Page 1

eBIMS

V100R001C00

Product Description

Issue

01

Date

2013-04-30

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2013. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://www.huawei.com

Email:

support@huawei.com

Page 3

eBIMS

Product Description

About This Document

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

Intended Audience

Symbol

Remarks

Indicates a hazard with a high level of risk that, if not

avoided, could result in death or serious injury.

Indicates a hazard with a medium or low level of risk

that, if not avoided, could result in minor or moderate

injury.

Indicates a potentially hazardous situation that, if not

avoided, could cause equipment damage, data loss, and

performance degradation, or unexpected results.

Provides a tip that may help you solve a problem or save

time.

Provides additional information to emphasize or

supplement important points of the main text.

This document is intended for:

Sales specialist

Technical support personnel

Maintenance personnel

Symbol Conventions

About This Document

The symbols that may be found in this document are defined as follows.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in previous issues.

Page 4

eBIMS

Product Description

About This Document

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Issue 01 (2013-04-30)

This issue is the first official release.

Page 5

eBIMS

Product Description

Contents

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document .................................................................................................................... ii

1 Positioning and Characteristics .................................................................................................. 1

1.1 Positioning .................................................................................................................................................................... 1

1.2 Characteristics............................................................................................................................................................... 2

2 Architecture .................................................................................................................................... 4

2.1 Overview ...................................................................................................................................................................... 4

2.2 Hardware ...................................................................................................................................................................... 4

2.3 Software ................................................................................................................................ ........................................ 7

3 Functions and Features ................................................................................................................ 8

3.1 Overview ...................................................................................................................................................................... 8

3.2 Resource Management .................................................................................................................................................. 9

3.3 Monitoring Management .............................................................................................................................................. 9

3.4 Report Management .................................................................................................................................................... 12

3.5 System Management ................................................................................................ ................................................... 13

4 Application Scenarios ................................................................................................................ 14

4.1 Overview .................................................................................................................................................................... 14

4.2 Application Scenarios ................................................................................................................................................. 14

5 Configuration ............................................................................................................................... 18

5.1 Overview .................................................................................................................................................................... 18

5.2 Typical Configuration ................................................................................................................................................. 18

6 Technical Specifications ............................................................................................................ 21

7 Acronyms and Abbreviations ................................................................................................... 24

8 Safety Precautions ....................................................................................................................... 25

Page 6

eBIMS

Product Description

1 Positioning and Characteristics

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

1 Positioning and Characteristics

About This Chapter

1.1 Positioning

This product description is oriented to the battery intelligent management system (eBIMS)

V100R001.

1.2 Characteristics

The eBIMS supports client-free fast deployment, comprehensively monitors the battery

temperature, voltage, and impedance, and achieves simple and fast operation.

1.1 Positioning

This product description is oriented to the battery intelligent management system (eBIMS)

V100R001.

Batteries, an indispensable part of sites, are the O&M focus. The correctness of battery

performance management, timeliness of battery fault rectification, and fix rate of network

problems caused by battery faults have a large impact on network status. Therefore, low-cost

automatic detection and analysis for batteries become key requirements of the management

service center. The Huawei eBIMS fully meets battery maintenance requirements by remotely

monitoring real-time battery status, detecting, predicting, and reporting battery faults, and

identifying batteries reaching their replacement thresholds and guiding the battery

replacement. Figure 1-1 shows the eBIMS solution.

Page 7

eBIMS

Product Description

1 Positioning and Characteristics

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Figure 1-1 eBIMS solution

1.2 Characteristics

The eBIMS supports client-free fast deployment, comprehensively monitors the battery

temperature, voltage, and impedance, and achieves simple and fast operation.

Simple Structure, Achieving Fast Deployment

The eBIMS uses the modular design. Wireless connection is used between the eBat and

eBox, reducing cables and simplifying installation.

The eBat connects to a battery using OT terminals. The eBox deployment is flexible and

convenient because the eBox can be installed on a wall or by using hook-and-loop

fasteners.

The eBIMS supports client-free installation and has a built-in database.

Simple Operation, Improving User Experience

The eBIMS uses the lightweight browser/server (B/S) architecture, uses the Web 2.0

technology, and allows users to perform access and operation using the Internet Explorer.

The intelligent report analysis function displays the battery temperature, impedance, and

voltage performance parameters using diversified graphs.

The configuration management function allows batch processing, achieving fast setting

of battery parameters.

Users can customize the home page to know the information to be concerned.

Real-Time Fault Monitoring, Reducing Battery Maintenance Costs Effectively

The eBIMS real-timely monitors and reports the temperature, voltage, and impedance

alarms of all batteries, preventing network accidents caused by battery faults.

The eBIMS monitors faults 24/7 and provides fault reminders in a timely manner, saving

the routine onsite maintenance costs of batteries.

Page 8

eBIMS

Product Description

1 Positioning and Characteristics

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

The eBIMS identifies single batteries that reach their replacement thresholds, avoiding

replacement of an entire battery string, reducing abnormal battery retirement from

networks, and saving costs.

Page 9

eBIMS

Product Description

2 Architecture

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

About This Chapter

2.1 Overview

This chapter briefly describes the eBIMS hardware and software architecture.

2.2 Hardware

2 Architecture

The eBIMS hardware includes the eBat and eBox.

2.3 Software

The eBIMS software architecture includes three parts: data collection, data exchange, and

application management.

2.1 Overview

This chapter briefly describes the eBIMS hardware and software architecture.

The eBIMS uses the modular design and includes the following basic function modules:

The eBIMS software management system includes auxiliary facilities like the server hardware system

and operating system.

2.2 Hardware

Battery detection module (eBat)

Battery module data collection unit (eBox)

eBIMS software management system

The eBIMS hardware includes the eBat and eBox.

eBat

The eBat is a battery detection module and communicates with the eBox using wireless

connection. The eBat has the following functions:

Page 10

eBIMS

Product Description

2 Architecture

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

No.

Item

Parameter

Remarks

—

Dimensions

48.5 mm (L) x 35 mm

(W) x 17 mm (H)

—

1

Radio

frequency (RF)

2.4 GHz

IEEE 802.15.4

The eBat communicates

wirelessly with the eBox

using RF 2.4 GHz.

2

Port

—

The eBat leads out four

cables from the port. Two

red cables and two black

cables are connected to

positive and negative

ends of a battery.

Detects the battery voltage.

Detects the battery impedance.

Detects the battery temperature.

Transmits detected battery information to the eBox.

The eBat is connected to the positive and negative ends of a battery using cables. Figure 2-1

shows the eBat appearance.

Figure 2-1 eBat appearance

Table 2-1 lists relevant parameters of the eBat.

Table 2-1 Technical specifications of the eBat

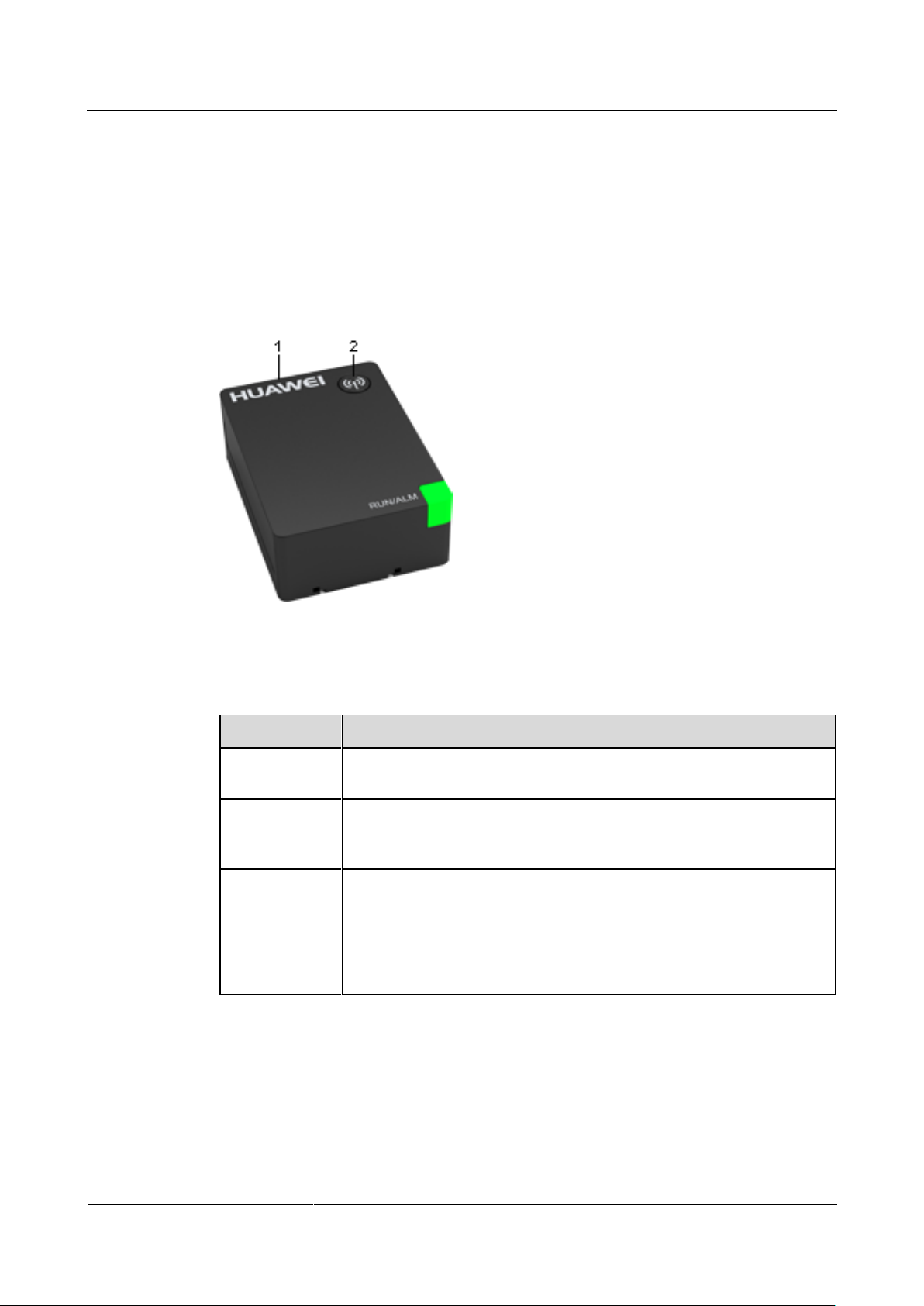

eBox

The eBox is a battery module data collection unit for collecting the battery

voltage/impedance/temperature data, and providing collected data to the eBIMS. The eBox

has the following functions:

Page 11

eBIMS

Product Description

2 Architecture

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

No.

Item

Parameter

Remarks

—

Dimensions

145 mm (L) x 95 mm

(W) x 33 mm (H)

-

1

RF 2.4 GHz

IEEE 802.15.4

The eBox communicates

wirelessly with the eBat

using RF 2.4 GHz.

2

GPRS antenna

-

The eBox communicates

with the upstream device

using GPRS wireless

connection.

3

Universal

Serial Bus

(USB) port

One

Used for device

debugging.

4

FE port

One

Using an RJ45 network

cable to communicate

with the upstream device.

5

SIM card

One

Allowing GPRS wireless

Collects the battery voltage.

Collects the battery impedance.

Collects the battery temperature.

Transmits battery parameters to the server.

Figure 2-2 shows the eBox appearance.

Figure 2-2 eBox appearance

Table 2-2 lists relevant parameters of the eBox.

Table 2-2 Technical specifications of the eBox

Page 12

eBIMS

Product Description

2 Architecture

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

No.

Item

Parameter

Remarks

connector

communication using a

SIM card.

6

Power port

One

Supplies power to the

eBox.

2.3 Software

The eBIMS software architecture includes three parts: data collection, data exchange, and

application management.

Figure 2-3 shows the basic architecture.

The eBox provides two types of upstream ports:

GPRS wireless port

FE port

Figure 2-3 Software architecture of the eBIMS

Page 13

eBIMS

Product Description

3 Functions and Features

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

About This Chapter

3.1 Overview

The eBIMS provides comprehensive battery management functions. The eBIMS real-timely

monitors and collects the battery temperature, impedance, and voltage to identify batteries

reaching their replacement thresholds, report alarms, guide replacement, and output relevant

reports.

3 Functions and Features

3.2 Resource Management

The eBIMS resource management covers management domains and physical resources

connected to the eBIMS.

3.3 Monitoring Management

Monitoring management includes functions like monitoring, collecting, displaying,

confirming, clearing, and shielding device alarms, and querying historical events and alarms.

These functions facilitate fast discovery, location, and handling of network or device faults.

3.4 Report Management

The eBIMS allows users to view and download basic report information, or output reports in

the Word, Excel, or PDF format.

3.5 System Management

System management includes user management, log management, and system configuration.

3.1 Overview

The eBIMS provides comprehensive battery management functions. The eBIMS real-timely

monitors and collects the battery temperature, impedance, and voltage to identify batteries

reaching their replacement thresholds, report alarms, guide replacement, and output relevant

reports.

Page 14

eBIMS

Product Description

3 Functions and Features

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

3.2 Resource Management

The eBIMS resource management covers management domains and physical resources

connected to the eBIMS.

Physical resources refer to all the devices connected to the eBIMS.

Management domain refers to a small network separated from a larger network by a

certain principle (region or device type) for easy network management. In resource

management, this type of small network is called a management domain. The eBIMS

management domains are classified by region, site, and equipment room.

Resource Management

Supports creation of a single management domain.

Supports creation of a single device or devices in batches.

Supports modification of management domain and device information.

Supports display of complete information of every battery as shown in Figure 3-1.

Figure 3-1 Battery information list

3.3 Monitoring Management

Monitoring management includes functions like monitoring, collecting, displaying,

confirming, clearing, and shielding device alarms, and querying historical events and alarms.

These functions facilitate fast discovery, location, and handling of network or device faults.

Alarms are classified into critical, major, minor, and warning alarms.

Critical alarm: indicates that services have been affected and requires immediate

rectification measures.

Major alarm: indicates that services have been affected and severe results may occur if

the alarm is not handled in a timely manner.

Minor alarm: indicates that services have not been affected but requires rectification

measures to prevent more severe faults.

Warning: indicates that services have not been affected, but potential faults that will

affect services have been detected.

Page 15

eBIMS

Product Description

3 Functions and Features

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

Displaying and Collecting Statistics on Alarms

The eBIMS real-timely monitors and receives alarms generated by managed devices, and

displays and collects statistics on alarms in various modes.

Alarm panel

− The alarm panel displays the alarm quantity and cleared alarms in the current alarm

list by severity.

Alarm histogram

− The alarm histogram is an eBIMS window displaying alarms. The alarm histogram

displays alarms of the managed objects by severity in graphs and numbers.

Querying Alarms

The eBIMS supports view of current alarms and query of historical alarms, events, and

performance statistics. Alarms that users need to pay attention to and handle are displayed in

the current alarm list.

Acknowledging an Alarm

Acknowledging an alarm indicates that a user has handled this alarm, which does not need to

be concerned. If needing to pay attention to this alarm again, unacknowledge this alarm and

take corresponding measures.

Clearing Alarms

Clearing alarms in a timely manner can effectively prevent service exceptions caused by

device malfunctions. The eBIMS supports automatic and manual clearing of alarms.

Shielding Alarms

Shielding rules can be set to shield the alarms that comply with the shielding rules. Shielded

alarms can be viewed in the list of shielded alarms.

Page 16

eBIMS

Product Description

3 Functions and Features

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

Supports graphic display of the battery impedance

Figure 3-2 Battery impedance comparison

Supports graphic display of the battery temperature

Figure 3-3 Battery temperature comparison

Page 17

eBIMS

Product Description

3 Functions and Features

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

Supports graphic display of the battery voltage

Figure 3-4 Battery voltage comparison

3.4 Report Management

The eBIMS allows users to view and download basic report information, or output reports in

the Word, Excel, or PDF format.

By default, the eBIMS outputs the following types of reports:

Site battery statistics report

Battery analysis report

Report Management

Report management includes generating, viewing, enabling, disabling, modifying, and

deleting a report.

Generating a report

− Users can create a report task to generate a report. After a report is generated, the

report is saved in the storage area and sent by e-mail if configured.

Viewing a report

− After a report is generated, users can view all report contents.

Enabling a report

− Users start a report task.

Disabling a report

− Users stop a report task.

Page 18

eBIMS

Product Description

3 Functions and Features

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

Modifying a report

− Users modify a report task based on needs.

Deleting a report

− Users delete an unnecessary report task.

3.5 System Management

System management includes user management, log management, and system configuration.

User Management

The eBIMS supports user information management and system security configuration.

Creating and modifying users

Creating and modifying roles

Changing user passwords

Setting account policies

Controlling login IP addresses

Controlling login time

Managing user sessions

Setting idle timeout

Log Management

The eBIMS allows users to view logs to learn about the eBIMS operating status and

operations. The eBIMS logs include security logs, system logs, and operation logs.

Security logs record security operations for the eBIMS, such as user login, changing a

password, creating a user, and user logout.

System logs record events for the eBIMS such as abnormal running, device faults,

periodical operations, and database dump.

Operation logs record user operations on the eBIMS such as adding a device.

System Configuration

System configuration includes component upgrade, database setting, and e-mail server setting.

Component upgrade

Setting database dump

Setting the notification e-mail server

Database dump settings are as follows:

Setting log database dump

Setting alarm database dump

Setting performance database dump

Page 19

eBIMS

Product Description

4 Application Scenarios

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

About This Chapter

4.1 Overview

The eBIMS can be deployed inside an outdoor cabinet or indoor equipment room. An

equipment room can be a data center power battery room or a site equipment room.

4.2 Application Scenarios

4 Application Scenarios

This section briefly describes the scenarios requiring the eBIMS and typical eBIMS

deployment scenarios.

4.1 Overview

The eBIMS can be deployed inside an outdoor cabinet or indoor equipment room. An

equipment room can be a data center power battery room or a site equipment room.

Deployment inside an outdoor cabinet

− Both the eBats and eBox are installed inside the outdoor cabinet. The eBats are

connected to batteries and the eBox is installed inside the cabinet using

hook-and-loop fasteners. One eBox is installed for each cabinet.

Deployment inside a data center power battery room

− Both the eBats and eBox are installed inside the indoor equipment room. The eBats

are connected to batteries and multiple eBoxes are installed on a wall using screws.

One eBox manages 250 eBats.

Deployment inside a site equipment room

− Both the eBats and eBox are installed inside the indoor equipment room. The eBats

are connected to batteries and the eBox is installed on a wall using screws. One eBox

manages 250 eBats.

4.2 Application Scenarios

This section briefly describes the scenarios requiring the eBIMS and typical eBIMS

deployment scenarios.

Page 20

eBIMS

Product Description

4 Application Scenarios

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

Scenarios Requiring the eBIMS

Typical scenarios:

1. Outdoor sites encounter network problems because battery aging due to

overcharge/overdischarge/undercharge/underdischarge deteriorates backup time. In this

case, maintenance costs are increased because multiple site visits are required to confirm

the battery location and quantity, check battery performance, and determine whether to

replace batteries.

2. Routine testing and inspection of batteries inside equipment rooms require much human

power. Moreover, one-by-one battery check cannot accurately determine the battery

status, causing much waste.

Deployment Inside an Outdoor Cabinet

The eBats and eBox are deployed in an outdoor cabinet. They communicate with each other

wirelessly. The eBox transmits collected battery data to the server. Users log in to the server to

perform real-time monitoring and operations. This solution achieves real-time monitoring and

detection of battery status, predicts fault risks, and avoids futile site visits. Maintenance costs

are reduced. Figure 4-1 shows details of this scenario.

Figure 4-1 Deployment inside an outdoor cabinet

Page 21

eBIMS

Product Description

4 Application Scenarios

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

Deployment Inside a Data Center Power Battery Room

The eBats and eBoxes are deployed in a data center power battery room. They communicate

with each other wirelessly. Multiple eBoxes transmit collected battery data to the server. Users

log in to the server to perform real-time monitoring and operations. This solution achieves

real-time detection of battery status and avoids onsite tests, saving costs. Moreover, this

solution accurately identifies batteries reaching their replacement thresholds, avoiding waste.

Figure 4-2 shows details of this scenario.

Figure 4-2 Deployment inside a data center power battery room

Deployment Inside a Site Equipment Room

The eBats and eBox are deployed in a site equipment room. They communicate with each

other wirelessly. The eBox transmits collected battery data to the server. Users log in to the

server to perform real-time monitoring and operations. This solution achieves real-time

detection of battery status and avoids onsite tests, saving costs. Moreover, this solution

accurately identifies batteries reaching their replacement thresholds, avoiding waste. Figure

4-3 shows details of this scenario.

Page 22

eBIMS

Product Description

4 Application Scenarios

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

Figure 4-3 Deployment inside a site equipment room

Page 23

eBIMS

Product Description

5 Configuration

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

About This Chapter

Configuration Item

Configuration Description

eBIMS software

eBIMS

eBat

Multiple

5.1 Overview

5.2 Typical Configuration

5 Configuration

5.1 Overview

The eBIMS uses modular deployment. The typical configuration includes the software system,

a set of matched hardware, multiple eBats, and one eBox.

The eBats, connected to batteries using cables, real-timely monitor the battery voltage,

current, and impedance, and wirelessly communicate with the eBox.

The eBox manages the eBats and transmits collected battery data to the server of the

software system.

Users log in to the eBIMS client to real-timely monitor battery status and take

corresponding measures based on actual situations.

5.2 Typical Configuration

The typical eBIMS configuration includes the software system, matched hardware facilities,

eBats, and eBox as shown in Table 5-1.

The software system requires matched facilities on both the server and client sides.

Typical eBIMS Configuration

Table 5-1 Typical eBIMS configuration

Page 24

eBIMS

Product Description

5 Configuration

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Configuration Item

Configuration Description

NOTE

The number of eBats is determined by the

eBox management capacity and the battery

quantity. One eBox manages a maximum of

250 eBats and one eBat is used for each

battery.

There are 2 V and 12 V batteries.

eBox

One. The eBox quantity varies with

management scenarios.

Matched facilities of the software system

Refer to Table 5-2 and Table 5-3.

Configuration Item

Configuration Description

Basic hardware configuration

CPU: 2 x four-core, 2.4 GHz or above

Memory: 32 GB or above

Disk: 2 TB or above

Operating system

Windows 7 or Windows Server 2008 R2

Standard

Database

MySQL 5.5

Configuration Item

Configuration Description

Hardware configuration

CPU: Intel(R) Pentium(R) dual CPU

E2180 @ 2.00 GHz

Memory: 2 GB or above

Operating system

Windows XP, Windows 7, or Windows

Server 2008

Browser

Internet Explorer 8.0 or later

NOTE

Ensure that the Internet Explorer 8.0 works in

standard browsing mode. Perform the

following steps to check whether the Internet

Explorer 8 is in standard browsing mode:

1. Open Internet Explorer 8.0 and

choose Tools > Compatibility View.

Matched Facilities of the Software System on the Server Side

Table 5-2 Matched facilities of the software system on the server side

Matched Facilities of the Software System on the Client Side

Table 5-3 Matched facilities of the software system on the client side

Page 25

eBIMS

Product Description

5 Configuration

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Configuration Item

Configuration Description

In the Compatibility View dialog box, check

Display intranet sites in Compatibility View

and Display all websites in Compatibility

View and ensure that they are not selected.

Windows 2008 has a strict security policy.

Contact the operating system administrator to

modify the security policy before using

Internet Explorer 8.0 to log in to the client that

runs on Windows 2008.

Monitor resolution

1024 x 768 or higher

Page 26

eBIMS

Product Description

6 Technical Specifications

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

6 Technical Specifications

Technical Specifications

Description

Maximum eBoxes managed by the eBIMS

The eBIMS supports a maximum of 3000

eBoxes.

Maximum eBats managed by an eBox

One eBox supports a maximum of 250

eBats.

Maximum clients connected to a server

A maximum of 100 clients can visit one

server at the same time.

Effective transmission distance between the

eBat and eBox

50 meters to 100 meters

Wireless transmission frequency band

between the eBat and eBox

2.4 GHz

Technical Specifications

Description

Working voltage

1.5 V DC to 3.3 V DC

Working temperature range

-20°C to 65°C

Voltage detection range

1.5 V DC to 3.3 V DC

Temperature detection range

-20°C to 65°C

impedance detection range

0.1 Mohms to 20 Mohms

Voltage detection precision

2%

Temperature detection precision

The temperature difference is ±2°C in an

environment with the temperature range of

-25°C to 70°C.

The eBIMS involves eBIMS, eBat, and eBox technical specifications.

Table 6-1 Key technical specifications of the eBIMS

Table 6-2 Key technical specifications when an eBat monitors a 2 V DC battery

Page 27

eBIMS

Product Description

6 Technical Specifications

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Technical Specifications

Description

impedance detection precision

0.01 Mohms

Quiescent Current

21 mA

Technical Specifications

Description

Working voltage

11 V DC to 17 V DC

Working temperature range

-20°C to 65°C

Voltage detection range

11 V DC to 17 V DC

Temperature detection range

-20°C to 65°C

impedance detection range

1.5 Mohms to 60 Mohms

Voltage detection precision

2%

Temperature detection precision

The temperature difference is ±2°C in an

environment with the temperature range of

-25°C to 70°C.

impedance detection precision

0.1 Mohms

Quiescent Current

7 mA

Technical Specifications

Description

Frequency band supported by GPRS

communication

850 MHz/900 MHz/1800 MHz/1900 MHz

Working voltage

-36 V DC to -72 V DC

Working current

300 mA DC Max.

Working temperature range

-20°C to 65°C

Working relative humidity (RH)

5% to 95% RH

Working altitude

-60 meters to 4000 meters

Table 6-3 Key technical specifications when an eBat monitors a 12 V DC battery

An eBat can monitor a 2 V or 12 V DC battery.

Table 6-4 Key technical specifications of the eBox with GPRS

Page 28

eBIMS

Product Description

6 Technical Specifications

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

Technical Specifications

Description

Working voltage

-36 V DC to -72 V DC

Working current

200 mA DC Max.

Working temperature range

-20°C to 65°C

Working relative humidity (RH)

5% to 95% RH

Working altitude

-60 meters to 4000 meters

Table 6-5 Key technical specifications of the eBox with FE

Page 29

eBIMS

Product Description

7 Acronyms and Abbreviations

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

7 Acronyms and Abbreviations

Acronym or Abbreviation

Full Name

eBIMS

Battery intelligent management system

eBox

Battery module data collection unit

eBat

Battery detection module

B/S

Browser/Server

FE

Fast Ethernet

RF

Radio frequency

Page 30

eBIMS

Product Description

8 Safety Precautions

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

FCC Part 15

8 Safety Precautions

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

This device does not cause harmful interference.

This device must accept any interference received, including interference that may cause

undesired operation.

If this device is modified without authorization from Huawei, the device may no longer

comply with FCC requirements for Class B digital devices. In that a case, your right to use the

device may be limited by FCC regulations. Moreover, you may be required to correct any

interference to radio or television communications at your own expense.

This device has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This device generates, uses and radiates radio frequency energy. If it is not installed and used

in accordance with the instructions, it may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this device does cause harmful interference to radio or television reception, which can be

determined by turning the device off and on, the user may take one or more of the following

measures:

Reorient or relocate the receiving antenna.

Reinforce the separation between the device and receiver.

Connect the device into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio or TV technician for assistance.

This equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled

environment. This transmitter must not be co-located or operating in conjunction with any

other antenna or transmitter. This equipment should be installed and operated with a minimum

distance of 20 centimeters between the radiator and your body.

The manufacturer is not responsible for any radio or TV interference caused by unauthorized

modifications to this equipment. Such modifications could void the user authority to operate

Page 31

eBIMS

Product Description

8 Safety Precautions

Issue 01 (2013-04-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

the equipment.

Canada Regulatory Compliance

RSS-Gen statement

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including interference that may

cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil

ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

RSS-210 statement:

This device complies with Industry Canada RSS-210. Operation is subject to the following

two conditions: (1) this device may not cause interference, and(2) this device must accept any

interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

RSS-210. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas

produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioé

lectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Loading...

Loading...