Page 1

User manual

I-V500w – SOLAR I-Ve

I-V400w – SOLAR I-Ww

Find Quality Products Online at: sales@GlobalTestSupply.com

Copyright HT ITALIA 2017 Release EN 2.00 - 24/03/2017

www.GlobalTestSupply.com

Page 2

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

Table of contents:

1. SAFETY PRECAUTIONS AND PROCEDURES .......................................................... 3

1.1. Preliminary instructions ..................................................................................................... 3

1.2. During use ......................................................................................................................... 4

1.3. After use ............................................................................................................................ 4

1.4. Overvoltage categories - Definitions ................................................................................. 4

2. GENERAL DESCRIPTION ........................................................................................... 5

2.1. Introduction ........................................................................................................................ 5

2.2. Instrument features ........................................................................................................... 5

3. PREPARATION FOR USE ........................................................................................... 6

3.1. Initial checks ...................................................................................................................... 6

3.2. Instrument power supply ................................................................................................... 6

3.3. Storage .............................................................................................................................. 6

4. DESCRIPTION OF PARTS .......................................................................................... 7

4.1. Instrument description ....................................................................................................... 7

4.2. Keyboard description ......................................................................................................... 8

4.3. Display description ............................................................................................................ 8

4.4. Initial screen ...................................................................................................................... 8

5. MAIN MENU ................................................................................................................. 9

5.1. SET – Instrument settings ................................................................................................. 9

5.1.1. General .................................................................................................................................... 9

5.1.2. Measurement units ................................................................................................................ 10

5.1.3. Date/Time ............................................................................................................................... 10

5.1.4. Remote unit/Solarim. ............................................................................................................. 11

5.1.5. Irradiance ............................................................................................................................... 12

5.1.6. DC Clamp (SOLAR I-Vw or SOLAR I-Ve) ............................................................................. 12

5.2. EFF – SETTINGS FOR TESTING PV SYSTEMS (SOLAR I-Vw or SOLAR I-Ve) .......... 13

5.2.1. Settings for PV systems with single-MPPT inverter - single-phase AC output ..................... 13

5.2.1.1. Instrument settings ........................................................................................................................... 13

5.2.1.2. PV plant parameters ........................................................................................................................ 14

5.2.2. Settings for PV with single/multi MPPT inverter – single/three phase AC output .......................... 15

5.2.2.1. Instrument settings ........................................................................................................................... 15

5.2.2.2. PV plant parameters ........................................................................................................................ 16

5.2.2.3. MPP300 status ................................................................................................................................ 17

5.2.3. Selection of the compensation relationship of temperature effects ....................................... 18

5.3. DB – Module database .................................................................................................... 19

5.3.1. How to define a new PV module ............................................................................................ 20

5.3.2. How to modify a PV module ................................................................................................... 21

5.3.3. How to delete a PV module ................................................................................................... 21

6. HOW TO OPERATE ................................................................................................... 22

6.1. Testing PV systems (SOLAR I-Vw or SOLAR I-Ve) ........................................................ 22

6.1.1. Testing of PV systems with single-MPPT inverter - single-phase AC output ........................ 23

6.1.2. Test PV systems with single/multi-MPPT inverter – single/three-phase AC output ................... 27

6.2. I-V curve measurement ................................................................................................... 33

6.2.1. I-V curve measurement by use of instrument ........................................................................ 33

6.2.2. I-V curve measurement by use of remote unit SOLAR-02 .................................................... 37

6.2.2.1. I-V curve test by remote unit SOLAR-02 in RF connection .............................................................. 37

6.2.2.2. I-V curve test by remote unit SOLAR-02 in synchro recording ......................................................... 41

6.2.3. Meaning of measurement results .......................................................................................... 46

6.3. Quick Check on PV modules and strings (IVCK) ............................................................ 47

6.3.1. General information ............................................................................................................... 47

6.3.2. Preliminary settings ................................................................................................................ 48

6.3.3. Fast check IVCK without irradiance measurement ................................................................ 49

6.3.4. Fast check IVCK with irradiance measurement ..................................................................... 51

6.3.5. Reset Media ........................................................................................................................... 53

6.4. List of display messages ................................................................................................. 54

7. STORING DATA ......................................................................................................... 55

7.1. Saving test results of PV checks (SOLAR I-Vw or SOLAR I-Ve) .................................... 55

7.2. Saving test results of I-V curve test ................................................................................. 55

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 1

Page 3

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

7.3. Managing the results ....................................................................................................... 56

7.3.1. Recall data of PV checks at display (SOLAR I-Vw or SOLAR I-Ve) ..................................... 56

7.3.2. Recall data of I-V curve tests at display ................................................................................. 57

7.3.2.1. View data – Numerical screens ........................................................................................................ 58

7.3.2.2. View data – Graphic screens of I-V curve ........................................................................................ 59

7.3.2.3. View data – Graphic screens of power ............................................................................................. 60

7.3.3. Delete data ............................................................................................................................. 61

8. CONNECTING THE INSTRUMENT TO A PC ............................................................ 62

8.1. Connecting by optical/USB cable C2006 ........................................................................ 62

8.2. Connecting by WiFi ......................................................................................................... 63

9. MAINTENANCE .......................................................................................................... 64

9.1. General ............................................................................................................................ 64

9.2. Battery replacement ........................................................................................................ 64

9.3. Instrument cleaning ......................................................................................................... 64

9.4. End of life ........................................................................................................................ 64

10. TECHNICAL SPECIFICATIONS ................................................................................. 65

10.1. Yield test technical feratures (SOLAR I-Vw, SOLAR I-Ve) .............................................. 65

10.2. I-V test technical features (I-V and IVCK) ....................................................................... 67

10.3. Safety specifications ........................................................................................................ 68

10.3.1. General .................................................................................................................................. 68

10.4. General characteristics .................................................................................................... 69

10.5. Environment conditions ................................................................................................... 69

10.6. Accessories ..................................................................................................................... 69

11. APPENDIX ................................................................................................................. 70

11.1. Testing photovoltaic systems (SOLAR I-Vw, SOLAR I-Ve) ............................................. 70

11.2. Notes on MPPT (Maximum Power Point Tracker) .......................................................... 71

11.3. Theoretical aspects of the I-V curve measurement ......................................................... 72

11.3.1. Typical errors on I-V curves and troubleshooting .................................................................. 73

12. SERVICE .................................................................................................................... 75

12.1. Warranty conditions ......................................................................................................... 75

12.2. Service ............................................................................................................................ 75

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 2

Page 4

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

1. SAFETY PRECAUTIONS AND PROCEDURES

The word “instrument” in this manual means generically both the models I-V400w, I-V500w,

SOLAR I-Vw or SOLAR I-Ve e SOLAR I-Ve except notation specifically indicated. This

instrument has been designed in compliance with directives IEC/EN61010-1 regarding

electronic measuring instruments. Before and while measuring, carefully follow the

instructions below:

Do not perform voltage or current measurements in humid environments

Do not perform measurements near explosive gas or material and fuels or in dusty

environments

Avoid contact with the circuit tested if no measurement is being performed

Avoid contact with exposed metal parts, test terminals not in use, circuits, etc.

Do not perform any measurement if instrument anomalies are detected, such as

deformations, breaks, leakage of substances, no display reading, etc.

Only use original HT accessories

In this manual, following symbols are used:

CAUTION: Follow the instructions given in this manual; improper use may

damage the instrument, its components or create dangerous situations for the

operator

High voltage: risk of electrical shock

Double insulation

DC voltage or current

AC voltage or current

Ground reference

1.1. PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in the environmental conditions specified in

§ 10.5. Do not use in different environmental conditions.

The instrument may be used for measuring of VOLTAGE and CURRENT in CAT II

1000V DC or CAT III 300V to ground, maximum voltage 1000V between inputs (IV400w and SOLAR I-Vw or SOLAR I-Ve) or 1500V (I-V500w and SOLAR I-Ve) Do not

use on systems exceeding the limit values specified in § 10.1 and § 10.2

We recommend to follow the ordinary safety rules aimed at: your protection against

dangerous currents, the instrument’s protection against improper use.

Only the accessories provided with the instrument guarantee compliance with safety

standards. They must be in good conditions and must be replaced, if necessary, with

identical models.

Check that batteries are correctly inserted.

Before connecting the test cables to the circuit being tested, check that the desired

function has been selected.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 3

Page 5

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

1.2. DURING USE

We recommend to carefully read the following recommendations and instructions:

CAUTION

Failure to comply with the CAUTIONs and/or instructions may damage the

instrument and/or its components or cause dangers to the operator.

The symbol “ ” indicates the charge level. When there are five bars, it

means that batteries are fully charged; a decrease in the number of bars

down to “ ” indicates that the batteries are almost low. In this case,

interrupt tests and replace the batteries according to the indications given

in § 9.2. The instrument is capable of keeping data stored even

without batteries.

1.3. AFTER USE

When measuring operations are completed, turn off the instrument by pressing and

holding the ON/OFF key for a few seconds. Should the instrument remain unused for a

long time, remove batteries and follow the indications given in § 3.3.

1.4. OVERVOLTAGE CATEGORIES - DEFINITIONS

Standard IEC/EN61010-1 (Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements) defines what a measurement

category (usually called “overvoltage category”) is. At § 6.7.4: Measuring circuits it quotes:

Circuits are divided into the following measurement categories:

Measurement Category IV is for measurements performed at the source of the low-

voltage installation.

Examples are electricity meters and measurements on primary overcurrent protection

devices and ripple control units.

Measurement Category III is for measurements performed in the building installation.

Examples are measurements on distribution boards, circuit breakers, wiring, including

cables, bus-bars, junction boxes, switches, socket-outlets in the fixed installation, and

equipment for industrial use and some other equipment, for example, stationary motors

with permanent connection to fixed installation.

Measurement Category II is for measurements performed on circuits directly

connected to the low voltage installation.

Examples are measurements on household appliances, portable tools and similar

equipment.

Measurement Category I is for measurements performed on circuits not directly

connected to MAINS.

Examples are measurements on circuits not derived from MAINS, and specially

protected (internal) MAINS-derived circuits. In the latter case, transient stresses are

variable; for that reason, the norm requires that the transient withstand capability of the

equipment is made known to the user.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 4

Page 6

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

2. GENERAL DESCRIPTION

2.1. INTRODUCTION

The instrument was designed to perform complete yield test on single-phase (and three-

phase if combined with optional accessory MPP300) PV installations with calculations of

efficiencies (SOLAR I-Vw or SOLAR I-Ve) and to perform all I-V curve tests on single

modules (panels) or complete strings of photovoltaic (PV) plants in order to verify the reference

parameters given by the manufacturers.

2.2. INSTRUMENT FEATURES

The instrument can perform the following tests:

Check Single phase PV installations (EFF - SOLAR I-Vw and SOLAR I-Ve)

DC voltage and current measurements (1000V for SOLAR I-Vw 1500V for SOLAR I-Ve)

AC TRMS voltage and current measurements

DC/AC power measurement

Solar irradiation [W/m2] measured by use of reference cell connected to unit SOLAR-02

Module and environ. temp. measurement by means of probe connect to SOLAR-02

Use of compensation relationships on PDC measurements

Immediate evaluation of result OK/NO of a test

Checks with programmable IP from 5s to 60min

Testing single/three-phase PV systems (MPP – SOLAR I-Vw, SOLAR I-Ve + MPP300)

Measurement of 3 DC voltages and currents

Measurement of DC string power and total DC power

Measurement of 3 AC TRMS voltages and currents

Measurement of total AC power

Measurement of irradiation [W/m2] by means of a reference cell connected to SOLAR-02

Module and environ. temp. measurement by means of probe connect to SOLAR-02

Application of compensation relationships to DC efficiency.

Immediate evaluation of result OK/NO of a test

Parameter recording of a PV system with 5s to 60min programmable IP

I-V Curve measurement

Voltage, current, power of PV module/string 1000VDC, 15ADC (SOLAR I-Vw, I-V400w)

I-V/power module/string 1500VDC-10ADC or 1000VDC-15ADC (SOLAR I-Ve, I-V500w)

Activation of manual or automatic measurement

PV module/string temperature measurement

Irradiance measurement [W/m2] by using reference cell

Numerical and graphical results of I-V curve with 4-wire method

Comparison of results with standard conditions (STC) and OK/NO final response

Internal customizable database for definition up to 30 PV modules

Annual degradation evaluation of PV modules/strings/fields

Internal memory for saving test and Optical/USB interface for PC connection

Quick Check (IVCK)

Fast test of open voltage and short circuit current up to 1000V DC, 15A (SOLAR I-Vw,

I-V400w) and up to 1500VDC, 15A (SOLAR I-Ve, I-V500w)

Activation of manual or automatic measurement

Immediate evaluation (OK/NO) of test results

The instrument has an innovative electronic function selector to simply set operations with

internal parameters, a backlit display, the contrast adjustment and a HELP key in order to

give a valid help to the operator during the meter’s connection to the plants. An

enable/disable Auto Power OFF feature is available after about 5 minutes of idleness.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 5

Page 7

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

3. PREPARATION FOR USE

3.1. INITIAL CHECKS

Before shipment, the instrument’s electronics and mechanics have been carefully checked.

All possible precautions have been taken to have the instrument delivered under optimal

conditions. However, we recommend to rapidly check the instrument in order to detect

possible damage occurred during transport. Should you detect anomalies, please

immediately contact the dealer.

It is also recommended to check that the package contains all parts indicated in § 10.6. In

case of discrepancies, please contact the dealer. Should it be necessary to return the

instrument, please follow the instructions given in § 12.

3.2. INSTRUMENT POWER SUPPLY

The instrument is battery supplied. For battery type and life, see § 10.4.

The symbol “ ” indicates the charge level. When there are five bars next to the battery

symbol, it means that batteries are fully charged; a decrease in the number of bars down

to “ ” indicates that the batteries are almost low. In this case, interrupt tests and

replace the batteries according to the indications given in § 9.2.

The instrument is capable of keeping data stored even without batteries.

The instrument is provided with advanced algorithms to maximize the batteries’ life.

During instrument operation, a further short pressing of the key turns on the display’s

backlighting (if battery voltage level is high enough). In order to save battery efficiency,

backlighting automatically turns off after approx. 30 seconds.

A frequent use of back lighting reduces the batteries’ life

3.3. STORAGE

In order to guarantee precise measurements, after a long period of the instrument’s

storage under extreme environmental conditions, wait until it recovers its normal conditions

(see § 10.5).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 6

Page 8

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

4. DESCRIPTION OF PARTS

4.1. INSTRUMENT DESCRIPTION

CAPTION:

1. Inputs

2. Display

3. Connector for opto insulated cable

4. Arrows/ENTER key

5. GO/STOP key

6. SAVE key

7. ON/OFF key

8. HELP / key

9. ESC/MENU key

Fig. 1: Description of the front part of the instrument

CAPTION:

1. Input for irradiance probe (I-V) / DC

transducer clamp (EFF – SOLAR IVw, SOLAR I-Ve)

2. Input for auxiliary temperature probe

(I-V) / AC transducer clamp (EFF –

SOLAR I-Vw, SOLAR I-Ve)

3. C1, C2 inputs for current

measurement (I-V) / voltage

measurement (EFF – SOLAR I-Vw,

SOLAR I-Ve)

4. P1, P2 inputs for voltage

measurement (I-V) / AC voltage

(EFF – SOLAR I-Vw, SOLAR I-Ve)

Fig. 2: Description of the upper part of the instrument

CAPTION:

1. Connector for opto insulated cable

connection

Fig. 3: Description of the instrument’s side

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 7

Page 9

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

4.2. KEYBOARD DESCRIPTION

The keyboard includes following keys:

ON/OFF key to switch on/off the instrument

ESC/MENU key to exit the selected menu without confirming and to activate

menu management

keys to move the cursor through the different screens in order to

select the desired programming parameters

ENTER key to confirm the modifications and the selected programming

parameters and to select the function from the menu

GO/STOP key to start measurements

SAVE key to save the measured values

HELP key (long pressure) to display an indicative outline of the connections

between the instrument and the system being tested in the function set

key (short pressure) to turn on the display’s backlighting

4.3. DISPLAY DESCRIPTION

The display is a graphic module with a resolution of 128 x 128

dots. The display’s first line indicates the system date/hour

and the battery charge indicator.

In the bottom part the functionality of ENTER key and the

active mode is displayed

The symbol indicates the presence of an active radio

connection with the selected remote unit (SOLAR-02 or

MPP300).

The flashing symbol indicates that the instrument is

currently searching for a radio connection with the selected

remote unit (SOLAR-02 or MPP300).

4.4. INITIAL SCREEN

When turning on the instrument, the instrument displays the

initial screen for a few seconds. It displays the following:

The instrument’s model

The manufacturer’s name

Internal presence of modules for RF (Radio Frequency)

and WiFi connection

The serial number (SN:) of the instrument

The firmware version (FW:) in the instrument's memory

The date of the last calibration (Calibration date:)

Then, the instrument switches to the last function selected.

15/05/10 15:34:26

Selection

I – V

SOLAR

I-Vw

RF-Wi SN:15345678

FW: 7.07 H4

Calibration date:

09/02/2016

HT

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 8

Page 10

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5. MAIN MENU

Pressing the MENU/ESC key in any allowable condition of

the instrument displays the main menu screen, in which the

instrument may be set, the saved measures can be displayed

and the desired measuring function may be set (item EFF

only appears for instrument SOLAR I-Vw or SOLAR I-Ve).

Select by cursor the desired options and confirm by pressing

ENTER

5.1. SET – INSTRUMENT SETTINGS

Move the cursor to SET by means of the arrow keys (,)

and confirm with ENTER. Subsequently, the displays shows

the screen which provides access to the various instrument’s

settings.

The settings will remain valid also after switching off the

instrument

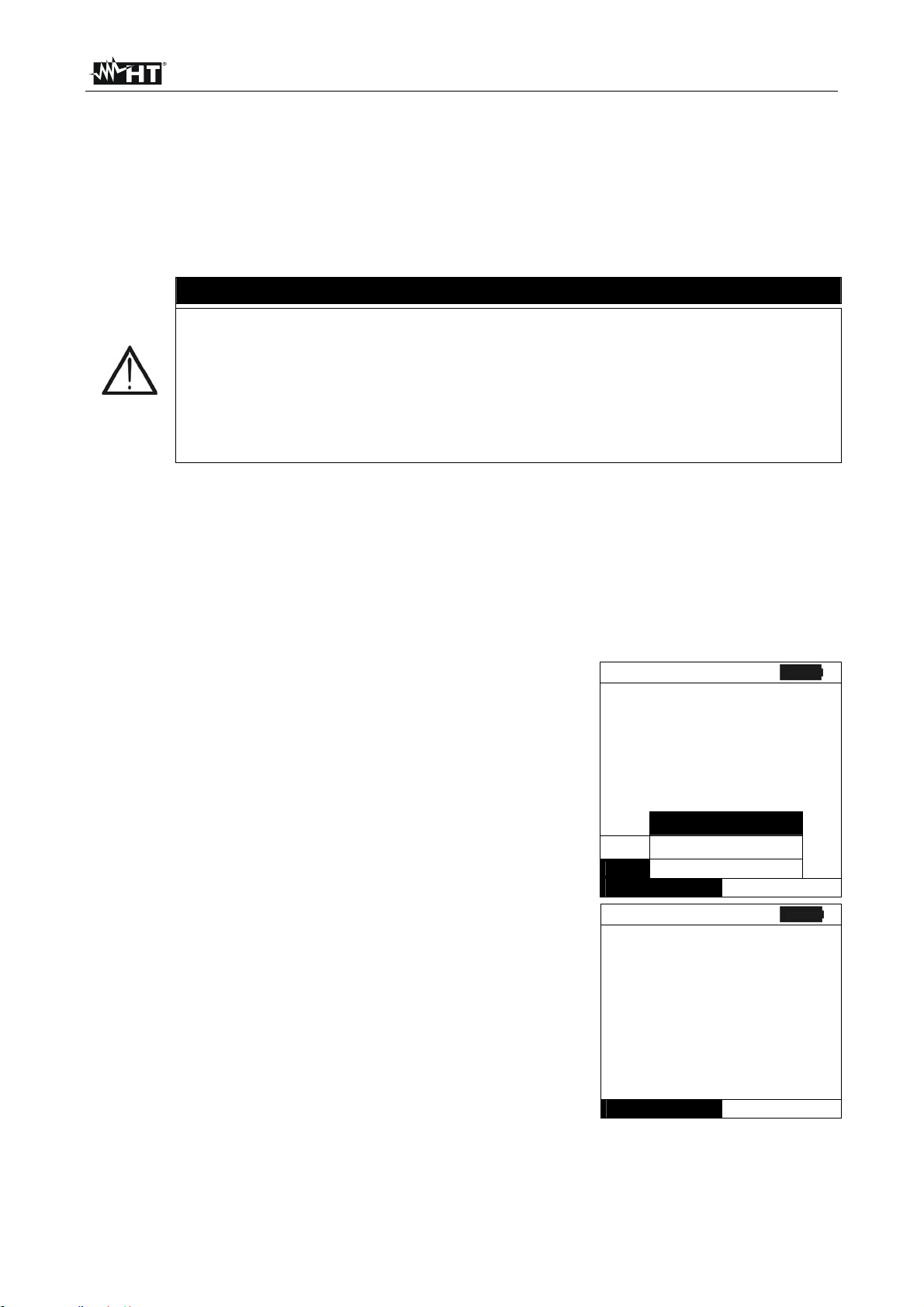

5.1.1. General

1. Move the cursor to “General” by means of the arrow keys

(,) and confirm with ENTER

2. The displays shows the screen which allows:

Setting the instrument language

Setting the enable/disable of auto power off

Adjusting the contrast of display

Enabling the acoustic signal when pressing a key

Setting the enable/disable of WiFi interface inside each

section of main menu for using the instrument with the

HTAnalysis APP (in the PC section the WiFi interface is

always on). With WiFi enabled the “ ” symbol is shown

in the bottom right side of the display. The enable of

WiFi interface means a higher consumption of the

batteries

3. By means of the arrow keys (,) and select the desired

option by means of the arrow keys (,)

4. Confirm with SAVE and the “Data saved” message is

displayed for a while. Press the ESC/MENU key to exit

without saving and to go back to the previous screen

15/05/10 15:34:26

I - V

I-V Test

EFF Yield Test

SET

Settings

DB

Modules

MEM

Data Recall

PC

PC connection

ENTER to select.

MENU

15/05/10 15:34:26

General

Meas. Unit

Date and Time

Remote Unit/Solarim.

Irradiance

DC Clamp

ENTER to select.

SET

15/05/10 15:34:26

Language : English

AUTOPOWEROFF:NO

Contrast: 10

Key Beep: NO

WiFi: NO

SAVE to store data

SET

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 9

Page 11

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.1.2. Measurement units

This § allows setting the default measurement units of some internal parameters included

in the database (DB) for the management of PV modules (§ 5.3)

1. Move the cursor to “Meas. Unit” by means of the arrow

keys (,) and confirm with ENTER.

2. The display shows the screen which allows selecting the

measurement units of parameters shown by the meter.

15/05/10 15:34:26

Parameter

3. Press ESC/MENU to exit without saving any setting.

4. Move the cursor to “Parameter” by means of the arrow

keys (,) and confirm with ENTER.

5. The display shows the screen which allows selecting the

measurement units of typical parameters of the modules:

Alpha possible selection: “%/°C” and “mA/°C”

Beta possible selection: “%/°C” and “mV/°C”

Gamma possible selection: “%/°C” and “W/°C”

Tolerance possible selection: “%” and “W”

6. Set the desired units by means of the arrow keys (,).

7. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit without

saving and to go back to the previous screen.

5.1.3. Date/Time

1. Move the cursor to “Date/Time” by means of the arrow

keys (,) and confirm with ENTER

2. The display shows the screen which allows setting the

system date/time both in the European (EU) or USA (US)

format.

3. Set the values by means of the arrow keys (,).

4. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit without

saving and to go back to the previous screen.

ENTER to select

15/05/10 15:34:26

Alpha

Beta

Gamma

Tolerance

15/05/10 15:34:26

Year

Month

Day

Hour

Minute

Format

: mA/°C

: mV/°C

: W/°C

: %

SAVE to store data

: 2009

: 06

: 15

: 09

: 53

: EU

SAVE to store data

MENU

SET

SET

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 10

Page 12

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

Alp

5.1.4. Remote unit/Solarim.

This section allows selecting the type of remote unit to be used (if available) and setting

the values of typical parameters (Sensitivity and Alpha) of the reference irradiance cell

supplied with the meter. The values of these parameters, which are printed on the

back label of the cell, depend on the type of PV modules on test.

1. Move the cursor to “Remote unit” by means of the arrow

keys (,) and confirm with ENTER

2. The display shows the screen which allows:

Select the type of remote unit to be used for testing PV

systems (SOLAR I-Vw or SOLAR I-Ve):

15/05/10 15:34:26

Remote U EFF MPP300

Remote U I-V: : NO

Sens.

: 31.0 mV/kW/m2

ha : 0.060 %/°C

o NO: Remote unit disabled

o SOLAR: Use of SOLAR-02

o MPP300: Use of MPP300 (optional)

Enable/disable the use of the remote unit SOLAR-02 for

I-V measurements (opt. for I-V400w and I-V500w). In

SAVE to store data

SET

case the use of the remote unit has not been enabled, it

will be possible to set the sensitivity values (sens.) of the

reference cell provided, expressed in “mV/kW*m-2”, and

of the Alpha parameter.

3. Set the value by means of the arrow keys (,)

4. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit without

saving and to go back to the previous screen

CAUTION

For EFF measurements (testing of PV systems – SOLAR I-Vw or SOLAR I-

Ve), disabling the remote unit entails:

The impossibility of carrying out Irradiation and Temperature

measurements by means of unit SOLAR-02

The impossibility of using the unit MPP300 (if available)

Consequently, it will be impossible to obtain a result for the test carried out.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 11

Page 13

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.1.5. Irradiance

1. Move the cursor to “Irradiance” by means of the arrow

keys (,) and confirm with ENTER.

2. The display shows the screen with the options: “ Irr min

IV” which allows to set the minimum threshold of

15/05/10 15:34:26

Irr min IV

Irr min EFF

: 0 W/m2

: 600 W/m2

measured irradiance expressed in W/m2, used by meter as

reference during the I-V curve measurements and “Irr min

EFF” (SOLAR I-Vw or SOLAR I-Ve which allows to set the

minimum threshold of measured irradiance expressed in

W/m2, used by meter as reference during the check PV

efficiency measurements

SAVE to store data

SET

3. Set the value by means of the arrow keys (,). The

accuracy indicated in this manual is granted under

condition indicated in § 10.1 and § 10.2. In I-V curve

measurement the value is set within the 0 800 W/m2

interval while 400 800 W/m

2

for the PV check

operations (SOLAR I-Vw or SOLAR I-Ve)

4. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit without

saving and to go back to the previous screen.

CAUTION

The “0 W/m2” setting for parameter “Min Irr IV” allows carrying out I-V

measurements without the following conditions being checked:

Connection of reference cell to input IRR of the instrument

Unsteady irradiation values

Number of modules consistent with the measured open circuit voltage

5.1.6. DC Clamp (SOLAR I-Vw or SOLAR I-Ve)

This option allows setting a possible correction factor K for the DC clamp, in order to improve

current measurement. If present, the correction factor is indicated on the rear label of the clamp

itself, indicated as:

K= X.xxx

In case no label is present, set k = 1.000

1. Move the cursor to “DC Clamp” by means of the arrow

keys (,) and confirm with ENTER

2. The item: “DC clamp k” is shown at display to set the

corrective factor in a interval within 0.950 and 1.050. Set

15/05/10 15:34:26

DC clamp k

: 1.000

the value by means of the arrow keys (, )

3. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit without

saving and to go back to the previous screen

SAVE to store data

SET

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 12

Page 14

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.2. EFF – SETTINGS FOR TESTING PV SYSTEMS (SOLAR I-VW OR SOLAR I-VE)

Further in this manual, the acronym MPPT (Multiple Power Point Tracker) shall indicate

the characteristic of the DC/AC converter (inverter), capable of maximizing the DC power

which can be taken from the photovoltaic field. See § 11.2 for further details.

5.2.1. Settings for PV systems w i th single-MPPT inverter - single-phase AC output

Check beforehand the settings made in MENUSETRemote Unit and check that you

have selected “SOLAR” as setting for parameter “R. unit”.

5.2.1.1. Instrument settings

1. Press MENU key, move the cursor to “EFF” by means of

the arrow keys (,) and confirm with ENTER. The

screen with the values of electrical parameters relative to

PV generator is displayed

15/05/10 15:34:26

Prp - - -

Irr - - - W/m2

Pnom 0.000 kW

Tc - - - °C

Te - - - °C

Pdc 0.0 kW

Vdc 0.000 V

Idc 0.0 A

ndc - - -

GO – Start rec

Select

EFF

2. Press ENTER key. The options Set PV plant and Set

Instrum. are displayed

3. By means of the arrow keys (,) to select Set Instrum.

and confirm with ENTER. The herewith screen is shown:

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 0.000 kW

Tc - - - °C

Te - - - °C

Pdc 0.0 kW

Vdc 0.000 V

Idc 0.0 A

ndc - - -

Set PV plant

Set Instrum.

Select

EFF

4. By means of the arrow keys (,) the herewith

parameters are set:

IP (integration period) used by meter during yield test

recording. The values I 5s, 10s, 30s, 60s, 120s, 300s,

600s, 900s, 1800s, 3600s are selectable

15/05/10 15:34:26

IP

: 5 s

FS DC clamp

FS AC clamp

: 1000 A

: 1000 A

The full scale (FS) of DC clamp used on DC current

measurement with selectable value within 1A 3000A

The full scale (FS) of AC clamp used on AC current

measurement with selectable value within 1A 3000A

5. Press the SAVE key to save the settings made; the

SAVE to store data

EFF

message “Data saved” will be displayed for a few

seconds. Press the ESC/MENU key to exit without saving

and go back to the previous screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 13

Page 15

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.2.1.2. PV plant parameters

1. Press MENU key, move the cursor onto EFF by using the

arrow keys (,) and confirm with ENTER. The display

shows the values of the output electrical parameters of

the photovoltaic generator (DC side).

2. Press the ENTER key. The instrument shows the

following options: “Set PV plant“ and “Set Instrum“.

3. Use the arrow keys (,) to select “Set PV plant” and

confirm with ENTER. The instrument shows the following

screen:

4. By means arrow keys ( , ) the herewith parameters

are set:

Pmax maximum nominal power of the PV

installation expressed in kW

Gamma coefficient of variation of power with the

temperature, standard parameter of PV module

(range: -0.3 -0.5%/°C typical)

Noct nominal working temperature of a PV cell,

standard parameter of PV module (range: 42 48°C

typical)

Te, Tc set of default values of environmental

temperature and PV module temperature. These

values are considered by the meter only without the

auxiliary probe connected to emote unit SOLAR-02

Corr. Type set the corrective term Ptpv for DC

efficiency calculation and for maximum DC efficiency

visualization (see § 5.2.3)

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 0.000 kW

Tc - - - °C

Te - - - °C

Pdc 0.0 kW

Vdc 0.000 V

Idc 0.0 A

ndc - - -

GO – start rec

Select

EFF

15/05/10 15:34:26

Prp - - - W/m2

Irr - - - W/m2

Pnom 0.000 kW

Tc - - - °C

Te - - - °C

Pdc 0.0 kW

Vdc 0.000 V

Idc 0.0 A

ndc - - -

Set PV plant

Set Instrument

Select

15/05/10 15:34:26

Pmax

: 3.500 kW

Gamma

Noct

Te

Tc

Corr. Type

: 0.45 %/°C

: 40 °C

: 45 °C

:

EFF

: 45 °C

T. Env

SAVE to store data

EFF

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 14

Page 16

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.2.2. Settings for PV with single/multi MPPT inverter – single/three phase AC output

See § 11.2 for further details about the meaning of MPPT. This mode requires unsing the

remote unit MPP300 (optional). Check beforehand the settings made in

MENUSETRemote Unit and check that you have selected “MPP300” as setting for

parameter “R. unit”.

5.2.2.1. Instrument settings

1. Press the MENU key, position the cursor onto EFF by

using the arrow keys (,) and confirm with ENTER.

The display shows the screen here to the side, which

contains the global parameters of the system.

2. Press the ENTER key. The instrument shows the

following options: MPP300 status, System Par. and

Instrument settings.

3. Use the arrow keys (,) to select “Instrument

settings” and confirm with ENTER. The instrument shows

the following screen:

4. By using the arrow keys ( , ) it is possible to set:

the integration period (IP) which can be used by the

instrument when testing the parameters of a PV

system. The following values can be selected: 5s, 10s,

30s, 60s, 120s, 300s, 600s, 900s, 1800s, 3600s

The FS of the DC clamp used for measuring DC

current with value selectable between 1A 3000A

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 150.0 kW

Tc - - - °C

Te - - - °C

Pdc - - - kW

Pac - - - kW

ndc - - -

nac - - -

GO - start Rec

Select

MPP

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 150.0 kW

Tc - - - °C

Te - - - °C

Pdc - - - kW

Pac - - - kW

ndc - - -

nac - - -

MPP300 Status

Set PV plant

Set Instrum.

Select

MPP

15/05/10 15:34:26

IP

: 5 s

FS DC clamp:

FS AC clamp:

Clamp Type:

Dc inputs

Ac sytem

1000 A

1000 A

STD

1+2+3

3phase

The FS of the AC clamp used for measuring AC

current with value selectable between 1A 3000A

The type of AC clamp used: STD (standard) or FLEX

(flexible clamp)

The number of DC inputs to be used for measuring:

SAVE to store data

MPP

1, 1+2, 1+2+3

The type of AC electrical system: SINGLE, 4 wires

5. Press the SAVE key to save the settings made; the

message “Data saved” will be displayed for a few

seconds. Press the ESC/MENU key to exit without saving

and go back to the previous screen.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 15

Page 17

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

C

5.2.2.2. PV plant parameters

1. Press MENU key, position the cursor onto EFF by using

the arrow keys (,) and confirm with ENTER. The

display shows the screen here to the side, which contains

the global parameters of the system.

2. Press the ENTER key. The instrument shows the

following options: MPP300 status, Set PV plant. and Set

Instrum.

3. Use the arrow keys (,) to select “Set PV plant” and

confirm with ENTER. The instrument shows the following

screen:

4. By using the arrow keys ( , ) it is possible to set:

Pmax maximum rated power of PV installation

expressed in kW

Range coefficient of power variation with

temperature, characteristic parameter of PV modules

(typically in range: -0.3 -0.5%/C)

Noct rated operating temperature of the cell,

characteristic parameter of PV modules (typically in

range: 42 48°C)

Te, Tc setting of default values of environmental

and PV module temperatures. These values are taken

into consideration by the instrument only when probe

is not connected to unit SOLAR-02

Corr. Type Setting of the compensation

relationship on the calculation of Pdc power and the

maximization of DC performance (see § 5.2.3)

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 150.0 kW

Tc - - - °C

Te - - - °C

Pdc - - - kW

Pac - - - kW

ndc - - -

nac - - -

GO – start rec.

Select

MPP

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 0.000 kW

Tc - - - °C

Te - - - °C

Pdc 0.0 kW

Vdc 0.000 V

Idc 0.0 A

ndc - - -

MPP300 status

Set PV plant

Set instrum.

Select

15/05/10 15:34:26

Pmax

: 3.500 kW

Gamma

: 0.45 %/°C

Noct

Te

: 40 °C

Tc

: 45 °C

orr.Type.

:

MPP

: 45 °C

T. Env

SAVE to store data

MPP

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 16

Page 18

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.2.2.3. MPP300 status

If SOLAR I-Vw or SOLAR I-Ve is near MPP300, the general parameters of MPP300 may

be displayed.

1. Position the cursor onto EFF by using the arrow keys

(,) and confirm with ENTER. The display shows the

screen here to the side, which contains the global

parameters of the system.

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 150.0 kW

Tc - - - °C

Te - - - °C

Pdc - - - kW

Pac - - - kW

ndc - - -

nac - - -

GO – start rec.

Select

MPP

2. Press the ENTER key. The instrument shows the

following options: MPP300 status, Set PV plant and Set

Instrum.

3. Use the arrow keys (,) to select “MPP300 status”

and confirm with ENTER. The instrument shows the

screen here to the side, which indicates the main general

parameters of the instrument.

15/05/10 15:34:26

Power supply P.Sup.

Battery In use

Charge 99%

SOLAR-02

detected

Version 1.01

SN 11010030

MPP300 status

SI

Set PV plant

Set instrum.

Select

MENU

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 17

Page 19

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

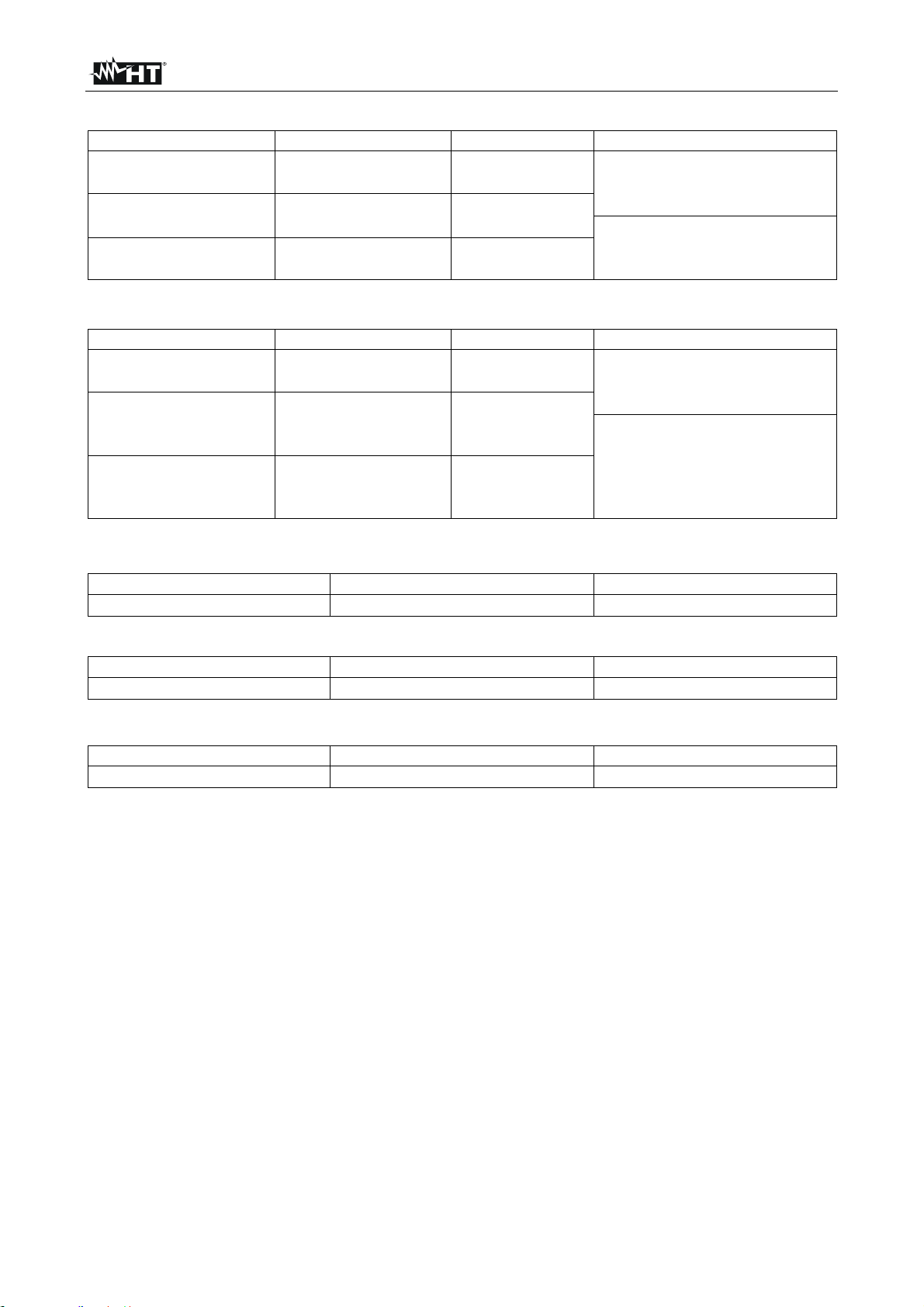

5.2.3. Selection of the compensation relationship of temperature effects

This option allows selecting the relationship to be used to correct the measurements

performed according to the modules’ temperature. The following correction modes are

available:

- T.mod.: Correction factor Rfv2 related to PV module Temp. (Italian guideline CEI-82-25)

- T.env: Correction factor Rfv2 related to environment Temp. (Italian guideline CEI-82-25)

- ndc: PRp (Performance ratio for active power) corrected by PV module Temp.

CAUTION

If it’s performed a test according to Italian guideline it is recommended to select

Corr.

Type

T.mod.

T.amb.

“T.env.” correction

Temperature (Tcel) PRp calculation Ref.

asTmodule_MeTcel

R

Irr

20TambTcel NOCT

800

fv2

PRp

40)-(Tcel- 1

Rfv

-

2

100

G

P

ca

G

p

STC

P

n

C)40Tcel (if 1

C)40Tcel (if

CEI

82-25

25

P

ca

P

- - -

n

2

W/m

W/m

kW

kW

2

C%/

C%/

G

dc

where:

Symbol Description Meas. unit

G

p

G

STC

P

n

P

ca

NOCT Normal Operating Cell Temperature (@ 800W/m2, 20°C, AM=1.5, vel. Aria =1m/s).

Irradiance on PV module surface

Standard Irradiance = 1000

Nominal Power = sum of all power module (Pmax ) included in the part of PV plant under test

AC Active Power measured

Thermal Coefficient factor

2Rfv

Absolute value of Pmax thermal coefficient

asTmodule_MeTcel

PRp

G

STC

p

1

T

100

cel

For further details see § 11.1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 18

Page 20

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.3. DB – MODULE DATABASE

The meter allows defining up to 30 different PV modules, further to a DEFAULT situation

(not editable and not erasable) which can be used as reference case when no piece of

information about the module under test is available.

The parameters which can be set, with reference to 1 module, are described below in

Table 1 together with their range, resolution and validity condition.

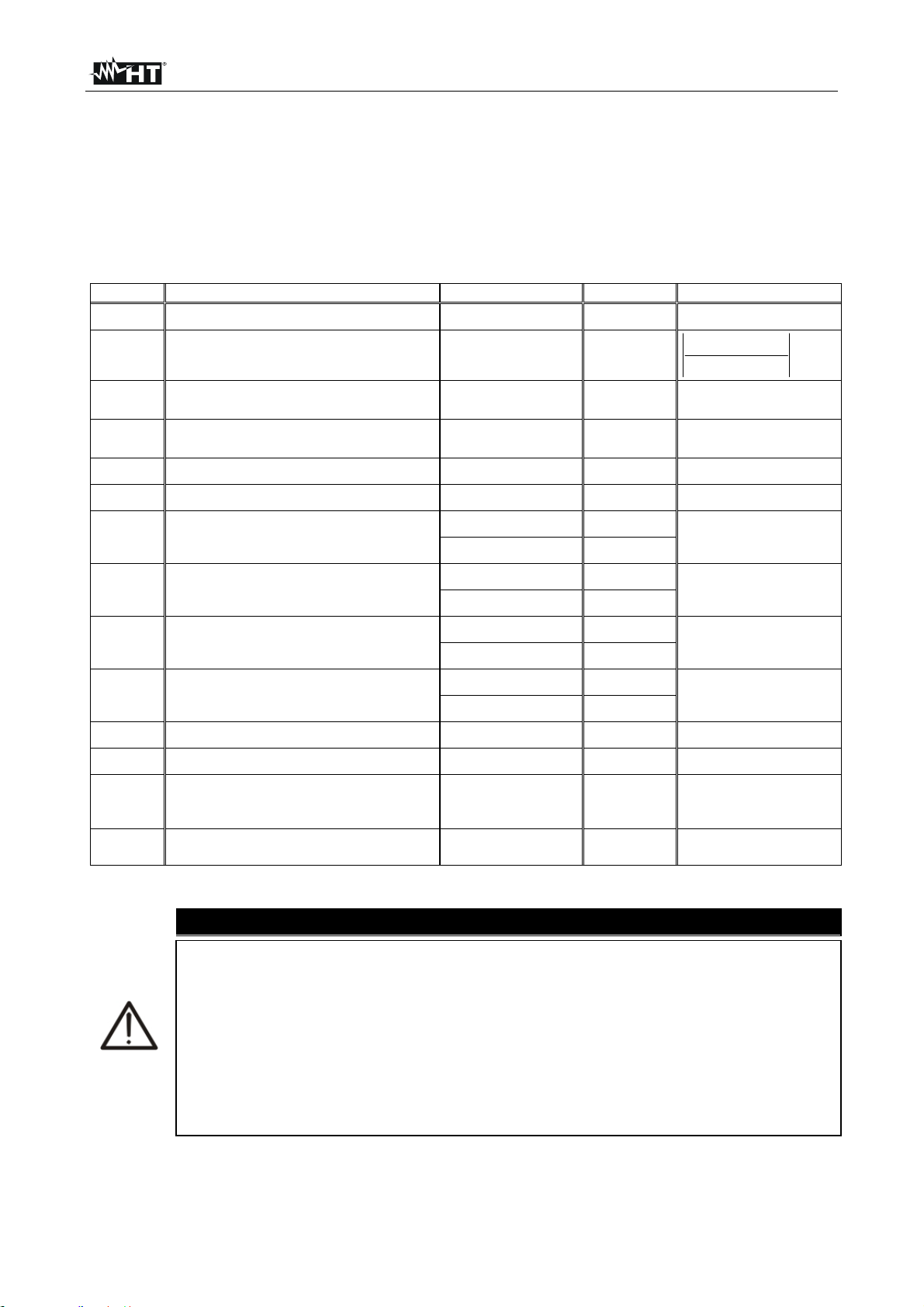

Symbol Description Range Resolution Condition

Nms Number of modules for string

Pmax Maximum nominal power of module

Voc Open voltage

Vmpp Voltage on point of maximum power

Isc Short circuit current

Impp Current on point of maximum power

Toll -

Toll +

Alpha Isc temperature coefficient

Beta Voc temperature coefficient

Gamma Pmax temperature coefficient

NOCT Nominal working temperature of cell

Tech. Effects due to PV technology

Degr

Negative tolerance for Pmax provided

by the module manufacturer

Positive tolerance for Pmax provided

by the module manufacturer

Percentage of annual performance

degradation

1 50

50 4800W

15.00 99.99V

100.0 320.0V

15.00 99.99V

100.0 320.0V

0.5 15.00A

0.5 15.00A

0% 25.0%

0 99W

0 25%

0 99W

-0.1000.100%/°C

-15.00 15.00mA/°C

-0.99 -0.01%/°C

-0.999 -0.001V/°C

-0.99 -0.01%/°C

0 100°C

STD (standard)

CAP(capacitive eff.)

HIT (hybrid techn.)

0.0 25.0%/yr

1

1W

0.01V

0.1V

0.01V

0.1V

0.01A

0.01A

0.1%

1

0.1%

1

0.001%/°C

0.01mA/°C

0.01%/°C

0.001V/°C

0.01%/°C

1°C

0.1%/yr

max

100*Tol-/Pnom< 25

100*Tol+/Pnom< 25

100*Alpha / Isc 0.1

100*Beta/Voc 0.999

IVP

mppmpp

P

max

Voc Vmpp

Voc Vmpp

Isc Impp

Isc Impp

01.0

Table 1: Typical parameters of PV modules

CAUTION

The “Tech” item is referred to the choose of the technology of the module

on test. Select the “STD” option for test on “STANDARD” PV modules,

“CAP” option for test on higher capacitive effects PV modules or HIT

(modules with HIT/HIP hybrid technology

A wrong choose of the type of technology can lead to a negative outcome of

the final test

The “Degr” item is referred to the power performance degradation of a PV

module/strings/field expressed in annual percentage (maximum limit set =

25%)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 19

Page 21

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

5.3.1. How to define a new PV module

1. Move the cursor to “DB” by means of the arrow keys

(,) and confirm with ENTER. The display shows the

screen with:

The type of selected module

The parameter associated to the module (see Table 1)

2. Select the “DEFAULT” module by means of the arrow

keys (,) and confirm with ENTER.

3. Press ENTER, select the “New” command and confirm

again with ENTER. Use the arrow keys (,) to scroll all

internal parameters.

4. By using the internal virtual keyboard it is possible to

define the name of the module (ex: SUNPOWER 210) by

means the arrow keys (,,,). Press ENTER to digit

the characters of the desired name.

5. Press the SAVE key to save the inserted name of the

module as defined or ESC/MENU key to exit without

saving.

6. Digit the value of each parameter of the defined module

(see Table 1) based on the manufacturer’s data sheet.

Move the cursor to the row of the parameter by means of

the arrow keys (,) and set the value by means of the

arrow keys (,). Press and hold (,) for a quick

setting of values.

7. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit

without saving and to go back to the previous screen.

CAUTION

If the value of any parameter is unknown press and hold the HELP key for

some seconds to set the default values

After pressing the SAVE key, the meter checks all the conditions shown in

Table 1 and, if one or more of these conditions do not occur, some error

messages are shown by the display (§ 6.5) and the meter does not save

the configuration before any error is solved. Solve the error condition

before saving.

15/05/10 15:34:26

Type : DEFAULT

Pmax = 185 W

Voc = 44.5 V

Vmpp = 37.5 V

Isc = 5.40 A

Impp = 4.95 A

Toll- = 0 %

Select

15/05/10 15:34:26

DB

Type : DEFAULT

Pmax = 185 W

Voc = 44.5 V

Vmpp = 37.5 V

Isc = 5.40 A

Impp = 4.95 A

Toll- = 0 %

New

Select

15/05/10 15:34:26

DB

Type :

Pmax = 185 W

Voc = 44.5 V

KEYBOARD

SUNPOWER 210

ABCDEFGHI J KL MNOP

QRS T UVWXYZ- +0 1 2 3

4 5 6 7 8 9 SPACE DEL

15/05/10 15:34:26

Type : SUNPOWER 210

Pmax = 0 W

Voc = 0.0 V

Vmpp = 0.0 V

Isc = 0.00 A

Impp = 0.00 A

Toll- = 0 %

DB

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 20

Page 22

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

S

210

5.3.2. How to modify a PV module

1. Select the PV module to be modified from the internal

database by means of arrow keys (,).

2. Press the ENTER key and select the “Modify” command

by means the arrow key ().

3. Confirm the selection with ENTER.

4. By using the internal virtual keyboard it is possible to

define a different name of the module by means of arrow

keys (,,,). Press ENTER to digit any character of

the desired name.

5. Press the SAVE key to save the new name of the module

as defined or to access the new setting of parameters.

6. Select the desired parameters to be modified by means of

arrow keys (,) and change values by means of arrow

keys (,). Press and hold the (,) for a quick setting

of values. If the value of any parameter is unknown, press

and hold the HELP key for some seconds to set the

default values.

7. Confirm with SAVE and the “Saved data” message is

displayed for a while. Press ESC/MENU key to exit

without saving and to go back to the previous screen.

5.3.3. How to delete a PV module

1. Select the PV module to be deleted from the internal

database by means of arrow keys (,).

2. Press the ENTER key and select “Delete” command by

means of arrow key () to delete the selected module.

3. Press the ENTER key and select “Del. All” command by

means of arrow key () to delete all modules in the

database (except for “DEFAULT”).

4. Confirm the selection with ENTER or press ESC/MENU to

exit

CAUTION

It is not possible to modify or delete the “DEFAULT” PV module which is the

standard reference factory module.

15/05/10 15:34:26

Type: SUNPOWER210

Pmax = 210 W

Voc = 47.70 V

Vmpp = 40.00 V

Isc = 5.75 A

New

Modify

Delete

Del. All

Select

15/05/10 15:34:26

DB

Type: SUNPOWER210

Pmax = 185 W

Voc = 44.5 V

KEYBOARD

UNPOWER

ABCDEFGHI J KL MNOP

QRS T UVWXYZ- +0 1 2 3

4 5 6 7 8 9 SPACE DEL

SAVE/ESC

15/05/10 15:34:26

Type : SUNPOWER 210

Pmax = 210 W

Voc = 47.70 V

Vmpp = 40.00 V

Isc = 5.75 A

Impp = 5.25 A

Toll- = 5 %

15/05/10 15:34:26

DB

Type: SUNPOWER210

Pmax = 210 W

Voc = 47.70 V

Vmpp = 40.00 V

Isc = 5.75 A

New

Modify

Delete

Del. All

Select

DB

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 21

Page 23

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

6. HOW TO OPERATE

6.1. TESTING PV SYSTEMS (SOLAR I-VW OR SOLAR I-VE)

For the sake of simplicity, further in this manual, the word “string” will be used, although

often the term “photovoltaic field” would be more correct. From the point of view of the

instrument, the management of a single string or of more parallel strings (photovoltaic field)

is identical. Furthermore, the acronym MPPT (Multiple Power Point Tracker) shall indicate

the characteristic of the DC/AC converter (inverter), capable of maximizing the DC power

which can be taken from the photovoltaic field (see the § 11.2 for further details), the

acronym PRp shall indicated the Performance ratio (evaluated on active powers).

For the evaluation of the PRP only, the measurement of the DC (voltage

and current) is not strictly necessary

Conversely it is necessary if you want to evaluate the performance of the

photovoltaic section (ndc) and DC / AC conversion (nac)

Simbol Description Unit

PRp Performance Ratio (calculated through Active power)

Irr Irradiance W/m2

Pnom Total Nominal power of the PV section under test. kW

Tc Module Temperature °C

Te Environment Temperature °C

Pdc, Pdcx Total DC power measured, DC power of PV field x (x=1,2,3) kW

Pac, Pacx Total AC power measured, AC power of phase x (x=1,2,3,) kW

ndc DC efficiency

nac AC efficiency

Vdc, Vdcx DC Voltage, DC voltage of PV field x (x=1,2,3) V

Idc, Idcx DC current, DC current of PV field x (x=1,2,3) A

Vac, Vacx AC Voltage, AC voltage of PV field x (x=1,2,3) V

Iac, Iacx AC current, AC current of PV field x (x=1,2,3) A

Symbols description

CAUTION

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 22

Page 24

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

6.1.1. Testing of PV systems w i th single-MPPT inverter - single-phase AC output

The SOLAR I-Vw or SOLAR I-Ve meter (master) can perform check tests of efficiencies on

single phase PV installations by using the irradiance and temperature probes which are

connected to the remote unit SOLAR-02. This remote unit communicates with the master

unit (for the synchronization and download data operations) through a wireless radio-

frequency (RF) which is active with a maximum distance of about 1m between units.

CAUTION

The maximum voltage between C1, and C2 inputs is 1000VDC (for SOLAR

I-Vw) or 1500VDC (for SOLAR I-Ve) and between P1 and P2 inputs is 265V

AC rms. Do not measure voltages exceeding the limits prescribed by this

manual. Should you exceed the voltage limits you could damage the

instrument and/or its components or endanger your safety

In order to guarantee the operator’s safety, while making the connections,

disable the system being measured by means of the switches/breakers

upstream and downstream of the DC/AC converter (inverter).

Fig. 4: Connection of meter for check on single phase PV installation

1. Check and, if necessary, set the sensitivity of the reference cell on SOLAR-02 consistently

with the type of PV modules which will be measured (please refer to the User Manual of

SOLAR-02)

2. We recommend making a preliminary evaluation of the value of irradiation on the surface of

the PV modules being tested by means of unit SOLAR-02 (operating independently) and the

reference cell

3. Switch on SOLAR I-Vw or SOLAR I-Ve. Check and if necessary modify the basic

settings of meter relative to the minimum irradiance threshold, the FS of DC and AC

transducer clamps, the IP and the parameters of the PV installation on test (see § 5.1.1,

§5.1.5 and §5.2)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 23

Page 25

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

4. In order to guarantee the operator’s safety, disable the system being measured by means of

the switches/breakers upstream and downstream of the DC/AC converter (inverter)

5. In case of inverters provided with more than one power tracker (MPPT), only leave the

string corresponding to the first MPPT connected, as shown in Fig. 4. Then, it will be

necessary to repeat the operations described below by only leaving the string corresponding

to the second MPPT connected, then to the third, etc.

6. Bring SOLAR I-Vw or SOLAR I-Ve and SOLAR-02 nearer (maximum distance of 1m

between them). All instruments must be switched on (see the User Manual of SOLAR-2

for further details)

7. On SOLAR I-Vw or SOLAR I-Ve, press the MENU key, select the function EFF and press

ENTER; wait for the two units to start communicating with each other. This condition is

highlighted by the contemporary presence of the following indicators:

Symbol steady (not flashing) on the display of SOLAR I-Vw or SOLAR I-Ve

Symbol steady (not flashing) on the display of SOLAR-02

8. Connect the C2 and C1 inputs respectively to the positive and negative polarity of the

output string. Connect the P1 and P2 inputs to the phase and neutral conductors

respecting the colors as shown in Fig. 4

9. Connect the output connector of the DC clamp to the IDC1 input.

CAUTION

BEFORE CONNECTING THE DC CLAMPS TO THE CONDUCTORS

Switch on the clamp, check the LED indicating the status of the clamp’s

internal batteries (if present), select the correct range, press the ZERO key

on the DC clamp and check on the display of SOLAR I-Vw or SOLAR I-Ve,

the actual zeroing of the corresponding Idc value (values up to 0.02A are

acceptable).

10. Connect the DC current clamp to the positive string output conductor by respecting

the direction of the arrow on the clamp itself as indicated in Fig. 4. Position the DC

clamp in point so far from the inverter and avoid that the jaws stay close to the negative

conductor

11. Connect the AC current clamp to the Phase L1 conductor by respecting the direction

of the arrow on the clamp itself as indicated in Fig. 4. Position the AC clamp as far as

possible from the inverter and avoid that the jaws stay close to the neutral conductor.

Connect the output of the clamp to the IAC input of the instrument

12. Power on the system on test

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 24

Page 26

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

13. The display shows the first screen containing the values

of the electrical parameters on the DC side of the inverter.

14. By means of arrow key to access to the second screen

with the values of electrical parameters of the AC side of

inverter. Before to start the recording:

Verify the symbol “ ” blinking at display which

means the search by the meter of RF connection with

the remote unit SOLAR-02

Verify that the Pac active power should be a positive

value. In the opposite case open the AC clamp and

rotate of 180 degree on the phase conductor

Verify that the AC efficiency ac = Pac / Pdc should be

a consistent value (e.g.: a situation of ac > 1 is not

physically possible)

15. With remote unit always close to the main unit press

GO/STOP key to start the recording. The “Rec. Start

waiting…” message is shown at display of main unit and the

“HOLD” message is shown at display of SOLAR-02 more

than the indication of residual time for “00” instance

16. When the “00” instant after the press of GO/STOP key is

reached, the recording starts and the units are correctly

synchronized. In these conditions the message “Rec

running…” is displayed on the main unit and the

“Recording…” message is displayed on the SOLAR-02

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 3.500 kW

Tc 45 °C

Te 30 °C

Pdc 3.125 kW

Vdc 389 V

Idc 8.01 A

ndc - - -

GO – start rec.

Select

EFF

15/05/10 15:34:26

Pdc 3.125 kW

Vdc 389 V

Idc 8.01 A

ndc - - - °C

Pac 3.012 kW

Vac 231 V

Iac 13.03 A

nac 0.96

GO – start rec

Select

EFF

15/05/10 15:34:26

Pdc 3.125 kW

Vdc 389 V

Idc 8.01 A

ndc - - - °C

Pac 3.012 kW

Vac 231 V

Iac 13.03 A

nac 0.96

Rec. Start waiting…

Select

EFF

15/05/10 15:35:00

Pdc 3.125 kW

Vdc 389 V

Idc 8.01 A

ndc - - - °C

Pac 3.012 kW

Vac 231 V

Iac 13.03 A

nac 0.96

Rec. Running…

Select

EFF

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 25

Page 27

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

971

30

0.9

17. At any time it will be possible to analyze the current

recording status by pressing the MENU key. The following

information will be shown:

starting date and time of recording

the value set for the integration period

the number of periods elapsed from the beginning

of the recording

the remaining memory capacity for recording

Press the ESC key to exit the screen

15/05/10 15:35:00

Start

14/02/00 17:18:00

Period: 5s

IP Number 61

Rec. Time 0d 1h

Rec. running

Select

MPP

18. Now it is possible to bring the unit SOLAR-02 near the PV strings to measure irradiation and

temperature by means of the relevant probes. When the distance between unit SOLAR-02

and SOLAR I-Vw or SOLAR I-Ve does not allow the RF connection, on the display of

SOLAR-02, the symbol “ ” flashes for approx. 30s and then disappears, while SOLAR IVw or SOLAR I-Ve continues searching for the connection for approx. 1 minute.

19. Position the reference cell onto the surface of the PV modules. Please refer to the relevant

User Manual for a correct assembly.

20. Put the temperature sensor in contact with the rear side of the module and fasten it with

some tape; prevent touching it with your fingers (as this could alter the measure).

21. Wait some seconds in order to permit a stable measure by probes and then connect the

irradiation and temperature probes respectively to the inputs PYRA/CELL and TEMP

of the SOLAR-02 unit.

22. Wait for “READY” message displayed on SOLAR-02. This event indicates that the

instrument has detected some data with solar irradiation > minimum limit threshold (see

§ 5.1.5)

23. Wait at least 1 minute in order to recording more valid samples

24. Disconnect the irradiation and temperature probes from unit SOLAR-02 and bring the unit

near SOLAR I-Vw or SOLAR I-Ve (max distance 1m).

25. The main unit SOLAR I-Vw or SOLAR I-Ve must be in EFF mode. If there is no flashing

symbol “ ”, press key to activate the RF connection search again.

26. Press the key on SOLAR-02 to active the RF connection. On the main unit the message

“ RF connection active” is displayed

27. To stop testing, press the GO/STOP key on instrument

SOLAR I-Vw or SOLAR I-Ve and confirm with ENTER that

you want to stop recording.

28. The display of SOLAR I-Vw or SOLAR I-Ve will show the

message “DOWNLOAD” to indicate that the data will be

transferred to the main unit during its various phases.

29. After the automatic data transfer phase, the instrument:

Do not show any results if do not exist on the PV

installation a “stable irradiance” condition more than the

minimum irradiance threshold.

15/05/10 15:35:00

Irr

Pnom 3.500 kW

Tc 45.1 °C

Te

Pdc 3.125 kW

Pac 2.960 kW

ndc 0.86

nac

Analysis Result

Select

W/m2

.5 °C

5

EFF

Display the best performance values if during the recording, the Irradiance values

reached the “stable” condition and its values were higher than the minimum irradiance

threshold.

30. Press SAVE to save the results (see § 7.1) or ESC to exit the screen of the results and

go back to the initial screen

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 26

Page 28

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

6.1.2. Test PV systems with single/multi-MPPT inverter – single/three-phase AC

output

The instrument SOLAR I-Vw or SOLAR I-Ve, used together with remote units SOLAR-02

and MPP300 (optional), allows testing PV systems characterized by 1 or more strings (with

the same direction and inclination) and single-phase or three-phase output.

The remote unit MPP300 is capable of communicating with SOLAR I-Vw or SOLAR I-Ve

(to manage synchronization and data download) and with the remote unit SOLAR-02 (for

recording irradiation and temperature values) via a wireless radiofrequency (RF)

connection, which is active up to a maximum distance of 1m between the units.

Fig. 5: Connection of MPP300 for testing a single-phase PV system

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 27

Page 29

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

Fig. 6: Connection of MPP300 for testing a three-phase PV system

CAUTION

When SOLAR I-Vw or SOLAR I-Ve is set in order to use MPP300 as a

remote unit, ALL connections relevant to electrical quantities (voltages and

currents) must be carried out on unit MPP300. SOLAR I-Vw or SOLAR IVe must have no voltage nor current connected to its inputs.

The maximum voltage for the inputs of MPP300 is 1000VDC between

inputs VDC1, VDC2, VDC3 and 600VAC between inputs VAC1, VAC2,

VAC3. Do not measure voltages exceeding the limits given in this manual.

Exceeding these limits could result in electrical shocks to the user and

damage to the instrument.

In order to guarantee the operator’s safety, while making the connections,

disable the system being measured by means of the switches/breakers

upstream and downstream of the DC/AC converter (inverter).

1. Check and, if necessary, set the sensitivity of the reference cell on SOLAR-02 consistently

with the type of PV modules which will be measured (please refer to the User Manual of

SOLAR-02).

2. We recommend making a preliminary evaluation of the value of irradiation on the surface of

the PV modules being tested by means of unit SOLAR-02 (operating independently) and the

reference cell

3. Switch on SOLAR I-Vw or SOLAR I-Ve, check and, if necessary, change the settings

relevant to the type of remote unit, to the minimum irradiation threshold, to the full scale of

the AC and DC clamps, to the integration period and to the parameters of the system being

measured (see § 5.1.4, § 5.1.5, § 5.1.6, § 5.2.2).

4. In order to guarantee the operator’s safety, disable the system being measured by means of

the switches/breakers upstream and downstream of the DC/AC converter (inverter).

5. Bring SOLAR I-Vw or SOLAR I-Ve, SOLAR-02 and unit MPP300 nearer (maximum

distance of 1m between them). All instruments must be switched on (see the User

Manuals of SOLAR-2 and MPP300 for further details).

6. On SOLAR I-Vw or SOLAR I-Ve, press the MENU key, select the function EFF and press

ENTER; wait for the three units to start communicating with each other. This condition is

highlighted by the contemporary presence of the following indicators:

Symbol steady (not flashing) on the display of SOLAR I-Vw or SOLAR I-Ve

Symbol

steady (not flashing) on the display of SOLAR-02

MASTER and REMOTE LEDs flashing green on unit MPP300

7. Connect the VDC1(+) and VDC1(-) inputs of unit MPP300 to the output terminals of the

string, respecting the polarities and the colours indicated in Fig. 5 or Fig. 6

8. Repeat the operation described in the step above for other possible DC power trackers

to be monitored by using the VDC2 and VDC3 inputs according to the number of DC

inputs set (see § 5.2.1.1).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 28

Page 30

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

0.9

9. Connect the output connector of the DC clamp to the IDC1 input of unit MPP300.

CAUTION

BEFORE CONNECTING THE DC CLAMPS TO THE CONDUCTORS

Switch on the clamp, check the LED indicating the status of the clamp’s

internal batteries (if present), select the correct range, press the ZERO key

on the DC clamp and check on the display of SOLAR I-Vw or SOL AR I-V e

the actual zeroing of the corresponding Idc value (values up to 0.02A are

acceptable).

10. Insert the DC current clamp onto the positive output conductor of the string, respecting the

direction of the arrow found on the clamp itself as indicated in Fig. 5 or Fig. 6. Position the

clamp toroid as far as possible from the inverter and from the negative output conductor of

the string itself.

11. Repeat the operations described in the two steps above for other possible DC power

trackers to be monitored by using the IDC2 and IDC3 inputs according to the number of DC

inputs set (see § 5.2.1.1).

12. Connect the VAC1 and N inputs of unit MPP300 to the Phase and Neutral conductors

respectively, respecting the polarities and the colors indicated in Fig. 5 or Fig. 6. In case of

three-phase systems in which no Neutral conductor is available, connect input N to earth.

13. In case of inverter with three-phase output (see settings in § 5.2.1.1), repeat the

operation described in the step above for the remaining phases by using the VAC2 and

VAC3 inputs of MPP300.

14. Connect the AC clamp to the Phase L1 conductor, respecting the direction of the arrow

found on the clamp itself as indicated in Fig. 5 or Fig. 6. Position the clamp toroid as far as

possible from the inverter and from the Neutral conductor. Connect the clamp output to the

IAC1 input of MPP300.

15. In case of inverter with three-phase output (see settings in § 5.2.1.1), repeat the operation

described in the step above for the remaining phases by using the IAC2 and IAC3 inputs of

MPP300.

16. Restore the operation of the electrical system being measured.

17. The display of SOLAR I-Vw or SOLAR I-Ve will show the

values of the general electrical parameters of the system

being measured. In particular, in this screen:

Pdc = General DC power (sum of the string powers)

Pac = AC power (if single-phase) or sum of the ac

powers (if three-phase)

We recommend checking that the values of the electrical

parameters (Pnom, Pdc, Pac) and of the ac performance

(ac) are consistent with the system being measured (e.g.:

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 3.500 kW

Tc - - - °C

Te - - - °C

Pdc 3.125 kW

Pac 2.960 kW

ndc - - -

nac

GO – start rec

Select

5

MPP

ac > 1 is not physically acceptable)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

EN - 29

Page 31

I-V400w - I-V500w - SOLAR I-Vw - SOLAR I-Ve

0.9

0.9

18. On SOLAR I-Vw or SOLAR I-Ve, press key () to access

the second screen which contains the values of the

output DC parameters of the strings according to the

number of DC inputs set (see § 5.2.1.1). In particular, in

this screen:

Vdcx = DC voltage of string x

Idcx = DC current of string x

Pdx = DC power of string x.

We recommend checking that the values of the electrical

parameters (Vdc, Idc, Pdc) are consistent with the system

being measured.

19. On SOLAR I-Vw or SOLAR I-Ve, press key () to access

the third screen which contains the values of the electrical

parameters on the AC side of the inverter, consistently

with the settings made in § 5.2.2 (single-phase, threephase 4 wires). In particular, in this screen:

Vacxy = AC voltage between Phase and Neutral (if

single-phase) or between Phases x and y (if threephase)

Iacx = AC current of phase x

Pacx = AC power of phase x

We recommend checking that the values of the electrical

parameters (Vac, Iac, Pac) are consistent with the system

being measured.

20. Keeping the three instruments near each other (max

distance approx. 1m), press the GO/STOP key on SOLAR I-

Vw or SOLAR I-Ve to start testing. Consequently:

The display of SOLAR I-Vw or SOLAR I-Ve shows the

message “rec. start waiting”

The display of SOLAR-02 shows the message “HOLD”

and the time, expressed in seconds, remaining before the

recording is started