Human HumaStar 300 Service manual

HumaStar 300

|

Service Manual

Cat No. 17901s/2

REVISION LIST OF THE MANUAL

Rev. /DATE. REVISION DESCRIPTION

SYSTEM VERSION

COPYRIGHT

Copyright 2010, Human GmbH, Wiesbaden, Germany. All rights reserved.

No part of this documentation may be reproduced in any form, nor processed, copied or

distributed by means of electronic systems, without prior permission of Human GmbH in

writing. Since all precautionary measures were taken into account in producing these operating

instructions, the manufacturer accepts no responsibility for any errors or omissions. This includes any liability for damage that could arise from possible incorrect operation based on this

information. Subject to changes without notice as result of technical development.

SERVICE UND SUPPORT

Contents

TABLE OF CONTENTS

1 SAFETY INSTRUCTIONS

1.1 INTRODUCTION 1

1.2 USER WARRANTY 1

1.3 INTENDED USE OF THE INSTRUMENT 2

1.4 GENERAL SAFETY WARNINGS 2

1.5 DISPOSAL MANAGEMENT CONCEPT 3

1.6 INSTRUMENT DISINFECTION 3

1.7 BIOHAZARD WARNING 4

2 THE ANALYZER - HUMASTAR 300 7

2.1 GENERAL DESCRIPTION 7

2.2 MAIN CHARACTERISTICS 7

2.3 OPERATION 10

2.4 USER WARRANTY 11

2.5 INSTALLATION 12

2.5.1 Unpacking 12

2.5.2 Installation 13

2.5.3 Environmental Requirements 13

2.5.4 Livel setting of Analyzer 13

2.5.5 Operating-Temperature-Limits 13

2.5.6 Power Requirements 14

2.6 ASSEMBLY PROCEDURE 14

2.6.1 External Connections 14

2.6.2 Connections in the back of the Analyzer 15

2.6.3 Hydraulic Connections 16

2.7 ANALYZER COMPONENTS 17

2.7.1 Monitor 17

2.7.2 TOP View of the analyzer 17

2.7.3 Analytical Plate 17

2.7.4 Reagent Chamber 18

2.7.5 Reagent Arm 19

2.7.6 Sample Tray 19

2.7.7 Sampling Arm 21

2.7.8 Probe Washing Well 22

2.7.9 Sample and Reagent Diluter 22

2.7.10 Peristaltic Washing Pumps 24

2.7.11 Photometer Module 24

1

2.8 SOFTWARE 24

3 OVERALL BLOCK DIAGRAMM (P/N: EI0110.01) 27

3.1 POWER SUPPLY CONNECTIONS (P/N:EI0107.01) 27

3.2 MAIN POWER SUPPLY ASSEMBLY (P/N: AY0097.04) 29

3.2.1 PCB Power Distribution (P/N: 17970/27) 29

3.2.2 Transformer (P/N: EM0050.01) 30

3.2.3 PC Power Supply (P/N: 17956/1) 30

3.2.4 Power Supply + 24V (P/N: 17956/2) 31

3.3 POWER SUPPLY BOARD (P/N: 17970/7) 31

3.4 POWER SUPPLY MAINTENANCE 33

3.4.1 To remove the Power supply 33

3.4.2 Replacement of the PC Power Supply 35

3.4.3 Main Power Switch Replacement 35

3.4.4 Fuse Replacement 36

3.4.5 To replace Transformer 36

3.4.6 Replace Power Supply + 24V 37

3.4.7 Replacement of the Power Distribution Board 37

3.5 TROUBLE SHOOTING GUIDE 37

3.6 SPARE PARTS 41

3.7 ENCLOSED DOCUMENTATION 43

3.7.1 EI0110.01.0.DW (block diagram) 43

3.7.2 EI0107.01.0.DW (block diagram) 43

3.7.3 EI0107.01.0.SC (electrical diagram) 43

3.7.4 17970/27.B.SC (electrical diagram) 43

3.7.5 17970/27.A.PM (assembly drawing) 43

3.7.6 EM0050.01.B.SC (electrical diagram) 43

3.7.7 EA0067.02.0.SC (electrical diagram) 43

3.7.8 17970/7.A.SC (electrical diagram) 43

3.7.9 17970/7.B.PM (assembly drawing) 43

4 INTERFACE PUMP - VALVES (P/N: 17970/24) 55

4.1 MAINTENANCE 57

4.1.1 To Replace Pump Interface and valves 57

4.2 TROUBLE SHOOTING GUIDE 58

4.3 SPARE PART LIST 60

4.4 ENCLOSED DOCUMENTATION 60

4.4.1 17970/24.A.SC (electric diagram pag. 1/3) 60

4.4.2 17970/24.A.SC (electric diagram pag. 2/3) 60

4.4.3 17970/24.A.SC (electric diagram pag. 3/3) 60

Contents

4.4.4 17970/24.A.PM (assembly drawing) 60

5 POWER SUPPLY PHOTOMETER LAMP (P/N: 17970/10) 67

5.1 TROUBLE SHOOTING GUIDE 68

5.2 SPARE PART LIST 68

5.3 ENCLOSED DOCUMENTATION 69

5.3.1 17970/10.A.SC (electrical diagram) 69

5.3.2 17970/10.A.PM (assembly drawing) 69

6 MICROPROCESSOR ASSEMBLY (P/N: EA0073.02) 73

6.1 CPU SLAVE (P/N:17970/8) 74

6.2 MOTHER BOARD (P/N: 17970/9) 82

6.3 MAINTENANCE 85

6.3.1 CPU slave board replacement 85

6.3.2 Mother Board replacement 85

6.4 TROUBLE SHOOTING GUIDE 86

6.5 SPARE PART LIST 89

6.6 ENCLOSED DOCUMENTATION 90

6.6.1 EB0045.00.B.SC (electrical diagram) 90

6.6.2 17970/8.A.PM (assembly drawing) 90

6.6.3 17970/9.A.SC (electrical diagram) 90

6.6.4 17970/9.B.PM (assembly drawing) 90

7 DILUTER DRIVER (P/N: 17970/11) 97

7.1 MAINTENANCE 99

7.1.1 Replacement of Driver Board 99

7.2 TROUBLE SHOOTING GUIDE 100

7.3 SPARE PART LIST 101

7.4 ENCLOSED DOCUMENTATION 101

7.4.1 17970/11.A.SC (electrical diagram) 101

7.4.2 17970/11.C.PM (assembly drawing) 101

8 MOTOR CONTROL ASSEMBLY (P/N:AY0113.01, AY0114.01) 105

8.1 M/B MOTOR CONTROL MOTOR (P/N: 17970/26) 105

8.2 M/B MOTOR CONTROL (P/N: 17970/26) 107

8.3 DRIVER FOR STEPPER MOTOR (P/N:17970/20 - 23) 109

8.4 MAINTENANCE CONTROL MOTOR ASSEMBLY 111

8.4.1 Driver module replacement 111

8.4.2 Replacement of M/B Contorl motor board 111

8.5 TROUBLE SHOOTING GUIDE 112

8.6 SPARE PART LIST 114

8.7 ENCLOSED DOCUMENTATION 115

8.7.1 17970/26.A.SC (electrical diagram) 115

8.7.2 17970/26.A.PM (assembly drawing) 115

8.7.3 17970/26.A.SC (electical diagram) 115

8.7.4 17970/26.A.PM (assembly drawing ) 115

8.7.5 EB0092.01.A.SC (electrical diagram) 115

8.7.6 EB0092.02.A.PM (assembly drawing) 115

8.7.7 EB0092.03.A.PM (assembly drawing) 115

8.7.8 EB0092.04.A.PM (assembly drawing) 115

8.7.9 EB0092.05.A.PM (assembly drawing) 115

8.7.10 EB0092.06.A.PM (assembly drawing)

115

9 DATA PROCESSING OF THE OPTICAL SIGNAL 127

9.1 PREAMPLIFIER (P/N: 18720/8) 127

9.2 CONVERTER A/D (P/N: 17970/19) 128

9.3 PHOTOMETER (P/N:17970/30) 130

9.4 MAINTENANCE 131

9.4.1 Photometer Module 131

9.4.2 Replacement of the preamplifier 131

9.5 TROUBLE SHOOTING GUIDE 132

9.6 SPARE PART LIST 135

9.7 ENCLOSED DOCUMENTATION 135

9.7.1 18720/8.A.SC (electrical diagram) 135

9.7.2 18720/8.A.PM (assembly drawing) 135

9.7.3 17970/19.A.SC (electrical diagram) 135

9.7.4 17970/19.B.PM (assembly drawing) 135

10 PERSISTALTIC PUMP DRIVER (P/N: EB0033.XX) 141

10.1 LINEAR PUMP DRIVER (P/N:EB0122.01) 143

10.2 MAINTENANCE 144

10.2.1 Replacement Peristaltic Pump Driver Board 144

10.2.2 Replacement of the linear pump driver board P6 145

10.3 TROUBLE SHOOTING GUIDE 145

10.4 SPARE PART LIST 147

10.5 ECLOSED DOCUMENTATION 147

10.5.1 8EB0033.01.A.SC (electrical diagram) 147

10.5.2 EB0033.01.A.PM (assembly drawing) 147

Contents

10.5.3 EB0033.02.A.SC (electrical diagram) 147

10.5.4 EB0033.03.A.SC (electrical diagram) 147

10.5.5 EB0033.03.0.PM (assembly drawing) 147

10.5.6 EB0122.01.0.SC (electrical diagram) 147

10.5.7 8EB0122.01.0.PM (electrical drawing) 147

11 ENCODER MOTORE 157

11.1 ENCODER MOTOR + HOME (P/N EB0120.01) 159

11.2 MAINTENANCE 162

11.2.1 Replacement of the Encoder board 162

11.3 TROUBLE SHOOTING GUIDE 163

11.4 SPARE PART LIST 164

11.5 ENCLOSED DOCUMENTATION 165

11.5.1 EB0072.01.A.SC (electrical diagram) 165

11.5.2 EB0072.01.A.PM (assembly drawing) 165

11.5.3 EB0120.00.0.SC (electrical diagram) 165

11.5.4 EB0120.01.0.PM (assembly drawing) 165

12 LIQUID LEVEL SENSOR (P/N:17970/31) 171

12.1 MAINTENANCE 172

12.1.1 Replacement of Level Sensor and its flat cable 172

12.2 TROUBLE SHOOTING GUIDE 173

12.3 SPARE PART LIST 174

12.4 ENCLOSED DOCUMENTATION 174

12.4.1 17970/31.0.SC (electical diagram) 174

12.4.2 17970/31.0.PM (assembly drawings) 174

13 OPTICAL SENSOR (P/N: EB0086.XX, PN: EA0071.01, P/N:

EA0075.01)

13.1 MAINTENANCE 179

13.2 TROUBLE SHOOTING GUIDE 180

13.3 SPARE PART LIST 180

13.4 ENCLOSED DOCUMENTATION 181

13.4.1 EB0086.00.0.SC (electrical diagram) 181

13.4.2 EA0071-75.00.0.SC (electrical diagram) 181

179

14 COMPUTER MODULE (P/N: AY0096.01, P/N: AY0199.01) 185

14.1 COMPUTER PC MASTER (P/N: 17889) 186

14.2 PASSIVE BOARD 6 SLOT ISA BUS (P/N: 17810/7) 187

14.3 MULTI - SERIAL PORT (P/N: 910.002.031) 188

14.3.1 Check and the configuration multi-serial board parameters 188

14.4 CONFIGURATION OF BIOS 190

14.5 TO INSTALL SOFTWARE FROM CD-ROM TO HARD DESK 193

14.5.1 To Save the SW Archives 194

14.5.2 Preparation HW 194

14.5.3 Update SW 194

14.5.4 To Restore HW 195

14.5.5 To Restore SW 195

14.6 MAINTENANCE 195

14.6.1 To Replace the PC MAster Board 195

14.6.2 To Replace the multi-serial Board 196

14.6.3 To Replace the Hard Disk and the Floppy Driver 196

14.6.4 To Replace the passive ISA BUS Board 196

14.7 TROUBLE SHOOTING GUIDE 196

14.8 SPARE PART LIST 199

15 MISCELLANEOUS 201

15.1 DILUTER (P/N: AY0069.05) 201

15.2 AIR PUMP (P/N: AY0121.02) 202

15.3 COOLING SYSTEM (P/N: AY0115.01) 202

15.4 THERMOSTAT (P/N: AY0131.01) 203

15.5 MAINTENANCE 203

15.5.1 Diluter 203

15.5.2 Thermostat 206

15.5.3 Cooling System 208

15.6 TROUBLE SHOOTING GUIDE 212

15.7 SPARE PART LIST 213

15.8 ENCLOSED DOCUMENTATION 214

15.8.1 AY0121.00.0.SC (electrical diagram) 214

15.8.2 M0145.01.0.SC (electrical diagram) 214

15.8.3 AY0115.01.0.SC (electrical diagram) 214

15.8.4 EA0098.01.0.SC (electrical diagram) 214

Contents

16 HYDRAULIC SYSTEM (P/N: HY0012.01) 221

16.1 HYDRAULICS OF THE SAMPLING SYSTEM 221

16.2 HYDRAULICS OF THE INCUBATION BATH 221

16.3 HYDRAULICS OF WASHING AND DRYING THE CUVETTES 222

16.4 WASTE HYDRAULICS 222

16.5 MAINTENANCE 222

16.5.1 General RuLes 222

16.5.2 Peristaltic Pumps 223

16.6 TROUBLE SHOOTING GUIDE 226

16.7 SPARE PART LIST 228

16.8 ENCLOSED DOCUMENTATION 229

16.8.1 HY0012.01.F.CM (Hydraulic diagram page 1 out of 4) 229

16.8.2 HY0012.01.F.CM (Hydraulic diagram page 4 out of 4) 229

16.8.3 HY0012.01.F.CM (Spare part list page 2 out of 4) 229

16.8.4 HY0012.01.F.CM (Spare part Iist page 3 out of 4) 229

17 TEST PROGRAM 235

17.1 DESCRIPTION 235

17.2 DIAGNOSTIC UTILITY 236

17.3 TO RUN DIAGNOSTICS USING THE TESTER.EXE 237

17.3.1 Important Notes and Precautions 237

17.3.2 Utility Reagent System 238

17.3.3 Utility Reaction cuvette - Measuring System 244

17.3.4 Utility of the Sampling System 249

17.4 PRINTMETH.EXE 253

17.5 SATSMITH.EXE 256

17.6 SAVEDBCHEM.EXE 257

17.7 COMMUNICATION PROTOCOL 258

17.7.1 Data Exchange with Host computer 258

17.7.2 Host computer Setup 259

17.7.3 Connections 259

17.7.4 Protocol Structure 259

17.7.5 Transfer of a WorkList (Reception from Host) 260

17.7.6 Transferring Results to Host computer 262

18 MAINTENANCE 267

18.1 PREFACE 267

18.2 OPERATING PROGRAM CHECKS 267

18.2.1 Reagent System 268

18.2.2 Sampling System 269

18.2.3 Reaction and Measurement System Checks 270

18.3 DEVICED FOR MAINTENANCE 272

18.3.1 To remove casing 273

18.4 PHOTOMETER MODULE 275

18.4.1 Photometer 275

18.4.2 To Equalize and Replace Filters 277

18.4.3 Replace Motor and Belt. 280

18.4.4 Replace and clean lenses 281

18.5 TEMPERATURE ADJUSTMENT AND CONTROL 281

18.5.1 Check Temperature in Incubation Bath 281

18.5.2 Check Temperature in the Reagent Chamber 283

18.6 PREPARATION SYSTEM 283

18.6.1 Sampling Arm, vertical movement (Probe) 284

18.6.2 Sampling Arm, rotational movement 286

18.6.3 Reagent Chamber 290

18.6.4 Sample Plate 293

18.7 MEASUREMENT SYSTEM 296

18.7.1 Check Reaction and Measurement Plate 297

18.7.2 Cuvette Washing Arm 303

18.8 PROGRAMMED MAINTENANCE 308

18.8.1 Daily Check 308

18.8.2 Every two weeks 309

18.8.3 Once a month or when necessary 309

18.8.4 Every six months or when necessary 310

18.8.5 Replace Photometer Lamp 310

18.8.6 Programmed Maintenance Table 310

Contents

19 GENERAL TROUBLE SHOOTING GUIDE 313

19.1 PROBLEMS WITH POWER SUPPLY 313

19.2 PROBLEMS WITH MASTER COMPUTER AND ITS CPU SLAVES 313

19.3 PROBLEMS WITH DILUTER 314

19.4 MECHANICAL MOVEMENT PROBLEMS 314

19.5 TEMPERATURE PROBLEMS 315

19.6 PROBLEMS WITH PHOTOMETER, PRE-AMPLIFIER AND LAMP 315

19.7 PROBLEMS WITH UNRELIABLE RESULTS 316

19.8 PREPARATION PROBLEMS 318

19.9 PROBLEMS WITH LEVEL SENSORS AND MIXER 319

19.10 PROBLEMS COOLING SYSTEM 321

19.11 PROBLEMS WITH THERMOSTAT 321

19.12 PROBLEMS WITH PUMPS AND VALVES 322

19.13 LEAKAGE PROBLEMS 322

19.14 PROBLEMS WITH PRINTER 323

19.15 WARNING SIGNALS, ALARMS AND FLAGS 324

20 ACCESSORIES AND SPARE PARTS 327

20.1 ACCESSORIES AND GENERAL SPARE PARTS 327

20.2 ELECTRONIC BOARDS 328

20.3 CABLE KIT MASTER COMPUTER (P/N: KG0058.01) 329

20.4 FUSES 329

20.5 PROGRAMMABLE DEVICES 329

20.6 GENERAL SPARE PARTS 330

20.7 INTERFERENCE FILTERS AND OPTICAL PARTS 330

20.8 COMPLETE MODULES 331

20.9 CONNECTORS AND HYDRAULIC ACCESSORIES 331

20.10 FLAT CABLES IN MOVEMENT 332

20.11 FLAT CABLES FIXED 332

20.12 CALBES UNIPOLAR 332

20.13 MOTORS 333

20.14 ENCORDER ASSEMBLIES 334

20.15 BELTS 334

20.16 SERVICE KIT (P/N:KG0065.01) 334

20.17 BAR CODE READER ASSEMBLY (P/N:AY0133.01) 335

20.18 KIT BAR CODE READER SAMPLES (P/N: KG0055.02) 335

20.19 KIT BAR CODE READER REAGENTS (P/N: KG0055.03) 336

20.20 KIT BAR C. READER REAG-SAMPLE (P/N: KG0056.01) 336

20.21 ISE MODULE (P/N: KG0019.01) 336

20.22 DEVICES FOR MAINTENANCE (P/N: KG0070.01) 337

21 OPTIONAL MODULES 339

21.1 BAR CODE READER 339

21.1.1 Bar Code Reader Interface (P/N: EB0111.01) 340

21.1.2 Assembly Procedure and Maintenance 340

21.1.3 Bar Code Reader Optical Alignment 342

21.1.4 Trouble Shooting Guide 347

21.1.5 Spare Part List 348

21.2 DOCUMENTATION 349

21.3 ISE MODULE (P/N: KG0019.04) 352

21.3.1 Introduction 352

21.3.2 Some Highlights and Specifications 353

21.3.3 ISE Control Board (P/N: EB0181.02) 354

21.3.4 pERISTALTIC PUMP DRIVE (p7n. eb0161:05-06) 357

21.3.5 Serial adapter Board (P/N: EB0171.01) 359

21.3.6 Power Supply for the ISE Module 359

21.3.7 REagents and Solutions needed 359

21.3.8 The ISE Module Parts 360

21.3.9 Mounting and Connecting 361

21.3.10 Operative Procedure 365

21.3.11 Urine determination 366

21.3.12 Maintenance 366

21.3.13 Trouble Shooting Guide 371

21.3.14 Spare Part List 373

21.4 DOCUMENTATION 376

Contents

Contents

safety InstruCtIons 1

1 SAFETY INSTRUCTIONS

1.1 Introduction

This manual is considered as a part of the instrument; it has to be at the

operator’s hand as well as at the maintenance operator’s availability. For

accurate installation, use and maintenance, please read the following

instructions carefully. In order to avoid instrument damage or personal

injury, carefully read the ”GENERAL SAFETY WARNINGS”, describing the suitable

operating procedures. In case of breakdowns or any troubles with the instrument, apply to the local Technical Service.

1.2 User Warranty

HUMAN warrants that instruments sold by one of its authorised

representatives shall be free of any defect in material or workmanship, provided

that this warranty shall apply only to defects which become apparent within

one year from the date of delivery of the new instrument to the purchaser.

The HUMAN representative shall replace or repair any defective item at no

charge, except for transportation expenses to the point of repair.

This warranty excludes the HUMAN representative from liability to replace

any item considered as expendable in the course of normal usage, e.g.: lamps,

valves, syringes, glassware, fuses, diskettes, tubing etc.

The HUMAN representative shall be relieved of any liability under this warranty

if the product is not used in accordance with the manufacturer‘s instructions,

altered in any way not specified by HUMAN, not regularly maintained, used with

equipment not approved by HUMAN or used for purposes for which it was not

designed.

HUMAN shall be relieved of any obligation under this warranty, unless a

completed installation / warranty registration form is received by HUMAN

within 15 days of installation of this product.

This warranty does not apply to damages incurred in shipment of goods. Any

damage so incurred shall be reported to the freight carrier for settlement or

claim.

2

1.3 Intended Use of the Instrument

[IVD]

The instrument is intended for in vitro diagnostic application by

professional users. It has to be used for the expected purposes and in perfect

technical conditions, by qualified personnel, in working conditions and

maintenance operations as described in this manual, according to the GENERAL

SAFETY WARNINGS. This manual contains instructions for professional qualified

operators.

1.4 General Safety Warnings

Use only chemical reagents and accessories specified and supplied by

HUMAN and/or mentioned in this manual. Place the product so that it has proper

ventilation.

The instrument should be installed on a stationary flat working surface, free

from vibrations.

Do not operate in area with excessive dust.

Work at room temperature and humidity, according to the specifications listed

in this manual.

Do not operate this instrument with covers and panels removed.

Only use the power cord specified for this product, with the grounding

conductor of the power cord connected to earth ground.

Use only the fuse type and rating specified by the manufacturer for this

instrument, use of fuses with improper ratings may pose electrical and fire

hazards.

To avoid fire or shock hazard, observe all ratings and markings on the

instrument.

Do not power the instrument in potentially explosive environment or at risk of

fire.

Prior to cleaning and/or maintaining the instrument, switch off the instrument

and remove the power cord.

For cleaning use only materials specified in this manual, otherwise parts may

become damaged. It is recommended always to wear protective apparel and

eye protection while using this instrument. Respective warning symbols, if

appearing in this manual, should be carefully considered.

Gerätename | User manual

safety InstruCtIons 3

1.5 Disposal Management Concept

The currently valid local regulations governing disposal must be observed. It is in

the responsibility of the user to arrange proper disposal of the individual

components.

All parts which may comprise potentially infectious materials have to be

disinfected by suitable validated procedures (autoclaving, chemical treatment)

prior to disposal. Applicable local regulations for disposal have to be carefully

observed.

The instruments and electronic accessories (without batteries, power packs etc.)

must be disposed off according to the regulations for the disposal of electronic

components.

Batteries, power packs and similar power source have to be dismounted from

electric/electronic parts and disposed off in accordance with applicable local regulations.

1.6 Instrument Disinfection

Analytical instruments for in vitro diagnostic involve the handling of human

samples and controls which should be considered at least potentially infectious. Therefore every part and accessory of the respective instrument which

may have come into contact with such samples must equally be considered as

potentially infectious.

Before doing any servicing on the instrument it is very important to

thoroughly disinfect all possibly contaminated parts. Before the instrument is

removed from the laboratory for disposal or servicing, it must be decontaminated.

Decontamination should be performed by authorised well-trained personnel

only, observing all necessary safety precautions. Instruments to be returned

have to be accompanied by a decontamination certificate completed by the

responsible laboratory manager.

If a decontamination certificate is not supplied, the returning

laboratory will be responsible for charges resulting from nonacceptance of the instrument by the servicing centre, or from authority’s

interventions.

4

1.7 Biohazard warning

Analytical instruments for in vitro diagnostic application involve the handling

of human samples and controls which should be considered at least potentially

infectious. Therefore every part and accessory of the respective

instrument which may have come into contact with such samples must equally be

considered as potentially infectious.

For safety reasons, we have labeled instruments with the

„BIOHAZARD“ warning label below.

FIGURE 1

Biological Hazard

Symbol

Gerätename | User manual

safety InstruCtIons 5

Notes:

6

Gerätename | User manual

the analyzer - humastar 300 7

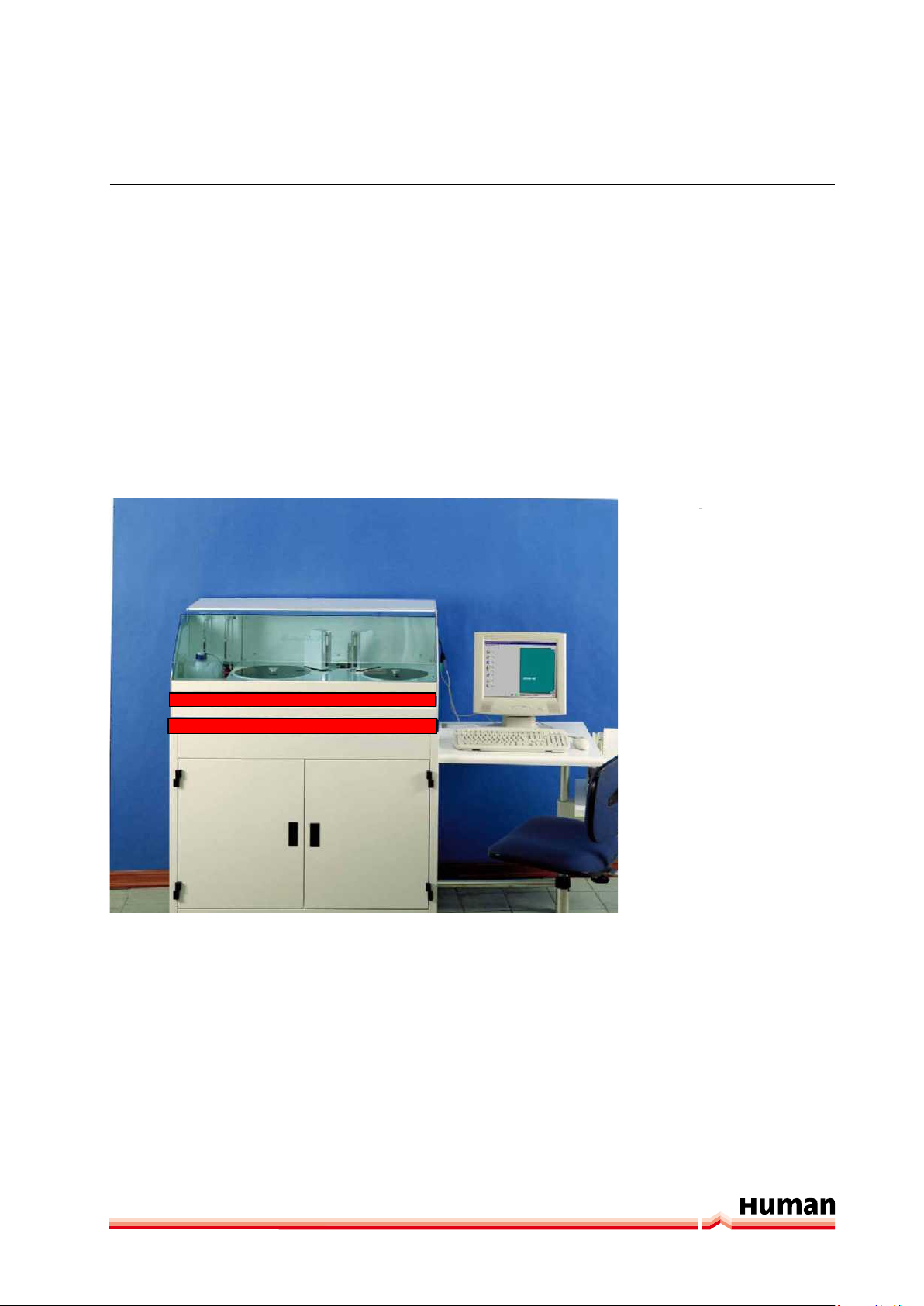

2 THE ANALYZER - HUMASTAR 300

2.1 General Description

HUMASTAR 300 – is an automatic Random Access Clinical Chemistry Analyzer.

HUMASTAR 300 – with its sophisticated updated software offers great versatility and speed of operation. Its unique characteristics and user friendliness make

this analyzer the top in its class with its productivity and throughput of 300

Clinical Chemistry tests plus 180 ISE tests per hour.

FIGURE 2

2.2 Main Characteristics

HUMASTAR 300 is an automatic Random Access Clinical Chemistry analyzer

fully controlled by a MASTER computer (industrial Pentium) and three CPU

slaves. Smart operation, where all the required test for Patient #1 are processed

before starting on Patient #2, with an immediate print-out of the Patient report.

Speed: 300 test/h independently of method used, including 180 electrolytes

with the built-in ISE module.

8

SAMPLE CAPACITY: 40 PRIMARY TUBES or small plastic sample cups; including

16 places reserved for Standards and Controls, plus 4 places for STATS. Possibility to add samples continuously during operation, up to 240 Patients with up

to 30 different chemistries can be processed at a time.

REAGENT CAPACITY: 30 On-line reagents. Both 50 ml reagent bottles and 8 ml

reagent tubes are placed in the Reagent plate. Each reagent container can be

individually cooled or left at room temperature.

REAGENT VOLUME: Is automatically monitored with an On-line inventory The

number of tests available in each reagent container is displayed on the monitor..

OPEN SYSTEM: an unlimited number of user programmable Chemistry and Immunoassay methods can be programmed.

AUTOMATIC PRE-DILUTION OF SAMPLES: upon request, with 15 different dilution ratios.

BAR CODE READER built-in to identify the samples and /or reagents. (optional).

WALK-AWAY OPERATION: once patients are programmed, all operations are

fully automatic. The reaction cuvettes are automatically washed and dried to

assure a non-stop operation.

INCUBATION takes place in quartz cuvettes immersed in a liquid bath at 37°C to

assure perfect temperature control of the reactions at all times.

DIRECT READING: a built-in multi-filter photometer measures the samples directly in their cuvettes, several times during incubation at 8 different wavelength. Each sample has its own reagent-cuvette blank measured before the

addition of sample.

I.S.E MODULE: (optional) built-in for the simultaneous determination of Sodium,

Potassium and Chloride.

AUTOMATIC REPETITION OF TESTS – results that are critical, outside of linear

range or due to substrate depletion are automatically pre-diluted and repeated.

REAGENT VOLUME: 300 µl of reagent is sufficient to run any test.

Gerätename | User manual

the analyzer - humastar 300 9

LIQUID LEVEL SENSOR: both the reagent and Sampling Probes have built-in

liquid sensors and mixer to assure a correct sample preparation.

KEYBOARD: a full keyboard for easy programming of patients with demographics, including a mouse for easy operation and navigation inside the software.

SOFTWARE: user friendly software with graphic presentation guides the operator step by step through all operations.

HELP ON-LINE: special program to assist the operator at all times during programming and operation.

ON-LINE QUALITY CONTROL: Program checks the precision during standardization and daily operation. Controls are displayed over a period of 60 days, including graph, Mean value, S.D. and %CV.

STATS: an INTELLIGENT STOP enables to introduce a STAT sample at any time

and report its result within only 12 minutes, without interfering with the normal routine operation.

PATIENT REPORTS: are user personalized on a 80 column printer. All result data

is automatically memorized on the built-in hard disk and available for future

consultation.

PRINT ON LINE: if activated it will print results immediately after their final measurement.

GRAPHIC DISPAY: possibility to view the curve of any test for each individual

patient as well as all calibration and Quality control curves.

TEST COUNTER: displays the number and the type of test performed on the analyzer.

MANUAL INPUT OF RESULTS – for tests performed manually or on other instruments to be presented on the final Patient Report.

ARCHIVE ERRORS: a list of errors and warnings of the last 90 days are displayed.

COMMUNICATION: in real time with HOST computer according to ASTM proto-

cols.

10

BI-DIRECTIONAL INTERFACE: via a built-in serial port RS 232/C connection to EDP

systems.

2.3 Operation

The analyzer is a self sufficient system that uses some peripherals, such as Mo-

nitor, Mouse, keyboard and printer.

The analyzer consists in three parts:

- Reagent Plate Chamber: plate containing 30 On-line reagents with a choice to

cool or leave the reagents at room temperature.

- Sample Plate: consisting of 4 segments each holding 10 primary

tubes and 10 small plastic cups for automatic pre-dilution. The center of the plate is reserved for 4 STATS,

and 16 places for Standards and controls.

- Analytical System: consists of a reaction plate with 39 quartz cuvettes,

sitting in a liquid bath at 37°C. A built-in multi-filter

photometer measures the mAbs of the samples directly in the cuvettes. A built-in Wash system automatically washes and dries the cuvettes after use for

a continuous operation.

A reagent probe (with a built-in liquid level sensor) aspirates the reagent and

transfers it into the quartz reaction cuvette. The Reagent is incubated in the

liquid bath at 37°C for 90 sec. During its incubation time, it is measured (this

becomes the reagent/cuvette BLANK for each test).

The Sampling Probe (with its built-in liquid level sensor and mixer) aspirates and

deposits the sample by mixing i into the warm reagent to start the reaction.

Both Sampling and the Reagent arms are automatically washed both internally

and externally, dried and are ready to prepare the next sample.

The 12 seconds operational cycle consists in:

- A) Reagent aspiration, dispensing and measurement Reagent/Cuvette

BLANK

- B) Sample aspiration, dispensing, mixing, a sample measurement

- C) A final sample measurement and calculation

- D) Wash and dry cuvette

- E) Measurement of 20 samples in each cycle. (Each sample is measured every

24 sec – 2 working cycles)

Gerätename | User manual

the analyzer - humastar 300 11

The operation is Patient Oriented. All tests for Patient ONE are prepared before

starting on patient TWO. A full patient report is printed as soon as all the result

data for a given patient are available.

All patient data as well as the analyzer calibrations and their graph are stored

on a hard disk. A built-in user friendly Help and Maintenance programs are a

perfect guide for the operator.

2.4 User Warranty

HUMAN warrants that instruments sold by it or by one of its authorized dealers

shall be free of any defect in material or workmanship, provided that this warranty shall apply only to defects which become apparent within one year from

the date of delivery of the new instrument to the purchaser.

HUMAN shall replace or repair any defective item in its factory in Rome at no

charge, except transportation changes. Instruments for repair have to be sent

to HUMAN with all transportation charges prepaid.

This warranty excludes HUMAN from liability to replace any item considered as

expendable in the course of normal usage, e.g.: lamps, valves, syringes, fuses,

diskettes, monitor, tubing etc.

HUMAN shall be relieved of any liability under this warranty if the product is

not used in accordance with the manufacturer‘s instructions, not regularly

maintained, used with equipment not approved by HUMAN or used for purposes for which it was not designed.

HUMAN shall be relieved of any obligation under this warranty, unless:

1. A completed installation /warranty registration form is received by HUMAN

within 15 days of installation of this product.

2. The Buyer, within the applicable period of time, returns the defective product

or part thereof, freight pre-paid at Buyer‘s expense, to HUMAN.

This warranty does not apply to damages incurred in shipment of goods. Any da-

mage so incurred shall be reported to the freight carrier for settlement or claim.

HUMAN reserves the right to reject any warranty claim on any item that has

been altered or has been returned by non-acceptable means of transportation

or packaging. In all cases, HUMAN has the sole responsibility for determining

the causes and nature of the failure, Crony’s determination with regard thereto

shall be final.

12

Notice: Once the carrier

has taken possession of

the system for transportati-

on from the factory, carrier

assumes all liability until

delivery. All claims for

damage due to transportati-

on must be filed with the

carrier as soon as possible.

2.5 Installation

2.5.1 UNPACKING

Shipping and packing materials have been selected to provide maximum protection during transportation under normal handling conditions.

FIGURE 3

Shipping crate

The system

serial number

is identified as the

serial number of

the Analyzer.

Examine the shipping cartons for indications of damage, e.g. crushed or indented walls, holes or gouges, water damage, etc. Have the carrier note any such

damage on the delivery receipt; this will simplify formulating a claim if any of

the instruments or parts are damaged.

Open the carton from the top and remove the instrument with care. As shown

on the graph above. It is recommended that two people help with the removal

of the instrument from its carton and plastic bag. Save all cartons and packing

material until you are sure you have received everything and all is in good working condition.

Gerätename | User manual

Loading...

Loading...