Huebsch YU120S Tumbler-Dryer Parts Diagram

Tumble Dryers

TMB1268C

120 Pound Capacity

170 Pound Capacity

Models Through Serial No. 0907000048

Refer to Page 7 for Mo del Numbers

Troubleshooting

www.alliancelaundry.com

Part No. 70399901R2

December 2016

Table of

Contents

Section 1 – Safety Information...............................................................3

Locating an Authorized Service Person ................................................5

Safety Warnings and Decals..................................................................5

Safety Precautions for Servicing Tumble Dryers..................................5

Section 2 – Introduction..........................................................................6

Model Identification..............................................................................6

Customer Service...................................................................................8

Serial Plate Location..............................................................................8

How a Tumble Dryer Works.................................................................9

Section 3 – Troubleshooting..................................................................10

1. Motor Does Not Start..................................................................11

2. Motor Overload Protector Cycles Repeatedly............................12

3. Motor Runs But Cylinder Does Not Turn...................................13

4. Motor Does Not Stop..................................................................14

5. No Heat Condition (Non-CE and Non-Australian Models)........15

6. Gas Burner Does Not Ignite........................................................17

7. Burner Ignites and Goes Out Repeatedly....................................19

8. Burner Shuts off Prematurely .....................................................20

9. Burner Repeatedly Cycles Off On High Limit Thermostat........21

10. Steam Valve or Burner Does Not Shut-off.................................22

11. Clothes Do Not Dry....................................................................23

12. Tumble Dryer Overheating.........................................................24

13. Burners Not Burning Properly - Gas Models..............................25

14. Loading Door Opens During Operation......................................26

15. Tumble Dryer Runs But No Steam To Coils - Steam Models....27

16. Water In Steam Line - Steam Models.........................................28

17. Tumble Dryer Will Not Start, Time On Drying Timer, Door

Closed..........................................................................................29

18. Motor Runs But Will Not Heat...................................................31

19. Cylinder Turns, But Will Not Heat.............................................32

Section 4 – Adjustments........................................................................34

20. Main Gas Burner Air Inlet Shutters (All Gas Models)...............34

21. Airflow Switch............................................................................35

22. Loading Door Strike....................................................................35

23. Cylinder Belt Tension............. ......... ......... ..................................36

24. Cylinder Clearance............................................................... .......38

25. Drive Belt Tension......................................................................40

26. Fan Belt Tension.........................................................................41

Section 5 – Hybrid Timer Control Troubleshooting..........................43

27. Control Has No Display – OPL Models.....................................44

28. Display Flashes “dr” With Door Closed – OPL Models ............46

29. Motor Will Not Start/Run – OPL Models...................................48

30. Unit Will Not Heat – Gas – OPL Models...................................50

31. Error Codes.................................................................................53

© Copyright 2016, Alliance Laundry Systems LLC.

All rights reserved. No part of the contents of this book may be reproduced or tran smitted in any form or by any means withou t

the expressed written consent of the publisher.

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Section 6 – On Premise Micro Control (RM) Troubleshooting ........54

32. Control Has No Display..............................................................55

33. Door Open Indicator...................................................................57

34. Motor Will Not Start/Run...........................................................60

35. Unit Will Not Heat – Gas/Steam ................................................62

36. Error Codes.................................................................................65

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

Section 1

Danger indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Warning indicat es a hazardous situation

that, if not avoided, could cause severe

personal injury or death.

WARNING

Caution indicates a hazardous situation

that, if not avoided, may cause minor or

moderate personal injury or property

damage.

CAUTION

• Failure to install, maintain and/or operate

this product according to the

manufacturer’s instructions may result i n

conditions which can produce serious

injury, death and/or property damage.

• Do not repair or replace any part of the

product or attempt any servicing unless

specifically recommended or published

in this Service Manual and unless you

understand and have the skills to carry

out the servicing.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

product is properly grounded and to

reduce the risk of fire, electric shock,

serious injury or death.

W006R2

WARNING

Safety Information

Throughout this manual and on machine decals, you

will find precautionary statements (“CAUTION”,

“WARNING”, and “DANGER”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, se rvicer, and those

maintaining the machine.

In the interest of safety, some general precautions

relating to the operation of this machine follow.

Additional precaution ary statements (“IMPORTANT”

and “NOTE”) are followe d by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not follow ed.

NOTE: The word “NOTE” is used to communic ate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Safety Information

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the tumbler

before servicing.

• Never start the tumbler with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

tumbler is properly grounded.

W240

WARNING

Repairs that are made to your products by

unqualified persons can result in hazards

due to improper assembly or adjustments

subjecting you, or the inexperienced

person making such repairs, to the risk of

serious injury, electrical shock, or death.

W007

WARNING

If you or an unqualified person perform

service on your product, you must assume

the responsibility for any personal injury or

property damage which may result. The

manufacturer will not be responsible for

any injury or property damage arising from

improper service and/or service

procedures.

W008

CAUTION

IMPORTANT INFORMATION: During the

lifetime of a tumble dryer, it may require service.

The information contained in this manual was

written and is intended for use by qualified service

technician s who are familiar with the sa fety

procedures required in t he repair of a tumble d ryer,

and who are equipped with the proper tools and

testing equipment.

NOTE: The WARNING and IMPORTANT

instructions appearing in this manual are not meant

to cover all possible conditions and situations that

may occur. It must be understood that common

sense, caution and carefulness are factors which

CANNOT be built into this tumble dryer. These

factors MUST BE supplied by the person(s)

installing, maintaining or operating the tumble

dryer.

Always contact your dealer, distributor, service agent

or the manufacturer on any prob lems or conditions you

do not understand.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

Safety Information

Locating an Authorized Service Person

Alliance Laundry Systems is not responsible for

personal injury or propert y dama ge res ulting from

improper service. Review all service information

before beginning repairs.

Warranty service must be performed by an

authorized technician, using authorized factory

parts. If service is required after the warranty

expires, Alliance Laundry Systems also

recommends contacting an authorized technician

and using authorized factory parts.

Safety Warnings and Decals

SAFETY WARNINGS and decals have been provided

in key locations to re mind you of important prec autions

for the safe ope ra ti on a nd mai nt ena nce of your tumble

dryer. Please take the time t o review these warnings

before proceeding with service work.

All decals have been desig ned and applied to withst and

washing and cleaning. Decals should be checked

periodically to be sure they have not been damaged,

removed, or painted. Refer to the Parts Manual for

ordering replacement decals.

Safety Precautions for Servicing Tumble Dryers

Disconnect electrical service.

Shut off supply gas valve before servicing gas

components.

Access panel MUST be reinstalled after

inspection or servicing of tumble dryer is

completed.

Use a non-corrosive leak detecting compound

to check all pipe connect ions for ga s leaks. DO

NOT USE AN OPEN FLAME TO CHECK

FOR GAS LEAKS!

Belt guard MUST be reinstalled after

inspection or servicing of tumble dryer is

completed.

Contactor box cover MUST be reinstalled

after inspection or servicing of electric and/or

reversing tumble dryer is completed.

Loading door switch MUST be operational

before putting tumble dryer into service.

Junction box cover MUST be rein sta ll ed aft er

inspection or servicing of tumble dryer is

completed.

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Section 2

Introduction

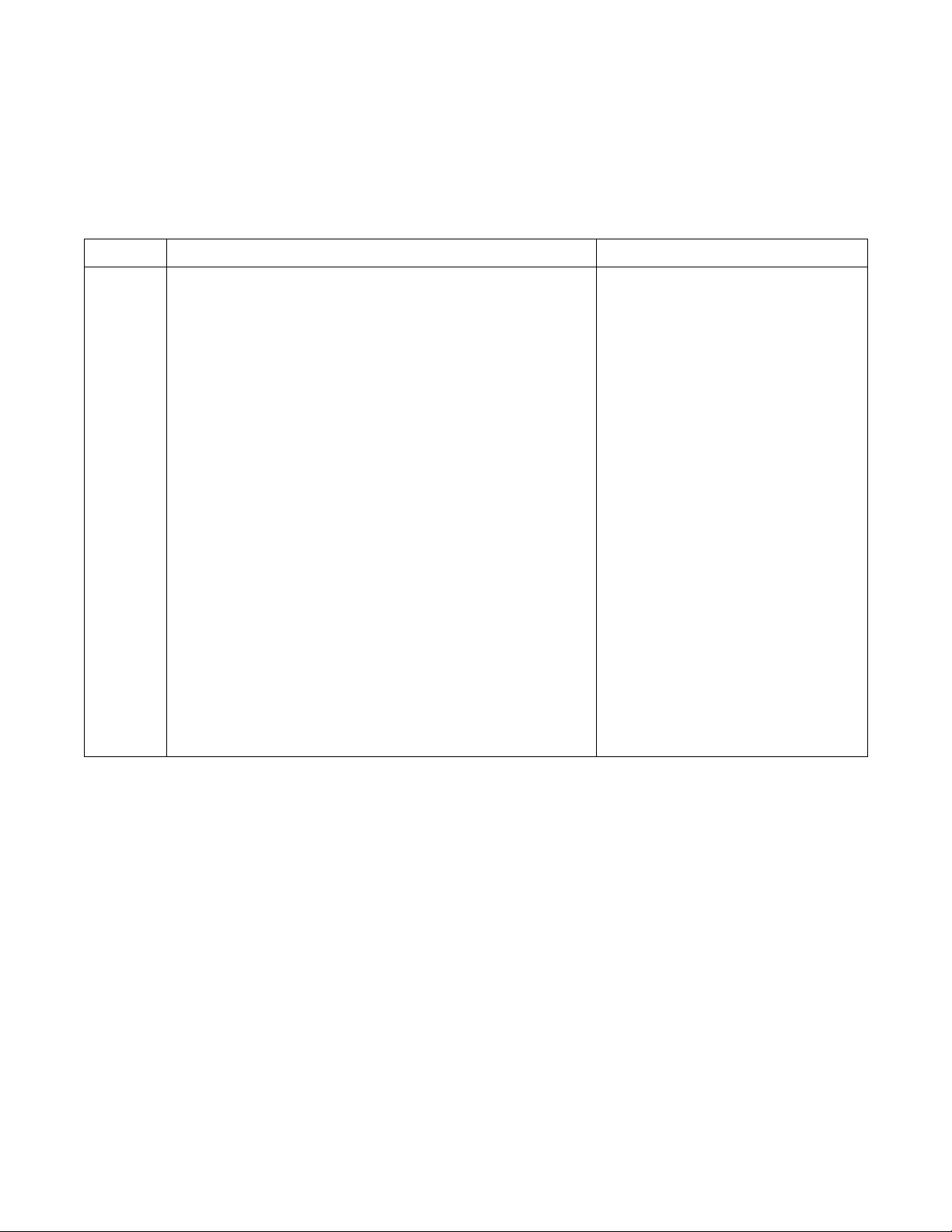

Model Identification

Information in this manual is applicable to these models :

Gas Steam/Thermal Oil

HT120L

HT120N

HU120L

HU120N

IPD120G2-IT120L

IPD120G2-IT120N

KA120L

KA120N

KT120L

KT120N

KU120L

KU120N

LA120L

LA120N

LT120L

LT120N

LU120L

LU120N

PA120L

PA120N

PT120L

PT120N

120

Pound

AT120L

AT120N

CA120L

CA120N

CT120L

CT120N

CU120L

CU120N

DR120G2-BA120L

DR120G2-BA120N

DR120G2-BT120L

DR120G2-BT120N

DR120G2-BU120L

DR120G2-BU120N

GA120L

GA120N

GT120L

GT120N

GU120L

GU120N

HA120L

HA120N

PU120L

PU120N

SA120L

SA120N

ST120L

ST120N

SU120L

SU120N

UA120L

UA120N

UT120L

UT120N

UU120L

UU120N

WT120L

WT120N

XT120L

XT120N

XU120L

XU120N

YT120L

YT120N

AT120S

CT120S

CT120T

CU120S

CU120T

DR120S2-BT120S

DR120S2-BT120T

DR120S2-BU120S

DR120S2-BU120T

GT120S

GT120T

GU120S

GU120T

HT120S

HT120T

HU120S

HU120T

IPD120S2-IT120S

IPD120S2-IT120T

KT120S

KT120T

KU120S

KU120T

LT120S

LT120T

LU120S

LU120T

PT120S

PT120T

PU120S

PU120T

ST120S

ST120T

SU120S

SU120T

UT120S

UT120T

UU120S

UU120T

WT120S

WT120T

XT120S

XT120T

XU120S

XU120T

YT120S

YT120T

YU120S

YU120T

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

170

Pound

AT170L

AT170N

CA170L

CA170N

CT170L

CT170N

CU170L

CU170N

DR170G2-BA170L

DR170G2-BA170N

DR170G2-BT170L

DR170G2-BT170N

DR170G2-BU170L

DR170G2-BU170N

GA170L

GA170N

GT170L

GT170N

GU170L

GU170N

HA170L

HA170N

Gas Steam/Thermal Oil

HT170L

HT170N

HU170L

HU170N

IPD170G2-IT170L

IPD170G2-IT170N

KA170L

KA170N

KT170L

KT170N

KU170L

KU170N

LA170L

LA170N

LT170L

LT170N

LU170L

LU170N

PA170L

PA170N

PT170L

PT170N

PU170L

PU170N

SA170L

SA170N

ST170L

ST170N

SU170L

SU170N

UA170L

UA170N

UT170L

UT170N

UU170L

UU170N

WT170L

WT170N

XT170L

XT170N

XU170L

XU170N

YT170L

YT170N

AT170S

CT170S

CT170T

CU170S

CU170T

DR170S2-BT170S

DR170S2-BT170T

DR170S2-BU170S

DR170S2-BU170T

GT170S

GT170T

GU170S

GU170T

HT170S

HT170T

HU170S

HU170T

IPD170S2-IT170S

IPD170S2-IT170T

KT170S

KT170T

KU170S

KU170T

LT170S

Introduction

LT170T

LU170S

LU170T

PT170S

PT170T

PU170S

PU170T

ST170S

ST170T

SU170S

SU170T

UT170S

UT170T

UU170S

UU170T

WT170S

WT170T

XT170S

XT170T

XU170S

XU170T

YT170S

YT170T

Includes models with the following control suffixes:

R3 – reversing DX4 OPL RQ – reversing dual digital timer

RD – reversing DMP OPL RT – reversing manual timer

RM – reversing OPL micro

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Introduction

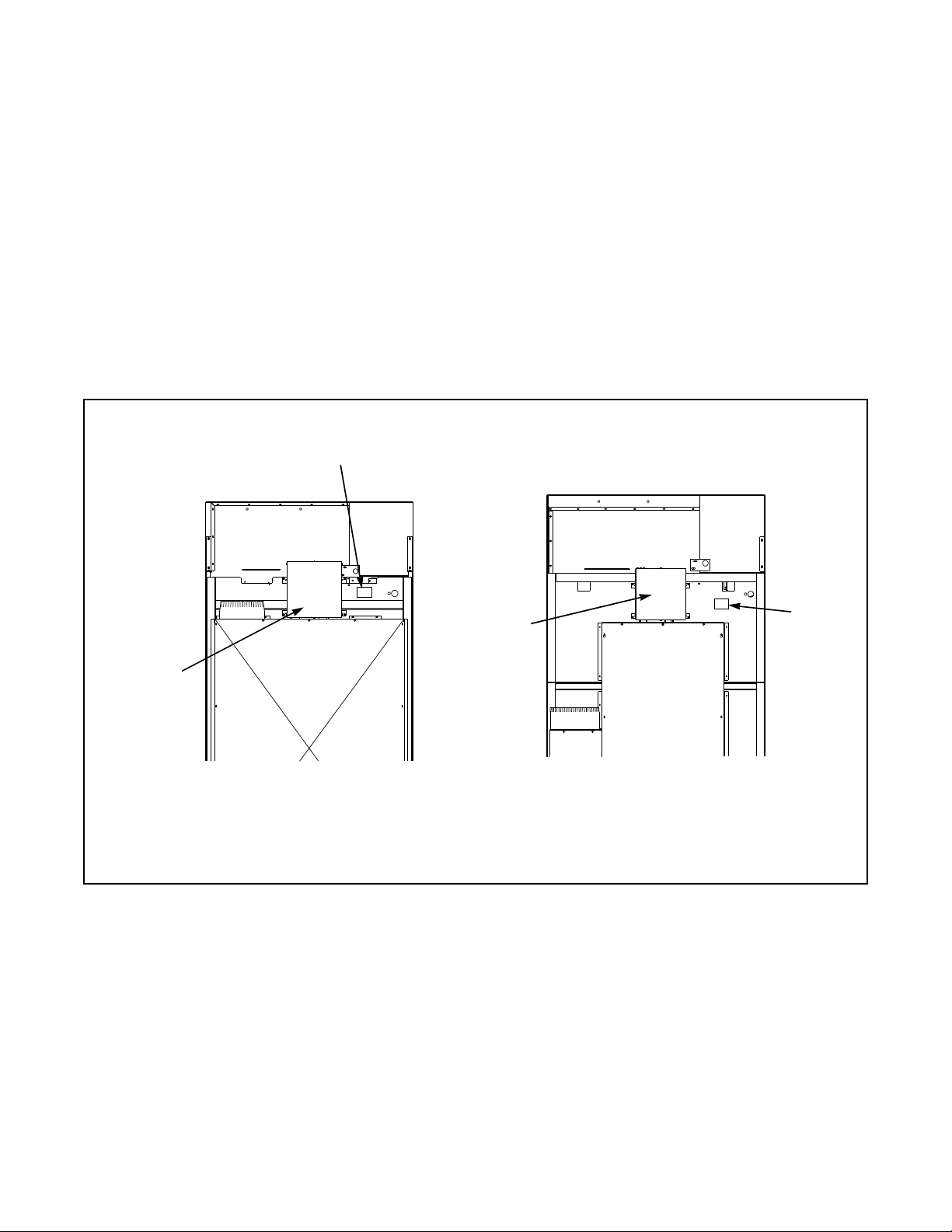

TMB1764S

120 Pound

Junction

Box

Cover

Serial

Plate

TMB1765S

Serial

Plate

Junction

Box

Cover

170 Pound

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

Serial Plate Location

When calling or wri ting about your p rodu ct, be sure to

mention model and serial numbers. Model and serial

numbers are located on serial plate as shown.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

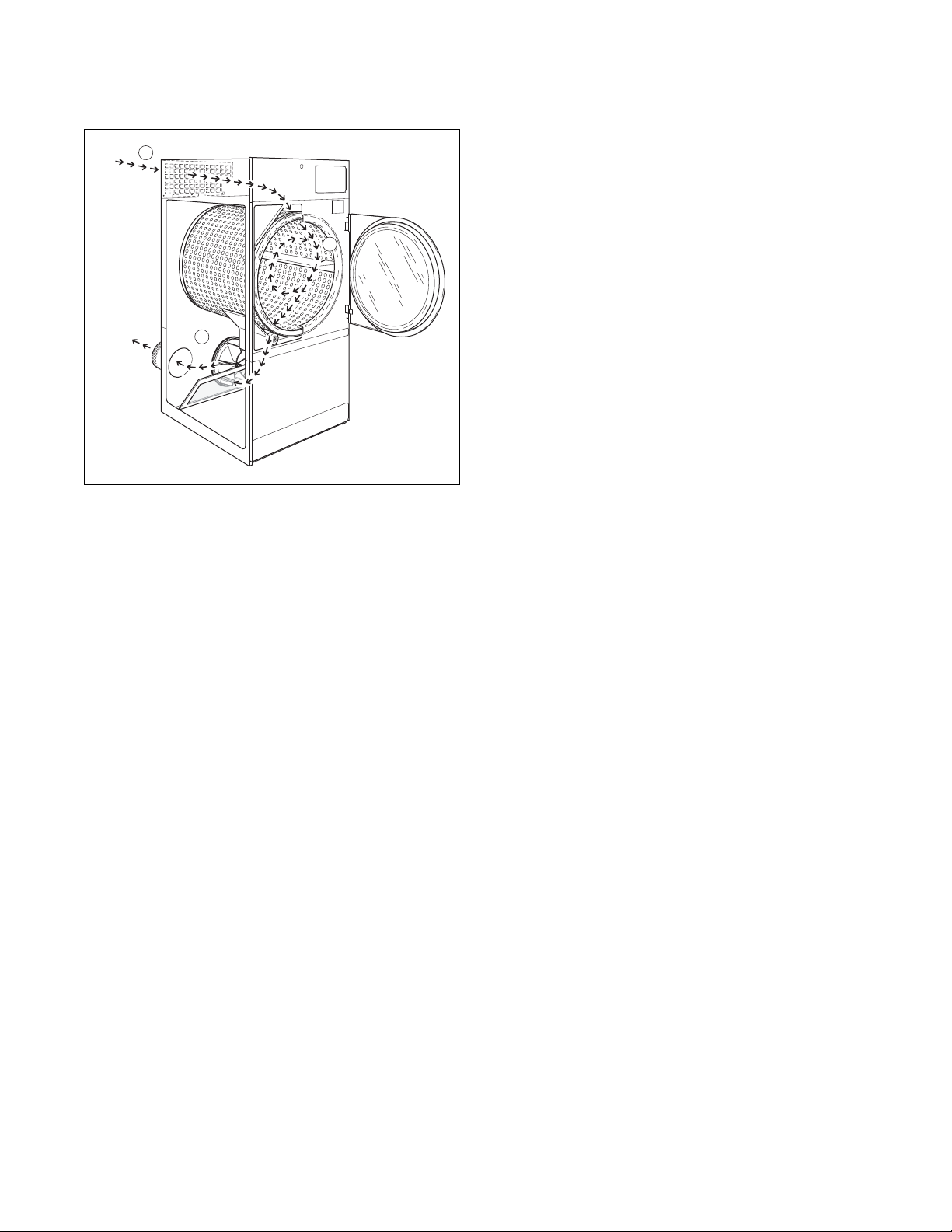

How a Tumble Dryer Works

1

2

3

Introduction

A tumble dryer uses heated air to dry loads of laundry.

① When the motor is started, the exhaust fan pulls

room temperature air in through the air intake at

the rear of the tumble dryer and over the heat

source (burner flame f or gas , heatin g elem ent for

electric, and coil for steam).

② The heated air moves into the cylinder, where it is

circulated through the wet load by the tumbling

action of the cylinder.

③ The ai r t hen passes through the lint filter, exha ust

fan, and is vented to the outdoors.

TMB2347S

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

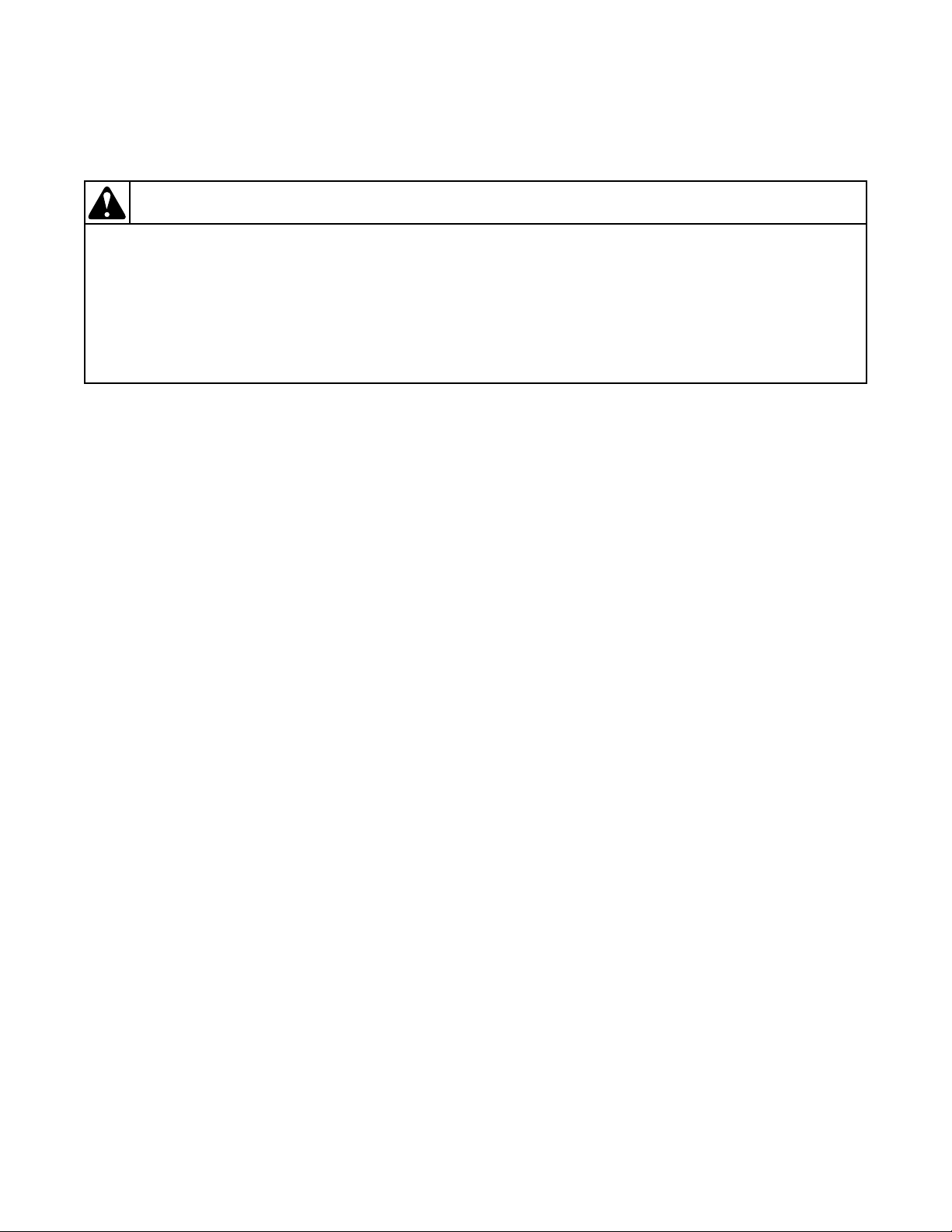

Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumble dryer before servicing.

• Close gas shut-off valve to gas tumble dryer before servicing.

• Close steam valve to steam tumble dryer before servicing.

• Never start the tumble dryer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumble dryer is properly grounded.

W002R1

WARNING

IMPORTANT: Refer to appropriate wiring

diagram for aid in testing tumble dryer

components.

Section 3

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

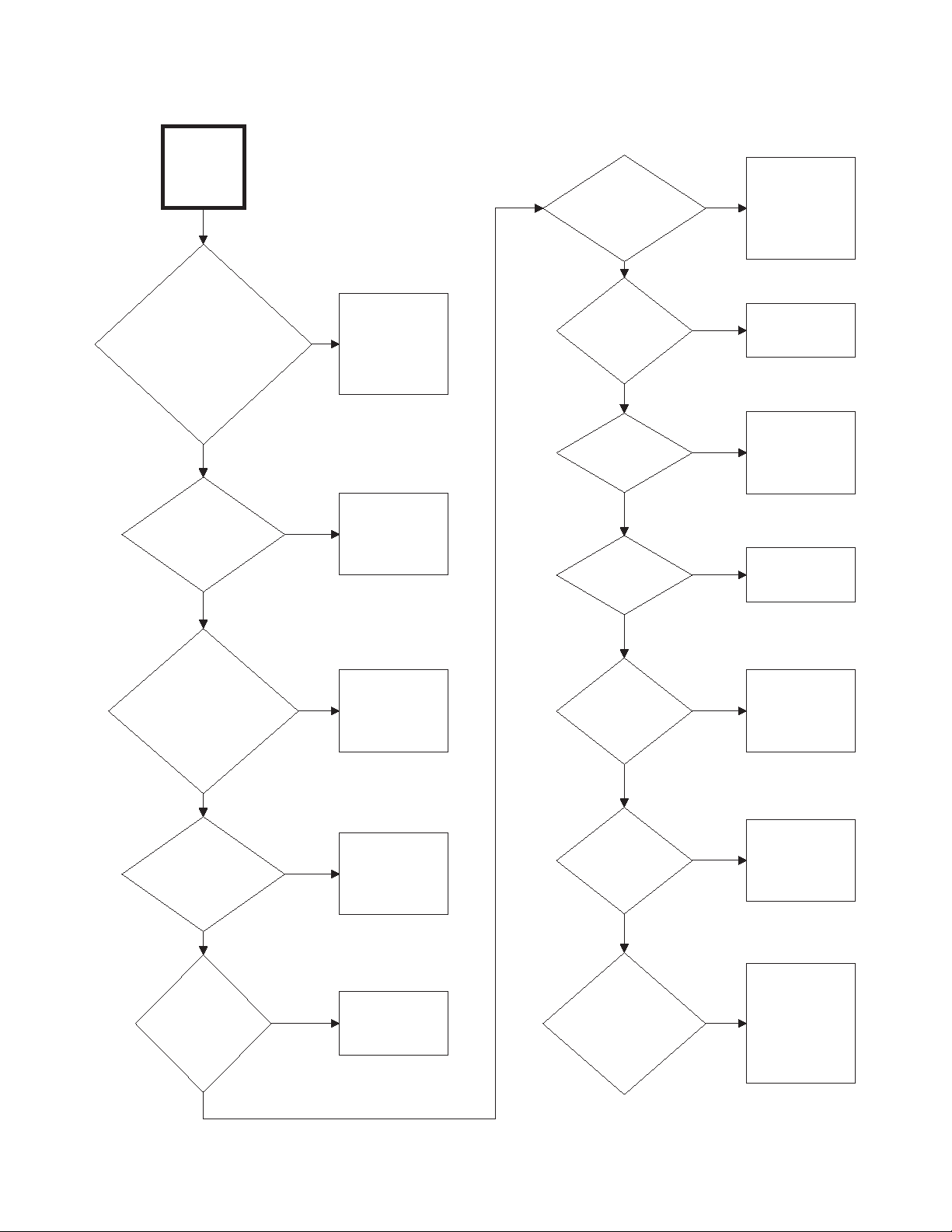

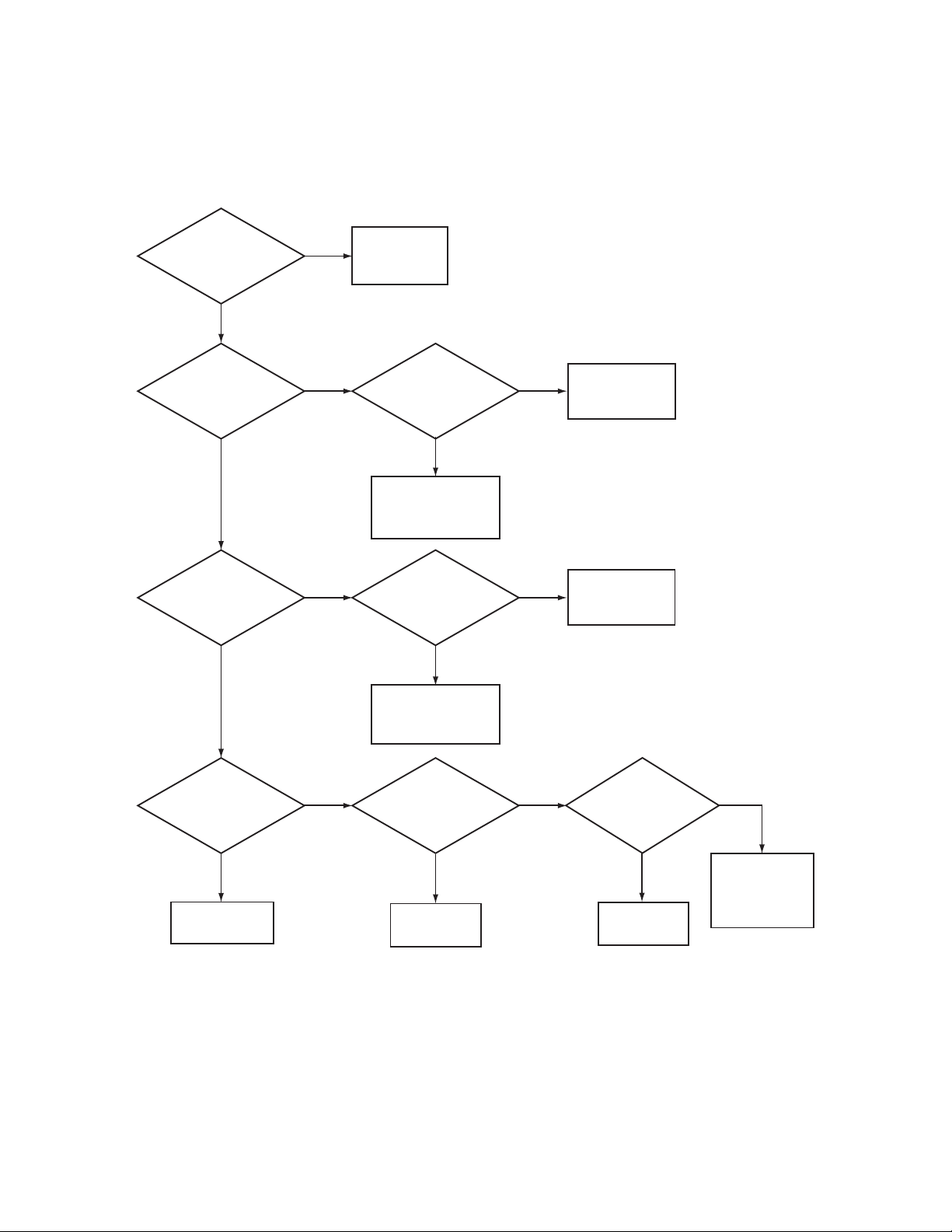

1. Motor Does Not Start

Motor does

not start

Is electrical power

off, has circuit

breaker tripped or

has control fuse

blown?

Check service

to tumbler.

Check primary

and secondary

fuses.

Is transformer

inoperative?

Replace

transformer.

Is loading door

open or is door

switch

inoperative?

Close door or

test switch and

replace if

inoperative.

Is lint panel

switch not

closing?

Test lint panel

switch, replace

if inoperative.

TMB1918S

Are trunnion

bearings

binding?

Replace

trunnion

bearings.

Is start circuit

not

completed?

Press start

switch or test

switch and

replace if

inoperative.

Are idler

bearings

binding?

Replace

bearings.

Is motor

inoperative?

Have motor

tested and

replace if

inoperative.

Is relay

inoperative?

Replace relay.

Is timer

improperly

set?

Turn drying

timer clockwise

to desired

setting.

Is timer

inoperative?

Test timer and

replace if

inoperative.

Is there

broken, loose

or incorrect

wiring?

Refer to wiring

diagram

located on

back of tumbler

or in literature

packet.

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

Troubleshooting

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

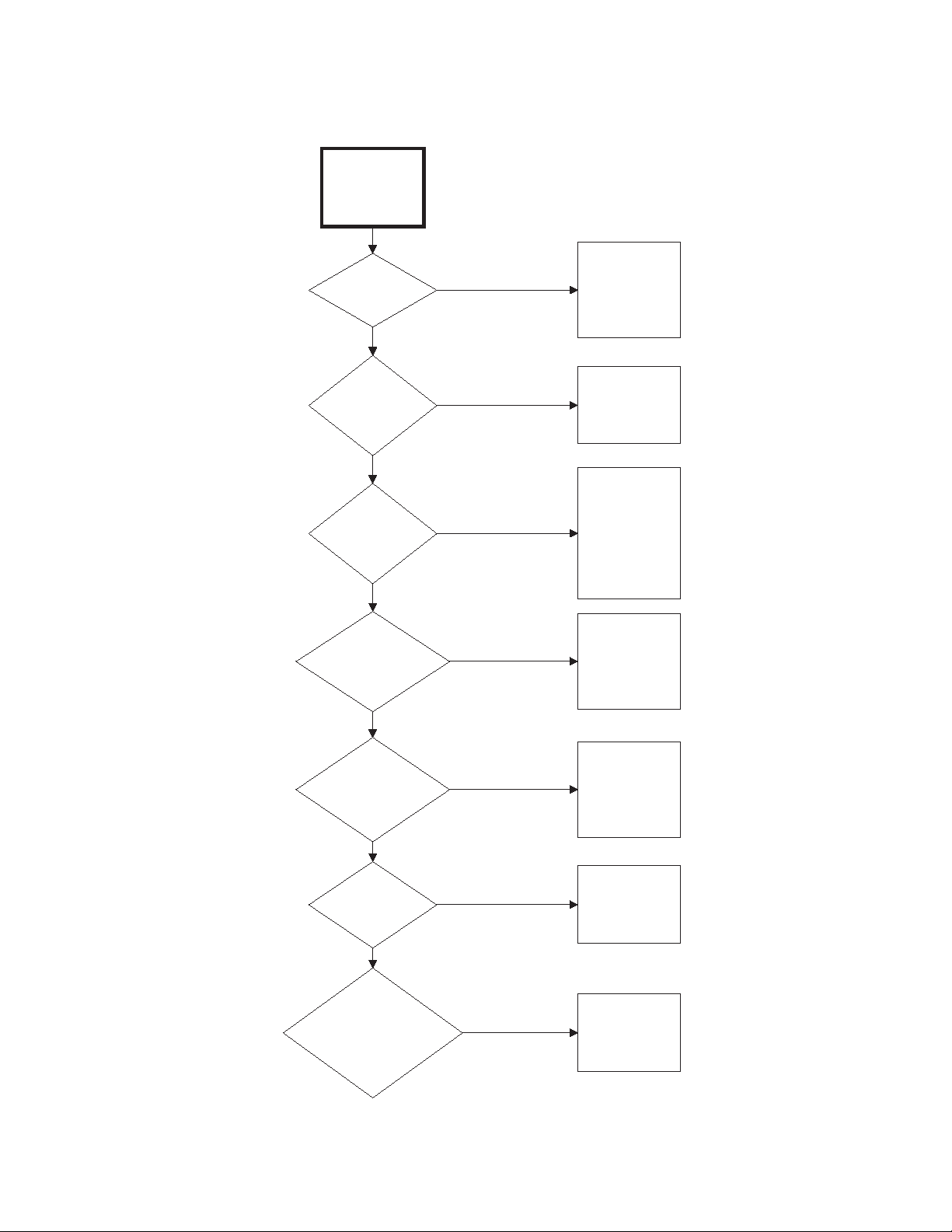

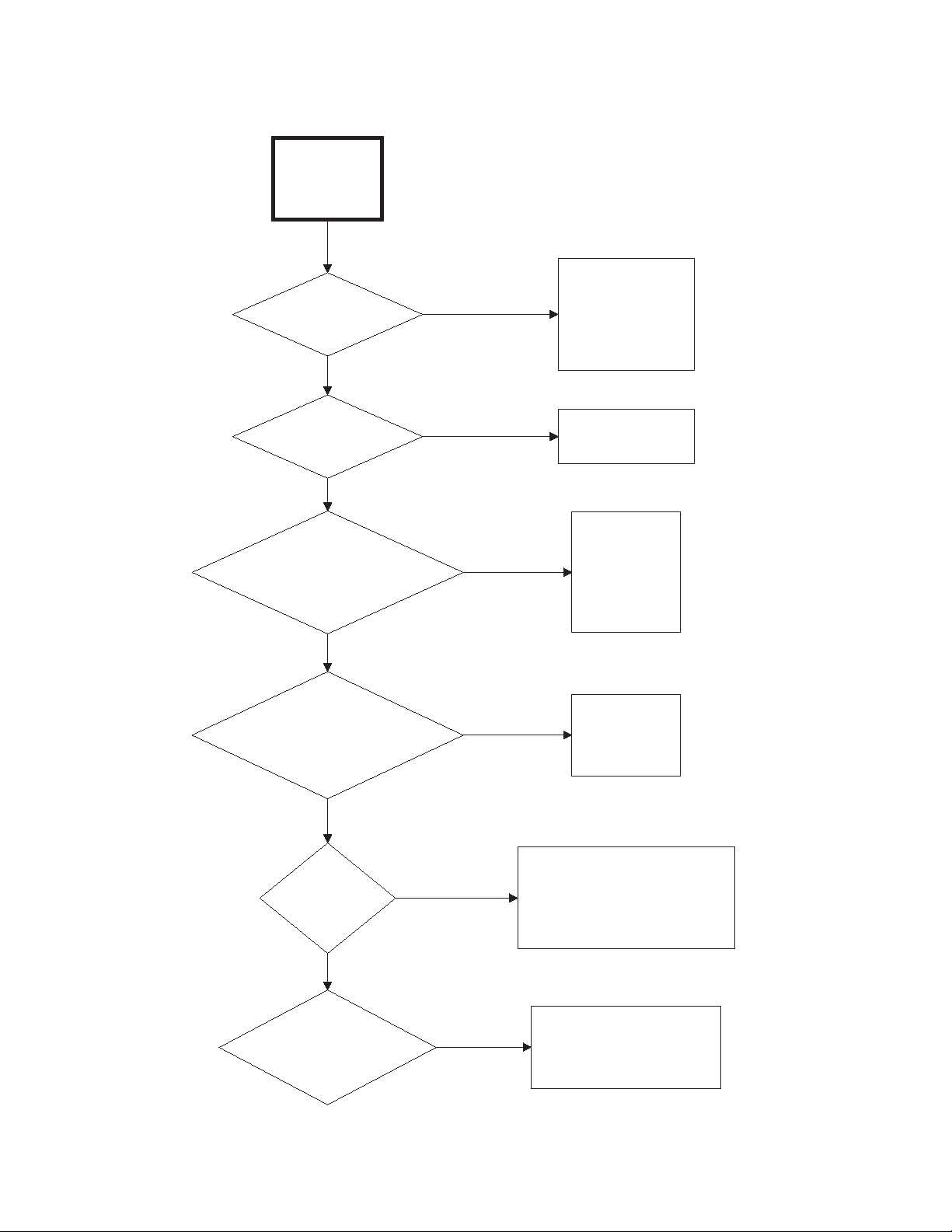

Troubleshooting

Motor overload

protector

cycles

repeatedly

Is voltage

incorrect?

Refer to the

Installation

Manual for

electrical

requirements.

Is clothes

load too

large?

Remove part of

load.

Is clothes

cylinder

binding?

Check cylinder

for binding.

Refer to

Adjustments

Section for

cylinder

adjustment.

Is wiring

inadequate?

Check with an

electrician to

ensure that

wiring is

adequate.

Is make-up

air

inadequate?

Refer to

Installation

Manual for

make-up air

requirements.

Has lint

built up?

Clean lint

accumulation

on and around

motor.

Is there broken,

loose or

incorrect wiring?

Refer to wiring

diagram

located inside

contactor box.

TMB1874S

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

2. Motor Overload Protector Cycles Repeatedly

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

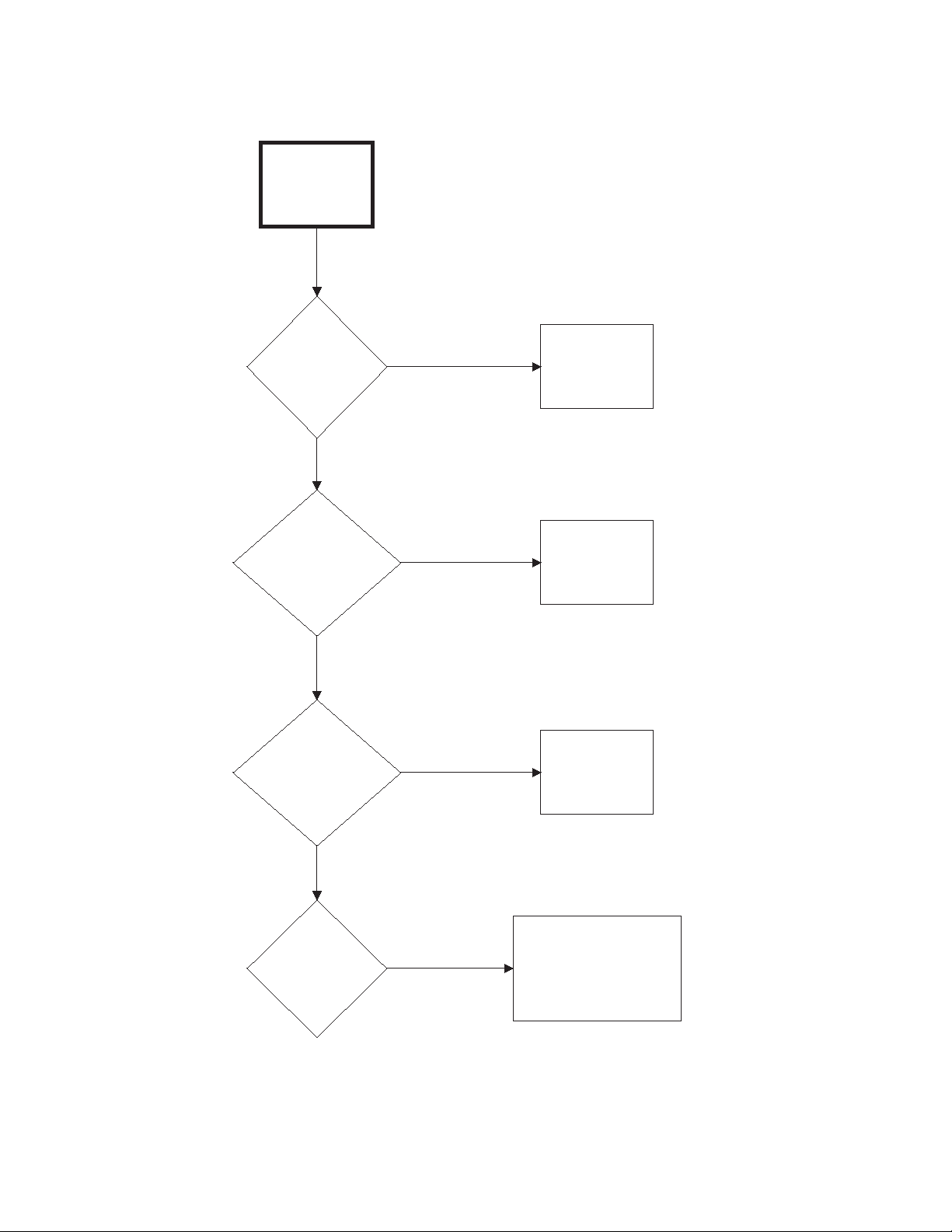

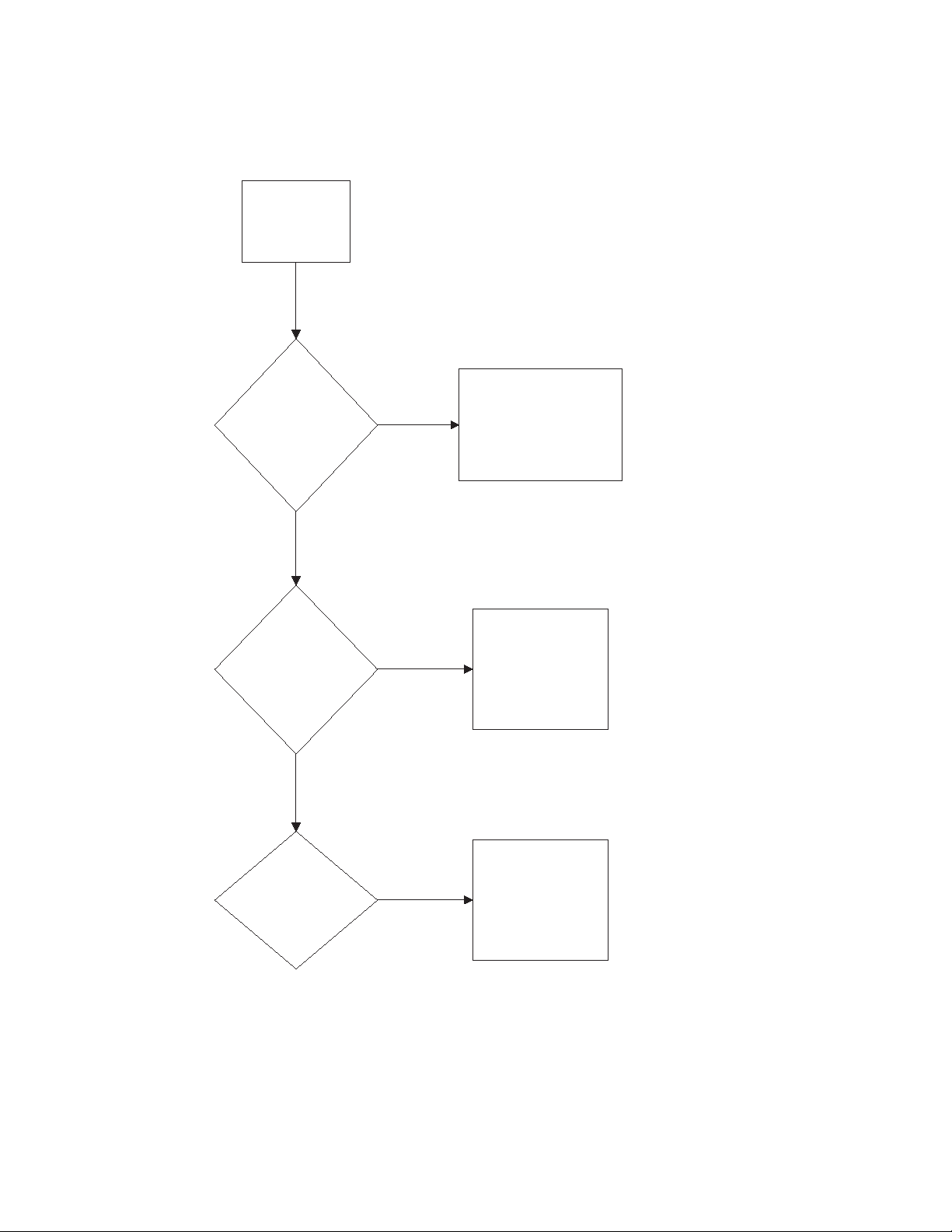

3. Motor Runs But Cylinder Does Not Turn

Motor runs but

cylinder does

not turn

Troubleshooting

Is motor

drive pulley

loose?

No

Are cylinder

belts broken

or loose?

No

Is drive belt

broken or

loose?

Ye s

Ye s

Ye s

Tighten drive

pulley bushing

screws.

Replace or

adjust belts.

Replace or

adjust belt.

70399901

No

Check cylinder for

Is cylinder

binding?

Ye s

binding. Refer to

Adjustments Section

for proper cylinder

adjustment.

TMB1919S

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

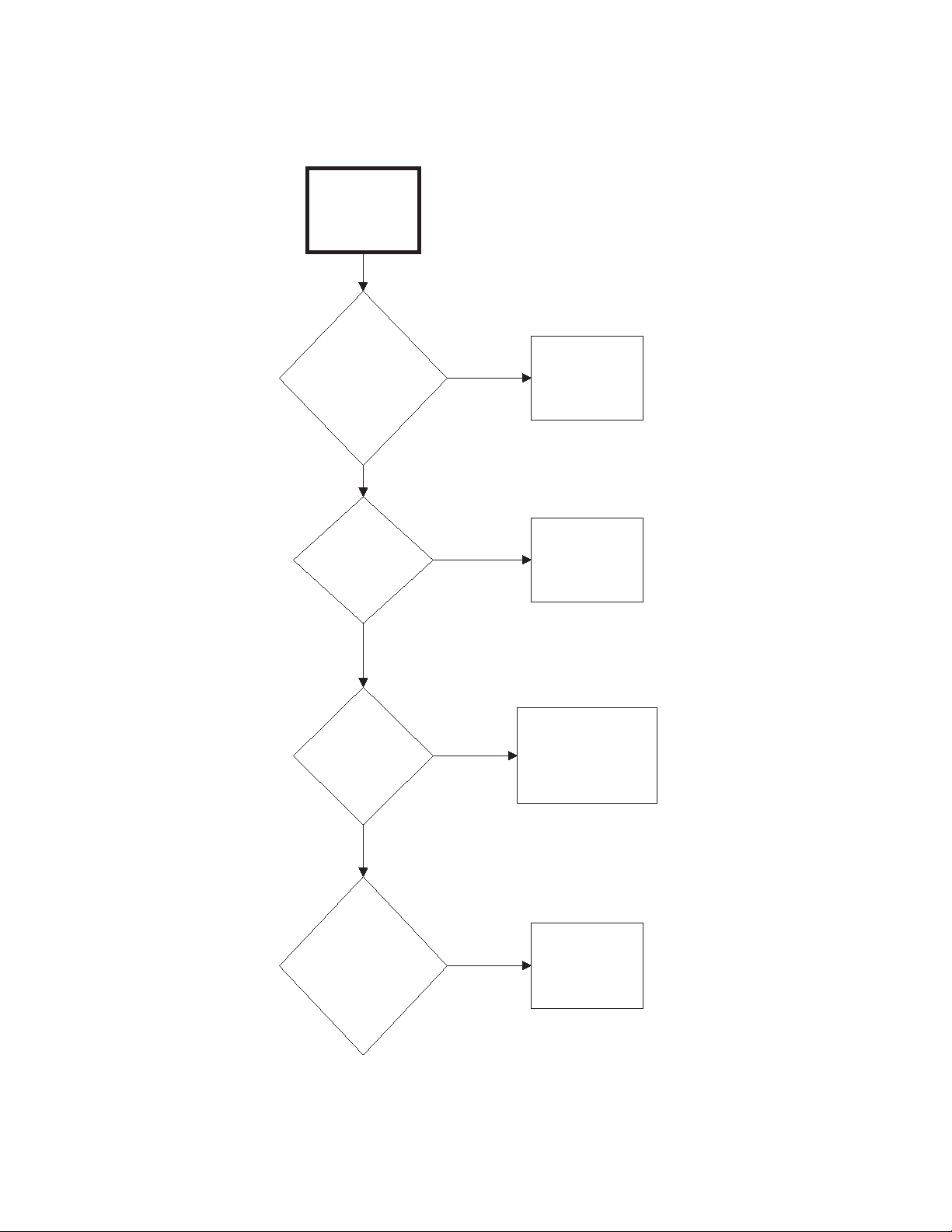

Troubleshooting

Motor does not

stop

Is door switch

or lint panel

switch

inoperative?

Test switches

and replace if

inoperative.

Is timer

inoperative?

Test timer and

replace if

inoperative.

Is motor

contactor

inoperative?

Test motor

contactor and

replace if

inoperative.

TMB1920S

Yes

No

Yes

Yes

Is wiring

incorrect?

Refer to wiring

diagram located on

back of tumbler or

in literature packet.

Yes

No

No

4. Motor Does Not Stop

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

5. No Heat Condition (Non-CE and Non-Australian Models)

Ignition Control Module Function

There are four comp onents to the igni tion system :

the module, the spark ignitor, the high voltage

cable and ground wire. When 24 VAC is applied

between the TH and GND terminals on the

module, the module will send the high voltage

signal to the igniter and 24 VAC to the gas valve

coils. Gas will hit the sparking igniter and flame

will be established. The igniter being engulfed in

flame will create a millivolt electric signal that is

sent back to the modu le by the hig h voltage cable;

this is what th e mod ule sees as fl ame recogn ition .

If the millivolt signal is not at the module in ten

seconds, the module will go into safety lockout.

The voltage will be cut from the igniter and gas

valve coils and will not be stored until voltage is

cycled at the module.

Intermittent Heat Test Procedure

On ignition control modules with date codes

higher than 08t2, perform the following test.

Troubleshooting

Start the tumble dryer and run for 10 minutes

(verify that the tumble dryer is heating properly).

After the 10 minute cycle, re-start the tumble

dryer and once again verify the unit is heating.

Repeat this proc edure 3 tim es. If th e tumble dryer

passes this test, the ignition control module is

operating properly and SHOULD NOT be

changed. Refer to SECTION 3 for additional

service procedures.

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

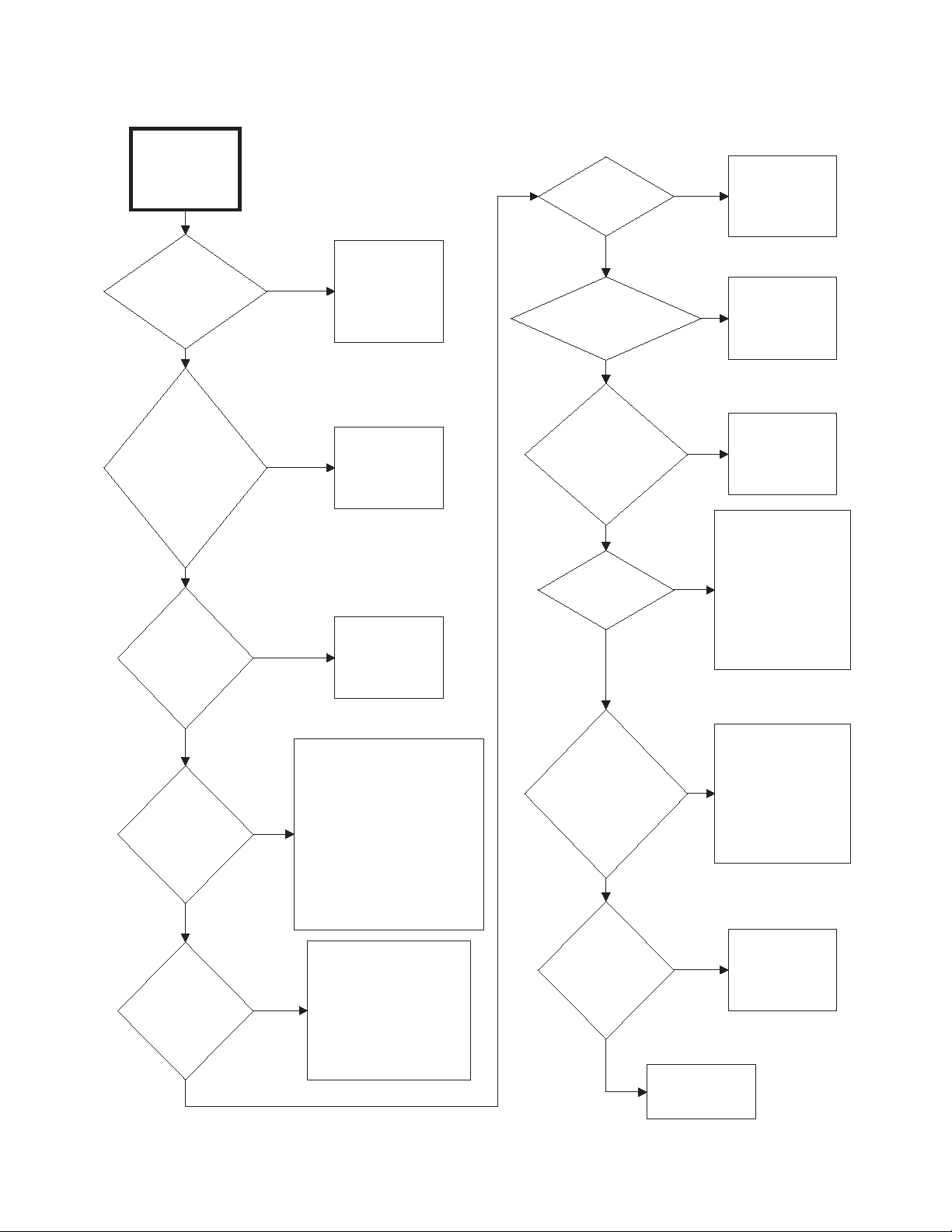

Troubleshooting

5. No Heat Condition (Non-CE and Non-Australian Models) (continued)

Is the Ignition Control

Module’s red light on?

Yes

Does the igniter

spark?

Yes

Does the igniter

spark but no

flame is produced?

No

Yes

No

No

Refer to

Burner Shuts off

Prematurely

paragraph.

Is there

24 volts AC between

the TH and GND terminals

on the module?

Yes

Replace igniter and high

voltage lead. Retest unit. If

unit still does not spark,

replace module.

Is there

24 volts AC at the gas

valve coils when igniter

is sparking?

Yes

Refer to Burner Shuts

No

circuit troubleshooting.

Check wiring between

No

gas valve and module.

off Prematurely

paragraph for heat

If wiring is good,

replace module.

Does the flame turn

off after igniter

stops sparking?

No

Replace module.

Yes

Verify that gas is supplied

to the machine. If gas and

voltage are present,

replace gas valve or coils.

Is the igniter

positioned properly

in the flame, and does the

flame look good?

No

Adjust position of

igniter and retest.

Yes

Is there continuity

between GND terminal on

module and machine?

No

Verify machine is

properly grounded.

Yes

Replace igniter and

high voltage lead.

Retest unit. If it still

does not sense flame,

replace module.

TMB2411S

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

6. Gas Burner Does Not Ignite

Gas burner

does not ignite

Is exhaust

system

inadequate?

Refer to the

Installation

Manual for

exhaust system

requirements.

Is drying timer

not selected

or

inoperative?

Set drying

timer or replace

if inoperative.

Is

thermostat

inoperative?

Test thermostat

and replace if

inoperative.

Is gas

supply

insufficient?

Open partially closed gas

shut-off valve or correct low

gas pressure. Check

manifold pressure and

adjust to pressure specified

on serial plate. If pressure

cannot be obtained, have

gas supplier check main

pressure.

Are orifices

incorrect?

Tumbler is equipped for

type of gas specified on

serial plate. If orifices

are different from that

specified on serial

plate, obtain and install

proper orifices.

TMB1921S-a

Is igniter

inoperative?

Test igniter and

replace if

inoperative.

Is igniter control

inoperative?

Test igniter

control and

replace if

inoperative.

Are gas valve

coils

inoperative?

Test coils and

replace if

inoperative.

Is there lint

buildup?

Clean lint

compartment after

every eight-hour

shift. Check back

draft damper for lint

accumulation.

Check ductwork for

lint build-up.

Is make-up

air or

ductwork

inadequate?

Refer to

Installation

Manual to ensure

that ductwork and

make-up air

openings are sized

properly.

Is airflow

switch

inoperative?

Test switch and

replace if

inoperative.

Continued on

next page.

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Troubleshooting

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Troubleshooting

TMB1921S-b

Continued from

previous page.

Is lint door

panel not

closed

properly?

Open lint door panel,

place lint door and

panel back on tumbler

(ensuring a tight fit).

Is there

broken, loose

or incorrect

wiring?

Refer to wiring

diagram located on

back of tumbler or

in literature packet.

Is there

improper fan

rotation?

May be due to

improper wiring

resulting in low

airflow. Refer to

Installation

Manual.

Yes

No

Yes

No

Yes

6. Gas Burner Does Not Ignite (continued)

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70399901

7. Burner Ignites and Goes Out Repeatedly

Burner ignites

and goes out

repeatedly

Is gas pressure

insufficient?

Check gas supply

and pressure. Low

flame will not

maintain sensor

conductivity.

Are burner ports

plugged?

Check burner tubes

for build-up.

Is exhaust system or

make-up air

inadequate?

Refer to

Installation

Manual for

exhaust and

make-up air

requirements.

Is high limit or cabinet

limit thermostat

inoperative?

Test thermostat

and replace if

inoperative.

TMB1922S

Are orifices

improper?

Tumbler is equipped for type of

gas specified on serial plate. If

orifices are different from that

specified on serial plate, obtain

and install proper orifices.

Is flame recognition

circuit improper?

Replace high voltage lead.

Replace igniter.

Replace ignition control

module.

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

Troubleshooting

70399901

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Loading...

Loading...