Hubbell TX008‐2RS, TX011‐3R, TX011‐2S, TX011‐3T3, TX012‐2RS Installation, Operation And Maintenance Manual

...

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL FOR

THE HUBBELL MODEL TX/HX TANKLESS

WATER HEATER

ELECTRIC HEATER COMPANY

Edition 2011

2

Important Safety Information

1. You must read and follow all instructions. Serious bodily injury or death could occur

if you ignore this warning.

2. All circuit breakers and/or disconnect switches servicing the heater must be turned off

when installing, uninstalling, or repairing this water heater.

3. The Hubbell Tankless Water Heater must be grounded.

4. The unit must be installed by a licensed electrician and plumber.

5. The unit must be wired in accordance with the current version of the National

Electrical Code (US) or Canadian Electric Code (Canada).

6. This installation must comply with all national, state, and local plumbing and

electrical codes.

7. When the heater is not within sight of the electrical circuit breakers, an additional

local means of disconnection of all ungrounded conductors must be provided that is

within sight of the appliance or a circuit breaker lockout must be used. (Ref. NEC

422.31)

8. If the Hubbell Tankless Water Heater is installed in a location where water damage

could occur in the event of a leak, it is recommended that a drip pan be installed and

connected to a suitable drain. Alternatively, an active water leak detector and shut off

valve can be installed to turn off your water supply in the event a leak is detected.

9. If water supply has a high mineral content, a water softening system is recommended.

Damage to the water heater resulting from scale or hard minerals will not be covered

under warranty.

10. When the heater is installed in a well water system or if the plumbing system is prone

to introducing air into the heater, it is highly recommended that an air separator be

installed in the cold water feed to the heater to avoid possible failure of the heating

element and/or heating chamber.

3

TABLE OF CONTENTS

SECTION TITLE PAGE No.

I TANKLESS WATER HEATER OPERATING PRINCIPLE 4

II GENERAL DESCRIPTION AND CONSTRUCTION 5

III INSTALL ATION 9

IV OPERATION AND MAINTENANCE 21

V TROUBLESHOOTING 26

VI SERVICING & REPLACEMENT OF PARTS 32

VII PARTS LIST 36

VIII WARRANTY 37

4

SECTION I – TANKLESS WATER HEATER OPERATING PRINCIPLE

How the Hubbell Tankless Water Heater Works:

For the most part, operating the new tankless water heater is very similar to using any

traditional water heater system. However, it is very important that all of the set-up

procedures and operating instructions are carefully read to ensure maximum performance

and energy savings from the new water heater.

The Hubbell Tankless Water Heater does not store hot water like a conventional tank-type

water heater. It contains high powered heating elements that are capable of heating water

instantly on-demand as needed. As soon as there is a hot water demand, a sophisticated flow

sensor within the heater recognizes the demand and initiates the heating process. This

sensor measures the water flow rate while two other sensors measure the incoming and

outgoing water temperature. This information is transmitted continually to the

microprocessor controller which determines the precise amount of power to send to the

heating elements to heat the water to the desired temperature. The Hubbell tankless water

heater only uses as much power as is needed to meet the demand by fully modulating the

heating elements from 0 to 100%.

It is important to keep in mind that all tankless water heaters are subject to a maximum flow

rate. If this flow rate is exceeded, the heater will not be capable of fully heating water. The

amount of water that can be heated by the tankless water heater at any given time will

depend on the model selected and the incoming water temperature. See the charts in Section

II to determine the maximum flow rates.

Moreover, since a tankless water heater eliminates the ongoing thermal losses caused by

storing hot water in a tank, there will be a significant energy savings compared to a

conventional tank type water heater.

5

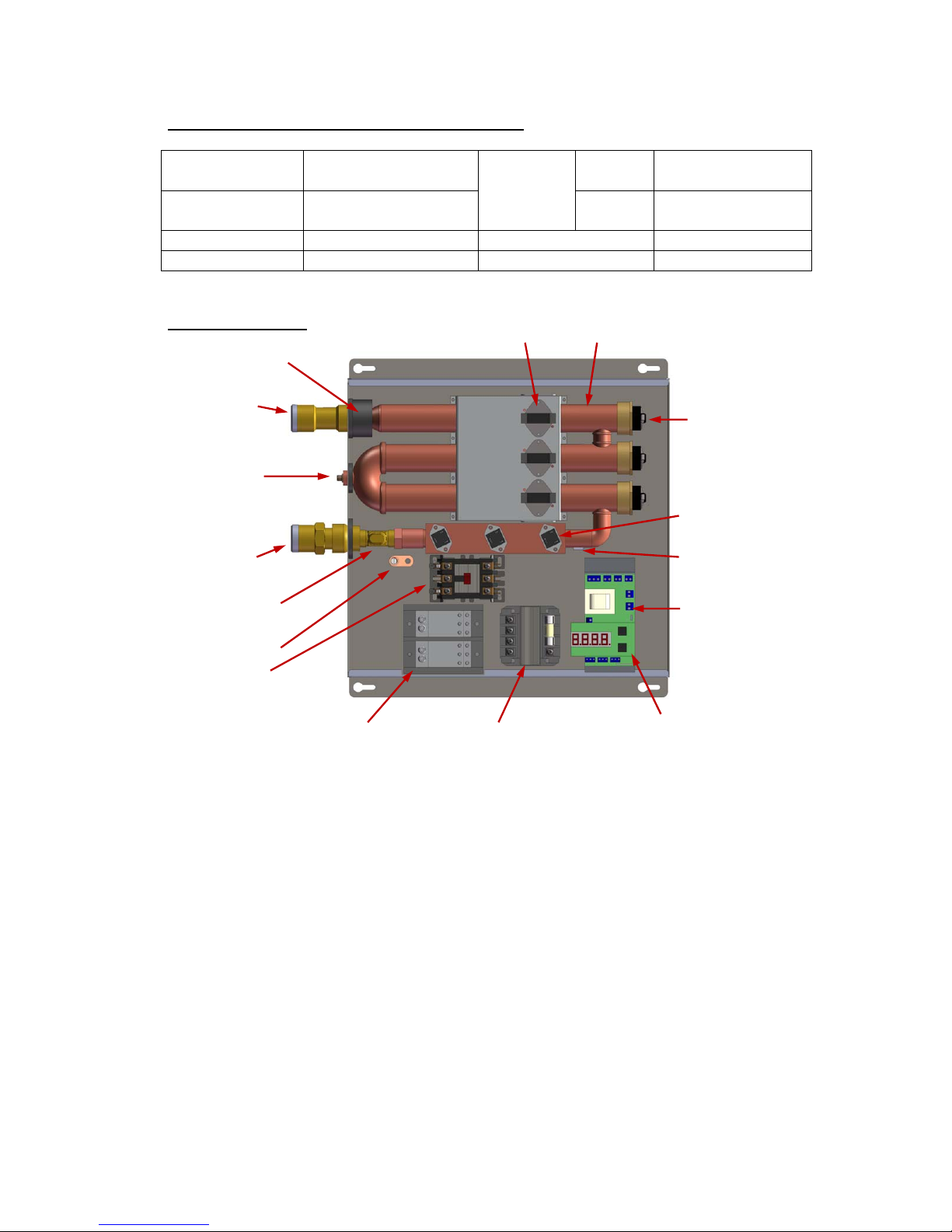

Heating Elements

Heating Chamber Hi-Limit Switches

Inlet Thermistor

Outlet Thermistor

Element Switching

Devices (Triacs)

Temperature

Controller

LED Digital Display

(with buttons)

Power Distribution Block

Ground Lug

Hot Water

Outlet

Cold Water

Inlet

Drain

Flow Meter

Magnetic

Contactor

Transformer

SECTION II – GENERAL DESCRIPTION AND CONSTRUCTION

Technical Specifications Common to All Models:

Materials: Copper Exchanger /

Stainless Steel Casing

Plumbing

Connection:

Low

Flow

¾” Copper, CPVC,

or PEX Tube

Energy

Efficiency:

98%

High

Flow

1” MNPT

Voltage: 208-600 Volts Operating Range: 5 – 150 psi

Frequency: 50 / 60 Hz Protection: Thermal Auto Reset

Product Overview:

Notes:

1. Power distribution blocks are only installed on single phase models.

2. Magnetic contactors are only installed on 3-phase models.

3. Transformers are only installed on 3-phase models over 240 volts.

4. 2-Element models will have a plug in the lowest element chamber and have only two hi-

limit switches and triacs installed.

Typical 2/3-Element Model

6

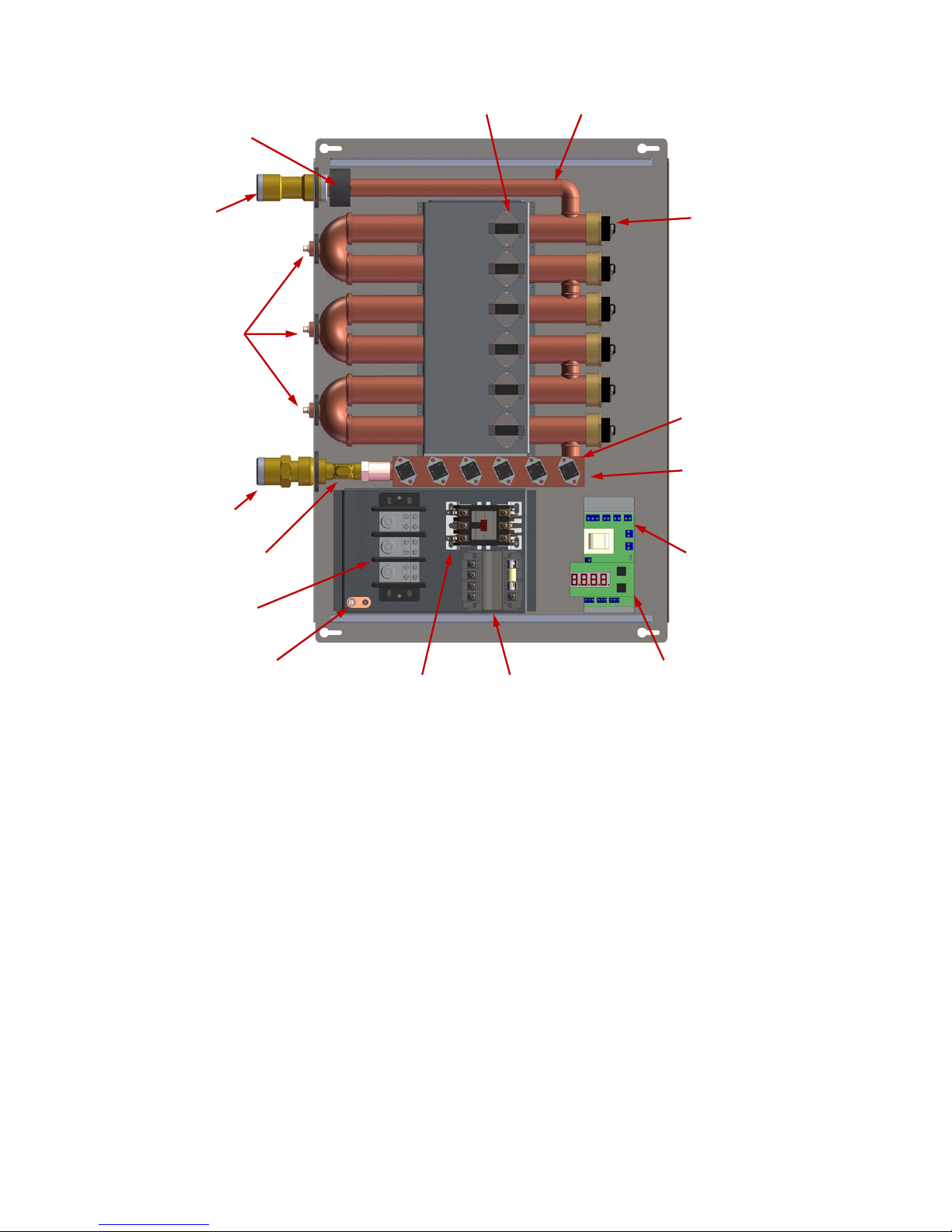

Heating Elements

Inlet Thermistor

(beneath triac

plate)

Outlet Thermistor

Element Switching

Devices (Triacs)

Temperature

Controller

LED Digital Display

(with buttons)

Magnetic Contactor

Ground Lug

Hot Water

Outlet

Cold Water

Inlet

Drains

Flow Meter

Hi-Limit Switches

Heating Chamber

Transformer

Power

Distribution

Bl

ock

Notes:

1. Power distribution blocks are only installed on single phase models and 3-phase models

that require two magnetic contactors. Single phase models use a 2-pole power

distribution block.

2. Magnetic contactors are only installed on 3-phase models. One or two magnetic

contactors may be installed as required.

3. Transformers are only installed on 3-phase models over 240 volts.

Typical 6-Element Model

7

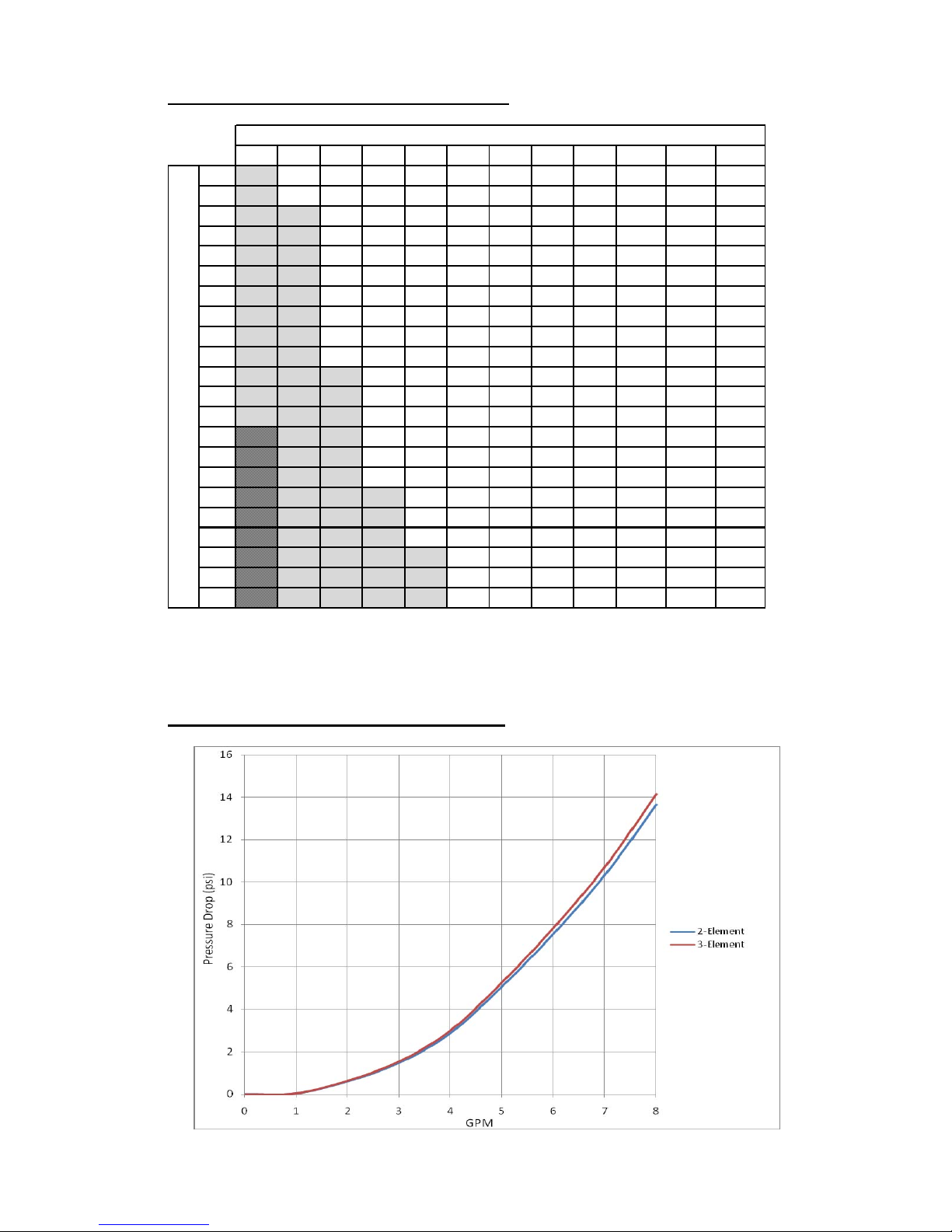

Tankless Water Heater Maximum Flow Rates:

5°F 10°F 20°F 30°F 40°F 50°F 60°F 70°F 80°F 100°F 120°F 140°F

8

10.9 5.5 2.7 1.8 1.4 1.1 0.9 0.8 0.7 0.5 0.5 0.4

11

15.0 7.5 3.8 2.5 1.9 1.5 1.3 1.1 0.9 0.8 0.6 0.5

12

16.4 8.2 4.1 2.7 2.1 1.6 1.4 1.2 1.0 0.8 0.7 0.6

13

17.8 8.9 4.4 3.0 2.2 1.8 1.5 1.3 1.1 0.9 0.7 0.6

14

19.1 9.6 4.8 3.2 2.4 1.9 1.6 1.4 1.2 1.0 0.8 0.7

15

20.5 10.3 5.1 3.4 2.6 2.1 1.7 1.5 1.3 1.0 0.9 0.7

16

21.9 10.9 5.5 3.6 2.7 2.2 1.8 1.6 1.4 1.1 0.9 0.8

18

24.6 12.3 6.2 4.1 3.1 2.5 2.1 1.8 1.5 1.2 1.0 0.9

20

27.3 13.7 6.8 4.6 3.4 2.7 2.3 2.0 1.7 1.4 1.1 1.0

21

28.7 14.4 7.2 4.8 3.6 2.9 2.4 2.1 1.8 1.4 1.2 1.0

24

32.8 16.4 8.2 5.5 4.1 3.3 2.7 2.3 2.1 1.6 1.4 1.2

25

34.2 17.1 8.5 5.7 4.3 3.4 2.8 2.4 2.1 1.7 1.4 1.2

27

36.9 18.5 9.2 6.2 4.6 3.7 3.1 2.6 2.3 1.8 1.5 1.3

30

20.5 10.3 6.8 5.1 4.1 3.4 2.9 2.6 2.1 1.7 1.5

31

21.2 10.6 7.1 5.3 4.2 3.5 3.0 2.6 2.1 1.8 1.5

33

22.6 11.3 7.5 5.6 4.5 3.8 3.2 2.8 2.3 1.9 1.6

36

24.6 12.3 8.2 6.2 4.9 4.1 3.5 3.1 2.5 2.1 1.8

40

27.3 13.7 9.1 6.8 5.5 4.6 3.9 3.4 2.7 2.3 2.0

42

28.7 14.4 9.6 7.2 5.7 4.8 4.1 3.6 2.9 2.4 2.1

48

32.8 16.4 10.9 8.2 6.6 5.5 4.7 4.1 3.3 2.7 2.3

50

34.2 17.1 11.4 8.5 6.8 5.7 4.9 4.3 3.4 2.8 2.4

54

36.9 18.5 12.3 9.2 7.4 6.2 5.3 4.6 3.7 3.1 2.6

Maximum Flow Rate (GPM) at Temperature Rise (°FΔT)

Power (kW)

1. Shaded values indicate that a High Flow (HX) unit is required.

2. Blank values indicate that the flow rate will exceed the flow capability of the flow meter.

3. For alternate power (kW) values, the maximum flow rate can be calculated using the

formulas on the following page.

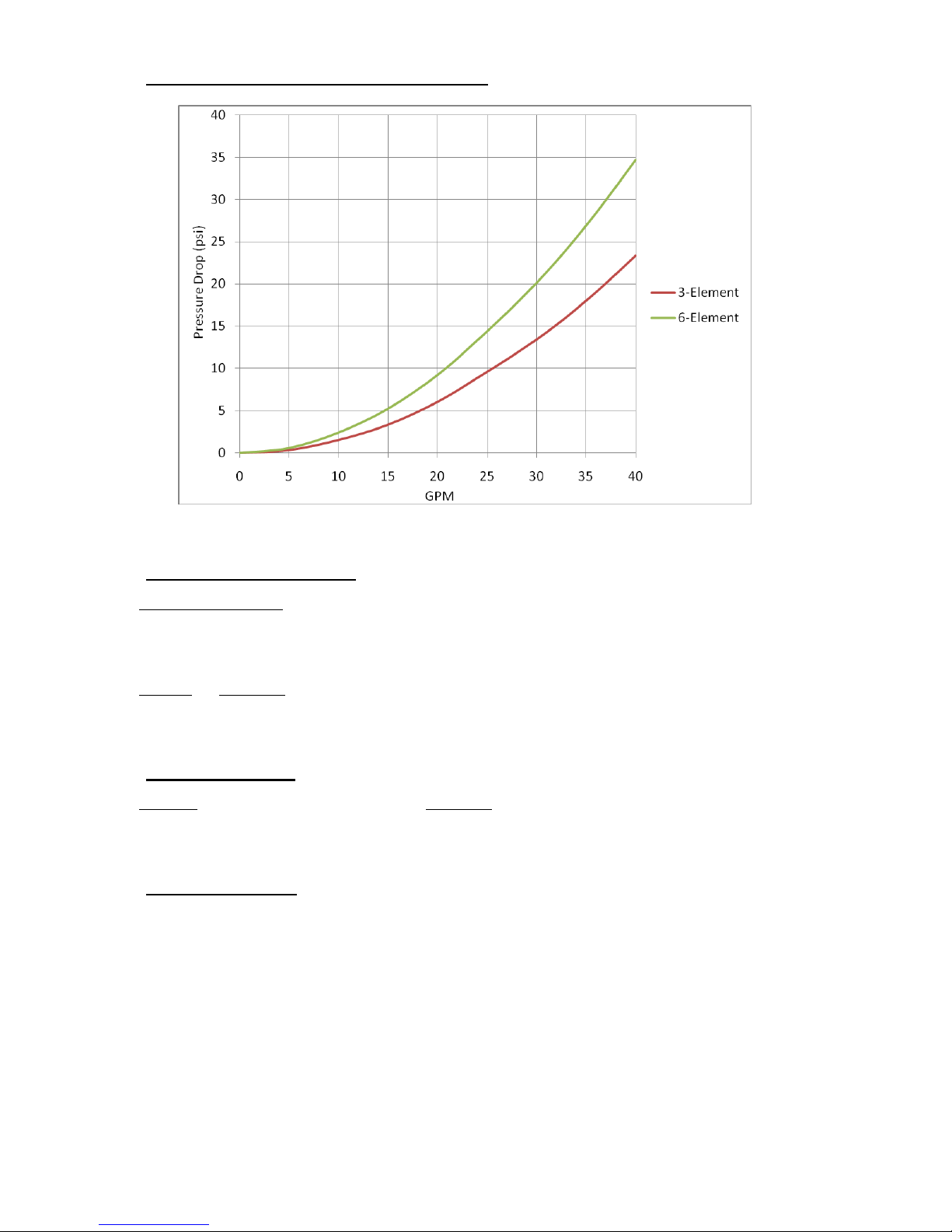

Tankless Low Flow Pressure Drop Chart (TX):

8

Tankless High Flow Pressure Drop Chart (HX):

Wattage De-rating Formula:

Applied Voltage

2

× Rated Wattage = Actual Wattage

Rated Voltage

2

For example: If installing a 27 kW unit when actual voltage is 212 V,

212

2

=

44,944

= 0.78 × 27,000 W = 21,060 W @ 212 V

240

2

57,600

Amperage Formula:

Watts

= Amps (Single Phase)

Watts

÷1.73 = Amps (3-Phase)

Volts Volts

Flow Rate Formulas:

To determine power (kW) requirement

____GPM × ____ °F ΔT × 0.1465 = ____ kW

To determine temperature rise

____ kW × 6.824 ÷ ____ GPM = ____°F ΔT

To determine flow rate

____ kW × 6.824 ÷ ____ °FΔT = ____ GPM

9

SECTION III – INSTALLATION

WARNING: Serious bodily injury or death may occur if the following warnings are

ignored.

• All circuit breakers and/or disconnect switches servicing this heater must be turned

off before installing, repairing or uninstalling this water heater.

• Installation of this product is restricted to indoor locations.

• Installation

MUST

be done by a licensed electrician and licensed plumber.

Locating and Mounting Instructions:

The Hubbell tankless water heater can be installed just about anywhere. Due to the small

size of the water heater, it can be mounted in many small spaces. However, there are some

important guidelines to follow that will ensure that the installation is both safe and

convenient in the event that future servicing is required.

This product is designed to be installed indoors only. The unit may be installed in an

outdoor location as long as it is mounted in a suitable enclosure that protects it from rain,

splashed water, direct sunlight, debris, and insects. This product should NOT be installed in

a location where it may be subjected to freezing temperatures. If the water inside the tankless

water heater freezes, it can cause severe and permanent damage that is not covered under the

warranty. If you suspect that the tankless water heater may have frozen, do not turn on the

heater until it has thawed and it has been inspected for leaks.

When selecting an installation location, give consideration to the existing plumbing

configuration, location of your main electrical panel, and location of the point of use. Try to

choose a location that does not require major plumbing alterations, that is close to the main

electrical panel (this will reduce the amount of wire needed to install), and that is physically

close to the hot water fixtures. By locating the heater close to the points of use, this will

reduce the amount of time it takes for the hot water to travel from the water heater to the

point of use. Consideration should also be given to future servicing. Do NOT locate the

water heater in a location that is difficult to access. In most cases, installing the tankless

water heater in the same location as the old conventional tank-type water heater will make

the most sense.

Avoid installing the tankless water heater in a location prone to excessive humidity,

moisture, or dust, or in an area where it may be splashed with water or other liquids. Do

NOT install under water pipes or air conditioning lines that might leak or condense moisture

that could then drip onto the heater. Do NOT install above electrical boxes or junctions.

If installation of the water heater will be on a second floor, make sure that all code

requirements for such installations as required for your area are followed. Hubbell

recommends that a drip pan (connected to a drain) is installed below the water heater to

avoid property damage in the unlikely event of a leak. Alternatively, an active water leak

detector and shut-off valve designed to turn off the water supply in the event that a leak is

ever detected may be installed.

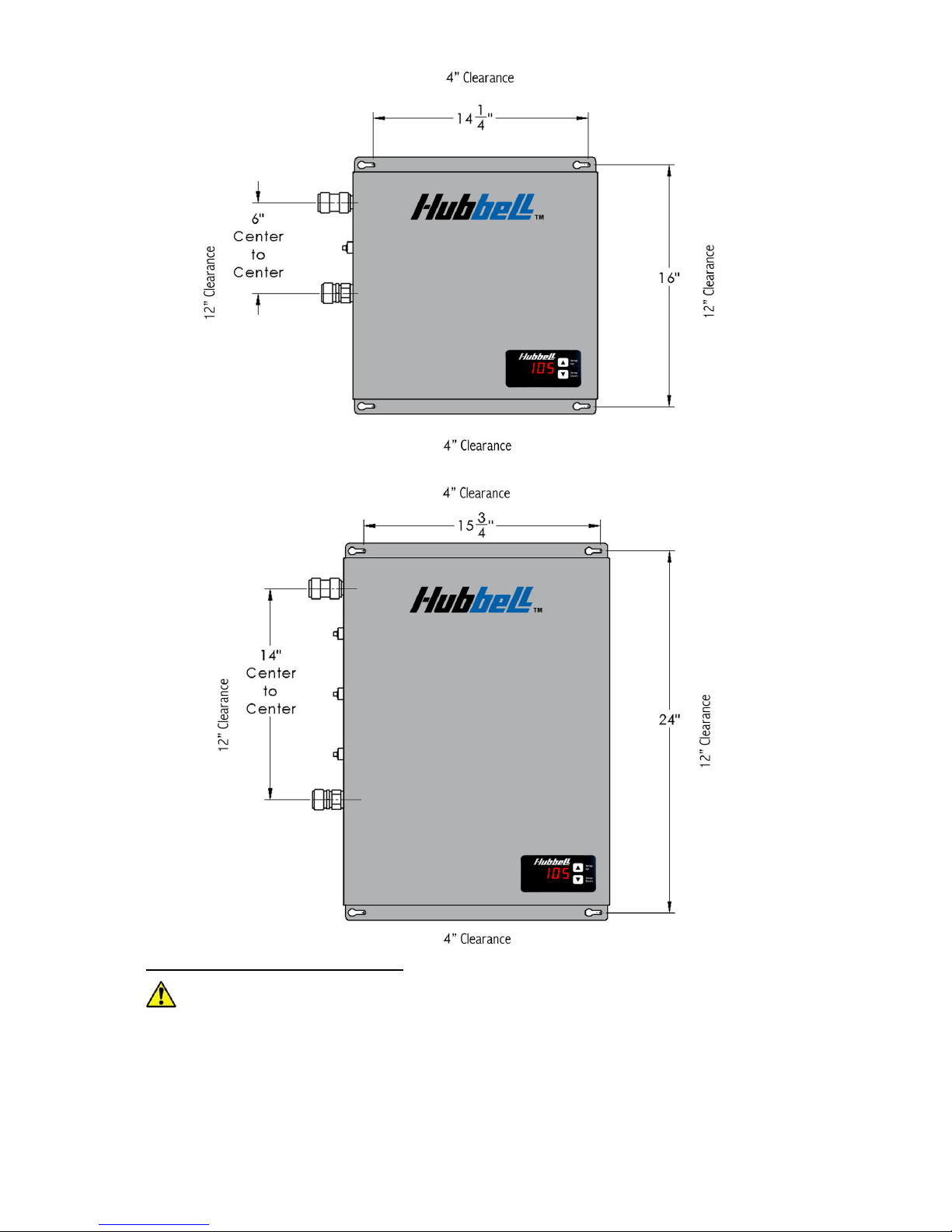

Mounting the unit:

• Leave a minimum of 12” to both sides and 4” on the top and bottom of the unit.

• Mount the water heater securely to the wall by putting four (4) screws through the

mounting holes.

• Install a ¼” diameter bead of sealing caulk around the entire perimeter of the heater

between the heater back panel and the wall. This prevents any moisture or debris

from accumulating.

10

Plumbing Installation Instructions:

IMPORTANT INFORMATION:

• Ensure all fitting installations comply with local plumbing and building codes.

•

This water heater does not require a temperature and pressure (T&P) relief valve.

You may install a T&P relief valve if the county, city or state plumbing code requires

it.

• Installations in the Commonwealth of MASSACHUSETTS and KENTUCKY require

a

T&P

relief valve.

11

• When connecting to a plumbing system that utilizes Flex or PVC, a

T&P

relief valve

should be used as added safety.

•

Do not connect the unit directly to CPVC pipe. You must use at least three feet of

copper pipe prior to connecting to any CPVC connection.

• WARNING:

Do not solder any pipes with the unit connected to the pipes. Doing so

will damage the flow meter and void your warranty.

•

Before energizing the heater, run water for a minimum of three (3) minutes and

verify that all air has been removed.

•

Installation of an air separator device is recommended for installations where air can

be easily introduced into the water system (i.e. Well water systems, lake pumps, and

other municipal systems).

• A shut off valve MUST be installed on inlet side of unit. A shut off valve on the

outlet is recommended.

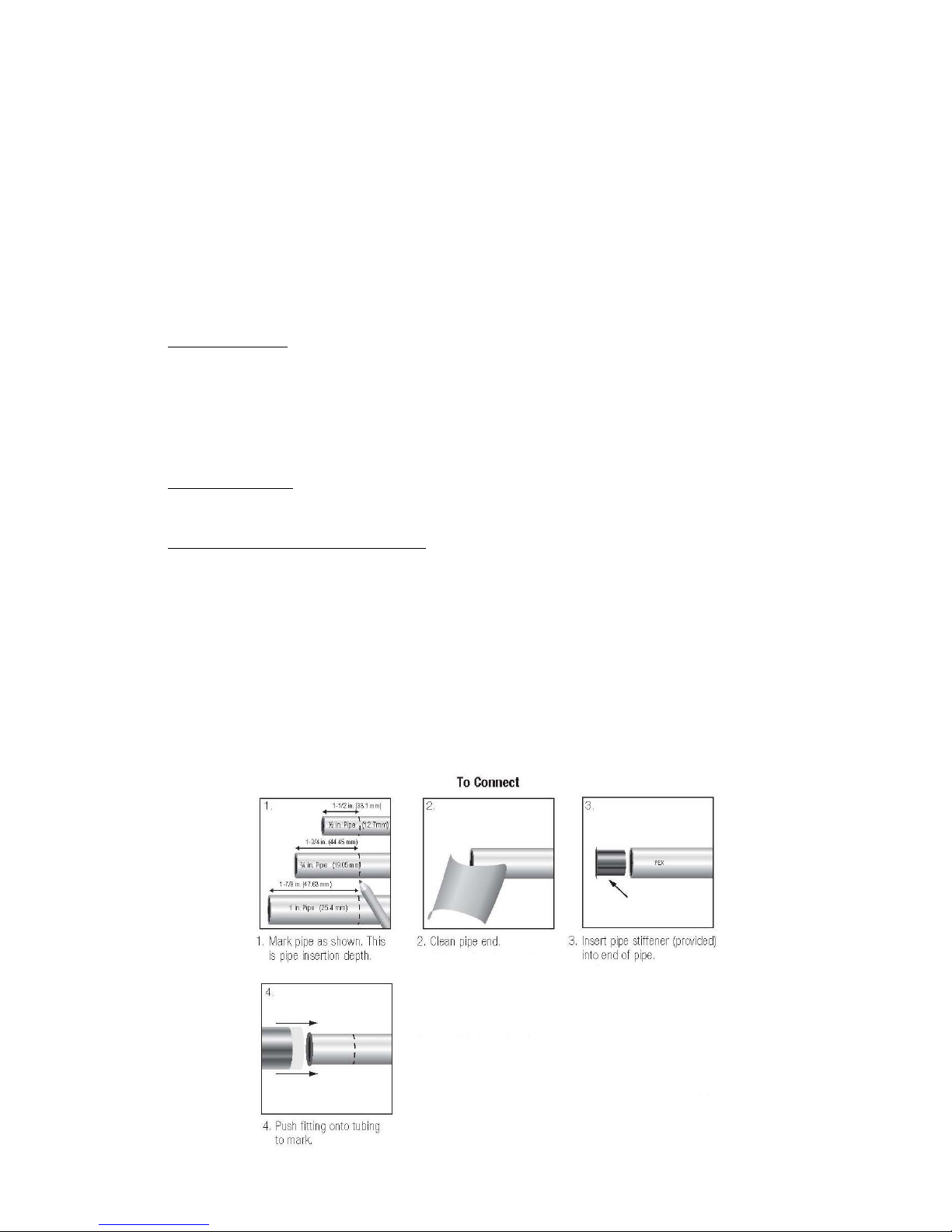

Pipe Preparation:

• Cut the tube so that the ends are square. WARNING: Ensure that there are no burrs or

damage to the

cut end. This will prevent any damage to the internal o-ring.

• Once the tubing end is cut square and clean, mark the pipe to be installed at a distance

of 1 ¾” from the end of the pipe. This is the insertion depth.

• Check that fittings and tubing are

clean, in good condition and are free from damage

and foreign objects.

Flushing the Line:

•

Before connecting the copper pipe to the water heater, it is extremely important to

flush the lines to eliminate all plumbing paste, residue, or debris in the lines.

Installation to Quick-Connect Fitting:

• If using PEX tubing, insert the supplied stiffener into the end of the pipe.

•

To assemble correctly, the tubing needs to be pushed into the fitting until it reaches

the mark previously scribed. Push the tube firmly with a slight twisting action until it

reaches the tube stop.

• Connect the cold water line to the water heater inlet marked cold water. Connect the

hot water line to the water heater outlet marked hot water.

•

After inserting both fittings, open the hot water faucet and allow water to run

through the water heater for at least three (3) minutes, cycling the flow on and off

every minute. This process clears all the air from the lines and must be performed

prior to turning on the power at the unit.

WARNING:

Failure to do this may

damage the flow meter or heating elements and will void your warranty.

12

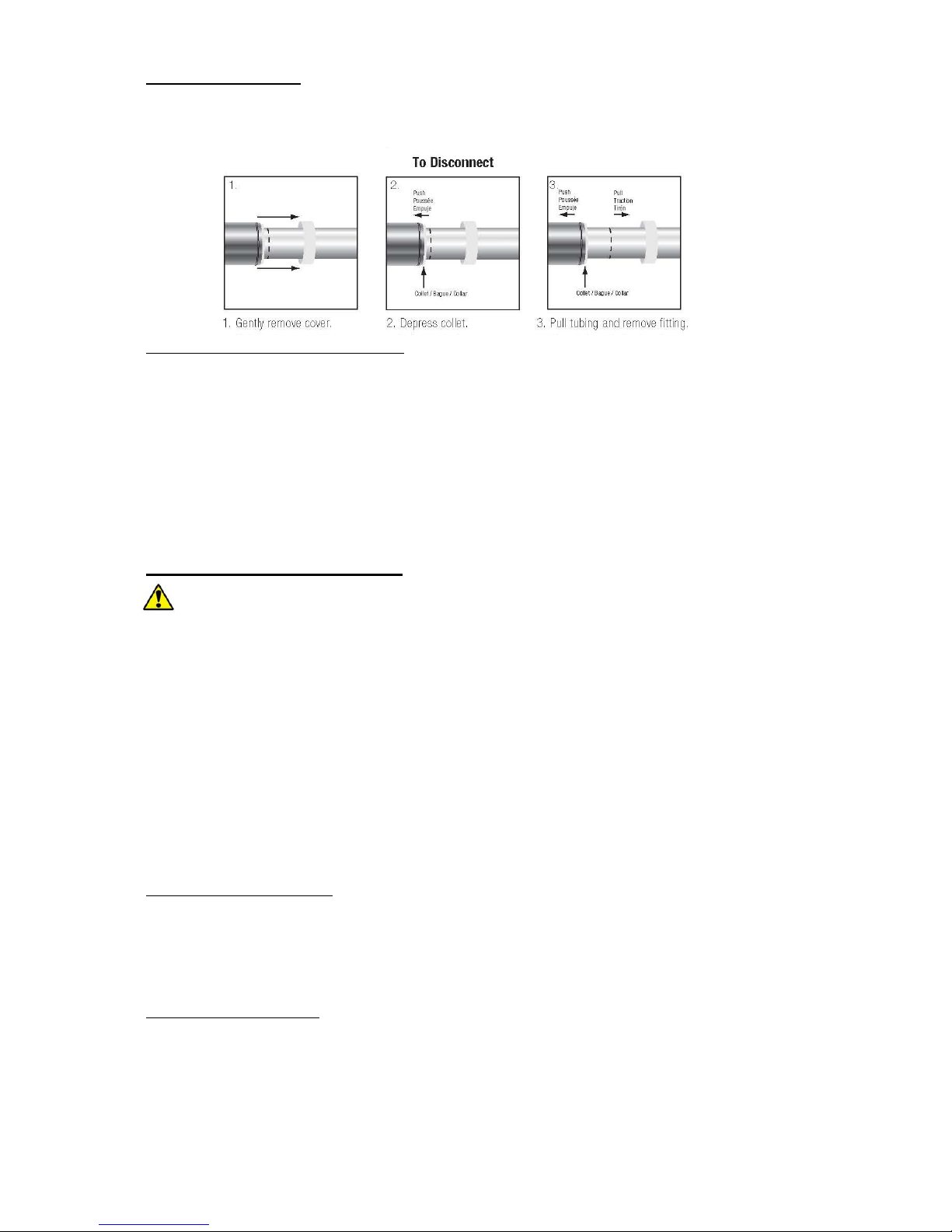

Disconnecting a Joint:

• Gently remove the cover to the quick-connect fitting.

• Depress the collet of the quick-connect fitting and pull the tubing to remove the quick-

connect fitting.

Checking for Leaks and Purging Air:

• If unit has been wired, verify all circuit breakers supplying power to the unit are

turned off.

• Open all hot water taps supplied by the unit and inspect water connections for leaks.

• With all hot water taps still open, allow the water to run for a minimum of 3

minutes. Inspect each tap to ensure all air in the lines has been purged. This process

purges all the air from the water lines and MUST be performed prior to turning on the

power at the unit.

WARNING:

FAILURE TO FOLLOW THIS STEP CAN CAUSE

PERMANENT DAMAGE TO THE HEATING ELEMENTS.

• Close all hot water taps.

Electrical Installation Instructions:

IMPORTANT INFORMATION:

• The unit must be wired in accordance with the current version of the National

Electrical Code (US) or Canadian Electric Code (Canada).

• The unit must have its own independent circuits.

• When the heater is not within sight of the electrical circuit breakers, an additional

local means of disconnection of all ungrounded conductors must be provided that is

within sight of the appliance or a circuit breaker lockout must be used. (Ref. NEC

422.31)

• Wire entry must be through the electrical KO provided in the bottom of the unit.

• For Canada, per Canadian Electric Code, C22.1-02, the unit must be wired by a single

feed installation with one (1) double-pole circuit breaker.

• For US, the unit may be wired by a single feed installation with one (1) double-pole

circuit breaker or by a multiple feed installation with multiple double-pole circuit

breakers.

Wiring to the water heater:

• Connect the pow er wi re from the main pa nel to the power dist ribution block or

magnetic contactor as applicable.

•

Connect the main ground wire to the ground lug in the heater.

•

Make sure the connections are securely tightened.

Electrical Specifications:

Listed in the following tables are the electrical specifications for each tankless water heater

model.

Loading...

Loading...