Page 1

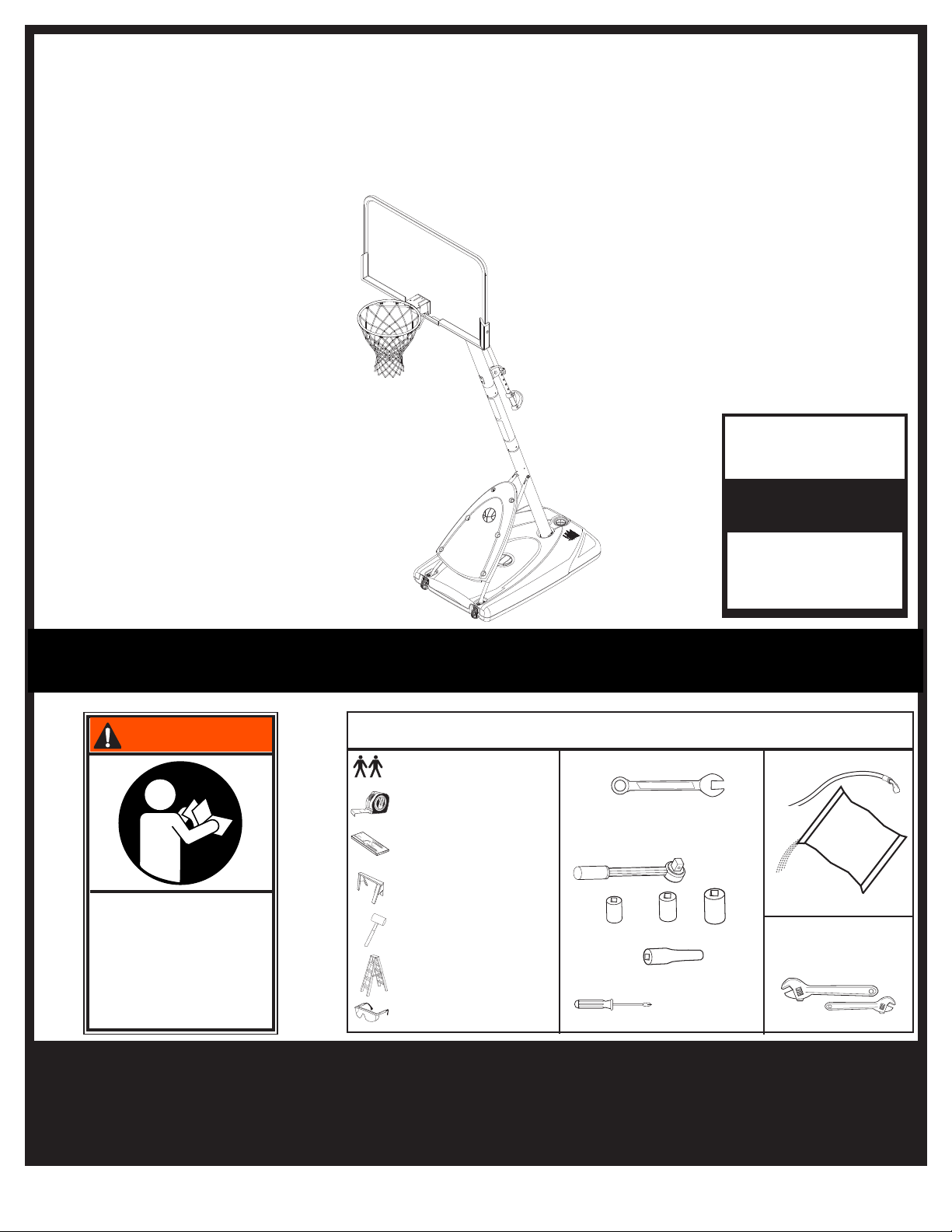

Portable System

Owners Manual

Customer Service Center

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • U.S.A.

Adult Assembly

Required.

Write Model Number

From Box Here:

This manual, accompanied by sales receipt, should be saved and kept on hand as a convenient reference, as it

contains important information about your model.

WARNING!

READ AND UNDERSTAND

OPERATOR'S MANUAL

BEFORE USING THIS UNIT.

FAILURE TO FOLLOW

OPERATING INSTRUCTIONS

COULD RESULT IN INJURY

OR DAMAGE TO

PROPERTY.

• 2 People

• Tape Measure

• Wood Board (scrap)

• Sawhorse or Support Table

• Hammer

• Step Ladder 8 ft. (2.4m)

• Safety Glasses

REQUIRED TOOLS AND MATERIALS:

• (2 each) Wrenches

1/2" 9/16" 3/4"

AND/OR

(2) Socket Wrenches and Sockets

1/2" 9/16" 3/4"

• Extension

• Phillips-Head Screwdriver

• Garden Hose or Sand

SAND

SAND

(300 lb.)

(300 lb.)

(136 kg)

(136 kg)

• Optional: Large & Small

Adjustable Wrenches

Toll-Free Customer Service Number for U.S: 1-800-558-5234,

For Canada: 1-800-284-8339,

For Europe: 00 800 555 85234 (Sweden: 009 555 85234),

For Australia: 1-800-333 061

Internet Address: http://www.huffysports.com

© COPYRIGHT 2005 by SPALDING

1

02/06 ID# M661144

Page 2

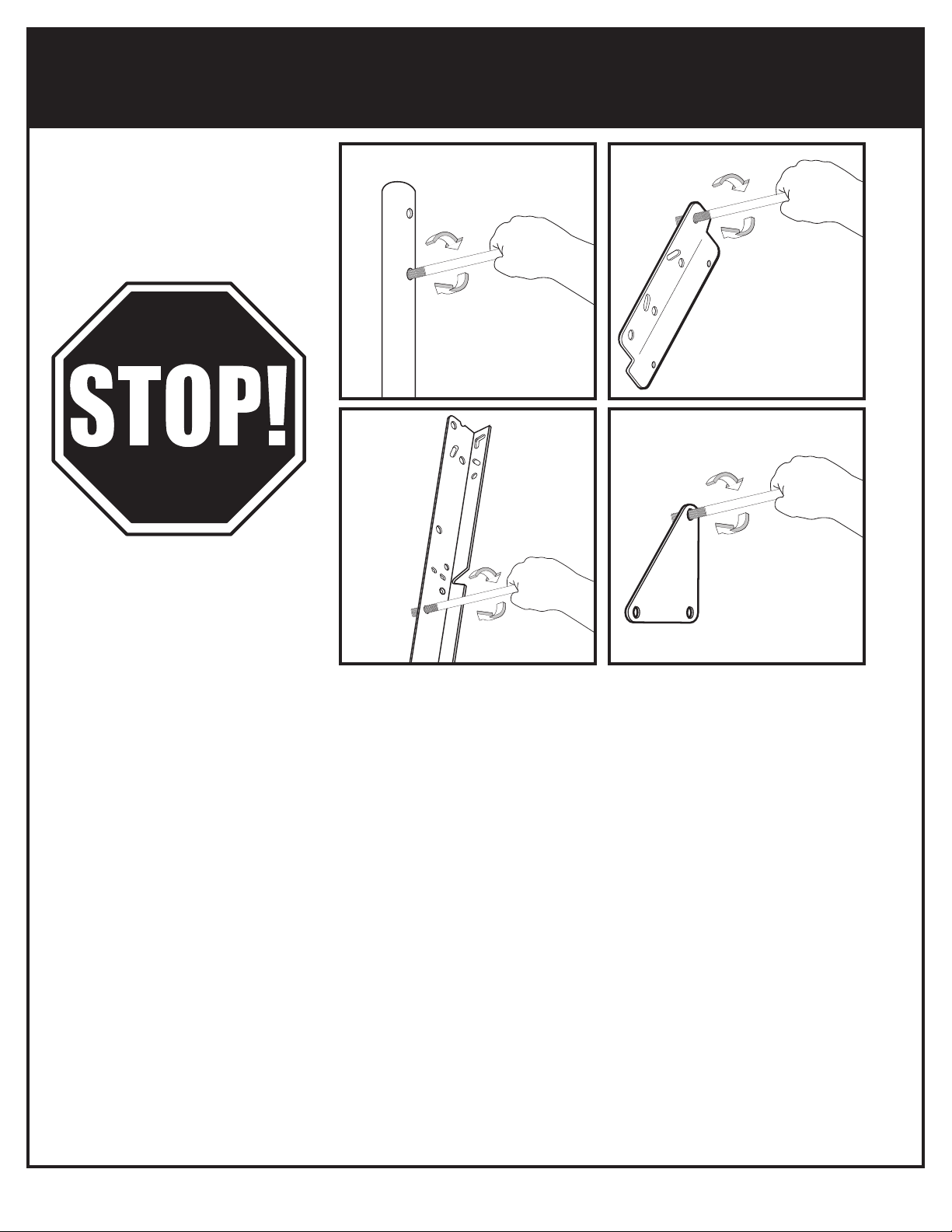

BEFORE YOU START!

To ensure optimal playability of backboard system, a close tolerance fit between the elevator

components and hardware is required. Test-fit large bolts into large holes of elevator tubes,

backboard brackets, and triangle plates. Carefully rock them in a circular motion to ream out

any excess paint from holes if necessary.

NOTE: Not all items pictured are included with every model.

ID# M661144 02/06

2

Page 3

10-3/4" High

4" Wide

PMS 021 for

Warning

Owner must ensure that all players know and follow these rules

for safe operation of the system.

WARNING

•

D

O NOT HANG on the rim or any part of the system including

backboard, support braces or net.

•

During play, especially when performing dunk type activities,

keep player's face away from the backboard, rim and net.

Serious injury could occur if teeth/face come in contact with

backboard, rim or net.

•

Do not slide, climb, shake or play on base and/or pole.

•

After assembly is complete, fill system completely with water

or sand. Never leave system in an upright position without

filling base with weight, as system may tip over causing

injuries.

•

When adjusting height or moving system, keep hands and

fingers away from moving parts.

•

Do not allow children to move or adjust system.

•

During play, do not wear jewelry (rings, watches, necklaces,

etc.). Objects may entangle in net.

•

Surface beneath the base must be smooth and free of gravel or

other sharp objects. Punctures cause leakage and could cause

system to tip over.

•

Keep organic material away from pole base. Grass, litter, etc.

could cause corrosion and/or deterioration.

•

Check pole system for signs of corrosion (rust, pitting,

chipping) and repaint with exterior enamel paint. If rust has

penetrated through the steel anywhere, replace pole

immediately.

•

Check system before each use for proper ballast, loose

hardware, excessive wear and signs of corrosion and repair

before use.

•

Check system before each use for instability.

•

Do not use system during windy and/or severe weather

conditions; system may tip over. Place system in the storage

position and/or in an area protected from the wind and free

from personal property and/or overhead wires.

•

Never play on damaged equipment.

•

When moving system, use caution to keep mechanism from

shifting.

•

Keep pole top covered with cap at all times.

•

Do not allow water in tank to freeze. During sub-freezing

weather add 2 gallons of non-toxic antifreeze, sand or empty

tank completely and store. (Do not use salt.)

•

While moving system, do not allow anyone to stand or sit on

base or have added ballasting on base.

•

Do not leave system unsupervised or play on system when

wheels are engaged for moving.

•

Use Caution when moving system across uneven surfaces.

System may tip over.

•

Use extreme caution if placing system on sloped surface.

System may tip over more easily.

•

See instruction manual for proper installation and

maintenance.

R

ead and understand warnings listed

below before using this product

.

F

ailure to follow these warnings may

result in serious injury and/or

property damage

.

ID#: 561000 01/06

MUNSELL NOTATION

Hue Value Chroma

5.0 YR 6.0/15

Equiv. CIE Data

(Y%) x y

30.05 0.5510 0.4214

Approx. PMS Color

13 parts yellow

3 parts Warm Red

1/4 part Black

Warning Area = Orange

Size = 4" x 6.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

In the U.S.: 1-888-713-5488

In the U.S.: 1-800-558-5234

In Canada: 1-800-284-8339

In the U.S.: 1-800-334-9111

In the U.S.: 1-800-558-5234

In Canada: 1-800-284-8339

3

02/06 ID# M661144

Page 4

Size = 4" x 5.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

2

2

1

3

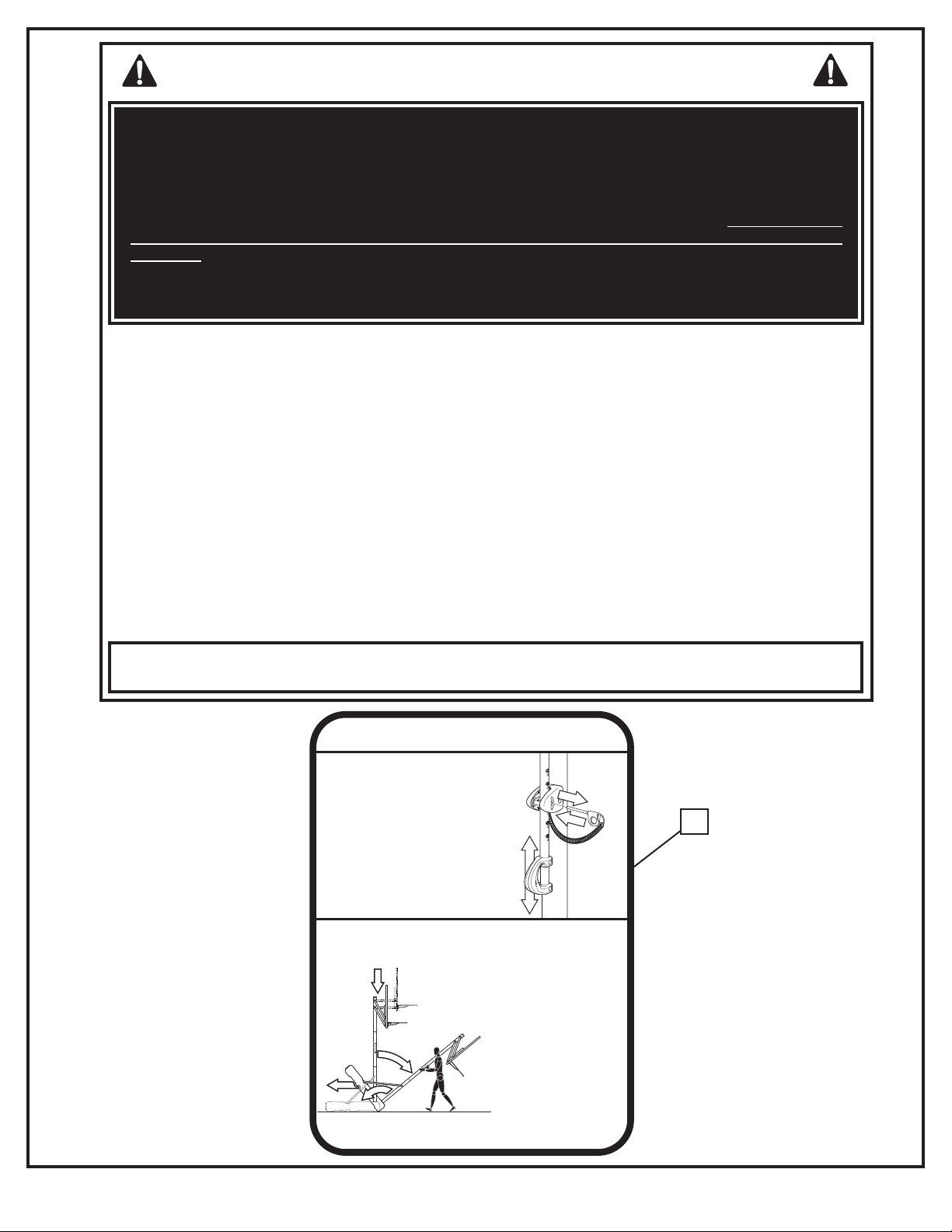

TO ADJUST BACKBOARD:

1. While holding handle, remove pin.

2. Move elevator up or down to

desired height.

3. Replace pin full length to lock

system at desired height.

511679 05/05

1

2

4

3

MOVING SYSTEM

Adjust basketball backboard

height to lowest position.

While holding pole, rotate

basketball system forward

until wheels engage with

ground.

Move basketball system to

desired location.

Carefully rotate basketball

system upright.

1.

2.

3.

4.

5.

Check system for stability.

HEIGHT ADJUSTMENT

SAFETY INSTRUCTIONS

FAILURE TO FOLLOW THESE SAFETY INSTRUCTIONS MAY RESULT IN SERIOUS INJURY OR

PROPERTY DAMAGE AND WILL VOID WARRANTY.

Owner must ensure that all players know and follow these rules for safe operation of the system.

To ensure safety, do not attempt to assemble this system without following the instructions carefully. Check

entire box and inside all packing material for parts and/or additional instruction material. Before beginning

assembly, read the instructions and identify parts using the hardware identifier and parts list in this

document. Proper and complete assembly, use, and supervision are essential for proper operation and to

reduce the risk of accident or injury. A high probability of serious injury exists if this system is not installed,

maintained, and operated properly.

• If using a ladder during assembly, use extreme caution.

• Two (2) capable adults are recommended for this operation.

• Check base regularly for leakage. Slow leaks could cause system to tip over unexpectedly.

• Seat the pole sections properly (if applicable). Failure to do so could allow the pole

sections to separate during play and/or transport of the system.

• Climate, corrosion, or misuse could result in system failure.

• Minimum operational height is 6' 6" (1.98 m) to the bottom of backboard.

• This equipment is intended for home recreational use only and NOT excessive competitive

play.

• Read and understand the warning label affixed to pole.

• The life of your basketball pole depends on many conditions. The climate, placement of

the pole, location of the pole, exposure to corrosives such as pesticides, herbicides, or

salts are all important.

If technical assistance is required, contact Customer Service.

•

• Adult supervision is recommended when adjusting height.

ID# M661144 02/06

Most injuries are caused by misuse and/or not following instructions.

Use caution when using this system.

46

4

Page 5

NOTICE TO ASSEMBLERS

Adult Assembly Required. Dispose of ALL packaging materials promptly.

ALL basketball systems, including those used for DISPLAYS, MUST be assembled and ballasted with

sand or water according to instructions. Failure to follow instructions could result in SERIOUS INJURY.

It is NOT acceptable to devise a makeshift weight system.

IMPORTANT!

Remove all contents from boxes.

Be sure to check inside pole sections;

hardware and additional parts are packed inside.

WARNING: IF YOUR SYSTEM IS EQUIPPED WITH AN ACRYLIC

BACKBOARD, EXAMINE BACKBOARD FOR ANY DAMAGE THAT MAY

HAVE OCCURRED DURING SHIPMENT. CRACKS IN THE BACKBOARD

COULD RESULT IN SUDDEN BREAKAGE. IF BACKBOARD IS DAMAGED

IN ANY WAY PRIOR TO OR AFTER ASSEMBLY, CALL TOLL-FREE

NUMBER:

U.S. 1-800-558-5234; CANADA: 1-800-284-8339; http://www.huffysports.com

PRODUCT REGISTRATION:

Please remember to complete your product registration form on-line at:

www.huffysports.com/customer_support/product_registration.

5

02/06 ID# M661144

Page 6

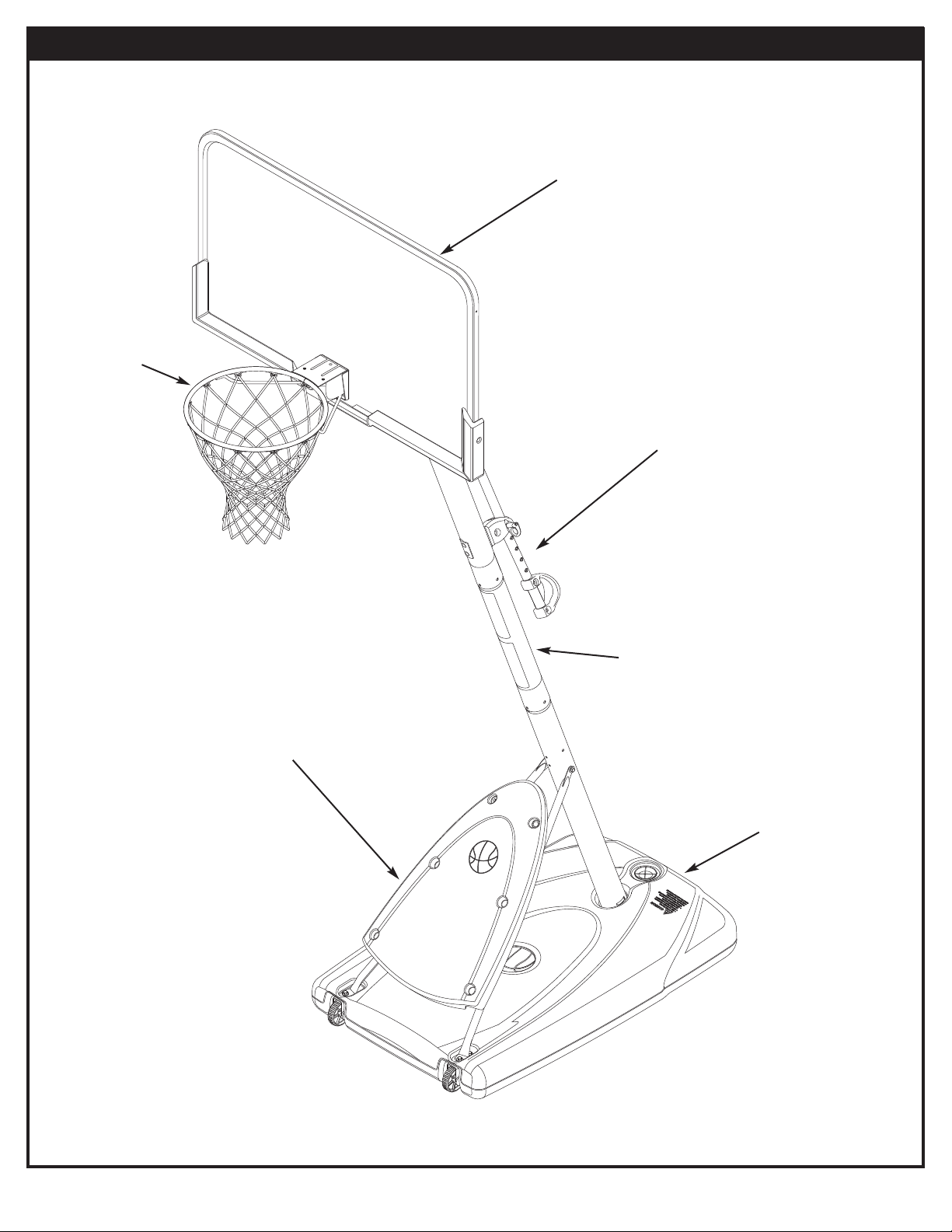

RIM

Get to know the basic parts of your basketball system...

BACKBOARD

ELEVATOR

SYSTEM

FRONT

PANEL

POLE

BASE

ID# M661144 02/06

6

Page 7

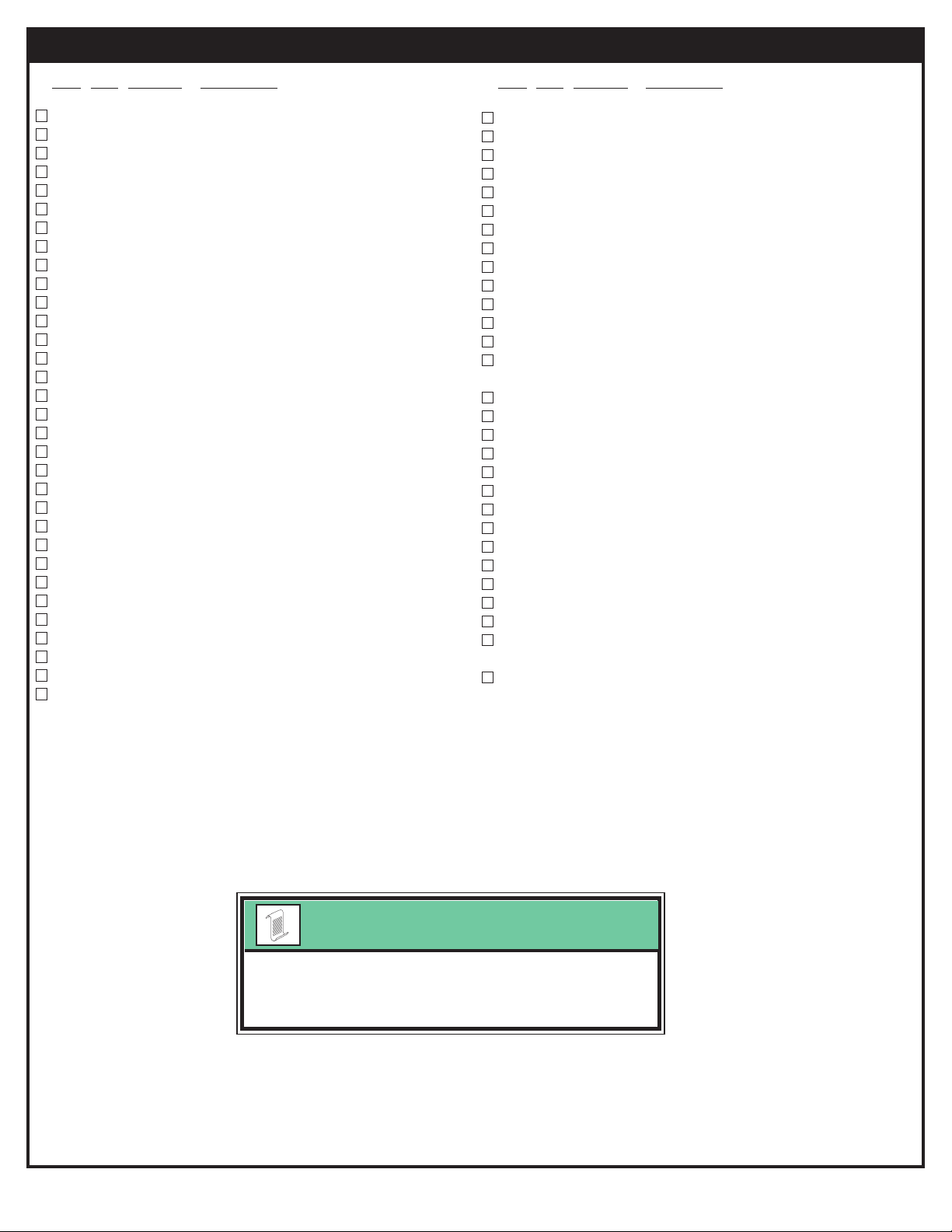

PARTS LIST - See Hardware Identifier

Item Qty. Part No. Description

1 1 266000 Base

2 2 908184 Strut, Pole to Base

3 1 804833 Exacta Height Assembly

4 1 FR908006 Top Pole Section

5 1 FR918107 Middle Pole Section

6 1 FR908179 Bottom Pole Section

7 2 108183 Wheel Bracket

8 2 266200 Wheel, 4 Inch

9 2 108182 Rod, Axle

10 1 203099 Nut, Ny-lock, 5/16-18

11 6 203063 Nylon Insert Lock Nut, 3/8-16

12 1 202662 Bolt, Hex Head, 5/16-18 x 4-1/2 Long

13 4 206938 Pushnut, 7/16 Shaft Diameter

14 7* 203100 Hex Flange Nut 5/16-18

15 1 204832 Bracket, Pole Mount

16 2 203053 Carriage Bolt, 5/16-18 x 4 Long

17 4 203232 Washer, Flat, 3/4” O.D.

18 4 204962 Bolt, Hex Head, 5/16-18 x .625 Long

19 2 206360 Bolt, Hex Head, 3/8-16 x 2-5/8 Long

20 2 204858 Spacer, Plastic Biscuit

21 2 204857 Spacer, Metal 1/2” O.D. x 1.44 Long

22 2 204859 Cover, Pin Slide

23 1 203038 Carriage Bolt, 5/16-18 x 2-3/4 Long

24 1 204850 Pin, Locking

25 1 204853 Lanyard, Black Coil

26 4 203527 Spacer, .530 I.D. x 1.5 Long

27 2 908256 Bracket, Backboard Support

28 1 266100 Cover, Front

29 6 206244 Bolt, Hex Head, 1/2-13 x 8 Long

30 4 201642 Spacer, Plastic, .530 I.D. x .625 Long

31 7 206340 Lock Nut, Hex 1/2-13

32 2 904820 Elevator Tube, Lower - Long

Qty. Part No. Description

Item

33 1 204837 Spring, Counter Balance

34 1 Rim

5 2 904808 Elevator Tube, Upper - Short

3

36 2 201682 Spacer, .530 I.D. x 1.875

37 2 900867 Plate, Triangle, (Black)

8 1 207103 Cap, Pole Top

3

39 2 200520 Screw, #8 x 3/4 Long

40 1 202605 Bolt, Hex, 1/2-13 x 4.25 Long

1 1 266300 Cap, Base

4

42 1 206990 Reinforcement Bracket

43 1 Net

4 4* 205528 Bolt, Hex Flange, 5/16-18 x 1 Long

4

45 4* 203309 Washer, Flat, 3/8

46 1 511679 Label, Height Adjustment and Moving

FR511679

47 6 203738 Carriage Bolt, 5/16-18 x 1.75 Long

48 6 200982 Nut, Locking, 5/16-18

49 1 108181 Plate, Pole Mouting

50 2 203331 Bolt, Hex Head, 3/8-16 x 1.5 Long

51 6 203218 Washer, Flat, 5/16

52 4 204961 Bolt, Hex Head, 3/8-16 x 0.625 Long

53 1 200516 Cover, Bolt End, Vinyl

54 1 900033 Bracket, Slam Jam

55 1 203796 Bolt, Tee, 3/8-16, 5” Long

56 1 200318 Bracket, Reinforcement, Slam Jam

57 1 203472 Spring, Rim

58 1 203795 Nut, Special, 3/8-16

59 1 203470 Washer, Flat, 1.5 O.D.

60 1 200503 Cover, Black OR

200504 Cover, Red

61 1 202795 Logo, NBA

* YOU MAY HAVE EXTRA PARTS WITH THIS MODEL.

NOTE

Hardware kit is designed for more than one

style of basketball system. Not all hardware

will be used.

7

02/06 ID# M661144

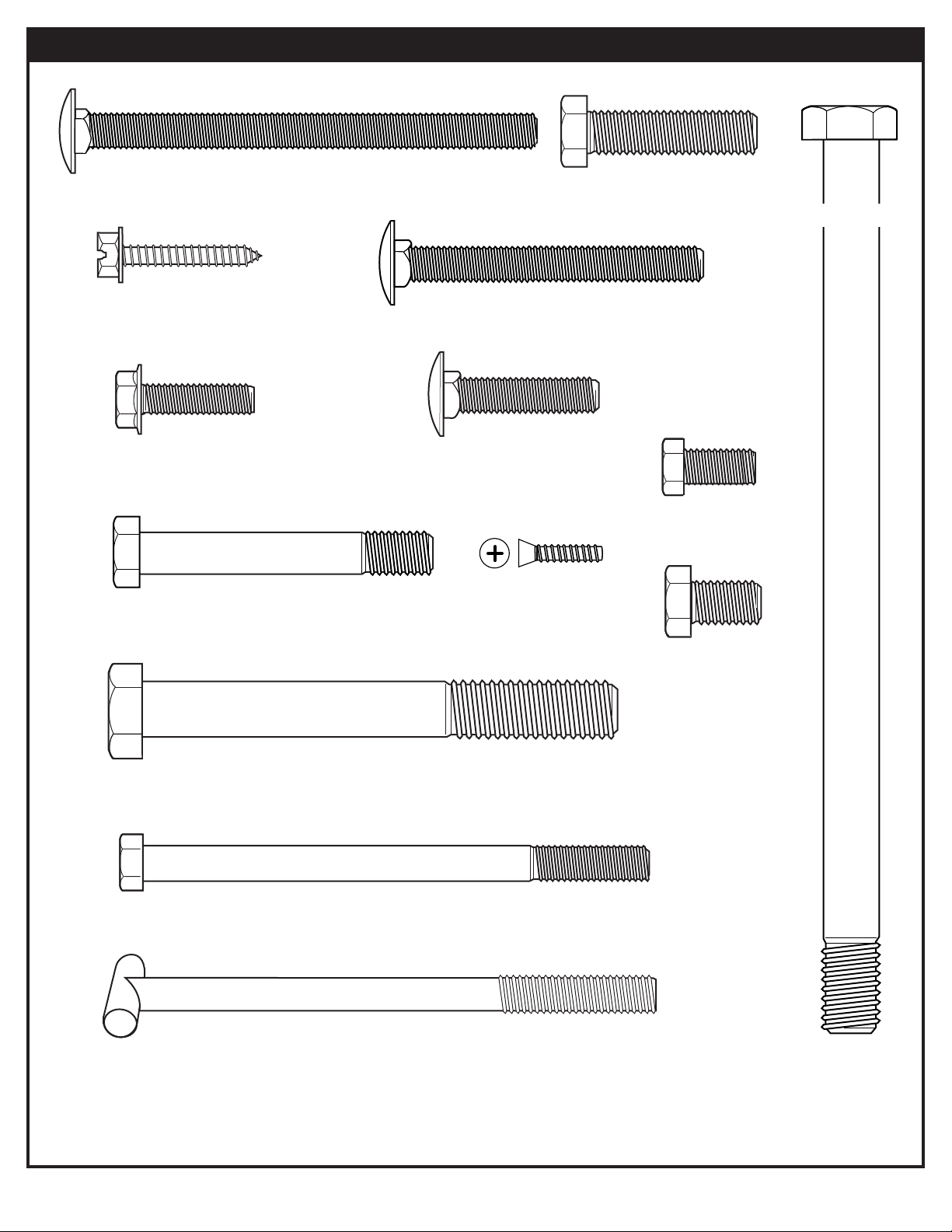

Page 8

HARDWARE IDENTIFIER (BOLTS & SCREWS)

#63 (6)

#44 (4)*

#19 (2)

#16 (2)

#19 (2)

#29 (6)

Item #23 (1)*

#47 (6)

#18 (4)

#39 (2)

#40 (1)

#12 (1)

#55 (1)

#52 (4)

ID# M661144 02/06

* You may have extra parts with this model.

8

Page 9

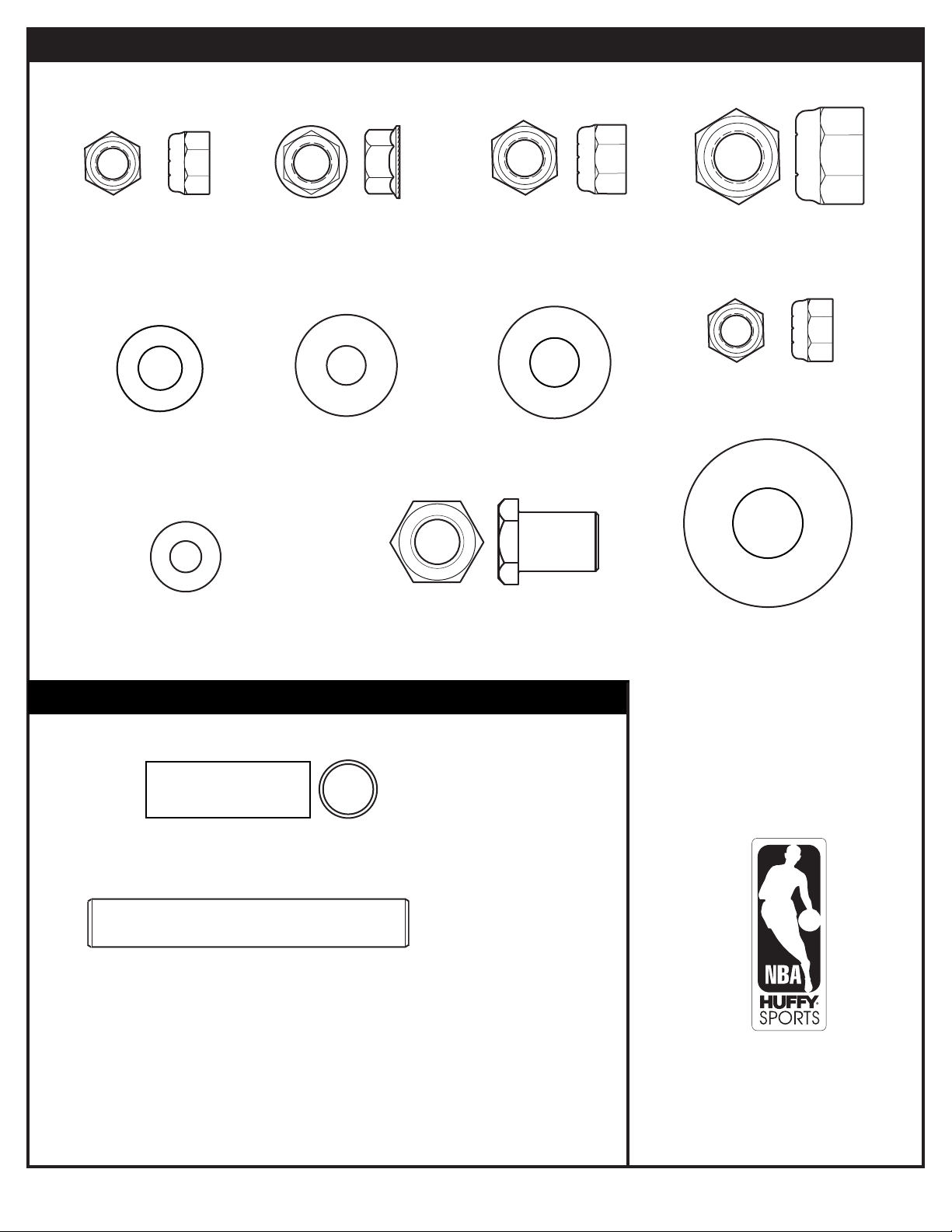

HARDWARE IDENTIFIER (NUTS & WASHERS)

#10 (1)

#17 (4)

#64 (6)

#14 (7)*

#51 (6)

#58 (1)

#11 (6)

#45 (4)*

#31 (7)

#48 (6)

#59 (1)

HARDWARE IDENTIFIER (STEEL SPACERS)

#21 (2)

#9 (2)

#13 (1)

9

02/06 ID# M661144

Page 10

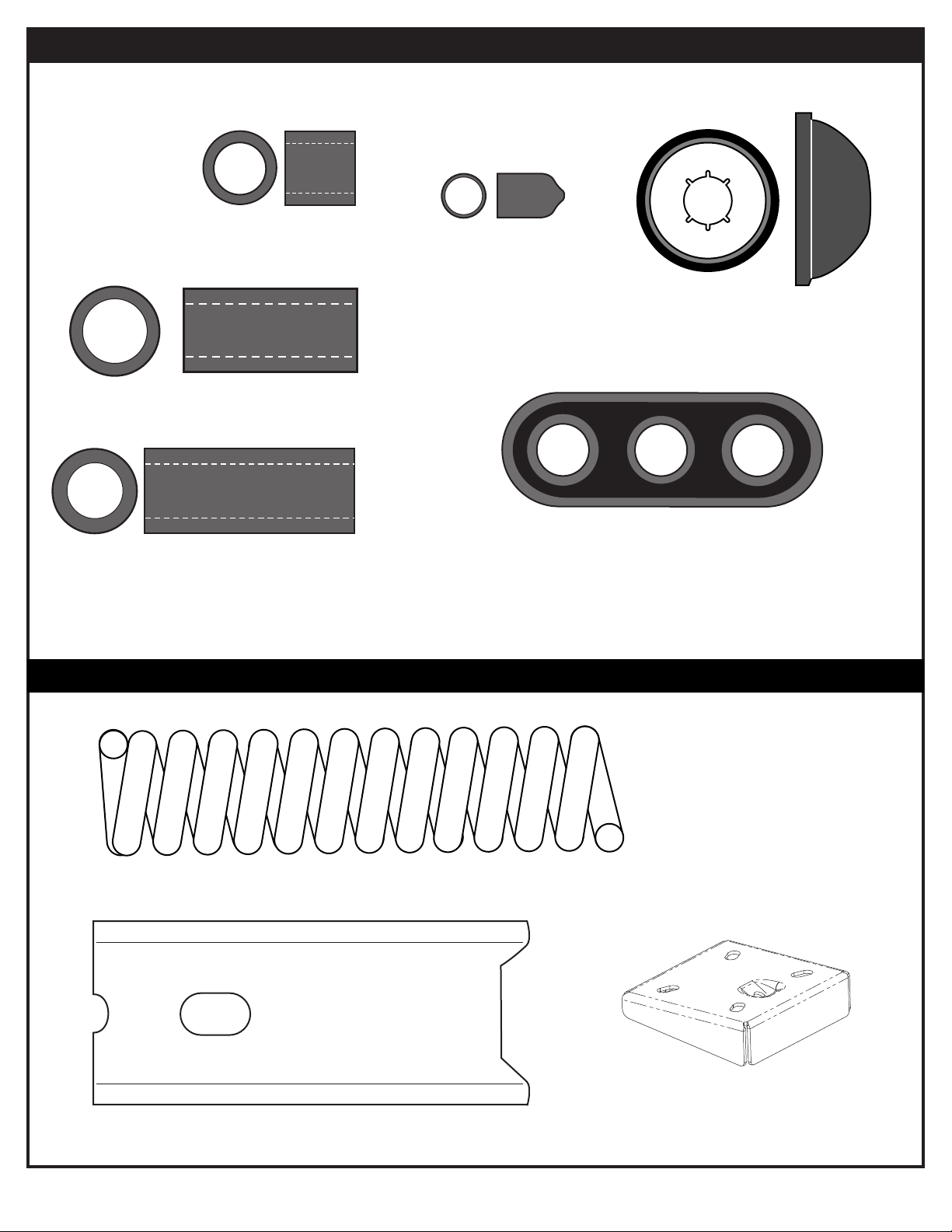

HARDWARE IDENTIFIER (PLASTIC SPACERS CAPS & CLIPS)

#30 (4)

#53 (1)

#13 (4)

#26 (4)

#36 (2)

#20 (2)

HARDWARE IDENTIFIER (OTHER)

#57 (1)

ID# M661144 02/06

#54 (1)

#56 (1)

10

Page 11

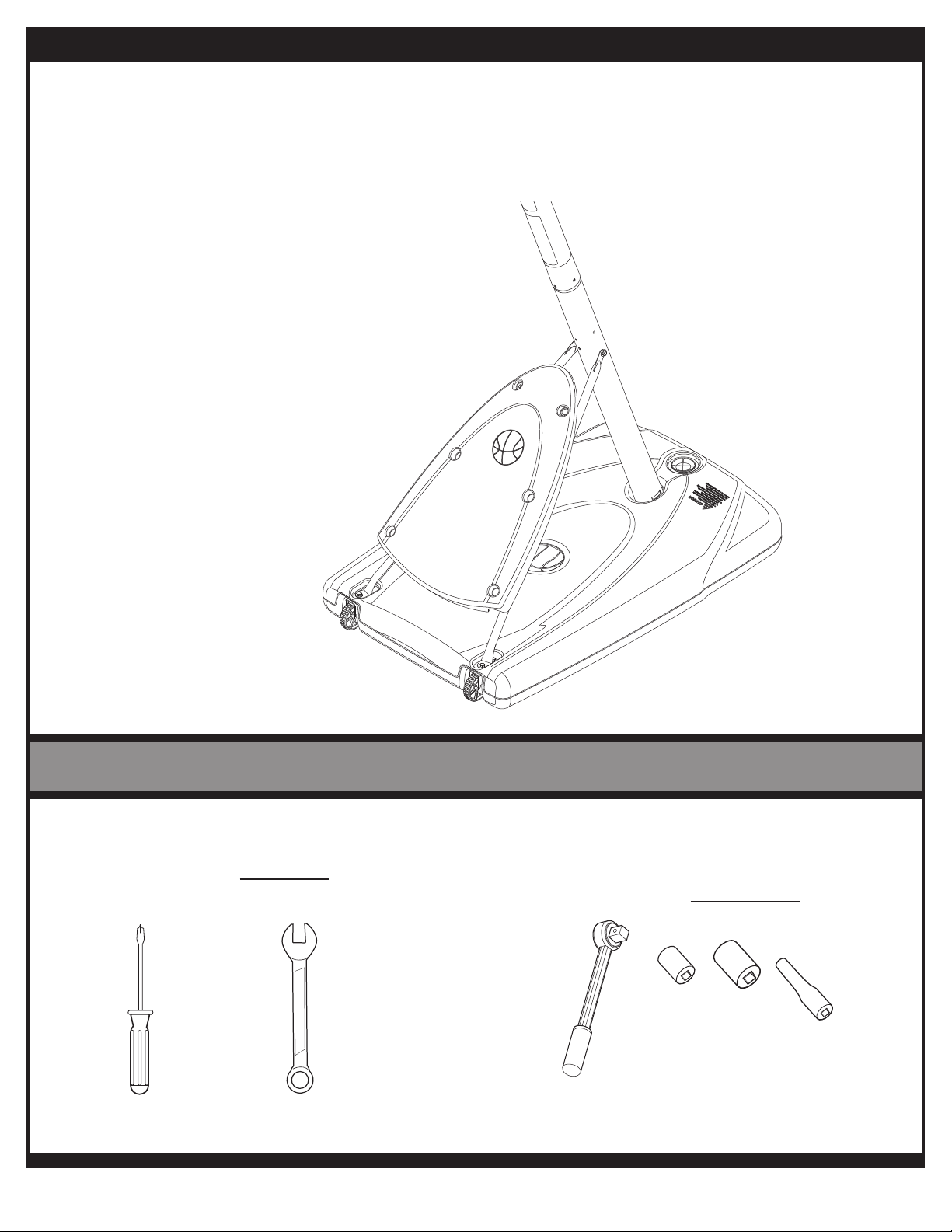

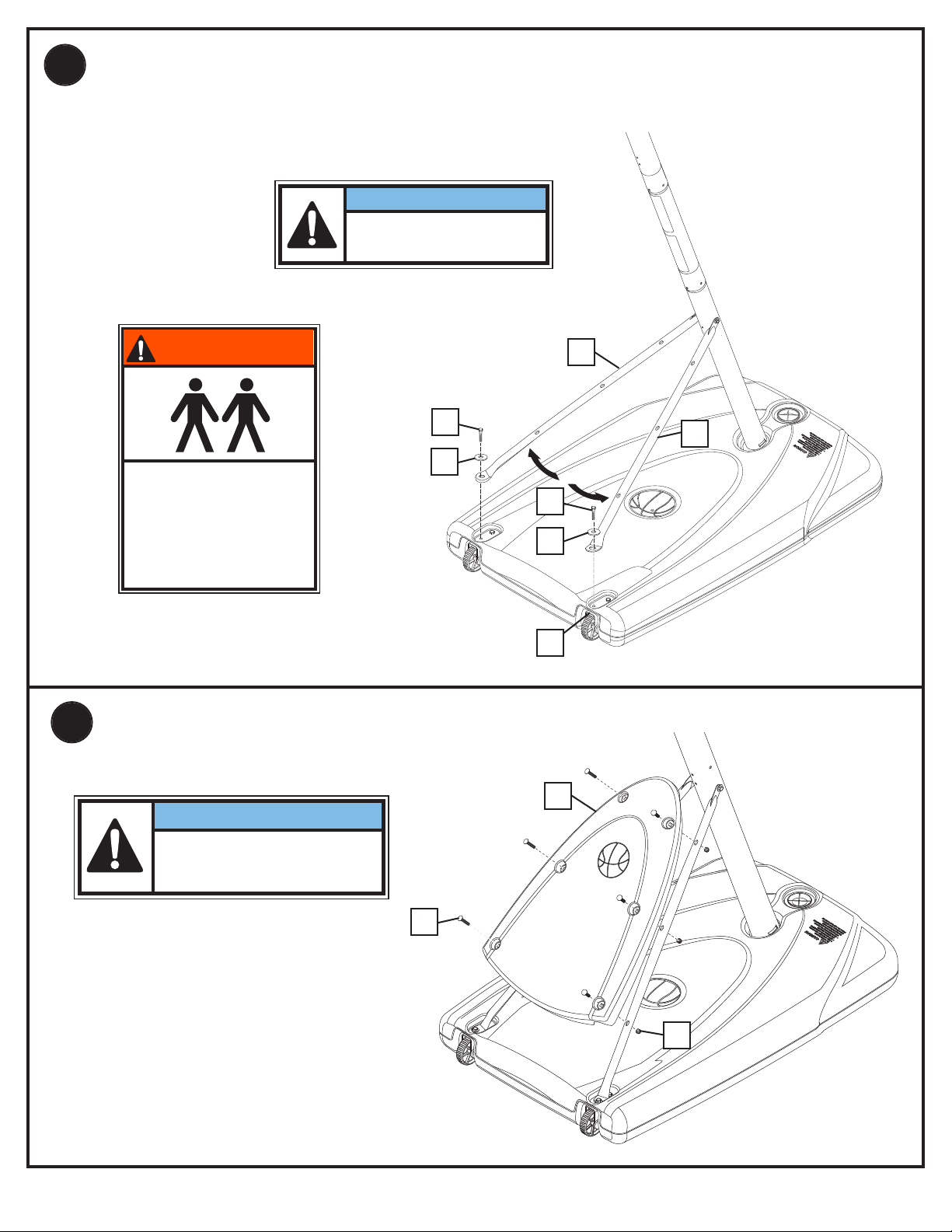

SECTION A: ASSEMBLE THE BASE

This is what your system will look like when you’ve finished

this section.

Phillip

Screwdriver

s-Head

TOOLS REQUIRED FOR THIS SECTION

Wrenches:

(1) 1/2” and (1) 9/16”

And/Or:

11

(2) Socket W

1/2” 9/16”

renches

and Socket

02/06 ID# M661144

s

Extension

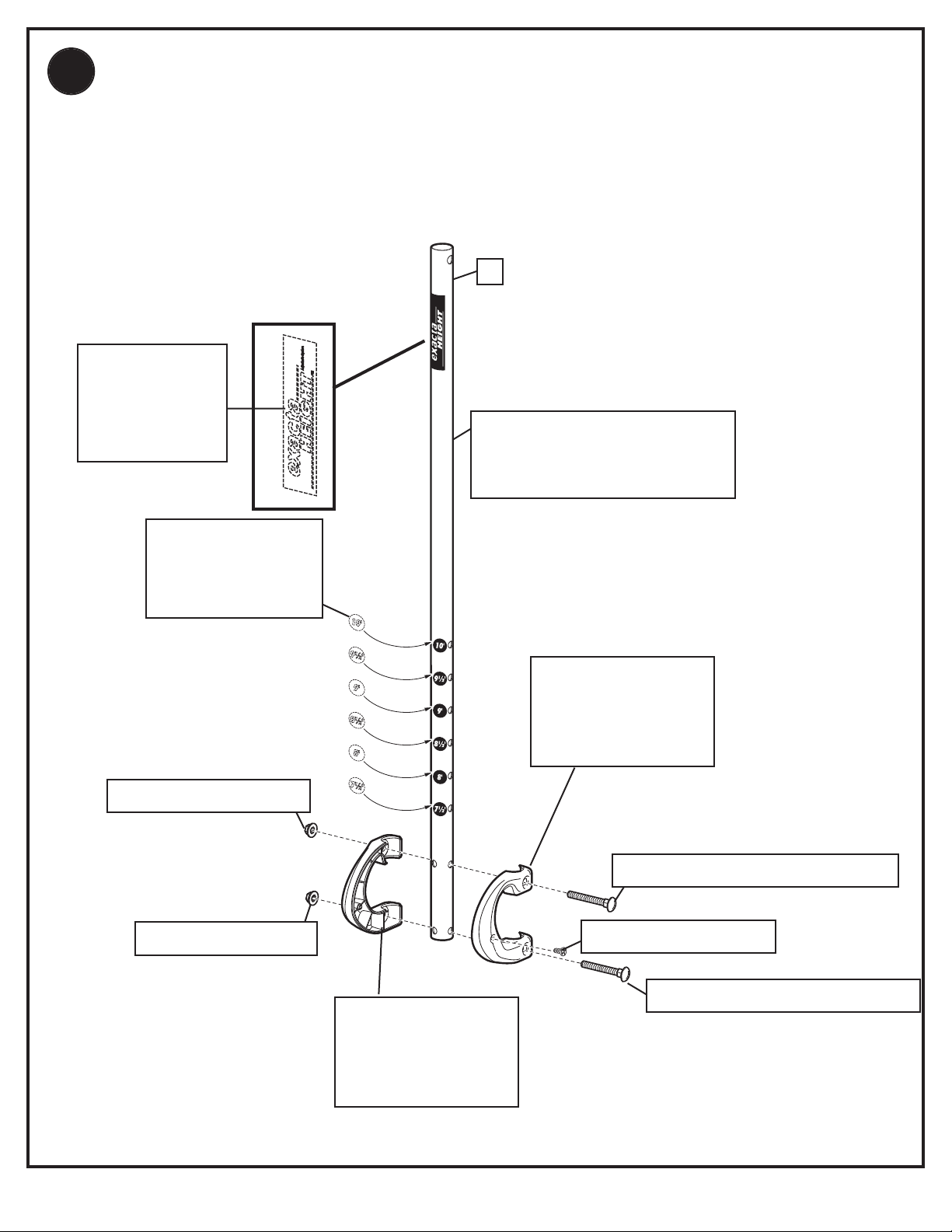

Page 12

1.

Check the following pre-assembled handle areas for tightness: Screw P/N 204803,

Nut P/N 203100, Carriage Bolts P/N 203103.

Label,Height

Indicator

P/N 204872

3

Height Adjustment Rod

P/N 904833

Label,Height

Indicator

P/N 204872

Nut P/N 203100

Nut P/N 203100

Handle, Right

P/N 204856

Carriage Bolt P/N 203103

Screw P/N 204803

ID# M661144 02/06

Carriage Bolt P/N 203103

Handle, Left

P/N 204855

12

Page 13

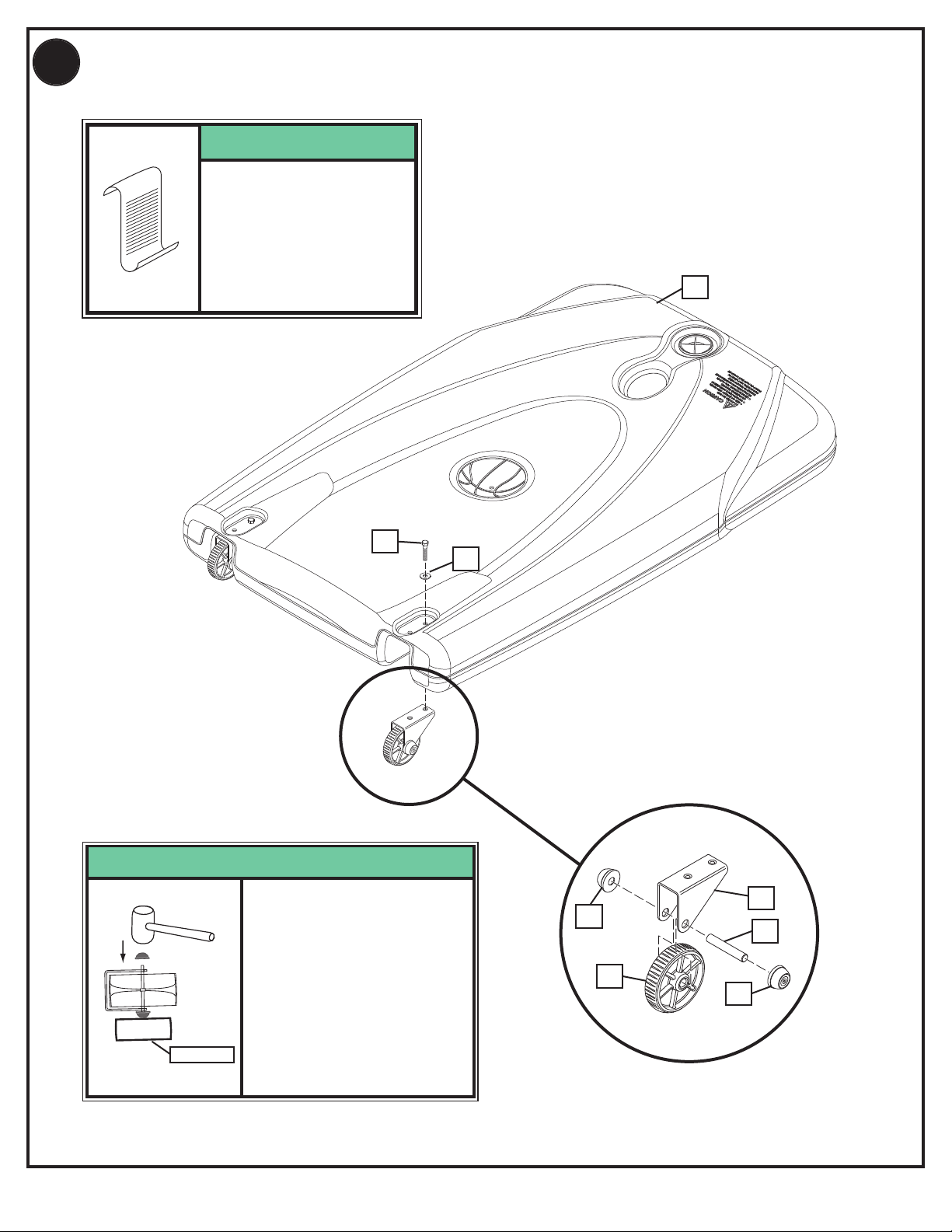

Complete wheel assembly as shown in Figure A. Secure wheel bracket (7), wheel (8), axle (9), and push

2.

nuts (13) to the tank (1) with a single bolt (18) and washer (51). Repeat procedure for opposite wheel.

NOTE:

Do not install both

bolts into the wheel

assembly at this time.

The front bolt will be

installed during strut

assembly in Step 3 of

this section

1

Wood Block

18

NOTE:

TO INSTALL SECOND

PUSHNUT:

• Assemble Pushnut,

Wheels, Axle, And Wheel

Bracket As Shown.

• Support Pushnut/Axle

From The End With A

Block Of Wood To Install

The Second Pushnut Onto

The Axle.

51

7

13

9

8

13

Fig. A

13

02/06 ID# M661144

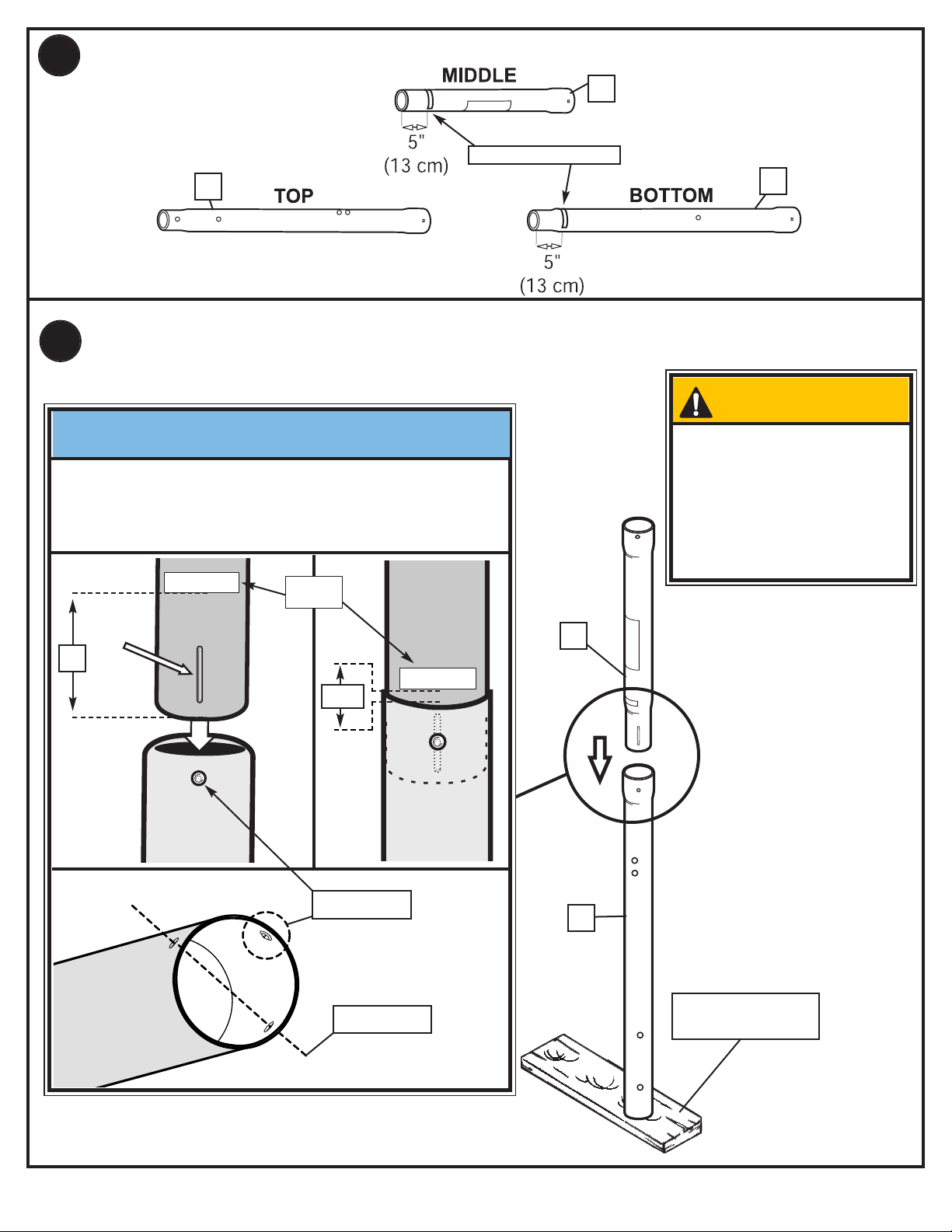

Page 14

3.

Identify pole sections.

5

Identification Sticker

4

6

While maintaining alignment, bounce middle pole section (5) into top section (4)

4.

using a wood scrap as shown until the top pole no longer moves toward the pole

identification sticker on the middle pole.

CAUTION!

IMPORTANT!

Align dimple of top pole section (4)

into trough of middle pole section (5)

as shown.

middle pole

ID

STICKER

THE IDENTIFICATION STICKER IS

LOCATED 5" FROM THE END OF

THE POLE. WHEN PROPERLY

POUNDED TOGETHER, THE POLE

SECTIONS SHOULD HAVE A 3-1/2"

MINIMUM OVERLAP, LEAVING 11/2" BETWEEN THE OVERLAPPING

POLE AND THE IDENTIFICATION

STICKER.

5"

1-1/2"

DIMPLE

HOLE

5

middle pole

4

WOOD SCRAP

(NOT SUPPLIED)

ID# M661144 02/06

14

Page 15

Bounce top and middle pole assembly (4 and 5) onto bottom pole section (6) using a

5.

wood scrap as shown. Bounce until the top and middle pole assembly no longer

moves toward the pole identification mark on the bottom pole.

IMPORTANT!

Align dimple of middle pole section (5)

into trough of bottom pole section (6)

CAUTION!

as shown.

THE IDENTIFICATION STICKER IS

LOCATED 5" FROM THE END OF

THE POLE. WHEN PROPERLY

POUNDED TOGETHER, THE POLE

SECTIONS SHOULD HAVE A 3-1/2"

MINIMUM OVERLAP, LEAVING 1-1/2"

BETWEEN THE OVERLAPPING

POLE AND THE IDENTIFICATION

STICKER.

1-1/2"

Bottom pole

5"

Bottom pole

ID

STICKER

DIMPLE

HOLE

4

RODS SHOWN ARE

FOR VISUAL

REPRESENTATION

5

OF ALIGNMENT

AND ARE NOT

SUPPLIED WITH

THE HARDWARE

WOOD SCRAP

SUPPLIED)

(NOT

15

6

02/06 ID# M661144

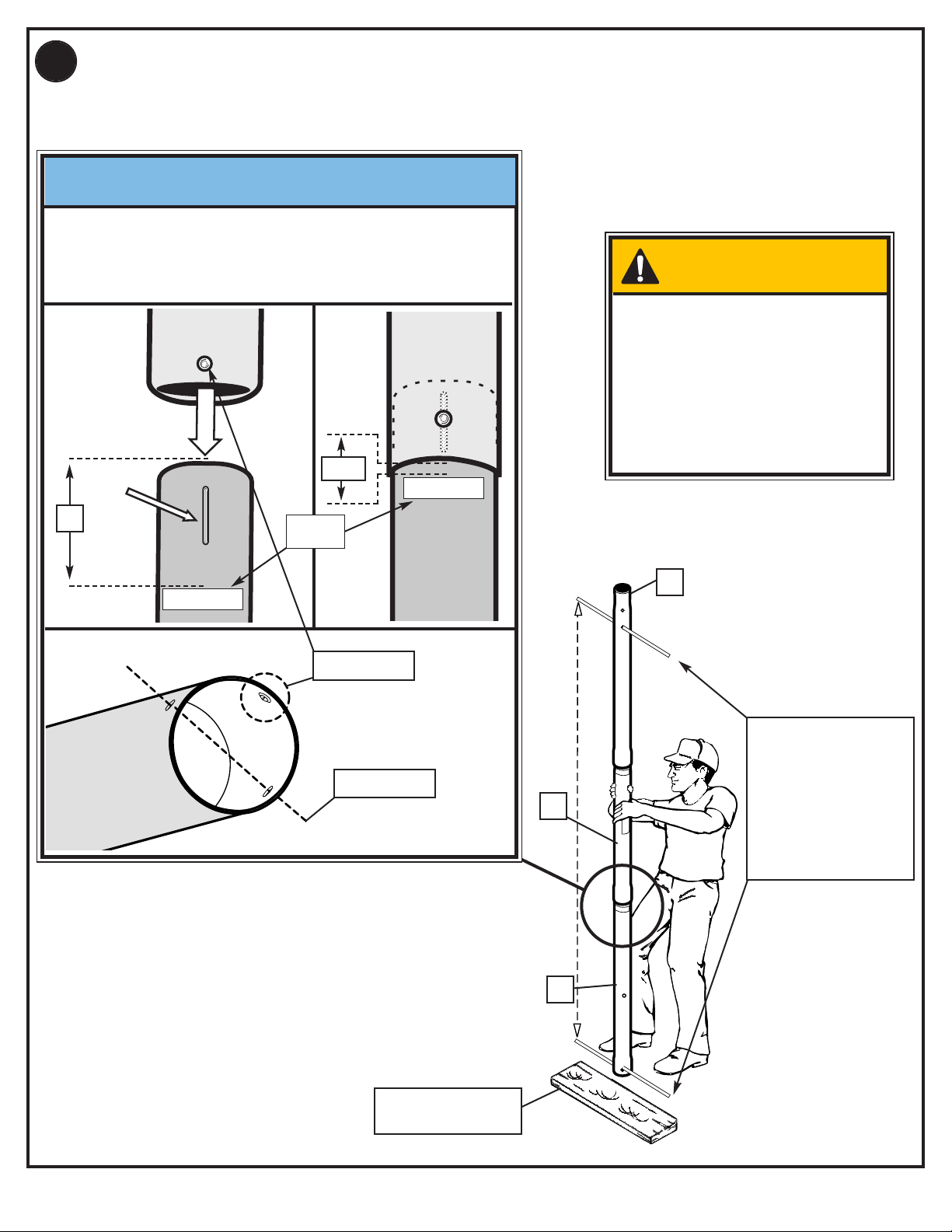

Page 16

6.

Attach pole assembly to base (1) as shown. Secure pole assembly to tank using bolts (50) and

pole mounting bracket (49) as shown.

6

WARNING!

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

FAILURE TO FOLLOW

THIS WARNING COULD

RESULT IN SERIOUS

INJURY AND/OR

PROPERTY DAMAGE.

7.

Secure tank struts (2) to pole as shown. Place cover (53) over exposed end of bolt

as shown.

6

1

IMPORTANT!

DO NOT TIGHTEN

COMPLETELY

50

49

53

10

49

50

51

12

51

WARNING!

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

FAILURE TO FOLLOW

THIS WARNING COULD

RESULT IN SERIOUS

INJURY AND/OR

PROPERTY DAMAGE.

ID# M661144 02/06

2

16

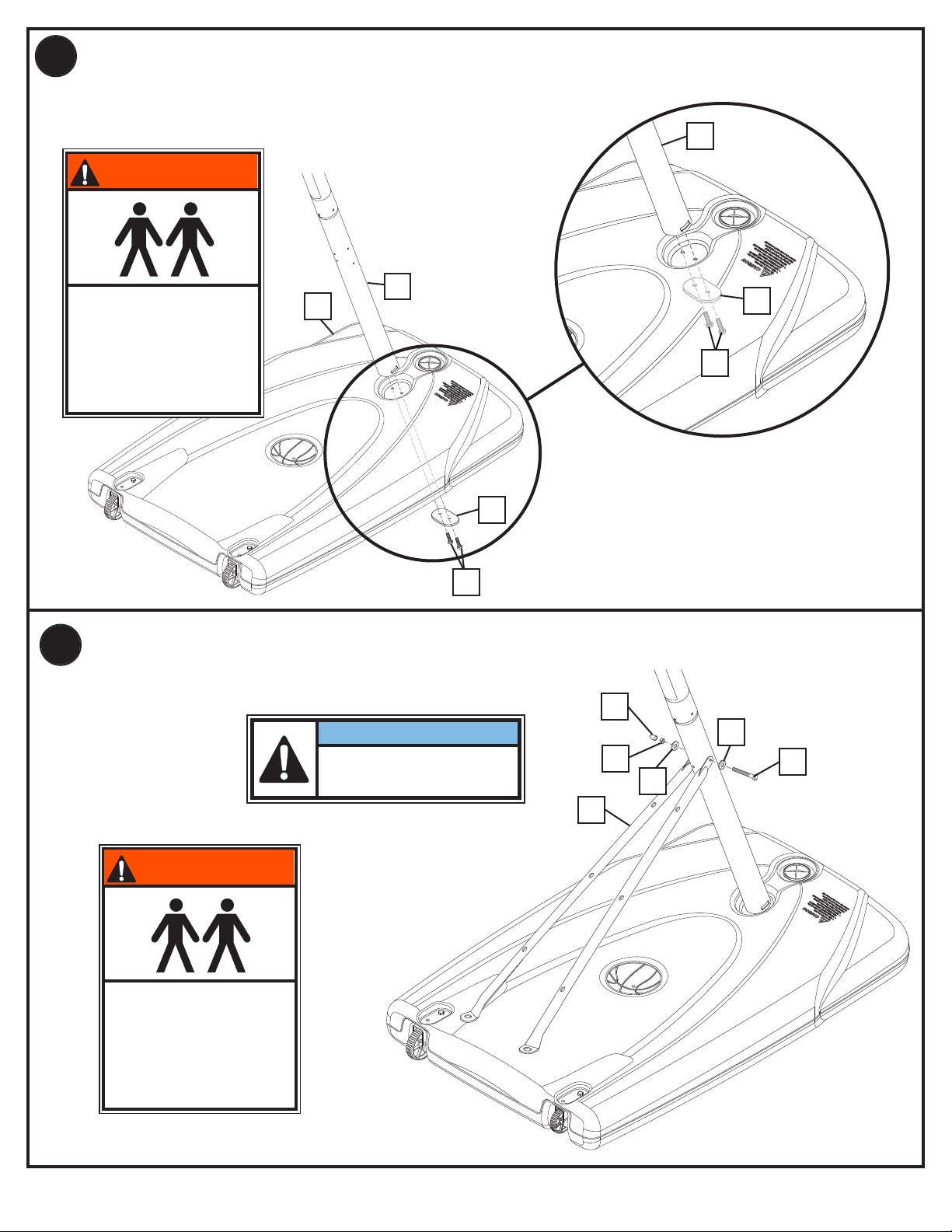

Page 17

8.

Rotate non-secured ends of tank struts (2) outward to mounting holes in tank as

shown. Secure ends of tank struts (2) to wheel bracket (7), as shown. Repeat for

opposite side.

IMPORTANT!

DO NOT TIGHTEN

COMPLETELY

9.

WARNING!

18

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

FAILURE TO FOLLOW

THIS WARNING COULD

RESULT IN SERIOUS

INJURY AND/OR

PROPERTY DAMAGE.

Secure cover (28) to tank struts (2) using

bolts (47) and nuts (48) as shown.

IMPORTANT!

TIGHTEN

COMPONENTS

COMPLETELY (STEPS 7-9)

ALL

51

2

2

18

51

7

28

47

17

48

02/06 ID# M661144

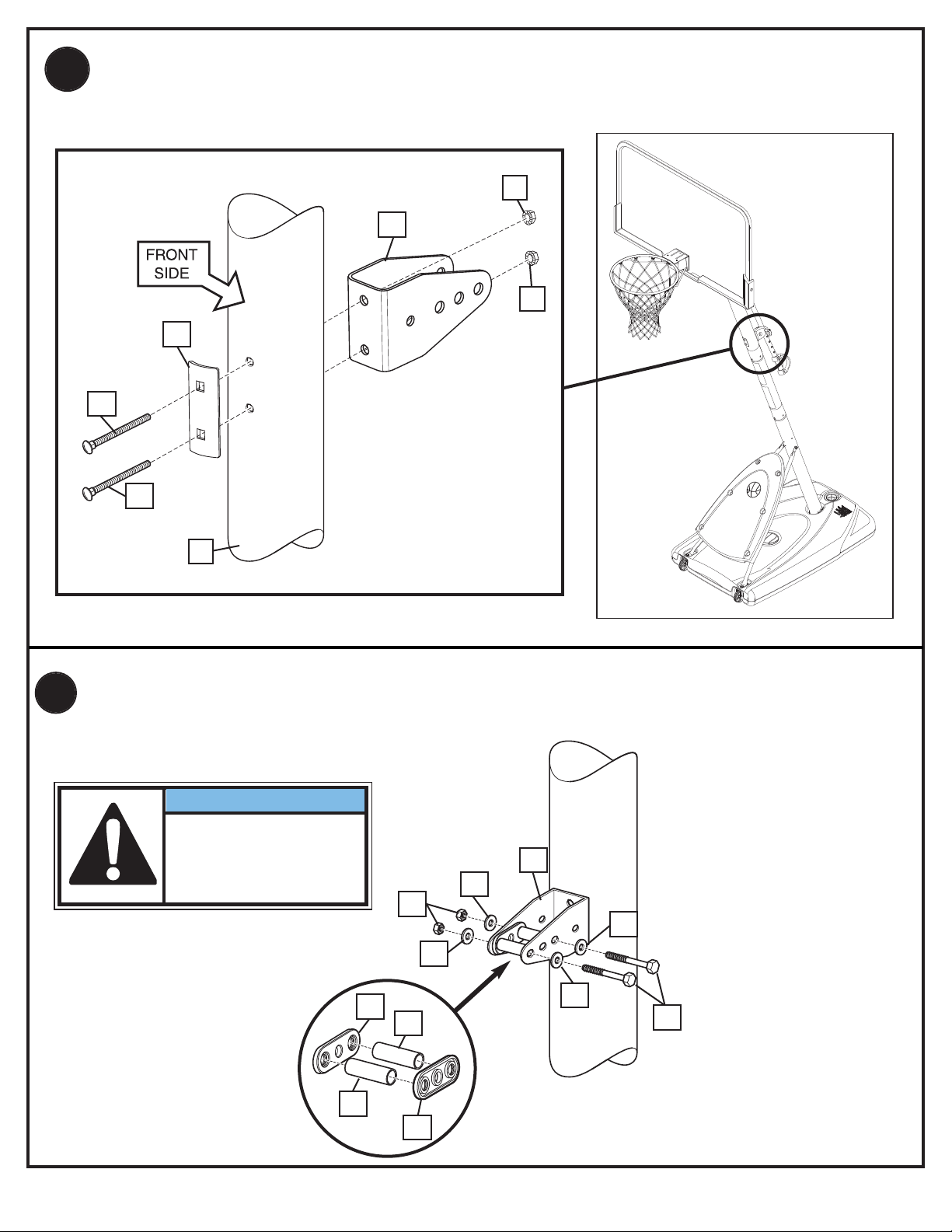

Page 18

10.

Install pole mount bracket (15) and reinforcement bracket (42) with carriage

bolts (16) as shown. Tighten flange nuts (14) completely.

14

15

14

42

16

16

11.

4

Attach spacers (20, 21) to pole mount bracket (15) with bolts (19), washers (17),

and nuts (11) as shown.

IMPORTANT!

Tighten just until

washers (17) stop

moving.

17

11

17

20

21

15

17

17

19

ID# M661144 02/06

21

20

18

Page 19

12.

Assemble lanyard (25) to locking pin (24) as shown (FIG A). Attach covers (22)

onto pole mount bracket (15) with carriage bolt (23) and nut (14) as shown.

FIG. A

25

24

23

25

24

14

22

IMPORTANT!

Loop end of pin

lanyard (25) over

carriage bolt (23)

as it passes

through the pole

mount bracket (15)

during this

assembly.

15

25

22

23

24

13.

Insert handle assembly through pole mount assembly as

shown. Lock pole assembly in place at the 10’ (3.05 m)

mark with pin (24).

24

19

02/06 ID# M661144

Page 20

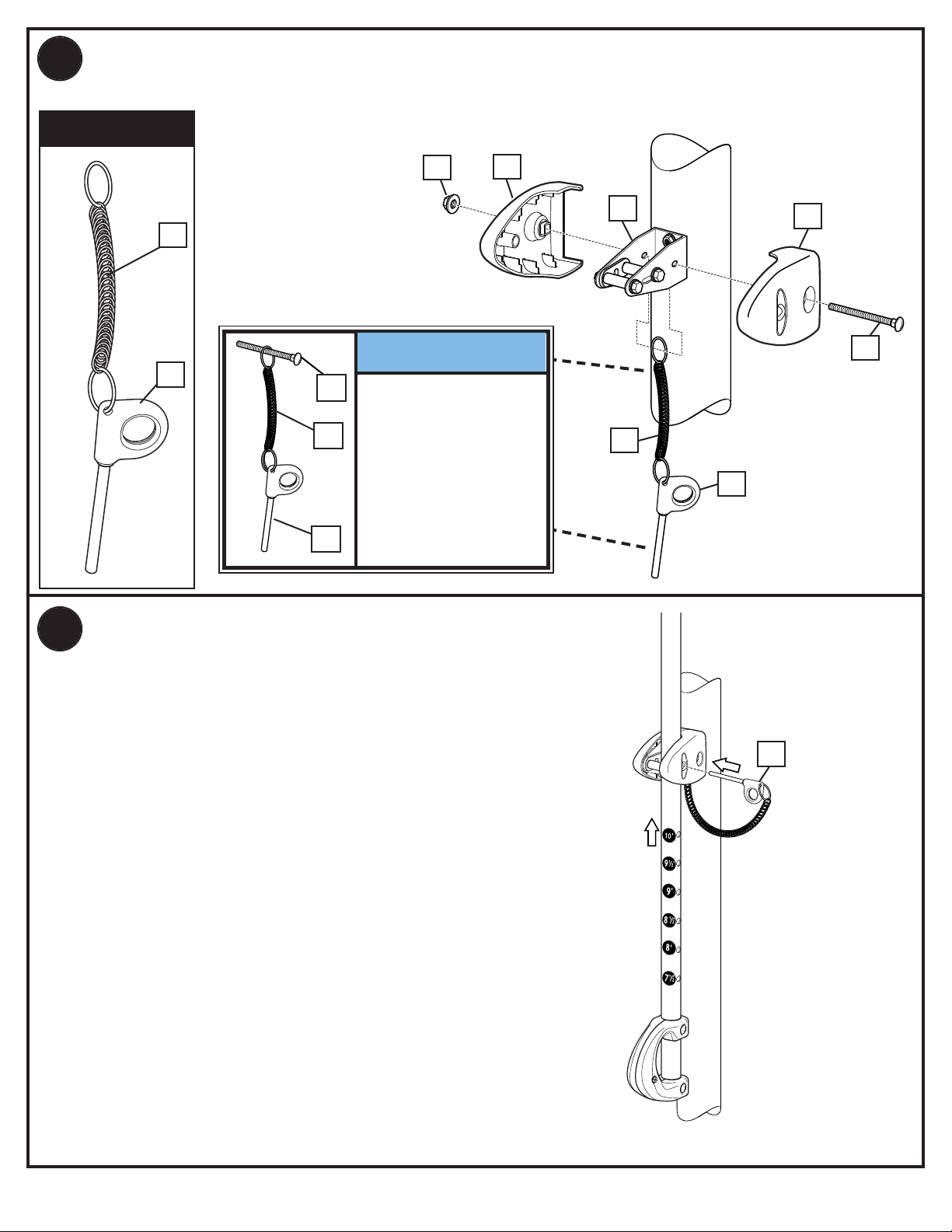

SECTION B: ATTACH THE BACKBOARD

This is what your system will look like when

you’ve finished this section.

TOOLS REQUIRED FOR THIS SECTION

Wrenches:

(2) 1/2", (2) 9/16”, and (2) 3/4”

Phillips-Head

Screwdriver

And/Or

Sawhorse

(2) Socket Wrenches

and Sockets

1/2” 9/16”

Extension

3/4”

Identify

elevator tubes.

TOWARDS

ID# M661144 02/06

35

BOARD

Upper Elevator tube

Lower Elevator tube

32

20

TOWARDS

POLE

Page 21

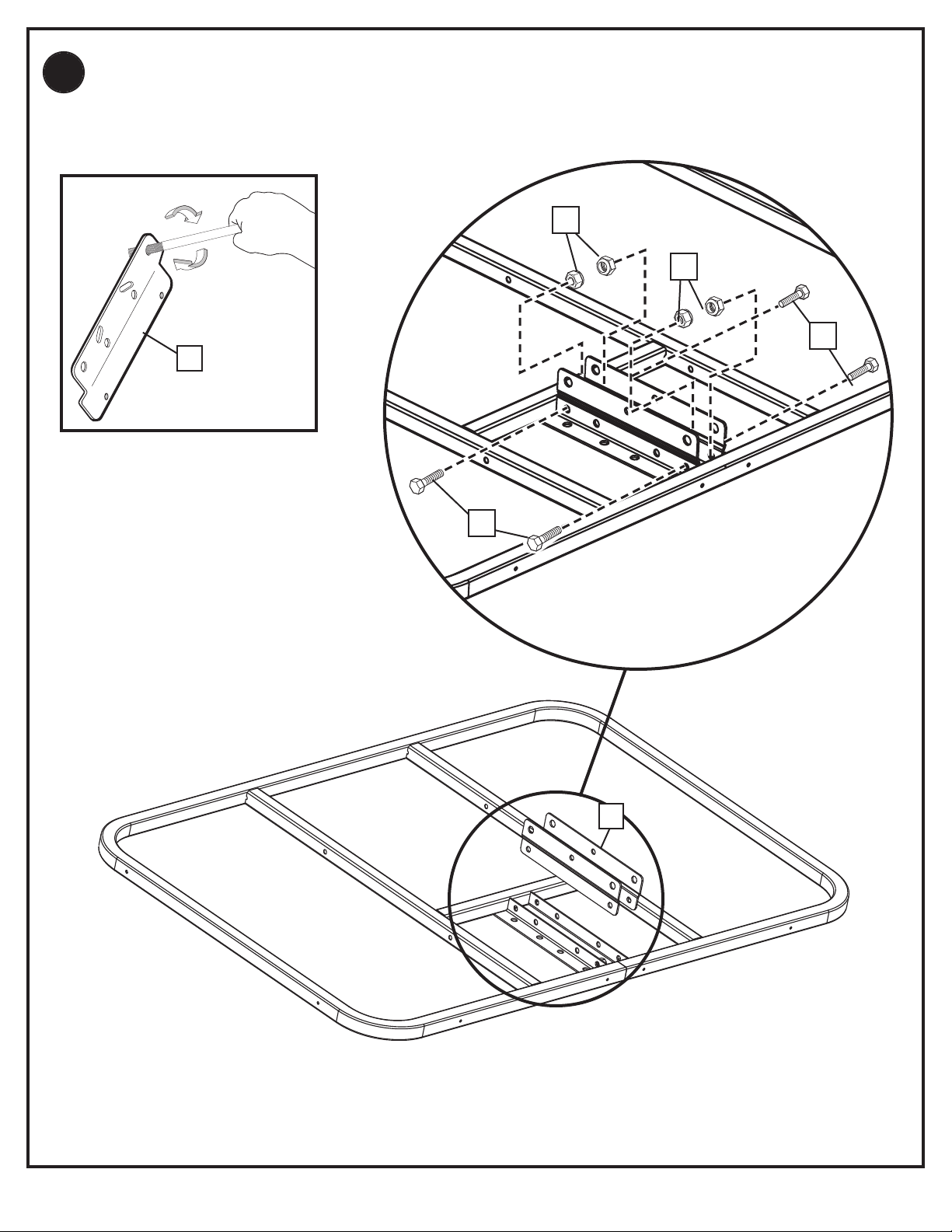

Assemble backboard brackets (27) using bolts (52), and nuts (11) as shown.

1.

11

11

27

52

52

27

21

02/06 ID# M661144

Page 22

Support pole on sawhorse. Attach triangle plates

2.

(37) and elevator tubes (35 & 32) to top pole (4)

using bolts (40 & 29) and nuts (31).

Install pole cap (38).

WARNING!

USE CAUTION; ELEVATOR

ASSEMBLY IS HEAVY.

TWO PEOPLE REQUIRED FOR

THIS PROCEDURE. FAILURE TO

FOLLOW THIS WARNING

COULD RESULT IN SERIOUS

INJURY AND/OR PROPERTY

DAMAGE.

29

31

32

37

4

31

30

37

30

35

31

30

35

40

38

32

ID# M661144 02/06

COMPLETED ASSEMBLY

22

Page 23

Install handle assembly to lower elevator tubes (32) using bolt (29), spacers (36),

3.

and nut (31) as shown.

36

4

36

29

31

35

35

NOTE:

Before going on to

next step,

adjustable system

assembly is set to the

10’ (3.05 m) setting.

23

make sure

02/06 ID# M661144

Page 24

4.

Attach lower elevator tubes (32) and counter balance spring (33) to backboard

support brackets (27) using spacers (26), bolt (29), and nut (31) as shown.

27

32

29

26

5.

Attach upper elevator tubes (35)

to backboard support brackets

(27) using spacers (26), bolt (29),

and nut (31) as shown.

32

33

26

29

31

26

ID# M661144 02/06

31

24

Page 25

Insert T-bolt (55) into rim bracket (54) then,

6.

attach that assembly to board using bolts (44)

and nuts (14)

14

14

55

7.

Insert bolt (29) through left side

upper elevator tube (35), then

stretch spring (33) onto bolt (29).

Insert bolt (29) through right side

upper elevator tube (35) and

secure with nut (31).

WARNING!

USE EYE PROTECTION

WHEN INSTALLING

SPRINGS.

54

54

44

31

35

33

25

35

29

02/06 ID# M661144

Page 26

8.

A Fit rim (34) securely into bracket (54) as shown. Allow T-bolt (55) to slip through center

hole in rim (34).

B Install reinforcement bracket (56) onto T-bolt (55) as shown.

C Install spring (57) onto T-bolt (55) as shown.

D Install special nut (58) and washer (59) onto T-bolt (55).

E Tighten nut (58) until flush with end of T-bolt (55).

Install Slam Jam Rim to Backboard

B

A

56

34

C

57

55

55

54

D

58

55

59

ID# M661144 02/06

E

55

58

59

26

Page 27

SAND

450 LBS

.

(204 KG)

Install net (43).

9.

1

.

10.

2.

3.

4.

Roll completed assembly to desired position. Fill tank with water (approx.

34 gallons (129 Liters)) or sand (approx. 300 lbs. (136 kg)) and rotate the

cap (41) into base (1).

WARNING!

DO NOT LEAVE

ASSEMBLY UNATTENDED

WHEN EMPTY; IT MAY TIP

OVER.

CAUTION!

ADD TWO GALLONS (7.6

41

1

LITERS) OF NON-TOXIC

ANTIFREEZE IN SUBFREEZING CLIMATES.

NOTE:

IF USING SAND:

SAND

SAND

(300 lb.)

(300 lb.)

(136 kg)

(136 kg)

2 GALLONS OF

ANTI-FREEZE IS

NOT

REQUIRED

27

02/06 ID# M661144

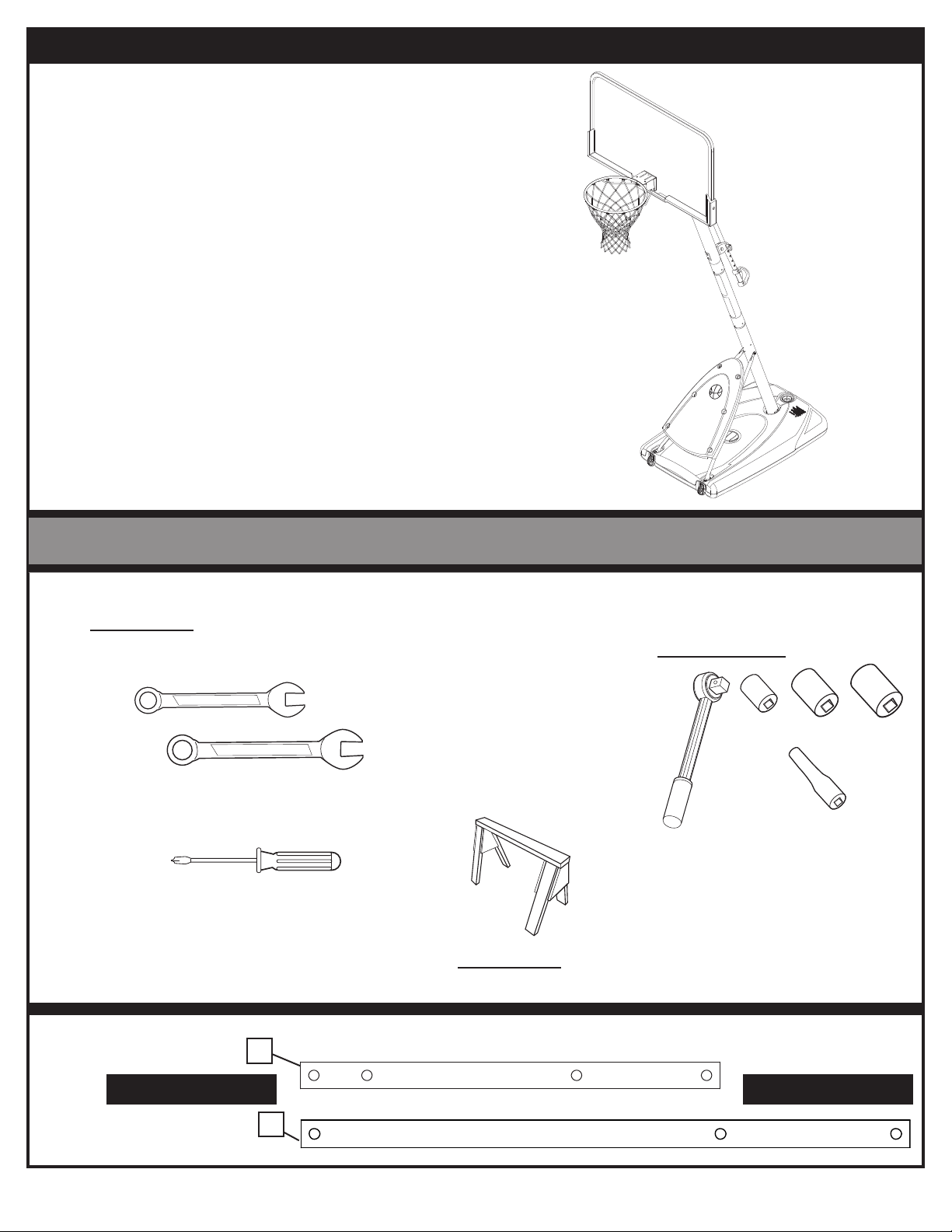

Page 28

SECTION C: APPLY HEIGHT AND MOVING LABEL & HEIGHT ADJUSTMENT

Apply height adjustment and moving label (46) to front of pole as shown.

1.

WARNING!

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

FAILURE TO FOLLOW THIS

WARNING COULD RESULT

IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

10 ft.

(3.05 m)

46

NOTE:

Peel protective

film from surface

of acrylic

backboard prior

to use.

A. While holding handle, remove pin (24).

2.

B. Move elevator up or down to desired height.

C. Replace pin (24) full length to lock system at desired height.

ID# M661144 02/06

WARNING!

DO NOT

CHILDREN TO

ADJUST HEIGHT

ALLOW

.

24

A.

C.

B.

28

Page 29

SECTION D: COVER

1.

34

60

39

39

34

2.

60

61

29

02/06 ID# M661144

Page 30

Item Qty. Part No. Description

SECTION E: BOARD PAD

PARTS LIST

See Hardware Identifier)

(

Item Qty. Part No. Description

1 2 266102 Lock Nut, Nylon Insert

2 6 206151 Washer 1/4 ID 1 O.D.

3 6 202871 Screw, Hex, 1/4 x 3/4 Slotted

4 1 205225 Board Pad, Right (46-50” Board”)

204318 Board Pad, Right (42” Board”)

#1 (2)

#3 (6)

#7 (4)

#2 (6)

#8 (2)

5 1 206292 Board Pad, Middle - 46” Board

6 1 205226 Board Pad, Left (46-50” Board”)

7 4 205233 Washer, #10 Flat

8 2 205232 Screw, Hex, 10-24 x 7/8 Long

HARDWARE IDENTIFIER

#4 (1)

#6 (1

205241 Board Pad, Middle - 48” Board

205566 Board Pad, Middle - 50” Board

204319 Board Pad, Left (42” Board”)

#5 (1)

206292

205241

205566

4

206292 (#5)

Use center board pad # 206292

(5) if you have a 46” backboard.

5

NOTE:

205241 (#5)

Use center board pad # 205241

(5) if you have a 48” backboard.

6

4

205566 (#5)

Use center board pad # 205566

(5) if you have a 50” backboard.

6

The center board pad is not

required if you have a 44”

backboard. Only the left and right

board pads will be used.

ID# M661144 02/06

30

Page 31

Assemble board pad sections (4, 5, and 6) together with hardware

1.

(7, 8, and 1) as shown in Figure Aand tighten completely.

IMPORTANT!

FIG. A

7

8

DO NOT OVER TIGHTEN!

7

7

1

1

7

8

NOTE:

The center board pad is not required if you

have a 44” backboard. Only the left and

right board pads will be used.

See figure B.

7

6

1

FIG. B

5

8

4

4

7

6

2

FIG. C

3

6

2.

Loosely install hardware (2, 3) into holes as shown in

Figure C. Att

and tighten completely

ach board pads (4, 5, and 6) with hardware

.

2

FIG. D

5

4

3

2

3

ABB. D

6

NOTE:

Part # 205241, # 206292 or #205566 (5) is

not used on 44” acrylic backboards as shown

in Figure D.

31

4

3

2

02/06 ID# M661144

Page 32

Assemblage exclusivement réservé à un adulte.

Zusammenbau nur durch Erwachsene ALLE Verpackungsmaterialien

sofort wegwerfen.

FRANÇAIS

DEUTSCH

Il montaggio va eseguito da persone adulte.

Système portable - Manuel de

l'utilisateur

Service clientèle

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • É.-U.

Gebrauchsanleitung für tragbare

Systeme

Kundendienstzentrale

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • U.S.A.

Manual del Propietario del Sistema

Portátil

Centro de Servicio al Cliente

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • EE.UU.

Ce manuel, accompagné du justificatif d'achat, devra être conservé pour

référence ultérieure, dans la mesure où il contient des informations

importantes sur votre modèle.

Diese Anleitung sollte zusammen mit dem Kaufbeleg griffbereit

aufbewahrt werden, da sie wichtige Informationen über Ihr Modell enthält.

ESPAÑOL

AVERTISSEMENT!

WARNUNG!

¡ADVERTENCIA!

LISEZ CE MANUEL D'UTILISATION AVANT

D'UTILISER CET APPAREIL

Il presente manuale, accompagnato dallo scontrino, deve essere

conservato e tenuto a portata di mano come documento di facile

consultazione, in quanto contiene informazioni importanti su questo

modello.

SOUS PEINE DE BLESSURES OU DE

DÉGÂTS MATÉRIELS.

DAS BENUTZERHANDBUCH VOR

GEBRAUCH DIESES PRODUKTS

SORGFÄLTIG DURCHLESEN.

Inscrivez ici le numéro de modèle qui apparaît sur la

boîte:

Die Modellnummer vom Verpackungskarton hier

EIN MISSACHTEN DIESER

BETRIEBSANLEITUNG KANN

VERLETZUNGEN ODER SACHSCHÄDEN

ZUR FOLGE HABEN.

eintragen:

LEA Y ENTIENDA EL MANUAL DEL

Escriba aquí el número de modelo que viene en la caja:

Numéro vert du Service clientèle - États-Unis : 1-800-558-5234, Canada : 1-800-2284-8339,

Europe : 00 800 555 85234 (Suède : 009 555 85234), Australie : 1-800-632 7921 Adresse Internet : http://www.huffysports.com

Gebührenfreie Telefonnummer für die USA: 1-800-558-5234, für Kanada: 1-800-284-8339, für Europa: 00 800 555 85234 (Schweden: 009

555 85234), für Australien: 1-800-632 7921 Internet-Adresse: http://www.huffysports.com

OPERADOR ANTES DE USAR ESTA

UNIDAD.

SI NO SE SIGUEN LAS INSTRUCCIONES DE

OPERACIÓN SE PODRÍA OCASIONAR UNA

LESIÓN O DAÑOS A LA PROPIEDAD.

Número telefónico sin costo del Departamento de Servicio al Cliente en EE.UU.: 1-800-558-5234,

Para Canadá: 1-800-284-8339, Para Europa: 00 800 555 85234 (Suecia: 009 555 85234), Para Australia: 1-800-632 7921 Dirección en

Internet: http://www.huffysports.com

ID# M661144 02/06

32

Page 33

OUTILS ET MATÉRIEL

SAND

450 LBS

.

(204 KG)

SAND

450 LBS

.

(204 KG)

SAND

450 LBS

.

(204 KG)

REQUIS:

BENÖTIGTE WERKZEUGE

UND MATERIALIEN:

HERRAMIENTAS Y

MATERIALES REQUERIDOS:

• Deux (2) adultes

capables

Mètre

•

• Planche en bois (chute)

• Chevalet de sciage ou

table

• Marteau

• Lunettes de sécurité

• Échelle de 2,4 m

• un tournevis cruciforme

• Deux clés et/ou clés à douilles et

deux douilles (douilles longues

recommandées).

• Zwei (2) zur Ausführung dieser

Arbeit fähige Erwachsene

• Maßband

• Holzstück (Ausschuß)

• Sägebock oder Stütztisch

• Hammer

• Schutzbrille

• Stufenleiter, 2,4 m (8 Fuß)

• ein

Kreuzschlitzschraubenzieher

• (je 2) Schrauben - und/oder Steckschlüssel

(tiefe Einsätze empfohlen).

• Dos (2) adultos capaces

• Cinta de medir

• Tabla de madera (un

trozo)

Caballete o mesa de

•

apoyo

• Martillo

• Gafas de seguridad

• Escalera de mano de 8

pies (2.4 m)

• un destornillador Phillips

• (2 de cada una) llaves de tuercas

y/o llaves de tuercas de boca

tubular y casquillos (se

recomiendan casquillos profundos).

(300 lb.)

(300 lb.)

(136 kg)

(136 kg)

3/4"

7/16" 1/2" 9/16"

ET/OU

7/16" 1/2" 9/16" 3/4"

• Une extension est recommandée.

• Tuyau d'arrosage ou sable

SABLE

SABLE

OUTILS ET MATÉRIEL

FACULTATIFS:

7/16" 1/2" 9/16" 3/4"

UND/ODER

7/16" 1/2" 9/16" 3/4"

• Verlängerung wird empfohlen • Se recomienda una extensión

Manguera de jardín o arena

• Gartenschlauch oder Sand

SAND

SAND

(300 lb.)

(300 lb.)

(136 kg)

(136 kg)

•

WEITERE NÜTZLICHE

WERKZEUGE UND MATERIALIEN:

MATERIALES OPCIONALES:

7/16" 1/2" 9/16" 3/4"

Y/O

7/16" 1/2" 9/16" 3/4"

ARENA

ARENA

(300 lb.)

(300 lb.)

(136 kg)

(136 kg)

HERRAMIENTAS Y

Petites et grandes clés anglaises

•

• Große und kleine verstellbare

Schraubenschlüssel

33

• Llaves de tuercas ajustables

grandes y pequeñas

02/06 ID# M661144

Page 34

AVANT DE COMMENCER!

VORBEREITENDE MASSNAHMEN

¡ANTES DE COMENZAR!

Pour garantir l'utilisation optimale du panneau, les composants du

système élévateur et la visserie doivent être bien ajustés (serrés). À

titre d'essai, insérez les gros boulons dans les gros trous des tubes

du système élévateur, des supports du panneau et des plaques

triangulaires. Basculez-les avec précaution en imprimant un

mouvement circulaire pour éliminer l'excédent de peinture, si

nécessaire.

REMARQUE: No todos los artículos ilustrados se incluyen con cada

modelo.

Um sicherzustellen, dass das Korbwandsystem optimal für den

Spielbetrieb geeignet ist, müssen die Komponenten der

Verlängerungsvorrichtung und die verschiedenen Befestigungsteile

fest miteinander verschraubt werden. Große Schrauben zur Probe in

die großen Löcher der Verlängerungsrohre, Korbwandklammern und

Dreiecksplatte stecken und diese vorsichtig in einer Kreisbewegung

hin- und herbewegen, um eventuelle Farbrückstände aus den

Bohrungen zu entfernen.

NOTA: No todos los artículos ilustrados se incluyen con cada

modelo.

Apprenez à connaître les

composants de base de votre

système de basket-ball.....

Machen Sie sich mit den

wichtigsten Teilen Ihres

Basketballsystems vertraut…

Conozca las piezas básicas de su

sistema de baloncesto…

Para asegurar el óptimo rendimiento del sistema del respaldo en el

juego, se requiere un ajuste de tolerancia estrecha entre los

componentes del elevador y el herraje. Pruebe el ajuste de los

pernos grandes en los orificios grandes de los tubos elevadores,

soportes del respaldo y placas triangulares. Cuidadosamente

muévalos en círculos para eliminar cualquier exceso de pintura, si es

necesario.

HINWEIS: Nicht jedem Modell sind alle abgebildeten Teile

beigepackt.

AVANT

VORDERSEITE

PARTE FRONTAL

CERCEAU

KORBRAND

BORDE

SECTION DE POTEAU SUPÉRIEURE

OBERES STANGENTEIL

SECCIÓN SUPERIOR DEL POSTE

SYSTÈME ÉLÉVATEUR

VERLÄNGERUNGSBAUGRUPPE

CONJUNTO DEL ELEVADOR

ID# M661144 02/06

SECTION DE POTEAU CENTRALE

MITTLERES STANGENTEIL

SECCIÓN MEDIA DEL POSTE

SOCLE

BASE

BASE

CHARIOT

RÄDERGRUPPE

CONJUNTO DEL CARRO PORTAMUELA

34

Page 35

10-3/4" High

4" Wide

PMS 021 for Warning

Le propriétaire doit s'assurer que tous les joueurs connaissent et

suivent ces règles d'utilisation sûre du système.

AVERTISSEMENT

•

NE VOUS SUSPENDEZ PAS sur le cerceau ou sur une autre partie

du système, y compris le panneau, les supports ou le filet.• Durant le jeu, en particulier lorsque vous faites un smash, gardez le

visage à l'écart du panneau, du cerceau et du filet. Risque de

blessures graves si les dents ou le visage viennent heurter le

panneau, le cerceau ou le filet.

•

Ne glissez et ne montez pas sur le socle et/ou le poteau, ne les

secouez pas et ne jouez pas dessus.

•

Une fois le montage terminé, remplissez complètement le système

d'eau ou de sable. Ne laissez jamais le système à la verticale sans

lester le socle, car le système risque de basculer et de causer des

blessures.• Lorsque vous réglez la hauteur ou que vous déplacez le système,

gardez les mains et les doigts à l'écart des pièces en mouvement.• Interdisez aux enfants de déplacer ou de régler le système.• Avant le jeu, retirez vos bijoux (bagues, montres, colliers, etc.). Ces

objets peuvent se prendre dans le filet.

•

La surface située sous le socle doit être lisse, sans gravier ou

autres objets coupants. Les perforations causent des fuites et

risquent de faire basculer le système.• Maintenez les substances organiques à l'écart du socle du poteau.

L'herbe, les ordures, etc. risquent de causer la corrosion et/ou la

détérioration du système.

•

Vérifiez l'état du système (signes de corrosion comme rouille,

piqûres, écaillage) et repeignez avec de la peinture émail pour

extérieur. Si de la rouille a piqué l'acier en tout point, remplacez

immédiatement le poteau.

•

Vérifiez le système avant chaque utilisation (lest, visserie mal

serrée, usure excessive et signes de corrosion) et réparez avant

utilisation.• Vérifiez la stabilité du système avant chaque utilisation.• N'utilisez pas le système les jours de vent fort et/ou de tempête ; le

système risque de se renverser. Placez le système dans sa position

de stockage et/ou dans un lieu protégé du vent et loin de biens

personnels et/ou câbles suspendus.

•

Ne jouez jamais sur du matériel abîmé.• Lorsque vous déplacez le système, soyez prudent pour empêcher

le mécanisme de se déséquilibrer.• Maintenez le poteau bouché à tout moment.• Ne laissez pas geler l'eau du socle. Par moins de 0 degré Celcius,

ajoutez 8 litres d'antigel non toxique ou du sable, ou bien videz

complètement et stockez. (N'utilisez pas de sel.)• Durant le déplacement du système, personne ne doit se tenir

debout ou assis sur son socle, ni surlester le socle.

•

Ne laissez pas le système sans supervision et ne jouez pas sur le

système lorsque les roues se sont enclenchées pour le

déplacement.

•

Soyez prudent lorsque vous déplacez le système sur des surfaces

irrégulières, car il risque de basculer.• Soyez extrêmement prudent si vous placez le système sur une

déclivité. Il risque de se renverser plus facilement.• Pour les instructions d'installation et d'entretien, reportez-vous au

guide fourni.

Lisez les avertissements indiqués ci-

dessous avant d'utiliser ce produit.

sous peine d'encourir des blessures

graves et/ou des dégâts matériels.

Réf.: FR556790 05/05

MUNSELL NOTATION

Hue Value Chroma

5.0 YR 6.0/15

Equiv. CIE Data

(Y%) x y

30.05 0.5510 0.4214

Approx. PMS Color

13 parts yellow

3 parts Warm Red

1/4 part Black

Warning Area = Orange

Size = 4" x 6.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

Aux États-Unis : 1-888-713-5488

In the U.S.: 1-800-558-5234

Au Canada: 1-800-284-8339

Aux États-Unis : 1-800-334-9111

Aux États-Unis : 1-800-772-5346

10-3/4" High

4" Wide

PMS 021 for Warning

Der Eigentümer muss sicherstellen, dass alle Spieler diese Regeln für

einen sicheren Betrieb des Systems kennen und befolgen.

ACHTUNG

•

NICHT am Korbrand oder irgendeinem anderen Teil des Systems,

einschl. Korbwand, Stützstreben oder Netz HÄNGEN.• Während des Spielbetriebs, besonders bei Slam-Dunk-Manövern,

müssen die Spieler ihr Gesicht von Korbwand, Korbrand und Netz fern

halten. Der Kontakt von Zähnen/Gesicht mit der Korbwand, dem

Korbrand oder dem Netz kann schwere Verletzungen zur Folge haben.

•

Nicht auf dem Sockel und/oder der Stange herumrutschen, klettern,

daran rütteln oder damit spielen.

•

Nach dem Zusammenbau das System ganz mit Wasser oder Sand

füllen. Das System niemals in aufrechter Position stehen lassen, ohne

den Sockel zu beschweren, da es andernfalls umkippen und

Verletzungen verursachen kann.

•

Beim Einstellen der Höhe oder beim Transport des Systems Hände und

Finger von beweglichen Teilen fern halten.• Kindern darf das Verschieben oder Einstellen des Systems nicht

gestattet werden.

•

Beim Spielen keinen Schmuck (Ringe, Armbanduhren, Halsketten usw.)

tragen. Gegenstände dieser Art können sich im Netz verfangen.

•

Die Oberfläche unter dem Sockel muss glatt und frei von Kies oder

anderen scharfkantigen Gegenständen sein. Löcher verursachen Lecks

und können ein Umkippen des Systems zur Folge haben.

•

Organische Materialien vom Stangensockel fern halten. Gras, Abfälle

usw. können Korrosion und/oder Abbauerscheinungen verursachen.

•

Das Stangensystem auf Anzeichen von Korrosion (Rost,

Narbenbildung, Abblättern) untersuchen und mit Emailaußenfarbe neu

lackieren. Wenn sich an irgendeiner Stelle Rost durch den Stahl

hindurch gefressen hat, muss die Stange sofort ersetzt werden.

•

Das System vor jeder Benutzung auf den richtigen Ballast, lose

Befestigungsteile, übermäßige Abnutzungserscheinungen und

Anzeichen von Korrosion untersuchen; vor jedem Einsatz

entsprechende Korrekturmaßnahmen bzw. Reparaturen durchführen.

•

Die Stabilität des Systems vor jedem Gebrauch überprüfen.• Das System nicht bei windigen und/oder unwirtlichen

Witterungsverhältnissen benutzen, da es unter diesen Umständen

umkippen kann. Das System in seine Lagerposition versetzen und/oder

in einen windgeschützten Bereich bringen, in dem sich weder

Sachwerte noch oberirdische Kabel befindend.

•

Niemals an bzw. mit einer beschädigten Ausrüstung spielen.• Beim Transport des Systems darauf achten, dass sich der

Mechanismus nicht verschiebt.• Das obere Stangenende muss jederzeit mit einer Kappe abgedeckt sein.• Das Wasser im Tank darf keinesfalls gefrieren. Bei Gefriertemperaturen

den Tank mit 7,5 l eines ungiftigen Gefrierschutzmittels oder Sand

füllen oder ihn völlig entleeren und lagern. (Kein Salz verwenden.)

•

Beim Verschieben des Systems darf niemand auf dem Sockel stehen

oder sitzen oder diesen mit zusätzlichem Ballast beschwert haben.

•

Das System nicht unbeaufsichtigt lassen oder damit spielen, wenn die

Räder zum Transport eingestellt sind.• Beim Transport des Geräts über unebene Flächen vorsichtig vorgehen.

Das System kann umkippen.

•

Beim Aufstellen des Systems auf einer geneigten Fläche mit großer

Vorsicht vorgehen. Das System kann unter diesen Bedingungen

leichter umkippen.

•

Die ordnungsgemäße Installation und Wartung ist dem

Gebrauchshandbuch zu entnehmen.

Vor Gebrauch dieses Produkts die

nachstehenden Warnhinweise lesen und

beachten.

Ein Missachten dieser Warnung kann zu

schweren Verletzungen und/oder Sachschäden

führe

Bestell-Nr.: GE556790 05/05

MUNSELL NOTATION

Hue Value Chroma

5.0 YR 6.0/15

Equiv . CIE Data

(Y%) x y

30.05 0.5510 0.4214

Approx. PMS Color

13 parts yellow

3 parts Warm Red

1/4 part Black

Warning Area = Orange

Size = 4" x 6.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

In den USA: 1-888-713-5488

In den USA: 1-800-558-5234

Kanada: 1-800-284-8339

In den USA: 1-800-334-9111

In den USA: 1-800-772-5346

Kanada: 1-800-284-8339

10-3/4" High

4" Wide

PMS 021 for Warning

El propietario debe asegurarse de que todos los jugadores

conozcan y obedezcan estas reglas para la operación segura del

sistema.

ADVERTENCIA

•

NO SE CUELGUE del borde ni de ninguna parte del sistema,

inclusive el respaldo, las abrazaderas de apoyo y la red.

•

Durante el juego, especialmente cuando se realizan actividades de

tipo clavada (dunk), el jugador debe mantener la cara alejada del

respaldo, el borde y la red. Si los dientes o la cara entran en

contacto con el respaldo, el borde o la red, se puede sufrir una

lesión grave.

•

No se deslice, suba, sacuda ni juegue en la base y/o en poste.• Cuando complete el montaje, llene completamente el sistema con

agua o arena. Nunca deje el sistema en posición vertical sin llenar la

base con un peso, ya que el sistema se podría caer y causar

lesiones.

•

Al ajustar la altura o mover el sistema mantenga las manos y los

dedos alejados de las partes movibles.

•

No permita que los niños muevan o ajusten el sistema.• Durante el juego, no use joyería (anillos, relojes, collares, etc.). Estos

objetos se podrían atorar en la red.

•

La superficie debajo de la base se debe mantener lisa y sin grava ni

otros objetos filosos. Las perforaciones pueden causar fugas y

provocar que el sistema se caiga.

•

Mantenga los materiales orgánicos alejados de la base del poste. El

césped, la basura, etc. podrían causar corrosión y/o deterioro de la

base del poste.

•

Revise que el sistema del poste no tenga señales de corrosión

(oxidación, picaduras, desconchaduras) y si las tiene vuelva a

pintarlo con pintura de esmalte para exteriores. Si la corrosión

penetró a través del acero en cualquier área, reemplace

inmediatamente el poste.

•

Antes de cada uso revise el sistema para verificar que esté

adecuadamente equilibrado, que no tenga herraje suelto, desgaste

excesivo ni signos de corrosión, y repárelo si es necesario.

•

Verifique la estabilidad del sistema antes de cada uso.• NO use el sistema durante condiciones climáticas severas y/o con

mucho viento, ya que el sistema se podría caer. Coloque el sistema

en posición de almacenamiento y/o en un área protegida del viento y

sin propiedad personal y/o cables suspendidos.

•

Nunca juegue en equipo dañado.• Cuando mueva el sistema, tenga cuidado para evitar que el

mecanismo cambie de lugar.

•

Siempre mantenga la parte superior del poste cubierta con la tapa.• No permita que el agua del tanque se congele. En clima con

temperaturas de congelamiento añada dos galones de

anticongelante no tóxico, arena, o vacíe completamente el tanque y

almacénelo. (No use sal.)

•

Al mover el sistema no permita que nadie se pare o siente en la base

o añada lastre adicional en la base.

•

No deje el sistema sin supervisión ni juegue en el sistema cuando

las ruedas estén embragadas para rodar.

•

Tenga cuidado al mover el sistema sobre superficies irregulares. El

sistema se podría ladear.

•

Use extremado cuidado si va a colocar el sistema en una superficie

inclinada. El sistema se podría caer más fácilmente.

•

Consulte el manual de instrucciones para ver la instalación y el

mantenimiento adecuados.

Lea y entienda las advertencias que se

encuentran a continuación antes de usar este

producto.

Si no se observan estas advertencias se

podrían causar lesiones graves y/o daños

materiales.

N/P: SP556790 05/05

MUNSELL NOTATION

Hue Value Chroma

5.0 YR 6.0/15

Equiv . CIE Data

(Y%) x y

30.05 0.5510 0.4214

Approx. PMS Color

13 parts yellow

3 parts Warm Red

1/4 part Black

Warning Area = Orange

Size = 4" x 6.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

En EE.UU.: 1-888-713-5488

En EE.UU.: 1-800-558-5234

En Canadá: 1-800-284-8339

En EE.UU.: 1-800-334-9111

En EE.UU.: 1-800-772-5346

En Canadá: 1-800-284-8339

35

02/06 ID# M661144

Page 36

Size = 4" x 5.5"

C

orner Radius = 3/8"

D

ie Cut Label

3.25 Mil Vinyl

A

ll Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

I

llustrator 8.0 = EPS

B

acking + 1/16 Circumference

Rolls of 500

2

2

1

3

P

OUR AJUSTER LE PANNEAU :

1. Tout en tenant la poignée, retirez la goupille.

2. Montez ou abaissez le système

élévateur jusqu'à la hauteur voulue.

3

. Remettez la goupille à sa place

en l'enfonçant à fond, pour bloquer

le système à la hauteur désirée.

F

R511679 05/05

1

2

4

3

DÉPLACEMENT DU SYSTÈME

RÉGLAGE DE LA HAUTEUR

1

. Placez le panneau de basket-ball

à sa position la plus basse.

2. Tout en tenant le poteau, tournez

l

e système de basket-ball vers

l

'avant jusqu'à ce que les roues

touchent le sol.

3. Amenez le système de basketb

all à l'emplacement désiré.

4. Redressez avec précaution le

système de basket-ball.

5

. Vérifiez la stabilité du système.

Size = 4" x 5.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

A

ll Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

2

2

1

3

E

INSTELLEN DER KORBWAND:

1. Bei festgehaltenem Griff den

Stift herausziehen.

2.

Die Verlängerungsvorrichtung bis zur

gewünschten Höhe nach oben oder

u

nten verschieben.

3.

Den Stift zum Verriegeln des Systems

a

uf der gewünschten Höhe ganz

hineinschieben.

GE511679 05/05

1

2

4

3

TRANSPORTSYSTEM

Die Basketball-Korbwand auf

die niedrigste Position

e

instellen.

1.

Die Stange festhalten; zur

s

elben Zeit das

Basketballsystem nach vorne

drehen, bis die Räder den

B

oden berühren.

2.

Das Basketballsystem an den

gewünschten Ort fahren.

3.

Das Basketballsystem

v

orsichtig in die aufrechte

Position drehen.

4.

5.

Die Stabilität des Systems

ü

berprüfen.

HÖHENEINSTELLUNG

Size = 4" x 5.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

2

2

1

3

PARA AJUSTAR EL RESPALDO:

1.

Mientras sujeta la manija, quite

el pasador.

2.

Mueva el elevador hacia arriba o

hacia abajo a la altura deseada.

3.

Vuelva a colocar el pasador a toda

su longitud para fijar el sistema a

la altura deseada.

SP511679 05/05

1

2

4

3

MOVIMIENTO DEL SISTEMA

Ajuste la altura del respaldo

de baloncesto a la posición

más baja.

1.

Mientras sujeta el poste, gire

hacia adelante el sistema de

baloncesto hasta que las

ruedas toquen el piso.

2.

Mueva el sistema de

baloncesto a la ubicación

deseada.

3.

Gire cuidadosamente el

sistema de baloncesto hasta

que quede en posición vertical.

4.

5.

Revise la estabilidad del

sistema.

AJUSTE DE LA ALTURA

CONSIGNES DE SÉCURITÉ

SUIVEZ CES CONSIGNES DE SÉCURITÉ SOUS PEINE DE PROVOQUER DES BLESSURES GRAVES, DES DÉGÂTS

e propriétaire doit s'assurer que tous les joueurs connaissent et suivent ces règles d'utilisation sûre du système.

L

Par mesure de sécurité, n'essayez pas de monter ce système sans suivre scrupuleusement les

i

nstructions. Vérifiez le carton et l'intérieur de tout le matériel d'emballage pour y trouver les

pièces et/ou d'autres instructions. Avant de commencer le montage, lisez les instructions et

identifiez les pièces à l'aide de la liste d'identification et de la liste des pièces de ce document.

n montage, une utilisation et une supervision corrects et complets sont indispensables à un

U

bon fonctionnement et à la réduction des risques d'accident ou de blessure. Il existe un haut

risque de blessures graves si ce système n'est pas correctement installé, entretenu et utilisé.

•

Si vous utilisez une échelle en cours de montage, soyez extrêmement prudent.

• Il est recommandé de s’y prendre à deux (2) (adultes) pour réaliser cette opération.

• Vérifiez régulièrement le socle pour vous assurer qu'il ne fuit pas. Les petites fuites risquent d'entraîner le

basculement intempestif du système.

• Emboîtez correctement les sections de poteau (le cas échéant). Elles risquent sinon de se déboîter en

cours de jeu et/ou de transport du système.

• Les conditions climatiques, la corrosion ou une mauvaise utilisation risquent de provoquer la panne du

système.

• La hauteur minimale d'utilisation est de 1,98 m jusqu'à la base du panneau.

• Ce matériel est réservé à un but récréatif à domicile et NON PAS à un jeu extrêmement compétitif.

• Lisez et comprenez l'étiquette d'avertissement fixée au poteau.

• La durée de vie de votre poteau de basket-ball dépend de bien des facteurs. Le climat, la position du

poteau, son emplacement, son exposition à des agents corrosifs tels que des pesticides, des herbicides

ou des sels sont tous des facteurs importants.

P

•

our toute assistance technique, contactez le service clientèle.

•

La supervision d'un adulte est recommandée pour le réglage de la hauteur.

La plupart des blessures sont causées par une utilisation impropre et/ou le non-respect des instructions.

MATÉRIELS ET L'ANNULATION DE LA GARANTIE.

.

Soyez prudent lorsque vous utilisez ce système.

SICHERHEITSHINWEISE

IN MISSACHTEN DIESER SICHERHEITSHINWEISE KANN ZU SCHWEREN VERLETZUNGEN ODER SACHSCHÄDEN FÜHREN UND

E

Der Eigentümer muss sicherstellen, dass alle Spieler diese Regeln für einen sicheren Betrieb des Systems kennen und befolgen.

Aus Sicherheitsgründen darf dieses System nur unter sorgfältiger Beachtung der Anleitung zusammengebaut

w

erden. Den ganzen Karton und alle darin befindlichen Verpackungsmaterialien auf Bauteile und/oder

zusätzliche Anleitungen inspizieren. Vor Beginn des Zusammenbaus die Anleitung durchlesen und anhand des

Schlüssels zur Identifizierung der Befestigungsteile und der Teileliste in diesem Dokument die einzelnen

Bauteile bestimmen. Eine ordnungsgemäße und vollständige Montage, Verwendung und Aufsicht sind für den

richtigen Betrieb und zur Reduzierung des Unfall- oder Verletzungsrisikos absolut erforderlich. Bei einer

u

nsachgemäßen Installation und Wartung und bei einem falschen Betrieb dieses Systems besteht ein hohes

Risiko schwerer Verletzungen.

MACHT DIE GARANTIE UNWIRKSAM.

• Bei Gebrauch einer Leiter während des Zusammenbaus extrem vorsichtig vorgehen.

Diese Arbeit sollte von zwei (2) dazu fähigen Erwachsenen ausgeführt werden.

•

• Den Sockel regelmäßig auf Leckstellen untersuchen. Langsam austretende Füllmittel können ein

unerwartetes Umkippen des Systems verursachen.

Die einzelnen Stangenteile richtig zusammenfügen (falls anwendbar), Andernfalls können sich die

•

Stangenteile beim Spielbetrieb und/oder während des Transports des Systems voneinander lösen.

• Klimatische Bedingungen, Korrosion oder Fehlgebrauch kann zu Systemdefekten führen.

Die Mindestspielhöhe beträgt 1,98 m (6,5 Fuß) bis zum unteren Rand der Korbwand.

•

• Diese Vorrichtung ist nur für den Freizeitgebrauch zu Hause, NICHT aber für ein übermäßig

wettkampfbetontes Spiel vorgesehen.

Den an der Stange angebrachten Warnaufkleber aufmerksam lesen.

•

Die Nutzungsdauer Ihrer Basketballstange hängt von zahlreichen äußeren Umständen ab.

•

Klimabedingungen, Platzierung und Aufstellort der Stange, Angriffe durch korrodierende Substanzen wie

Ungeziefer- und Pflanzenvernichtungsmittel oder Salz - all das sind wichtige Faktoren.

•

Technische Unterstützung kann vom Kundendienst angefordert werden.

• Alle Höhenverstellungen sollten von Erwachsenen beaufsichtigt werden.

Die meisten Verletzungen werden durch einen Fehlgebrauch bzw. ein Missachten der Anleitungen

Bei der Verwendung dieses Systems vorsichtig vorgehen.

INSTRUCCIONES DE SEGURIDAD

EL INCUMPLIMIENTO DE ESTAS INSTRUCCIONES DE SEGURIDAD PUEDE DAR COMO RESULTADO LESIONES GRAVES O DAÑOS

El propietario debe asegurarse de que todos los jugadores conozcan y obedezcan estas reglas para la operación segura del sistema.

Por su seguridad, no intente montar este sistema sin seguir cuidadosamente las instrucciones.

Revise toda la caja y el interior de todo el material de embalaje para encontrar todas las piezas

y/o material instructivo adicional. Antes de comenzar el montaje, lea las instrucciones e

ID# M661144 02/06

identifique las piezas usando el identificador de herraje y la lista de piezas contenidos en este

documento. Es esencial el montaje completo, y el uso y la supervisión adecuados para la

operación correcta del sistema y para reducir el riesgo de accidentes o lesiones. Existe una alta

probabilidad de sufrir lesiones graves si este sistema no se instala, mantiene y opera

adecuadamente.

• Si utiliza una escalera de mano durante el montaje, tenga mucho cuidado.

• Se recomienda que dos (2) adultos capaces realicen esta operación.

• Revise regularmente la base para detectar fugas. Las fugas lentas podrían causar que el sistema se cayera

inesperadamente.

Asiente correctamente las secciones del poste (si aplica). Si no lo hace, las secciones del poste podrían

•

separarse durante el juego y/o durante el transporte del sistema.

• El clima, la corrosión y el mal uso podrían ocasionar la falla del sistema.

• La altura mínima de operación es de 6 pies y 6 pulgadas (1.98 m) hasta la parte inferior del respaldo.

• Este equipo está diseñado únicamente para uso recreativo en el hogar y NO para juego competitivo

excesivo.

Lea y entienda la etiqueta de advertencia adherida en el poste.

•

La vida útil de su poste de baloncesto depende de muchas condiciones. El clima, la colocación del poste,

•

la ubicación del poste, la exposición a sustancias corrosivas tales como pesticidas, herbicidas o sales son

factores importantes.

Si requiere asistencia técnica, comuníquese con el Departamento de Servicio al Cliente.

•

• Se recomienda que el ajuste de la altura se realice bajo la supervisión de un adulto.

La mayoría de las lesiones son causadas por el uso inadecuado y/o por el incumplimiento de las

verursacht.

MATERIALES Y ANULARÁ LA GARANTÍA.

Tenga cuidado cuando use este sistema.

instrucciones.

36

Page 37

Des questions ou des

pièces manquantes ?

Appelez le numéro du service clientèle

(NUMÉRO GRATUIT) qui figure en première page!

STOP!STOP!

NE RETOURNEZ PAS au magasin !

Fragen oder fehlende Teile?

Rufen Sie die GEBÜHRENFREIE Telefonnummer

(in den USA und Kanada) auf der Vorderseite an!

HALT!HALT!

Gehen Sie NICHT zum Laden zurück!

¿Tiene preguntas o le faltan piezas?

¡Llame al número telefónico GRATUITO de Servicio

al Cliente que se indica en la primera página!

¡¡ALTO!ALTO!

¡NO regrese a la tienda!

IMPORTANT!

Videz entièrement les boîtes.

Veillez à vérifier l'intérieur des sections de poteau.

La quincaillerie et des pièces supplémentaires sont emballées à

l'intérieur.

WICHTIG!

Die Kartons vollständig auspacken.

Den Hohlraum in den Stangenteilen inspizieren.

Dort sind Befestigungs- und andere Kleinteile verpackt.

¡IMPORTANTE!

Saque todo el contenido de las cajas.

Asegúrese de revisar el interior de las secciones del poste.

Ahí se han empacado herraje y piezas adicionales.

AVERTISSEMENT: SI VOTRE SYSTÈME EST ÉQUIPÉ D'UN PANNEAU EN

ACRYLIQUE, EXAMINEZ-LE BIEN POUR VOUS ASSURER QU'IL N'A PAS

ÉTÉ ENDOMMAGÉ EN COURS DE TRANSPORT. S'IL EST FISSURÉ, IL

RISQUE DE SE CASSER SUBITEMENT. SI LE PANNEAU EST

ENDOMMAGÉ D'UNE QUELCONQUE MANIÈRE AVANT OU APRÈS

L'ASSEMBLAGE, APPELEZ LE NUMÉRO SANS FRAIS:

États-Unis 1-800-558-5234 ; CANADA : 1-800-284-8339 ;

http://www.huffysports.com

WARNUNG: BEI EINEM MIT EINER ACRYL-RÜCKWAND

AUSGESTATTETEN SYSTEM DIE KORBWAND AUF EVENTUELLE

SCHÄDEN UNTERSUCHEN, DIE WÄHREND DES VERSANDS

EINGETRETEN SEIN KÖNNEN. SPRÜNGE IN DER KORBWAND KÖNNEN

ZU DEREN PLÖTZLICHEM BRUCH FÜHREN. WENN DIE KORBWAND

VOR ODER NACH DEM ZUSAMMENBAU IN JEGLICHER WEISE

BESCHÄDIGT WIRD, RUFEN SIE DIE FOLGENDE GEBÜHRENFREIE

TELEFONNUMMER AN:

Innerhalb der USA: 1-800-558-5234; innerhalb KANADAS: 1-800-284-8339;

http://www.huffysports.com

ADVERTENCIA: SI SU SISTEMA ESTÁ EQUIPADO CON UN RESPALDO

DE ACRÍLICO, EXAMINE EL RESPALDO PARA VERIFICAR QUE NO HAYA

SUFRIDO DAÑOS DURANTE EL TRANSPORTE. LA PRESENCIA DE

GRIETAS EN EL RESPALDO PODRÍA OCASIONAR SU ROMPIMIENTO

REPENTINO. SI EL RESPALDO SE DAÑA DE ALGUNA MANERA ANTES

O DESPUÉS DE SU MONTAJE, LLAME AL NÚMERO TELEFÓNICO SIN

COSTO:

EE. UU. 1-800-558-5234; CANADÁ: 1-800-284-8339;

http://www.huffysports.com

37

ENREGISTREMENT DU PRODUIT :

Rappelez-vous de remplir votre formulaire d'inscription du

produit en ligne sur la page

www.huffysports.com/customer_support/product_registration.

PRODUKTREGISTRIERUNG:

Bitte vergessen Sie nicht, das Produktregistrierungsformular

online unter

www.huffysports.com/customer_support/product_registration

auszufüllen.

REGISTRO DEL PRODUCTO:

Por favor recuerde completar en línea el formulario de

registro de su producto en:

www.huffysports.com/customer_support/product_registration.

02/06 ID# M661144

Page 38

AVIS AUX PERSONNES CHARGÉES DU MONTAGE

Assemblage exclusivement réservé à un adulte. Jetez TOUT le matériel d'emballage dans les plus brefs

délais.

TOUS les systèmes de basket-ball Huffy Sports, y compris ceux utilisés en EXPOSITION, DOIVENT être

assemblés et lestés de sable ou d'eau, selon les instructions. Suivez ces instructions sous peine

d'encourir des BLESSURES GRAVES. Il est INACCEPTABLE de composer un système de lestage de

fortune.

HINWEIS FÜR DIE PERSONEN, DIE DEN ZUSAMMENBAU DURCHFÜHREN

Zusammenbau nur durch Erwachsene ALLE Verpackungsmaterialien sofort wegwerfen. Wie alle für

Kinder vorgesehene Produkte muss auch dieses regelmäßig auf lose Kleinteile inspiziert werden.

ALLE Basketballsysteme von Huffy Sports, einschließlich der zu Demonstrationszwecken benutzten

Systeme, müssen gemäß der Mont

werden. Ein Missachten dieser Anleitung kann SCHWERE VERLETZUNGEN zur Folge haben. Zum

Beschweren darf NICHT zu irgendwelchen Notbehelfsmaßnahmen gegriffen werden.

ageanleitung zusammengebaut und mit Sand oder Wasser beschwert

AVISO PARA LAS PERSONAS QUE REALIZAN EL MONTAJE

Il montaggio va eseguito da persone adulte. Eliminare prontamente TUTTI i materiali di imballaggio.

TODOS los sistemas de baloncesto de Huffy Sports, inclusive los usados para EXHIBICIÓN, DEBEN estar

montados y equilibrados con arena o agua, de acuerdo con las instrucciones. Si se ignoran estas

instrucciones se podría ocasionar una LESIÓN GRAVE. NO es aceptable improvisar un sistema de pesas

provisional.

ID# M661144 02/06

38

Page 39

LISTE DES PIÈCES

FRANÇAIS

Légende Qté No. de réf. Description

1 1 266000 Socle

2 2 908184 Contrefiche, poteau/socle

3 1 804833 Ensemble hauteur Exacta

4 1 FR908006 Section de poteau supérieure

5 1 FR918107 Section de poteau centrale

6 1 FR908179 Section de poteau inférieure

7 2 108183 Support de roues

8 2 266200 Roue, 10 cm

9 2 108182 Tige, axe

10 1 203099 Écrou, Ny-lock, 5/16-18

11 6 203063 Contre-écrou en nylon, 3/8-16

12 1 202662 Boulon, tête à six pans, 5/16-18

x 11,4 cm (long.)

13 4 206938 Écrou, diamètre d'axe 11 mm

14 9 203100 Écrou à bride à 6 pans, 5/16-18

15 1 204832 Support, poteau

16 2 203053 Boulon ordinaire, 5/16-18 x 4 cm long.

17 4 203232 Rondelle, plate 19 mm D.E.

18 4 204962 Boulon, tête à six pans, 5/16-18

x 15,8 mm long.

19 4 206360 Boulon, tête à six pans, 3/8-16

x 6,6 cm (long.)

20 2 204858 Entretoise, Biscuit, plastique

21 2 204857 Entretoise, métallique 12 mm D.E.

x 3,6 cm (long.)

22 2 204859 Protection, goupille

23 1 203038 Boulon ordinaire, 5/16-18 x 7 cm (long.)

24 1 204850 Goupille, blocage

25 1 204853 Cordon, spirale, noir

26 4 203527 Entretoise, 13,4 mm D.I. x 3,8 cm (long.)

27 2 908256 Support, panneau

28 1 266100 Couvercle, avant

29 6 206244 Boulon, six pans, 1/2-13 x 8 de long.

30 4 201642 Entretoise, plastique, 13,4 mm D.I.

x 1,6 cm (long.)

31 7 206340 Contre-écrou, six pans, 1/2-13

32 2 904820 Tube du système élévateur,

inférieur - Long

Légende

33 1 204837 Ressort, contrepoids

34 1 Cerceau

35 2 904808 Tube du système élévateur,

36 2 201682 Entretoise, 13,4 mm D.I. x 4,7 cm

37 2 900867 Plaque triangulaire (noire)

38 1 207103 Capuchon, haut du poteau

39 2 200520 Vis, #8 x 19 mm long.

40 1 202605 Boulon, 6 pans, 1/2-13 x 10,7 cm (long)

41 1 266300 Bouchon, socle

42 1 206990 Support de renforcement

43 1 Filet

44 4* 205528 Boulon, bride, six pans, 5/16-18

45 4 203309 Rondelle, plate 3/8

46 1 511679 Étiquette, réglage de hauteur

47 6 203738 Boulon ordinaire, 5/16-18 x 4,5 cm long.

48 6 200982 Écrou, 5/16-18

49 1 108181 Plaque, fixation de poteau

50 2 203331 Boulon, tête à six pans, 3/8-16

51 6 203218 Rondelle, plate, 5/16

52 4 204961 Boulon, tête à six pans, 3/8-16

53 1 200516 Cache, boulon, vinyle

54 1 900033 Support, Slam Jam

55 1 203796 Boulon, T, 3/8-16 x 12,7 cm long.

56 1 200318 Support, renforcement, Slam Jam

57 1 203472 Ressort, cerceau

58 1 203795 Écrou, spécial, 3/8-16

59 1 203470 Rondelle, plate 38 mm D.E.

60 1 200503 Protection du ressort, (noir)

61 1 202795 Etiquette, logo

* IL EST POSSIBLE QUE VOUS AYEZ D’AUTRES PIÈCES

AVEC CE MODÈLE.

Qté No. de réf. Description

supérieur - Court

x 2,54 cm (long.)

FR511679 et déplacement

x 4,5 cm long.

x 0,625 (long.)

200504 Protection du ressort, (rouge)

REMARQUE

Le kit de visserie est conçu pour plus d’un

style de système de basket-ball. T

visserie ne sera pas nécessairement

utilisée.

oute la

39

02/06 ID# M661144

Page 40

TEILELISTE

DEUTSCH

Nr. Anz. Teilenummer Beschreibung

1 1 266000 Sockel

2 2 908184 Verstrebung, Stange zu Sockel

3 1 804833 Exacta-Höheneinstellkomponenten

4 1 FR908006 Oberes Stangenteil

5 1 FR918107 Mittleres Stangenteil

6 1 FR908179 Unteres Stangenteil

7 2 108183 Radhalterung

8 2 266200 Rad, 4 Zoll Durchmesser

9 2 108182 Achsenstange

10 1 203099 Ny-Lock-Mutter, 5/16-18

11 6 203063 Nylon-Einschraubgegenmutter, 3/8-16

12 1 202662 Sechskantkopfschraube, 5/16-18

x 4-1/2 Länge

13 4 206938 Druckmutter, 7/16 Wellendurchmesser

14 9 203100 Sechskant-Flanschmutter, 5/16-18

15 1 204832 Stangenmontageklammer

16 2 203053 Schlossschraube, 5/16-18 x 4 Länge

17 4 203232 Flache Unterlegscheibe, 3/4" AD

18 4 204962 Sechskantkopfschraube, 5/16-18

x 0,625 Länge

19 4 206360 Sechskantkopfschraube, 3/8-16

x 2-5/8 Länge

20 2 204858 Abstandsstück, rund, Plastik

21 2 204857 Abstandsstück, Metall, 1/2" AD

x 1,44" Länge

22 2 204859 Stiftschiebeabdeckung

23 1 203038 Schlossschraube, 5/16-18 x 2-3/4 Länge

24 1 204850 Verriegelungsstift

25 1 204853 Abzugsleine, schwarze Rolle

26 4 203527 Abstandsstück, 0,530" ID x 1,5" Länge

27 2 908256 Korbwandstützklammer

28 1 266100 Frontabdeckung

29 6 206244 Sechskantkopfschraube, 1/2-13

x 8 Länge

30 4 201642 Abstandsstück, Plastik, 0,530" ID

x 0,625" Länge

31 7 206340 Sechskant-Gegenmutter, 1/2-13

32 2 904820 Unteres Verlängerungsrohr – lang

Anz. Teilenummer Beschreibung

Nr.

33 1 204837 Gegengewichtsfeder

34 1 Korbrand

35 2 904808 Oberes Verlängerungsrohr – kurz

36 2 201682 Abstandsstück, 0,530" ID x 1,875" Länge

37 2 900867 Dreiecksplatte (schwarz)

38 1 207103 Stangenendkappe

39 2 200520 Kreuzschlitzschraube Nr. 8, ¾" Länge

40 1 202605 Sechskantschraube, 1/2-13

x 4,25" Länge

41 1 266300 Deckel, Sockel

42 1 206990 Verstärkungshalterung

43 1 Netz

44 4* 205528 Sechskant-Flanschschraube, 5/16-18

x 1 Länge

45 4 203309 Flache Unterlegscheibe, 3/8

46 1 511679 Höheneinstell- und Transportaufkleber

FR511679

47 6 203738 Schlossschraube, 5/16-18 x 1,75" Länge

48 6 200982 Nylock-Mutter, 5/16-18

49 1 108181 Stangenmontageplatte

50 2 203331 Sechskantkopfschraube, 3/8-16

x 1,5" Länge

51 6 203218 Flache Unterlegscheibe, 5/16

52 4 204961 Sechskantkopfschraube, 3/8-16

x 0,625" Länge

53 1 200516 Schraubenendabdeckung, Vinyl

54 1 900033 Slam Jam-Halterung

55 1 203796 T-Nutenschraube, 3/8-16 x 5" Länge

56 1 200318 Slam Jam-Verstärkungshalterung

57 1 203472 Korbrandfeder

58 1 203795 Spezialmutter, 3/8-16

59 1 203470 Flache Unterlegscheibe, 1,5" AD

60 6 200503 Abdeckung, schwarz

200504 Abdeckung, rot

61 6 202795 Firmenschild

* DIESEM MODELL KÖNNEN ZUSÄTZLICHE TEILE

BEIGEPACKT SEIN.

HINWEIS:

Die beiliegenden Befestigungsteile sind für

mehr als eine Ausführung des

Basketballsystems vorgesehen. Es werden

nicht alle Befestigungsteile benötigt.

ID# M661144 02/06

40

Page 41

Artículo Cant. Pieza N.º Descripción

1 1 266000 Base

2 2 908184 Puntal, poste a base

3 1 804833 Conjunto Exacta Height

4 1 FR908006 Sección superior del poste

5 1 FR918107 Sección media del poste

6 1 FR908179 Sección inferior del poste

7 2 108183 Soporte de la rueda

8 2 266200 Rueda, 4 pulgadas

9 2 108182 Varilla, eje

10 1 203099 Tuerca, Ny-lock, 5/16-18

11 6 203063 Tuerca de nilón del

inserto de seguridad, 3/8-16

12 1 202662 Perno, cabeza hexagonal, 5/16-18

x 4-1/2 de longitud

13 4 206938 Tuerca dentada, eje del

diámetro de 7/16

14 9 203100 Tuerca, brida hexagonal, 5/16-18

15 1 204832 Soporte, montaje del poste

16 2 203053 Perno cabeza de carro, 5/16-18

x 4 de longitud

17 4 203232 Arandela, plana, 3/4" D.E.

18 4 204962 Perno, cabeza hexagonal, 5/16-18

x .625 de longitud

19 4 206360 Perno, cabeza hexagonal, 3/8-16

x 2-5/8 de longitud

20 2 204858 Espaciador, oblongo, plástico

21 2 204857 Espaciador, metálico de 1/2” de D.E.

x 1.44 de largo

22 2 204859 Cubierta, corredera de perno

23 1 203038 Perno cabeza de carro, 5/16-18

x 2-3/4 de longitud

24 1 204850 Perno de fijación

25 1 204853 Acollador, espiral negro

26 4 203527 Espaciador, .530 D.I. x 1.5 de largo

27 2 908256 Soporte del respaldo

28 1 266100 Cubierta frontal

29 6 206244 Perno, cabeza hexagonal, 1/2-13

x 8 de longitud

30 4 201642 Espaciador, plástico, .530 D.I.

x .625 de largo

31 7 206340 Contratuerca, hexagonal, 1/2-13

32 2 904820 Tubo elevador, inferior (largo)

LISTA DE PIEZAS

ESPAÑOL

33 1 204837 Resorte, contrapeso

34 1 Borde

35 2 904808 Tubo elevador, superior (corto)

36 2 201682 Espaciador, .530 D.I. x 1.875

37 2 900867 Placa triangular, (negra)

38 1 207103 Tapa, parte superior del poste

39 2 200520 Tornillo, #8 x 3/4 de longitud

40 1 202605 Perno hexagonal 1/2-13

x 4.25 de longitud

41 1 266300 Tapa, base

42 1 206990 Soporte de refuerzo

43 1 Red

44 4* 205528 Perno, cabeza hexagonal, 5/16-18

x 1 de longitud

45 4 203309 Arandela plana, 3/8

46 1 511679 Etiqueta, ajuste de la altura

FR511679 y de movimiento

47 6 203738 Perno cabeza de carro, 5/16-18

x 1.75 de longitud

48 6 200982 Contratuerca, 5/16-18

49 1 108181 Placa, montaje del poste

50 2 203331 Perno, cabeza hexagonal, 3/8-16

x 1.5 de longitud

51 6 203218 Arandela plana, 5/16

52 4 204961 Perno, cabeza hexagonal, 3/8-16

x 0.625 de longitud

53 1 200516 Cubierta, extremo del perno, vinilo

54 1 900033 Soporte Slam Jam

55 1 203796 Perno, en T, 3/8-16, 5” de longitud

56 1 200318 Soporte de refuerzo, Slam Jam

57 1 203472 Resorte, borde

58 1 203795 Tuerca, especial 3/8-16

59 1 203470 Arandela, plana, 1.5 D.E.

60 6 200503 Cubierta, negra

200504 Cubierta, rojo

61 6 202795 Etiqueta del logotipo

* PUEDE HABER PIEZAS ADICIONALES EN ESTE MODELO.

Artículo

Cant. Pieza N.º Descripción

NOTA:

El juego de herraje está diseñado para más

de un estilo de sistemas de baloncesto. No

se usará todo el herraje.

41

02/06 ID# M661144

Page 42

IDENTIFICATION DES PIÈCES (BOULONS & VIS)

B

EFESTIGUNGSTEILESCHLÜSSEL (BOLZEN UND SCHRAUBEN)

IDENTIFICADOR DE HERRAJE (PERNOS Y TORNILLOS)

#63 (6)

#47 (6)

#16 (2)

#40 (1)

Item #23 (1)

#19 (2)

#19 (2)

#29 (6)

#39 (2)

#18 (4)

#12 (1)

#44 (4)*

IDENTIFICATION DES PIÈCES (ENTRETOISES EN ACIER)

BEFESTIGUNGSTEILESCHLÜSSEL

IDENTIFICADOR DEL

HERRAJE (ESPACIADORES DE ACERO)

(ABST

#21 (2)

* IL EST POSSIBLE QUE VOUS AYEZ D'AUTRES PIÈCES AVEC CE MODÈLE.

* DIESEM MODELL KÖNNEN ZUSÄTZLICHE TEILE BEIGEPACKT SEIN.

* PUEDE HABER PIEZAS ADICIONALES EN ESTE MODELO.

#55 (1)

ANDSSTÜCKE

#9 (2)

AUS ST

#52 (4)

AHL)

ID# M661144 02/06

42

Page 43

IDENTIFICATION DES PIÈCES (ÉCROUS & RONDELLES)

B

EFESTIGUNGSTEILESCHLÜSSEL (MUTTERN UND UNTERLEGSCHEIBEN)

IDENTIFICADOR DE HERRAJE (TUERCAS Y ARANDELAS)

#10 (1)

#14 (7)*

#11 (6)

#48 (6)

#31 (7)

#45 (4)*

#51 (6)

#17 (4)

#64 (6)

#58 (1)

#59 (1)

IDENTIFICATION DES PIÈCES (ENTRETOISES, CAPUCHONS & PINCES EN PLASTIQUE)

BEFESTIGUNGSTEILESCHLÜSSEL (ABSTANDSSTÜCKE, KAPPEN UND CLIPS AUS KUNSTSTOFF)

IDENTIFICADORES DEL HERRAJE (TAPAS DE LOS ESPACIADORES Y SUJETADORES DE PLÁSTICO)

#30 (4)

#26 (4)

#13 (4)

#20 (2)

#36 (2)

#53 (1)

IDENTIFICATION DES PIÈCES (AUTRES)

BEFESTIGUNGSTEILESCHLÜSSEL (SONSTIGE)

IDENTIFICADOR DE HERRAJE (OTROS)

#57 (1)

#56 (1)

#54 (1)

43

02/06 ID# M661144

Page 44

SECTION A : MONTAGE DU SOCLE

BAUABSCHNITT A: ZUSAMMENBAU DES SOCKELS

SECCIÓN A: MONTAJE DE LA BASE

Voici à quoi ressemblera votre système lorsque

vous en aurez fini avec cette section:

So sieht das System aus, wenn Sie mit diesem

Bauabschnitt fertig sind:

Así es como se verá su sistema cuando haya

terminado esta sección:

OUTILS REQUIS POUR CETTE SECTION

FÜR DIESEN BAUABSCHNITT BENÖTIGTES WERKZEUG

HERRAMIENTAS REQUERIDAS PARA ESTA SECCIÓN

(2) Clés

(2) Schraubenschlüssel

(2) Llaves

9/16” and 1/2”

ET/OU

UND/ODER

Y/O

(2) Clés à douilles et douilles

teckschlüssel und Einsätze

S

(2)

(2) Llaves de tuercas de boca tubular y casquillos de

un tournevis cruciforme

ein Kreuzschlitzschraubenzieher