Page 1

R230D

Hardware Installation and

Maintenance Guide

Issue 01

Date 2015-12-12

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Copyright © Huawei Technologies Co., Ltd. 2015. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://e.huawei.com

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Page 3

R230D

Hardware Installation and Maintenance Guide

Intended Audience

This document describes hardware features and basic installation of the R230D to help you

understand R230D hardware structure and software configuration.

This document is intended for:

l Network planning engineers

About This Document

About This Document

l Hardware installation engineers

l Commissioning engineers

l Onsite maintenance engineers

l System maintenance engineers

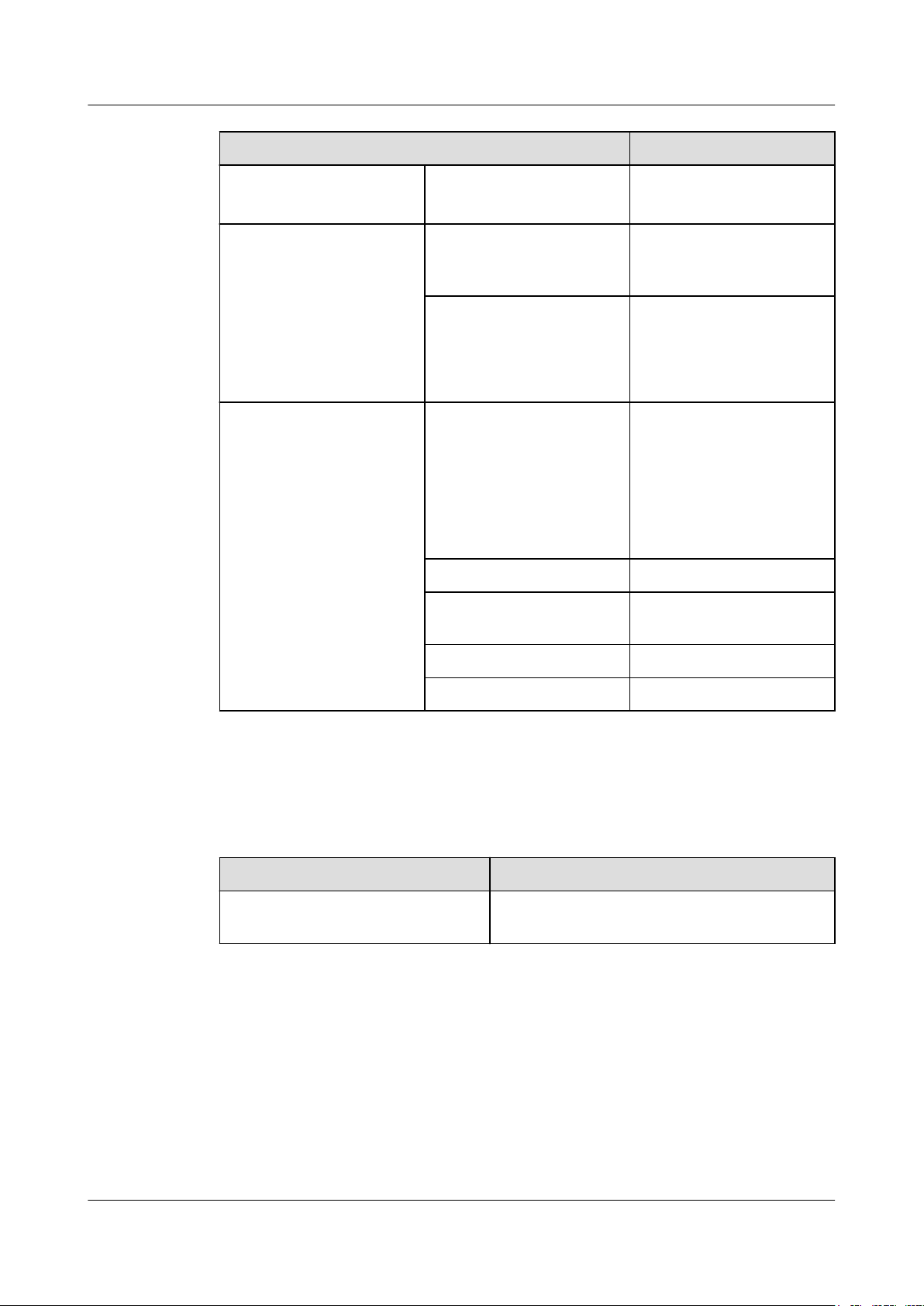

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol

Description

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in

equipment damage, data loss, performance

deterioration, or unanticipated results.

NOTICE is used to address practices not

related to personal injury.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

Page 4

NOTE

R230D

Hardware Installation and Maintenance Guide

Symbol Description

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 01 (2015-12-12)

This issue is the first official release.

About This Document

Calls attention to important information,

best practices and tips.

NOTE is used to address information not

related to personal injury, equipment

damage, and environment deterioration.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Page 5

R230D

Hardware Installation and Maintenance Guide Contents

Contents

About This Document.....................................................................................................................ii

1 Product Overview..........................................................................................................................1

1.1 Device Structure............................................................................................................................................................. 1

1.2 Indicator Description...................................................................................................................................................... 2

1.3 Basic Specifications........................................................................................................................................................4

1.4 Ordering Information......................................................................................................................................................5

2 AP Installation............................................................................................................................... 6

2.1 Preparing for Installation................................................................................................................................................ 6

2.2 Installation Flowchart..................................................................................................................................................... 7

2.3 Unpacking the Equipment.............................................................................................................................................. 8

2.4 Determining the Installation Position............................................................................................................................. 8

2.5 Installing the R230D.......................................................................................................................................................9

2.5.1 Installing the R230D on a Wall or Ceiling.................................................................................................................. 9

2.5.2 Installing the R230D in an 86-type Box.................................................................................................................... 11

2.6 Checking the Device After Installation........................................................................................................................ 13

2.7 Powering on the Device................................................................................................................................................13

3 Logging In to the Device............................................................................................................ 14

3.1 Logging In to the Device Using STelnet/Telnet........................................................................................................... 14

4 Hardware Failures....................................................................................................................... 16

4.1 An device Fails to Be Powered On...............................................................................................................................16

5 Appendix.......................................................................................................................................17

5.1 On-site Cable Assembly and Installation..................................................................................................................... 17

5.1.1 Cable Assembly Precautions..................................................................................................................................... 17

5.1.2 Assembling Power Cables......................................................................................................................................... 18

5.1.3 Assembling Ethernet Cables......................................................................................................................................27

5.1.4 Installing Cable Accessories......................................................................................................................................40

5.1.5 Replacing the Mold of the Crimping Tool.................................................................................................................56

5.2 Environmental Requirements for Device Operation.................................................................................................... 59

5.2.1 Environmental Requirements for an Equipment Room............................................................................................ 59

5.2.2 Requirements for Power Supply................................................................................................................................67

5.3 Equipment Grounding Specifications...........................................................................................................................70

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Page 6

R230D

Hardware Installation and Maintenance Guide Contents

5.3.1 General Grounding Specifications.............................................................................................................................70

5.3.2 Grounding Specifications for an Equipment Room.................................................................................................. 70

5.3.3 Grounding Specifications for Devices.......................................................................................................................70

5.3.4 Grounding Specifications for Communications Power Supply.................................................................................71

5.3.5 Grounding Specifications for Signal Cables............................................................................................................. 72

5.3.6 Specifications for Laying Out Grounding Cables..................................................................................................... 72

5.4 Engineering Labels for Cables..................................................................................................................................... 73

5.4.1 Introduction to Labels................................................................................................................................................73

5.4.2 Engineering Labels for Optical Fibers.......................................................................................................................81

5.4.3 Engineering Labels for Network Cables................................................................................................................... 84

5.4.4 Engineering Labels for User Cables..........................................................................................................................85

5.4.5 Engineering Labels for Power Cables....................................................................................................................... 86

5.5 Guide to Using Optical Modules.................................................................................................................................. 89

5.6 Fault Tag....................................................................................................................................................................... 92

5.7 Installation Checklist.................................................................................................................................................... 93

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

Page 7

1

2

R230D

Hardware Installation and Maintenance Guide

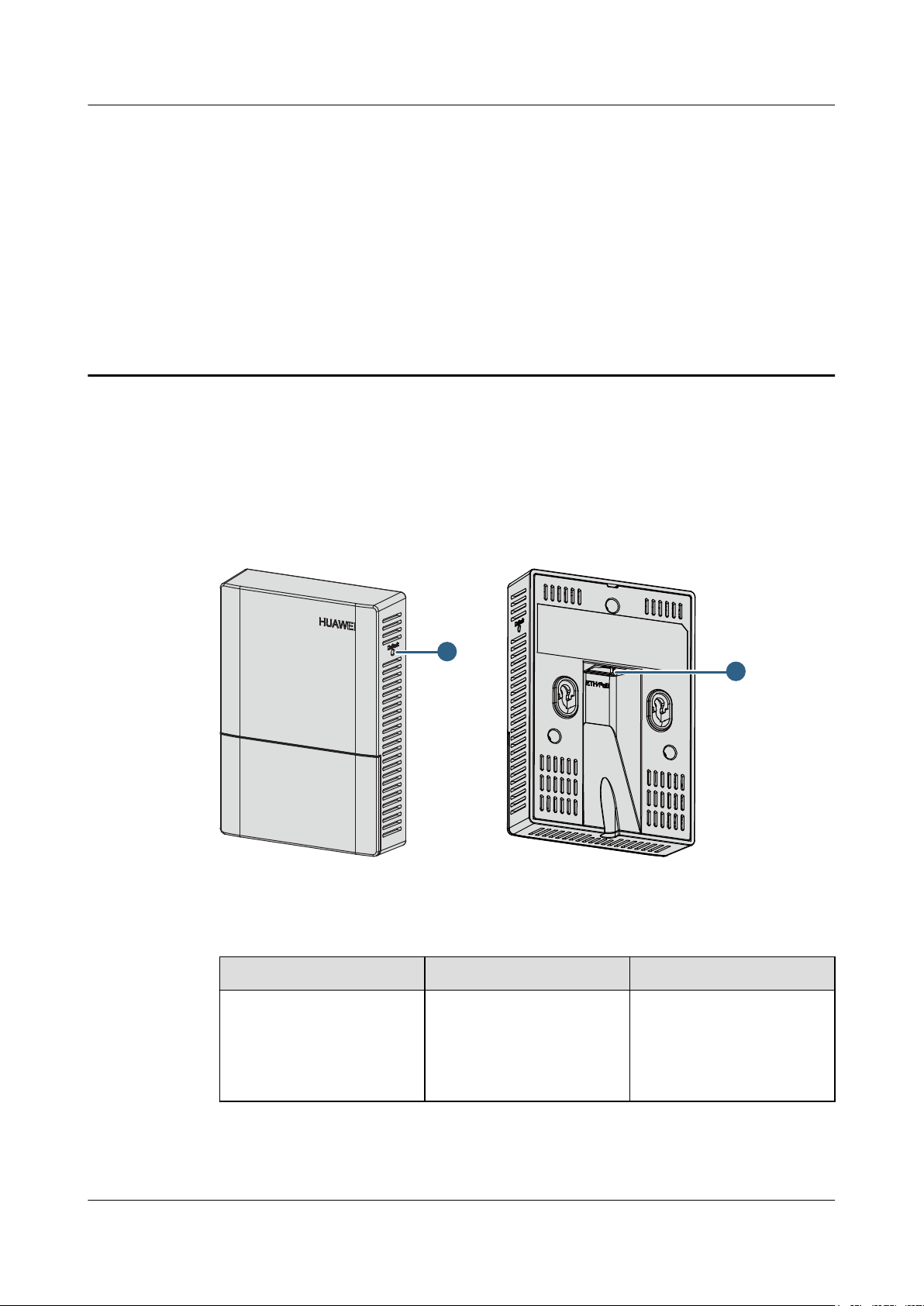

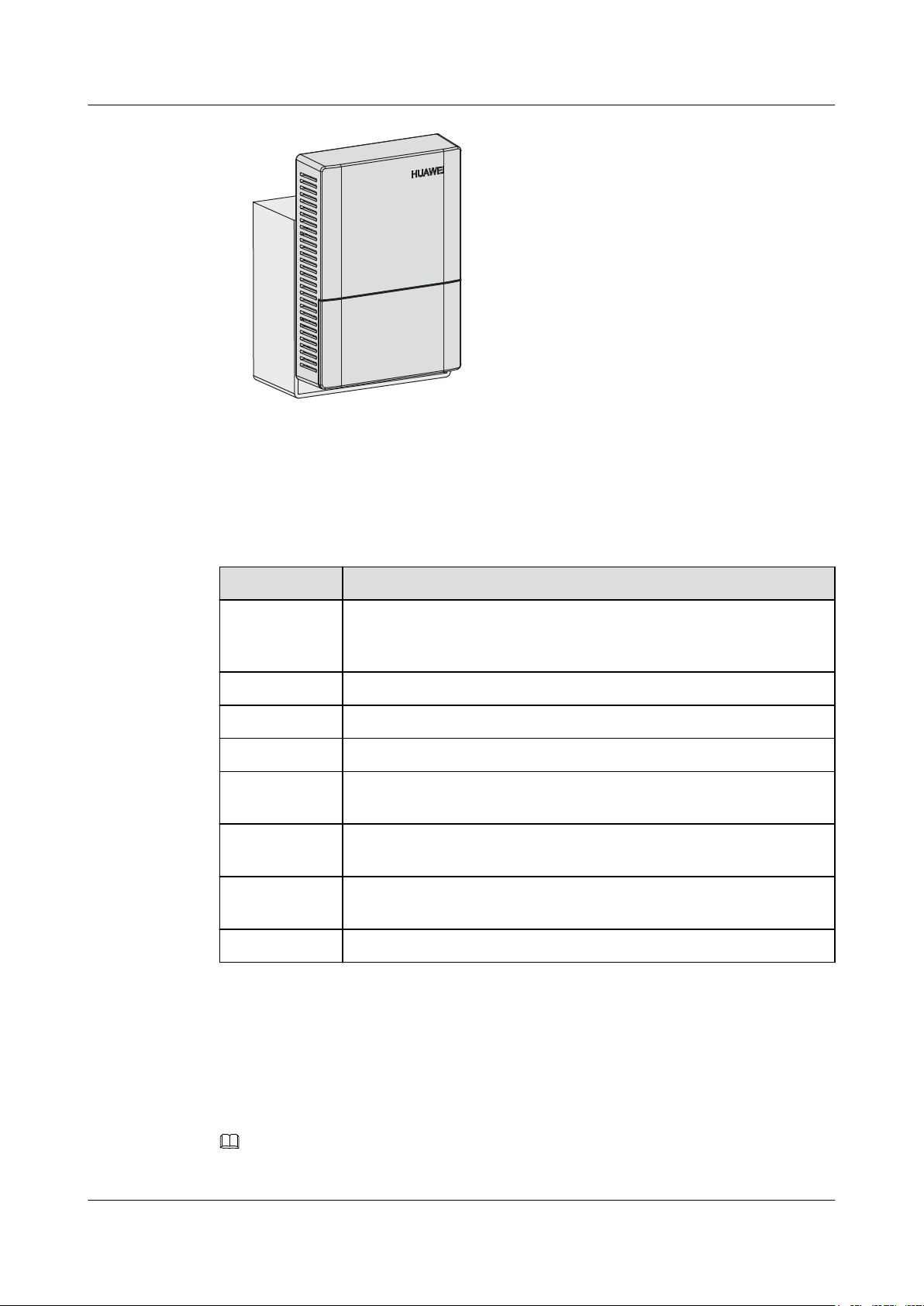

1.1 Device Structure

Figure 1-1 shows the appearance of the R230D.

1 Product Overview

1 Product Overview

Figure 1-1 Appearance of the R230D

Table 1-1 describes interfaces on the R230D.

Table 1-1 Interfaces on the R230D

No.

Name Description

1 Default Reset button used to restore

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

factory settings and restart

the R230D if you hold down

the button more than 3

seconds.

1

Page 8

Indicator

R230D

Hardware Installation and Maintenance Guide

No. Name Description

2 ETH/PoE 10/100 Mbit/s auto-sensing

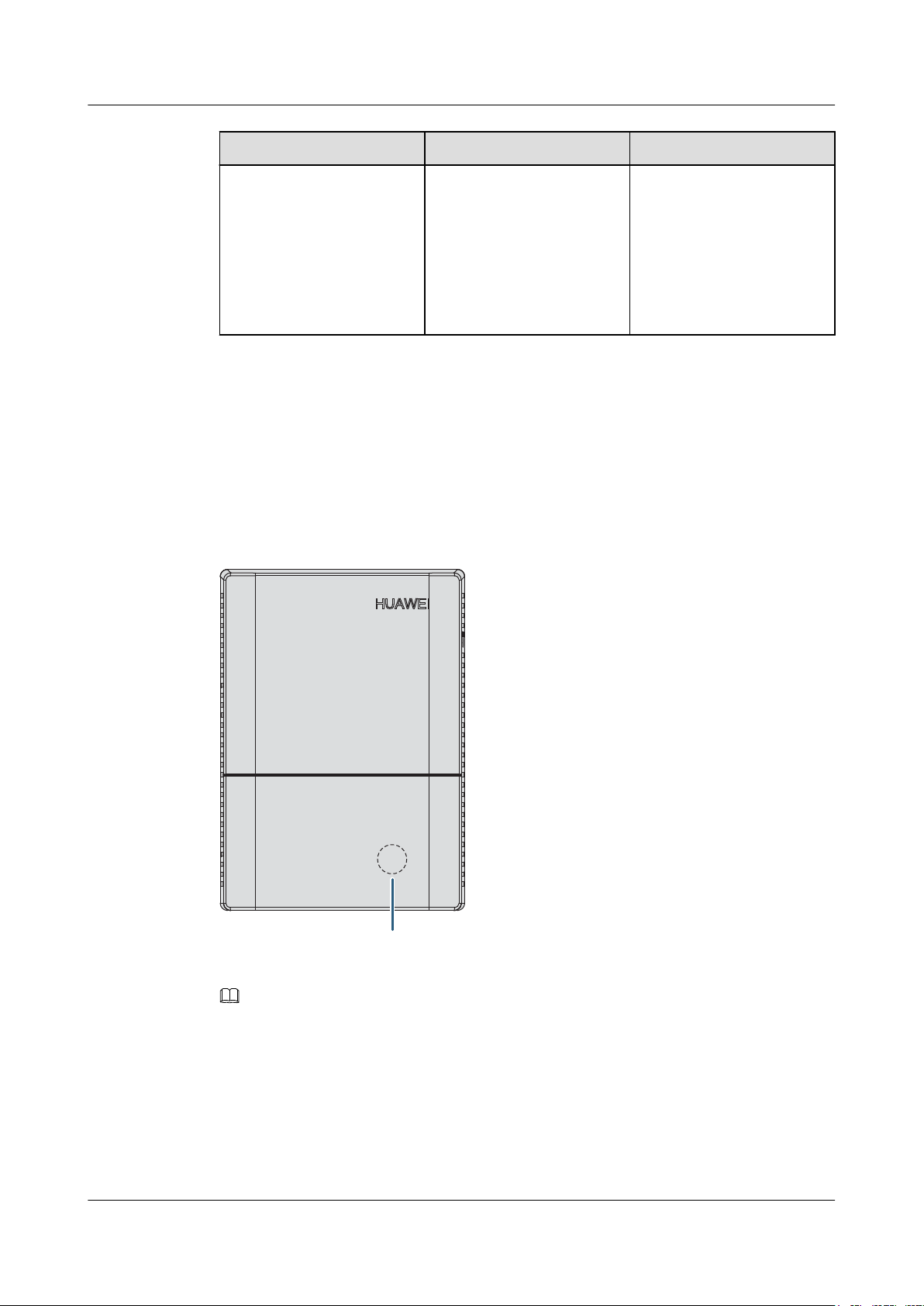

1.2 Indicator Description

LED Indicator

The R230D provides only one indicator, as shown in Figure 1-2.

1 Product Overview

network interface used to

connect to the central AP

and supports PoE power

input. Cat 5e network cables

or higher must be used,

which cannot exceed 100

meters.

Figure 1-2 Indicator on the R230D

NOTE

l The indicator is located inside the panel, which turns on after the AP is powered on.

l Indicator colors may vary slightly at different temperature.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Page 9

R230D

Hardware Installation and Maintenance Guide

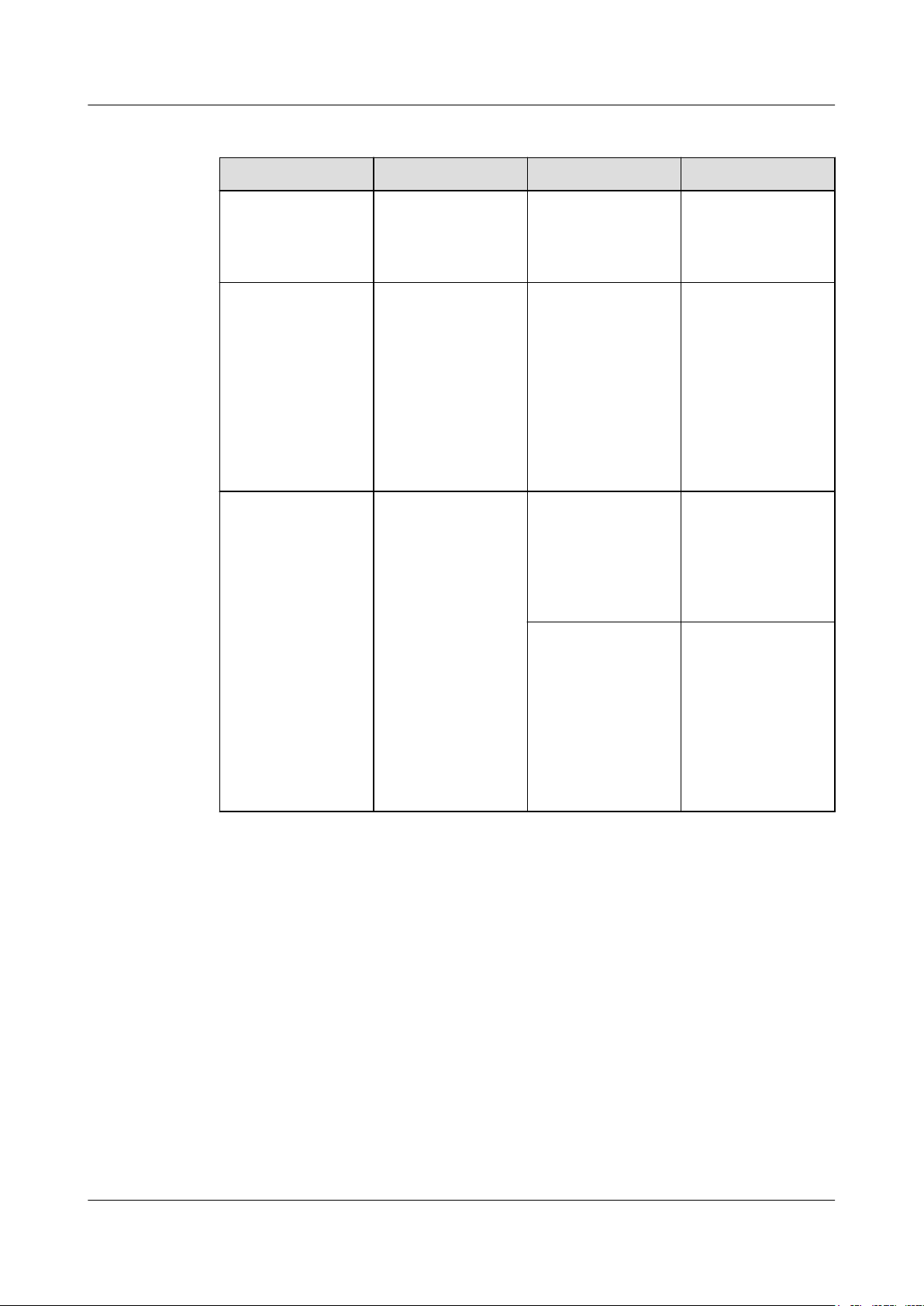

Table 1-2 Description of the indicator on the R230D

Type Color Status Description

1 Product Overview

Default status after

Green Steady on The AP is just

power-on

Software startup

status

Green Steady on after

blinking once

Running status Green Blinking once every

2s (0.5 Hz)

Blinking once every

5s (0.2 Hz)

powered on and the

software is not

started yet.

After the system is

reset and starts

uploading the

software, the

indicator blinks

green once. Until the

software is uploaded

and started, the

indicator remains

steady green.

The system is

running properly, the

Ethernet connection

is normal, and STAs

are associated with

the AP.

The system is

running properly, the

Ethernet connection

is normal, and no

STA is associated

with the AP. The

system is in low

power consumption

state.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

Page 10

R230D

Hardware Installation and Maintenance Guide

Type Color Status Description

1 Product Overview

Alarm Green Blinking once

Alarm Green every

0.25s (4 Hz)

l The software is

being upgraded.

l After the

software is

uploaded and

started, the AP

working in Fit

AP mode

requests to go

online on the AC

and maintains

this state until it

goes online

successfully on

the AC (before

the CAPWAP

link is

established).

l The AP

registration fails

(the CAPWAP

link is

disconnected).

Fault

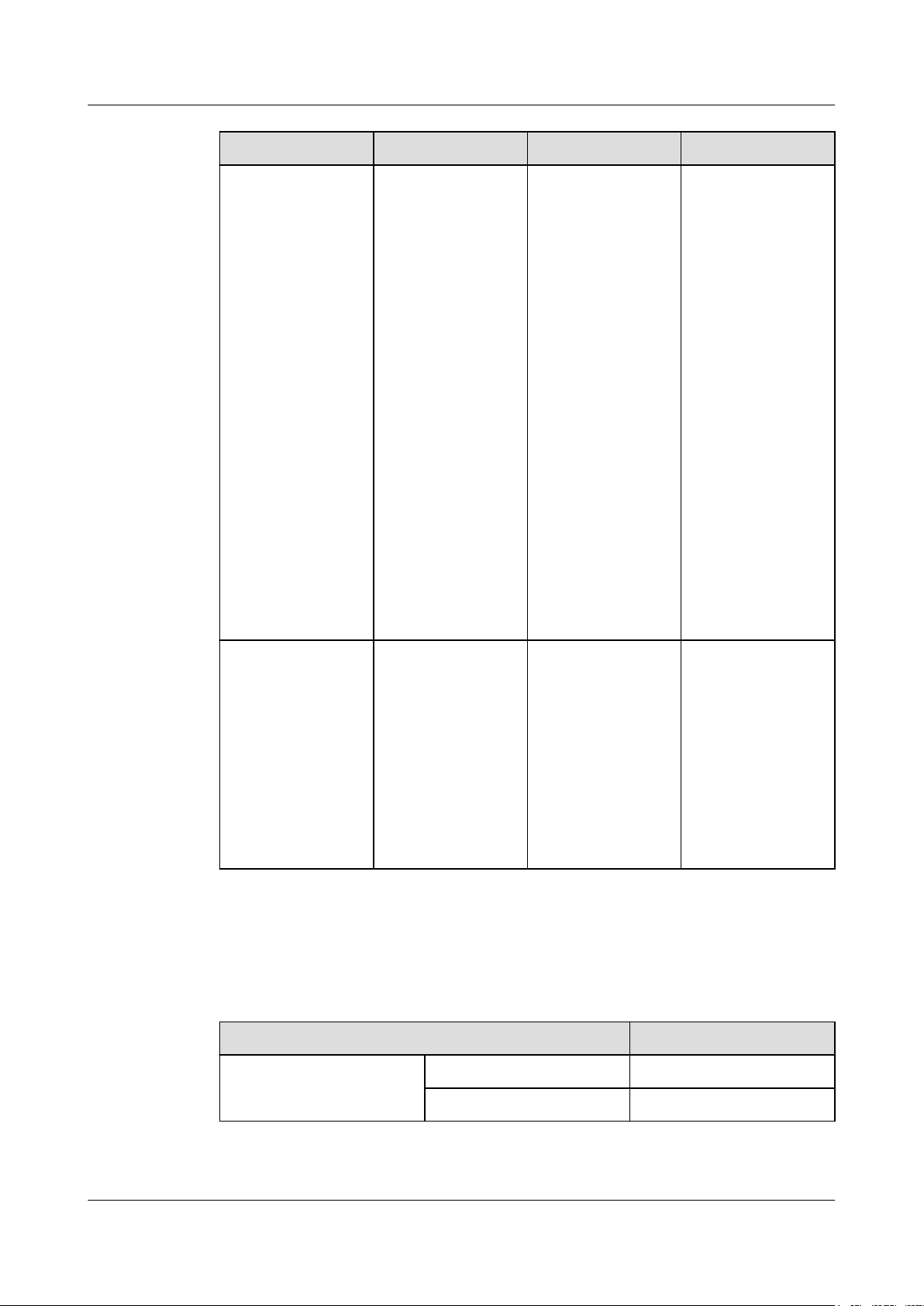

1.3 Basic Specifications

Table 1-3 Basic specifications of the R230D

Item

Technical specifications Dimensions (W x D x H) 120 mm x 86 mm x 26 mm

Red Steady on A fault that affects

services has

occurred, such as a

DRAM detection

failure or system

software loading

failure. The fault

cannot be

automatically

rectified and must be

rectified manually.

Description

Weight 0.1 kg

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

Page 11

R230D

Hardware Installation and Maintenance Guide

Item Description

1 Product Overview

System memory

Power parameters Power input

Maximum power

consumption

Environment specifications Operating temperature and

altitude

Storage temperature -40°C to +70°C

Operating humidity 5% to 95% (non-

l 128 MB DDR2

l 32 MB flash memory

l PoE power supply in

compliance with IEEE

802.3af

5.1 W

NOTE

The actual maximum power

consumption depends on local

laws and regulations.

-60 m to 1800 m: 0°C to

40°C

1,800 m to 5,000 m: The

highest operating

temperature reduces by 1°C

every time the altitude

increases by 300 m.

condensing)

1.4 Ordering Information

To place an order, contact technical support personnel.

Part Number

50082748 Broadband Network Terminal,R230D,

Ingress Protection Rating IP20

Atmospheric pressure 70 kPa to 106 kPa

Part Description

1*RJ45,11ac, 2*2 Double Frequency

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

Page 12

R230D

Hardware Installation and Maintenance Guide

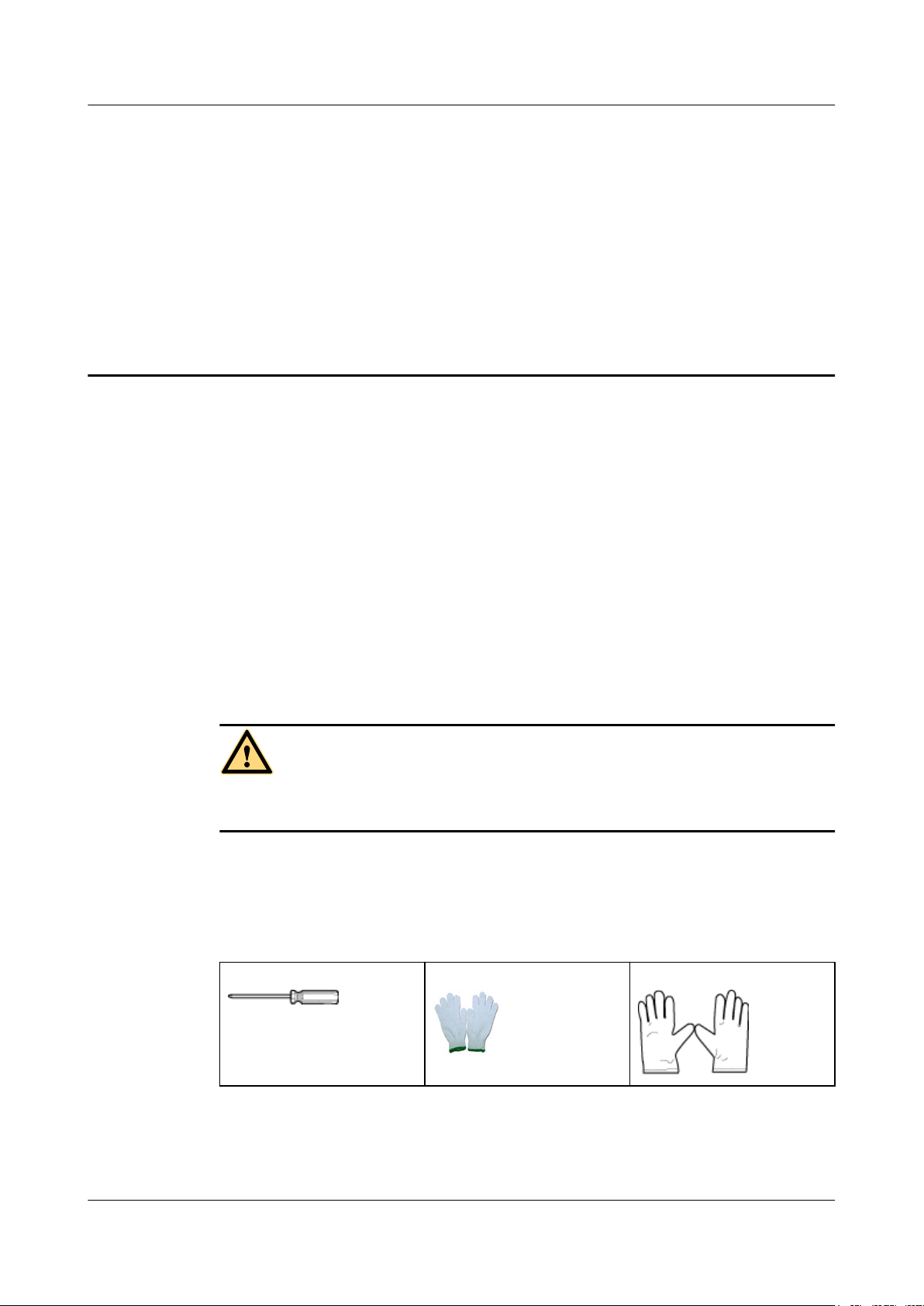

2.1 Preparing for Installation

This section describes safety precautions and tool preparations for AP installation.

2 AP Installation

2 AP Installation

Safety Precautions

l Take proper measures to prevent injuries and device damage.

l Place the device in a dry and flat position away from any liquid and prevent the device

l Keep the device clean.

l Do not put the device and tools in the aisles.

Only the qualified personnel are permitted to install and remove the device and its

accessories. Before installation and operation, read the safety precautions carefully.

Tool Preparation

To install APs, prepare tools listed in Table 2-1.

Table 2-1 Tools

Phillips screwdriver

from slipping.

CAUTION

Protective gloves ESD gloves

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

Page 13

R230D

Hardware Installation and Maintenance Guide

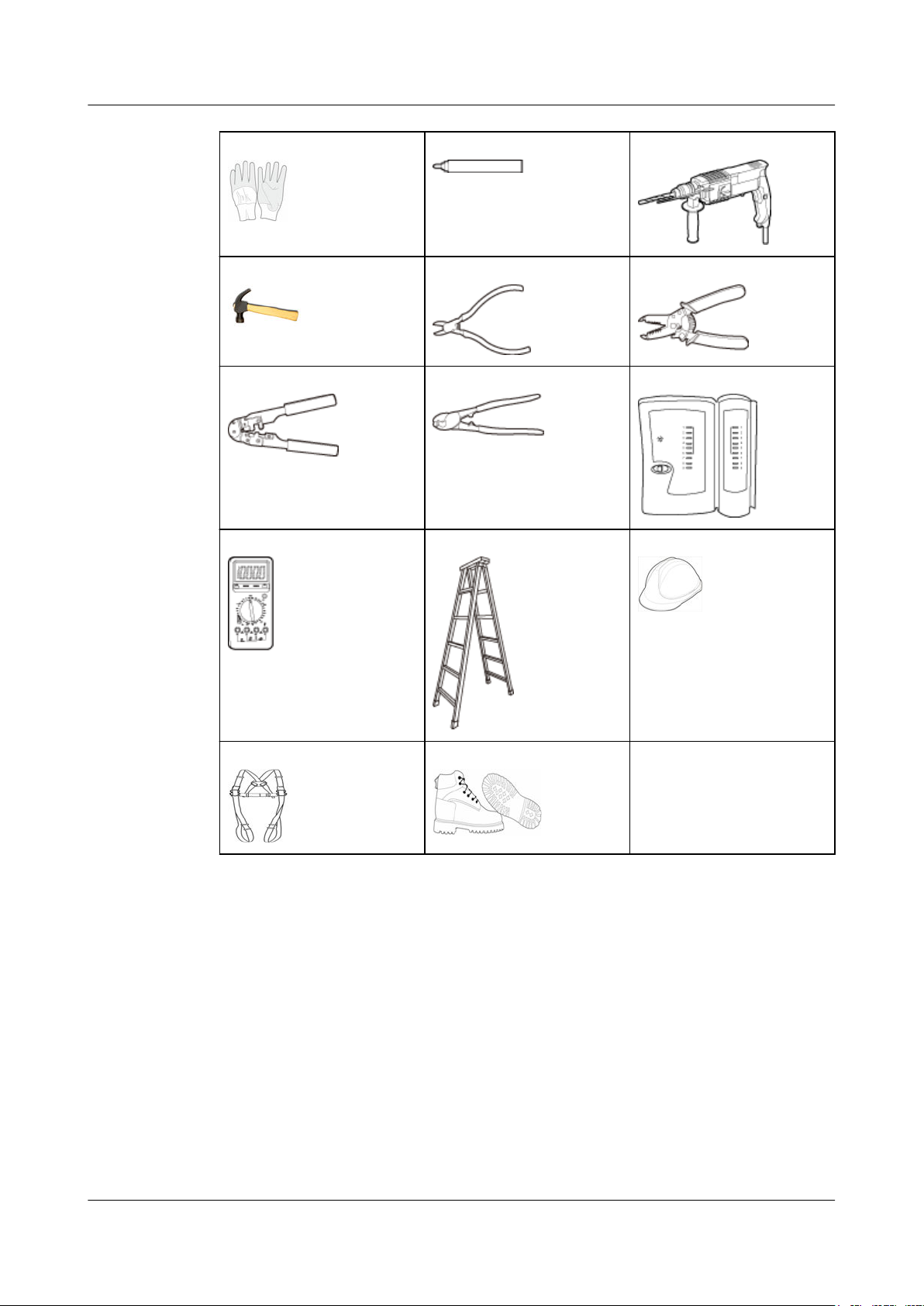

Slip-proof glove Marker Hammer drill

Claw hammer Diagonal pliers Wire stripper

RJ45 crimping tool Cable cutter Network cable tester

2 AP Installation

Multimeter Ladder Safety helmet

Safety belt Anti-skid shoes -

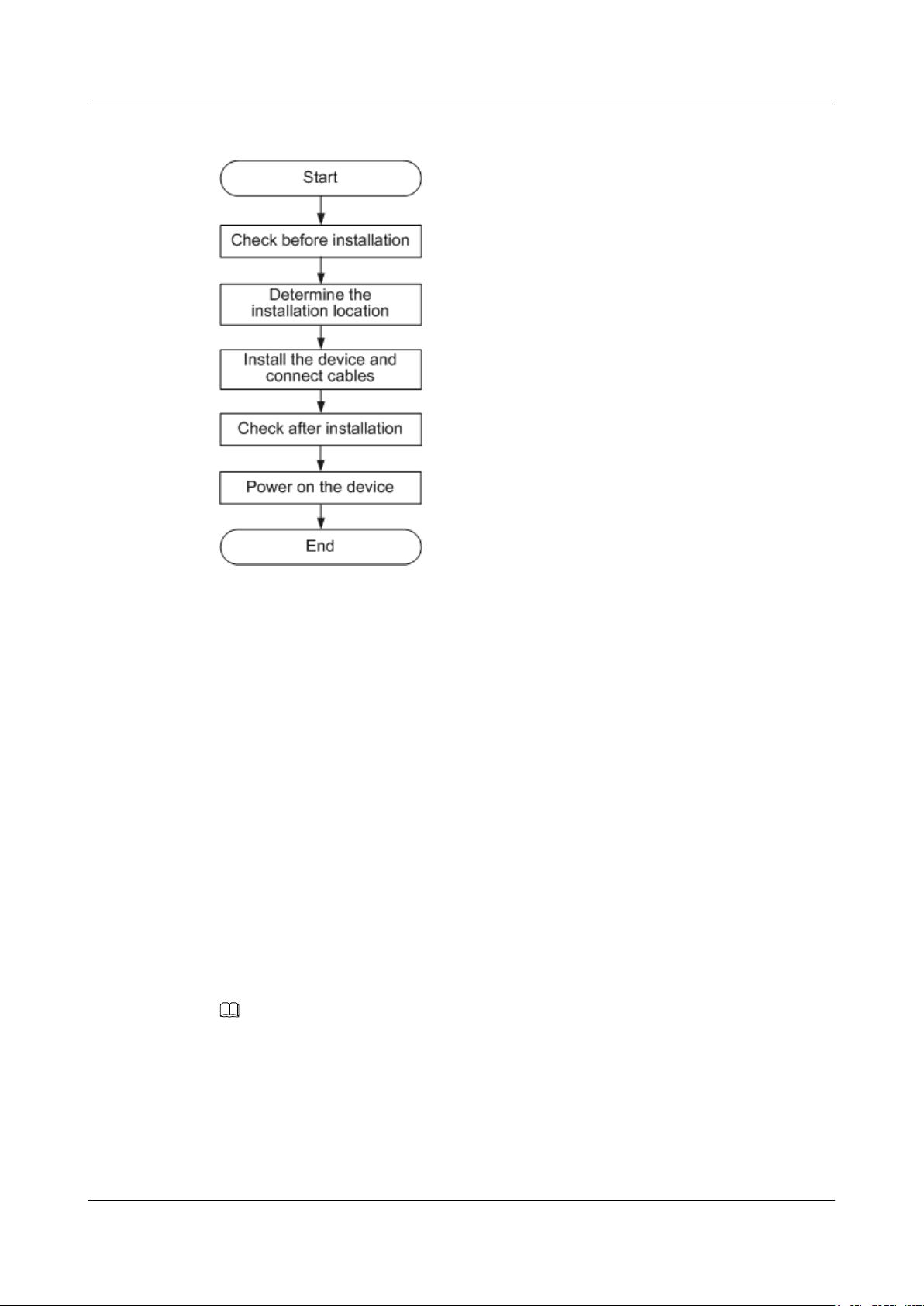

2.2 Installation Flowchart

The following figure shows the process.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

Page 14

R230D

Hardware Installation and Maintenance Guide

Figure 2-1 Installation flowchart

2 AP Installation

2.3 Unpacking the Equipment

Before unpacking the carton, ensure that the packing carton is intact and not damaged or

soaked. If the equipment is found eroded or damped, stop unpacking, check for the reason,

and contact the supplier.

Check items in the carton against the packing list (included in the Quick Start Guide) and

ensure that all items listed in the packing list are included in the shipment. If the quantity of

the goods is inconsistent with the packing list, contact the supplier or agent.

Usually, the packing list contains the following items.

l Remote radio unit

l Screws (including the plastic expansion tubes)

l Quick Start Guide

l Warranty card

l MAC address label

l SN label

NOTE

If a PoE adapter is required, you need to purchase it separately.

2.4 Determining the Installation Position

l Do not deploy the device in places with high temperature, dust, noxious gas, unstable

voltage, much vibrations, or strong noise, or in places near flammable or explosive

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

Page 15

R230D

Hardware Installation and Maintenance Guide

materials and interference sources such as a large radar station, radio station, and

transformer station.

l Install the device in a site that is free from leaking or dripping water, heavy dew, and

humidity, and take protective measures to prevent water from flowing into the equipment

along the cable.

l Place the AP far away from electronic devices that may produce radio interference, such

as microwave ovens, antennas, and other radio communication devices. For details, see

Table 2-2.

l Install the device in hidden places and ensure that the device do not disturb daily work

and life of residents.

l Make the engineering design by fully considering such factors as hydrology, geology,

earthquake, electric power, and traffic. The selected site should comply with the

environment design specifications of communications equipment.

Table 2-2 General anti-interference requirements

2 AP Installation

Scenario

Indoor

installation

NOTE

If antennas are embedded into APs, the deployment distance requirements on the antennas are those on APs.

Deployment Distance Requirement

l There should be at least a 7 m distance between antennas.

l The antennas should be placed at least 2 m from the 4G antennas of

the carrier.

l The antennas should be placed far away from electronic devices that

may produce interference, such as microwave ovens.

2.5 Installing the R230D

NOTE

Remove the protective film on the surface before installation to prevent electrostatic discharge.

2.5.1 Installing the R230D on a Wall or Ceiling

Installing the R230D on a wall or ceiling requires expansion screws delivered with the

R230D. The procedure is as follows:

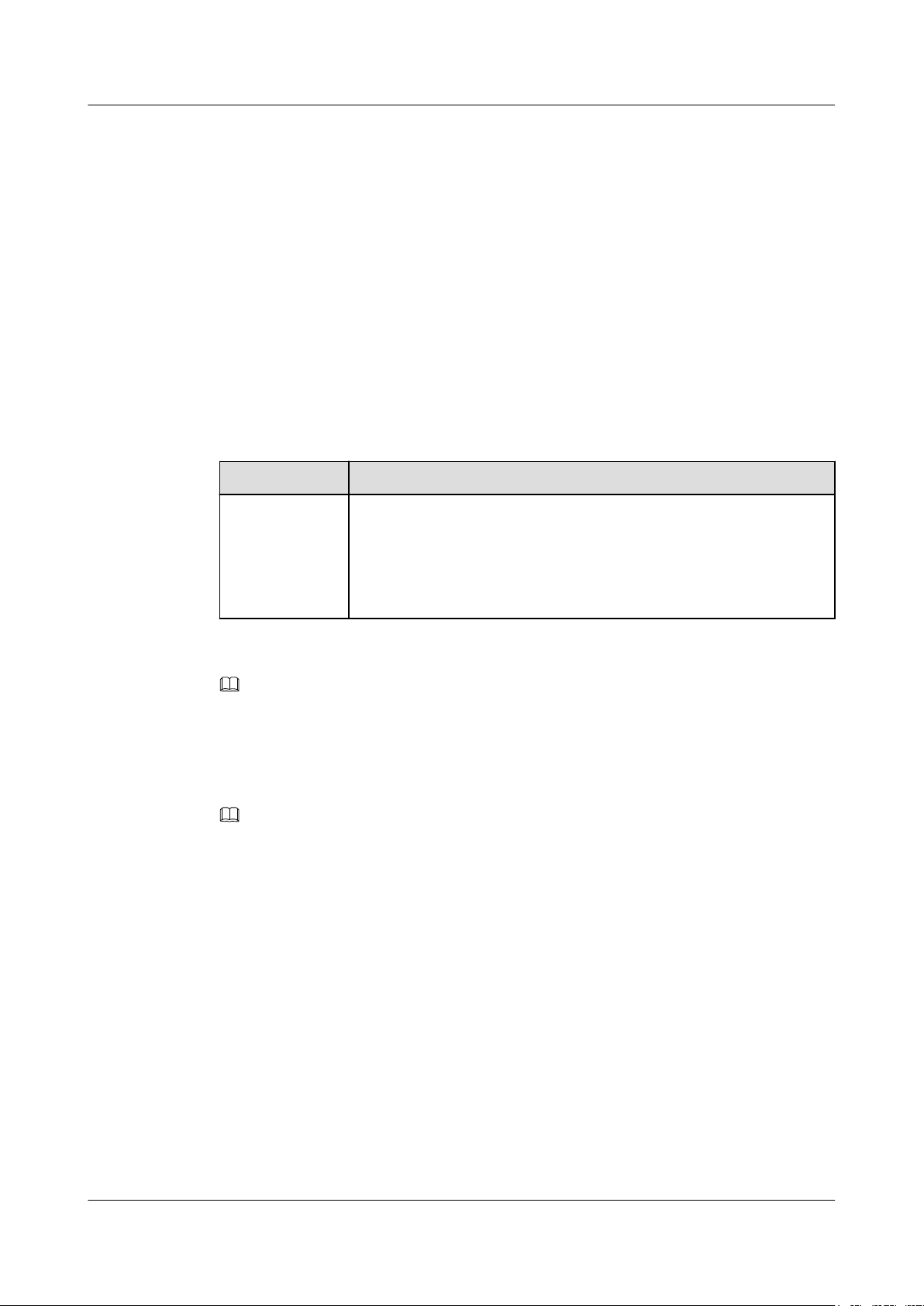

1. Determine the installation area on the wall or ceiling and use a marker to mark the

drilling positions (the distance between the two drilling positions should be 60 mm).

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

Page 16

60mm

a

b

Ø6

25mm~30mm

R230D

Hardware Installation and Maintenance Guide

2. Drill holes in the marked positions and install the plastic expansion tubes.

2 AP Installation

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

a. Use a 6 mm drill bit to drill holes in the marked positions.

b. Hammer the plastic expansion tubes into the holes.

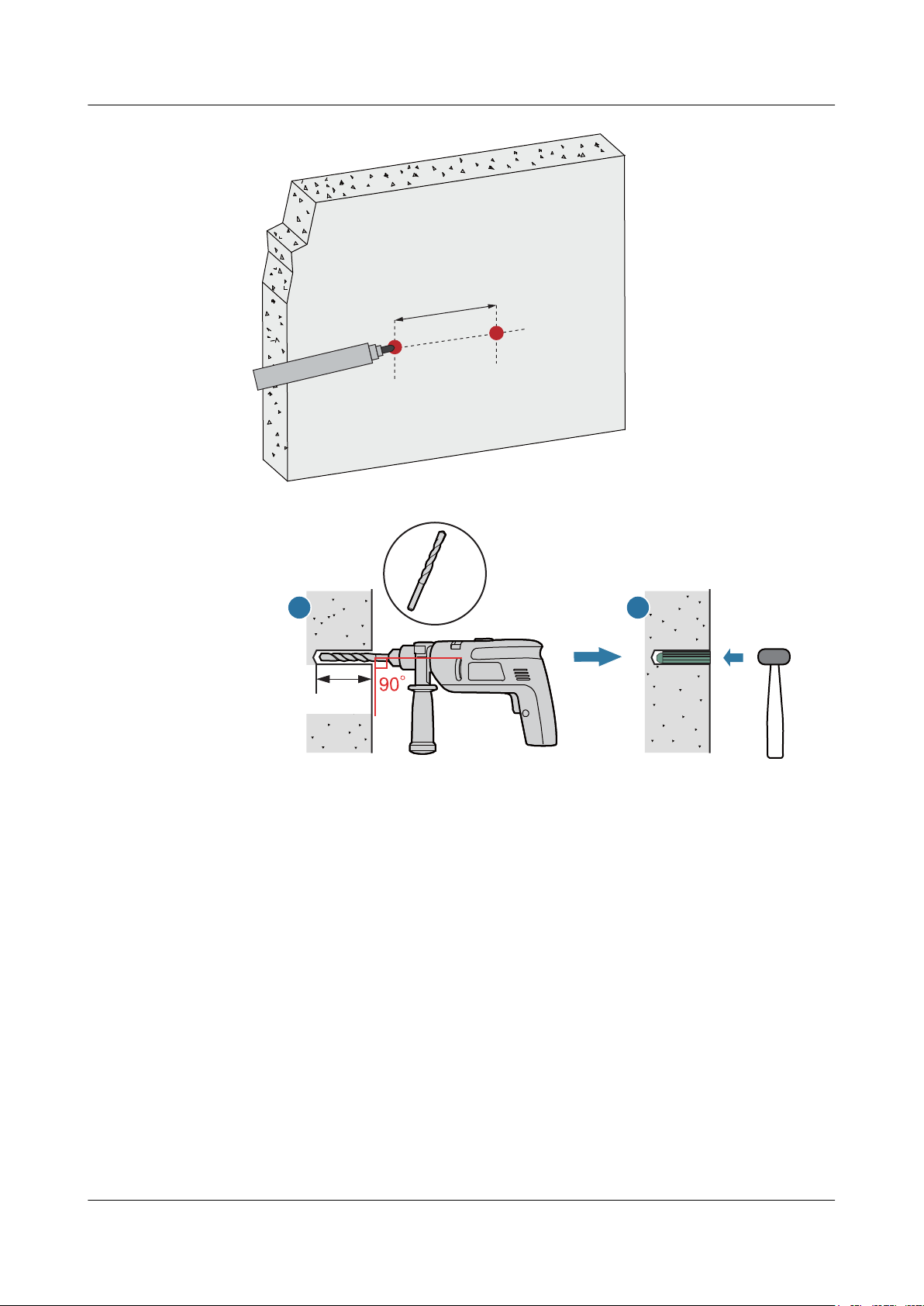

3. Insert the network cable into the ETH/PoE interface at the rear of the device. (Category 5

enhanced cables or higher must be used. The length of the cables cannot exceed 100 m.)

Open the front cover of the device and align screws on both sides with the plastic

expansion tubes. Secure the device using the phillips or torx security self-tapping screws

(a torx security screw has a security pin in the center to prevent theft and can be

tightened by a T20 torx security screwdriver which needs to be prepared separately by

customers).

10

Copyright © Huawei Technologies Co., Ltd.

Page 17

0.3N•m

ST3.5

0.3N•m

ST3.5

R230D

Hardware Installation and Maintenance Guide

4. Close the cover.

2 AP Installation

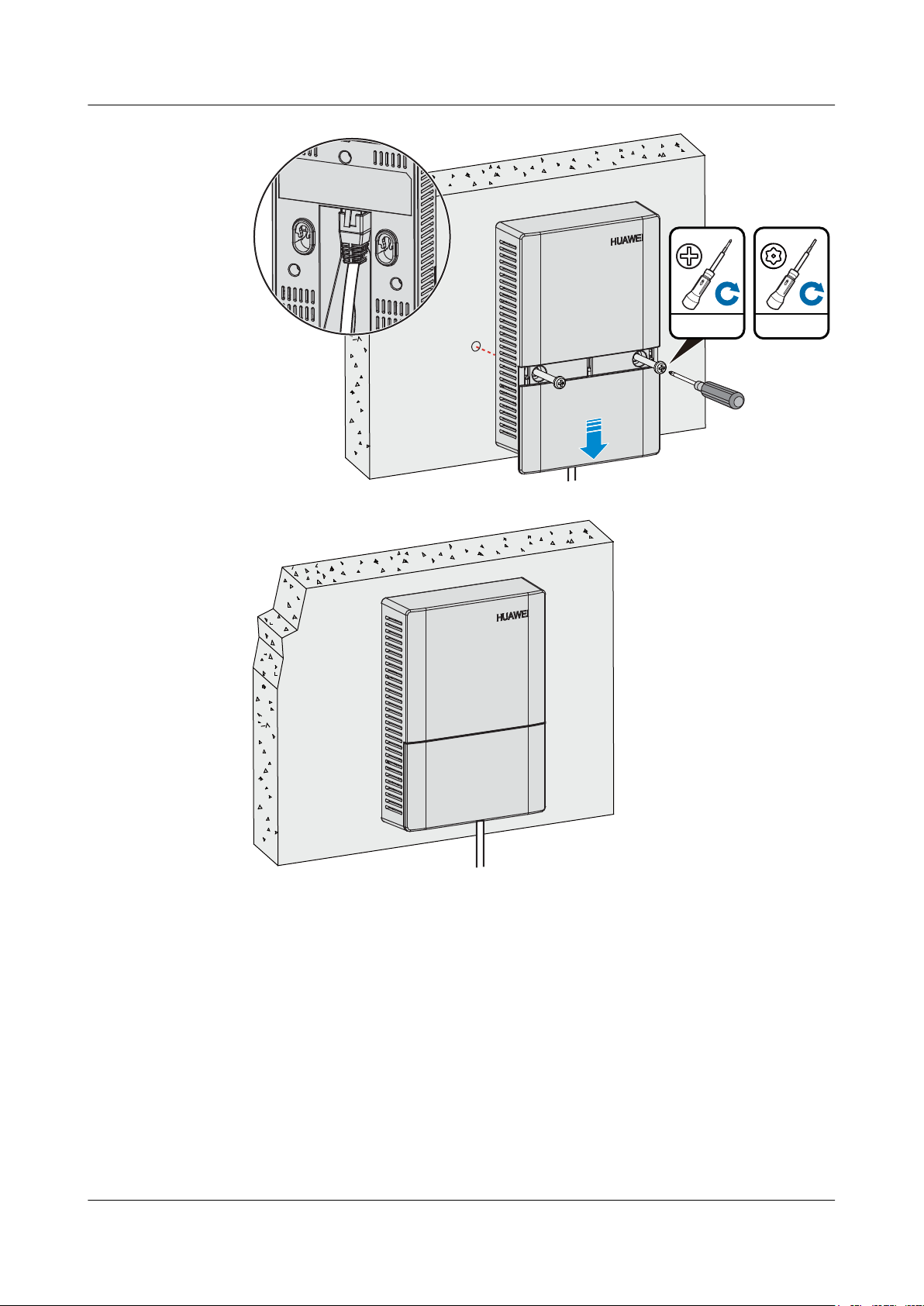

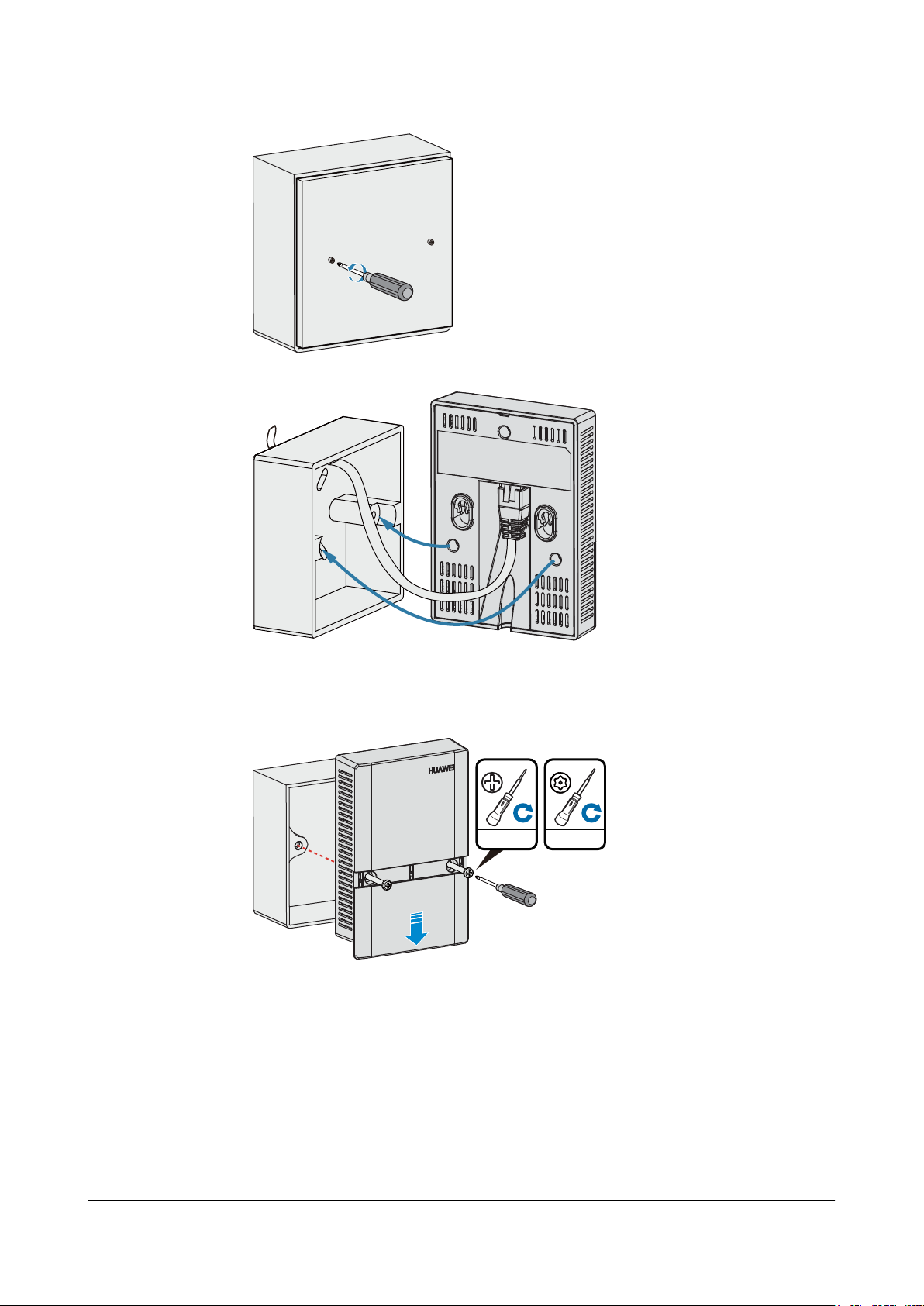

2.5.2 Installing the R230D in an 86-type Box

Installing the R230D in an 86-type box requires expansion screws delivered with the R230D.

The procedure is as follows:

1. Use a screwdriver to remove the 86-type panel from the wall (skip this step if no 86-type

panel is installed on the wall).

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

Page 18

1N•m

M4

1N•m

M4

R230D

Hardware Installation and Maintenance Guide

2. Connect the network cable to the ETH/PoE interface.

2 AP Installation

3. Open the front cover of the device and align screws on both sides with the screw holes in

the 86-type box. Secure the device using phillips or torx security machine screws (a torx

security screw has a security pin in the center to prevent theft and can be tightened by a

T20 torx security screwdriver which needs to be prepared separately by customers).

4. Close the cover.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

Page 19

R230D

Hardware Installation and Maintenance Guide

2.6 Checking the Device After Installation

Table 2-3 shows the items to be checked after installation is complete.

2 AP Installation

Table 2-3 Installation checklist

No.

1 The device is installed by strictly following the design draft. The

2 The device is securely installed.

3 The power cables are intact and not spliced.

4 Terminals of the power cables are welded or cramped firmly.

5 All power cables are not short-circuited or reversely connected and must

6 The power cables and ground cables are separated from other cables and

7 Connectors of signal cables are complete, intact, and tightly connected.

8 Labels on cables are clear and correct.

Check Item

installation position meets space requirements, with maintenance space

reserved.

be intact with no damage.

bundled separately.

The signal cables are not damaged or broken.

2.7 Powering on the Device

After the installation is complete, observe indicators on the device to determine the system

running status. For details, see 1.2 Indicator Description.

NOTE

Do not frequently power on and off an device.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

Page 20

R230D

Hardware Installation and Maintenance Guide

3 Logging In to the Device

3 Logging In to the Device

3.1 Logging In to the Device Using STelnet/Telnet

You can log in to the device using STelnet V2 or Telnet to configure, manage, and maintain

the device in the CLI.

NOTE

l By default, only the STelnet V2 service is enabled on the device.

l Telnet has security vulnerabilities. You are not advised to enable the Telnet service.

Before logging in to the device, complete the following tasks:

l Power on the device.

l Prepare network cables used to connect device interfaces.

The following table lists the default configuration of the device. You are advised to change the

default user name and password on your first login.

Table 3-1 Default configuration of the device

Parameter

User name admin

Password admin@huawei.com

IP address 169.254.1.1

Subnet mask 255.255.0.0

Default Setting

NOTE

If the device is already online on the AC, you can remotely log in to the AC on a local terminal and run the

display ap all command to check the IP address of the device.

The following example uses the default parameters and is used for reference only.

Step 1 Use network cables and a LAN switch to connect the PC to the network interface of the

device.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

Page 21

R230D

Hardware Installation and Maintenance Guide

Step 2 Assign the PC with an IP address on the same network segment as the default IP address of

the device so that the PC and device are reachable to each other.

If the device uses the default settings, the IP address of the PC must be in the network

segment 169.254.0.0/16 but cannot be 169.254.1.1. 169.254.1.100 is recommended.

Step 3 Start the CLI on the PC and access the IP address 169.254.1.1 of the device using STelnet V2.

Step 4 Enter the user name and password as prompted to log in to the user interface.

----End

3 Logging In to the Device

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

Page 22

R230D

Hardware Installation and Maintenance Guide

4 Hardware Failures

4.1 An device Fails to Be Powered On

Fault Description

4 Hardware Failures

The SYS indicator of a device is off.

Possible Causes

l The power sourcing equipment does not support the PoE function or is faulty.

l The power sourcing equipment is incorrectly configured (the PoE function is disabled or

the power-off time range is improperly set).

l The line is faulty (the network cable or distribution frame is damaged).

l The device is faulty.

Troubleshooting Procedure

1. Check whether the power sourcing equipment supports PoE or is faulty.

2. Check whether the configuration on the power sourcing equipment causes PoE power

supply errors, such as the PoE function is disabled or the power-off time range is

incorrectly set.

3. Check whether the network cable or distribution frame is faulty.

4. If the device still cannot be powered on, the device itself is faulty. Contact Huawei

technical support engineers or Huawei agent and ask them to replace the device.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

Page 23

R230D

Hardware Installation and Maintenance Guide

5 Appendix

5.1 On-site Cable Assembly and Installation

5 Appendix

5.1.1 Cable Assembly Precautions

Checking the Appearance of Cables

l If the cable jacket or insulation is visibly dirty, clean it before assembly.

l If the jacket or insulation of a cable has visible damage, irreparable scuffing, or other

defects, do not use the cable.

l If the shield layer of a cable is damaged, do not use the cable.

l If the cable jacket or insulation cracks after the cable is bent or twisted, discard this cable

and check whether other cables have the same problem. If other cables have the same

problem, replace these cables.

Checking the Appearance of Connectors

l Do not use connectors with visible defects, damage, rust or scuffing.

l Do not use connectors if their shells or pins have exposed part or uneven plating, or their

pins are lost, broken, or bent.

l Do not use connectors that have dirt on their pins or in their jacks or if there are

conductors between pins or between pins and the shell.

Precautions for Assembly

l Use dedicated tools or tools delivered by Huawei and follow the methods given here

during assembly.

l Hold terminals of cables instead of pulling the cables themselves when installing or

removing cable components.

l Take the following precautions when cutting or stripping cables:

– Make cables slightly longer than necessary.

– Coil cables longer than 2 m (6.56 ft) after cutting. Bind and fasten the coils using

bundling ropes. The inner diameters of the coils should be larger than 20 times the

outer diameters of the cables.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

Page 24

R230D

Hardware Installation and Maintenance Guide

– When stripping the jackets of cables, avoid damaging the shield layers (braid or

aluminum foil), insulation, core conductors, and other jackets that do not need to be

stripped.

– After assembling cables, cut all visible cross sections of jackets to ensure that the

cross sections are arranged neatly.

– Do not touch the core conductors of cables with your hands. Terminate exposed

conductors in a timely way after stripping off insulation so that the surface of the

conductors does not become oxidized.

l Take the following precautions when crimping and connecting cables or connectors:

– The terminals and conductors should be connected tightly after they are crimped.

They should not be moved or turned.

– Cut all the exposed copper wires.

– Try to avoid a second crimping of sleeves.

– Keep all the conductors clean and aligned.

NOTE

The connectors, cables, and tools provided by different vendors may be different. The figures in this

document are for your reference only.

5 Appendix

5.1.2 Assembling Power Cables

Assembling the OT Terminal and Power Cable

Context

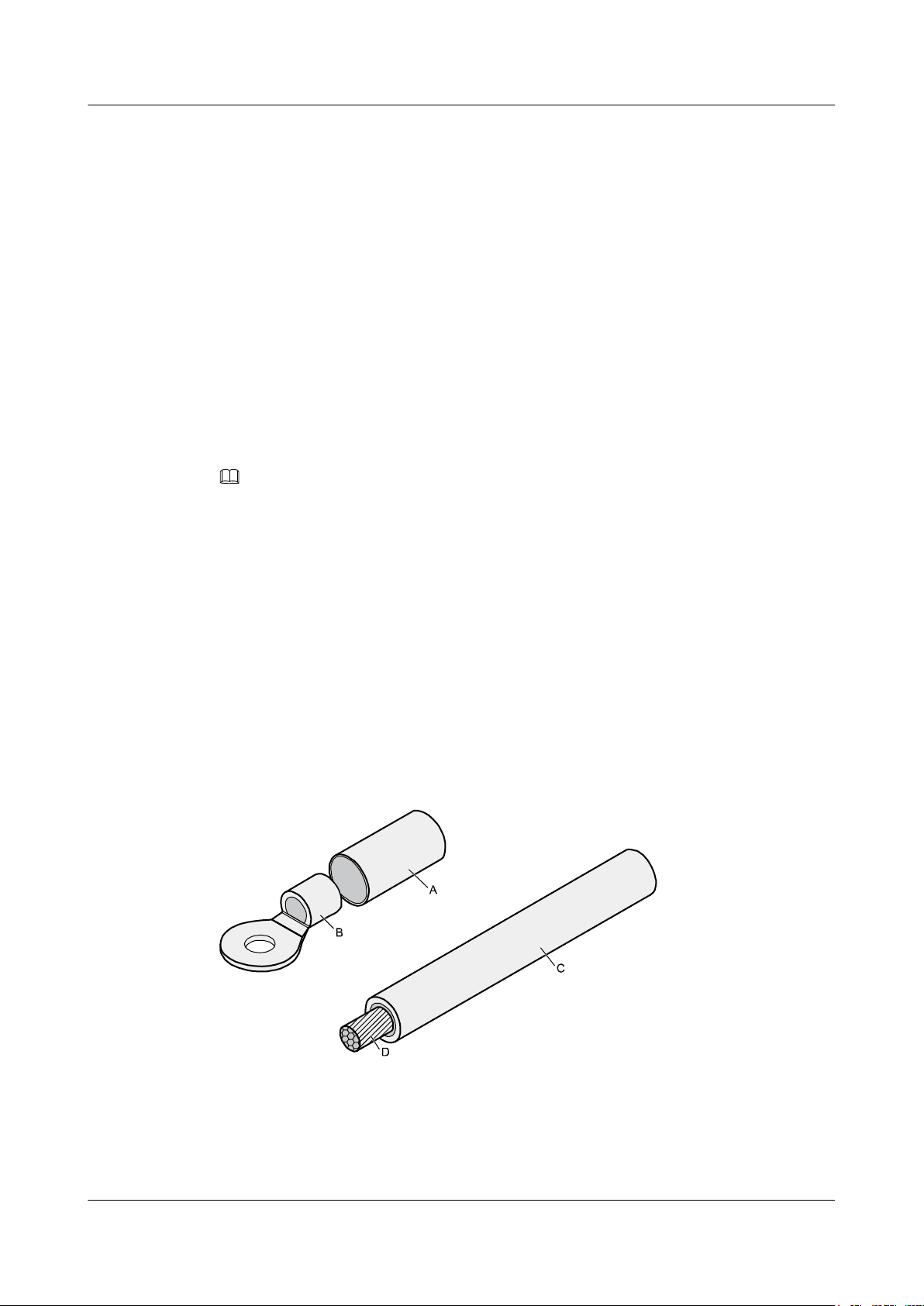

Figure 5-1 shows the components of an OT terminal and a power cable.

Figure 5-1 Components of an OT terminal and a power cable

A. Heat-shrinkable tubing B. Bare crimping terminal C. Insulation D. Conductor

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

Page 25

R230D

Hardware Installation and Maintenance Guide

Procedure

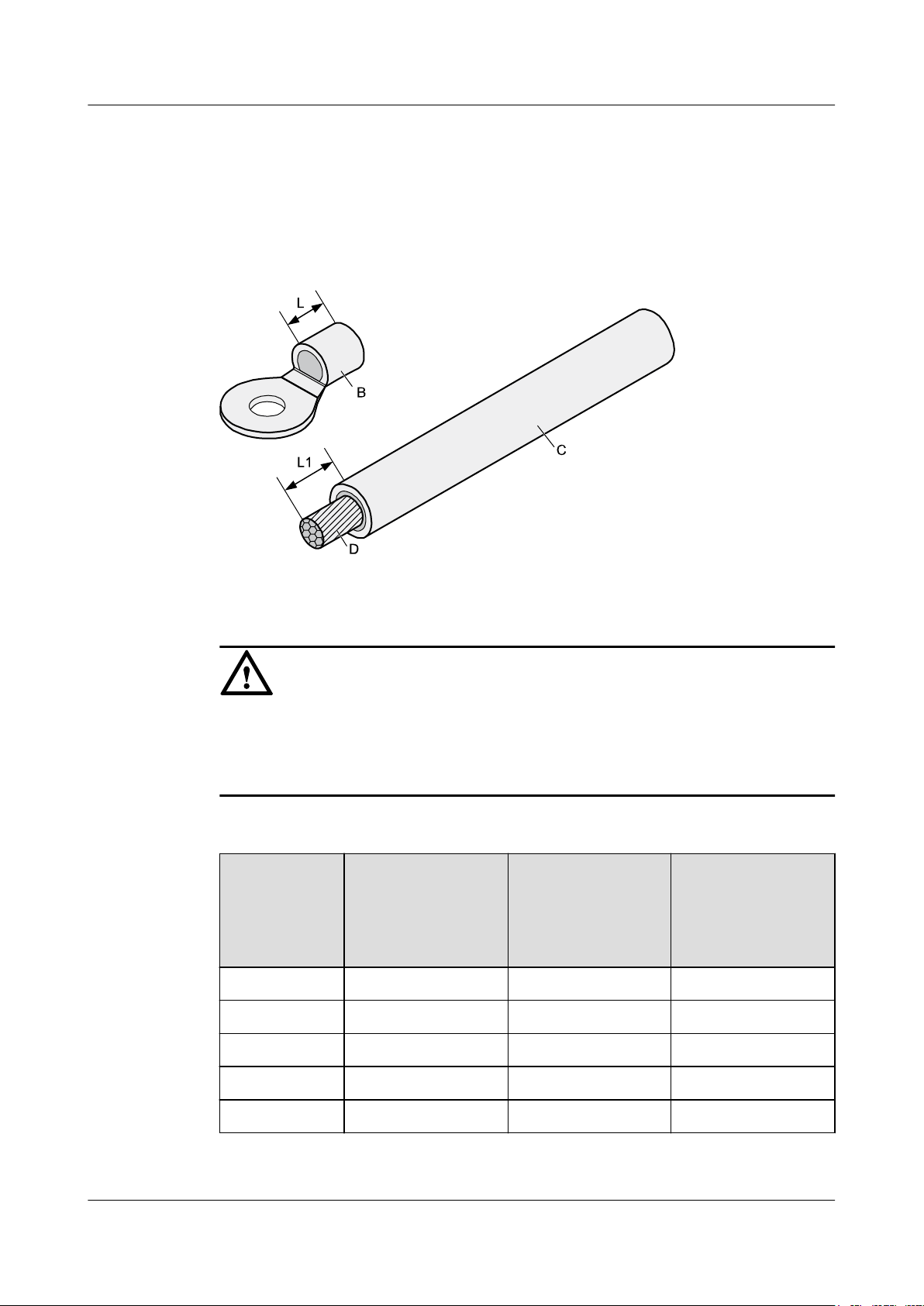

Step 1 Based on the cross-sectional area of the cable conductor, strip a length of insulation coating C

to expose the conductor D of length L1, as shown in Figure 5-2. The recommended values of

L1 are listed in Table 5-1.

Figure 5-2 Stripping a power cable (OT terminal)

5 Appendix

NOTICE

l When you strip a power cable, do not damage the conductor of the cable.

l If the bare crimping terminal is not provided by Huawei, the value of L1 is 1 mm (0.04 in.)

to 2 mm (0.08 in.) greater than the value of L.

Table 5-1 Mapping between the cross-sectional area of the conductor and the value of L1

CrossSectional

Area of

Conductor

(mm2(in.2))

1 (0.002) 7 (0.28) 10 (0.015) 11 (0.43)

1.5 (0.002) 7 (0.28) 16 (0.025) 13 (0.51)

Value of L1

(mm(in.))

Cross-Sectional

Area of Conductor

(mm2(in.2))

Value of L1

(mm(in.))

2.5 (0.004) 7 (0.28) 25 (0.039) 14 (0.55)

4 (0.006) 8 (0.31) 35 (0.054) 16 (0.63)

6 (0.009) 9 (0.35) 50 (0.077) 16 (0.63)

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Page 26

R230D

Hardware Installation and Maintenance Guide

NOTE

If you are proficient in assembling OT terminals and power cables, you can obtain the value of L1 by

comparing the part to be crimped with the power cable.

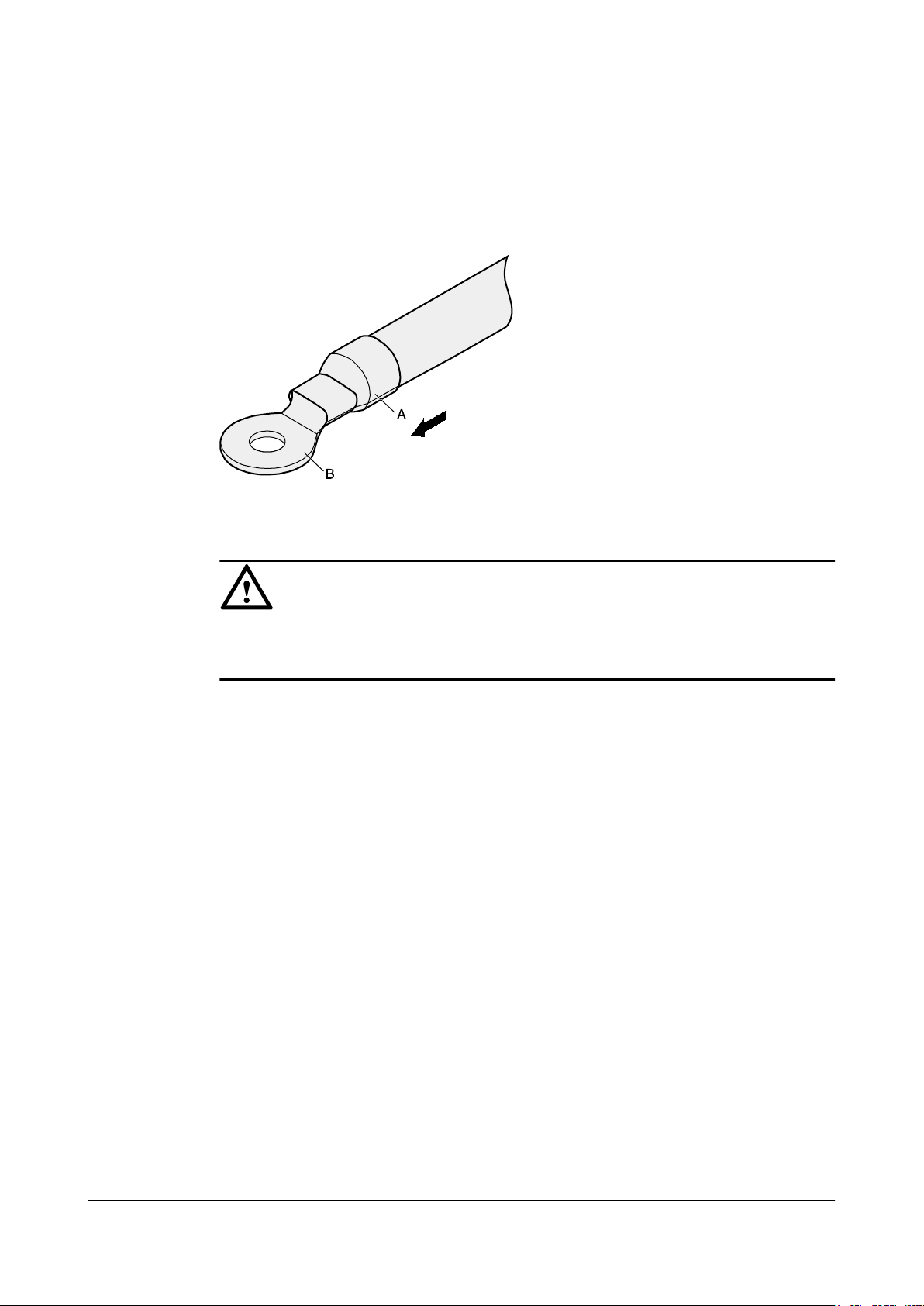

Step 2 Put the heat-shrinkable (A) tubing onto the bare crimping terminal, as shown in Figure 5-3.

Figure 5-3 Putting the heat shrink tubing onto the bare crimping terminal

5 Appendix

Step 3 Put the OT terminal B onto the exposed conductor, and ensure that the OT terminal is in good

contact with the insulation coating C, as shown in Figure 5-3.

NOTICE

After the conductor is fed into the OT terminal, the protruding part of the conductor, or L2 in

Figure 5-3, must not be longer than 2 mm (0.08 in.).

Step 4 Crimp the joint parts of the bare crimping terminal and the conductor, as shown in Figure 5-4.

NOTE

The shapes of crimped parts may vary with the crimping dies.

Figure 5-4 Crimping the joint parts of the bare crimping terminal and the conductor (OT

terminal)

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Page 27

R230D

Hardware Installation and Maintenance Guide

Step 5 Push the heat shrink tubing (A) toward the connector until the tube covers the crimped part,

and then use a heat gun to heat the tube, as shown in Figure 5-5.

Figure 5-5 Heating the heat shrink tubing (OT terminal)

5 Appendix

NOTICE

Stop heating the shrink tubing when the connector is securely locked in the shrink tubing. Do

not heat the shrink tubing too long as this may damage the insulation coating.

----End

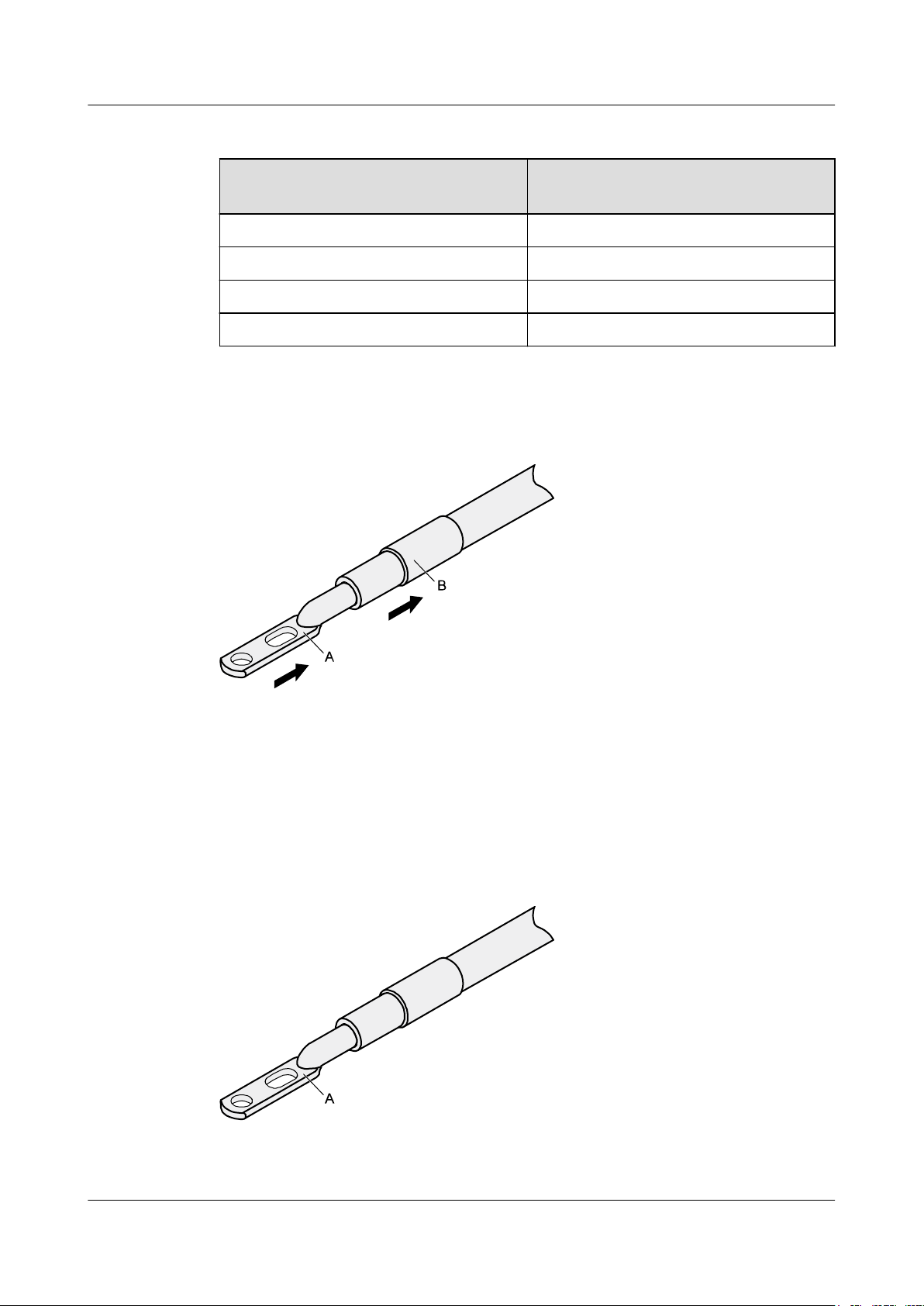

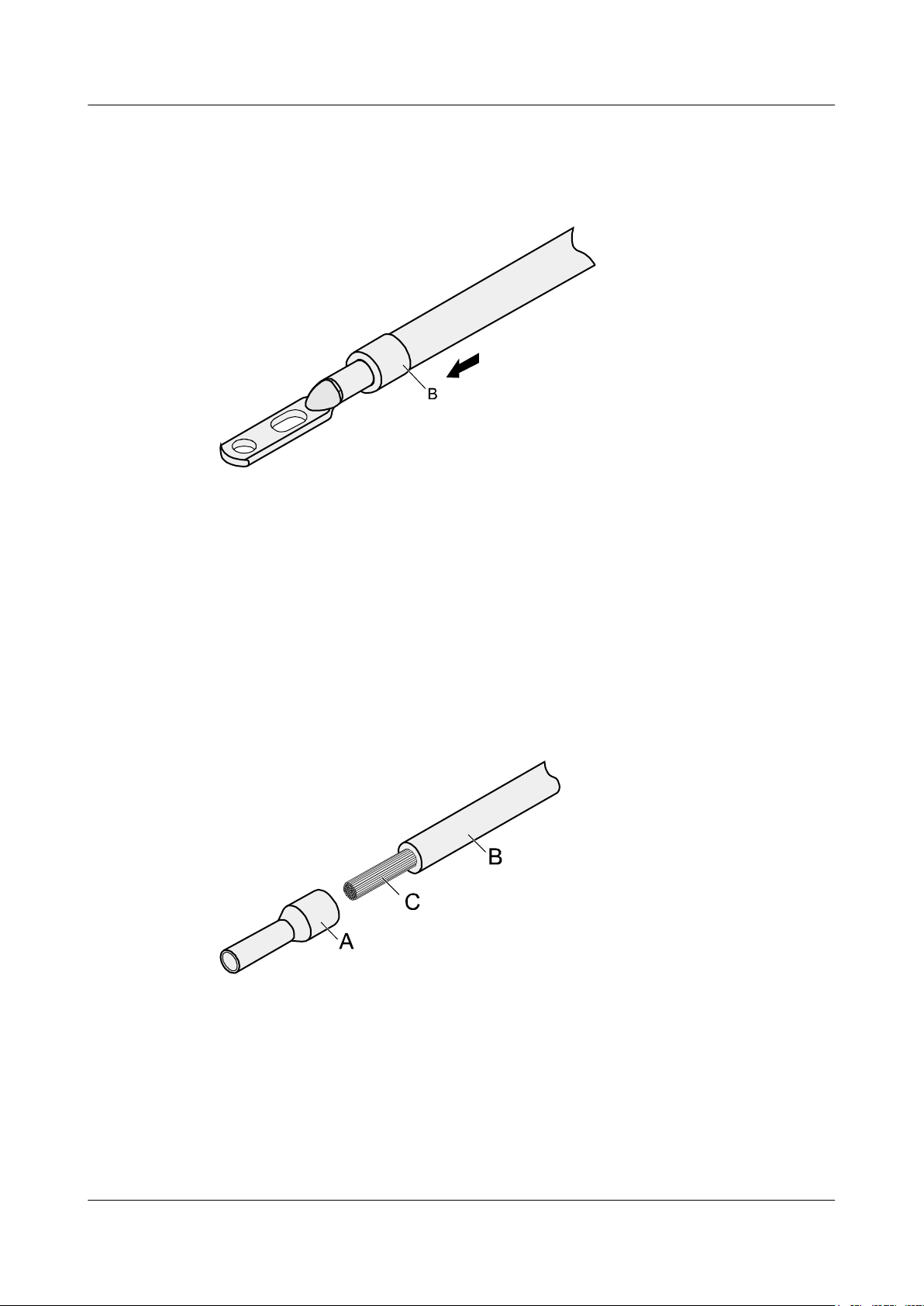

Assembling the JG Terminal and Power Cable

Context

Figure 5-6 shows the components of a JG terminal and a power cable.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

Page 28

R230D

Hardware Installation and Maintenance Guide

Figure 5-6 Components of a JG terminal and a power cable

5 Appendix

Procedure

Step 1 Strip a part of the insulation to expose the cable conductor with a length of L, as shown in

A. JG terminal B. Heat-shrinkable tubing C. Insulation layer of a power

cable

D. Conductor of a power cable

Figure 5-7. The recommended values of L are listed in Table 5-2.

NOTICE

l When you strip a power cable, do not damage the conductor of the cable.

l If the bare crimping terminal is not provided by Huawei, you can adjust the value of L as

required.

Figure 5-7 Stripping a power cable (JG terminal)

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Page 29

R230D

Hardware Installation and Maintenance Guide

Table 5-2 Mapping between the cross-sectional area of the conductor and the value of L

5 Appendix

Cross-Sectional Area of Conductor

Value of L (mm(in.))

(mm2(in.2))

16 (0.025) 13 (0.51)

25 (0.039) 14 (0.55)

35 (0.054) 16 (0.63)

50 (0.077) 16 (0.63)

Step 2 Put the heat shrink tubing onto the bare crimping terminal, as shown in Figure 5-8.

Figure 5-8 Putting the heat shrink tubing onto the bare crimping terminal

Step 3 Put the bare crimping terminal onto the exposed conductor, and ensure that the bare crimping

terminal is in good contact with the insulation of the power cable, as shown in Figure 5-8.

Step 4 Crimp the joint parts of the bare crimping terminal and the conductor, as shown in Figure 5-9.

Figure 5-9 Crimping the joint parts of the bare crimping terminal and the conductor (JG

terminal)

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

Page 30

R230D

Hardware Installation and Maintenance Guide

Step 5 Push the heat shrink tubing toward the connector until the tube covers the crimped part, and

then use a heat gun to heat the tube, as shown in Figure 5-10.

Figure 5-10 Heating the heat shrink tubing (JG terminal)

5 Appendix

----End

Assembling the Cord End Terminal and the Power Cable

Context

Figure 5-11 shows the components of a cord end terminal and a power cable.

Figure 5-11 Components of a cord end terminal and a power cable

A. Cord end terminal B. Insulation layer of a power cable C. Conductor of a power cable

Procedure

Step 1 Strip a part of the insulation to expose the cable conductor with a length of L1, as shown in

Figure 5-12. The recommended values of L1 are listed in Table 5-3.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

Page 31

R230D

Hardware Installation and Maintenance Guide

NOTICE

When you strip a power cable, do not damage the conductor of the cable.

Figure 5-12 Stripping a power cable (cord end terminal)

5 Appendix

Table 5-3 Mapping between the cross-sectional area of the conductor and the value of L1

CrossSectional

Area of

Conductor

(mm2(in.2))

1 (0.002) 8 (0.31) 10 (0.015) 15 (0.59)

1.5 (0.002) 10 (0.39) 16 (0.025) 15 (0.59)

2.5 (0.004) 10 (0.39) 25 (0.039) 18 (0.71)

4 (0.006) 12 (0.47) 35 (0.054) 19 (0.75)

6 (0.009) 14 (0.55) 50 (0.077) 26 (1.02)

Step 2 Put the cord end terminal onto the conductor, and ensure that the conductor is aligned with the

edge of the cord end terminal, as shown in Figure 5-13.

Value of L1

(mm(in.))

Cross-Sectional

Area of Conductor

(mm2(in.2))

Value of L1

(mm(in.))

NOTICE

After the conductor is fed into the cord end terminal, the protruding part of the conductor

must not be longer than 1 mm (0.04 in.).

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

Page 32

R230D

Hardware Installation and Maintenance Guide

Figure 5-13 Putting the cord end terminal onto the conductor

Step 3 Crimp the joint parts of the cord end terminal and the conductor, as shown in Figure 5-14.

Figure 5-14 Crimping the cord end terminal and the conductor

5 Appendix

Step 4 Check the maximum width of the tubular crimped terminal. The maximum width of a tubular

crimped terminal is listed in Table 5-4.

Table 5-4 Maximum width of a tubular crimped terminal

Cross-Sectional Area of Tubular

Terminal (mm2(in.2))

Maximum Width of Crimped Terminal

W1 (mm(in.))

0.25 (0.0004) 1 (0.04)

0.5 (0.0008) 1 (0.04)

1.0 (0.0015) 1.5 (0.06)

1.5 (0.0023) 1.5 (0.06)

2.5 (0.0039) 2.4 (0.09)

4 (0.006) 3.1 (0.12)

6 (0.009) 4 (0.16)

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

Page 33

R230D

Hardware Installation and Maintenance Guide

5 Appendix

Cross-Sectional Area of Tubular

Terminal (mm2(in.2))

10 (0.015) 5.3 (0.21)

16 (0.025) 6 (0.24)

25 (0.039) 8.7 (0.34)

35 (0.054) 10 (0.39)

----End

Maximum Width of Crimped Terminal

W1 (mm(in.))

5.1.3 Assembling Ethernet Cables

Assembling the Shielded RJ45 Connector and Ethernet Cable

Context

Figure 5-15 shows the components of an RJ45 connector and a shielded Ethernet cable.

Figure 5-15 Shielded RJ45 connector and cable

A. Jacket of connector B. Metal shell of connector C. Wire holder of

connector

E. Jacket of Ethernet cable F. Shield layer of Ethernet

cable

G. Twisted-pair wires -

D. Plug of connector

Procedure

Step 1 Fit the jacket of the connector onto the Ethernet cable, as shown in Figure 5-16.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

Page 34

R230D

Hardware Installation and Maintenance Guide

Figure 5-16 Fitting the jacket of the connector onto the Ethernet cable

Step 2 Remove a 30 mm (1.18 in.) long section of the jacket, cut off the nylon twine inside the

jacket, and cut a no more than 5 mm (0.20 in.) cleft in the jacket, as shown in Figure 5-17.

5 Appendix

NOTICE

l When you remove a section of the jacket, do not damage the shield layer of the twisted-

pair cable.

l When you remove the shield layer, do not damage the insulation of the twisted-pair cable.

Figure 5-17 Removing the jacket of a twisted-pair cable (unit: mm (in.))

Step 3 Fit the metal shell onto the twisted-pair cable. The shield layer is covered by the metal shell,

as shown in Figure 5-18.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

Page 35

C

G

R230D

Hardware Installation and Maintenance Guide

Figure 5-18 Fitting the metal shell onto the twisted-pair cable

Step 4 Fit the metal shell onto the twisted-pair cable until the shield layer is covered completely.

Along the edge of the metal shell, cut off the aluminum foil shield layer and ensure that there

is no surplus copper wire. The exposed twisted-pair cable is about 20 mm (0.79 in.) long, as

shown in Figure 5-19.

5 Appendix

Figure 5-19 Removing the shield layer of a twisted-pair cable (unit: mm (in.))

Step 5 Lead the four pairs of twisted-pair wires through the wire holder, as shown in Figure 5-20 and

Figure 5-21. Ensure that the colored wires are in the correct location in the cable.

Figure 5-20 Leading wires through the wire holder

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

Page 36

White-Green

Green

White-Orange

Orange

Blue

White-Blue

White-Brown

Brown

Brown

Wh ite-Brown

Green

White-Blue

Blue

White-Green

Orange

White-Orange

Pin 8

Pin 1

R230D

Hardware Installation and Maintenance Guide

Figure 5-21 Cable locations in a wire holder

Step 6 Align the four pairs of cables in the holder, as shown in Figure 5-22. The connections

between the wires and the pins are shown in Figure 5-23 and listed in Table 5-5.

5 Appendix

Figure 5-22 Four pairs of cables on a wire holder

Figure 5-23 Connections between wires and pins

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

Page 37

R230D

Hardware Installation and Maintenance Guide

Table 5-5 Connections between wires and pins (using a straight-through cable as an example)

Matching Pins of Wires Wire Color

1 White-Orange

2 Orange

3 White-Green

4 Blue

5 White-Blue

6 Green

7 White-Brown

8 Brown

5 Appendix

Step 7 Cut off the surplus cables along the lower edge of the wire holder, as shown in Figure 5-24.

Figure 5-24 Cutting off surplus cables

Step 8 Put the connector body onto the wire holder and turn the metal shell by 90°, as shown in

Figure 5-25.

NOTE

Ensure that the wire holder is in good contact with the connector body.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

Page 38

R230D

Hardware Installation and Maintenance Guide

Figure 5-25 Putting the connector body onto the wire holder

Step 9 Push the metal shell toward the connector body until the wire holder and the connector body

are engaged completely. Crimp the connector, as shown in Figure 5-26.

5 Appendix

Figure 5-26 Crimping the connector

Step 10 Push the jacket towards the metal shell until the metal shell is covered. This completes the

assembly of one end of the cable, as shown in Figure 5-27.

Figure 5-27 Pushing the metal shell

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

Page 39

A

B

C

R230D

Hardware Installation and Maintenance Guide

Step 11 To complete the assembly of the other end, repeat Step 1 through Step 10.

----End

Assembling an Unshielded RJ45 Connector and Ethernet Cable

Context

Figure 5-28 shows the components of an unshielded RJ45 connector and cable.

Figure 5-28 Components of an unshielded RJ45 connector and cable

5 Appendix

Procedure

Step 1 Remove a 16-mm (0.63 in.) long section of the jacket, as shown in Figure 5-29.

A. Plug of connector B. Jacket C. Twisted-pair wires

NOTICE

When you remove the shield layer, do not damage the insulation of the twisted-pair cable.

Figure 5-29 Removing the jacket of a twisted-pair cable (unit: mm (in.))

Step 2 Align the four pairs of wires and cut the ends neatly, as shown in Figure 5-30. The

connections between the wires and the pins are listed in Table 5-6.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

Page 40

C

16

White-Orange

White-Green

Orange

Blue

White-Blue

Green

White-Brown

Brown

Pin 8

Pin 1

R230D

Hardware Installation and Maintenance Guide

Figure 5-30 Connections between wires and pins (unit: mm (in.))

Table 5-6 Connections between wires and pins (using a straight-through cable as an example)

5 Appendix

Matching Pins of Wires

Wire Color

1 White-Orange

2 Orange

3 White-Green

4 Blue

5 White-Blue

6 Green

7 White-Brown

8 Brown

Step 3 Feed the cable into the plug, and crimp the connector, as shown in Figure 5-31.

NOTE

When inserting the cable, check from the side or bore of the plug to ensure that the cable is completely

seated in the plug.

Figure 5-31 Crimping the connector

Step 4 To complete the assembly of the other end, repeat Step 1 through Step 3.

----End

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

Page 41

R230D

Hardware Installation and Maintenance Guide

Checking the Appearance of Contact Strips

Context

l To ensure proper contact between the crimped wires and the wire conductors, the heights

and sizes of the contact strips must be standard and the same.

l The contact strips must be parallel to each other, with an offset of less than ± 5°. The top

margin of a strip must be parallel to the axis of the connector, with an offset of less than

± 10°.

l To ensure conductivity, the surface of the contact strips must be clean.

l The contact strips must be in good contact with the RJ45 socket. The plastic separators

must remain intact and be aligned.

l The contact strip blade must extend beyond the ends of the wires. The ends of the wires

must be in contact with the edge of the RJ45. The distance between them must be less

than 0.5 mm (0.02 in.).

Procedure

5 Appendix

Step 1 Hold the crimped connector, with the front side facing you, and check whether the contact

strips are of the same height. The height should be 6.02 ± 0.13 mm (0.237 ± 0.005). If a

measuring tool is not available, you can compare the connector with a standard connector.

Figure 5-32 shows an unqualified piece, and Figure 5-33 shows a qualified piece.

NOTE

All unqualified pieces must be crimped again.

Figure 5-32 Contact strips of different heights

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

Page 42

R230D

Hardware Installation and Maintenance Guide

Figure 5-33 Contact strips of the same height

Step 2 Hold an RJ45 connector and turn it 45°. Observe the top edges of the metal contact strips.

Figure 5-34 shows an unqualified piece.

Figure 5-34 Unparallel contact strips of different heights

5 Appendix

Step 3 Check whether the contact strips are clean. If they are not clean and the dirt cannot be

removed, replace it with a new RJ45 connector. Figure 5-35 shows an unqualified piece.

Figure 5-35 Dirt on a contract strip

Step 4 Check whether the contact strips and the plastic separators are well aligned and intact. If a

separator is skewed and cannot be fixed, replace it with a new RJ45 connector. Figure 5-36

shows an unqualified piece.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

Page 43

R230D

Hardware Installation and Maintenance Guide

Figure 5-36 Skewed plastic separators

Step 5 Hold the connector with the side facing towards you, and check whether you can see the

cross-sections of the wires. Ensure that the ends of the wires are in good contact with the edge

of the RJ45, and that the contact strip blade extends beyond the ends of the wires and is

crimped with the wires. If not, replace the connector. Figure 5-37 shows an unqualified piece.

5 Appendix

Figure 5-37 Wires not in good contact with the edge of the RJ45

----End

Testing the Connection of Assembled Cables

Context

Huawei provides two types of Ethernet cables: straight-through cables and crossover cables.

l Straight-through cables are connected in a one-to-one manner. They are used to connect

terminals such as a computer or switch to network devices. Table 5-7 lists the

connections of core wires in a straight-through cable.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

Page 44

Pin8

Pin1

R230D

Hardware Installation and Maintenance Guide

Table 5-7 Connections of core wires in a straight-through cable

RJ45 Connector 1 RJ45 Connector 2 Core Wire Color Twisted or Not

2 2 Orange Twisted

1 1 Orange-White

6 6 Green Twisted

3 3 Green-White

4 4 Blue Twisted

5 5 Blue-White

8 8 Brown Twisted

7 7 Brown-White

l Crossover cables are connected in a crossover manner. They are used to connect

terminals such as two computers or switches. Table 5-8 lists the connections of core

wires in a crossover cable.

5 Appendix

Table 5-8 Connections of core wires in a straight crossover cable

RJ45 Connector 1

RJ45 Connector 2 Core Wire Color Twisted or Not

6 2 Orange Twisted

3 1 Orange-White

2 6 Green Twisted

1 3 Green-White

4 4 Blue Twisted

5 5 Blue-White

8 8 Brown Twisted

7 7 Brown-White

Figure 5-38 shows the pins of an RJ45 connector.

Figure 5-38 Pins of an RJ45 connector

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

Page 45

R230D

Hardware Installation and Maintenance Guide

Procedure

Step 1 Feed both connectors of the cable into the ports of the cable tester.

Step 2 After the connectors are properly inserted, turn on the tester. If the indicators from 1 to G turn

on simultaneously, you can infer that the pins work normally and the wires are correctly

connected.

NOTE

Turn the switch to the S position to slow down lighting of the indicators so that you can see the

indicators more clearly, as shown in Figure 5-39.

Figure 5-39 Testing the conduction and connections of wires

5 Appendix

Step 3 Gently shake the connector and repeat Step 2 to check whether the metal contact strips are in

good contact with the core wires and Ethernet ports, as shown in Figure 5-40.

Figure 5-40 Checking the reliability

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

Page 46

R230D

Hardware Installation and Maintenance Guide

The procedure for testing a crossover cable is the same as that for testing a straight-through

cable except for the sequence in which the indicators turn on, which depends on the wire

connections of a crossover cable.

The Ethernet cable is qualified if the indicators turn on in the following sequence:

At the master (left) section of the tester, the indicators turn on in the sequence of 1-8-G. At the

slave (right) section of the tester, the indicators turn on in the sequence of 3-6-1-4-5-2-7-8-G.

If the indicators do not come on in this sequence, the Ethernet cable is unqualified.

NOTE

If a tester is not available, you can use a multimeter to perform a simple test, as shown in Figure 5-41.

Figure 5-41 Testing the connection of an Ethernet cable

5 Appendix

----End

5.1.4 Installing Cable Accessories

Precautions for Installing Cable Accessories

Tools

NOTE

The illustrations in this document may differ from actual situations, but the installation methods are the

same. For example, in this document, the adapters of cable connectors have separate interfaces. In the

actual situation, the adapters may have interfaces fixed on equipment.

Use dedicated tools provided or specified by Huawei and follow the installation procedure

described here.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

Page 47

R230D

Hardware Installation and Maintenance Guide

Bending Radius

Unless otherwise specified, bending radius (R) of cables or fibers must meet the requirements

listed in Table 5-9.

Table 5-9 Bending radius of cables or fibers

5 Appendix

Cable or Fiber

Ordinary cable In normal cases, R ≥ 2d. When the cable is

Fiber R ≥ 40 mm (1.57 in.); Bending angle > 90°

NOTE

The letter d indicates the diameter of a cable or fiber.

Precautions for Installation

l Hold terminals of cables instead of pulling the cables themselves when installing or

removing cable components.

l Do not insert a connector forcibly when the connector is blocked. Use a dedicated tool to

pull out the connector. Install the connector again after you check that the pins are

inserted properly.

l Before tightening screws on cable connectors, ensure that the connectors are properly

connected to their adapters. Tighten the screw with appropriate force using a flat-head or

Phillips screwdriver instead of bare hands or an electric screwdriver. If the screw cannot

be screwed into the tapped hole, determine the reason and try again. Do not apply too

much force, or the screw or adapter may be damaged.

Bending Radius (R)

connected with a connector, R ≥ 5d.

l When removing densely aligned cables or fiber connectors, use dedicated pliers such as

cable-pulling pliers and fiber-pulling pliers.

l Do not twist, bend, stretch, or extrude fibers during installation.

l Cover the idle fiber connectors with dust caps. Remove the dust caps before using the

fiber connectors.

Requirements for Cable Routing

l To protect cables, remove the burrs in the cable through-holes or install protective rings

in the holes.

l To ease the connection and to avoid stress, keep cable joints slack. After connecting

multiple cables to a connector that has multiple interfaces, keep the cables slack to avoid

generating stress.

l Bind or clean cables gently because cable distortion affects signal quality.

l Keep cables away from moveable components such as doors.

l Sharp objects must not touch cable wiring to prevent damage to cables.

l To protect power cables, route power cables of the active and standby power modules

separately.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

Page 48

R230D

Hardware Installation and Maintenance Guide

Installing Power Adapters

Installing the OT Terminal

Procedure

l Install an OT terminal.

a. Align the hole of the OT terminal (conductor upward) with a connecting hole, as

shown in Figure 5-42.

Figure 5-42 Aligning the OT terminal with a connecting hole

5 Appendix

NOTE

When you install an OT terminal, the crimping sleeve is installed as shown in Figure 5-43,

where A is correct and B is incorrect.

Figure 5-43 Installing an OT terminal, showing the orientation of crimping sleeve

b. Place the spring washer and flat washer in turn, mount a matching screw, and fasten

it clockwise, as shown in Figure 5-44.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

42

Page 49

R230D

Hardware Installation and Maintenance Guide

Figure 5-44 Installing two terminals back to back

NOTICE

5 Appendix

Ensure that the OT terminal is not in contact with other terminals or metal

components.

c. Move the cable slightly and ensure that it is securely connected, as shown in Figure

5-45.

Figure 5-45 Installed OT terminal

l Install two OT terminals on a post.

Before you install two OT terminals on a post, ensure that the two terminals can be

installed on the post and that the electrical connecting pieces have a large contact area.

Two OT terminals can be installed using any of these methods:

– Bend the upper OT terminal at a 45- or 90-degree angle, as shown in Figure 5-46.

– Cross the two terminals, as shown in Figure 5-47.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

43

Page 50

R230D

Hardware Installation and Maintenance Guide

Figure 5-46 Bending the upper OT terminal at a 45- or 90-degree angle

Figure 5-47 Crossing two terminals

5 Appendix

NOTICE

If the two terminals are different sizes, place the smaller one above the bigger one. A

maximum of two terminals can be installed on a post.

l To remove an OT terminal, loosen the screw counterclockwise.

----End

Installing the Cord End Terminal

Procedure

Step 1 Hold a cord end terminal upright and place it on a terminal jack, as shown in Figure 5-48. To

ensure bump contact and dense connection, place the plain side of the terminal outwards.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

44

Page 51

R230D

Hardware Installation and Maintenance Guide

Figure 5-48 Placing a terminal on a terminal jack vertically

Step 2 Insert the terminal into the jack vertically, and turn the screw clockwise to fasten the terminal,

as shown in Figure 5-49.

5 Appendix

Figure 5-49 Feeding the terminal into the jack

NOTICE

l Ensure that the exposed section of the terminal is less than 2 mm (0.079 in.) in length.

l Do not press the insulation of the terminal.

l Insert only one terminal into one jack.

Step 3 Move the cable slightly and ensure that it is securely connected.

Step 4 Before you remove a cord end terminal, loosen the screw counterclockwise.

----End

Installing Ethernet Adapters

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

45

Page 52

R230D

Hardware Installation and Maintenance Guide

Installing a Shielded Ethernet Connector

Procedure

Step 1 Hold the male and female connectors, with the male connector facing the female connector, as

shown in Figure 5-50.

Figure 5-50 Holding the male and female shielded connectors

5 Appendix

Step 2 Insert the male connector into the female connector, as shown in Figure 5-51.

Figure 5-51 Feeding the male shielded connector into the female shielded connector

Step 3 When you hear a click, the cable connector is completely inserted in the port. (The clip on the

cable connector pops up to fix the connector in the port.) Pull the connector slightly and

ensure that it is securely connected, as shown in Figure 5-52.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

46

Page 53

R230D

Hardware Installation and Maintenance Guide

Figure 5-52 Installed shielded Ethernet connector

Step 4 To remove an Ethernet connector, press the locking key and pull out the connector, as shown

in Figure 5-53.

5 Appendix

Figure 5-53 Removing a shielded Ethernet connector

----End

Installing an Unshielded Ethernet Connector

Procedure

Step 1 Hold the male and female connectors, with the male connector facing the female connector, as

shown in Figure 5-54.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

47

Page 54

R230D

Hardware Installation and Maintenance Guide

Figure 5-54 Holding the male and female unshielded connectors

Step 2 Feed the male connector into the female connector, as shown in Figure 5-55.

Figure 5-55 Feeding the male connector into the female unshielded connector

5 Appendix

Step 3 A crisp click indicates that the connector is locked by the locking key. Pull the connector

slightly and ensure that it is securely connected. Figure 5-56 shows an installed Ethernet

connector.

Figure 5-56 Installed unshielded Ethernet connector

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

48

Page 55

R230D

Hardware Installation and Maintenance Guide

Step 4 To remove an Ethernet connector, press the locking key and pull out the connector, as shown

in Figure 5-57.

Figure 5-57 Removing an unshielded Ethernet connector

5 Appendix

----End

Installing Fiber Connectors

Context

NOTICE

l After you remove the dustproof cap, ensure that the fiber pins are clean and install them as

soon as possible.

l When you disassemble fiber connectors, you must use a dedicated tool if the connectors

are densely installed.

Cleaning Fiber Connectors

Procedure

Step 1 Clean the pins of a fiber connector by using lint-free cotton and alcohol.

Step 2 Clean the pins again by using dust-free cotton. If necessary, clean the pins by using an air gun.

Ensure that the pins are free from any fiber or debris.

----End

Installing an FC Fiber Connector

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

49

Page 56

R230D

Hardware Installation and Maintenance Guide

Procedure

Step 1 Remove the dustproof cap of the FC connector and store it for future use.

Step 2 Align the core pin of the male connector with that of the female connector, as shown in

Figure 5-58.

Figure 5-58 Aligning the male connector with the female connector

5 Appendix

Step 3 Align the male connector with the female connector and gently push the male connector until

it is completely seated in the female connector, as shown in Figure 5-59.

Figure 5-59 Feeding the male connector into the female connector

Step 4 Fasten the locking nut clockwise and ensure that the connector is securely installed, as shown

in Figure 5-60.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

50

Page 57

R230D

Hardware Installation and Maintenance Guide

Figure 5-60 Fastening the locking nut

Step 5 To disassemble an FC fiber connector, loosen the locking nut counterclockwise, and gently

pull the male connector, as shown in Figure 5-61.

5 Appendix

Figure 5-61 Disassembling an FC fiber connector

----End

Installing an LC Fiber Connector

Procedure

Step 1 Remove the dustproof cap of the LC fiber connector and store it for future use.

Step 2 Align the core pin of the male connector with that of the female connector, as shown in

Figure 5-62.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

51

Page 58

R230D

Hardware Installation and Maintenance Guide

Figure 5-62 Aligning the male connector with the female connector

Step 3 Align the male connector with the fiber adapter and gently push the male connector until it is

completely seated in the fiber connector, as shown in Figure 5-63.

Figure 5-63 Feeding the male connector into the female connector

5 Appendix

Step 4 A clicking sound indicates that the male connector is locked, as shown in Figure 5-64.

Figure 5-64 Installed LC connector

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

52

Page 59

R230D

Hardware Installation and Maintenance Guide

Step 5 To disassemble an LC fiber connector, press the locking nut to release the locking clips from

the bore, and gently pull the male connector, as shown in Figure 5-65.

Figure 5-65 Disassembling an LC fiber connector

5 Appendix

----End

Installing the SC Fiber Connector

Procedure

Step 1 Remove the dustproof cap of the SC fiber connector and store it for future use.

Step 2 Align the core pin of the male connector with that of the female connector, as shown in

Figure 5-66.

Figure 5-66 Aligning the male connector with the female connector

Step 3 Feed the fiber connector into the female connector, with your fingers holding the shell of the

fiber connector (not the pigtail). When you hear a click, the fiber connector is secured by the

clips (internal parts, not illustrated in the figure). Pull the fiber connector gently. If the

connector does not loosen, the installation is complete. See Figure 5-67.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

53

Page 60

R230D

Hardware Installation and Maintenance Guide

Figure 5-67 Installed SC fiber connector

Step 4 To disassemble an SC fiber connector, hold the shell of the connector (do not hold the fiber)

and gently pull the connector in the direction vertical to the adapter. Unlock the male

connector, and then separate it from the shell, as shown in Figure 5-68.

5 Appendix

Figure 5-68 Disassembling an SC fiber connector

----End

Installing an MPO Connector

Procedure

Step 1 Remove the dustproof cap of the MPO fiber connector and store it for future use.

Step 2 Align the core pin of the male connector with that of the female connector, as shown in

Figure 5-69.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

54

Page 61

R230D

Hardware Installation and Maintenance Guide

Figure 5-69 Aligning the male connector with the female connector

Step 3 Hold the shell labeled "PUSH" and feed the male connector into the female connector until

you hear a clicking sound. The male and female connectors are securely installed, as shown in

Figure 5-70.

5 Appendix

Figure 5-70 Installed MPO fiber connector

Step 4 To disassemble an MPO fiber connector, hold the shell labeled "PULL" and remove the male

connector, as shown in Figure 5-71.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

55

Page 62

R230D

Hardware Installation and Maintenance Guide

Figure 5-71 Disassembling an MPO fiber connector

----End

5.1.5 Replacing the Mold of the Crimping Tool

5 Appendix

Procedure

Step 1 Hold the handles of a pair of COAX crimping tools. Loosen the two fastening screws

Step 2 Hold the handles of the COAX crimping tools to open the self-locking mechanism. The jaw

counterclockwise, as shown in Figure 5-72.

Figure 5-72 Loosening two fastening screws

of the COAX crimping tools opens automatically, as shown in Figure 5-73.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

56

Page 63

R230D

Hardware Installation and Maintenance Guide

Figure 5-73 Pliers jaw opening automatically

5 Appendix

Step 3 Remove the mold from the COAX crimping tools, as shown in Figure 5-74.

Figure 5-74 Removing the mold from the COAX crimping tools

Step 4 Place the mold to be installed into the jaw of the COAX crimping tools and align the screw

holes, as shown in Figure 5-75.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

57

Page 64

R230D

Hardware Installation and Maintenance Guide

Figure 5-75 Installing a new mold in the COAX crimping tool

5 Appendix

NOTICE

Keep the short side of the mold inwards and the long side outwards, with the teeth of the mold

aligning from the larger size to the smaller size.

Step 5 Hold the handles of the COAX crimping tools tightly to match the mold and the jaw

completely. Align the screw holes, as shown in Figure 5-76.

Figure 5-76 Aligning the screw holes

Step 6 Hold the handles of the COAX crimping tools with one hand. Tighten the two fastening

screws clockwise. Figure 5-77 and Figure 5-78shows the mold installed in the COAX

crimping tool.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

58

Page 65

R230D

Hardware Installation and Maintenance Guide

Figure 5-77 Mold installed in the COAX crimping tool

Figure 5-78 An installed mold

5 Appendix

----End

5.2 Environmental Requirements for Device Operation

5.2.1 Environmental Requirements for an Equipment Room

Requirements for Selecting a Site for an Equipment Room

When designing a project, consider the communication network planning and technical

requirements of the equipment. Also consider hydrographic, geological, seismic, power

supply, and transportation factors.

Construction, structure, heating and ventilation, power supply, lighting and fire-proof

construction of the equipment room should be designed by specialized construction designers

to suit the environmental requirements of devices. The equipment room should also follow

local regulations concerning the industrial construction, environmental protection, fire safety,

and civil air defense. Construction must conform to government standards, regulations, and

other requirements.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

59

Page 66

R230D

Hardware Installation and Maintenance Guide

The equipment room should be located in a place free from high temperature, dust, toxic

gases, explosive materials, or unstable voltage. Keep the equipment room away from

significant vibrations or loud noises, as well as power transformer stations.

The specific requirements for selecting a site for an equipment room are as follows:

l The room should be located at a distance of at least 5 km (3.11 mi.) from heavy pollution

sources such as smelting and coal mines. It should be located at a distance of at least 3.7

km (2.30 mi.) from moderate pollution sources such as chemical, rubber, and

galvanization factories. It should be located at a distance of at least 2 km (1.24 mi.) from

light pollution sources such as packinghouses and tanyards. If these pollution sources

cannot be avoided, ensure that the equipment room is upwind of the pollution sources. In

addition, use a high-quality equipment room or protection products.

l The room should be located away from livestock farms, or be upwind of the livestock

farms. Do not use an old livestock room or fertilizer warehouse as the equipment room.

l The equipment room must be far away from residential areas. An equipment room that is

not far away from residential areas must comply with equipment room construction

standards to avoid noise pollution.

l The room should be located far away from industrial and heating boilers.

l The room should be at least 3.7 km (2.30 mi.) away from the seaside or salt lake.

Otherwise, the equipment room should be airtight with cooling facilities. In addition,

alkalized soil cannot be used as the construction material. Otherwise, equipment suitable

for wet conditions must be used.

l The doors and windows of the equipment room must be kept closed to maintain an

airtight room.

l Using steel doors to ensure sound insulation is recommended.

l No cracks or openings are allowed on the walls or floors. The outlet holes on the walls or

windows must be sealed. Walls must be constructed such that they are smooth, wearresistant, dustproof, flame retardant, sound insulated, heat absorptive, and have

electromagnetic shielding.

l The air vent of the room should be far from the exhaust of city waste pipes, big cesspools

and sewage treatment tanks. The room should be in the positive pressure state to prevent

corrosive gases from entering the equipment room and corroding components and circuit

boards.

l It is recommended that the room be on or above the second floor. If this requirement

cannot be met, the ground for equipment installation in the room should be at least 600

mm (23.62 in,) above the maximum flood level.

l The equipment room should be strong enough to resist winds and downpours.

l The room should be located away from dusty roads or sand. If this is unavoidable, the

doors and windows of the equipment room must not face pollution sources.

l Do not place air conditioning vents near the equipment so that they blow directly on the

equipment because condensation may be blown into the equipment.

l Do not use decorative materials that contain sulfur in the equipment room.

5 Appendix

Equipment Room Layout

An equipment room usually contains mobile switching equipment, telecommunications

equipment, power supply equipment, and other auxiliary equipment. To ensure easy

maintenance and management, place the equipment in different rooms. Figure 5-79 shows the

layout of the equipment room.

Issue 01 (2015-12-12) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

60

Page 67

Control room Generator room

Transmission

room

Main communication

equipment room

Power distribution

room

Battery room

Substation room

Communication cable and optical cable

Power cable

R230D

Hardware Installation and Maintenance Guide

Figure 5-79 Layout of the equipment room

5 Appendix

Construction Requirements for the Equipment Room