Hubbell ATU500CRP, ATD500CRP, ATU500C, ATD1000C, ATU1000C Installation Instructions Manual

...Page 1

H-MOSS® Adaptive Technology Sensors

ATD Series, ATU Series, ATP/AHP Series

Installation Instructions

DESCRIPTION

Hubbell Adaptive Technology (AT series) ceiling mount occupancy sensors are designed to reduce installation time and prevent

callbacks resulting from improper sensor adjustment. Hubbell AT series sensors study their environment and automatically

adjust the time delay and sensitivity to optimize the sensor’s performance for the specic application. Hubbell AT sensors must

be used in conjunction with a Hubbell control unit. The control units provide a 24VDC power supply for 1 to 3 sensors. The

correct control unit must be selected for the operating voltage of the application. Hubbell offers the following control units:

- CU300A(U)(M): 100-277V AC, 50/60 Hz.

- CU300HD: 100-277V AC, 50/60 Hz.

- CU347A: 347V AC, 60 Hz.

Each sensor is supplied with the hardware necessary for ceiling mounting.

FEATURES

• Adaptive Technology reduces installation time and prevents callbacks.

• Available in passive infrared (ATP/AHP series), ultrasonic (ATU series), dual technology - passive

infrared and ultrasonic (ATD series) models.

• Various models available for coverage areas from 500 to 2000 square feet.

• Isolated relay and photocell options provided on sensors with “RP” sufx.

• Visual motion indicators: ultrasonic-green LED, passive infrared-red LED.

• Sensor/ AAR* Capacity:

- CU300A(U)(M): 1 to 4 combined

- CU300HD: 1 to 6 combined

- CU347A: 1 to 3 combined

* Maximum of 2 AARs per control unit

PRE-INSTALLATION

1. NOTICE: For installation by a qualied electrician in accordance with national and local codes and

the following instructions.

2. NOTICE: For indoor use only.

3. CAUTION: RISK OF ELECTRIC SHOCK. Disconnect power before installing. Never wire

energized electrical components.

4. CAUTION: USE COPPER CONDUCTORS ONLY.

5. Check to see that the device’s rating is suitable for the application.

6.

When installing the Hubbell AT Series sensors, observe the maximum rated capacity of

the associated control unit:

- CU300A(U)(M): 15A Incandescent (1800W Tungsten) at 120V AC, 60 Hz.

20A Ballast (2400W Fluorescent) at 120V AC, 60 Hz.

20A Ballast (5540W Fluorescent) at 277V AC, 60 Hz.

- CU300HD: 20A, 120V AC Incandescent. 20A 120V AC or 277V AC Ballast.

Motor loads; 1 HP @ 120V AC, 2 HP @ 240/277V AC.

- CU347A: 15A Ballast (5205W) at 347V AC, 60 Hz.

7. NOTICE: Do not install if any damage to product is noted.

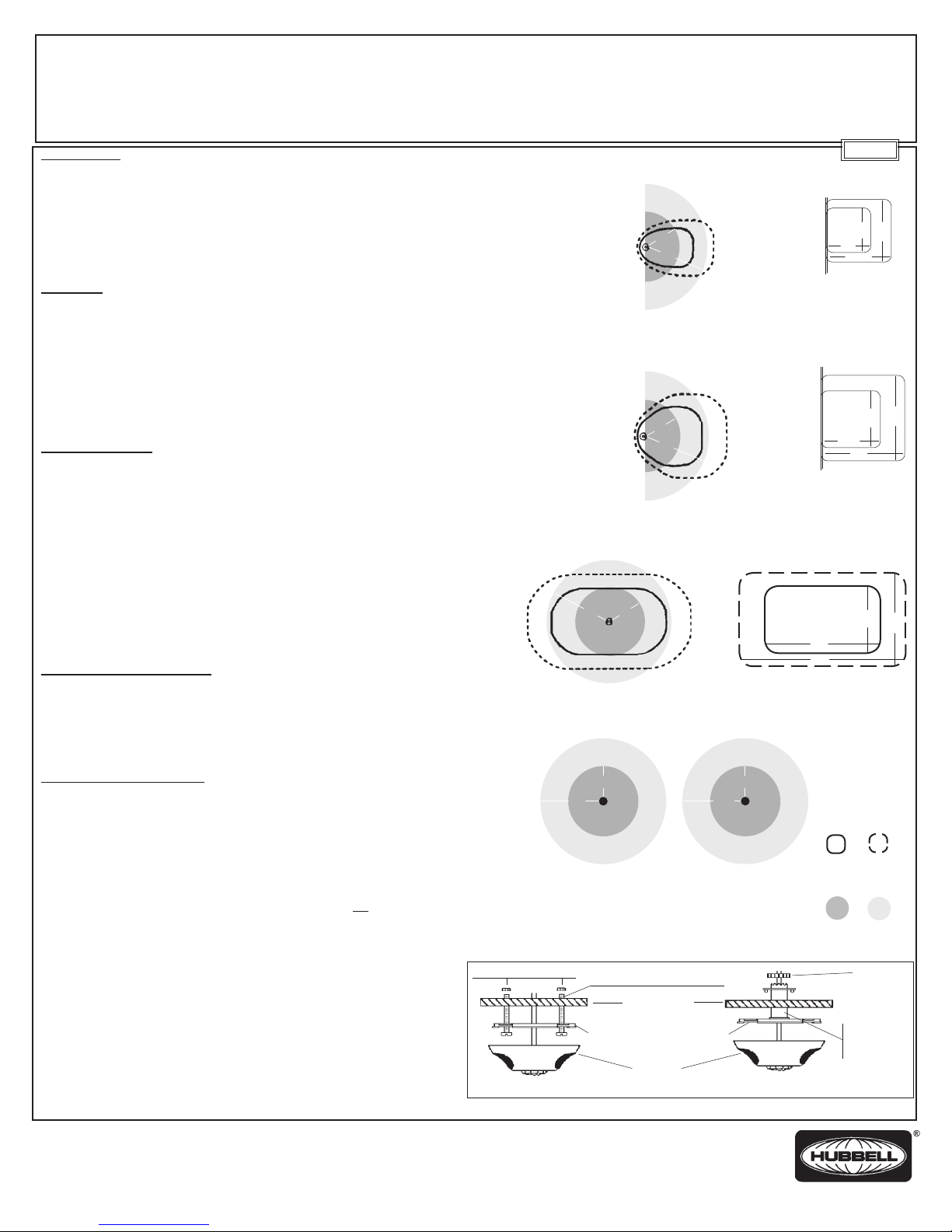

COVERAGE AND PLACEMENT

The patterns of coverage for the AT sensors are provided at right.

• Mounting ceiling height: 8 to 12 feet.

•

The sensors must be mounted at least 4’ from HVAC vents to avoid air current interference.

•

For interior use only. These sensors should NOT be installed in damp locations such as near

a shower or steam source, in wet locations, or where exposed to rain unless PIR sensors

are used combined with ACIPE (NEMA 4X Enclosure) for outdoor and damp locations.

• Do NOT install in view of strong direct or reected light sources.

INSTALLATION OF SENSORS

1. Disconnect Power.

2. Install CU series control units and, if applicable, AAR Add-A-Relay. See installation

instructions for these products.

3. Mount the sensor. The sensor must be mounted on the ceiling for proper operation. An

arrow is molded into the cover plate of the sensor. This should be used as a general

guideline to the direction of the coverage pattern. Fine tuning will be explained later.

Mounting options:

• For hard ceilings: Mount to a junction box.

•

For false ceilings: Attach the cover plate by either using machine screws and punching a small

hole through the ceiling tile for the sensor wires (Figure A, below) OR using the threaded

mounting post then running the sensor wires through the center of the post, (Figure B, below).

4. Attach the sensor to the cover plate by aligning the keys in the cover plate with those in the

sensor housing. Rotate the sensor housing until proper orientation is achieved.

5.

Using 3 conductor low voltage cable (18 to 22 AWG Type CL2, CL2P, CL2PR or CMR

as appropriate), connect the sensor and accessories to the control unit. Low voltage

wiring should not exceed 250 feet from the control unit to the last sensor. See control

unit installation instructions for wiring diagram.

6.

Insulate all exposed leads with Listed/Certied electrical tape or twist-on connectors

(wire nuts).

7. Restore the power to the control unit.

8.

Conrm the correct coverage by simulating motion in the coverage area which will be typical for

the application. If the desired coverage is not achieved, relocate the sensor to produce the desired

coverage. Test the sensor. To locate the test knob, remove the lens retainer and lens. Turn the black

timer knob fully counterclockwise from any clockwise position. Replace lens and retainer. The lights will

now turn off 8 seconds after motion stops. Reset timer for application. When installing sensors which

use passive infrared detection, the coverage pattern can be modied through the use of a lens mask.

Wiring Device-Kellems

Hubbell Incorporated (Delaware)

Shelton, CT 06484

1-800-288-6000

www.hubbell-wiring.com

PD1463 (PAGE 1) 11/13

nuts (tighten by hand)

0 5 10 15 20 25 30 35 40 45 50 55 60

0

5

10

15

20

25

30

35

40

45

•

Fig. A

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

12’

•

22’

•

ATD500C

ATD500CRP

0 5 10 15 20 25 30 35

0

5

10

15

20

25

30

35

40

45

•

22’

12’

•

12’

22’

•

ATD1000C

ATD1000CRP

•

ATD2000C

ATD2000CRP

•

12’

22’

ATP1500C

ATP1500CRP

•

ATP600C

ATP600CRP

13.5’

AHP1500CRP

6-32 machine screws (2)

ceiling tile

twist-lock cover plate

sensor

Caution: Attach wire nuts above ceiling tile

•

6.5’

Fig. B

17’

ATU500C

ATU500CRP

23’

ATU1000C

ATU1000CRP

45’

64’

ATU2000C

ATU2000CRP

ULTRASONIC

Minor

Motion

INFRARED

Minor

Motion

(tighten by hand)

English

17’

23’

23’

23’

32’

22’

Major

Motion

Major

Motion

nut

threaded

mounting

post

32’

32’

Page 2

MASKING THE INFRARED LENS (for ATD and ATP/AHP series sensors only)

This procedure is only required for applications where the passive infrared coverage pattern must be modied to prevent the pattern from extending out of

doorways into corridors. Three masks are provided with the sensors (one way sensors include 2 masks). Select the correct mask for the application based on

the descriptions below.

Using the Conference Room Mask

Using the 180º Mask

Using the Cutout Mask

0 5 10 15 20 25 30 35 40 45

0

5

10

15

20

25

30

This mask is used

when a Hubbell-DT is

mounted in the center

35

40

45

of a long rectangular

room (i.e. conference rooms). The mask provides a more

rectangular infrared pattern and prevents any spillage out

doorways at the sides of the room.

The 180º mask is best

suited for an overthe-door installation.

When the sensor is

installed inside the threshold of a doorway, you must

prevent the infrared coverage from spilling into the

adjacent corridor. New infrared pattern shown above.

0 5 10 15 20 25 30 35 40 45

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30 35 40 45

0

5

10

15

20

This mask is scored on

the inside so it is easy

to achieve the perfect

mask for any application.

25

30

35

40

45

Simply trim away the

sections where coverage is necessary and leave the

portions where you want to prevent coverage. Lines on the

coverage pattern above represent the scores in the mask.

To install the selected lens, remove the lens retainer ring and lens. Insert the mask behind the lens. Be

certain to orient the mask properly to achieve the desired results. Replace the lens and lens retainer.

AMBIENT LIGHT LEVEL CONTROL OPTION (for models followed by RP sufx only)

The sensor is factory preset to turn the lights on regardless of the ambient light (natural light) level. Setting the ambient light level control will prevent the lights

from turning on when the ambient light is above the set level. The ambient light must be at the desired level to properly set this feature. To set the ambient light

level control:

1. Turn the black timer knob fully counter clockwise to the 8 second test mode.

2. Adjust the blue photocell knob fully clockwise. This will keep the lights off regardless of the ambient light.

3. Leave the sensor’s coverage area. The lights should turn off after about 8 seconds.

4. When the lights turn off, re-enter the area.

5. Slowly turn the blue photocell knob counterclockwise until the lights turn on.

The sensor is now set to prevent the lights from turning on when the ambient light level is above the set threshold.

ISOLATED RELAY OPTION (for models followed by RP sufx only)

The isolated relay can be used to interface the sensor with an auxiliary system. Normally open and normally closed contacts are available. For normally open

contacts, utilize the yellow/white and blue/white wires. For normally closed contacts, utilize the black/white and blue/white wires.

SENSOR CONTROLS & MODIFICATIONS

Hubbell Adaptive Technology sensors are designed to optimize performance by automatically adjusting the sensitivity and time delay to meet the application.

The sensor controls can be modied for custom operation. The modication options are outlined below.

Purpose Off On

B

Bank A DIP

Switches

Ultrasonic

Sensitivity (Red)

Timer

(Black)

Ultrasonic

Sensitivity

(Green)

Daylight Leveling

(Blue) Off

Bank B DIP

Switches

Bank

1

2

3

4

off on

Bank

1

2

3

4

off on

Strong airow Normal or very low Strong airow present

Compensator airow

Over Doorway Mounting Sensor mounted away Sensor mounted over

from door doorway

Automatic/Manual Timer Timer set automatically Manual timer setting

Sensitivity Adjust OFF = Auto ON = Manual

Purpose Off On

A

Manual Override Full automatic operation Manual lights on

Threshold Auto Threshold Adjust High Sensitivity

Motion Indicator Override LED ash when presence Disable LED lights

is detected

Reset learned settings Normal Toggle On and Off

Knob Color:

Control

Green:

Ultrasonic

Sensitivity

Red:

Infrared

Sensitivity

Black:

Timer

Blue:

Daylight

Leveling

Function

Sets the ultrasonic range Sensor analyzes room

Sets the infrared range Same as above Room (surface) temp.

Sets the length of time

lights will remain on after

last motion is sensed

Sets level of daylight

needed to prevent the lights

from turning on

**When a function is set to “Automatic Operation”, the initial setting is determined by the position of the knob, CCW is counter-clockwise, CW is clockwise

PD1463 (PAGE 2) 11/13

Automatic Operation

and sets sensitivity to

optimal setting

Timer setting generally

increased during learning

period, then decreases to

minimize “ON” time

No automatic operation N/A Linear range setting

Conditions Analyzed in

Automatic Operation

Air currents

False-on occurrences

False-off occurrences

Lens dirt

Signal-to-noise ratio

False-off occurrences

Error free operation decreases the timer setting

Knob Setting Under

Manual Operation**

Linear range setting

Full CCW = min (off)

Full CW = max range

Same as above 75%

Linear range setting

Full CCW = min (8 sec.)

Full CW = max (40 min)

Full CCW = min daylight

Full CW = max (off)

Recommended

Manual Setting

50%

33%

10 min.

Off

unless

used

Page 3

Capteurs à temporisation adaptable H-MOSS

Série ATD, Série ATU, Série ATP/AHP

Directives de montage

DESCRIPTION

Les capteurs de mouvement à temporisation adaptable de Hubbell (série AT), à monter au plafond, ont été conçus en vue

de réduire le temps de montage et d’éliminer les appels de service suite à un mauvais réglage du capteur. Les capteurs de la

série AT de Hubbell étudient l’environnement et règlent automatiquement la temporisation et la sensibilité en vue d’optimiser

le rendement du capteur pour l’application spécique. Les capteurs AT de Hubbell doivent être utilisés conjointement avec un

module de commande Hubbell. Le module de commande procure une alimentation de 24 V CC pour 1 à 3 capteurs et doit

être choisi en fonction de la tension du circuit à commander. Hubbell offre les modules de commande suivants:

- CU300A(U)(M): 100-277 V ca, 50/60 Hz. - CU347A: 347 V ca, 60 Hz.

- CU300HD: 100-277 V ca, 50/60 Hz.

Chaque capteur est fourni avec les accessoires nécessaires pour le montage au plafond.

CARACTÉRISTIQUES

• La technologie d’adaptation réduit le temps de montage et élimine les appels de service.

• Différents modèles de capteurs sont disponibles: à infrarouges passifs (série ATP/AHP), ultrasoniques

(série ATU), double technologie à infrarouges passifs et ultrasoniques (série ATD).

• Divers modèles sont disponibles pour couvrir des zones de 46 m2 à 186 m2.

•

Les capteurs dont le numéro de référence est accompagné du sufxe «RP» sont munis d’un relais isolé et d’une cellule photoélectrique.

• Indicateurs de mouvement visuels: DEL verte, ultrasoniques; DEL rouge, infrarouges passifs.

• Capacité du capteur/AAR*:

- CU300A(U)(M): 1 à 4 combinés

- CU300HD: 1 à 6 combinés

- CU347A: 1 à 3 combinés

*Maximum de 2 AARs par unité de commande

PRÉPARATION AU MONTAGE

1. AVIS - Doit être installé par un électricien qualié conformément aux codes de l’électricité nationaux et

locaux et selon les directives suivantes.

2. AVIS - Pour usage intérieur seulement.

3. ATTENTION - RISQUE DE CHOC ÉLECTRIQUE. Débrancher le circuit avant de procéder au

montage. Ne jamais câbler des composants électriques dans un circuit sous tension.

4. ATTENTION - EMPLOYER UNIQUEMENT DES CONDUCTEURS EN CUIVRE.

5. S’assurer que les caractéristiques nominales de ce dispositif conviennent à l’application.

6. Lors du montage, respecter les valeurs maximum assignées:

- CU300A(U)(M): 15 A, incandescent (1800 W tungstène) à 120 V ca, 60 Hz.

20 A, ballast (2400 W uorescent) à 120 V ca, 60 Hz.

20 A, ballast (5540 W uorescent) à 277 V ca, 60 Hz.

- CU300HD: 20 A, 120 V ca incandescent. 20 A 120 V ca ou 277 V ca ballast.

Charges de moteur; 1 HP à 120 V ca, 2 HP à 240/277 V ca.

- CU347A: 15 A, ballast (5205 W) à 347 V ca, 60 Hz.

7. AVIS - Ne pas installer si des dommages au module sont observés.

POSITIONNEMENT ET PORTÉE

La portée des capteurs AT est illustrée à droite.

• Hauteur de montage au plafond: 2,4 à 3,7 mètres.

• Les capteurs doivent être montés à au moins 1,20 m des bouches de chauffage et de

ventilation an d’éviter l’interférence causée par les courants d’air.

• Pour usage intérieur seulement.

•

Pour l’intérieur seulement. Ces capteurs NE doivent PAS être installés dans des endroits humides comme près de

douches ou de sources de vapeur, dans des endroits mouillés ou exposés à la pluie sauf si les capteurs PIR sont

utilisés conjointement avec des ACIPE (enveloppe NEMA 4X) convenant à l’extérieur et des endroits humides.

• NE PAS monter le capteur face à une source de lumière intense directe ou rééchie.

MONTAGE DU CAPTEUR

1. Débrancher le circuit.

2.

Installer les modules de commande de la série CU et, si nécessaire, les relais Add-A-Relay AAR.

Consulter les directives de montage de ces dispositifs.

3.

Monter le capteur. Le capteur doit être monté au plafond pour assurer son bon fonctionnement. La

èche gravée sur le couvercle du capteur indique la direction générale de la portée. Les directives

pour le réglage plus précis sont données plus loin.

Options de montage :

• pour plafond dur : monter sur une boîte de dérivation

•

pour faux plafond : xer la plaque couvercle en utilisant les vis et en perçant un petit trou

dans la tuile du plafond pour passer les ls du capteur (gure A) OU en utilisant la tige de

montage letée et en passant les ls du capteur dans le centre de la tige (gure B).

4.

Fixer le capteur à la platine couvercle en alignant les encoches du couvercle sur celles du boîtier

du capteur. Faire tourner le boîtier du capteur jusqu’à l’orientation voulue.

5.

Au moyen d’un câble basse tension à 3 conducteurs (de 18 à 22 AWG, type CL2,

CL2P, CL2PR ou CMR selon le cas), raccorder le capteur et les accessoires au

module de commande. La longueur du câblage basse tension séparant l’unité

de commande du dernier capteur ne doit pas excéder 76,2 mètres. Consulter les

directives du module de commande pour le diagramme de câblage.

6.

Isoler tous les conducteurs découverts au moyen de ruban isolant ou de raccords

à torsader homologués.

7. Remettre le module de commande sous tension.

8.

Vérier l’exactitude de couverture en simulant des niveaux de mouvement dans la zone de

couverture typique pour l’application. Si la couverture désirée n’est pas atteinte, déplacer le capteur

pour obtenir la couverture voulue. Pour atteindre le bouton de test, enlever l’anneau de retenue

de la lentille et la lentille. Tourner le bouton de temporisation noir à fond dans le sens contraire des aiguilles d’une montre. Remettre la lentille et l’anneau de retenue en place. Les lumières s’éteindront 8

secondes après l’arrêt de mouvement. Régler la temporisation selon les besoins. Si des capteurs à infrarouges passifs sont installés, on peut, à l’aide d’un masque, modier le patron de couverture.

Wiring Device-Kellems

Hubbell Incorporated (Delaware)

Shelton, CT 06484

1-800-288-6000

www.hubbell-wiring.com

PD1463 (PAGE 1) 11/13

écrous (serrer à la main)

10

12

14

0

2

4

6

8

10

12

14

0 2 4 6 8 10 12 14 16 18

0

2

•

4

6

8

10

12

14

6,7 m

ATD2000C

ATD2000CRP

•

3,7

6,7

•

ATP1500C

ATP1500CRP

AHP1500CRP

vis 6-32 (2)

plafond

platine couvercle

capteur

Attention: établir les raccordements

Fig. A

au-dessus du plafond

0 2 4 6 8 10

0

2

4

6

8

3,7 m

6,7 m

•

ATD500C

ATD500CRP

0 2 4 6 8 10

•

3,7 m

6,7 m

•

3,7 m

•

•

•

ATD1000C

ATD1000CRP

•

2

4,1

ATP600C

ATP600CRP

Fig. B

5,2 m

ATU500C

ATU500CRP

7 m

ATU1000C

ATU1000CRP

13,7 m

19,5 m

ATU2000C

ATU2000CRP

ULTRASONIQUE

Mouvement

Mineur

INFRAROUGE

Mouvement

Mineur

écrou

(serrer à la main)

tige de

suspension

filetée

MD

Français

7 m

5,2 m

7 m

7,m

9,8 m

6,7 m

Mouvement

Majeur

Mouvement

Majeur

9,8 m

6,7 m

Page 4

MASQUAGE DE LA LENTILLE À INFRAROUGES (pour les capteurs ATD et ATP/AHP uniquement)

Cette procédure n’est requise que pour les applications où le patron de couverture à infrarouges passifs doit être modié pour éviter qu’il ne s’étende au-delà des

ouvertures de porte jusqu’aux couloirs. Trois masques sont fournis avec les capteurs (le capteur unidirectionnel inclut 2 masques). Choisir le masque approprié à

l’application en fonction des descriptions ci-dessous.

Utilisation du masque pour salle de

Utilisation du masque à 180º

Utilisation du masque à découper

conférence

0 2 4 6 8 10 12 14

0

2

4

6

8

Ce masque est

utilisé pour le

montage du

10

12

14

Hubbell-DT au

centre d’une

longue salle rectangulaire (salle de conférence). Le

masque offre un patron de couverture à infrarouges

rectangulaire et empêche la dispersion vers les

ouvertures de portes sur les côtés de la salle.

Le masque à 180º

convient parfaitement

pour un montage

au-dessus de la

porte. Lorsque le

capteur est monté à l’intérieur du seuil de la porte,

il faut empêcher la dispersion de la couverture à

infrarouges vers le couloir adjacent. La nouvelle

couverture à infrarouges est illustrée ci-haut.

0 2 4 6 8 10 12 14

0

2

4

6

8

10

12

14

0 2 4 6 8 10 12 14

0

2

4

6

Le masque comporte

des rainures sur la face

interne pour pouvoir

facilement l’adapter

8

10

12

14

à n’importe quelle

application. Il suft

simplement de découper les sections où la couverture est

désirée et de laisser en place les parties ne nécessitant

pas de couverture. Les lignes sur le patron de couverture

ci-haut représentent les rainures sur le masque.

Pour monter la lentille choisie, enlever l’anneau de retenue de la lentille et la lentille. Insérer le masque à l’arrière de la lentille.

S’assurer de donner l’orientation adéquate au masque pour obtenir le résultat souhaité. Replacer la lentille et son anneau de retenue.

OPTION DE RÉGLAGE EN FONCTION DU NIVEAU DE LUMIÈRE AMBIANTE (uniquement pour les modèles dont le numéro de référence comporte le sufxe RP)

Le capteur est réglé en usine pour allumer les lumières quel que soit le niveau de lumière ambiante (lumière naturelle). Le réglage du seuil de lumière ambiante

empêche les lumières de s’allumer lorsque le niveau de lumière ambiante dépasse le seuil établi. La lumière ambiante doit être au niveau désiré pour pouvoir effectuer

ce réglage de façon adéquate. Pour régler la commande du seuil de lumière ambiante :

1. Tourner le bouton noir de temporisation dans le sens contraire des aiguilles d’une montre jusqu’au mode de test de 8 secondes.

2.

Tourner le bouton bleu de la cellule photoélectrique à fond dans le sens horaire. Ce réglage maintiendra les lumières éteintes quel que soit le niveau de lumière ambiante.

3. Sortir de la zone de couverture du capteur. Les lumières devraient s’éteindre au bout de 8 secondes.

4. Une fois les lumières éteintes, revenir dans la zone.

5. Tourner lentement le bouton bleu de la cellule photoélectrique dans le sens contraire des aiguilles d’une montre jusqu’à ce que les lumières s’allument.

Le capteur est réglé pour empêcher les lumières de s’allumer lorsque le niveau de lumière ambiante est supérieur au seuil établi.

OPTION DE RELAIS ISOLÉ (uniquement pour les modèles dont le numéro de référence comporte le sufxe RP)

Le relais isolé peut être utilisé comme interface entre le capteur et un système auxiliaire. Des contacts normalement ouverts et normalement fermés sont disponibles.

Pour les contacts normalement ouverts, utiliser les ls jaune/blanc et bleu/blanc. Pour les contacts normalement fermés, utiliser les ls noir/blanc et bleu/blanc.

COMMANDES DU CAPTEUR ET MODIFICATIONS

Les capteurs à temporisation adaptable de Hubbell ont été conçus pour optimiser le rendement par le réglage automatique de la sensibilité et de la temporisation

appropriées à l’application. Les commandes du capteur peuvent être modiées en vue d’une exploitation sur mesure. Les options de modication sont décrites ci-

dessous.

Commutateurs DIP

Groupe A

Sensibilité

Infrarouges

(rouge)

Temporisation

(noir)

Couleur du

bouton :

Commande

Vert :

Sensibilité

ultrasonique

Rouge :

Sensibilité

infrarouge

Noir :

Temporisation

Bleu :

Niveau de la

lumière du jour

Fonction

Règle la portée

ultrasonique

Règle la portée infrarouge Le capteur analyse la pièce

Règle le temps pendant

lequel les lumières resteront

allumées après cessation du

mouvement

Règle le niveau de lumière du

jour requis pour empêcher les

lumières de s’allumer

Le capteur analyse la pièce

et règle la sensibilité au

point optimal

et règle la sensibilité au

point optimal

La temporisation est augmentée

pendant la période d’acquisition

et diminuée par

réduire le temps pendant lequel

les lumières restent allumées

Ne fonctionne pas

automatiquement

* Lorsqu’une fonction est en mode automatique, le réglage initial correspond à la position du bouton.

SCAM = sens contraire des aiguilles d’une montre. SAM = sens des aiguilles d’une montre.

PD1463 (PAGE 2) 11/13

Sensibilité

ultrasonique

(vert)

Niveau de

lumière du jour

(bleu) Off

Commutateurs DIP

Groupe B

Fonctionnement

automatique

la

suite pour

Groupe

1

2

3

4

off on

Groupe

1

2

3

4

off on

Conditions analysées en

mode automatique

Courants d’air

Faux allumages

Faux arrêts

Température ambiante

Lentille sale

Rapport signal/bruit

Faux arrêts

En opération normale,

le réglage de temporisation est réduit

Sans objet

Fonction Off On

Compensateur de Courant d’air normal Courant d’air fort

B

courant d’air fort ou faible présent

Montage au-dessus Capteur monté loin Capteur monté au-dessus

d’une porte d’une porte d’une porte

Temporisation Réglage automatique de Réglage manuel de

automatique / manuelle la temporisation la temporisation

Réglage de la sensibilité OFF = Automatique ON = Manuel

Fonction Off On

Annulation de priorité Fonctionnement Allumage manuel de

A

manuelle entièrement automatique l’éclairage

Point de consigne Réglage automatique Haute sensibilité

du point de consigne

Annulation de l’indicateur La DEL clignote à la La DEL est inactive

de mouvement detection de mouvement

Rappel des réglages Normal Commutation ON et OFF

acquis

Réglage du bouton en

mode manuel*

Réglage linéaire de la portée

SCAM à fond = min. (éteint)

SAM à fond = portée max.

Réglage linéaire de la portée

SCAM à fond = min. (éteint)

SAM à fond = portée max.

Réglage linéaire de la tempor.

SCAM à fond = min. (8 sec.)

SAM à fond = max. (40 min.)

Réglage linéaire lumière du jour

SCAM à fond = Lumière min.

SAM à fond = max. (hors service)

Réglage manuel

recommandé

50 %

75 %

33 %

10 min.

Off

sauf à

l’usage

Page 5

Detectores de tecnología adaptable H-MOSS

Serie ATD, Serie ATU, Serie ATP/AHP

Instrucciones de instalación

DESCRIPCIÓN

Los detectores de ocupación jados al techo de tecnología adaptable (Serie AT) están diseñados para reducir el tiempo de instalación y evitar las

demandas de servicio técnico resultantes de un ajuste incorrecto del detector. Los detectores de la serie AT de Hubbell estudian su ambiente y ajustan

automáticamente el retardo y la sensibilidad para optimizar el rendimiento del detector para cada aplicación especíca. Los detectores AT de Hubbell

deben usarse conjuntamente con unidades de control de Hubbell. Las unidades de control suministran energía de V=24 para 1 a 3 detectores. Debe

elegirse la unidad de control apropiada para la tensión de funcionamiento de la aplicación. Hubbell ofrece las siguientes unidades de control:

- CU300A(U)(M): 100-277 V~, 50/60 Hz. - CU347A: 347 V~, 60 Hz.

- CU300HD: 100-277 V~, 50/60 Hz.

Cada detector se provee con los accesorios necesarios para jarlo al techo.

CARACTERÍSTICAS

• La tecnología adaptable reduce el tiempo de instalación y evita las demandas de servicio técnico.

• Disponible en modelos con infrarrojos pasivos (serie ATP/AHP), ultrasonidos (serie ATU), y tecnología

doble: infrarrojos pasivos y ultrasonidos (serie ATD).

• Diversos modelos disponibles para áreas de cobertura de 45 a 185 m².

•

Con los detectores que llevan el sujo “RP”, se proveen opciones con relé y células fotoeléctricas aislados.

•

Indicadores visuales de movimientos: LED verde en los ultrasonidos, LED rojo en los infrarrojos pasivos.

• Capacidad del sensor/AAR*:

- CU300A(U)(M): 1 a 4 combinados

- CU300HD: 1 a 6 combinados

- CU347A: 1 a 3 combinados

* Máximo de 2 AARs por unidad de control

PREPARACIÓN PARA LA INSTALACIÓN

1. AVISO - Para ser instalado por un electricista calicado, de acuerdo con los códigos eléctricos

nacionales y locales y siguiendo estas instrucciones.

2. AVISO - Para uso interior únicamente

3. CUIDADO - RIESGO DE CHOQUE ELÉCTRICO. Desconectar la corriente antes de la instalación.

No conectar nunca componentes eléctricos en un circuito energizado.

4. CUIDADO - UTILIZAR SOLAMENTE CONDUCTORES DE COBRE.

5. Asegurarse de que las características nominales del dispositivo sean apropiadas para la aplicación.

6. Al instalar los detectores de la serie AT de Hubbell, respetar la capacidad nominal máxima del módulo de

control appropiado:

- CU300A(U)(M): Incandescente de 15 A (tungsteno de1800 W) a 120 V~, 60 Hz.

Balasto de 20 A (uorescente de 2400 W) a 120 V~, 60 Hz.

Balasto de 20 A (uorescente de 5540 W) a 277 V~, 60 Hz.

- CU300HD: 20 A, 120 V~, incandescente. 20 A, 120 V~ ó 277 V~, balasto.

Cargas de motor; 1 HP @ 120 V~, 2 HP a 240/277 V~.

- CU347A: Balasto de 15 A (5205 W) a 347 V~, 60 Hz.

7. AVISO - No instalar si se advierte un daño visible en el dispositivo.

COBERTURA Y COLOCACIÓN

A la derecha se indican los planos de cobertura de los detectores AT.

• Altura del cielorraso de montaje: 2,4 à 3,7 metros.

•

Los detectores deben jarse a 1,20 m, como mínimo, de equipos de ventilación para evitar la

interferencia de corrientes de aire.

•

Para uso en interiores únicamente. Estos sensores NO deben ser instalados en sitios húmedos tales como

cerca de duchas o fuentes de vapor, en lugares mojados, o donde estén expuestos a lluvia a menos que se

utilicen sensores PIR combinados con ACIPE (NEMA 4X caja) para exteriores o lugares húmedos.

• NO instalarlos frente a fuentes de luz intensa directa o reejada.

INSTALACIÓN DE LOS DETECTORES

1. Desconectar la corriente.

2. Instalar las unidades de control de la serie CU y, si corresponde, los relés Add-A-Relay

(AAR). Ver las instrucciones de instalación para estos productos.

3.

Montar el detector, que debe estar jado al techo para funcionar correctamente. En la placa de cobertura

del detector hay una echa moldeada, que debe usarse como guía general para la orientación del plano

de cobertura. Más adelante se explicará cómo sintonizarlo con precisión. Opciones de montaje:

• Para techos rígidos: Instalar una caja de derivación.

•

Para falsos cielorrasos: Fijar la placa de cobertura con tornillos para metales y perforando un pequeño

oricio a través del cielorraso para pasar los cables del detector (Figura A) O BIEN usando vástago de

suspensión roscado y pasando los cables del detector por el centro del vástago (Figura B).

4.

Fijar el detector a la placa de cobertura alineando las ranuras de la placa con las de la caja

del detector. Hacer girar la caja del detector hasta obtener la orientación apropiada.

5.

Usando un cable de baja tensión de 3 conductores (18 a 22 AWG de tipo CL2, CL2P, CL2PR o CMR,

según corresponda), conectar el detector y los accesorios a la unidad de control. Los alambres de

bajo voltaje no deben exceder 76,2 metros desde la unidad de control hasta el último sensor. Ver el

diagrama de cableado en las instrucciones de instalación del módulo de control.

6.

Aislar todos los conductores expuestos con cinta aislante o conectores de rosca homologados.

7. Restablecer la corriente en la unidad de control.

8.

Conrmar la cobertura correcta simulando los movimientos dentro del área cubierta que

serán típicos en la aplicación Si no se logra la cobertura deseada, colocar el detector

en otra posición para obtener la cobertura correcta. Ensayar el detector. Para encontrar

la perilla de ensayo, retirar el retén de la lente y la lente. Hacer girar la perilla negra del

temporizador a fondo en sentido contrario a las agujas del reloj desde cualquier posición

del dial. Volver a colocar la lente y el reten. Las luces se apagarán 8 segundos después

de haber cesado el movimiento. Volver a regular el temporizador para la aplicación.

Al instalar detectores de infrarrojos pasivos, el plano de cobertura se podrá modicar

aplicando una máscara en la lente.

Wiring Device-Kellems

Hubbell Incorporated (Delaware)

Shelton, CT 06484

1-800-288-6000

www.hubbell-wiring.com

PD1463 (PAGE 1) 11/13

tuercas (ajustar con la mano)

Fig. A

0

2

4

6

8

10

12

14

0

2

4

6

8

10

12

14

0 2 4 6 8 10 12 14 16 18

0

2

•

4

6

8

10

12

14

6,7 m

3,7 m

•

ATD2000C

ATD2000CRP

•

3,7

6,7

•

ATP1500C

ATP1500CRP

AHP1500CRP

tornillos 6-32 (2)

techo

placa de cobertura

detector

Cuidado: instalar los conectores de

rosca por encima del techo

0 2 4 6 8 10

•

3,7 m

6,7 m

•

ATD500C

ATD500CRP

0 2 4 6 8 10

•

3,7 m

6,7 m

•

ATD1000C

ATD1000CRP

•

2

4,1

•

ATP600C

ATP600CRP

ATU2000C

ATU2000CRP

Movimiento

Movimiento

(ajustar con la mano)

Fig. B

MR

Español

5,2 m

5,2 m

7 m

ATU500C

ATU500CRP

7 m

9,8 m

ATU1000C

ATU1000CRP

6,7 m

13,7 m

19,5 m

ULTRASÓNICO

Movimiento

Menor

INFRARROJOS

Menor

Mayor

Movimiento

Mayor

tuerca

vástago de

suspensión

roscado

7,m

7 m

9,8 m

6,7 m

Page 6

CÓMO ENMASCARAR LA LENTE DE LOS DETECTORES INFRARROJOS (únicamente para detectores de las series ATD y ATP/AHP)

Este procedimiento sólo se requiere para las aplicaciones en que el plano de cobertura con infrarrojos pasivos debe modicarse para evitar que se expanda a través de

las puertas hacia los pasillos. Con los detectores se proveen tres máscaras (los detectores unidireccionales incluyen 2 máscaras). Elegir la máscara apropiada para la

aplicación, a partir de las descripciones siguientes.

Para usar la máscara de sala de conferencias

Para usar la máscara de 180°

Para usar la máscara de recorte

0 2 4 6 8 10 12 14

0

2

4

6

8

Esta máscara se usa

cuando se monta un

Hubbell-DT en el

10

12

14

centro de una sala

rectangular larga (p. ej., una sala de conferencias).

La máscara proporciona un plano de infrarrojos más

rectangular y evita que la detección se expanda por

las puertas laterales de la sala.

La máscara de 180° es

la más apropiada para

una instalación sobre

la puerta. Cuando el

detector se instala hacia el interior del vano de

una puerta, se debe impedir que la cobertura de

infrarrojos se expanda al pasillo contiguo. A la

derecha se muestra el nuevo plano del infrarrojo.

0 2 4 6 8 10 12 14

0

2

4

6

8

10

12

14

0 2 4 6 8 10 12 14

0

2

4

6

Esta máscara lleva

muescas en su interior,

de modo que es fácil

lograr la máscara

8

10

12

14

perfecta para cualquier

aplicación. Simplemente

hay que desprender las secciones en que es necesaria la

cobertura y dejar las porciones en que se quiere evitar la

cobertura. Las líneas en el plano de cobertura a la derecha

representan los recortes en la máscara.

Para instalar la lente elegida, retirar el aro retén y la lente. Insertar la máscara detrás de la lente. Asegurarse de orientar

correctamente la máscara para lograr los resultados deseados. Volver a colocar la lente y su aro retén.

OPCIÓN DE CONTROL DEL NIVEL DE LUZ AMBIENTE (únicamente para los modelos que llevan el sujo RP)

El detector está regulado en fábrica para encender las luces, independientemente del nivel de luz ambiente (luz natural). La regulación del control del nivel de luz

ambiente evitará que las luces se enciendan cuando el nivel de luz ambiente sea superior al nivel prejado. La luz ambiente debe estar al nivel deseado para regular

correctamente este artefacto. Para regular el control del nivel de luz ambiente:

1. Girar la perilla negra del temporizador en sentido contrario a las agujas del reloj al máximo, hasta el modo test de 8 segundos.

2.

Ajustar la perilla azul de la célula fotoeléctrica al máximo en el sentido de las agujas del reloj. De este modo las luces se mantendrán apagadas, cualquiera sea la luz ambiente.

3. Salir del área de cobertura del detector. Las luces deberían apagarse después de 8 segundos.

4. Cuando las luces se apaguen, volver a entrar al área.

5. Girar lentamente la perilla azul de la célula fotoeléctrica en sentido contrario a las agujas del reloj, hasta que las luces se enciendan.

El detector ha quedado regulado para evitar que las luces se enciendan cuando el nivel de luz ambiente sea superior al umbral jado.

OPCIÓN CON RELÉ AISLADO (únicamente para modelos que lleven el sujo RP)

El relé aislado puede usarse para conectar el detector con un sistema auxiliar. Se ofrecen contactos normalmente abiertos y normalmente cerrados.

Para los contactos normalmente abiertos, utilizar los cables amarillo/blanco y azul/blanco.

Para los contactos normalmente cerrados, utilizar los cables negro/blanco y azul/blanco.

CONTROLES Y MODIFICACIONES DE LOS DETECTORES

Los detectores de tecnología adaptable de Hubbell están diseñados para optimizar su funcionamiento ajustando automáticamente la sensibilidad y el retardo del modo

que convenga a la aplicación.

Los controles del detector pueden modicarse para funcionar a medida de las necesidades. A continuación se exponen las opciones de modicación.

Finalidad Off On

Compensador de Corriente de aire Corriente de aire fuerte

B

corrientes de aire fuertes normal o muy baja presente

Montaje sobre Detector montado alejado Detector montado por

vano de puerta de la puerta encima de la puerta

Temporizador Temporizador regulado Reglaje manual

automático/manual automáticamente del temporizador

Ajuste de la sensibilidad OFF = Automático ON = Manual

Finalidad Off On

Anulación manual Funcionamiento Encendido manual

A

totalmente automático

Umbral Ajuste automático Alta sensibilidad

del umbral

Anulación indicador El LED guiña cuando se Inhabilita los LED

de movimientos detecta una presencia

Reajustar los reglajes Normal Encendido y apagado

adquiridos

Condiciones analizadas

en el funcionamiento

automático

Corrientes de aire

Encendidos falsos

Apagados falsos

Suciedad de la lente

Relación señal-ruido

Falsos apagados

El funcionamiento

sin error disminuye el

reglaje del temporizador

No se aplica Reglaje lineal de la cobertura

Reglaje de la perilla*

Funcionamiento manual

Reglaje lineal de la cobertura

CAR a fondo = mín (apag.)

SAR a fondo = cobertura máx.

Igual que el anterior

Reglaje lineal de la cobertura

CAR a fondo = mín (8 seg.)

SAR a fondo = máx (40 min.)

CAR a fondo = mín. luz diurna

SAR a fondo = máx. (apagado)

Reglaje manual

recomendado

50 %

75 %

33 %

10 min.

Off

salvo que

se use

Conmutadores DIP

grupo A

Sensibilidad

Infrarrojos (rojo)

Temporizador

(negro)

Colorde la

perilla:

Control

Verde:

Sensibilidad

ultrasónica

Rojo:

Sensibilidad

infrarrojos

Negro:

Temporiza-

Azul:

Nivel de luz

diurna

Finalidad

Regula la cobertura

ultrasonica

Regula la cobertura de

infrarrojos

Regula el tiempo que las

luces quedarán encendidas

después de detectar el último

movimiento

Regula el nivel de luz

diurna necesario para evitar

que las luces se enciendan

Sensibilidad

ultrasonidos

(verde)

Nivel de luz

diurna (azul)

Grupo

1

2

3

4

off on

apagado

Grupo

Conmutadores DIP

grupo B

Funcionamiento

automático

El detector analiza el local

y ja la sensibilidad para el

ajuste óptimo

Igual que el anterior Temperatura local

El reglaje del temporizador

aumenta durante el período de

aprendizaje, luego disminuye

hasta minimizar el tiempo

«encendido»

No funciona

automáticamente

1

2

3

4

off on

* Cuando una función se regula en “Funcionamiento automático”, el reglaje inicial está determinado por la posición de la perilla.

CAR signica en sentido contrario a las agujas del reloj, SAR en el sentido de las agujas del reloj.

0 2 4 6 8 10 12 14

0 5 10 15 20 25 30 35 40 45

PD1463 (PAGE 2) 11/13

Loading...

Loading...