Page 1

Hubbell Industrial Controls, Inc.

LXi Fire Pump Controllers

For use with Electric Motor

Driven Fire Pumps – Microprocessor Type

Brochure 6300M

Hubbell Fire pump Motor Controllers are designed to comply with

the latest standard of the National

Fire Protection Association for the

installation of stationary pumps for

fire protection (NFPA-20).

Models

The following combination

controllers are available:

♦ Model LXi-1100 - Solid State

Soft Start/Stop combined Manual and Automatic controllers

are designed to control squirrel

cage motors where the power

source does not permit full voltage starting and to reduce mechanical and hydraulic stress on

plumbing.

• May 2004 • Replaces August 2002

6300M

♦ Model LXi-1200 - Across-the-

Line combined Manual and

Automatic Controllers are designed to control squirrel cage

motors by means of Across-theLine starting.

♦ Model LXi-1300 - Autotrans-

former combined Manual and

Automatic Controllers are designed to control squirrel cage

motors where the power source

does not permit full voltage

starting.

♦ Model LXi-1400 - Reduced

Voltage Primary Resistor Start

combined Manual and Automatic Controllers are designed

to control squirrel cage motors

by means of Primary Resistor

starting.

♦ Model LXi-1600 - Wound Rotor

Manual Controllers are designed

to control wound rotor motors

driving multi-stage fire pumps.

They are available with five

speed points (standard) through

nine speed points (optional).

NYC MEA Approved.

LXi-1200 Shown

New Small Cabinet Design For Some Models

♦ Model LXi-1700 - Part Winding

combined Manual and Automatic Controllers are designed

to control squirrel cage motors

by means of Part Winding

Starting.

♦ Model LXi-1800 - (Closed) &

LXi-1900 (Open) Transition -

Wye/Delta combined Manual

and Automatic Controllers with

ATS are designed to control

squirrel cage motors by means

of Wye/Delta Starting either

Open or Closed Transition.

Features

♦ LXi Microprocessor Logic &

Control

♦ Coordinated design engineered,

built, tested and labeled by one

manufacturer

♦ Suitable for use as service en-

trance equipment

♦ Full compliment of visual indi-

cators

♦ Communications port

♦ LCD display shows system

pressure, and simultaneous

reading of all phases for amps

and volts

♦ Full range of horsepower ratings

and voltages

♦ Ample cable bending space

♦ Printer Available

♦ Digital Pressure Recording

♦ New Small Cabinet Design

Saves Pump Room Space

Examples:

40h x 22w x 13 deep for maximum of

40wp @ 208v-230V, 75hp @ 480v

Page 2

Fire Pump Controllers with LXi Logic

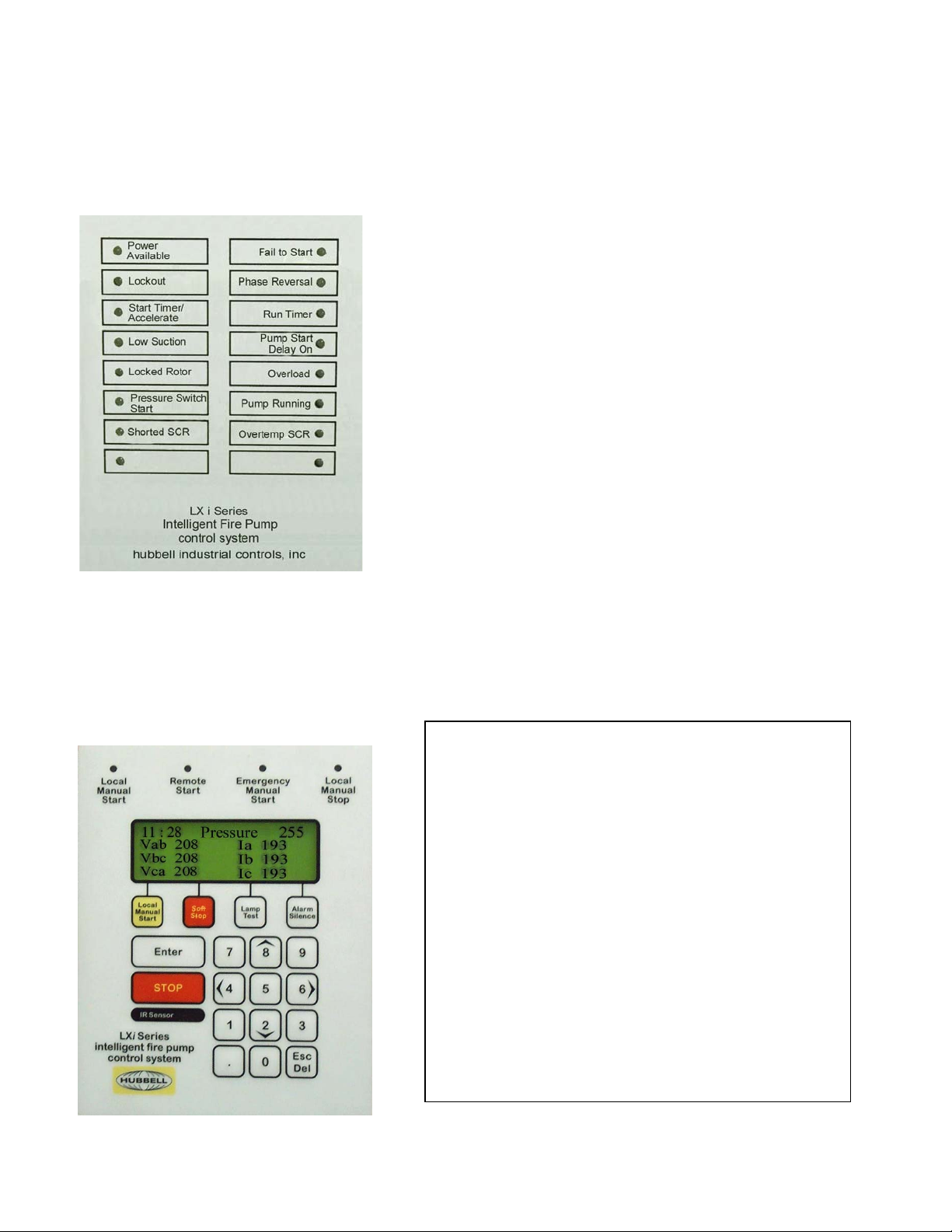

The LED display module is mounted on the enclosure flange, the LED’s are multi-color, red for

critical alarms, yellow for informational indications, and green for status.

A total of (16) LED’s are available to match most any requirement for alarm indications.

Standard Indications for LXi controllers

• Power Available

• Lockout

• Start Time/Acceleration (reduced

voltage/current models only)

• Low Suction

• Locked Rotor

• Pressure Switch Start

• Shorted SCR (LXi-1100 only)

• Fail to Start

• Phase Reversal

• Run Timer

• Pump Start Delay On

• Overload

• Pump Running

• Overtemp SCR (LXi-1100 only)

The LCD display/programming module displays four screens of (4) lines x 20 characters per screen.

Each individual screen may be scrolled in the display by the operator without a password. The LCD

display/programming module is mounted in the enclosure flange.

Main Screen Real Time Information

• System Pressure

• Simultaneous 3-Phase Volts – Phase to Phase

• Simultaneous 3-Phase Amps

(4) Additional LED’s

• Local Manual Start

• Remote Start

• Emergency Manual Start

• Local Manual Stop

The system pressure settings are set using

the touch pad after a password is entered .

Page 3

General Specifications for

These fire pump controllers are factory assembled, wired, and tested as a unit assembly, and conform to the

requirements of the latest editions of NFPA-20 and NFPA-70, and are Listed/Approved by and bear the label of

Underwriters’ Laboratories and Factory Mutual. The controllers are equipped with Hubbell’s

logic.

The controllers are of the combined manual/automatic type and furnished in a floor mounted drip-proof steel

Type 2 enclosure with lifting eyes. The enclosures are red with a non-glare surface. The controllers are

designed, tested, and marked for the rated horsepower and 3-phase voltage and frequency in a 40 degree C.

ambient.

All electrical components are accessible from the front for maintenance and service. No components or

component wiring are on the door of the enclosure. The controllers have a common operating handle for both

the line isolating switch and the controller circuit breaker mounted in the enclosure flange. The minimum

withstand rating for the fire pump controller is 100,000 amps RMS symmetrical at 200-480 volts. The

controllers are Listed/Approved with UL/FM as “Suitable For Use As Service Equipment”.

The controllers have separate and independent pressure settings with minimum run timing capable of a setting

up to 10 minutes. Settings of the pressures should be established at the time of the field acceptance test.

Provisions are included to allow manual or automatic shutdown in the field.

LXi

Controllers

LXi

microprocessor

Provided are two sets of Form “C” contacts for Pump Running, Phase Reversal, and Power/Phase Failure, and

one set of Form “C” contacts for Trouble. The Trouble contacts are activated by the following: Invalid

Configuration Memory, Emergency Manual Start, Pump Running, Phase Failure, Phase Reversal, Overload,

Locked Rotor, Fail-to-Start, and Lockout.

These controllers are equipped with

flash based CPLD (

An RS232 serial port shall be supplied for downloading event history to a PC for analysis and printing.

The digital pressure readings and settings are displayed on the

LCD screen is 4 x 20 (4 lines of 20 characters) per screen, and the screens may be scrolled to give a total of

320 characters. The real time display gives simultaneous 3-phase digital amps and volts for the pump power,

and digital display for the system pressure, reducing the need for scrolling during startup.

The event alarm caches are compartmentalized, and none of the compartments over-ride other compartments.

The compartments allow for analysis of four types of information events without having to look through all

events including those not related to a problem. Events are shown with Date and Time for each event

occurrence:

1. Events that have occurred during a pump idle period

2. Events that occurred during the last start period

3. Events that occurred during the last run period

4. Events that occurred during the last stop period.

complex-programmable logic device).

LXi intelligent fire pump control system logic.

The boot-up time for the logic is 3 seconds or less.

LXi LCD

mounted on the enclosure flange. The

All firmware is non-volatile

The LED display is mounted on the enclosure flange and includes LED as shown on page 2 of this brochure.

Programming of the

Programming is password protected so that only authorized personnel can change the logic functions.

LXi

logic accomplished from the touch pad mounted on the enclosure flange.

Page 4

Horsepower Ratings

This table summarizes the major electrical & horsepower configurations that are available. For special configurations consult the factory.

Full Service Fire Pump Controllers

Normal Source

Voltage Hz HP Range

208

220/240

380/415

440/480

50/60 15-200 100,000 †

50/60 15-200 100,000 †

50/60 15-350 100,000 †

50/60 15-400 100,000 †

Optional Short Circuit Ratings

of 150,000 and 200,000 amps are available

Withstand Rating

Amps Symmetrical

Temperature Range - 41ºF (5ºC) to 104ºF (40ºC); Optional 130ºF/55ºC Rating Available

† Consult Factory for higher ratings.

Controller Selection Chart

This table summarizes the starting characteristics of the controls.

For specific information, please request specification sheets from the factory.

Model

Number

LXi

-1100

LXi

-1200

LXi

-1300

LXi

-1400

LXi

-1600

LXi

-1700

LXi

-1800

LXi

-1900

Type of

Starting

Solid State Soft

Start/Stop

Full Voltage

(Across-the-line)

Autotransformer

Primary Resistor

Manual - Secondary

Resistor Special

Regulated

Part-Winding

Wye-Delta

Closed Transition

Wye-Delta

Open Transition

Motor

Requirements

Standard

Motor

Standard

Motor

Standard

Motor

Standard

Motor

Wound Rotor

Motor

Special

Motor w/ Part

Winding

6 or 12 Lead

Delta Wound

Motor

6 to 12 Lead

Delta Wound

Motor

Starting Characteristics

Voltage

@ Motor

Line

Current

Starting

Torque

0-100% 45-100% 0-100%

100% 100% 100%

Taps at

80%, 65%,

50%

64%

42%

25%

64%

42%

25%

50% 50% 25%

100% 25-50% 25-50%

100% 65% 48%

100% 33% 33%

100% 33% 33%

Description of Operation

Motor is started with reduced voltage via SCR’s in each phase to

limit inrush and provide smooth stepless acceleration to full speed

and deceleration to full stop greatly reduces water hammer.

Motor is started Across-the-Line with no additional impedance nor

special connections to reduce inrush or starting torque.

Motor is started with 3 phase autotransformer in primary to limit

inrush. Multiple taps (manually set) provide variable starting

characteristics. Closed circuit transition to full speed.

Motor is started with resistance in each phase to limit inrush.

Closed circuit transition to full speed.

Motor is started with resistance in the secondary rotor circuit to

limit inrush and to regulate multiple speed points. Built per

application to provide acceleration and speed control.

Motor is started on one part of its 2 windings to limit inrush.

Closed circuit transition to second winding at full speed.

Motor is started connected Wye to reduce voltage across

windings and reduce inrush. Closed circuit transition to Delta

winding/full speed.

Motor is started connected Wye to reduce voltage across

windings and reduce inrush. Open circuit transition to Delta

winding/full speed.

Hubbell Industrial Controls, Inc.

a subsidiary of Hubbell Incorporated

4301 Cheyenne Drive, Archdale, N.C. 27263

Telephone (336) 434-2800 • FAX (336) 434-2803

http://www.hubbell-icd.com

Sales@hubbell-icd.com

Loading...

Loading...