Page 1

HUAWEI TECHNOLOGIES CO., LTD.

SmartPSB2000L Smart PV Safety Box

Quick Guide

Issue: 03

Part Number: 31509508

Date: 2018-05-18

Page 2

1

Overview

1

• The information in this document is subject to change due to version upgrades or other reasons. Every effort

has been made in the preparation of this document to ensure accuracy of the contents, but all statements,

information, and recommendations in this document do not constitute a warranty of any kind, express or implied.

• Only qualified and trained electrical technicians are allowed to operate the device.

• Carefully read this document and the precautions before installing the device. Failure to comply with the

storage, installation, and operation regulations specified in this document may cause device damage, which is

not covered by Huawei's warranty.

• If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

• Use insulated tools when installing the device. For personal safety, wear proper personal protective equipment

(PPE).

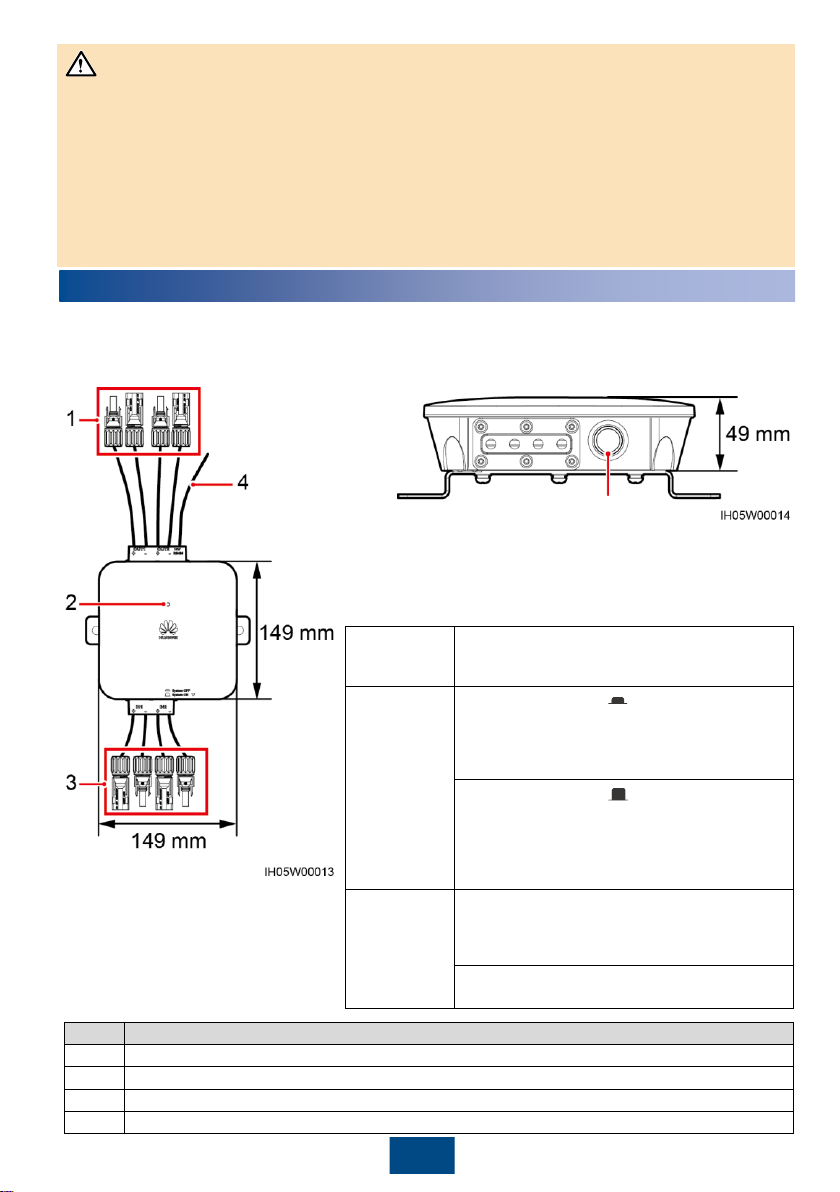

The SmartPSB2000L smart PV safety box (safety box for short) is a key component that implements rapid

shutdown and module monitoring for Huawei SUN2000P-375W smart PV optimizers. The safety box is easy to

install, operate, and maintain.

Shutdown button

NOTICE

Rapid shutdown means that the power generation system consisting

of optimizers, smart PV safety boxes, and inverters decreases the DC

voltage to the safe voltage range (≤ 30 V) within the specified period

(≤ 30s).

No.

Description

1

Two routes of output terminals, cable length (including terminals) 250 mm

2

An LED indicator showing the running status of the safety box

3

Two routes of input terminals, cable length (including terminals) 150 mm

4

RS485 communication, PE, and 12 V power cables, 340 mm long

Copyright © Huawei Technologies Co., Ltd. 2018. All rights

reserved.

Prerequisites

An optimizer is installed for each PV module, and

the rapid shutdown function of the safety box is

enabled.

Trigger by

button press

If the shutdown button (

) is pressed, the safety

box enters the rapid shutdown state. The LED

indicator is steady red, and the inverter turns off the

AC output. This product cannot be used as a

substitute for the emergency stop switch.

If the shutdown button (

) is released, the safety

box exits the rapid shutdown state. The LED

indicator is steady red within 10 minutes. The output

voltages of the optimizer and inverter are restored

10 minutes later. The LED indicator of the safety box

changes from steady red to steady green.

Trigger by

power failure

If the AC power fails, the safety enters the rapid

shutdown state. The inverter and optimizer stop

output and communication. The LED indicators of

the safety box and inverter are off.

If the AC power resumes, the inverter, optimizer,

and safety box restore to the normal state.

Page 3

2

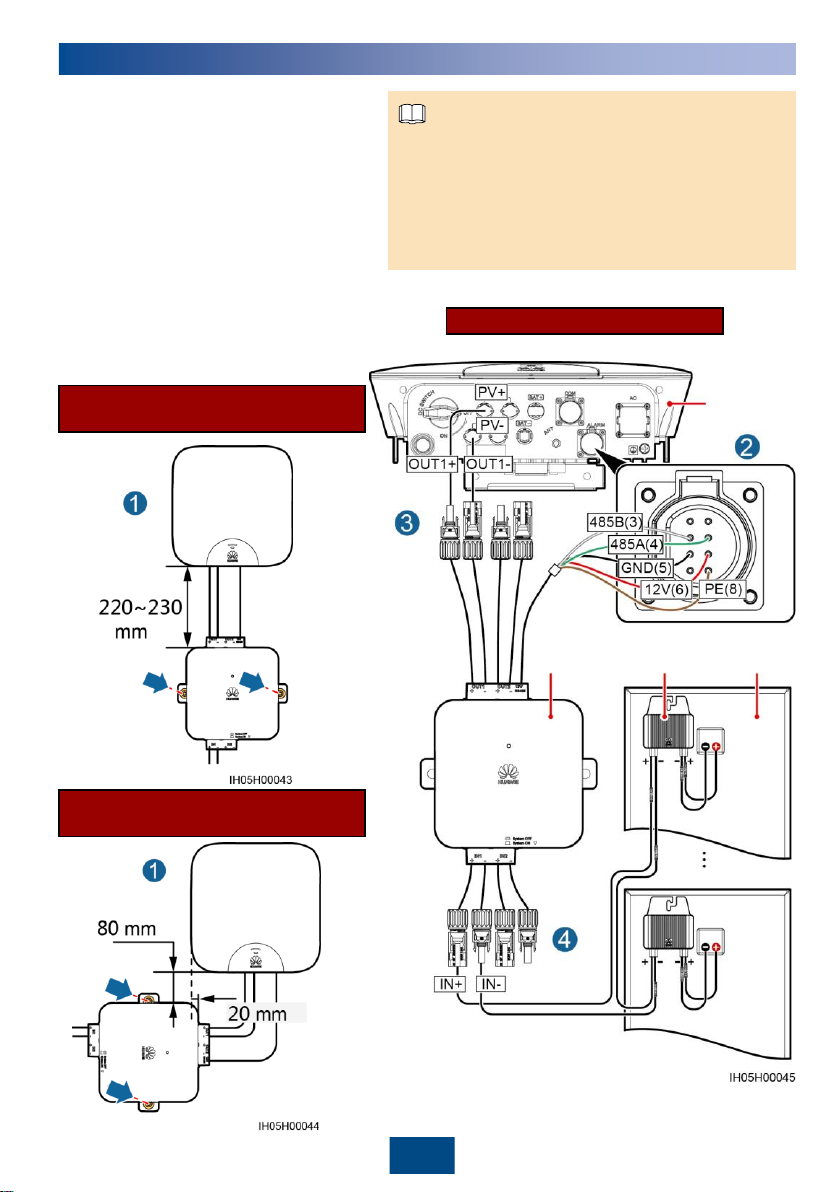

Installation Mode 2

(Recommended Distance)

2

Installation and Cable Connections

Wiring Diagram

1. Each input of the safety box supports serial connection of

up to 15 optimizers, and the string voltage should be less

than 600 V DC.

2. After the cord end terminal is removed, the PE cable of the

safety box and the communication PE cable of the power

meter can be connected together to the communication

terminal (pin 8) of the inverter.

NOTE

1. Install the safety box under or on a side of an

inverter with the delivered M6x60 expansion

bolts. It is recommended that an M8 drill bit

be used to drill holes. The torque should be

4.5–5.5 N·m.

2. Connect the RS485 communications, PE,

and 12 V power cables from the safety box to

the corresponding port on the inverter.

3. Connect the output terminals of the safety

box to the DC input ports of the inverter (one

route is used as an example in the right

figure).

4. Connect the input terminals of the safety box

to the output ports of the optimizer string

(one route is used as an example in the right

figure).

Inverter

Safety box Optimizer PV module

Installation Mode 1

(Recommended Distance)

Page 4

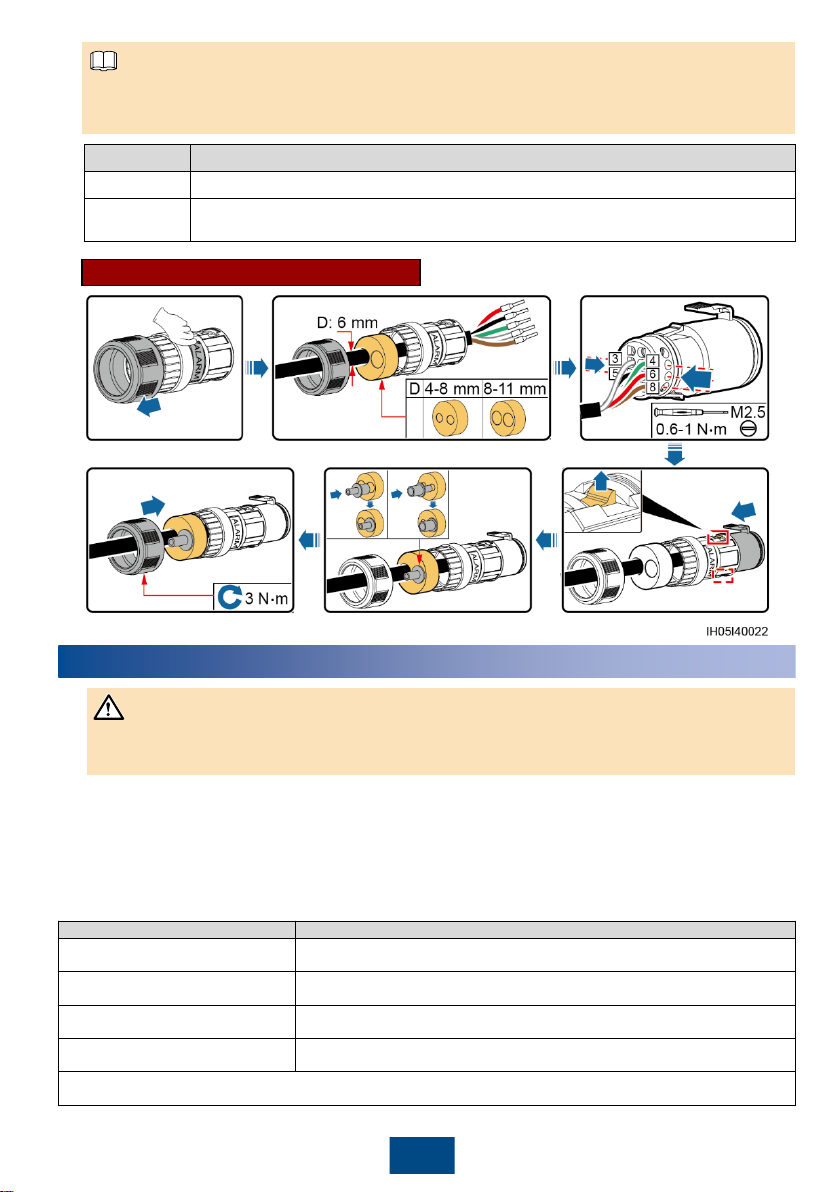

3

Port Inverter Model

COM SUN2000L-3KTL-CN, SUN2000L-4KTL-CN, SUN2000L-5KTL-CN

ALARM

SUN2000L-2KTL, SUN2000L-3KTL, SUN2000L-3.68KTL, SUN2000L-4KTL, SUN2000L-

4.6KTL, SUN2000L-5KTL

Depending on the inverter model, the RS485 communications, PE, and 12 V power cables need to be

connected to the COM or ALARM port of the inverter. The pins are wired in the same way.

COM or ALARM Terminal Connection

1. Switch on the AC circuit breaker between the inverter and the power grid (the AC voltage of the power grid

should be in the range allowed by the inverter).

2. Turn the DC switch at the bottom of the inverter to the ON position.

3. Observe the LED indicator on the safety box. The status change sequence should be: blinking green at long

intervals > blinking green at short intervals. If the LED indicator is abnormal, check whether cables are

connected correctly and securely.

3

Powering On the Safety Box

NOTE

LED Status Description

Blinking green at long intervals

Power on self test.

Blinking green at short intervals

Communicating with the inverter properly and not communicating with the

optimizer.

Steady green

Communicating with the inverter and optimizer properly.

Steady red

Shutdown.

Blinking green at long intervals: on for 1s and then off for 1s

Blinking green at short intervals: on for 0.2s and then off for 0.2s

1. Check whether all cables to the safety box are properly connected.

2. Input and output terminals are correctly paired, and no crossover exists.

NOTICE

Page 5

Adding the Safety Box

4.1

1. Log in to the app and access

the Operation console

screen.

2. Choose Device maintenance >

Add/Delete device and tap Smart

PV safety box.

4

1. The near-end FusionHome app (app for short) is a mobile phone app that locally communicates with the

inverter over WiFi for alarm query, parameter configuration, routine maintenance, and commissioning.

2. Requirements for the mobile phone operating system: Android 4.4 or later, iOS 8.0 or later.

3. For details about app connection and login, see the inverter manual available onsite. User interfaces (UIs) on

the Android system are used as an example. The actual UIs prevail.Log in to http://solar.huawei.com and

choose SERVICES > Download Center to obtain the latest document.

4. The inverter and safety box cannot perform any commissioning tasks when the AC power is disconnected.

4

FusionHome App

NOTE

NOTE

1. If the safety box icon is green, the safety box is running properly.

2. If the safety box icon is yellow, the safety box is in self test state.

3. If the safety box icon is gray, the safety box is abnormal in communication. Check whether its cable connections

and communications parameters are correct.

4. If the safety box icon is red, the safety box has shut down.

3. After the safety box is added

successfully, the safety box icon

is displayed.

Adding Optimizers

4.2

Automatic search: Automatically search for optimizer SNs and string numbers. You need to manually modify

device names and locations.

Manual configuration: Manually configure the SNs, string numbers, device names, and locations of optimizers.

Add optimizers by automatic search or manual configuration.

Page 6

2. The optimizer search takes about 10

minutes. If you tap Stop searching,

the information of the optimizers

already found will be saved.

3. After the search is canceled or

completed, the screen for

enabling Rapid shutdown is

displayed (see section 4.3).

5

1. Tap Auto search.

Manual Configuration

4. If you tap No in the previous step,

the screen for adding devices is

displayed. Tap Manual config and

tap the optimizer to modify optimizer

information.

5. Modify optimizer information.

2. Tap Manual config.

Automatic Search

3. By default, two strings are

configured. Tap Add optimizer.

1. When installing optimizers,

remove the SN bar codes

and attach them to their

respective positions on the

same layout form. For details,

see the usage instructions on

the rear of the form.

For details about the optimizer

icon, see section 5.1.

NOTE

6. Tap Submit and the screen

for enabling Rapid shutdown

is displayed (see step 3).

Page 7

6

Performing Rapid Shutdown Check

4.3

4. Enter optimizer information to

add all optimizers in sequence

by scanning their QR codes or

manually entering their SNs.

1. After optimizer search is

complete, the screen for enabling

Rapid shutdown is displayed

automatically.

1. You need to enable Rapid shutdown and start Rapid shutdown

check only if an optimizer is installed for each PV module. To support

the rapid shutdown function, enable Rapid shutdown (disabled by

default) for the safety box. If Rapid shutdown is disabled, the rapid

shutdown function is ineffective.

2. If optimizers are installed only for certain PV modules, the rapid

shutdown function is ineffective no matter whether you enable Rapid

shutdown or press the shutdown button.

3. Rapid shutdown check is displayed only if Rapid shutdown is

enabled.

NOTE

6. If you stop the searching, the

entered optimizer information is

saved. You can tap Manual

config to add a new optimizer

or tap the optimizer to modify

optimizer information.

5. Tap Submit. Automatic search

for optimizers begins and will last

about 5 minutes. After the search

is completed, the screen for

enabling Rapid shutdown is

displayed (see section 4.3).

4. If you did not enable Rapid

shutdown or perform rapid

shutdown check, you can still tap

the shutdown box icon to access

the screen for enabling Rapid

shutdown or performing rapid

shutdown check.

3. After Rapid shutdown is enabled,

a dialog box for performing rapid

shutdown check is automatically

displayed. Even if you tap No, the

rapid shutdown function is still

valid.

2. If you enable Rapid shutdown,

check whether an optimizer is

installed for each PV module.

If you tap No, the screen for

adding devices is displayed.

Page 8

7

(Optional) Upgrading the Software4.4

1. Obtain the upgrade file from your dealer or Huawei engineers.

2. On the Android system, you can copy the upgrade file to the mobile phone. The upgrade file name extension

must be .zip, the file can be flexibly stored, and Manually select is supported.

3. On the iOS system, you can import the upgrade file to the app through a mailbox. The upgrade file name

extension must be .zip, and Manually select is not supported.

4. Upgrading the safety box or optimizer lasts for 10–20 minutes.

NOTE

2. Select the appropriate upgrade

package and finish the upgrade.

1. Choose Upgrade device on the

Operation console screen to

upgrade the optimizer or smart PV

safety box.

5. Press the Rapid shutdown

button within 60s as prompted.

If you tap Exit, the screen for

adding devices is displayed.

6. After rapid shutdown succeeds,

release the button as prompted.

The inverter will start in 10 minutes.

Page 9

1. If the LED indicator of the safety box is blinking green slowly (at 0.5 Hz), check whether its communications

cable is connected correctly or check its communications parameter settings. The same RS485 baud rate should

be set for the safety box, inverter, power meter, and battery that implement RS485 communication.

2. If setting safety box communications parameters fails, set the inverter baud rate to 9600 bps, and then perform

three cycles of press + release operations on the shutdown button within 1 minute. Then, the RS485

communications parameters of the safety box are restored to default values, and the LED indicator blinks red

and green (red for 0.25s, green for 0.25s, lasts for 20s).

3. If the message "The PLC frequency band is congested. Switch the frequency band." is displayed on the app,

change the PLC frequency band. The change process takes about 3 minutes. Do not power off the safety box.

Communication Fault

5.1

4.3

5

Maintenance

8

4. After communication is successful, the optimizer

information is displayed in Device info on the

Operation console screen.

1. Log in to the app, access the

Operation console screen,

and then choose Comm

config.

2. Choose Smart PV safety box

configuration. Then set RS485

baud rate and PLC frequency band.

3. Choose RS485 Setting, and

then set the Baud rate for the

inverter.

Baud rate

9600 (default), 19200

Frequency

band

500K

-3.7M (default),

1.5M

-4.7M

Optimizer output power

Optimizer position

Green

The optimizer is running properly.

Gray

The optimizer runs abnormally. Check whether its SN

and position information are correct.

Then search

the

optimizer again.

Red

The optimizer is faulty. Troubleshoot according to the

optimizer manual.

Page 10

9

Replacing the Safety Box

5.2

(1) Log in to the app and access the

Operation Console screen.

Choose Grid-connect config >

Expert.

(2) Choose Feature parameters and enable

Unlock optimizer. Unlock optimizer exits

automatically after unlocking is complete.

NOTICE

Replace the safety box if any of the following faults

occurs.

• The appearance is seriously damaged.

• Cables are seriously damaged.

• The LED indicator status does not match the actual

status.

• The key button is damaged and fails.

• The key button is not damaged, but the shutdown

function fails.

• Obtain the user's consent before replacing the safety

box, as the inverter may have no output during the

replacement.

• The safety box can be replaced only 30 seconds after

you turn off the DC input switch on the inverter and

the switch on the AC output loop.

1. Turn off the DC input switch on the inverter and the

switch on the AC output loop.

2. Remove the old safety box.

3. Install a new safety box, as shown in the chapter 2.

4. Turn on the DC input switch on the inverter and the

switch on the AC output loop.

5. Log in to the FusionHome app, add the safety box (see

section 4.1), unlock optimizers (as shown in the

following figure), and then add the optimizers again

(see sections 4.2 and 4.3). You need to perform this

step when replacing the safety box, optimizer, or

inverter.

Page 11

10

6

Technical Specifications

Item

Specifications

Maximum input voltage

600 V

DC

Maximum input current

15 A

Maximum short

-circuit current

15 A

Maximum number of inputs

2

Maximum output voltage

600 V

DC

Maximum output current

15 A

Maximum number of outputs

2

DC power supply

12 V

DC

Protection level

IP65

Power consumption

<

3 W

Noise

<

35 dB

Cooling mode

Natural cooling

Display

LED

Installation mode

Wall

-mounted

Dimensions

149 mm x 149 mm x 49 mm

(excluding cables)

Weight

0.8 kg (

including cables)

Input and output terminals

H4 x 2/H4 x 2

Operating temperature

–

30°C to +55°C

Operating humidity

5

%–95% RH

Operating altitude

0

–4000 m (≥ 2000 m: 1

°

C/200 m derating)

Storage temperature

–

40°C to +70°C

Storage humidity

5%

–95% RH

Networking mode

PLC, RS485

Safety compliance

IEC62109

Electromagnetic compatibility (EMC)

IEC61000

-6-2, IEC61000-6-3

Mean time between failures (MTBF)

500,000 hours

Design life

25 years (excluding field replaceable parts)

Environmental protection

RoHS

Page 12

Huawei Technologies Co., Ltd.

Huawei Industrial Base, Bantian, Longgang

Shenzhen 518129 People's Republic of China

www.huawei.com

Loading...

Loading...