Page 1

Satellite Dish Installation

Guide

Model: DW 3000 One-Way

November 19, 2001

1031361-0202

Revision B

Page 2

Copyright © 2000-2001 Hughes Network Systems, a Hughes Electronics Corporat ion company

All rights reserved. This publication and its contents are proprietary to Hughes Ne twork Sy stems, a

Hughes Electronics Corporation company . No part of this publication may be reproduced in any form

or by any means without the written perm ission of Hughes Network Systems, 11717 Exploration

Lane, Germantown, Maryland 20876.

Hughes Network Systems has made every effort to ensure the correctness and completeness of the

material in this document. Hughes Network Systems shall not be liable for errors contained herein.

The information in this document is subject to change without notice. Hughes Network Systems

makes no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose.

Trademarks

All trademarks, marks, names, or product names referenced in this publication are the property of

their respective owners, and Hughes Network Systems neither endorses nor otherwise sponsors

any such products or services referred to herein.

Page 3

Table of Contents

Satellite Dish Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conventions Used in this Guide . . . . . . . . . . . . . . . . . . . . . . . . . 2

A Word to the Do-It-Yourselfer . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing Software and Locating the Satellite . . . . . . . . . . . . . . 6

Choosing Where to Install the Satellite Dish . . . . . . . . . . . . . . . 7

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selecting a Mounting Option . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing The Mount on a Wooden Deck Post . . . . . . . . . . . . . 12

Installing the Mount on a Wood Framed Roof . . . . . . . . . . . . . 15

Installing the Mount on Concrete or Concrete Masonry Walls. 20

Installing the Mount Onto a Metal Pole . . . . . . . . . . . . . . . . . . 22

Installing the Cap Onto the Satellite Dish. . . . . . . . . . . . . . . . . 23

Installing the LNB/Waveguide . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the Feed Arm to the Satellite Dish. . . . . . . . . . . . . 26

Installing the Satellite Dish/Cap Ass embly onto the Mast . . . . 27

Installing and Routing Interior Cable . . . . . . . . . . . . . . . . . . . 28

Installing Exterior Cables and Connecting to Ground Block . 29

Connecting the Coaxial Cable to the LNB . . . . . . . . . . . . . . . . 30

Overview of Grounding the Satellite System . . . . . . . . . . . . . . 31

Grounding the Mast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Grounding the Metal Pole Mount . . . . . . . . . . . . . . . . . . . . . . . 35

Attaching the Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Pointing the Satellite Dish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

iii

Page 4

iv

Page 5

SATELLITE DISH KIT COMPONENTS

YOUR SATELLITE DISH KIT SHOULD INCLUDE THE FOLLOWING ITEMS:

Mast and Base

Satellite Dis h (rear view)

Plate

Feed Arm

Azimuth/Elevation Cap

Shroud

Brace kit

LNB/Waveguide Assembly

Also included are the indoor

items that are necessary to

connect the satellite dish

and your computer. See the

installation guide that comes

with the software and indoor

components (packaged separately in the antenna box)

for a complete list.

PARTS LIST

You r kit al so co ntains a ssorted har dware. Depen ding on how you ins tall an d groun d your syste m, you may have some

hardware left over when you are done. You will have to supply other items. Go to page 4 to view a table that lis ts w ha t y ou w i l l

need to supply .

• M4 Allen screws, Qty: 4

• Red O-ring, Qty : 1

• Galvanized washers, 3/8-inch Qty: 6

• Allen wrench, 3mm, Qty: 1

• Lag scre w s , 1/4-inch x 4-inc h, Qty: 4

• Lag scre w s , 3/8-inch x 2-inc h, Qty: 4

• Lag scre w s , 3/8-inch x 4-inc h, Qty: 6

• 5/16-inch Nyl ock nuts, Qty : 4

• 5/16-inch Lock washer, Qty: 1

• 1/4-20 He x -H ea d Nut, Q ty : 1

• 5/16-18 x 2-inch Hex screw, Qty: 1

• 5/16-18 Wedge nut, Qty: 1

• 5/16-inch F lat washer , Qty: 5

• Galvanized washers, 1/4-inch, Qty: 4

• 1/4-20 x 1/2-inch He x -Hea d Bolt, Qty: 1

• 1/4-inch Lo c k washer (star w asher for

grounding ), Qty: 1

1

Page 6

CON VENTIONS USED IN THIS GUIDE

The following conventions are used throughout this guide to h elp you become familiar with possible safety and equipment hazards.

This safe ty al ert symbol is us ed to a lert you to hazards or

hazardous situ ations that can res ul t in personal injury. A

signal word,

with the alert symbol to indicate the likelihood and

potential se verity of injury.

DANGER

Indicates an immine nt haza rd or unsa f e pr actic e whic h, if

not avoided, will result in death or severe personal injury .

WARNING

Indicates a hazard or unsafe practice which, if not

avoided, could result in death or severe personal injury.

DANGER, WARNING

CAUTION

, or

, is used

CAUTION

Indicates a hazard or unsafe practice which, if not

avoided, might result in moderate or minor personal injury.

CAUTION

When used without the alert symbol, indicates a hazard or

unsafe pr a ctic e that might resu lt in pr op erty dam ag e .

Note: A note pr esents ad ditional informati on.

2

Page 7

A WOR D TO THE DO-IT-YOUR SELF ER

We recommend you ask a professional satellite installer to mount your satellite dish and run your cables, but we recognize that

some people will elect to do their own installation. If you are one of these people, or if you are undecided about whether or not to

perform your own install at i on, please cons i der the following.

• Mounting the satellite dish to a concrete or masonry foundation, exposed deck timber, or metal pole are the best options for the

homeowner because you can see that the fasteners are properly inst alled.

• Mounting the satellite dish t o the house roo f is a desirable mounting method on ly if you are positi ve that you can dril l the holes for

lag screws within 1/16-inch of the center of t he rafters or trusses. Thi s requires s pecial tools and e xpertise. If you mus t mount t o a

roof, pick a location where the roof is unfinished and accessible from the inside so that you can reinfor ce it if necessary and assure

yourself that the fasteners penetrated the rafters or trusses without splintering them.

• Do not depend on consumer quality stud fi nders to locat e rafters underneath asphalt shingl es because the y may gi ve false positiv e

readings or miss rafters entirely.

• Given a choice, it is always best not to penetrate a roof.

• If a lag screw misses the rafter or truss but is securely fastened in the sheathing, the satellite dish could pull the lag screws out of

the sheathing or peel the sheathing aw ay from t he raft er or t russ during hi gh wi nd l oads.

• If you plan to upgrade to a Two-Way System, which requires that the satellite dish be installed by a professional installer, we suggest you revie w the cop y o f its satellite dish installation manual, HNS part number 1031362-0201, on your software installation

CD. The manual can help you understand the Two-Way System installation requi rements.

• When cabling, if there is even a remote possibility that you will upgrade t o either a DIRECTV

extra cables to save yourself future effort.

• If you plan to or think you may upgrade to a Two-Way System, be sure to install your base plate so that its center is 5 feet above

ground.

• Best grounding results are achiev ed with quad shi elded RG6 coaxial cabl e with a shield resist ance of less than 0.6 o hms per 1 00

feet.

• If you install the satellite dish yourse lf , you must su ppl y a num ber of i tems. S ee the f ollo wing t able.

®

system or a T wo-Way System, run

3

Page 8

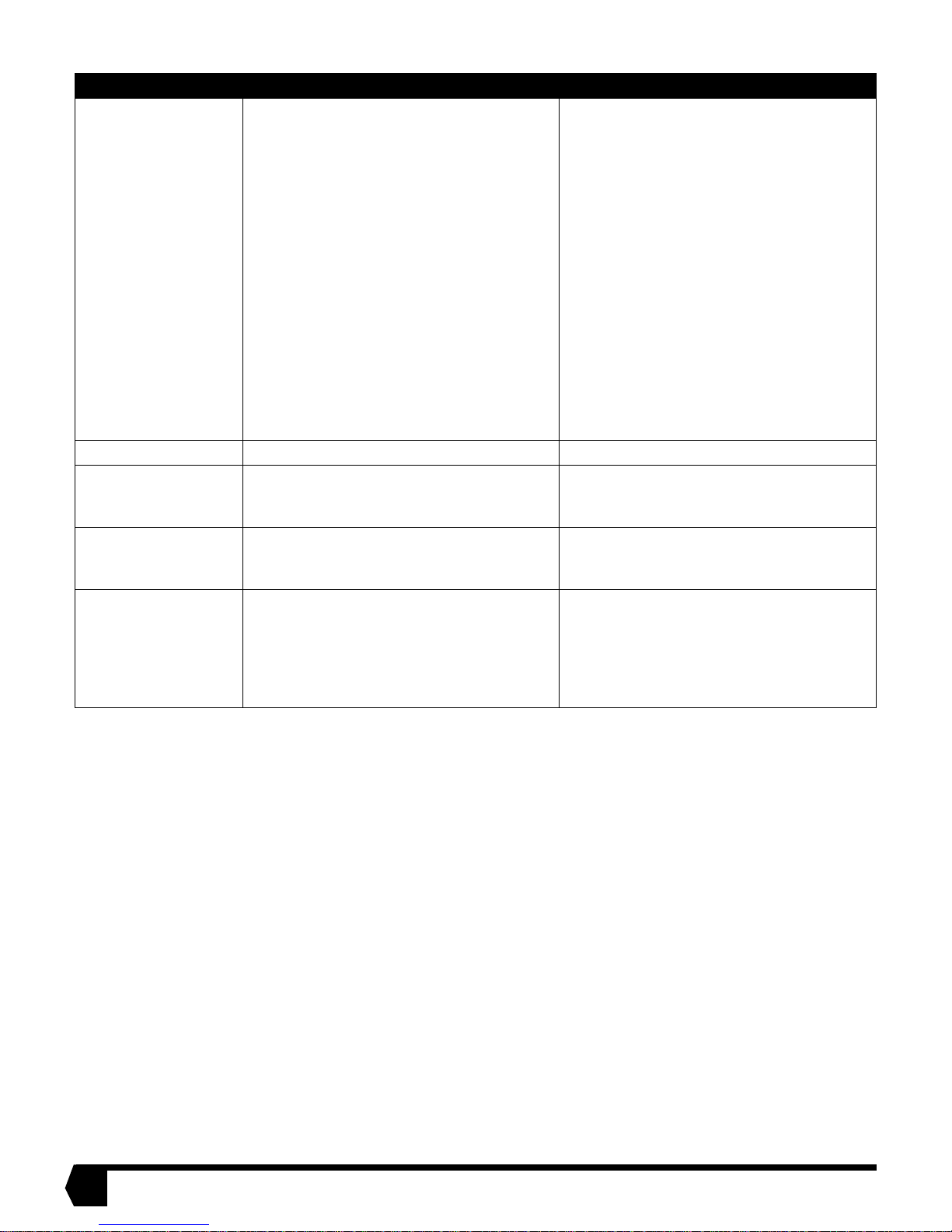

Type of installation Parts you must supply Tools you must supply

ALL INSTALLATIONS

• Coaxial cable (see “Cable specifications” on

page 9)

• Weatherproof 360° cable connectors

• Cable ties

• Insulated U -sh aped tacks

• F-type ground block and screws

• 1/4-inch washer (fo r grounding if no t u sin g RG-6

quad shielded cable)

• #6 wash er (to help with drilling)

• Silicone sea la nt

• 8AWG aluminum and/or 14AWG copper ground

wire, as required for installation or grounding

scheme

• If not using R G -6 qu ad shield coaxial ca ble, one

split bolt with nut for connections at the ground

block

•Compass

• Angle finder or protr acto r

• Carpenter’s level

• Pencil or chalk

• Ladder or stepladder

• Electric drill

• Ruler and tape measure

• Adjustab l e w r en ch (socket preferred)

• Torque wrench (up to 18 ft.-lb s .)

• Open-end o r s ocket wrenches: 3/16, 1/2, 5/16,

7/16, 9/16-inc h

• Needle-nose pliers

• Lineman pliers

•String

• #2 Phillips or sim il ar screwdriver

• Flat-blade screwdriver

• Hammer

• Permanent marker

Wood post

Wood frame roof

All parts supplied • Drill bits: 3/8, 1/4 , a nd 1/8-inch

• If you decide to use 5/16-inch x 4-inch lag screws

• Drill bits: 3/8, 1/4 , 1/8, and 5/32-inc h

for this i nstallatio n, yo u must p rovid e them and the

5/16-inch galvanized washers

Concrete masonry or

concrete wall

• 3/8-inch x 3 -inc h Hilti sleeve anchor, Qty: 6

• If also insta lling op tional br ace kit, 1 /4- inch x 2 -1/4-

• Hammer drill

• Masonry drill bits: 3/8-in ch

inch Hilti sleeve anchor, Qty: 4

Metal pole

• Metal pole, 2-3/8-inch diameter, 9 feet long,

schedule 40 galvanized

• 1-inch x 2-3/8-inch ground clamp for metal pole

• Hole-digging tools

• Wheelbarro w or co ncret e mixin g bo x

•Hacksaw

• 40-lb. bags quick-setting concrete, Qty: 3

• If not using R G -6 qu ad-shielded cable, one 5/8inch by 10-foot ground rod and ground rod clamp

4

Page 9

INTRODUCTION

N

e

s

e

t

t

This Satellite Dish Insta llation Guide Model: DW 3000 OneWay provides information required to assemble your satellite

dish and establish contact with the satellite.

OTHER USEFUL GUIDES

The installation guide included with the software and indoor

equipment gives an overview of the entire installation process,

including the modem and software installation.

WHAT IS INCLUDED IN THE SATELLITE BROADBAND SYSTEM

The satellite broadband system consists of several major components:

• The receive modem

• The satellite dish assembly that is installed outside

• Cables for connecting the receive mod em and your comp uter

•Software

• This guide and the installation guide included with the software and indoor equipment

This guide is intended for an installer experienced in perfo rming the various installation tasks. Depending on how you will

install the satellite dish, you may be required to:

• Use a power drill to drill holes into your house.

• Locate rafters or trusses and drill holes in the exact center of

them.

• Determine whether there are water pipes, electrical wiring, or

gas lines hidden in the walls near where you wi ll be dril ling.

• Route coaxial cable through the foundation wall, under

floors, and through interior walls.

• Ground the satellite dish and coaxial cable as recommended

in the National Electrical Code (published by the National

Fire Protection Association, Batterymarch Park, Quincy, MA

02269).

If you do not feel comfortable performing these tasks or complying with installation requirements, contact your dealer, or

call 1-866-347-3292 for information on having your system

installed by an authorized professional installer.

BASIC STEPS OF SATELLITE DISH INSTALLATION

To install your satellite dish, follow these basic steps:

1. Install the software and receive modem so that you can

determine pointing values for your sat elli te dis h

2. Choose an installation site

3. Select a mounting method

4. Install the m ount

5. Assemble the satellite dish

6. Install the sa tell ite dish on th e m ount

7. Run cable and ground wire t o connect and grou nd t he entire

assembly

8. Aim the satellite dish

ote: if you think you may later upgrade to th

two-way option (both receive and tr ansmit signal

via satellite), you should at this time install th

antenna assembly in a location or manner no

readily accessible to children and at least 5 fee

above gr ound.

INSTALLATION AND YOUR HOME

The Federal Communications Commission (FCC) has a rule

that generally forbids local governments and homeowners

associations from preventing installation of DBS dishes one

meter or smaller in size (in Alaska, the dish size limit does not

apply). For more information, please visit the FCC’s Web site

at www.fcc.gov. Use the site search engine to find the FCC

F a ct Sh eet on Pl acement of Ant ennas .

5

Page 10

INSTALLING SOFTWARE AND LOCATING THE SATELLITE

Before you can install the satellite dish, you must select an installation site. Before you can select an installation s ite, you must determine the direction you will aim the satellite dish. You determine that dir ection by installing the s ys tem software, which will tell you

the direction.

The satellite is located approximately 22,300 miles in geostationary orbit above the equator. The satellite travels above Earth’s equator from west to east at a speed matching that of Earth’s rotation, thus appearing stati onary in relati on to th e Earth’s surface. To aim

the satellite dish at the satellite, you need to kno w the azimuth, ele vation, and polarization angles. As sho wn in the f igures belo w, you

set the satellite d ish to the correc t azi muth angle by tu rnin g it fr om s ide to side , and s et t he elevation by tilting th e dish up or down.

You set the polarization by rotating the satellite d ish. The polariza tion setti ng rotates the satelli te dish to the corr ect orientation for

your geographic location. This varies from one part of the country to another and is different for different satellites. Polarization is

positive in the eastern United States and negative in the western United States. Remember that it is important to pay attention to positive (+) and ne g a tive (-) signs when recording and using poi nt ing values.

Before you install the satellite dish, the receive modem and software must be installed. To install the software, see the installation

guide that came with your software and indoor equipment fo r specif ic in structions. Aft er you ins tall the modem and softwa re, run t he

software program. It will take you to an Antenna Pointing screen, where you will be asked to enter your location or zip code. The

software will provide the azimu th, el evation, and polarizatio n ang les. W rite them below. The pictures below will help you vis ualize

these terms.

Elevation: Azimuth: Polarization:

Elevation Down

Azimuth Right

Polarization

Positive

Elevation Up

Azimuth Left

Polarization

Negative

6

Page 11

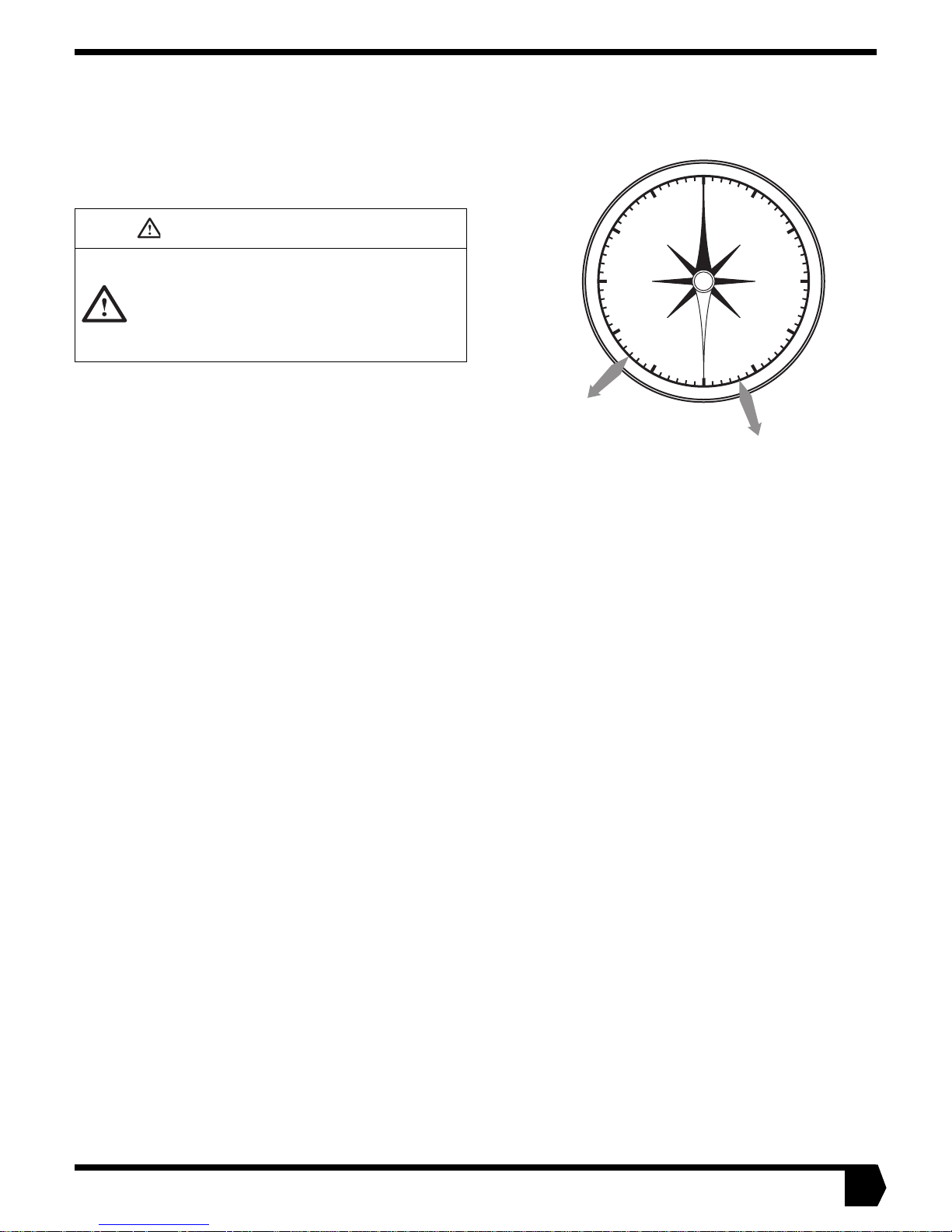

CHOOSING WHERE TO INSTALL THE SATELLITE DISH

TOOLS NEEDED

• Hand-held magnetic compass

• Angle finder or protractor

• Carpenter’s level or straight edge

CAUTION

• Peo pl e can trip, fall into or oth erw ise b um p int o the sat ellite dish.

• Lacerations, bruises, or other impact injuries could

occur .

• Choose an installation site away from where people

are likely to work, ride, or play.

Perform the following steps to select the best site to install the

satellite dish.

1. Go to the location where you plan to install the satellite

dish. It should be a close as possible to the computer, to

minimize the length of the cable run. If the total cable length

required is more than 150 feet see the cable specifications

on page 9.

2. Face south and hold the compass level so the needle can

rotate freely. When the needle stops rotating, it will be

pointing north. Carefully, so as not to disturb the needle,

rotate the body of the compass so that the 0° or N mark

printed on the compass aligns with the painted end of the

needle. The compass is now aligned with magnetic north.

Note: Metal near the compass may affect your reading. If you are

standing near a meta l structure, such as a shed or air conditioning

unit, move several feet away and repeat the measurement. Holding the

compass too close to a large metal belt buckle can have the sam e

effect.

3. Draw an imaginary line from the center of the compass to

the azimuth value you recorded on page 6. This is the direction to point the satellite dish. Use a rock or some other

object to mark the location where you are standing. Then

pick a landmark in the distance that aligns with the magnetic azimuth bearing, or mark the azimuth direction in

some other way.

.

300

270

Example 1

225° Azimuth

0

330

N

NW

W

SW

240

210

Figure 1

30

NE

E

SE

S

150

180

Example 2

160° Azimuth

60

90

120

7

Page 12

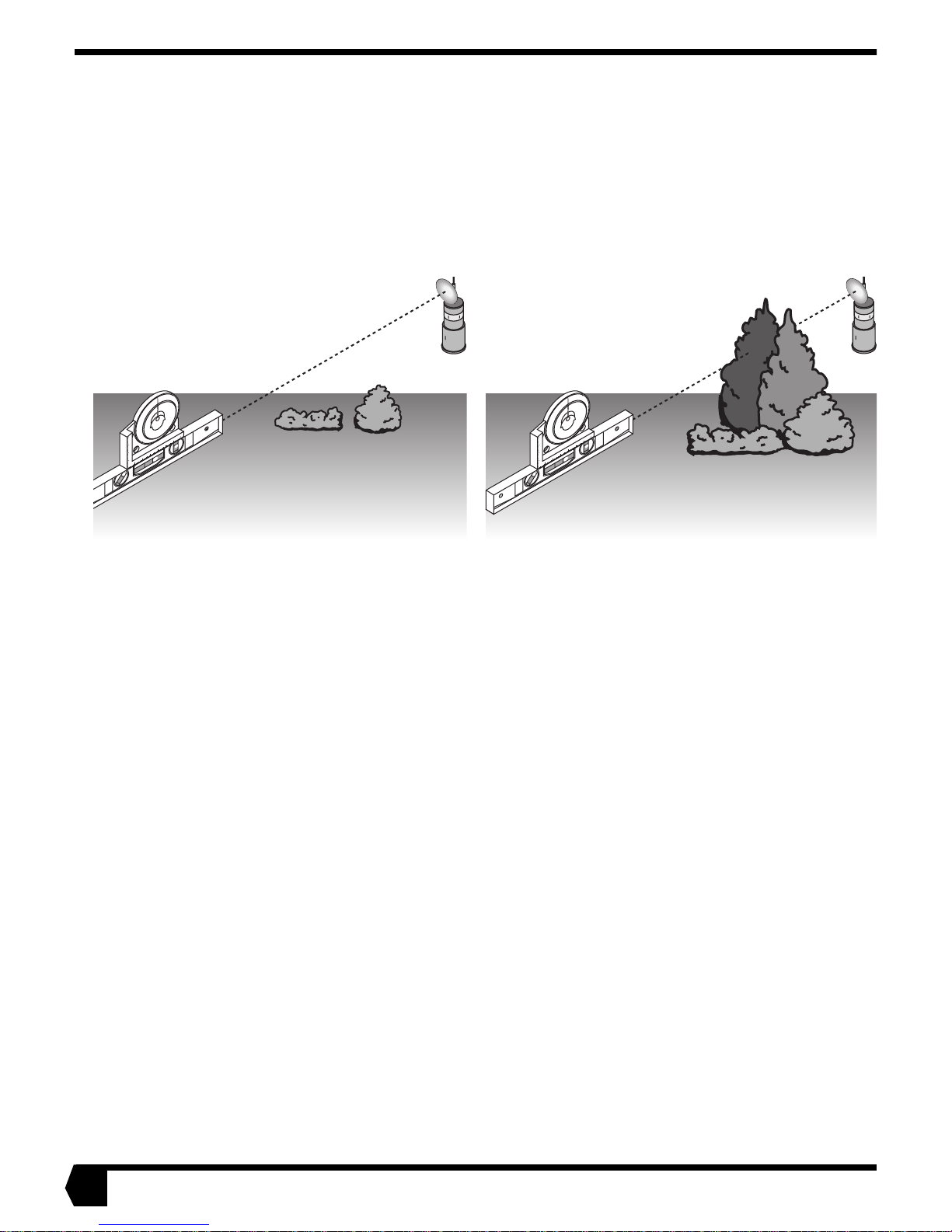

CHOOSING WHERE TO INSTALL THE SATELLITE DISH

4. Using the angle finder and a carpenter’s level or straight

edge, verify that there is an unobstructed line-of-sight

toward the satellite as shown in the diagram b elow. To do

this, align the level along the azimuth bea ring. Then, using

the angle finder, lift the front end of the straight edge to correspond to the elevation angl e you recorded on page 6. Sight

along the straight edge to verify that there are no obstruc-

Good View

(Clear line-of-sight, no

obstructions in the way)

4

5

0

90

5

4

4

5

90

2 1

0

45

3

2

1

Figure 2

tions (such as buildings or trees) blocking the view. Take

into account future tree growth; if you are installing during

the fall or winter, take into account spring and summer leaf

growth. Also, avoid installing the satellite dish next to electrical equipment such as air-conditioning units, because they

can cause signal interference.

Poor View

(Obstructed line-ofsight, trees are blocking the signal)

4

5

0

90

5

4

4

5

90

2 1

0

45

3

2

1

8

Page 13

CABLE SPECIFICATIONS

Note: Coaxial cables with copper clad steel center conductor are not recommended.

Note: Do not use splitters.

Note: Line amplifiers are required for Receive cable runs of more than 150 ft.

You must use plenum grade cable if the cable is to be run in plenum space which is carrying return air for the air circulation system,

Check local laws to see if plenum grade cable is required in other locations.

If the Receive cable run length is less than 150 ft., then no line amplifier is required. If the Receive cable run length is greater than

150 ft., but less than 30 0 ft., then install a line ampl ifi er in the R ecei ve cable only, a minimum of 25 ft . and up to 30 ft. f rom the LNB.

A line amplifier, if needed, can be installed only in the Receive cable, not in the Transmit cable. (There is no Transmit cable in the

one-way product.)

Line amplifier specification: Channel Master 5113 IF D or equivalent.

Grounding and Cable Choice

Your choice of grounding scheme may affect your choice of cable;

Grounding the Sa tellit e System” on pa ge 31

meeting the National Electrical Code grounding requirements is easier if you use RG-6 with

solid copper center conductor and quad shield. How ever, y o u can als o meet the

requirements by using RG-6 with solid copper center conductor only and g rounding the

mast as described in the Overview.

for information about grounding. Note that

Recommended cable specifications for Two-Way and One-Way Systems

Cable length from sat ellite

dish to computer

Up to 300 ft. RG6 with solid copper

300 ft. to 420 ft. RG6 with solid copper

Important: A higher gra de of cab l e can be used f o r an inst allati on whe re a lo w er gr ade is

specified. Fo r exa mple , an RG6 cab le with sol id copper cent er conducto r and quad shiel d

can be used for installations w here th e c able length is less th an 300 ft. Never use a lower

grade of cable than specified. Be sure to record the grade of the cable used for your

installation. The grade is printed on the cable every few feet. Never use a cable which

does not have the manufacturers name and its grade clearly printed on it!

Type of cable to be used

Receive Transmit

center conductor

(CommScope 5729 or

equivalent)

center conductor

(CommScope 5729 or

equivalent)

see “Overview of

RG6 with solid copper

center conductor

(CommScope 5729 or

equivalent)

RG6 with solid copper

center conductor and quad

shield (CommScope 5781

or equivalent)

9

Page 14

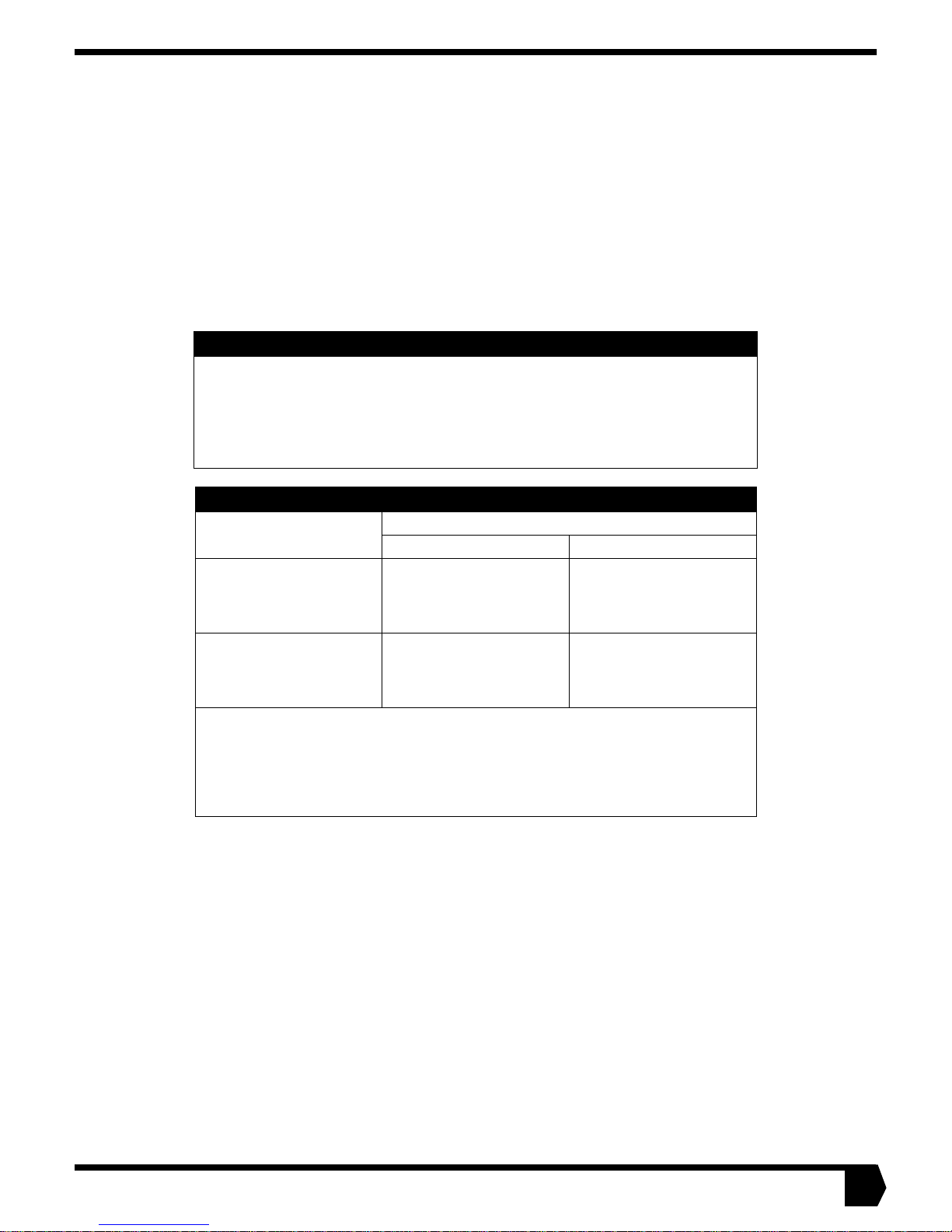

SELECTING A MOUNTING OPTION

Based on the satellite dish installation site, decide on th e best

surface for mounting your satellite dish. The base plate and

mast assembly that came with your satellite dish is called a uni-

versal mount. Some mounting options require only the universal mount. Other mounting options requ ire that you also use

the two struts (called a brace kit) that came assembled with

your satellite dish kit. The struts slip over the mast and provide

addition support.

CAUTION

• Before installing the universal mount brace kit, you

should obtain an analysis from a structural engineer to

confirm that the install ation site is sui table f or mou nting

your sate llite dish using the br a ce kit.

• Failure to ensure that the installation site is capable of

supporting the weigh t o f th e satellite dish c ou ld result

in personal injury or property damage.

CAUTION

The satellite d ish sh ould not be inst alled on a wood fr ame

roof unless the interior of the roof is unfinished so that

placement of la g s crews can be verified and the ro of

reinforc ed if n ec es sa ry.

Note: If you plan to later upgrade your system to two-way (both

receive and tra nsmit signals via satellite), you must install the satellite

dish in a location not readily accessible to children and at least 5 feet

above ground to avoid any risk of harm from radio frequency energy

emitted when transmitting signals to the satellite.

Note: Professional installation of your one-way satellite dish is

strongly r ecommended. I f you do in stall the satellite d ish your self, y ou

must:

• F ollow the in structions in this manual pr e cisely

• Install the satellite dish no higher than 30 feet above grade

• Install the satellite dish only on approved surfaces, and NOT on

any other surfaces

• If necessary, be able to locate wood members from behind the roof

• If necessary, install lag scr ews in the center of wood memb ers

INSTALLING THE SATELLITE DISH ON A WOOD DECK POST

You can use the univ ersal mount to install the satellite dish on a

6-inch x 6-inch Southern Pine wood deck post.

See “Installing The Mount on a Wooden Deck Post” on

page 12.

G-218

Figure 3

INSTALLING THE SATELLITE DISH ON TYPICAL WOOD

ROOF CONSTRUCTION

You can use the universal mount and brace kit to install the satellite dish on typical wood roof construction.

See “Installing the Mount on a Wood Framed Roof” on

page 15.

10

Figure 4

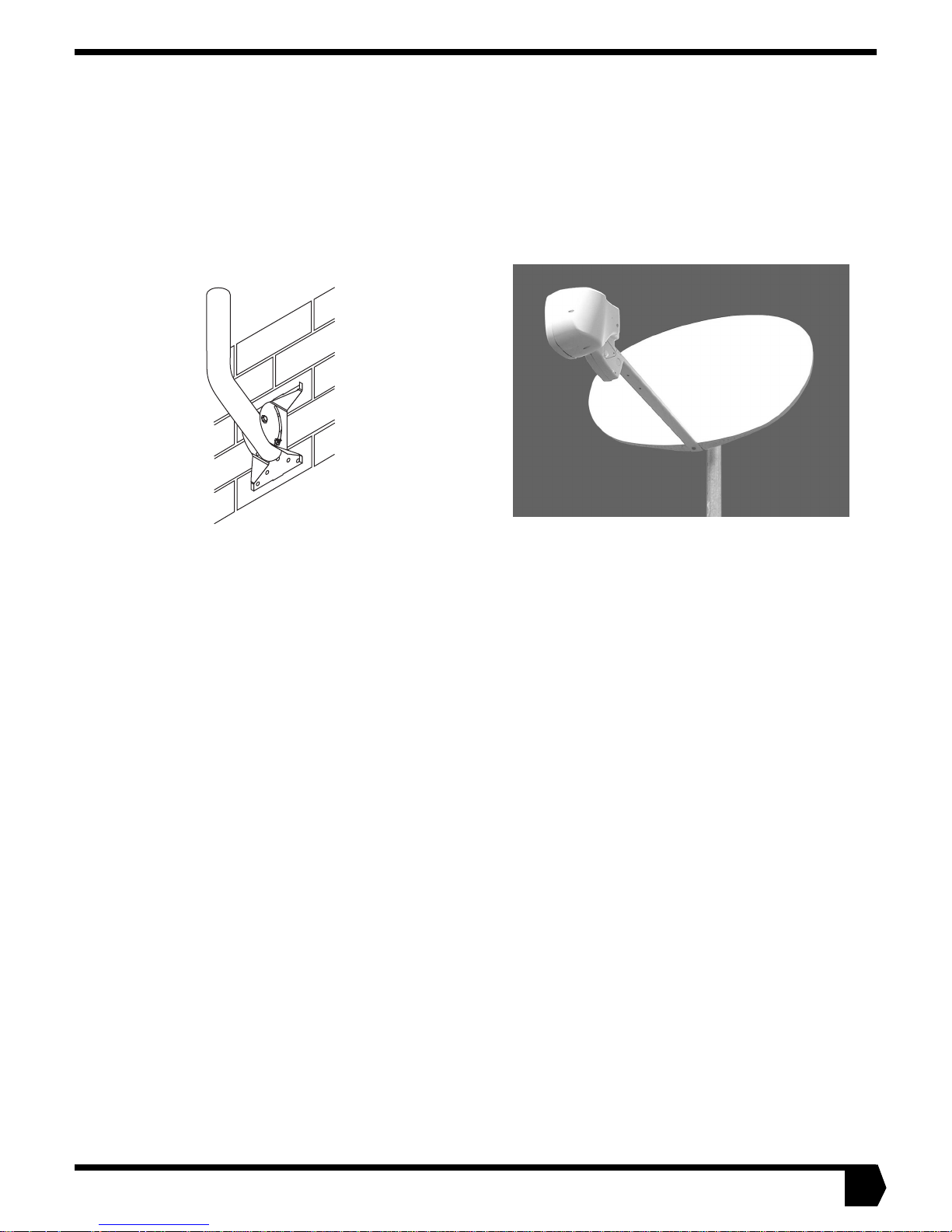

Page 15

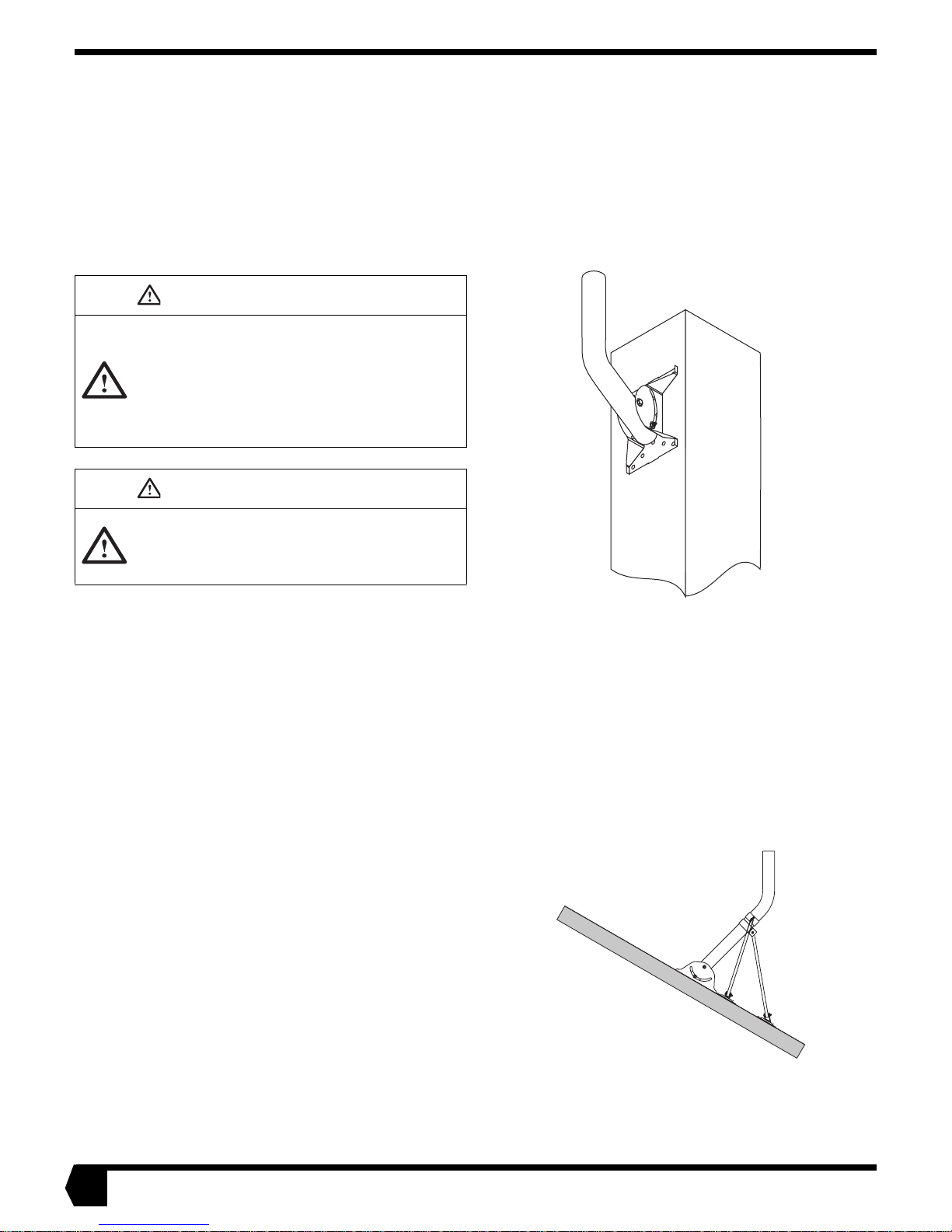

SELECTING A MOUNTING OPTION

INSTALLING THE SATELLITE DISH ON CONCRETE OR CONCRETE MASONRY WALLS

You can use the universal mount to install the satellite dish on

concrete masonry or concrete walls. The brace kit can also be

installed for greater stability, but is not required.

See “Installing the Mount on Concrete or Concrete

Masonry walls” on page 20.

Figure 5

INSTALLING THE SATELLITE DISH ON A METAL POLE

You can install the satellite dish directly on a 9-foot metal pole.

If you choose this mount option you will not need the universal

mount or universal mount brace kit. Store them for possible

future use.

See “Installing the Mount Onto a Metal Pole” on page 22.

Figure 6

11

Page 16

INSTALLING THE MOUNT ON A WOODEN DECK POST

The satellite dish can be installed on a 6-inch x 6-inch Southern Pine wood deck support post. The post can be no more than 8 feet

tall. It must be adequately attached at top and bottom. Posts made of other species of wood may be used as long as their material

properties match or exceed those of Southern Pine. Posts made of other species of wood whose material properties do not match or

exceed those of Southern Pine require engineering evaluation and approval before being used. The satellite dish may not be installed

on an unsupported wooden po st.

PARTS NEEDED TOOLS NEEDED

• Lag screws, 3/8-inc h x 4-inch, Qty: 6

• W a sh ers, 3/8-inch, Qty: 6

• Silicone se alant

• Carpenter’s level

• P e ncil

• Ruler

• 9/16 and 1/2-inch socket wrench

• Electric drill

• Drill bits, 3/8, 1/4, and 1/8-inch

• Torque wrench

up to 18 ft-lbs)

• Ladder

(capabl e o f t orq ui ng

12

Figure 7

Page 17

INSTALLING THE MAST ONTO A W OODEN DEC K POST

INSTALLATION PROCEDURE

DANGER

• If the sat elli te d ish contacts electric power lines, y o u

will be killed or s eriou sly injured.

• Before starting the installation procedure, make sure

there are no power lines nearby.

CAUTION

• The satellite dish cannot be installed on an unsupported wood post of any size.

• Install the satellite dish only on a w o od en deck post.

• Install the satellite dish only as described in this man -

ual.

Note: for an installation to be successful, the mast must be plumb. Replumb the mast wheneve r in str ucted to do so, an d re-plumb it whenever you feel it is necessary .

1. Orient the universal mount so the square hole in the base

plate is at the top as in Figure 8 before installation.

2. Use a 1/2-inch socket wrench to loosen the adjustment nuts

and swing the mast so that it is oriented as in Figure 9.

3. Mark the centerline of the deck post.

4. W ith an assistant place the base plate on the centerline at the

spot you plan to install it (see Figur e 8).

5. Loosen the pivot bolt and adjustment nuts and plumb the

mast in two perpendicular directions (see Figure 9). If you

successfully plumb the mast proceed to s tep 6. If yo u cannot

plumb the mast find another locat ion to install the satellit e

dish. Note: it is essential that the mast be plumb. If you can-

not make the mast plumb at this point, f i nd another ins tallation site.

6. Mark the center of the base plate’s top center hole.

7. Drill a hole on the center mark in the manner described

below. Note: to avoid drilling too deeply, wrap a piece of

masking tape around the drill bit shank at the proper depth

so that you can see when you should stop d ri lling.

Drill a 1/8-inch pilot hole 2 inches deep.

Going into the pilot hole, drill a 1/4-inch hole 4 inches deep.

Going into the 1/4-inch hole, drill a 3/8-inch hole to a depth

equal to the unthreaded portion of the 3/8-inch x 4-inch lag

screw.

8. Fill the holes with silicone sealant and apply silicone sealant

to the entire back side of the base plate. Apply enough so

that it will press out around the edges when it is fastened

down (see Figure 10). Doing this will help prevent water

from seeping into the wood.

Top left center

All lag screws

3/8-inches x 4-inches

Bottom left center

Carpenter's level

Plumb vial

Bubble

Bubble must

be centered

between

marks

Mast

Pivot bolt

Adjustment nut

(2 places)

Sealant

Top

Bottom

Figure 8

Figure 9

Top right center

Top center

Center line

Bottom center

Bottom right

center

Mast

(top view)

Level

G-21848

11/16/00

Figure 10

13

Page 18

INSTALLING THE MAST ONTO A W OODEN DEC K POST

9. Install a 3/8-inch w as her on a 3/8-inch x 4- inch lag s crew.

10. Use a 9/16-inch socket wrench to screw the lag screw into

the top center hole of the base plate (see Figure 11). You

may need to swing the mast out of the way temporarily.

Tighten the screw snugly so that the base plate can barely

move.

Do not pound the lag screws into the post with a hammer or mallet.

Doing so may split the wood and r ender the post unus able.

11. Re-plumb the mast in two perpendicular directions as you

did in step 5. You may need to make adjustments to the mast

and/or the base plate.

12. Tighten the lag screw snugly s o that the base canno t move.

13. Use a 1/2-inch socket wrench to tighten the adjustment nuts.

14. Re-plumb the mast. (Tightening the nuts can move the mast

off plumb.) Note: the mast must be plumb before proceed-

ing.

15. Repeat step 6 and step 8 to drill holes for the top left center,

top right center, bottom left center, and bottom right center

holes. See Figure 11.

Note: You must mark the center of all remaining screw holes

accurately. A Stanley Jumbo Self Centering Nail Set or similar

product will produce the best results. A #6 washer can also be

used to guide your pencil as it marks the hole center

Note: the base plate must not move when you drill the holes.

16. Fill the holes with silicone sealant.

17. Install a 3/8-inch washer on each of the 3/8-inch x 4-inch

lag screws.

18. Use a 9/16-inch socket wrench to screw the lag screw into

the four holes. Do not tighten the screw s f ully.

19. R e-plumb th e mast and snu g down the four screws firmly.

20. Use a 1/2-inch socket wrench to loosen the mast adjustment

nuts and swing the mast down so you hav e access t o the bot tom center hole.

21. Repeat steps 6 and 7 to drill holes for the bottom center

hole.

Note: the base plate must not move when you drill the hole.

22. Fill the hol e with silicone s ealant .

23. Install a 3/8-inch washer on the final 3/8-inch x 4-inch lag

screw.

24. Use a 9/16-inch socket wrench to screw the lag screw into

the lower center hole. Do not tighten the screw fully.

25. R e-plumb th e mast and snu g down the lag screw.

26. Use a torque wrench to sung down t he mast ad just ment nuts

to 18 ft.-lbs. Confirm the mast is pl umb afte r torqui ng.

Note: The mast must be plumb before you can proceed. If you cannot

plumb the mast, repeat the installation or find another installation site.

Continue with section “I nstalling the Cap O nto the Satellite

Dish” on page 23.

Top left center

All lag screws

3/8-inches x 4-inches

Bottom left center

Top

Bottom

Figure 11

Top right center

Top center

Center line

Bottom center

Bottom right

center

14

Page 19

INSTALLING THE MOUNT ON A WOOD FRAMED ROOF

You can install the satellite dish onto a wood framed roof. You must use the brace kit. The minimum size for roof truss members is 2

inches x 4 inches. Roof rafters must be nominal 2x material (2x4, 2x6, etc.) Either size roof rafters or trusses must be16 t o 24 inches

on center. The roof surface must consist of relatively thin, resilient materials, such as asphalt or composite shingles, sheet metal, or

similar materials, over wood sheathing with a thickness of 3/4 inch or le ss. Satellite dishes cannot be installe d on flat roofs, slate

roofs, or Spanish tile roof ing made of cl ay or other bri t tle materials. The roof pitch (or slope) must be between 3:12 and 12:12.

All center hole lag screws must be centered in the rafter or truss to which they are attached. For this reason, you must be able to

locate rafters and trusses and the center of rafters and trusses with a high degree of accuracy, which can be difficult to do. Home construction varies a great deal. Construction styles, materials, and dimensions can all vary widely. In addition, stud finders give false

readings on multilayered surfaces, such as a roof. Also, you need experience in home construction to be able to determine the exact

location of rafters and trusses and their centers. The satellite dish should not be installed on a wood frame roof unless the interior of

the roof is unfinished so that placement of lag screws can be verified and the rafters or trusses reinforced if necessary.

If you do not have the knowledge and experience to accurately locate rafters and trusses and the center of rafters and trusses with a

high degree of re liabi lit y, you should contact a p rofessional satellit e di sh i ns talle r f or inst allat ion.

Large-timber roofs with frequent spacing of members are also permitted. These are constructed of wood members larger than the

nominal 2x sizes, and include post and beam structures with members from 4 inches x 4 inches and larger. The members cannot be

spaced more than 24 inches on center. Their phy sical properties must match or exceed those of Spruce-Pine-Fir #2.

PARTS NEEDED TOOLS NEEDED

• Lag screws, 3/8-inc h x 4-inch, Qty: 2

• Lag screws, 1/4-inch x 4-inch, Qty: 4 (5/16-inch x

4-inch recommended if available)

• Lag screws, 3/8-inc h x 2-inch, Qty: 4

• W a sh ers, 3/8-inch, Qty: 6

• Washers, 1/4-inch, Qty: 4 (5/16-inch if needed)

• Silicone se alant

• Carpenter’s lev el

• Pencil or chalk

• Ruler

• Socket wrenches, 7/16, 1/2, and 9/16-

inch

• Electric drill

• Drill bits, 3/ 8- , 1/ 4-, 1/8, and 5/32-in ch

• Torque wrench (can torqu e u p to 18 ft-

lbs)

• Ladder

Figure 12

15

Page 20

INSTALLING THE MOUNT ON A WOOD FRAMED ROOF

Corner holes

Corner holes

Top center hole

Bottom center hole

Centerline

Rafter or truss

0

INSTALLATION INSTRUCTIONS

DANGER

• If the sat elli te d ish contacts electric power lines, y o u

will be killed or s eriou sly injured.

• Before starting the installation procedure, make sure

there are no power lines nearby.

CAUTION

• Rafters or truss es m u st be located 16 to 24 inch e s

apart on center, except for large-timber ro ofs, which

can be located no m or e th an 24 inches apart on center.

• The roof surface must consist of relatively thin, resilient

materials, such as asphalt or composite shingles,

sheet metal, or sim ila r m a te rials , over woo d sh ea thin g

with a thickn es s that must not exceed 3/4 inch .

• Satellite dishes cannot be installed on slate roofs or

Spanish tile roofing made of clay or other brittle materials.

• The roof pitch (also called slope) must be between

3:12 and 12:12.

• The sat elli te dish cannot be installed on a flat ro of.

• Center hole lag screw s

or truss.

• The satellite dish should not be installed on a wood

frame roof un les s the interior is unfinis he d so that

placement of la g s cr ews can be verified and the roof

reinforced if n ec es sa ry.

• Install the satellite dish only as described in this man ual.

must

be centere d in t he rafter

.

Carpenter's level

Plumb vial

Bubble

Bubble must

be centered

between

marks

Mast

Pivot bolt

Center hole lag

screws are 3/8 inches

by 4 inches

Corner lag screws

are 3/8 inches

by 2 inches

Figure 13

Mast

(top view)

Level

CAUTION

If you do not have the knowledge and experience to

accurately loc ate rafters and the ce nte r o f rafters with a

high degree of re liability, you should contact a prof essiona l

satellite dish install er f or insta llation .

Before you begin, make sure the rafters or trusses (called members) in your house are located 16 to 24 inches on center.

Remember that 2 x 4 and 2 x 6 inch members are actually

1-1/2 inches thick.

Note: for an installation to be successful, the mast must be plumb. Replumb the mast wheneve r in str ucted to do so, an d re-plumb it whenever you feel it is necessary .

1. Orient the universal mount so the square hole in the base

plate is at the top as in Figure 13 before installation.

2. Use a 1/2-inch socket wrench to loosen the adjustment nuts

and swing the mast so that it is oriented as in Figure 14.

3. Mark the centerline of the rafter or truss.

16

Adjustment nut

(2 places)

T0

Figure 14

Page 21

4. W ith an assistant place the base plate on the centerline at the

Corner holes

Corner holes

Top center hole

Bottom center hole

Centerline

Rafter or truss

s

0

spot you plan to install it (see Figur e 15).

5. Plumb the mast in two perpendicular directions (Figure 16).

If you successfully plumb the mast proceed to step 6. If you

cannot plumb the mast find another location to install the

satellite dish. Note: it is ess ential th at the mas t be plumb. If

you cannot make the mast plumb at this point, find another

installation site.

6. Mark the center of the base plate’s top center hole

(Figure 15).

7. Drill a hole on the center mark in the manner described

below.

Note: to avoid drilling too deeply, wrap a piece of masking tape

around the dr ill bi t sh ank at the proper depth so tha t you can see

when you should stop drilling .

Drill a 1/8-inch pilot hole 2 inches deep.

Going into the pilot hole, drill a 1/4-inch hole 4 inches deep.

Going into the 1/4-inch hole, drill a 3/8-inch hole to a depth

equal to the unthreaded portion of the 3/8-inch x 4-inch lag

screw.

Note: You must mark the center of all screw holes accurately. A Stanley Jumbo Self Centering Nail Set or similar

product wi ll produce the best r e su lts. A #6 was her can al s o

be used to guide your pencil as it marks the hole center.

8. Apply silicone sealant in the holes and to the entire back

side of the base plate. Apply enough so that it will press out

around the edges when the plate is fastened down.

9. Install a 3/8-inch w as her on a 3/8-inch x 4- inch lag s crew.

10. Use a 9/16-inch socket wrench to screw the lag screw into

the top center hole of the base plate (see Figure 15). You

may need to swing the mast out of the way temporarily.

Tighten the screw snugly so that the base plate can barely

move.

Note: Do not pound the lag scre ws into the rafter or truss with a hammer or mallet. Doing so may split the wood and render the rafter or

truss unusable.

11. Re-plumb the mast in two perpendicular directions as you

did in step 5. You may need to make adjustments to the mast

and/or the base plate. If you adjust the base plate, do not

move the center of the bottom center hole off the centerline

more than 1/16-inch.

12. Tighten the lag screw snugly s o the base pl ate cannot move.

13. Use a 1/2-inch socket wrench to tighten the adjustment nuts.

14. Re-plumb the mast. (Tightening the nuts can move the mast

off plumb.) Note: the mast must be plumb before proceed-

ing.

15. Adjusting the drilling depth for the 3/8-inch by 2-inch lag

screws, repeat steps 6 and 7 to drill holes for the four corner

holes. See Figure 15.

Note: the base plate must not move when you drill the holes.

INSTALLING THE MAST ON A WOOD FRAMED ROOF

Carpenter's level

Plumb vial

Bubble

Bubble must

be centered

between

marks

Mast

Pivot bolt

Adjustment nut

(2 places)

Center hole lag

screws are 3/8 inche

by 4 inches

Corner lag screws

are 3/8 inches

by 2 inches

Figure 15

Mast

(top view)

Level

T0053

Figure 16

17

Page 22

INSTALLING THE MOUNT ON A WOOD FRAMED ROOF

16. Fill the holes with silicone sealant.

17. Install a 3/8-inch washer on each of the 3/8-inch x 2-inch

lag screws.

18. Use a 9/16-inch socket wrench to screw the lag screw into

the four holes. Note: do not overtighten the screws. You may

strip the screw threads.

19. R e-plumb th e mast and snu g down the four screws firmly.

20. Use a 1/2-inch socket wrench to loosen the mast adjustment

nuts and swing the mast down so you hav e access t o the bot tom center hole.

21. Repeat steps 6 and 7 to drill holes for the bottom center

hole. Note: the base plate must not move when you drill

the hole.

22. Fill the holes with silicone sealant.

23. In stall a 3/8-inch w asher on the 3/8-i nch x 4-inch lag screw.

24. Use a 9/16-inch socket wrench to screw the lag screw into

the lower center hole. Do not tighten the screw fully.

25. R e-plumb th e mast and snu g down the lag screw.

26. Use a torque wrench to sung down t he mast ad just ment nuts

to 18 ft.-lbs. Confirm the mast is pl umb afte r torqui ng.

Note: The mast must be plumb before you can proceed. If you cannot

plumb the mast, repeat the installation or find another installation site.

Figure 17

INSTALLING THE BRACE KIT

1. Slip the short 18-inch strut coll ar ont o the mas t as sh own in

Figure 17.

2. Secure the collar to the mast by using a 7/16-inch socket

wrench to tighten the Nylock nut installed on the bolt.

3. Position the strut mounting plate below the mast and base

plate so the two screw holes are exactly in line vertically

with the mast base plate center holes (see Figure 18).

4. Mark the center of the mounting plate top center hole (see

Figure 17).

5. Drill a hole on the center mark in the manner described

below. Note: to avoid drilling too deeply, wrap a piece of

masking tape around the drill bit shank at the proper depth

so that you can see when you should stop d ri lling.

Drill a 5/32-inch hole 4 inches deep.

Going into the 5/32-inch hole, drill a 1/4-inch hole to a

depth equal to the unthreaded portion of the 1/4-inch x

4-inch lag screw.

6. Fill the holes with silicone sealant, and apply silicone sealant to the bottom of the mounting plate.

7. Install a 1/4-i nch washer on the 1/ 4-inch x 4-inch lag screw .

8. Use a 7/16-inch socket wrench to screw the lag screw into

the mounting plate hole. Note: Do not pound the lag screws

into the rafter with a h ammer or malle t. Do ing s o ma y sp li t

the wood and damage the raf ter or t ru ss.

Center line

Top center hole

Bottom center hole

Figure 18

18

Page 23

INSTALLING THE MOUNT ON A WOOD FRAMED ROOF

9. Detach the strut from the mounting plate and repeat step 5

through step 9 for the lower center hole. Reattach the strut

when done.

10. Secure the collar to the mast by using a 7/16-inch socket

wrench to tighten the Nylock nut installed on the bolt.

11. Re-plumb the mast.

12. Slip t he long 25 -in ch strut collar o ver the mast until it fits as

shown in Figur e 19.

13. Position the strut so that its mounting plate center holes are

on center of the rafter immediately to the left (or to the right

if you prefer). The 25-inch strut should be at approximately

a 90° angle to the 18-inch strut. At the same time, minimize

any angle formed between the 25-inch strut and the centerline of the mast base plate (see Figure 19).

14. R epeat step 4 t hrough s tep 10 for the 25-inch st rut mounti ng

plate.

15. R e-plumb the mast . If you had to l oosen the adjust ment nuts

to plumb the mast, snug them again to 18 ft.-lbs.

Note: The mast must be plumb before you can proceed. If you cannot

plumb the mast, repeat the steps above or find another installation

site.

Continue with section “I nstalling the Cap O nto the Satellite

Dish” on page 23.

Figure 19

19

Page 24

INSTALLING THE MOUNT ON CONCRETE OR CONCRETE MASONRY WALLS

The satellite dish can be attached to concrete masonry (cinder blocks) or concrete walls. The concrete masonry (cinder block) or concrete walls must be a minimum of 8 inches thick. Attachment anchors can be placed no closer than 12 inches from any discontinuous

surface, such as a window, door, or edge of a wall. Anchors can not be installed in mortar joints or within 2 inches of mortar joints.

You must use the specified Hilti sleeve anchors. Ins tall onl y the si x anchors speci f i ed; do not install additional anchors.

The satellite dish cannot be installed on masonry veneered wall construction or on any synthetic stucco wall surface (also called

Exterior Insulation and Finish Systems (EIF S).

Note that you can use the brace kit to improve the mount’s stability if you wish. If you use the brace kit, do not install the strut mounting plates within 12 inches of any discontinuous surface, such as a window, door, or edge of a wall. Its anchors must be tightened to

5 ft.-lbs.

PARTS NEEDED TOOLS NEEDED

• 3/8-inch x 3-inch Hilti sleeve anchors, Qty: 6

• If installin g th e optional brace k it, 1 / 4- inc h by

2-1/4-inch Hilti sleev e anchors, Qty: 4

• Ladder

• Carpenter’s level

• Pencil

• Tape measure

• Hammer

• Hammer drill

• Masonry drill bits, 3 /8-in ch (a nd 1/4 -inch

if needed)

• Wrench, 9/ 16 and 1/2-in ch or ad justab l e

(1/4-inch if needed)

• Torque wrench (up to 18 ft-lbs )

• Blow out air bulb

20

Figure 20

Page 25

INSTALLING THE MOUNT ON CONCRETE OR CONCRETE MASONRY WALLS

n

8

/

INSTALLATION PROCEDURE

DANGER

• If the sat elli te d ish contacts electric power lines, y o u

will be killed or s eriou sly injured.

• Before starting the installation procedure, make sure

there are no power lines nearby.

CAUTION

Corner holes

Top center hole

Cinder block

or concrete

2 in.

min.

A

• Attach the satellite dish only to concrete masonry (cinder blocks) or concrete walls at least 8 inches thick.

• Do not attach the satellit e dish to stu cco or to maso nry

veneered surfaces.

• Do not ins tall anchors within 12 in ch es from any discontinuous surf ace, su ch as a w indow, door, or ed ge of

a wall.

• Anchors ca n not be insta lled in mortar joints or within 2

inches of mortar joints.

• Install the s atellite dish only as d es cribe d in th is manual.

Do not drill holes within 12 inches of any discontinuous surface such as a window, door, or edge of a wall. Note: for an

installation to be success ful, the mast must be plumb. Re-plumb the

mast whenever i nstru cted to do so , and re-plumb it whene ver y ou fe el

it is necessary .

1. Orient the base plate as in Figure 21.

2. Place the base plate so that no anchor will be placed closer

than 12 inches from any discontinuous surface, such as a

window, door, or edge of a wall. If you are installing on a

cinder block surface, place it so the outside holes are positioned over the block surfaces. Do not drill into the mortar

between the blocks or closer than 2 inches to any mortar

joints. If you plan to install the brace kit, consider placement

of the strut mounting pl ates at this t ime a lso.

3. Hav e a helper hold the mast and base plate in place. Using a

carpenter’s level, plumb the mast in at least two different

locations on the side of the mast (see Figure 21). These two

measurements should be at right angles to each other. If the

mast is plumb, go to step 5. Otherwise, use a 1/2-inch socket

wrench to loosen the adjustment nuts.

4. Swing the mast until it is plu mb with the level. If you are

still unable to plumb the mast, find another site to install the

satellite dish.

Note: It is essential that the mast be plumb. If you cannot make the

mast plumb at this point, f in d anoth er inst allat ion sit e.

Note: If you loosen the adjustment nuts at any poi nt during installation so that you can move or plumb the mast, be sure to tighten them

snugly after re- plumbing the ma st.

5. Mark the location of the top center, bottom center, and four

corner holes of the base plate onto the concrete surface

(Figure 22). Remove the mount from the wall.

Mortar

Bottom center hole

Corner holes

Figure 21

Carpenter's level

Plumb vial

Bubble

Bubble must

be centered

between

marks

Mast

Pivot bolt

Adjustment nut

(2 places)

Mast

(top view)

Level

G-21

11/16

Figure 22

6. Use a 3/8-inch masonry dril l bill and dri ll 3/8-inch x

3-inch holes where you made the pencil marks. Clean out

the holes with a blow out bulb.

7. With the bolts flush to the top of the nuts, tap the sleeve

anchors to drive them into the holes.

8. Using a 9/16-inch wrench, remove the bolts from the

anchors.

9. Place the mount back on the wall, carefully centering the

base plate holes over the holes you just drilled.

10. Plumb the mast.

11. Using a torque wrench, reinstall the anchors, tightening

them to 10 ft. lbs.

12. Verify the mast is still plumb and tighten t he two adjus tment

nuts to 18 ft.-lbs.

21

Page 26

INSTALLING THE MOUNT ONTO A METAL POLE

a

a

a

a

a

a

a

a

aa

aaa

a

a

a

a

a

a

a

aa

The satellite dish can be installed on a metal pole that you place in the ground. With this option, you will attach the dish and cap

mount directly to the pole. Note: With a metal pole installation, you w ill n ot n eed the ma st a nd ba se pl ate incl uded in you r sa te llite

dish kit. Store it fo r pos sibl e fu ture use.

PARTS NEEDED TOOLS NEEDED

• Metal pole , 2-3/8 inch o utsid e diamet er, schedule 40 galvanized

water pipe, 9 feet lo ng

• Three 40-pound bags of quick-setting concrete

DANGER

• If the sat elli te d ish contacts electric power lines, y o u

will be killed or s eriou sly injured.

• Before starting the installation procedure, make sure

there are no power lines nearby.

DANGER

• Call local utility companies before digging to avoid

striking undergroun d cab l es , pipes , or lines .

• Striking or cutting under gro und cab l es , pipe s, or line s

can cause pers onal injury or property damage .

1. Use the hacksaw to cut the bottom edge of the pole at a 45degree angle (see Figure 23). This will prevent the pole

from rotating over time.

2. Dig a hole at least 8 inches in diameter and at least 36

inches deep (see Figure 24). If you live in an area where the

frost line goes below 30 inches, dig the hole at least 6 inches

deeper than the frost line.

3. Place the bottom 3 feet of the pole in the hole and use rocks

or similar objects to stabilize the pole vertically.

4. With the carpenter’s level, plumb the pole along its side.

Use at least two different locations at right angles to each

other (see Figure 25).

5. When the pole is plumb, use rocks or guy wires and stakes

to hold it in place.

Note: In order for the installation to be successful, the pole must be

plumb. Mak e sur e the pole is securely held in place while the concr ete

is drying.

6. Confirm the pole is still plumb and adjust if necessary.

7. Prepare the quick-drying concrete according to directions

on the package and fill the hole. Slope the top of the concrete downward away from the pole to impro v e drainage.

8. Let the concrete dry for 24 hours.

Continue with section “I nstalling the Cap O nto the Satellite

Dish” on page 23.

• Hole digg in g t oo l s

• Wheelbarrow or concrete mixing box

• Carpenter’s lev el

Cut this section from the pole

Figure 23

Metal post

8 inches

mínimum

Figure 24

Carpenter's level

Plumb vial

Bubble

Bubble must

be centered

between

marks

Pole

Pole

(top view)

Level

• Pencil

• Hacksaw

Pole

10-inch to 2-inch

slope for water run-off

Grade

36 inches

mínimum

6 inches below

frost line

Figure 25

22

Page 27

INSTALLING THE CAP ONTO THE SATELLITE DISH

PARTS NEEDED TOOLS NEEDED

• Azimuth/Elevation (AZ/EL) cap assembly

• Satellite dish

• 5/16-inch Nylock nuts,

You will set the satellite dish elevation and polarization, which

you wrote down in this manual on page 6, before attaching the

azimuth/elevation (AZ/EL) cap to the satellite dish. As you set

them, refer to Figure 26. Note the cap has an arrow, labeled

“Top,” to show you how to orient the cap vertically. See

Figure 29 on page 24.

1. Use a 1/2-inch socket wrench or open-end wrench to loosen

the four polarization nuts.

2. Refer to page 6 of this manual to find the elevation value.

3. Orient the cap assembly so that the “TOP” label is at the

upper right. The elevat i on bolt will also be on t he right.

4. Use a 1/2-inch socket wrench or open-end wrench to loosen

the AZ/EL bracket bolt nut and elevat ion nut s .

5. Using your fingers, retighten the three nuts until you cannot

tighten them further.

6. Still using your fingers, loosen each of the nuts one revolution.

7. Locate the red elevation reference mark on the elevation

scale on the left side of the cap assembly. See Figure 27 and

Figure 28 on the next page to help you locate the mark. The

Qty: 4

• 5/16-inch f lat washers

Qty: 4

• 7/16-inch open-end wrench or socket wrench

• 1/2-inch open-end wrench or socket wrench

• Torque wrench (can accept 1/2-inch socket and

exert 12 ft-lbs. of torque)

leading edge of the metal plate is the elevation reference

mark.

8. Use a 1/2-inch socket wrench or open-end wrench to turn

the elevation bolt head until the leading edge of the red

mark is at the correct value. You may need to turn the bolt

head a number of times until the leading edge of the red

mark reaches the correct value.

9. When the leading edge of the red mark is at the correct e levation value, tighten the bracket bolt nut and the two elevation nuts. Do not tighten the elevation pi v ot nut.

10. Refer to page 6 to find the polarization value.

11. Locate the polarization scale. It is at the top of the AZ/EL

cap (Figure 29).

12. Turn the AZ/EL to the correc t polarizatio n value. Align the

mark on the top of the AZ/EL with the correct value on the

polarization scale. Figure 29 shows a setting of positive 3

degrees.

13. When the polarization is at the correct value, tighten the

four polarization nuts. As you tighten, make sure the polarization remains at the proper value.

Figure 26

Bracket bolt nut

Elevation bolt head

Elevation bolt

Clamp bolts (3)

Elevatio n pivot

Polarizati on sc ale

TOP label

Polarization nuts (4)

Elevation nuts (one each side)

23

Page 28

INSTALLING THE CAP ONTO THE SATELLITE DISH

Read the leadi

Thi

14. Place the AZ/EL cap over the studs sticking out from the

back of the satellite dish (see Figure 30). Make sure the

AZ/EL cap mount bolt holes are properly aligned with the

studs. The elevation bolt should be on the right, and that the

arrow labeled “TOP” should point to the top of the satellite

dish. Make sure the sa tellite di sh is orien te d so th at the s ection that has a hole in its rim is on the bottom.

15. Install four 5/16-inch Nylock nuts and 5/16-inch flat washers on the studs. Use a torque wrench with 1/2-inch socket

to torque to 12 ft.-lbs.

ng edge of the red elevation mark.

picture shows the elevation set to 34°.

Figure 28

s

Elevation Reference Mark

Figure 27

Figure 29

Figure 30

24

Page 29

INSTALLING THE LNB/WAVEGUIDE

PARTS NEEDED TOOLS NEEDED

• LNB/W aveguide ass embly

• M4 Allen screws, Qty: 4

• M4 Lock w ash ers, Qty: 4

1. Facing the front of the feed arm, locate the red mark on the

right side of the rectangular section with four holes (see

Figure 31).

2. Install the O -ring in the circular depression in the fee d arm

(see Figure 32.) Note that the circular depression contains

four small depressions at 12, 3, 6, and 9 o’clock. These are

pinch points. Be sure t o push th e O-ring i n at these point s to

achieve a better seal.

3. Orient the LNB/waveguide so that the flat side of the LNB

faces your body, and the red mark is on the right (see

Figure 33).

4. Line up the feed arm rectangular section with the waveguide

so that the four screw holes align. The tw o red marks should

be on the same side but may or may not align exactly. Use

the red marks as guides. What is important is that the four

screw holes align (see Figure34).

5. Install the M4 Allen screws and lock washers with the Allen

wrench that is provided.

• Feed arm

• O-ring

• Allen wrench (supplied)

Figure 32

Red mark

Figure 31

LNB

Waveguide

Figure 33

Red Mark

Figure 34

25

Page 30

CONNECTING THE FEED ARM TO THE SATELLITE DISH

PARTS NEEDED

• Fe ed arm w ith feed assembly (LNB and w aveguid e) attached

• Satellite dis h

• 5/16-18 wedge nut

• 5/16-18 hex bolt

• 5/16-inch f lat washer

• 5/16-inch l ock washe r

TOOLS NEEDED

• 1/2-inch open-end wren ch or socket wrench

• Torque wrench (with 1/2-inch socket capable of torquing to 10 ft-

lbs.)

Note: Be sure that the feed arm and feed assembly are positioned as

shown in Figure35.

Note: If you are installing the satellite dish assembly on a metal pole

mount, it is probably easiest to attach the feed arm after you have

installed the satellite dish on the pole. See “Installing the satellite

dish/cap assembly onto the mast ” on page 27.. However, if you are

using a ladder, it may be easier to attach the feed arm to the satellite

dish before installing it on the mast or metal p ole.

1. Insert the 5/16-18 wedge nut thin end first into the slot provided on the back of the satellite dish. The wedge nut is

keyed so that it will fit properly in its slot in the dish in only

one way. Make sure the hole in the wedge nut is aligned

with the hole in the dish so the bolt can be installed (see

Figure 35).

2. Install the feed arm into the feed support socket on the

underside of the satellite dish. Since you may have the satellite dish turned upside down in order to insert the feed arm,

take care to remember that your orientation is currently the

opposite of that shown i n Fi gur e 35.

3. Secure the feed arm with a 5/16-inch flat washer, 5/16-inch

lock washer, and 5/16-18 hex bolt. Use a torque wrench to

tighten the hex bolt 8 to 10 ft-l bs.

Antenna dish

5

/

-18 wedge nut

16

Feed arm

5

/

-inch flat washer

16

5

/

-inch lock washer

16

5

/

-18 hex bolt

16

Wedge nut

Figure 35

26

Page 31

INSTALLING THE SATELLITE DISH/CAP ASSEMBLY ONTO THE MAST

PARTS NEEDED TOOLS NEEDED

• Satellite d is h/c ap as se m bly

• Mast

1. Lightly grease the area at the end of the mast or metal pole

that will be covered by the AZ/EL cap. Doing this ensures it

will be easy to adjust the azimuth. Any grease will do. You

can use automotive grease, or household grease such as

Vaseline or lard.

2. Use a 1/2-inch open-end w rench to loosen the three clamp

nuts so the collar will be able to slide over the mast or metal

pole.

To satellite

• 1/2-inc h o p en-end wrench

• Grease

3. Lift the satelli te dish/cap assembly and slide the AZ/EL cap

collar onto the mast tube or metal pole (see Figure 36). The

satellite dish should be facing toward the satellite.

4. Tighten the three mast clamp nuts all the way; then loosen

them just enough to move the satellite dish side to side and

adjust the azimuth. The clamp bolts should be as snug as

possible, but still allow the satellite dish to be moved from

side to side.

Mast or metal pipe

Figure 36

Clamp bolt nuts (3)

Place AZ/EL cap over

mast or metal pipe

27

Page 32

INSTALLING AND ROUTING INTERIOR CABLE

PARTS NEEDED TOOLS NEEDED

• RG-6 coaxial cable

• Cabl e ties

• Silicone se alant

• 14 AWG copper/8 A WG aluminum

grounding wi re

This section consists of routing a coaxial cable from the outside wall into your house to the receive modem connected to

your computer. In most installations, there is more than one

way to get the cable to its inside destination. If the receive

modem is located near an inside wall, you can use the crawl,

basement, or attic spaces. Use cable ties where necessary.

When routing the cable to the receive modem, take the shortest

possible path and always protect it from physical damage. You

may need to feed a length of string through tight access hole(s)

and then pull the cable through.

It is important to remember that each cable is actually installed

in two sections. One section runs from your receive modem to

the ground block, which is installed where the cable exits the

house. The other section runs from the ground block to the

LNB.

Cable is usua lly sold in lengths of 100, 75, 50 , and 25 fee t. If

the distances between your receiver and ground block, or

ground block and antenn a, are not appr oximatel y thos e lengths ,

you may have to cut and strip the cable and install the weatherproof connectors.

Remember that you must use 14 AWG copper grounding wire

if the ground wire will come within 12 inches of the soil or

masonry.

Select your grounding scheme at this time (see “Overview of

Grounding the Satellite System” on page 31). When the

grounding scheme requires access to the internal building

ground, feed the 14 AWG copper/8AWG aluminum wire from

the ground block with the RG6 coaxial cable. Connect the 14

AWG copper/8AW G aluminum ground wire to the grounding

scheme you select or as specified by NEC or local code

requirements.

• Electric drill and 1 /2-i nc h b it

• String

• Screwd riv e r (i f in stall wall plate)

1. Choose a spot on the outside wall where you will drill a

hole. It should be near the satellite dish.

2. After verifying that there are no wires or pipes blocking the

location where you want to feed the coaxial cable into the

building, drill a 1/2-inch hole through the out side w al l.

3. Feed the cable into the access hole and route it to the receive

modem. Depending on the installation site, cable could be

routed through a floor or wall, or directly to the rear of the

computer. If the cable comes out of a wall, you can use a

wall plate for a more professional look.

If your grounding scheme requires, also feed the ground

wire at this time. Remember to use copper wire if your

ground scheme requires it, or if the cable will come within

12 inches of masonry or soil.

4. Connect the cable to the receive modem.

5. Seal the outside access hole with silicone sealant.

6. Estimate the total length of cable used thus far. Then estimate how much more able is need to reach t he LNB. You

will need this information to de termine if a line amplifier

may be required.

7. If yo u pl an to l ater c onvert to a Two-Way System, or install

any DIRECTV

tional cable at this time. Y o u may install that cable through a

separate hole to avoid dri lling a large hole in your wall.

®

upgrade kits, consider installing the addi-

WARNING

• Verify bef or e you drill that there are no electrical wires

in the wall ne ar where you will be drilling.

• You may be killed o r seriously inju red if y ou co ntact wir ing while drilling.

CAUTION

• V erify before you drill that there are no pipes in the wall

near where y ou will be drilling.

• Damaging pipes may cause property damage.

• Never use a staple gun to attach coaxial cable to a

wall.

28

Page 33

INSTALLING EXTERIOR CABLES AND CONNECTING TO GROUND BLOCK

0

PARTS NEEDED TOOLS NEEDED

• Type RG-6 coaxial cable

• 14 AWG copper/ 8 AWG ground wire

• F-type g r ound block an d screws

• Cabl e ties or U-shaped ta cks

• If needed , s plit bolt and clamp

nut

INSTALLATION PROCEDURE

This section describes routing and installin g the coaxial cable

between the low-noise block (LN B) on the dish and th e groun d

block. You may have to bury the coaxial cable, particularly if

you use a metal pole install. Use only quality burial specified

cables. When normal coaxial cable is buried, its useful life is

shortened. The outer cover d ecays in the soil, absor bs moisture,

and corrodes. Cables suitable for burial use a special outer

cover that resists breakdown. Some of these cables use flooded

gel and treated shields. This coating r esists corrosion if water

gets into the cable. By using quality burial specified cables,

you avoid problems in the future.

An important goal of your cable installation is to protect the

cable from physical damage and moisture penetration. To protect the cable from physical damage, secure it to walls or other

stable surfaces with cable ties. This prevents the cable from

sagging and being damage d b y people steppi ng on it or runn ing

over it with yard equipment. Prevent moisture penetration by

using weatherproof connectors, and by sealing any connection

that is exposed to the elements. Drip loops provide a connection with additional protection by preventing moisture from

traveling down the cable and entering the connection.

Remember that the grounding wire must be 14 AWG copper if

it passes within 12 inches of masonry or soil.

Note: if you do not use RG6 quad shielded cable (CommScope 5781

or equivalent) you must run a ground wire from the mast base plate to

the ground block (see page 31) a nd install it and the ground block

ground wire onto a split bolt and clamp nut.

• Flat-b lade screwdriver

• Phillips-hea d scr ewdriver

• Hammer

• 14/8 AWG wire cutters

• 7/16-inch open-end wrench

3. Connect one end of the 14 AWG copper/ 8AWG aluminum

ground wire to the ground terminal of the ground block.

4. Connect the other end of the ground wire to the grounding

scheme. If necessary, secure the ground wire with cable ties

or insulated U-shaped tacks.

5. Select a le ngth of cable that can be routed easily between

the LNB on the feed assembly and the ground block.

6. Connect the coaxial cable to the ground block (see

Figure 38). Form a drip loop and secure the cable with cable

ties. A drip loop 2 or 3 inches in diameter is large enough;

the diameter can be no more than 14 inches.

7. Connect the interior cable (coming out of the access hole in

the wall) to the opposite side of the ground block (see

Figure 37). Form a drip loop and secure w ith cable ties.

8. Tighten the cable connections with a 7/16-inch wrench.

Into building

Sealant

To antenna

CAUTION

• V erify before you drill that there are no pipes in the wall

near where y ou will be drilling.

• Damaging pipes may cause property damage.

WARNING

• Verify bef or e you drill that there are no electrical wires

in the wall ne ar where you will be drilling.

• You may be killed o r seriously inju red if y ou co ntact wir ing while drilling.

1. Determine where you will install the ground block. It must

be near where the coaxial cable enters the building. Plan a

short and straight path for the ground wire from the ground

block to the grounding scheme.

2. Secure the ground block to a stable mounting surface with

two screws (see Figure37).

Ground wire

G-2268

Figure 37

Ground block

14 AWG/8 AWG wire

Coaxial cable(s)

(only one cable

for single LNBs)

G-22814 F

06/29/01

Figure 38

29

Page 34

CONNECTING THE COAXIAL CABLE TO THE LNB

Connect the cable and the LNB s o as to achieve a configuration

like that in the illustrations below. Remember that it may

require some patience to work all the cable through the feed

arm.

CAUTION

• Coaxial ca ble can corrode if exposed to m oisture.

• Use weath erproof conn ector s .

1. Work the cable through the feed arm (see Figure39.)

2. Connect the cable to the LNB connection (see Figure 40).

3. Tighten the cable connection with a 7/16-inch wrench.

4. Apply silicone gel to the cable connection.

5. Secure with cable ties.

6. Add up all the cable lengths for the Receive cable and consult the cable specifications on page 9 to determine whether

you need to install a line amplifier.

Coaxial cable

connector

Coaxial cable

G-22006 F

1/18/01

Figure 39

Figure 40

30

Page 35

OVERVIEW OF GROUNDING THE SATELLITE SYSTEM

The two basic methods for mounting the satellite dish (universal mount with or without brace kit and pole mount) require

different grounding procedures, as specified in National Electrical Code (NEC) Articles 250, 800, 810, and 820.

Both methods use the RG6 quad-shielded coaxial cable shield,

ground block, and ground wire for the system and protective

ground. The RG6 quad-shielded coaxial cable is connected to

the ground block and serves as the system and protective

ground. The ground block is located at the point the coaxial

cable enters the building. The ground wire is connected to the

ground block and routed to the earth ground using one of the

three ground schemes in Figure 41. The cable shield must be

less than .6 ohms per 100 ft; if it is not, a 14 AWG copper or

8 AWG aluminum ground wire must be run from the satellite

dish base ground to the ground block. The connectors must be

waterproof 360-degree compression type connectors. The

specified RG6 cable and connector must be used to meet NEC

requirements. These items are available through your local

electronics supply store.

Three Ground Schemes

for

Ground

POLE MOUNT GROUNDING

The mast (which is the metal pole in this mount method) is

grounded to the satellite dish via an NEC-approved ground

wire and clamp. The mast clamp must have a good electrical

connection to the mast pole. The RG6 coaxial cable shield connects the satellite dish to the ground blo ck. An NEC-approved

ground wire is used to connect the ground block to earth

ground using one of the three schemes shown in Figure 41.

When the mast requires a separate ground rod the NEC

requires that a 6 AWG copper wire must connect the mast

ground rod to the building earth ground.

UNIVERSAL MOUNT GROUNDING

The mast is grounded to the satellite dish via an NEC-approved

ground wire. The RG6 coaxial cable connects the satellite dish

to the ground block. The RG6 shield is used for system and

protective ground. An NEC-approved 8 AWG aluminum

ground wire is used to connect the ground block to the earth

ground using one of the three schemes shown in Figure 41.

(GND) Block Wire

GND Rod

2. GND Block

Water Pipe

1. AC GND

1. AC GND

2. GND Block

Floor

AC GND Wire

1.GND Rod

2. Water Pipe

Spilt Bolt Tap

GND Block

AC GND

Figure 41

31

Page 36

GROUNDING THE MAST

PARTS NEEDED TO O LS N EED ED

• 1/4-20 x 1/2-inch hex -he ad grounding b olt

• 1/4-inch star washer

• 1/4-inch w ash er

• 1/4-inch Nylock nut

• 5/8-inch x 8-foot ground rod and ground rod clamp

Remember the metal pole grounding procedure is dif ferent . See “Groundi ng the Metal P ole Mount” on page35.

Note: if you do not use RG6 quad shielded cable (CommScope 5781 or equivalent) you must run a ground wire from the mast base plate to the

ground bloc k and install it and the gr ound bloc k gr ound wire onto a split bolt and clamp nut.

DANGER

• Failure to properly ground the antenna dish

may result in sev e re personal injury or death.

• Do not attempt to ground the antenna dish

unless you have the skills to do so in accordance with

NEC code .

CAUTION

• The Nationa l E lec tric C od e (N EC ) and local codes

require the antenna dish to be grounded to

the alternating current main earth ground point.

• Grounding the system helps protect against damage

caused by s tatic voltage buildup, nearby light nin g

strikes, an d power line cr os sin gs.

• Failure to ground the system will void your

warranty .

• 8 AWG aluminu m g r ound wire (14 AWG copp er

ground wire if you come within 12 inches of masonry)

• Cable ties

• U-shaped tacks

• 3/8-inch hose clamp

• Adjustable wrench

• Needle nose pliers

• Lineman pliers

• 14/8 AWG wire cutters

32

Page 37

GROUNDING THE MAST

U

ast Ground (G

)

GROUNDING USING RG-6 QUAD-SHIELDED CABLE

1. Ren 8 AWG aluminum ground wire (14 AWG copper

ground wire if the wire comes within 12 inches of masonry)

from the base plate to the LNB. Route through the inside of

the mast and feed arm. Leave 6 inches of slack at the base

plate in case you ever need to remove the wire.

2. Lay the end of the ground wire parallel to the coaxial cable

connector .

3. Install the 3/8-inch hose clamp on the crimped part of the Fconnector below the F-connector nut. Make sure it goes

around both the coaxial cable and the ground wire.

4. Insert the 1/4-20 x 1/2-inch hex-head grounding bolt

through the grounding hole on the mast base plate (see

Figure 43).

5. Install the 1/4-inch star washer, 1/4-inch washer, and 1/4inch Nylock nut onto the bolt.

6. Wrap the 8 AWG aluminum ground wire (or 14 AWG copper wire if you pass within 12 inches of masonry) around

the bolt between the start washer and 1/4-inch washer, then

use a wrench to tighten the nut.

7. If necessary, secure the ground wire using the cable ties

or insulated U-shaped tacks. The final configuration should

match Figure 42.

AC Mains

1. Gnd Rod

AC Mains