Human Photometer Humalyzer 2000 Service manual

Service Manual

!"#$%&'()*+,,,

Rev. C2-96

Release approved

Cat.-No.: 18390 |

! |

|

INTRODUCTION ........................................................................................................ |

3 |

PRINCIPLES OF OPERATION................................................................................... |

3 |

PHOTOMETER........................................................................................................... |

3 |

TEMPERATURE CONTROL ...................................................................................... |

3 |

FLOWCELL AND VACUUM PUMP ............................................................................ |

4 |

DISPLAY, KEYPAD, AND THERMAL PRINTER ........................................................ |

4 |

SYSTEM CONTROL................................................................................................... |

4 |

TROUBLESHOOTING................................................................................................ |

5 |

POWER SUPPLY ....................................................................................................... |

5 |

PHOTOMETER........................................................................................................... |

5 |

FLOWCELL ................................................................................................................ |

6 |

VALVE ........................................................................................................................ |

6 |

VACUUM PUMP AND PUMP CONTROL PCB........................................................... |

7 |

TEMPERATURE CONTROL ...................................................................................... |

7 |

MAIN PCB................................................................................................................... |

7 |

INTERNAL PRINTER ................................................................................................. |

8 |

KEYPAD ..................................................................................................................... |

8 |

DISPLAY..................................................................................................................... |

8 |

SERIAL PORT ............................................................................................................ |

8 |

ERROR MESSAGES .................................................................................................. |

9 |

SERVICE PROCEDURES ........................................................................................ |

11 |

OPENING THE INSTRUMENT................................................................................. |

11 |

CLEANING THE FLOWCELL................................................................................... |

12 |

FLOWCELL TUBING REPLACEMENT .................................................................... |

13 |

FLOWCELL ADJUSTMENT ..................................................................................... |

15 |

FLOWCELL DISASSEMBLY .................................................................................... |

16 |

VALVE TUBING REPLACEMENT ............................................................................ |

17 |

VACUUM ADJUSTMENT ......................................................................................... |

18 |

LAMP REPLACEMENT ............................................................................................ |

20 |

FILTER REPLACEMENT.......................................................................................... |

21 |

FILTER LABEL ......................................................................................................... |

23 |

CALIBRATION.......................................................................................................... |

25 |

CALIBRATION AND ABSORBANCE LINEARITY .................................................... |

26 |

RESTORE CALIBRATION DATA ............................................................................. |

27 |

RESTORE FILTER LABELS..................................................................................... |

28 |

Service Manual HUMALYZER 2000 |

Page 1 |

TEMPERATURE CALIBRATION .............................................................................. |

29 |

ABSORBANCE CALIBRATION ................................................................................ |

30 |

SPECIFICATIONS .................................................................................................... |

31 |

REPLACEMENT PARTS .......................................................................................... |

33 |

DIAGRAMS............................................................................................................... |

36 |

BLOCK DIAGRAM .................................................................................................... |

36 |

PCB LAYOUTS......................................................................................................... |

36 |

MAIN PCB................................................................................................................. |

36 |

PUMP CONTROL PCB............................................................................................. |

36 |

INTERFACE PCB ..................................................................................................... |

36 |

PRINTER PCB.......................................................................................................... |

36 |

INCUBATION BLOCK PCB ...................................................................................... |

36 |

PRINTER PCB.......................................................................................................... |

36 |

INCUBATION BLOCK PCB ...................................................................................... |

36 |

SCHEMATICS .......................................................................................................... |

36 |

MAIN PCB................................................................................................................. |

36 |

PUMP CONTROL PCB............................................................................................. |

36 |

INTERFACE PCB ..................................................................................................... |

36 |

PRINTER PCB.......................................................................................................... |

36 |

INCUBATION BLOCK PCB ...................................................................................... |

36 |

Service Manual HUMALYZER 2000 |

Page 2 |

-./01234/51.

The instrument is a general-purpose, bichromatic photometer system with six available wavelengths and 37°C incubation. Two additional wavelengths are optional, for a total of eight filters. A removable flowcell provides extremely rapid fluid sampling with low carryover. A built-in vacuum pump and an external autoclavable waste bottle with level sensing are supplied standard. When the flowcell is removed, the instrument accepts standard 12 mm round tubes as well as 1 cm square cuvettes. The instrument also contains an incubation block with 12 round tube stations. Both the incubation block and the read well are temperature controlled to 37°C.

605.45789:*1;*<790=/51.

6>1/1?9/90

The light from a tungsten-halogen lamp is passed horizontally though the tube or flowcell and the sample it contains. The sealed box on the opposite side of the read well contains a rotating filter wheel and photodiode. The filter wheel contains eight interference filters of various wavelengths, and is speed controlled to approximately 3 rps under software control. As each filter passes in front of the photodetector, an infrared optical switch triggers a sampling of the peak voltage produced by the photodetector. The voltage is then fed to a comparator which compares the sampled voltage to the output of an exponential capacitor decay circuit. The pulse at the output of the comparator enables a 16 bit counter in an 8254 programmable timer. The photodetector output is proportional to the intensity of the light, whereas the width of the positive phase of the comparator output is proportional to the absorbance. The resistance across the log cap (RC decay) determines the base of the log (10 for absorbance) and is used to adjust the low-end absorbance calibration (gain). Another potentiometer is used to adjust the high-end absorbance (offset).

@9?790=/309*41./018

The incubation block and read well are maintained at 37_C by means of thermistors (10k @25_C). These thermistors are multiplexed at 0.5 second rate into the feedback path of oscillator U14A. The waveform at U14A is a sawtooth of approximately 1.2 Vpp amplitude centered at +2.5 V. Schmitt triggers U11 convert this to a square wave for current reversal and to drive the CLK2 input of U4. The microprocessor heats the system to maintain the frequency of this signal at 2.08 kHz, the 37_C set point.

Power resistors located on the bottom of the incubation block are switched to 115VAC via an opto-triac. A red LED located on the block PCB illuminates when heat is on. A similar system is employed for the read well except that driver U10 applies 12VDC (raw) across heater resistors located on the cell PCB.

Service Manual HUMALYZER 2000 |

Page 3 |

A81B4988*=.2*C=433?*63?7

An integral DC vacuum pump maintains a constant vacuum on an external waste bottle, by means of a solid-state vacuum sensor circuit on the pump control PCB . A solenoid-operated pinch valve is opened for a precise interval under microprocessor control, to apply this vacuum to the flowcell. Sample (or air) is drawn through the flowcell and into the waste bottle. Sensor wires built into the bottle cap are used in conjunction with a detector circuit on the pump control PCB to indicate a full condition on the waste bottle.

D5:78=EF*G9E7=2F*=.2*@>90?=8*605./90

A 24 x 2 line character Liquid Crystal Display (LCD) is mounted inside the cover. Two 4 x 4 membrane switch keypads are sealed behind the front panel overlay. The LCD connects to the interface PCB via a 14-pin DIP cable. The tails of the keypad switch layers are fed through the cover and are connected to the interface PCB. The printer assembly, consisting of a 20-column thermal printer, the printer PCB, and metal supports, is mounted to the rear dress panel and is connected to the interface PCB via a 14-pin DIP cable.

HE:/9?*I1./018

The instrument is based on the 8 bit Z80 microprocessor. The software is permanently stored in a 27256 EPROM. A battery-backed non-volatile RAM (random access memory) chip (MK48T08) incorporating a real-time clock is used store data such as calibration, test setups, samples, and also maintains the date and time. A static RAM chip (6264) is used for temporary storage. Almost all digital I/O is accomplished with an 8255 Programmable Peripheral Interface. Time intervals and pulse widths are measured using the counter channels of an 8254 programmable timer.

Service Manual HUMALYZER 2000 |

Page 4 |

@013J89:>11/5.K

The instrument incorporates solid-state electronics in a very reliable field-proven design. In this section, each subassembly or component group is discussed, possible problems and solutions are outlined.

61B90*H3778E

The power supply consists of a transformer, two diode bridges, and three regulators. Line voltage supplied to the transformer is converted to 36 VAC, center tapped, which feeds diode bridge BR2. The center tap is used as a reference for regulators VR4 and VR5, which provide +15 VDC and -15 VDC for analog circuitry. Another transformer output supplies 11VAC to diode bridge BR1, which provides +12VDC (raw, 11-13 VDC nominal) to the system, and VR3 regulates this down to +5VDC for the logic and other low voltage control circuits.

A "dead" instrument may be just a blown fuse. However, a blown fuse may indicate a problem on the main PCB or transformer. Also, the voltage select switch setting must match the line voltage. If there is no voltage present at J6, check the fuse. To replace the fuse, disconnect the power cable and open the instrument. Remove the two #4 screws holding the AC cover to the rear panel and lift the AC cover off towards the front of the instrument. Locate the double clip fuse holder mounted on the inside of the rear panel. Locate the blown fuse and remove it with a fuse puller, or carefully pry it out with a small screwdriver. Install a 0.6A 3AG slow blow fuse. Use only the recommended fuse. Do not substitute other rating! Replace the AC cover.

If voltage is present at J6, check for input voltage on VR3, VR4, and VR5. If no voltage is present, the diode bridge BR1 or BR2 may have failed.

6>1/1?9/90

The photometer assembly can be examined as several component systems:

¨ |

Read well assembly and cell heat PCB |

¨ |

Lamp and brackets |

¨ |

Photometer PCB |

¨ |

Filter wheel and motor. |

The read well assembly serves to hold the tube or flowcell centered on the cell block, between a fixed plate and a spring loaded plate. Mechanical adjustments are not required. The presence of a tube or flowcell is detected by an opto pair (phototransistor and IR LED) mounted at the ends of the cell heat PCB. A stainless steel plunger in the bottom center of the cell block forces a small spring plate into the light path between the opto pair.

The lamp is tungsten-halogen, rated at 6V, 10W, and is intended to be maintenance free for the life of the instrument, since the lamp is turned off automatically after 30 minutes of instrument inactivity. However, under heavy usage the lamp remains on for longer periods and may require replacement as the output becomes low near the end of its service life. In addition, a physical shock to the instrument may necessitate lamp replacement due to filament breakage. The lamp and lens brackets simply hold the

Service Manual HUMALYZER 2000 |

Page 5 |

lamp and lens in alignment with the rest of the assembly. The brackets provide adjustments in both horizontal and vertical dimensions, so that the filament can be centered on the light path. The lamp must be replaced if output becomes low or the lamp fails completely. To check for low lamp output, run test #186. Press #(L", then type 186 and press (L@(). The instrument prints the detected voltage for each filter. The printout shows the wavelength, position, and the voltage for each filter. The voltages should be between 2 and 10 volts. If all or most of the voltages are low, the lamp is the likely suspect. As a final check, measure the voltage at the lamp terminals. If the lamp voltage is much lower than 4.5 VDC, the regulator circuitry on the main PCB (Q6 and VR1) may be the problem. Otherwise, replace the lamp. Refer to the section "Lamp Replacement".

The photometer PCB contains a photodiode, a very sensitive op amp circuit and phototransistors. Because the photodetector and related circuitry is solid-state, it should require no service. Do not attempt to modify the photometer PCB.

The filter wheel turns on a shoulder screw shaft and is driven by the filter wheel motor via a neoprene belt. The filter wheel itself requires no adjustments. The optical interference filters contained in the wheel are of metal deposition type construction and are intended to be maintenance free for the life of the instrument. However, in a non-ideal environment where extreme humidity or temperature are encountered, optical characteristics on one or more filters may be compromised. Run test # 186 as described above. If only one or two filter voltages are low, the filter(s) may be suspect. Refer to the service procedure "Filter Replacement".

A81B4988

If proper care is taken to clean the flowcell between uses, especially after highly proteinaceous liquids have been sampled, the flowcell itself should require little or no maintenance.

The flowcell should be cleaned regularly as described in "Cleaning the Flowcell". If the flowcell tubing has become damaged or the flowcell is clogged, the flowcell can be disassembled for cleaning and parts replacement. Refer to the service procedures "Flowcell Tubing Replacement" and "Flowcell Disassembly".

Erratic readings (excessive dither) may be a result of trapped air in the flowcell. This can be caused by improper installation of, or failure of the flowcell tubing or coupling tubes. See the section "Flowcell Tubing Replacement". Check the insertion depth of the flowcell tubes into the coupling tubes. Ensure that a leak-free seal is made and that no tubes are kinked or pinched off.

C=8M9

The valve uses a short length of silicone tubing. If the valve operates but no sample is drawn up, the pinch valve tubing may be blocked. To check for clogged valve tubing, unscrew the flowcell vacuum line from the Luer fitting. Press PURGE and listen for aspiration. If you hear aspiration, the valve is operating, but the flowcell is clogged. If you do not hear aspiration, the valve tubing is clogged. See the section "Valve Tubing Replacement".

Service Manual HUMALYZER 2000 |

Page 6 |

C=433?*63?7*=.2*63?7*I1./018*6IN

The vacuum pump and pump control PCB should require no maintenance. If the vacuum pump runs continuously, you probably have a leak in the vacuum side. Check the waste bottle cap and fittings. Check that the tubing is firmly seated on barbs and all fittings are tight. Turn the fittings only until finger-tight. Do not over-tighten the plastic Luer fittings! If the waste bottle is located at a higher or lower level than the instrument, such as on a shelf, or if the instrument is used at very high altitudes, the vacuum trimpot may require adjustment. See the section "Vacuum Adjustment". If the vacuum pump is taking longer to achieve full vacuum (runs much longer than usual, but otherwise works), the exhaust filter is likely clogged and should be replaced. In the event that the exhaust filter gets wet due to a waste bottle spill, it must be replaced. See the section "Exhaust Filter Replacement".

@9?790=/309*I1./018

The temperature control system is very stable and ordinarily does not require adjustment or recalibration. In the event calibration must be verified or re-established, refer to the section "Temperature Calibration".

#=5.*6IN

Under normal circumstances, there are no adjustments to be made to the main PCB. Circuit failures are highly unlikely, but if they occur, it is recommended that the repairs be performed by factory authorized technicians. There are ten test points on J8 which provide access to a number of vital signals. The instrument can be observed in operation with an oscilloscope. Typical test point waveforms are shown in Figure 4.

Figure 4

> 4 V

J8-3

FHOME

< 1 V

>4 V

J8-2

FCNT

<1 V

<10 V

J8-5 2AP

> 2 V

Sample

< 30 m V BASELINE HASH

WAVEFORMS MEASURED AT J8 WHILE READING BLANK 12 mm BOROSILICATE TUBE WITH 1 ml WATER

ONE REV OF FILTER WHEEL - 340 ms DURING READINGS

MINIMUM PEAK HEIGHT 2V, MAX 10V

Hold |

|

|

|

|

|

OPTIONAL |

|

|

|

340 nm |

FILTERS |

630 nm |

580 nm |

545 nm 505 nm 405 nm |

Home

Service Manual HUMALYZER 2000 |

Page 7 |

-./90.=8*605./90

The internal printer is a 20-column thermal type device which prints ASCII characters using a 5 x 7 dot matrix. There are no adjustments. However, a printer jam can occur if the printer paper tears and becomes lodged in the printer mechanism, thus preventing the print head from moving freely. If the instrument displays "Printer is jammed!", or if the print head does not return to the home position, check for obstructions in the print head path..

I$"@-<L

D1*.1/*=778E*=.E*;1049*/1*/>9*B>5/9*490=?54*705./*>9=2O*D1*.1/*:40=/4>*/>9 78=/9.*10*70E*B5/>*:>=07*1JP94/:Q*@>5:*B588*29:/01E*/>9*705./90O

Carefully remove any paper or debris with a pair of tweezers. Turn off the power switch, wait 5 seconds, then turn on the power switch. The print head should move to the right side and then return to home position at the left.

An alternate method of removing a particularly stubborn wad of paper is to move the print head manually. To do this, remove the rear dress panel. Look at the front of the printer mechanism. Locate the small gear on the right side which turns the grooved steel print head shaft. Turn the gear so that the print head moves away from paper wad and the paper can be easily removed. Turn the power switch off and back on again as described above.

G9E7=2

The keypad is a sealed membrane switch layer which is not serviceable. You can test the keypad by pressing $"R, then pressing all keys except I%($)*and (L@(). Note that each key causes the instrument to beep and display a character. Press I%($) and the display clears. Press (L@()*to end the test.

D5:78=E

The display is a 24 x 2 line super twisted nematic liquid crystal display module with integral controller. The display should be clearly legible at all times, with no dark spots or stray dots. There are no adjustments.

H905=8*610/

By using a special cable, a serial printer or computer with a serial port may be connected. This is a male 9-pin DB-style connector using RS-232 signals in a nonstandard pinout. The data format is 2400 baud, 8 bits, 1 stop bit, and no parity.

The pinout for the serial port is:

1GND

2TX

3RX/DTR 4-9 NC

Contact your distributor to obtain a serial printer cable.

Service Manual HUMALYZER 2000 |

Page 8 |

(0010*#9::=K9:

Error messages are displayed when the instrument fails to operate correctly. They are intended to help the operator locate the problem. If error messages appear frequently, a hardware problem is usually indicated.

The following error messages indicate possible interface or component problems.

Lamp Failure |

The lamp does not appear to illuminated at all. Low |

|

voltages were detected for all filter positions. See the |

|

section "Photometer" under "Troubleshooting". |

Lamp Output Low |

The lamp does not appear to be illuminated |

|

sufficiently. Low voltages were detected for some filter |

|

positions. This is possibly due to degraded filters. See |

|

the section "Photometer" under "Troubleshooting". |

Printer Paper Jam |

The internal printer paper path is obstructed. Clear |

|

the paper path. If the paper path is clear, Check the |

|

14-pin DIP cable connecting the printer PCB to the |

|

interface PCB. |

Printer Not Ready |

The external printer attached to the parallel port or |

|

serial port is out of paper or otherwise unable to print. |

|

If chronic, this may indicate an incorrectly wired |

|

external cable. |

Waste is Full ! XX |

The waste material has reached the level sensors. If |

|

the waste bottle is empty, check the sensor cable, |

|

jack, and internal wiring for shorts. On the pump |

|

control PCB, check U2A, Q2 and U3. Check the cable |

|

from the pump control PCB to the main PCB. |

Empty Waste-Press Enter |

See "Waste is Full !", above. |

Filter Wheel Err |

The instrument cannot correctly detect pulses from |

|

the filter wheel. Check the photometer LED board and |

|

the phototransistors Q12 and Q13 on the photometer |

|

PCB. See the section "Photometer" under |

|

"Troubleshooting". |

Vacuum Leak |

The self-check routine was unable to achieve vacuum |

|

within the prescribed length of time. Check for leaks at |

|

the waste bottle and at all connections. |

Service Manual HUMALYZER 2000 |

Page 9 |

The following error messages indicate possible failure of the NV RAM U3, or the address decoding logic at U6,U7, and U16. U3 can be checked by substitution.

**Memory Error** |

The checksum failed when a stored test was recalled. |

|

The test was deleted. |

Filter Labels 7& 8 Clrd |

The stored filter labels were corrupted or not found. |

|

See the section "Restore Filter Labels". |

Water Values Reset |

The stored water absorbances were corrupted or not |

|

found. |

Do Temp Test 210! |

The stored temperature calibration values were |

|

corrupted or not found. See the section "Restore |

|

Calibration". |

Do ABS Test 212! |

The stored absorbance calibration values were |

|

corrupted or not found. See the section "Restore |

|

Calibration". |

Service Manual HUMALYZER 2000 |

Page 10 |

H90M549*601492309:

<79.5.K*/>9*-.:/03?9./

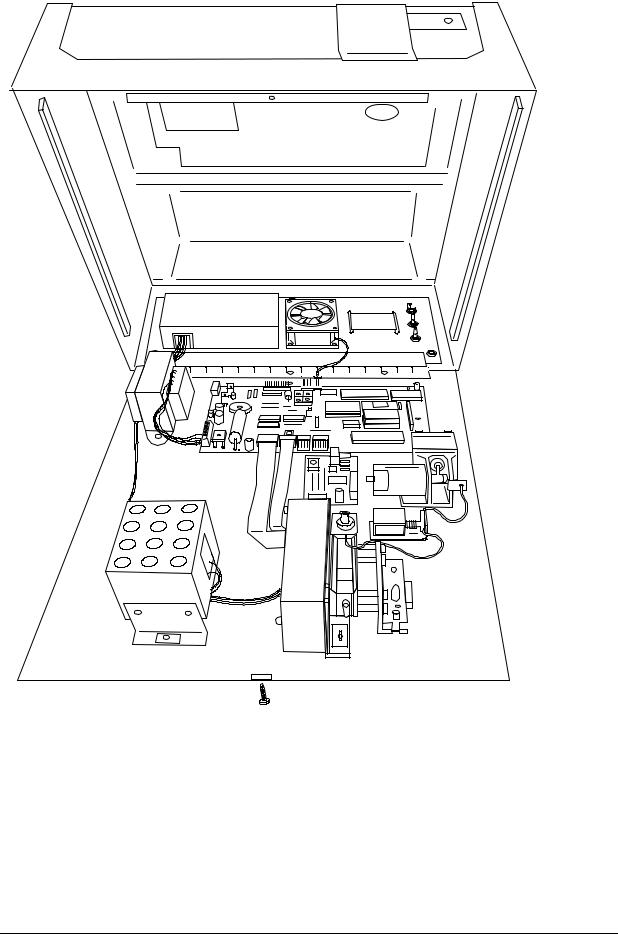

Refer to Figure 3., Instrument Interior. The cover is hinged at the rear panel, and can be raised to allow access to the inside of the instrument. Disconnect the power cable, the tubing, and the sensor lead from the rear panel. Move the instrument forward until the front edge overhangs the work surface. Locate and remove the cover screw from the underside of the front edge. Gently lift the front of the cover upward, taking care to clear the incubation block and photometer. Prop the cover open with a suitable object.

Do not force the cover backwards. Damage to the cover or fittings may result.

Service Manual HUMALYZER 2000 |

Page 11 |

To reinstall the cover, reverse the procedure. Carefully lower the cover until it seats on the chassis, taking care to clear the incubation block and the Luer fitting. Replace the screw.

I89=.5.K*/>9*A81B4988

The flowcell should be cleaned when the instrument will not be used for an extended period, e.g. overnight, end of shift, and when storing the flowcell. Proper cleaning will help to prevent clogging of the flowcell tubing and valve tubing. Cleaning is extremely important to obtaining accurate, repeatable results. If reagent, serum, or other proteinaceous fluid is allowed to dry in the flowcell, it is extremely difficult to remove and its presence can affect test results.

To clean the flowcell:

1. Purge with air for at least 5 seconds.

2. Aspirate several ml of flowcell cleaning solution. Allow the solution to remain in the flowcell for 3 minutes.

3. Aspirate 15 ml of distilled water then purge with air for 5 seconds.

4. Aspirate 0.1N sodium hydroxide (NaOH ). Allow the solution to remain in the flowcell for 3 minutes.

5. Purge with air for at least 5 seconds.

6. Aspirate 0.1N hydrochloric acid (HCl). Allow the solution to remain in the flowcell for 3 minutes.

7. Purge with at least 15 ml of deionized water.

8. If the flowcell is to be removed for storage, purge with air until no more fluid can be seen flowing into the waste bottle. Otherwise, leave the flowcell filled with water.

Service Manual HUMALYZER 2000 |

Page 12 |

A81B4988*@3J5.K*)978=49?9./

The flowcell utilizes 1.2 mm I.D. Teflon tubing for the sample and exit tubes. Replacement tubing is included with the tubing kit. Follow this procedure to replace the flowcell tubing.

1. Remove the flowcell. Unscrew the Luer and lift the flowcell out of the read well.

2. Remove the cover screws and lift off the upper flowcell cover.

3. Refer to Figure 5-A. Disconnect the tube from the steel tube, then remove the exit tube. Pull the exit tube out through the bulkhead. Remove the cell insert screws and pull the cell insert and the sample tube out. Remove the sample tube from the steel tube.

4. Select the long or the short sample tube. The short sample tube must be used when the sample volume is set to 350 µl or less. Carefully press fit the end of the sample tube with the red dot (swaged end) to the steel tube on the cell insert, and feed the other end upward through the cell body. !5./S grasp the tubing with a small piece of #400 grit emery paper. Do not kink the tubing. Refer to Figure 5-C for the proper orientation. Do not reverse the orientation as improper sampling will result. Install the cell body and screws.

5. Feed the exit tube in through the rear of the flowcell. Press the exit tube at least 7 mm to ensure a leak-free seal.

Figure 5-A

Service Manual HUMALYZER 2000 |

Page 13 |

Figure 5 - B

Figure 5 –

Figure 5 – D

7MM

Service Manual HUMALYZER 2000 |

Page 14 |

A81B4988*$2P3:/?9./

The flowcell must be adjusted after replacing the flowcell tubing, or any time the cell insert is removed or the adjustment set screw is disturbed.

1. With the instrument on, lift the flowcell out of the read well. Do not unscrew the fitting.

2. Press #(L". Type 189 and press (L@(). The instrument will continuously report the detector voltage at 405 nm. Record this value for reference in the next step.

3. Sample deionized water. Visually confirm there are no air bubbles in the cell window.

4. Insert the flowcell into the read well until it bottoms out. Note the value displayed. If the displayed value is more than 50% greater than the value you recorded in step 2, no adjustment is needed.

5. If the displayed value is less than 50% greater than the value in step 2, Remove the flowcell. Adjust the set screw with the hex wrench supplied. Turn the set screw 1/4 turn in either direction and go to step

4. If the value in step 4 increases, turn the set screw in the same direction. If it decreases, turn the setscrew in the opposite direction.

6. Repeat steps 4 and 5 until the displayed value is at a maximum.

7. When complete, press I%($)*twice to return to the main prompt. You must read new water values as described in "Flowcell Configuration".

Service Manual HUMALYZER 2000 |

Page 15 |

Loading...

Loading...