Page 1

ENGLISH

User manual

Copyright HT ITALIA 2012 Version EN 2.00 - xx/xx/2012

Page 2

Page 3

MPP300

Table of contents:

1. PRECAUTIONS AND SAFETY MEASURES ............................................................... 2

1.1. Preliminary instructions ..................................................................................................... 2

1.2. During use ......................................................................................................................... 3

1.3. After use ............................................................................................................................ 3

1.4. Definition of measurement (overvoltage) category ............................................................ 3

2. GENERAL DESCRIPTION ........................................................................................... 4

2.1. Introduction ........................................................................................................................ 4

2.2. Instrument functions .......................................................................................................... 4

3. PREPARATION FOR USE ........................................................................................... 5

3.1. Initial checks ...................................................................................................................... 5

3.2. Instrument power supply ................................................................................................... 5

3.3. Calibration ......................................................................................................................... 5

3.4. Storage .............................................................................................................................. 5

4. OVERVIEW .................................................................................................................. 6

4.1. Instrument description ....................................................................................................... 6

4.2. Description of the indication LEDs .................................................................................... 6

4.3. MASTER instrument .......................................................................................................... 6

4.3.1. Displaying the status of MPP300 by means of MASTER instruments of Type 1 .................... 7

4.3.2. Displaying the status of MPP300 by means of MASTER instruments of Type 2 .................... 7

5. SETTINGS ON MASTER INSTRUMENTS ................................................................... 8

5.1. MASTER instruments OF type 1 - Remote unit settings .................................................. 8

5.2. MASTER instruments OF type 2 – Remote unit settings .................................................. 8

6. OPERATING INSTRUCTIONS ..................................................................................... 9

6.1. PV system testing for instruments of Type 1 (SOLAR I-V) ................................................ 9

6.1.1. Te s t i n g o f P V s ys t e m s w i t h s i ng l e / m u l t i - M P P T in v e r t e r - s i ng l e / t h r e e - p ha s e A C o u t p u t .......................... 9

6.2. PV system testing for instruments of Type 1 (SOLAR 300N) .......................................... 15

6.2.1. Te s t i n g o f P V s y st e m s w i t h s i n gl e / m u l t i - M P P T i nv e r t e r - s i n g le / t h r e e - p h a se A C o u t p u t ........................ 15

7. MAINTENANCE .......................................................................................................... 21

7.1. General information ......................................................................................................... 21

7.2. Status of the internal rechargeable batteries ................................................................... 21

7.3. Cleaning the instrument .................................................................................................. 21

7.4. End of life ........................................................................................................................ 21

8. TECHNICAL SPECIFICATIONS ................................................................................. 22

8.1. Technical specifications for test on PV systems ............................................................. 22

8.2. Reference standards ....................................................................................................... 23

8.3. General characteristics .................................................................................................... 23

8.4. Environmental conditions for use .................................................................................... 23

8.5. Accessories ..................................................................................................................... 23

9. APPENDIX – THEORETICAL OUTLINE .................................................................... 24

9.1. Testing photovoltaic systems .......................................................................................... 24

9.2. NOTES on MPPT (Maximum Power Point Tracker) ........................................................ 25

10. SERVICE .................................................................................................................... 26

10.1. Warranty conditions ......................................................................................................... 26

10.2. Service ............................................................................................................................ 26

EN - 1

Page 4

MPP300

1. PRECAUTIONS AND SAFETY MEASURES

The instrument has been designed in compliance with directive IEC/EN61010-1 relevant to

electronic measuring instruments. Before and while carrying out measurements, observe

the following indications and read all notes preceded by the symbol with the utmost

attention

In case the instrument is used in a way different from the one described in this

user manual, this could result in a failure of the protections the instrument is

provided with

Do not carry out any voltage or current measurement in humid environments

Do not carry out any measurements in case gas, explosive materials or flammables are

present, or in dusty environments

Avoid contact with the circuit being measured if no measurements are being carried out

Avoid contact with exposed metal parts, with unused measuring probes, circuit s, etc

Do not carry out any measurement in case you find anomalies in the instrument such as

deformation, breaks, substance leaks, absence of display on the screen, etc

Pay special attention when measuring voltages higher than 20V, since a risk of

electrical shock exists

Only use original accessories

In this manual, and on the instrument, the following symbols are used:

CAUTION: observe the instructions given in this manual; an improper use could

damage the instrument or its components

High voltage danger: electrical shock hazard

Double insulation

DC voltage or current

AC voltage or current

Connection to earth

1.1. PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in an environment with pollution level 2 and

in the environmental conditions specified in § 8.4. Do not use in different environmental

conditions

We recommend following the normal safety rules devised to protect the user from

dangerous currents and the instrument from an incorrect use

The instrument may be used for measuring VOLTAGE in CAT III 1000V DC or CAT IV

300V AC to earth. Do not use on systems exceeding the limit values specified in § 8

The instrument may be used for measuring CURRENT by means of external clamp

transducers

Only original HT accessories guarantee safety standards. They must be in good

conditions and replaced with identical models, when necessary

Before connecting the measuring cables to the circuit being measured, check that the

instrument has been correctly set

CAUTION

EN - 2

Page 5

MPP300

1.2. DURING USE

Please carefully read the following recommendations and instructions:

CAUTION

Failure to comply with the notes and/or instructions may damage the

instrument and/or its components or be a source of danger for the

operator

The red flashing “POWER” LED indicates that the internal rechargeable

batteries are almost flat. In this case, connect the external power supply

as described in § 7.2

The IDC1, IDC2, IDC3 input connectors are type 4-pole type. Use only

clamps with 4-pin output connector or interpose adapter ACON3F4M

between the clamp output connector and the instrument input.

The instrument maintains the data stored also in case of flat battery

The instrument is particularly sensitive to ESD nearby and on the USB

port while it is operating; we recommend connecting the cables to the USB

port when the instrument is off

1.3. AFTER USE

When measurements are completed, turn off the instrument by pressing and holding the

ON/OFF key for some seconds. If the instrument is not to be used for a long time, please

follow the instructions given in § 3.4

1.4. DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard “IEC/EN61010-1: Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements” defines what measurement

category, commonly called overvoltage category, is. § 6.7.4: Measured circuits, reads:

Circuits are divided into the following measurement categories:

Measurement category IV is for measurements performed at the source of the low-

voltage installation

Examples are electricity meters and measurements on primary overcurrent protection

devices and ripple control units

Measurement category III is for measurements performed on installations inside

buildings

Examples are measurements on distribution boards, circuit breakers, wiring, including

cables, bus-bars, junction boxes, switches, socket-outlets in the fixed installation, and

equipment for industrial use and some other equipment, for example, stationary motors

with permanent connection to fixed installation

Measurement category II is for measurements performed on circuits directly

connected to the low-voltage installation

Examples are measurements on household appliances, portable tools and similar

equipment

Measurement category I is for measurements performed on circuits not directly

connected to MAINS

Examples are measurements on circuits not derived from MAINS, and specially

protected (internal) MAINS-derived circuits. In the latter case, transient stresses are

variable; for that reason, the standard requires that the transient withstand capability of

the equipment is made known to the user

EN - 3

Page 6

MPP300

2. GENERAL DESCRIPTION

2.1. INTRODUCTION

Dear Customer, thank you for choosing one of the instruments in our range. If used

according to the instructions given in this manual, the instrument you have just purchased

will guarantee accurate and reliable measures. The instrument is designed to guarantee

maximum safety, thanks to a newly conceived development, which ensures double

insulation and enables the instrument to reach overvoltage category CAT III 1000V DC

and CAT IV 300V AC (to earth)

The instrument has been designed as an accessory for an instrument, hereafter called the

MASTER instrument (see par. 4.3), for the purpose of carrying out testing operations on

single-phase and three-phase PV systems.

Together with a MASTER instrument, MPP300 is the ideal solution for testing and

analyzing the possible problems linked to possible low efficiency values of photovoltaic

systems

2.2. INSTRUMENT FUNCTIONS

The instrument has the following features:

Measurement of 3 DC voltages and currents

Measurement of DC string power and total DC power

Measurement of 3 AC TRMS voltages and currents

Measurement of total AC power

Measurement of irradiation [W/m2] by means of a reference cell connected to unit

SOLAR-02

Measurement of panel and environmental temperature by means of probe PT300N

connected to SOLAR-02

Testing of PV systems with single/multi-MPPT inverter - single/three-phase AC output

Parameter recording of a PV system with 5s to 60min programmable IP

Internal memory for data saving

RF/USB interface for transferring the data to the MASTER instrument

EN - 4

Page 7

MPP300

3. PREPARATION FOR USE

3.1. INITIAL CHECKS

Before shipping, the instrument has been checked from an electric as well as mechanical

point of view. All possible precautions have been taken so that the instrument is delivered

undamaged. However, we recommend checking it to detect any damage possibly suffered

during transport. In case anomalies are found, immediately contact the dealer.

We also recommend checking that the packaging contains all components indicated in

§ 8.5. In case of discrepancy, please contact the Dealer. In case the instrument should be

returned, please follow the instructions given in § 10.

3.2. INSTRUMENT POWER SUPPLY

The instrument only operates with a Li-ION rechargeable battery (3.7V, 1900mAh) housed

inside the instrument itself. Use the external power supply A0055 provided to recharge the

battery. For indications on the status of the battery, please refer to § 7.2

The instrument maintains the data stored also in case of completely flat battery.

3.3. CALIBRATION

The instrument has the technical specifications described in this manual. Its performance

is guaranteed for 12 months from the date of purchase.

3.4. STORAGE

In order to guarantee precise measurement, after a long storage time under extreme

environmental conditions, wait for the instrument to come back to normal condition (see

the environmental specifications contained in § 8.4).

EN - 5

Page 8

MPP300

4. OVERVIEW

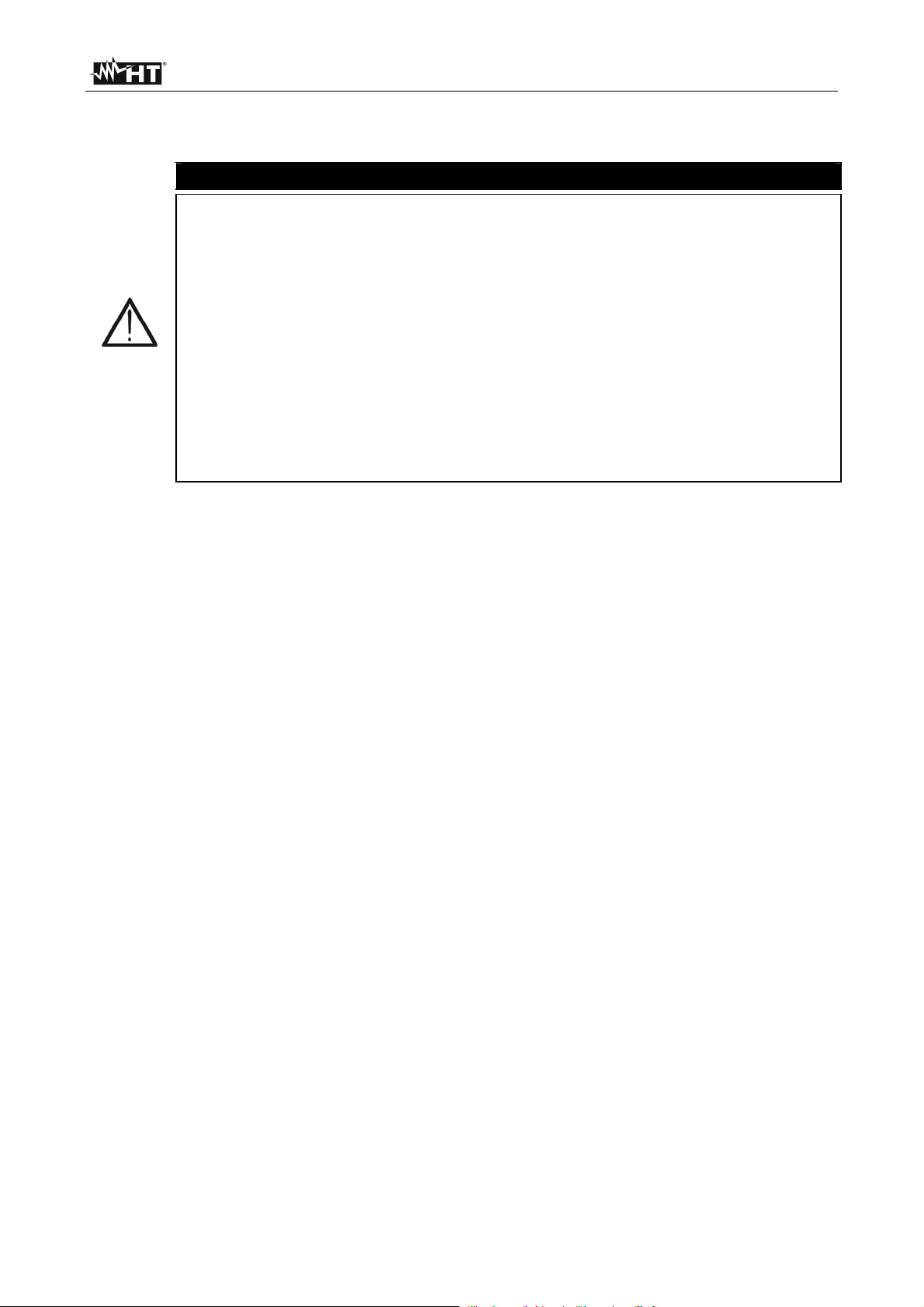

4.1. INSTRUMENT DESCRIPTION

CAPTION:

1. DC voltage inputs

2. DC current inputs

3. AC voltage inputs

4. AC current inputs

5. Indication LEDs

6. USB connector (only for

MASTER instruments of Type

2, see § 4.3)

7. ON/OFF key

8. Connector for external supply

Fig. 1: Description of the instrument’s front panel

4.2. DESCRIPTION OF THE INDICATION LEDS

LED name Status Description

POWER

STATUS

MASTER

REMOTE

GREEN steady

GREEN flashing

RED flashing

GREEN steady

GREEN flashing

RED flashing

RED steady

GREEN flashing

OFF

GREEN flashing

OFF

MPP300 supplied by external power supply

MPP330 supplied by internal batteries

Batteries of MPP300 almost flat

MPP300 in synchronization phase before starting recording

MPP300 in recording phase

MPP300 memory full

Internal error of MPP300 (see § 4.3.1 and Message table in the

User Manual of the MASTER instrument)

MPP300 is connecting to the MASTER unit

MPP300 is NOT connecting to the MASTER unit

MPP300 is connecting to unit SOLAR-02

MPP300 is NOT connecting to unit SOLAR-02

Table 1: Description of the indication LEDs on MPP300

4.3. MASTER INSTRUMENT

MPP300 may be controlled only by the following MASTER instruments:

MASTER instrument Instrument type Firmware Fw update

SOLAR I-V 1 (RF connection) 5.02 or higher C a n b e c a r r i e d o u t b y t h e u se r

SOLAR 300N 2 (USB connection) 1.27 or higher Ca n b e c a rr i e d o u t b y t h e u s e r

Table 2: Characteristics of the MASTER instruments

All controls are sent to the instrument via RF communication (MASTER

instrument of Type 1) or via USB port (MASTER instrument Type 2)

We recommend the user verifies that the software version (Firmware) in

the MASTER instrument to which MPP300 should be connected is

consistent with the indications given in Table 2. This information is present

in the initial screen shown when switching on the MASTER instrument.

The results of the measurements carried out by MPP300 are sent to the

MASTER instrument to which it is connected and shown on the master

instrument’s display. All measures stored in the MASTER instrument’s

memory can be subsequently displayed and can be transferred to a PC

CAUTION

EN - 6

Page 9

MPP300

4.3.1. Displaying the status of MPP300 by means of MASTER instruments of Type 1

In case the MASTER instrument is near MPP300, it is possible to display the general

parameters and obtain information about a possible error state of MPP300 (STATUS LED

red steady). For a description of the error conditions, please refer to the Message table in

the User Manual of the MASTER instrument

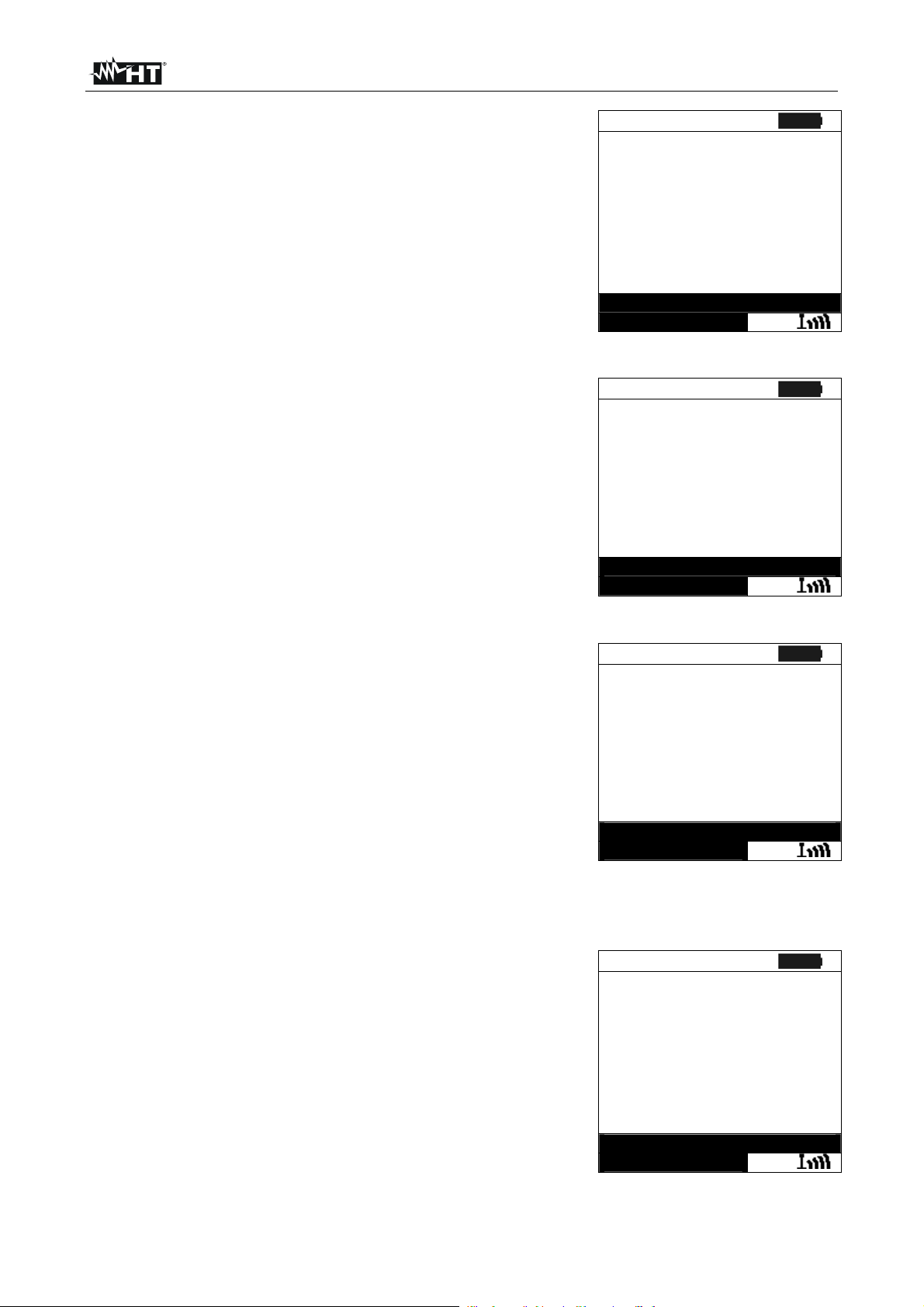

1. Position the cursor onto EFF by using the arrow keys

(,) and confirm with ENTER. The display shows the

screen here to the side, which contains the global

parameters of the system

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 150.0 kW

Tc - - - °C

Te - - - °C

Pdc - - - kW

Pac - - - kW

ndc - - -

nac - - -

GO – start rec

Select

MPP

2. Press the ENTER key. The instrument shows the

following options: MPP300 status, Set PV Plant and Set

Instrument

3. Use the arrow keys (,) to select “MPP300 status” and

confirm with ENTER. The instrument shows the screen

here to the side, which indicates the main general

parameters of the instrument

15/05/10 15:34:26

Power supply Batt

Battery In use

Charge 99%

SOLAR-02 detected SI

Version 1.01

SN 11010030

MPP300 Status

Set .PV plant

Set Instrument

Select

MENU

4.3.2. Displaying the status of MPP300 by means of MASTER instruments of Type 2

In case the MASTER instrument is connected to MPP300 though USB cable, it is possible

to display the general parameters and obtain information about a possible error state of

MPP300 (STATUS LED red steady). For a description of the error conditions, please refer

to the Message table in the User Manual of the MASTER instrument

In GENERAL MENU select the “Instrument informations” icon and press ENTER key. The

herewith screen is shown by the instrument:

12/09/2006 – 16:55:10

INSTRUMENT INFORMATIONS

Model: MPP300

SN: xxxxxxxx

Hw: xx

Fw: 1.xx

Press ESC key (or smart icon ) to back to GENERAL MENU screen.

EN - 7

Page 10

MPP300

5. SETTINGS ON MASTER INSTRUMENTS

Instructions are given according to the Type of instruments, classified according to Table 2.

Further in this manual, a brief description is provided of the settings of the MASTER

instrument for use together with MPP300. For an exhaustive description of the controls

and functions of the MASTER instrument, please refer to the User Manual of the

instrument itself.

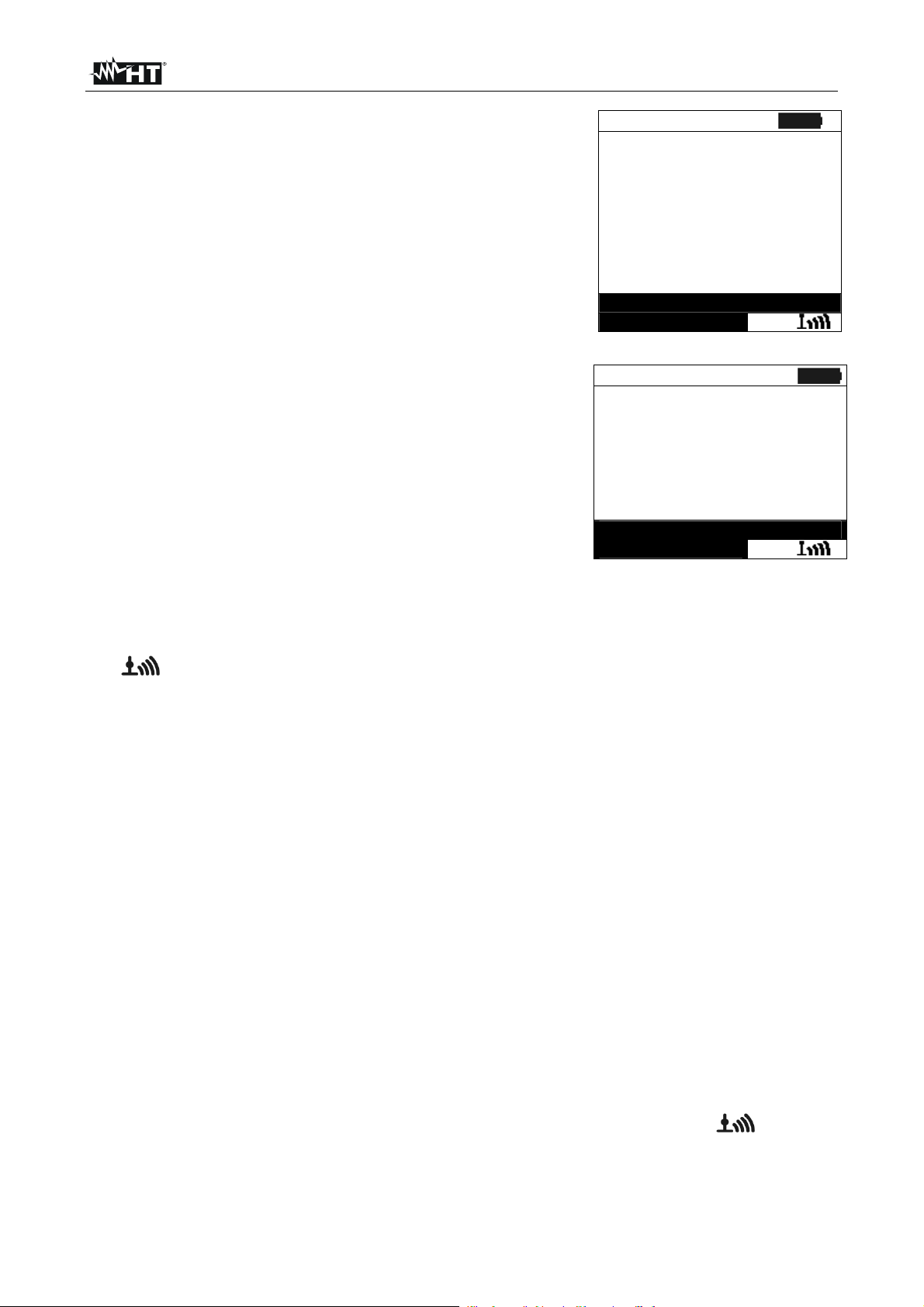

5.1. MASTER INSTRUMENTS OF TYPE 1 - REMOTE UNIT SETTINGS

Turn on the instrument, press the MENU key, position the cursor onto SET by using the

arrow keys (,) and confirm with ENTER. The display shows the screen which lists the

different settings of the instrument

1. Position the cursor onto Remote Unit by using the arrow

keys (,) and confirm with ENTER

2. In parameter “Remote U EFF”, set MPP300

3. Press SAVE to confirm

15/05/10 15:34:26

Remote U EFF MPP300

Remote U I-V NO

Sens.

Alpha : 0.060 %/°C

:31.0mV/kW/m2

SAVE to save

SET

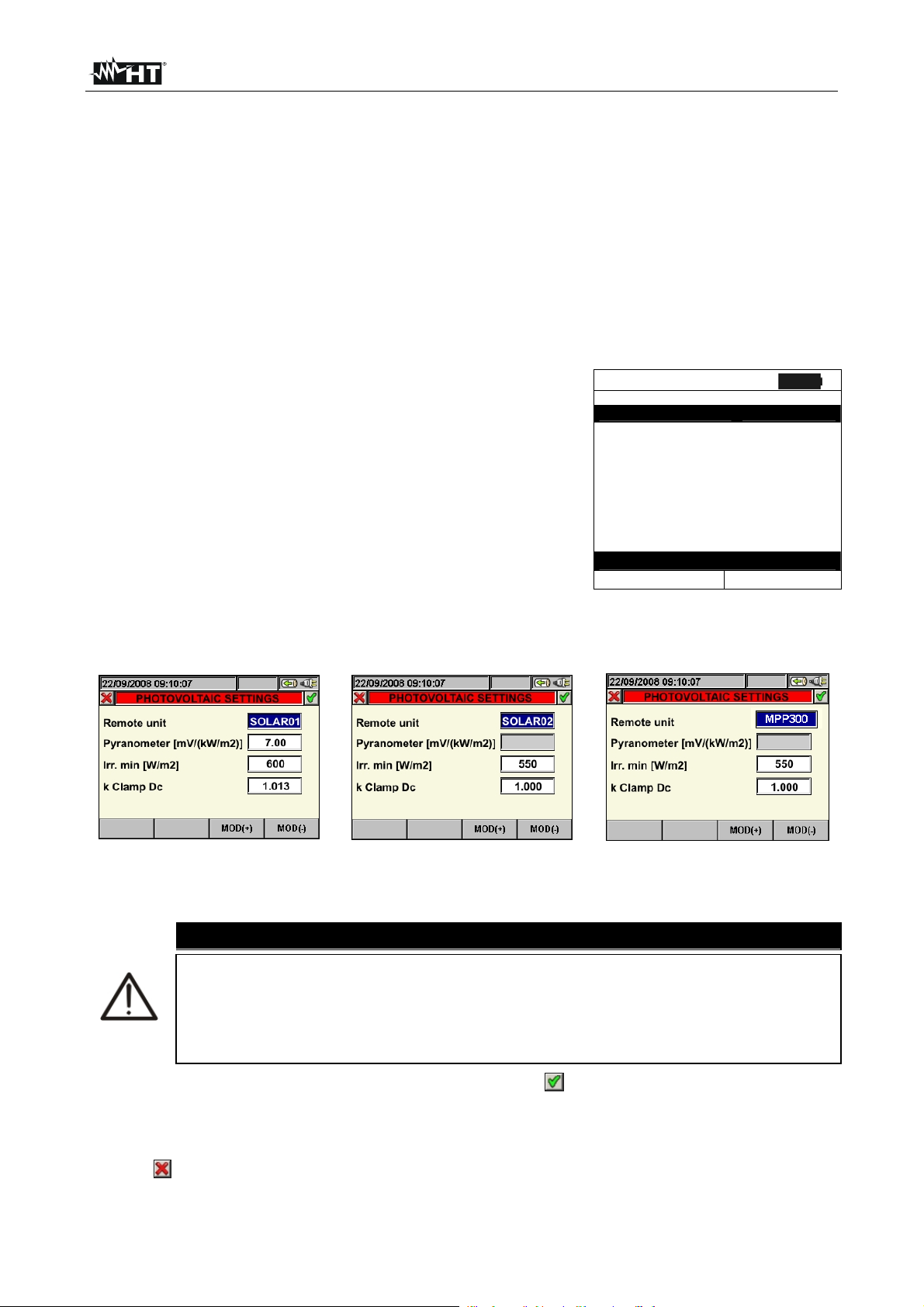

5.2. MASTER INSTRUMENTS OF TYPE 2 – REMOTE UNIT SETTINGS

In the GENERAL MENU select ANALYZER SETTINGS, press the F2 key or touch the

“ADVANCED” item on the display. The herewith screens are shown by the meter:

Selection of rem. U. SOLAR-01 Selection of rem. U. SOLAR-02 Selection of rem. U. MPP300

1. By means of the F3 or F4 key (or items MOD(+) or MOD(-) on the display), select the

desired unit SOLAR01 or SOLAR02, MPP300

CAUTION

The selection of remote unit MPP300 automatically disables the “Pyranometer”

field as the sensitivity of the used irradiance probe (pyranometer or reference

cell) should be set inside the internal menu of SOLAR-02 (see user manual of

SOLAR-02). The selection of the type of system MPP-1 or MPP-3 shall

automatically force MPP300 as remote unit type.

2. Press the SAVE or ENTER key (or the smart icon ) to save the selected setting by

confirming with “Ok”. In this way, the settings made will remain valid also after turning

off the instrument.

3. To quit the settings made or to exit without saving, press the ESC key (or the smart

icon ).

EN - 8

Page 11

MPP300

6. OPERATING INSTRUCTIONS

Further in this manual, a brief description is provided of the use of MPP300 together with

the MASTER instrument. For an exhaustive description of the controls and functions of the

MASTER instrument, please refer to the User Manual of the instrument itself.

For the sake of simplicity, further in this manual, the word “string” will be used, although

often the term “photovoltaic field” would be more correct. From the point of view of the

instrument, the management of a single string or of more parallel strings (photovoltaic field)

is identical. Furthermore, the acronym MPPT (Multiple Power Point Tracker) shall indicate

the characteristic of the DC/AC converter (inverter), capable of maximizing the DC power

which can be taken from the photovoltaic field, the acronym PRp shall indicated the

Performance ratio (evaluated on active powers). See § 9.1 for further details

For the evaluation of the PRP only, the measurement of the DC (voltage and

current) is not strictly necessary. Conversely it is necessary if you want to

evaluate the performance of the photovoltaic section (ndc) and DC / AC

conversion (nac)

6.1. PV SYSTEM TESTING FOR INSTRUMENTS OF TYPE 1 (SOLAR I-V)

6.1.1. Testing of PV systems with single/multi-MPPT inverter - single/three-phase AC output

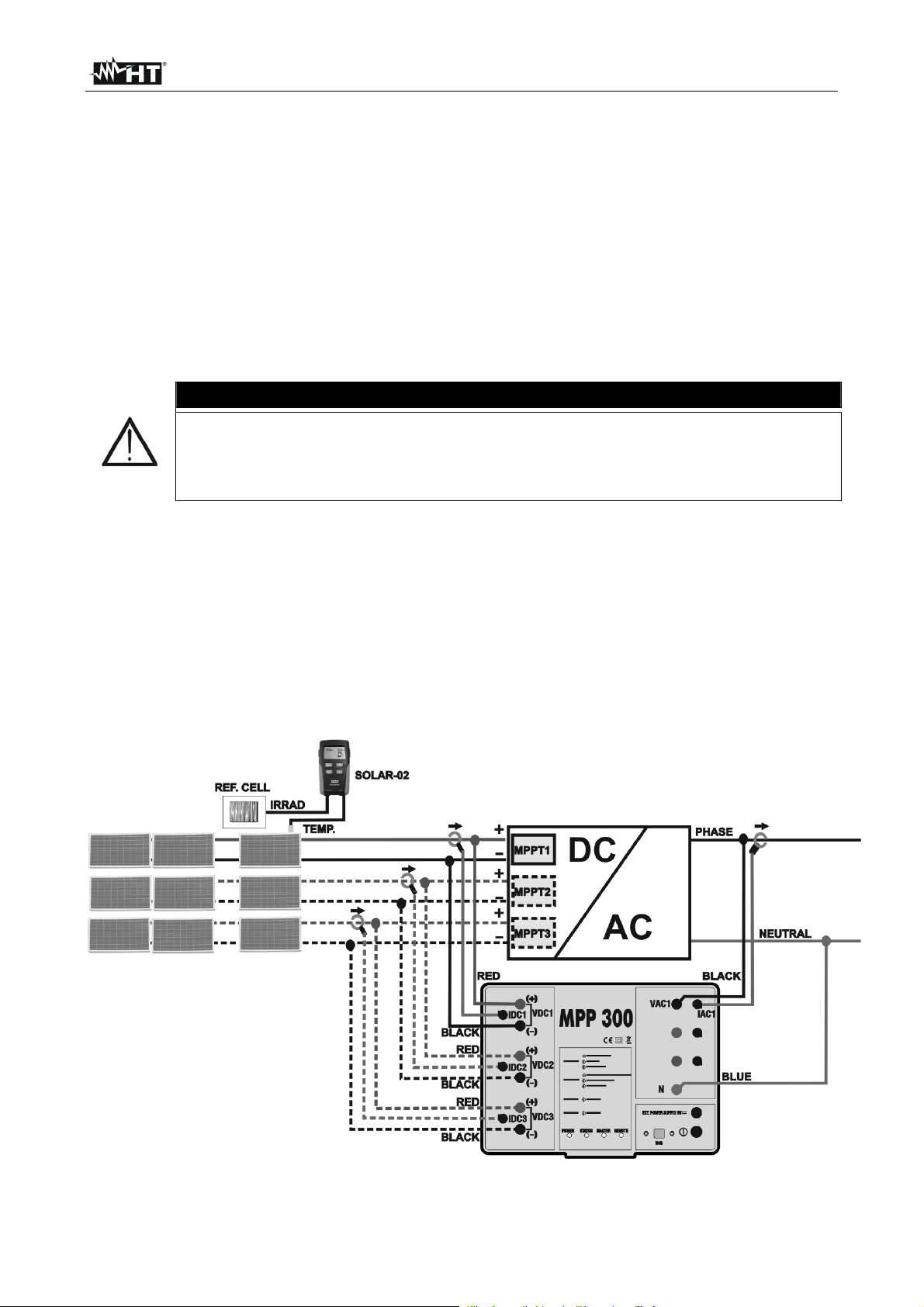

The instrument SOLAR I-V, used together with remote units SOLAR-02 and MPP300,

allows testing PV systems characterized by 1 or more strings (with the same direction and

inclination) and single-phase or three-phase output

The remote unit MPP300 is capable of communicating with SOLAR I-V (to manage

synchronization and data download) and with the remote unit SOLAR-02 (for recording

irradiation and temperature values) via a wireless radiofrequency (RF) connection, which

is active up to a maximum distance of 1m between the units

ATTENTION

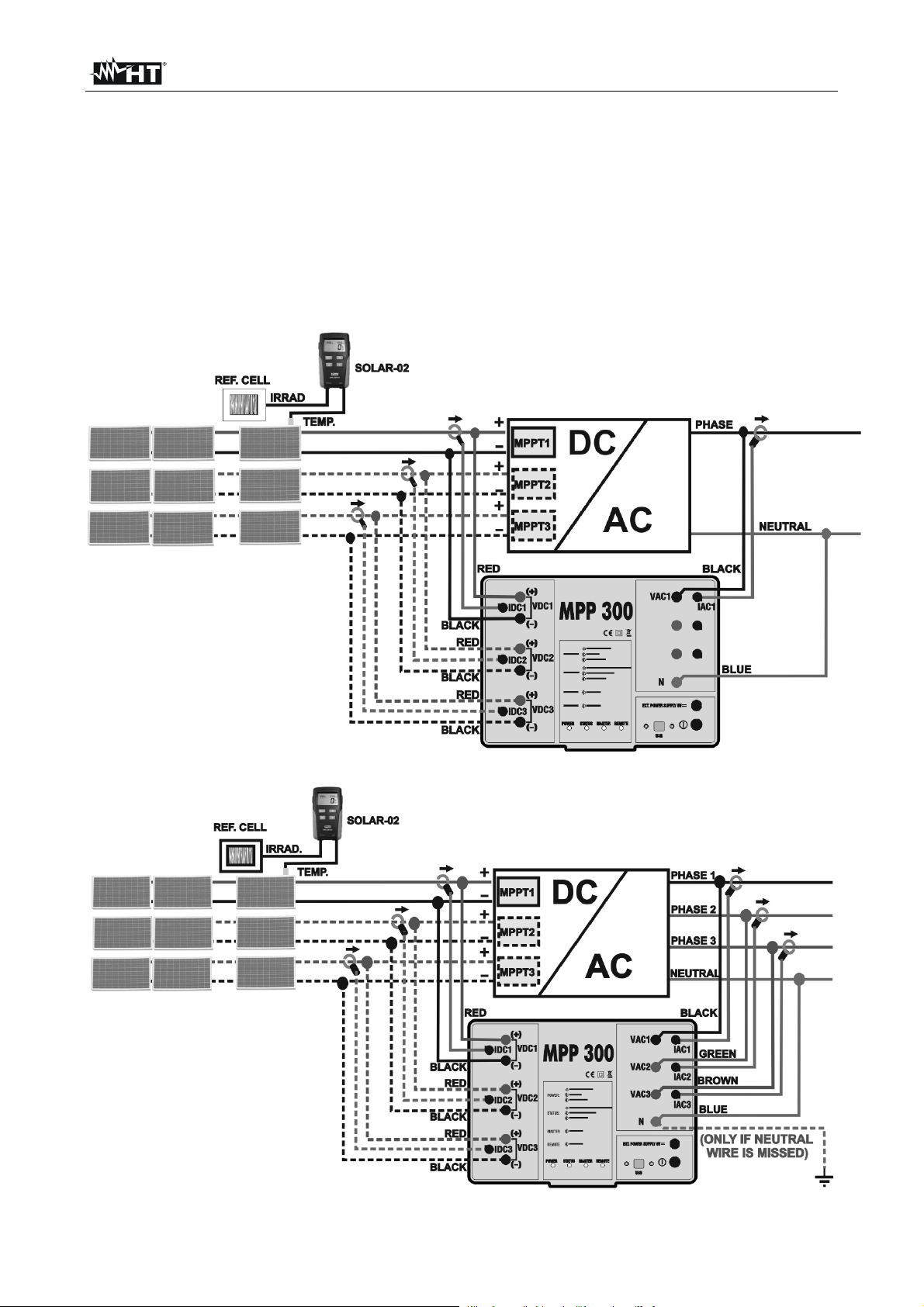

Fig. 2: Connection of MPP300 for testing a single-phase PV system

EN - 9

Page 12

MPP300

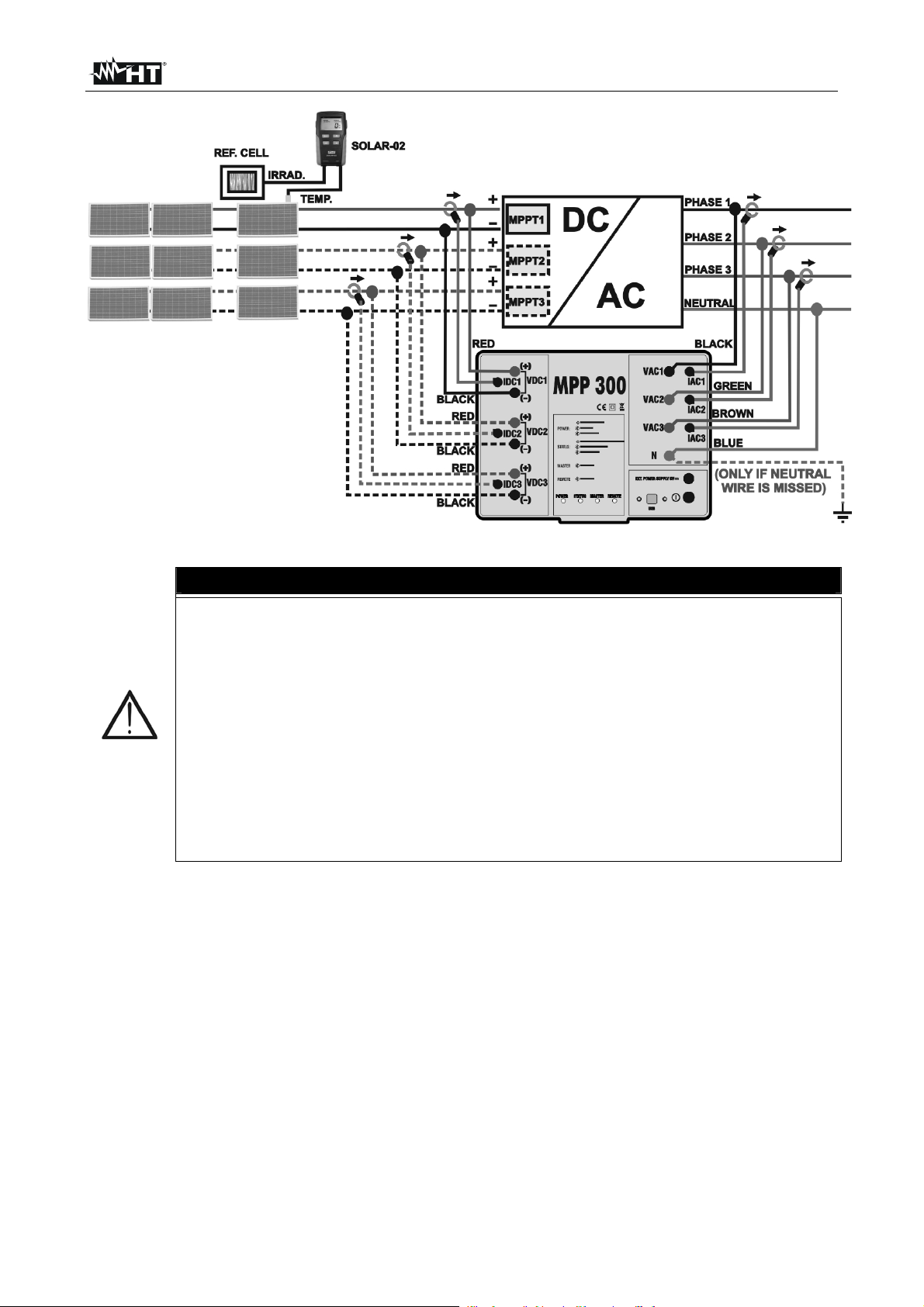

Fig. 3: Connection of MPP300 for testing a three-phase PV system

CAUTION

When SOLAR I-V is set in order to use MPP300 as a remote unit, ALL

connections relevant to electrical quantities (voltages and currents) must

be carried out on unit MPP300. SOLAR I-V must have no voltage nor

current connected to its inputs

The maximum voltage for the inputs of MPP300 is 1000VDC between

inputs VDC1, VDC2, VDC3 and 600VAC between inputs VAC1, VAC2,

VAC3. Do not measure voltages exceeding the limits given in this manual.

Exceeding these limits could result in electrical shocks to the user and

damage to the instrument

In order to guarantee the operator’s safety, while making the connections,

disable the system being measured by means of the switches/breakers

upstream and downstream of the DC/AC converter (inverter)

1. Check and, if necessary, set the sensitivity of the reference cell on SOLAR-02 consistently

with the type of PV modules which will be measured (please refer to the user manual of

SOLAR-02)

2. We recommend making a preliminary evaluation of the value of irradiation on the surface of

the PV modules being tested by means of unit SOLAR-02 (operating independently) and the

reference cell

3. Switch on SOLAR I-V, check and, if necessary, change the settings relevant to the type of

remote unit, to the minimum irradiation threshold, to the full scale of the AC and DC clamps,

to the integration period and to the parameters of the system being measured (see the User

Manual of SOLAR I-V)

4. In order to guarantee the operator’s safety, disable the system being measured by means of

the switches/breakers upstream and downstream of the DC/AC converter (inverter)

EN - 10

Page 13

MPP300

5. Bring SOLAR I-V, SOLAR-02 and unit MPP300 nearer (maximum distance of 1m between

them). All instruments must be switched on (see the User Manuals of SOLAR-2 and

MPP300 for further details)

6. On SOLAR I-V, press the MENU key, select the function EFF and press ENTER; wait for

the three units to start communicating with each other. This condition is highlighted by the

contemporary presence of the following indicators:

Symbol steady (not flashing) on the display of SOLAR I-V

Symbol steady (not flashing) on the display of SOLAR-02

MASTER and REMOTE LEDs flashing green on unit MPP300

7. Connect the VDC1(+) and VDC1(-) inputs of unit MPP300 to the output terminals of the

string, respecting the polarities and the colors indicated in Fig. 2 or Fig. 3.

8. Repeat the operation described in the step above for other possible DC power trackers to be

monitored by using the VDC2 and VDC3 inputs according to the number of DC inputs set

(see the user manual of SOLAR I-V)

9. Connect the output connector of the DC clamp to the IDC1 input of unit MPP300

CAUTION

BEFORE CONNECTING THE DC CLAMPS TO THE CONDUCTORS

Switch on the clamp, check the LED indicating the status of the clamp’s

internal batteries (if present), select the correct range, press the ZERO key

on the DC clamp and check on the display of SOLAR I-V the actual zeroing

of the corresponding Idc value (values up to 0.02A are acceptable)

10. Insert the DC current clamp onto the positive output conductor of the string, respecting

the direction of the arrow found on the clamp itself as indicated in in Fig. 2 or Fig. 3.

Position the clamp toroid as far as possible from the inverter and from the negative

output conductor of the string itself

11. Repeat the operations described in the two steps above for other possible DC power

trackers to be monitored by using the IDC2 and IDC3 inputs according to the number of

DC inputs set (see the User Manual of SOLAR I-V)

12. Connect the VAC1 and N inputs of unit MPP300 to the Phase and Neutral conductors

respectively, respecting the polarities and the colours indicated in Fig. 2 or Fig. 3. In

case of three-phase systems in which no Neutral conductor is available, connect input

N to earth

13. In case of inverter with three-phase output (see the User Manual of SOLAR I-V), repeat

the operation described in the step above for the remaining phases by using the VAC2

and VAC3 inputs of MPP300

14. Connect the AC clamp to the Phase L1 conductor, respecting the direction of the

arrow found on the clamp itself as indicated in Fig. 2 or Fig. 3. Position the clamp

toroid as far as possible from the inverter and from the Neutral conductor. Connect the

clamp output to the IAC1 input of MPP300

15. In case of inverter with three-phase output (see the User Manual of SOLAR I-V), repeat

the operation described in the step above for the remaining phases by using the IAC2

and IAC3 inputs of MPP300

16. Restore the operation of the electrical system being measured

EN - 11

Page 14

MPP300

0.9

0.9

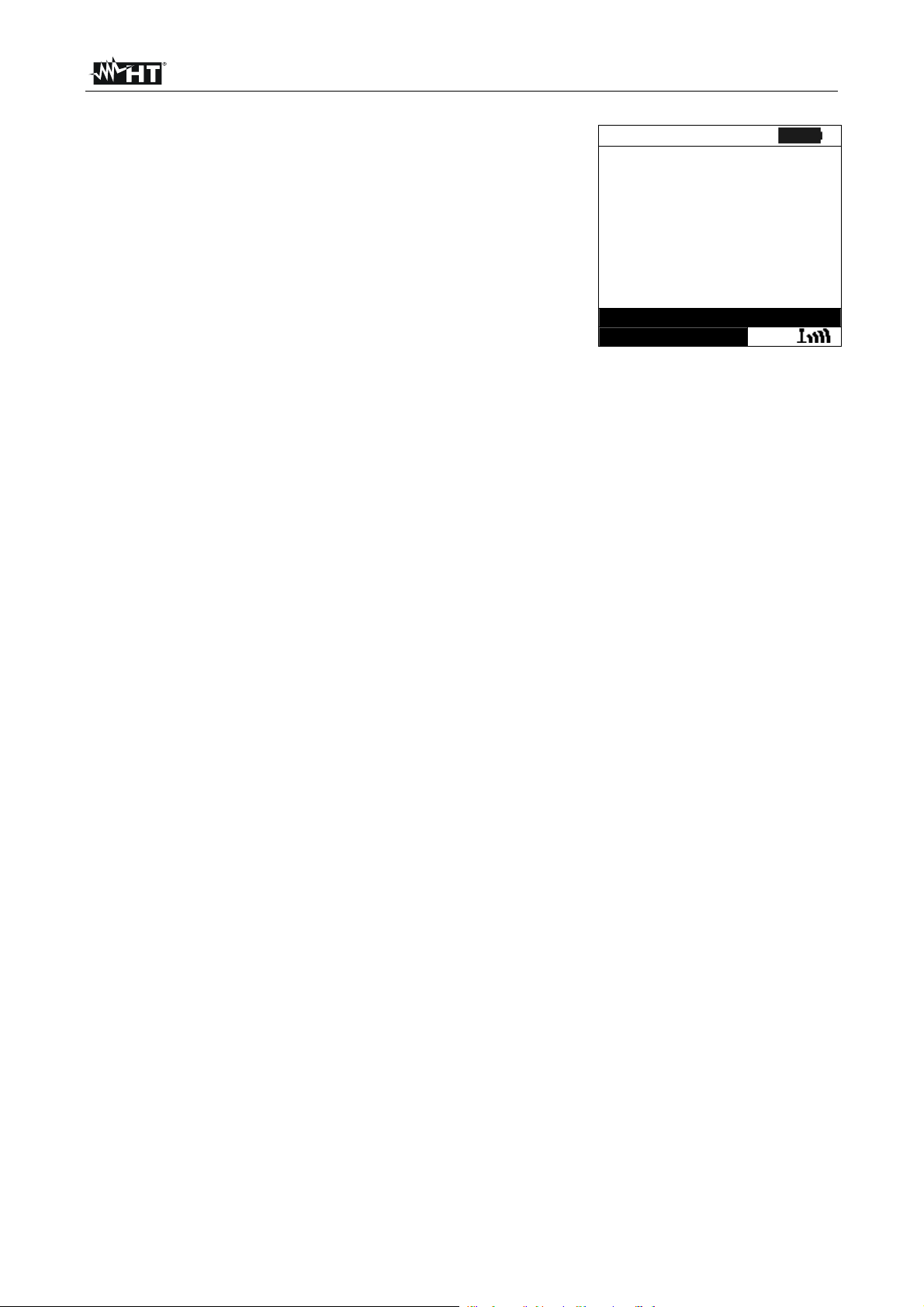

17. The display of SOLAR I-V will show the values of the

general electrical parameters of the system being

measured

In particular, in this screen:

Pdc = General dc power (sum of the string powers)

Pac = ac power (if single-phase) or sum of the ac powers (if

three-phase)

We recommend checking that the values of the electrical

parameters (Pnom, Pdc, Pac) and of the ac performance

(ac) are consistent with the system being measured (e.g.:

ac > 1 is not physically acceptable)

18. On SOLAR I-V, press key () to access the second

screen which contains the values of the output DC

parameters of the strings according to the number of DC

inputs set (see the User Manual of SOLAR I-V)

In particular, in this screen:

Vdcx = dc voltage of string x.

Idcx = dc current of string x.

Pdx = dc power of string x.

We recommend checking that the values of the electrical

parameters (Vdc, Idc, Pdc) are consistent with the system

being measured

19. On SOLAR I-V, press key () to access the third screen

which contains the values of the electrical parameters on

the AC side of the inverter, consistently with the settings

made (see – SOLAR I-V user’s manual, single-phase,

three-phase 4 wires).

In particular, in this screen:

Vacxy = ac voltage between Phase and Neutral (if singlephase) or between Phases x and y (if three-phase)

Iacx = ac current of phase x

Pacx = ac power of phase x

We recommend checking that the values of the electrical

parameters (Vac, Iac, Pac) are consistent with the system

being measured

20. Keeping the three instruments near each other (max distance

approx. 1m), press the GO/STOP key on SOLAR I-V to start

testing. Consequently:

The display of SOLAR I-V shows the message “Rec. start

waiting”

The display of SOLAR-02 shows the message “HOLD” and

the time, expressed in seconds, remaining before the

recording is started

On MPP300, the STATUS LED turns on green (not flashing)

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 3.500 kW

Tc - - - °C

Te - - - °C

Pdc 3.125 kW

Pac 2.960 kW

ndc - - -

nac

GO – start rec

Select

15/05/10 15:34:26

Vdc1 460.1 kW

Vdc2 461.4 V

Vdc3 462.5 A

Idc1 2.25 A

Idc2 2.31 A

Idc3 2.21 A

Pdc1 1.035 kW

Pdc2 1.066 kW

Pdc3 1.024 kW

GO – start rec

Select

15/05/10 15:34:26

Vac12 401.4 V

Vac23 401.1 V

Vac31 400.1 V

Iac1 4.26 A

Iac2 4.26 A

Iac3 4.27 A

Pac1 987 W

Pac2 986 W

Pac3 985 W

GO – start rec

Select

Example of a screen for

PV systems with threephase output

15/05/10 15:34:26

PRp - - -

Irr - - - W/m2

Pnom 3.500 kW

Tc - - - °C

Te - - - °C

Pdc 3.125 kW

Pac 2.960 kW

ndc - - -

nac

Rec.Start Waiting

Select

5

MPP

MPP

MPP

5

MPP

EN - 12

Page 15

MPP300

0.9

21. Upon reaching the instant “00” after pressing the GO/STOP

key, the test is started and the three units are

synchronized with each other. In these conditions:

The display of SOLAR I-V shows the message “rec.

running”

The display of SOLAR-02 shows the message

“Recording…”

On MPP300, the STATUS LED flashes green

22. At any time it will be possible to analyze the current

recording status by pressing the MENU key. The following

information will be shown:

starting date and time of recording

the value set for the integration period

the number of periods elapsed from the beginning of the

recording

the remaining memory capacity for recording

Press the ESC key to exit the screen

15/05/10 15:35:00

PRp - - -

Irr - - - W/m2

Pnom 3.500 kW

Tc - - - °C

Te - - - °C

Pdc 3.125 kW

Pac 2.960 kW

ndc - - -

nac

Rec. running

Select

15/05/10 15:35:00

Start

14/02/00 17:18:00

Period: 5s

IP Number 61

Rec. time 0d 1h

Reg. in corso

Rec running

Select

5

MPP

MPP

23. Now it is possible to bring the unit SOLAR-02 near the PV strings to measure irradiation and

temperature by means of the relevant probes. When the distance between unit SOLAR-02

and MPP300 does not allow the RF connection, on the display of SOLAR-02 the symbol

“ ” flashes for approx 30s and then disappears. Unit MPP300 steadily searches for the

RF connection with unit SOLAR-02

24. Position the reference cell onto the surface of the PV modules. Please refer to the relevant

User Manual for a correct assembly

25. Put the temperature sensor in contact with the rear side of the panel and fasten it with some

tape; prevent touching it with your fingers (as this could alter the measure)

26. Wait for a few seconds to allow the probes to reach a steady measure and then connect the

irradiation probe to input PYRA/CELL and the temperature probe to input TEMP of unit

SOLAR-02

27. Wait for the message “READY” to appear on the display of SOLAR-02 to indicate that the

unit has detected the data with solar irradiation > minimum threshold set (see the User

Manual of SOLAR I-V)

28. With the message “READY” shown on the display, wait for approximately 1 minute in

order to take a certain number of samples

29. Disconnect the irradiation and temperature probes from unit SOLAR-02 and bring the unit

near unit MPP300. Bring the main unit SOLAR I-V near MPP300 too. The three units

must be near each other (max distance 1m)

30. The main unit SOLAR I-V must be in EFF mode; if no flashing symbol “ ” appears,

press key to activate the RF connection search again

31. Press key on SOLAR-02 to activate the RF connection again. Consequently, the main

unit will show the message “radio connection activated”

EN - 13

Page 16

MPP300

0.82

971

30

0.9

32. To stop testing, press the GO/STOP key on instrument

SOLAR I-V and confirm with ENTER that you want to stop

recording

33. The display of SOLAR I-V will show the message “DATA

DOWNLOAD” to indicate that the data will be transferred to

the main unit during its various phases

34. After the automatic data transfer phase, the instrument:

Do not show any results if do not exist on the PV

installation a “stable irradiance” condition more than the

minimum irradiance threshold (see see user’s manual of

MASTER instrument) or all PRp values are not valid (PRp

> 1.15).

Display the best performance values if during the

recording, the Irradiance values reached the “stable”

condition and its values were higher than the minimum

irradiance threshold (see user’s manual of MASTER

instrument).

35. Press SAVE to save the results or ESC to exit the screen of

the results and go back to the initial screen

15/05/10 15:35:00

PRp

Irr

Pnom 3.500 kW

Tc 45.1 °C

Te

Pdc 3.125 kW

Pac 2.960 kW

ndc 0.86

nac

Analysis Result

Select

W/m2

.5 °C

5

MPP

EN - 14

Page 17

MPP300

6.2. PV SYSTEM TESTING FOR INSTRUMENTS OF TYPE 1 (SOLAR 300N)

6.2.1. Testing of PV systems with single/multi-MPPT inverter - single/three-phase AC output

The instrument SOLAR300N, used together with remote units SOLAR-02 and MPP300

(optional), allows carrying out long recordings on PV systems characterized by 1 or more

PV fields (with the same direction and inclination), each connected to an MPPT of the

inverter (see § 9.1) and single-phase or three-phase output. The remote unit MPP300 is

capable of communicating with SOLAR300N via USB cable (to manage data

synchronization and download) and with the remote unit SOLAR-02 (for recording

irradiation and temperature values) via a wireless radiofrequency (RF) connection, which

is active up to a maximum distance of 1m between the units.

Fig. 4: Connection of MPP300 for testing a single-phase PV system

Fig. 5: Connection of MPP300 for testing a three-phase PV system

EN - 15

Page 18

MPP300

CAUTION

When SOLAR300N is set in order to use MPP300 as a remote unit, ALL

connections relevant to electrical quantities (voltages and currents) must

be carried out on unit MPP300. SOLAR300N must have no voltage nor

current connected to its inputs.

The maximum voltage for the inputs of MPP300 is 1000VDC between

inputs VDC1, VDC2, VDC3 and 600VAC between inputs VAC1, VAC2,

VAC3. Do not measure voltages exceeding the limits given in this manual.

Exceeding these limits could result in electrical shocks to the user and

damage to the instrument.

In order to guarantee the operator’s safety, while making the connections,

disable the system being measured by means of the switches/breakers

upstream and downstream of the DC/AC converter (inverter).

1. Check and, if necessary, set the sensitivity of the reference cell on SOLAR-02

consistently with the type of PV modules which will be measured (please refer to the

User Manual of SOLAR-02).

2. We recommend making a preliminary evaluation of the value of irradiation on the

surface of the PV modules being tested by means of unit SOLAR-02 (operating

independently) and the reference cell

3. Switch on SOLAR300N, check and, if necessary, change the settings relevant to the

type of remote unit, to the minimum irradiation threshold, to the full scale of the AC and

DC clamps, to the parameters of the system being measured and to the value of the

integration period (see SOLAR300N user’s manual).

4. In order to guarantee the operator’s safety, disable the system being measured by

means of the switches/breakers upstream and downstream of the DC/AC converter

(inverter).

5. Connect SOLAR300N to the MPP300 unit via the USB cable and bring SOLAR-02 and

MPP300 nearer (max distance approx. 1 m). All instruments must be switched on

(see the User Manuals of SOLAR-2 and MPP300 for further details). The display of

SOLAR300N must show (for 5 seconds) the message “MPP300 connected”.

6. On SOLAR300N, access the GENERAL MENU, select the function View Measures

and press ENTER; wait for the three units to start communicating with each other. This

condition is highlighted by the contemporary presence of the following indicators:

a. Symbol steady (not flashing) on the display of SOLAR-02

b. MASTER and REMOTE LEDs flashing green on unit MPP300

7. Connect the VDC1(+) and VDC1(-) inputs of the MPP300 unit to the output terminals of

the string, paying attention to the polarity and the colours indicated in Fig. 4 or Fig. 5.

8. Repeat the operation described in the step above for other possible DC power trackers

to be monitored by using the VDC2 and VDC3 inputs according to the number of DC

inputs set (see SOLAR300N user’s manual).

EN - 16

Page 19

MPP300

9. Connect the output connector of the DC clamp to the IDC1 input of unit MPP300.

CAUTION

BEFORE CONNECTING THE DC CLAMPS TO THE CONDUCTORS

Switch on the clamp, check the LED indicating the status of the clamp’s

internal batteries (if present), select the correct range, press the ZERO key

on the DC clamp and check on the display of SOLAR300N the actual

zeroing of the corresponding Idc value (values up to 0.02A are acceptable).

10. Insert the DC current clamp onto the positive output conductor of the string, respecting

the direction of the arrow found on the clamp itself as indicated in Fig. 4 or Fig. 5.

Position the clamp toroid as far as possible from the inverter and from the negative

output conductor of the string itself.

11. Repeat the operations described in the two steps above for other possible DC power

trackers to be monitored by using the IDC2 and IDC3 inputs according to the number of

DC inputs set(see SOLAR300N user’s manual).

12. Connect the VAC1 and N inputs of unit MPP300 to the Phase and Neutral conductors

respectively, respecting the polarities and the colours indicated in in Fig. 4 or Fig. 5. In

case of three-phase systems in which no Neutral conductor is available, connect input

N to earth.

13. In case of inverter with three-phase output (see SOLAR300N user’s manual), repeat

the operation described in the step above for the remaining phases by using the VAC2

and VAC3 inputs of MPP300.

14. Connect the AC clamp to the Phase L1 conductor, respecting the direction of the arrow

found on the clamp itself as indicated in Fig. 4 or Fig. 5. Position the clamp toroid as far

as possible from the inverter and from the Neutral conductor. Connect the clamp output

to the IAC1 input of MPP300.

15. In case of inverter with three-phase output (see SOLAR300N user’s manual), repeat

the operation described in the step above for the remaining phases by using the IAC2

and IAC3 inputs of MPP300.

16. Restore the operation of the electrical system being measured.

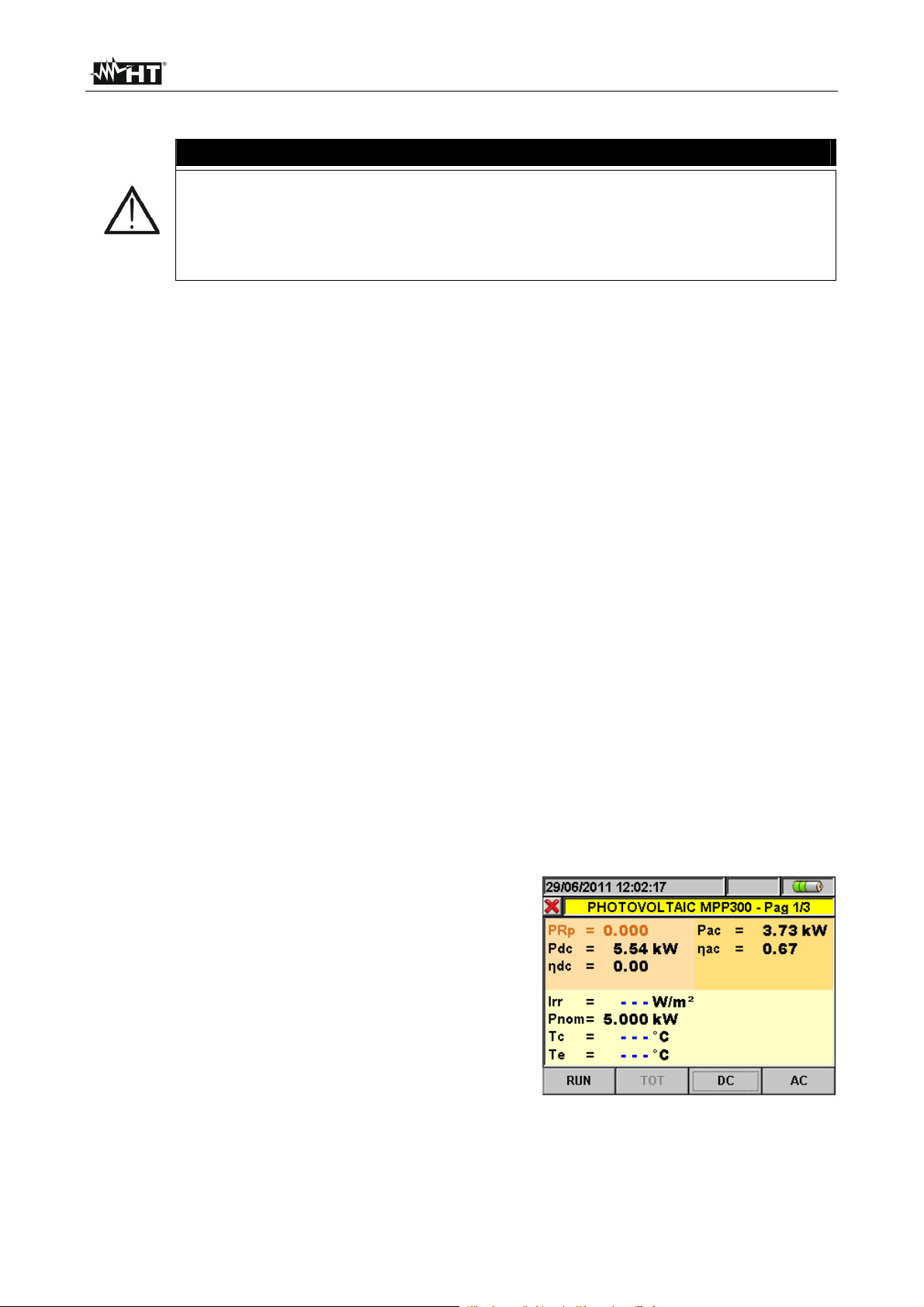

17. The display of SOLAR300N will show the values

of the general electrical parameters of the system

being measured.

In particular, in this screen:

Pdc = General dc power (sum of the string powers)

Pac = ac power (if single-phase) or sum of the ac

powers (if three-phase)

We recommend checking that the values of the

electrical parameters (Pnom, Pdc, Pac) and of the ac

performance (ac) are consistent with the system

being measured (e.g.: ac > 1 is not physically

acceptable).

EN - 17

Page 20

MPP300

18. On SOLAR300N, press key F3 to access the

second screen which contains the values of the

output DC parameters of the strings according to

the number of DC inputs set (see SOLAR300N

user’s manual).

In particular, in this screen:

Vdcx = dc voltage of string x.

Idcx = dc current of string x.

Pdx = dc power of string x.

We recommend checking that the values of the

electrical parameters (Vdc, Idc, Pdc) are consistent

with the system being measured.

19. On SOLAR300N, press key F4 to access the third

screen which contains the values of the electrical

parameters on the AC side of the inverter,

consistently with the settings made (see

SOLAR300N user’s manual - single-phase, threephase 4 wires).

In particular, in this screen:

Vacxy = ac voltage between Phase and Neutral (if

single-phase) or between Phases x and y (if threephase)

Iacx = ac current of phase x

Pacx = ac power of phase x

We recommend checking that the values of the

electrical parameters (Vac, Iac, Pac) are consistent

with the system being measured.

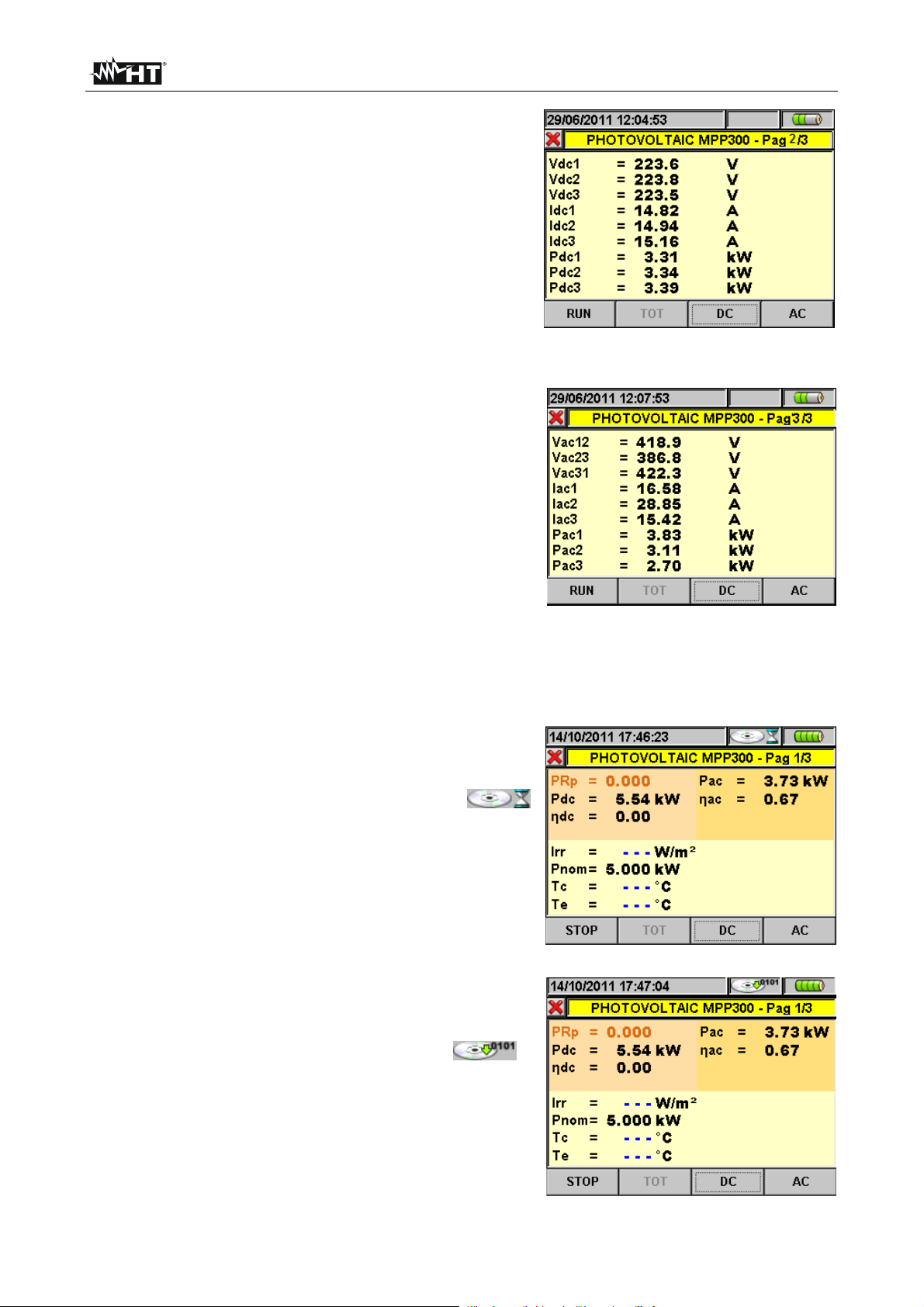

20. Keeping the three instruments connected, press the

F1 key on SOLAR300N to start recording.

Consequently:

a. The display of SOLAR300N shows the icon .

The display of SOLAR-02 shows the message

“HOLD” and the time, expressed in seconds,

remaining before the recording is started

b. On MPP300, the STATUS LED turns on green (not

flashing)

Example of a DC screen for PV

systems with 3 MPPTs

Example of an AC screen for PV

systems with three-phase

output

21. Upon reaching the instant “00” afte r pres sin g the F1

key, the test is started and the three units are

synchronized with each other. In these conditions:

a. The display of SOLAR300N shows the icon .

b. The display of SOLAR-02 shows the message

“Recording…”

c. On MPP300, the STATUS LED flashes green

EN - 18

Page 21

MPP300

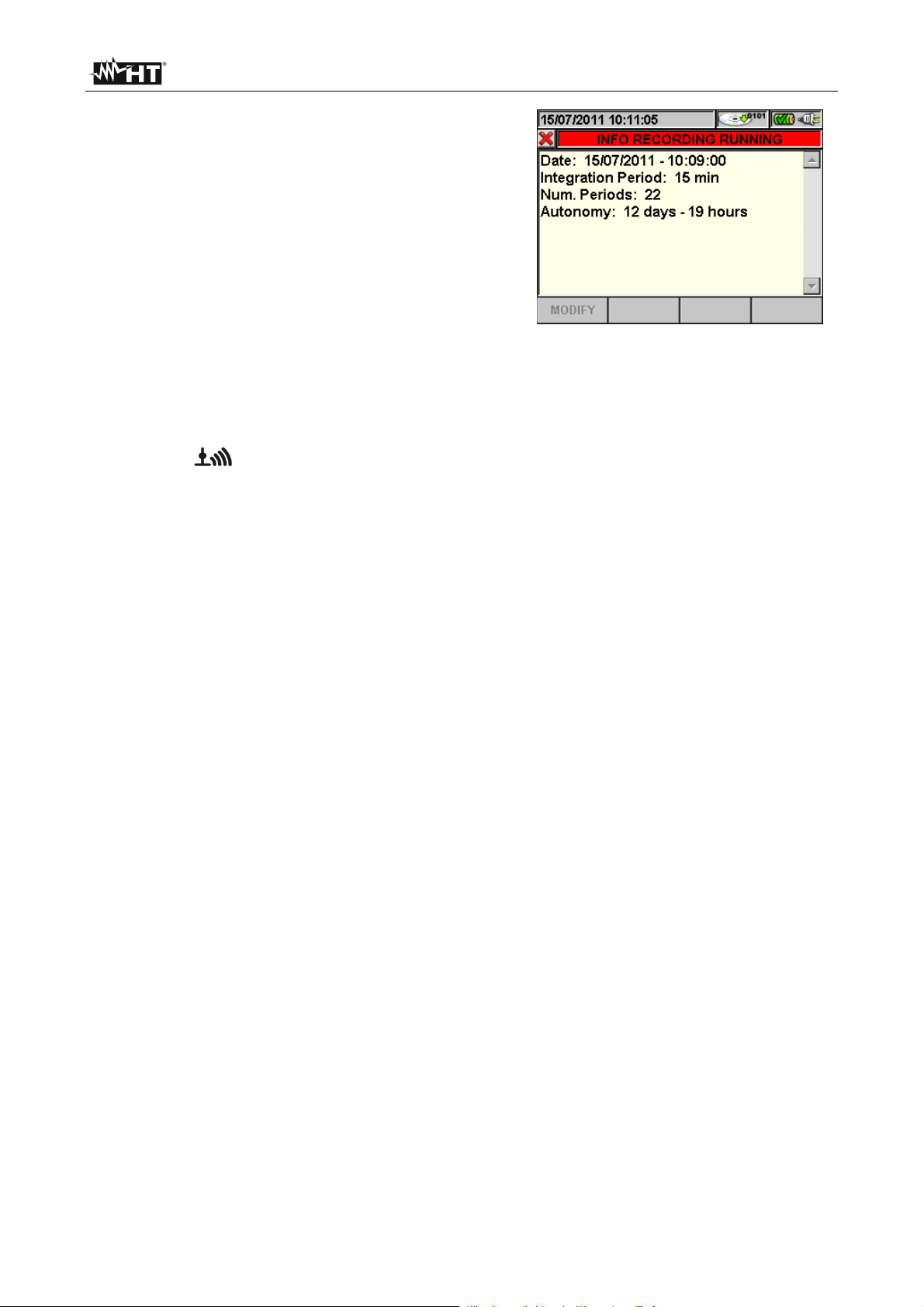

22. At any time while recording it will be possible to

analyze its current status by selecting the button

Saved data management in the GENERAL

MENU. The following information will be shown:

a. starting date and time of recording

b. the value set for the integration period

c. the number of periods elapsed from the

beginning of the recording

d. the remaining memory capacity for

recording

Press the ESC key to exit the screen

23. Now it is possible to bring the unit SOLAR-02 near the PV strings to measure irradiation and

temperature by means of the relevant probes. When the distance between unit SOLAR02 and MPP300 does not allow the RF connection, on the display of SOLAR-02 the

symbol “

” flashes for approx 30s and then disappears. Unit MPP300 steadily

searches for the RF connection with unit SOLAR-02.

24. Position the reference cell onto the surface of the PV modules. Please refer to the relevant

User Manual for a correct assembly.

25. Put the temperature sensor in contact with the rear side of the module and fasten it with

some tape; prevent touching it with your fingers (as this could alter the measure).

26. Wait for a few seconds to allow the probes to reach a steady measure and then connect the

irradiation probe to input PYRA/CELL and the temperature probe to input TEMP of unit

SOLAR-02.

27. Wait for the message “READY” to appear on the display of SOLAR-02 to indicate that the

unit has detected the data with solar irradiation > minimum threshold set (see SOLAR300N

user’s manual).

28. With the message “READY” shown on the display, wait for a time period at least equal to the

set integration period (see SOLAR300N user’s manual) in order to take a significant number

of samples (>=2).

29. Disconnect the irradiation and temperature probes from unit SOLAR-02 and bring the unit

near unit MPP300. The two units must be near each other (max distance 1m).

30. Connect (if disconnected) the SOLAR300N unit to the MPP300 unit. The MASTER LED

must always be flashing to indicate the connection between SOLAR300N and MPP300.

31. Press key on SOLAR-02 to activate the RF connection again. Consequently, the

REMOTE LED on unit MPP300 will start flashing.

EN - 19

Page 22

MPP300

32. To stop recording, press the GO/STOP key on the

instrument SOLAR300N and confirm with ENTER that

you want to stop recording.

33. The display of SOLAR300N will show various

messages indicating the different phases of data

transfer to the main unit. The transferred data will be

saved automatically.

34. After the automatic data transfer phase, the

instrument:

Do not show any results if do not exist on the PV

installation a “stable irradiance” condition more

than the minimum irradiance threshold (see see

user’s manual of MASTER instrument) or all PRp

values are not valid (PRp > 1.15).

Display the best performance values if during the

recording, the Irradiance values reached the “stable”

condition and its values were higher than the

minimum irradiance threshold (see user’s manual of

MASTER instrument).

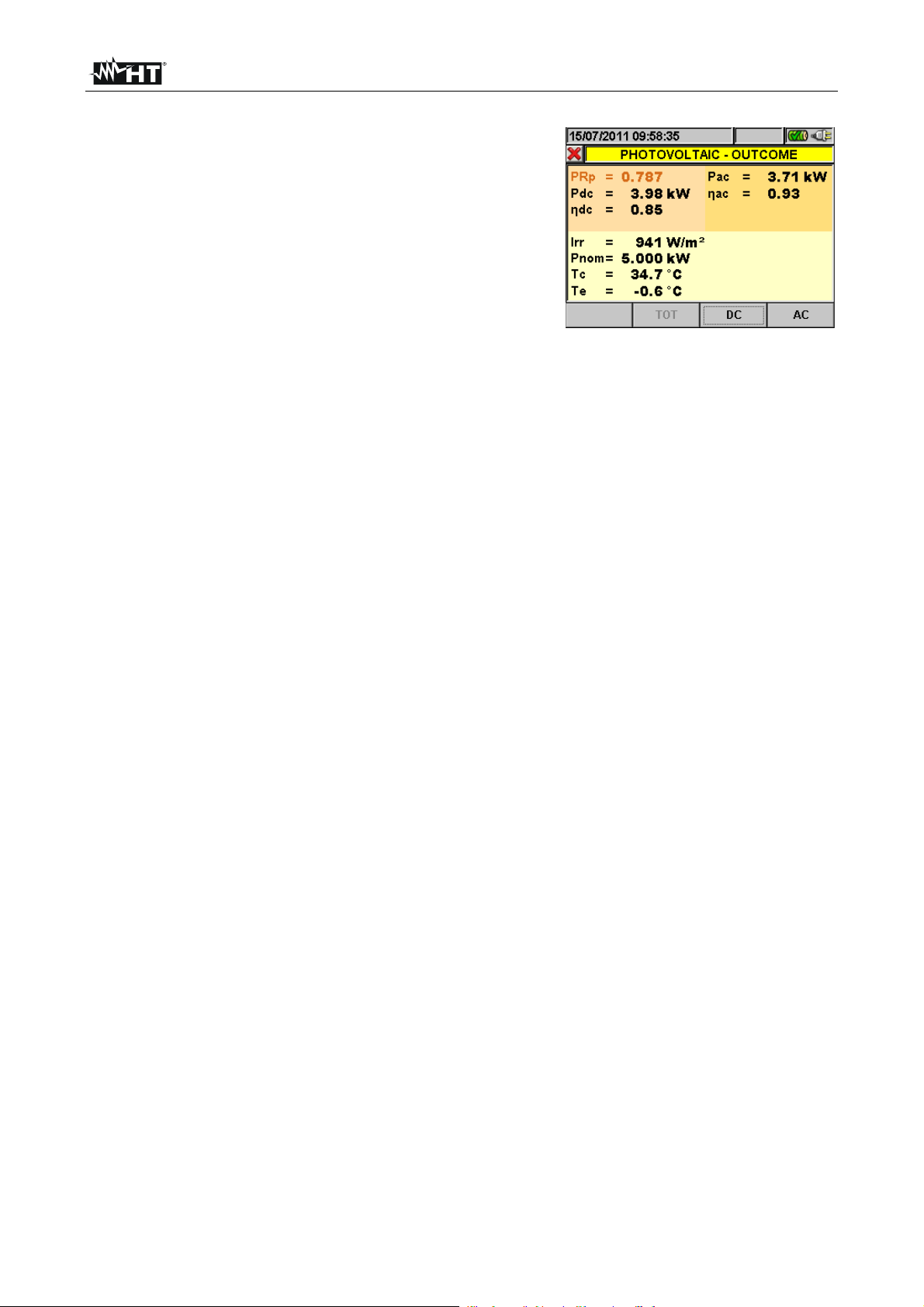

35. Press SAVE to save the obtained results. Pressing the

key will display the virtual keyboard for adding possible

comments. Further pressing the SAVE key will archive

the measure and the added comments and will go back

to the initial screen for a new measurement.

Example of a result combined

with MPP300

EN - 20

Page 23

MPP300

7. MAINTENANCE

7.1. GENERAL INFORMATION

The instrument you purchased is a precision instrument. While using and storing the

instrument, carefully observe the recommendations listed in this manual in order to prevent

possible damage or danger during use. Do not use the instrument in environments with

high humidity levels or high temperatures. Do not expose to direct sunlight. Always switch

off the instrument after use.

7.2. STATUS OF THE INTERNAL RECHARGEABLE BATTERIES

The status of the POWER LED provides indications about the operating/charge status of

the instrument’s internal rechargeable batteries

POWER: GREEN steady: MPP300 supplied by external power supply

GREEN flashing: MPP330 supplied by internal batteries

RED flashing: Batteries of MPP300 almost flat

In case the LED indicates the condition of almost flat batteries, we

recommend connecting the instrument to power supply. It is not necessary

to stop possible measurements in progress to connect the power supply

If the instrument detects a too low battery voltage, it stops possible

recordings in progress and switches off

The instrument maintains the data stored also in case of flat battery

7.3. CLEANING THE INSTRUMENT

Use a soft and dry cloth to clean the instrument. Never use wet cloths, solvents, water, etc

7.4. END OF LIFE

CAUTION

CAUTION: this symbol indicates that the appliance, its accessories and the

internal batteries must be collected separately and correctly disposed of

EN - 21

Page 24

MPP300

8. TECHNICAL SPECIFICATIONS

8.1. TECHNICAL SPECIFICATIONS FOR TEST ON PV SYSTEMS

Uncertainty is indicated as [%reading + (no. of digits) * resolution] at 23°C ± 5°C, <80%HR

DC voltage

Range [V] Resolution [V] Uncertainty

10.0 999.9

Phase-Neutral AC TRMS voltage

Range [V] Frequency Resolution [V] Uncertainty

10.0 300.0 42.5 69.0Hz

Max peak factor: 1,5

Phase-Phase AC TRMS voltage

Range [V] Frequency Resolution [V] Uncertainty

50.0 594.0 42.5 69.0Hz

Max peak factor: 1,5

DC current (by means of external clamp transducer)

Range Resolution Uncertainty

5.0mV 319.9mV

320.0mV 999.9mV (0.5rdg)

Current values corresponding to a voltage < 5mV are zeroed

0.1mV

AC TRMS current (by means of external clamp transducer STD type)

Range Frequency Resolution Uncertainty

5.0mV 219.9mV

220.0mV 999.9mV (0.5rdg)

Peak factor <= 1.5 – Current values corresponding to a voltage < 5mV are zeroed.

42.5 69.0Hz

0.1mV

AC TRMS current (by means of external clamp transducer of FLEX 8.5uV/A – FS 100A type)

Range Frequency Resolution Uncertainty

0.008 8.50mV 42.5 69.0Hz

Peak factor <= 1.5 – Current values < 1A are zeroed.

0.001mV

AC TRMS current (by means of external clamp transducer of FLEX 8.5uV/A – FS 1000A type)

Range Frequency Resolution Uncertainty

0.085 85.0mV 42.5 69.0Hz

Peak factor <= 1.5 – Current values < 5A are zeroed.

0.01mV

DC power (Vmeas > 150V) ; AC power (Vmeas > 200V, PF=1)

Clamp FS [A] Range [W] Resolution [W] Uncertainty

1< FS 10

10< FS 100

100< FS 1000

Vmeas = voltage at which power is measured; Imeas = measured current

0.000k 9.999k

10.00k 99.99k

0.00k 99.99k

100.0k 999.9k

0.0k 999.9k

1000k 9999k

0.1

0.1

0.1

(0.5rdg + 0.06%FS)

(0.5rdg + 0.06%FS)

(0.5%rdg + 7dgt)

(0.5%rdg + 15dgt)

0.001k

0.01k

0.01k

0.1k

0.1k

1k

(0.5rdg + 2dgt)

(0.5rdg + 2ddgt)

(0.7rdg + 2dgt)

Protection against

overcharge

10V

Protection against

overcharge

10V

Protection against

overcharge

10V

Protection against

overcharge

10V

(0.7rdg + 3dgt)

(Imeas < 10%FS)

(0.7rdg)

(Imeas 10%FS)

EN - 22

Page 25

MPP300

8.2. REFERENCE STANDARDS

Instrument safety: IEC/EN61010-1

Safety of measuring accessories: IEC/EN61010-031

Technical documentation: IEC/EN61187

Insulation: double insulation

Mechanical protection: IP 40

Pollution level: 2

Measurement category: CAT III 1000V DC, Max 1000V between DC inputs

CAT IV 300V AC to earth, max 600V between AC inputs

8.3. GENERAL CHARACTERISTICS

Memory

Memory capacity: 2 MBytes

Integration Period: 5,10,30,60,120,300,600,900,1800,3600s

Battery duration (with SOLAR-02): approx. 1.5 hours (@ PI = 5s)

approx. 8 days (@ PI = 600s)

Characteristics of radio module

Frequency range: 2.400 2.4835GHz

R&TTE category: Class 1

Max transmission power: 30W

Max RF connection distance: 1m (39in)

Power supply

Internal power supply: Internal rechargeable Li-ION battery (3.7V, 1900mAh)

Battery duration >3 hours

External power supply: AC/DC power supply 100240VAC/50-60Hz – 5VDC

Mechanical characteristics

Dimensions (L x W x H): 300 x 265 x 140mm ; (12 x 10 x 6in)

Weight (batteries included): 1.2kg (2lv)

8.4. ENVIRONMENTAL CONDITIONS FOR USE

Reference temperature: 23° ± 5°C (73° ± 41°F)

Operating temperature: 0 ÷ 40°C (32 ÷ 104°F)

Allowable relative humidity: <80%HR

Storage temperature: -10 ÷ 60°C (14 ÷ 140°F)

Storage humidity: <80%HR

Max operating altitude: 2000m (*) (6562ft)

(*) Prescriptions for the use of the instrument at altitudes between 2000 and 5000m

As regards inputs, the instrument must be considered as downgraded to overvoltage

category CAT II 1000V DC and CAT III 300V to earth max 1000V between inputs. The

marks and symbols found on the instrument are valid only when the instrument is used at

altitudes <2000m

CAUTION

This instrument satisfies the requirements of Low Voltage Directive 2006/95/EC

(LVD) and of EMC Directive 2004/108/EC

8.5. ACCESSORIES

See the attached packing list

EN - 23

Page 26

MPP300

9. APPENDIX – THEORETICAL OUTLINE

9.1. TESTING PHOTOVOLTAIC SYSTEMS

According to the requirements of the laws in force, the result of the test depends on

settings about Temperature effects compensation and PRp calculations (see MASTER

instrument settings):

Corr.Typ

e

Tmod

Tamb

or

Tenv

Tcel value PRp calculation

Tcel = PV Module Temp. measured

Tcel = PV module Temp. calculated

G

NOCT

20TambTcel

800

P

PRp

p

Rfv

ca

G

p

2

G

STC

P

n

Guidelin

e

CEI

82-25

(Italian

Guideline)

nDC

Tcel = PV Module Temp. measured

G

PRp

G

STC

p

1

T

100

cel

25

P

ca

P

n

- - -

where:

Symbol Description Meas. unit

G

p

G

STC

P

n

P

ca

Rfv

2

NOCT Normal Operating Cell Temperature (@ 800W/m2, 20°C,

40)-(Tcel- 1

100

C)40Tcel (if 1

C)40Tcel (if

Irradiance on PV module surface

Standard Irradiance = 1000

Nominal Power = sum of all power module (Pmax )

included in the part of PV plant under test

AC Active Power measured

Thermal Corrective factor

Absolute value of Pmax thermal coefficient

AM=1.5, vel. Aria =1m/s).

W/m

W/m

kW

kW

2

2

C%/

C%/

Previous relationship are valid if Irradiance > Min Irraddiance value (see user manual

of the MASTER instrument) and the Irradiance values are “steady”: if IP 1min (Irr

max – Irr min) < 20W/m

2

The final OUTCOME can be:

Non-displayable: if the obtained values are inconsistent (e.g. PRp >1.15) or if

irradiation has never reached a steady value > minimum threshold set (see user’s

manual of MASTER instrument).

The maximum performance point (PRp) of the system

The highest performance (maximum value of PRp) is detected according with previous

relationships.

EN - 24

Page 27

MPP300

9.2. NOTES ON MPPT (MAXIMUM POWER POINT TRACKER)

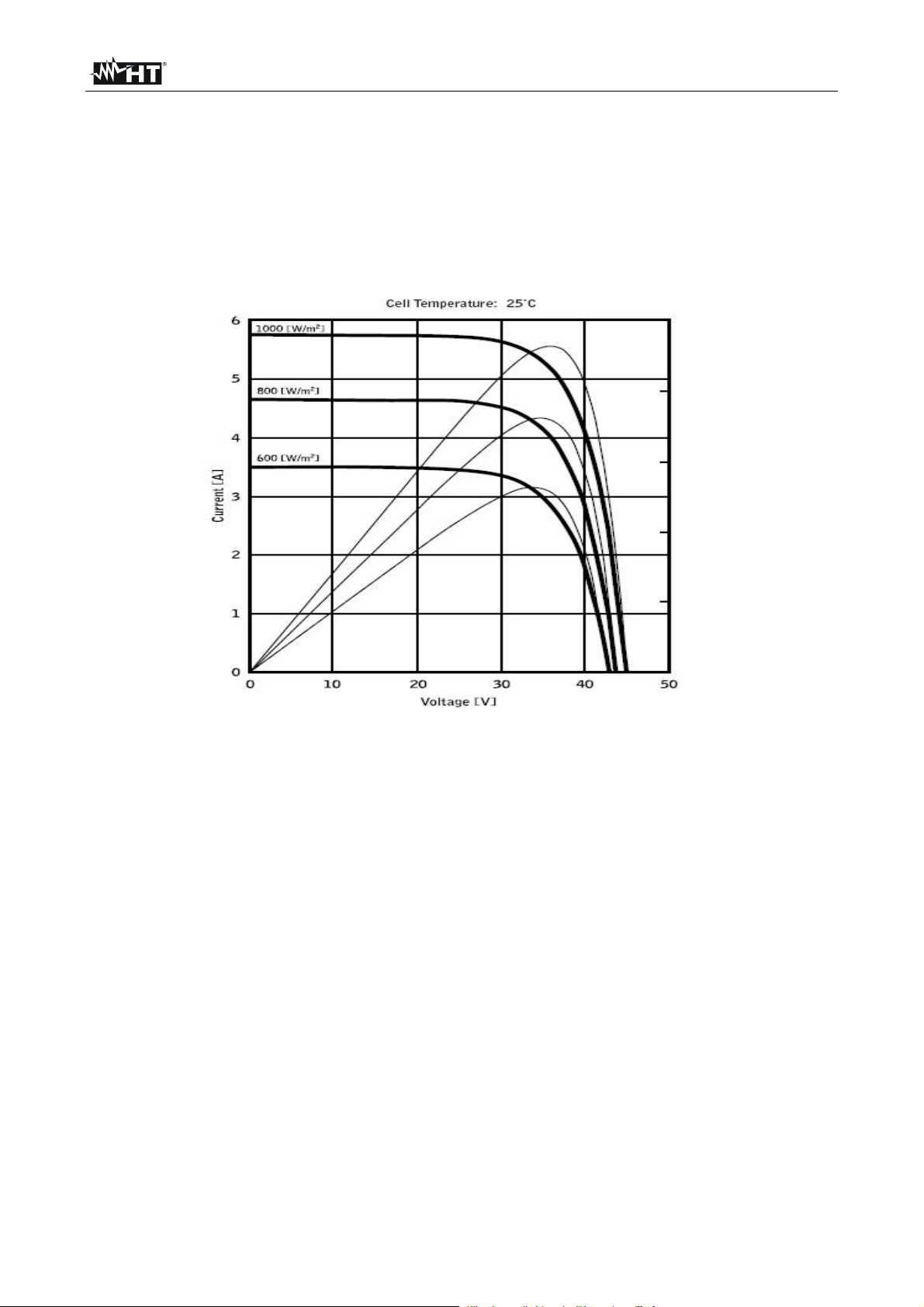

Solar irradiation on a surface such as the surface of a photovoltaic system has extremely

variable characteristics, since it depends on the position of the sun with respect to the

surface and on atmospheric conditions (typically, on the presence of clouds). A

photovoltaic module presents, for different solar irradiation values, and for different

temperature values, a range of characteristic curves of the type shown in the following

figure. In particular, the figure shows three I-V curves (in bold) which correspond to three

values (1000, 800, 600W/m2) of solar irradiation

On each characteristic curve there is one single point in which the power transfer towards

a hypothetical charge supplied by the photovoltaic module is maximized. The maximum

power point corresponds to the voltage-current pair for which the product V*I is maximum,

where V is the value of voltage at the module’s terminals and I is the current which runs in

the circuit obtained by closing the module on a hypothetical charge

With reference to the figure above, the product V*I is represented, for the three solar

irradiation values mentioned above, through the three curves in thinner lines

The figure shows that, as stated above, these curves only have one single maximum point.

For example, for 1000W/m2, the maximum power point corresponds to a voltage value of

approx. 36V and to a current value of approx. 5.5A. Obviously, if the power provided by

the system is maximized, it is possible to make the most of the system, both in case the

system is connected to mains, and in case it is stand-alone

MPPT is an inbuilt device in the inverters. It typically reads the voltage and current values

at any instant, calculates their product (i.e. the power in Watts) and, by causing small

variations in the conversion parameters (duty cycle), it is capable of determining, by

comparison, if the photovoltaic module is working in maximum power conditions or not.

According to the result, it operates again on the circuit in order to bring the system to an

optimal condition The reason why MPPTs are used is simple: a photovoltaic system

without MPPTs may operate anyway; however, with the same solar irradiation, it provides

less energy.

EN - 25

Page 28

MPP300

10. SERVICE

10.1. WARRANTY CONDITIONS

This instrument is warranted against any material or manufacturing defect, in compliance

with the general sales conditions. During the warranty period, defective parts may be

replaced. However, the manufacturer reserves the right to repair or replace the product

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer’s charge. However, shipment will be agreed in advance. A report will

always be enclosed to a shipment, stating the reasons for the product’s return. Only use

original packaging for shipment; any damage due to the use of non-original packaging

material will be charged to the Customer. The manufacturer declines any responsibility for

injury to people or damage to property

The warranty shall not apply in the following cases:

Repair and/or replacement of accessories (not covered by warranty)

Repairs that may become necessary as a consequence of an incorrect use of the

instrument or due to its use together with non-compatible appliances

Repairs that may become necessary as a consequence of improper packaging

Repairs which may become necessary as a consequence of interventions performed

by unauthorized personnel

Modifications to the instrument performed without the manufacturer’s explicit

authorization

Use not provided for in the instrument’s specifications or in the instruction manual

The content of this manual cannot be reproduced in any form without the manufacturer’s

authorization

Our products are patented and our trademarks are registered. The manufacturer

reserves the right to make changes in the specifications and prices if this is due to

improvements in technology

10.2. SERVICE

If the instrument does not operate properly, before contacting the After-sales Service,

please check the conditions of the battery and of the cables. Should the instrument still

operate improperly, check that the product is operated according to the instructions given

in this manual

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer’s charge. However, shipment will be agreed in advance. A report will

always be enclosed to a shipment, stating the reasons for the product’s return. Only use

original packaging for shipment; any damage due to the use of non-original packaging

material will be charged to the Customer

EN - 26

Page 29

ESPAÑOL

Manual de Instrucciones

Copyright HT ITALIA 2012 Versión ES 2.00 - 12/10/2012

Page 30

Page 31

MPP300

Indice:

1. PRECAUCIONES Y MEDIDAS DE SEGURIDAD ....................................................... 2

1.1. Instrucciones preliminares ................................................................................................. 2

1.2. Durante el uso ................................................................................................................... 3

1.3. Después del uso ................................................................................................................ 3

1.4. Definición categoría de medida (Sobretensión) ................................................................ 3

2. DESCRIPCIÓN GENERAL ........................................................................................... 4

2.1. Introducción ....................................................................................................................... 4

2.2. Funcionalidad del instrumento .......................................................................................... 4

3. PREPARACIÓN PARA EL USO ................................................................................... 5

3.1. Controles iniciales ............................................................................................................. 5

3.2. Alimentación del instrumento ............................................................................................ 5

3.3. Calibración ........................................................................................................................ 5

3.4. Almacienamiento ............................................................................................................... 5

4. NOMENCLATURA ........................................................................................................ 6

4.1. Descripción del instrumento .............................................................................................. 6

4.2. Descripción LED indicadores ............................................................................................ 6

4.3. Instrumentos MASTER ...................................................................................................... 6

4.3.1. Visualización estado MPP300 a través instrumentos MASTER de Tipo 1 ............................. 7

4.3.2. Visualización estado MPP300 a través instrumentos MASTER de Tipo 2 ............................. 7

5. PROGRAMACIÓN INSTRUMENTOS MASTER .......................................................... 8

5.1. Instrucciones para MASTER tipo 1- Configuración U. remota .......................................... 8

5.2. Instrucciones para MASTER tipo 2- Configuración U. remota .......................................... 8

6. INSTRUCCIONES OPERATIVAS ................................................................................ 9

6.1. Chequeo instal. FV para instrumentos de tipo 1 (SOLAR I-V) .......................................... 9

6.1.1. Te st e o In st a l. F V c o n I nv e rt e r Mo n o/ M ul t i M P PT - S a l id a C A mo n o/ t ri f á si c o .............................. 9

6.2. Chequeo instal. FV para instrumentos de tipo 2 (SOLAR300N) ..................................... 15

6.2.1. Te s t eo Inst a l. FV co n I n v e r t er Mono/ M ul t i MP P T - S a l i d a CA m o n o / t r i f á s i c o ............................ 15

7. MANTENIMIENTO ...................................................................................................... 21

7.1. Generalidades ................................................................................................................. 21

7.2. Estado de las batería internal recargables ...................................................................... 21

7.3. Limpieza del instrumento ................................................................................................ 21

7.4. Fin de vida ....................................................................................................................... 21

8. ESPECIFICACIONES TÉCNICAS .............................................................................. 22

8.1. CaracterÍsticas técnicas verificación instalaciones FV .................................................... 22

8.2. Normas de referencia ...................................................................................................... 23

8.3. Características generales ................................................................................................ 23

8.4. Condiciones ambientales de uso .................................................................................... 23

8.5. Accesorios ....................................................................................................................... 23

9. APENDICE – CONCEPTOS TEÓRICOS ................................................................... 24

9.1. Verificación de las instalaciones FV ................................................................................ 24

9.2. Conceptos sombre MPPT (Maximum Power Point Tracker) ........................................... 25

10. ASISTENCIA .............................................................................................................. 26

10.1. Condiciones de garantía ................................................................................................. 26

10.2. Asistencia ........................................................................................................................ 26

ES - 1

Page 32

MPP300

1. PRECAUCIONES Y MEDIDAS DE SEGURIDAD

El instrumento ha sido proyectado conforme a la directiva IEC/EN61010-1 en relación a

los instrumentos de medida electronicos. Antes y durante la realización de las medidas

atenerse a las siguientes indicaciones y leer con particular atención todas las notas

precedidas con el símbolo

Cuando el instrumento fuera utilizado en modo diverso del especificado en

este manual de instrucciones, las protecciones previstas podrían verse

comprometidas.

No realizar medidas de tensión o corriente en ambientes húmedos

No realizar medidas en presencia de gas o materiales explosivos, combustibles o en

ambientes con polvo

Evite contactos con circuito en examen si no se están realizando medidas

Evite contactos con partes metálicas expuestas, con terminales de medida inutilizados,

circuitos, etc

No realice ninguna medida cuando se encuentren anomalías en el instrumento como,

deformaciones, roturas, fugas de sustancias, ausencia de visualización en el

visualizador, etc

Preste particular atención cuando se realicen medidas de tensión superiores a 20V por

el riesgo de shock elétrico.

Utilice solo los accesorios originales

En este manual y en el instrumento se utilizan los siguientes símbolos:

Atención: atenerse a las instrucciones descritas en el manual; un uso impropio

podría causar daños al instrumento o a sus componentes

Peligro alta tensión: riesgos de shock electrico

Doble aislamiento

Tensión o corriente CC

Tensión o corriente CA

Referencia a tierra

1.1. INSTRUCCIONES PRELIMINARES

Este instrumento ha sido proyectado para uso en ambientes con nivel de polución 2 y

en condiciones ambientales específicas al § 8.4. No use en condiciones ambientales

diferentes

Le invitamos a seguir las reglas normales de seguridad orientadas para protegerla

contra corrientes peligrosas y proteger el instrumento contra un uso erróneo

El instrumento puede ser utilizado para medidas de TENSION en CAT III 1000V CC o

CAT IV 300V CA respecto a tierra. No lo utilice sobre circuitos que superen los límites

especificados en el § 8.1.

El instrumento puede ser utilizado para medidas de CORRIENTE a través de

transductores de pinza externos.

Solo los accesorios originales HT garantizan los estándares de seguridad. Estos

deben estar en buenas condiciones y sustituidos, si fuera necesario, con modelos

idénticos

Antes de conectar los cables de medida al circuito en examen, controle que el

instrumento haya sido correctamente configurado.

ATENCIÓN

ES - 2

Page 33

MPP300

1.2. DURANTE EL USO

Le rogamos que lea atentamente las recomendaciones y las instrucciones siguientes:

ATENCIÓN

La falta de observación de las advertencias y/o instrucciones puede dañar

el instrumento y/o sus componentes o ser fuente de peligro para el

usuario

El LED “POWER“ rojo intermitente indica que las baterías internas

recargables están casi descargadas. Entonces conecte el alimentador

externo como se describe en el § 7.2

Los conectores de entrada del instrumento IDC1, IDC2, IDC3 son del

tipo a 4 pines. Utilice sólo pinzas con conector a 4 pines o

interponga el adaptador ACON3F4M entre la pinza y la entrada del

instrumento.

El instrumento es capaz de mantener los datos memorizados incluso en

condiciones de baterías descargadas

El dispositivo presenta una particular susceptibilidad a las ESD en

proximidad y sobre el puerto USB mientras está operativo, se aconseja la

conexión del cableado a la toma USB con el instrumento apagado

1.3. DESPUÉS DEL USO

Cuando finalicen las medidas, apague el instrumento manteniendo pulsada la tecla

ON/OFF durante algunos segundos. Si se prevee no utilizar el instrumento durante un

largo período atenerse a lo especificado en el § 3.4.

1.4. DEFINICIÓN CATEGORÍA DE MEDIDA (SOBRETENSIÓN)

La norma "IEC/EN61010-1: Prescripciones de seguridad para aparatos electricos de

medida, control y para uso en laboratorio, Parte 1: Prescripciones generales", define lo

que se entiende por categoría de medida, llamada de forma común categoría de

sobretensión. En el § 6.7.4: Circuitos de medida, esta cita:

Los circuitos se subdividen en las siguientes categorías de medida:

La categoría de medida IV sirve para las medidas efectuadas sobre una fuente de

una instalación de baja tensión

Ejemplos son los contadores electricos y las medidas sobre dispositivos primarios de

protección de las sobrecorrientes y sobre las unidades de regulación de la ondulación

La categoria de medida III sirve para las medidas efectuadas en instalaciones en el

interior de edificios

Ejemplos son las medidas sobre paneles de distribución, disyuntores, cableados,

comprendidos los cables, las barras, las cajas de unión, los interruptores, las tomas de

instalación fijas y los aparatos destinados al uso industrial y otras instrumentaciones,

por ejemplo los motores fijos con conexión de instalación fija

La categoria de medida II sirve para las medidas efectuadas sobre circuitos

conectados directamente a la instalación de baja tensión

Ejemplos son las medidas sobre aparatos de uso doméstico, utensilios portatiles y

aparatos similares

La categoria de medida I sirve para las medidas efectuadas sobre circuitos no

conectados directamente a la RED DE DISTRIBUCION

Ejemplos son las medidas sobre no derivados de la RED y derivados de la RED pero

con protección particolar (interna). En este último caso las peticones de transitorios son

variables, por este motivo (OMISSIS) se solicita que el usuario conozca la capacidad

de la resistencia a los transitorios de la instrurmentación

ES - 3

Page 34

MPP300

2. DESCRIPCIÓN GENERAL

2.1. INTRODUCCIÓN

Estimado Cliente, le agradecemos por haber escogido un instrumento de nuestro

programa de venta. El instrumento adquirido por usted, siga lo descrito en el presente

manual, le garantizará medidas exactas y fiables.

El instrumento está realizado en modo de garantizarle la máxima seguridad gracias a un

desarrollo de nueva concepción que asegura el doble aislamiento y la categoría de

sobretensión CAT III 1000VCC y CAT IV 300VCA(respecto a Tierra).

El instrumento ha sido proyectado como accesorio de un instrumento llamado MASTER

(ver § 4.3) para poder realizar las operaciones de prueba sobre instalaciones FV

Monofásica y Trifásica.

MPP300 en combinación con un instrumento MASTER es la solución ideal para el control

y el análisis de posibles problemas unidos a eventuales valores de eficiencia de las

instalaciones fotovoltaicas.

2.2. FUNCIONALIDAD DEL INSTRUMENTO

Las siguientes caracteristicas están disponibles:

Medida 3 tensiones y corrientes CC

Medida potencias strings CC y total CC

Medida 3 tensiones y corrientes CA TRMS

Medida potencia total CA

Medida irradiación [W/m2] a través de una célula de referencia conectada a la unidad

SOLAR-02

Medida temperatura paneles y ambiente a través de la sonda PT300N conectada al

SOLAR-02

Registración parámetros de una instalación FV con PI programable de 5s a 60min

Prueba Instalaciones FV con Inverter Mono/Multi MPPT - Salida CA mono/trifásico

Memoria interna para el guardado de los datos

Interfaz RF/USB para trasferencia de los datos al instrumento MASTER

ES - 4

Page 35

MPP300

3. PREPARACIÓN PARA EL USO

3.1. CONTROLES INICIALES

El instrumento, antes de ser enviado, ha sido controlado desde el punto de vista eléctrico

y mecánico. Han sido tomadas todas las precauciones posibles para que el instrumento

pueda ser entregado sin daños. Pero se aconseja controlarlo para determinar eventuales

daños sufridos durante el transporte. Si se encontraran anomalías contactar

inmediatamente con el distribuidor.

Se aconseja además controle que el embalaje contenga todas las partes indicadas en el §

8.5. En caso de discrepancias contactar con el distribuidor. Si fuese necesario cambiar el

instrumento se ruega seguir las instrucciones descritas en el § 10

3.2. ALIMENTACIÓN DEL INSTRUMENTO

El instrumento funciona exclusivamente con una batería recargable Li-ION (3.7V,

1900mAh) ubicada en el interior del instrumento. Utilice el alimentador externo A0055 en

dotación para la recarga de la batería. Para las indicaciones sobre el estado de la batería

ver lo descrito en el § 7.2.

El instrumento es capaz de mantener los datos memorizados también con la batería

completamente descargada.

3.3. CALIBRACIÓN

El instrumento refleja las caracteristicas técnicas descritas en el presente manual. Sus

prestaciones están garantizadas durante 12 meses desde la fecha de compra

3.4. ALMACIENAMIENTO

Para garantizar medidas precisas, después de un largo período de almacenaje en

condiciones ambientales extremas, espere que el instrumento vuelva a las condiciones

normales (ver § 8.4)

ES - 5

Page 36

MPP300

4. NOMENCLATURA

4.1. DESCRIPCIÓN DEL INSTRUMENTO

LEYENDA:

1. Entradas Tensiones CC

2. Entradas Corrientes CC

3. Entradas Tensiones CA

4. Entradas Corrientes CA

5. LEDs indicadores

6. Conector USB (sólo para

instrumentos MASTER Tipo 2,

ver § 4.3)

7. Tecla ON/OFF

8. Conector para Alim. externo

Fig. 1: Descripción panel frontal del instrumento

4.2. DESCRIPCIÓN LED INDICADORES

Nombre LED Estado Descripción

POWER

STATUS

MASTER

REMOTE

VERDE fijo

VERDE Intermitente

ROJO intermitente

VERDE fijo

VERDE Intermitente

ROJO intermitente

ROJO fijo

VERDE Intermitente

APAGADO

VERDE Intermitente

APAGADO

Tabla 1: Descripción LED indicadores de MPP300

MPP300 alimentado a través del alimentador externo

MPP330 alimentado con baterías internas

Baterías MPP300 casi agotadas

MPP300 en fase de sincronización antes del inicio del registro