tilting the loading bridge on uneven

and soft ground.

1

– Jerky braking during tipping.

– Tipping with an engaged parking

brake.

– Failure to clean the cargo bed after

every use.

– Tipping viscous load materials e.g.

asphalt, soil, loamy sand.

– Tipping large rocks.

– Tipping with an inclined combination.

– Tipping under high-voltage

transmission lines (open power

lines).

Safety

17

Check, adjust and secure before each journey

1

In the chassis area

Note the following in general:

– Connect the supply lines

– Establish the electrical connections

– Retract the support devices and lock

them

– Check the tyres and rims for damage

– Check the tyre pressure, including

the spare wheel

– Check the tightening torque of the

wheel nuts

– In the case of a new trailer, retighten

the wheel nuts after 50 km and after

the first journey with a load

– Secure the:

spare wheel / spare wheel holder,

wheel chock

– Check the trailer lights, repair

defective lights

– Adhere to the permissible gross

weight

– Release the brakes and only start

driving when the brake operating

pressure has been reached

– Drain the compressed air tank

– Check the number plate and signs

– Check the attachment of the tubular

drawbar

– Check that the coupling (eyelet) is in

perfect condition

– Appropriately lock the trailer coupling

– Ensure that the loading bridge is

secured in the tilting bearings

– Check the number plate and signs

– Ensure that the telescopic cylinder

has been appropriately retracted

In the body area

Close and secure all body components,

such as:

– Tailgate

– Drop sides, side

– Toolbox

– Climbing aids

– Ensure that the load distribution is

balanced

– Use roll-up tarpaulin as required

18

Safety

Basic safety instructions regarding the tilting process

Tippers have a high risk of falling over.

They may fall over while tilting the load

and cause major injuries and serious

damage to goods.

Tipper accidents have varied causes and

usually result when a combination of

several issues was neglected during the

tipping process.

We are listing the most important issues

below, so that the risk of falling over can

be minimised.

Clean cargo bed

The inside surfaces of the cargo

bed must be kept clean to

prevent bulk goods from sliding

off!

Thoroughly clean the cargo bed after

each transport.

Total mass / weight

Higher loads increase the risk of

falling over!

Exceeding the max. permitted

total mass strongly increases the

risk of falling over.

Adhere to the permitted total mass

and the max. load capacity as well as

the max. axle loads.

Do not overload the cargo bed - as this

has a negative effect on this vehicle

component and the tilting moment.

Safe handling of tippers

Uneven / soft ground

Tilting on a soft / uneven ground

significantly reduces the stability

of the vehicle during the tilting

process!

Check before tilting that the vehicle

stands on firm and even ground which can usually be seen with the

naked eye.

Tyre pressure / load distribution

Uneven tyre pressure (different

on the right and left side) as well

as uneven load distribution

increase the risk of falling over!

Regularly check the tyre pressure -

establish the same tyre pressure in all

tyres.

Evenly distribute the goods across the

whole lengths / width of the cargo bed.

1

Safety

19

Safe handling of tippers

1

Unfavourable wind conditions

The risk of falling over increases

with the height to which the

loading bridge is raised at winds

above a strength of 5 Bft

(Beaufort scale = 35 km/h - small

deciduous trees start to sway)!

Check from which side the wind is

blowing before the tilting process and

tilt against the wind where possible.

Avoid lifting the lowing bridge fully up

when the side wind is strong.

Perform the tilting at fair speed.

Tipping at building sites

Sufficient distance must be kept

when tipping at fortified

excavation pits!

Maintain a distance of at least 1 m

from the excavation pit when tipping.

Tipping on slopes

A sufficient distance must be

maintained when tipping on

slopes!

Maintain a distance of at least 2 m

from the slope when tipping.

Ensure that the slope angle does not

exceed the following values:

- 45° on soft ground

- 60° on firm ground

- 80° on rock / rocky ground

Maintain a larger distance if you are

not sure.

Braking during tilting

The chassis must be able to

compensate fo the forces during

the tipping process.

The parking brake may not be activated

during the tipping process!

The operating brake may not be

continuously activated!

Check that the parking brake has

been released before the tipping

process.

Release the operating brake gently

and repeatedly - not suddenly - during

the tipping process.

Dragging bulk goods

Bulk goods that are difficult to

move from the cargo bed can be

dragged by a controlled

movement of the vehicle.

This process must be carried out

slowly and very carefully!

Very slowly drive forwards and gently

activate the operating brake - do not

stop suddenly.

Jacking up the air-suspension

A lowered chassis - supported

by a jack - provides more

stability for the vehicle.

The air-suspension should

always be lowered completely

where possible!

Use the lifting / lowering system to

lower the air-suspension completely

or switch on the automatic lowering

facility.

20

Safety

Safe handling of tippers

1

Total vehicle combination extended

During the tilting process, the

total vehicle combination must:

be arranged with the towing

vehicle and the trailer aligned /

stretched out.

This ensures stability!

Check that the total vehicle

combination is arranged as straight as

possible before tipping.

Height of the loading bridge

Tipping under power lines poses

the risk of an electric shock!

Remain seated in the driver's

cab in the event of an electric shock!

Check before tipping that no exposed

power lines are nearby or maintain a

safety distance of at least 5 m.

Tipping pieces of rock

Tipping pieces of rock poses a

high risk.

Pieces of rock may fall down

during the tipping process and

knock against the tailgate / drop

sides, vehicle body or tailgate

suspension, which may in turn

cause the vehicle to fall over!

Check before transporting pieces of

rock that your version of the vehicle is

suitable for that purpose.

Safety

21

Safety instructions

1

Signal words

DANGER

Describes an immediate risk

Death or major injuries will result when

this risk is not avoided.

WARNING

Describes a possibly dangerous

situation

Death or major injuries may result when

this risk is not avoided.

CAUTION

Describes a possibly dangerous

situation

Light or minor injuries may result when

this risk is not avoided.

NOTICE

Describes a possibly dangerous

situation

Damage to goods may result when this

risk is not avoided.

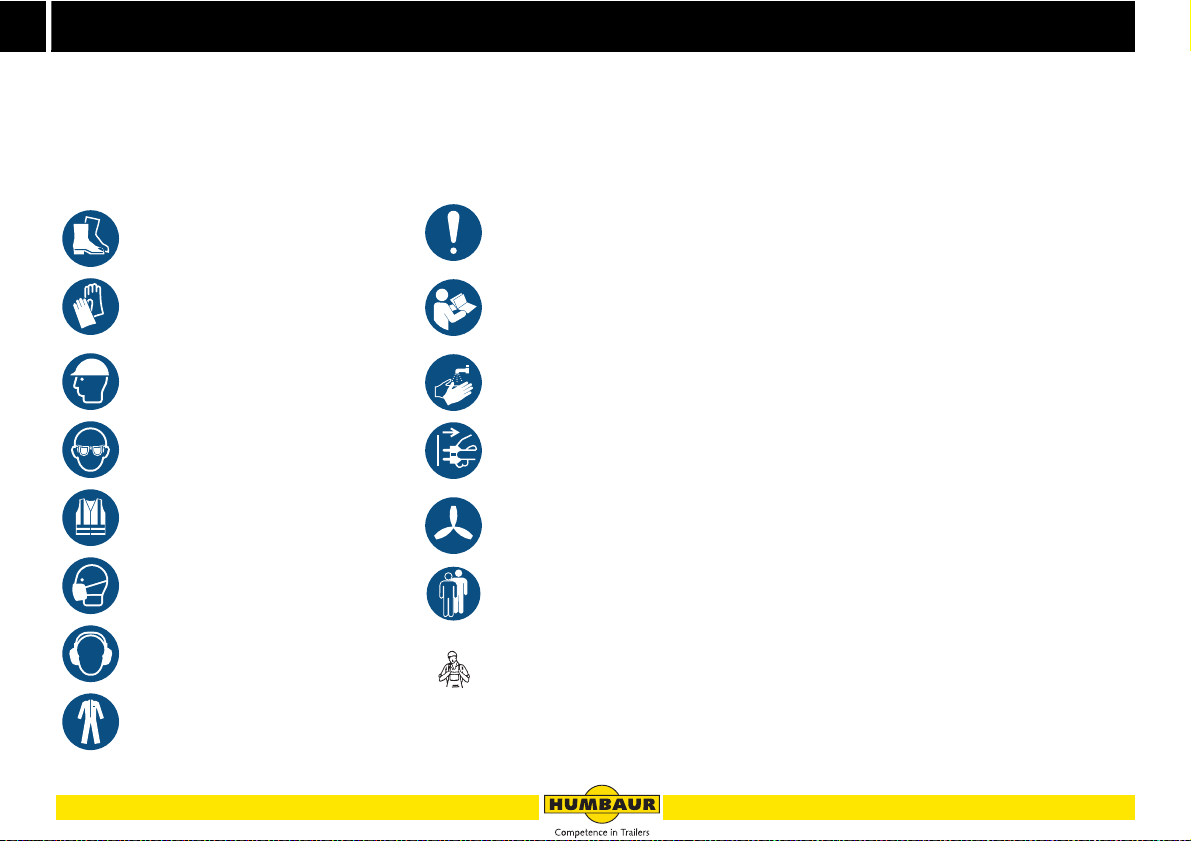

General mandatory signs.

Refers to information that must

be considered and adhered to in

order to ensure safe use.

Also forward all warnings and

instructions to other users or to auxiliary

staff!

Text highlighting

The following symbols in front of text are

used in these instructions:

(Arrow) Request for action

- (Dash) List

1. (Number) List of components

22

Safety

Warning signs used

The following warning signs may be used

in these operating instructions and on the

product.

Take note of these warning signs and

behave very carefully in such cases.

Warning of hazard point!

Be careful - several factors could

put persons at risk here.

Risk of crushing!

For limbs such as:

Hands / fingers / feet.

Risk of crushing!

For body / body parts.

Falling hazard!

Risk of electric shock!

Dangerous voltage.

Risk of impact!

Dropping objects.

Safety instructions

Risk of chemical burns!

Leaking battery acid.

Risk of poisoning!

Poisonous substances.

Risk of injury!

Obstacles in the head area.

Risk of slipping!

Risk of tripping!

1

Burn hazard!

Hot surfaces.

Risk of explosion!

Explosive operating materials.

Risk of impact!

Keep distance.

Safety

23

Personal protective equipment / rules prohibitions

1

Personal protective equipment

Wear the prescribed personal protective

equipment (PPE) during all work

described in these instructions.

This includes the following:

Safety shoes,

Sturdy footwear

Protective clothes

Protective helmet

Protective goggles

High-visibility clothing,

High-visibility vest

Protective mask,

Breathing protection

Hearing protection

Mandatory signs

Adhere to the following directives /

requests for action during all work

described in these instructions.

Important note!

To be considered and adhered

to

Read the operating instructions

before performing a task

Thoroughly wash your hands

Pull out the mains connector

before working on live

components

Ensure good ventilation

Perform tasks as a 2-person

team.

Instructions by support person

required

Protective clothing

24

Safety

Personal protective equipment / rules prohibitions

1

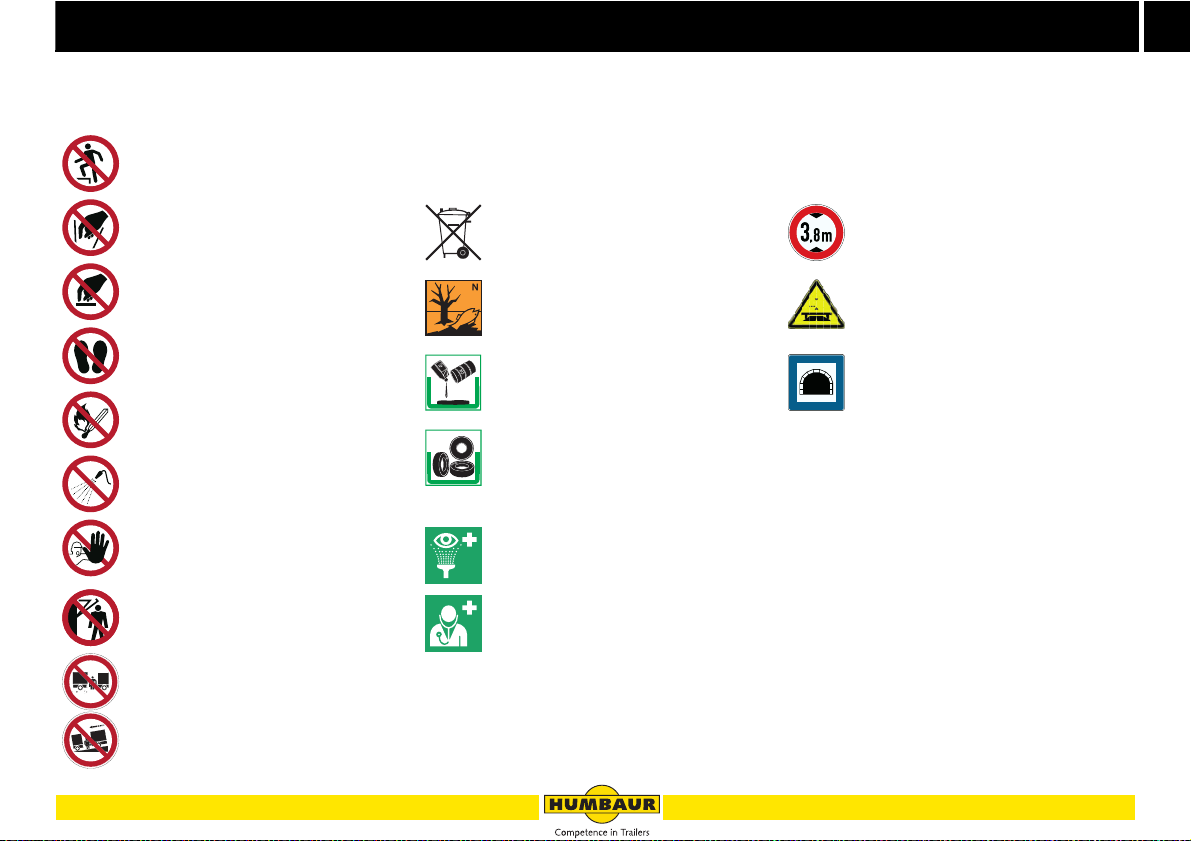

Prohibitory signs

Adhere to these prohibitions.

Do not climb up.

Do not reach in.

Do not touch.

Do not step onto the surface.

Open fire prohibited,

e.g. cigar, lighter.

Do not splash with water,

e.g. high-pressure cleaner.

Access prohibited,

Keep unauthorised persons out.

Stepping behind swivel arm /

moving parts prohibited.

Stepping between towing

machine and the trailer is.

Other important symbols

Take note of the following symbols for

professional disposal as well as first aid

in emergencies.

Problem waste!

Disposal in domestic waste not

allowed.

Risk of

environmental pollution.

Professional waste oil disposal,

Do not dispose of oil into the

environment.

Professional waste tyre

disposal,

Do not dispose of old tyres into

the environment.

Immediately rinse eyes with lots

of water.

Visit a doctor.

Traffic signs regarding height

Please take note of the following,

important traffic signs regarding height

information in public transport.

Maximum vehicle height!

This height may not be

exceeded.

Caution - height limitation at

m

bridges / underpasses!

Tunnel - limited height!

Take note of the maximum

height information.

Letting the trailer run against the

towing vehicle is prohibited.

Safety

25

Personal protective equipment / rules prohibitions

1

26

Safety

2

General information

27

HTK product description

I - 001

14

11

12

13

1

16

10

19

21

15

20

17

18

2

HTK 19 t

3 4

2

1

Pic. 1 Side view

6

5 7

8

9

10

I - 001

Pic. 2 Rear / front view

28

General information

I - 002

Loading...

Loading...