Page 1

Hubbell Industrial Controls, Inc.

A subsidiary of Hubbell Incorporated

4301 Cheyenne Dr.

Archdale, NC 27263

Instruction Manual

Model LX3000

HUBBELL

Telephone (336) 434-2800

FAX (336) 434-2803

Diesel Engine

Fire Pump Controller

Publication No. 203

December 2003

Page 1 of 17

Page 2

Instruction Manual

LX3000 Diesel Fire Pump Controller

Introduction

Model LX3000 engine controllers, automatically control the operation of diesel engine driven centrifugal fire

pumps.

Installation

1. Consult the Controller nameplate to verify that the DC voltage and ground polarity matches the engine

battery. Also verify that the Controller AC power requirement matches available AC power.

2. Set the CONTROLLER ON / OFF - RESET SWITCH (inside controller) to the OFF position.

AUTION: Before drilling and punching holes in the cabinet for wiring connections, cover the

C

components inside the cabinet with a protective covering. Debris may cause shorts or

prevent operation of components.

3. 2 holes are pre-punched in the top left side of the cabinet for conduit entry.

4. Connect the water line to the INLET side of the solenoid valve located on the left side of the Controller.

Connect a drain line to the DRAIN side of the valve.

5. Connect Engine and Battery leads to TB1-1 through 12, connect the AC input to TB2-1 through 5, and

connect required alarm contacts, all per the Field Connection drawing supplied with the controller.

6. Connect remote start normally closed input contacts (if used) to TB1-13 and battery common.

7. Connect lockout/low suction normally open input contacts (if allowed by local jurisdiction) to TB1-14 and

battery common.

Start Up Instructions

1. Adjust the pressure switch set points to meet water system requirements. The adjustment switches are

located on the pressure switch control board, which is contained inside the pressure recorder enclosure.

Open the pressure recorder door and loosen the two chart plate screws. Swing the chart plate outwards to

gain access to the pressure switch control board. Set the STOP (HIGH) pressure setting on the upper three

switches. Set the START (LOW) pressure setting on the lower three switches.

The Green LED on the left (Excitation Voltage) indicates that the Gauge Transducer is connected and

power is available to the recorder. The middle LED (Relay Status) is bi-colored to indicate the status of the

output relay contacts. If this LED is green, pressure is above the Stop pressure. If the LED is red, pressure

is below the Start pressure. The red LED to the right (CAUTION) indicates the Start pressure is set higher

than the Stop pressure and needs to be corrected.

2. Set the recorder time using a coin or screwdriver to turn the chart hub clockwise to the time indicator on

the right side of the chart.

3. Remove the pen tip cover. If necessary, adjust the pen with the adjusting screw in the upper left corner of

the dial plate. The recorder accuracy is 2% of scale.

4. Adjust the weekly Test Timer for the correct timing settings as follows:

Set the time

1) Press the Reset button to clear the memory

Page 3

2) Press and hold the clock symbol key during entire time setting procedure.

a) Press the Day key to bring the actual day of the week into display.

b) Press the h button to set the hours and the m button to set the minutes. If the keys are depressed for

more than a second, the digits will advance rapidly.

c) Release the clock key when finished with the settings. The colon between the hours and minutes will

be flashing indicating the timer has started.

Programming

1) To set the Timer to start the engine once a week and run for a selected period of time.

Press Timer once (do not keep depressed) The display will show “1ON and “--:--“for the time.

a) Press h+ m+ to set the ON time.

b) Press Day to select the day of the week to run.

c) Press Timer key to enter program. The display will show 1”OFF”.

d) Program OFF command using steps b-d above.

e) Press the key to return to time od day display.

2) To review the programming

a) Press Timer key to review the individual commands as preprogrammed, at any time, be brought

consecutively into the display for revision or checking. Revisions are carried out by writing over the

existing programs using the steps outlined above.

5. Set Control Settings – also see attached drawing for locations of items 5 through 11.

a. Set the pressure switch start time delay (P/SWT DELAY SEC) on the Main Logic Board. The

adjustment range is 0 to 15 seconds in 1 second increments.

b. Set the AC Power Loss Delay Time on the Main Logic Board. The adjustment range is 0 to 90

seconds in 6 second increments.

c. Set the Auto Stop time switch (SW6). Settings are none, 15 minutes or 30 minutes.

d. Set the AC PowerLoss Start switch (SW4–2). Setting is on or off.

e. Set the AC Loss Audible Alarm switch (SW4-1). Setting is on or off.

6. Controller Testing

a. Verify pressure is above the Stop setting.

b. Turn CONTROLLER ON / OFF SWITCH to the ON position

Check the Test Timer to make sure that the Timer contacts are not about to close. Closure of the Timer

contacts during testing causes incorrect results.

Manual Start

a. Turn the AUTOMATIC / MANUAL SWITCH to the MANUAL position.

b. Operate the MANUAL CRANK # 1 switch or the MANUAL CRANK # 2 switch. Release as soon as the

engine starts.

Page 4

c. Turn the AUTOMATIC / MANUAL SWITCH to the AUTO position to stop the engine.

Automatic Engine Cranking in TEST

a. Disconnect engine wire from TB1-1 to prevent starting.

b. Press the TEST PUSHBUTTON on the weekly TEST TIMER. The solenoid valve opens to discharge

water, and the pressure switch contacts close to initiate cranking.

c. The controller will crank the engine on battery 1 for 15 second intervals followed by 15 second rest period.

It will then crank 15 seconds on battery 2, followed by 15 second rest period. This cycle is repeated 3

times, then cranking should will stop and the FAILURE TO START light comes on, the alarm sounds, and

the Common TROUBLE relay is energized.

d. Turn the CONTROLLER ON / OFF to the OFF position.

e. Reconnect the starter motor cable(s).

Automatic Pressure Start

a. With the AUTOMATIC / MANUAL SWITCH in the AUTO position, lower the system pressure below the

Start pressure.

b. The engine will start and run until pressure is above the Stop setting and the STOP button is pressed, or the

CONTROLLER ON / OFF SWITCH is turned to the OFF position, or the optional Automatic Stop Timer,

typically set for 15 or 30 minutes, stops the engine.

Battery Failure Test

a. With the AUTOMATIC / MANUAL SWITCH in the AUTO position, disconnect the battery wire on

TB1-6. The BATTERY NO.1 FAILURE LED should come on within two minutes. The alarm should

sound and the Common TROUBLE relay should energize. Reconnect the wire to TB1-6. Reset the alarm

by turning the CONTROLLER ON / OFF - RESET SWITCH from CONTROLLER ON to OFF - RESET

position then back to the CONTROLLER ON position.

b. Disconnect the battery wire on TB1-8. The BATTERY NO.2 FAILURE LED should come on within two

minutes. The alarm should sound and the Common TROUBLE relay should energize. Reconnect the wire

to TB1-8. Reset the alarm by turning the CONTROLLER ON / OFF - RESET SWITCH from

CONTROLLER ON to OFF - RESET position then back to the CONTROLLER ON position.

Charger Failure Test

a With the AUTOMATIC / MANUAL SWITCH in the AUTO position, disconnect the wire on TB1-6, and

disconnect the AC input to charger(s) no. 1. BATTERY NO.1 FAILURE & CHARGER 1 FAILURE light

should come on within two minutes. The alarm should sound and the Common TROUBLE relay should

energize. Reconnect the wire to TB1-6, reset the alarm by turning the CONTROLLER ON / OFF - RESET

SWITCH from CONTROLLER ON to OFF - RESET position then back to the CONTROLLER ON

position.

b Repeat the above for battery No. 2 & charger(s) no. 2, using the wire on TB1-8

Low Oil Pressure Test

a. With the AUTOMATIC / MANUAL SWITCH in the AUTOMATIC position, start the engine by

depressing the TEST PUSHBUTTON on the Weekly Timer.

Page 5

b. Wait 10 seconds for the Oil Pressure Delay interval to expire, then momentarily jumper TB1-4 to TB1-11.

The alarm will sound and the Common Trouble relay will energize. The LOW OIL PRESSURE LED will

come on and remain on after the engine stops.

c. Turn the CONTROLLLER ON / OFF - RESET SWITCH to the OFF - RESET position then back to the

CONTROLLER ON position to reset the LOW OIL PRESSURE Alarm.

High Water Temperature Test

a. WITH the AUTOMATIC / MANUAL SWITCH in the AUTOMATIC position, start the engine by

depressing the TEST PUSHBUTTON on the Weekly Timer.

b. Momentarily jumper the TB1-5 to TB1-11. The alarm will sound and the Common Trouble relay will

energized. The HIGH WATER TEMPERATURE LED will come on and remain on after the engine stops.

c. Turn the CONTROLLLER ON / OFF - RESET SWITCH to the OFF - RESET position then back to the

CONTROLLER ON position to reset the HIGH WATER TEMPERATURE Alarm.

Optional Remote Start

a. With the

AUTOMATIC / MANUAL SWITCH

in the

AUTO

position, open the remote start contacts, TB1-12

& 13, starting the engine.

b. Turn the CONTROLLER ON / OFF SWITCH to the OFF position to stop engine.

c. Close the remote start contacts.

Optional AC Power Failure Start (if enabled)

a. With the

AUTOMATIC / MANUAL SWITCH

to the

AUTO

position, disconnect the AC power supply to the

Controller.

b. After the pre-set time delay (0 to 90 seconds) the engine will start. The audible alarm should sound,

POWER LOSS

LED will come on, and both the Common

TROUBLE

AC POWER LOSS

and

relays will

energize.

c. Reconnect the AC power to reset the alarms.

d. Turn the

CONTROLLER ON / OFF - RESET SWITCH

to the

OFF - RESET

position to stop the engine.

End of Startup Testing

AC

Switches

1. Automatic/Manual – Selects automatic or manual mode.

2. Crank Battery 1 – Cranks the engine using battery 1.

3. Crank Battery 2 – Cranks the engine using battery 2.

4. Stop – Stops the engine in automatic if there are no start conditions and control switch is in “Auto”.

5. Normal/ Silence – Silences optional pump house alarm only. Standard alarms required NFPA 20 cannot be

silenced.

Page 6

Troubleshooting

Hazardous voltage

will shock, burn,

!

DANGER

or cause death.

Do not touch

until ALL power

is disconnected.

ARNING: Disconnect AC power to the Controller before servicing to prevent shock or accident

W

hazard.

Before troubleshooting, perform the following checks:

a. visual inspection for physical damage.

b. ensure that all switches are in the normal operating position.

c. ensure that the engine controls are set for operation.

d. ensure that all wiring connections are secure.

e. review the Startup procedure for proper operation to help determine if one of the system boards is faulty.

Page 7

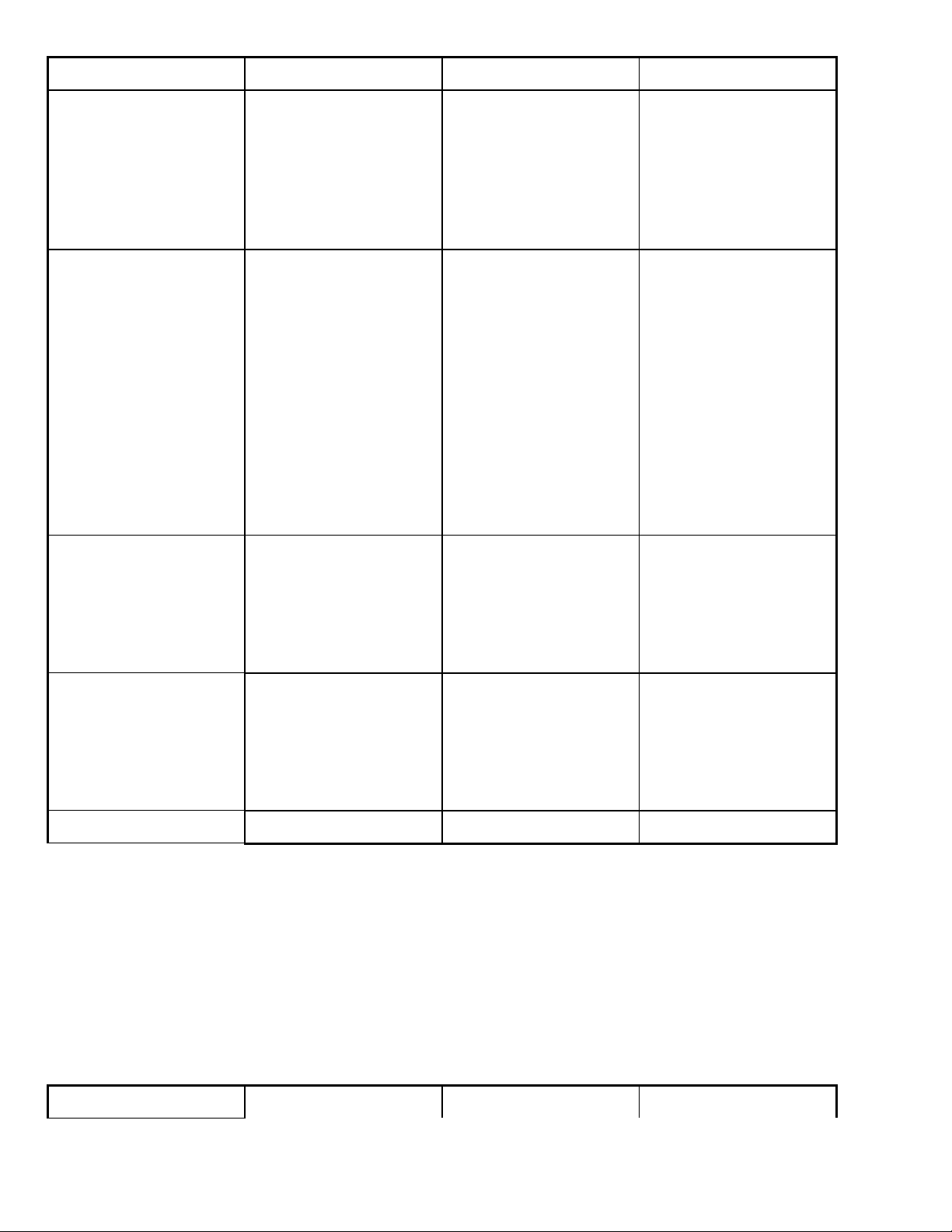

Table 6-1 Troubleshooting

Condition Possible cause Checks Action

Engine does not crank

with MANUAL

START

Engine does not crank

using MANUAL

START - Battery No. 1

Batteries Voltmeters should read

at least 12.5 or 25 VDC

Check each battery in

bank for correct voltage

Battery circuits

MANUAL CRANK #1

switch

Check battery and

ground connections

Check battery voltage

Check battery cables

and connections

Check engine starter

cables and connections

Check battery voltage

while holding

MANUAL CRANK #1

switch

Check electrolyte

Test and recharge bad

battery(s)

Replace battery(s) with

good battery(s)

Clean and tighten

connections as

necessary

Clean and tighten

connections as

necessary

Refer to schematic

Use volt/ohm meter to

determine which

component is faulty

Engine does not crank

using MANUAL

START - Battery No. 2

If voltage checks indicate batteries and circuits OK then the engine starter or the pilot (or starting)

contactors are faulty.

MANUAL CRANK #2

switch

Check battery voltage

while holding

MANUAL CRANK #2

switch

Refer to schematic

Use volt/ohm meter to

determine which

component is faulty

Page 8

Table 6-1 Troubleshooting (Continued)

Condition Possible cause Checks Action

Engine cranks but does

not start

Engine continues to

crank after starting

AUTOMATIC /

MANUAL SWITCH

set to AUTO

Or

Test Mode Active

Water and fuel solenoid

circuits

Water and fuel solenoid

valves

Engine Crank Relay or

Main Logic Board

faulty

Engine Run signal

absent

Magnetic Pickup or

circuit faulty

Check battery voltage

Check WATER and

FUEL Relay

Check solenoids

Check fuel and water

lines

Check engine, fuel, fuel

filter

Check Crank 1 and

Crank 2 relays on

Engine Relay Board

Check Run LED on

Main Logic Board

Check for Pickup signal

at Main Logic Board

Clean and tighten

connections

Replace Engine Relay

Board

Replace Main Logic

Board

Replace solenoid(s) or

valve(s)

Complete necessary

engine repairs

Replace Engine Relay

Board.

Replace Main Logic

Board

Replace magnetic

Pickup

Engine does not crank

in TEST or AUTO

Engine cranks with

MANUAL START

Water and fuel

solenoids energized

Engine does not crank

in AUTO when water

pressure decreases

Engine cranks with

MANUAL START

Relay, or Main Logic

Board faulty

Pressure Switch, or

Main Logic Board

faulty

Check Crank 1 and

Crank 2 relays on

Engine Relay Board

Press P/S TEST button If cranking cycle begins

Replace Engine Relay

Board

Replace Main Logic

Board

refer to Appendix B

Pressure Switch /

Recorder

Replace Main Logic

Board

Table 6-1 Troubleshooting (Continued)

Page 9

Condition Possible cause Checks Action

Engine stops without

having to press STOP

button or before run

time is complete

Test Timer or Test

Pushbutton does not

start engine

AUTOMATIC /

MANUAL SWITCH in

AUTO

Engine starts after

pressure drop

Alarm does not sound,

Associated light not on

Water and Fuel

solenoid circuits and

valves, or

Main Logic Board

faulty

No power to solenoid

drain valve, or faulty

valve

Faulty Timer

Alarm faulty

LED Display faulty

Check Water and Fuel

Relay

Check Water Dump

Solenoid Relay

Check solenoid valve

Check Timer

program

Check alarm Replace alarm

Replace Engine Relay

Board

Replace Main Logic

Board

Replace Engine Relay

Board

Replace valve

Replace Timer

Replace LED Display

No BATTERY

FAILURE indication

Engine cranks

Main Logic Board

faulty

Power Sense Board

faulty

Main Logic Board

faulty

Table 6-1 Troubleshooting (Continued)

Check Power Sense

Board

Replace Main Logic

Board

Replace Power Sense

Board

Replace Main Logic

Board

Condition Possible cause Checks Action

Page 10

No HIGH ENGINE

TEMP indication

Engine overspeed does

not stop engine

No indication

Water temperature

switch

Faulty or mis-adjusted

magnetic sensor

Connect a jumper

across the water

temperature switch on

the engine

Start engine with

MANUAL START

switch

Verify that engine starts

and alarm sounds

Check sensor

installation

Replace water

temperature switch

Replace sensor

Indication but engine

does not stop under

overspeed simulation

Cranking and rest

periods greater than or

less than 15 ± 2 sec.

Engine cranks less than

six times

Engine continues to

crank in AUTO

position but does not

start

Controller does not

crank engine with good

battery

Engine cranking and

indication OK

Main Logic Board

faulty

Main Logic Board

faulty

Engine Relay Board

faulty

Main Logic Board

faulty

Check Main Logic

Board

Check Engine Relay

Board

Check Main Logic

Board

Replace Main Logic

Board

Replace Main Logic

Board

Replace Engine Relay

Board

Replace Main Logic

Board

Page 11

Table 6-1 Troubleshooting (Continued)

Condition Possible cause Checks Action

Engine does not crank

with Remote Start

Cranks when water

pressure decreases

Engine does not start

after AC power loss

Engine does not stop

with optional AUTO

STOP

Note

Remote switch faulty

Main Logic Board

faulty

Power Sense Board or

Main Logic Board

faulty

Another start condition

present

Main Logic Board

faulty

Check switch and

switch circuits

Check Main Logic

Board

Check Power Sense

Board

Check Main Logic

Board

Check controller start

conditions

Check Main Logic

Board

Repair circuits

Replace switch

Replace Main logic

Board

Replace Power Sense

Board

Replace Main Logic

Board

Replace Main Logic

Board

The above troubleshooting guide does not represent all possible conditions or problems. If the above

information can not resolve a problem, consult the factory or a local representative for further assistance.

Page 12

Page 13

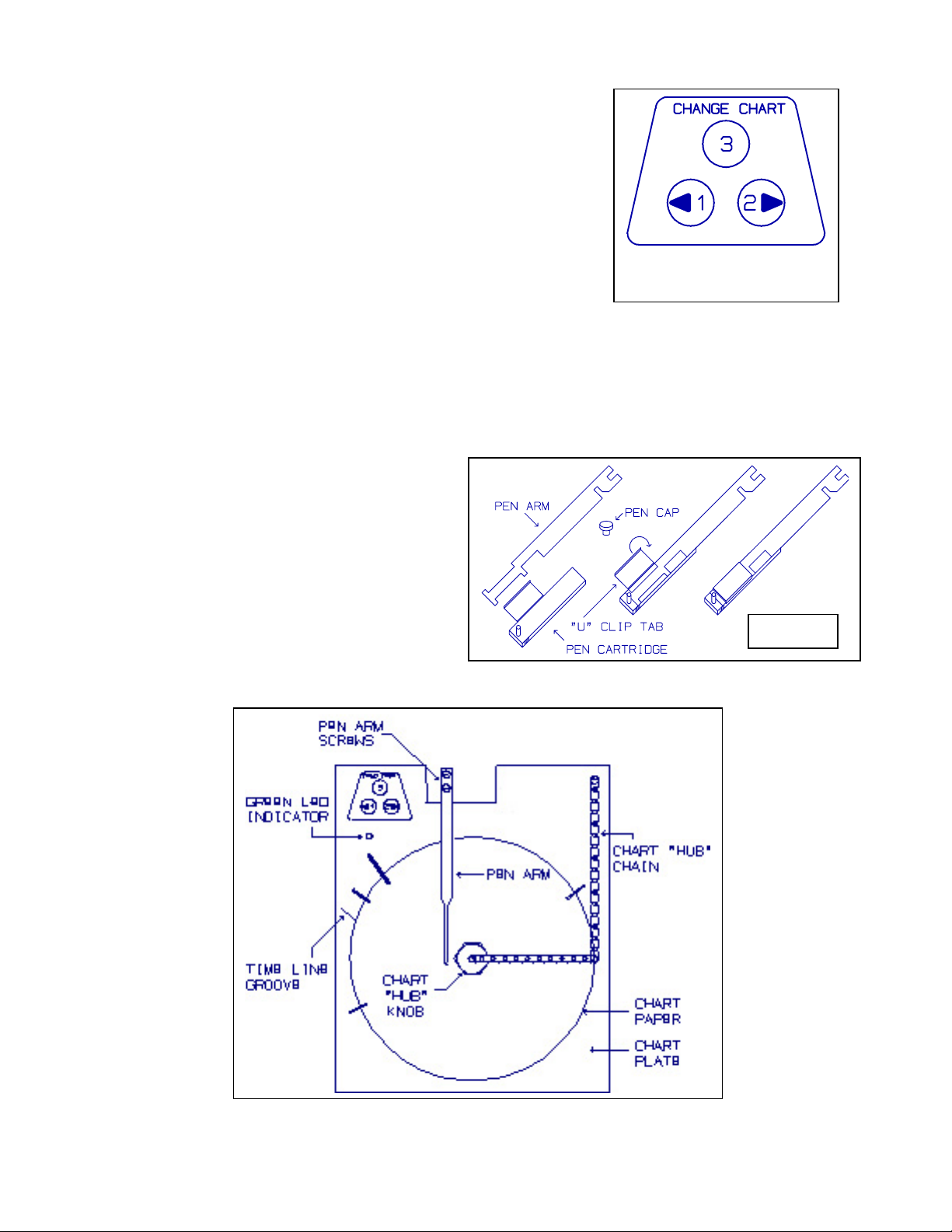

Pressure Switch / Recorder

Changing the Chart Paper

First, locate the “change chart” button (#3) located in the upper left

corner of the recorder. Press and hold this button for approximately one

(1) second until the pen begins to move to the left of the chart. Wait

until the pen has moved completely off of the chart. To remove the

chart paper, unscrew (counter-clockwise) the “hub” knob at the center

of the chart. Remove the old chart paper and position the new one so

that the correct time coincides with the time line groove on the chart

plate. Refer to Figure 3 for the location of the time line groove on the

left side of the chart plate. Re-attach the chart “hub” knob and screw securely (by hand) against the chart.

Press the “change chart” button (#3) again for approximately one (1) second until the pen begins to move back

onto the chart paper.

Figure 1

Pen replacement

Slide the used pen cartridge off the pen arm. Slide on new cartridge and remove tip cover.

To replace the pen, loosen the two screws that hold

the pen arm and the pen cartridge, and metal pen arm

be removed as an assembly. Refer to Figure 3 for

the location of the pen arm screws. Unsnap the

plastic “U” clip tab of the pen cartridge from the

metal pen arm (see Figure 2), remove and discard the

old pen cartridge. Replace the new cartridge by

opening the hinge and snapping it securely around

the metal pen arm.

Figure 2

Figure 3 - RECORDER ASSEMBLY

Page 14

Figure 4

(3)

Pressure Settings

SEE NOTE

Status LED’S

Stop Pressure

Start Pressure

Page 15

Battery Charger

Introduction

The Power Sense Board monitors the charging current and voltage of both chargers. LED’s indicate that the

chargers are supplying current output, that the battery / charger voltage is above 90%, and that AC Power is

available to power the chargers.

Specifications

LED Indication

READY, green

CHARGING, yellow

CHARGE CURRENT, green

On indicates float condition

On indicates charge in progress

Charging current greater than or equal to current indicated

ARNING: Lead acid batteries generate explosive gases during normal operation.

W

Precautions: Do not work alone.

Wear eye protection and protective clothing.

Have soap and water available in case of skin contact with acid.

If acid enters eye, immediately flush eyes with cold running water for ten minutes and

get medical attention.

If problems develop, check all connections and clean the battery terminal connections. Use the LED indicators

on the chargers and the LOBC as an aid to determine the cause of any potential problems. Return faulty

chargers to the factory.

AUTION: Always disconnect the AC power source before disconnecting the batteries when

C

performing maintenance.

Page 16

Troubleshooting Chart

Symptom Possible cause Solution

All charger LED’s off,

cabinet CHARGER FAILURE

indicating light on

Charge Current LED’s scroll,

cabinet CHARGER FAILURE

indicating light on

6

The charger LED’s scroll in order as follows: Charge Current LED’s 10 A to 2 A, Charging, Ready.

1) No AC power

2) Charger AC fuse blown

6

1) Battery connections

reversed,

2) Charger DC fuse blown

1) Check for 120 V Charger power

2) Hubbell recommends that the

charger be returned for repair

1) Check battery connections

2) Hubbell recommends that the

charger be returned for repair

Troubleshooting Chart (Continued)

Symptom Possible cause Solution

Charging LED blinking, Battery voltage high due to

Engine charging circuit

supplying charging voltage

above control charger value.

10 A Charge Current LED

flashing

Ready LED does not come on,

Charger stopped charging due

to high temperature

1) Battery capacity too high

Batteries do not charge fully

2) Excessive load on batteries

3) Short to ground

4) Battery terminals corroded

5) Battery has faulty cell

Troubleshoot engine charging

circuit

Allow charger time to cool

Improve ventilation in area

1) Check battery rating, must be

less than 200 Ah

2) Verify load is normal

3) Clear the short

4) Clean battery terminals

5) Check battery/Replace

Contact the local Hubbell representative to request additional information, parts, or drawings.

Page 17

Location and Description of Control Settings

Loading...

Loading...