Huebsch YU075T Tumbler-Dryer Parts Diagram

Tumble Dryers

TMB795C

50 Pound Capacity

75 Pound Capacity

Starting Serial No. 0904004427

Refer to Page 7 for Model Numbers

Troubleshooting

www.alliancelaundry.com

TMB795C

Part No. 70422101R1

April 2013

Table of

Contents

Section 1 – Safety Information .......................................................... 5

Locating an Authorized Service Person ............................................... 7

Safety Warnings and Decals................................................................. 7

Safety Precautions for Servicing Tumblers .......................................... 7

Section 2 – Introduction ..................................................................... 8

Model Identification ............................................................................. 8

Serial Plate Location............................................................................. 11

Customer Service.................................................................................. 11

Wiring Diagram .................................................................................... 11

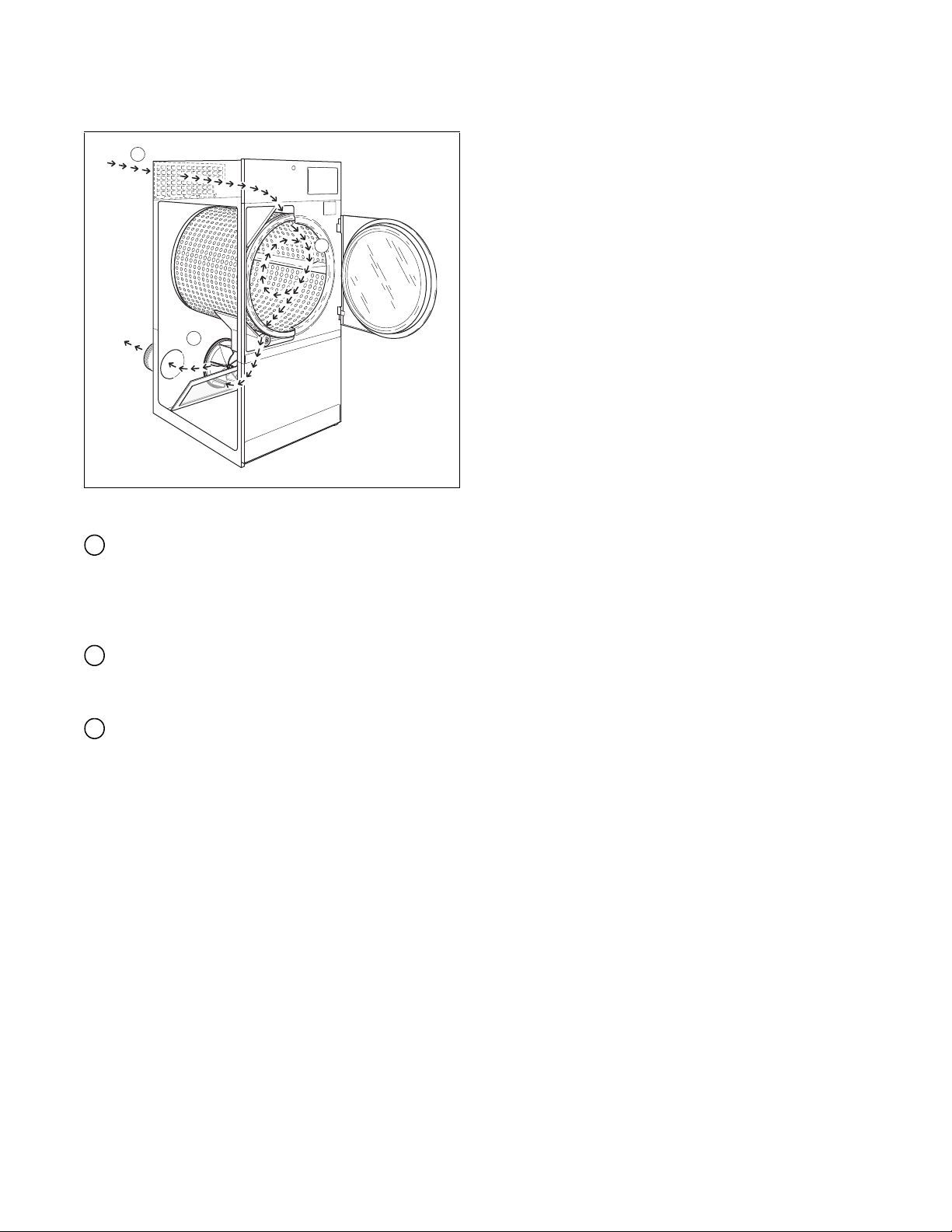

How a Tumble Dryer Works ................................................................ 12

Theory of Operation of Instant Electronic Ignition .............................. 12

Theory of Operation ............................................................................. 13

Temperature Sensor .............................................................................. 14

Section 3 – Troubleshooting............................................................... 16

1. Motor Does Not Start............................................................... 17

2. Motor Overload Protector Cycles Repeatedly ......................... 18

3. Motor Runs But Cylinder Does Not Turn................................ 19

4. Motor Does Not Stop ............................................................... 20

5. No Heat Condition (Non-CE and Non-Australian

Models) .................................................................................... 21

6. Heating Element Does Not Heat or Burner Does

Not Ignite ................................................................................. 23

7. Igniter Does Not Shut Off After Gas Ignition —

Gas Burner ............................................................................... 25

8. Heating Element or Burner Shuts Off Prematurely ................. 26

9. Heating Element or Burner Repeatedly Cycles Off

On High Limit Thermostat ............................................................... 27

10. Heating Element or Burner Does Not Shut-Off....................... 28

11. Clothes Do Not Dry ................................................................. 29

12. Tumble Dryer Overheating ...................................................... 30

13. Burners Not Burning Properly — Gas Models........................ 31

14. Loading Door Opens During Operation................................... 32

15. Tumble Dryer Runs But No Steam To Coils —

Steam Models........................................................................... 33

16. Water In Steam Line — Steam Models ................................... 34

17. Door Open Light and Display Flash With Door Closed ......... 35

18. Display Shows “SH” and Signals Sounds ............................... 36

19. Display Shows “OP” and Signal Sounds Three Minutes

After Tumble Dryer is Started ................................................ 37

20. Motor Runs, Time on Drying Timer But No Heat................... 38

21. No Main Burner Flame, Igniter Does Not Spark..................... 40

22. Steam OM Control: No Heat With Cycle Selected,

Unit Running and Calling For Heat ......................................... 41

23. OM and RM Control: No Start With Cycle Selected,

Start Button Pressed and Door Closed..................................... 42

© Copyright 2013, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

70422101R1 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

24. OM Control: No Display After Selecting One

of the ON/SELECT Keys......................................................... 44

25. Electric OM Control: No Heat With Cycle Selected,

Unit Running and Calling For Heat ......................................... 45

26. Gas OM Control: No Heat With Cycle Selected,

Unit Running and Calling For Heat ......................................... 47

27. OM Control: No Fan Motor Rotation With Cycle

Selected and Start Pressed........................................................ 49

28. OM Reversing Control: No Cylinder Rotation

or Reversing Capabilities......................................................... 51

29. Coin Does Not Fall into Coin Vault or Coin Drop

Sensor Does Not Register that Coin Has Been Entered ................... 53

30. Cylinder Is “Stained” ............................................................... 56

Section 4 – Fire Supression System Troubleshooting...................... 57

31. Tumble Dryer Does Not Operate and Light Is On................... 58

32. Water Discharge, but No Fire .................................................. 59

33. Tumble Dryer Does Not Operate and Light Is Off .................. 60

34. Tumble Dryer Operates, but Water Does Not

Discharge and Light Is On ....................................................... 61

Section 5 – Adjustments ..................................................................... 63

35. Main Gas Burner Air Inlet Shutters (Gas Models) .................. 63

36. Airflow Switch......................................................................... 64

37. Loading Door Switch............................................................... 64

38. Loading Door Catch................................................................. 65

39. Aligning Door Strike................................................................ 65

40. Drive Belt Tension................................................................... 66

41. Cylinder Clearance................................................................... 69

42. Cleaning Coin Drop ................................................................. 70

Section 6 – Micro Display Control (MDC) Troubleshooting.......... 73

43. Coins Ignored When Entered................................................... 73

44. Control Has No Display........................................................... 74

45. Door Open Indicator ................................................................ 76

46. Motor Will Not Start/Run ........................................................ 78

47. Unit Will Not Heat – Gas......................................................... 81

48. Unit Will Not Heat – Steam..................................................... 84

49. Unit Will Not Heat – Electric .................................................. 87

50. Error Codes .............................................................................. 90

Section 7 – NetMaster Troubleshooting –

KT075 Models Only............................................................................ 91

51. No Infrared Communication .................................................... 92

52. Coins Ignored When Entered................................................... 93

53. No Display ............................................................................... 94

54. “Door Open” Indicator............................................................. 96

55. No Start/Run ............................................................................ 98

56. Unit Will Not Heat – Gas......................................................... 100

57. Unit Will Not Heat – Steam..................................................... 103

58. Unit Will Not Heat – Electric .................................................. 105

2 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

59. CE Models No Display ............................................................ 108

60. CE Models “Door Open” Indicator.......................................... 110

61. CE Models No Start/Run ......................................................... 112

62. CE Models Will Not Heat – Gas.............................................. 114

63. CE Models Will Not Heat – Steam.......................................... 117

64. CE Models Will Not Heat – Electric ....................................... 119

Section 8 – On Premise Micro Control (OM) Troubleshooting ..... 122

65. Control Has No Display........................................................... 123

66. Door Open Indicator ................................................................ 125

67. Motor Will Not Start/Run ........................................................ 127

68. Unit Will Not Heat – Gas......................................................... 130

69. Unit Will Not Heat – Steam..................................................... 133

70. Unit Will Not Heat – Electric .................................................. 135

71. Error Codes .............................................................................. 138

Section 9 – Hybrid Timer Control Troubleshooting ....................... 139

72. Coins Ignored When Entered................................................... 140

73. Control Has No Display – QT and RQ Control Suffixes......... 141

74. Display Flashes “dr” With Door Closed –

QT and RQ Control Suffixes1 ................................................. 43

75. Vend Satisfied, No In Use LED –

SD and SX Control Suffixes1 .................................................. 46

76. In Use LED Lit, No Motor Run –

SD and SX Control Suffixes1 .................................................. 49

77. Motor Will Not Start/Run – SD and SX Control Suffixes....... 151

78. Motor Will Not Start/Run – QT and RQ Control Suffixes...... 153

79. Unit Will Not Heat – Gas – SD and SX Control Suffixes ....... 155

80. Unit Will Not Heat – Gas – QT and RQ Control Suffixes ...... 158

81. Unit Will Not Heat – Electric – QT and RQ Control

Suffixes1 .................................................................................. 61

82. Error Codes .............................................................................. 164

Section 10 – Electronic Control Troubleshooting............................ 165

83. No Infrared Communication .................................................... 166

84. Coins Ignored When Entered

L and W Control Suffixes only167

85. No Display ............................................................................... 168

86. “Door Open” Indicator............................................................. 170

87. No Start/Run ............................................................................ 172

88. Unit Will Not Heat – Gas......................................................... 175

89. Unit Will Not Heat – Steam..................................................... 178

90. Unit Will Not Heat – Electric .................................................. 180

91. CE Models No Display ............................................................ 184

92. CE Models “Door Open” Indicator.......................................... 186

93. CE Models No Start/Run ......................................................... 188

94. CE Models Will Not Heat – Gas/Steam................................... 191

95. CE Models Will Not Heat – Electric ....................................... 194

70422101R1 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 11 – LED OPL and UniLinc Troubleshooting.................... 197

96. No Fan Motor Rotation ............................................................ 198

97. No Drive Motor Rotation......................................................... 201

98. Stove and Cabinet Limit Errors ............................................... 204

99. No Display ............................................................................... 206

100. Airflow Errors .......................................................................... 208

101. Fan Motor Centrifugal Switch Error ........................................ 210

102. Close Door Indication .............................................................. 212

103. Moisture Sensor Error .............................................................. 214

Troubleshooting the Moisture Sensor Circuit....................................... 216

104. Troubleshooting at the Control ................................................ 216

105. Troubleshooting From Control to Slip Ring Assembly ........... 218

106. Troubleshooting At Slip Ring Assembly ................................. 220

107. Troubleshooting From Slip Ring Assembly to

Moisture Sensing Baffle and Basket........................................ 220

108. Troubleshooting from Basket Shaft to Moisture

Sensing Baffle with Machine Basket Removed....................... 220

109. Troubleshooting at the Moisture Sensing Baffles

with Machine Basket Removed ............................................... 221

110. Fan Motor Contactor Error ...................................................... 222

111. Rotation Sensor Error............................................................... 224

112. Shorted or Open Thermistor .................................................... 226

113. Fuses and Transformer Configuration Jumper......................... 228

114. Dip Switch/Harness Index Mismatch ...................................... 229

115. Electronic Control Testing ....................................................... 230

Diagnostic Test Descriptions................................................................ 232

116. Diagnostic Testing ................................................................... 239

4 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 1

Danger indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Warning indicates a hazardous situation

that, if not avoided, could cause severe

personal injury or death.

WARNING

Caution indicates a hazardous situation

that, if not avoided, may cause minor or

moderate personal injury or property

damage.

CAUTION

• Failure to install, maintain and/or operate

this product according to the

manufacturer’s instructions may result in

conditions which can produce serious

injury, death and/or property damage.

• Do not repair or replace any part of the

product or attempt any servicing unless

specifically recommended or published

in this Service Manual and unless you

understand and have the skills to carry

out the servicing.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

product is properly grounded and to

reduce the risk of fire, electric shock,

serious injury or death.

W006R2

WARNING

Safety Information

Throughout this manual and on machine decals, you

will find precautionary statements (“CAUTION”,

“WARNING”, and “DANGER”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and those

maintaining the machine.

In the interest of safety, some general precautions

relating to the operation of this machine follow.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

70422101R1 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Safety Information

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the tumble

dryer before servicing.

• Never start the tumble dryer with any

guards/panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

tumble dryer is properly grounded.

W240R1

WARNING

Repairs that are made to your products by

unqualified persons can result in hazards

due to improper assembly or adjustments

subjecting you, or the inexperienced

person making such repairs, to the risk of

serious injury, electrical shock, or death.

W007

WARNING

If you or an unqualified person perform

service on your product, you must assume

the responsibility for any personal injury or

property damage which may result. The

manufacturer will not be responsible for

any injury or property damage arising from

improper service and/or service

procedures.

W008

CAUTION

IMPORTANT INFORMATION: During the

lifetime of a tumbler, it may require service. The

information contained in this manual was written

and is intended for use by qualified service

technicians who are familiar with the safety

procedures required in the repair of a tumbler, and

who are equipped with the proper tools and testing

equipment.

NOTE: The WARNING and IMPORTANT

instructions appearing in this manual are not meant

to cover all possible conditions and situations that

may occur. It must be understood that common

sense, caution and carefulness are factors which

CANNOT be built into this tumbler. These factors

MUST BE supplied by the person(s) installing,

maintaining or operating the tumbler.

Always contact your dealer, distributor, service agent

or the manufacturer on any problems or conditions you

do not understand.

6 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Safety Information

Locating an Authorized Service

Person

Alliance Laundry Systems is not responsible for

personal injury or property damage resulting from

improper service. Review all service information

before beginning repairs.

Warranty service must be performed by an

authorized technician, using authorized factory

parts. If service is required after the warranty

expires, Alliance Laundry Systems also

recommends contacting an authorized technician

and using authorized factory parts.

Safety Warnings and Decals

SAFETY WARNINGS and decals have been provided

in key locations to remind you of important precautions

for the safe operation and maintenance of your tumbler.

Please take the time to review these warnings before

proceeding with service work.

All decals have been designed and applied to withstand

washing and cleaning. Decals should be checked

periodically to be sure they have not been damaged,

removed, or painted.

Safety Precautions for Servicing

Tumble rs

Prior to servicing tumbler:

• Disconnect electrical service and “lockout” to

prevent unintentional connection.

• Shut off supply gas valve.

• Allow machine to cool prior to servicing.

After servicing tumbler:

• Control/access panels must be reinstalled.

• Motor/drive/belt guards must be reinstalled.

• Contactor/junction/accessory box covers must

be reinstalled.

• Use a non-corrosive leak detection solution to

check all pipe connections for gas leaks. DO

NOT USE AN OPEN FLAME TO CHECK

FOR GAS LEAKS!

• The loading door switch, lint door switch and

airflow switch must be operating properly.

70422101R1 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

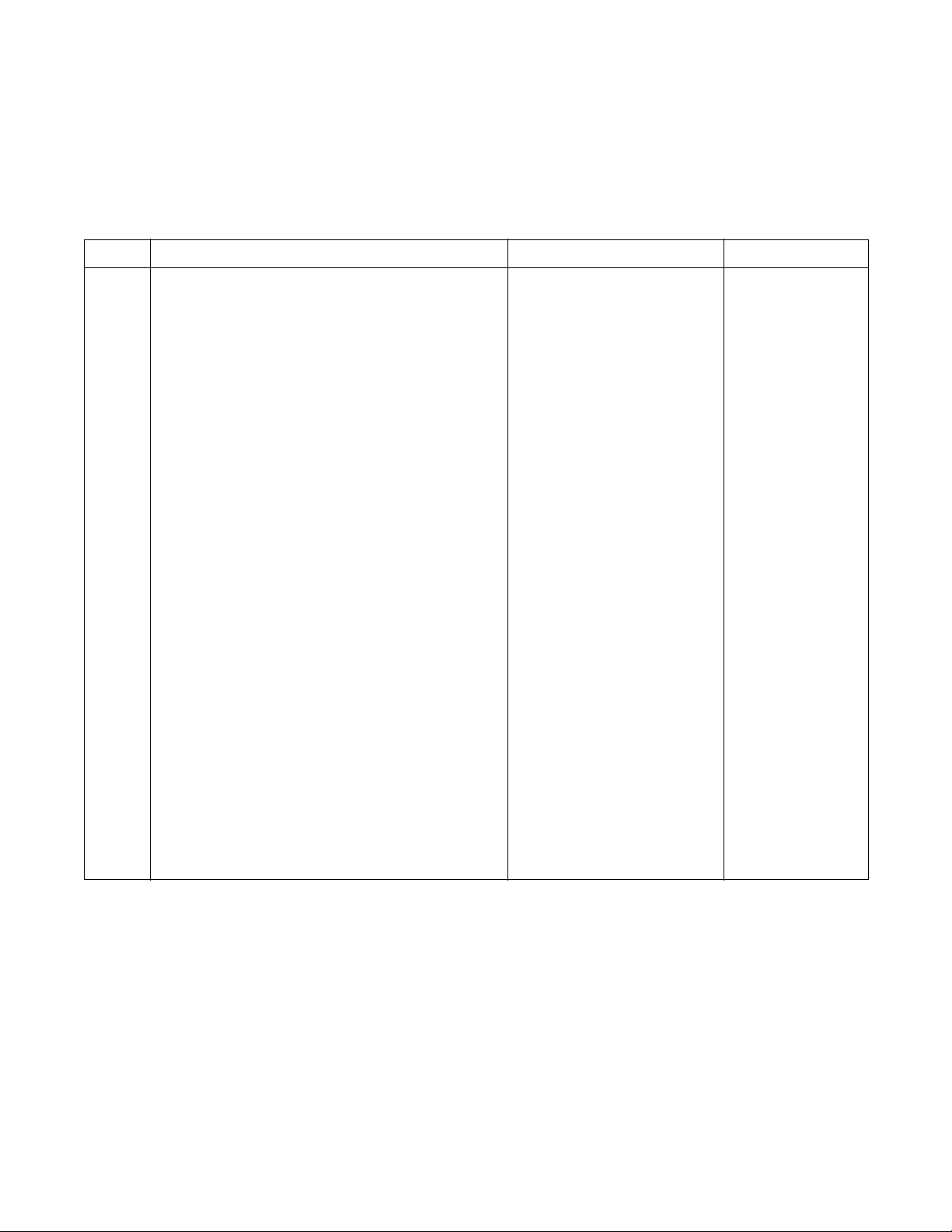

Section 2

Introduction

Model Identification

Information in this manual is applicable to these models:

Gas Steam/Thermal Oil Electric

PK050N

PT050L

PT050N

PU050L

PU050N

SA050L

SA050N

SK050N

ST050D

ST050L

ST050N

SU050L

SU050N

UA050L

UA050N

UK050N

UT050L

UT050N

UU050L

UU050N

YT050L

YT050N

YU050L

YU050N

50

Pound

CA050L

CA050N

CK050N

CT050L

CT050N

CU050L

CU050N

DR50G2-BA050L

DR50G2-BA050N

DR50G2-BK050N

DR50G2-BT050D

DR50G2-BT050L

DR50G2-BT050N

DR50G2-BU050L

DR50G2-BU050N

DR55G2-BA050L

DR55G2-BA050N

DR55G2-BT050D

DR55G2-BT050L

DR55G2-BT050N

DR55G2-BU050L

DR55G2-BU050N

GA050L

GA050N

GK050N

GT050L

GT050N

GU050L

GU050N

HA050L

HA050N

HK050N

HT050D

HT050L

HT050N

HU050L

HU050N

IPD50G2

IT050L

IT050N

KA050L

KA050N

KK050N

KT050L

KT050N

KU050L

KU050N

LA050L

LA050N

LK050N

LT050L

LT050N

LU050L

LU050N

PA050L

PA050N

CT050S

CT050T

CU050S

CU050T

DR50S2-BT050S

DR50S2-BT050T

DR50S2-BU050S

DR50S2-BU050T

DR55S2-BT050S

DR55S2-BT050T

DR55S2-BU050S

DR55S2-BU050T

GT050S

GT050T

GU050S

GU050T

HT050S

HT050T

HU050S

HU050T

IPD50S2

IT050S

IT050T

KT050S

KT050T

KU050S

KU050T

LT050S

LT050T

LU050S

LU050T

PT050S

PT050T

PU050S

PU050T

ST050S

ST050T

SU050S

SU050T

UT050S

UT050T

UU050S

UU050T

YT050S

YT050T

YU050S

YU050T

CT050E

CU050E

DR50E2-BT050E

DR50E2-BU050E

DR55E2-BT050E

DR55E2-BU050E

GT050E

GU050E

HT050E

HU050E

IPD50E2

IT050E

KT050E

KU050E

LT050E

LU050E

PT050E

PU050E

ST050E

SU050E

UT050E

UU050E

YT050E

YU050E

(continued)

NOTE: Control suffixes listed on next page.

8 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

75

Pound

CA075L

CA075N

CK075N

CT075L

CT075N

CU075L

CU075N

DR75G2-BA075L

DR75G2-BA075N

DR75G2-BK075N

DR75G2-BT075D

DR75G2-BT075L

DR75G2-BT075N

DR75G2-BU075L

DR75G2-BU075N

DR80G2-BA075L

DR80G2-BA075N

DR80G2-BT075D

DR80G2-BT075L

DR80G2-BT075N

DR80G2-BU075L

DR80G2-BU075N

GA075L

GA075N

GK075N

GT075L

GT075N

GU075L

GU075N

HA075L

Introduction

(continued)

Gas Steam/Thermal Oil Electric

HA075N

HK075N

HT075D

HT075L

HT075N

HU075L

HU075N

IPD75G2

IT075L

IT075N

KA075L

KA075N

KK075N

KT075L

KT075N

KU075L

KU075N

LA075L

LA075N

LK075N

LT075L

LT075N

LU075L

LU075N

PA075L

PA075N

PK075N

PT075L

PT075N

PU075L

PU075N

SA075L

SA075N

SK075N

ST075D

ST075L

ST075N

STF75L

STF75N

SU075L

SU075N

UA075L

UA075N

UK075N

UT075L

UT075N

UTF75L

UTF75N

UU075L

UU075N

YT075L

YT075N

YU075L

YU075N

CT075S

CT075T

CU075S

CU075T

DR75S2-BT075S

DR75S2-BT075T

DR75S2-BU075S

DR75S2-BU075T

DR80S2-BT075S

DR80S2-BT075T

DR80S2-BU075S

DR80S2-BU075T

GT075S

GT075T

GU075S

GU075T

HT075S

HT075T

HU075S

HU075T

IPD75S2

IT075S

IT075T

KT075S

KT075T

KU075S

KU075T

LT075S

LT075T

LU075S

LU075T

PT075S

PT075T

PU075S

PU075T

ST075S

ST075T

SU075S

SU075T

UT075S

UT075T

UU075S

UU075T

YT075S

YT075T

YU075S

YU075T

CT075E

CU075E

DR75E2-BT075E

DR75E2-BU075E

DR80E2-BT075E

DR80E2-BU075E

GT075E

GU075E

HT075E

HU075E

IPD75E2

IT075E

KT075E

KU075E

LT075E

LU075E

PT075E

PU075E

ST075E

SU075E

UB075E

UT075E

UU075E

YT075E

YU075E

NOTE: Control suffixes listed on next page.

70422101R1 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

Includes models with the following control suffixes:

3B – reversing DX4 vended KB – reversing single coin OM – OPL micro

3O – DX4 OPL KC – single coin QT – dual digital timer

3V – DX4 vended KW – reversing prep for coin R3 – reversing DX4 OPL

3W – reversing DX4 prep for coin KX – prep for coin RD – reversing DMP OPL

3X – DX4 prep for coin KY – prep for card RE – reversing LED OPL

BB – reversing basic electronic, coin KZ – reversing prep for card RM – reversing OPL micro

BC – basic electronic, coin LB – reversing network adaptable RQ – reversing dual digital timer

BG – basic electronic, OPL mode coin RU – reversing UniLinc OPL

BL – basic electronic, central pay LC – network adaptable coin SD – single drop

for coin LW – reversing network adaptable, SX – single drop, prep for coin

BW – reversing basic electronic, prep prep for coin UO – UniLinc OPL

for coin LX – network adaptable, prep for WB – reversing network ready coin

BX – basic electronic, prep for coin coin WC – network ready coin

BY – basic electronic, prep for card LY – network adaptable, prep for WW – reversing network ready, prep

BZ – reversing basic electronic, prep card for coin

for card LZ – reversing network adaptable, WX – network ready, prep for coin

DO – DMP OPL prep for card WY – network ready, prep for card

DV – DMP vended NC – NetMaster coin WZ – reversing network ready, prep

DX – DMP prep for coin NX – NetMaster, prep for coin for card

EO – LED OPL NY – NetMaster, prep for card

10 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Serial Plate Location

10

2

0

4

0

30

50

60

0

10

5

PU

SH

TO

ST

AR

T

HE

AT

COOL

D

OWN

HIGH

TEMPERATURE

LOW

15

0

Serial

Plate

TMB2235N

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are found on serial plate on the rear of

machine and inside door.

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized parts

distributor.

For technical assistance, call (920) 748-3121.

Wiring Diagram

The wiring diagram is located inside the junction or

contactor box.

The wiring diagram part number is in the lower portion

of the electrical data on the serial plate.

70422101R1 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

TMB2347S

123

How a Tumble Dryer Works

1

2

3

TMB2347S

A tumble dryer uses heated air to dry loads of laundry.

When the motor is started, the exhaust fan pulls

room temperature air in through the air intake at

the rear of the tumble dryer and over the heat

source (burner flame for gas, heating element for

electric, and coil for steam).

The heated air moves into the cylinder, where it is

circulated through the wet load by the tumbling

action of the cylinder.

Theory of Operation of Instant

Electronic Ignition

IMPORTANT: The Non-CE Marked Instant

Electronic Ignition system will attempt to light the

gas by sparking for approximately 15 seconds. If

gas ignition does not take place within

approximately 15 seconds, the Instant Electronic

Ignition control will go into safety lockout and the

valve will no longer open until Instant Electronic

Ignition control is reset. To reset Instant Electronic

Ignition control, remove power from control by

opening and closing the tumble dryer door. If

condition persists, check that the gas shut-off valve

is in “on” position and that the gas service is

properly connected.

If condition persists:

1. Check resistance of high tension lead

(approximately 1000 ohms/inch), and replace if

not within resistance range.

2. Check voltage present at valve.

3. Check that machine is properly grounded.

4. Check the gap between igniter and burner tube

(gap should be 1/4-3/8 inch).

5. Check that burner ports are not blocked or

plugged under the igniter.

The air then passes through the lint filter, exhaust

fan, and is vented to the outdoors.

12 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

1

2

6

5

4

3

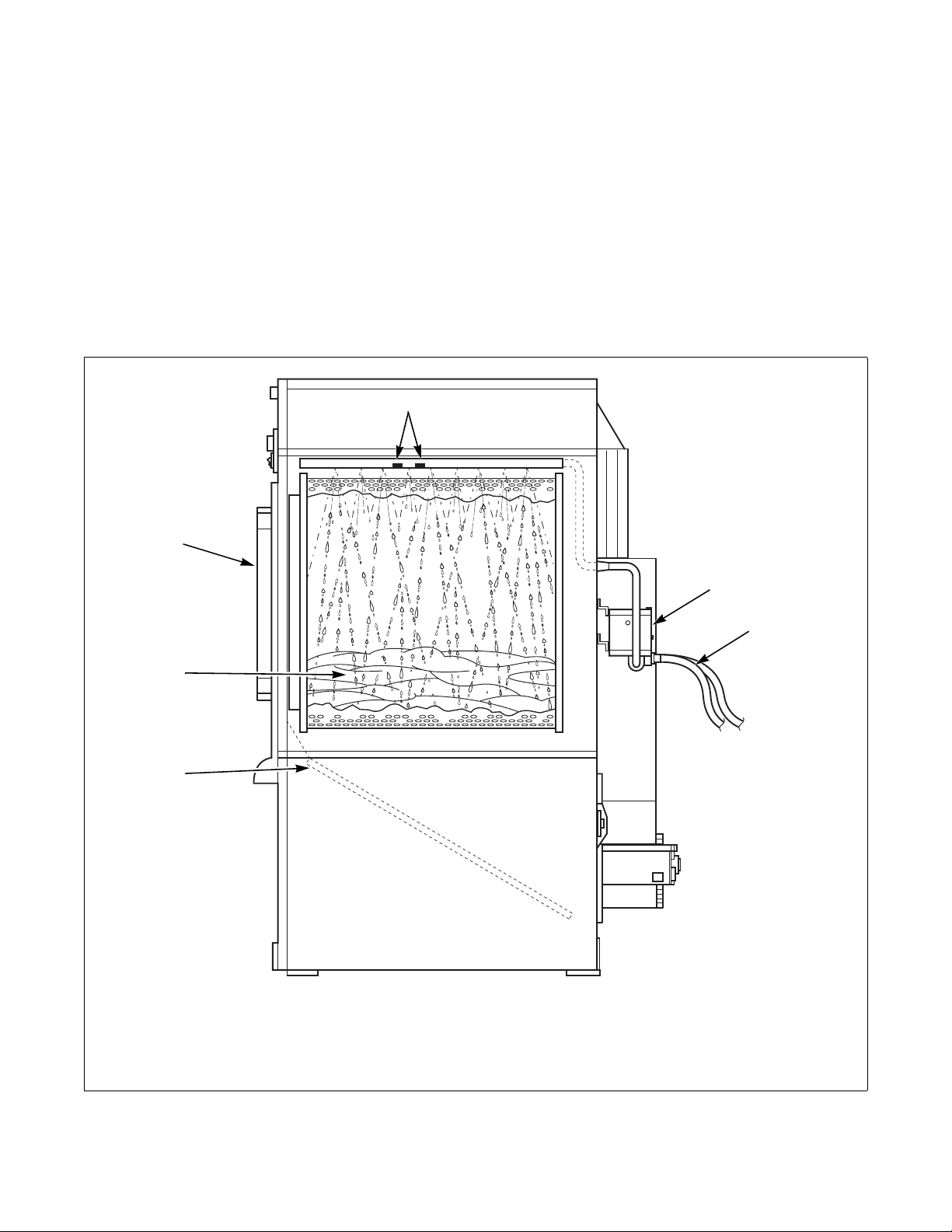

Fire Suppression System Theory of

Operation

IMPORTANT: The fire suppression system is

designed to diminish a laundry fire starting inside a

fire suppression system equipped tumble dryer.

The fire suppression system is not designed to stop

or eliminate high temperature and spontaneous

combustion situations. Follow all instructions in the

installation manual to ensure the fire suppression

system operates properly. Train all operators in the

proper preventative maintenance of the fire

suppression system.

IMPORTANT: For safety purposes, do not operate

tumble dryer if a fire has occurred.

1 Temperature Sensors 4 Lint Screen

2 Fire Suppression System Control Box 5 Load

3 Water Flow to Machine 6 Loading Door

TMB1998N

Figure 1

70422101R1 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

3

4

5

6

7

1

2

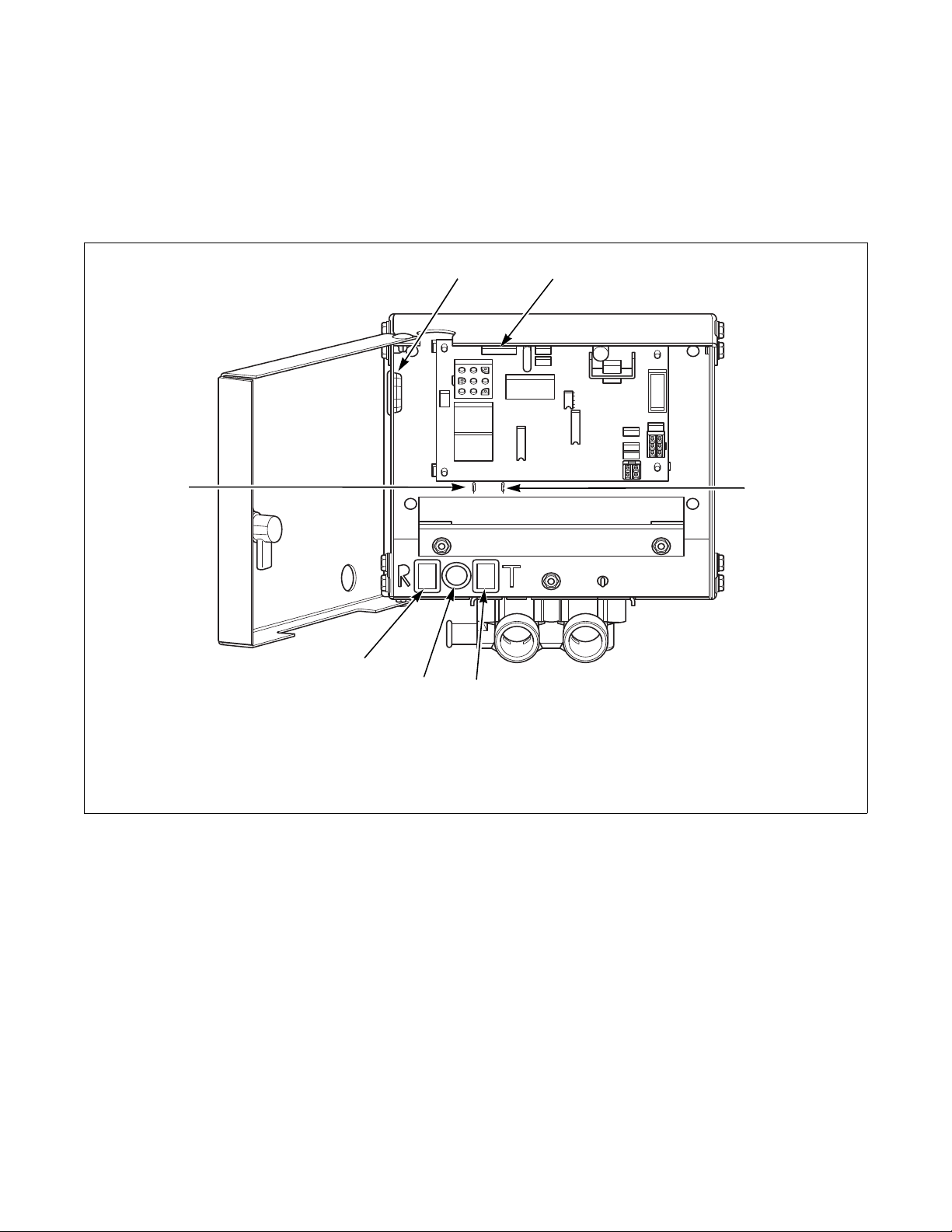

Temperature Sensor

Two temperature sensors are located in the cylinder

area of the tumble dryer to provide temperature

readings. Refer to Figure 1 and Figure 2. These

temperature sensors will trigger a mode change based

on a pre-set temperature trip-point.

TMB1999N

1 Opening for Auxiliary Alarm Cable 5 Light

2 Fuse 6 Reset Button

3 Auxiliary Alarm Fast-On Connection 7 Auxiliary Alarm Fast-On Connection

4 Test Button

Figure 2

TMB1999N

14 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

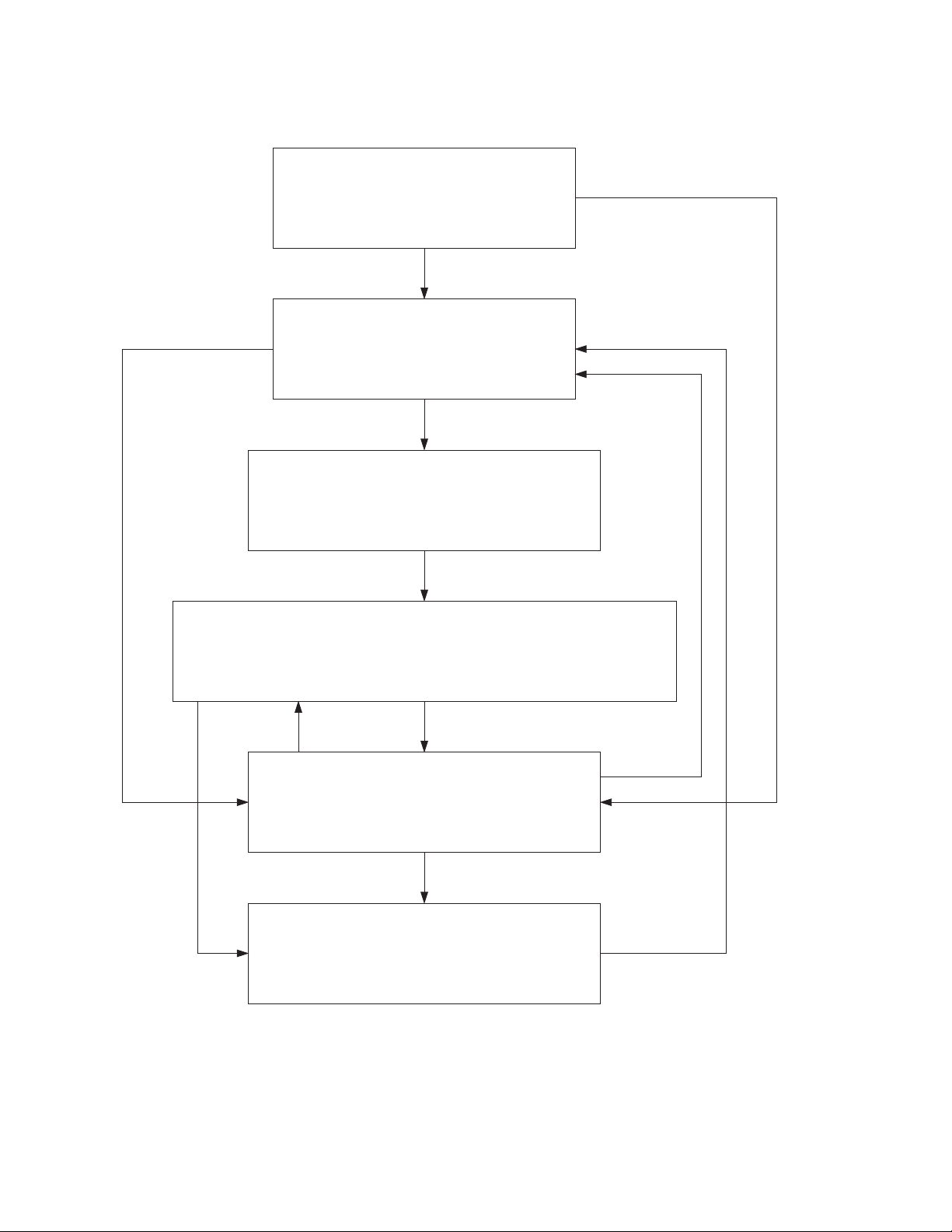

Modes of Operation

Power-Up Mode

Sends power to control, begins a stat us check

of the system. Can send control into Idle Mode

or Lockout Mode.

Idle Mode

Machine is operable while it monitors

temperature sensor readings. Control will enter

Power Disconnect Mode if temperature

trip-point is exceeded.

Power Disconnect Mode

Machine is disabled and controls on front will not

operate, will enter Power Disconnect Mode for one

second, then Water On Mode.

Water On Mode

Machine is disabled and controls on front will not operate. Remain in this mode

for 90 seconds, then enter Lockout Mode. Can enter Lockout Error Mode if both

temperature sensors become open, which occ urs when temperature is below

40° F (4° C). Will enter Idle Mode if reset button is pressed. Refer to

Figure 2.

Lockout Mode

Machine is disabled and controls on front will not

op erat e. Control monitors temperat ure readings. Enters

Water On Mode if temperature trip-point is exceeded.

Will enter Idle Mode if reset button is pressed.

Lockout Error Mode

Machine is disabled and controls on front will not

operate. Water dispenses for four minutes. When the

res et butt on is pres s ed, the c ont rol enters I dle

Mode.

If tempe ratu re

trip-point exceeded

If both temperature

sensors become open

Whe n res et

button is pressed

If reset b ut ton

is pressed

Introduction

70422101R1 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

WARNING

IMPORTANT: Refer to appropriate wiring

diagram for aid in testing tumble dryer

components.

Section 1

16 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

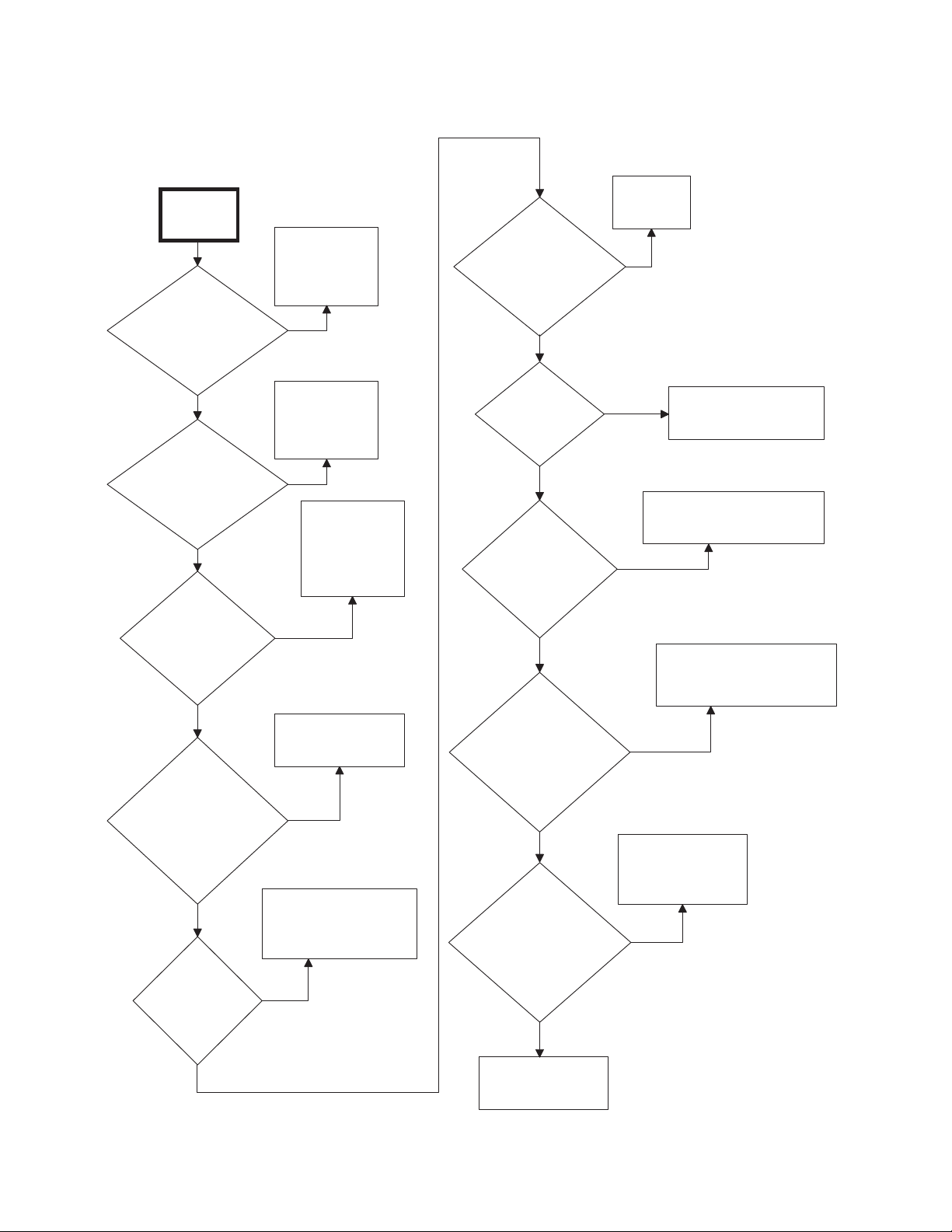

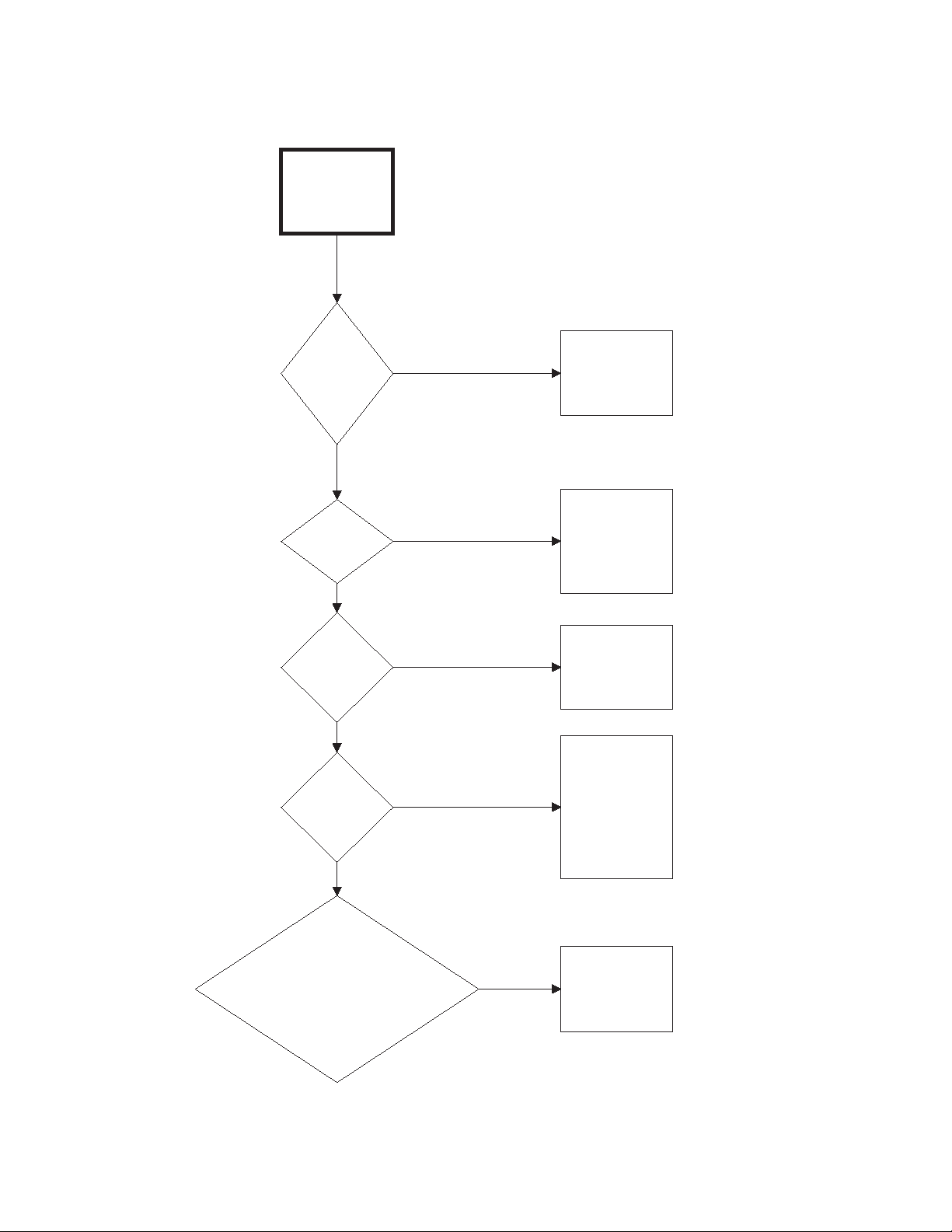

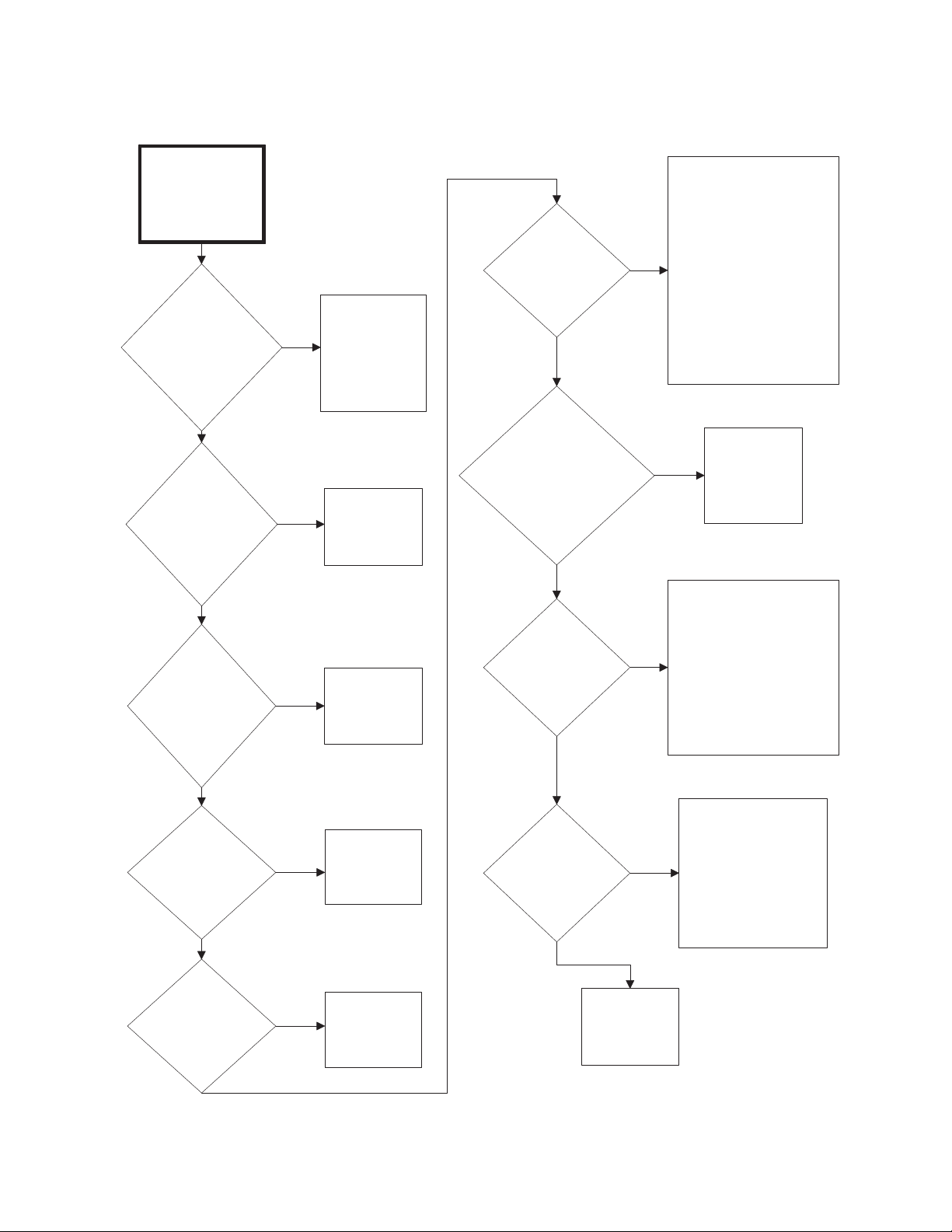

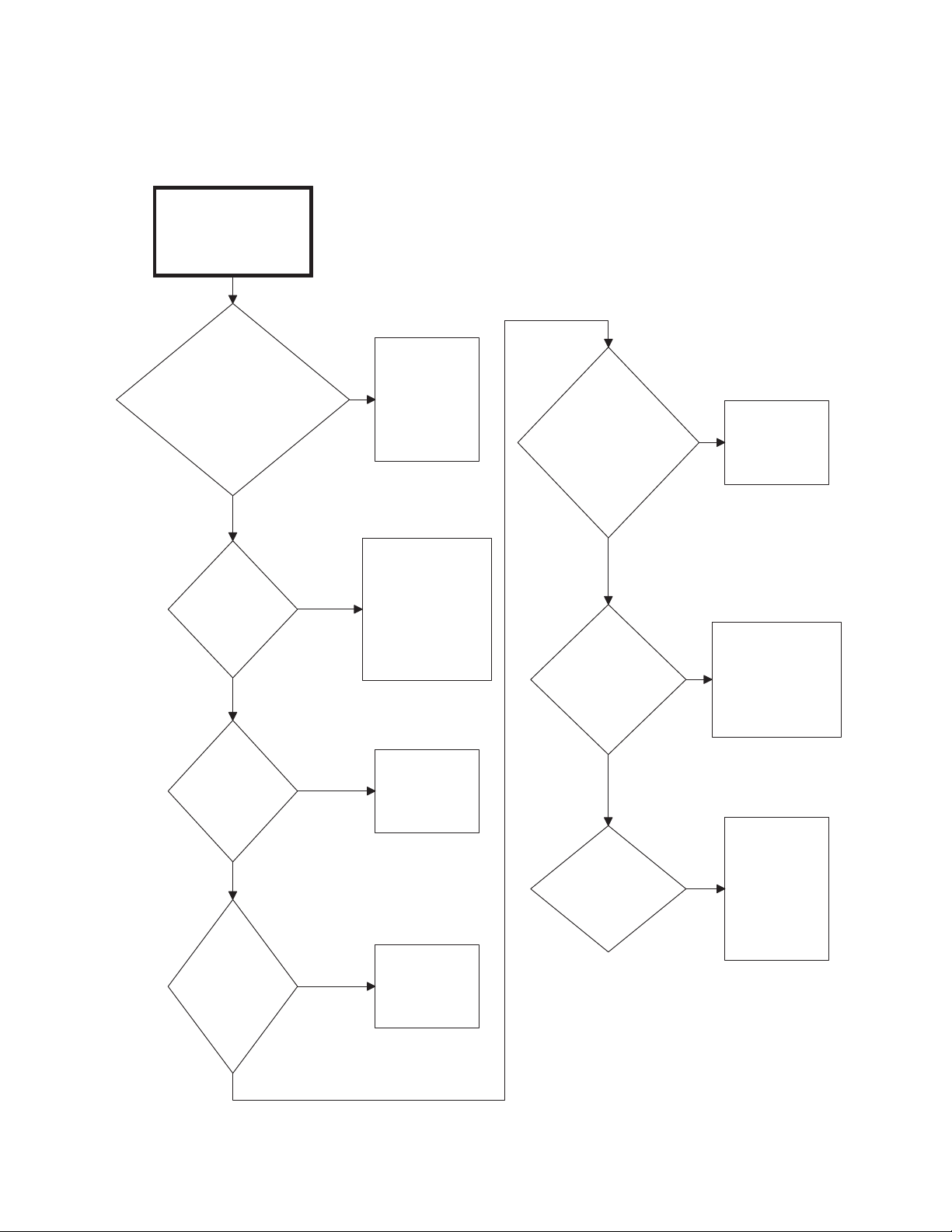

1. Motor Does Not Start

Motor does

not start

Is electrical

power off or

have any fuses

blown?

Check power

and fuses.

Replace fuses

if necessary.

Is loading door

open or is door

switch

inoperative?

No

Close door or

test switch and

replace if

inoperative.

Is lint door

open or is lint

door switch

inoperative?

Close lint door,

confirm switch

is positioned to

actuate with

door closed.

Is

trunnion shaft

assembly

binding in

trunnion housing

bearings?

Replace trunnion

housing bearings.

Is start

circuit

incomplete?

Yes

Yes

Press start switch or

test switch and replace

if inoperative.

Yes

Is idler shaft

binding in idler

housing

bearings?

Replace

bearings.

Yes

Is motor

inoperative?

Have motor tested and

replace if inoperative.

Yes

Non-Metered

Models: Is

timer set

properly?

Turn drying timer clockwise

to desired setting.

Non-Metered

Models: Are the

timer or relay

inoperative?

No

Test timer and relay and

replace if inoperative.

Metered

Models:

Are proper coins

inserted in

accumulator?

If motor still does

not start, replace

motor.

Check that proper

coins are inserted.

Yes

Yes

No

No

No

No

Yes

No

No

Yes

Yes

No

TMB2264S

No

TMB2264S

Troubleshooting

70422101R1 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

TMB1874S

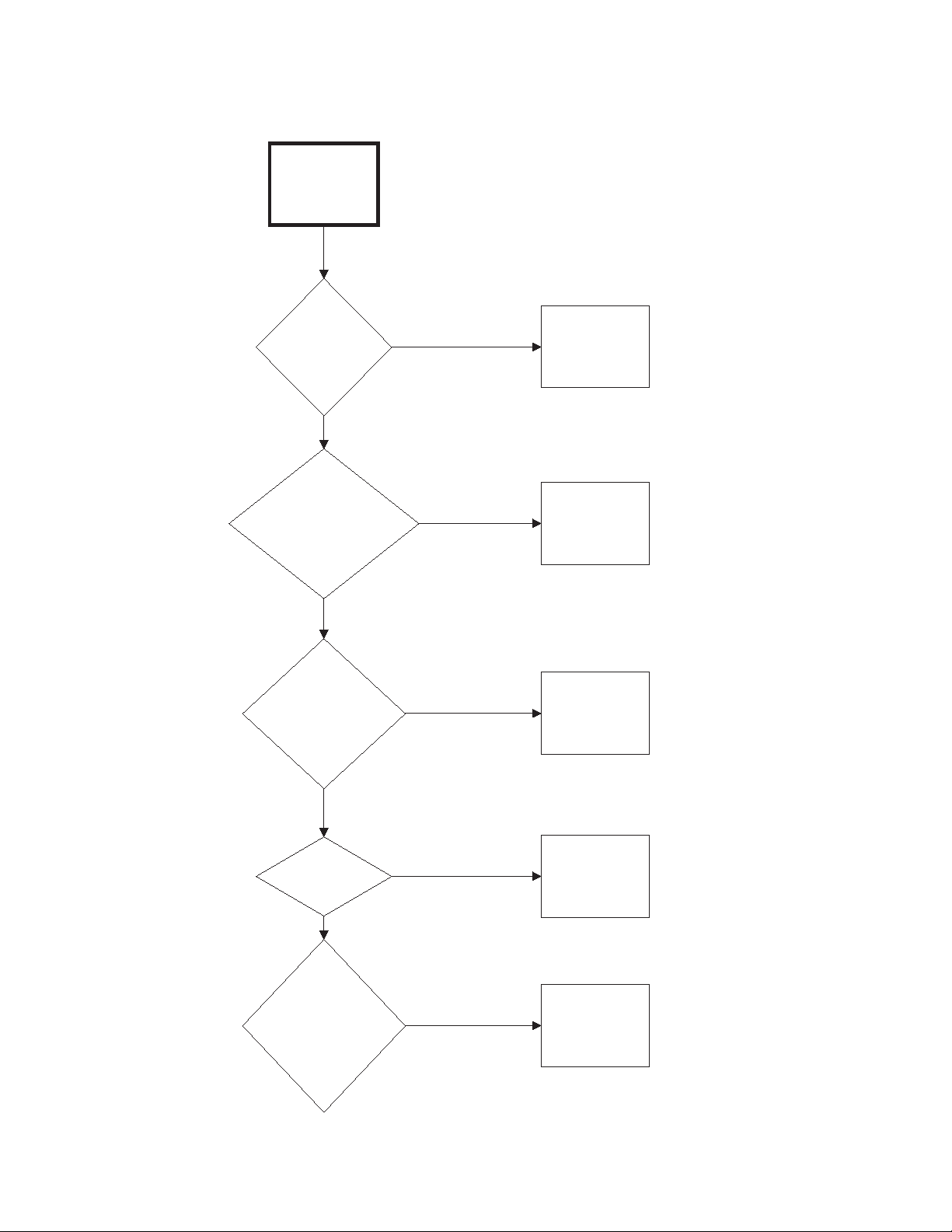

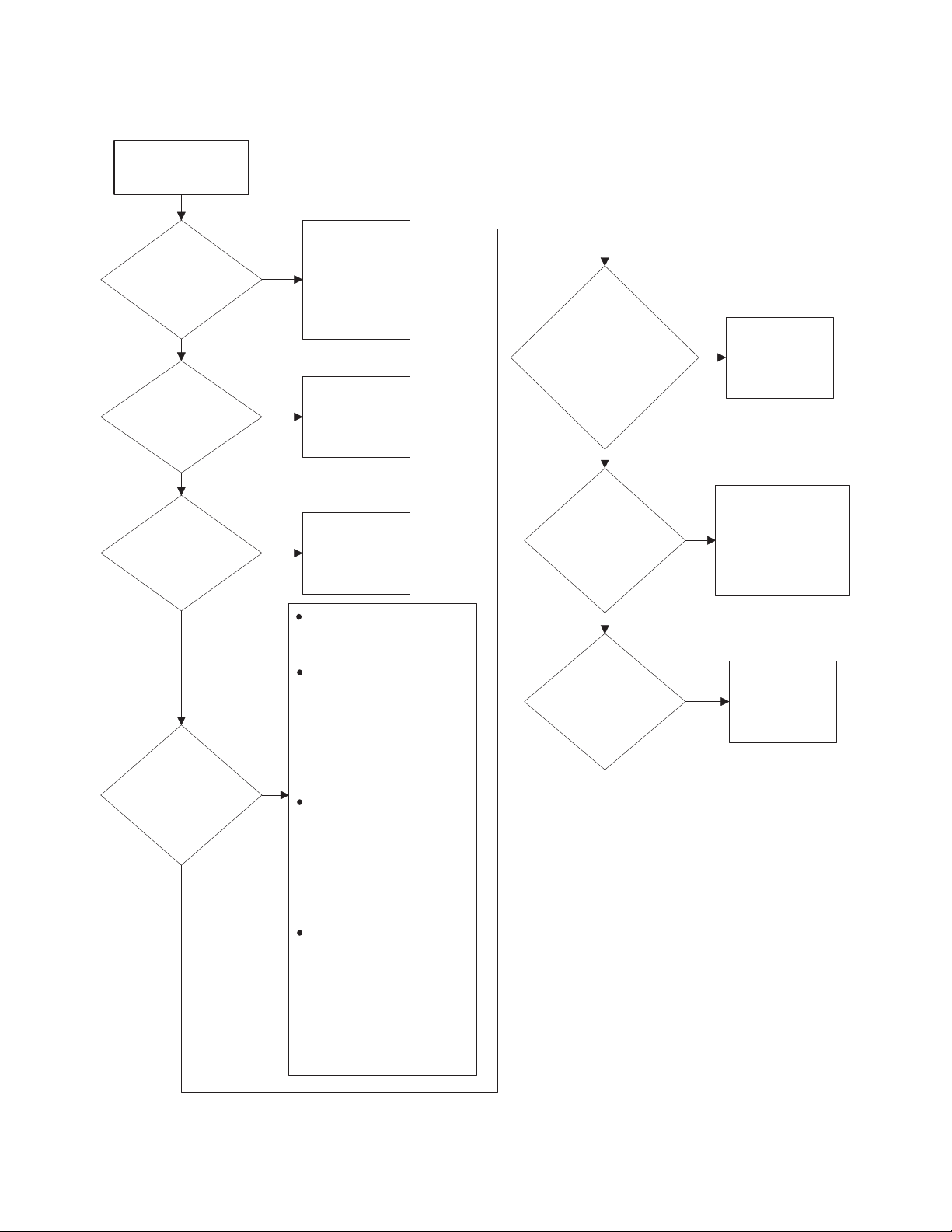

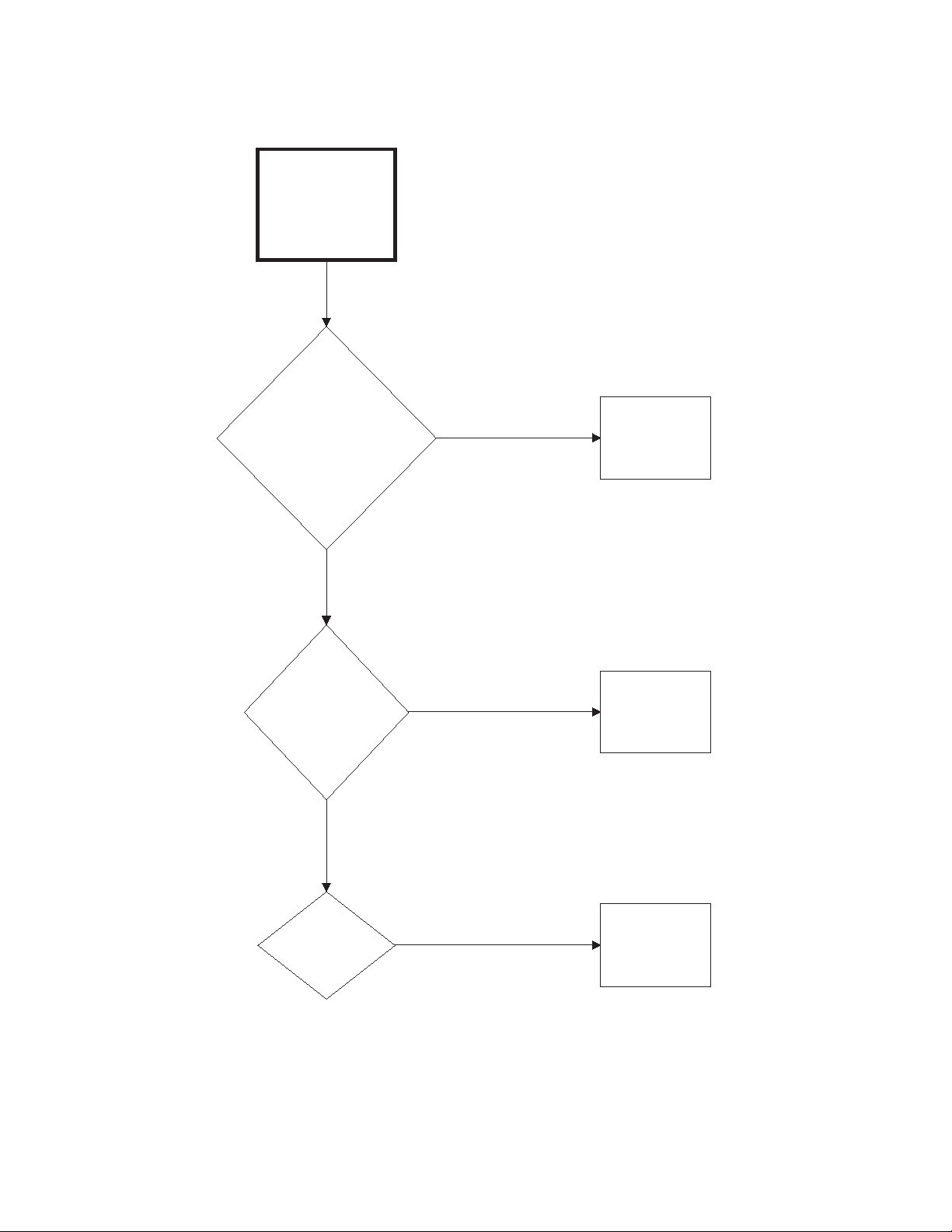

2. Motor Overload Protector Cycles Repeatedly

Motor overload

protector

cycles

repeatedly

Is voltage

incorrect?

No

Yes

Refer to the

Installation

Manual for

electrical

requirements.

Is clothes

load too

large?

No

Is clothes

cylinder

binding?

No

Is wiring

inadequate?

No

Is make-up

air

inadequate?

Yes

Yes

Yes

Yes

Remove part of

load.

Check cylinder

for binding.

Refer to

Adjustments

Section for

cylinder

adjustment.

Check with an

electrician to

ensure that

wiring is

adequate.

Refer to

Installation

Manual for

make-up air

requirements.

No

Has lint

built up?

No

Is there broken,

loose or

incorrect wiring?

18 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Yes

Yes

Clean lint

accumulation

on and around

motor.

Refer to wiring

diagram

located inside

contactor box.

TMB1874S

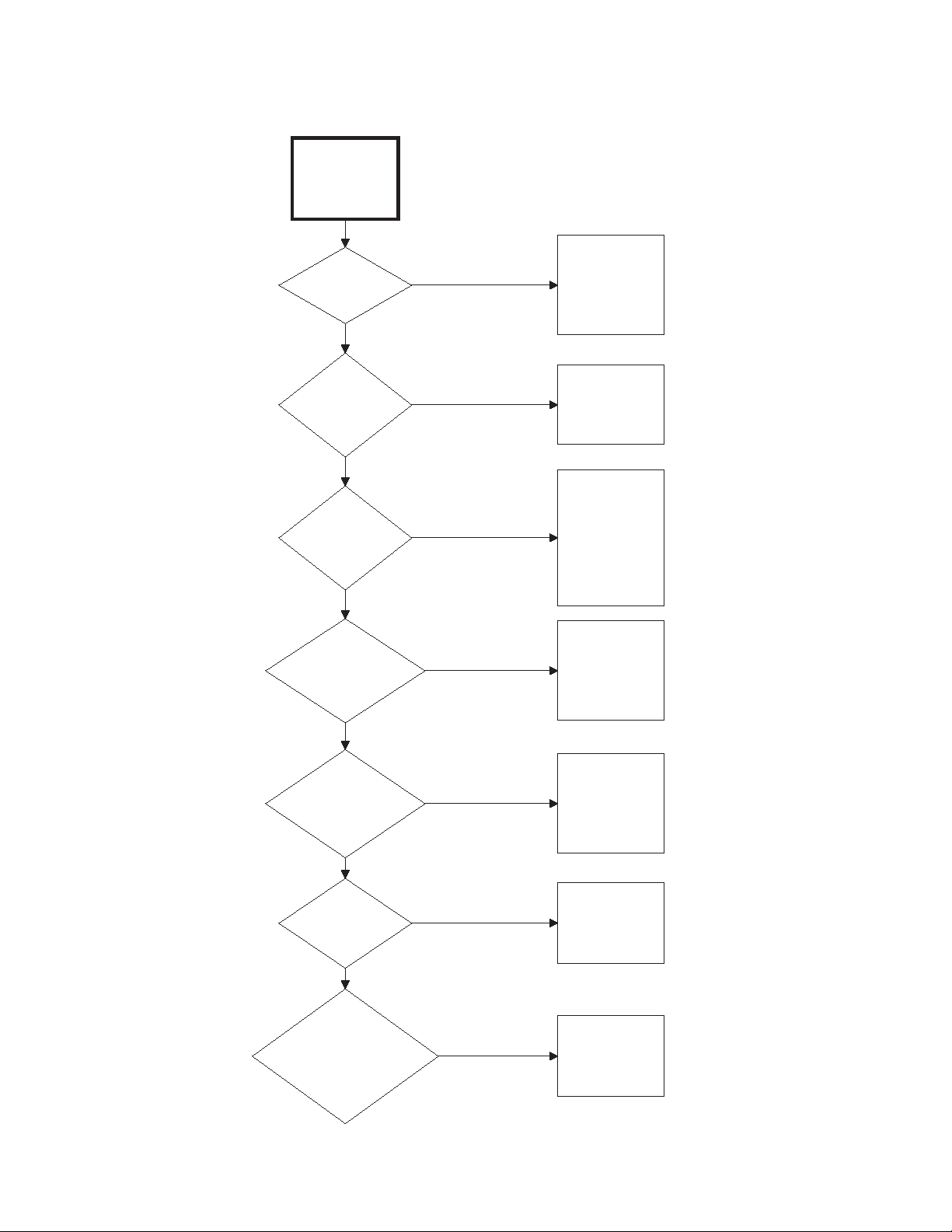

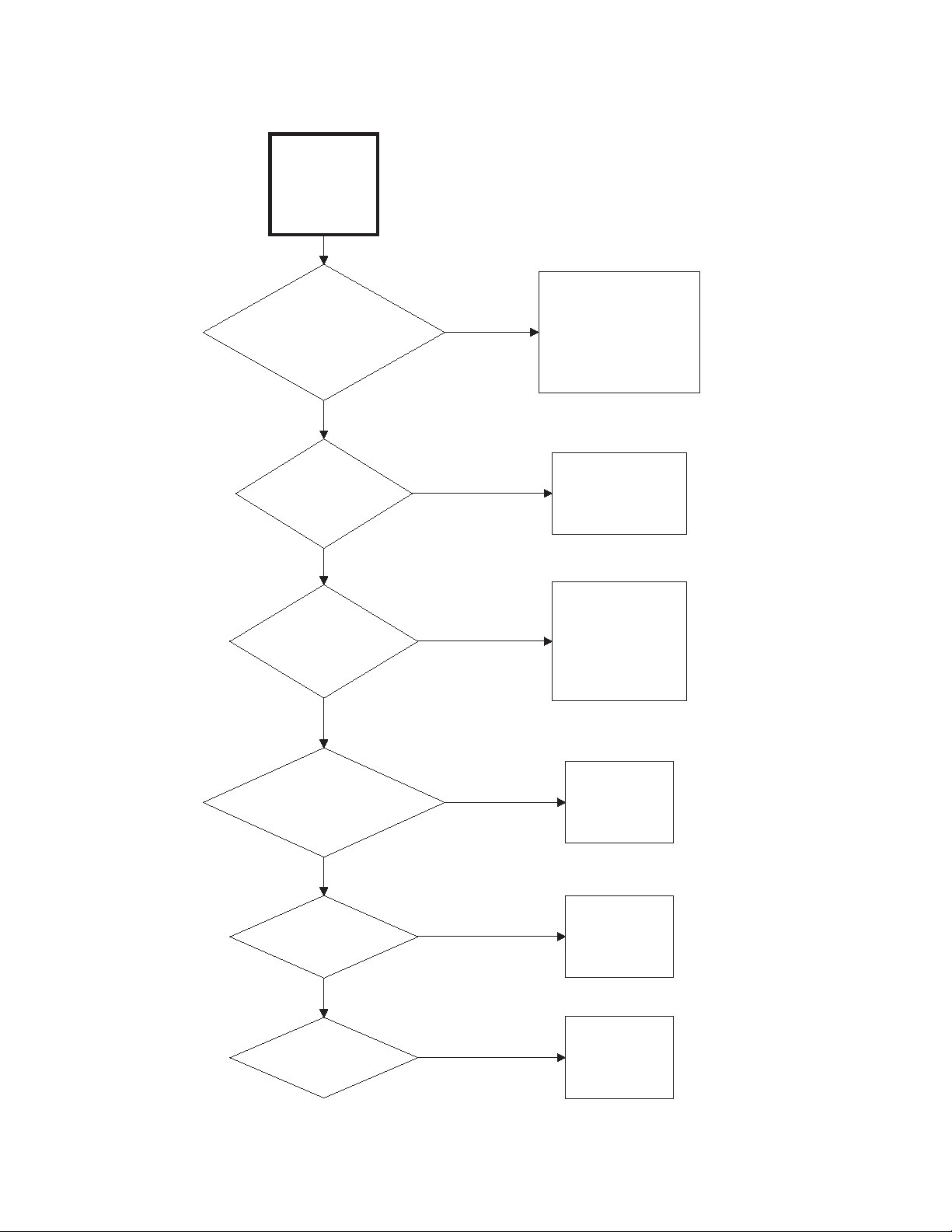

3. Motor Runs But Cylinder Does Not Turn

TMB1875S

Motor runs but

cylinder does

not turn

Troubleshooting

Is motor

drive

pulley

loose?

No

Is sheave

loose?

No

Is belt

broken

or loose?

No

Is

cylinder

binding?

No

Yes

Yes

Yes

Yes

Confirm key is

in place,

tighten

setscrews.

Confirm key is

in place,

tighten

setscrews and

bushing.

Replace or

adjust belt.

Check cylinder

for binding.

Refer to

Adjustments

Section for

proper cylinder

adjustment.

Does cylinder turn

counterclockwise when

viewed from front of

machine (3 Phase

models only)?

Yes

Switch power

leads L1 and

L2 to correct

rotation.

TMB1875S

70422101R1 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

TMB1876S

4. Motor Does Not Stop

Motor does not

stop

Is door

switch

inoperative?

No

Non-Metered

Models: Is timer

or relay

inoperative?

No

Metered

Models: Is

accumulator

inoperative?

Yes

Yes

Yes

Test switch and

replace if

inoperative.

Test timer and

relay and

replace if

inoperative.

Te st

accumulator

and replace if

inoperative.

No

Refer to wiring

Is wiring

incorrect?

Yes

diagram

located inside

contactor box.

No

Is motor relay

or motor

contactor

inoperative?

Yes

Check

relay/contactor

and replace if

inoperative.

TMB1876S

20 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5. No Heat Condition (Non-CE and Non-Australian Models)

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumble dryer before servicing.

• Close gas shut-off valve to gas tumble dryer before servicing.

• Close steam valve to steam tumble dryer before servicing.

• Never start the tumble dryer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumble dryer is properly grounded.

W002R1

WARNING

Ignition Control Module Function

There are four components to the ignition system: the

module, the spark igniter, the high voltage cable and

ground wire. When 24 VAC is applied between the TH

and GND terminals on the module, the module will

send the high voltage signal to the igniter and 24 VAC

to the gas valve coils. Gas will hit the sparking igniter

and flame will be established. The igniter being

engulfed in flame will create a millivolt electric signal

that is sent back to the module by the high voltage

cable; this is what the module sees as flame

recognition. If the millivolt signal is not at the module

in ten seconds, the module will go into safety lockout.

The voltage will be cut from the igniter and gas valve

coils and will not be restored until voltage is cycled at

the module.

Troubleshooting

Intermittent Heat Test Procedure

On ignition control modules with date codes higher

than 08t2, perform the following test.

Start the tumble dryer and run for 10 minutes (verify

that the tumble dryer is heating properly). After the 10

minute cycle, re-start the tumble dryer and once again

verify the unit is heating. Repeat this procedure 3

times. If the tumble dryer passes this test, the ignition

control module is operating properly and SHOULD

NOT be changed. Refer to Troubleshooting Manual

for additional service procedures.

70422101R1 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

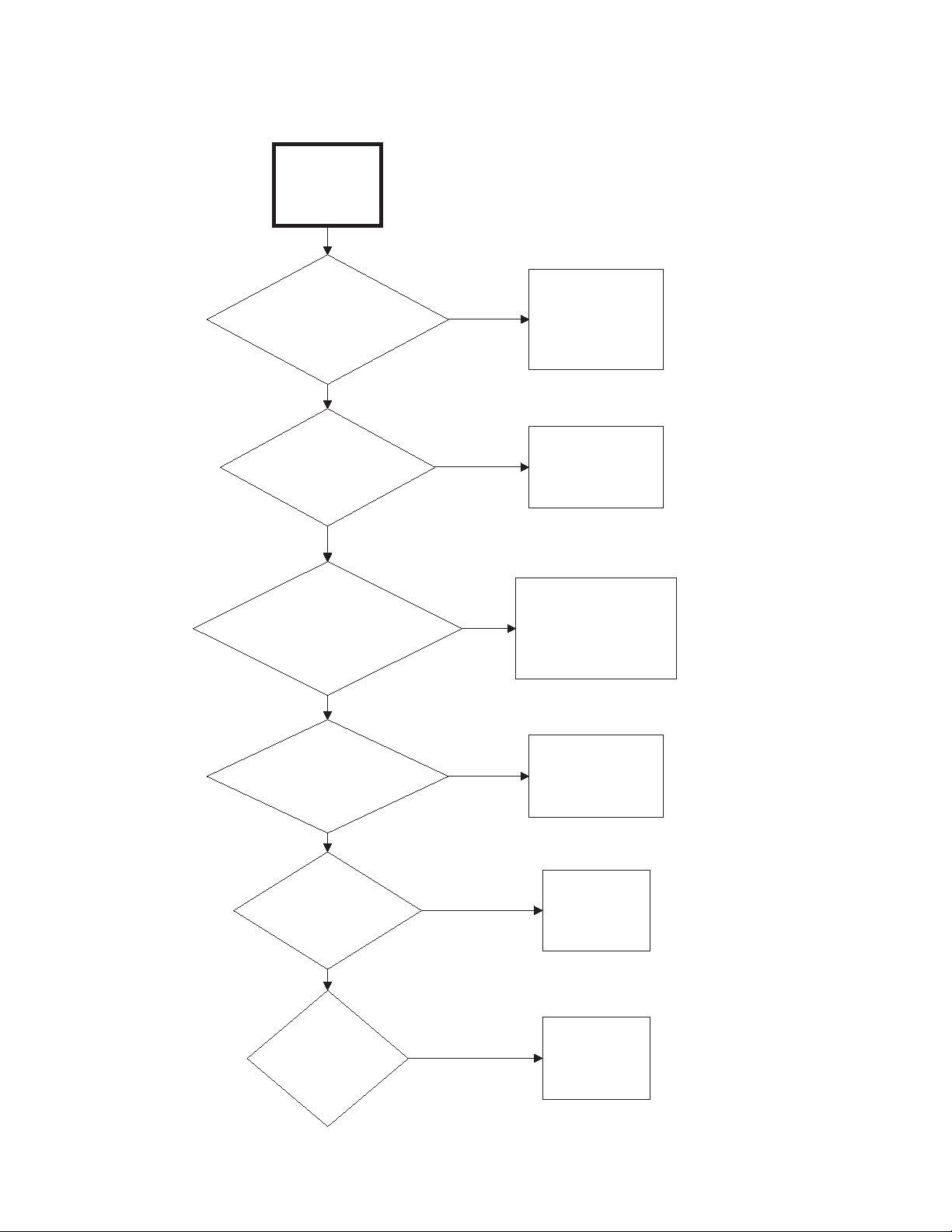

Troubleshooting

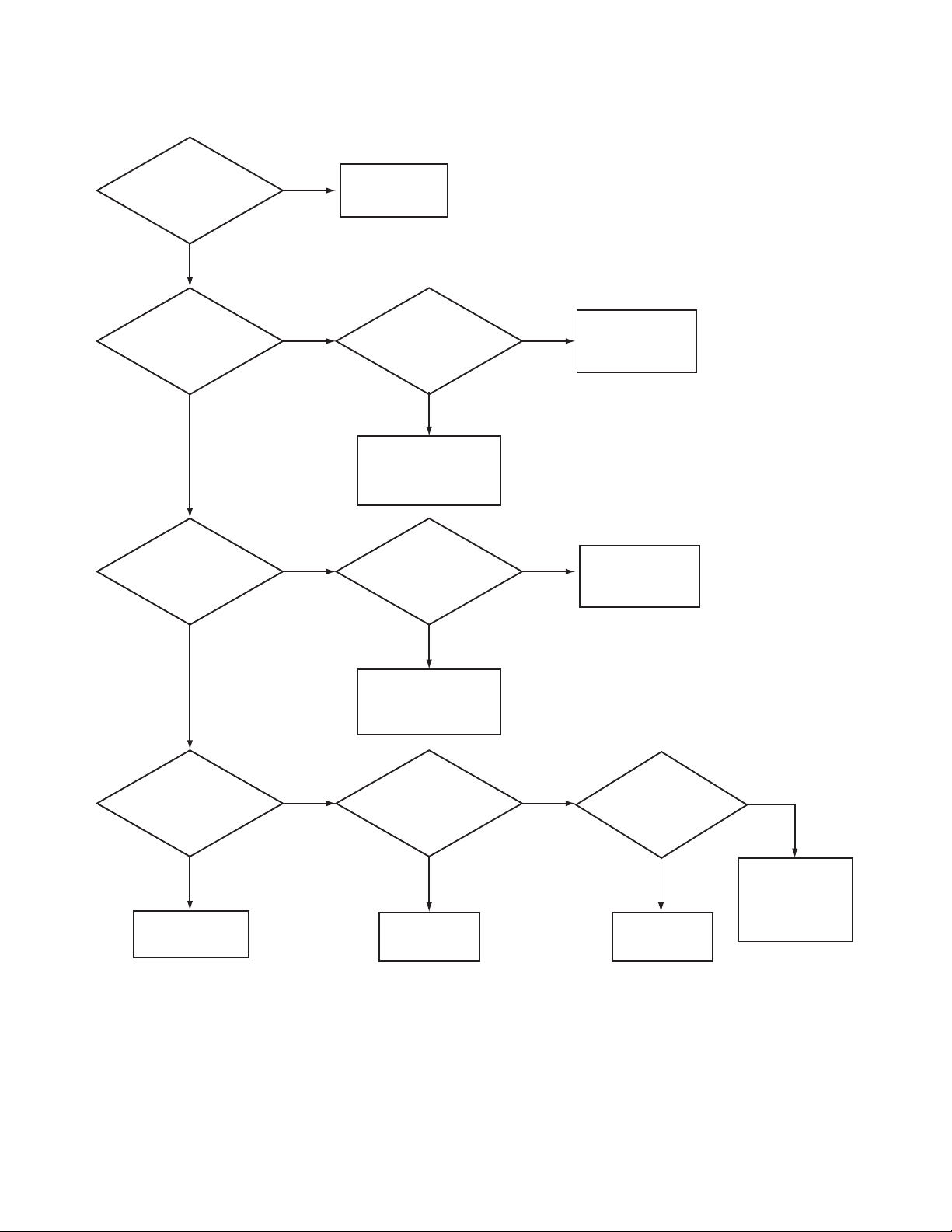

Is the Ignition Control

Module’s red light on?

No

No

Yes

Yes

Refer to

Paragraph 7.

Replace igniter and high

voltage lead. Retest unit. If

unit still does not spark,

replace module.

No

Refer to Paragraph 7

for heat circuit

troubleshooting.

Is there

24 volts AC between

the TH and GND terminals

on the module?

Yes

No

Check wiring between

gas valve and module.

If wiring is good,

replace module.

Yes

Yes

Is there continuity

between GND terminal on

module and machine?

No No

Does the igniter

spark but no

flame is produced?

No

Yes

Is there

24 volts AC at the gas

valve coils when igniter

is sparking?

Is the igniter

positioned properly

in the flame, and does the

flame look good?

Does the igniter

spark?

Verify that gas is supplied

to the machine. If gas and

voltage are present,

replace gas valve or coils.

Does the flame turn

off after igniter

stops sparking?

No

Yes

Replace module.

Adjust position of

igniter and retest.

Yes

Verify machine is

properly grounded.

Replace igniter and

high voltage lead.

Retest unit. If it still

does not sense flame,

replace module.

TMB2395S

5. No Heat Condition

22 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

6. Heating Element Does Not Heat or Burner Does Not Ignite

Heating element

does not heat or

burner does not

ignite

Is there

improper or

inadequate

exhaust or

make-up air?

Refer to

Installation

Manual for

exhaust and

make-up air

requirements.

Are there

blown fuses

or tripped

circuit

breakers?

Check fuses

or circuit

breakers.

Is drying

timer not

selected or

inoperative?

Set drying

timer or

replace if

necessary.

Is "No Heat"

selected on

control?

Select

temperature

option.

Is control

relay

inoperative?

Test relay and

replace if

inoperative.

Is thermistor

inoperative?

Test thermistor by

removing harness from

thermistor terminals.

Check resistance across

terminals, should read

approximately 50,000

Ohms at 77°F.

Resistance should

decrease with a

temperature increase.

Replace thermistor if

inoperative.

Electric Models:

Are heating

elements or

contactors

inoperative?

Check heat

contactors

and elements.

Replace if

necessary.

Gas Models:

Is gas supply

insufficient?

Open partially closed gas

shut-off valve, or correct

low gas pressure. Check

inlet pressure and

compare to pressure

specified on serial plate.

If pressure cannot be

obtained, contact gas

supplier.

Continued on

next page

Gas Models:

Are orifices

incorrect?

Tumbler is equipped

for type of gas

specified

on serial plate at

0-2,000 feet altitude.

Refer to Installation

Manual .

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

Ye s

No

TMB2324S-a

TMB2324S-a

Troubleshooting

70422101R1 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

Clean lint

compartment after

every eight hour shift.

Continued from

previous page

Gas Models:

Are gas valve coils

inoperative?

Test coils and

replace if

available as a

service part,

otherwise

replace valve.

Gas Models:

Is igniter

inoperative?

Gas Models:

Is igniter control

inoperative?

Test igniter and

replace if

inoperative.

Test igniter

control and

replace if

inoperative.

Is

airflow switch

inoperative?

Check back draft

damper for foreign

objects, lint

accumulation or other

causes that may

prevent damper from

opening.

Check ductwork for lint

build-up. Refer to

Installation Manual to

ensure that ductwork

and make-up air

openings are sized

properly.

Check exhaust outlet. If

a screen has been

installed on the outlet, it

may be clogged with

lint or frozen over in

winter. NEVER install a

screen over the

exhaust outlet.

Is lint door

panel not

closed

properly?

Open lint door

panel. Place lint

door panel back on

tumbler ensuring a

tight fit.

Is there

broken, loose

or incorrect

wiring?

Refer to wiring

diagram

located inside

contactor box.

Ye s

No

Ye s

No

Ye s

No

Gas and Electric

Models: Is high

limit thermostat

inoperative?

Test thermostat

and replace if

inoperative.

Ye s

No

Yes

No

Ye s

No

Ye s

TMB2324S-b

No

TMB2324S-b

6. Heating Element Does Not Heat or Burner Does Not Ignite (continued)

24 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7. Igniter Does Not Shut Off After Gas Ignition — Gas Burner

Igniter does not

shut off after

gas

ignition - gas

burner

Is tumbler not

properly equipped for

type of gas being

used?

Tumbler is equipped for

type of gas specified on

serial plate at 0-2,000

feet altitude. Refer to

Installation Manual.

Is there

insufficient gas

supply?

Open partially

closed gas shut-off

valve or correct low

gas pressure.

Is burner flame

adjusted

improperly?

Refer to

Adjustments

Section for

recommended

burner flame

adjustment.

Is electrode assembly

incorrectly installed?

Check

assembly for

correct

alignment.

Is igniter control

inoperative?

Test igniter

control and

replace if

inoperative.

Is wiring

incorrect?

Refer to wiring

diagram

located inside

contactor box.

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

TMB1878S

TMB1878S

Troubleshooting

70422101R1 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

TMB1879S

8. Heating Element or Burner Shuts Off Prematurely

Heating

element or

burner shuts off

prematurely

Refer to

Is there improper or

inadequate exhaust

and/or make-up air?

No

Ye s

Installation

Manual for exhaust

and make-up air

requirements.

Gas Models: Is

there insufficient

gas supply?

No

Gas Models: Is tumbler

not properly equipped

for type of gas used?

No

Gas Models: Is

burner flame

improperly adjusted?

No

Ye s

closed gas shut-off

valve or correct low

pressure.

Tumbler is equipped for

Open partially

type of gas specified on

Ye s

serial plate at 0-2,000

feet altitude. Refer to

Installation Manual.

Refer to

Ye s

Adjustments

Section for burner

flame adjustment.

Is high limit

thermostat

cycling off?

Ye s

Refer to

Paragraph 8.

No

Is there

broken, loose

or incorrect

wiring?

Ye s

Refer to wiring

diagram

located inside

contactor box.

TMB1879S

26 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9. Heating Element or Burner Repeatedly Cycles Off On High Limit

Heating element or

burner repeatedly

cycles off on high

limit thermostat

Is external exhaust

system longer than

recommended or is

there inadequate

make-up air?

Refer to

Installation

Manual for

exhaust and

make-up air

requirements.

Is lint

screen

clogged?

Remove screen

and clean. Lint

screen and

compartment

should be cleaned

after every eight

hour shift.

Is there lint

in tumbler

ducts?

Clean tumbler

ducts.

Is there lint

in external

exhaust

system?

Disassemble

exhaust

system and

clean.

Is high limit

thermostat

cycling at too

low a

temperature?

Replace

thermostat.

Is lint door

panel not

closed

properly?

Open lint door

panel, place lint

door panel back

on tumbler

ensuring a tight fit.

Is backdraft

damper not

operating?

Check for

foreign

objects, lint

accumulation

or other

possible

obstructions.

TMB1880S

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

TMB1880S

Thermostat

Troubleshooting

70422101R1 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

TMB1881S

10. Heating Element or Burner Does Not Shut-Off

Heating element or

burner does not

shut-off

Gas Models: Are

there impurities on

gas valve seat,

preventing valve

from closing?

Yes

Replace gas

valve.

No

Is drying

timer, relay or

contactor

inoperative?

No

Is wiring

incorrect?

Yes

Yes

Replace timer,

relay or

contactor.

Refer to wiring

diagram

located inside

contactor box.

TMB1881S

28 70422101R1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...