HRS DF11 Service Manual

A266

2mm Double-Row Connector (Product Compliant to UL/CSA Standard)

DF11 Series

■Features

1. Space-saving on Board Realized

Double rows of 2mm pitch contact has been condensed

within the 5mm width.

The multiple number of signals can be secured in the same

space as the conventional 2mm single-row contact.

2. Broad Variation

The insulation displacement and crimping methods are

prepared for connection. Thus, board to cable, in-line,

board to board connectors are provided in order to widen a

board design variation.

In addition, "Gold" or "Tin" can be selected for the plating

according application, while the SMT products line up.

3. Applicable Wire Covers Wide Range

According to the double rows of 2mm pitch compact

design, the applicable wire can cover AWG22 to 30.

4. The ID Type Connector Achieves Connection

Work.

Using the full automatic insulation displacement machine,

the complicated multi-harness can be easily connected,

reducing the man-hour and eliminating the manual work

process.

■Applications

Business equipments such as copy machine, printer and so on.

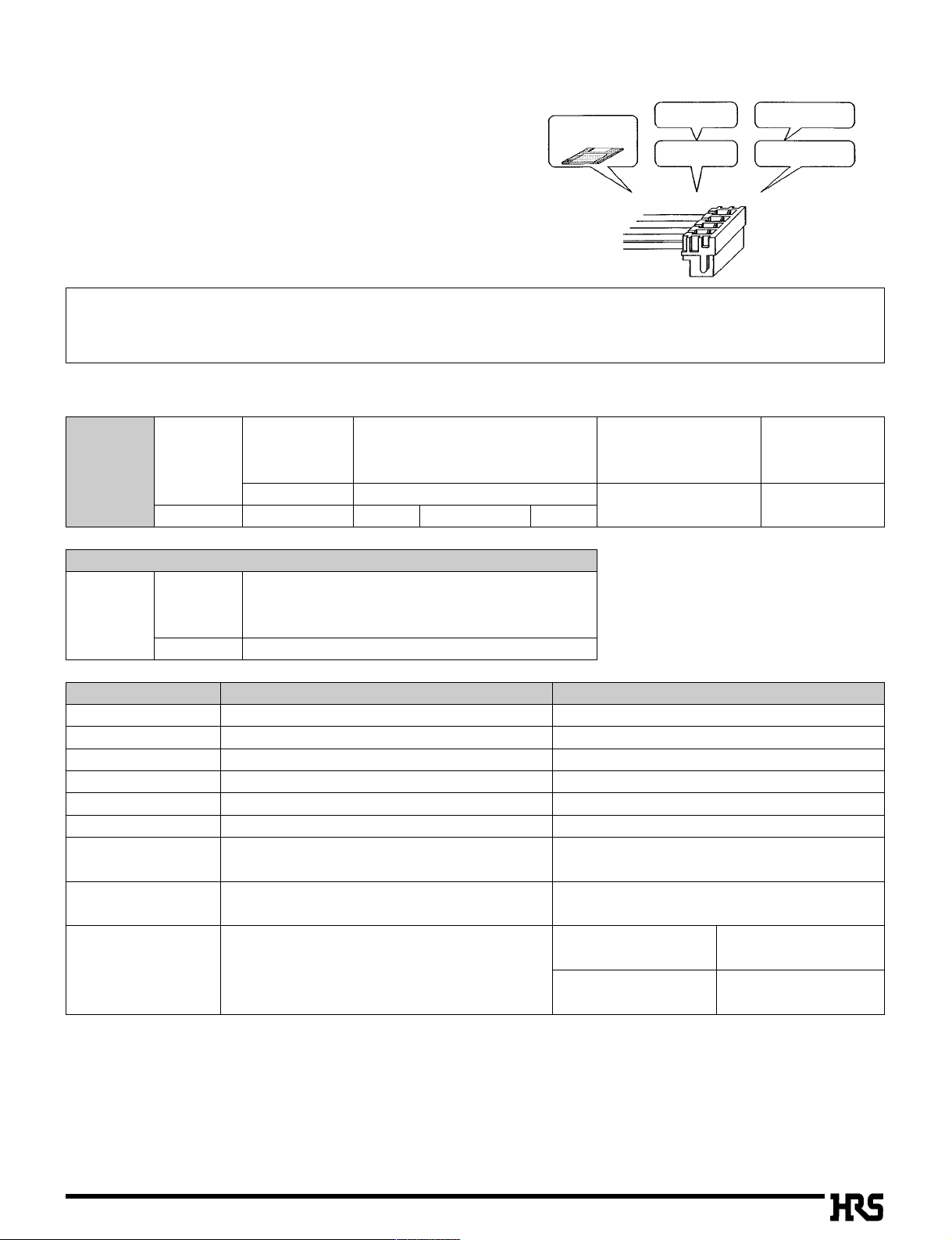

Rib to prevent

mis-insertion

Simple lock

Rib to prevent contact

mis-insertion as well as

disimilar contact mis-insertion

4 wall box style

5mm

查询DF11-10DEP-2A供应商

A267

■Product Specifications

Current rating

(Note 1)

Voltage rating

Crimping

Insulation Displacement

Crimping

250V AC

Insulation Displacement

100V AC

AWG

22 to 26:

2A

Wire size AWG 28 : 1A

AWG 30 : 0.5A

Wire size AWG 26 : 1A

Operating Temperature Range

Operating Humidity Range

Storage Temperature Range

Storage Humidity Range

■UL·CSA Safety Standard File No.

UL :E52653

CSA :LR95109

-30 to 85ç Note 2

40 to 80%

-10 to 60ç Note 3

40 to 70%

Note 1: Includes temperature rise caused by current flow.

Note 2: The term "storage" refers to products stored for long period of time prior to mounting and use. Operating Temperature Range and

Humidity range covers non conducting condition of installed connectors in storage, shipment or during transportation.

Item Specification Condition

1. Insulation Resistance 1000M

ohms

min. 500V DC

2. Withstanding voltage

No flashover or insulation breakdown.

650V AC/1 minute

3. Contact Resistance 30m

ohms

max. 100mA

4.

Single Insertion/Extraction Force

0.3N (30gf) min., 4.4N(450gf) min.

Measured by the square steel-made pin of 0.5±0.002mm

5. Vibration

No electrical discontinuity of 1µs or more

Frequency: 10 to 55 Hz, single amplitude of 0.75 mm, 2 hours in each of the 3 directions.

6.

Humidity (Steady state)

Contact resistance: 30m ohms max. Insulation resistance: 500M ohms min.

96 hours at temperature of 40ç and humidity of 90% to 95%

7. Temperature Cycle

Contact resistance: 30m ohms max. Insulation resistance: 1000M ohmsmin.

(-55ç: 30 minutes ➝ 15 to 35ç: 2 to 3 minutes

(-85ç: 30 minutes ➝ 15 to 35ç: 2 to 3minutes) 5 cycles

8.

Durability (Mating/un-mating)

Contact resistance: 30m

ohms

max.

Tin plated: 30 cycles

Gold plated:50 cycles

Flow: Manual soldering:

9.

Resistance to Soldering heat

No deformation of components affecting performance.

250ç for 10 seconds 300ç for 2 seconds

Reflow: Manual soldering:

At the recommended temperature profile

300ç for 3 seconds

■Features of DF11 Insulation Displacement Machine

(

Single Core Punching Full Automatic ID Machine AM700/DF11

)

● 5 Major Features of ID Machine AM700/DF11

1. Perform the multi-harness.

2. The setup time has been widely reduced. (10 minutes maximum)

3. Space saving design.

(About half space compared with the conventional machine)

4. Minimize initial cost with low cost.

5. The harness data can be saved in the floppy disk and easily

changed.

■Points

Since the DF11 insulation displacemention allows double rows ID with a single part, the harness service is completed with

machine connection only.

Rating

Current rating

Voltage rating

UL-CSA Safety Standard Approved Specification

30V AC

AWG 22 : 2A

Wire size AWG

24 to 28

: 1A

AWG 30 : 0.5A

Rating

Data storage

Low cost

Multi-harness

Half space

Setup in 10 minutes

A268

■Material

DF11

-

* DS - 2C

qewrt

q Series Name : DF11

w

Number of Contacts

: 4 to 32

e Connector Type

DS : Double Row socket

DP : Double Row pin header

DEP: Double Row in-line plug

r Contact Pitch : 2mm

t

Connection Form/Contact Style

C : Crimping socket

R26 :

Insulation Displacemented socket for AWG26

DSA: Straight through hole

DS : Right angle through hole

V : Straight SMT

A : Adaptor

Product Type

Part MateriaI Finish Remarks

Crimping Socket Insulator Polyamide Black UL94V-0

Crimping Contact for Socket

Contact Phosphor copper

Tin plated or gold plated

–––––––

ID Socket

Insulator Polyamide Black UL94V-0

Contact Phosphor copper

Tin plated

–––––––

Receptacle

Insulator Polyamide Black UL94V-0

Contact

Phosphor copper Tin plated or gold plated

–––––––

Pin Header

Insulator Polyamide Black UL94V-0

Contact Brass

Tin plated or gold plated

–––––––

Insulator Polyamide Beige UL94V-0

SMT Header Contact Brass

Tin plated or gold plated

–––––––

Metal fittings Brass

Tin plated

–––––––

In-line Plug Insulator Polyamide Black UL94V-0

In-line

Plug Crimping Contact

Contact Phosphor copper

Tin plated or gold plated

–––––––

In-line Adaptor

Insulator Polyamide Black UL94V-0

Contact Brass

Tin plated

–––––––

■Ordering Information

●Connector

Note: HRS tin plating takes action against whisker.

DF11 - EP2428PCFA

qrew

q Contact Type

Blank

: For socket

EP : For in-line plug

w Applicable Wire Size

22 : AWG22

2428 : AWG24 to 28

30 : AWG30

e

Contact Type/Packaging Type

SCF : Socket contact, Embossed tape

SC : Socket contact, Bag

PCF : Plug contact, Embossed tape

PC : Plug contact, Bag

r

Plating Type

Blank : Tin plated

A : Gold plated

●Contact

A269

[Specific No.] –* *, (* *)

Blank :Tin plated, 100 pcs. per bag

(21) :Tin plated, Tube packaging

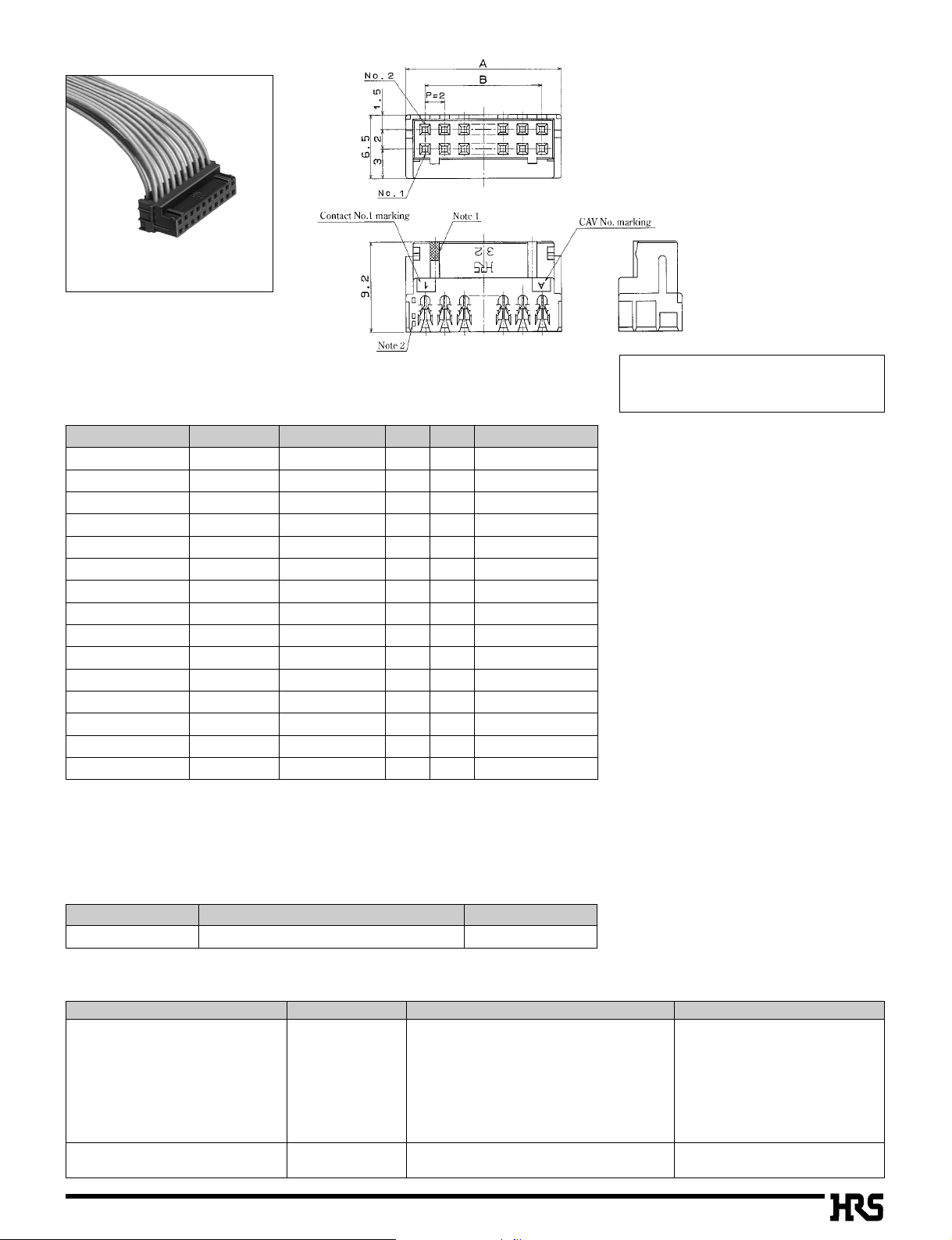

Photo: Cable connection status

Part Number CL No.

Unit: mm

DF11- 4DS-2R26(**)

DF11- 6DS-2R26(**)

DF11- 8DS-2R26(**)

DF11-10DS-2R26(**)

DF11-12DS-2R26(**)

DF11-14DS-2R26(**)

DF11-16DS-2R26(**)

DF11-18DS-2R26(**)

DF11-20DS-2R26(**)

DF11-22DS-2R26(**)

DF11-24DS-2R26(**)

DF11-26DS-2R26(**)

DF11-28DS-2R26(**)

DF11-30DS-2R26(**)

DF11-32DS-2R26(**)

543-0652-0-**

543-0653-3-**

543-0654-6-**

543-0655-9-**

543-0656-1-**

543-0657-4-**

543-0658-7-**

543-0659-0-**

543-0660-9-**

543-0661-1-**

543-0662-4-**

543-0663-7-**

543-0664-0-**

543-0665-2-**

543-0666-5-**

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

22.0

24.0

26.0

28.0

30.0

32.0

34.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

22.0

24.0

26.0

28.0

30.0

188

140

112

94

80

70

62

56

50

46

42

40

36

34

32

Number of Contacts

A B

Tube Packaging Quantity

■ID Socket

Note1: The specific No. "None" item is delivered per bag unit (100 pcs.). Please order products per bag unit.

Note2:

To use the full automatic insulation displacement machine to punch the DF11 single contact, the (20) tube packaging specification

should be applied.

Note3: Please order the tube packaging products by multiplying the packaging quantity ( pcs.).

■Applicable Cable

Part Number Applicable Cable Jacket Diameter

DF11-*DS-2R26 UL1061 AWG26 (7/0.16) Ø0.9 to 1.05mm

■DF11-*DS-2R Insulation Displacement Machine

Type Part Number Connection Type Remarks

■Effective harness form

1. DF11-both ended, one ended

Punching full automatic ID

2. DF11-DF11, separation

The connector is applicable to

machine DF11 single contact

AM700/DF11 3. DF11-DF3, separation

(20) tube packaging.

■Effective harness length

100 to 2,000mm

■

Continuity Inspection Mechanism Equipped

SA700/DF11

Desktop ID Machine

CL903-0013-5

■

Used for DF11 only, No restricted condition

Desktop machine for small lot

Note1:

Port 1-piece indicates odd number row,

and port 2- pcs. indicate even number row.

Note2: Use the dip type header as follows.

· Straight angle type: DF11-*DP-2DSA(08

)

· Angle type: DF11-*DP-2DS(24

)

Loading...

Loading...