Page 1

HN System

Installation Manual for .98 m Ku-band Upgradeable Antenna Model AN6-098P

1037312-0001

Revision A

March 2, 2007

Page 2

Copyright © 2007 Hughes Network Systems, LLC

All rights reserved. This publication and its contents are proprietary to Hughes Network Systems,

LLC. No part of this publication may be reproduced in any form or by any means without the written

permission of Hughes Network Systems, LLC, 11717 Exploration Lane, Germantown, Maryland

20876.

Hughes Network Systems, LLC has made every effort to ensure the correctness and completeness

of the material in this document. Hughes Network Systems, LLC shall not be liable for errors

contained herein. The information in this document is subject to change without notice. Hughes

Network Systems, LLC makes no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose.

Trademarks

Hughes, Hughes Network Systems, and HughesNet are trademarks of Hughes Network Systems,

LLC. All other trademarks are the property of their respective owners.

Page 3

Important safety information

For your safety and protection, read this entire installation manual

before you attempt to install the satellite antenna. In particular,

read this safety section carefully. Keep this safety information

where you can refer to it if necessary.

Types of warnings used in this manual

This section introduces the various types of warnings used in this

manual to alert you to possible safety hazards.

DANGER

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation, which, if not

avoided, may result in minor or moderate injury.

CAUTION

Indicates a situation or practice that might result in property

damage.

• Important safety information

1037312-0001 Revision A

iii

Page 4

Product warning labels

The following safety alert labels are affixed to the satellite

antenna feed support tube, transmitter, and antenna reflector:

Feed support tube

Transmitter

• Important safety information

iv

1037312-0001 Revision A

Reflector (back side)

Safety alert labels on the antenna assembly

These labels advise that the antenna emits radio frequency (RF)

energy. Because of this potential safety hazard, observe all

cautions on these labels and in the following section (

installation safety) concerning RF radiation.

Antenna

Page 5

Antenna installation safety

Observe the following precautions when installing the satellite

antenna. This manual also includes additional safety alerts where

appropriate concerning specific installation

procedures.

WARNING

Only Hughes-certified installers may install or service

Hughes earth stations and components. Installers must

expressly acknowledge the Hughes requirements for

Hughes installations.

DANGER

If you work on a roof, tower, or other high structure or use a

ladder or scaffold to access the work site, follow these

precautions to prevent personal injury or death:

• Walk only on sound roof structures.

• Make sure the antenna assembly and installation

surface are structurally sound so they can support all

loads (equipment weight, ice, and wind).

• Use appropriate safety equipment (for example, a

lifeline), depending on the work location.

• Follow all safety precautions from the manufacturers of

all safety equipment and other equipment used.

• Perform as many procedures as possible on the ground.

DANGER

• To avoid electric shock, stay at least 20 ft from power

lines.

• If any part of the antenna or mount assembly comes in

contact with a power line, call your local power

company to remove it. Do not try to remove it yourself.

Failure to heed these warnings could result in serious injury

or death.

• Important safety information

1037312-0001 Revision A

v

Page 6

WARNING

• Do not work in high wind or rain or if a storm, lightning,

or other adverse weather conditions are present or

approaching.

• Do not attempt to assemble, move, or mount the

antenna on a windy day. Even a slight wind can

unexpectedly create strong, unexpected forces on the

antenna surface.

• Important safety information

vi

1037312-0001 Revision A

Page 7

CAUTION

Observe these precautions to avoid exposure to RF

radiation, a potential safety hazard:

• The antenna must be installed in a location or manner

not readily accessible to children and in a manner that

prevents human exposure to potentially harmful levels

of radiation.

• Antennas mounted in Puerto Rico, the continental

United States, or at any site with greater than a 30°

elevation angle must be installed such that the lower lip

of the antenna reflector is at least 5 ft above any surface

upon which a person might be expected to stand, and

ft 3 inches from any opening (such as a door or

3

window) in a building or adjacent structure.

• Antennas mounted in Canada, Alaska, Hawaii, or any

site with less than a 30° elevation must be installed

such that the lower lip of the antenna reflector is at least

ft 9 inches above any surface upon which a person

5

might be expected to stand, and 3 ft 3 inches from any

opening (such as a door or window) in a building or

adjacent structure.

• The antenna must be mounted such that no object

which could reasonably be expected to support a

person is within 6 ft 7 inches of the edges of a

cylindrical space projecting outward from the antenna

reflector toward the satellite.

• If the above distance requirements cannot be met, the

antenna must be mounted in a controlled area

inaccessible to the general public, such as a fenced

enclosure or a roof.

• The antenna must be mounted such that there is no

object outside the controlled area which could

reasonably be expected to support a person within

ft 7 inches of the edges of a cylindrical space

6

projecting outward from the antenna reflector toward

the satellite.

• A fenced installation must have a locked entry, and the

fenced area must be large enough to protect the general

public from exposure to potentially harmful levels of

radiation.

• Access to a roof installation in a commercial, industrial,

or institutional environment must be limited by a door or

a permanently fastened ladder that is locked to deny

access to the general public.

Failure to observe these cautions could result in injury to

eyes or other personal injury.

• Important safety information

1037312-0001 Revision A

vii

Page 8

CAUTION

• All installations of any type or size must carry an

industry standard and government approved Radiation

Hazard Caution label on the feed arm.

• A fenced or roof installation in a commercial, industrial,

or institutional environment must carry a Radiation

Hazard Caution sign on the access door, gate, or

permanently mounted access ladder that is within plain

sight of anyone approaching the antenna from the front

or sides of the reflector.

Failure to observe these cautions could result in injury to

eyes or other personal injury.

Some installations may require additional precautions. See also

the HN System Antenna Site Preparation and Mount

Installation Guide (1035678-0001).

viii

• Important safety information

1037312-0001 Revision A

Page 9

Contents

Important safety information . . . . . . . . . . . . . . . . . . . . . iii

Types of warnings used in this manual . . . . . . . . . . . . . . . . . . . iii

Product warning labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Antenna installation safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Scope and audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Revision record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

The model AN6-098P antenna. . . . . . . . . . . . . . . . . . . . . . . . . . .2

Antenna installation summary . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tasks related to antenna installation . . . . . . . . . . . . . . . . . . . . . .4

Selecting the installation site . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installing the antenna mount . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installing the IDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Approved cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Chapter 2

Antenna parts and required tools. . . . . . . . . . . . . . . . . . .7

Antenna kit components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Related components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Two antenna kits for two radio types . . . . . . . . . . . . . . . . . . . .8

Inspecting the antenna parts . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Description of main components . . . . . . . . . . . . . . . . . . . . . .10

Az/El and reflector bracket assembly. . . . . . . . . . . . . . . . .10

Antenna reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Feed support tube and feed rods. . . . . . . . . . . . . . . . . . . . .12

Feed horn and waveguide transition. . . . . . . . . . . . . . . . . .13

Radio mounting adapter . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Radio mounting brackets (for J-type radio only). . . . . . . .14

Radio assembly types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

J-type radio assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Vertical shim kit (if required). . . . . . . . . . . . . . . . . . . . .15

Cradle-type radio assembly . . . . . . . . . . . . . . . . . . . . . . . .16

• Contents

1037312-0001 Revision A

ix

Page 10

Small hardware parts lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Additional parts for J-type radio. . . . . . . . . . . . . . . . . . . . . . .19

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Chapter 3

Assembling the antenna. . . . . . . . . . . . . . . . . . . . . . . . . .21

Determining the pointing values . . . . . . . . . . . . . . . . . . . . . . . .21

General instructions for assembling the antenna . . . . . . . . . . . .22

Installing the Az/El and reflector bracket assembly. . . . . . . . . . 23

Attaching the reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Installing the feed support tube . . . . . . . . . . . . . . . . . . . . . . . . .27

Attaching the feed rods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Securing the feed support tube . . . . . . . . . . . . . . . . . . . . . . . .28

Tightening the hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Chapter 4

Installing a J-type radio assembly . . . . . . . . . . . . . . . . .31

Installing a shim for vertical transmit polarization . . . . . . . . . .32

Installing the radio assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Attaching the upper mounting bracket . . . . . . . . . . . . . . . . . .36

Attaching the feed horn and transition to the radio assembly 37

Mounting the radio assembly on the feed support tube . . . . .39

Chapter 5

Installing a cradle-type radio assembly . . . . . . . . . . . . .43

Installing the radio assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Attaching the feed horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Mounting the radio assembly on the feed support tube . . . . .45

Setting polarization for the cradle-type radio. . . . . . . . . . . . . . .47

Calculating the radio polarization setting. . . . . . . . . . . . . . . .47

For a horizontal uplink /vertical downlink . . . . . . . . . . . . .47

For a vertical uplink / horizontal downlink. . . . . . . . . . . . .47

Setting the radio polarization . . . . . . . . . . . . . . . . . . . . . . . . .48

Chapter 6

Cabling and connections . . . . . . . . . . . . . . . . . . . . . . . . .49

Previous cabling work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Routing the cables at the ODU. . . . . . . . . . . . . . . . . . . . . . . . . .50

Ground connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Connecting the transmit and receive cables . . . . . . . . . . . . . . . .52

Transmit cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Receive cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

• Contents

x

1037312-0001 Revision A

Page 11

Chapter 7

Pointing the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Antenna pointing overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Using the installation software . . . . . . . . . . . . . . . . . . . . . . . .56

Peaking the signal (description) . . . . . . . . . . . . . . . . . . . . . . .56

Personnel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Pointing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Prerequisites for antenna pointing . . . . . . . . . . . . . . . . . . . . . . .57

Outdoor pointing interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Installing the OPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

OPI block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Adjusting the antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Adjustment locations on the antenna . . . . . . . . . . . . . . . . . . .60

Setting coarse elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Fine elevation adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Receive pointing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Initial elevation setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Setting polarization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Setting azimuth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

If you cannot detect a signal. . . . . . . . . . . . . . . . . . . . . . . .65

Peaking the signal (procedure) . . . . . . . . . . . . . . . . . . . . . . . .66

Isolating the transmit signal . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Manual ACP test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Automatic ACP test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Final steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Remove the OPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Check for safety labels and signs . . . . . . . . . . . . . . . . . . . . . .69

Subsequent steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Acronyms and abbreviations . . . . . . . . . . . . . . . . . . . . .71

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

• Contents

1037312-0001 Revision A

xi

Page 12

xii

• Contents

1037312-0001 Revision A

Page 13

Figures

Chapter 1

1. Hughes model AN6-098P .98 m satellite antenna with radio . . . . . . . . . . . . . . .2

Chapter 2

2. Shipping container contents—main components . . . . . . . . . . . . . . . . . . . . . . . . .9

3. Az/El and reflector bracket assembly (pre-assembled as one unit) . . . . . . . . . .10

4. Antenna reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5. Feed support tubes (two types). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6. Feed rods (two types) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

7. Feed horn and waveguide transition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

8. Radio assembly mounting adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

9. Radio assembly mounting brackets and adapter. . . . . . . . . . . . . . . . . . . . . . . . .14

10. J-type radio assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

11. Shim for vertical transmit polarization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

12. Cradle-type radio assembly (shown with mounting adapter). . . . . . . . . . . . . . .16

13. Cradle-like rotation of the cradle-type radio assembly . . . . . . . . . . . . . . . . . . .17

Chapter 3

14. Making sure the mast is plumb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

15. Az/El and reflector bracket assembly on the mast . . . . . . . . . . . . . . . . . . . . . . .24

16. Reflector in correct position for installation. . . . . . . . . . . . . . . . . . . . . . . . . . . .25

17. Mounting the reflector on the reflector bracket . . . . . . . . . . . . . . . . . . . . . . . . .26

18. Attaching feed rods to the reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

19. Attaching the feed rods to the feed support tube . . . . . . . . . . . . . . . . . . . . . . . .28

20. Attaching the feed support tube to the reflector rim. . . . . . . . . . . . . . . . . . . . . .28

21. Tightening nuts on feed rods and feed support tube. . . . . . . . . . . . . . . . . . . . . .29

22. Completed antenna assembly (without radio) . . . . . . . . . . . . . . . . . . . . . . . . . .29

Chapter 4

23. Shim location next to TRIA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

24. Horizontal shim and vertical shim for transmit polarization . . . . . . . . . . . . . . .33

25. Direction of TRIA rotation for vertical polarization . . . . . . . . . . . . . . . . . . . . .34

26. TRIA position for horizontal and vertical transmit polarization . . . . . . . . . . . .35

27. Attaching the upper mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

28. Feed horn with waveguide transition attached . . . . . . . . . . . . . . . . . . . . . . . . . .37

29. O-ring in groove in waveguide transition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

30. Attaching the waveguide transition to the TRIA . . . . . . . . . . . . . . . . . . . . . . . .38

• Figures

1037312-0001 Revision A

xiii

Page 14

31. Securing the feed horn clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

32. Attaching the radio assembly to the feed support tube. . . . . . . . . . . . . . . . . . . .40

33. Attaching the radio assembly to the feed support tube. . . . . . . . . . . . . . . . . . . .41

Chapter 5

34. Attaching the feed horn and radio assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .44

35. O-ring in groove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

36. Mounting the radio on the feed support tube . . . . . . . . . . . . . . . . . . . . . . . . . . .46

37. Rear circular bracket with polarization scale . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Chapter 6

38. Transmit and receive cable configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

39. Ground screw on J-type radio assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

40. Ground screw on cradle-type radio assembly. . . . . . . . . . . . . . . . . . . . . . . . . . .52

41. Transmit connector – J-type radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

42. Transmit connector – cradle-type radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

43. Receive connector – J-type radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

44. Receive connector – cradle-type radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Chapter 7

45. OPI (optional pointing tool) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

46. OPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

47. Adjusting elevation, polarization, and azimuth . . . . . . . . . . . . . . . . . . . . . . . . .59

48. Pointing adjustments on the antenna—elevation, polarization, and azimuth. . .60

49. Setting coarse elevation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

50. Fine elevation adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

51. Polarization adjustment on the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

52. Azimuth adjustments on the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

xiv

• Figures

1037312-0001 Revision A

Page 15

Tables

Chapter 2

1. Two antenna kit configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. Small hardware parts used in antenna kits for both radio types . . . . . . . . . . . . .18

3. Additional small hardware parts included in the antenna kit for the

J-type radio assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4. Tools required to install and point the antenna. . . . . . . . . . . . . . . . . . . . . . . . . .20

5. Tool sizes matched to hardware sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Chapter 3

6. Torque specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

• Tables

1037312-0001 Revision A

xv

Page 16

xvi

• Tables

1037312-0001 Revision A

Page 17

About this document

Scope and audience

Organization

This manual explains how to assemble, install, and point the

Hughes model AN6-098P

qualified installers who are familiar with satellite antenna

installation practices and are capable of properly applying the

information presented.

This manual is divided into the following chapters and appendix:

• Chapter 1 – Overview includes a summary of the installation

steps and tells you where to find information about tasks

related to antenna installation.

• Chapter 2 – Antenna parts and required tools describes the

parts provided in the antenna kit and tools required for

antenna installation.

• Chapter 3 – Assembling the antenna provides instructions for

assembling and installing the antenna.

• Chapter 4 – Installing a J-type radio assembly provides

instructions for installing the J-type radio assembly.

• Chapter 5 – Installing a cradle-type radio assembly provides

instructions for installing the cradle-type radio assembly.

• Chapter 6 – Cabling and connections provides information

about making connections to the radio assembly.

• Chapter 7 – Pointing the antenna explains how to point the

antenna at the satellite, connect the transmitter, and acquire

the satellite signal.

.98 m antenna. It is written for

An acronyms and abbreviations list and an index are included at

the back of the manual.

• About this document

1037312-0001 Revision A

xvii

Page 18

Related publications

The HN System Antenna Site Preparation and Mount

Installation Guide (1035678-0001) contains detailed information

about:

• Safety considerations for mount and antenna installations

• Site surveys

• Trimasts and other types of antenna mounts

• Antenna installations on various types of surfaces

• Requirements for antennas that will be used in a Ka-band

system or will later be upgraded for use in a Ka-band system

Additional related publications are identified in Tasks related to

antenna installation on page 4.

Revision record

This section describes the revision history of this manual.

Revision Date of issue Scope

A March 2, 2007 Initial release

xviii

• About this document

1037312-0001 Revision A

Page 19

Chapter 1

Overview

This chapter presents an overview of the Hughes model

AN6-098P

• The model AN6-098P antenna on page 2

• Antenna installation summary on page 3

• Tasks related to antenna installation on page 4

.98 m Ku-band antenna in the following sections:

Chapter 1 • Overview

1037312-0001 Revision A

1

Page 20

The model AN6-098P antenna

Each remote terminal at a customer site requires an antenna and

radio assembly to communicate with the system satellite and the

Network Operations Center (NOC). The antenna is connected to

the remote terminal (also known as the indoor unit, or IDU) by a

transmit cable and a receive cable.

The Hughes model AN6-098P .98 m Ku-band antenna is

designed for both Ku-band and Ka-band applications.

shows the model AN6-098P antenna, installed, with a radio

assembly.

Figure 1

Chapter 1 • Overview

2

1037312-0001 Revision A

Figure 1: Hughes model AN6-098P .98 m satellite antenna with radio

Page 21

Antenna installation summary

The antenna installation steps and related tasks are summarized

below. The steps in bold type are documented in this manual.

1. Choose an installation site.

2. Select a method for mounting the antenna.

3. Install the antenna mount.

Note: A critical requirement is that the mast must be plumb.

The antenna assembly cannot be adjusted to correct for a mast

that is not plumb.

4. Install the IDU.

Note: Install the IDU before installing the antenna so you

can use the installation software to determine the pointing

values (azimuth, elevation, and polarization).

5. Determine the pointing values (azimuth, elevation,

and polarization) – Chapter 3

6. Install the Az/El and reflector bracket assembly on the

mast – Chapter

3

7. Install the antenna reflector – Chapter 3

8. Install the feed rods and feed support tube – Chapter 3

9. Install the radio assembly –

Chapter 4 (J-type radio) or Chapter 5 (cradle-type radio)

Note: The J-type and cradle-type radio assemblies are

described in

Radio assembly types on page 15.

10. Run cables between the IDU and ODU locations.

11. Ground the antenna assembly.

12. Connect cables to the ODU – Chapter 6

13. Point the antenna – Chapter 7

For the steps not shown in bold type, see the following section,

Tasks related to antenna installation.

Note: Outdoor unit (ODU) refers to the antenna, radio assembly,

and antenna mount.

Follow all steps in the order they are presented. Do not tighten

any hardware until you are instructed to do so.

Chapter 1 • Overview

1037312-0001 Revision A

3

Page 22

Tasks related to antenna installation

This section explains where you can find information on tasks

related to antenna installation.

Selecting the installation

site

Installing the antenna

mount

Factors you should consider in selecting an installation site are

discussed in the HN System Antenna Site Preparation and

Mount Installation Guide (1035678-0001). The installation site

and mounting method may be specified in the customer-specific

installation specification.

A suitable antenna mount must be installed before the antenna

can be installed. Acceptable mounting methods are:

• Non-penetrating mount

• Trimast (may be used on a wood-frame roof or wood or

masonry wall)

• Pole or pedestal mount

Most installations in a commercial, industrial, or institutional

environment use a non-penetrating roof mount.

For pole or pedestal mounts that require a concrete base, you

must allow at least 24 hr for the concrete to cure before you can

install the antenna. Plan accordingly.

For complete information concerning antenna mount installation,

refer to:

• The customer-specific installation specification

• The HN System Antenna Site Preparation and Mount

Installation Guide

Installing the IDU

Chapter 1 • Overview

4

1037312-0001 Revision A

Grounding

The customer-specific installation specification may include

customer-specific guidelines concerning mount installation. Use

only the mounting method described in the specification. For

mount installation instructions, see the HN

Preparation and Mount Installation Guide.

See the installation manual for the IDU (also referred to as a

remote terminal.)

The entire antenna assembly must be grounded. For grounding

information, refer to your training; best grounding practices; the

Hughes Field Service Bulletin (FSB), HNS Broadband

Requirements for RG-6 and RG-11 IFL Cable Connectors,

Ground Blocks and Ground Block Location (FSB 50518_01C);

and applicable parts of the National Electrical Code (NEC).

System Antenna Site

Page 23

Approved cables

For a list of approved cables for the interfacility link (IFL)

between the antenna and the remote terminal, see the Hughes

FSB, IFL Cable, Approved List (with lengths) for DW7x00,

DW60xx, and DW40xx Domestic Installations

(FSB_060316_01A). The FSB lists the maximum cable length

for each approved cable type, for both 1-W and 2-W radios.

How the cable is run depends on the specific installation site.

Route and connect the IFL cable according to your training and

best practices.

Chapter 1 • Overview

1037312-0001 Revision A

5

Page 24

Chapter 1 • Overview

6

1037312-0001 Revision A

Page 25

Chapter 2

Antenna parts and required tools

This chapter describes the parts provided in the model AN6-098P

antenna kit. It includes the following sections:

• Antenna kit components on page 8

• Radio assembly types on page 15

• Small hardware parts lists on page 18

• Too ls on page 20

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

7

Page 26

Antenna kit components

Related components The following are related components that are not part of the

This section describes the main components of the .98 m antenna

kit:

• Az/El and reflector bracket assembly

• Antenna reflector

• Feed support tube and feed rods

• Feed horn

• Mounting parts for radio assembly

For details see Description of main components on page 10.

antenna kit:

• Radio assembly (J-type or cradle-type) – See Radio assembly

types on page 15.

• Antenna mount – For general information about antenna

mounts, see

Installing the antenna mount on page 4.

Two antenna kits for two

radio types

You can install the .98 m antenna with either of two radio types,

the J-type radio or cradle-type radio, which are described in

Radio assembly types on page 15.

To support these two radio types, the antenna kit is available in

two configurations, as listed in

Table 1. In this manual, the

antenna kit is used to refer to either kit.

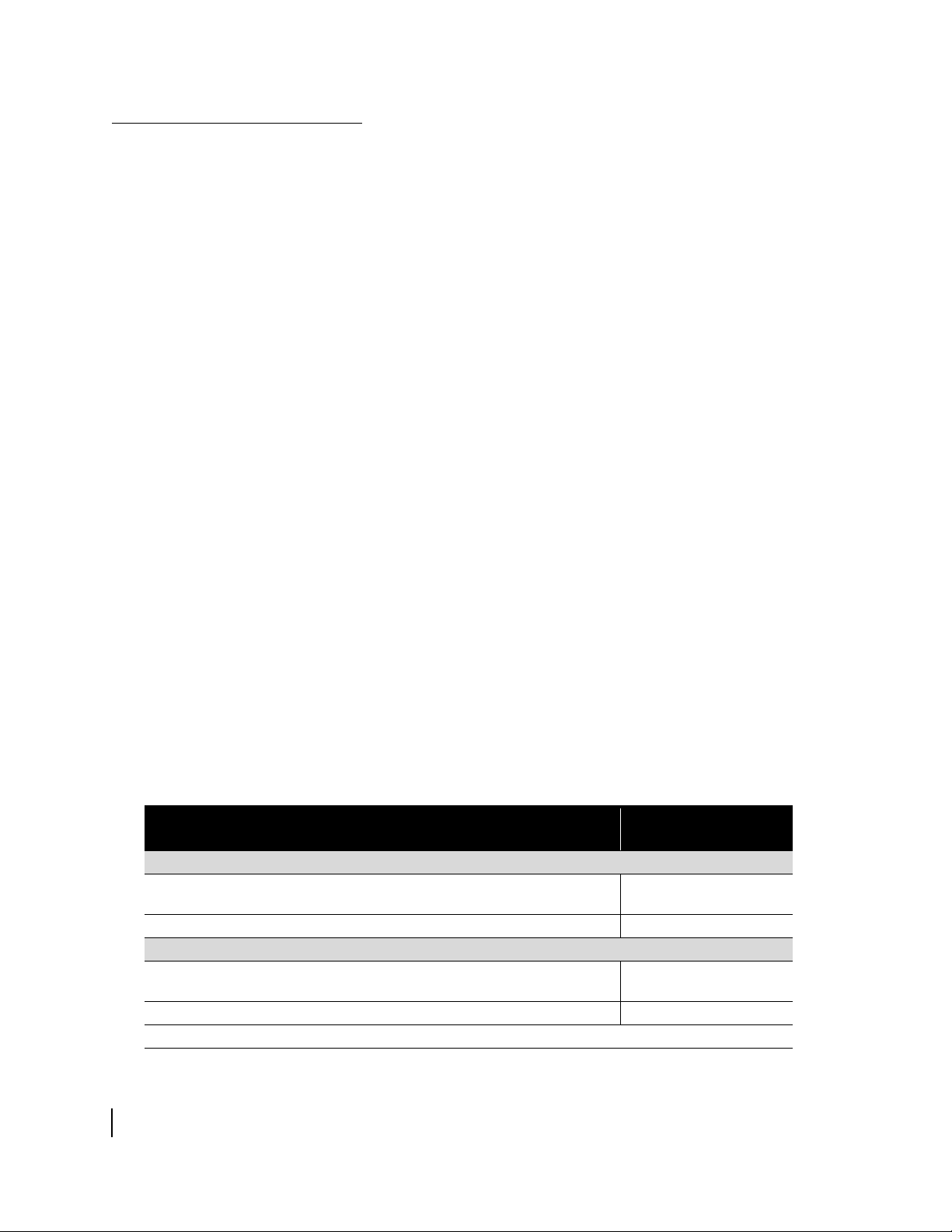

Each antenna kit consists of two boxes of parts, as detailed in

Figure 2. Most parts are common to both antenna kits. The main

parts that are different in the two kits are the feed support tube,

feed rods, and parts used to mount the radio assembly.

Before proceeding, refer to Table 1 and make sure you have the

correct antenna kit.

Table 1: Two antenna kit configurations

Box contents

Antenna kit for J-type radio

Box 1 – Az/El and reflector bracket assembly, feed horn, mounting brackets

and adapter for radio assembly, waveguide transition, and other parts.

Box 2 – Reflector, feed support tube, feed rods, and other parts. P/N 1501111-0002

Antenna kit for cradle-type radio

Box 1 – Az/El and reflector bracket assembly, feed horn, adapter for radio

assembly, and other parts.

Box 2 – Reflector, feed support tube, feed rods, and other parts. P/N 1501111-0022

Box 1 is labeled Box 1 of 2. Box 2 is labeled Box 2 of 2.

Hughes part number

for each box

P/N 1501111-0001

P/N 1501111-0021

Chapter 2 • Antenna parts and required tools

8

1037312-0001 Revision A

Page 27

Inspecting the antenna

parts

Box 1 of 2

Az/El and reflector

bracket assembly

Feed horn

Radio mounting adapter

Included in kit for J-type radio only:

Radio mounting brackets

Waveguide transition

(attached to feed horn)

The antenna kit for each radio type is shipped in two boxes, as

shown in

Figure 2. The radio assembly is shipped separately. As

soon as possible, unpack and inspect the antenna parts and

hardware to make sure all parts have been received in good

condition.

Each main part is illustrated in the following sections, and the

small hardware parts are listed in

Tabl e 2 and Ta ble 3 on page 19.

If any parts appear to have been damaged in transit, immediately

contact the freight carrier. If any parts appear to be missing or

damaged but not as a result of handling in transit, contact your

dealer or distributor.

Antenna kit

(2 boxes)

Box 2 of 2

Antenna reflector

Feed support tube

Feed rods

The feed support tube and feed rods in the

two antenna kits, for the J-type or cradletype radio, are not interchangeable.

Small hardware parts such as fasteners are also

included in the boxes, as detailed in Tables 2 and 3.

T0172017

Figure 2: Shipping container contents—main components

Radio

assembly

J-type or cradle-type

Not

part of the antenna kit

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

9

Page 28

Description of main

components

The following sections describe and illustrate the antenna

assembly’s main components.

Az/El and reflector bracket

assembly

The Az/El mount assembly and reflector bracket assembly are

pre-assembled for installation as a single unit, as shown in

Figure 3. The Az/El mount assembly supports the antenna and is

used to point the antenna at the satellite. The reflector bracket

supports the antenna reflector.

Reflector

bracket

10

Figure 3: Az/El and reflector bracket assembly (pre-assembled as one unit)

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

Az/El mount

assembly

Canister

(slides onto mast)

Page 29

Antenna reflector The antenna reflector is shown in Figure 4.

Figure 4: Antenna reflector

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

11

Page 30

Feed support tube and

rods

feed

Tube for

J-type radio

The radio assembly mounts onto the feed support tube (Figure 5).

The feed rods (Figure 6) attach to the reflector and support the

feed support tube.

Each of the two antenna kits contains one feed support tube and

two feed rods, for the radio type supported by the specific antenna

kit.

Figure 5 shows both types of feed support tubes for the two

radio types. The feed support tube for the cradle-type radio is

stamped TG. Other letters or numbers may appear with TG.

g

n

o

l

a

r

Tube for

cradle-type radio

s

e

l

o

h

4

m

o

i

d

a

g

n

ti

n

u

o

e

c

a

f

r

u

s

6 holes along

mounting surface;

5 pass through tube

Figure 5: Feed support tubes (two types)

Figure 6 shows the two types of feed rods for the two radio types.

The rods in the two antenna kits (for each radio type) are different

lengths and are not interchangeable. The feed rods for the

cradle-type radio are stamped TG. Other letters or numbers may

appear with TG.

Rods for

J-type radio

Rods for

cradle-type radio

h

t

g

n

e

l

l

l

a

r

e

ov

s

e

h

c

n

i

5

.

8

2

g

n

e

l

l

l

ra

ve

o

s

e

h

c

n

i

5

.

0

3

Figure 6: Feed rods (two types)

h

t

12

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

Page 31

The feed support tube and the feed rods are the only main parts

included in both antenna kits that are different.

Feed horn and waveguide

transition

The feed horn (Figure 7) transmits and receives signals to and

from the reflector.

The J-type radio assembly requires a waveguide transition, as

shown in

Figure 7. In the antenna kit for the J-type radio, the

transition is attached to the feed horn at the factory, as shown in

Figure 7. As explained later in this manual, you attach the

transition the radio assembly.

The antenna kit for the cradle-type radio does not include a

waveguide transition because the feed horn attaches directly to

the cradle-type radio assembly.

Feed horn with

protective packing

material

Waveguide

transition

Figure 7: Feed horn and waveguide transition

CAUTION

• Do not remove the protective packing material from

the feed horn window until installation of the radio

assembly is complete.

• Do not attempt to remove the feed horn window at

any time.

• Be careful not to damage the feed horn window.

Do not touch the plastic film.

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

13

Page 32

Radio mounting adapter The mounting adapter shown in Figure 8 is used for both radio

types to mount the radio assembly on the feed support tube.

Figure 8: Radio assembly mounting adapter

Radio mounting brackets

J-type radio only)

(for

The antenna kit for the J-type radio assembly (only) includes two

mounting brackets (

Figure 9) that are used to secure the radio

assembly to the feed support tube, as illustrated in Figure 10 on

page 15.

Upper bracket

Lower bracket

14

Figure 9: Radio assembly mounting brackets and adapter

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

Page 33

Radio assembly types

J-type radio assembly Figure 10 shows the J-type radio assembly, referred to as J-type

The radio assembly is not part of the antenna kit; however, radio

assembly installation is included in this manual because the

antenna and radio assembly are usually installed at the same time.

There are two possible radio assemblies available for the

.98 m

antenna, the J-type radio assembly or cradle-type radio assembly.

because its waveguide is shaped something like the letter J.

J-shaped

waveguide

Figure 10: J-type radio assembly

J-type refers to the overall design of the radio; therefore, two

radios with different model numbers may both be J-type radios.

Vertical shim kit (if required)

A vertical transmit shim kit may be required for the J-type radio

assembly only. If the installation specification states that vertical

transmit polarization is required, you will need to obtain and

install a vertical shim kit (

Figure 11) in the radio assembly.

Otherwise, a vertical shim is not required. For more information,

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

15

Page 34

see Installing a shim for vertical transmit polarization on

page 32.

Figure 11: Shim for vertical transmit polarization

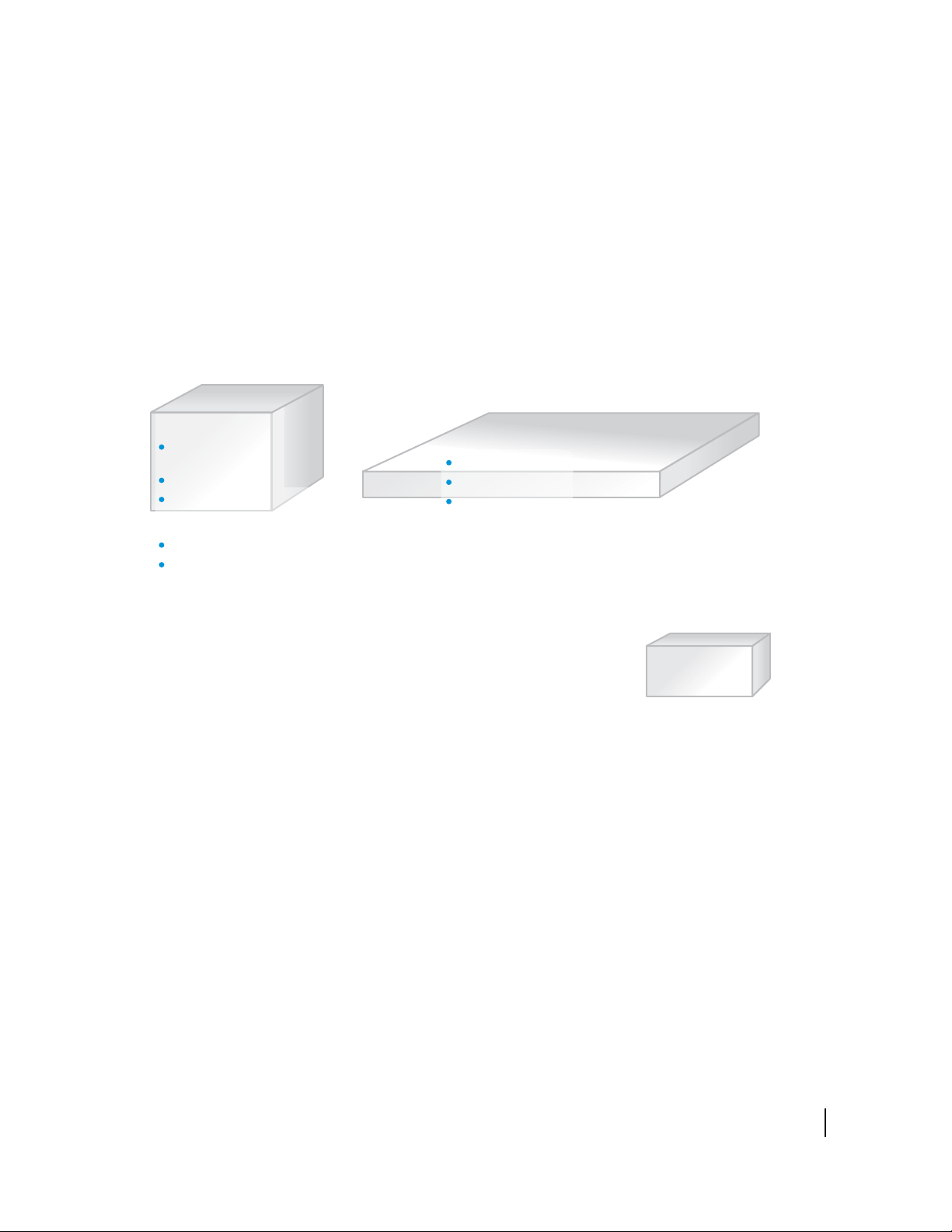

Cradle-type radio assembly Figure 12 illustrates the cradle-type radio assembly. The main

parts of the radio assembly are mounted on two circular brackets

so they can be rotated, similar to the movement of a cradle, to set

the polarization of the feed horn. The arrows in

Figure 13 indicate

how the radio assembly can be rotated.

16

Figure 12: Cradle-type radio assembly (shown with mounting adapter)

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

Page 35

Figure 13: Cradle-like rotation of the cradle-type radio assembly

Cradle-type refers to the overall design of the radio; therefore,

two radios with different model numbers may both be cradle-type

radios.

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

17

Page 36

Small hardware parts lists

Tables 2 and 3 list the small hardware parts included in the

antenna kits for the two radio types (J-type and cradle-type).

The parts listed in Table 2 are included in both kits, for both radio

assembly types.

Table 2: Small hardware parts used in antenna kits for both radio types

Part Quantity Comments

For assembling the antenna

¼-20 × 1-3/8-inch thread-cutting screws 4 These parts are used for attaching the:

¼-20 × 1-inch hex bolts 3

¼-20 × 2-inch hex bolt 1

¼-inch flat washers 8

¼-inch lock washers 4

¼-inch hex nuts 4

For mounting the radio assembly (both types)

0.9-inch inside diameter O-ring * 1 These parts are used for both radio assemblies, to:

No. 6-32 × 0.5-inch socket-head cap screws * 7

No. 6 internal tooth lock washers * 7

Silicone grease capsule 1

5/16-18 × 2.25-inch carriage bolts 2

5/16-inch flat washers 4

5/16-inch lock washers 4

5/16-inch hex nuts 2

* In the antenna kit for the J-type radio, the waveguide transition is attached to the feed horn at the factory, so

these parts are factory installed.

• Reflector

• Feed rods

• Feed support tube

The hardware for each task is specified in Chapter 3

– Assembling the antenna.

• Attach the feed horn

• Mount the radio assembly

The hardware for each task is specified in:

• Chapter 4 – Installing a J-type radio assembly

• Chapter 5 – Installing a cradle-type radio

assembly

18

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

Page 37

Additional parts for

J-type radio

The parts listed in Table 3 are included only in the antenna kit for

the J-type radio. The antenna kit for the J-type radio also includes

the part listed in

Tabl e 2.

Tab le 3 : Additional small hardware parts included in the antenna kit for the J-type radio assembly

Part Quantity Comments

1-inch inside diameter O-ring 1 These parts are used to attach the:

M4 x 12-mm socket-head cap screws 4

M4 lock washers 4

5/16-18 × 1-inch hex bolts 2

¼-20 × 1-inch hex bolts 2

¼-20 × 0.75-inch carriage bolts 4

¼-inch flat washers 4

¼-inch lock washers 6

¼-inch hex nuts 4

Feed horn clamp 1

• Waveguide transition to the radio assembly

• Upper mounting bracket to the transmitter

• Upper and lower mounting brackets to each other

The hardware for each task is specified in Chapter 4

– Installing a J-type radio assembly.

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

19

Page 38

Tools

Tabl e 4 lists the tools required to install and point the antenna.

Table 4: Tools required to install and point the antenna

Tool Details

(2) 7/16-inch

combination wrenches *

(2) ½-inch combination

wrenches *

Torque wrench With ½-inch and 7/16-inch sockets capable of torquing to 15 ft-lb.

M7 hex key For J-type radio.

7/64-inch hex key For cradle-type radio. The 7/64-inch hex key is included in the

Long-shaft hexagonal

ball driver, 3-mm

Torque wrench for

hexagonal socket

Bubble level Used to make sure the mast is plumb.

Compass Hand-held, magnetic.

Pencil Carpenter’s pencil.

Outdoor pointing

interface (OPI)

Ladder If needed.

* A socket wrench with 7/16-inch and ½-inch sockets makes some tasks easier, but for some

nuts or bolts there is not enough clearance to use a socket wrench.

For ¼-inch bolts. Some nuts and bolts require a second wrench

to prevent turning.

For 5/16-inch bolts. Two of the canister nuts are not accessible

with a socket wrench. Some nuts and bolts require a second

wrench to prevent turning.

antenna kit.

For socket-head cap screws (Allen screws) with a 3-mm

hexagonal socket. Driver shaft should be at least 5 inches long.

(Recommended for attaching or removing the J-type radio

assembly to or from the waveguide transition. A short-arm hex

key is provided with the screws, but the long-shaft ball driver is

much easier. The long-shaft ball driver cannot be used for the

cradle-type radio.)

Must fit a 3-mm hexagonal socket and be capable of torquing to

15 inch-lb.

Optional. Hughes P/N 1031393-0002. Portable repeater that

displays signal strength values during antenna pointing. For

additional information, see

Installing the OPI on page 58.

20

See the HN System Antenna Site Preparation and Mount

Installation Guide (1035678-0001) for a more complete list of

tools and items that may be needed for installation.

Tabl e 5 specifies the correct tool size for each hardware size

included in the antenna kit:

Chapter 2 • Antenna parts and required tools

1037312-0001 Revision A

Table 5: Tool sizes matched to hardware sizes

Hardware size Tool size

¼-inch 7/16-inch

5/16-inch ½-inch

#6-32 socket-head cap screw 7/64-inch hex key

M4 x 20 mm screw M7 key wrench

Page 39

Chapter 3

Assembling the antenna

This chapter explains how to install:

• The Az/El and reflector bracket assembly – The Az/El

mount assembly and reflector bracket assembly are

pre-assembled for installation as a single unit, as shown in

Figure 3 on page 10.

• The antenna reflector

• The feed rods and feed support tube – The feed rods attach

to the reflector and help support the feed support tube.

Radio installation is covered in Chapter 4 for the J-type radio and

Chapter 5 for the cradle-type radio.

Topics in this chapter include:

• Determining the pointing values on page 21

• General instructions for assembling the antenna on page 22

• Installing the Az/El and reflector bracket assembly on

page 23

• Attaching the reflector on page 25

• Installing the feed support tube on page 27

Determining the pointing values

CAUTION

Before you install the antenna, read all safety information in

the section titled

Satellite-based commissioning (SBC) is an automated web-based

method for pointing the antenna. SBC configures the IDU,

calculates its exact location, and uses the location and other

information to help you point the antenna. SBC calculates the

values you use to set the antenna’s azimuth, elevation, and

polarization, based on the information you enter and the satellite

you select. It then downloads the necessary software and

completes the IDU registration process.

Important safety information on page iii.

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

21

Page 40

In this manual, installation software refers to installation,

pointing, and commissioning software accessed through the IDU,

which works in conjunction with SBC.

Before proceeding, use the installation software to determine the

initial values to use for setting azimuth, elevation, and

polarization. Record these values and keep them handy for

reference as you install and point the antenna. To use the

installation software, follow the instructions in the IDU

installation manual for commissioning the IDU.

General instructions for assembling the antenna

Before you assemble the antenna, read these important

instructions:

• Mast – The mast must be installed before you can install the

antenna. For information on antenna mounting methods, see

the HN System Antenna Site Preparation and Mount

Installation Guide (1035678-0001). The mast must have an

3

outside diameter of 2-

⁄8 inches (2.375 inches).

• Sequence of steps – When you assemble the antenna, follow

the instructions in this chapter in the order they are

presented.

• Tightening hardware– Do not tighten any nuts or other

hardware until you are instructed to do so. (See also the next

item, Torque.)

• Torque – To ensure successful installation of the antenna, you

must tighten all nuts and socket-head cap screws to the

maximum torque values shown in

Tabl e 6. This is a critical

requirement.

Table 6: Torque specifications

Fastener

¼-inch bolts 6 ft-lb

5/16-inch bolts 15 ft-lb

¼-20 thread-cutting screws used to

secure reflector bracket to reflector

No. 6-32 and M4 socket-head cap

screws

Maximum

torque

10 ft-lb

15 inch-lb

22

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

For bolts that use a split lock washer, tighten the bolt until the

washer is flattened, but do not tighten the bolt further. When

the washer is flattened, this indicates that sufficient torque

has been applied.

Page 41

Installing the Az/El and reflector bracket assembly

Bubble must be centered

between marks.

Follow these steps to install the Az/El and reflector bracket

assembly onto the mast:

1. Before you install the Az/El and reflector bracket assembly

onto the mast pipe, use a bubble level to make sure the mast is

plumb.

Check the mast at two perpendicular locations, as shown in

Figure 14.

Note: The mast must be plumb. The antenna assembly

cannot be adjusted to correct for a mast that is not plumb.

To make sure the mast is

plumb, check with the level

in two positions at right

angles to each other.

Mast

Level

Bubble

level

Mast

2nd level

position

Top view

Side view

Figure 14: Making sure the mast is plumb

T0172005

2. Slide the canister of the Az/El and reflector bracket assembly

down onto the mast.

Figure 15 shows the Az/El and reflector bracket assembly on

the mast.

Note: The mast must have an outside diameter of

3

2-

⁄8 inches (2.375 inches).

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

23

Page 42

Top canister nut

(1 of 3)

Reflector

bracket

Az/El mount

assembly

Figure 15: Az/El and reflector bracket assembly on the mast

3. Optional: If you adjust the antenna elevation now to the

coarse elevation value, before installing the reflector, it’s

easier than making this adjustment after the reflector is

attached. You can make this adjustment now or do it as part

of the antenna pointing procedure. (See

Setting coarse

elevation on page 61.)

4. Rotate the Az/El and reflector bracket assembly until the

reflector side is oriented in the general direction of the

satellite.

If necessary, loosen the canister nuts just enough to allow the

assembly to rotate.

5. Snug the three canister nuts just enough to prevent the

assembly from rotating. Do not tighten the nuts at this time.

24

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

Page 43

Attaching the reflector

Follow these instructions to attach the antenna reflector to the

reflector bracket.

Note: This task is easier if someone assists you.

1. Orient the reflector so the HughesNet logo on the front is

near the top, as shown in

Figure 16.

Hole for

attaching

feed rod

Hole for attaching

feed support tube

Figure 16: Reflector in correct position for installation

Hole for

attaching

feed rod

2. Lift the reflector and align the four mounting holes on the

back of the reflector with the four mounting holes on the

reflector bracket. See

Note: To make it easier to position the reflector and insert

the screws (steps

Az/El and reflector bracket assembly beyond the 80° mark on

the elevation scale so the surface of the reflector bracket that

attaches to the reflector is nearly horizontal. Then you can lay

the reflector on the bracket, with the holes in the reflector

facing the bracket. This method (not illustrated here) is

especially useful when one person installs the antenna.

To use this method you must loosen the fine elevation

adjustment nuts and elevation lockdown bolts identified in

Figure 48 on page 60. Be sure to tighten the elevation

lockdown bolts before laying the reflector on the bracket.

Figure 17.

2 and 3), you can adjust the elevation of the

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

25

Page 44

Reflector attached to bracket

Arrows above point to mounting screws. One screw,

indicated by the gray arrow, is not visible in this photo.

Figure 17: Mounting the reflector on the reflector bracket

Mounting holes (arrows)

on back of reflector

3. Insert two ¼-20 × 1-

3

⁄8-inch hex thread-cutting screws

(without washers) through the upper holes on the reflector

bracket and into the reflector holes indicated in

Figure 17

(upper arrows on the right photo).

4. Partially tighten the screws.

5. Insert two ¼-20 × 1-

1

⁄16-inch hex thread-cutting screws

(without washers) through the lower holes on the reflector

bracket and into the lower reflector holes.

6. Tighten each screw a little; then move on to the next screw.

7. Use a torque wrench to tighten the screws to 10 ft-lb force

maximum.

CAUTION

To avoid damaging the mounting holes in the back of the

reflector, do not overtighten the reflector bracket screws.

Use a torque wrench.

26

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

Page 45

Installing the feed support tube

Install the feed rods and feed support tube as explained in the

following two sections. These instructions apply to both types of

feed support tubes and feed rods, that is, the tube and feed rods

for the J-type radio or cradle-type radio.

Note: If you are installing an antenna that will use a cradle-type

radio assembly, make sure the feed support tube and feed rods are

stamped TG. (Other letters or numbers may appear with TG.) If

these parts are not stamped TG, they are the wrong parts for the

cradle-type radio. Contact Installer Support to obtain the correct

parts.

Attaching the feed rods

Attach the feed rods to the reflector:

1. Attach the feed rods to the rim of the reflector as shown in

Figure 18.

The feed rod end with the longer flat part attaches to the

reflector rim; the end with the shorter flat part attaches to the

feed support tube (as shown in

Figure 19 on page 28).

Point the lower end of each feed rod inward, toward the space

in front of the lower part of the reflector. When both feed rods

are correctly installed, their lower ends are just a few inches

apart.

¼-inch

flat washer

¼-20 x 1-inch

hex bolt

Feed rod

¼-inch

flat washer

Reflector

rim

¼-inch lock

washer

¼-inch hex nut

T0172006

Detail – Attaching left feed rod

(right rod – same but opposite)

Figure 18: Attaching feed rods to the reflector

Note: The photos in this section show the feed support tube

and rods for the J-type radio. These parts for the cradle-type

radio are very similar and are installed in the same way.

2. Tighten each nut just enough to keep the hardware in place.

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

27

Page 46

Securing the feed support

tube

Secure the feed support tube:

1. Attach the lower ends of the feed rods to the feed support

tube as follows: Insert the ¼-20 × 2-inch hex bolt through the

tube, and use the hardware shown in

Figure 19.

Make sure the flat end of the feed support tube points toward

the reflector.

2. Tighten the nut just enough to keep the hardware in place.

Feed

support

tube

Feed rodFeed rod

Feed rod ends attached to feed

support tube, in front of reflector

Figure 19: Attaching the feed rods to the feed support tube

Back of

reflector

Rim

3. Attach the flat end of the feed support tube to the rim of the

4. Tighten the nut just enough to keep the hardware in place.

Flat end of feed

support tube

¼-20 x 2-inch

hex bolt

¼-inch

flat washer

reflector, as shown in

¼-inch hex nut

¼-inch lock washer

¼-inch flat washer

Reflector rim

¼-inch flat washer

flat washer

Detail

Figure 20.

¼-20 x 1-inch

hex bolt

Detail

¼-inch

¼-inch hex nut

¼-inch lock

washer

T0172007

Feed

support

tube

Side view

T0172008

28

Figure 20: Attaching the feed support tube to the reflector rim

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

Page 47

Tightening the hardware

Tighten the hardware as follows:

1. Tighten the three nuts on the reflector rim (indicated by the

black arrows in

Figure 21).

2. Tighten the nut where the feed rods attach to the feed support

tube (indicated by the white arrow in

Figure 21: Tightening nuts on feed rods and feed support tube

Figure 21).

The antenna is now assembled, as shown in Figure 22, and ready

for installation of the radio assembly.

• If you are installing a J-type radio, go to Chapter 4 –

Installing a J-type radio assembly, on page 31.

• If you are installing a cradle-type radio, go to Chapter 5 –

Installing a cradle-type radio assembly, on page 43.

Figure 22: Completed antenna assembly (without radio)

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

29

Page 48

30

Chapter 3 • Assembling the antenna

1037312-0001 Revision A

Page 49

Chapter 4

Installing a J-type radio assembly

This chapter applies to the J-type radio assembly only. If you are

installing a cradle-type radio assembly, go to

Installing a cradle-type radio assembly, on page 43.

This chapter includes:

• Installing a shim for vertical transmit polarization on

page 32

• Installing the radio assembly on page 36

CAUTION

• Do not remove the protective packing material from the

feed horn window until installation of the radio

assembly is complete.

• Do not remove the protective covering from the small

end of the feed horn until you are ready to attach the

waveguide transition.

• Be careful not to damage the feed horn window. Do not

touch the plastic film.

Chapter 5 –

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

31

Page 50

Installing a shim for vertical transmit polarization

Follow the instructions in this section only if the installation

specification or service order states that vertical transmit

polarization is required. (The vertical shim kit is not used with

the cradle-type radio.)

If vertical transmit polarization is not required, go to Installing

the radio assembly on page 36.

The radio assembly is shipped with a horizontal transmit

polarization shim installed. If vertical transmit polarization is

required, you must remove the horizontal shim and replace it with

a vertical transmit polarization shim.

Note: If you need to change from horizontal to vertical transmit

polarization on an antenna that has the radio assembly already

installed on the feed support tube, you will have to remove the

radio assembly from the feed support tube before you can follow

the instructions in this section.

Figure 23 shows where the shim is located and shows three of the

four Allen screws that hold the shim in place.

TRIA

Shim

(See also

Figure 24.)

Allen screws

(4 total)

Figure 23: Shim location next to TRIA

Waveguide

To replace the horizontal shim with a vertical shim, follow these

steps:

1. Obtain a vertical transmit polarization shim kit (Hughes

model VTX-SHIM-KIT, P/N 1033809-0001).

Figure 24 on page 33 shows what a vertical shim looks like.

2. Loosen and remove the four Allen screws that hold the shim

in place. See

Figure 23.

3. Separate the end of the waveguide from the shim.

32

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

Page 51

X here identifies horizontal shim. This X

is visible when the parts are assembled.

Figure 24 illustrates the difference between the horizontal

shim and vertical shim. Note the positions of the alignment

pins.

TRIA

Horizontal shim in place

O-ring

Horizontal shim

Figure 24: Horizontal shim and vertical shim for transmit polarization

Vertical shim in place

(In this photograph, the TRIA

has not yet been rotated.)

“ – ” mark here identifies vertical shim. This

mark is visible when the parts are assembled.

Alignment

pins

Alignment

pins

Ver ti c a l s h i m

4. Remove the horizontal shim and O-ring.

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

33

Page 52

5. Install the vertical shim and O-ring in the same location.

Because of its shape and alignment pins on the

transmit/receive isolation assembly (TRIA), the vertical shim

can only be installed in the position shown in

Figure 24

(upper right photo). Note the position of the alignment pins.

Likewise, the horizontal shim can only be installed in one

position.

Because of the shim’s alignment pins, you must rotate the

TRIA 90

° from its horizontal polarization position. You must

rotate the TRIA before you re-attach the waveguide end so

you can insert the shim alignment pins into the waveguide

end plate. See Figures

25 and 26.

Figure 25: Direction of TRIA rotation for vertical polarization

34

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

Page 53

Figure 26 shows how the TRIA is positioned for horizontal

transmit polarization compared to how it is positioned for

vertical transmit polarization.

Horizontal polarization

TRIA

TRIA

TRIA rotated for vertical polarization

Figure 26: TRIA position for horizontal and vertical transmit

polarization

6. Make sure the O-ring shown in Figure 25 on page 34 is in

place in the shim.

7. With the TRIA correctly positioned (rotated), place the

waveguide end plate against the shim.

8. Insert and tighten the four Allen screws.

At this point the radio assembly is ready to be installed.

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

35

Page 54

Installing the radio assembly

This section explains how to install the J-type radio assembly.

You must use the antenna kit indicated in

Tabl e 1 on page 8 for

the J-type radio assembly.

Attaching the upper

mounting bracket

Note: The transmitter may look a little

different than the one shown here.

Attach the upper mounting bracket to the transmitter:

1. Place the upper mounting bracket onto the transmitter, in the

position shown in

Figure 27.

Align the two bolt holes in the bracket with the holes in the

transmitter.

2. Secure the bracket to the transmitter with two

5

⁄16-18 × 1-inch

hex bolts, lock washers, and flat washers.

3. Tighten the bolts.

Mounting

bracket

Figure 27: Attaching the upper mounting bracket

Bolts

Transmitter

36

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

Page 55

Attaching the feed horn and

transition to the radio

assembly

The feed horn and waveguide transition are shipped from the

factory pre-attached, as shown in

Waveguide

transition

O-ring

groove

Figure 28: Feed horn with waveguide transition attached

Figure 28.

Attach the square end of the waveguide transition (with the feed

horn attached) to the radio assembly—specifically, to the

transmit/receive isolation assembly, or TRIA:

1. Apply silicone grease to the O-ring groove in the waveguide

transition. See

Figure 29.

The silicone grease is provided in a small plastic capsule.

2. Place the O-ring (1-inch inside diameter) in the O-ring

groove in the square end of the waveguide transition.

Note: The O-ring and small hardware for the square end of

the waveguide transition are shipped in a bag that contains

four socket-head cap screws.

O-ring

Figure 29: O-ring in groove in waveguide transition

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

37

Page 56

3. Place the neck of the feed horn into the upper mounting

bracket, and position the square end of the waveguide

transition close to the TRIA. See

Make sure the feed horn packing material is out of the way so

it will not get stuck between the feed horn neck and the upper

mounting bracket.

4. Attach the square end of the waveguide transition to the

TRIA using the provided M4 × 12-mm socket-head cap

screws and M4 lock washers with teeth on the inner edges.

Figure 30.)

(See

Insert the screws in the direction indicated by the white

arrows in

Make sure the O-ring remains in the O-ring groove.

White arrows indicate

location of cap screws and

direction to insert them.

Radio assembly

(TRIA)

Figure 30.

A fourth

cap screw

is not

visible

here.

Figure 30.

Feed

horn

38

Figure 30: Attaching the waveguide transition to the TRIA

5. Use a long-shaft 3-mm ball driver to tighten the M4 cap

screws.

6. Place the feed horn clamp over the neck of the feed horn, as

shown in

7. Insert two ¼-20 × 1-inch hex bolts (with lock washers)—one

on each side of the clamp.

Make sure the packing material is out of the way so it will not

get stuck under the clamp.

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

Figure 31.

Page 57

8. Tighten the bolts alternately, a little at a time.

Figure 31: Securing the feed horn clamp (arrow)

Mounting the radio

assembly on the feed

support tube

To mount the radio assembly on the feed support tube, first mount

the lower mounting bracket on the feed support tube:

1. Position the lower mounting bracket and mounting adapter on

the feed support tube, with the bolt holes aligned, as shown in

Figure 32.

There are four holes on the top surface of the feed support

tube. Two of these holes are oval slots. Use the round hole

and oval slot closest to the reflector to mount the radio.

(See Figure 32.)

2. Insert two

5

⁄16-18 × 2.5-inch carriage bolts from above, one

into each of the two mounting holes.

3. From below, place a

5

⁄16-inch flat washer, lock washer, and

hex nut on each bolt.

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

39

Page 58

4. Tighten the nuts.

5/16-18 x 2.5-inch

carriage bolts

Match round hole

in adapter to round

hole in tube.

Match oval slot in adapter

to oval slot in tube.

T0172015

Lower mounting bracket

Mounting adapter

Feed support tube

Figure 32: Attaching the radio assembly to the feed support tube

Attach the upper and lower mounting brackets to each other, as

shown in

Figure 33:

1. Place the radio assembly (attached to the upper bracket in

previous steps) onto the lower bracket.

2. Align the four mounting holes on the upper and lower

mounting brackets.

3. Insert a ¼-20 × 0.75-inch carriage bolt through each of the

four mounting holes.

4. From below, place a ¼-inch flat washer, lock washer, and hex

nut on each bolt.

40

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

Page 59

5. Tighten the four bolts.

1/4-20 x 0.75-inch

carriage bolts

Upper

mounting

bracket

T0172018

Figure 33: Attaching the radio assembly to the feed support tube

6. Remove the protective packing material from the feed horn

window.

This completes installation of the radio assembly.

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

41

Page 60

42

Chapter 4 • Installing a J-type radio assembly

1037312-0001 Revision A

Page 61

Chapter 5

Installing a cradle-type radio assembly

This chapter applies to the cradle-type radio assembly only. If

you are installing a J-type radio assembly, go to

Installing a J-type radio assembly, on page 31.

This chapter includes:

• Installing the radio assembly on page 44

• Setting polarization for the cradle-type radio on page 47

CAUTION

• Do not remove the protective packing material from the

feed horn window until installation of the radio

assembly is complete.

• Be careful not to damage the feed horn window. Do not

touch the plastic film.

Chapter 4 –

Chapter 5 • Installing a cradle-type radio assembly

1037312-0001 Revision A

43

Page 62

Installing the radio assembly

This section explains how to install the cradle-type radio

assembly. You must use the antenna kit indicated in

Tabl e 1 on

page 8 for the cradle-type radio assembly.

Attaching the feed horn

7. To attach the feed horn to the radio assembly, refer to Figures

34 and 35 and follow steps 1 through 3 below.

Screws and

washers

Feed horn

O-ring

Figure 34: Attaching the feed horn and radio assembly

T0172013

1. Remove the protective covering from the small end of the

feed horn.

CAUTION

• If you do not remove the protective covering from the

small end of the feed horn, the system may operate, but

with degraded performance.

• Do not remove the protective packing material from the

feed horn window until you finish installation of the

radio assembly.

44

Chapter 5 • Installing a cradle-type radio assembly

1037312-0001 Revision A

Page 63

2. Apply silicone grease to the O-ring groove in the feed horn.

3. Place the O-ring (0.9-inch inside diameter) in the groove.

Note: The O-ring is shipped in a bag that contains seven

socket-head cap screws for attaching the feed horn. Six screws

are required; one is an extra part.

Make sure the O-ring remains in the O-ring groove.

O-ring

Figure 35: O-ring in groove

Mounting the radio

assembly on the feed

support tube

Use the mounting adapter to attach the radio assembly to the feed

support tube. Refer to

Figure 36 as you follow these instructions:

1. Place the mounting adapter and radio assembly onto the feed

support tube.

2. Align the mounting holes in the base of the radio assembly,

mounting adapter, and feed support tube.

There are six holes on the top surface of the feed support

tube. Use the oval slot at the end of the tube and the second

hole from the bend in the tube, as shown in

3. From below, insert two

5

⁄16-inch lock washer and flat washer on each bolt) through

5

⁄16-18 × 2.25-inch hex bolts (using a

Figure 36.

the feed support tube, adapter, and base.

Chapter 5 • Installing a cradle-type radio assembly

1037312-0001 Revision A

45

Page 64

4. Tighten the bolts securely.

Match oval slot in

adapter to oval slot at

the end of the tube.

Match round hole in adapter to

second hole from bend in tube.

T0172014

Figure 36: Mounting the radio on the feed support tube

5. Remove the protective packing material from the feed horn

This completes installation of the radio assembly.

window.

5/16-18 2.5-inch

×

hex bolts

Mounting adapter

Feed support tube

46

Chapter 5 • Installing a cradle-type radio assembly

1037312-0001 Revision A

Page 65

Setting polarization for the cradle-type radio

To set polarization for the cradle-type radio, you adjust the radio,

not the antenna. This section explains how to calculate and set the

polarization value for the cradle-type radio assembly.

Calculating the radio

polarization setting

For a horizontal

uplink

/vertical downlink

To calculate the polarization setting, refer to the section for the

type of uplink and downlink that will be used. In these

instructions, SBC initial value refers to the polarization value

calculated by the installation software.

To calculate the radio polarization setting for a horizontal

/ vertical downlink:

uplink

1. Multiply the SBC initial value by –1,

then offset the result by 90° as follows:

If the SBC initial value is positive, add 90.

If the SBC initial value is negative, subtract 90.

Example 1, positive initial value of 41°

41 × –1 = –41

Add 90:

–41 + 90 = 49

Radio polarization setting = 49°

Example 2, negative initial value of –41°

–41 × –1 = 41

Subtract 90:

41 – 90 = –49

Radio polarization setting = –49°.