HRS DF7 Service Manual

1

3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TÜV Listed)

DF7 Series

2004.7

■Features

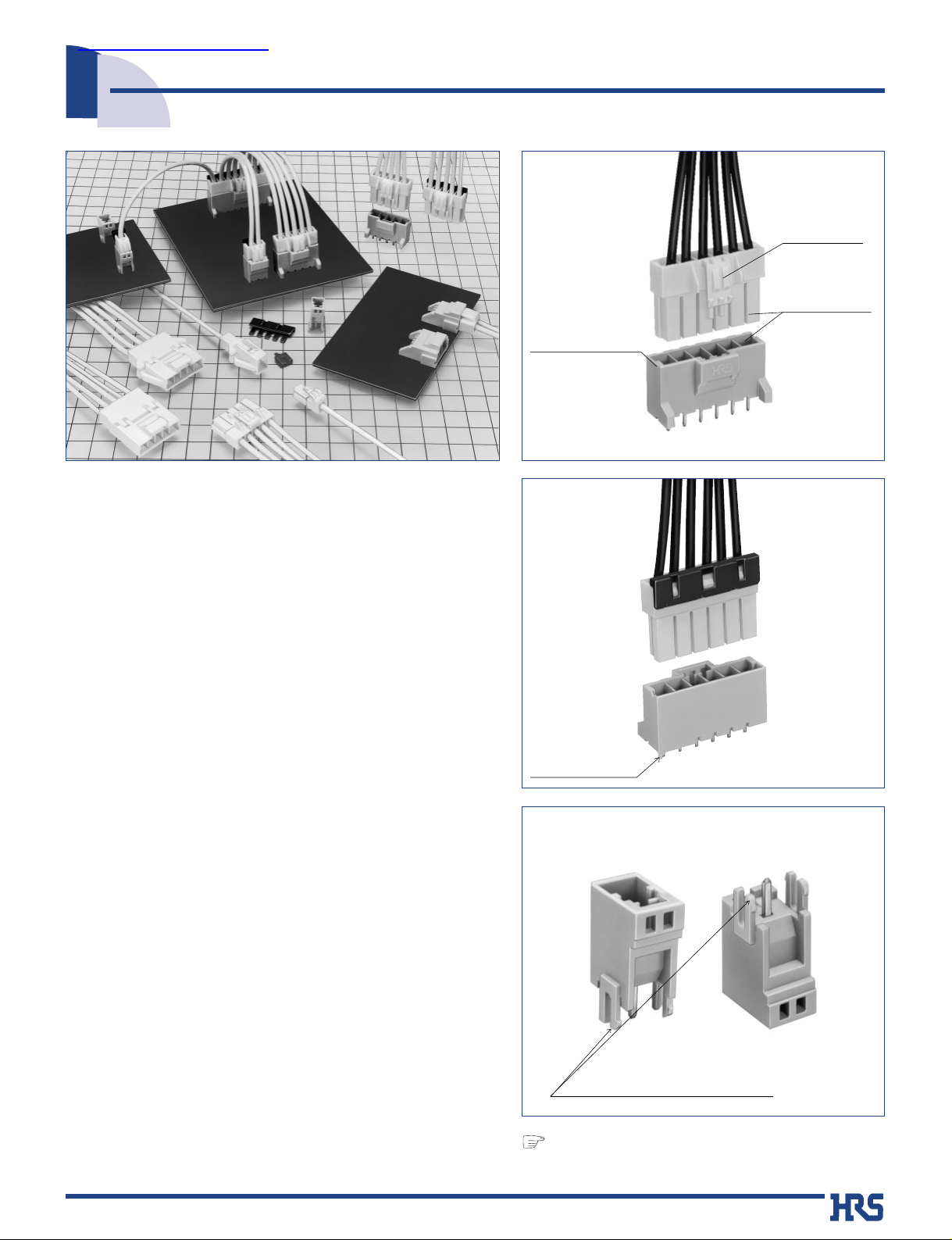

1. Complete Locking Function

Reliable interior lock protects mated connectors from

accidental disconnection.

2. Increased Contact Retention of Crimped

Contacts and Prevention of Incomplete

Insertion

Separate contact retainer increases the contact

retention, assures and visually confirms the complete

contact insertion.

3. Molded-in Contact Retention Tabs

Handling of terminated contacts during the assembly and

termination is easier and avoids entangling of wires,

since there are no protruding metal tabs.

4. Incorrect Insertion Prevention

Connectors are polarized to assure correct mating with

corresponding parts.

5.Solder Crack Prevention

Glass reinforced resin is used in the pin header bodies to

prevent solder cracks caused by the heat shrinkage.

6. Prevention of Incorrect Board Placement

Built-in locating posts assure correct connector

placement and orientation on the board.(2-12 pos.)

7. Supports Sealing after Installation.

Sealing compound can be applied to the board installed

connector for distance of 6 mm max. from the mounting

surface (9 mm max. for single position).

8.Cost Effective Tooling

The same crimping tools are used to terminate socket

and pin contacts.

9. Prevention of Short Circuits between

Adjacent Contacts

Each contact is completely surrounded by the insulator

housing, electrically isolating it from adjacent contacts.

Completely

enclosed

locking system

Complete

Locking

Function

Board Eyelet mounting

One pos. type can also be mounted

to boards that have eyelets.

Continued.

Guide post

Prevention of

Incorrect Connections

Full barrier

between adjacent

contacts.

查询DF7-1618PC供应商

2

■Ordering information

DF7 -

**

Series name: DF7, DF7A, DF7E

Number of contacts: 1 to 5

Connector type

S: Socket

DS: Double-row socket

P: Header

DP: Double-row Header

EP: In-line plug

RS/P: Retainer

Contact pitch: 3.96mm(7.92 mm)

Type of housing: header

C: Crimp housing

DSA: Straight header

DS: Right-angle header

Blank: Retainer

1

2

3

4

5

Applicable Conductor

1618: AWG 16 to AWG 18

2022: AWG 20 to AWG 22

2426: AWG 24 to AWG 26

Packaging

SCF: Socket contacts / Reel

SC: Socket contacts / Bag

PCF: Plug contacts / Reel

PC: Plug contacts / Bag

6

7

1 6

SCF

7

DF7 -

*

S-3.96 C

1 2 3 4 5

10. 10 A maximum Current

Connector can carry current of 10 A per contact with

#16 AWG conductor.Refer to page 3 for current

ratings for multi-position connectors using other

conductor sizes.

11. Color Variations

1 pos. is available in a standard 3 colors: natural,

blue, and red.

12. Supports Eyelets

1 pos. can be mounted to boards which have eyelets

attached.

■Applications

Office equipment, power supplies for industrial, medical

and instrumentation applications, variety of consumer

electronic and electrical applications.

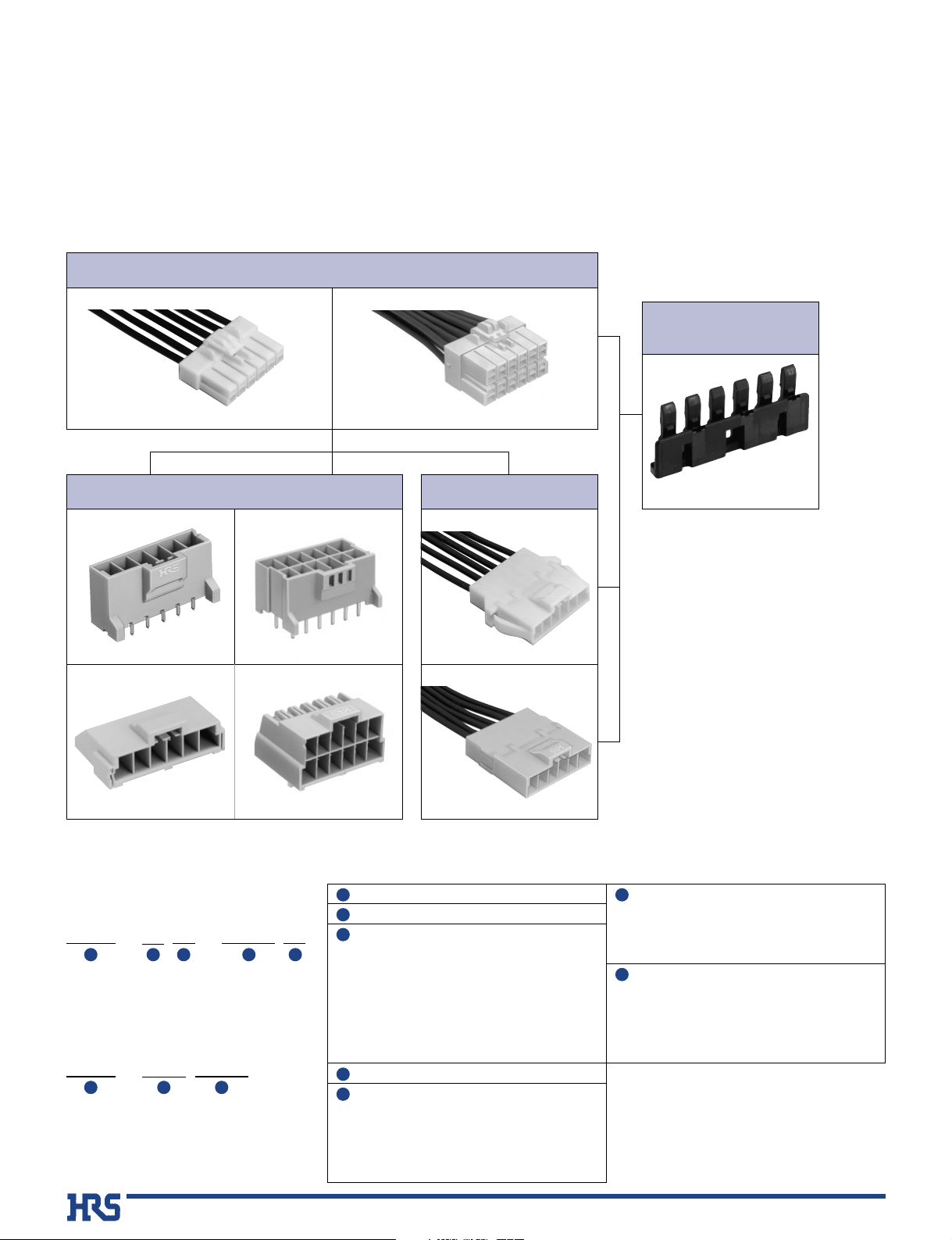

Crimp Sockets

Header

Refer to page 4 for details.

●

Single row, straight type

●

Single row, right angle type

Refer to page 5 for details.

Refer to page 11 for details.

●

Double rows, straight type

●

Double row, right angle type

Refer to page 11 for details.

In-line plug

●Panel lock type

Shown with

terminated and installed contacts.

Refer to page 7 for details.

Shown with

terminated and installed contacts.

Refer to page 6 for details.

Retainer

(optional, order separately)

Refer to page 10 for details.

●Single row ●Double rows

Shown with terminated

and installed contacts.

Refer to page 8, 9 for details.

Shown with terminated

and installed contacts.

Refer to page 12 for details.

●

Socket, Header

●

Contacts

3

■Materials

Product

Sockets

Headers

In-line plug

Retainer

Crimp contacts

Part

Insulator

Insulator

Contact

Insulator

Insulator

Contacts

Material

Polyamide

Polyamide

(Glass reinforced)

High conductivity copper alloy

Polyamide

Polyamide

High conductivity copper alloy

Finish

Color: White

Color: Beige (Single row)

Color: Grey (Double row)

Tin-lead plating (Note)

Color: White

Color: Black

Tin plating (Note)

Remarks

UL94V-0

UL94V-0

---------------UL94V-0

UL94V-0

----------------

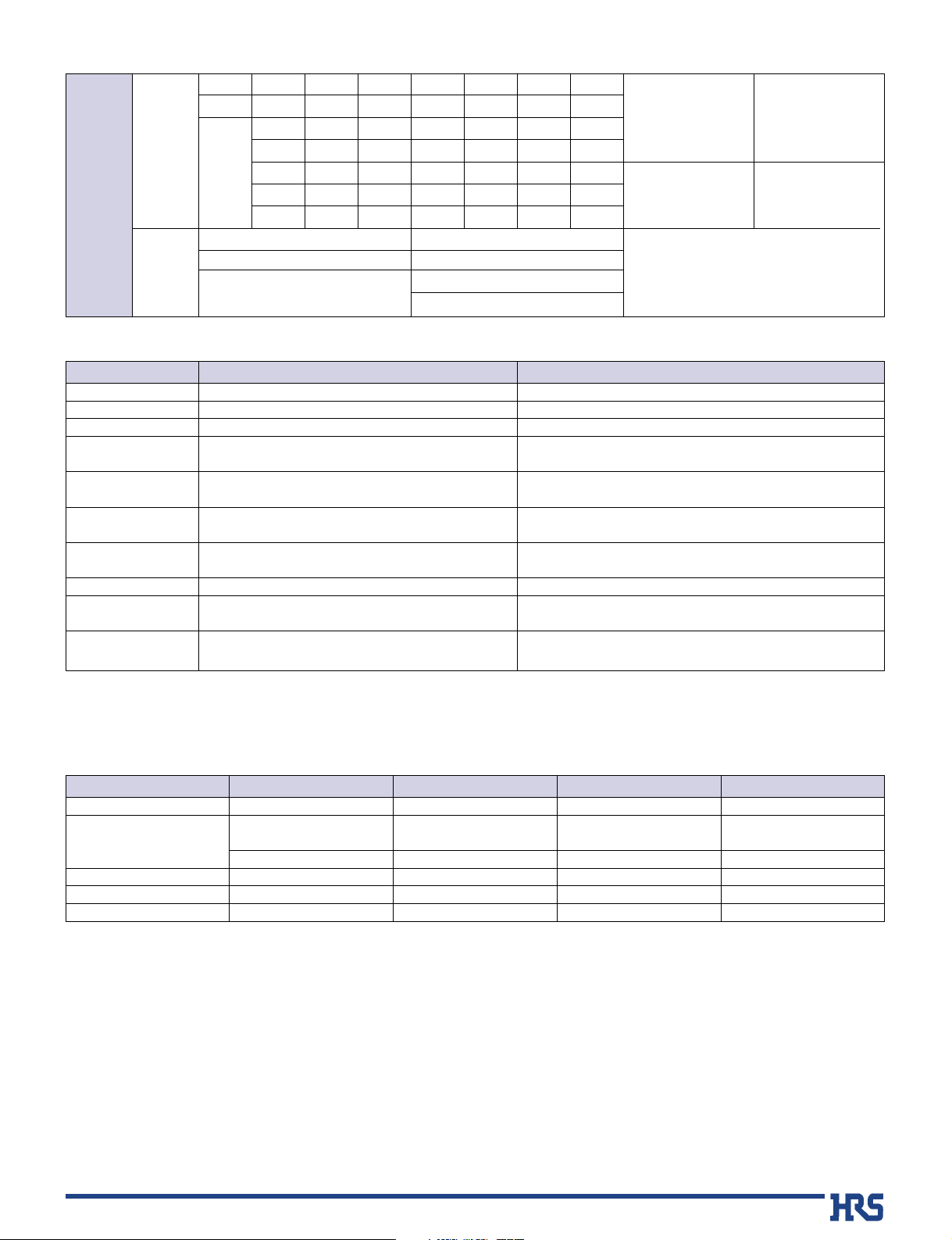

■Product Specifications

Ratings

Current

rating

Row

No. of contacts

AWG16 AWG18 AWG20 AWG22 AWG24 AWG26

1 2~10 10A 7A 5A 4A 4A 3A

4 10A 9A 7A 6A 4A 3A

6 9A8A6A5A4A3A

2 8 9A 8A 6A 5A 4A 3A

10 8A 7A 5A 4A 4A 3A

12 8A 7A 5A 4A 4A 3A

Operating temperature range

Operating humidity range

Storage temperature range

Storage humidity range

-10çto 60ç (Note 2)

40% to 70% (Note 2)

-35ç to 85ç (Note 1)

20% to 80%

Voltage

rating

Specificatoin

UL/C-UL

TÜV

AC630V

AC/DC 600V

AC/DC 600V(7.92mm pitch)

AC/DC 300V (3.96mm pitch)

UL/C-UL/TÜV

UL

C-UL

TÜV

File No.and Recognition No

:E52653

:E52653

:R9750437

10 m ohms max. 20mV max., 1mA

500 V DC

1500 V AC for 1 minute

Measured with a steel pin of 0.64 x 1.2 ± 0.002 mm

Contact resistance of 20 m ohms max.

Frequency 10 to 55 Hz, single amplitude of 0.75 mm, 3 axis, 2

hours

Acceleration of 490 m/s

2

, 11 ms duration, sine half-wave

waveform, 3 cycles in each of the 3 axis.

Temperature 40

ç ± 2ç, 90% to 95% RH, 96 hours

(-55ç: 30 minutes →5 to 35ç: 5 minutes →85ç: 30 minutes →5

to 35ç: 5 minutes) for 5 cycles

Flow solder temperature 250ç, 10 seconds

Manual soldering: Soldering iron temperature 300ç, 3 seconds

Contact resistance(Initial value)

1000 M ohms min.

No flashover or Insulator breakdown

0.3N min., 4.5N max.

30 cycles

No momentary disconnections of 1 µs min.

No electrical discontinuity of 1 µs. min.

Contact resistance 20 m ohms max.

Contact resistance of 20 m ohms max.

No deformation of the insulator parts affecting

performance

11. Contact resistance

12.

Insulator resistance

13.

Withstanding voltage

14.

Insertion-Extraction force

(per contact)

15. Durability

(mating/unmating)

16. Vibration

17. Shock

18. Humidity

19. Temperature cycle

10. Resistance to

soldering heat

Item Specification Condition

Note 1: Includes temperature rise caused by the current flow.

Note 2: The term “storage” refers to products stored for long period of time prior to mounting and use. Operating Temperature Range

and Humidity range covers non- conducting condition of installed connectors in storage, shipment or during transportation.

Note: Hirose Electric's plating incorporates anti-whisking compounds.

4

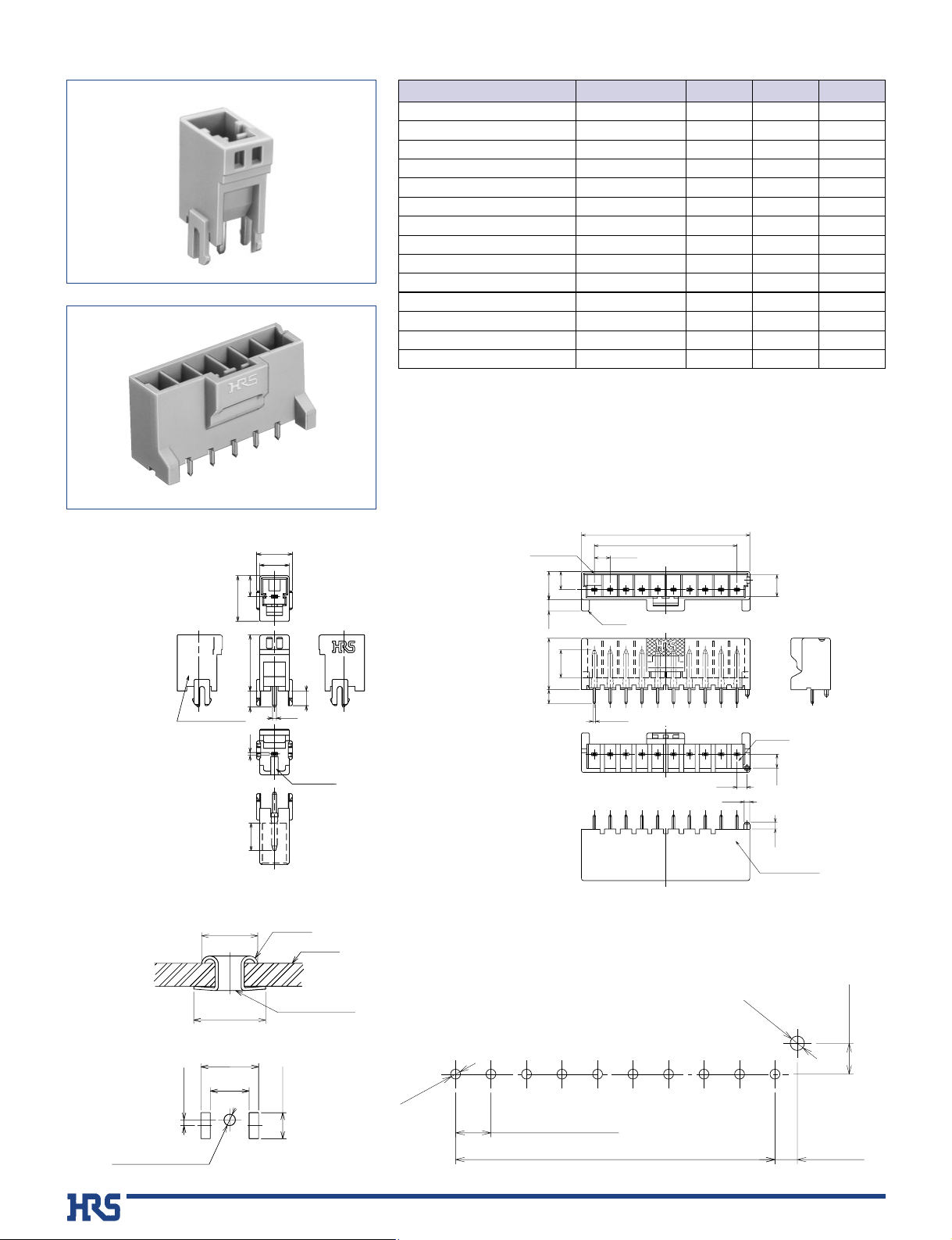

■ Straight header

B PCB mounting pattern (Board thickness: 1.6 ± 0.1)

Cavity No.

B

DF7

3.45

2.49

Ø1.4

1.7

12.9

3.5

7

M0.64

A

B

P=3.96

5.5

4.55

7.12.8

(Note2)

10

No. of contacts

indicator (Note3)

6L09

Production Lot No.

P=3.96±0.05(7.92±0.05)

3.45±0.05

2.49±0.05

B±0.1

Ø1.1

+0.1

0

Ø1.6

+0.1

0

0.64

7.8

6

6.44

9.9

12.23.5

3.2

0.84

Cavity No.

1

A

9E26

7.8

6

4.55

Production Lot No.

9E26

Board

Ø3.9 MAX

Ø5 MAX

0.8±0.1

5.4

+0.1

_0.3

8±0.1

3.6±0.1

Eyelet

Soldering side

Note 5: One pos. type can also be mounted to boards

that have installed eyelets.

Ø1.6

+0.15

_0.25

mm Without eyelet

for eyelet

1.4

+0.1

_ 0

1 Pos. 2 to 10 Pos.

1 Pos.

2 to 10 Pos.

1 Pos.

2 to 10 Pos.

CL No.

CL680-0133-1

CL680-0036-5

CL680-0037-8

CL680-0038-0

CL680-0039-3

CL680-0040-2

CL680-0041-5

CL680-0042-8

CL680-0043-0

CL680-0044-3

CL680-0108-4

CL680-0109-7

CL680-0110-6

CL680-0111-9

DF7- 1P-3.96DSA

DF7- 2P-3.96DSA

DF7- 3P-3.96DSA

DF7- 4P-3.96DSA

DF7- 5P-3.96DSA

DF7- 6P-3.96DSA

DF7- 7P-3.96DSA

DF7- 8P-3.96DSA

DF7- 9P-3.96DSA

DF7-10P-3.96DSA

DF7- 2P-7.92DSA

DF7- 3P-7.92DSA

DF7- 4P-7.92DSA

DF7- 5P-7.92DSA

1

2

3

4

5

6

7

8

9

10

2

3

4

5

-------------

10.40

14.36

18.32

22.28

26.24

30.20

34.16

38.12

42.08

14.36

22.28

30.20

38.12

-------------

3.96

7.92

11.88

15.84

19.80

23.76

27.72

31.68

35.64

7.92

15.84

23.76

31.68

Part Number

Number of contacts

A B

Note 1) Bag packaging (100 pieces/bag). Order by number of bags.

Note 2) The 2 pos. type does not have walls on both sides.

Note 3)

DF7-2P-7.92DSA plug has #2 contact positions of DF7-3P-3.96DSA without contacts inserted and the number of pos. indication is 2.

(Mating receptacle: DF7#-3S-3-96C)

DF7-3P-7.92DSA plug has #2 and #4 contact positions of DF7-5P-3.96DSA without contacts inserted and the number of pos. indication is 3.

(Mating receptacle: DF7#-5S-3-96C)

DF7-4P-7.92DSA plug has #2, #4 and #6 contact of DF7-7P-3.96DSA without contacts inserted and the number of pos. indication is 4.

(Mating receptacle: DF7#-7S-3-96C)

DF7-5P-7.92DSA plug has #2, #4, #6 and #8 contact positions of DF7-9P-3.96DSA without contacts inserted and the number of pos. indication is 5.

(Mating receptacle: DF7#-9S-3-96C)

5

Note 1) Tray packaging. Order by number of quantity in the tray.

Note 2)

DF7-2P-7.92DS plug has #2 contact positions of DF7-3P-3.96DS without contacts inserted and the number of pos. indication is 2.

(Mating receptacle: DF7#-3S-3-96C)

DF7-3P-7.92DS plug has #2 and #4 contact positions of DF7-5P-3.96DS without contacts inserted and the number of pos. indication is 3.

(Mating receptacle: DF7#-5S-3-96C)

DF7-4P-7.92DS plug has #2, #4 and #6 contact of DF7-7P-3.96DS without contacts inserted and the number of pos. indication is 4.

(Mating receptacle: DF7#-7S-3-96C)

DF7-5P-7.92DS plug has #2, #4, #6 and #8 contact positions of DF7-9P-3.96DS without contacts inserted and the number of pos. indication is 5.

(Mating receptacle: DF7#-9S-3-96C)

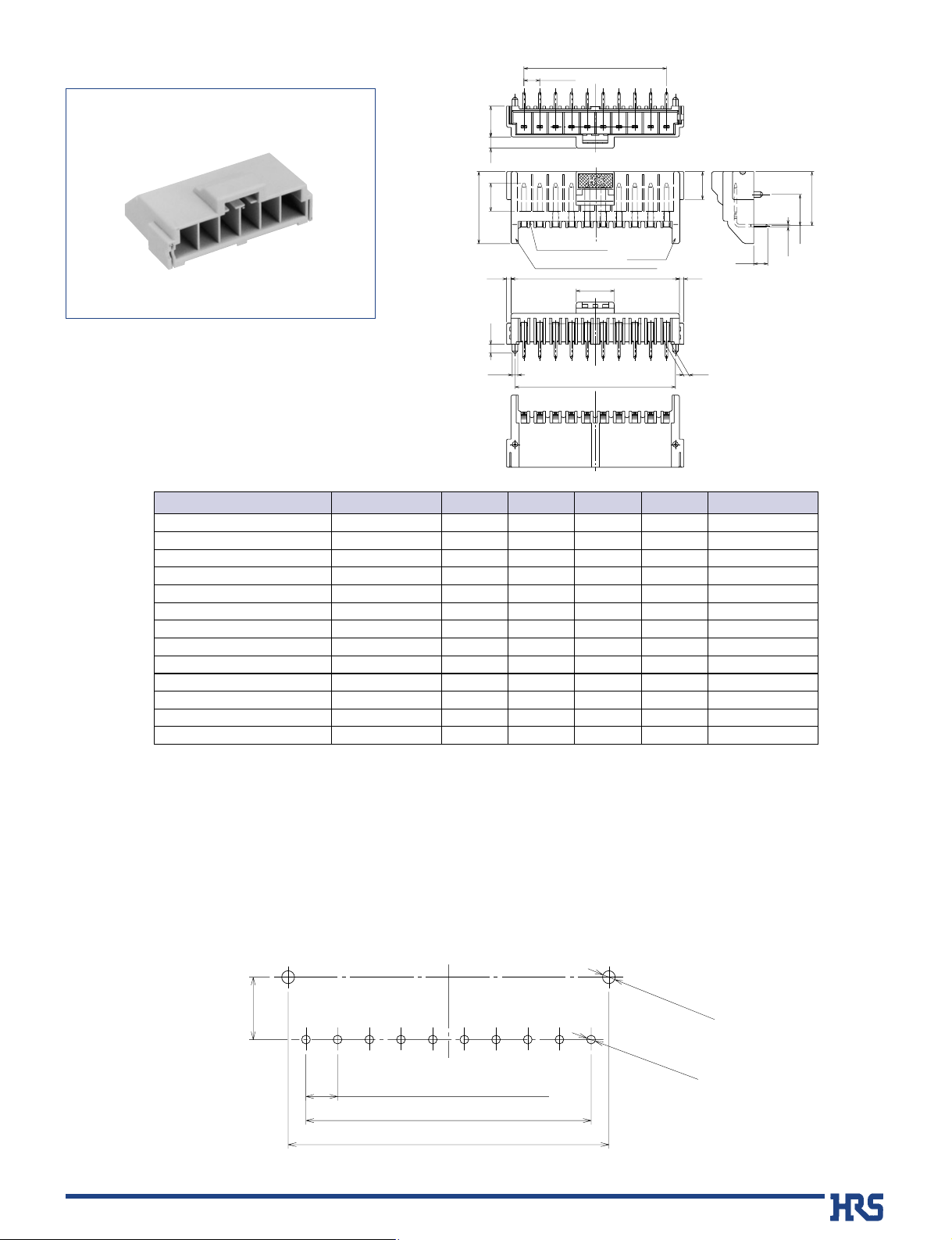

■ Right angle header

B PCB mounting pattern (Board thickness: 1.6 ± 0.1)

CL No.

CL680-0081-0-24

CL680-0082-2-24

CL680-0083-5-24

CL680-0084-8-24

CL680-0085-0-24

CL680-0086-3-24

CL680-0087-6-24

CL680-0088-9-24

CL680-0089-1-24

CL680-0124-0-24

CL680-0125-3-24

CL680-0126-6-24

CL680-0127-9-24

DF7- 2P-3.96DS(24)

DF7- 3P-3.96DS(24)

DF7- 4P-3.96DS(24)

DF7- 5P-3.96DS(24)

DF7- 6P-3.96DS(24)

DF7- 7P-3.96DS(24)

DF7- 8P-3.96DS(24)

DF7- 9P-3.96DS(24)

DF7-10P-3.96DS(24)

DF7- 2P-7.92DS(24)

DF7- 3P-7.92DS(24)

DF7- 4P-7.92DS(24)

DF7- 5P-7.92DS(24)

2

3

4

5

6

7

8

9

10

2

3

4

5

3.96

7.92

11.88

15.84

19.80

23.76

27.72

31.68

35.64

7.92

15.84

23.76

31.68

10.40

14.36

18.32

22.28

26.24

30.20

34.16

38.12

42.08

14.36

22.28

30.20

38.12

8.40

12.36

16.32

20.28

24.24

28.20

32.16

36.12

40.08

12.36

20.28

28.20

36.12

114

84

66

60

48

42

36

36

30

84

60

42

36

Part Number

Number of contacts

A B C Quantity per tray

P=3.96

7.72.8

A

A

A

7

7.8

1.1

3.5

1.4

M0.64

7

18

6L09

10

1.1

2.2

Ø1.4

No. of contacts indicator (Note2)

10

Production Lot No.

Cavity No.

B

9.5

C

13.5

7.8±0.05

P=3.96±0.05(7.92±0.05)

A±0.1

C±0.05

2_Ø1.6

*_Ø1.1

+0.1

0

+0.1

0

Loading...

Loading...