DBS3900 LampSite

Installation Guide

Issue

08

Date

2016-05-30

HUAWEI TECHNOLOGIES CO., LTD.

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2016. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://www.huawei.com

Email:

support@huawei.com

DBS3900 LampSite

Installation Guide

About This Document

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

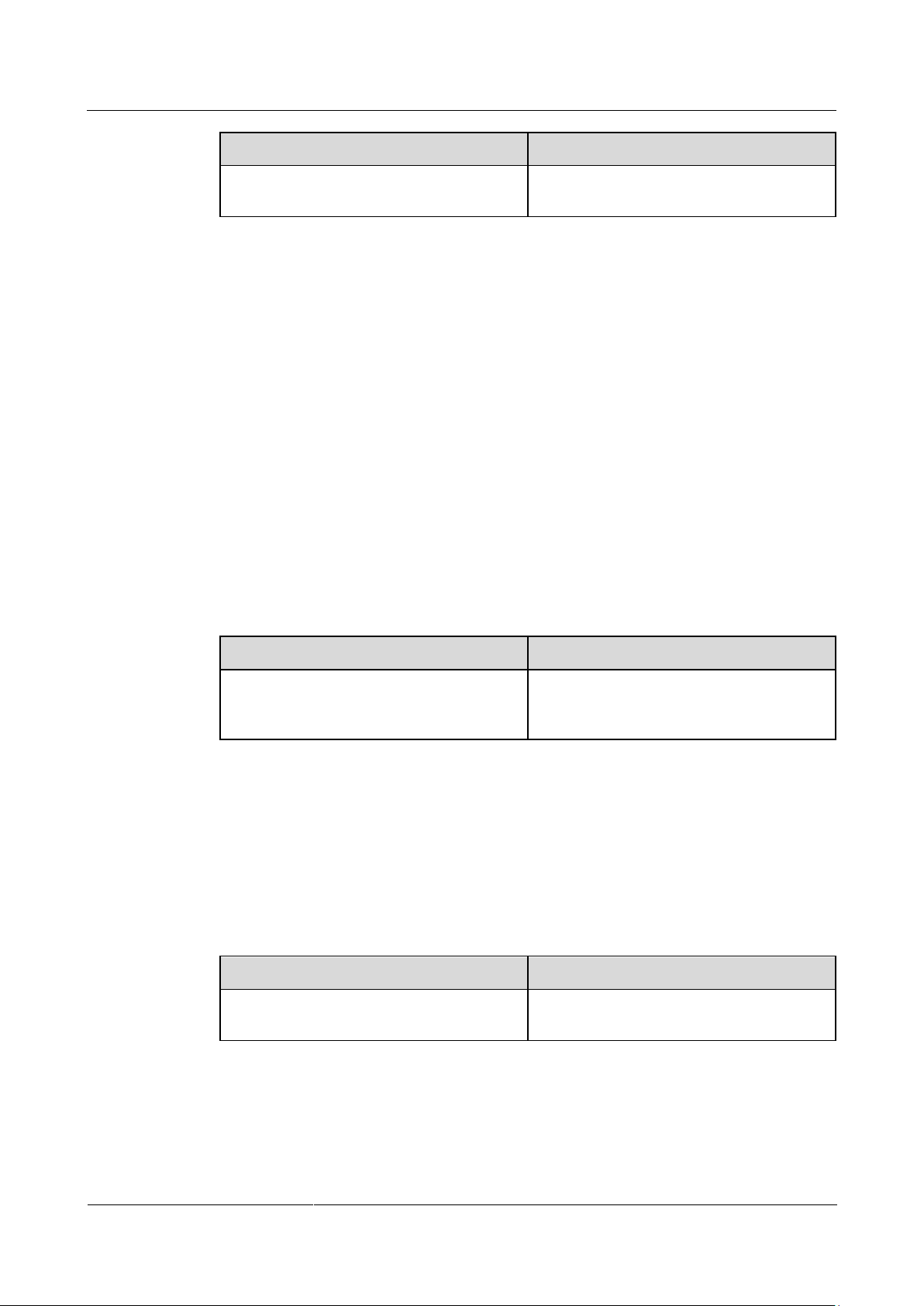

Overview

Product Name

Solution Version

Product Version

DBS3900 LampSite

SRAN10.1 and later

versions

RAN17.1 and later versions

eRAN8.1 and later versions

eRAN TDD 8.1 and later

versions

V100R010C10 and later

versions

About This Document

This document describes how to install the modules and cables for the BBU, DCU3900,

RHUB3908, pRRU3901, pRRU3902, pRRU3907, pRRU3911, and pRRU3911+WIFI. It also

provides checklists for hardware installation.

Unless otherwise specified, BBU in this document refers to BBU3900 and BBU3910.

DCU3900 in this document refers to DCU.

RHUB3908 in this document refers to RHUB.

Unless otherwise specified, pRRU in this document refers to pRRU3901, pRRU3902, pRRU3907,

pRRU3911, and pRRU3911+WIFI.

Product Version

The following table lists the product version related to this document.

Intended Audience

This document is intended for:

BTS installation personnel

DBS3900 LampSite

Installation Guide

Contents

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Contents

About This Document .................................................................................................................... ii

1 Changes in DBS3900 LampSite Installation Guide ............................................................... 1

2 Installation Preparations ............................................................................................................. 5

2.1 Reference Documents ................................................................................................................................................... 5

2.2 Preparing Tools and Instruments................................................................................................................................... 5

2.3 Requirements for Installation Personnel ....................................................................................................................... 7

3 Unpacking and Checking ............................................................................................................ 8

4 Installing a BBU .......................................................................................................................... 10

5 Installing a DCU.......................................................................................................................... 11

6 Installing an RHUB .................................................................................................................... 12

6.1 Information About the Installation .............................................................................................................................. 12

6.1.1 Installation Scenarios ............................................................................................................................................... 13

6.1.2 Installation Clearance Requirements ....................................................................................................................... 18

6.1.3 Installation Environment .......................................................................................................................................... 21

6.2 Installation Process ..................................................................................................................................................... 23

6.3 Installing an RHUB .................................................................................................................................................... 24

6.3.1 Installing an RHUB in a 19-Inch Cabinet or Rack .................................................................................................. 24

6.3.2 Installing an RHUB in a 19-Inch Shelf .................................................................................................................... 27

6.3.3 Installing an RHUB on a Wall ................................................................................................................................. 30

6.4 Installing RHUB Cables ............................................................................................................................................. 34

6.4.1 Requirements for Cable Layout ............................................................................................................................... 34

6.4.2 Cable List ................................................................................................................................................................. 37

6.4.3 Cable Connections ................................................................................................................................................... 43

6.4.4 Cable Installation Process ........................................................................................................................................ 44

6.4.5 Installing PGND Cable ............................................................................................................................................ 45

6.4.6 Installing Ethernet Cable ......................................................................................................................................... 47

6.4.7 Installing CRPI Optical Cables ................................................................................................................................ 50

6.4.8 Installing Alarm Cable (Optional) ........................................................................................................................... 53

6.4.9 Installing Power Cable ............................................................................................................................................. 53

6.5 Checking the RHUB Hardware Installation................................................................................................................ 55

DBS3900 LampSite

Installation Guide

Contents

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

6.6 Power-on Check on an RHUB .................................................................................................................................... 56

7 Installing a pRRU3901................................................................................................................ 59

7.1 Information About the Installation .............................................................................................................................. 60

7.1.1 Product Family......................................................................................................................................................... 60

7.1.2 Installation Scenario ................................................................................................................................................ 60

7.1.3 Space Requirements ................................................................................................................................................. 64

7.1.4 Installation Environment Requirements................................................................................................................... 65

7.2 Obtaining the MAC Address (Optional) ..................................................................................................................... 66

7.3 Installation Process ..................................................................................................................................................... 67

7.4 Installing a pRRU3901 ............................................................................................................................................... 68

7.4.1 pRRU3901 Mounting Kits ....................................................................................................................................... 69

7.4.2 Installing a pRRU3901 on a Wall ............................................................................................................................ 70

7.4.3 Installing a pRRU3901 on a Ceiling ........................................................................................................................ 74

7.4.4 Installing a pRRU3901 on a Pole ............................................................................................................................. 77

7.4.5 Installing a pRRU3901 on a Plate ............................................................................................................................ 80

7.4.6 Installing a pRRU3901 on a Keel ............................................................................................................................ 83

7.4.7 Installing the Cabinet ............................................................................................................................................... 86

7.5 Installing pRRU3901 Cables ...................................................................................................................................... 93

7.5.1 Requirements for Cable Layout ............................................................................................................................... 93

7.5.2 pRRU3901 Cable List .............................................................................................................................................. 94

7.5.3 Cable Connections (Indoor) ..................................................................................................................................... 95

7.5.4 Cable Connections (Outdoor) .................................................................................................................................. 98

7.5.5 Cable Connections (LTE TDD) ............................................................................................................................... 99

7.5.6 pRRU3901 cable installation process .................................................................................................................... 101

7.5.7 Installing an Ethernet Cable ................................................................................................................................... 101

7.5.8 Installing an RF jumpers (Optional) ...................................................................................................................... 104

7.6 Checking the pRRU3901 Hardware Installation....................................................................................................... 106

7.7 Powering on the pRRU3901 ..................................................................................................................................... 107

8 Installing a pRRU3902 or pRRU3911 or pRRU3911+WIFI................................................ 109

8.1 Information About the Installation ............................................................................................................................ 110

8.1.1 Product Family....................................................................................................................................................... 110

8.1.2 Installation Scenario .............................................................................................................................................. 112

8.1.3 Space Requirements ............................................................................................................................................... 116

8.1.4 Installation Environment Requirements................................................................................................................. 117

8.2 Installation Process ................................................................................................................................................... 118

8.3 Installing a pRRU ..................................................................................................................................................... 119

8.3.1 Mounting Kits ........................................................................................................................................................ 119

8.3.2 Installing a pRRU on a Wall .................................................................................................................................. 120

8.3.3 Installing a pRRU on a Ceiling .............................................................................................................................. 124

8.3.4 Installing a pRRU on a Pole .................................................................................................................................. 127

8.3.5 Installing a pRRU on a Plate .................................................................................................................................. 129

DBS3900 LampSite

Installation Guide

Contents

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

8.3.6 Installing a pRRUon a Keel ................................................................................................................................... 136

8.3.7 Installing a pRRU on Steel Hangers ...................................................................................................................... 140

8.3.8 Installing the Cabinet ............................................................................................................................................. 144

8.4 Installing pRRU Cables ............................................................................................................................................ 148

8.4.1 Requirements for Cable Layout ............................................................................................................................. 148

8.4.2 Cable List ............................................................................................................................................................... 149

8.4.3 Cable Connections ................................................................................................................................................. 150

8.4.4 Cable Installation Process ...................................................................................................................................... 154

8.4.5 Installing a pRRU3902 Ethernet Cable .................................................................................................................. 154

8.4.6 Installing a pRRU3911/pRRU3911+WIFI Ethernet Cable .................................................................................... 159

8.4.7 Installing a pRRU3902 RF Jumper (Optional) ...................................................................................................... 163

8.4.8 Installing a pRRU3911 RF Jumper (Optional) ...................................................................................................... 165

8.5 (Optional) Installing a Combiner .............................................................................................................................. 167

8.6 Checking the pRRU Hardware Installation .............................................................................................................. 169

8.7 Powering on the pRRU ............................................................................................................................................. 170

9 Installing a pRRU3907 or pRRU3916 .................................................................................... 172

9.1 Information About the Installation ............................................................................................................................ 172

9.1.1 pRRU Product Family ........................................................................................................................................... 173

9.1.2 Constraints and Limitations ................................................................................................................................... 173

9.1.3 Installation Clearance and Space Requirements .................................................................................................... 176

9.1.4 Installation Environment Requirements................................................................................................................. 179

9.2 Installation Process ................................................................................................................................................... 180

9.3 Installing a pRRU ..................................................................................................................................................... 180

9.3.1 pRRU Mounting Kits ............................................................................................................................................. 180

9.3.2 Installing a pRRU on a Wall .................................................................................................................................. 182

9.3.3 Installing a pRRU on a Pole .................................................................................................................................. 185

9.4 Installing pRRU Cables ............................................................................................................................................ 187

9.4.1 Cabling Requirements............................................................................................................................................ 187

9.4.2 pRRU Cable List .................................................................................................................................................... 189

9.4.3 pRRU3907 Cable Connections .............................................................................................................................. 190

9.4.4 pRRU3916 Cable Connections .............................................................................................................................. 190

9.4.5 pRRU cable installation process ............................................................................................................................ 191

9.4.6 Installing a PGND Cable ....................................................................................................................................... 192

9.4.7 Installing a pRRU3907 RF Jumper ........................................................................................................................ 193

9.4.8 Installing a pRRU3916 RF Jumper ........................................................................................................................ 197

9.4.9 Opening the Cover Plate of a pRRU Cabling Cavity ............................................................................................. 199

9.4.10 Installing an Ethernet Cable ................................................................................................................................. 200

9.4.11 Closing the Cover Plate of a pRRU Cabling Cavity ............................................................................................ 202

9.5 Checking the pRRU Hardware Installation .............................................................................................................. 204

9.6 Powering on the pRRU ............................................................................................................................................. 205

10 (Optional) Installing the Extender-PoE90 .......................................................................... 207

DBS3900 LampSite

Installation Guide

Contents

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

vi

11 (Optional) Installing the EXD3902 and Cables ................................................................. 211

11.1 Installation Scenario................................................................................................................................................ 212

11.2 Installation Clearance and Space Requirements ..................................................................................................... 215

11.3 Installation Process ................................................................................................................................................. 218

11.4 Installing an EXD3902 ........................................................................................................................................... 218

11.4.1 EXD3902 Mounting Kits ..................................................................................................................................... 218

11.4.2 Installing an EXD3902 on a Wall ........................................................................................................................ 220

11.4.3 Installing an EXD3902 on a Pole ......................................................................................................................... 223

11.5 Installing EXD3902 Cables .................................................................................................................................... 225

11.5.1 Cabling Requirements .......................................................................................................................................... 225

11.5.2 EXD3902 Cable Connections .............................................................................................................................. 226

11.5.3 Installling a PGND cable ..................................................................................................................................... 227

11.5.4 Opening the Cover Plate of an EXD3902 Cabling Cavity ................................................................................... 229

11.5.5 Installing an Ethernet Cable ................................................................................................................................. 230

11.5.6 Closing the Cover Plate of an EXD3902 Cabling Cavity .................................................................................... 231

11.6 Checking the EXD3902 Hardware Installation ....................................................................................................... 232

11.7 Powering on the EXD3902 ..................................................................................................................................... 233

12 (Optional) Installing the PoE Surge Protector and Cables ............................................. 235

13 (Optional) Installing the RF Surge Protector and Cables ............................................... 237

14 (Optional) Installing the Cabinet and Cabinet Cables .................................................... 239

14.1 Installation Clearance Requirements ...................................................................................................................... 239

14.2 Mounting Bracket and Attachment Plate ................................................................................................................ 240

14.2.1 Mounting Bracket ................................................................................................................................................ 240

14.2.2 Attachment Plate .................................................................................................................................................. 242

14.3 Installing a Cabinet ................................................................................................................................................. 242

14.3.1 Installing the Cabinet on a Wall ........................................................................................................................... 242

14.3.2 Installing the Cabinet on a Pole ........................................................................................................................... 247

14.3.3 Installing the Cabinet on U-steel .......................................................................................................................... 250

14.3.4 Installing the Cabinet on Angle Steel ................................................................................................................... 254

14.3.5 Installing the Cabinet on Metal Grid.................................................................................................................... 257

14.3.6 Installing the Cabinet on the Floor ....................................................................................................................... 262

14.4 Installing Cabinet Cables ........................................................................................................................................ 266

14.4.1 Cable Connections ............................................................................................................................................... 266

14.4.2 Installing a PGND Cable for the Cabinet............................................................................................................. 269

15 Appendix .................................................................................................................................. 271

15.1 MAC Collection Template ...................................................................................................................................... 271

15.2 Assembling a Shielded RJ45 Connector and an Ethernet Cable ............................................................................. 272

15.3 DBS3900 LampSite Engineering Label .................................................................................................................. 276

15.4 Attaching an L-Shaped Label ................................................................................................................................. 278

15.5 Attaching a Sign Plate Label ................................................................................................................................... 280

DBS3900 LampSite

Installation Guide

1 Changes in DBS3900 LampSite Installation Guide

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

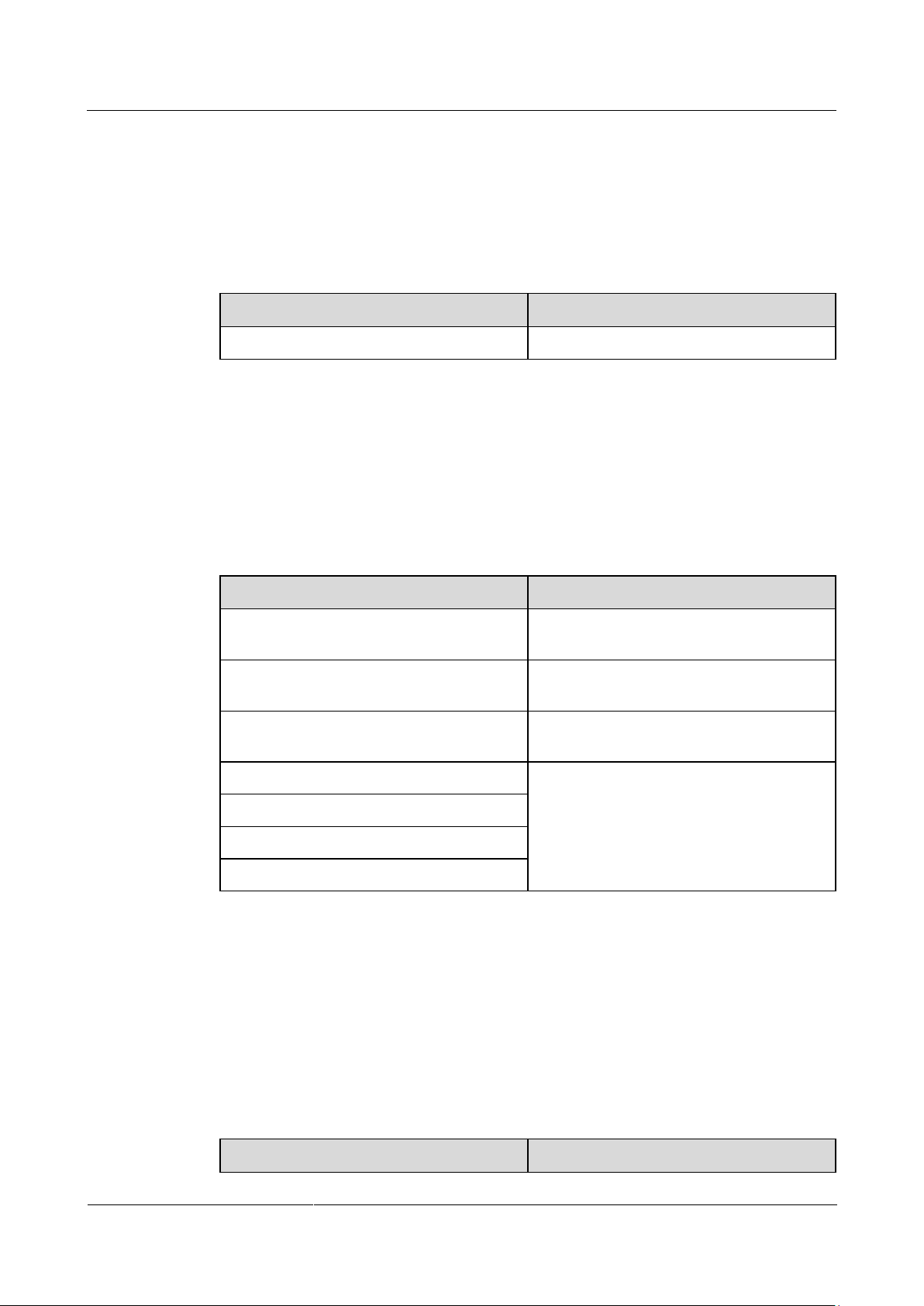

08 (2016-05-30)

Content

Change Description

8.4.5 Installing a pRRU3902 Ethernet Cable

Renamed the outdoor Extender to

Extender-PoE90.

8.4.6 Installing a

pRRU3911/pRRU3911+WIFI Ethernet

Cable

1 Changes in DBS3900 LampSite

Installation Guide

This chapter describes the changes in the DBS3900 LampSite Installation Guide.

This is the eighth commercial release.

07 (2015-12-30)

Compared with 07 (2015-12-30), this issue incorporates the following new topics:

8.3.4 Installing a pRRU on a Pole

10 (Optional) Installing the Extender-PoE90

11 (Optional) Installing the EXD3902 and Cables

Compared with 07 (2015-12-30), this issue incorporates the following changes:

Compared with 07 (2015-12-30), no information is deleted.

This is the seventh commercial release.

Compared with 06 (2015-10-30), this issue incorporates the following new topics:

8.4.6 Installing a pRRU3911/pRRU3911+WIFI Ethernet Cable

12 (Optional) Installing the PoE Surge Protector and Cables

13 (Optional) Installing the RF Surge Protector and Cables

14 (Optional) Installing the Cabinet and Cabinet Cables

Compared with 06 (2015-10-30), this issue incorporates the following changes:

DBS3900 LampSite

Installation Guide

1 Changes in DBS3900 LampSite Installation Guide

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Content

Change Description

Entire document

Added the information about pRRU3911

and the cabinet used in the outside scenario.

06 (2015-10-30)

Content

Change Description

6.4.7 Installing CRPI Optical Cables

Added the descriptions about the CPRI

optical fiber connection in sharing BBUs

with Macro Networks scenario.

Content

Change Description

Entire document

Added the RHUB that has no electrical

transmission port.

05 (2015-08-30)

Compared with 06 (2015-10-30), no information is deleted.

This is the sixth commercial release.

Compared with 05 (2015-08-30), this issue includes the following new topics:

9 Installing a pRRU3907 or pRRU3916

Compared with 05 (2015-08-30), no information is changed.

Compared with 05 (2015-08-30), no information is deleted.

This is the fifth commercial release.

04 (2015-07-30)

Compared with 04 (2015-07-30), no information is added.

Compared with 04 (2015-07-30), this issue incorporates the following changes

Compared with 04 (2015-07-30), no information is deleted.

This is the fourth commercial release.

Compared with 03 (2015-06-30), no information is added.

Compared with 03 (2015-06-30), this issue incorporates the following changes.

Compared with 03 (2015-06-30), no information is deleted.

DBS3900 LampSite

Installation Guide

1 Changes in DBS3900 LampSite Installation Guide

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

03 (2015-06-30)

Content

Change Description

Entire document

Added the descriptions about the DCU.

Content

Change Description

6.4.9 Installing Power Cable

Modified the RHUB configurations of

upper-level circuit breakers.

8.1.2 Installation Scenario

Deleted the minimum space requirements of

the pRRU3901.

8.1.3 Space Requirements

Deleted the minimum space requirements of

the pRRU3902.

8.3.2 Installing a pRRU on a Wall

Added the step about locking the protection

screw of pRRU3902.

8.3.3 Installing a pRRU on a Ceiling

8.3.5 Installing a pRRU on a Plate

8.3.6 Installing a pRRUon a Keel

Content

Change Description

02 (2015-05-08)

This is the third commercial release.

Compared with 02 (2015-05-08), this issue includes the following new topics:

5 Installing a DCU

Compared with 02 (2015-05-08), this issue incorporates the following changes:

Compared with 02 (2015-05-08), no information is deleted.

This is the second commercial release.

Compared with 01 (2015-03-23), no information is added.

Compared with 01 (2015-03-23), this issue incorporates the following changes:

Compared with 01 (2015-03-23), no information is deleted.

01 (2015-03-23)

This is the first commercial release.

Compared with draft B (2015-02-10), this issue includes the following new topics:

8 Installing a pRRU3902 or pRRU3911

Compared with draft B (2015-02-10), this issue incorporates the following changes:

DBS3900 LampSite

Installation Guide

1 Changes in DBS3900 LampSite Installation Guide

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

Content

Change Description

Entire document

Added the descriptions about the

pRRU3902.

Content

Change Description

6.1.1 Installation Scenarios

Added the descriptions about the RHUB

panel must not face upwards.

Content

Change Description

Entire document

The base station in the LampSite solution is

renamed DBS3900 LampSite.

Compared with draft B (2015-02-10), no information is deleted.

Draft B (2015-02-10)

This is a draft release.

Compared with draft A (2015-01-15), no information is added.

Compared with draft A (2015-01-15), this issue incorporates the following change:

Compared with draft A (2015-01-15), no information is deleted.

Draft A (2015-01-15)

This is a draft release.

Compared with Issue 08 (2014-12-30) of V100R009C00, no information is added.

Compared with Issue 08 (2014-12-30) of V100R009C00, this issue incorporates the following

change:

Compared with Issue 08 (2014-12-30) of V100R009C00, no information is deleted.

DBS3900 LampSite

Installation Guide

2 Installation Preparations

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

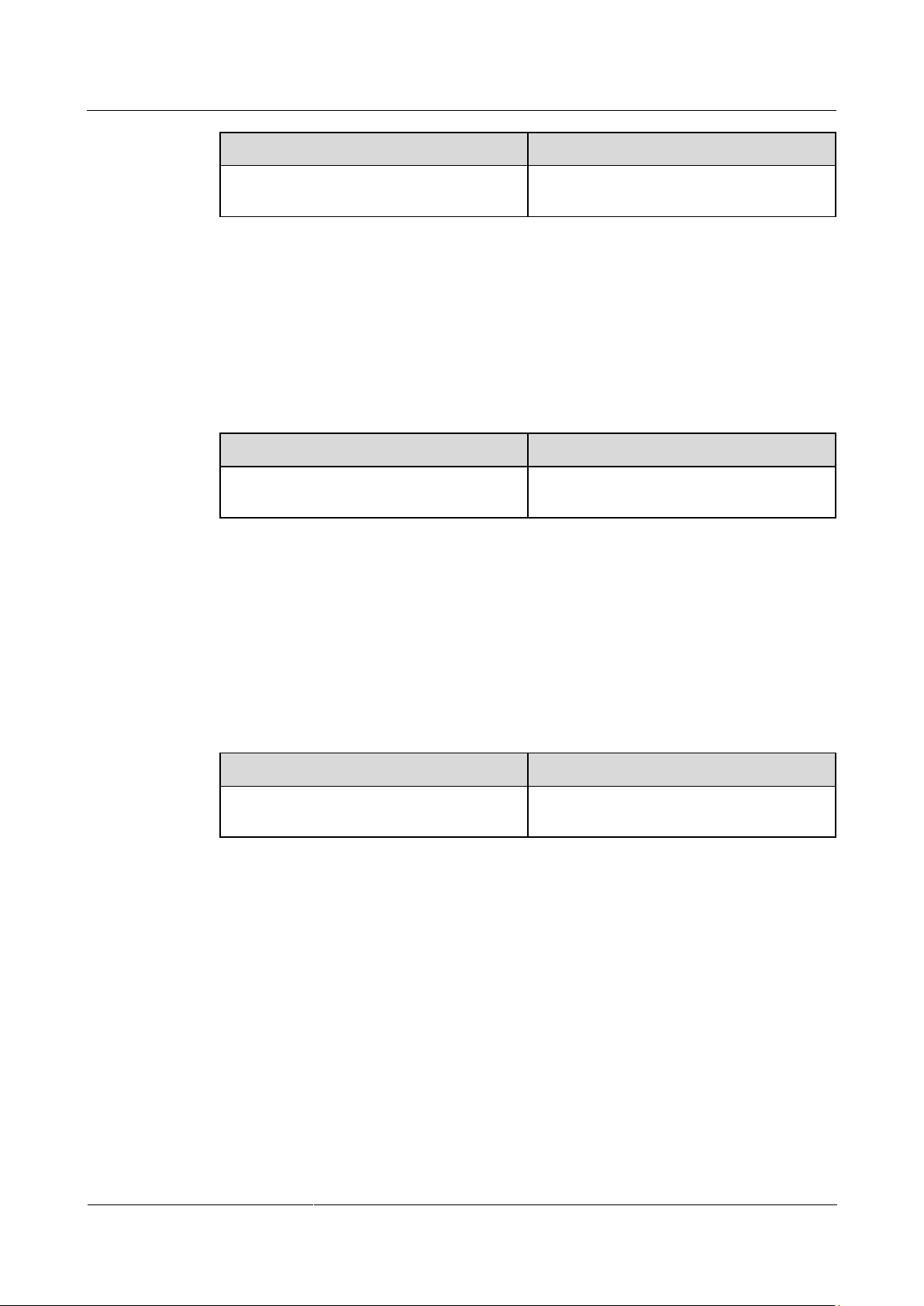

About This Chapter

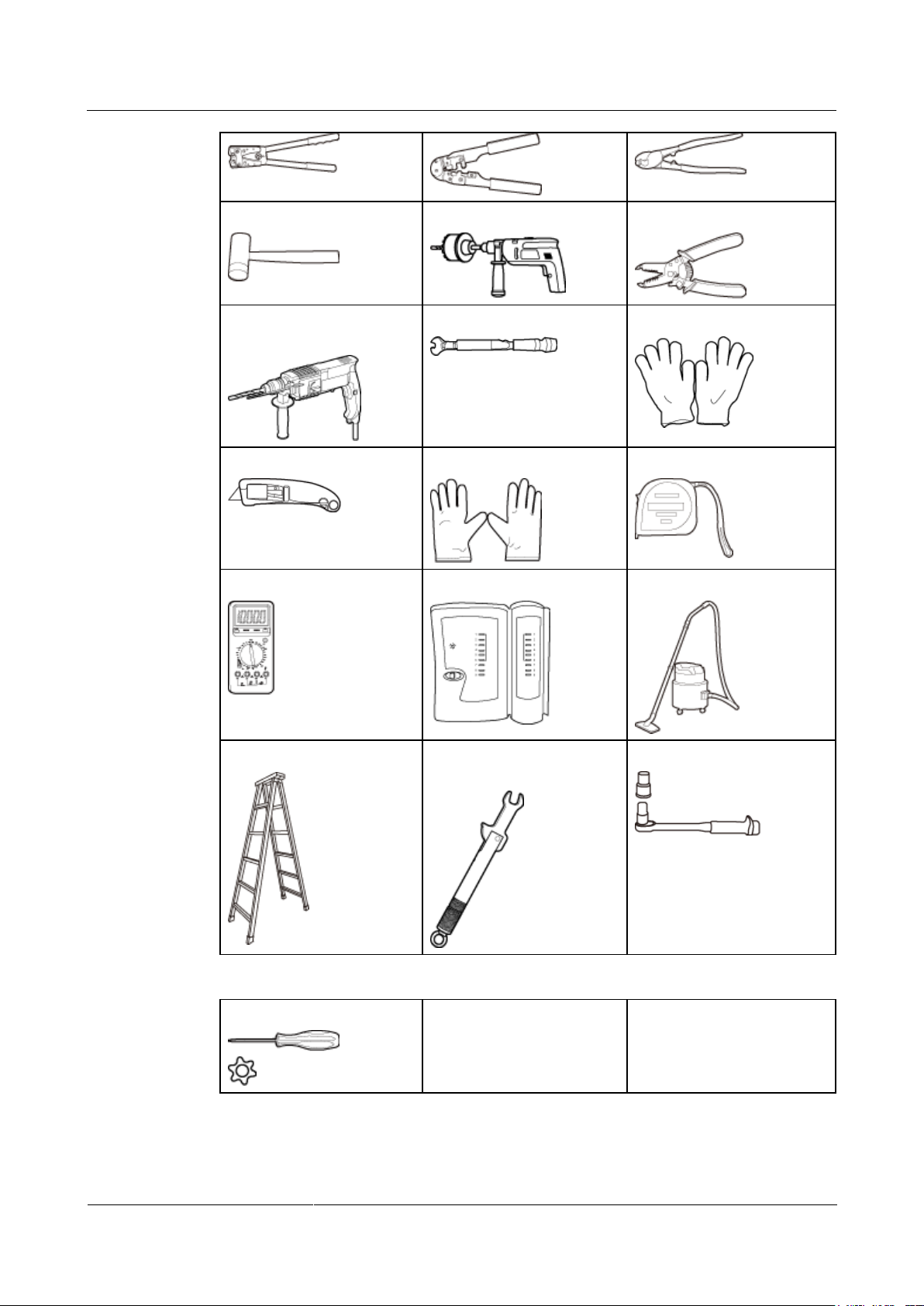

Marker

Level

Torque screwdriver

(M4 to M6)

Diagonal pliers

Power cable crimping tool

RJ11 crimping tool

Cable cutter

Before starting the installation, you must obtain the required reference documents, tools, and

instruments, and familiarize yourself with the skills required.

2.1 Reference Documents

Before the installation, you must read the following documents:

2 Installation Preparations

2.2 Preparing Tools and Instruments

This section describes the tools and instruments that must be prepared before the installation.

2.3 Requirements for Installation Personnel

This section describes requirements for installation engineers. They must be qualified and

trained, and familiar with correct operation methods and safety precautions before performing

any operations.

2.1 Reference Documents

Before the installation, you must read the following documents:

DBS3900 LampSite Hardware Description

Installation Reference

2.2 Preparing Tools and Instruments

This section describes the tools and instruments that must be prepared before the installation.

DBS3900 LampSite

Installation Guide

2 Installation Preparations

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

Rubber mallet

Crown saw (Ø60)

Wire stripper

Hammer drill (Ø6, Ø8 and

Ø12)

Torque wrench (Ø10 mm)

Protective gloves

Guarded blade utility knife

ESD gloves

Long measuring tape

Multimeter

Network cable tester

Vacuum cleaner

Ladder

Torque wrench for SMA

connector

Socket wrench (M6)

Hole screwdriver (T20)

–

-

DBS3900 LampSite

Installation Guide

2 Installation Preparations

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

2.3 Requirements for Installation Personnel

This section describes requirements for installation engineers. They must be qualified and

trained, and familiar with correct operation methods and safety precautions before performing

any operations.

Before the installation, pay attention to the following items:

Technical engineers must take Huawei training and be familiar with proper installation

and operation methods.

The number of installation personnel depends on the engineering schedule and

installation environment. Generally, three to five persons are required. Generally, only

three to five onsite personnel are necessary.

DBS3900 LampSite

Installation Guide

3 Unpacking and Checking

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

Context

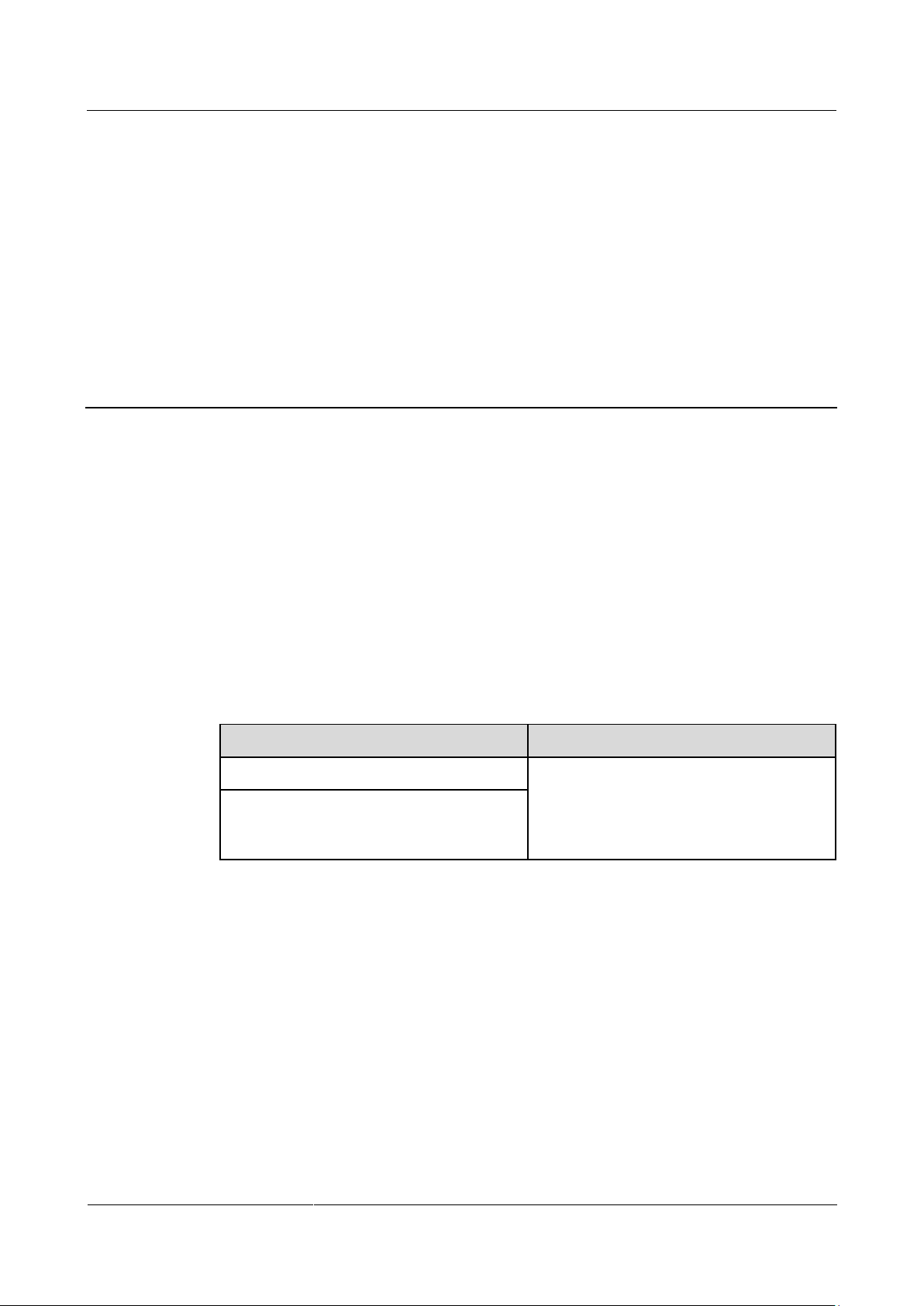

If...

Then...

The total number of the components is

consistent with that recorded in the

packing lists on all packing boxes

Go to Step 2.

The total number of the components is

inconsistent with that recorded in the

packing lists on all packing boxes

Report the problems and causes to the local

Huawei office.

If...

Then...

The exterior of each packing box is

intact

Go to Step 3.

3 Unpacking and Checking

This section describes how to unpack and check the delivered equipment to ensure that the

materials are complete and intact.

The following lists important notes when you are transporting, lifting, or installing the equipment or

components:

Protect them from colliding with doors, walls, shelves, or other objects.

Wear clean gloves and do not touch them with bare hands, sweat-soaked gloves, or dirty gloves.

Procedure

Step 1 Count the total number of the shipments.

Step 2 Check the exterior of each packing box.

You must power on the RHUB or pRRU within 7 days after it is unpacked.

DBS3900 LampSite

Installation Guide

3 Unpacking and Checking

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

If...

Then...

It is damaged or soaked

Report the problems and causes to the local

Huawei office.

The collision label is red

Do not unpack the packing box and claim

for compensation from the transportation

company.

Step 3 Check the type and quantity of the equipment in the boxes according to the packing list.

If...

Then...

The type and number are consistent

with the packing list on each packing

list

Sign the Packing List with the operator.

There is any shortage, wrong delivery,

or damaged equipment

Report the problems and causes to the local

Huawei office.

Perform the following operations to protect the components from any damages and help find

out the cause of any damage in future: 1. Store the unpacked equipment and packing materials

indoors. 2. Take photos of the storeroom, rusted or eroded equipment, packing box, and

packing materials. 3. File the photos.

----End

DBS3900 LampSite

Installation Guide

4 Installing a BBU

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

4 Installing a BBU

This chapter describes the process of installing a BBU.

For details about the installation of the BBU, see DBS3900 Installation Guide.

DBS3900 LampSite

Installation Guide

5 Installing a DCU

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

5 Installing a DCU

This chapter describes the process of installing a DCU.

For details about the installation of the DCU, see DCU3900 Installation Guide.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

About This Chapter

This chapter describes the process of installing an RHUB. RHUBs are classified into those

with electrical transmission ports and those with no electrical transmission ports. Unless

otherwise specified, this document uses the RHUBs with no electrical transmission ports as an

example.

6.1 Information About the Installation

6 Installing an RHUB

This section describes the information to be learnt before RHUB installation, including the

RHUB installation scenarios, clearance, and installation environment.

6.2 Installation Process

The RHUB installation involves installing an RHUB module, installing RHUB cables,

checking the RHUB hardware installation, and powering on the RHUB.

6.3 Installing an RHUB

An RHUB can be installed in a cabinet, rack, shelf, or on a wall.

6.4 Installing RHUB Cables

This section describes how to install cables for an RHUB.

6.5 Checking the RHUB Hardware Installation

After an RHUB is installed, check the installation of hardware including the devices and

related cables.

6.6 Power-on Check on an RHUB

This section describes the power-on check on the RHUB after the RHUB hardware is

installed and checked.

6.1 Information About the Installation

This section describes the information to be learnt before RHUB installation, including the

RHUB installation scenarios, clearance, and installation environment.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

6.1.1 Installation Scenarios

An RHUB can be installed in a 19-inch cabinet, rack, shelf, or on a wall.

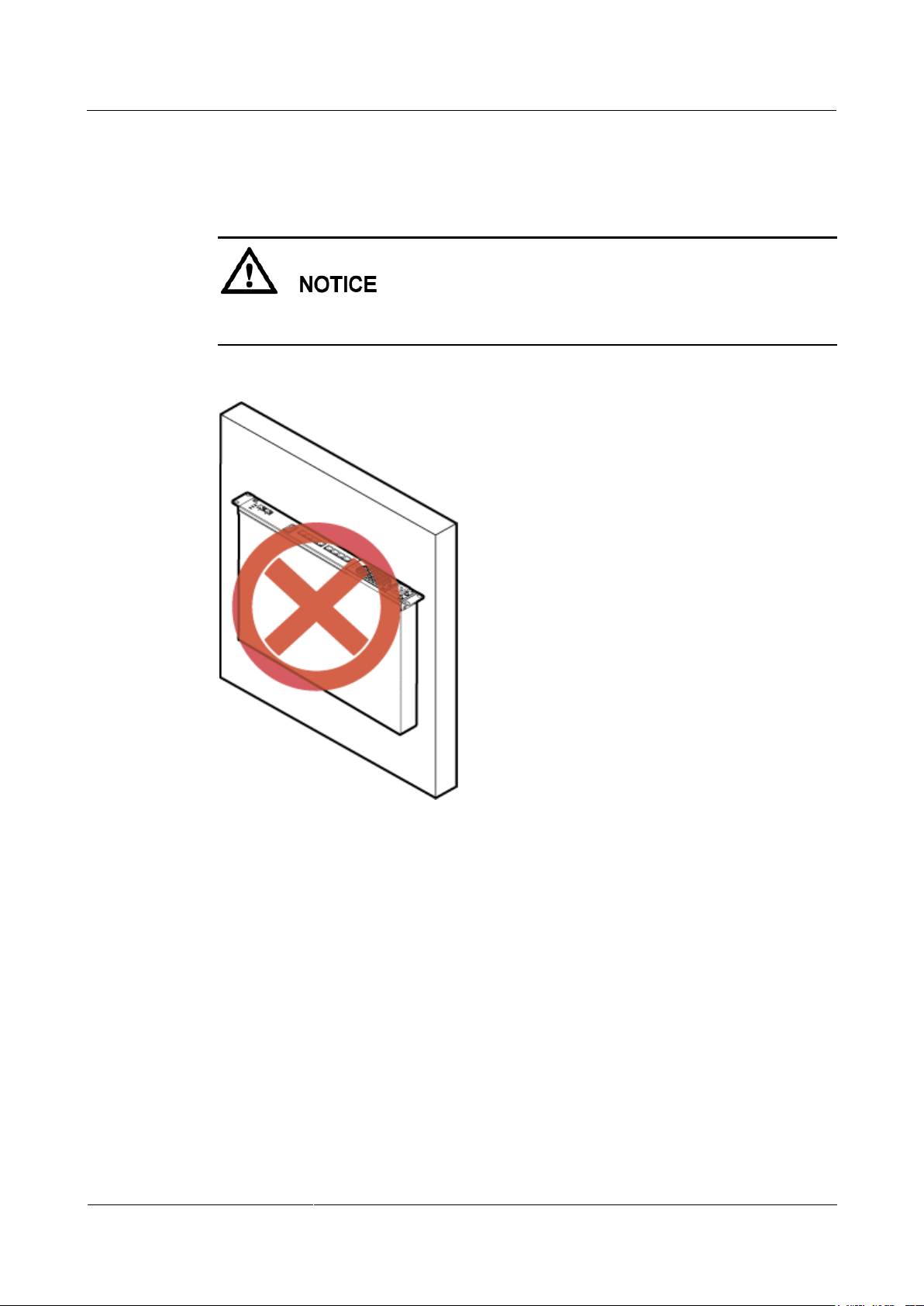

To prevent the RHUB from water drops, the RHUB panel must not face upwards (shown in

Figure 6-1) in any installation scenarios.

Figure 6-1 Improper installation mode

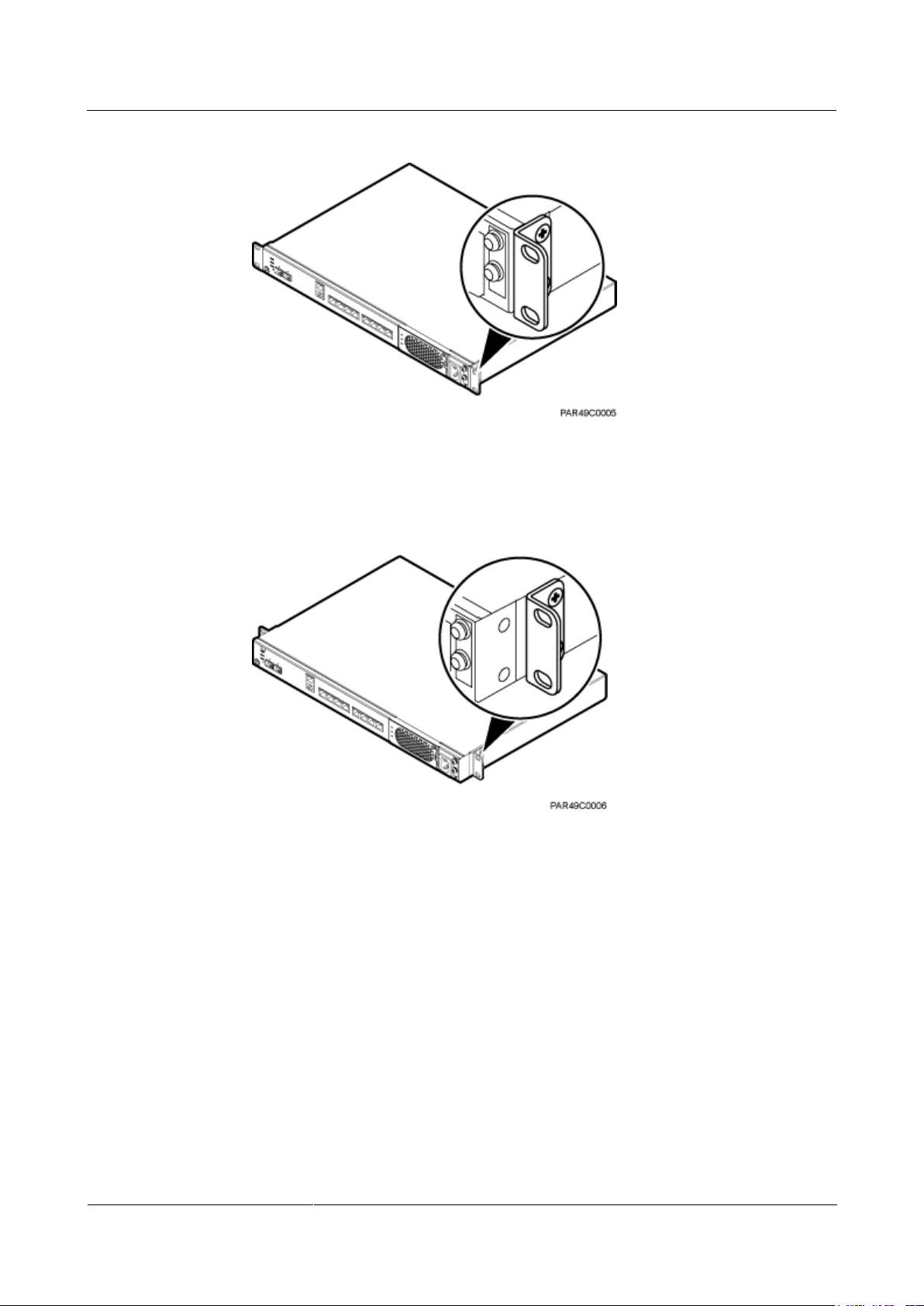

The RHUB mounting ears are installed in standard mode or reverse mode. The reverse mode

is used by default. The two installation modes are defined as follows:

In standard mode, the front of the mounting ear is aligned with the RHUB panel, as

shown in Figure 6-2.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

Figure 6-2 Installing mounting ears in standard mode

In reverse mode, the front of the mounting ear is 31 mm away from the RHUB panel, as

shown in Figure 6-3.

Figure 6-3 Installing mounting ears in reverse mode

Installing an RHUB in a 19-Inch Cabinet or Rack

Installing an RHUB in a 19-inch cabinet or rack: Secure the mounting ear to the mounting

bracket by using M6 screws.

If there are no other modules installed in the 1 U space near the RHUB, install the

RHUB directly. Otherwise, remove the modules before installing the RHUB.

Before installation, you need to check the installation mode supported by the rack and

adjust the position of the mounting ear.

Figure 6-4 and Figure 6-5 show RHUBs installed in a cabinet or rack, respectively.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

Figure 6-4 Installing an RHUB in a 19-inch cabinet or rack in standard mode

Figure 6-5 Installing an RHUB in a 19-inch cabinet in reverse mode

Installing an RHUB in a 19-Inch Shelf

When an RHUB is installed in a 19-inch shelf, the shelf must be installed on a wall. One shelf

can house multiple RHUBs with 1 U space between two RHUBs.

Figure 6-6 and Figure 6-7 show RHUBs installed in a 19-inch shelf.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

Figure 6-6 RHUB installed in a 19-inch shelf in standard mode

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

Figure 6-7 RHUB installed in a 19-inch shelf in reverse mode

Installing an RHUB on a Wall

An RHUB can be installed on a wall.

The wall on which an RHUB is installed must meet the following requirements:

When a single RHUB is installed, the wall must have a capacity of bearing at least four

times the weight of the RHUB.

Expansion bolts must be tightened to 10 N·m (88.507 bf·in.) to ensure the bolts work

properly and the wall remains intact without cracks in it.

Figure 6-8 shows an RHUB installed on a wall.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

Figure 6-8 RHUB installed on a wall

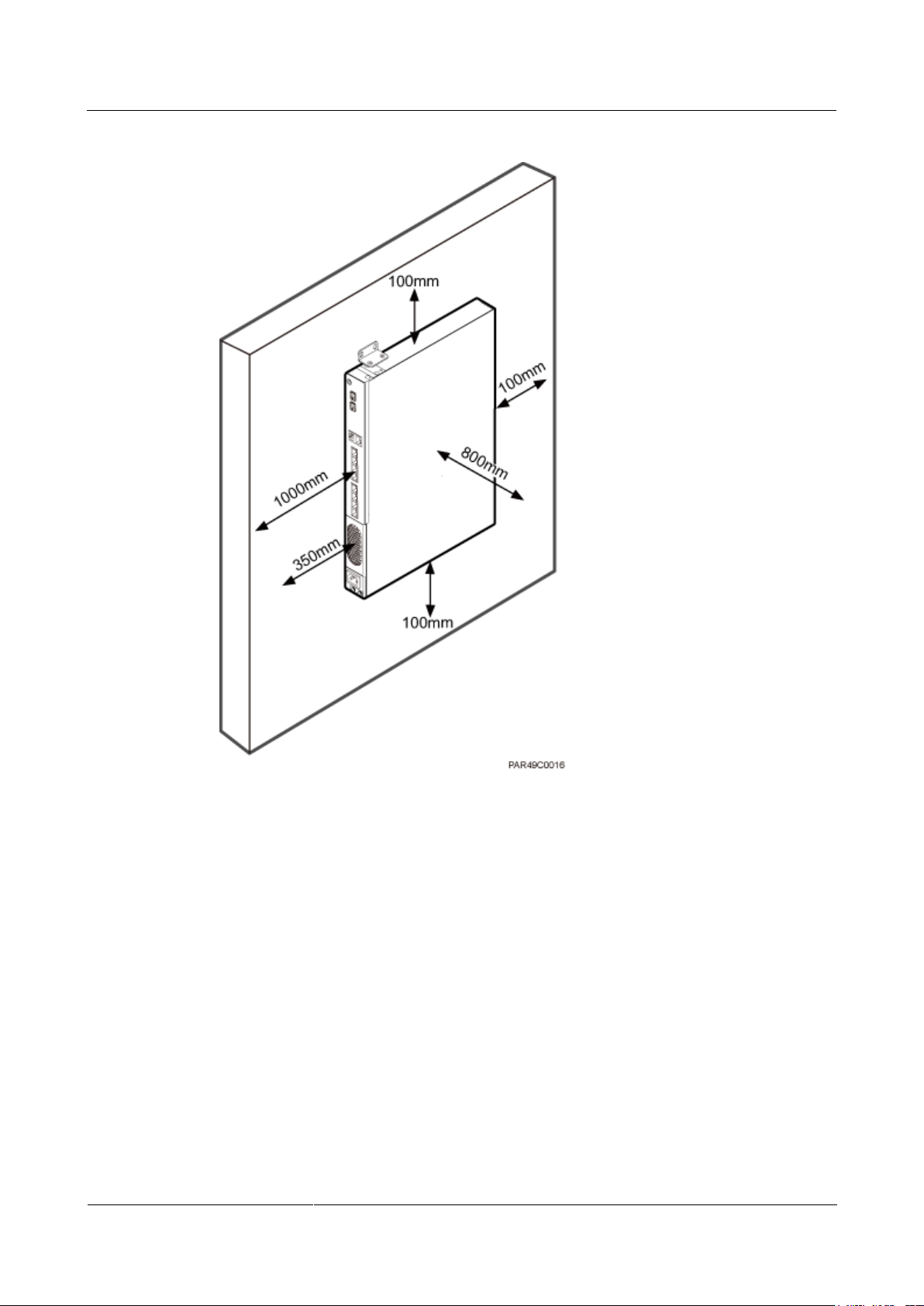

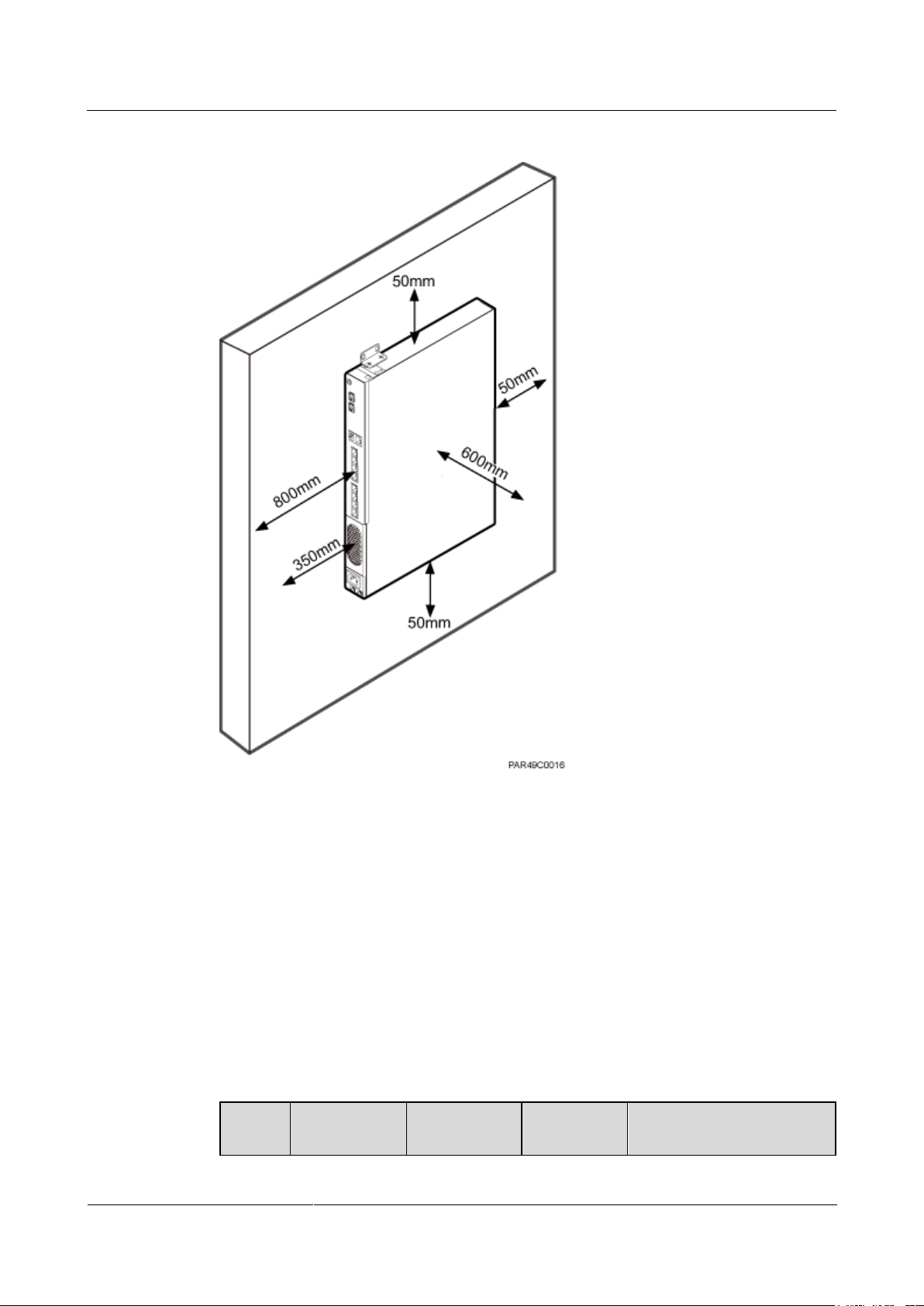

6.1.2 Installation Clearance Requirements

When an RHUB is installed in a 19-inch cabinet, rack, shelf, or on a wall, a minimum

clearance is required for easy cabling and operation and maintenance. A recommended

installation clearance is provided based on experience.

Do not install or place inflammable materials above or under an RHUB.

A clearance of 350 mm must be reserved in front of the air intake vent of the fan of the

power supply unit (PSU) for maintenance.

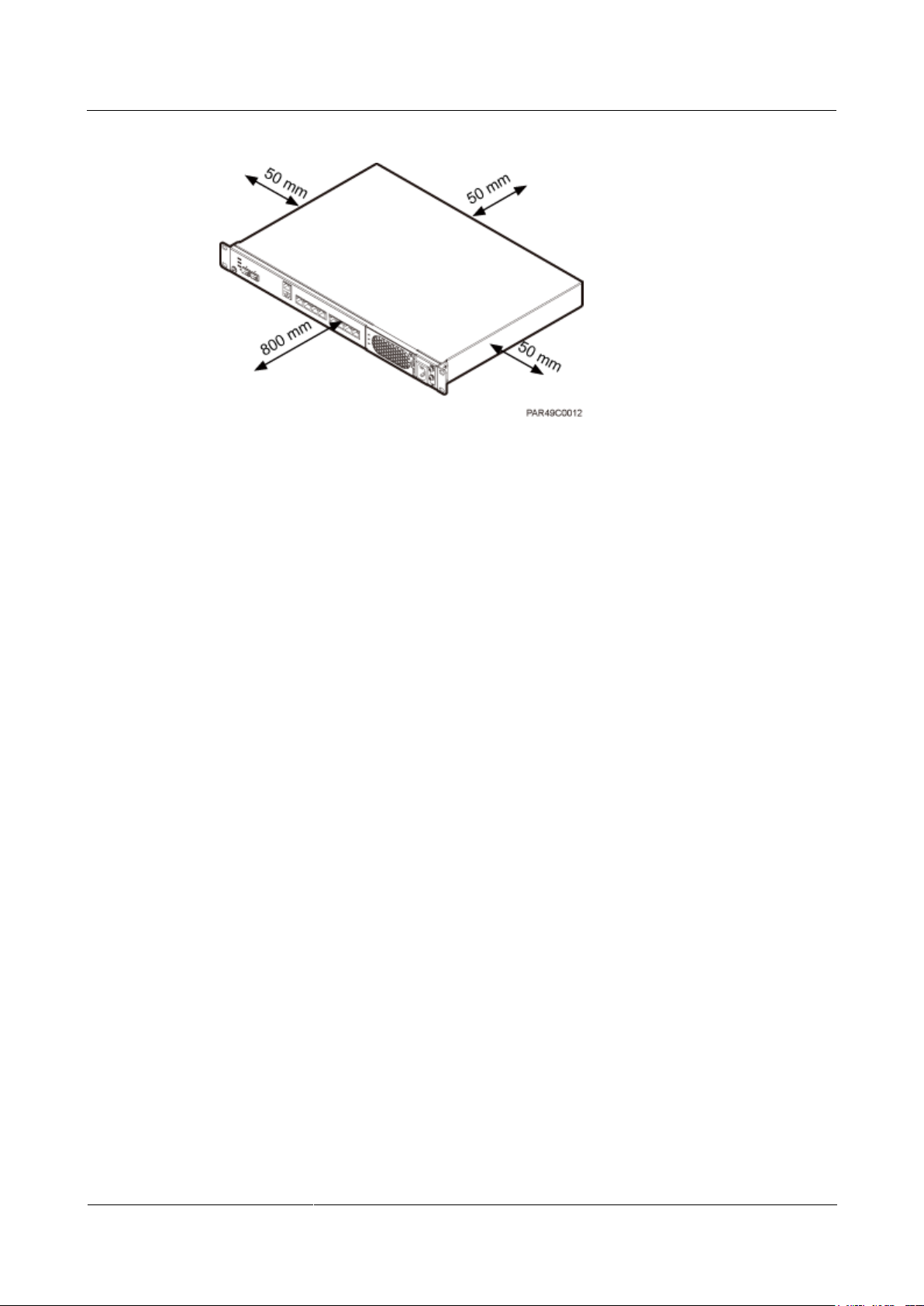

Figure 6-9 shows the installation clearance for the RHUB installed in a 19-inch cabinet, rack,

or shelf.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Figure 6-9 Installation clearance for an RHUB installed in a 19-inch cabinet, rack, or shelf

Figure 6-10 and Figure 6-11 shows the recommended and minimum installation clearance

respectively when the RHUB is installed on a wall.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Figure 6-10 Recommended installation clearance for a wall-mounted RHUB (unit: mm)

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

Figure 6-11 Minimum installation clearance for a wall-mounted RHUB (unit: mm)

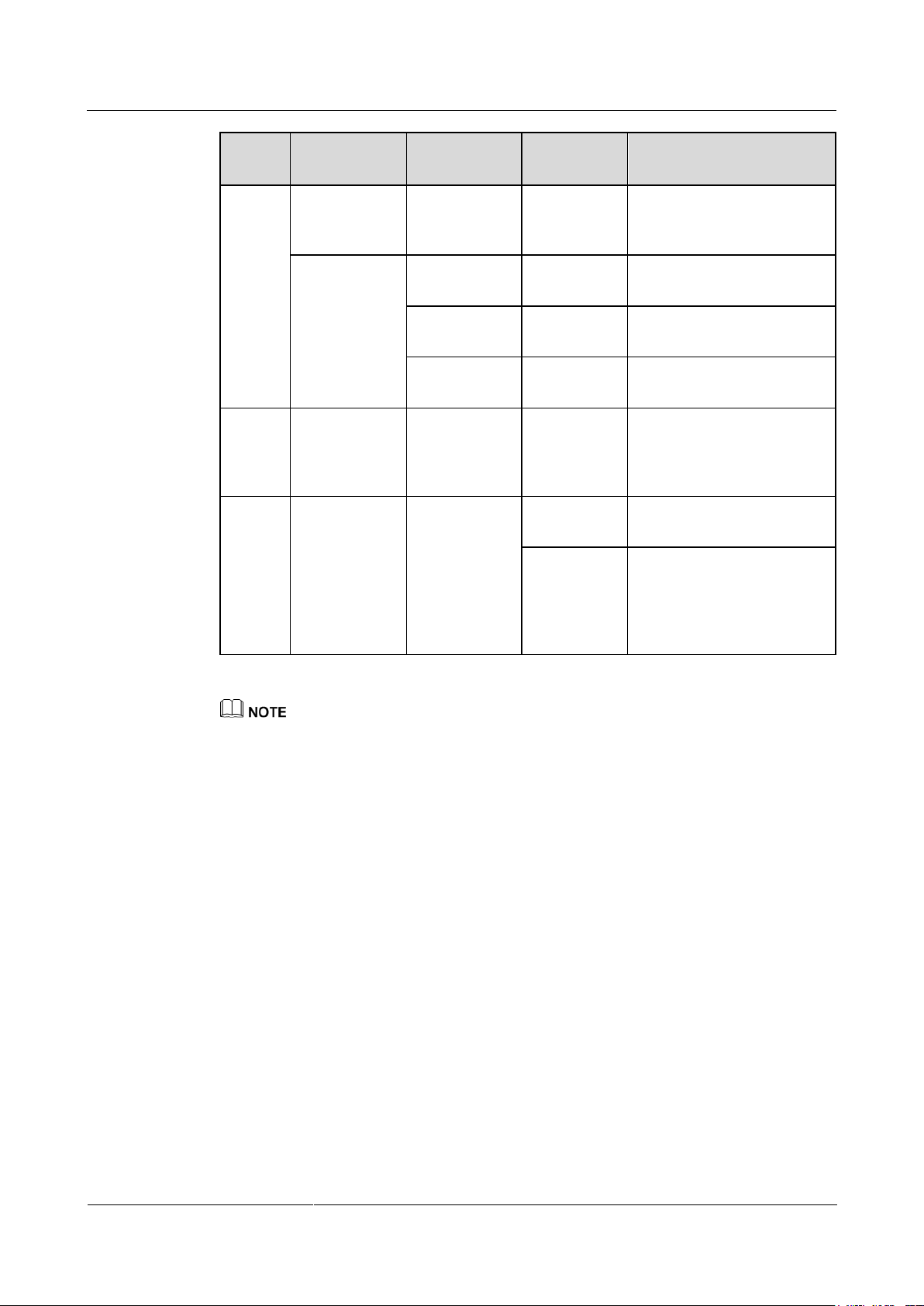

Specifi

cations

Installation

Scenario

RHUB

Quantity

Condition

Remarks

6.1.3 Installation Environment

The installation environment of an RHUB involves the running environment specifications for

the RHUB and other specifications.

RHUB Running Environment Specifications

Table 6-1 shows the environment specifications for the RHUB installed indoors.

The temperature and humidity of the installation position must ensure normal operation.

A cool and ventilated place is recommended.

The heat dissipation holes on the RHUB cannot be blocked.

Table 6-1 RHUB environment specifications

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Specifi

cations

Installation

Scenario

RHUB

Quantity

Condition

Remarks

Operati

ng

tempera

ture

Installed on a

wall or in a

19-inch rack.

N/A

-5°C to

+50°C

N/A

Installed in a

shelf.

1

-5°C to

+45°C

N/A

2

-5°C to

+43°C

N/A

3

-5°C to

+40°C

N/A

Relativ

e

humidit

y

Installed in all

scenarios.

N/A

5% RH to

95% RH

N/A

Altitude

N/A

N/A

-60 m to

+1800 m

Works properly.

1800 m to

4000 m

Above the 1800 m altitude,

the maximum operating

temperature decreases by

1°C each time the altitude

increases by 220 m.

Installing more than one RHUB, 1 U space is required between two RHUBs.

Other Running Environment Specifications

The RHUB cannot be installed at an air outlet of the heat dissipation box of an air

conditioner or other heat-generating appliances.

The RHUB cannot be installed near a strong heat source.

The RHUB cannot be installed in a position with water dripping, such as outdoor

equipment of air conditioners, pipe, and leaking or dripping roofs.

The installation position must be far from rains. If the RHUB is installed on a wall, there

must be no window on either side of the wall.

The installation position must be far away from high voltage, highly corrosive devices,

flammable or explosive substances, and electromagnetic interference such as power

stations, high-voltage substations, and wired TV towers.

The RHUB must be installed in a dry, ventilating, and dust-proof place.

If the RHUB is installed in parking areas or basements, the installation position must be

well-ventilated.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

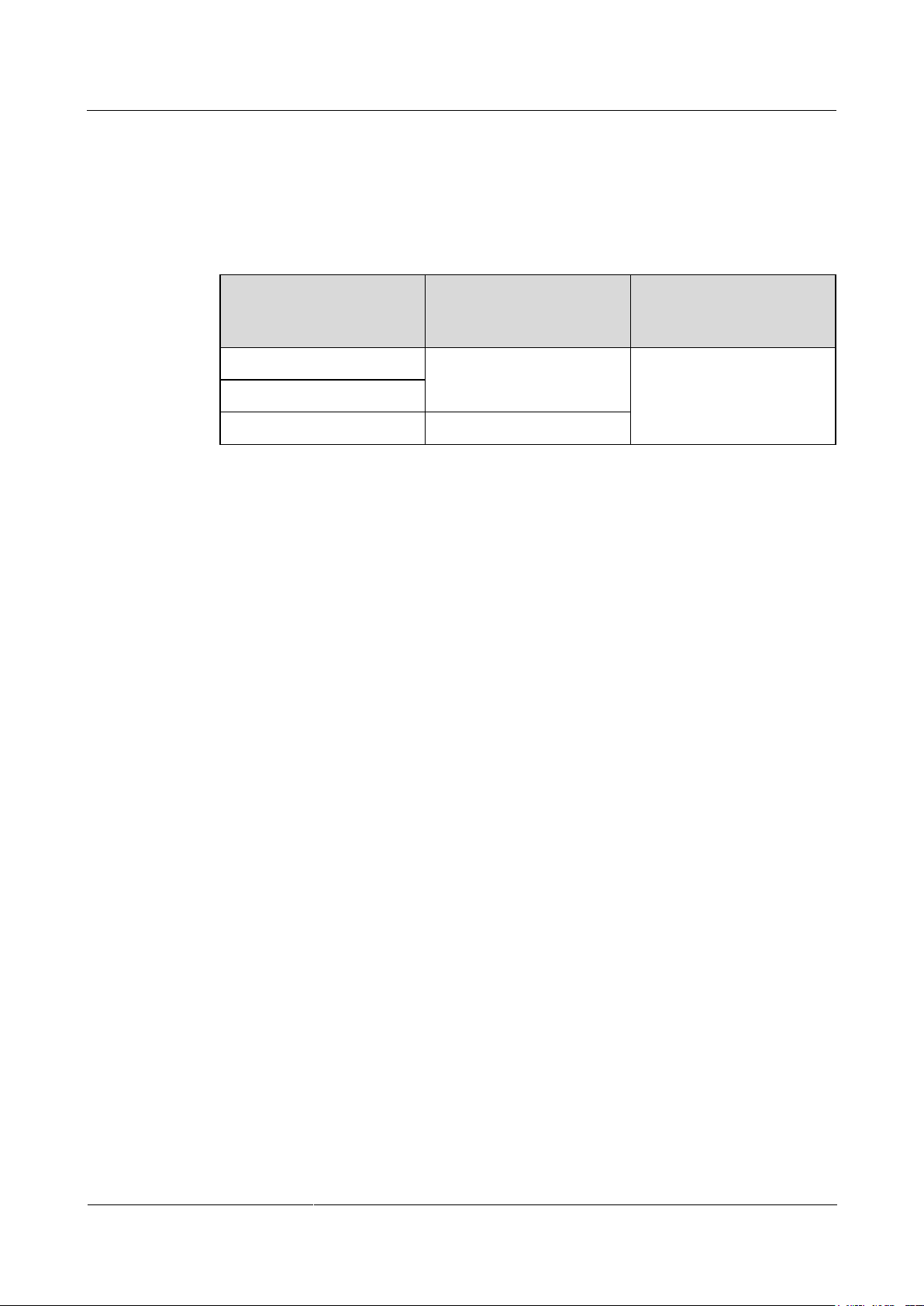

Requirements for the Upper-level Circuit Breaker

Power Supply

Upper-level AC Circuit

Breaker (For a single

RHUB)

Cross-Sectional Area of

the Input Power Cable

220 V AC single-phase

≥ 6 A

1.5 mm2

110 V AC dual-live-wire

110 V AC single-phase

≥ 12 A

Type C upper-level AC circuit breakers or slow-blow fuses must be used for power cables.

The maximum current must not exceed 16 A. Table 6-2 describes the recommended

specifications.

Table 6-2 Circuit breaker specifications for power cables

6.2 Installation Process

The RHUB installation involves installing an RHUB module, installing RHUB cables,

checking the RHUB hardware installation, and powering on the RHUB.

Figure 6-12 shows the RHUB installation process.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

Figure 6-12 RHUB installation process

6.3 Installing an RHUB

An RHUB can be installed in a cabinet, rack, shelf, or on a wall.

6.3.1 Installing an RHUB in a 19-Inch Cabinet or Rack

This section describes how to install an RHUB in a 19-inch cabinet.

Procedure

The following describes how to install an RHUB with mounting ears in reverse mode:

If necessary, request one more person for assistance.

a. With one hand holding it, align the mounting holes with the installation holes,

slowly push the RHUB into the required position in the cabinet, as shown in Figure

6-13.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

Figure 6-13 Pushing an RHUB into a cabinet

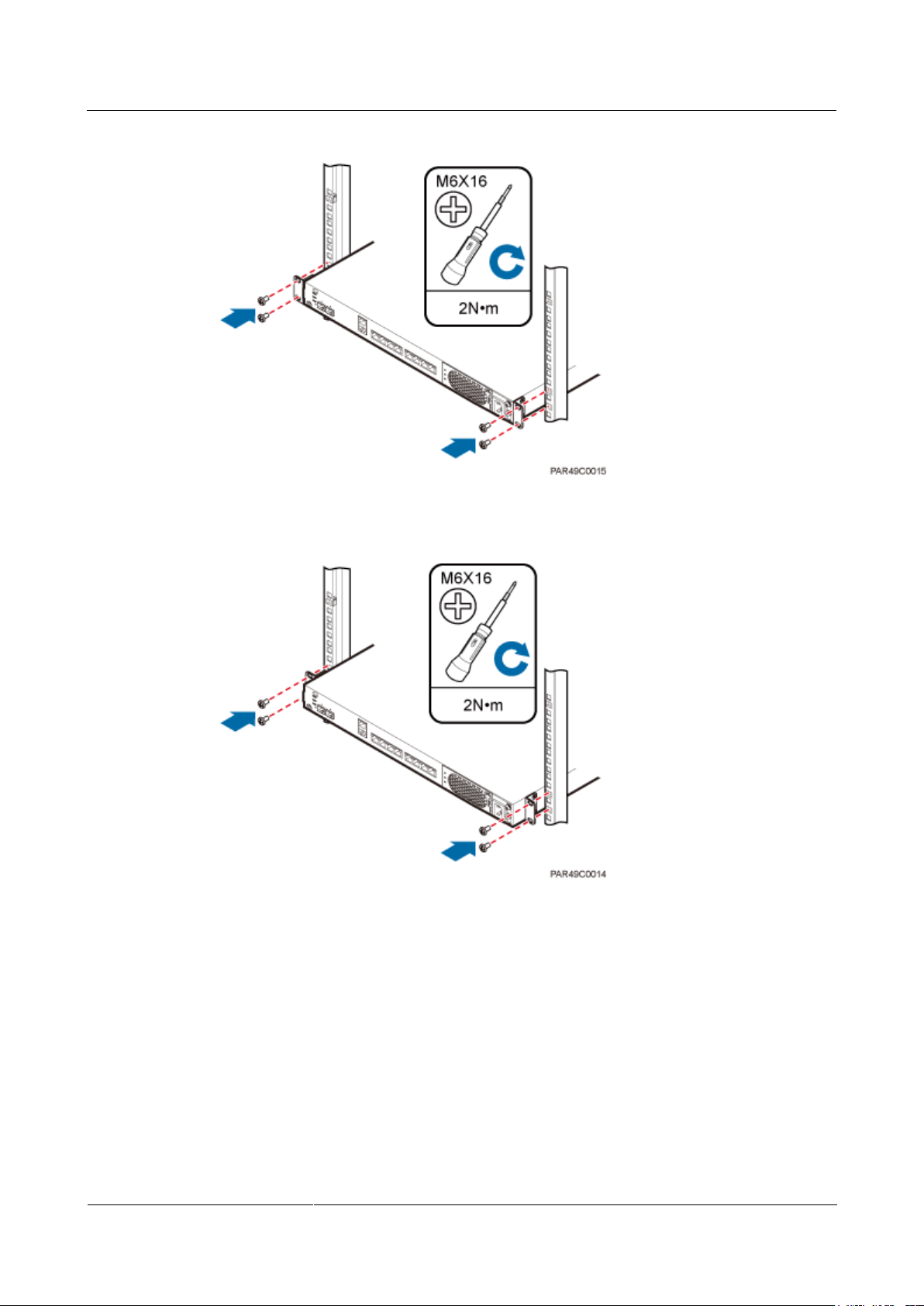

b. Use a torque screwdriver or Phillips screwdriver to tighten the four M6×16 screws

with a torque of 2 N•m, as shown in Figure 6-14.

Figure 6-14 Tightening screws

The following describes how to install an RHUB with mounting ears aligned with the

RHUB panel:

If necessary, request one more person for assistance.

a. Remove the mounting ears on both sides of the RHUB by removing the four M4×8

screws, as shown in Figure 6-15.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

Figure 6-15 Removing mounting ears and screws

b. Use a torque screwdriver or Phillips screwdriver to tighten the four M4×8 screws

with a torque of 1.4 N•m to install the removed mounting ears again, as shown in

Figure 6-16. The mounting ears must be aligned with the RHUB panel.

Figure 6-16 Installing mounting ears in standard mode

c. With one hand holding it, align the mounting holes with the installation holes,

slowly push the RHUB into the required position in the cabinet, as shown in Figure

6-17.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

Figure 6-17 Pushing an RHUB into a cabinet

d. Use a torque screwdriver or Phillips screwdriver to tighten the four M6×16 screws

with a torque of 2 N•m, as shown in Figure 6-18.

Figure 6-18 Tightening screws

----End

6.3.2 Installing an RHUB in a 19-Inch Shelf

If a shelf houses more than one RHUB, 1 U space is required between two RHUBs. The PSU

must be installed at the bottom of the cabinet.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

Procedure

The following describes how to install an RHUB with mounting ears installed in reverse

mode:

If necessary, request one more person for assistance.

a. With one hand holding it, align the mounting holes with the installation holes,

slowly push the RHUB into the required position in the shelf.

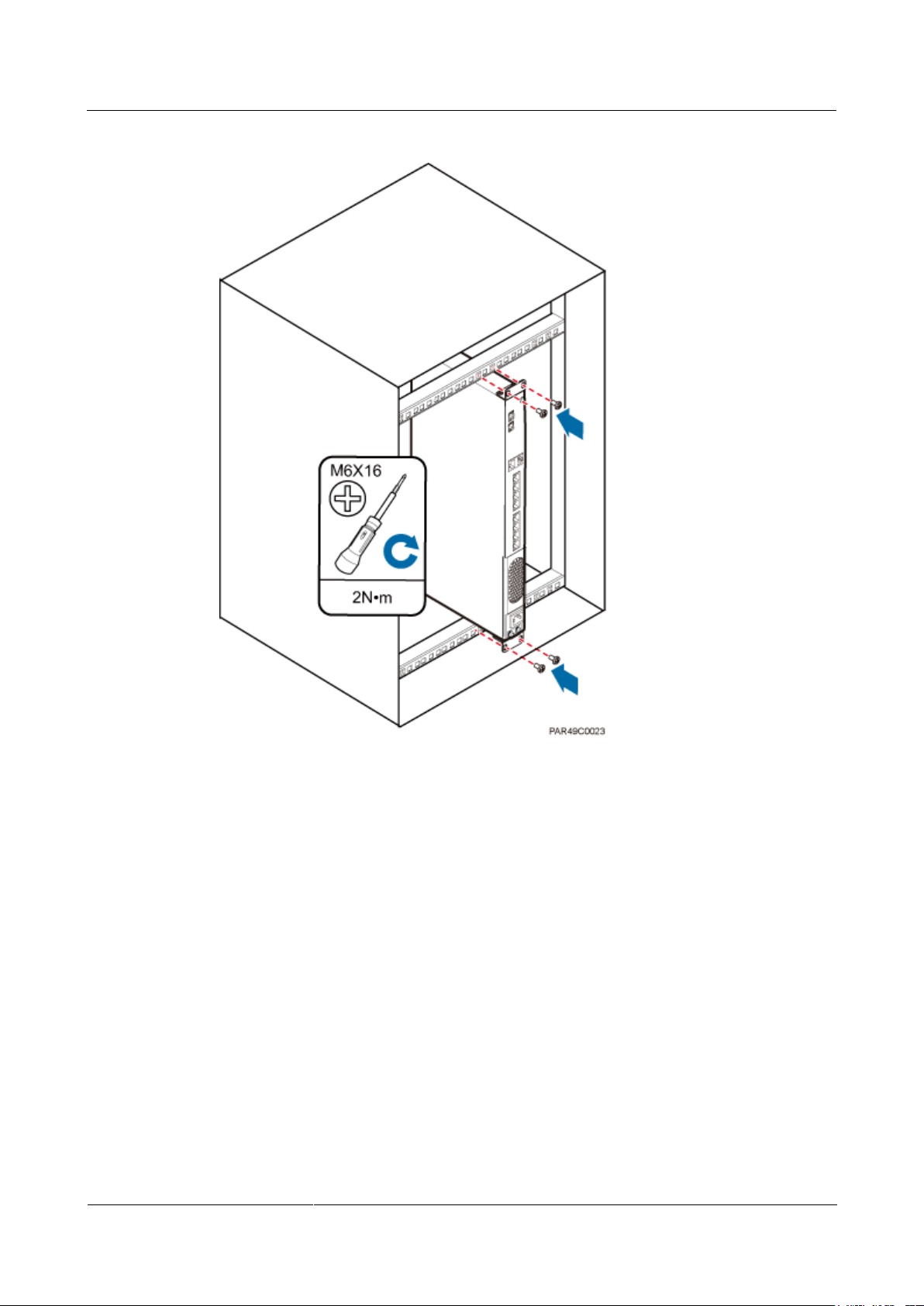

b. Use a torque screwdriver or Phillips screwdriver to tighten the four M6×16 screws

with a torque of 2 N•m, as shown in Figure 6-19.

Figure 6-19 Tightening screws

The following describes how to install an RHUB with mounting ears installed in

standard mode:

If necessary, request one more person for assistance.

a. Remove the mounting ears on both sides of the RHUB by removing the four M4×8

screws, as shown in Figure 6-20.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

Figure 6-20 Removing mounting ears and screws

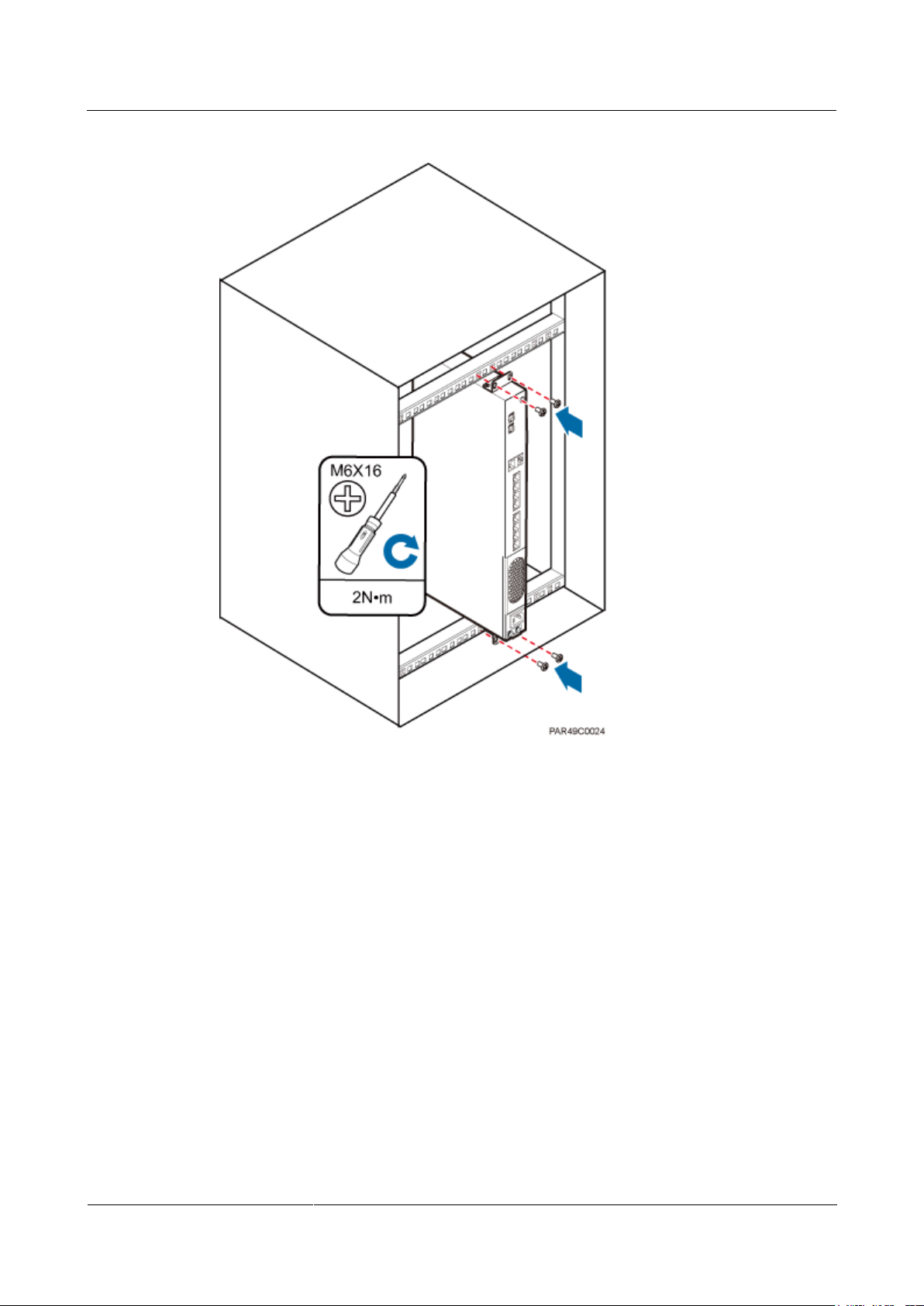

b. Use a torque screwdriver or Phillips screwdriver to tighten the four M4×8 screws

with a torque of 1.4 N•m to install the removed mounting ears again, as shown in

Figure 6-21. The mounting ears must be aligned with the RHUB panel.

Figure 6-21 Installing mounting ears in standard mode

c. With one hand holding it, align the mounting holes with the installation holes,

slowly push the RHUB into the required position in the cabinet, as shown in .

d. Use a torque screwdriver or Phillips screwdriver to tighten the four M6×16 screws

with a torque of 2 N•m, as shown in Figure 6-22.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

Figure 6-22 Tightening screws

----End

6.3.3 Installing an RHUB on a Wall

An RHUB can be installed on a wall.

Context

Suitable for mounting on concrete or other non-combustible surface only.

Procedure

Step 1 The mounting ears are installed in reverse mode by default. Before installing an RHUB on a

wall, modify the installation mode of the mounting ears on the RHUB.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

Use a torque screwdriver or Phillips screwdriver to remove the mounting ears on both

sides of the RHUB by removing the four M4×8 screws, as shown in Figure 6-23.

Figure 6-23 Removing screws and mounting ears

Rotate the mounting ears 90 degrees clockwise, and use a torque screwdriver or Phillips

screwdriver to secure the mounting ear with a torque of 1.4 N•m, as shown in Figure

6-24.

Figure 6-24 Installing mounting ears and screws

Step 2 Determine the position on the wall for installing the RHUB based on the requirements in the

engineering blueprint and 6.1.2 Installation Clearance Requirements. Place the RHUB to the

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

position to be installed against the wall, and then mark the four anchor points where the

(1) Level

(2) RHUB

(3) Wall

mounting ear screws are fastened using a marker, as shown in Figure 6-25.

Figure 6-25 Anchor points for installing an RHUB on a wall

To prevent inhalation or eye contact with dust, take adequate preventive measures when

drilling holes.

Step 3 Drill holes at the anchor point and install expansion bolts, as shown in Figure 6-26.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

Figure 6-26 Drilling holes and installing expansion bolts

(1) M6×60

expansion bolt

(2) Nut

(3) Spring

washer

(4) Flat washer

(5) Extension

tub

1. Use a hammer drill with bit 8 to drill holes with a diameter of 8 mm and a depth of 45

mm to 50 mm at the marked anchor points. All the holes have the same depth.

2. Use a vacuum cleaner to clear the dust inside and around each hole. If the distance

between two holes is incorrect, mark and drill holes again.

3. Partially tighten an expansion bolt and place it vertically into each hole.

4. Use a rubber mallet to hit the expansion bolt until the entire expansion sleeve is in the

hole.

5. Remove the M6×60 bolt, nut, spring washer, and flat washer from each expansion bolt in

sequence.

After removing an expansion bolt, ensure that the top of the expansion sleeve is level with the

wall. If it is not level, the RHUB cannot be installed on the concrete floor evenly and securely.

Step 4 Align the mounting holes with the four M6×60 expansion bolts. Install spring washer 6 and

flat washer 6 in sequence on each M6×60 expansion bolt, insert the bolts to each expansion

tub, and then use a torque wrench or socket wrench to tighten the four M6×60 bolts with a

torque of 5 N•m to secure the RHUB to the wall, as shown in Figure 6-27.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

Figure 6-27 Installing an RHUB on a wall

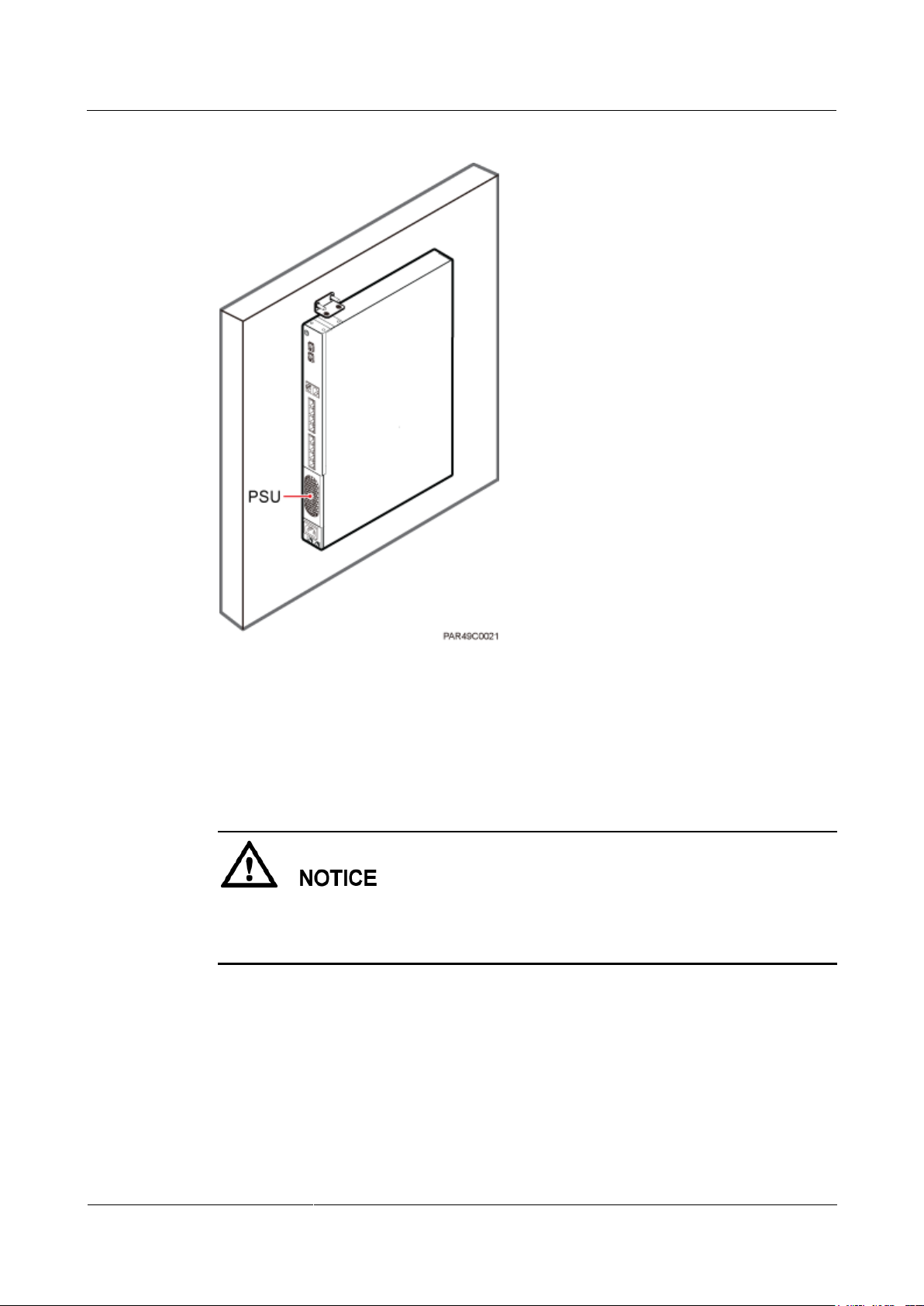

As shown in the preceding figure, when the RHUB is placed against the wall, ensure that the RHUB

panel is vertical to the ground and the PSU is on the lower part of the RHUB panel.

----End

6.4 Installing RHUB Cables

This section describes how to install cables for an RHUB.

6.4.1 Requirements for Cable Layout

Cables must be routed according to the specified cabling requirements to prevent signal

interference.

If a cable listed below is not required, skip the requirements for routing the cable.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

General Requirements for Cable Layout

National Standards

Code for Engineering Design of Generic Cabling System for Building and Campus (GB

50311-2007)

Code for Engineering Acceptance of Generic Cabling System for Building and Campus

(GB50312-2007).

Security Protection Engineering Technology Specifications (GB 50348-2004)

Code for Construction and Acceptance of the Electronic Information System Room (GB

50462-2008)

Code for Quality Acceptance of the Intelligent Building Engineering (GB 50339-2003)

Code for Quality Acceptance of Electric Engineering Construction in Building (GB

50303-2002)

Technical Specification for Construction and Acceptance of Telecommunication Conduit

Engineering (GB 50374-2006)

International Standards

Generic Cabling for Customer Premises (ISO/IEC 11801)

Commercial Building Telecommunications Cabling Standard (EIA/TIA 568)

Commercial Building Standard for Telecommunication Pathways and Spaces (EIA/TIA

569)

Administration Standard for Commercial Telecommunications Infrastructure (EIA/TIA

606)

Grounding and Bonding Requirements for Telecommunications in Commercial

Buildings (EIA/TIA 607)

Generic Cabling Systems for Information Technology (EN 50173)

Cabling Installation for Information Technology (EN 50174)

Bending radius

The bending radius of a power cable or a protection ground (PGND) cable is at least five

times the diameter of the cable.

The bending radius of an optical cable is at least 20 times the diameter of the optical

cable, and the minimum bending radius of the branch at each end of the optical cable is

30 mm.

The bending radius of the signal cable must be at least five times the diameter of the

cable.

Cable Binding

Cables of the same type are bound together.

Different types of cables must be separately routed with a minimum spacing of 30 mm

and cannot be entangled or crossed.

The cables are bound tightly and neatly and the cable sheath is intact.

The cable ties face the same direction and all cable ties bound at similar positions must

be in a straight line.

The extra length of each indoor cable tie must be cut off. A slack of 5 mm is reserved for

each outdoor cable tie. All cut surfaces have no sharp edges.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

Labels or nameplates are attached to both ends, joints, or turns of cables after they are

installed.

Safety

The steel pipe or fire-resistant rigid polyvinyl chloride pipe should be used for the cable

duct or for routing cables. The cross-sectional usage of the cable duct should be 30% to

50% and that of the pipe for routing cables should be 25% to 30%.

Cables are placed away from sharp objects or wall burrs. If these positions are inevitable,

protection pipes are required for the cables.

Cables are routed away from heat sources, or heat-insulation materials are added

between cables and heat sources.

Cables are routed away the cooling vents of the RHUB.

A clearance is reserved at turns of a cable or the position close to a device, facilitating

cable and device maintenance. The recommended clearance is about 0.1 m.

Requirements for Special Cables

Ethernet Cable

A maximum of 100 Ethernet cables can be bundled if no PVC pipes are used. If pipes are

used, a maximum of 24 Ethernet cables can be led through a pipe. In this case, ensure

that 1/3 space inside the pipes must be vacant.

The point at which an Ethernet cable is bundled must be spaced 400 mm or less from the

Ethernet port on an RHUB.

For the RHUB used in the elevator engine room on the rooftop, generator set for the

subway engine, and equipment room with central air conditioning, Ethernet cables must

be led through metallic conduits that are reliably grounded at both ends.

Power cable

Positions for routing power cables meet requirements of the engineering design.

Cables are routed only by qualified and trained personnel before all preparations are

made.

Cables are routed in an untangled and orderly fashion.

PGND cable

PGND cables are buried in the ground or routed indoors. They cannot be routed

overhead before they are routed into the equipment room.

Outer conductors of coaxial cables and both ends of the shield layers on shielded cables

are in proper electrical contact with the metal surface of the equipment to which they are

connected.

PGND cables and signal cables are installed in an untangled and orderly fashion. A

certain distance is reserved between them to prevent interference from each other.

Fuses or switches are not allowed on PGND cables.

Other devices cannot be used for electrical connections of PGND cables.

All the metal parts in the equipment are reliably connected to the ground terminal.

Optical cable

Cables are routed in an untangled and orderly fashion.

Optical fibers cannot be bound at turns.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

Cable

One End

The Other End

Connector

Installation

Position

Connector

Installation

Position

BBU PGND

Cable

OT terminal

(M4, 6 mm2 or

0.009 in.2)

Ground

terminal on the

BBU

OT terminal

(M8, 6 mm2 or

0.009 in.2)

External

ground bar

BBU Power

Cable

3V3 connector

-48V port on

UPEU in BBU

Depending on

the power

equipment

Depending on

the power

equipment

E1/T1 Cable

DB26 male

connector

E1/T1 port on

the UMPT,

GTMU, UELP,

WMPT, or

UTRP in the

BBU

Depending on

site

requirements

External

transmission

equipment

E1/T1 Surge

DB26 male

E1/T1 port on

DB25

INSIDE port

6.4.2 Cable List

The DBS3900 LampSite cable list includes BBU cable list, DCU cable list, RHUB cable list,

pRRU cable list.

Optical fibers cannot be stretched with too much force or stepped on, and they are far

away from sharp objects. Heavy objects cannot be placed on optical cables.

When optical cables are routed, the extra length of the cables is coiled around special

devices, such as a fiber coiler.

Even strength is applied when optical cables are coiled and optical cables cannot be bent

in a forcible manner.

Vacant optical connectors are covered with dust-proof caps.

Fiber optic cables cannot be squeezed by the cabinet door when routed through the

cabinet.

If optical cables need to be routed on the tower platform, the optical cables are routed

along the inner side of the guard rail and the distance between the guard rail and the

cable is the shortest one.

If optical cables need to be routed close to a device on the tower, the optical cables are

secured to the guard rail or pole with cable clips and the device cannot be far away from

the position for securing the optical cables.

If the optical cable close to a device on the tower is too long, the optical cables are

wrapped and secured to the tower.

BBU Cable List

The following table lists BBU3900 cables and BBU3910 cables.

Table 6-3 BBU3900&BBU3910 cable list

Except the CPRI fiber optic cable, for details about the cables exterior and related description in Table

6-3 and Table 6-4, see 3900 Series Base Station Cables.

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

Cable

One End

The Other End

Connector

Installation

Position

Connector

Installation

Position

Protection

Transfer Cable

connector

the UMPT,

GTMU, UELP,

WMPT, or

UTRP in the

BBU

connector

on the UELP in

the SLPU

FE/GE Ethernet

Cable

RJ45 connector

FE0 port

near

OUTSIDE

on the

UFLP in the

BBU

FE0 port on

the UMPT,

GTMU, or

WMPT in

the BBU

FE/GE port

on the

UTRP in

the BBU

FE/GE port

on the

LMPT in

the BBU

RJ45 connector

External

transmission

equipment

FE/GE Surge

Protection

Transfer Cable

RJ45 connector

FE0 port on the

UMPT,

GTMU, or

WMPT in the

BBU

FE/GE port on

the UTRP in

the BBU

RJ45 connector

FE0 port near

INSIDE on the

UFLP in the

SLPU

Interconnection

Cable Between

FE/GE Electrical

Ports

RJ45 connector

FE0 port on the

WMPT in the

BBU

RJ45 connector

FE0 port on the

GTMU in the

BBU

Interconnection

Cable Between

FE/GE Optical

Ports

LC connector

FE1 port on the

WMPT in the

BBU

LC connector

FE1 port on the

GTMU in the

BBU

FE/GE Fiber

Optic Cable

LC connector

FE1 port on the

WMPT,

GTMU,

LMPT, or

UMPT in the

FC, SC, or LC

connector

External

transmission

equipment

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

Cable

One End

The Other End

Connector

Installation

Position

Connector

Installation

Position

BBU

CPRI Optical

Fiber

DLC connector

CPRI port on

the GTMU,

WBBP, LBBP,

or UBRI in the

BBU

DLC connector

CPRI_W port

on an RRU

APMI-BBU

Monitoring Signal

Cable

RJ45 connector

MON1 port on

the UPEU or

UEIU in the

BBU

Twisted pair

TX+, TX-,

RX+, or RXport on the

APMI

HEUA-BBU

Monitoring Signal

Cable

RJ45 connector

M0N1 port on

the UPEU or

UEIU in the

BBU

RJ45 connector

COM_IN port

on the HEUA

CMUA-BBU

Monitoring Signal

Cable

RJ45 connector

M0N1 port on

the UPEU or

UEIU in the

BBU

RJ45 connector

COM_IN port

on the CMUA

CMUE-BBU

Monitoring Signal

Cable

RJ45 connector

M0N1 port on

the UPEU or

UEIU in the

BBU

RJ45 connector

COM_IN port

on the CMUE

CMUEA-BBU

Monitoring Signal

Cable

RJ45 connector

M0N1 port on

the UPEU or

UEIU in the

BBU

RJ45 connector

COM_IN port

on the

CMUEA

EMUA/EMUB

Monitoring Signal

Cable

RJ45 connector

M0N1 port on

the UPEU or

UEIU in the

BBU

DB9 male

connector

RS-485 port on

the EMUA

PSU

(EPW25-24S48D

) Monitoring

Signal Cable

RJ45 connector

EXT_ALM0

port on the

UPEU or

UEIU in the

BBU

Cord end

terminal

ALM terminal

on the PSU

(DC/DC)

PSU

(EPW25-24S48D

) In-Position

Signal Cable

RJ45 connector

EXT_ALM0

port on the

UPEU or

UEIU in the

BBU

RJ45 connector

RESENT port

on the PSU

(DC/DC)

BBU Alarm

Cable

RJ45 connector

EXT_ALM0

port on the

UPEU or

RJ45 connector

External alarm

device

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

Cable

One End

The Other End

Connector

Installation

Position

Connector

Installation

Position

UEIU in the

BBU

GPS Clock Signal

Cable

SMA male

connector

GPS port on

LMPT, USCU,

or UMPTa6 in

the BBU

Type N female

connector

GPS surge

protector

BBU

Interconnection

Signal Cables

DLC connector

M0 to M4 ports

on the UCIU in

the BBU

DLC connector

CI port on the

UMPT in the

BBU

Cable Between

Two Combined

Base Stations

DB15 male

connector

GCK port on

the UCIU in

the BBU

MD36 or

DB15 male

connector

DCTB or

DGLUb

Adapter Used for

Local

Maintenance

USBa

connector

USBa port on

the UMPT in

the BBU

Network

connector

Ethernet cable

Cable

One End

The Other End

Connector

Installation

Position

Connector

Installation

Position

PGND cable for

the BBU3910A

OT terminal

(M6, 16 mm2 or

0.025 in.2)

Ground

terminal on the

BBU3910A

OT terminal

(M8, 16 mm2 or

0.025 in.2)

Ground

terminal on the

ground bar

Power cable for

the BBU3910A

EPC4 connector

NEG(-) and

RTN(+) ports

on the

BBU3910A

Depending on

the power

equipment

Depending on

the power

equipment

Dry contact

alarm cable for

the BBU3910A

DB15

waterproof

male connector

(waterproof on

the connector's

both sides)

EXT_ALM port

on the

BBU3910A

Cord end

terminal

Equipment to

be monitored

RS485 alarm

cable for the

DB15

waterproof

EXT_ALM port

on the

RJ45 connector

COM_IN port

on the

a: The security of the USB port is ensured by encryption, and the USB port can be shut down using

commands. The USB commission port is used for commissioning the base station rather than

configuring and exporting information of the base station.

The following table lists BBU3910A cables.

Table 6-4 BBU3910A cable list

DBS3900 LampSite

Installation Guide

6 Installing an RHUB

Issue 08 (2016-05-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

Cable

One End

The Other End

Connector

Installation

Position

Connector

Installation

Position

BBU3910A

male connector

(waterproof on

the connector's

both sides)

BBU3910A

OPM50M

CPRI Optical

Fiber

DLC connector

CPRI port on

the BBU3910A

DLC connector

CPRI_W port

on an RRU

FE/GE fiber

optic cable

LC connector

GE1 port on the

BBU3910A

LC, FC, or SC

connector

External

transmission

equipment

FE/GE Ethernet

cable

RJ45 connector

GE0 port on the

BBU3910A

RJ45 connector

External

transmission

equipment

E1/T1 cable

DB26

waterproof

male connector

E1/T1 port on

the BBU3910A

Depending on

site

requirements

External

transmission

equipment

Cable

One End

The Other End

Connector

Connected

to...

Connector

Connected to...

PGND cable

OT terminal

(M4, 6 mm2

[0.009 in.2])

Ground screws

on the RHUB

OT terminal

(M6, 6 mm2

[0.009 in.2])

Ground terminal

on the external

ground bar

Power

Supply Cable