Page 1

HSM FA 500.3

Keep in a safe place for future use! 1.990.999.110 – 1005

OPERATING MANUAL

SHREDDER

english

Page 2

2 1005

FA 500.3

Contents

1 Proper use, warranty

....................................................................................................................3

2 Safety instructions .....................................................................................................................3

3 Overview ...................................................................................................................................4

4 Dimensions ...............................................................................................................................5

5 Transportation, installation ........................................................................................................6

6 Operating and display elements ...............................................................................................7

7 Start-up .....................................................................................................................................7

8 Malfunctions ..............................................................................................................................9

9 Maintenance and care ............................................................................................................11

10 Disposal / Recycling ................................................................................................................12

11 Scope of supply, accessories ..................................................................................................12

12 Technical data .........................................................................................................................13

13 Electric wiring diagrams ..........................................................................................................14

Cut size 1.9 x 15 mm ..............................................................................................................19

Page 3

1005 3

FA 500.3

Danger of injury

Do not reach into the paper feed

opening.

Splinters can cause injury

Wear protective goggles when destroying diskettes, CDs and hard

credit cards.

Danger of injury during intake

Do not go near the paper feed opening with long hair, loose clothing, ties,

scarves, necklaces, bracelets etc.

Do not destroy any material which

might become tangled, such as tapes,

binder ties or foil.

Switch off the shredder and pull

out the power plug before moving

or cleaning the shredder, or any other

task outside its normal scope of use.

Maintenance and service tasks may

only be performed by HSM customer

service and service engineers of our

dealers.

1 Proper use, warranty

The shredder is exclusively designed for destroying

paper and cardboard, as well as store cards, credit cards,

CD-ROMs and fl oppy disks. Its sturdy drive mechanism is

not damaged by paper clips and staples.

The document shredder is supplied as a single or

combined machine (with an HSM baling press). Please

observe the applicable instructions in the operating manual.

Our general business conditions are applicable. We

provide a one year warranty for the document shredder.

The warranty period is 6 months when used in multiple

shifts. This warranty excludes wear, damage due to

improper handling, natural depreciation, and actions

taken by third parties.

2 Safety instructions

Danger:

It is prohibited to operate one only machine

of a combination-version machine.

The safety clearances are only guaranteed

with the combined document shredder and

HSM press.

Ensure that no unauthorised persons can access the

document shredder. Do not leave the document shredder

switched on when it is unattended. The shredder may not

be operated by anyone under 16 years of age.

When the machine is not in use, it must be shut down

and secured against unauthorised use. To do so, you can

secure the mains switch with a padlock when it is in the

off position.

• Read the operating manual before starting up the

shredder.

• Do not remove or modify safety devices which guarantee the safe operation of the machine.

• Observe all safety instructions attached to the

machine.

• The shredder may not be operated by anyone under

16 years of age.

• Only open the front door once the machine has come

to a standstill.

• Carry out inspection and maintenance regularly.

• Switch off the shredder, disconnect the power plug

and call customer service in the following circumstances:

- Power cables or plugs are damaged

- Liquid has entered the shredder

- The shredder has been exposed to rain

- The machine does not work properly despite the

operating manual having been observed

- The shredder has been damaged

• No platforms or other raised surfaces may be placed

near the shredder if they encroach on the specifi ed

safety clearances.

Operating controls for your safety

Emergency stop switch bar

In the event of danger, press the emergency stop switch

bar immediately.

This switches off the shredder, and stops the cutting

block and feed belt.

Main switch (only Solo-version)

In the event of danger, turn the main

switch to “0”.

You can secure the main switch in

this position with a padlock to prevent

restarting.

Translation of the original operating instructions

Page 4

4 1005

FA 500.3

3 Overview

1 Main switch (only solo-version)

2 Safety instructions

3 Operating and display elements

4 Emergency stop switch bar

5 Loading tray

6 Intake conveyor

7 Braking swivel castors

8 Nameplate

9 Oil reservoir opening

1

7

8

HSM GmbH + Co. KG

Austrasse 1-9

88699 Frickingen / Germany

4

3

2

5

6

9

Page 5

1005 5

FA 500.3

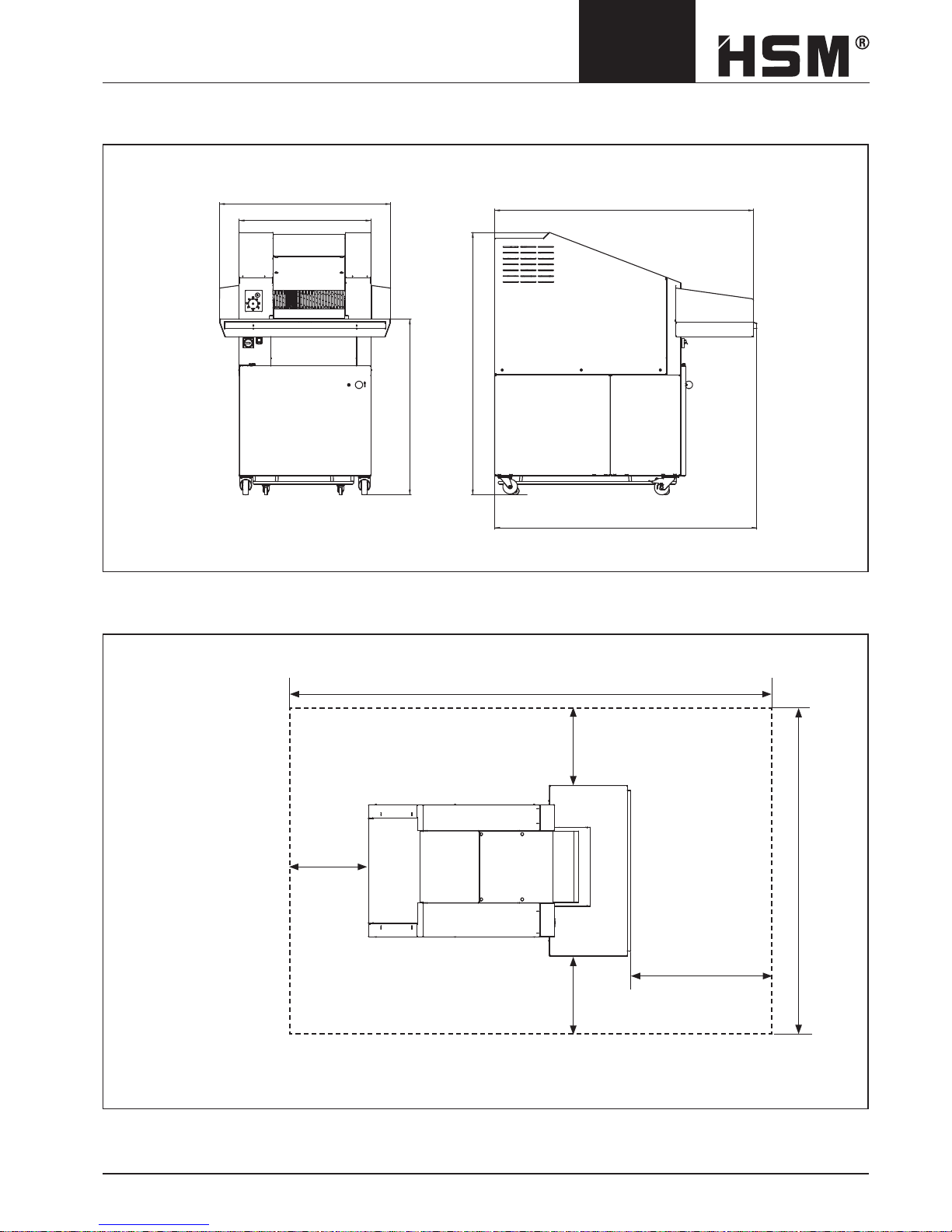

4 Dimensions

Space requirements for operation and maintenance

HSM FA 500.3

1792

1168

900

1200

1791,5

1769

1000

500

500500

3300

2200

Page 6

6 1005

FA 500.3

Mount the loading table onto the unit:

• Attach the table using the M 10 nuts (1)

Lock the front castors by pressing down the brake lever.

1

• Insert the plug (connection for emergency stop switch

bar) into the socket next to the main switch and turn it

to stop.

1

• Insert the machine’s power plug into the

CEE 3x32 A + N + PE connection socket on the

application site.

Notice: Extension cables are not permitted.

5 Transportation, installation

• During transport, observe the high centre of gravity of

the paper shredder!

• Place the pallet with the shredder in its packaging on

a smooth, level surface.

• Observe the instructions for unpacking.

• If you need to move the shredder through narrow

doors, you can wait until it is at its fi nal location before

fi tting the loading tray. Without the tray, the machine is

only 900 mm wide.

• The shredder may only be placed in dry rooms on

a hard, level fl oor – not on carpets. The fl oor load

on each roller is approximately 200 kg respectively

230 kg (machines with cutting unit 1.9 x 15 mm).

• The machine must be connected to a power source

which meets the specifi cations on the nameplate.

Make sure the power cable is unobstructed and that

nobody can tread on it

Page 7

1005 7

FA 500.3

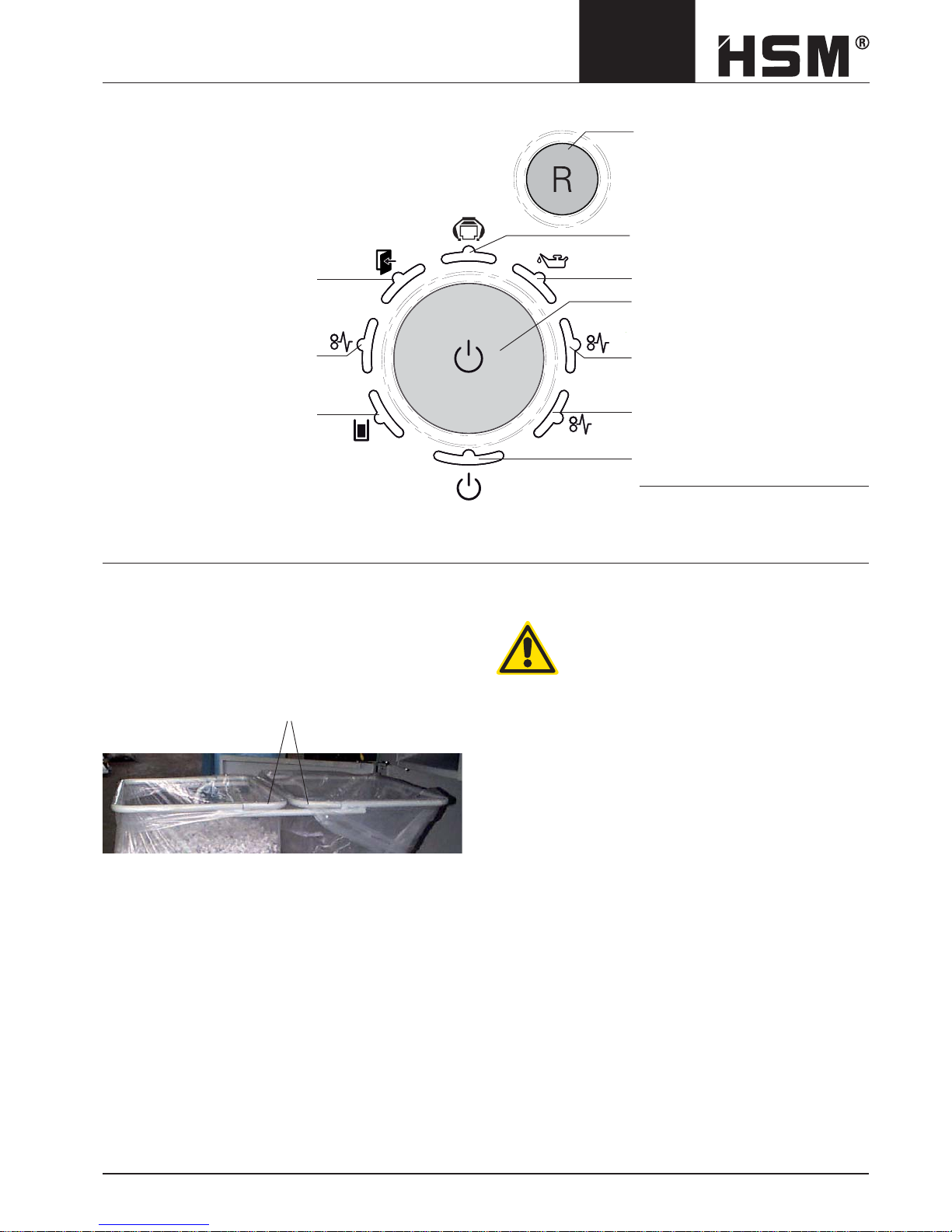

6 Operating and display elements

1

2

Z

Baling press operating status

(only for combined machines)

Indicator: oil reservoir empty

Function button

“On/off/start”

Indicator: Level 2 * overload

Indicator: Jam between the cutting units *

Indicator: ready for operation

* only for machines with

1.9 x 15 mm cutting widths

Indicator: Door open or

emergency stop was pressed

Indicator: Level 1

overload

Indicator: Paper container full

R button:

Cutting unit runs in reverse

7 Start-up

Attaching the waste bag (Solo version)

• Open the front door and pull out the waste trolley.

• You can modify the trolley from a double-chamber to a

single-chamber system by removing the brackets (1).

• Put in a new waste bag and fold it approximately

20 cm over the top frame tube. When using a twochamber system, make sure that there is also around

20 cm of plastic foil below the brackets (1).

• Push in the waste trolley and close the front door.

1

Inspecting the safety devices

Check that the safety devices are working

properly:

• At the start of each shift

• After any maintenance or repair work

Do not start the machine until you have checked the safety devices and found them to be in perfect working order.

If any defect arises during operation stop the machine

immediately and make sure it is corrected.

Page 8

8 1005

FA 500.3

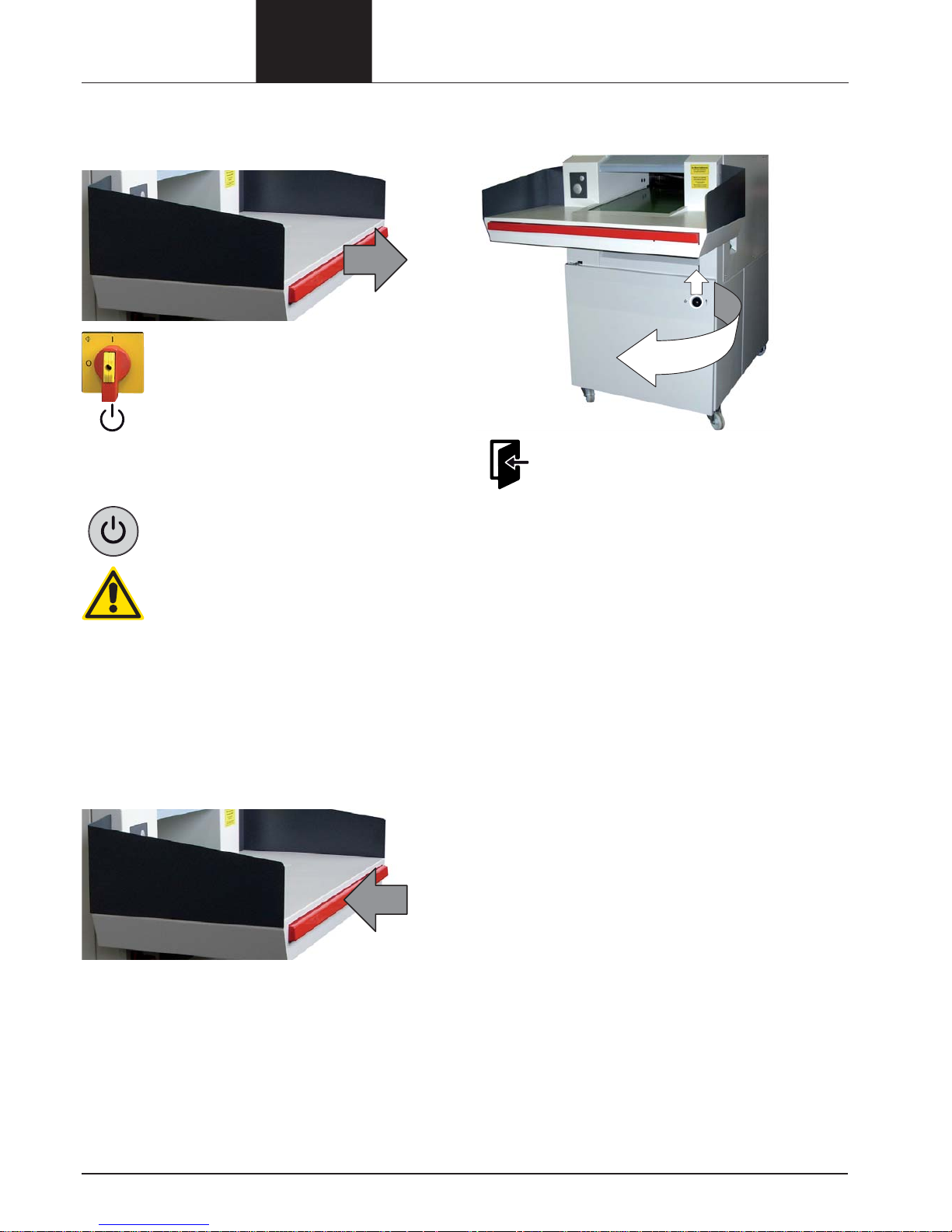

Switching on the paper shredder

• Activate the emergency stop control by pushing the

switch bar away from the machine.

• Solo-version: Turn the main switch to the

I position.

Combination-version: Turn the main switch

on the baling press to the I position.

The indicator „Ready for operation“ lights

up.

Note: If an error message lights up (such as “Door

open” or “Paper container full”), fi rst rectify

the error.

• Press the start button.

The cutting block and feed belt start up.

Caution!

The feed belt can run in reverse if the phase

wires in the power plug are incorrectly

connected.

Turn off the main switch immediately and

pull out the power plug!

Have an electrician change two of the three

phase wires.

Checking the emergency stop control

• Press the emergency stop switch bar while the

machine is running.

The shredder must switch off immediately. The cutting

block and the feed belt must stop.

The machine can only be switched on again once you

have pulled out the switch bar.

Inspecting the door switch

• Open the front door.

The indicator “Door open” must light up.

The cutting block and feed belt must stop.

After you close the door, the display should

go out and you can start the machine again

by pressing the start button.

Page 9

1005 9

FA 500.3

Shredding material

Place the material to be shredded on the loading tray and

then place batches on the feed belt.

If material that is not supposed to be shredded is mistakenly placed onto the belt, never attempt to pull it out

• Press the start button again.

The drive stops.

• Press the R-button.

The cutting block and feed belt run in

reverse.

• You can now remove the material from the

belt and start the shredder again by pressing the start button.

Note: Provided the cutting unit is running in the

shredding direction, you can stop it by

pressing the R button.

Waste bag full

The indicator “Paper container full” lights

up. The shredder switches off automatically.

• Press the reverse button for approx. 3 seconds.

Part of the material is pulled back into the

apparatus.

• Open the front door and shake the waste

trolley.

The cut material spreads in the cut mate-

rial sack and does not fall into the interior

of the shredder.

• Pull the waste trolley out and change the

cut material sack.

• Push the trolley back in and start the

shredder again by pressing the start

button.

Stopping the shredder

• Press the start button again.

The cutting block and feed belt stop.

The shredder switches to standby mode.

Switching off the shredder

• Turn the main switch on the paper shredder or the baling press to 0.

You can secure the main switch in this

position using a padlock.

8 Malfunctions

Check the following before calling customer service:

• Is the power plug connected?

• Is the shredder switched on?

• Is the front door closed?

• Is the waste bag full?

• Is there a paper jam in the shredder?

• Has the motor been overloaded?

Overload due to paper jam

“Overload” display (level 1 or level 2 – de-

pending on the machine model) lights up.

The cutting block automatically runs in

reverse for several seconds. Then the cutting unit switches off.

Caution!

The blade rollers can still cause injuries

even while they are not running. Do not

reach into the cutting apparatus! Wear

safety gloves!

Do not alternately press the “Forwards” and

“Reverse” buttons to remove the blockage.

This will damage the shredder.

• Take out the pile of paper.

• Press the start button and put less paper

on the feed belt.

Page 10

10 1005

FA 500.3

Electric motor overheated

“Overload” display (level 1 or level 2 – de-

pending on the machine model) fl ashes.

The shredder switches off automatically.

• Let the motor cool down for 20 - 30 minutes.

• Press the start button.

Door open or emergency stop was pressed

The indicator lights up.

The shredder switches off automatically.

• Close the front door and activate the

emergency stop control by pushing the

switch bar away from the machine.

• Press the start button.

Oil reservoir empty

“Oil reservoir empty” display lights up.

• Fill the reservoir with cutting apparatus oil.

order no. 1.235.997.500 for 5 litre container

The “Oil reservoir empty” signal is auto-

matically deactivated after the reservoir

is fi lled.

Note: The shredder remains operational even

when the oil reservoir is empty.

Note for machines with 1.9 x 15 mm cutting

widths:

Machines with the safety level 4 contain a two-level

cutting unit with 2 drives.

After starting the document shredder, level 2 starts

initially and about 1 second later level 1 starts in the

shredding direction. The drives are separately monitored

for possible overload by two rotation sensors. For level 1

overload, the drive is stopped and after a delay of approx.

0.5 seconds is switched into reverse for approx. 3 seconds.

Level 2 runs in the shredding direction again.

“Level 1 overload” message with illuminated red LED.

After reversing, the drive remains switched off.

The overload display disappears and the cutting unit

starts running in the shredding direction again when the

start button is pressed.

If it is not restarted – by pressing the start button – within

approx. 5 seconds, then level 2 is also automatically

switched off.

For level 2 overload, both drives are switched off and are

switched to reverse for approx. 4 seconds fi rstly for level 1

and then level 2.

Message: red “Level 2 overload” LED.

After reversing, the drives remain switched off.

The overload display disappears and the drives start

running in the shredding direction again when the start

button is pressed.

Jam between the cutting units

If a jam is detected between the two cutting units, the

drive for level 1 is stopped and switched into reverse.

“Jam between the cutting units” display

lights up

Drive 2 continues to run in the shredding direction until

the jam is cleared. If this is not possible, it switches off

after approx. 10 seconds.

If this is successful, the level 1 drive can be started again

in the shredding direction by pressing the start button. In

this case, the “Jam between the cutting units” message

disappears.

If the level 1 start does not take place within 10 seconds,

level 2 is automatically switched off.

Page 11

1005 11

FA 500.3

9 Maintenance and care

Cleaning the shredder:

• Switch off the shredder and disconnect the power

plug.

• Only use a soft cloth and mild soapy water for

cleaning. Never use scouring agent, cleaning fl uid,

petroleum or thinners.

Greasing the drive chains and cogs

(twice yearly)

• Switch off the shredder.

• Pull out the power plug.

• Remove the tray and the cover panels.

• Grease the cogs and the drive chains from the motor

to the cutting apparatus, the cutting block to the feed

belt and the cutting block to the regulating roller.

Recommended lubricating grease: K2K in accordance

with DIN 51502/DIN 51825

• Put the side cover panels and the tray back on.

F

E

T

T

G

R

E

A

S

E

G

R

A

S

O

G

R

A

I

S

S

E

V

E

T

F

E

T

T

G

R

E

A

S

E

G

R

A

S

O

G

R

A

I

S

S

E

V

E

T

F

E

T

T

G

R

E

A

S

E

G

R

A

S

O

G

R

A

I

S

S

E

V

E

T

Tightening the feed belt

The feed belt should not slip when loaded with material.

• Switch off the shredder.

• Loosen the hex nuts (1) on the left and right sides of

the snub roller.

• Loosen the lock nuts (2) of the tensioning bolts (3).

• Tighten the feed belt evenly using the tensioning

bolts.

Note:

Only tighten the feed belt until it stops slipping. The feed

belt bearing may be damaged if it is tightened too much.

• Tighten the hex nuts on the snub roller and the lock

nuts on the tensioning bolts again.

You must check that the feed belt runs

straight:

Switch on the shredder and let it run for

10 minutes. During this time, the feed belt

must run in the middle of the snub roller. If it

slips to the left or right edge, you must alter

the setting of the snub roller.

Checking the feed belt for wear

The surface of the feed belt can become worn after long

periods of use. If you can see the fabric inlay in the belt, it

must be replaced. Please notify our customer service.

1

1 23

23

Page 12

12 1005

FA 500.3

Cleaning the tensioning station (monthly)

• Remove the feeding table and the front panel of the

tensioning station.

• Remove particles and dirt.

Cleaning the conveyor-belt area (monthly)

• Remove the covers on both sides.

The cleaning openings in the conveyor-belt covers are

now accessible.

• Blow out the conveyor-belt area with compressed air

or use a vacuum cleaner to remove the dirt particles.

10 Disposal / Recycling

Dispose of the machine in an environmentally sound

way at the end of its service life. Observe the current

regulations when doing this. As legislation is subject to

ongoing changes, we request that you contact your local

authorities at the appropriate time. As the manufacturer,

HSM would be glad to advise you on the disposal of your

old machine.

11 Scope of supply, accessories

• Machine on pallet with a wooden frame, strapped with

packing tape and packed in foil

• 4 waste bags, order no. 1.513.995.000 for 2-chamber

system (Solo version)

• 1 waste bag, order no. 1.513.995.100 for 1-chamber

system (Solo version)

• Special cutting block oil

5 l container with spout, order no. 1.235.997.500

• Operating manual

Page 13

1005 13

FA 500.3

12 Technical data

EC declaration of conformity

The manufacturer HSM GmbH + Co. KG, Austrasse 1 - 9, D-88699 Frickingen hereby declares that the machine,

referred to here as

document shredder HSM FA 500.3

corresponds to the health and safety requirements of the following EC directives listed below due to its conception and

design of the version in which it was put into circulation by us:

Machinery directive 2006 / 42 / EC EMC directive 2004 / 108 / EC

Applied standards and technical specifi cations:

• EN 349:1993 + A1:2008 • EN 62061:2005

• EN 12100-1:2003 + A1:2009 • EN 12100-2:2003 + A1:2009

• EN 55014-1:2006 • EN 55014-2:1997 + A1:2001

• EN 61000-3-2:2006 • EN 60950-1:2006

• EN 61000-3-3:1995 + A1:2001 + A2:2005

Authorised representative for the compilation of technical documentation: Rolf Gasteier, HSM GmbH + Co. KG

Frickingen, 11.02.2010

Rolf Gasteier - Technical Director

Cutting type Cross cut

Cut size (mm) 10.5 x 40 - 76 7.5 x 40 - 80 6 x 40 - 53 1.9 x 15

Safety level DIN 32757 – 1 2234

Cutting capacity (sheets), DIN A4, 70g/m

2

80g/m

2

600 - 650

510 - 550

500 - 550

425 - 470

400 - 450

340 - 380

120 - 130

90 - 100

Throughput safety level 4 200 - 250 kg/h

Effective width 500 mm

Cutting speed 210 mm / s

Power supply 3 x 400 V, 50 Hz

Power for the maximum number of sheets 9.2 kW 5.5 + 4 kW

Plug CEE 3x32 A + N + PE

Safety fuse

Line safety switch

Type „gl“ 35 ampere

K or C / 32 ampere

Ambient conditions in operation:

Temperature

Relative humidity

Height above sea-level (MSL)

-10 °C to +40 °C

max. 90 %, without condensation

max. 2,000 m

Dimensions W x D x H (mm) 1170 x 1795 x 1795

Weight 790 kg 920 kg

Volume of the shredded paper container 530 l (2 x 265 l)

Page 14

14 1005

FA 500.3

13 Electric wiring diagrams

Legend:

=AV: Shredder

+S: in switch cabinet

+MA: on machine

+BF: Keypad

Solo

400 V / 50 Hz

Page 15

1005 15

FA 500.3

Page 16

16 1005

FA 500.3

Page 17

1005 17

FA 500.3

Page 18

18 1005

FA 500.3

Page 19

1005 19

FA 500.3

Solo

Cut size 1.9 x 15 mm

400 V / 50 Hz

Page 20

20 1005

FA 500.3

Page 21

1005 21

FA 500.3

Page 22

22 1005

FA 500.3

Page 23

1005 23

FA 500.3

Page 24

HSM GmbH + Co. KG

Austrasse 1-9

88699 Frickingen / Germany

Tel. +49 7554 21 00-0

Fax. +49 75 54 2100 160

info@hsm.eu

www.hsm.eu

HSM of America LLC

419 Boot Road

Downingtown, PA 19335

Tel. (610) 918-4894

(800) 613-2110

Fax (610) 918-4899

customerservice@hsmofamerica.com

info@hsmofamerica.com

www.hsmofamerica.com

HSM (UK) Ltd.

14 Attwood Road / Zone 1

Burntwood Business Park

Burntwood

Staffordshire

WS7 3GJ

Tel. +44(0) 1543.272.480

Fax +44(0) 1543.272.080

info@hsmuk.co.uk

www.hsmuk.co.uk

Loading...

Loading...