HRS HIF3B Service Manual

B15

Ribbon Cable connector Compliant with MIL Standard

HIF3B Series

■Features

1. Product Compliant with MIL Standard

HIF3B series has been developed as a product compliant with MIL

standard, and used for wide applications.

2. UL Approval Product

HIF3B series connectors are UL approved.

3. Mechanism to Prevent Mis-insertion

This connector is equipped with the mechanism to prevent Misinsertion as follows.

1 The system provides the convex area to insert the guide-key on the

pin header side, and to guide it in combination with the socket

convex area (MIL standard).

2

The system embeds and guides the polarizing key in the socket holes.

4. Applicable Cable AWG#28

The applicable cable is UL2651 AWG#28 flat cable (7 cores./

0.127mm, jacket dia. 0.9±0.1mm).

■Product Specifications

Note 1: Includes temperature rise caused by current flow.

Note 2: The term "storage" refers to products stored for long period of time prior to mounting and use. Operating Temperature Range and

Humidity range covers non conducting condition of installed connectors in storage, shipment or during transportation.

Rating

Current rating : 1A

Operating Temperature Range

:

–55 to +85ç(Note 1)Storage Temperature Range : –10 to +60ç(Note 2

)

Voltage rating : 200V AC Operating Moisture Range : 40 to 80% Storage Humidity Range : 40 to 70% (Note 2

)

Item Specification Condition

1. Insulation Resistance 1000M ohms min. 500V DC

2. Withstanding voltage

No flashover or insulation breakdown.

650V AC/1 minute

3. Contact Resistance 15m ohms max. 0.1A

4.

Vibration

No electrical discontinuity of 1µs or more

Frequency: 10 to 55 Hz, single amplitude of 0.75 mm, 2 hours in each of the 3 directions.

5.

Humidity (Steady state)

Insulation resistance: 1000M ohms min.

96 hours at temperature of 40ç and humidity of 90% to 95%

6. Temperature Cycle No damage, cracks, or parts looseness.

(-65ç: 30 minutes ➝ 15 to 35ç: 5 minutes max.

125ç: 30 minutes ➝ 15 to 35ç: 5 minutes max.) 5 cycles

7.

Durability (Mating/un-mating)

Contact resistance: 15m ohms max. 500 cycles

8.

Resistance to Soldering heat

No deformation of components affecting performance.

Flow: 260ç for 10 seconds

Manual soldering: 300ç for 3 seconds

■Material

Part Material Finish Remarks

Insulator PBT Black UL94V-0

D Beryllium copper

Connection area Gold plated

Socket Contact

Connection area Gold plated

–––––––

DA Copper alloy

Connection area Gold plated

Connection area Tin lead plated

Pin header contact Brass Selective Gold plated –––––––

查询HIF3B-16DA-2.54R供应商

B16

■Ordering Information

HIF 3B - * D A - 2.54 R

qw ret yu

q Series Name : HIF

w Series No. : 3B, 3BA, 3BB (50, 60, 64 contacts only

)

e

Number of contacts

: 16, 20, 26, 30, 34, 40, 50, 60, 64

r

Contact alignment

: D : Double

t A : VA type

y Contact pitch : 2.54mm

u Connection type

R : ID type

●Socket

HIF 3B - * P A - 2.54 DS

qw ret yu

q Series Name : HIF

w Series No. :

3B :

(14 contacts not included)

3BC: (10 contacts only)

3BA, 3BB: (50, 60, 64 contacts only) 3BD: (10 contacts only)

e

Number of contacts

: 16, 20, 26, 30, 34, 40, 50, 60, 64

r P : Pin header

t A : Selective gold plated

y Contact pitch : 2.54mm

u Contact style

DS : Right angle type

DSA : Straight type

●Pin Header

B17

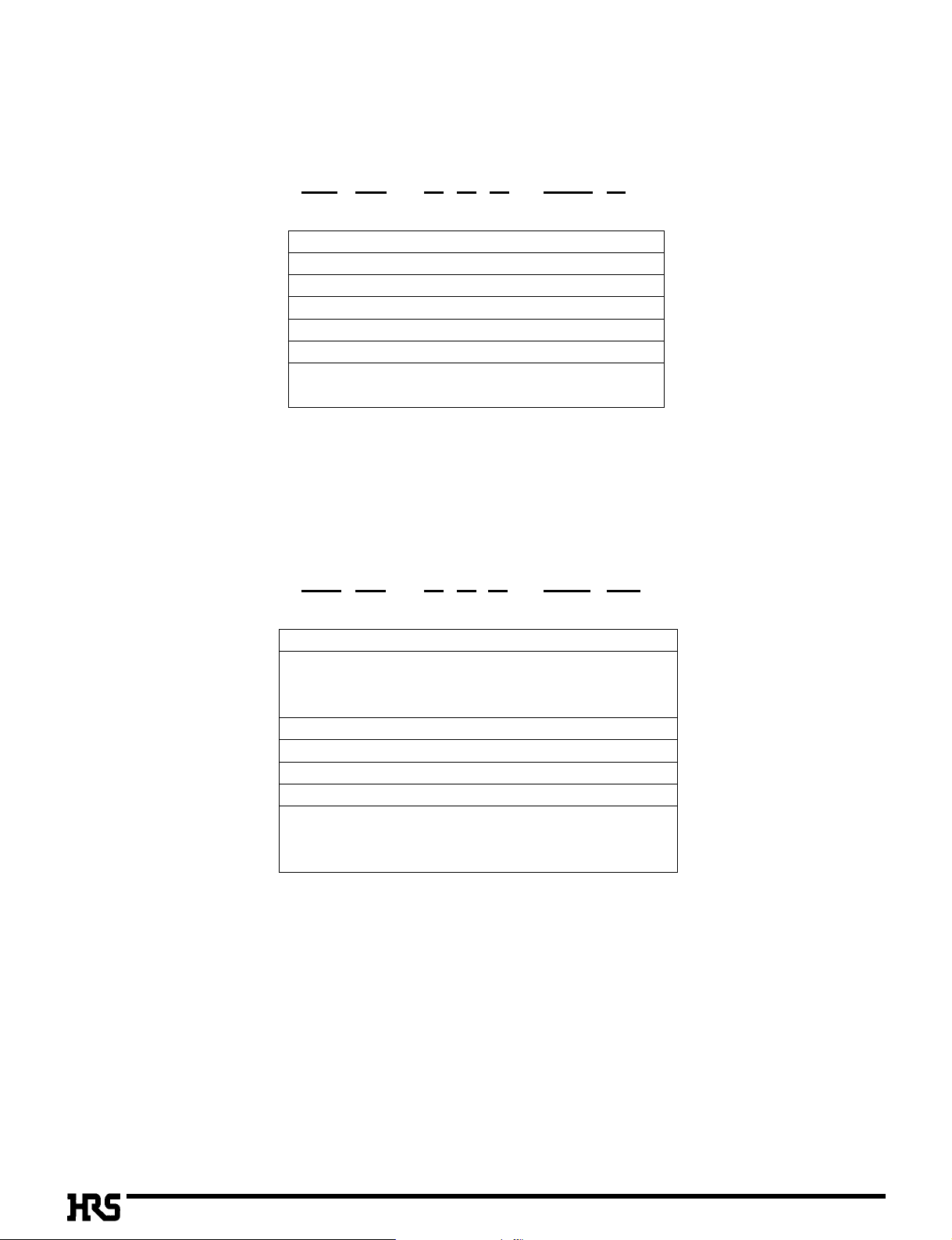

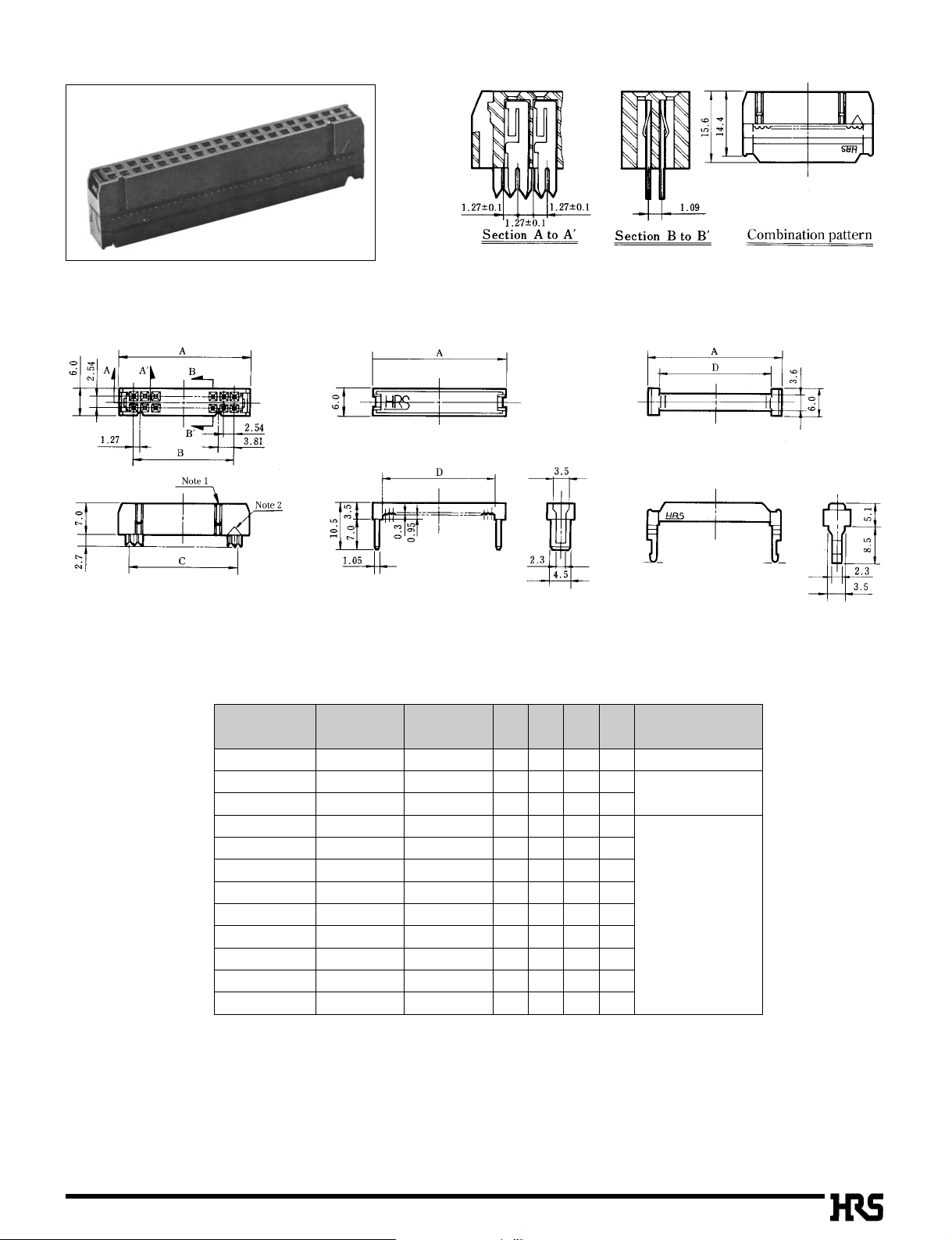

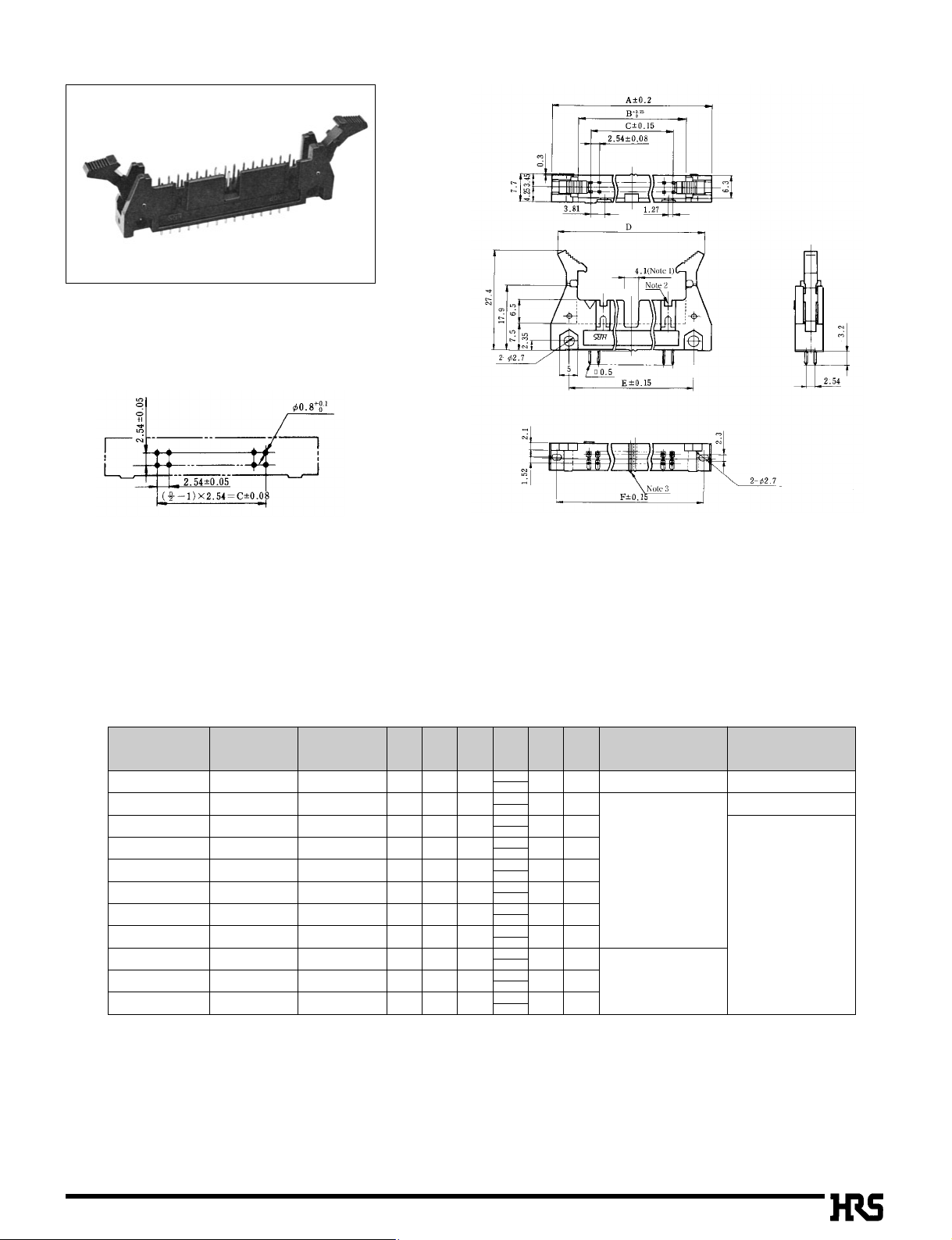

■Socket (With guide to prevent mis-insertion)

Unit:mm

★

★

★

★

★

★

★

★

★

★

★

★

★

Note1, Note2: The number of polarizing keys and polarizing keyways changes according to products. Refer to the list as shown below.

Note3: The 50, 60 and 64 contact connector contain two types of polarizing guides. Use the products, referring to Notes 1 and 2.

Note4: The 6 contact has no polarizing mark.

The products marked with ★comply with MIL standard.

Body Protector Clamp

CL No.Part Number

610-0032-3

610-0021-7

610-0022-0

610-0023-2

610-0024-5

610-0025-8

610-0026-0

610-0027-3

610-0028-6

610-0029-9

610-0041-4

610-0030-8

610-0042-7

610-0031-0

610-0043-0

HIF3BA- 6D-2.54R

HIF3BA-10D-2.54R

HIF3BA-14D-2.54R

HIF3BA-16D-2.54R

HIF3BA-20D-2.54R

HIF3BA-26D-2.54R

HIF3BA-30D-2.54R

HIF3BA-34D-2.54R

HIF3BA-40D-2.54R

HIF3BA-50D-2.54R

HIF3BB-50D-2.54R

HIF3BA-60D-2.54R

HIF3BB-60D-2.54R

HIF3BA-64D-2.54R

HIF3BB-64D-2.54R

Number of Contacts

6

10

14

16

20

26

30

34

40

50

50

60

60

64

64

A

12.19

17.27

22.35

24.89

29.97

37.59

42.67

47.75

55.37

68.07

68.07

80.77

80.77

85.85

85.85

CL No.Part Number

–––––––

610-0651-5

610-0652-8

610-0653-0

610-0654-3

610-0655-6

610-0656-9

610-0657-1

610-0658-4

610-0659-7

610-0671-2

610-0660-6

610-0672-5

610-0661-9

610-0673-8

HIF3BA-10DA-2.54R

HIF3BA-14DA-2.54R

HIF3BA-16DA-2.54R

HIF3BA-20DA-2.54R

HIF3BA-26DA-2.54R

HIF3BA-30DA-2.54R

HIF3BA-34DA-2.54R

HIF3BA-40DA-2.54R

HIF3BA-50DA-2.54R

HIF3BB-50DA-2.54R

HIF3BA-60DA-2.54R

HIF3BB-60DA-2.54R

HIF3BA-64DA-2.54R

HIF3BB-64DA-2.54R

B

5.08

10.16

15.24

17.78

22.86

30.48

35.56

40.64

48.26

60.96

60.96

73.66

73.66

78.74

78.74

C

6.35

11.43

16.51

19.05

24.13

31.75

36.83

41.91

49.53

62.23

62.23

74.93

74.93

80.01

80.01

D

7.72

12.8

17.88

20.42

25.5

33.12

38.2

43.28

50.9

63.6

63.6

76.3

76.3

81.38

81.38

Polarizing Guide

(Note 1)

One at center

One on right and left sides, resp.

One at center

One on right and left sides, resp.

One at center

One on right and left sides, resp.

One at center

Polarizing Keyway

(Note 2)

None

One on left side

One on right and

left sides, resp.

B18

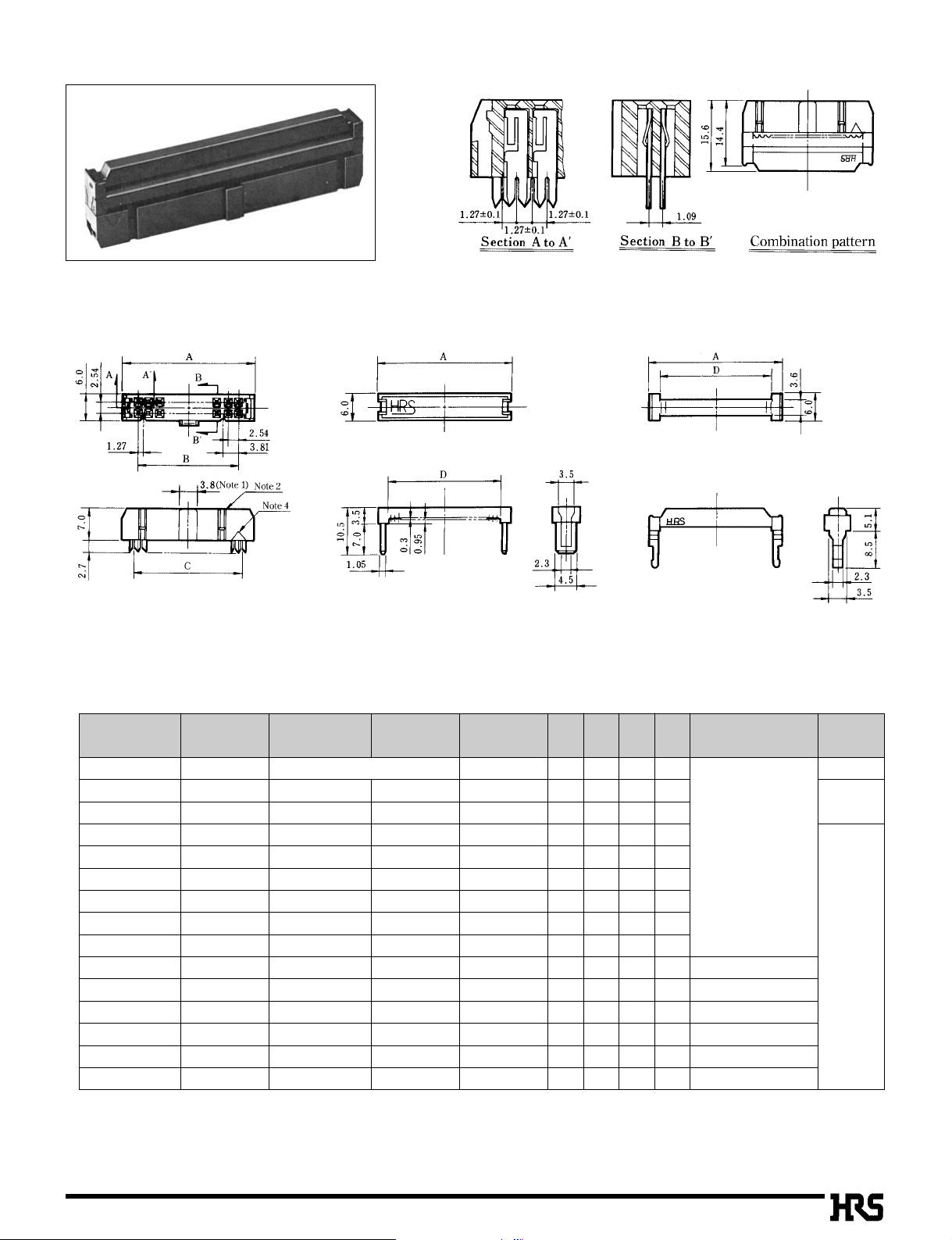

■Socket with Withdrawal Tab

Part Number CL No.

Unit : mm

HIF3BA-10D-2.54R-CL

HIF3BA-16D-2.54R-CL

HIF3BA-20D-2.54R-CL

HIF3BA-26D-2.54R-CL

HIF3BA-30D-2.54R-CL

HIF3BA-34D-2.54R-CL

HIF3BA-40D-2.54R-CL

HIF3BA-50D-2.54R-CL

HIF3BB-50D-2.54R-CL

HIF3BA-60D-2.54R-CL

HIF3BB-60D-2.54R-CL

HIF3BA-64D-2.54R-CL

HIF3BB-64D-2.54R-CL

610-0190-4

610-0192-0

610-0193-2

610-0194-5

610-0195-8

610-0196-0

610-0197-3

610-0198-6

610-0201-9

610-0199-9

610-0202-1

610-0200-6

610-0203-4

Number of Contacts

10

16

20

26

30

34

40

50

60

64

A B

17.27

24.89

29.97

37.59

42.67

47.75

55.37

68.07

80.77

85.85

5.3

12.9

18.0

25.5

30.5

35.8

43.4

56.0

68.5

73.8

B19

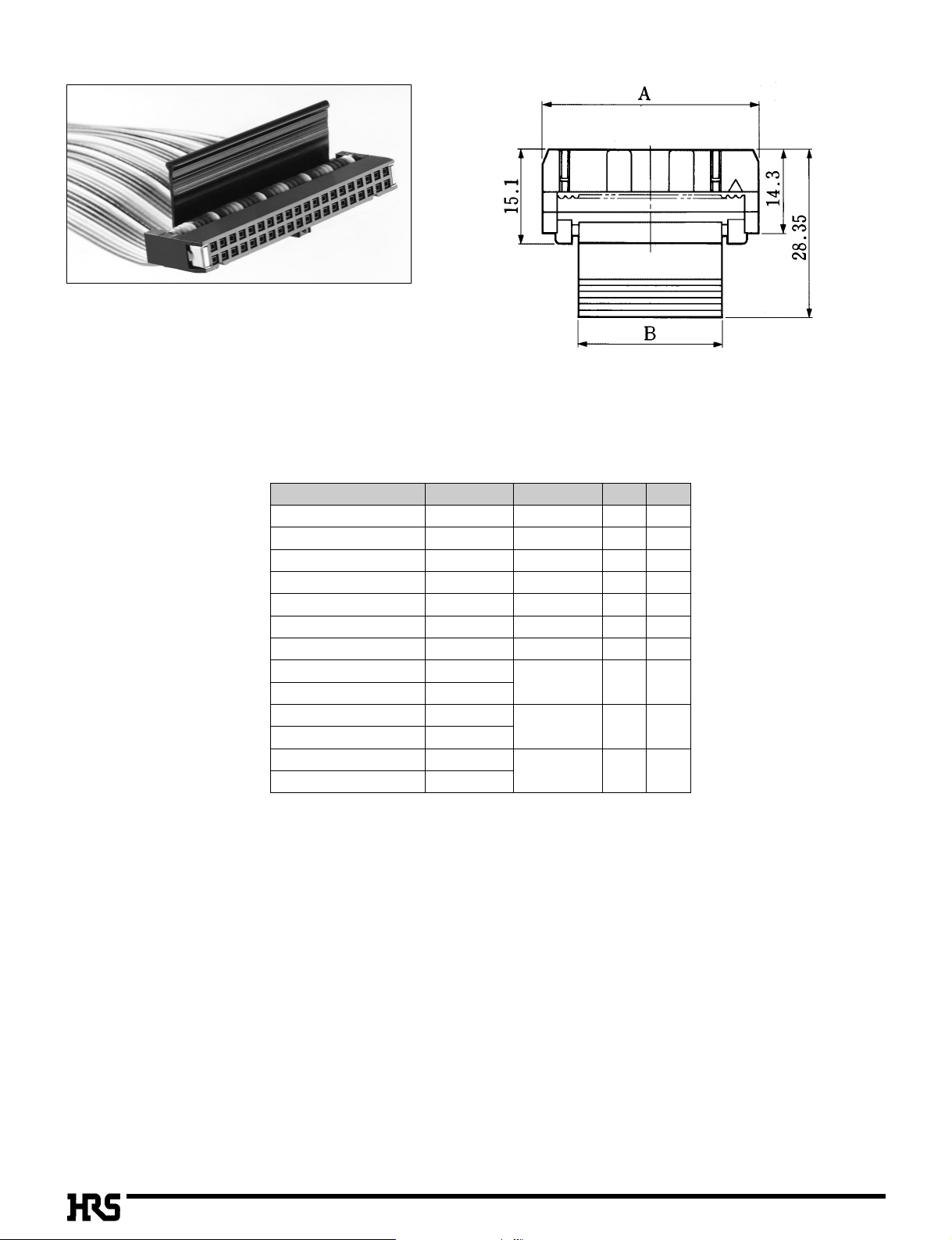

■Socket

Note1: The number of polarizing keys and polarizing keyways changes according to products. For details, refer to the list as shown below.

Note2: The 6 contact has no polarizing mark.

Body Protector Clamp

Unit:mm

★

★

★

★

★

★

★

★

★

★

★

The products marked with ★comply with MIL standard.

CL No.Part Number

610-0012-6

610-0001-0

610-0002-2

610-0003-5

610-0004-8

610-0005-0

610-0006-3

610-0007-6

610-0008-9

610-0009-1

610-0010-0

610-0011-3

HIF3B- 6D-2.54R

HIF3B-10D-2.54R

HIF3B-14D-2.54R

HIF3B-16D-2.54R

HIF3B-20D-2.54R

HIF3B-26D-2.54R

HIF3B-30D-2.54R

HIF3B-34D-2.54R

HIF3B-40D-2.54R

HIF3B-50D-2.54R

HIF3B-60D-2.54R

HIF3B-64D-2.54R

Number of Contacts

6

10

14

16

20

26

30

34

40

50

60

64

A

12.19

17.27

22.35

24.89

29.97

37.59

42.67

47.75

55.37

68.07

80.77

85.85

B

5.08

10.16

15.24

17.78

22.86

30.48

35.56

40.64

48.26

60.96

73.66

78.74

C

6.35

11.43

16.51

19.05

24.13

31.75

36.83

41.91

49.53

62.23

74.93

80.01

D

7.72

12.80

17.88

20.42

25.50

33.12

38.2

43.28

50.90

63.6

76.3

81.38

Polarizing Guide

(Note 1)

None

One on left side

One on right and

left sides, resp.

B20

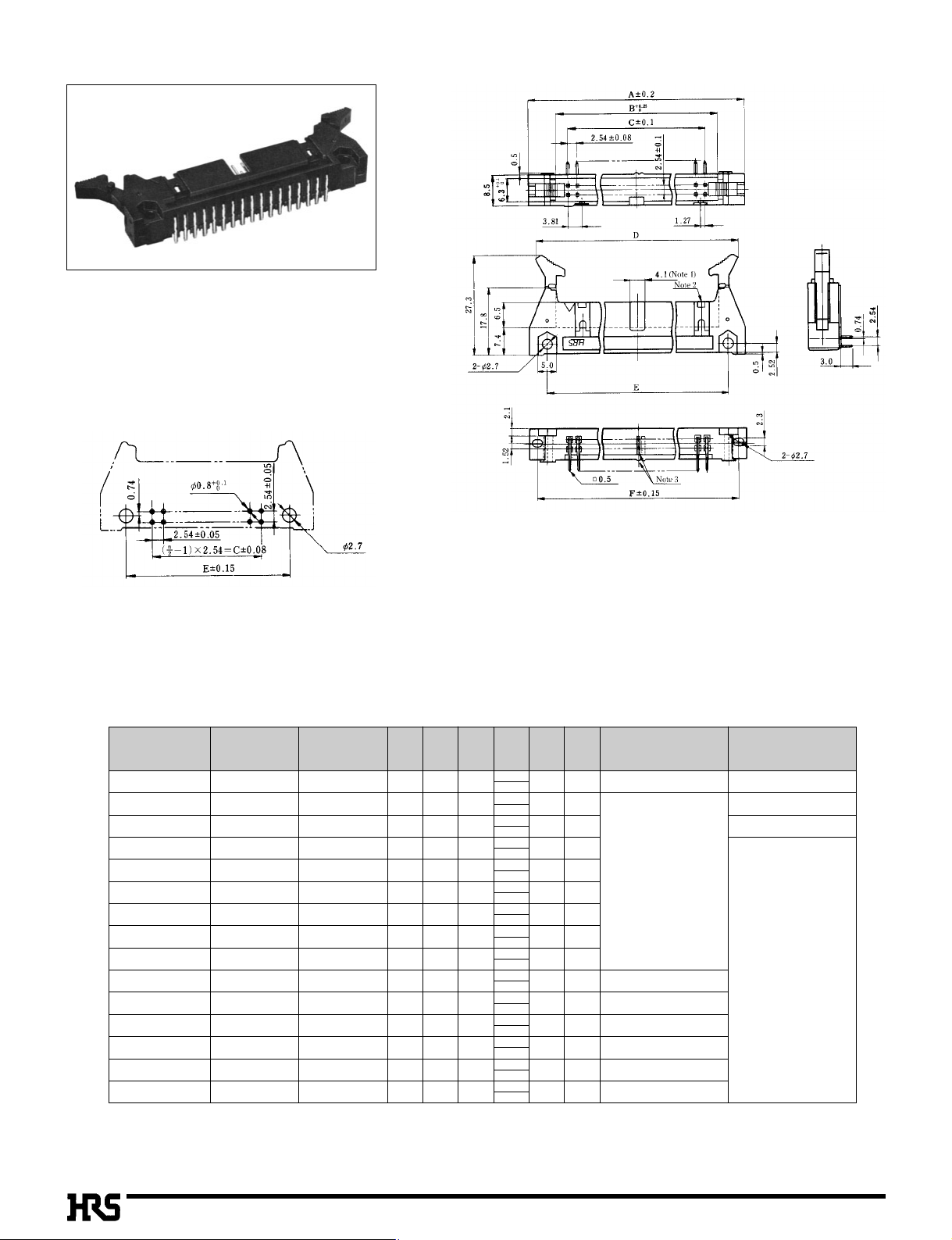

■Four Wall Angle Through hole

BPCB mounting pattern

Note 1, Note 2: The number of polarizing slot and key installed positions

changes according to products. Refer to the list as shown below.

Note 3: The spacer moves to the right according to the number of

contacts.

Note 4: The 10, 50, 60 and 64 contact connectors contain two types of

polarizing slots.

Use products, referring to (Note 1) (Note 2).

■

n=number of contacts

Unit:mm

★

★

★

★

★

★

★

★

★

★

★

★

★

★

The products marked with ★comply with MIL standard.

CL No.Part Number

610-0091-2

610-0171-0

610-0092-5

610-0093-8

610-0094-0

610-0095-3

610-0096-6

610-0097-9

610-0098-1

610-0099-4

610-0131-5

610-0100-1

610-0132-8

610-0101-4

610-0133-0

HIF3BA-10PA-2.54DS

HIF3BD-10PA-2.54DS

HIF3BA-14PA-2.54DS

HIF3BA-16PA-2.54DS

HIF3BA-20PA-2.54DS

HIF3BA-26PA-2.54DS

HIF3BA-30PA-2.54DS

HIF3BA-34PA-2.54DS

HIF3BA-40PA-2.54DS

HIF3BA-50PA-2.54DS

HIF3BB-50PA-2.54DS

HIF3BA-60PA-2.54DS

HIF3BB-60PA-2.54DS

HIF3BA-64PA-2.54DS

HIF3BB-64PA-2.54DS

Number of Contacts

10

10

14

16

20

26

30

34

40

50

50

60

60

64

64

A

32.0

32.0

37.1

39.6

44.7

52.3

57.4

62.5

70.1

82.8

82.8

95.5

95.5

100.6

100.6

B

17.5

17.5

22.6

25.1

30.2

37.8

42.9

48.0

55.6

68.3

68.3

81.0

81.0

86.1

86.1

C

10.16

10.16

15.24

17.78

22.86

30.48

35.56

40.64

48.26

60.96

60.96

73.66

73.66

78.74

78.74

E

21.8

21.8

26.9

29.5

34.5

42.2

47.2

52.3

59.9

72.6

72.6

85.3

85.3

90.4

90.4

27.9

27.9

33.0

35.5

40.6

48.3

53.3

58.4

66.0

78.7

78.7

91.4

91.4

96.5

96.5

F

Polarizing Slot

(Note 1)

None

One at center

One on right and left sides, resp.

One at center

One on right and left sides, resp.

One at center

One on right and left sides, resp.

One at center

Polarizing Key Install

(Note 2)

One on right side

None

One on right side

One on right and

left sides, resp.

D

28.14

MAX51.1

28.14

MAX51.1

33.24

MAX56.2

35.74

MAX58.7

40.84

MAX63.8

48.44

MAX71.4

53.54

MAX76.5

58.64

MAX81.6

66.24

MAX89.2

78.94

MAX101.9

78.94

MAX101.9

91.64

MAX114.6

91.64

MAX114.6

96.74

MAX119.7

96.74

MAX119.7

B21

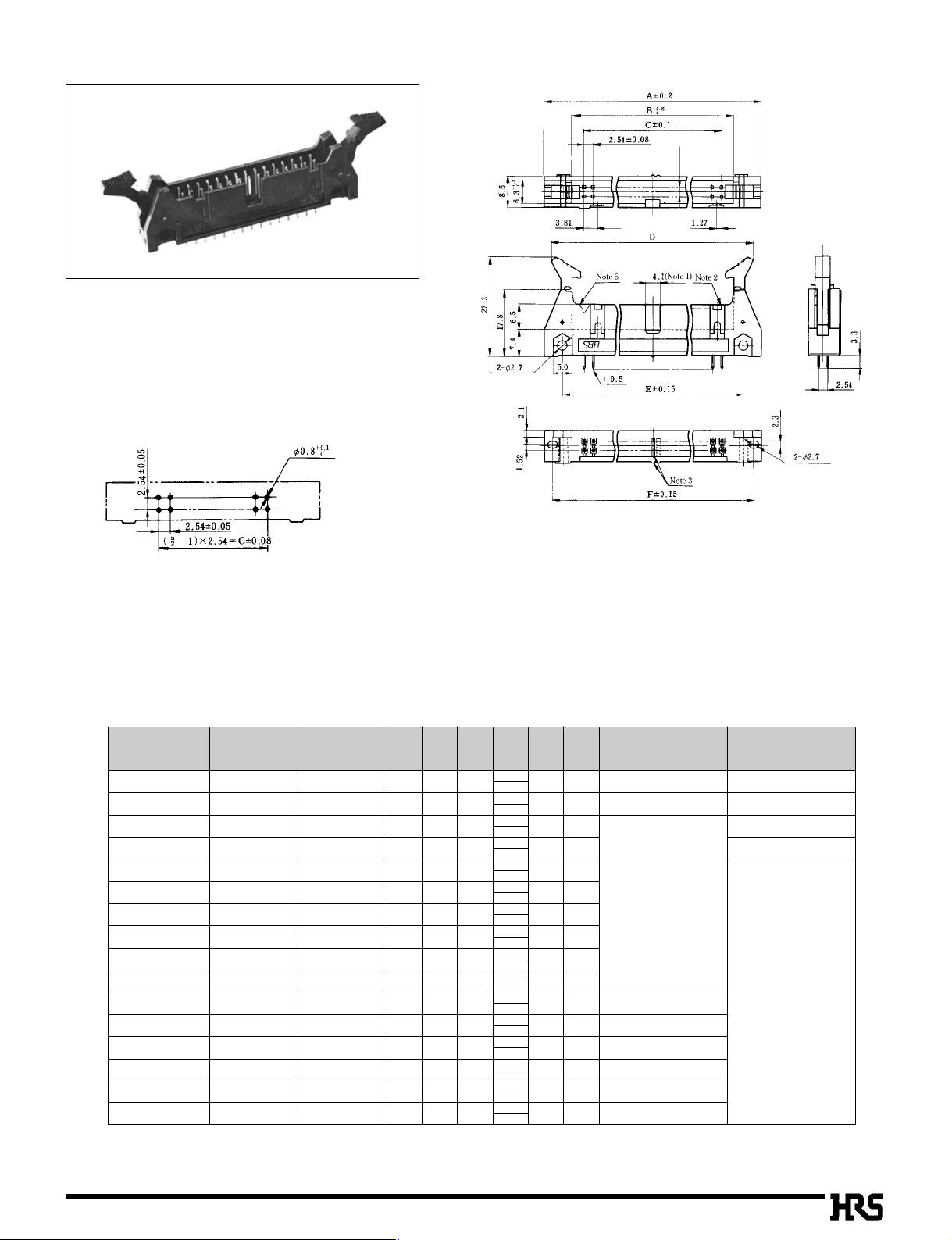

■Four-Wall Straight Through hole

BPCB mounting pattern

Note 1, Note 2: The number of polarizing slot and key installed positions

changes according to products. Refer to the list as shown below.

Note 3: The spacer moves to the right according to the number of

contacts.

Note 4: The 10, 50, 60 and 64 contact connectors contain two types of

polarizing slots.

Use products, confirming (Note 1) (Note 2).

Note 5: The 6 contact has no polarity mark.

■

n=number of contacts

Unit:mm

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

The products marked with ★comply with MIL standard.

CL No.Part Number

562-0503-9

610-0111-8

610-0181-3

610-0112-0

610-0113-3

610-0114-6

610-0115-9

610-0116-1

610-0117-4

610-0118-7

610-0119-0

610-0141-9

610-0120-9

610-0142-1

610-0121-1

610-0143-4

HIF3-6PA-2.54DSA

HIF3BA-10PA-2.54DSA

HIF3BD-10PA-2.54DSA

HIF3BA-14PA-2.54DSA

HIF3BA-16PA-2.54DSA

HIF3BA-20PA-2.54DSA

HIF3BA-26PA-2.54DSA

HIF3BA-30PA-2.54DSA

HIF3BA-34PA-2.54DSA

HIF3BA-40PA-2.54DSA

HIF3BA-50PA-2.54DSA

HIF3BB-50PA-2.54DSA

HIF3BA-60PA-2.54DSA

HIF3BB-60PA-2.54DSA

HIF3BA-64PA-2.54DSA

HIF3BB-64PA-2.54DSA

Number of Contacts

6

10

10

14

16

20

26

30

34

40

50

50

60

60

64

64

A

26.92

32.0

32.0

37.1

39.6

44.7

52.3

57.4

62.5

70.1

82.8

82.8

95.5

95.5

100.6

100.6

B

12.42

17.5

17.5

22.6

25.1

30.2

37.8

42.9

48.0

55.6

68.3

68.3

81.0

81.0

86.1

86.1

C

05.08

10.16

10.16

15.24

17.78

22.86

30.48

35.56

40.64

48.26

60.96

60.96

73.66

73.66

78.74

78.74

E

16.7

21.8

21.8

26.9

29.5

34.5

42.2

47.2

52.3

59.9

72.6

72.6

85.3

85.3

90.4

90.4

22.82

27.9

27.9

33.0

35.5

40.6

48.3

53.3

58.4

66.0

78.7

78.7

91.4

91.4

96.5

96.5

F

Polarizing Slot

(Note 1)

One at center

None

One at center

One on right and left sides, resp.

One at center

One on right and left sides, resp.

One at center

One on right and left sides, resp.

One at center

Polarizing Key Install

(Note 2)

None

One on right side

None

One on right side

One on right and

left sides, resp.

D

23.06

MAX46.02

28.14

MAX51.1

28.14

MAX51.1

33.24

MAX56.2

35.74

MAX58.7

40.84

MAX63.8

48.44

MAX71.4

53.54

MAX76.5

58.64

MAX81.6

66.24

MAX89.2

78.94

MAX101.9

78.94

MAX101.9

91.64

MAX114.6

91.64

MAX114.6

96.74

MAX119.7

96.74

MAX119.7

B22

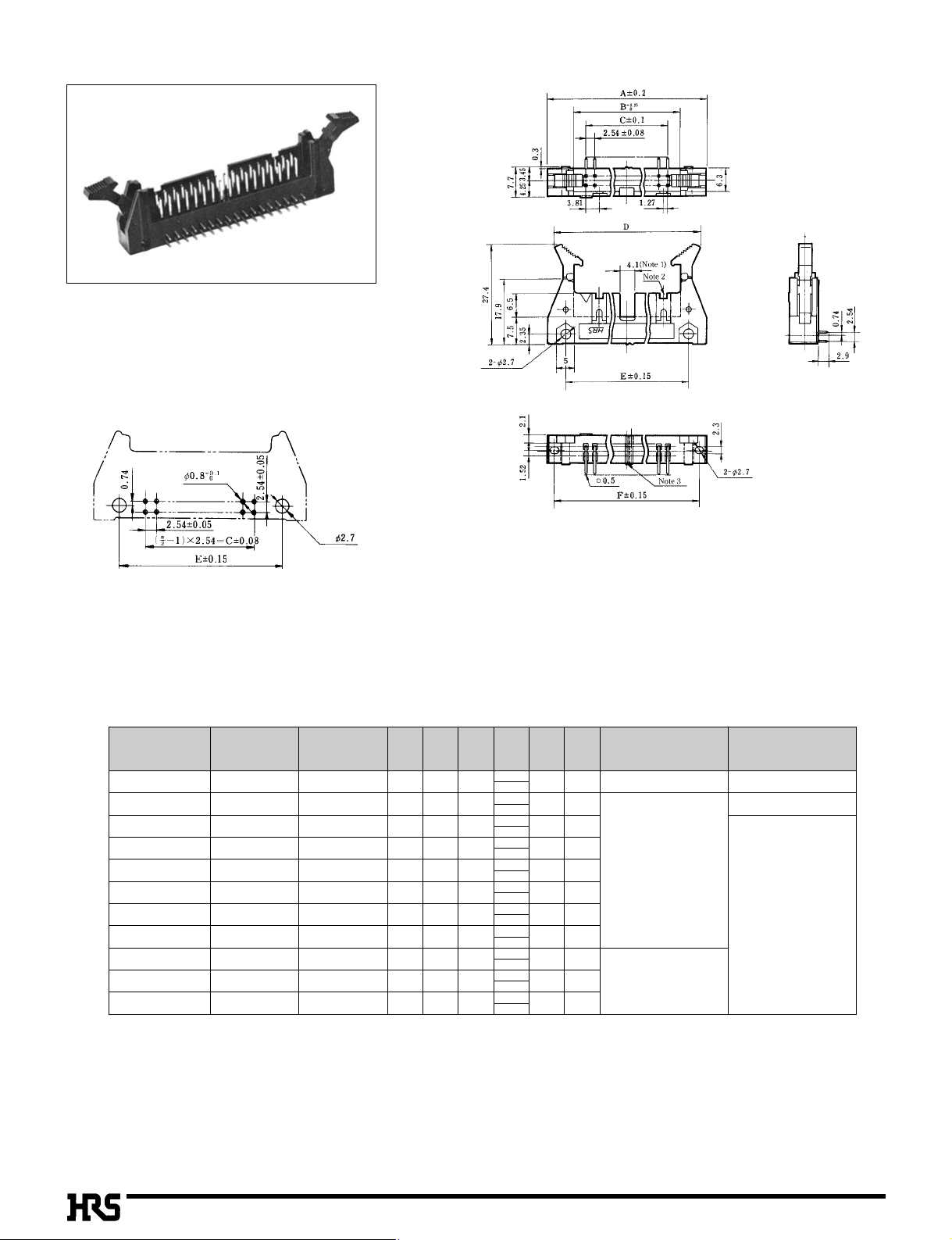

■Three Wall Angle Type

BPCB mounting pattern

Note 1, Note 2: The number of polarizing slot and key installed positions

changes according to products. Refer to the list as shown below.

Note 3: The spacer moves according to the number of contacts.

Note 4: The 10 contact connector consists of two types.

Use products, confirming (Note 1) (Note 2).

Note 5: The 6 contact has no polarity mark.

Note 6: The nut built-in specification product is also provided.

The product can be fixed by M2 screws from the rear side.

Use the screw of (board thickness) +4 mm under the neck.

■

n=number of contacts

Unit:mm

★

★

★

★

★

★

★

★

★

★

The products marked with ★comply with MIL standard.

CL No.Part Number

610-0051-8

610-0151-2

610-0052-0

610-0053-3

610-0054-6

610-0055-9

610-0056-1

610-0057-4

610-0058-7

610-0059-0

610-0060-9

HIF3BD-10PA-2.54DS

HIF3BC-10PA-2.54DS

HIF3BD-16PA-2.54DS

HIF3BD-20PA-2.54DS

HIF3BD-26PA-2.54DS

HIF3BD-30PA-2.54DS

HIF3BD-34PA-2.54DS

HIF3BD-40PA-2.54DS

HIF3BD-50PA-2.54DS

HIF3BD-60PA-2.54DS

HIF3BD-64PA-2.54DS

Number of Contacts

10

10

16

20

26

30

34

40

50

60

64

A

32.0

32.0

39.6

44.7

52.3

57.4

62.5

70.1

82.8

95.5

100.6

B

17.5

17.5

25.1

30.2

37.8

42.9

48.0

55.6

68.3

81.0

86.1

C

10.16

10.16

17.78

22.86

30.48

35.56

40.64

48.26

60.96

73.66

78.74

E

21.8

21.8

29.5

34.5

42.2

47.2

52.3

59.9

72.6

85.3

90.4

27.9

27.9

35.5

40.6

48.3

53.3

58.4

66.0

78.7

91.4

96.5

F

Polarizing Slot

(Note 1)

None

One at center

One on right and left sides, resp.

Polarizing Key Install

(Note 2)

One on right side

None

One on right and

left sides, resp.

D

28.14

MAX51.1

28.14

MAX51.1

35.74

MAX58.7

40.84

MAX63.8

48.44

MAX71.4

53.54

MAX76.5

58.64

MAX81.6

66.24

MAX89.2

78.94

MAX101.9

91.64

MAX114.6

96.74

MAX119.7

B23

■Three Wall Straight Through hole

BPCB mounting pattern

Note1,Note2: The number of polarizing slot and key installed positions

changes according to products. Refer to the list as shown

below.

Note3: The spacer moves to the right according to the number of

contacts.

Note4: The 10 contact connector consists of two types.

Use products, referring to (Note 1) and (Note 2).

Note5: The 6 contact has no polarity mark.

■

n=number of contacts

Unit:mm

★

★

★

★

★

★

★

★

★

★

The products marked with ★comply with MIL standard.

CL No.Part Number

610-0071-5

610-0161-6

610-0072-8

610-0073-0

610-0074-3

610-0075-6

610-0076-9

610-0077-1

610-0078-4

610-0079-7

610-0080-6

HIF3BD-10PA-2.54DSA

HIF3BC-10PA-2.54DSA

HIF3BD-16PA-2.54DSA

HIF3BD-20PA-2.54DSA

HIF3BD-26PA-2.54DSA

HIF3BD-30PA-2.54DSA

HIF3BD-34PA-2.54DSA

HIF3BD-40PA-2.54DSA

HIF3BD-50PA-2.54DSA

HIF3BD-60PA-2.54DSA

HIF3BD-64PA-2.54DSA

Number of Contacts

10

10

16

20

26

30

34

40

50

60

64

A

32.0

32.0

39.6

44.7

52.3

57.4

62.5

70.1

82.8

95.5

100.6

B

17.5

17.5

25.1

30.2

37.8

42.9

48.0

55.6

68.3

81.0

86.1

C

10.16

10.16

17.78

22.86

30.48

35.56

40.64

48.26

60.96

73.66

78.74

E

21.8

21.8

29.5

34.5

42.2

47.2

52.3

59.9

72.6

85.3

90.4

27.9

27.9

35.5

40.6

48.3

53.3

58.4

66.0

78.7

91.4

96.5

F

Polarizing Slot

(Note 1)

None

One at center

One on right and left sides, resp.

Polarizing Key Install

(Note 2)

One on right side

None

One on right and

left sides, resp.

D

28.14

MAX51.1

28.14

MAX51.1

35.74

MAX58.7

40.84

MAX63.8

48.44

MAX71.4

53.54

MAX76.5

58.64

MAX81.6

66.24

MAX89.2

78.94

MAX101.9

91.64

MAX114.6

96.74

MAX119.7

Loading...

Loading...