Page 1

OPERATING AND MAINTENANCE MANUAL FOR

T1000 CONTROLLER

ELECTRIC HEATER COMPANY

1

Page 2

CONTROLLER DESCRIPTION

CONTROL BOARD AND DISPLAY

The control board supplies all the necessary

function for heater operation. These include

control temperature, hi-limit cut-out, low water

detection, and leak detection.

CONTROLLER OPERATION

NOTE: All controller variables come preset from the factory to include a preset temperature of 185°F.

1. To turn unit on or off:

a. Press the ON/OFF button on the display module.

b. Note that the controller will resume its last mode of operation if power is disconnected.

2. To change setpoint temperature (the temperature is fully adjustable from 32° to 194°F (0°-90°C):

a. Press the UP and DOWN arrows simultaneously to enter setpoint change mode.

b. Press the UP or DOWN button to change the setpoint temperature.

c. Pressing and holding the UP or DOWN button will scroll through the setpoint temperature.

d. To leave setpoint change mode

i. Wait 5 seconds without pushing any buttons or press the UP and DOWN buttons

simultaneously.

3. To view the number of operational hours (the number of hours when a contactor is pulled in) and

software version:

a. Press the UP and DOWN arrows simultaneously to enter setpoint change mode.

b. Press the ON/OFF button.

c. Display will flash the software version (e.g. R14), HRS, followed by the hours in thousands

of hours, followed by the hours.

i. Example: r14, HrS, 123, 456; indicates software version R1.4 and 123,456 hours.

d. To leave operational hours mode

i. Wait 5 seconds without pushing any buttons or press the UP and DOWN buttons

simultaneously.

4. Configuration Menu. (NOTE: Configuration menu change should only be made by qualified

personnel).

a. To enter the configuration menu, press and hold the UP, DOWN, and ON/OFF buttons

simultaneously for 5 seconds.

b. To scroll through menu settings, press the ON/OFF button.

c. To make a change to a menu setting use either the UP or DOWN arrow.

d. Settings:

i. Relays – sets the number of magnetic contactors used in the heater.

1. r##, where ## is the number of magnetic contactors (01 or 02).

ii. Low water detection – sets the low water detection on or off.

1. LOn, for low water on. (Factory Default)

2. LOF, for low water off.

iii. Low water reset – sets the low water reset for either automatic or manual

1. LAU, for low water automatic reset. (Factory Default)

2. LAn, for low water manual reset.

2

Page 3

iv. Temperature units – sets the temperature units to either degrees Fahrenheit or

Celsius.

1. DEF, for degrees Fahrenheit. (Factory Default)

2. DEC, for degrees Celsius.

v. Differential – sets the number of degrees below setpoint that the heater will resume

heating after it has achieved setpoint.

1. d##, where ## is the differential in degrees (1 to 20). (Factory set at 02)

vi. Display – sets the display to either setpoint or actual temperature.

1. dSS, for display setpoint temperature. (Factory Default)

2. dSt, for display actual temperature.

e. To leave the configuration menu, wait 5 seconds without pushing any buttons or press the UP

and DOWN buttons simultaneously.

5. To reset any high-limit, no probe, or low water (when in manual reset mode) fault condition, press the

RESET button.

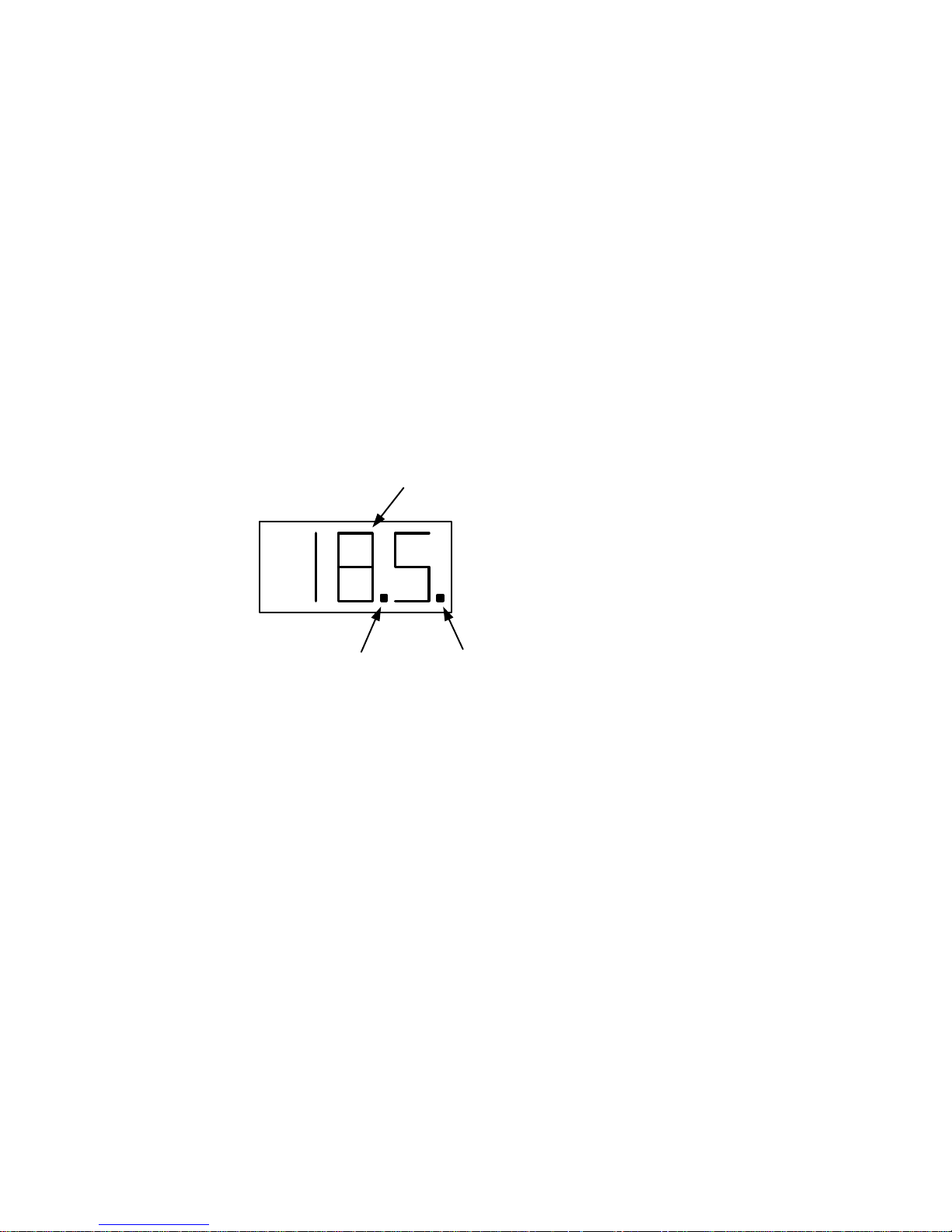

6. Display

a. By default the display will show the setpoint of the booster heater.

b. The decimal points on the display, as shown below, indicate that the controller is calling for a

contactor to pull in.

Setpoint

nd

Contactor

2

(if supplied)

1st Contactor

3

Page 4

WIRING OPTIONS

OPTIONAL REMOTE ALARM CONTACTS

1. If desired, the control board can be wired to a remote alarm to indicate a reset fault condition. These

fault conditions include over-temperature, no probe, and low water (when the configuration is set to

manual reset).

2. This alarm can be wired to the J4 connector on the control board as shown below. To facilitate this

installation, an optional adapter, Hubbell P/N PLUG ADAPTER J4, can be purchased to provide wire

connections.

J4 Connnector

Common

(NO)

(NC)

Note: Rating (resistive)

Max. Switching Power:

60W, 62.5VA

PLUG ADAPTER J4

FOR REMOTE ON/OFF CONTROL

To remotely control the On / Off operation of the heater, it is

recommended that a DPST switch or relay (by others) be used to break

both power legs (white and black wires) connected to the top two

terminals of the J5 connector on the control board. See diagram at

right.

Use a NC (Normally Closed) relay to turn the booster ON when energizing the relay

coil or to turn the booster OFF when de-energizing the relay coil.

Use a NO (Normally Open) relay to turn the booster OFF when energizing the relay

coil or to turn the booster ON when de-energizing the relay coil.

Wiring from Contactor,

Power Distribution Block,

or Transformer

Remote Rela y by Customer

Max. Switching Voltage:

220VDC, 250VAC

Max. Switching Current: 2A

Max. Carrying Current: 3A

Wiring by

Customer

1

2

3

4

Controller J5 Connector

4

Red Wire to

Contactor #2

Yellow Wire to

Contactor #1

Page 5

TROUBLESHOOTING

ERROR MESSAGES

1. Err, No, Prb

a. This message will flash when the controller does not detect that the probe is

connected to the control board. To clear this error reinsert the probe connector and

press RESET. If the error message does not clear, replace the probe assembly.

2. Err, too, hot, ### (where ### is the actual temperature of the water.)

a. This message will display if the temperature of the water exceed the high limit

temperature setpoint. To clear this error, wait until the temperature is below the

operating setpoint and press RESET. Note that the unit will not reset until the

indicated temperature is below 195°F. If this message continually occurs, follow

the troubleshooting flow chart for continuous over-temperature condition.

3. Err, No, H2O

a. This message will display when the water level in the tank has dropped below the

sensor probe. To clear this message, refill the tank. If the low water reset is set for

automatic, the error will clear. If the low water reset is set for manual, when the

tank is full press RESET. Check the heater and the piping for leaks. Check for

mineral buildup on the probe and clean as required. Check for continuity between

the yellow wire and ground. See diagram 2 on the following page.

4. Err, H2O, LEA

a. This message displays if the leak detection sensor determines there is water in the

base of the heater shell. To clear this message, remove the water from the leak

detection sensor. Check the unit and piping for leaks.

MISCELLANEOUS

1. If the display flashes when the unit is first turned on or turned on after maintenance,

check that the J5 terminal on the controller is engaging all four pins on the board.

2. Note that before replacing the control board, display, or probe, it is recommended that the

power supply to the booster heater be turned off at the main circuit breaker disconnect to

the booster heater to reset and clear the electronic controller.

CAUTION: Do not use plumber’s tape/Teflon tape/pipe dope when installing the probe. Tape

will prevent the low water detection system from operating properly and will cause false low

water errors. Lubricate O-ring prior to installation.

Tighten probe at the brass hex flats only. Use a 13/16” open ended socket or spark plug wrench.

Do not apply pressure, twist, or turn the black wire or the stainless steel jam nut, as this will

damage the probe.

5

Page 6

TROUBLESHOOTING FLOW CHARTS

No Hot Water

Continuous Low

Water

Temperature

Verify setpoint

Verify water inlet

pressure and

temperature

OK?

No

Correct fault

condition

Yes

Check for loose

wires and tighten

as necessary

contactor pull

Yes

Is the

display on?

Yes

Is there an

error

message?

No

Magnetic

in?

Yes OK?

See 'No Display'

No

Yes

Message section

No

Verifythat all wires

are installed and in

correct positions

No

(see wiring

flowchart

See Error

of this manual

OK?

diagrams)

208/240V

at contactor

Verify T1000

configuration

settings. Replace

control board, i f

needed

No

coil?

No

Yes

Replace contactor

Unit properly

sized?

No

Replace with

correctly sized unit

Diagram 1

Thermistor Resistance vs Temperature

(error ±3%)

70°F = 11883

80°F = 9299

90°F = 7334

100°F = 5828

110°F = 4664

120°F = 3758

130°F = 3048

140°F = 2488

150°F = 2043

160°F = 1687

170°F = 1400

180°F = 1169

190°F = 980

Correct amps

at elements?

Yes

Plug probe end into RJ45 pigtail

(not supplied). Check ohms

across terminal s 1 and 4

(see diagrams 1 & 2). Compare

this with the ohms the thermistor

should supply for the actual

temperature in the tank

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Replace faulty

element

Do ohms

match?

No

Replace probe

Diagram 2

Blue

Yellow

Green

Red

Black

White

OK? Contact factoryNo No

OK?

Probe End RJ45 Pigtail

Yes

No

To verify that

there is water

1

in the tank

2

3

4

5

6

yellow(#2) and

check for

continuity

between

ground.

6

Page 7

Continuous

over-temperature

condition

Diagram 3

White

Black

Red

Yellow

For 1 contactor:

check voltage across 1 & 4

For 2 contactor:

check voltage across 1 & 3 and 1 & 4

1

2

3

4

J5

contactors pull out

208/240V across

terminals 1 & 2 of J5 on

the control board as

Plug probe end into RJ45 pigtail

(not supplied). Check ohms

across terminals 1and 4

(see diagrams 1 & 2). Compare

this with the ohms the t hermistor

should supply for the actual

temperature in the tank

Do

at setpoi nt?

No

Is there

shown in the

diagram 3?

Yes

Yes

zero amp draw when the

contactors drop out at

No

Replace cont actor

Is there

setpoint?

No

Do ohms

match?

No

Yes

Yes

Correct

temperature

setpoint?

No

Properly set

temperature

setpoint

Replace control

board

Are configuration

settings set properly,

Yes

per Section III, Para.

4?

Yes

Contact f actory

No

Any or all buttons

do not work, but

display is

operational.

Re-seat ribbon

cable from display

to control board

Verify that the

display is properly

seated to the base

and that the

buttons click when

pressed.

Replace digi tal

display

Replace control

board

No

No

No

OK?

OK?

OK?

Replace probe

Individual di splay

elements do not

work or unusual

characters are

displayed

OK?

Re-seat ribbon

cable from display

to control board. Be

sure ribon cable is

not reversed.

Replace digital

display

Replace control

board

OK?

No

OK?

No

7

Page 8

No Displa y

Is the circuit

breaker tripped at

source?

No

Is the circuit

breaker tripped

inside heater

(if supplied)?

No

Yes

Yes

Reset circuit

breaker

Reset circuit

breaker

Press ON/OFF

button on heater

Is correct voltage

measured at power

distribut ion block or line

side of contactor for

each phase?

Yes

Is there 480V at

the line side of the

transform er

(480V models only)?

Yes

Is there

208/240V at the load side

of the transformer

(480V models only)?

No

Check incoming

No

No Check wiring

No

Transformer

OK?

power

Replace

Contact factory

Diagram 4

208/240V

1

terminals 1 & 2 of J5 on

2

3

4

J5

8

Yes

Is there

208/240V across

the control

board? (see

diagram 4)

Yes

Re-seat ribbon

cable from control

board to display

No

Check wiring

OK?

Replace digital

display

No

OK?

Replace control

board

No

OK?No

Page 9

SERVICING

CONTROL BOARD

1. Disconnect power from unit.

2. Disconnect display cable, probe cable (J3), leak detection wire (J2), ground wire (J7), and

terminal block (J5) from the control board. NOTE: The terminal block (J5) is removable

from the control board. Grasp the terminal block on the ends and pull straight away from

the board.

Ground Wire (J7) Display Cable Leak Detection Wire (J2) Probe Cable (J3)

Power Wire (Common, White) Connector (J5)

Power Wire (Black) Wire to #2 Wire to #1 Contactor (yellow)

Contactor (red)

(only for two contactor operation)

3. Remove four (4) screws securing control board to panel.

4. Remove and replace control board.

5. Reconnect wires disconnected in step 2. NOTE: When reconnecting the ribbon cable be

sure to have the key on the cable align with the slot in the connector.

6. Connect power to unit.

9

Page 10

SENSOR PROBE

1. Disconnect power from unit.

2. Shut off incoming water supply.

3. Attach hose to drain connection.

4. Lift manual release lever on relief valve to let air into system or break union on outgoing

water line.

5. Drain water from tank.

6. Disconnect probe wire from control board. (See picture)

Probe connection (J3)

7. Remove probe from tank using a 13/16” slotted socket or 13/16” spark plug wrench to

accommodate the probe cable.

NOTE: Care should be taken not to pull or put excessive force on the cable to probe

connection.

8. Install new #115 Buna-N o-ring gasket and

install new probe. NOTE: Hubbell

recommends lubricating the o-ring with Parker

O-Lube prior to installation. WARNING: Do

not remove the jam nut. To replace the probe,

remove the entire probe assembly from the

tank.

Probe

9. Reconnect probe wire to control board.

10. Refill tank.

11. Check for leaks. Retighten as required.

12. Note that to resume operation the controller will need to be reset by pressing the

‘RESET’ button on the display.

CAUTION: Do not use plumber’s tape/Teflon tape/pipe dope when installing the probe. Tape

will prevent the low water detection system from operating properly and will cause false low

water errors. Lubricate O-ring prior to installation.

Tighten probe at the brass hex flats only. Use a 13/16” open ended socket or spark plug wrench.

Do not apply pressure, twist, or turn the black wire or the stainless steel jam nut, as this will

damage the probe.

10

Loading...

Loading...