Page 1

AAU3940

Installation Guide

Issue 01

Date 2015-01-15

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Copyright © Huawei Technologies Co., Ltd. 2015. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or representations

of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Page 3

AAU3940

Installation Guide

Overview

About This Document

About This Document

This document describes procedures for installing an active antenna unit 3940 (AAU3940, which

is shortened to AAU in this document) and its cables. It also provides the checklists for hardware

installation.

Product Version

The following table lists the product versions related to this document.

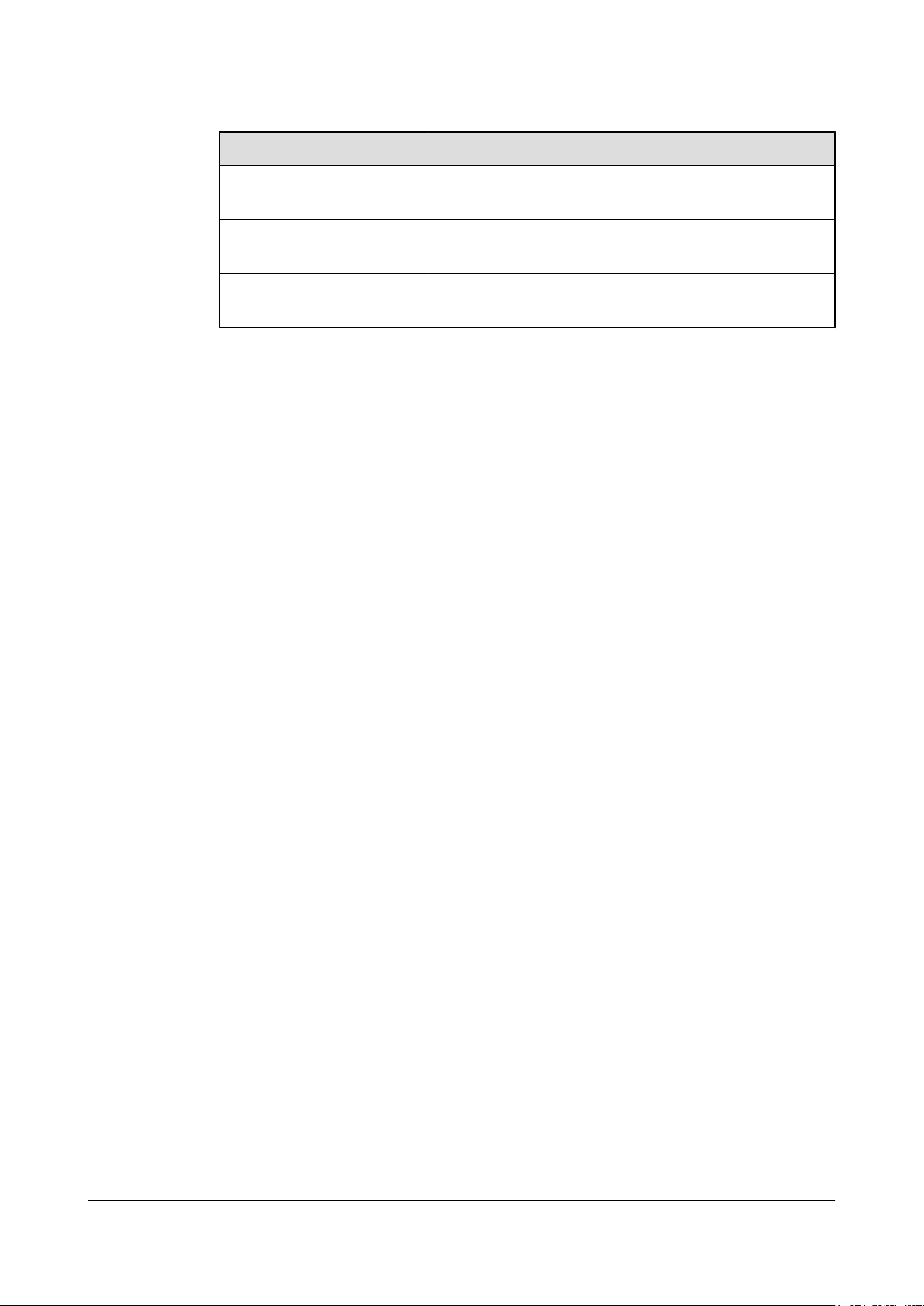

Product Name Solution Version Product Version

DBS3900

Intended Audience

l System engineers

l Installation personnel

l Maintenance engineers

Organization

l SRAN9.0 and later

l RAN16.0 and later

l eRAN7.0 and later

V100R009C00 and later

1 Changes in AAU3940 Installation Guide

This section describes changes in AAU3940 Installation Guide.

2 Overview

Before installing an AAU, you must be familiar with its installation options and installation

clearance requirements.

3 Installation Preparations

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

Page 4

AAU3940

Installation Guide

About This Document

This chapter lists the tools and instruments that must be obtained before the installation. It also

specifies the skills that the onsite personnel must have.

4 Unpacking Check

Unpack and check the delivered equipment to ensure that all materials are included and intact.

5 Installation Process

This chapter describes the process of installing an AAU.

6 (Optional) Installing an ODM

This section describes the procedure and precautions for installing an ODM.

7 Preprocessing the AAU Maintenance Cavity

Before installing an AAU, take power terminals out of its maintenance cavity and install optical

modules.

8 Lifting an AAU

Before installing an AAU on a pole, you need to lift the AAU to the installation position on the

pole.

9 Installing an AAU

This chapter describes the procedures for installing an AAU in different scenarios.

10 Installing AAU Cables

This section describes the procedure and precautions for installing AAU cables.

11 Closing a Maintenance Cavity

After all installation procedures are complete, you need to close the AAU maintenance cavity.

12 (Optional) Installing a Cord Cover for an ODM

This section describes a procedure for installing a cord cover for an ODM after all cables are

installed.

13 Adjusting the Horizontal Azimuth of an Antenna

This section describes the procedure for adjusting the horizontal azimuth of an antenna based

on coverage requirements after all cables are installed.

14 Installation Checklist

This section describes the checklist for AAU hardware installation.

15 Powering on an AAU

This section describes the procedure and precautions for powering on an AAU.

16 Appendix

This chapter describes auxiliary operations during an AAU installation process.

Conventions

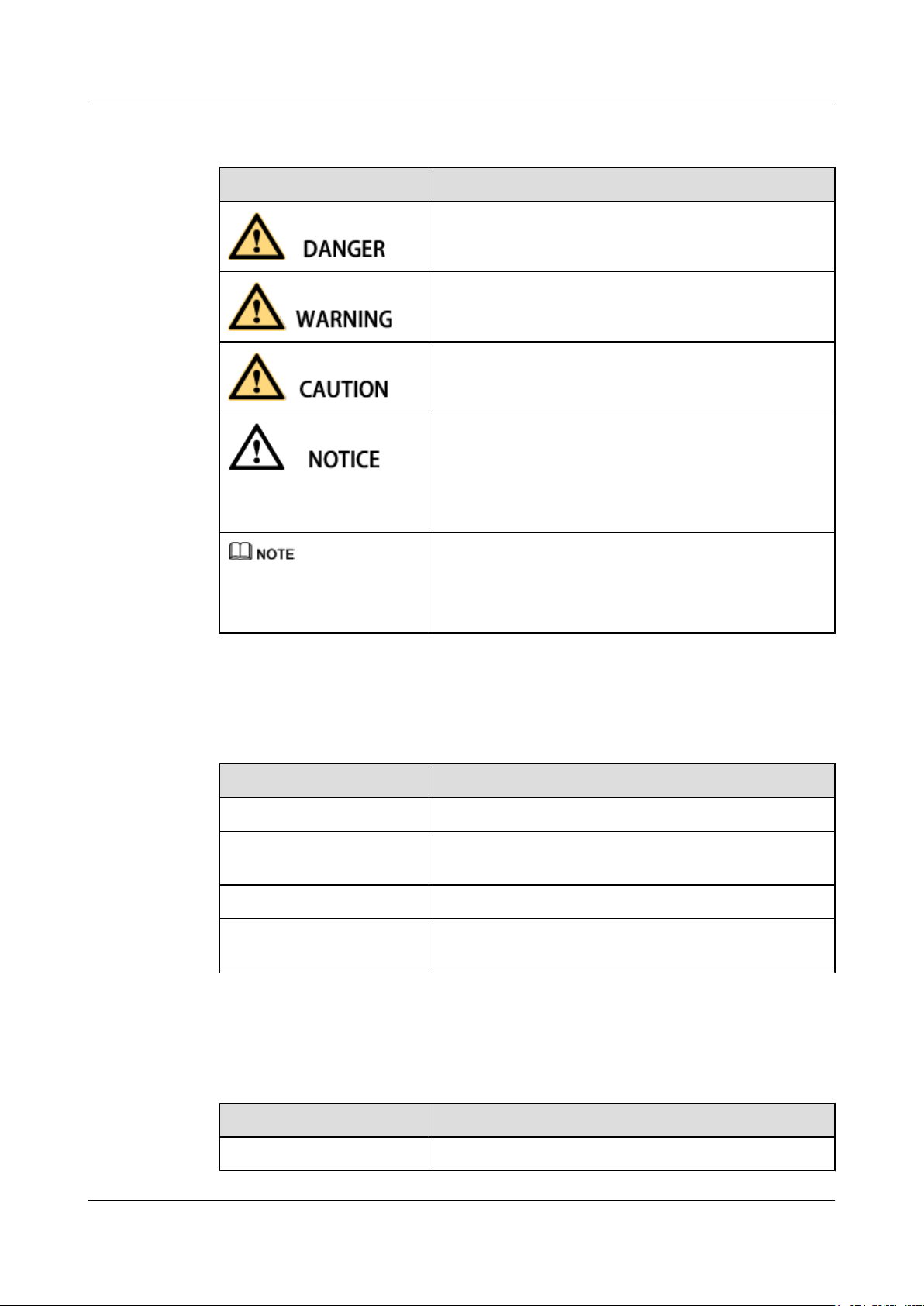

Symbol Conventions

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Page 5

AAU3940

Installation Guide About This Document

The symbols that may be found in this document are defined as follows.

Symbol Description

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to personal

injury.

Calls attention to important information, best practices and

tips.

NOTE is used to address information not related to personal

injury, equipment damage, and environment deterioration.

General Conventions

The general conventions that may be found in this document are defined as follows.

Convention Description

Times New Roman Normal paragraphs are in Times New Roman.

Boldface Names of files, directories, folders, and users are in

boldface. For example, log in as user root.

Italic Book titles are in italics.

Courier New

Examples of information displayed on the screen are in

Courier New.

Command Conventions

The command conventions that may be found in this document are defined as follows.

Convention Description

Boldface The keywords of a command line are in boldface.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Page 6

AAU3940

Installation Guide

About This Document

Convention Description

Italic Command arguments are in italics.

[ ] Items (keywords or arguments) in brackets [ ] are optional.

{ x | y | ... } Optional items are grouped in braces and separated by

vertical bars. One item is selected.

[ x | y | ... ] Optional items are grouped in brackets and separated by

vertical bars. One item is selected or no item is selected.

{ x | y | ... }

*

Optional items are grouped in braces and separated by

vertical bars. A minimum of one item or a maximum of all

items can be selected.

[ x | y | ... ]

*

Optional items are grouped in brackets and separated by

vertical bars. Several items or no item can be selected.

GUI Conventions

The GUI conventions that may be found in this document are defined as follows.

Convention Description

Boldface Buttons, menus, parameters, tabs, window, and dialog titles

are in boldface. For example, click OK.

> Multi-level menus are in boldface and separated by the ">"

signs. For example, choose File > Create > Folder.

Keyboard Operations

The keyboard operations that may be found in this document are defined as follows.

Format Description

Key Press the key. For example, press Enter and press Tab.

Key 1+Key 2 Press the keys concurrently. For example, pressing Ctrl+Alt

+A means the three keys should be pressed concurrently.

Key 1, Key 2 Press the keys in turn. For example, pressing Alt, A means

the two keys should be pressed in turn.

Mouse Operations

The mouse operations that may be found in this document are defined as follows.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

Page 7

AAU3940

Installation Guide About This Document

Action Description

Click Select and release the primary mouse button without moving

the pointer.

Double-click Press the primary mouse button twice continuously and

quickly without moving the pointer.

Drag Press and hold the primary mouse button and move the

pointer to a certain position.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

vi

Page 8

AAU3940

Installation Guide

Contents

Contents

About This Document.....................................................................................................................ii

1 Changes in AAU3940 Installation Guide..................................................................................1

2 Overview.........................................................................................................................................2

2.1 Installation Scenario.......................................................................................................................................................3

2.2 Installation Clearance Requirements..............................................................................................................................9

2.3 AAU Mounting Kits.....................................................................................................................................................11

2.4 ODM Description.........................................................................................................................................................12

2.5 Surge Protection Requirements....................................................................................................................................15

3 Installation Preparations............................................................................................................17

3.1 Documents....................................................................................................................................................................18

3.2 Tools and Instruments..................................................................................................................................................18

3.3 Requirements for Onsite Personnel..............................................................................................................................19

4 Unpacking Check........................................................................................................................21

5 Installation Process.....................................................................................................................23

6 (Optional) Installing an ODM..................................................................................................25

7 Preprocessing the AAU Maintenance Cavity.........................................................................30

8 Lifting an AAU.............................................................................................................................34

9 Installing an AAU........................................................................................................................37

9.1 Installing an AAU on a Pole.........................................................................................................................................38

9.2 Installing an AAU on the Top of a Pole.......................................................................................................................44

9.3 Installing an AAU on a Wall........................................................................................................................................48

10 Installing AAU Cables..............................................................................................................55

10.1 Cabling Requirements................................................................................................................................................56

10.2 Installing an AAU PGND Cable................................................................................................................................62

10.3 Installing an AAU Power Cable.................................................................................................................................67

10.4 Installing an ODM Power Cable................................................................................................................................72

10.5 Installing a Trunk CPRI Fiber Optic Cable Between an ODM and a BBU...............................................................73

10.6 Installing a CPRI Fiber Optic Cable Between an AAU and a BBU or Between an AAU and an ODM...................80

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

vii

Page 9

AAU3940

Installation Guide Contents

11 Closing a Maintenance Cavity................................................................................................86

12 (Optional) Installing a Cord Cover for an ODM.................................................................87

13 Adjusting the Horizontal Azimuth of an Antenna.............................................................89

14 Installation Checklist................................................................................................................93

15 Powering on an AAU................................................................................................................95

16 Appendix.....................................................................................................................................97

16.1 Assembling the OT Terminal and the Power Cable...................................................................................................98

16.2 Adding a Tool-Less Female Connector (Pressfit Type) to an AAU Power Cable on the AAU Side......................102

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

viii

Page 10

AAU3940

Installation Guide 1 Changes in AAU3940 Installation Guide

1 Changes in AAU3940 Installation Guide

This section describes changes in AAU3940 Installation Guide.

01 (2015-01-15)

This is the first commercial release.

Compared with issue Draft A (2014-10-30), no information is added to or deleted from this issue.

Compared with issue Draft A (2014-10-30), this issue includes the following changes.

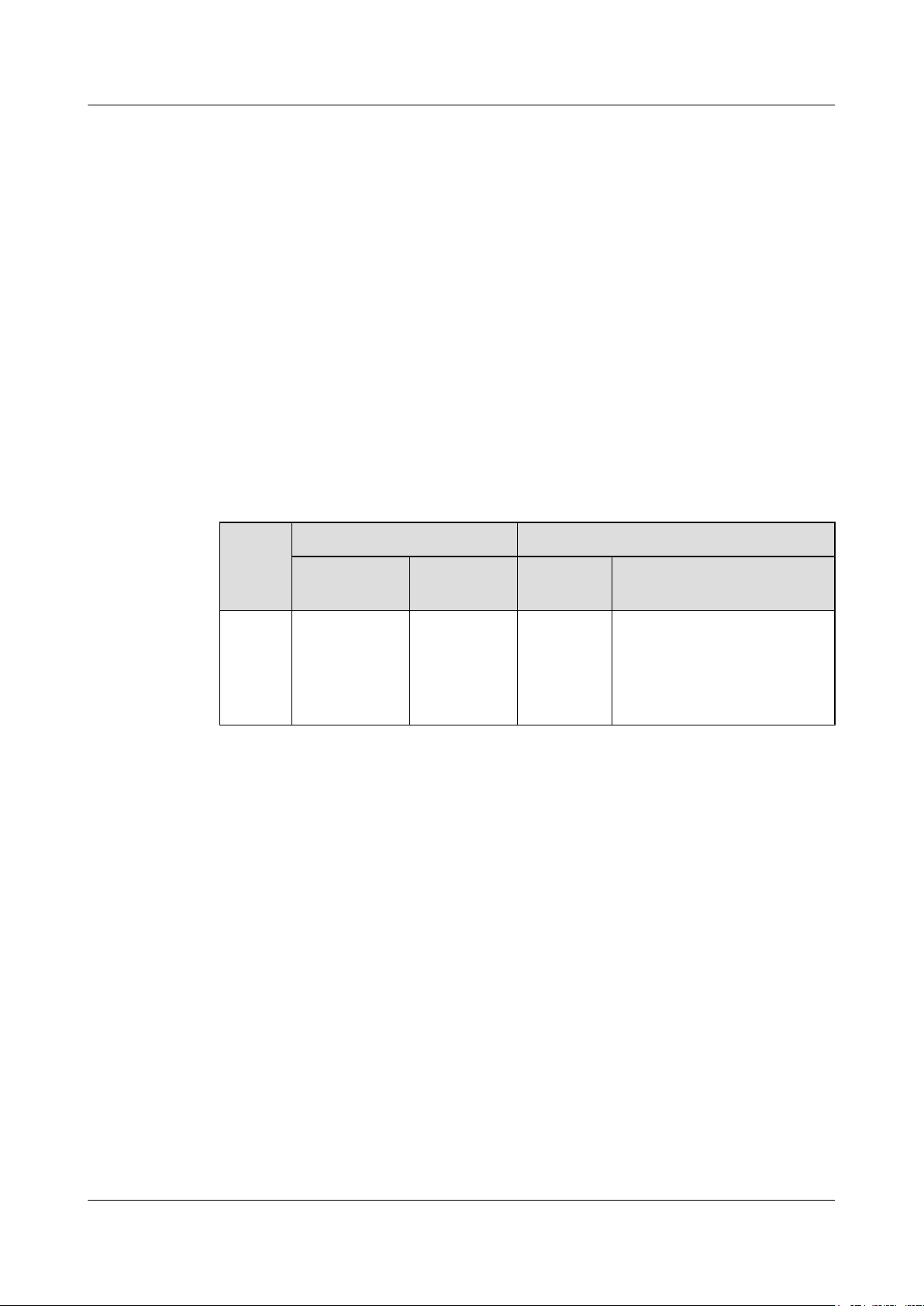

Topic Change Description

Entire document Some figure updates caused by the structure

Draft A (2014-10-30)

This is a draft.

modification of the AAU.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

Page 11

AAU3940

Installation Guide 2 Overview

2 Overview

About This Chapter

Before installing an AAU, you must be familiar with its installation options and installation

clearance requirements.

2.1 Installation Scenario

An AAU can be installed independently or can be installed together with an ODM04A (ODM

for short) on a pole, a wall, or the top of a pole.

2.2 Installation Clearance Requirements

This section describes installation clearance requirements in different scenarios.

2.3 AAU Mounting Kits

This section describes mounting kits for installing AAUs on a pole, a wall, and the top of a pole.

2.4 ODM Description

This section describes functions and specifications of an ODM.

2.5 Surge Protection Requirements

When an AAU is installed on a pole or the top of a pole, the AAU must meet the surge protection

requirements. Otherwise, surge protection measures must be taken.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Page 12

AAU3940

Installation Guide 2 Overview

2.1 Installation Scenario

An AAU can be installed independently or can be installed together with an ODM04A (ODM

for short) on a pole, a wall, or the top of a pole.

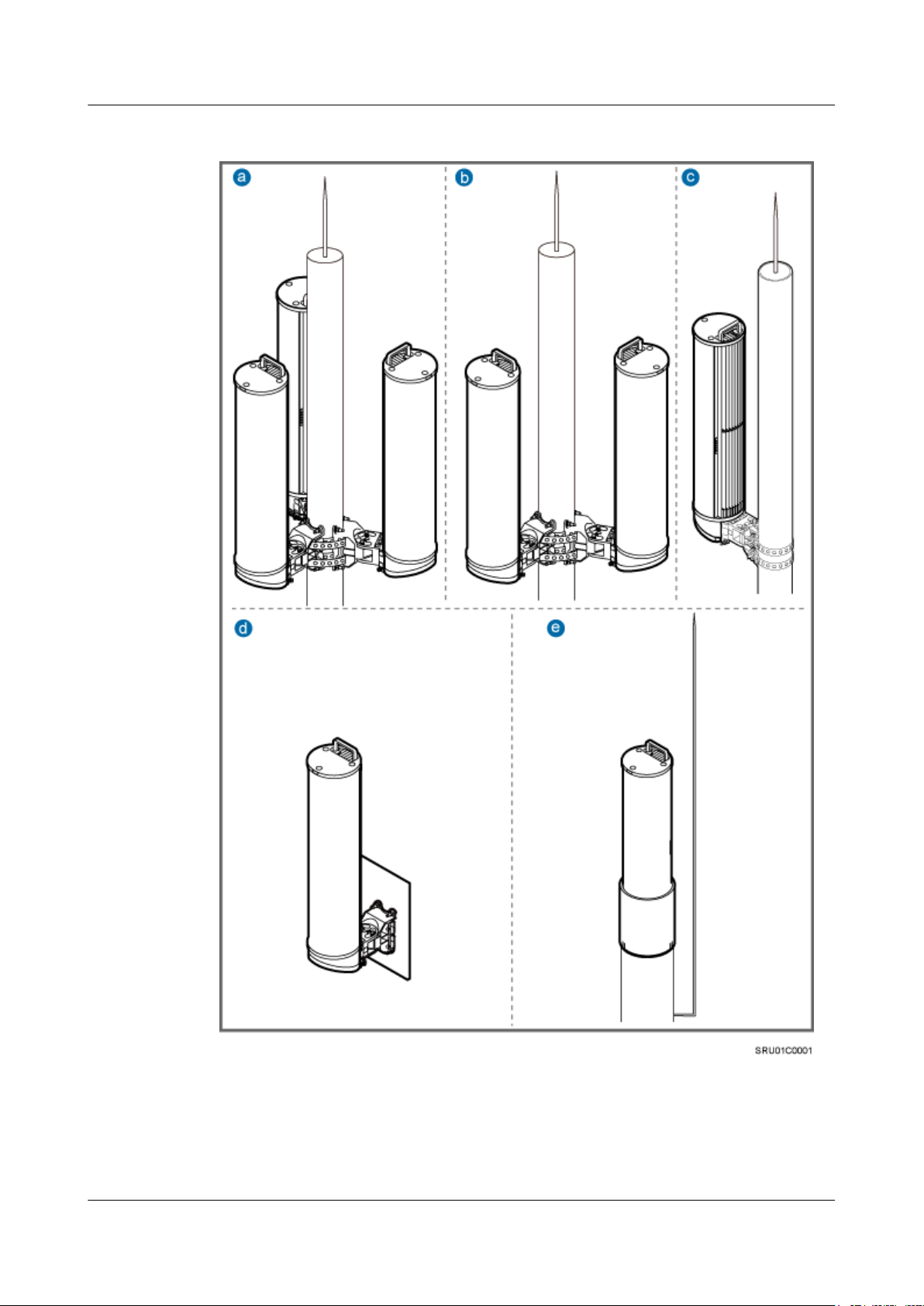

Installation Scenario Description

NOTE

An AAU has been camouflaged and the second camouflaging is not allowed in principle. If the second

camouflaging must be performed, you need to contact Huawei technical engineers for assessment.

The following figure shows scenarios in which AAUs are installed independently.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

Page 13

AAU3940

Installation Guide 2 Overview

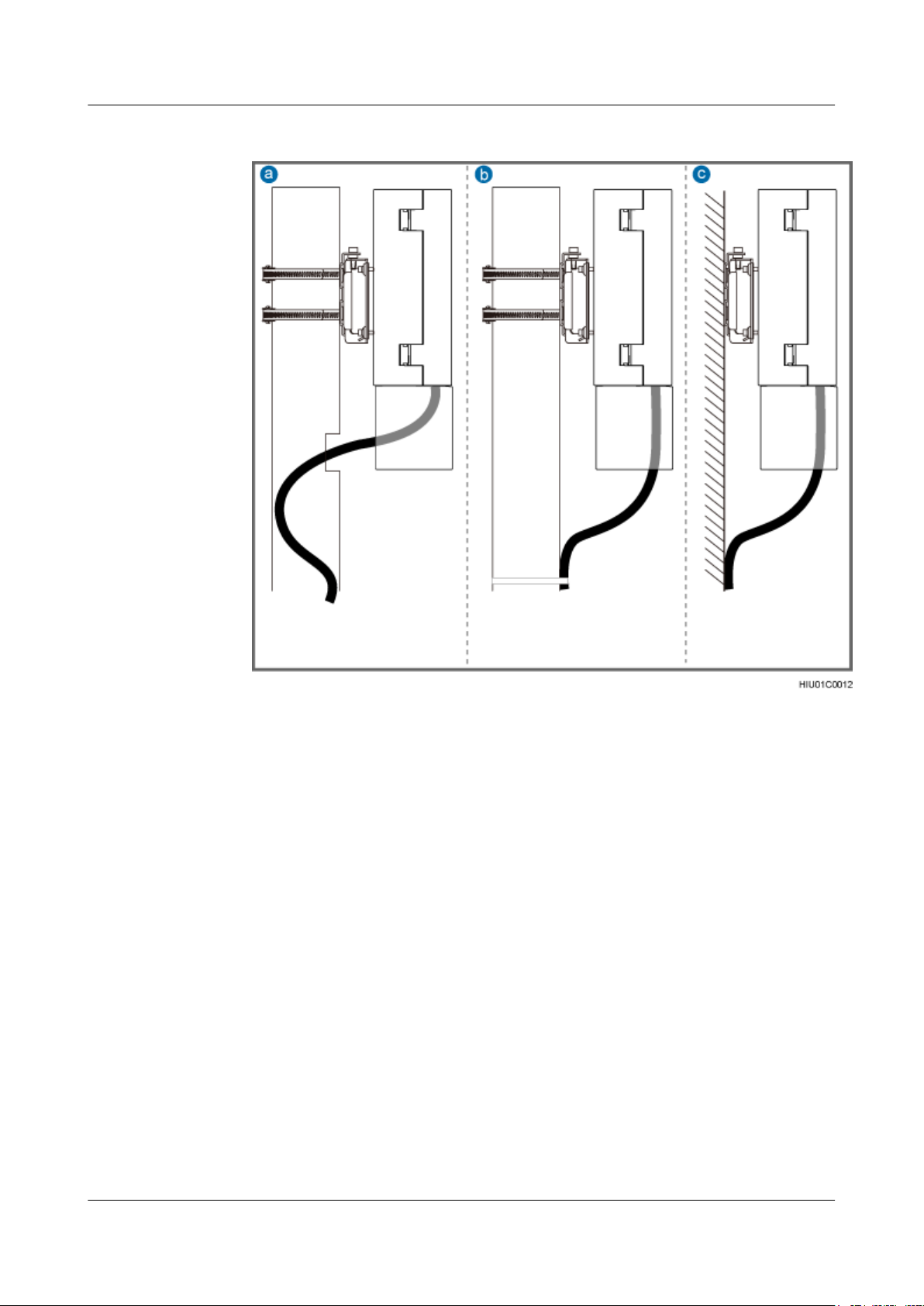

Figure 2-1 Scenario in which AAUs are installed independently

a: Scenario in which three AAUs are

installed on a pole

d: Scenario in which an AAU is

installed on a wall

b: Scenario in which two AAUs are

installed on a pole

e: Scenario in which an AAU is

installed on the top of a pole

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

c: Scenario in which one AAU is

installed on a pole

-

4

Page 14

AAU3940

Installation Guide 2 Overview

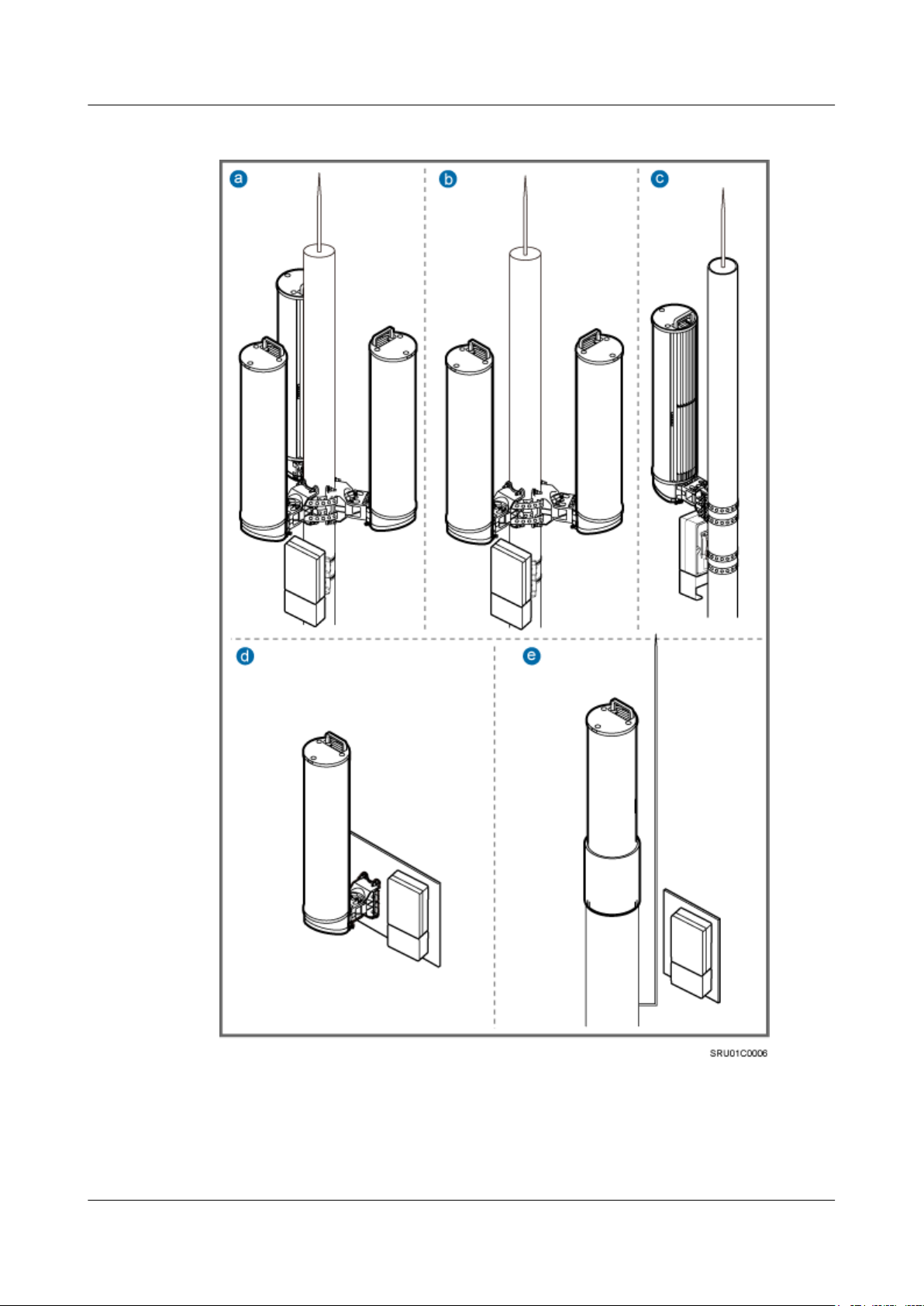

The following figure shows scenarios in which AAUs are installed together with ODMs.

NOTE

AAUs can also be installed together with optical distribution frames (ODFs). This document uses ODMs as

examples.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

Page 15

AAU3940

Installation Guide 2 Overview

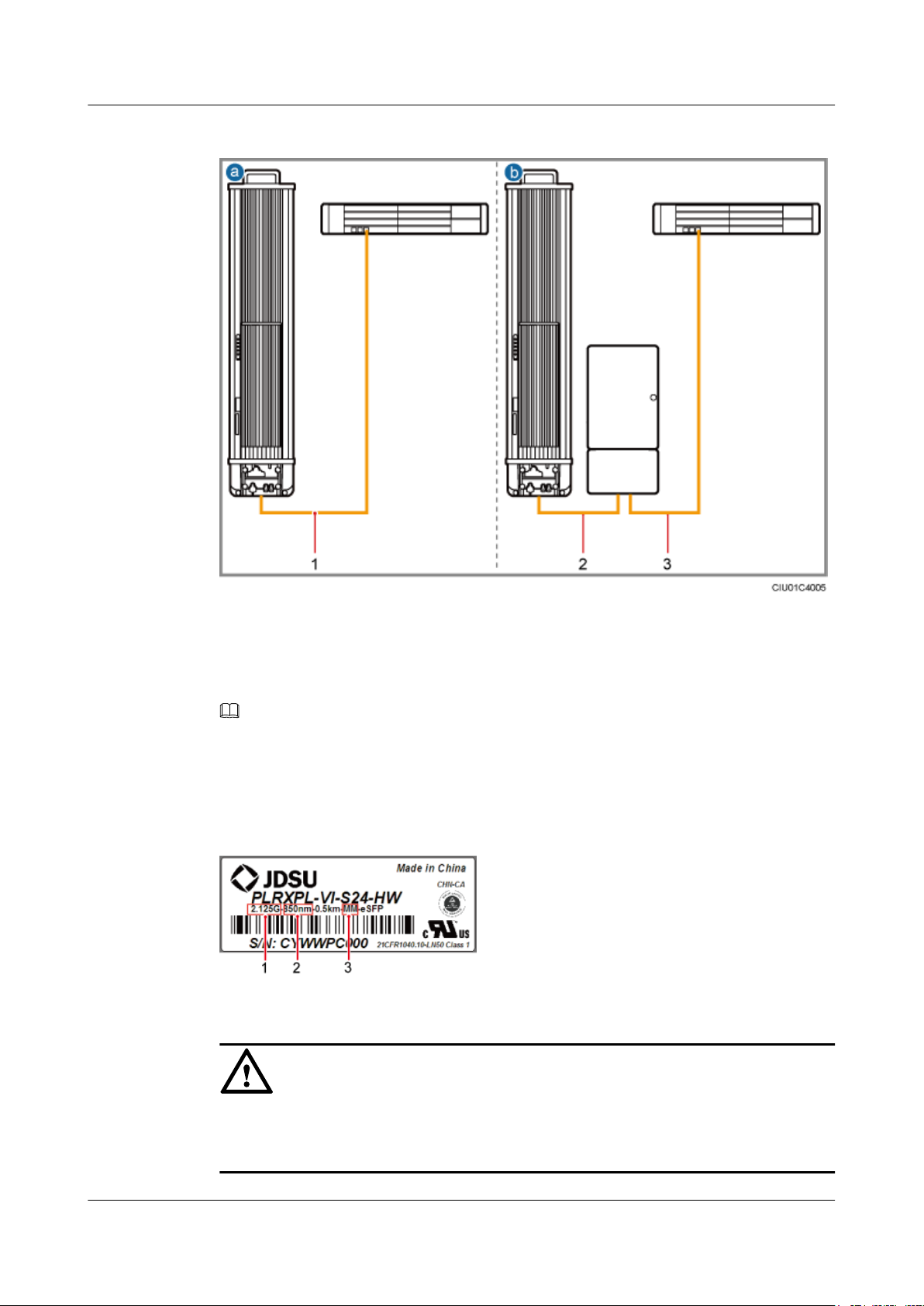

Figure 2-2 Scenarios in which AAUs are installed together with ODMs

a: Scenario in which three AAUs are

installed together with an ODM on a

pole

b: Scenario in which two AAUs are

installed together with an ODM on a

pole

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

c: Scenario in which an AAU is

installed together with an ODM on a

pole

6

Page 16

AAU3940

Installation Guide 2 Overview

d: Scenario in which an AAU is

installed together with an ODM on a

wall

e: Scenario in which an AAU is

installed on the top of a pole and an

ODM is installed on a wall

-

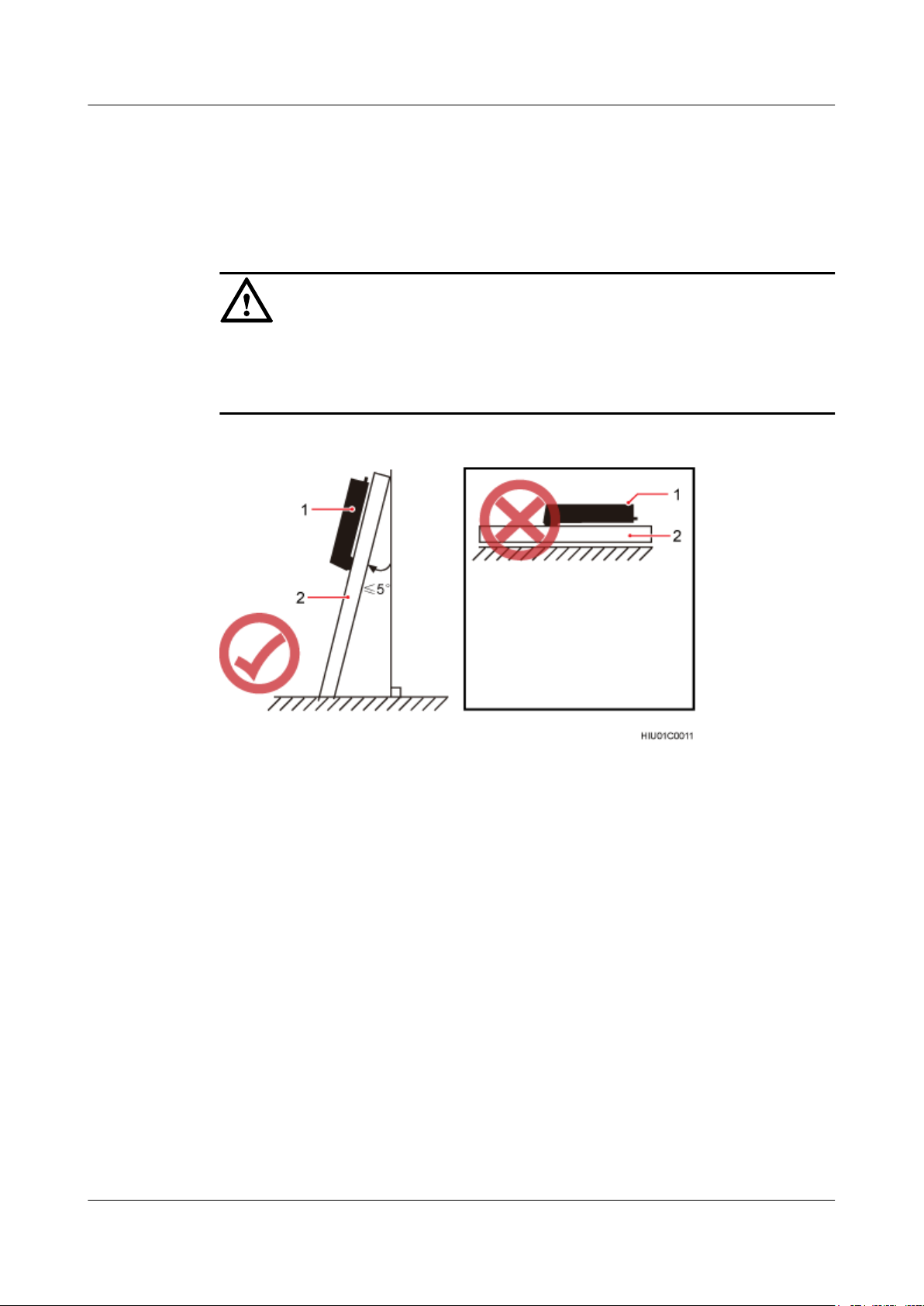

NOTICE

In all scenarios, AAUs are installed together with their bottoms facing downwards. The vertical

deviation angle of a support must be less than or equal to 5 degrees, as shown in the following

figure.

Figure 2-3 Vertical deviation angle of an AAU

(1) AAU

(2) Support (pole, top of a pole, or wall)

Requirements of Installation Scenarios

The following table describes the requirements for poles, walls, and tops of poles in the preceding

installation scenarios.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

Page 17

AAU3940

Installation Guide

2 Overview

Table 2-1 Requirements of installation scenarios

Installation

Scenario

One AAU is installed

on a pole.

Two AAUs are

installed on a pole.

Requirements

l The part of a pole for installing an AAU should have a diameter

of 60 mm to 300 mm (2.36 in. to 11.81 in.) and the recommended

wall thickness of a pole is greater than or equal to 4 mm (0.16 in.).

l If the part of a pole for installing an AAU has a diameter greater

than 300 mm (11.81 in.), an auxiliary pole is required for installing

the AAU.

l Two AAUs are installed back to back in most cases.

l The recommended wall thickness of a pole is greater than or equal

to 4 mm (0.16 in.).

l When AAUs are installed on the same level, the part of a pole for

installing the AAUs should have a diameter of 80 mm to 230 mm

(3.15 in. to 9.06 in.). When AAUs are installed on different levels,

the parts of a pole for installing the AAUs should have a diameter

of 60 mm to 230 mm (2.36 in. to 9.06 in.).

l If the part of a pole for installing AAUs has a diameter greater than

230 mm (9.06 in.), an auxiliary pole is required for installing the

AAUs.

Three AAUs are

installed on a pole.

AAUs are installed

on a wall.

An AAU is installed

on the top of a pole.

l The recommended wall thickness of a pole is greater than or equal

to 4 mm (0.16 in.).

l When AAUs are installed on the same level, the part of a pole for

installing the AAUs should have a diameter of 80 mm to 230 mm

(3.15 in. to 9.06 in.). When AAUs are installed on different levels,

the parts of a pole for installing the AAUs should have a diameter

of 60 mm to 230 mm (2.36 in. to 9.06 in.).

l If the part of a pole for installing AAUs has a diameter greater than

230 mm (9.06 in.), an auxiliary pole is required for installing the

AAUs.

A wall should have a load-bearing capacity of 80 kg (176.37 lb).

l The recommended wall thickness of a pole is greater than or equal

to 4 mm (0.16 in.).

l A flange plate must be installed on the top of a pole for attaching

an AAU to the pole.

l The recommended thickness of a flange plate is greater than or

equal to 6 mm (0.24 in.).

l To achieve neat installation, it is recommended that the diameter

of a pole be the same as that of a flange plate.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

Page 18

AAU3940

Installation Guide 2 Overview

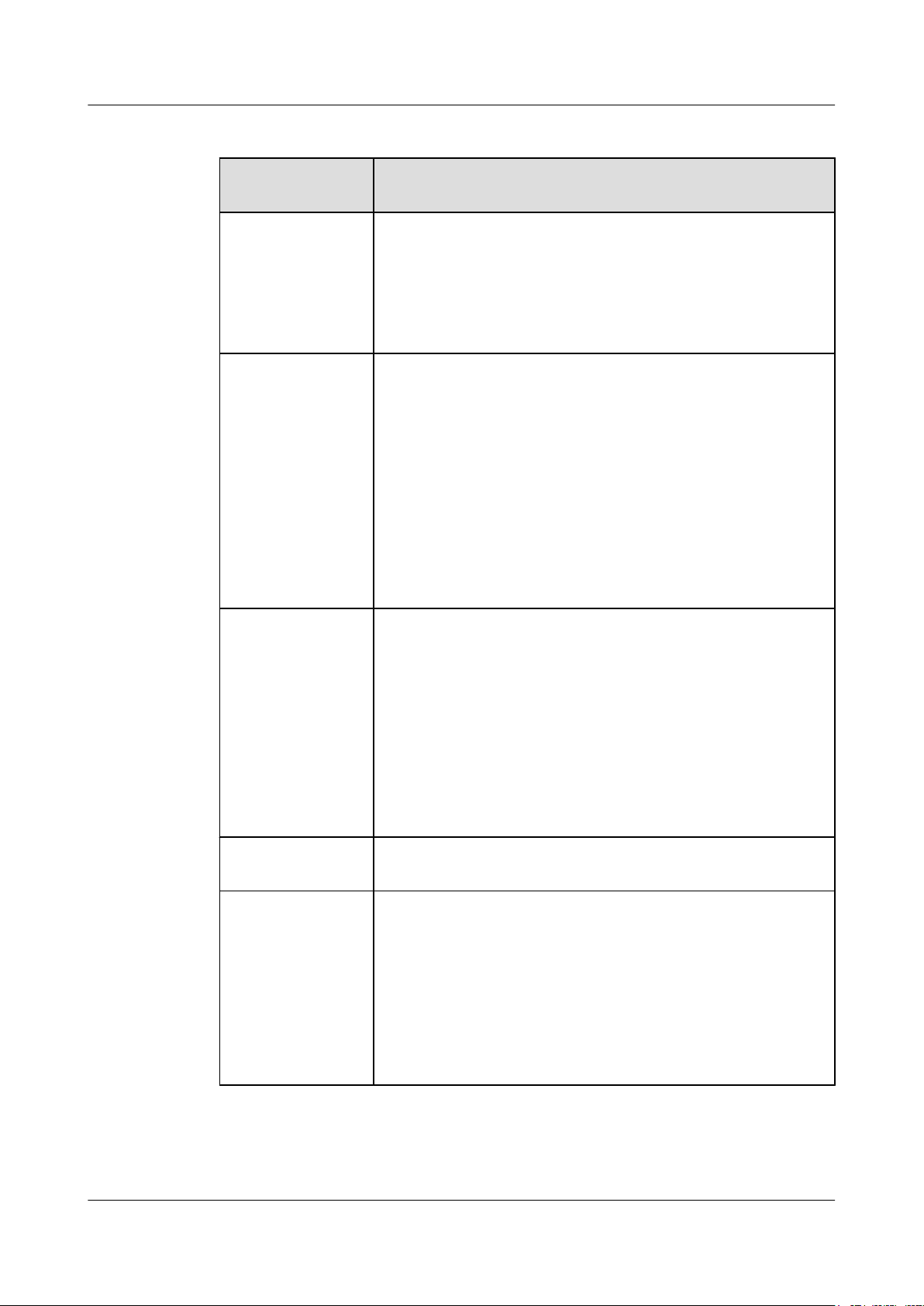

The method of connecting a flange plate to the top of a pole is determined by customers. The

following figure shows the design specifications of ports on a flange plate for connecting an

AAU.

Figure 2-4 Design specifications of ports on a flange plate

(1) Flange plate (2) Screw hole (3) Nut

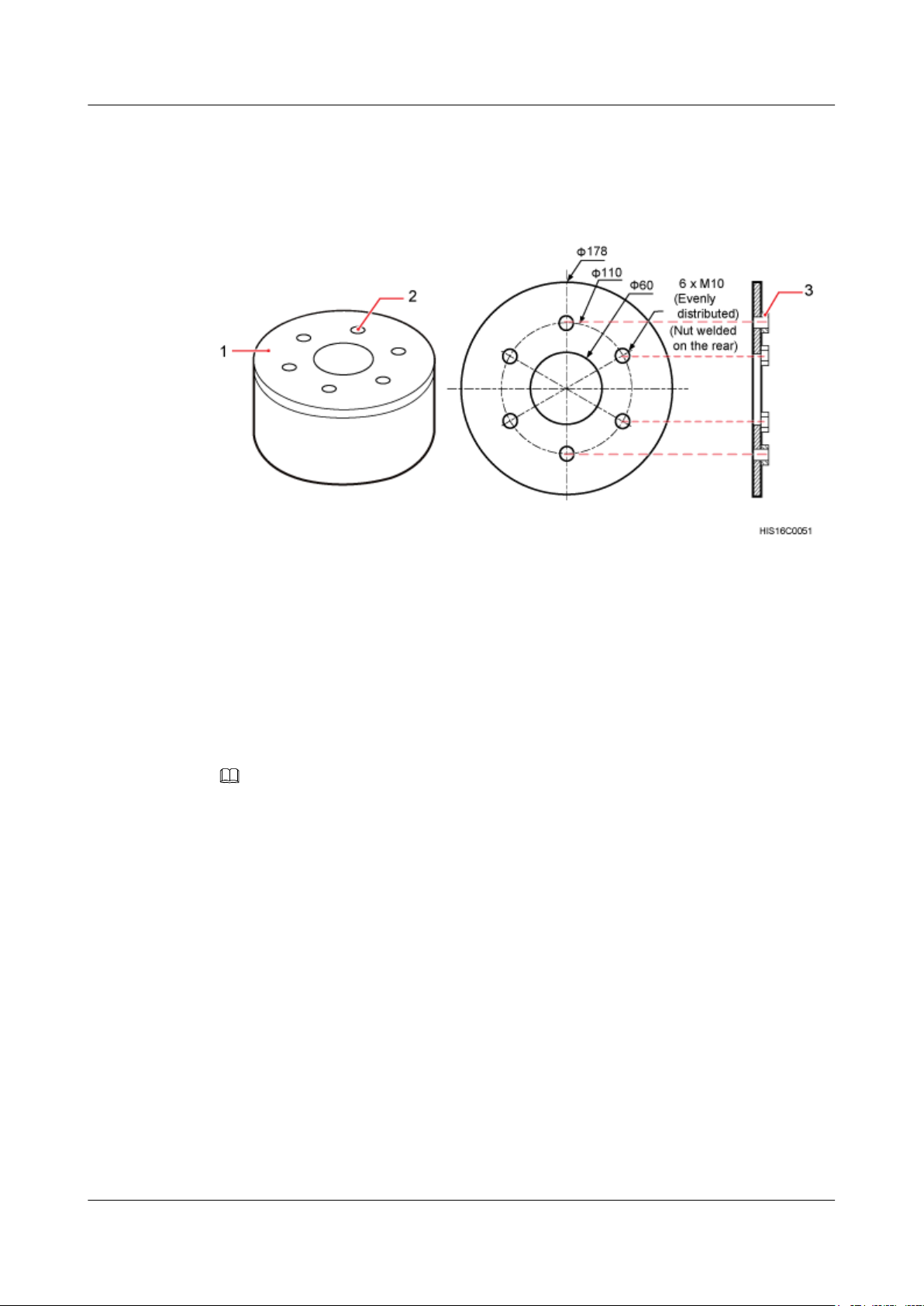

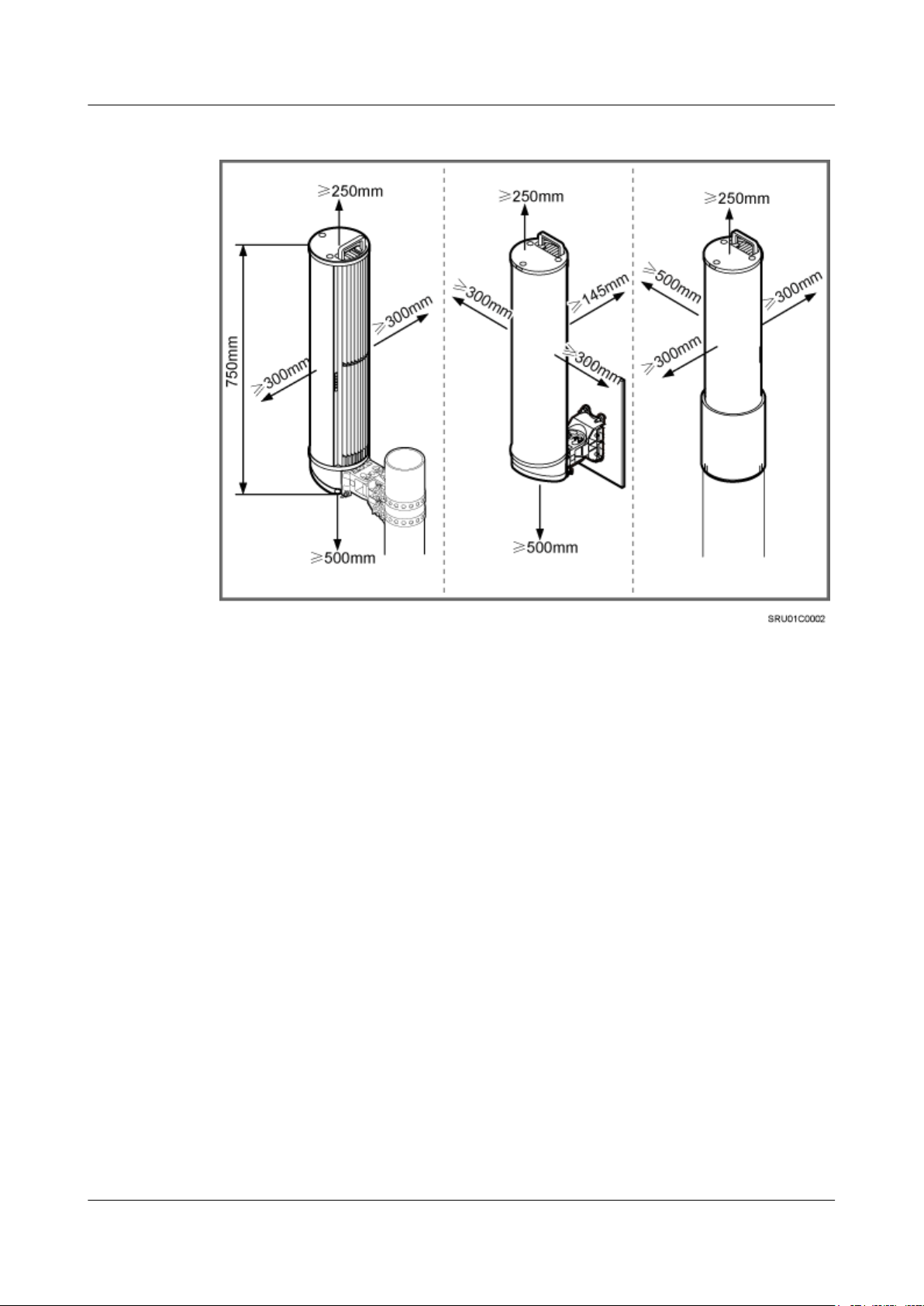

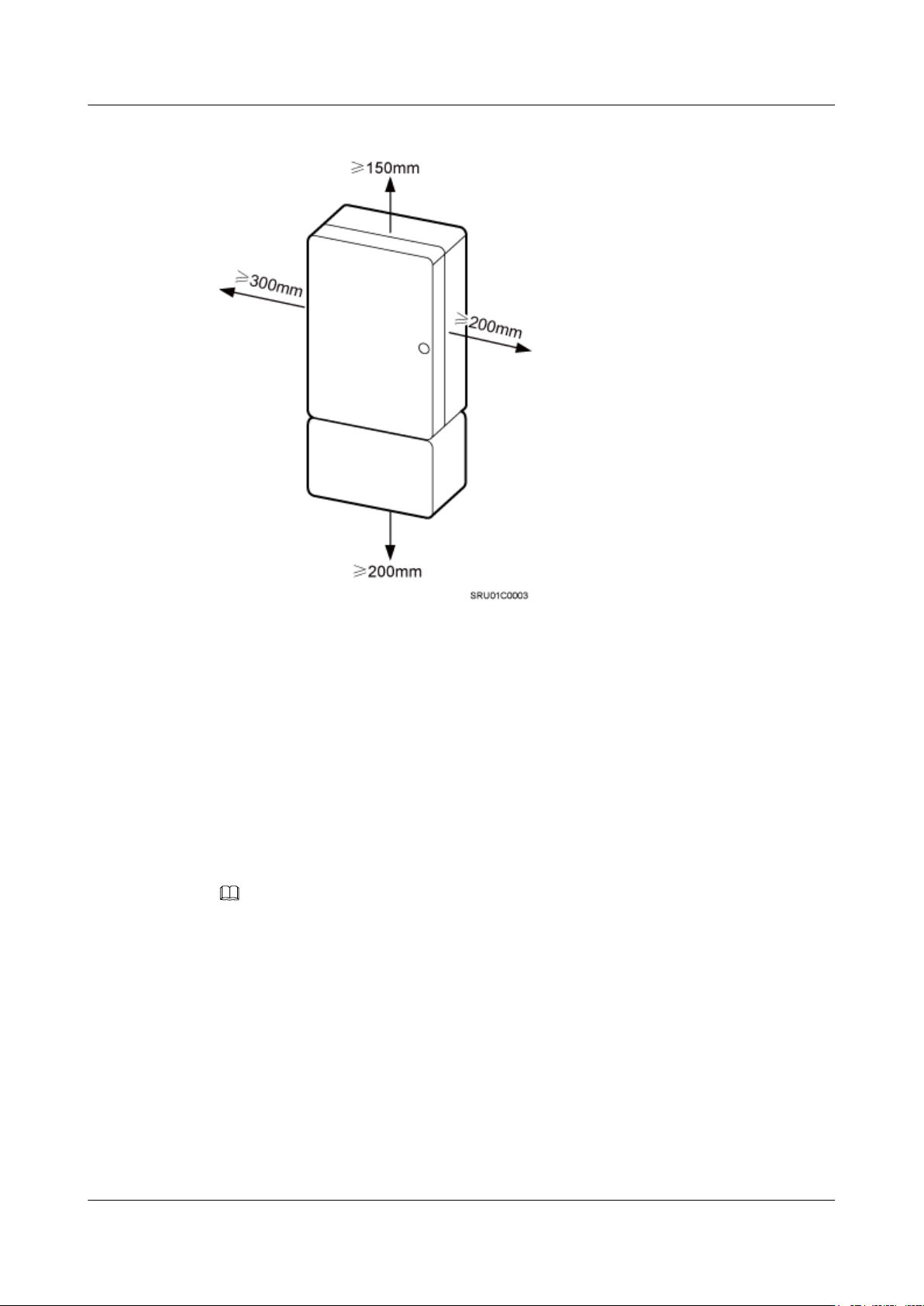

2.2 Installation Clearance Requirements

This section describes installation clearance requirements in different scenarios.

The following figure shows the clearance requirements for installing an AAU.

NOTE

The following figure shows the clearance requirements for independently installing an AAU. When an AAU is

installed together with an ODM, the clearance requirements are different.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

Page 19

AAU3940

Installation Guide 2 Overview

Figure 2-5 AAU installation clearance requirements

The following figure shows the clearance requirements for installing an ODM.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

Page 20

AAU3940

Installation Guide

2 Overview

Figure 2-6 ODM installation clearance requirements

2.3 AAU Mounting Kits

This section describes mounting kits for installing AAUs on a pole, a wall, and the top of a pole.

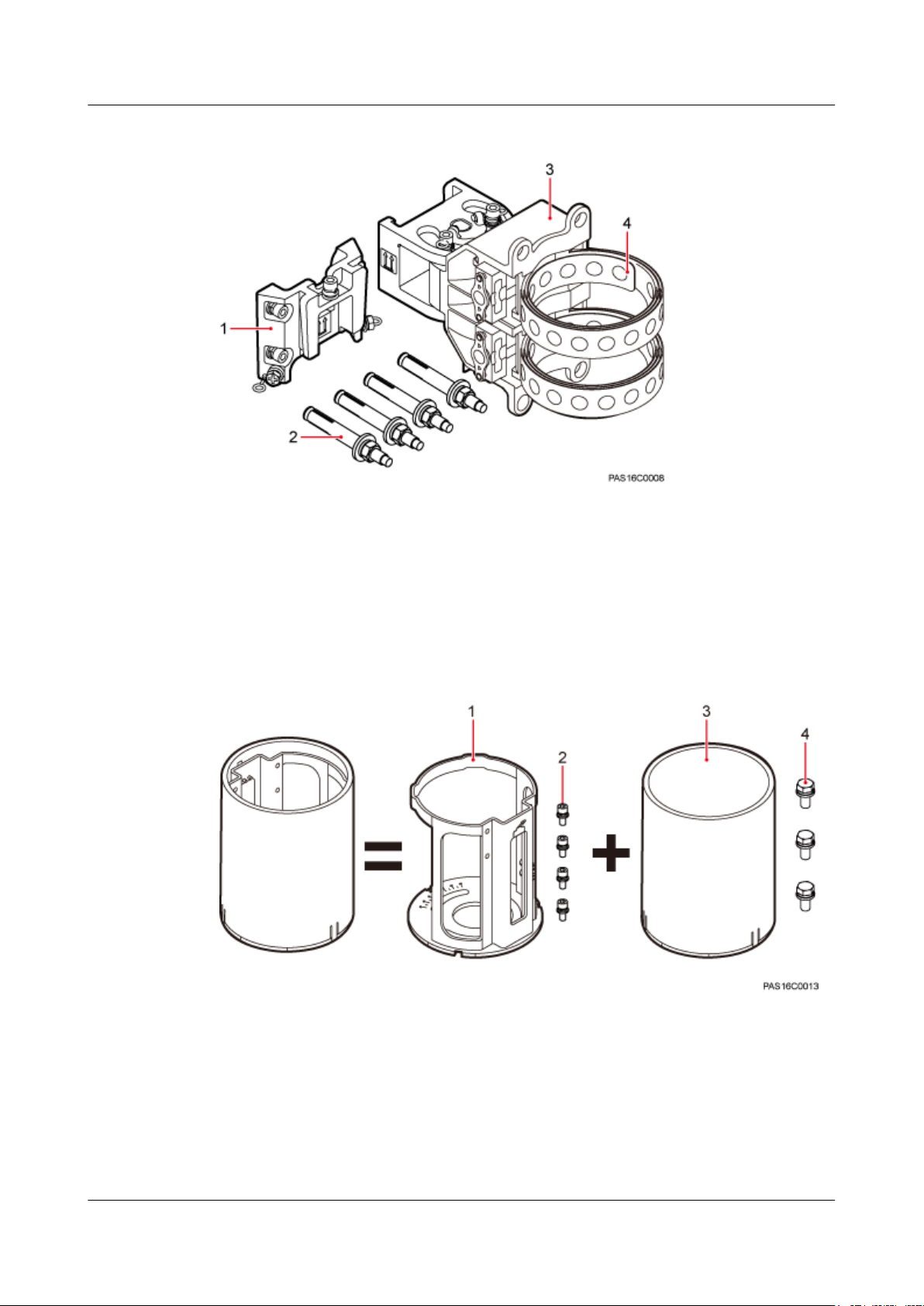

Mounting Kits for an AAU Installed on a Pole or Wall

The same mounting kits are used for installing an AAU on a pole and installing an AAU on a

wall. However, the procedure for installing an AAU on a pole is different from that for installing

an AAU on a wall. The following figure shows the mounting kits for an AAU.

NOTE

When an AAU is installed on a pole or wall, the main bracket and attachment plate are required.

l When an AAU is installed on a pole, M8x80 expansion anchor bolts are not required.

l When an AAU is installed on a wall, steel belts are not required. Therefore, you need to remove the steel

belts from mounting kits.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

Page 21

AAU3940

Installation Guide

2 Overview

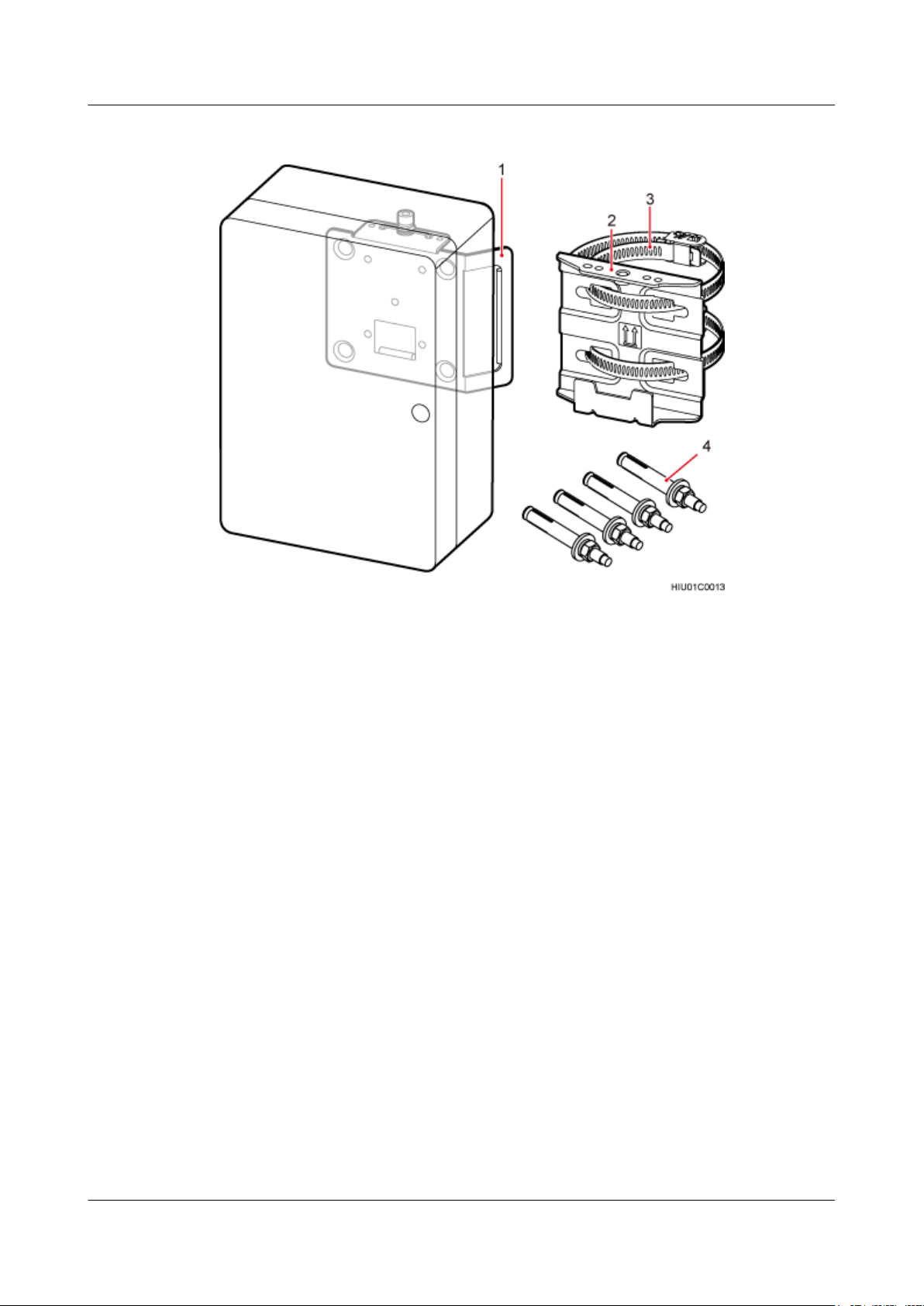

Figure 2-7 Mounting kits for an AAU installed on a pole or wall

(1) Attachment plate (2) M8x80 expansion anchor bolt (3) Main mounting bracket (4) Steel belt

Mounting Kits for an AAU Installed on the Top of a Pole

Mounting kits for installing an AAU on the top of a pole include a support and a landscaping

cover, as shown in the following figure.

Figure 2-8 Mounting kits installing for an AAU on the top of a pole

(1) Support

(2) M6x16 bolt (3) Landscaping cover (4) M10x30 bolt

2.4 ODM Description

This section describes functions and specifications of an ODM.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

Page 22

AAU3940

Installation Guide

Function

2 Overview

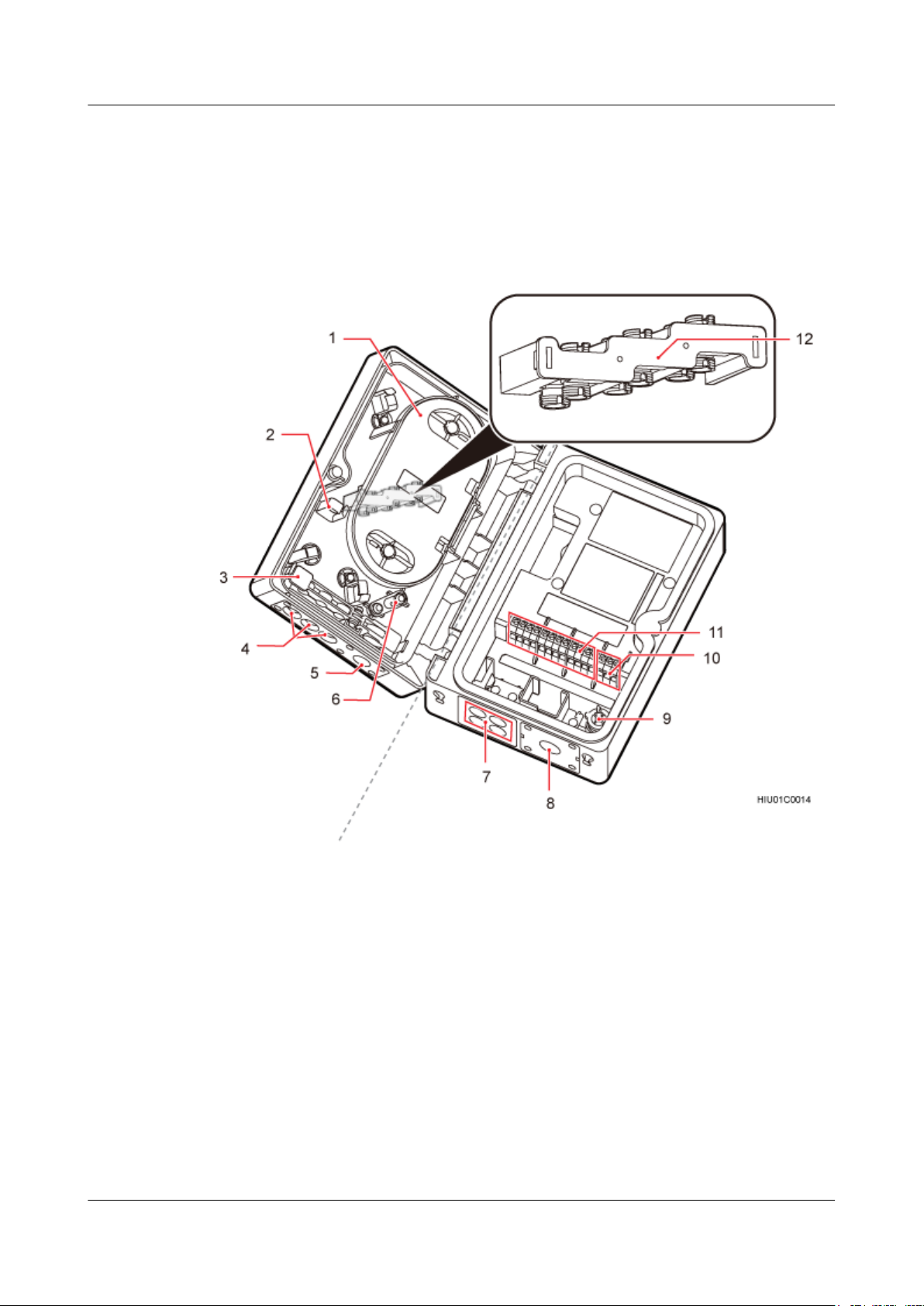

The ODM is an auxiliary low-power AC device for providing power distribution and fiber

distribution. The ODM cover provides fiber distribution and the ODM provides power

distribution. The following figure shows the structure of an ODM.

Figure 2-9 ODM structure

(1) Splicing tray (2) Fiber holder (3) Clip (4) Holes for output fiber

(5) Hole for the input fiber

optic cable

(9) Screwdriver (10) Terminal block for

(6) Hanger for the trunk

fiber optic cable

input power cables

(7) Cable holes for the

output power cables

(11) Terminal block for

output power cables

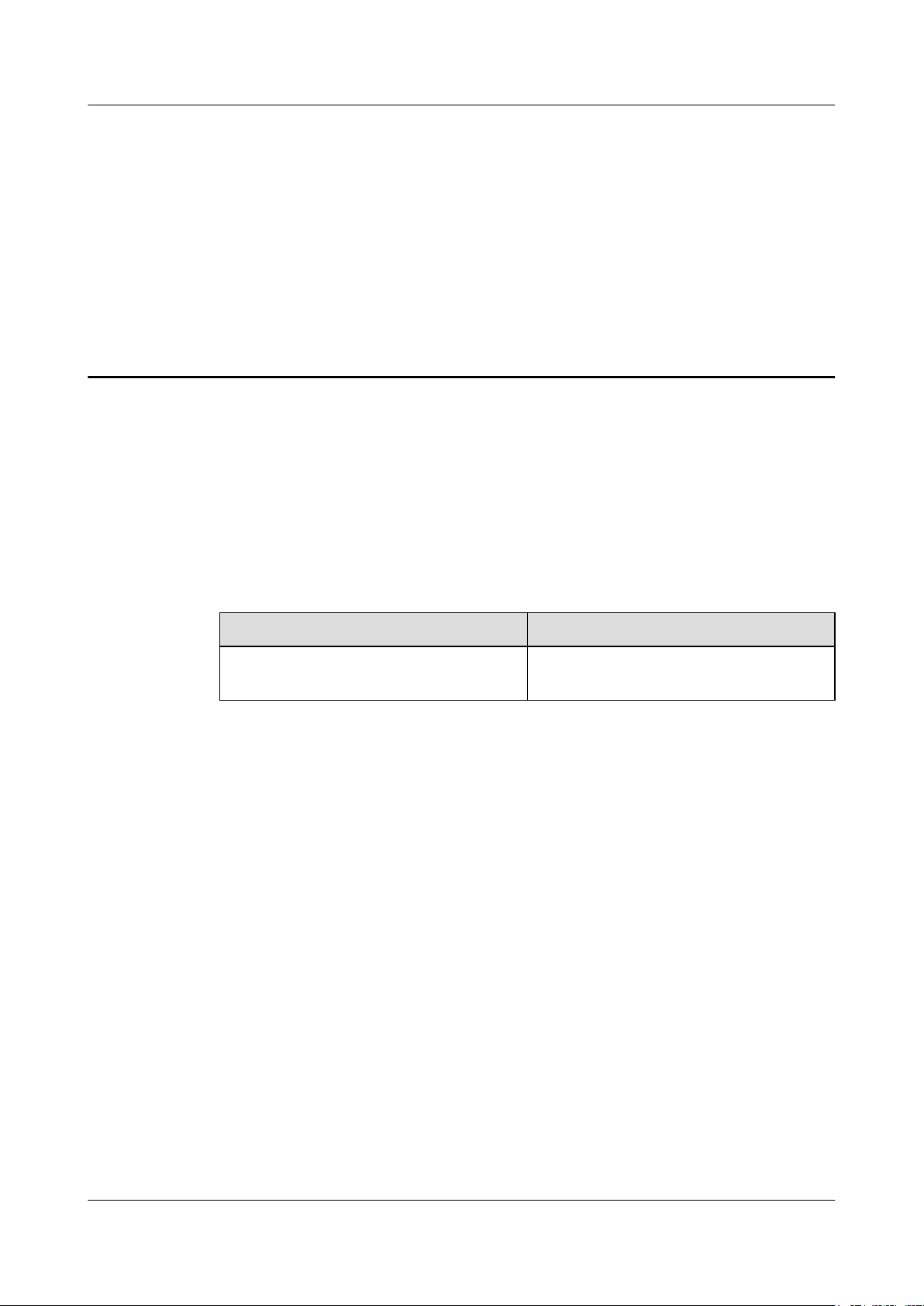

Specification

The following table describes the specifications of an ODM.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

optic cables

(8) Cable hole for the

input power cable

(12) Pigtail adapter

13

Page 23

AAU3940

Installation Guide 2 Overview

Table 2-2 ODM specifications

Item Specifications

Dimensions (H x W xD)232 mm x 158 mm x 96.5 mm (9.13 in. x 6.22 in. x 3.80 in.)

Upper-level circuit

20 A

breaker

Support power 1650 W

Power supply

capacity

Fiber division

capacity

Cable specifications

One AC power input and four AC power outputs (Each power output

is less than or equal to 400 W.)

One trunk fiber optic cable and three pairs of breakout fiber optic

cables (six breakout fiber optic cables)

l Cross-sectional area of an input power cable: 1.5 mm2 to 4 mm

(0.002 in.2 to 0.006 in.2). External diameter of an input power

cable: 8.3 mm to 15mm (0.33 in. to 0.59 in.)

l Cross-sectional area of an output power cable: 1.5 mm2 to 2.5

mm2 (0.002 in.2 to 0.004 in.2). External diameter of an output

power cable: 8.3 mm to 13.5 mm (0.33 in. to 0.53 in.)

l External diameter of an input fiber optic cable: 9.8 mm to 11 mm

(0.39 in. to 0.43 in.)

l External diameter of an output fiber optic cable: 7.0 mm (0.28 in.)

2

Mounting Kits

The following figure shows the mounting kits for an ODM.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

Page 24

AAU3940

Installation Guide

2 Overview

Figure 2-10 Mounting kits for an ODM

(1) Attachment plate (2) Mounting bracket (3) Steel belt (4) Expansion bolt

2.5 Surge Protection Requirements

When an AAU is installed on a pole or the top of a pole, the AAU must meet the surge protection

requirements. Otherwise, surge protection measures must be taken.

A direct lightning strike protection measure must be taken (that is, a lightning rod is installed)

if AAU installation meets the following conditions:

l When the AAU is installed on a pole or the top of a pole, the distance between the top of

the pole and the top of the AAU is less than 30 cm (0.98 ft).

l The AAU is not installed within the protection range of the lightning rod.

When a lightning rod is installed near the AAU installation position, the following conditions

must be met:

l The distance between the lightning rod and the top of the AAU must be greater than 30 cm

(0.98 ft).

l The lightning rod must be properly connected to the onsite ground grid.

l The AAU PGND cable must be routed along the inner side of the pole and is connected to

the ground bar of the onsite ground grid.

l In addition to the above conditions, the lightning rod installation must meet other building

surge protection requirements.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

Page 25

AAU3940

Installation Guide 2 Overview

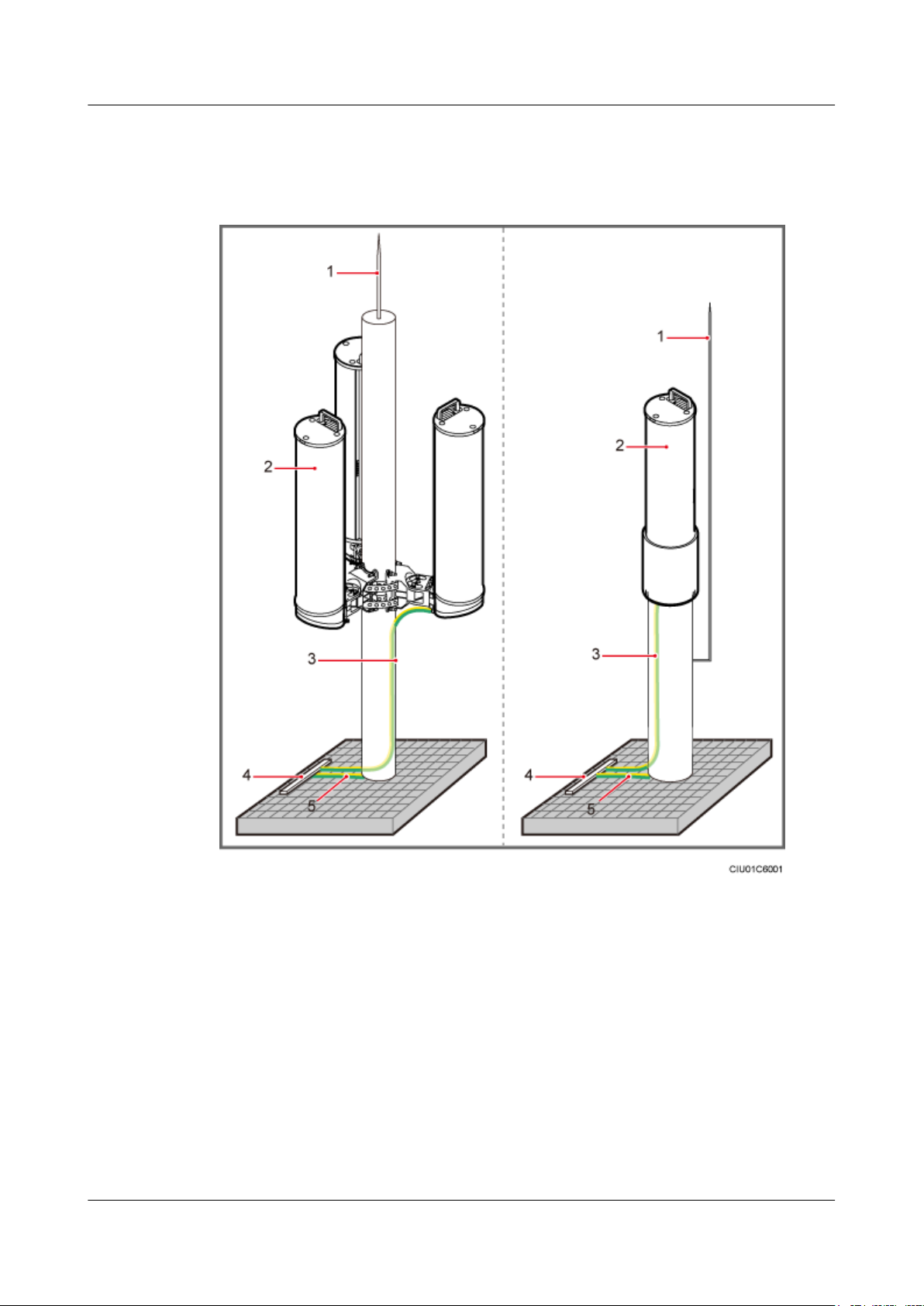

The following figure shows AAU installation scenarios in which surge protection measures are

taken.

Figure 2-11 AAU installation scenarios in which surge protection measures are taken

(1) Lightning rods (2) AAUs (3) AAU PGND cables

(4) Ground bars of ground girds (5) PGND cables for metal poles -

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

Page 26

AAU3940

Installation Guide 3 Installation Preparations

3 Installation Preparations

About This Chapter

This chapter lists the tools and instruments that must be obtained before the installation. It also

specifies the skills that the onsite personnel must have.

3.1 Documents

This section lists the documents that must be obtained before the installation.

3.2 Tools and Instruments

You must prepare the following tools and instruments before the installation.

3.3 Requirements for Onsite Personnel

Onsite personnel must be qualified and trained. Before performing any operation, onsite

personnel must be familiar with correct operation methods and safety precautions.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

Page 27

AAU3940

Installation Guide 3 Installation Preparations

3.1 Documents

This section lists the documents that must be obtained before the installation.

l Before the installation, familiarize yourself with related information in the following

documents:

– AAU3940 Hardware Description

– Safety Information

l During the installation, refer to the following document:

– Installation Reference

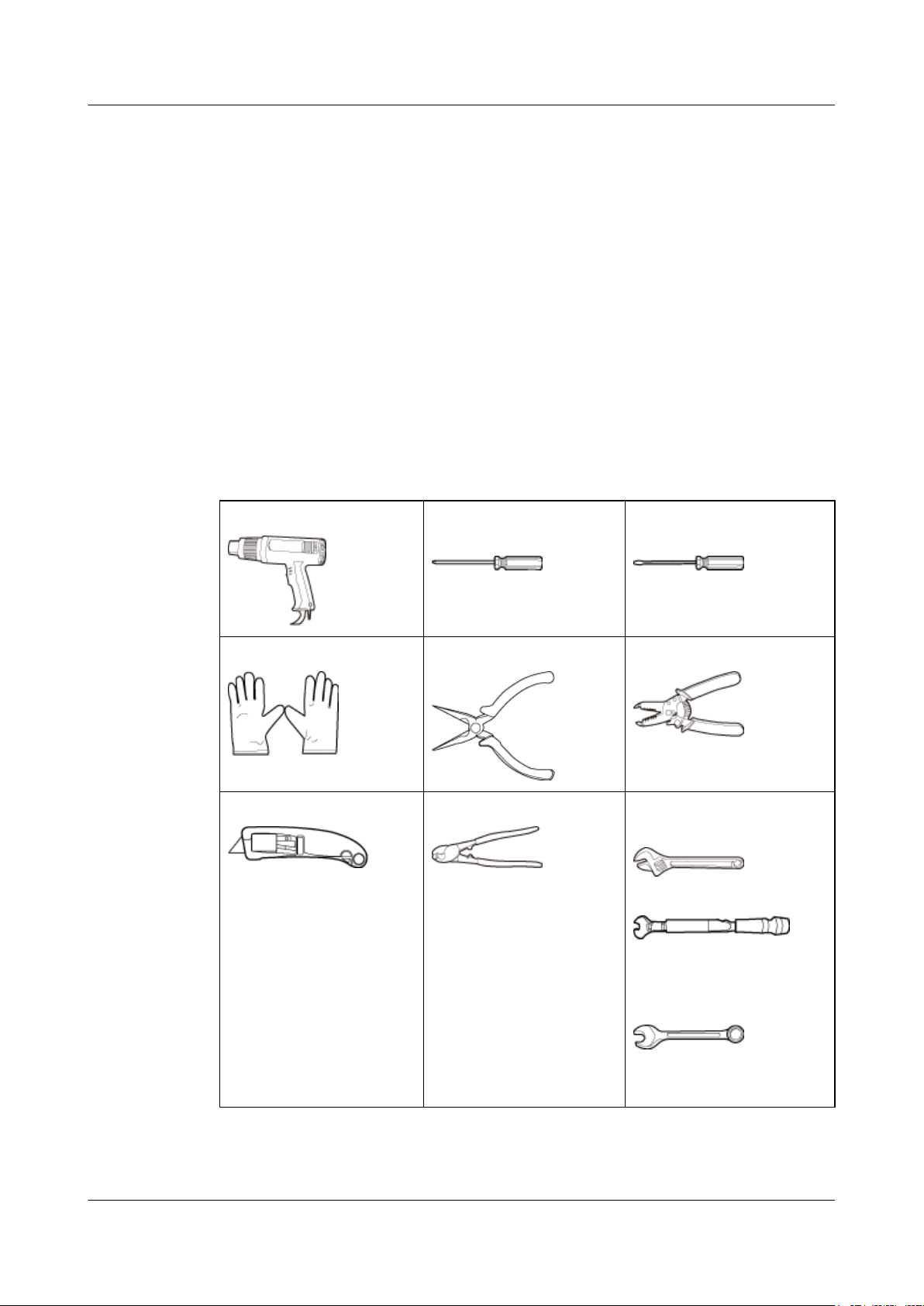

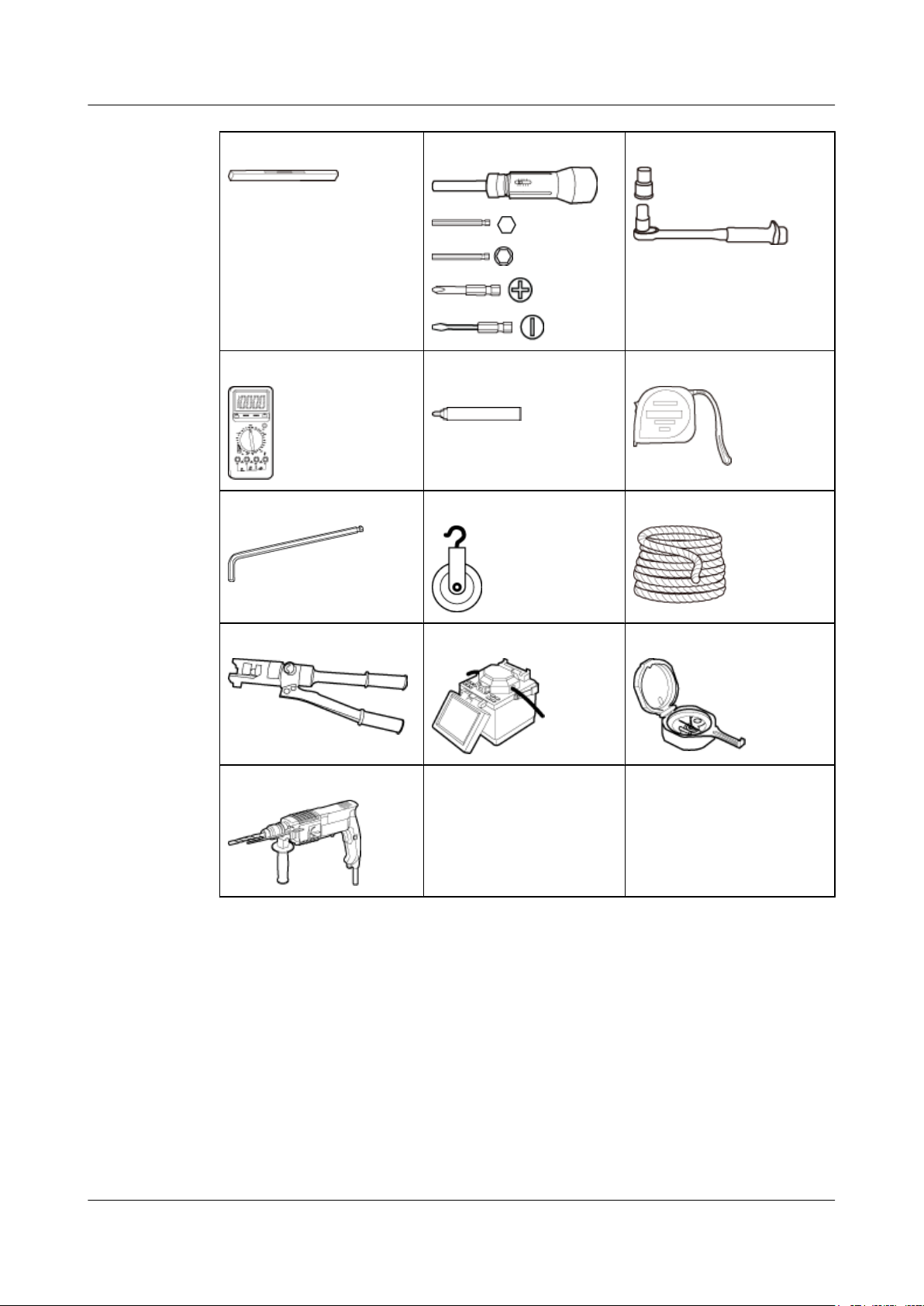

3.2 Tools and Instruments

You must prepare the following tools and instruments before the installation.

Heat gun

ESD gloves Needle-nose pliers Wire stripper

Utility knife Cable cutter

Phillips screwdriver (M3 to

M6)

Flat-head screwdriver (M3 to

M6)

Adjustable wrench (size ≥ 32

mm or 1.26 in.)

Torque wrench

Size: 16 mm (0.63 in.) and 32

mm (1.26 in.)

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Combination wrench

Size: 16 mm (0.63 in.) and 32

mm (1.26 in.)

18

Page 28

AAU3940

Installation Guide

3 Installation Preparations

Level Torque screwdriver Torque socket

Multimeter

Hex key Fixed pulley Lifting sling

Hydraulic pliers Fiber fusion splicer Geologic compass

Hammer drill

Marker (diameter ≤ 10 mm

or 0.39 in.)

Measuring tape

3.3 Requirements for Onsite Personnel

Onsite personnel must be qualified and trained. Before performing any operation, onsite

personnel must be familiar with correct operation methods and safety precautions.

The customer must pay attention to the following points before the installation:

l The customer's technical engineers must be trained by Huawei and be familiar with the

installation and operation methods.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Page 29

AAU3940

Installation Guide 3 Installation Preparations

l The number of onsite personnel depends on the engineering schedule and installation

environment. Generally, four to five onsite personnel are necessary.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Page 30

AAU3940

Installation Guide 4 Unpacking Check

4 Unpacking Check

Unpack and check the delivered equipment to ensure that all materials are included and intact.

Context

Procedure

Step 1 Check the total number of articles in each case according to the packing list.

NOTE

When transporting, moving, or installing equipment or components,

l Prevent them from colliding with doors, walls, shelves, or other objects.

l Avoid touching their unpainted metal surfaces with sweat-soaked or dirty gloves or bare hands.

NOTICE

Power on an AAU within 24 hours after unpacking it.

If... Then...

The total number tallies with the packing

list

Go to 2.

The total number does not tally with the

packing list

Step 2 Check the exterior of the packing case.

If... Then...

The outer packing case is intact Go to Step 3.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Find out the cause and report any missing

articles to the local Huawei office.

21

Page 31

AAU3940

Installation Guide 4 Unpacking Check

If... Then...

The outer packing is severely damaged or

soaked

Step 3 Check the type and quantity of the equipment in the cases according to the packing list.

If... Then...

Types and quantity of the articles tally with

those on the packing list

There are any goods missing, incorrectly

delivered, or damaged

Find out the cause and report the situation to

the local Huawei office.

Sign the Packing List with the customer.

Report the situation to the local Huawei office.

CAUTION

To protect the equipment and prevent damage to the equipment, you are advised to keep the

unpacked equipment and packing materials indoors, take photos of the stocking environment,

packing case or carton, packing materials, and any rusted or eroded equipment, and then file the

photos.

Step 4 Take the recording form out of the carton containing antennas and fill in the form according to

the actual situation.

NOTICE

Ensure that the RET SN on the antenna's name plate is consistent with that in the recording form.

----End

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Page 32

AAU3940

Installation Guide 5 Installation Process

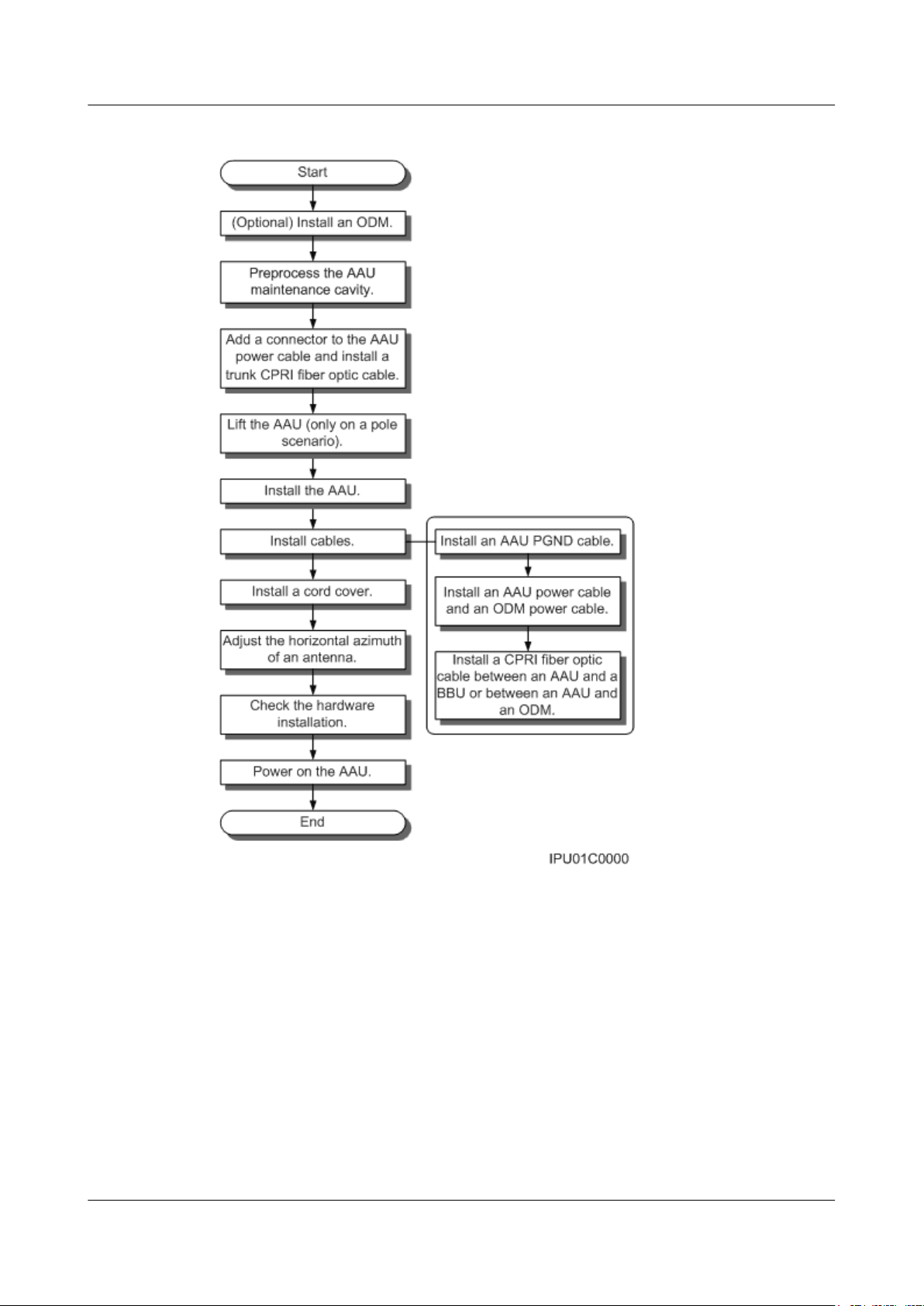

5 Installation Process

This chapter describes the process of installing an AAU.

The following figure shows the installation process.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

Page 33

AAU3940

Installation Guide 5 Installation Process

Figure 5-1 Installation process

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

Page 34

AAU3940

Installation Guide

Context

6 (Optional) Installing an ODM

6 (Optional) Installing an ODM

This section describes the procedure and precautions for installing an ODM.

Procedure

The part of a pole for installing the mounting bracket of an ODM should have a diameter of 114

mm to 380 mm (4.489 in. to 14.96 in.).

l Installing an ODM on a wall

1. Determine a position for installing an ODM on a wall, use a level to adjust the position

to ensure that the mounting bracket will be placed horizontally, and use a marker to

mark anchor points, as shown in the following figure.

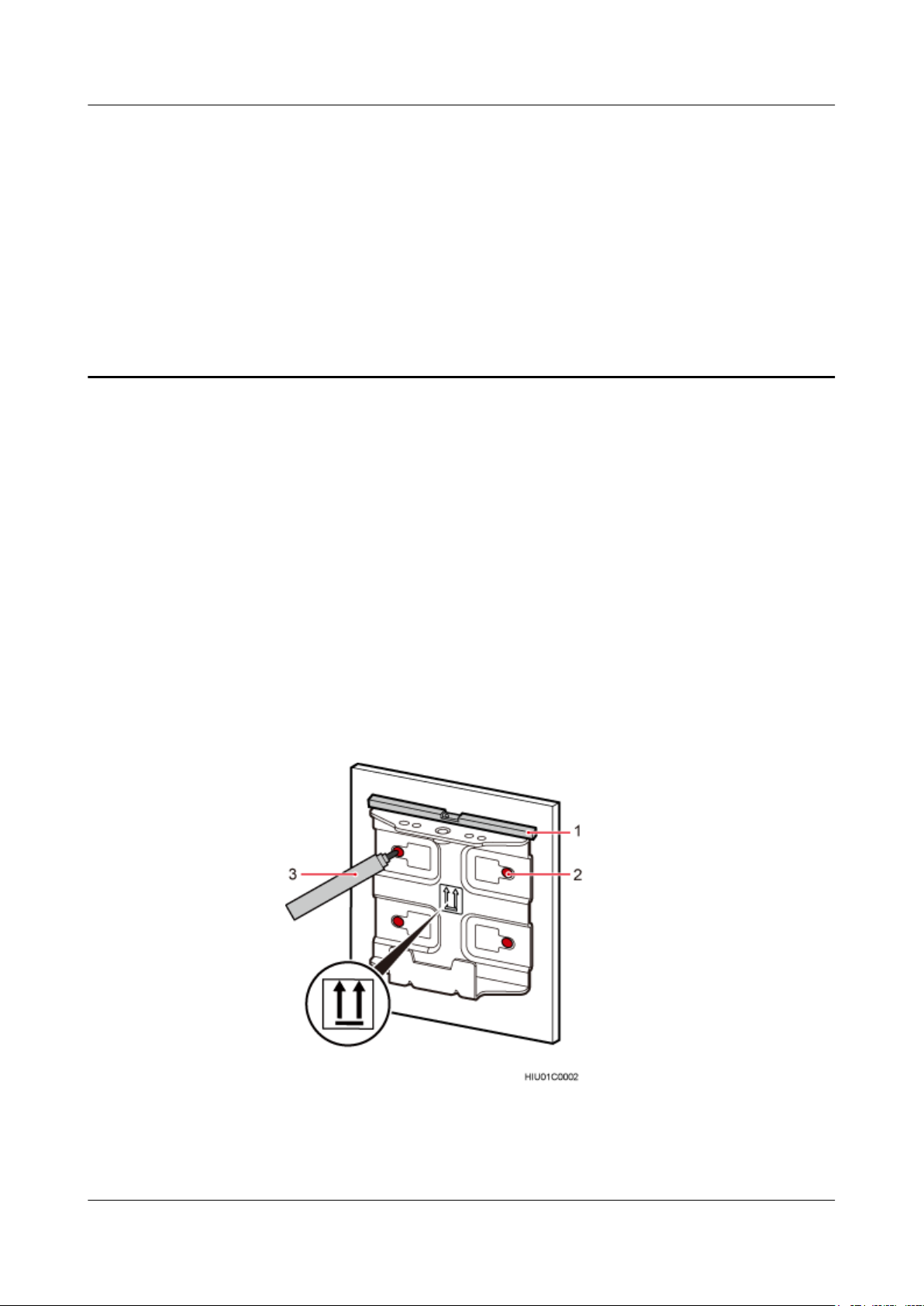

Figure 6-1 Determining a position for installing an ODM

(1) Level

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

(2) Screw hole (3) Marker

25

Page 35

AAU3940

Installation Guide

6 (Optional) Installing an ODM

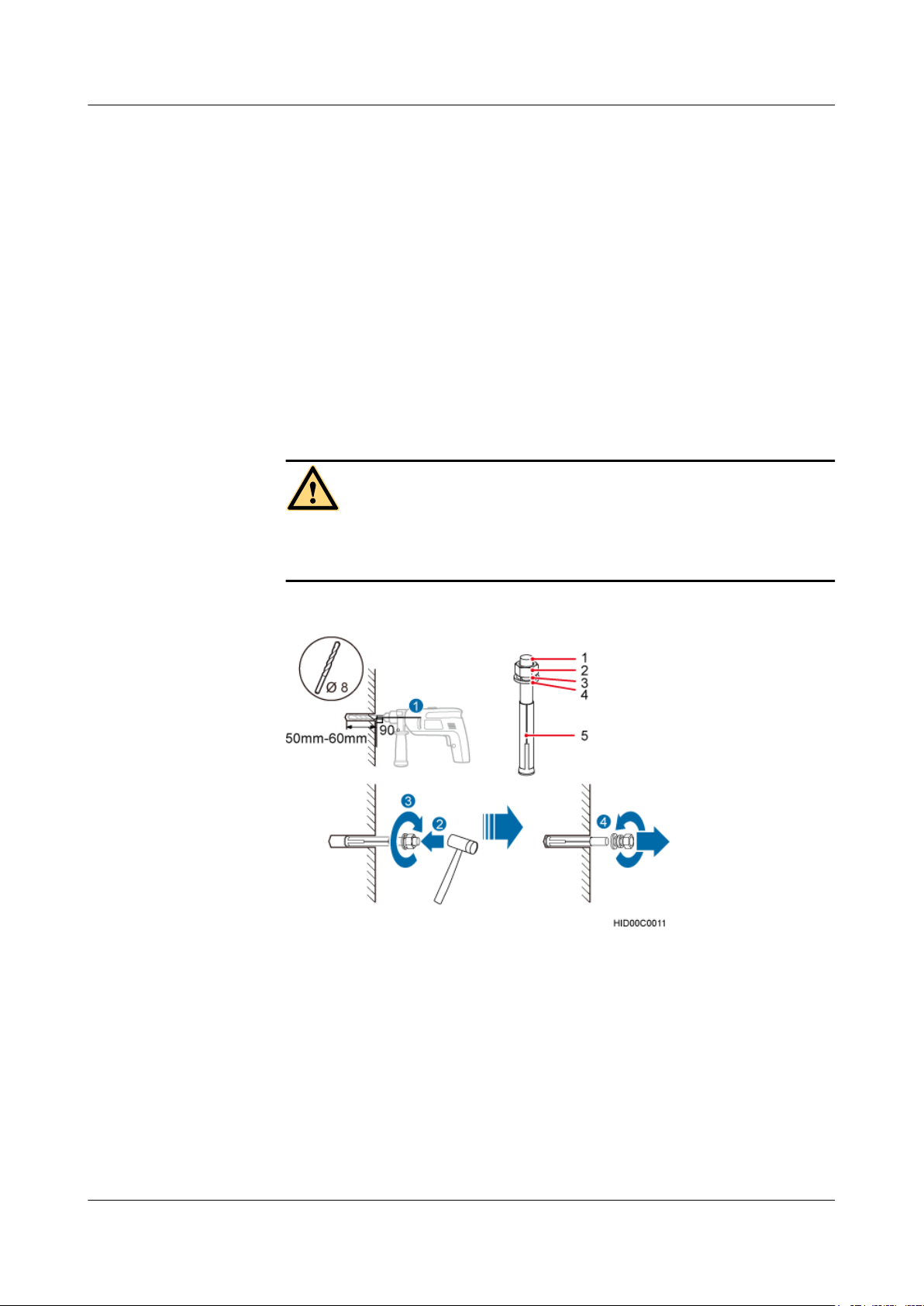

2. Drill holes at the anchor points and install expansion bolts in the holes, as shown in

the following figure.

a. Use a hammer drill with a Φ8 bit to drill holes vertically at the marked anchor

points. Ensure that the depth of each hole ranges from 50 mm to 60 mm (1.97 in.

to 2.36 in.).

b. Use a vacuum cleaner to clear the dust inside and around the holes, and measure

the distances between holes. If any of the holes is beyond the acceptable range,

mark a new anchor point and drill a new hole.

c. Tighten an expansion bolt slightly and place it vertically into each hole.

d. Use a rubber mallet to pound the expansion bolt until it goes into the hole

completely. Ensure that a 20 mm (0.79 in.) part of the expansion bolt is left

outside the wall.

e. Remove the M6x60 bolt, nut, spring washer, and flat washer in sequence.

CAUTION

Take proper safety measures to protect your eyes and respiratory tract against the dust

before drilling holes.

Figure 6-2 Drilling a hole and inserting an expansion bolt assembly

(1) M6x60 bolt

(2) Nut (3) Spring washer (4) Flat washer (5) Expansion tube

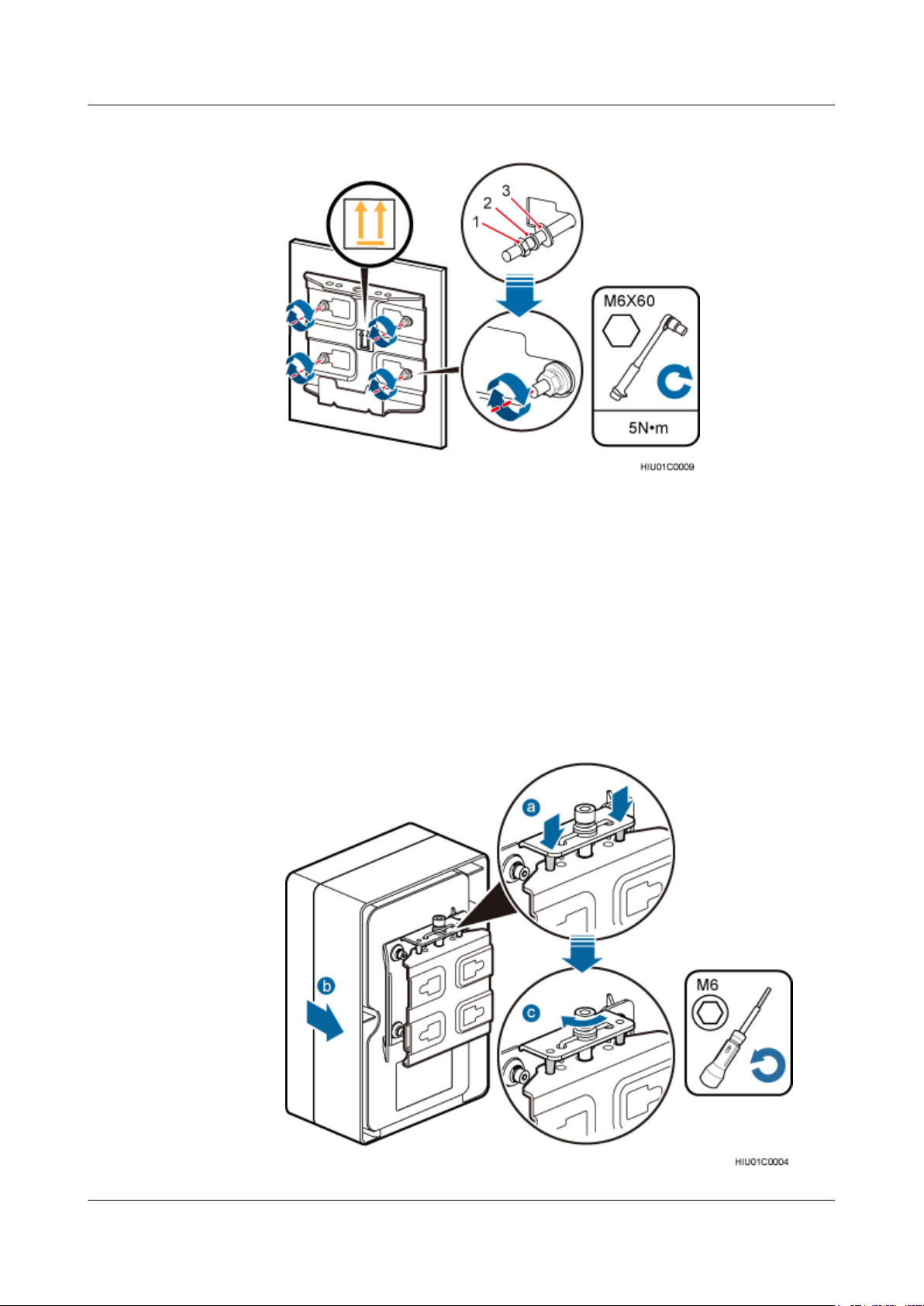

3. Place the mounting bracket against the installation position on the wall, and use four

M6x60 bolts to tighten the mounting bracket to 5 N·m (44.25 lbf·in.), as shown in the

following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

Page 36

AAU3940

Installation Guide 6 (Optional) Installing an ODM

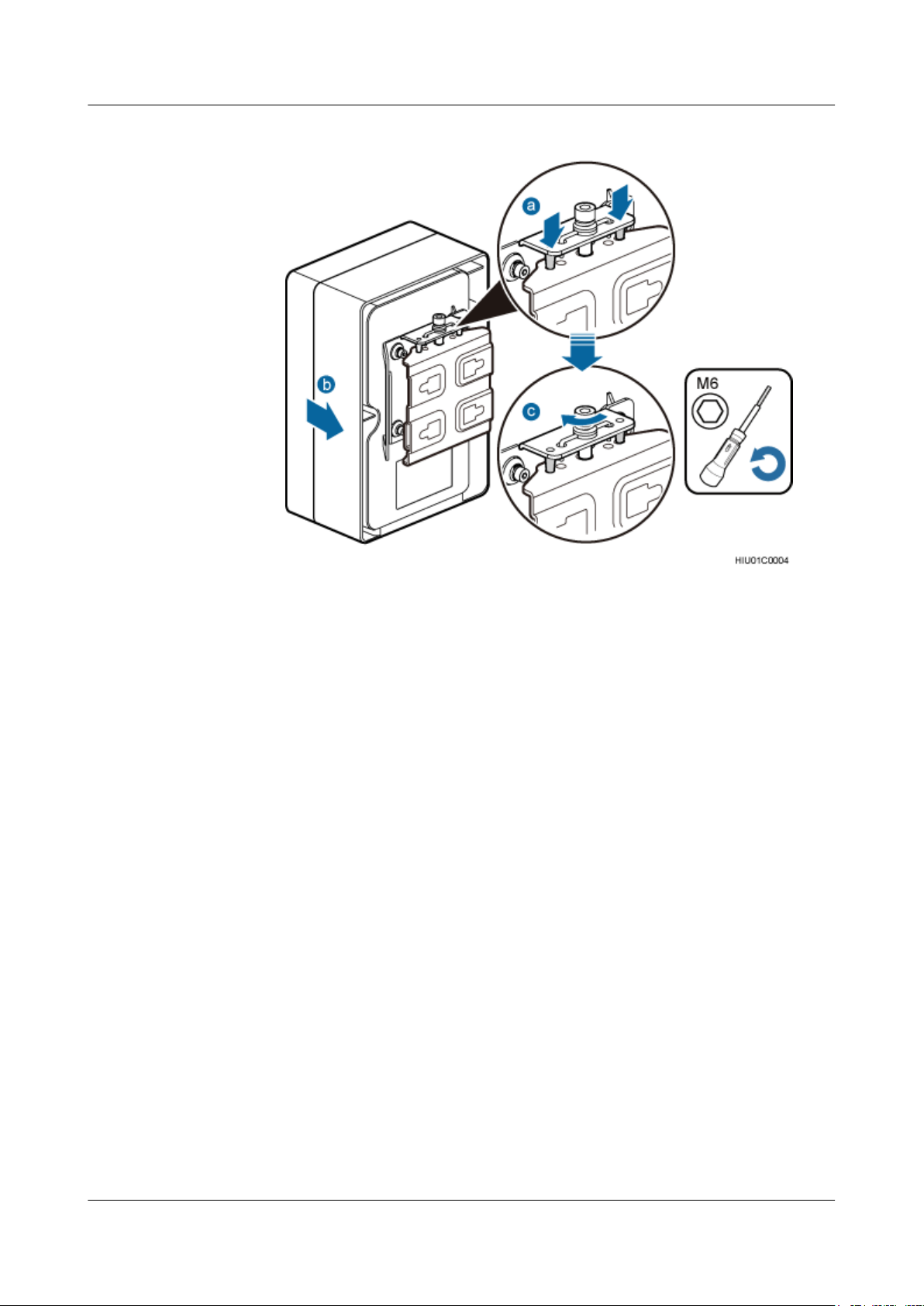

Figure 6-3 Tightening a mounting bracket to the installation position on a wall

(1) Nut (2) Spring washer (3) Flat washer

4. Fit the two dowels on the top of the ODM backplane into the mounting bracket, and

push the ODM case until it is attached onto the mounting bracket, as shown by

illustrations a and b in the following figure.

5. Use a double-headed inner hexagon tool to tighten the screw on the top of the

attachment plate clockwise to 7 N·m (61.95 lbf·in.), as shown by illustration c in the

following figure.

Figure 6-4 Installing an ODM to a mounting bracket

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

Page 37

AAU3940

Installation Guide 6 (Optional) Installing an ODM

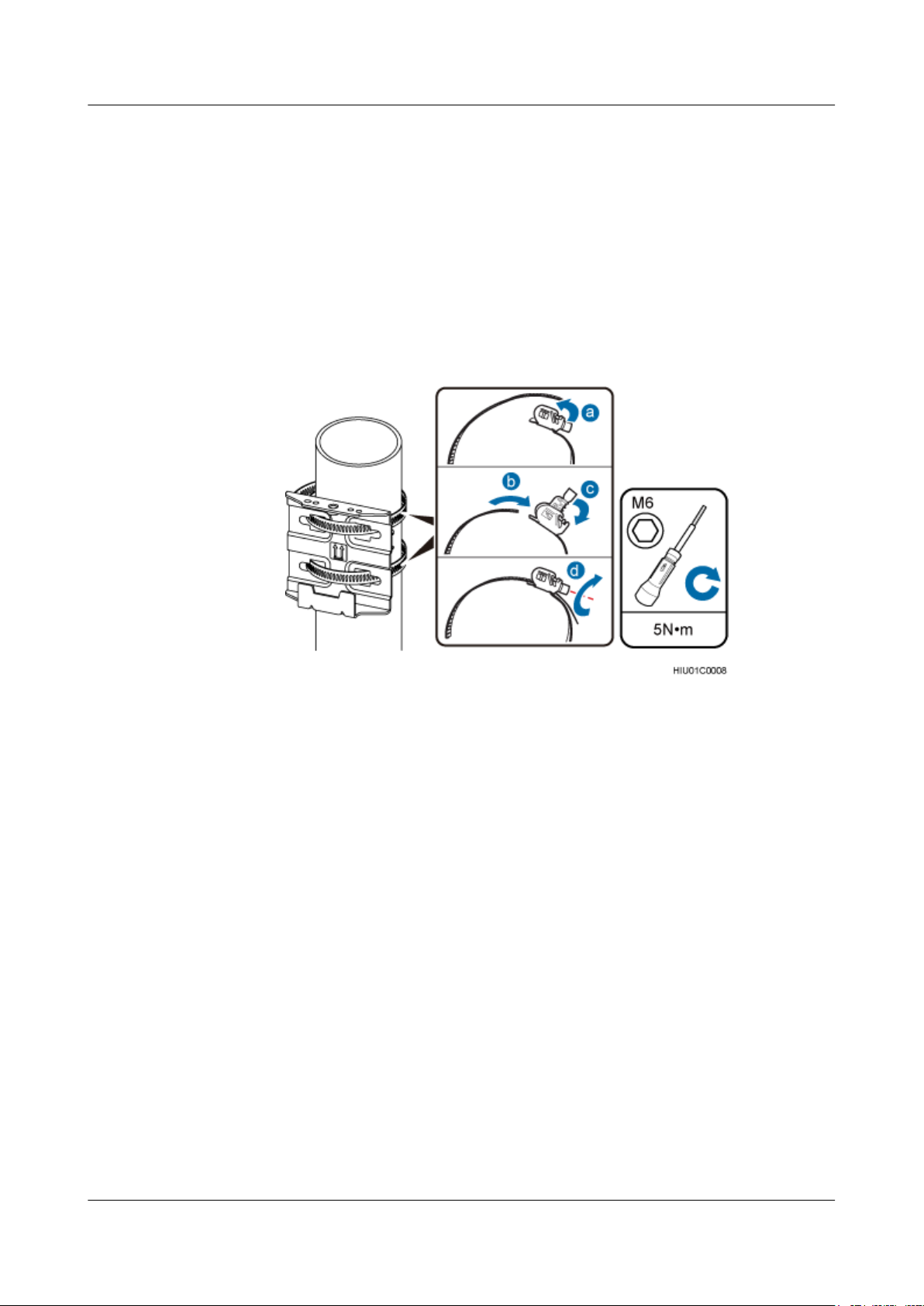

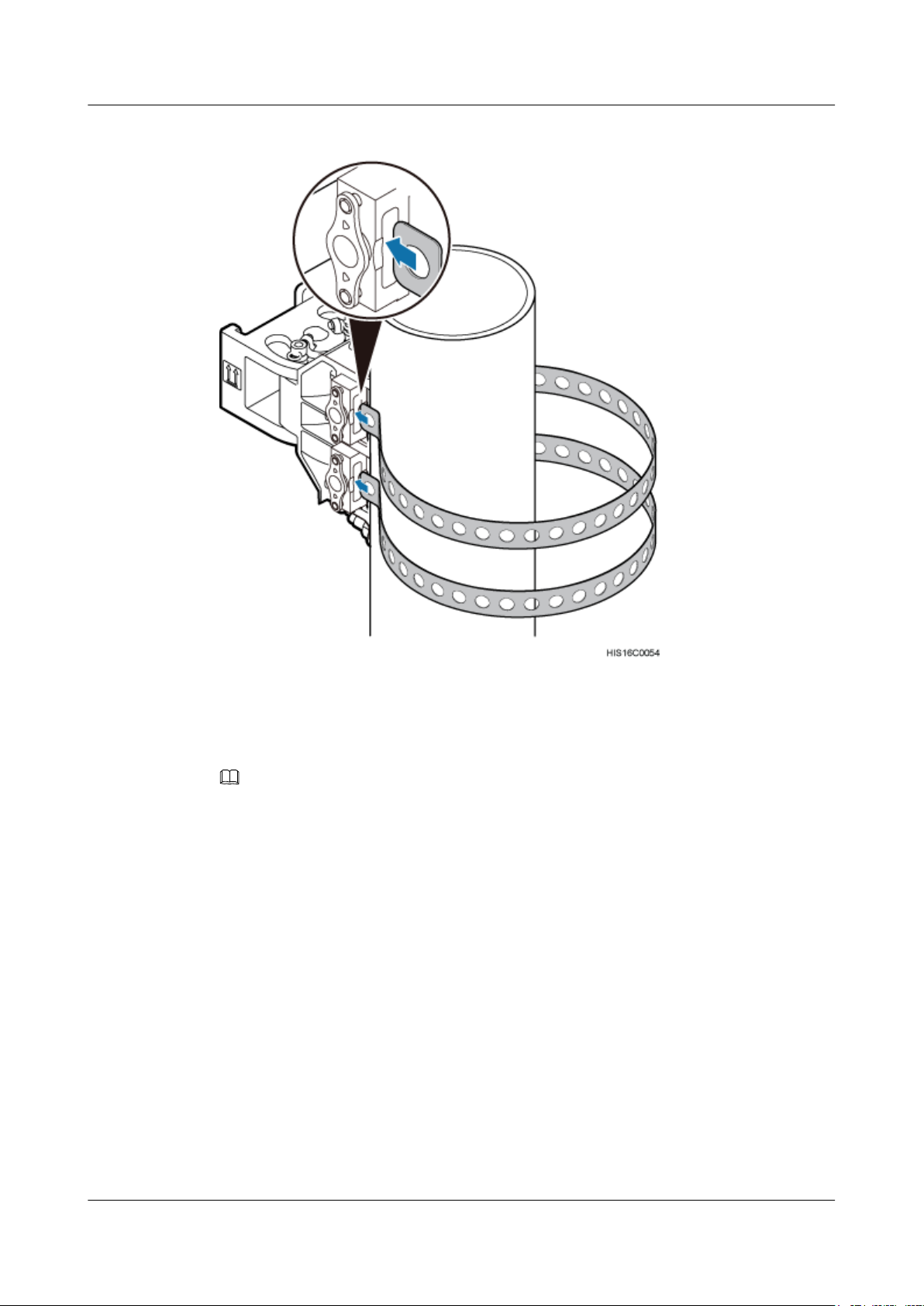

l Installing an ODM on a pole

1. Determine a position for installing an ODM on a pole, attach a mounting bracket to

the installation position on the pole, put the steel belts through the mounting bracket,

and wind the steel belts round the pole for one circle, as shown by illustrations a, b,

and c in the following figure.

2. Use an M6 inner hexagon wrench to tighten the bolts on the two steel belts alternately

to secure the mounting bracket to 5 N·m (44.25 lbf·in.), as shown by illustration d in

the following figure.

Figure 6-5 Securing a mounting bracket to a pole

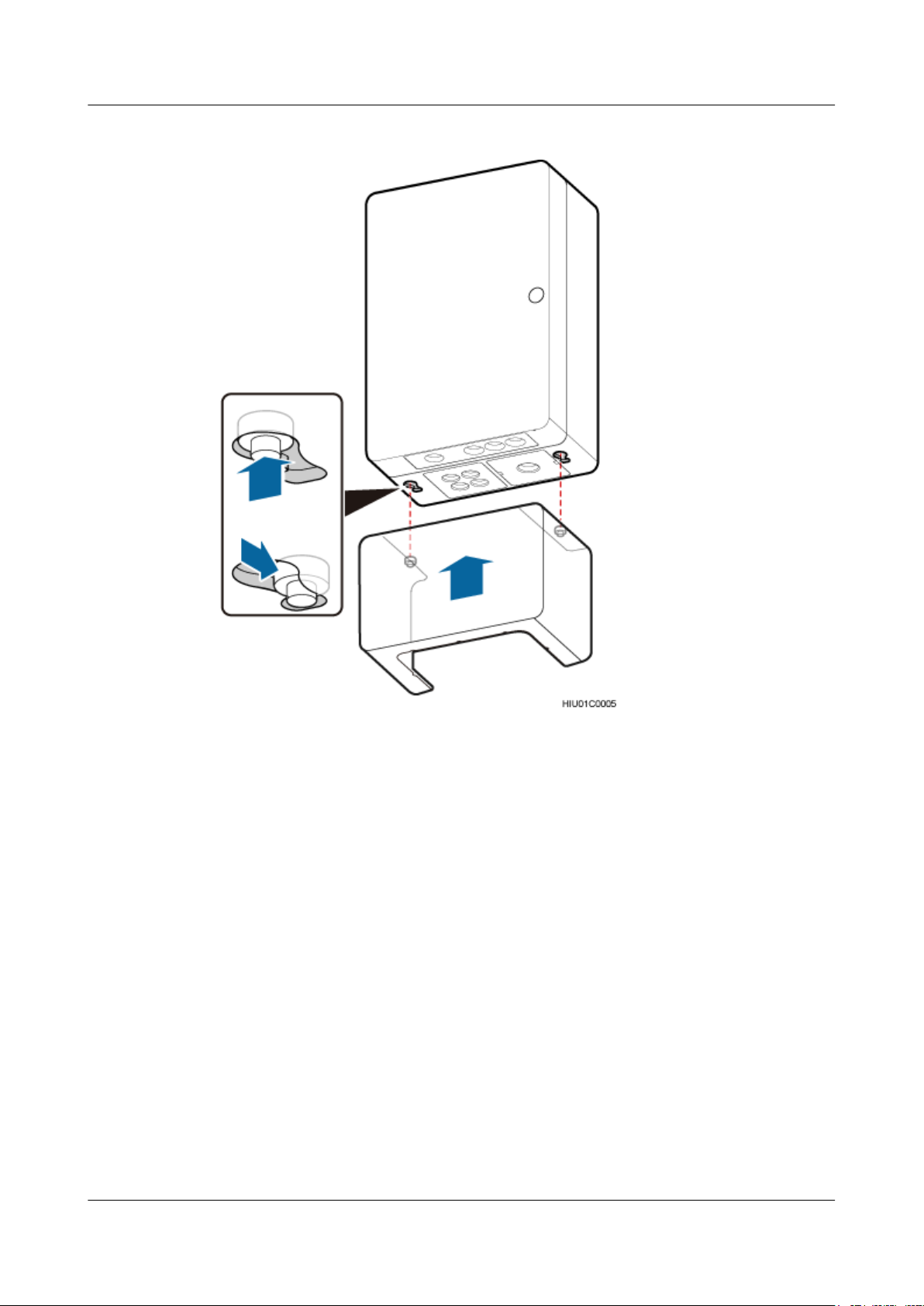

3. Fit the two dowels on the top of the ODM backplane into the mounting bracket, and

push the ODM case until it is attached onto the mounting bracket, as shown by

illustrations a and b in the following figure.

4. Use a double-headed inner hexagon tool to tighten the screw on the top of the

attachment plate clockwise to 7 N·m (61.95 lbf·in.), as shown by illustration c in the

following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

Page 38

AAU3940

Installation Guide 6 (Optional) Installing an ODM

Figure 6-6 Installing an ODM to a mounting bracket

----End

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

Page 39

AAU3940

Installation Guide

7 Preprocessing the AAU Maintenance Cavity

7 Preprocessing the AAU Maintenance Cavity

Before installing an AAU, take power terminals out of its maintenance cavity and install optical

modules.

Procedure

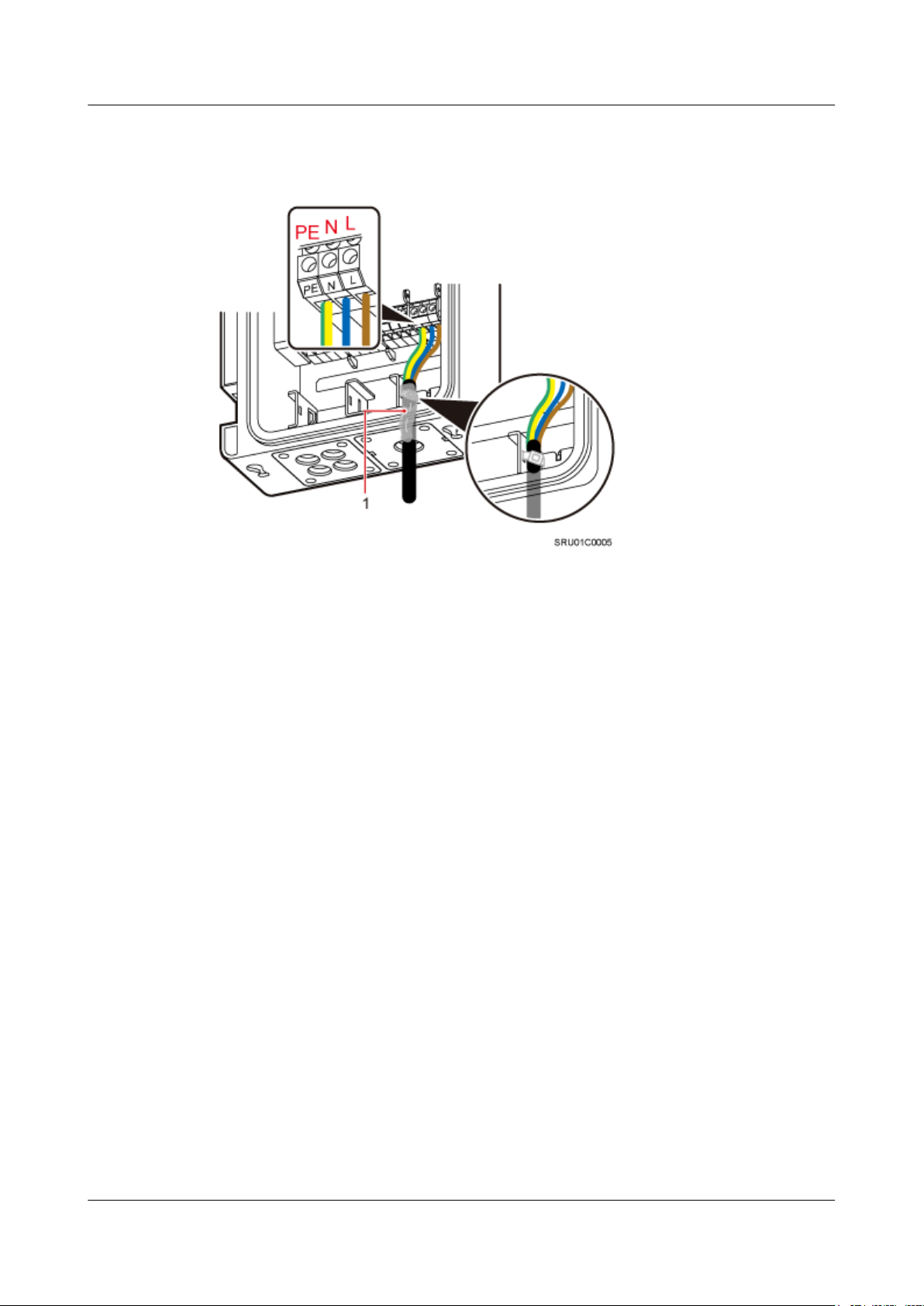

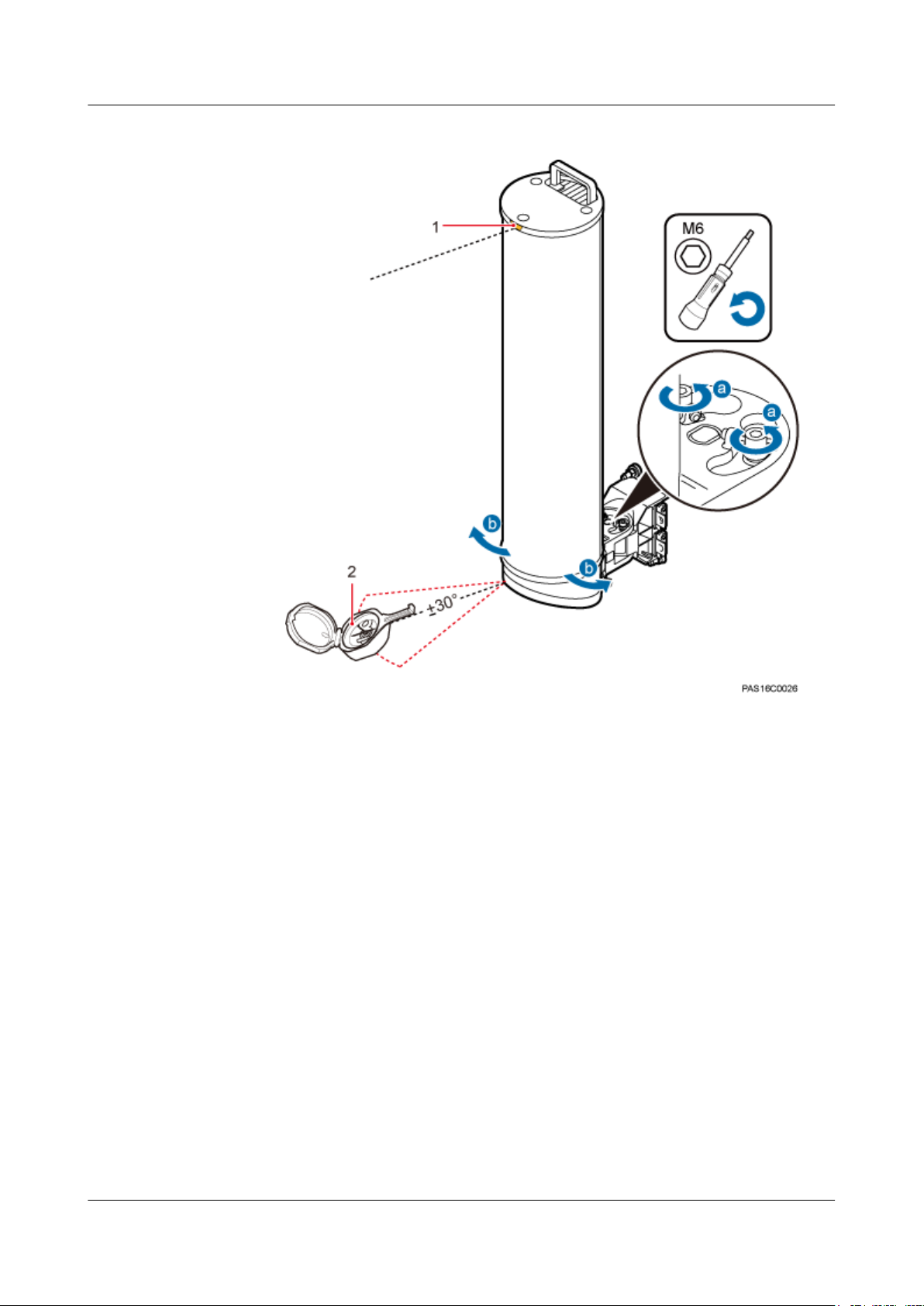

Step 1 Use an M6 inner hexagon torque screwdriver to loosen the screw on the maintenance cavity and

open the maintenance cavity. Then take out of power terminals, as shown in the following figure.

Figure 7-1 Taking out of power terminals

Step 2 Prepare power cables according to the instructions in 16.2 Adding a Tool-Less Female

Connector (Pressfit Type) to an AAU Power Cable on the AAU Side

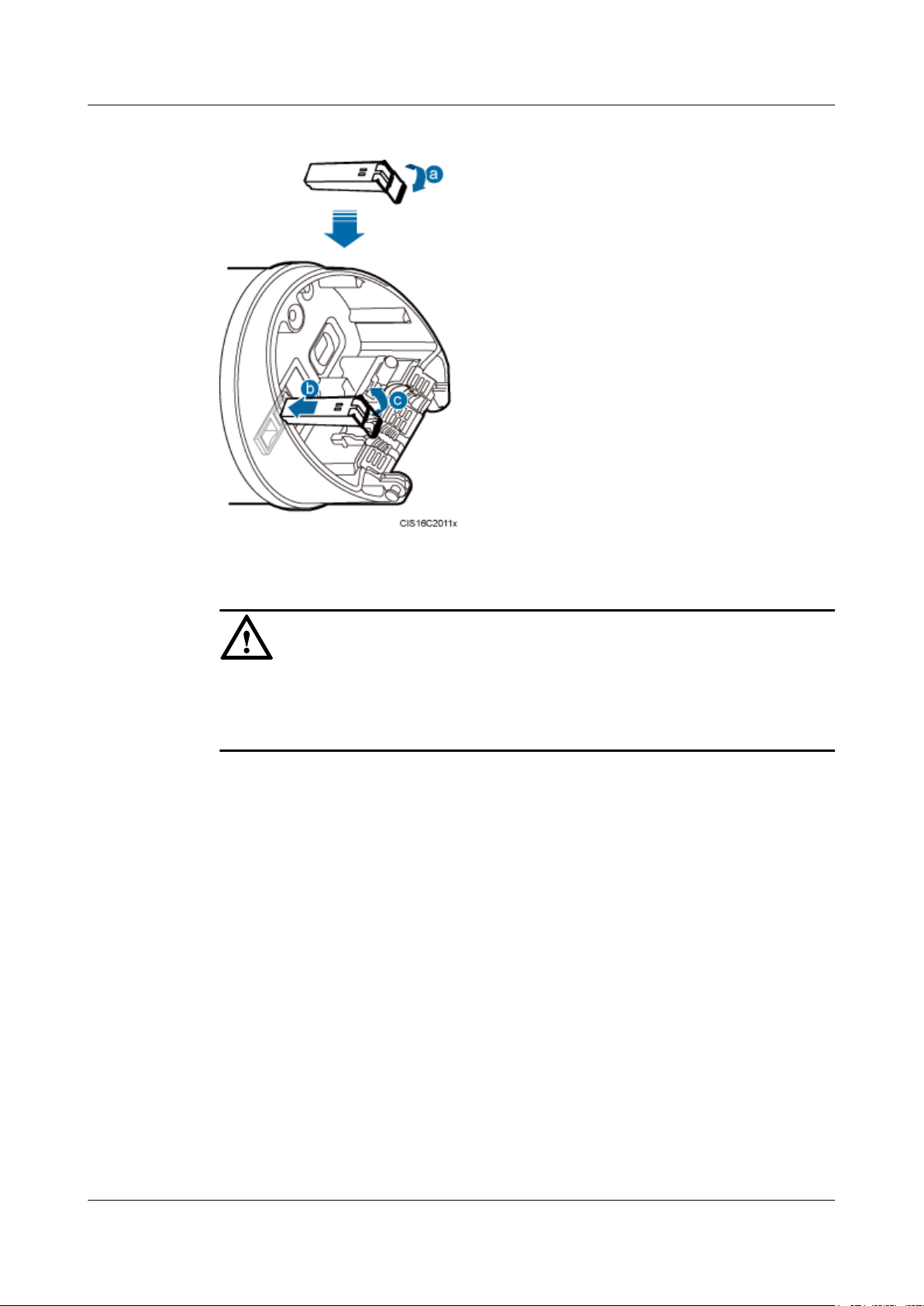

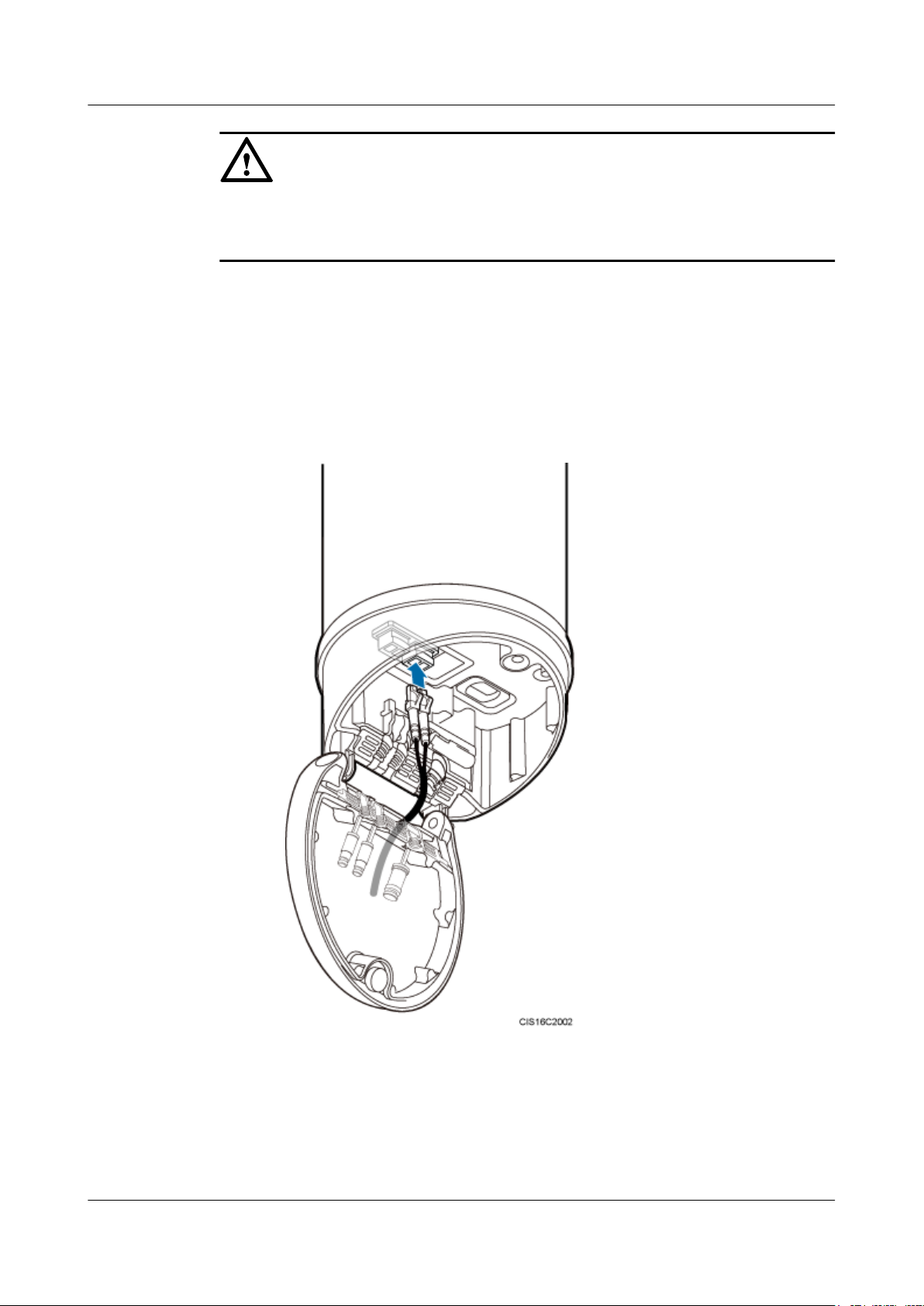

Step 3 Lower the puller of the optical module, insert the optical module into the CPRI port on the AAU,

and raise the puller, as shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

Page 40

AAU3940

Installation Guide 7 Preprocessing the AAU Maintenance Cavity

Figure 7-2 Installing the optical module

NOTICE

The performance of an optical module may deteriorate if it is exposed to the air for more than

20 minutes. Therefore, insert a fiber optic cable into an unpacked optical module within 20

minutes.

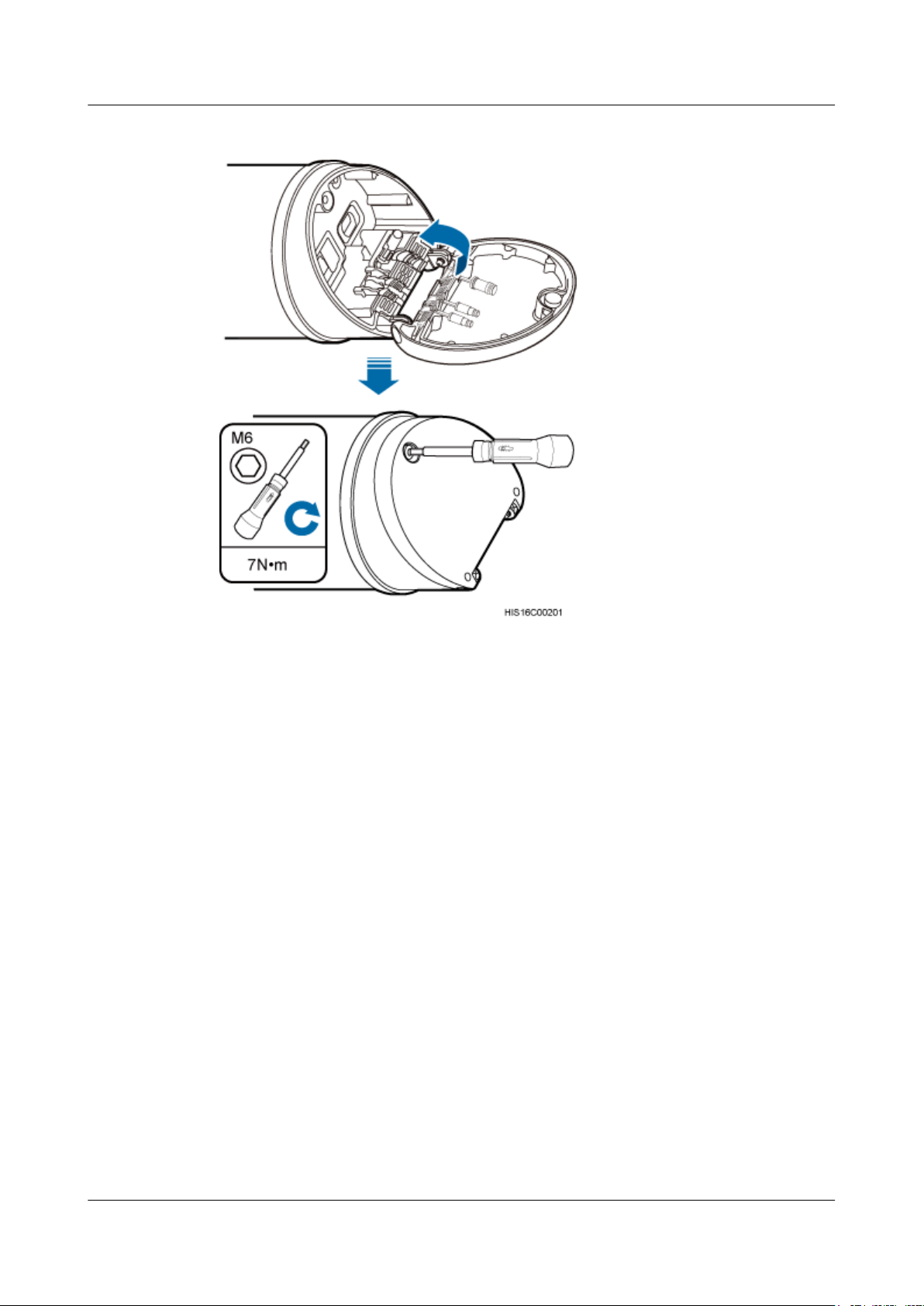

Step 4 Use an M6 inner hexagon torque screwdriver to tighten the screw on the maintenance cavity to

7 N·m (61.95 lbf·in.), as shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

Page 41

AAU3940

Installation Guide 7 Preprocessing the AAU Maintenance Cavity

Figure 7-3 Closing a maintenance cavity

Step 5 Install the attachment plate on the maintenance cavity of the AAU to be installed, and use an

M6 inner hexagon torque screwdriver to tighten the screws to 7 N·m (61.95 lbf·in.), as shown

in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

Page 42

AAU3940

Installation Guide 7 Preprocessing the AAU Maintenance Cavity

Figure 7-4 Installing an attachment plate

----End

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

Page 43

AAU3940

Installation Guide

Prerequisites

8 Lifting an AAU

8 Lifting an AAU

Before installing an AAU on a pole, you need to lift the AAU to the installation position on the

pole.

Context

Procedure

You have preprocessed the AAU maintenance cavity. For detailed operations, see 7

Preprocessing the AAU Maintenance Cavity.

It is recommended that a tail-lift truck be used to lift installation personnel and equipment to the

installation position. If there is no tail-lift truck, a reliable and safe scaffold can be used.

NOTICE

Do not work at heights when you meet any of the following situations:

l Thunder, lightning, rain, or wind greater than force 6 occurs.

l Water remains on the surface of the steel tube.

l There may be other danger.

After the above situations are eliminated, the Huawei security director and related technical

personnel must check all devices to be used before work start.

Step 1 Installation person A lifts and places the bound mounting kits to the scaffold platform, as shown

in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

Page 44

AAU3940

Installation Guide

8 Lifting an AAU

Figure 8-1 Lifting mounting kits

Step 2 Use the lifting sling to bind the handle on the top of the AAU and use the traction sling to bind

the lower part of the AAU, as shown in the following figure.

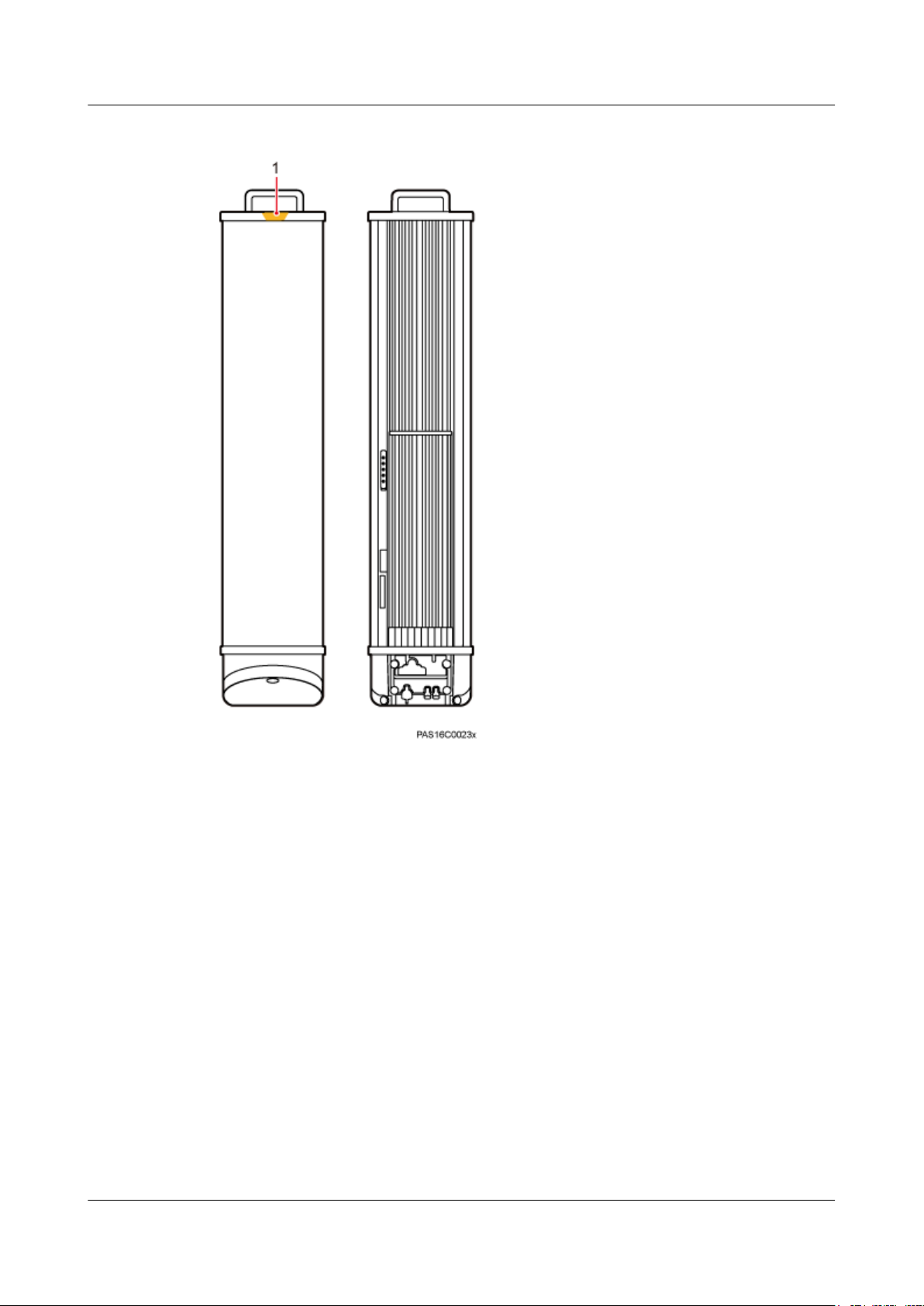

Figure 8-2 Binding an AAU

(1) Handle on the top

(2) Lifting sling (3) Traction sling

Step 3 Installation person A climbs up onto the scaffold and then lifts and places the AAU on the

scaffold platform, and installation person B pulls the traction sling outwards to prevent the AAU

from colliding with the scaffold, as shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

Page 45

AAU3940

Installation Guide 8 Lifting an AAU

Figure 8-3 Lifting an AAU

----End

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

Page 46

AAU3940

Installation Guide 9 Installing an AAU

9 Installing an AAU

About This Chapter

This chapter describes the procedures for installing an AAU in different scenarios.

9.1 Installing an AAU on a Pole

This section describes the procedure and precautions for installing an AAU on a pole.

9.2 Installing an AAU on the Top of a Pole

This section describes the procedure and precautions for installing an AAU on the top of a pole.

9.3 Installing an AAU on a Wall

This section describes the procedure and precautions for installing an AAU on a wall.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

Page 47

AAU3940

Installation Guide 9 Installing an AAU

9.1 Installing an AAU on a Pole

This section describes the procedure and precautions for installing an AAU on a pole.

Prerequisites

l You have preprocessed the AAU maintenance cavity. For detailed operations, see 7

Preprocessing the AAU Maintenance Cavity.

l You have lifted the AAU and mounting kits to the installation position on the pole. For

detailed operations, see 8 Lifting an AAU.

Context

NOTICE

Procedure

Step 1 Determine a position for installing the mounting kits on a pole.

Step 2 Attach the mounting kits to the installation position on the pole, wind each steel belt round the

Do not work at heights when you meet any of the following situations:

l Thunder, lightning, rain, or wind greater than force 6 occurs.

l Water remains on the surface of the steel tube.

l There may be other danger.

After the above situations are eliminated, the Huawei security director and related technical

personnel must check all devices to be used before work start.

pole for one circle, and put the steel belt through the sliding block of the mounting kits, as shown

in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

Page 48

AAU3940

Installation Guide 9 Installing an AAU

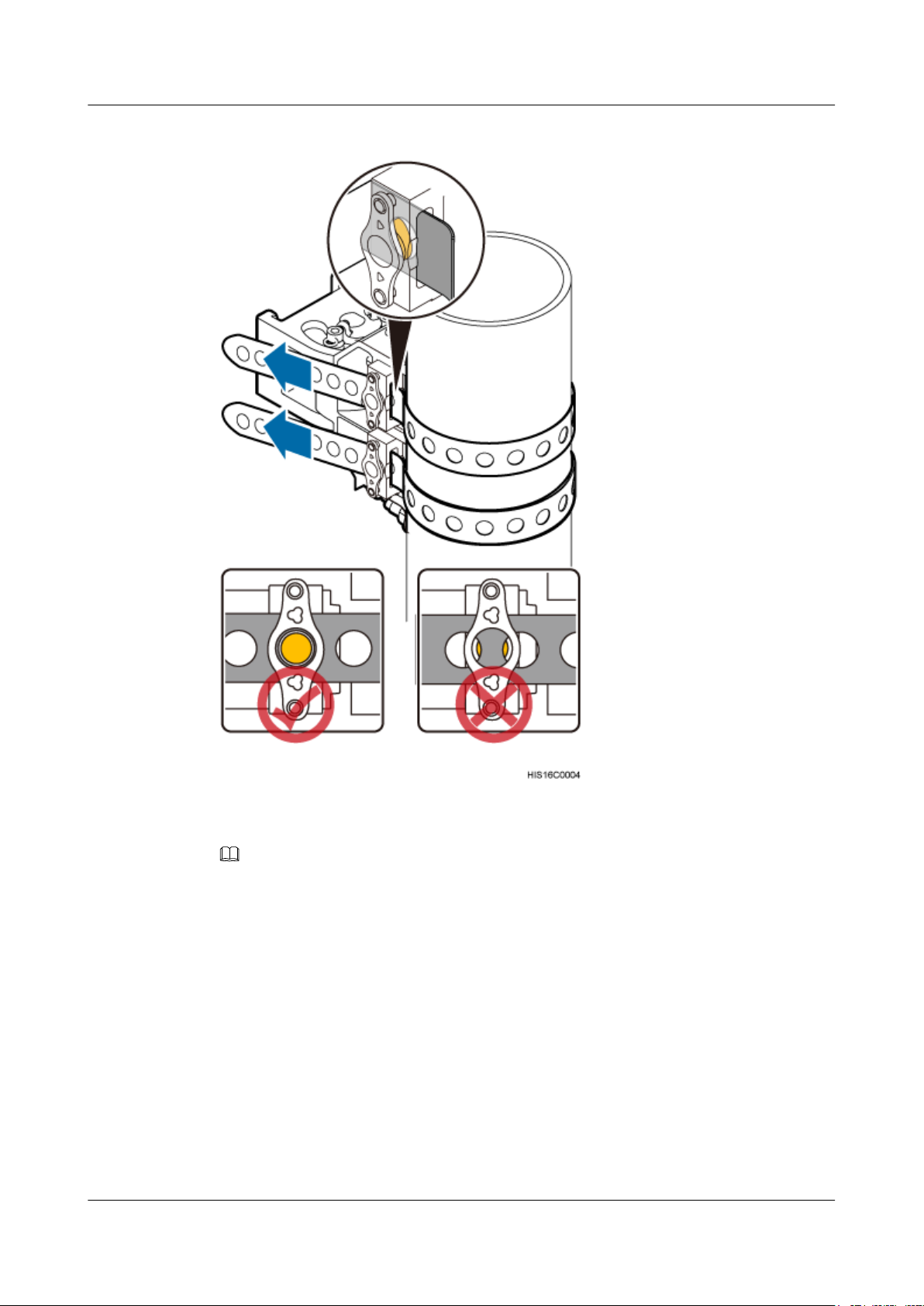

Figure 9-1 Putting the steel belt through the sliding block

Step 3 Pull the steel belts to align the holes on the steel belts with those on the sliding blocks, as shown

in the following figure.

NOTE

If the pin on a sliding block is located between two holes on a steel belt after the belt is securely attached

to the pole, slightly loosen the steel belt so that the pin goes through a hole on the steel belt.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

Page 49

AAU3940

Installation Guide 9 Installing an AAU

Figure 9-2 Installing the main mounting bracket

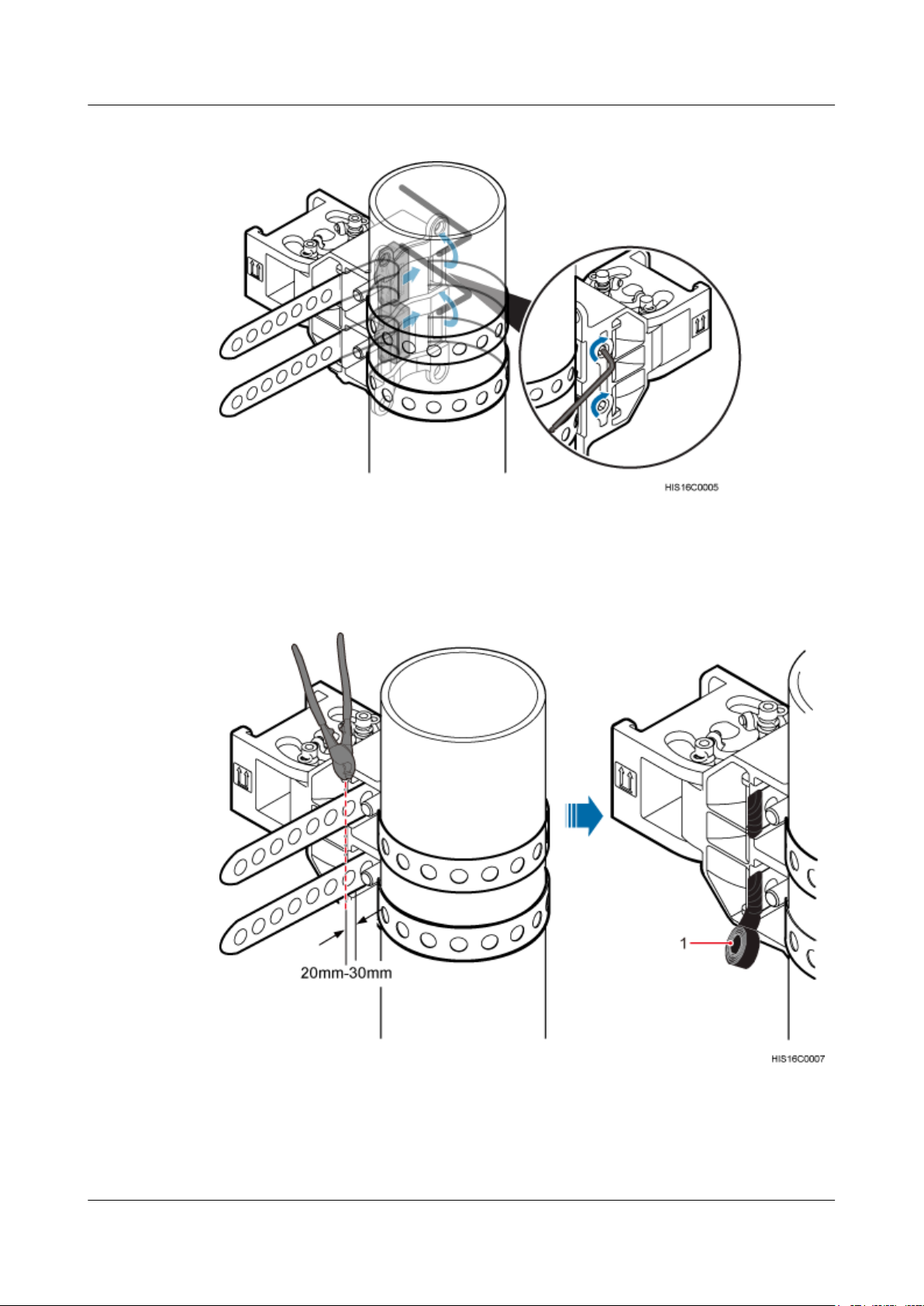

Step 4 Use an M10 inner hexagon wrench to tighten the bolts on the two steel belts alternately to secure

the main mounting bracket to 28 N·m (247.8 lbf·in.), as shown in the following figure.

NOTE

Tighten the bolts clockwise to slide a sliding block on a steel belt towards bolt heads and securely attach the

steel belt.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

Page 50

AAU3940

Installation Guide

Step 5 Use a cable cutter to cut off the excess of steel belts and reserve a slack of 20 mm to 30 mm

9 Installing an AAU

Figure 9-3 Securing a main mounting bracket

(0.79 in. to 1.18 in.), and wrap insulation tape around the ends of the belts to prevent personal

injury, as shown in the following figure.

Figure 9-4 Cutting off the excess of steel belts and wrapping insulation tape

(1) Insulation tape

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

Page 51

AAU3940

Installation Guide

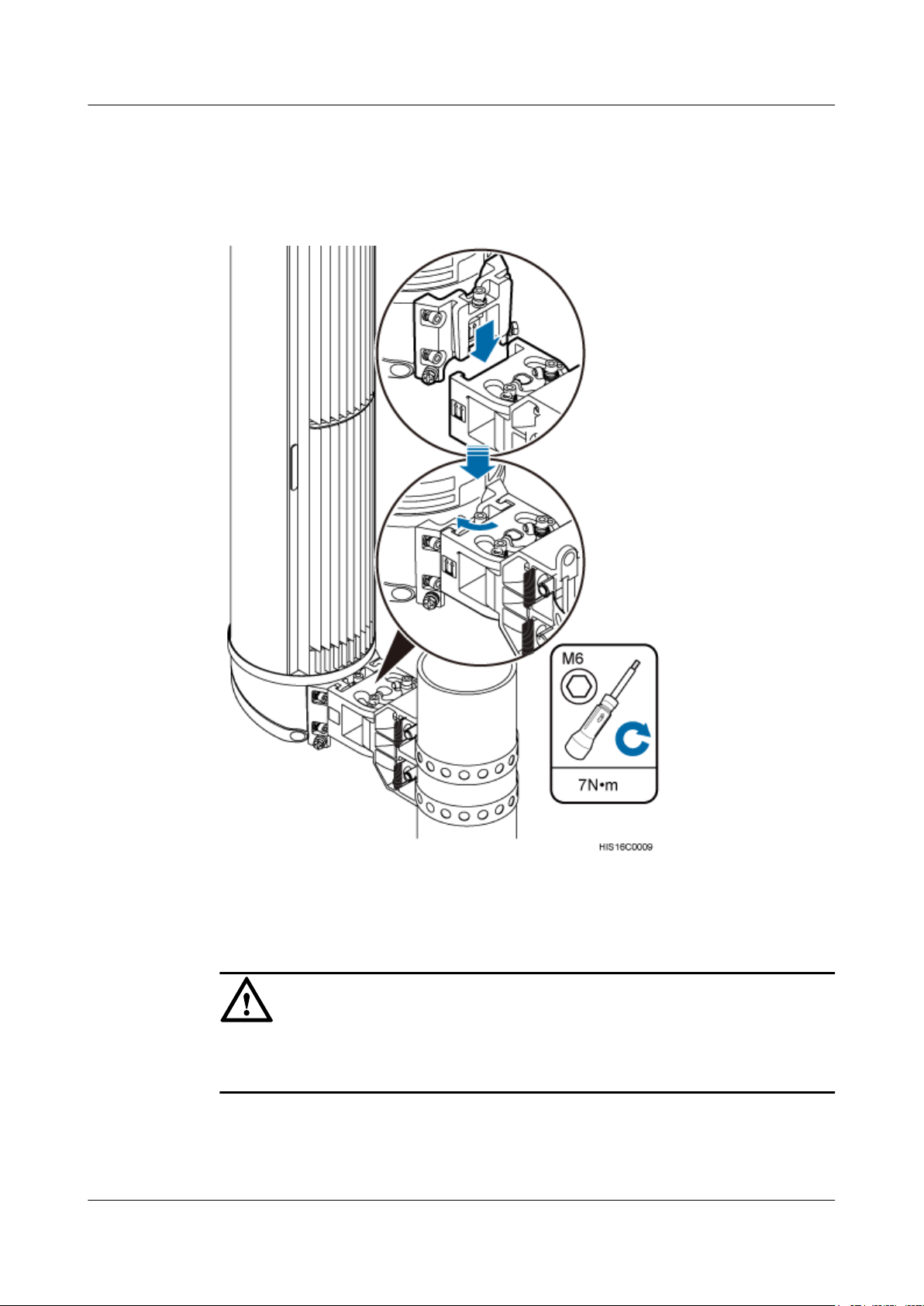

Step 6 Attach the AAU to the main mounting bracket, and use an M6 inner hexagon screwdriver to

9 Installing an AAU

tighten the screw on the main mounting bracket to 7 N·m (61.95 lbf·in.), as shown in the following

figure.

Figure 9-5 Installing an AAU on a main mounting bracket

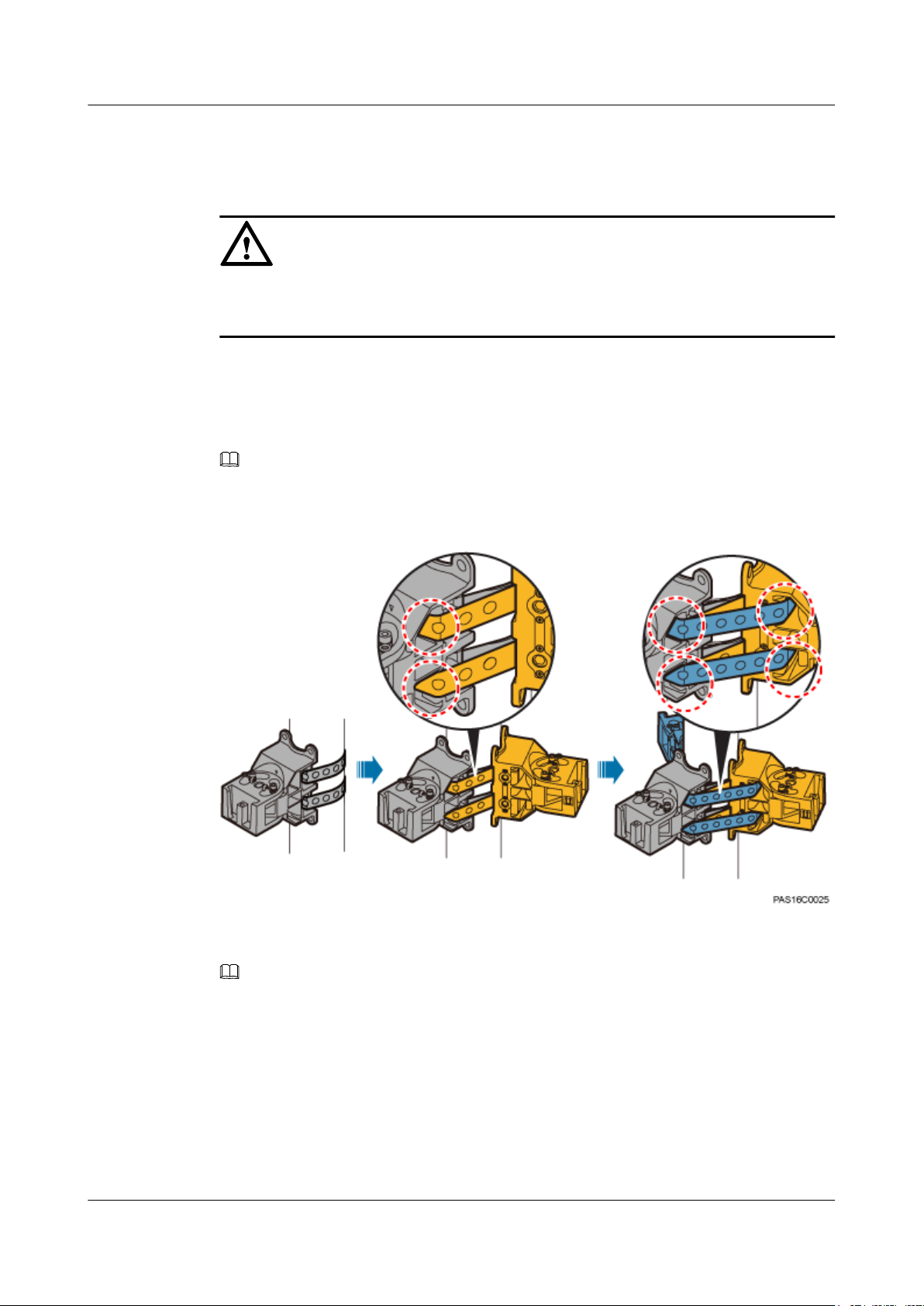

Step 7 Optional: Install the second AAU.

NOTICE

Before installing the second AAU, ensure that the mounting kits for the first AAU have been

securely installed.

1. Put the steel belts of the mounting kits for the second AAU through the evading holes of

the mounting kits for the first AAU, as shown in the following figure.

2. Install the mounting kits for the AAU according to steps Step 3 to Step 5.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

42

Page 52

AAU3940

Installation Guide

Step 8 Optional: Install the third AAU.

9 Installing an AAU

3. Install the AAU to the mounting kits according to Step 6.

NOTICE

Before installing the third AAU, ensure that the mounting kits for the first and second AAUs

have been securely installed.

1. Put the steel belts of the mounting kits for the third AAU through the evading holes of the

mounting kits for the first and second AAUs, as shown in the following figure.

2. Install the mounting kits for the AAU according to steps Step 3 to Step 5.

3. Install the AAU to the mounting kits according to Step 6.

NOTE

In the above figure, holes in dashed red circles are evading holes.

Figure 9-6 Putting the steel belts through the evading holes

NOTE

The following figure shows three AAUs installed on a pole.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

43

Page 53

AAU3940

Installation Guide

9 Installing an AAU

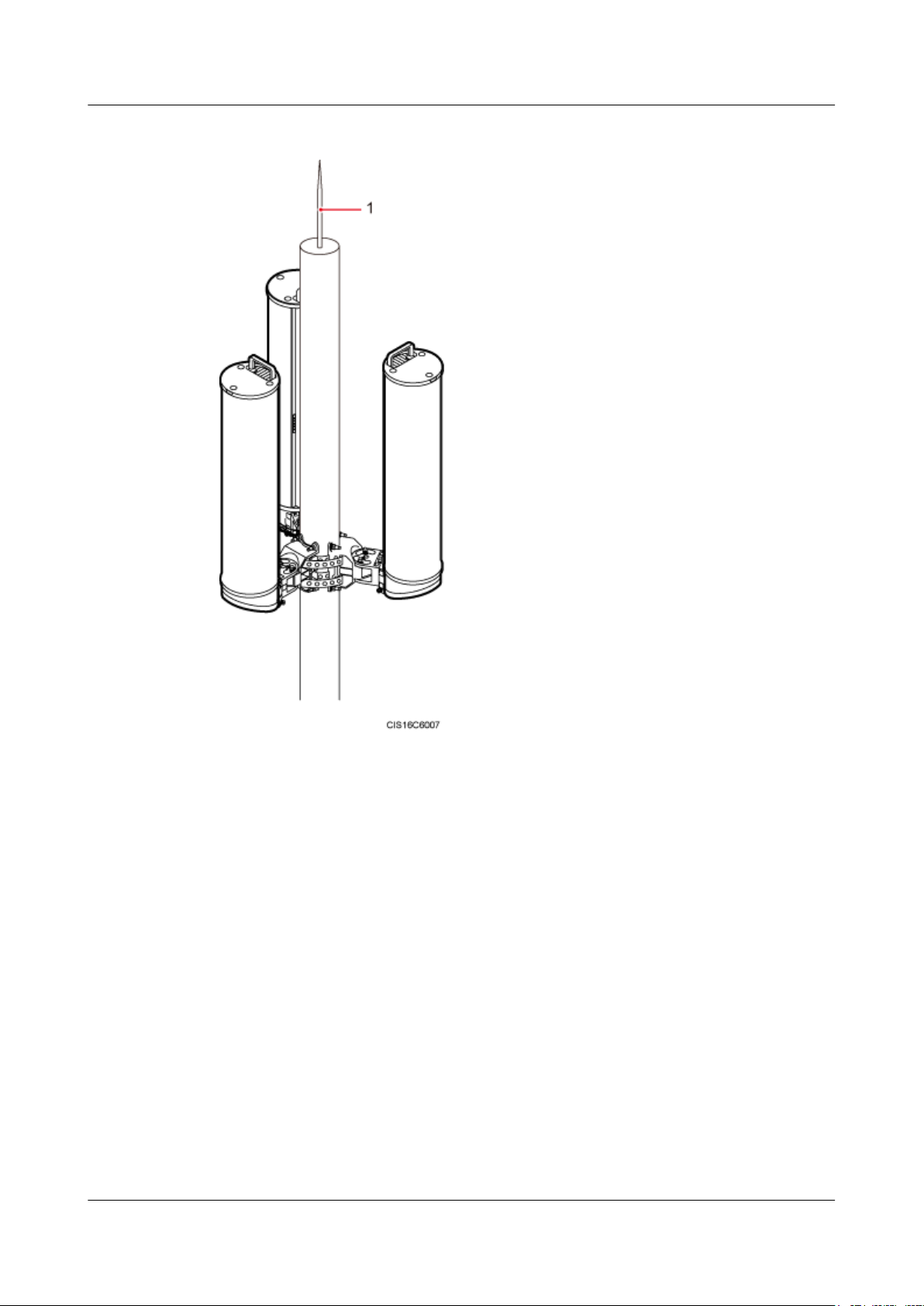

Figure 9-7 Three AAUs installed on a pole

(1) Lightning rod

----End

9.2 Installing an AAU on the Top of a Pole

This section describes the procedure and precautions for installing an AAU on the top of a pole.

Prerequisites

l You have preprocessed the AAU maintenance cavity. For detailed operations, see 7

Preprocessing the AAU Maintenance Cavity.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

44

Page 54

AAU3940

Installation Guide 9 Installing an AAU

Context

NOTICE

Do not work at heights when you meet any of the following situations:

l Thunder, lightning, rain, or wind greater than force 6 occurs.

l Water remains on the surface of the steel tube.

l There may be other danger.

After the above situations are eliminated, the Huawei security director and related technical

personnel must check all devices to be used before work start.

Procedure

Step 1 Lift the landscaping cover and remove it. Keep the landscaping cover for later installation.

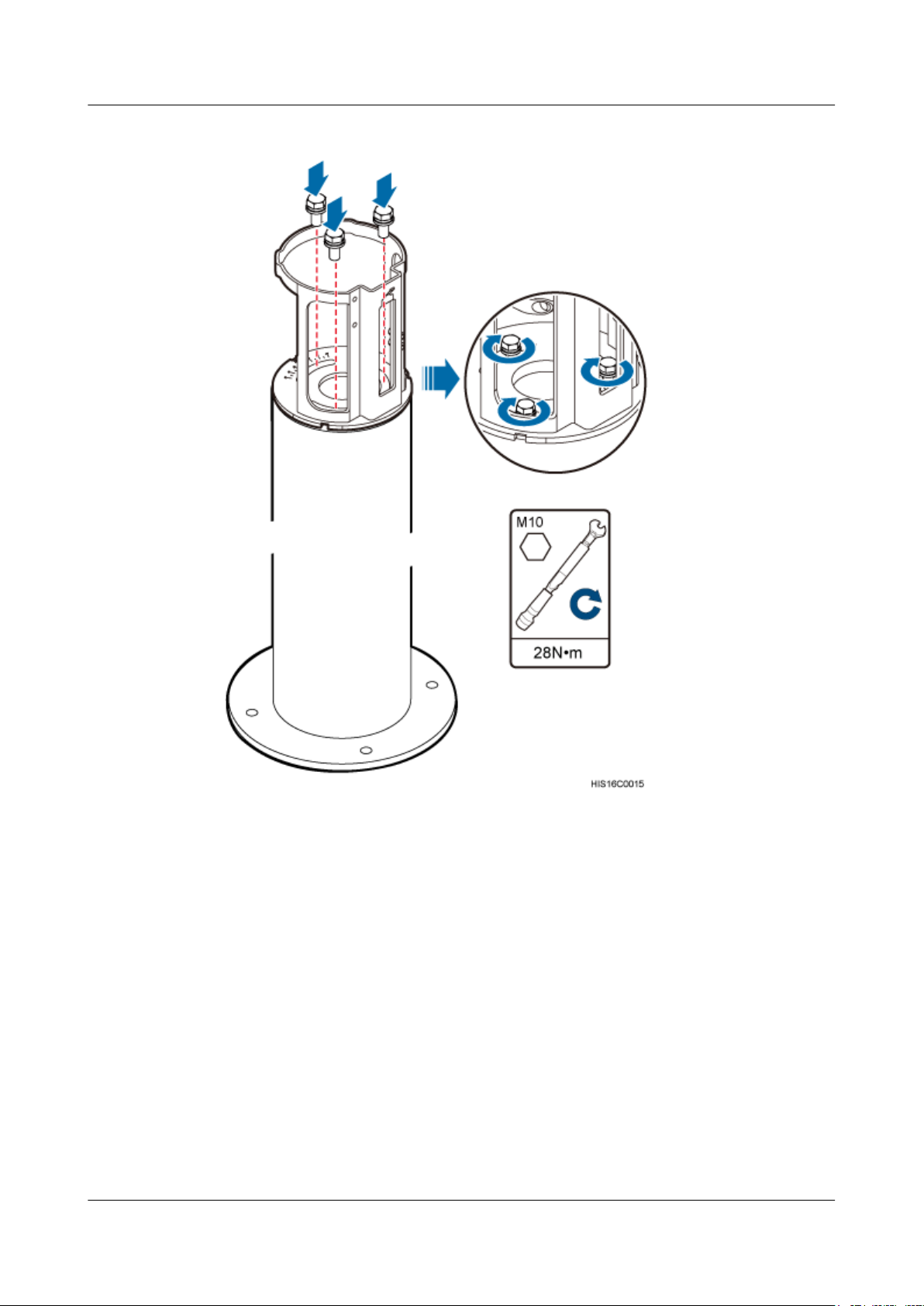

Step 2 Use a torque wrench to tighten three M10 screws to 28 N·m (247.8 lbf·in.) so that the mounting

bracket is secured to the top of a pole, as shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

45

Page 55

AAU3940

Installation Guide 9 Installing an AAU

Figure 9-8 Securing a mounting bracket

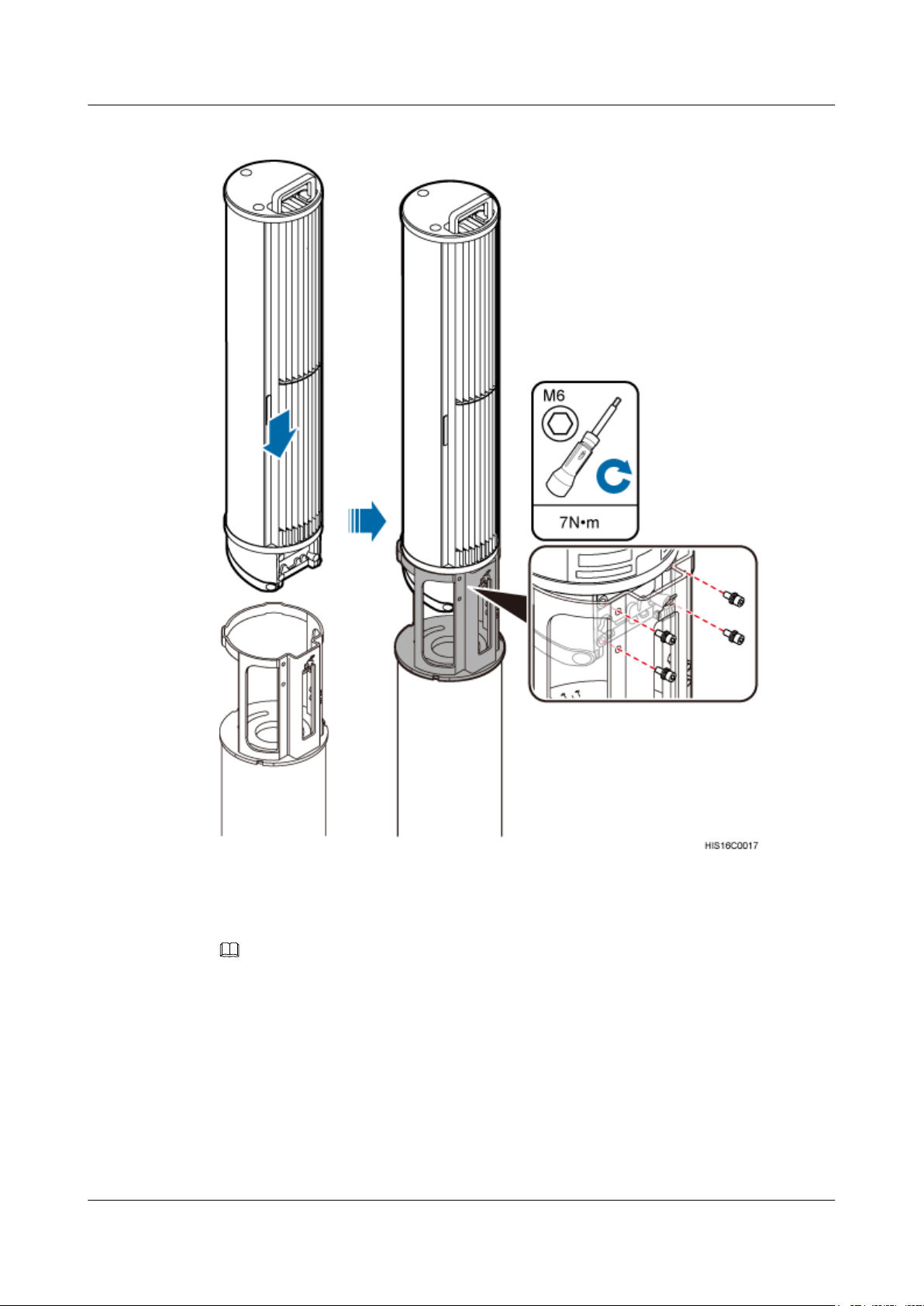

Step 3 Put the AAU on the mounting bracket on the top of a pole with both hands, and tighten four M6

inner hexagon bolts to secure the AAU, a shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

46

Page 56

AAU3940

Installation Guide

9 Installing an AAU

Figure 9-9 Installing an AAU

Step 4 Install the removed landscaping cover.

NOTE

It is recommended that the landscaping cover be installed after cables are connected.

1. Put the landscaping cover on the AAU, and press the elastomer on the mounting bracket

when the landscaping cover reaches the top of the mounting bracket so that it can slide

down.

2. Ensure that the three support braces of the landscaping cover slide into the troughs on the

bottom of the mounting bracket.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

47

Page 57

AAU3940

Installation Guide

9 Installing an AAU

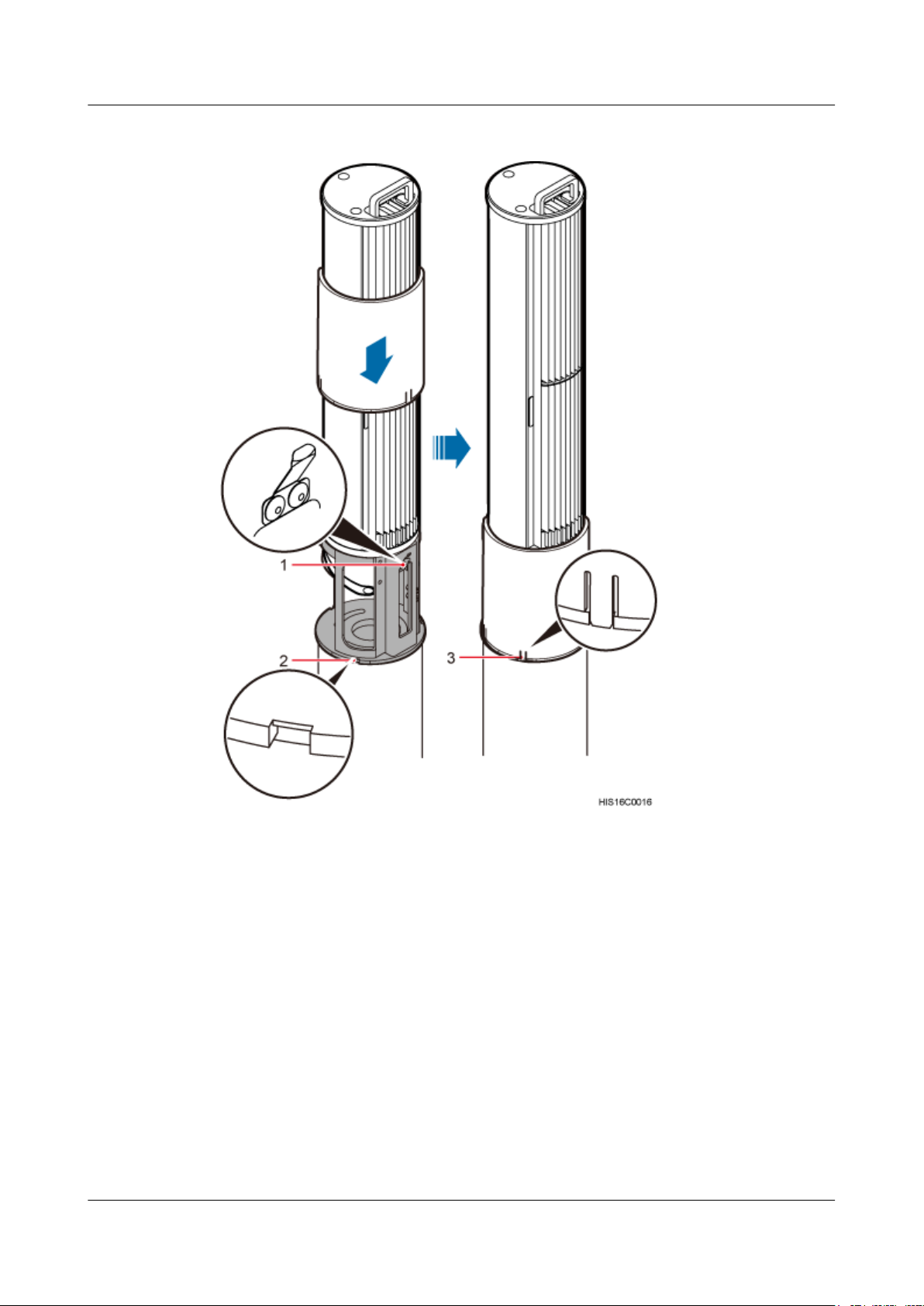

Figure 9-10 Installing a landscaping cover

(1) Elastomer (2) Trough (3) Support brace

----End

9.3 Installing an AAU on a Wall

This section describes the procedure and precautions for installing an AAU on a wall.

Prerequisites

l You have preprocessed the AAU maintenance cavity. For detailed operations, see 7

Preprocessing the AAU Maintenance Cavity.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

48

Page 58

AAU3940

Installation Guide 9 Installing an AAU

Procedure

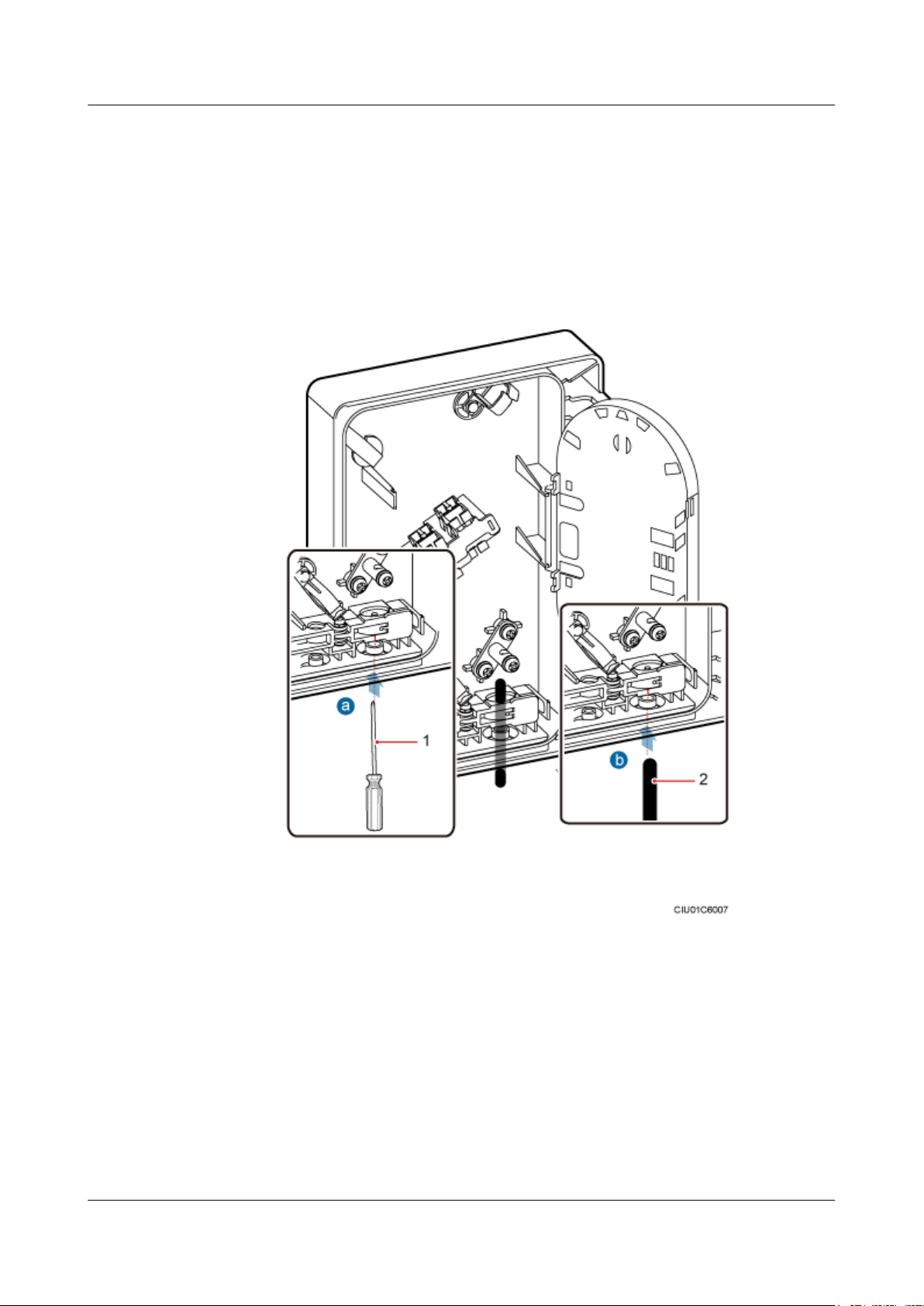

Step 1 Remove the steel belts from mounting kits, as shown in the following figure.

1. Use a Phillips screwdriver to remove four screws from the cover plate.

2. Use an M6 inner hexagon wrench to remove the bolts from the steel belts.

3. Remove the steel belts from the mounting kits.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

49

Page 59

AAU3940

Installation Guide

9 Installing an AAU

Figure 9-11 Removing steel belts

Step 2 Place the main bracket against the wall, use a level to verify that the main bracket is placed

horizontally, and use a maker to mark anchor points, as shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

50

Page 60

AAU3940

Installation Guide

9 Installing an AAU

Figure 9-12 Marking anchor points

(1) Level (2) Screw hole (3) Marker

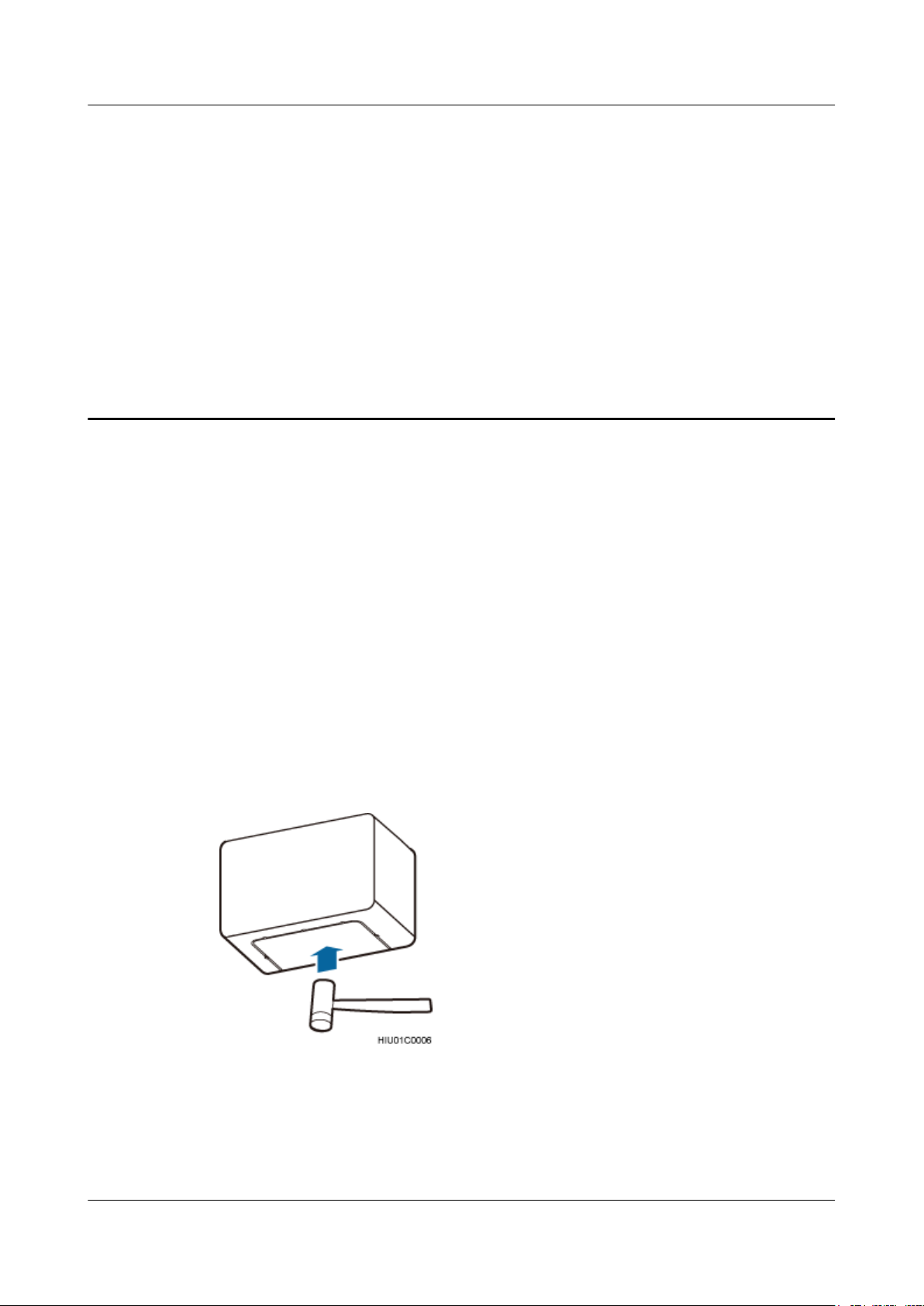

Step 3 Drill holes at the anchor points, and then insert expansion anchor bolts, as shown in the following

figure.

1. Use a hammer drill with a Φ10 bit to drill holes vertically at the marked anchor points.

Ensure that the depth of each hole ranges from 55 mm to 60 mm (2.17 in. to 2.36 in.).

2. Use a vacuum cleaner to clear the dust inside and around the holes, and measure the

distances between holes. If any of the holes is beyond the acceptable range, mark a new

anchor point and drill a new hole.

3. Tighten the expansion anchor bolts slightly and place one vertically into each hole.

4. Use a rubber mallet to hit the expansion bolt until the expansion tube completely enters the

hole.

5. Remove the nut, spring washer, and flat washer in sequence.

CAUTION

Take proper safety measures to protect your eyes and respiratory tract against the dust

before drilling holes.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

51

Page 61

AAU3940

Installation Guide 9 Installing an AAU

Figure 9-13 Drilling a hole and inserting expansion anchor bolts

(1) M8x80 bolt (2) Nut (3) Spring washer (4) Flat washer (5) Expansion tube

NOTICE

After dismantling an expansion anchor bolt, ensure that the top of the expansion tube is on

the same level as the wall. Otherwise, the main mounting bracket cannot be installed on

the wall evenly and securely.

Step 4 Place the main mounting bracket against the wall, use a torque wrench to tighten four M8 bolts

to 13 N·m (115.06 lbf·in.) and so that the main mounting bracket is securely installed on the

wall, as shown in the following figure.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

52

Page 62

AAU3940

Installation Guide 9 Installing an AAU

Figure 9-14 Installing the main mounting bracket

(1) Nut (2) Spring washer (3) Flat washer

Step 5 Install the attachment plate on the maintenance cavity of the AAU to be installed, and use an

M6 inner hexagon torque screwdriver to tighten the screws to 7 N·m (61.95 lbf·in.), as shown

in the following figure.

Figure 9-15 Installing an attachment plate

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

53

Page 63

AAU3940

Installation Guide 9 Installing an AAU

Step 6 Attach the AAU to the main mounting bracket, and tighten the bolts on the main mounting

bracket, as shown in the following figure.

Figure 9-16 Installing an AAU on a main mounting bracket

----End

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

54

Page 64

AAU3940

Installation Guide

About This Chapter

10 Installing AAU Cables

10 Installing AAU Cables

This section describes the procedure and precautions for installing AAU cables.

10.1 Cabling Requirements

Cables must be laid out according to the specified cabling requirements to prevent signal

interference.

10.2 Installing an AAU PGND Cable

This section describes the procedure and precautions for installing an AAU PGND cable.

10.3 Installing an AAU Power Cable

This section describes the process and precautions for installing an AAU power cable.

10.4 Installing an ODM Power Cable

This section describes the process and precautions for installing an ODM power cable when an

ODM is configured.

10.5 Installing a Trunk CPRI Fiber Optic Cable Between an ODM and a BBU

This section describes the procedure for installing a trunk CPRI fiber optic cable between an

ODM and a BBU when an ODM is configured.

10.6 Installing a CPRI Fiber Optic Cable Between an AAU and a BBU or Between an AAU and

an ODM

If no ODM is configured, a CPRI fiber optic cable is directly connected to a BBU. If an ODM

is configured, a CPRI fiber optic cable is connected to the ODM.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

55

Page 65

AAU3940

Installation Guide

10.1 Cabling Requirements

Cables must be laid out according to the specified cabling requirements to prevent signal

interference.

NOTE

If a cable listed below is not required, skip the cabling requirements of the cable.

General Cabling Requirements

Bending radius requirements

l The bending radius of a 7/8'' feeder must be greater than 250 mm (9.84 in.), and the bending

radius of a 5/4'' feeder must be greater than 380 mm (14.96 in.).

l The bending radius of a 1/4'' jumper must be greater than 35 mm (1.38 in.). The bending

radius of a super-flexible 1/2'' jumper must be greater than 50 mm (1.97 in.), and the bending

radius of an ordinary 1/2'' jumper must be greater than 127 mm (5 in.).

10 Installing AAU Cables

l The bending radius of a power cable or PGND cable must be at least three times its diameter.

l The bending radius of a fiber optic cable is at least 20 times of its diameter, and the bending

radius of a breakout cable is at least 30 mm (1.18 in.).

l The bending radius of an E1/T1 cable must be at least three times its diameter.

l The bending radius of a signal cable must be at least five times its diameter.

Cable binding requirements

l Cables of the same type must be bound together.

l Different types of cables must be separately laid out and bound, with a minimum distance

of 30 mm (1.18 in.) from each other.

l The cables must be bound tightly and neatly. The sheaths of the cables must not be damaged.

l The cable ties must face the same direction, and those at the same horizontal line must be

in a straight line.

l The excess of the indoor cable ties is cut off. The excess of 5 mm (0.197 in.) of the outdoor

cable ties is reserved, and the cut surfaces are smooth without sharp edges.

l After cables are installed, labels or nameplates must be attached to the cables at their ends,

curves, and interconnection positions.

Security requirements

l When routing cables, avoid sharp objects, for example sharp edges on the wall. If necessary,

use tubes to protect the cables.

l When routing cables, keep the cables away from heat sources and use heat insulation

materials to insulate the cables from the heat sources.

l Reserve a proper distance (0.1 m or 3.937 in. is recommended) between equipment and

cables especially at the cable curves to protect the cables and equipment.

Indoor cabling requirements

l Route each cable into the room through the feeder window.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

56

Page 66

AAU3940

Installation Guide 10 Installing AAU Cables

l Reserve drip loops for all cables outside the feeder window before routing them into the

room. Ensure that the radiuses of the drip loops are greater than or equal to the minimum

bending radiuses of the cables.

l When routing a cable into the room, ensure that a person is assisting you in the room.

l Apply waterproof treatment to the feeder window.

Outdoor Cabling Requirements

l After being connected to a ground clip on power cables, a ground cable must be routed

downwards to prevent water from entering the equipment to which the power cables

connect.

l Protect outdoor cables against potential damage. For example, put the cables through tubes.

l The cables to be protected include AC power cables, transmission cables, and cables laid

out underground.

l When routing cables through tubes on the ground below the cabinet, put a 30 mm to 50

mm (1.18 in. to 1.97 in.) length of the tubes into the base of the cabinet but do not put the

tubes into the cabinet. Use waterproof tape or waterproof silicon gel to block both ends of

the tubes and use sheet metal tabs to secure the tubes to the cable holes in the base.

l When routing cables through tubes along a metal cable trough below the cabinet, do not

put the tubes into the base of the cabinet but cover the cable trough and connect the tubes

to the cable holes in the base.

l Use clips to secure cables outdoors. For the method of installing a clip, see the installation

guide delivered with the clip.

l Arrange cables neatly along the routing direction and use clips to secure the cables.

l Determine the positions where the clips are installed according to the actual situation. For

example, 7/8" feeders are secured with clips at an interval of 1.5 m to 2 m (4.92 ft to 6.56

ft), CPRI fiber optic cables and power cables are secured with clips at an interval of 1 m

to 1.5 m (3.28 ft to 4.92 ft). Ensure that the clips are evenly spaced and in the same direction.

l When fastening cables with a clip, ensure that the cables are aligned neatly and are routed

through the holes in the clip. Do not stretch the cables too tightly.

NOTE

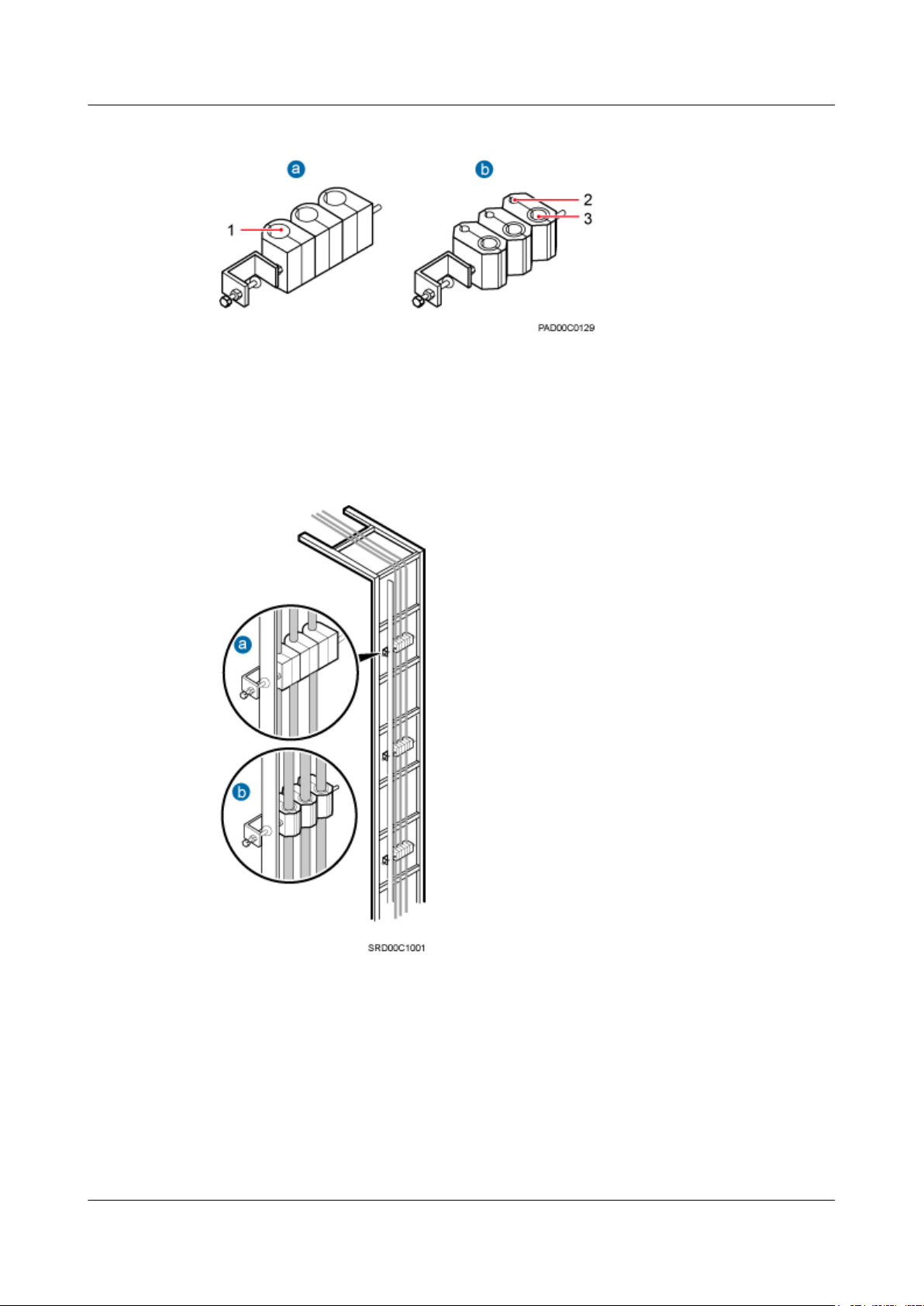

There are two types of clips: 3-hole clip and 6-hole clip, which are described as follows:

l A 3-hole clip is shown by illustration a in the following figure. It is often used to fasten feeders.

l A 6-hole clip is shown by illustration b in the following figure. It is often used to fasten power cables and

CPRI fiber optic cables.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

57

Page 67

AAU3940

Installation Guide

10 Installing AAU Cables

Figure 10-1 Exterior of the clips

(1) Cable hole for feeders (2) Cable hole for fiber optic cables (3) Cable hole for power cables

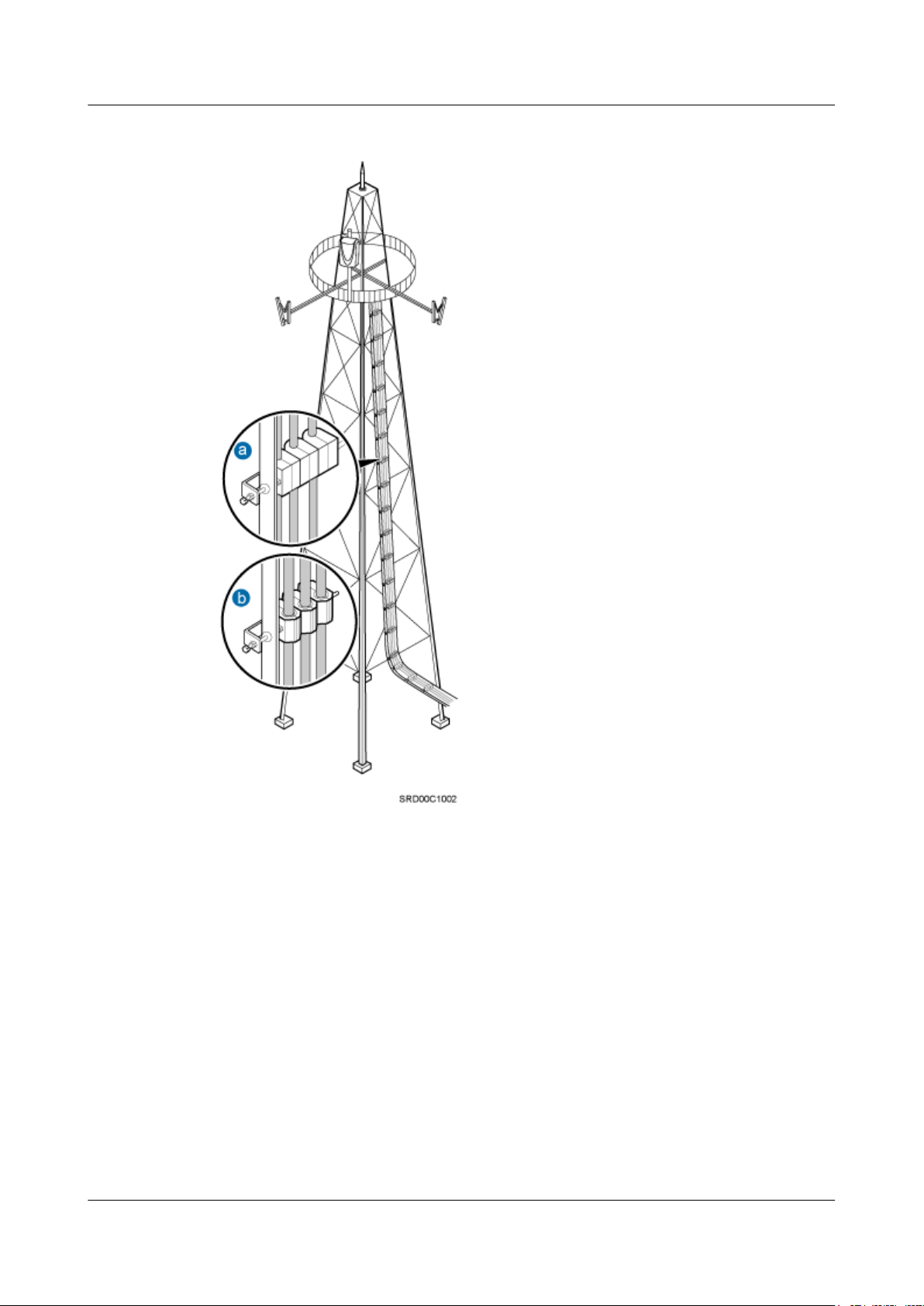

The following figure shows the cables secured on a cable tray.

Figure 10-2 Cables secured on a cable tray

(1) 3-hole clip

(2) 6-hole clip

The following figure shows the cables secured on a tower.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

58

Page 68

AAU3940

Installation Guide

10 Installing AAU Cables

Figure 10-3 Cables secured on a tower

(1) 3-hole clip (2) 6-hole clip

Special Cabling Requirements

Cabling of power cables

l Power cables must be installed in the position specified in engineering design documents.

l If the length of power cables is insufficient, replace the cables rather than adding connectors

or soldering joints to lengthen the cables.

l Cables can only be laid out under well-planned instructions. The cabling activities of fiber

optic cables are allowed only when qualified personnel and communication facilities are

available.

l Do not circle and twist cables.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

59

Page 69

AAU3940

Installation Guide

10 Installing AAU Cables

l After routing a DC power cable onto the platform on a tower, route it along the shortest

path to the rails surrounding the platform, and route it along the inside of the rails.

l After routing a DC power cable close to the equipment on a tower, use clips to secure the

power cable onto a pole or the rails surrounding the platform. Ensure that there is no

excessively long distance between the equipment and the position where the power cable

is secured.

Cabling of PGND cables

l PGND cables for a base station must be connected to the same group of ground bars.

l PGND cables must be buried in the ground or routed indoors.

l The external conductor of the coaxial wire and the shield layer of the shielded cable must

have proper electrical contact with the metal surface of the equipment to which they are

connected.

l PGND cables and signal cables must be installed separately. A certain distance must be

reserved between them to prevent interference from each other.

l Switches or fuses must not be installed on the PGND cables.

l Other devices must not be used for electrical connections of the PGND cables.

l All the metal parts in the housing of the equipment must be reliably connected to the ground

terminal.

Cabling of E1 cables

l E1 cables must not cross power cables, PGND cables, or RF cables when laid out. If

transmission cables are laid out with power cables, PGND cables, or RF cables in parallel,

the spacing between them must be greater than 30 mm (1.18 in.).

l E1 cables are lined up straight and bound neatly with cable ties.

l Sufficient slack is provided for E1 cables at turns.

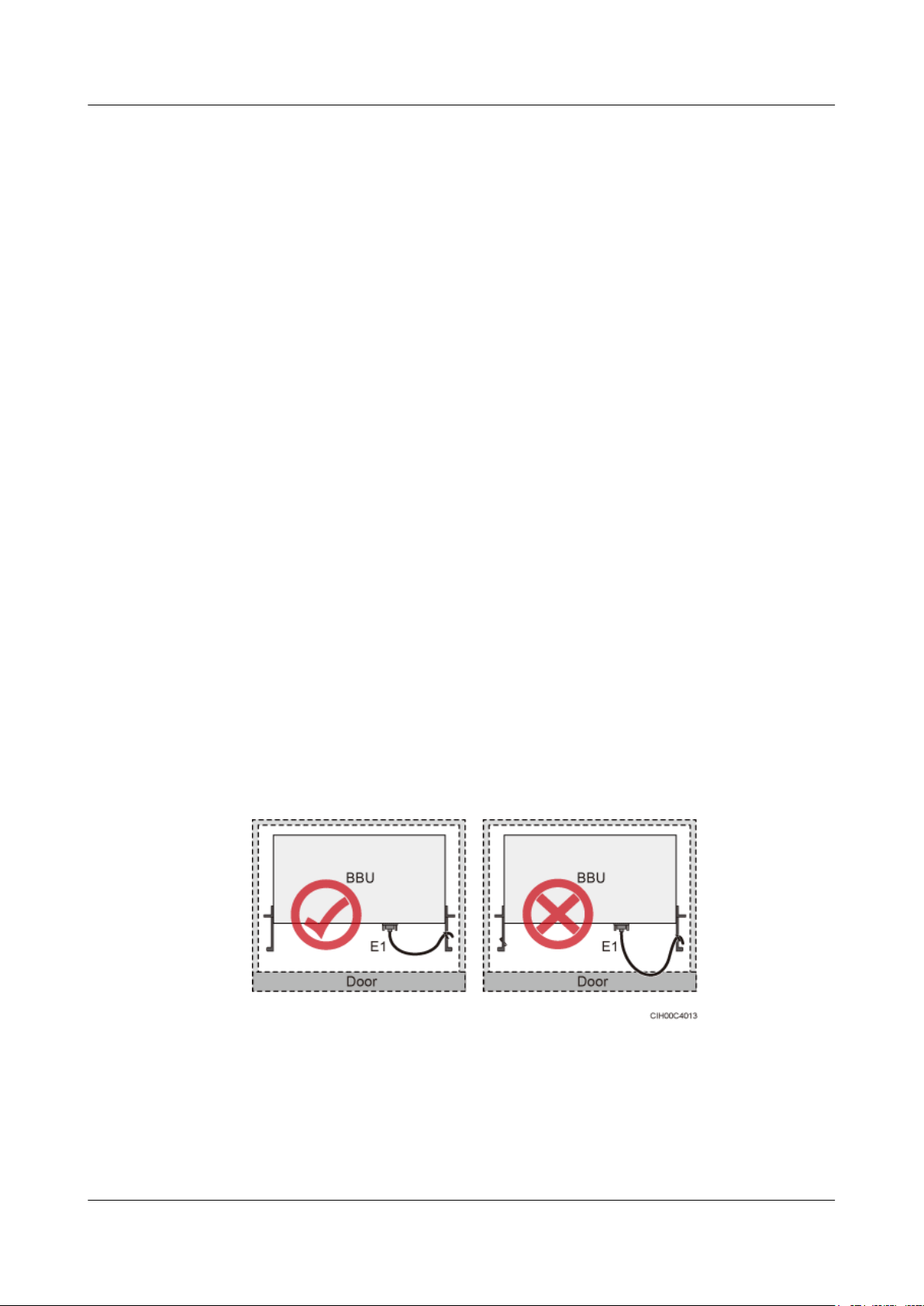

l E1 cables must not be pressed by the door of the cabinet when routed, as shown in the

following figure.

Figure 10-4 E1 cables routed in the cabinet

Cabling of fiber optic cables

l At least three people are required for laying out fiber optic cables. The cabling activities

of fiber optic cables are allowed only when qualified personnel and communication

facilities are available.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

60

Page 70

AAU3940

Installation Guide

10 Installing AAU Cables

l The operating temperature of fiber optic cables ranges from -40ºC to +60ºC (-40ºF to

+140ºF). If the actual temperature is beyond this range, take protective measures or select

another route.

l Do not circle and twist cables.

l Do not bind a fiber optic cable at the position where it bends.

l Do not stretch, step on, or place heavy objects on fiber optic cables. Keep the fiber optic

cables away from sharp objects.

l When fiber optic cables are routed, the excess of the fiber optic cables must be coiled around

special devices, such as a fiber coiler.

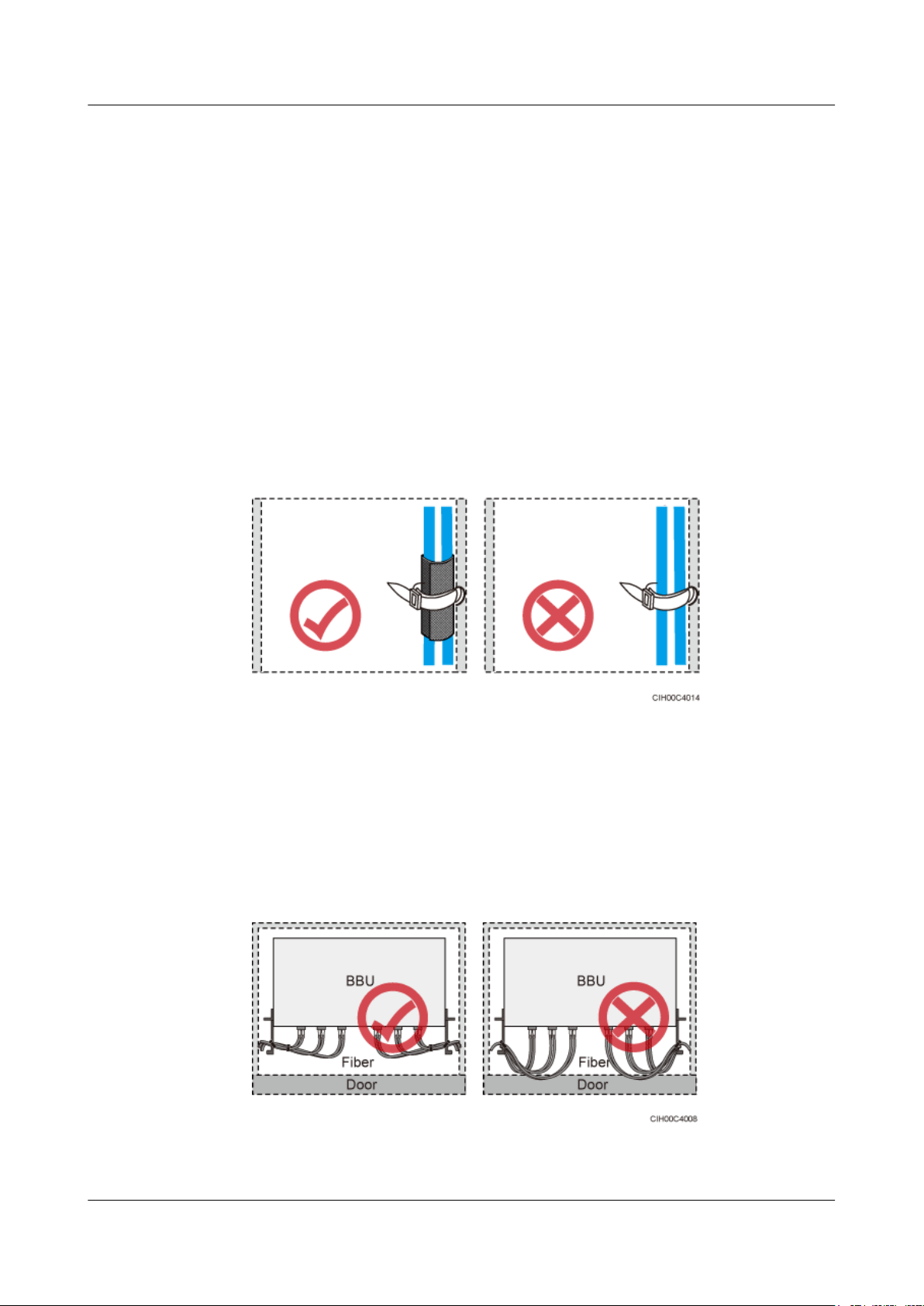

l An unarmored fiber optic cable must be bound using binding straps. If a fiber optic patch

cord needs to be secured in a cabinet or a piece of equipment, use binding straps to bind it

and then use cable ties to secure the binding straps to the cabinet or equipment. Ensure that

the fiber optic cables can flexibly move in the cable ties. Do not bend the fiber optic cables

sharply. The following figure shows how to bind the fiber optic cables correctly.

Figure 10-5 Binding fiber optic cables

l When coiling fiber optic cables, apply even strength. Do not bend the fiber optic cables

with force.

l Unused optical connectors must be covered with dustproof caps.

l The fiber optic cables must not be pressed by the door of the cabinet when routed, as shown

in the following figures.

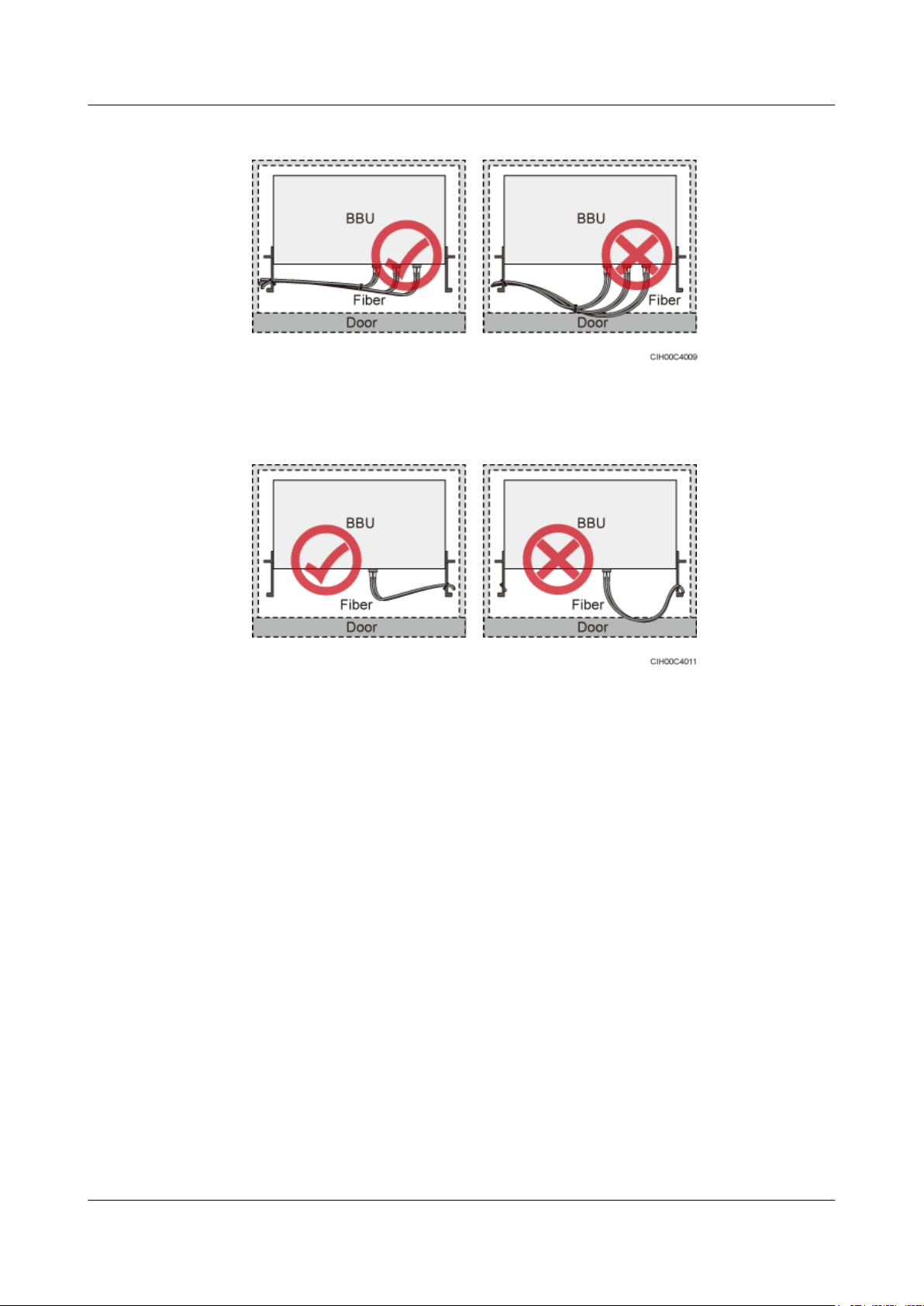

Figure 10-6 CPRI fiber optic cables routed in the cabinet (1)

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

61

Page 71

AAU3940

Installation Guide

10 Installing AAU Cables

Figure 10-7 CPRI fiber optic cables routed in the cabinet (2)

Figure 10-8 FE/GE fiber optic cables routed in the cabinet

l After routing a fiber optic cable onto the platform on a tower, route it along the shortest

path to the rails surrounding the platform, and route it along the inside of the rails.

l After routing a fiber optic cable close to the equipment on a tower, use clips to secure the

fiber optic cable onto a pole or the rails surrounding the platform. Ensure that there is no

excessively long distance between the equipment and the position where the cable is

secured.

l Coil the excess of the fiber optic cables near the equipment on the tower before securing

the cables on the tower.

10.2 Installing an AAU PGND Cable

This section describes the procedure and precautions for installing an AAU PGND cable.

Context

The following table lists the specifications of an AAU PGND cable.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

62

Page 72

AAU3940

Installation Guide 10 Installing AAU Cables

Table 10-1 Specifications of an AAU PGND cable

Procedure

Step 1 Prepare a PGND cable.

Step 2 Install the PGND cable.

Cable End Connecting to

the AAU

AAU PGND cable OT terminal (M6, 16

mm2 or 0.025 in.2)

1. Cut the cables to the length suitable for the actual cable route.

2. Add OT terminals to both ends of the cables according to the instructions in Assembling

the OT Terminal and the Power Cable.

1. Connect one end of the PGND cable with an M6 OT terminal to the ground bar of the

mounting kits for the AAU (shown by

bolt to 4.8 N·m (42.48 lbf·in.).

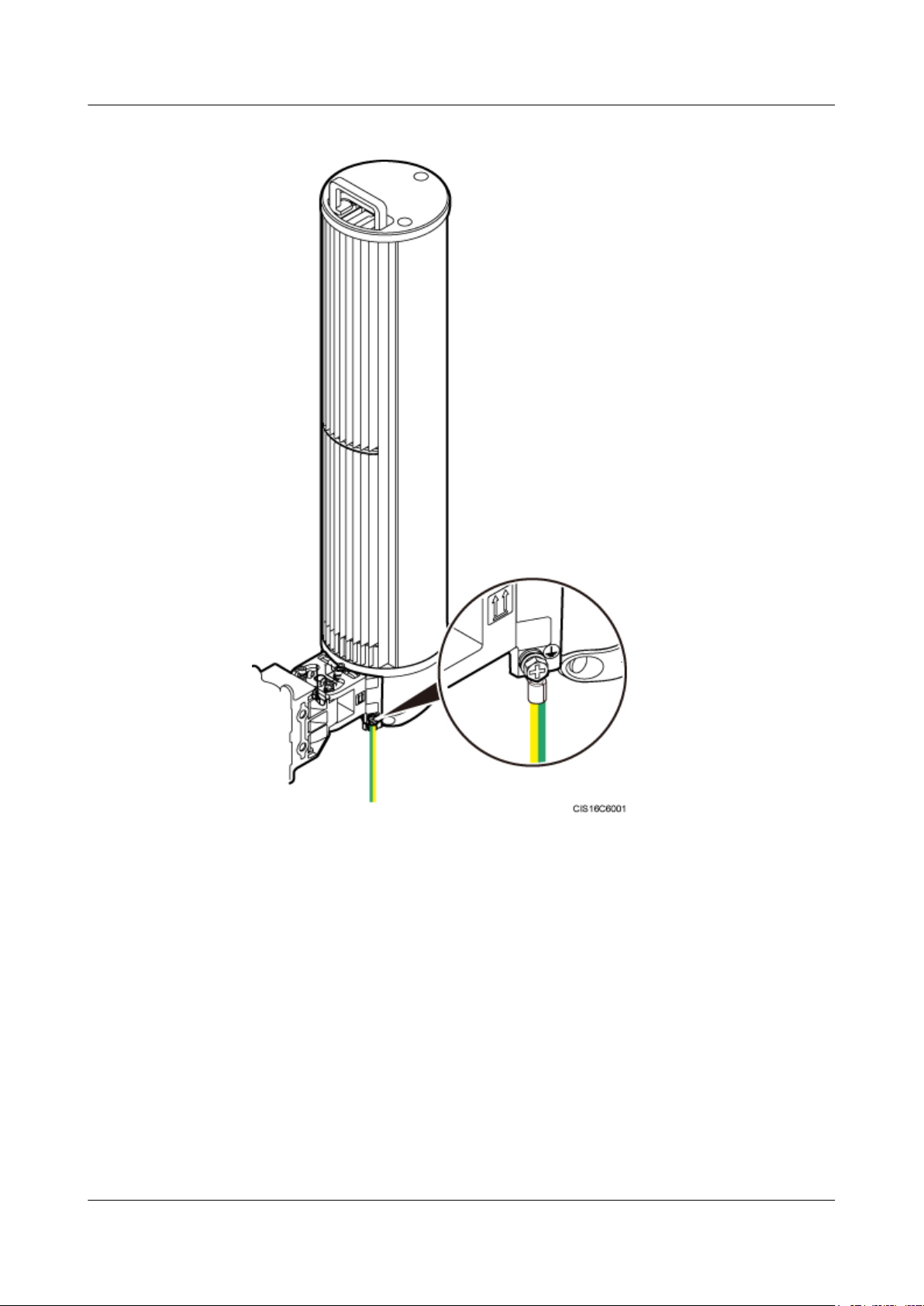

Figure 10-9, Figure 10-10, and Figure 10-11 show the methods of installing PGND cables

when an AAU is installed on a pole, when an AAU is installed on a wall, and when an AAU

is installed on the top of a pole, respectively.

End Connecting to

the Ground Bar

OT terminal (M8, 16

mm2 or 0.025 in.2)

), and use a torque wrench to tighten the ground

Color

Green and yellow

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

63

Page 73

AAU3940

Installation Guide 10 Installing AAU Cables

Figure 10-9 Installing a PGND cable when an AAU is installed on a pole

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

64

Page 74

AAU3940

Installation Guide 10 Installing AAU Cables

Figure 10-10 Installing a PGND cable when an AAU is installed on a wall

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

65

Page 75

AAU3940

Installation Guide

10 Installing AAU Cables

Figure 10-11 Installing a PGND cable when an AAU is installed on the top of a pole

NOTE

When installing a PGND cable, tightly press the OT terminal in the correct direction, as shown in

the following figure.

Figure 10-12 Installing an OT terminal correctly

2. Connect the other end of the PGND cable with an M8 OT terminal to the external ground

bar.

Step 3 Optional: When two or three AAUs are installed on a pole, equipotential cable(s) are required.

The following figure shows the method of installing equipotential cables between AAUs.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

66

Page 76

AAU3940

Installation Guide

10 Installing AAU Cables

Figure 10-13 Installing equipotential cables when multiple AAUs are installed on a pole

Step 4 Lay out the cables according to the instructions in Cabling Requirements, and use cable ties to

bind them.

Step 5 Label the installed cables according to the instructions in Attaching a Sign Plate Label.

----End

10.3 Installing an AAU Power Cable

This section describes the process and precautions for installing an AAU power cable.

Prerequisites

The AAU maintenance cavity has been opened.

Context

The following table describes AAU power cables used in different scenarios.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

67

Page 77

AAU3940

Installation Guide

10 Installing AAU Cables

Table 10-2 AAU power cables

ScenarioOne End The Other End

No

ODM is

configur

ed.

An

ODM is

configur

ed.

Connector Install

ation

Positi

on

Tool-less

female

connector

(pressfit type)

Tool-less

female

connector

(pressfit type)

POWE

R-IN

port on

an

AAU

POWE

R-IN

port on

an

AAU

Connector Installation Position

Depending

on the power

equipment

Cord end

terminal

Power equipment

L, N, and PE terminals near the

OUTPUT silkscreen on the ODM

CAUTION

AAU power cables must be routed and protected according to the local laws and regulations,

industry standards, and operators' standards.

CAUTION

When installing an AAU power cable for a running base station, connect the cable to the AAU

before connecting it to the power system. An incorrect sequence or reverse connection of the

power cable will cause damage to the AAU or injuries to the human body.

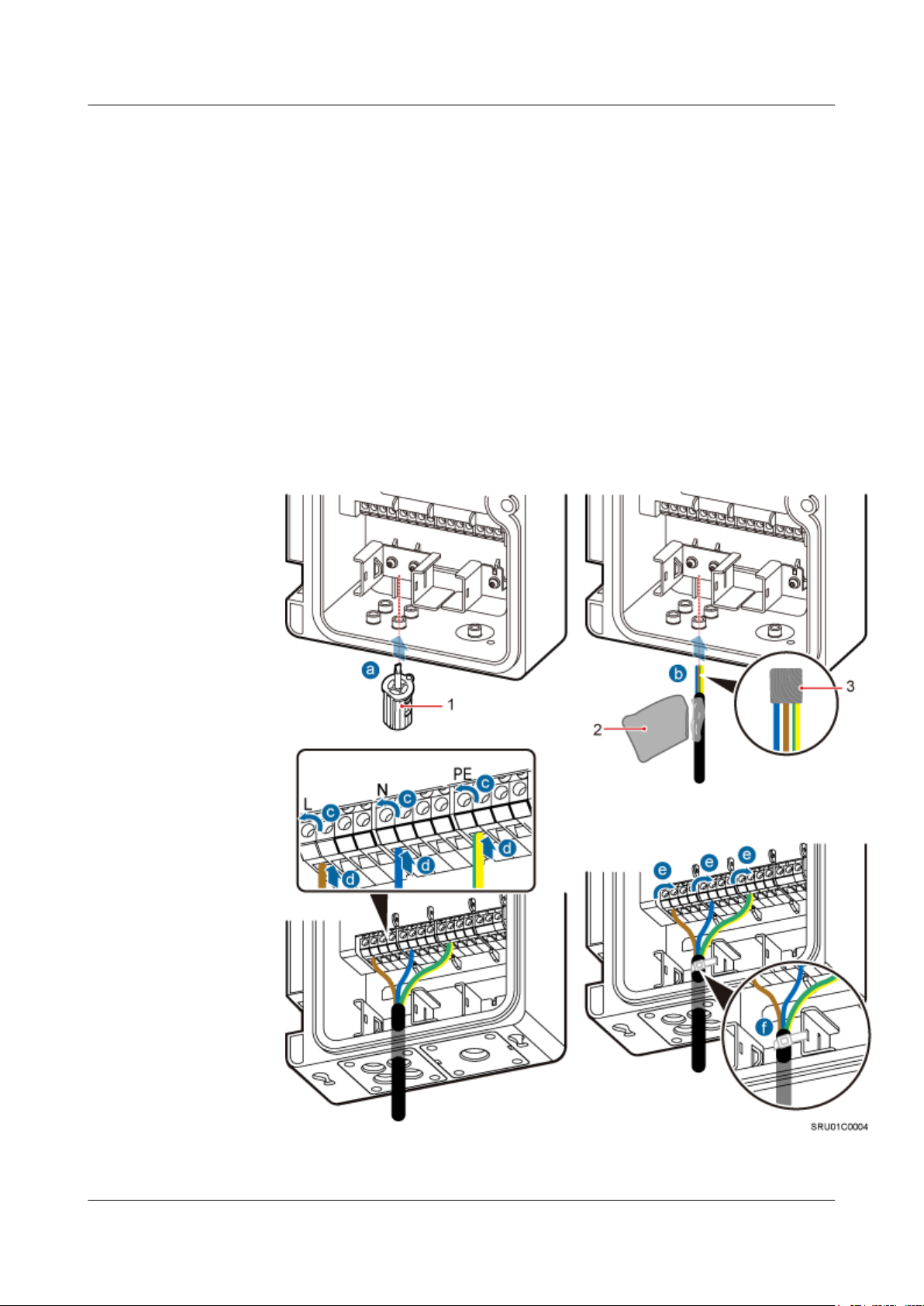

Procedure

l Protecting an AAU power cable using a tube

1. Cut the cable to the length suitable for the actual cable route.

2. Before adding connectors to the cable, put the cable through a PVC corrugated pipe

or metal tube. The length of the PVC corrugated pipe or metal tube depends on the

length of the cable. Waterproof the PVC corrugated pipe or metal tube, and ground

both ends of the metal tube.

l Preparing an AAU power cable

1. Add a tool-less female connector (pressfit type) to the AAU's AC power cable. For

details, see 16.2 Adding a Tool-Less Female Connector (Pressfit Type) to an AAU

Power Cable on the AAU Side.

2. Add the corresponding connector to the end of the AAU power cable connected to

power equipment according to the type of the port on the power equipment.

Issue 01 (2015-01-15) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

68

Page 78

AAU3940

Installation Guide

10 Installing AAU Cables

– If no ODM is configured, add the corresponding connector to the power cable