HRS FH17 Service Manual

25

Low Profile 0.5mm Pitch Connectors For FPC

FH17 Series

■Features

1. Low profile 0.5mm pitch FPC connectors

As products become lighter/thinner/shorter/smaller, requests for

thinly-made type FPC connectors are rapidly increasing. The FH17

Series is an ultra miniature version of the Hirose’s popular FH12

Series. FH17 has 35

%

-

45

% lower profile above the board.

*

FH17 : On-board type, height of 1.3 mm from board surface

*

FH17L: Offset standard type, height of 1.0 mm from board surface

*

FH17LR: Offset reverse type, height of 1.0 mm from board surface

2. Easy to use Flip-Lock Actuator

Flip-lock (rotating type) ZIF mechanism enables good connectivity

of FPC by a simple operation and light force. No board space is

required for flip lock operation as compared to slide lock ZIF

connectors.

3. Variety of Sizes and Options

In addition to the on-board type (FH17), board drop-in types (FH17L

and FH17LR) are also available. Selection will depend on the

application mounting. Connectors are available with 8 to 30

contacts.

4. Adaptable to thin-type FPC

It conforms to the thin-type FPC (0.17mm)now being used for small

size electronic equipment such as cameras, etc.

(Thin-type FPC: Specifications without stiffener of double-faced

FPC will reduce the cost of FPC. A single-faced FPC still requires

stiffener, but the reduced thickness is easier for manufacturers to

produce.

5. Packaged for Pick-and-Place machine

Embossed tape packaging allows automatic mounting.

■Applications

Mobile telephones, devices using LCDs, CD-ROMs, cameras, other

miniature devices

FH17L(board drop-in standard type)flip-lock mechanism

FH17LR (board drop-in reverse type) flip-lock mechanism

FH17 (on-board type) flip-lock mechanism

(

查询FH17-10S-0.5SH供应商查询FH17-10S-0.5SH供应商

26

■Product Specifications

100V DC

150V AC/1 minute

20 cycles

1mA

Frequency: 10 to 55 Hz, single amplitude of 0.75 mm,

2 hours in each of the 3 directions.

Acceleration of 490 m/s

2

, 11 ms duration,

sine half-wave waveform, 3 cycles in each of the 3 axis.

96 hours at temperature of 40ç and humidity of 90% to 95%

5 cycles under conditions as follows; Temperature:

-40ç / 15 to 35ç / 85ç / 15 to 35ç,

Time: 30 / 5 max. / 30 / 5 max.(minutes)

Reflow: At the recommended temperature profile

Manual soldering: 350±5ç for 3 seconds

Applicable FPC

t=0.17 Tin-lead plating

+0.03

-0.04

Item

1.

Insulation resistance

2.

Withstanding voltage

4.Durability

(Insertion/withdrawal)

3.Contact resistance

5.Vibration

6.Shock

7.Humidity

(Steady state)

8.

Temperature cycle

9.Resistance to

soldering heat

Specification

500M ohms minimum

No flashover or insulation breakdown.

50m ohms maximum

Contact resistance : 50m ohms maximum

No damage, cracks, or parts dislocation.

No electrical discontinuity of 1µs or more

Contact resistance: 50m ohms maximum.

No damage, cracks, or parts dislocation.

No electrical discontinuity of 1µs or more

Contact resistance: 50m ohms maximum

No damage, cracks, or parts dislocation.

Contact resistance: 50m ohms maximum

Insulation resistance: 50M ohms minimum

No damage, cracks, or parts dislocation.

Contact resistance: 50m ohms maximum

Insulation resistance: 50M ohms minimum

No damage, cracks, or parts dislocation.

No deformation of components affecting performance.

Conditions

(Note:4)

FH17L - 30S - 0.5 SH (05

)

1 2 3 4 5 6

■Ordering Information

Remarks

--------------

--------------

UL94V-0

UL94V-0

■Material

Part

Contact

Metal fittings

Insulated tape

Insulator

Insulator

Material

LCP

PPS

Phosphor bronze

Brass

Polyamide

Finish

--------------

-------------Tin-lead plating

Tin-lead plating

--------------

2

3

4

5

6

1

Ratings

Current rating

Voltage rating

0.4A DC

50V AC

Operating temp. range

Operatinghumidity range

-40 to +70ç(Note.1)

relative humidity 90% max.

(No dew-fall)

Storage temp. range

Storage Humidity range

-10 to +50ç(Note.2)

relative humidity 90% max.

(No dew-fall)

Note 1: Includes temperature rise caused by current flow.

Note 2: The term "storage" refers to products stored for long period of time prior to mounting and use. Operating Temperature Range and

Humidity range covers nonconducting condition of installed connectors in storage, shipment or during transportation.

Note 3. The above standards represent this series. The individual formal agreement should be based on the Specification.

Series Name FH17

Mounting Type None : On-Board type

L : Offset type

LR : Offset reverse type

Number of Contacts 8, 10, 15, 20, 24, 30

Contacts Pitch 0.5mm

Contact Style

SH : SMT horizontal mounting type

Plating specifications Blank : Tin-lead plating

(05)

: Gold plating

27

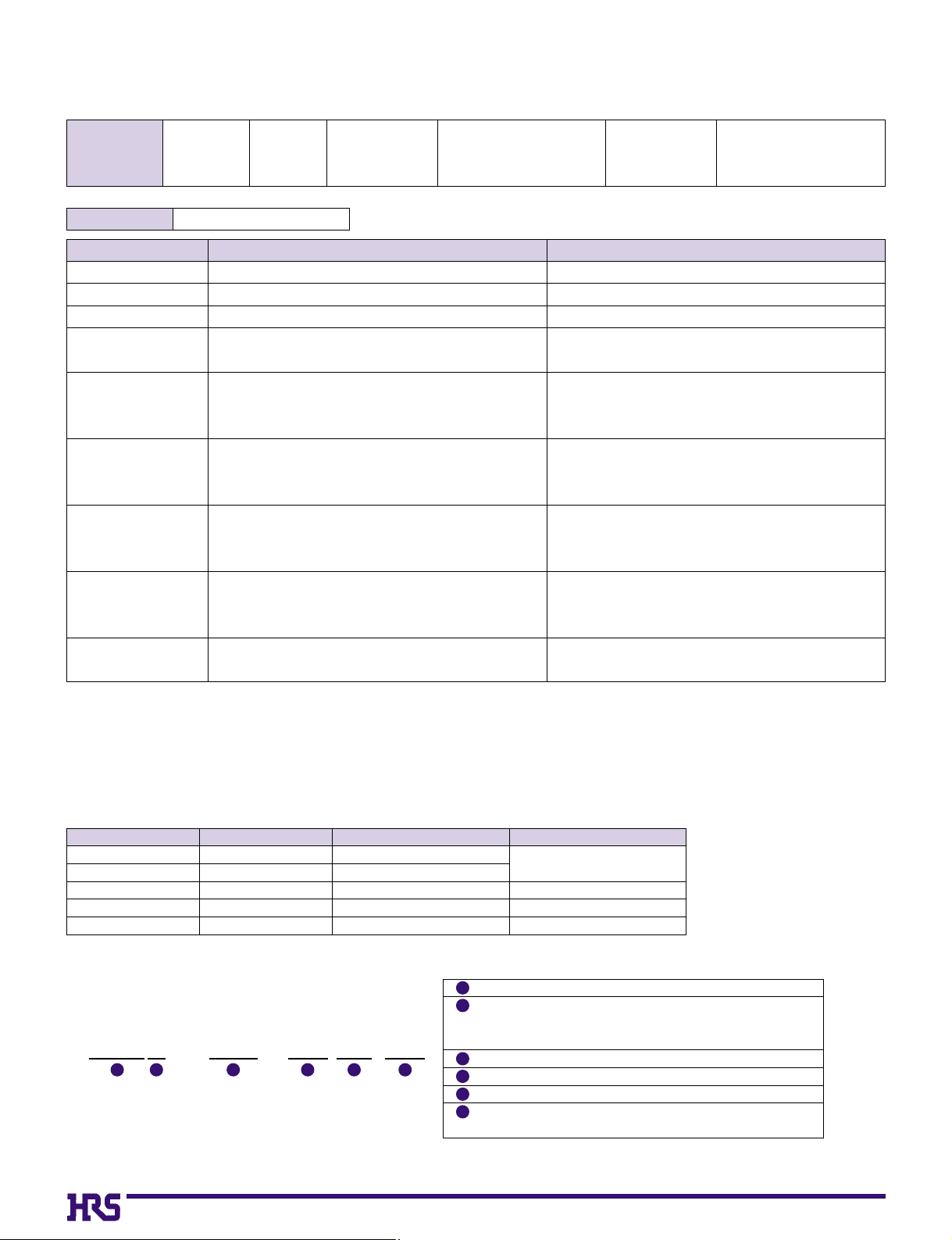

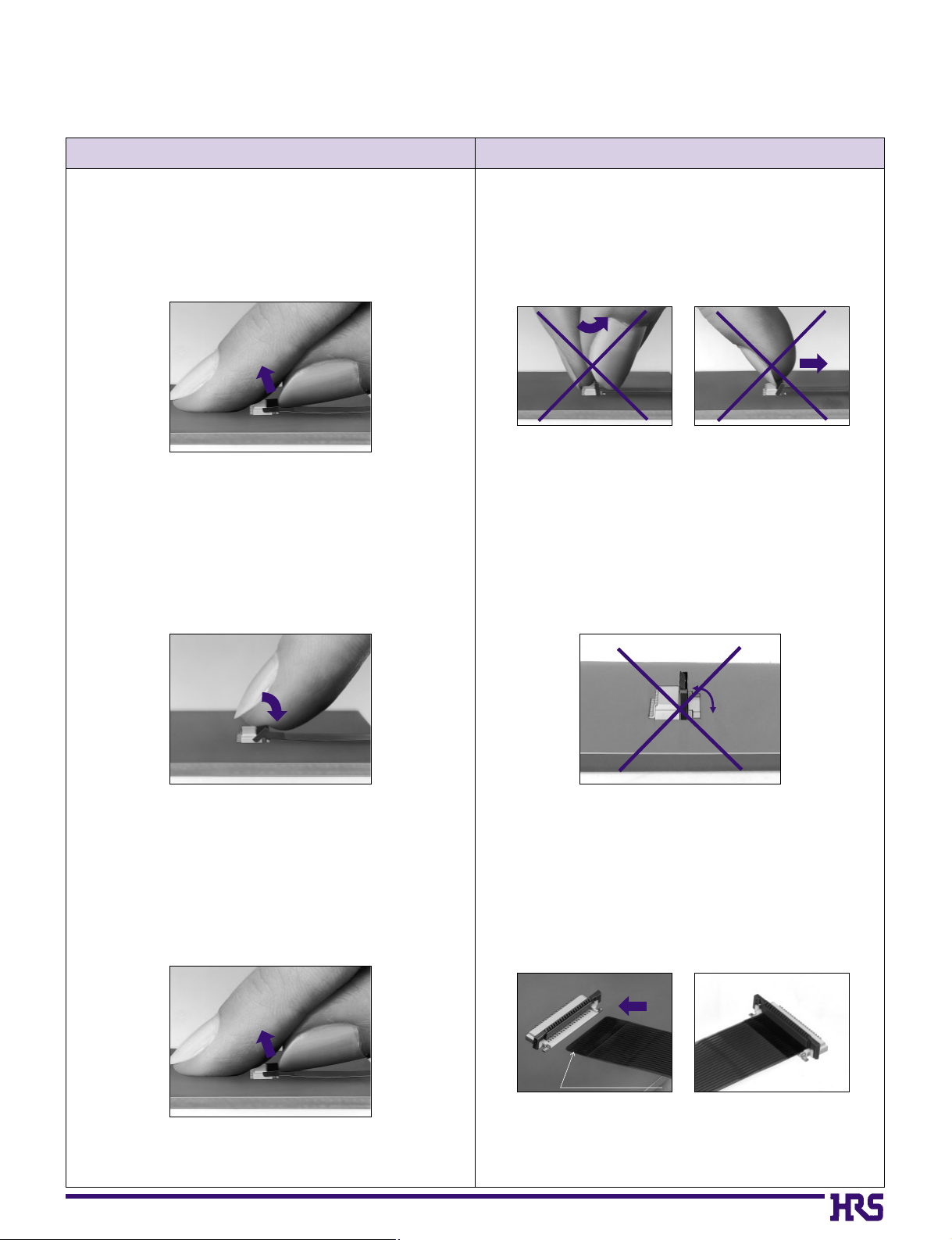

BConnector Operating Instructions, precautions and recommendations

Operation Precautions

1.FPC Termination procedure. Connector

installed on the board.

1) Lift up the actuator. Use thumb or index finger.

2) Rotate down the actuator until firmly closed.

It is critical that the inserted FPC is not moved and

remains fully inserted. Should the FPC be moved,

open the actuator and repeat the process, starting

with Step 1 above.

2) The connector will assure reliable performance

when the actuator is open to 90° maximum (see

fig.1) Do not exceed this angle, as this may cause

permanent damage to the connector.

2.FPC Removal

1) Lift up the actuator.

2) Carefully remove the FPC.

3) Assure that the FPC is fully inserted parallel to

mounting surface, with the exposed conductive

traces facing down.

FPC conductor surface

(Bottom side)

1) Do not apply excessive force or use any type of

tool to operate the actuator.

28

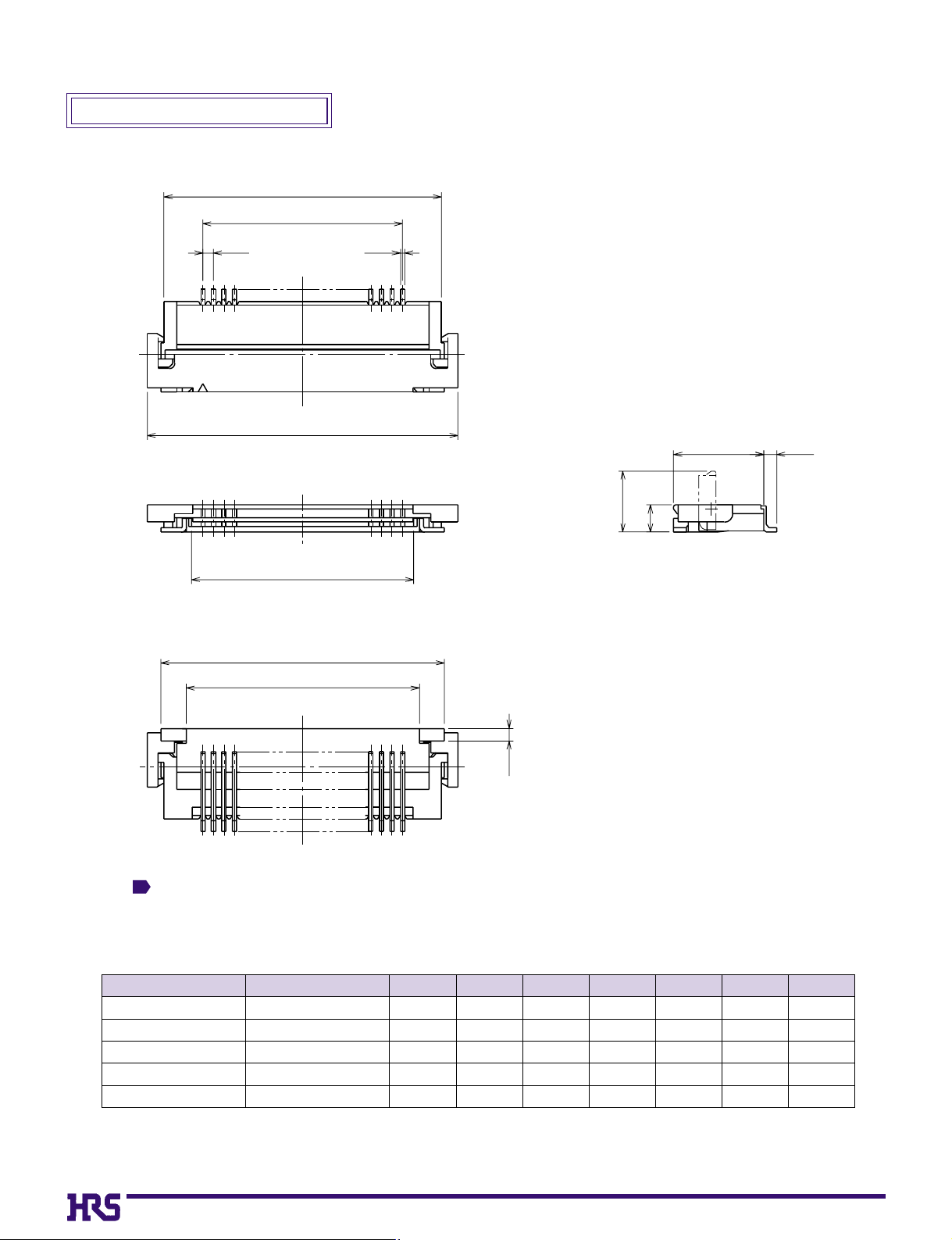

Note The coplanarity of each lead and metal fitting is within 0.1.

On-Board Type (FH17

)

(mm)

Note:Embossed tape reel packaging(2,000 pieces/reel).

Order by number of reels.

Part Number

FH17-10S-0.5SH

FH17-15S-0.5SH

FH17-20S-0.5SH

FH17-24S-0.5SH

FH17-30S-0.5SH

586-0638-8

586-0657-2

586-0637-5

586-0645-3

586-0625-6

10

15

20

24

30

08.2

10.7

13.2

15.2

18.2

04.5

07.0

09.5

11.5

14.5

09.8

12.3

14.8

16.8

19.8

05.57

08.07

10.57

12.57

15.57

08.5

11.0

13.5

15.5

18.5

06.1

08.6

11.1

13.1

16.1

CL No.

Number of

Contacts

A B C D E F

1

A

B

0.5

0.2

C

4.3

2.9

1.3

D

E

F

0.6

0.6

Loading...

Loading...