HRS AQUASAVE A6, AQUASAVE A63B, AQUASAVE A60B, AQUASAVE A62B Operating Instructions Manual

HRS AQUASAVE 6 Bar Range

6 bar Storage – 600 to 2,000 Litres

Operating & Instruction Manual

A60B

No Controls

A63B

3 Port Control

A62B

2 Port Control

Head Office

10-12 Caxton Way, Watford.

WD18 8JY t. 01923 232335

mail@hrs.co.uk www.hrshevac.co.uk

North & Factory

No 1 Rosemount Works, Elland

HX5 0EE t. 01422 317070

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

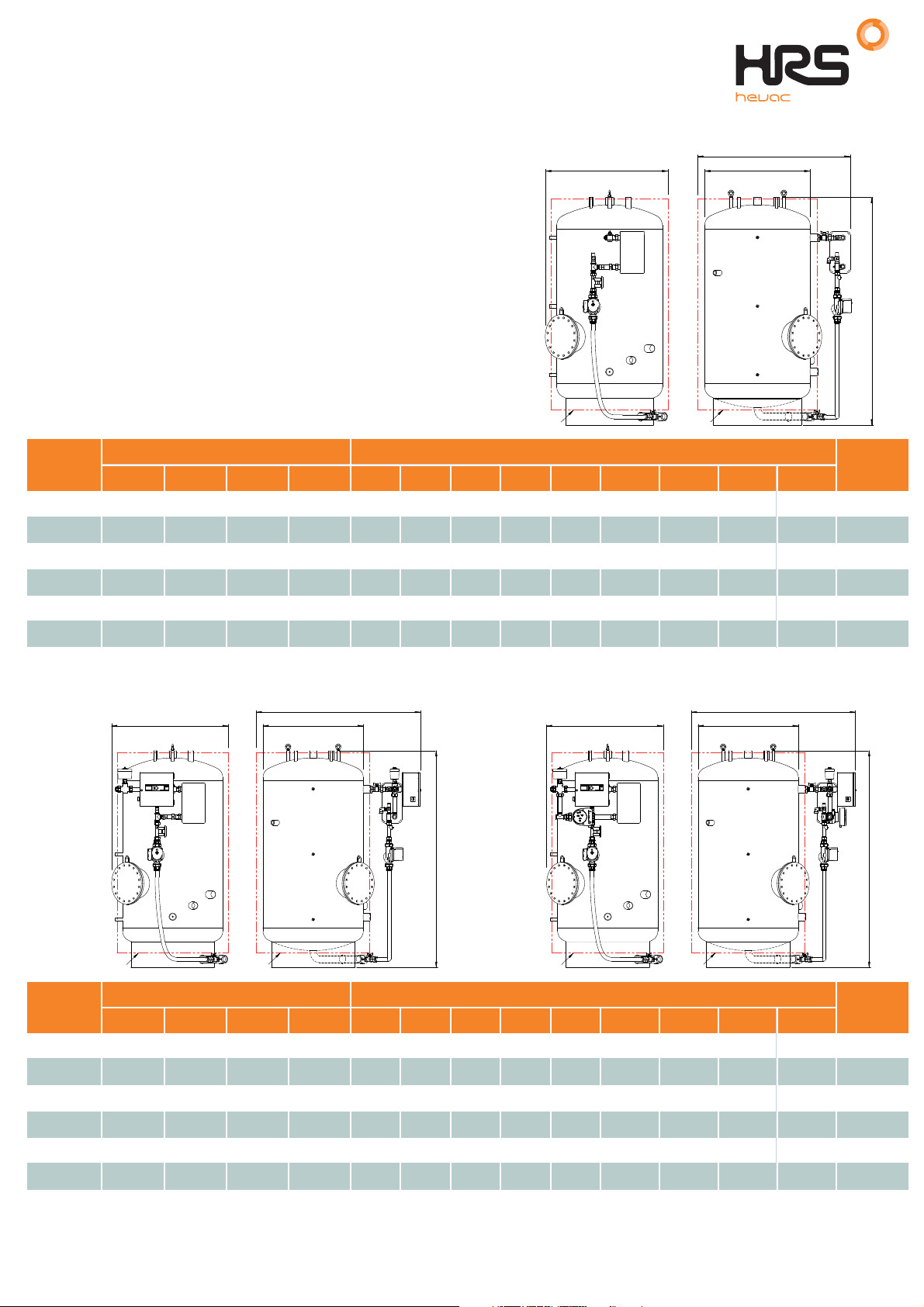

AquaSave A60B Dimensional Details

7

39 37

9

C

D B

9

7

Primary Inlet1

2

Primary Outlet

3 Secondary Flow

4 Secondary Return

6

6

4

5 Cold Feed

1111

6

A60B

6

1010

4

6

Instrument Connections (3-off)

7

Gauge Connections

8

Immersion Heater(s) - See Table

Safety Valve Connection(s) - Subject to Duty

9

10

Inspection Opening (DN250)

50mm Mineral Wool Insulation c/w Al. Stucco Cladding

11

Volume

(Litres)

600

800 1965 965 1205 1" 2" 1/2" 1/2" 3/8" 2" 295

1000 1945 1050 1305 1" 2" 1/2" 1/2" 3/8" 2" 335

1250 2020 1135 1405 1"

1500 2020 1220 1505

A B C D 1 2 3 4 5 6 7a 7b 8

1910 880 1105 1" 2"

700

800

900

1000

1"

1"

1"

1"

1100 1" 1" 1"2" 2" 1/2" 1/2" 3/8" 2" 400

6

8

8

6

8

5

Connections (Screwed BSP F)Dimensions

1"

1"

1"

1"2"

1/2" 1/2" 3/8" 2" 260

2"

2"

2"

2" 1/2" 1/2" 3/8" 2" 365

2000 2275 1305 1605 1200 1" 1" 1"2" 2" 1/2" 1/2" 3/8" 2" 540

1

2

A

Weight

(kg)

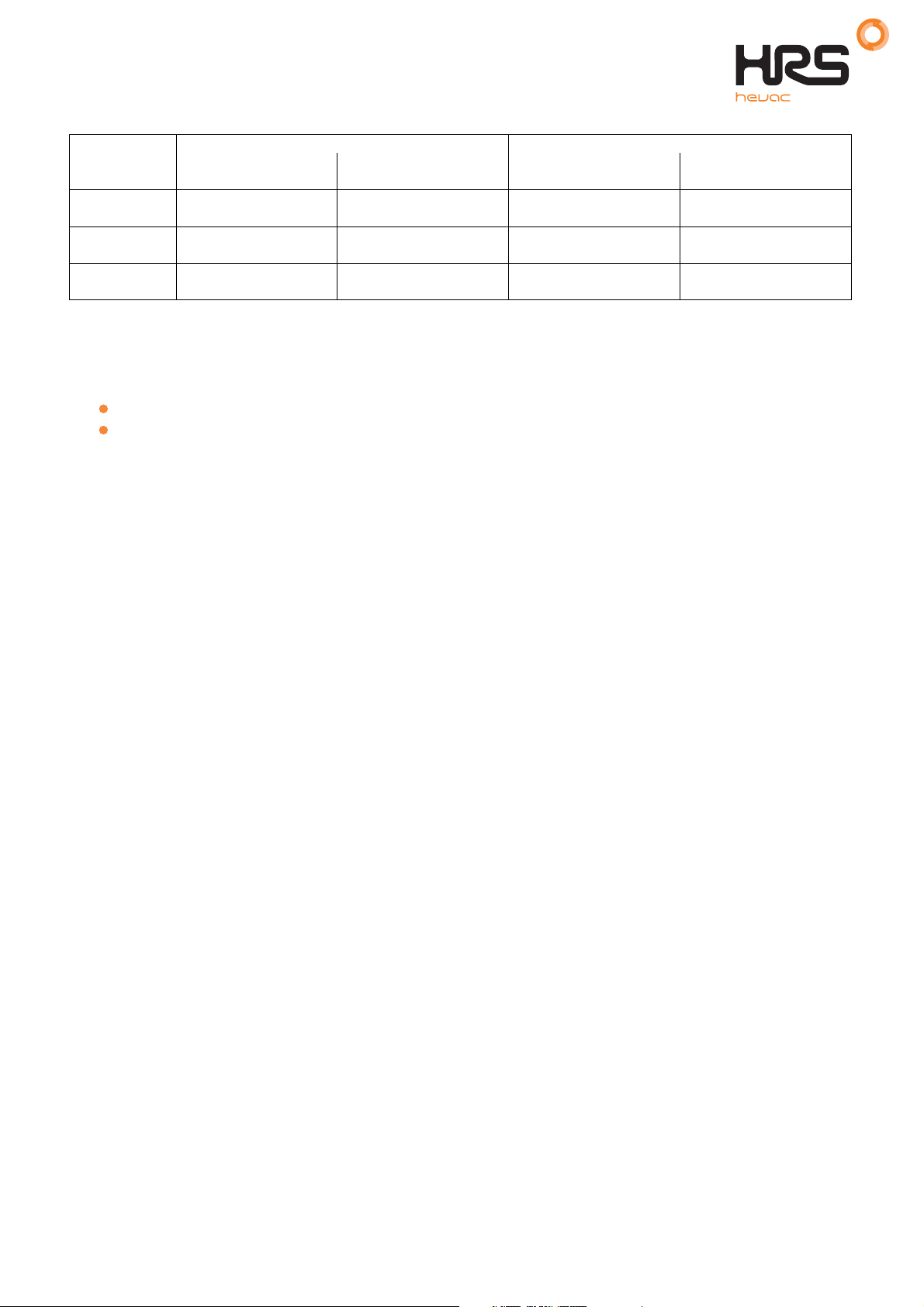

AquaSave A62B & A63B Dimensional Details

7

39 37

9

1

4

6

8

8

6

Volume

(Litres)

600 1910 910 1265 1" 2" 1/2" 1/2" 3/8" 2" 280

800 1965 965 1365 1" 2"

1000 1945 1050 1465 1" 2" 1/2" 1/2" 3/8" 2" 355

1250 2020 1135 1565 1"

1500 2020 1220 1665

8

5

1111

A B C D 1 2 3 4 5 6 7a 7b 8

C

DB

9

7

6

2

6

1010

6

4

A

1

2

6

6

Connections (Screwed BSP F)Dimensions

700

800

900

1000

1"

1"

1"

1"

1"

1"

1"

1"2"

1100 1" 1" 1"2" 2"

C

DB

7

39 37

9

8

8

8

5

4

1111

9

7

6

6

A63BA62B

6

2"

1/2" 1/2" 3/8" 2" 315

2"

2"

2"

1/2" 1/2" 3/8" 2" 385

1/2" 1/2" 3/8" 2" 420

1010

4

A

Weight

(kg)

2000 2275 1305 1765 1200 1" 1" 1"2" 2"

1/2" 1/2" 3/8" 2" 560

2 of 58 t.01923 232335 www.hrshevac.co.uk

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

Contents

Product overview .................................................................................................................. 51

1.1 Working pressure and temperature ...........................................................................................................6

1.2 Packing format ...........................................................................................................................................6

Options .................................................................................................................................. 72

2.1 A60B No Controls ................................................................7

2 B26A2.2 Port Control Valve

2.3 A63B ................................................................................................ .................................................8

3 Port Control Valve

Installation ............................................................................................................................. 93

3.1 Siting ..........................................................................................................................................................9

3.2 Hydraulic connections ...............................................................................................................................9

3.3 Basic assembly instructions .......................................................................................................................9

3.4 Commissioning ....................................................................................................................................... 10

Setting the DHW flow rate .................................................................................................. 114

Electrical connections ........................................................................................................ 125

5.1 A60B ................................................................................................ ............................................................... 12

5.2 A62B & A63B ................................................................................................................................................................... 12

5.3 Electrical power ratings table ................................................................................................................. 12

5.4 Current limiting fuses .............................................................................................................................. 12

Electrical installation of control box, A62B & A63 only ................................................... 136

6.1 Controller components ........................................................................................................................... 13

6.2 Electrical wiring diagram, A62B ................................................................ ..................................................................... 14

6.3 Electrical wiring diagram, A63B ................................................................ ..................................................................... 15

User instruction operator control panel Micro 3000 ......................................................... 167

7.2 Home screen .......................................................................................................................................... 17

7.3 Command symbols ................................................................................................................................. 17

7.4 Password and login ................................................................................................................................ 17

7.5 Setting the time and date ....................................................................................................................... 18

7.6 Changing the date format ....................................................................................................................... 18

7.7 Setting the daylight saving time .............................................................................................................. 18

7.8 Saving changes ...................................................................................................................................... 18

End user mode .................................................................................................................... 198

8.1 Set the hot water temperature ................................................................................................................ 19

8.2 Time programs ....................................................................................................................................... 19

8.3 Changing time and temperature in a time program................................................................................ 20

8.3.1 Special days ...................................................................................................................................... 20

8.4 Making a quick temperature change ...................................................................................................... 21

Technician menu ................................................................................................................ 229

9.1 Login ....................................................................................................................................................... 22

9.2 The technician Main menu ..................................................................................................................... 22

9.3 Configuration menu ................................................................................................................................ 23

9.4 S1 Menu Secondary Outlet .................................................................................................................... 24

9.5 Thermal Treatment Menu ....................................................................................................................... 24

9.6 Safety

9.7 Eco-Booster Function ............................................................................................................................. 25

9.8 Fouling function ...................................................................................................................................... 26

9.9 230V Triac menu .................................................................................................................................... 26

9.10 Autotest menu ........................................................................................................................................ 27

9.11 Clear alarm menu ................................................................................................................................... 28

Function....................................................................................................................................... 25

................................................................................................

................................................................

...............................................................

..........7

Service Menu ................................................................................................................. 2910

10.1 Change password for technician level ................................................................................................... 29

10.2 Login installer ......................................................................................................................................... 29

10.3 Menu Continue ....................................................................................................................................... 30

10.4 Operating hours ...................................................................................................................................... 31

10.5 Trending parameters menu .................................................................................................................... 32

10.6 Display the trend buffer ................................

...............................................................

........................... 33

t.01923 232335 www.hrshevac.co.uk 3 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

10.7 Point Data............................................................................................................................................... 33

Alarm menu ................................................................................................................... 3411

Parameters’ list................................................................................................................... 3512

Factory reset ....................................................................................................................... 3613

Modbus................................................................................................................................ 3714

14.1 Modbus communication ......................................................................................................................... 37

14.2 Connecting multiple Micro 3000 control boxes ...................................................................................... 37

14.3 Change Modbus parameters.................................................................................................................. 38

14.4 Modbus slave communication parameters............................................................................................. 39

Trouble shooting ................................................................................................................4015

Maintenance and repairs .................................................................................................... 4116

16.1 Antibacterial treatment of the AquaSTOR ............................................................................................ 42

16.2 Clean the copper brazed plate heat exchangers .................................................................................. 43

16.3 Open the control box .............................................................................................................................. 44

16.4 Set the number of pumps ....................................................................................................................... 44

16.5 Pumps’ number ...................................................................................................................................... 45

16.6 Add an extra sensor ............................................................................................................................... 45

16.7 Connect to 230V Triac output................................................................................................................. 45

16.8 Add relay 1 and relay 2 .......................................................................................................................... 45

16.9 Add a remote control contact ................................................................................................................. 45

Assembly of the charging kit to the AquaSTOR ............................. ................................. 4617

17.1 Attaching the heat exchanger insulation ................ ................................................................................ 49

17.2 Wiring the seconary shunt pump ........................................................................................................... 50

Flowcharts...........................................................................................................................5118

18.1 Flowchart A60B ................................................................ ........................................................................................ 51

18.2 Flowchart A62B ...................................................................................................................................... 52

18.3 Flowchart A63B ............................................. ................................................................ ....................................................... 53

Wiring the charging pump.................................................................................................. 5419

Special instructions for options ........................................................................................ 5520

20.1 Special instructions for A62B ................................................................ .................................................................. 55

20.1.1 Electrical wir

20.1.2 Wiring diagram .................................................................................................................................. 55

ing ................................................................................................................................. 55

Commissioning report........................................................................................................ 5621

Declaration of Conformity .................................................................................................. 5722

Warranty.............................................................................................................................. 5823

23.1 Spare parts............................................................................................................................................. 58

23.2 How to contact HRS Hevac .................................................................................................................... 58

4 of 58 t.01923 232335 www.hrshevac.co.uk

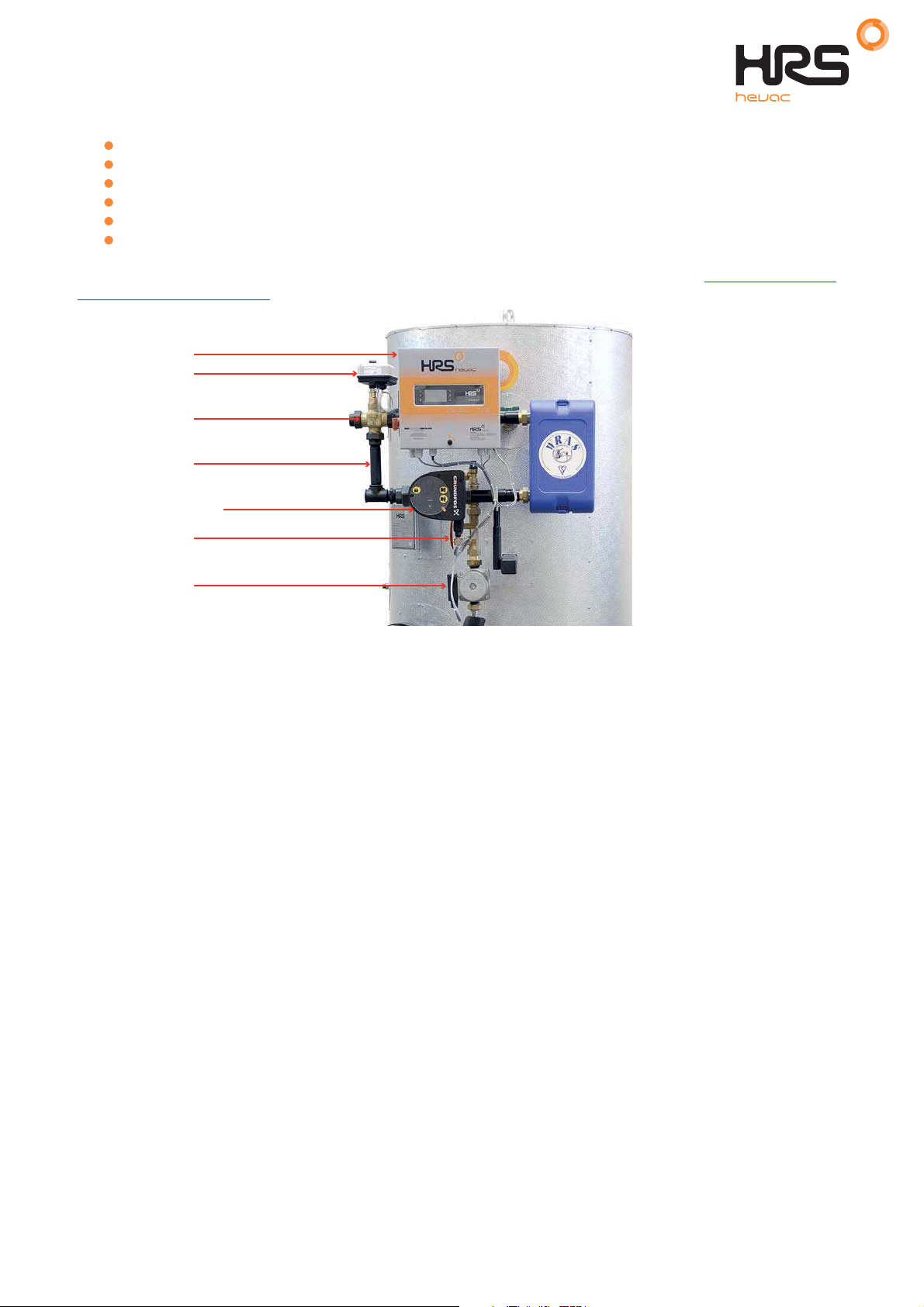

HRS Hevac Ltd AquaSave A6 Range

1.

Storage tank, stainless steel storage tank

with a heat-insulated cover

5.

Connector hose between tank and charging

pump, thermally-insulated

2.

Plate heat exchanger, 316-grade stainless steel

copper-welded

3.

Balancing valve

6.

Charging kit support

4

Charging pump

Installation, Operating & Instruction Manual

Product overview1

The basic version of the HRS Hevac AquaSave DHW heater, indirect (semi-instantaneous) system

comprises:

3

6

4

1

5

A60B

No Controls

2

22

3

3

4

6

4

6

11

5

A62B

2 Port Control

5

A63B

3 Port Control

t.01923 232335 www.hrshevac.co.uk 5 of 58

HRS Hevac Ltd AquaSave A6 Range

AquaSave

Model Type

PRIMARY SIDE

SECONDARY SIDE

Max working

pressure (bar)

Max temperature

(°C)

Max working

pressure (bar)

Max temperature

(°C)

A60B

10

110695

A62B10110695

A63B10110695

Installation, Operating & Instruction Manual

1.1 Working pressure and temperature

1.2 Packing format

AquaSave is delivered in two packages:

storage tank

exchanger kit

6 of 58 t.01923 232335 www.hrshevac.co.uk

Options2

Actuator

Control valve

Control box mounted on its

support

There are three different control systems available as option.

2.1 A60B - No Controls

Supplied with only the secondary charging circuit.

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

Follow the assembly instructions in

Primary flow connection

Primary return connection

17 Assembly of the

charging kit to the AquaSTOR

2.2 A62B - 2 Port Control Valve

One 2-port PN25 valve body

One Pt100 temperature sensor

One actuator, 230V 3 points with return to zero

One PID controller box with piping and support, depending on the model selected

The primary circuit is pre-assembled on the exchanger. Follow the assembly instructions in

charging kit to the AquaSTOR

17 Assembly of the

t.01923 232335 www.hrshevac.co.uk 7 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

2.3 A63B - 3 Port Control Valve

One 3-port control valve, PN16

One primary shunt pump, PN10

One actuator, 24V AC feed-in and 0-10V DC controller current

One PID controller box with Pt100 temperature sensor

Primary piping, sized differently according to heat exchanger type

Control box support

The primary circuit is pre-assembled on the exchanger. Follow the assembly instructions in

charging kit to the AquaSTOR.

Control box

Actuator

Control valve

Piping

Primar

y shunt pump

Balancing valve

Charging pump

17 Assembly of the

8 of 58 t.01923 232335 www.hrshevac.co.uk

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

Installation3

3.1 Siting

The AquaSave hot water heater shall be installed in a dry place where room temperature is below 40°C,

and ideally in ventilated premises.

AquaSave is placed preferably on a sub-base footing.

3.2 Hydraulic connections

Connect the charging kit (exchanger + control valve + charging pump) to the storage tank using the interlink kit.

Make arrangements for fitting the insulation onto the tank before connecting up the piping.

The indirect AquaSave module can run without a recirculation system fitted.

To avoid creating a galvanic coupling, check that the materials used in the installation have similar corrosion

potentials.

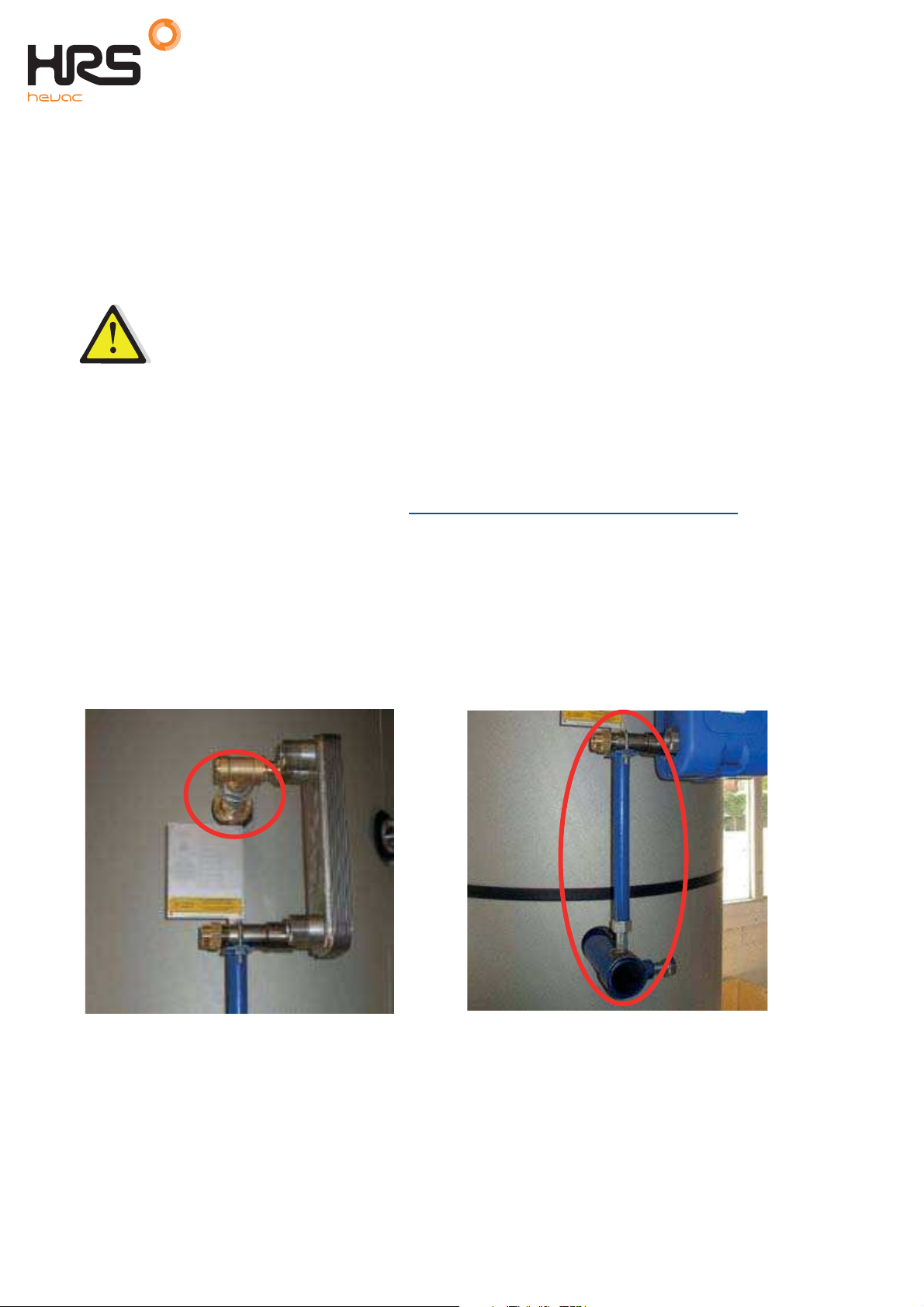

3.3 Basic assembly instrustions

Assembly: refer to the full instructions given in

Connect the primary supply and return connections.

Connect the cold water supply, hot water outlet and the recirculation system to the tank.

17 Assembly of the charging kit to the AquaSTOR.

Fit the tank with a safety valve, a drain valve in the top section and a draw-off in the bottom section.

NOTE: The valve is a compulsory fixture that has to be pre-loaded at the storage tank operating pressure.

NOTE: The safety valve on the charging kit only protects the secondary system – it will neither protect nor

surge-feed the installation and the volume stored, in correspo

The safety valve shall have the same diameter as the cold water inlet fixture

Top section connection Exchanger support + accessories

ndence with local rules.

t.01923 232335 www.hrshevac.co.uk 9 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

Bottom section connection, shut-off valve inserted between the conduit hose and the cold water inlet fixture.

3.4 Commissioning

Flood the various circuits and flush-bleed the pumps.

Power-up.

Set the secondary (charging) flow rate using the setting valve (read-off + setting)

NOTE: When first heated, the water in the tank will expand, increasing the pressure. A water hammer-arrestertype surge tank qualified for DHW systems may be fitted to prevent the relief valve from opening. Check the

water network pressure.

10 of 58 t.01923 232335 www.hrshevac.co.uk

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

Setting the DHW flow rate 4

The secondary DHW flow rate is set with the tank full and the primary circuit at nominal operating temperature

and at the available exchanger power capacity required for the generator.

1. Fully open up the control valve on the primary side.

2. If a 3-way control valve is fitted, wait for it to open completely.

3. Adjust the secondary flow circuit, as set out in the table below.

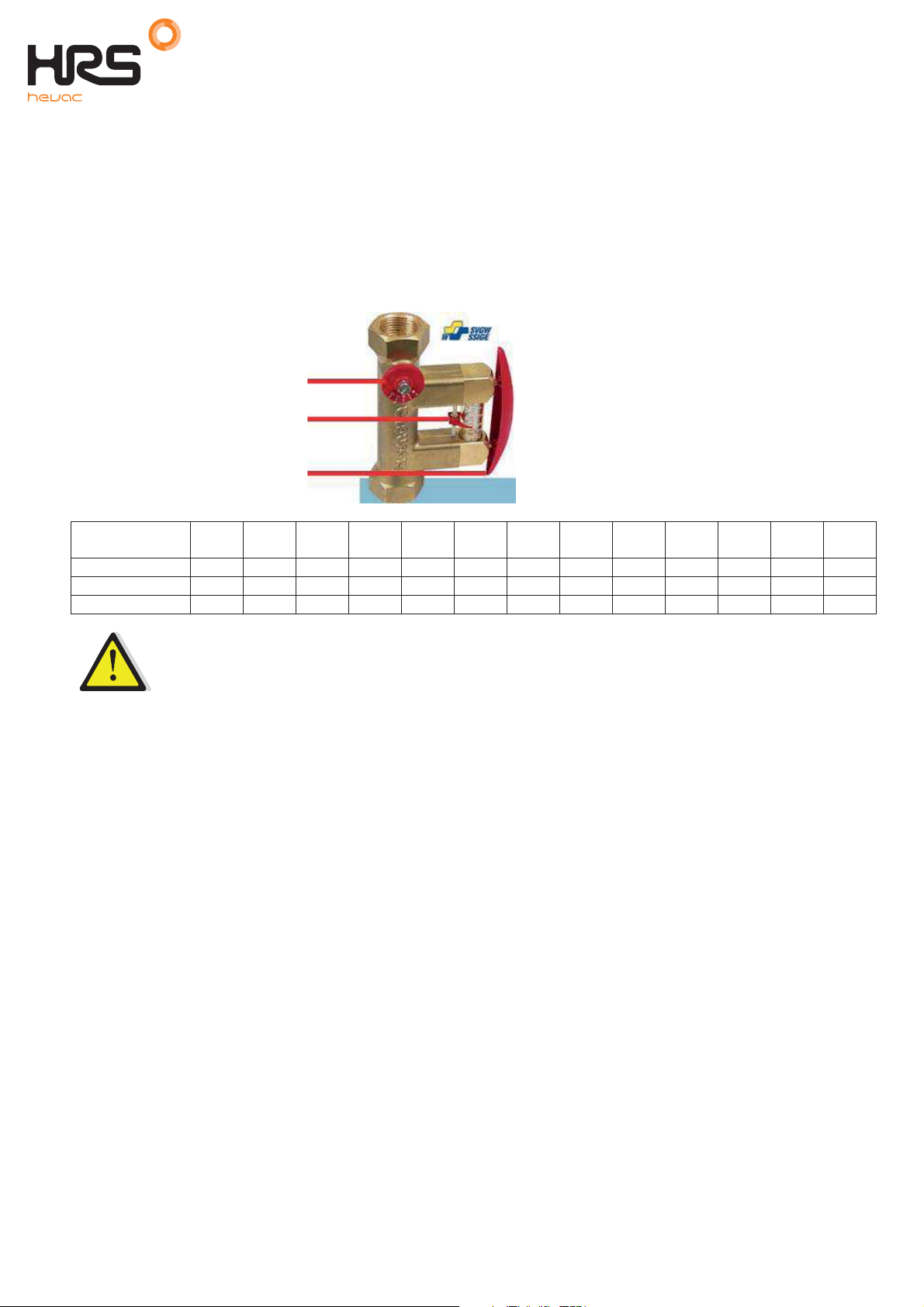

The flow rate can be read by pressing on the red pushbutton and readi

float.

Flow controller

Read-off index marker

Read-off pushbutton

P(kW)

DHW T(°C)

10 > 55°C 9.5 13 16 19 22 25.5 28.5 32 40 48 56 63 76

10 > 60°C 8.5 11.5 14 17 20 23 26 28 35 43 50 57 68

5 > 70°C 6 9 11 13 15 17 20 22 27 33 38 44 53

30 40 50 60 70 80 90 100 125 150 175 200 240

The recirculation flow rate has to be 60% maximum of the secondary flow rate.

ng the index marker against the

t.01923 232335 www.hrshevac.co.uk 11 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

Electrical connections5

All devices shall be connected up in compliance with the governing standards.

All work on control box and other electrical components must be done by qualified people.

The main electrical box should be equipped with short-circuits protection

5.1 A60B

The charging pump has to be powered constantly.

5.2 A62B & A63B

For more information about the Operator Control box, see chapter 6 Electrical installation of control box, option,

and forward.

Power the control box via a single-phase 230 V + ground.

Electrical system components pre-cabled according to the hardware ordered.

5.3 Electrical power ratings table

Primary pump

Unit Type

A60B

80 - 200 kW

A60B

>200 kW

A62B

80 - 200 kW

A62B

>200 kW

A63B

80 - 200 kW

A63B

>200 kW

1)

The electrical consumption of the control box and the actuator is 10W, 0.3A.

Figures are rounded up to the nearest value.

2)

Has no control box

type

- - UP20-45N 115W 0.5A 125W

- - UPS 32-80N 240W 1.05A 245W

- - UP20-45N 115W 0.5A 125W

- UPS 32-80N 240W

Magna 1 32-80 151W

Magna 1 32-80 151W

Primary pump

consumption.

W, A

1.22A

1.22A

SINGLE-PHASE 230 VOLTS + GROUND

Secondary

pump type

UP20-45N 115W

UPS 32-80N 240W

Secondary

pump

consumption,

W

1.05A

0.5A

1.05A

TOTAL +

Control box

2)

0.6A

2)

1.15A

0.8A

250W

1.17A

266W

2.02A

391W

2.57A

1)

5.4 Current limiting fuses

Power cards are equipped with fuses, labelled FU1 to FU5 on the printed circuit.

Fuse FU1 FU2 FU3 FU4 FU5

Protection

Size (mm)

Calibre

Voltage

Safety fuses are supplied inside the control box.

PUMP 1 N/A PUMP N/A PCB

6.3x32 6.3x32 6.3x32 6.3x32 6.3x32

2.5A 2.5A 250mA

250V 250V 250V 250V 250V

12 of 58 t.01923 232335 www.hrshevac.co.uk

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

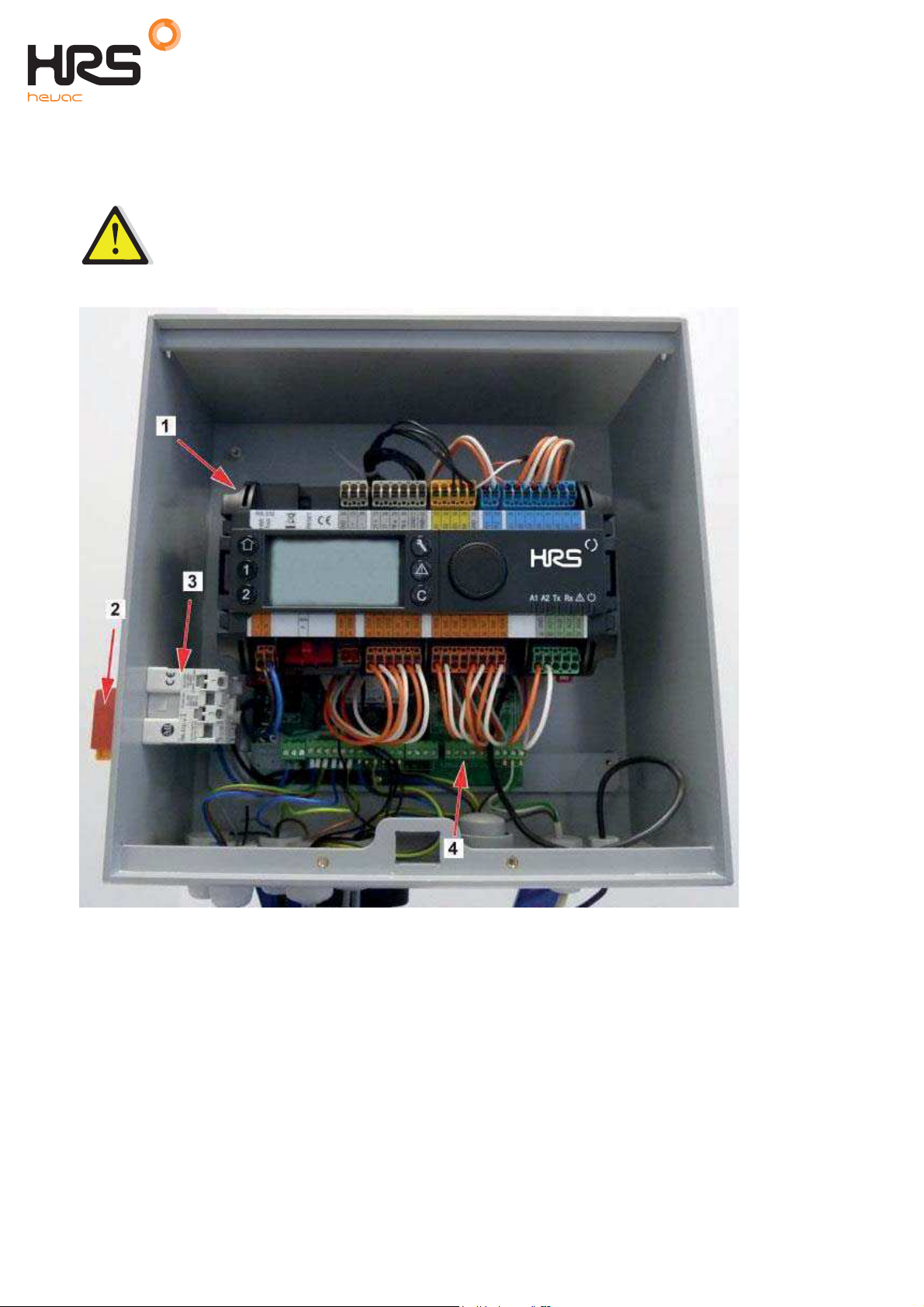

Electrical installation of control box, A62B & A63B only 6

Power supply the control box with 230VAC 50 Hz. The control box with the controller Micro 3000 is called the

secondary control box.

Human protections and protection against short circuits and over intensity must be installed in the

m

ain electric box.

6.1 Controller components

1 Controller, Micro 3000 3 Power Supply contact

2 Main switch 4 Printed Circuit Board

t.01923 232335 www.hrshevac.co.uk 13 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

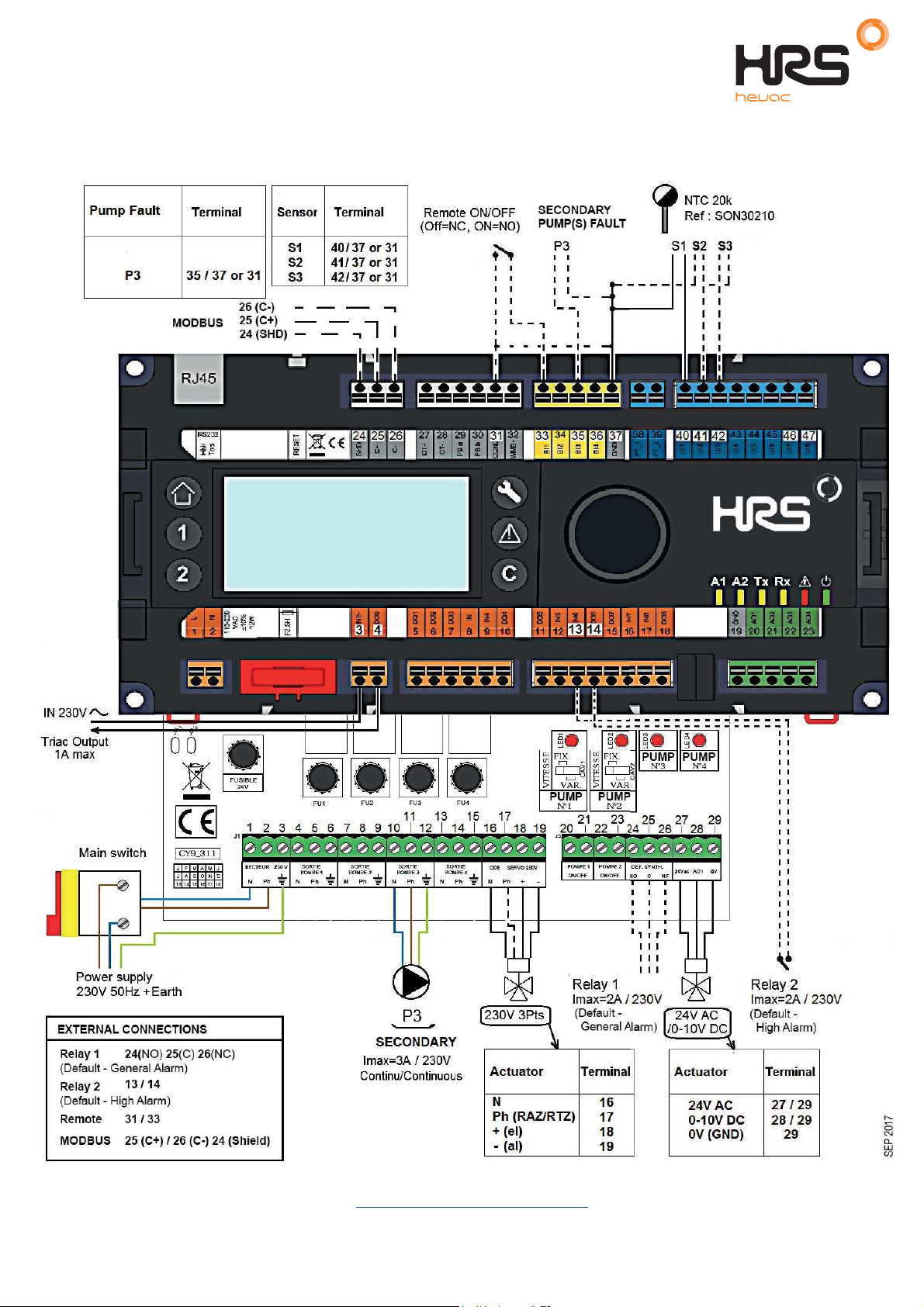

6.2 Electrical wiring diagram A62B

NOTE: When the remote control contact is open, the unit operates normally. If it is closed the unit is in standby.

NOTE: *) 230V 3pts actuator wiring, see

2

0 Special instructions for options

.

14 of 58 t.01923 232335 www.hrshevac.co.uk

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

6.3 Electrical wiring diagram A63B

NOTE: When the remote control contact is open, the unit operates normally. If it is closed the unit is in standby.

t.01923 232335 www.hrshevac.co.uk 15 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

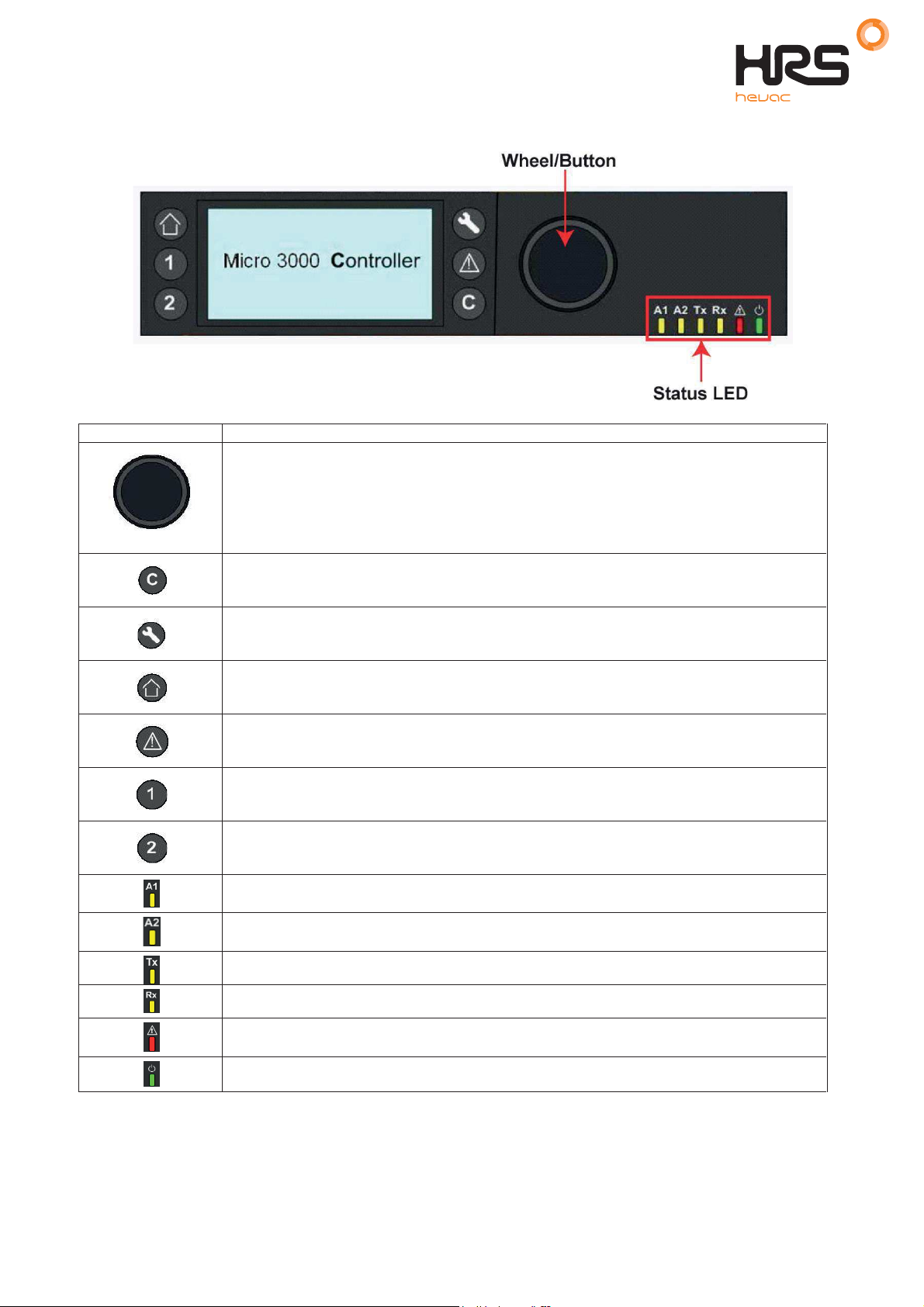

User instruction operator control panel Micro 3000 7

Button Function

Rotary button, wheel, for scrolling through the menus. Access sub-menus and change

settings by pressing it.

To activate the line or change a highlighted value, simply press the wheel.

Works like an Enter key.

Press to exit a level and return to the previous menu/parameter.

Works like an ESC key.

Press to access the maintenance / monitoring menu.

NOTE: Requires a password.

Press to go to the Home screen, Main Menu

Press to access the Alarm Menu.

Not used

Not used

Relay 1 activated.

Relay 2 activated..

Active data transmission

Active data reception

Alarm indicator

The Control box is switched on.

16 of 58 t.01923 232335 www.hrshevac.co.uk

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

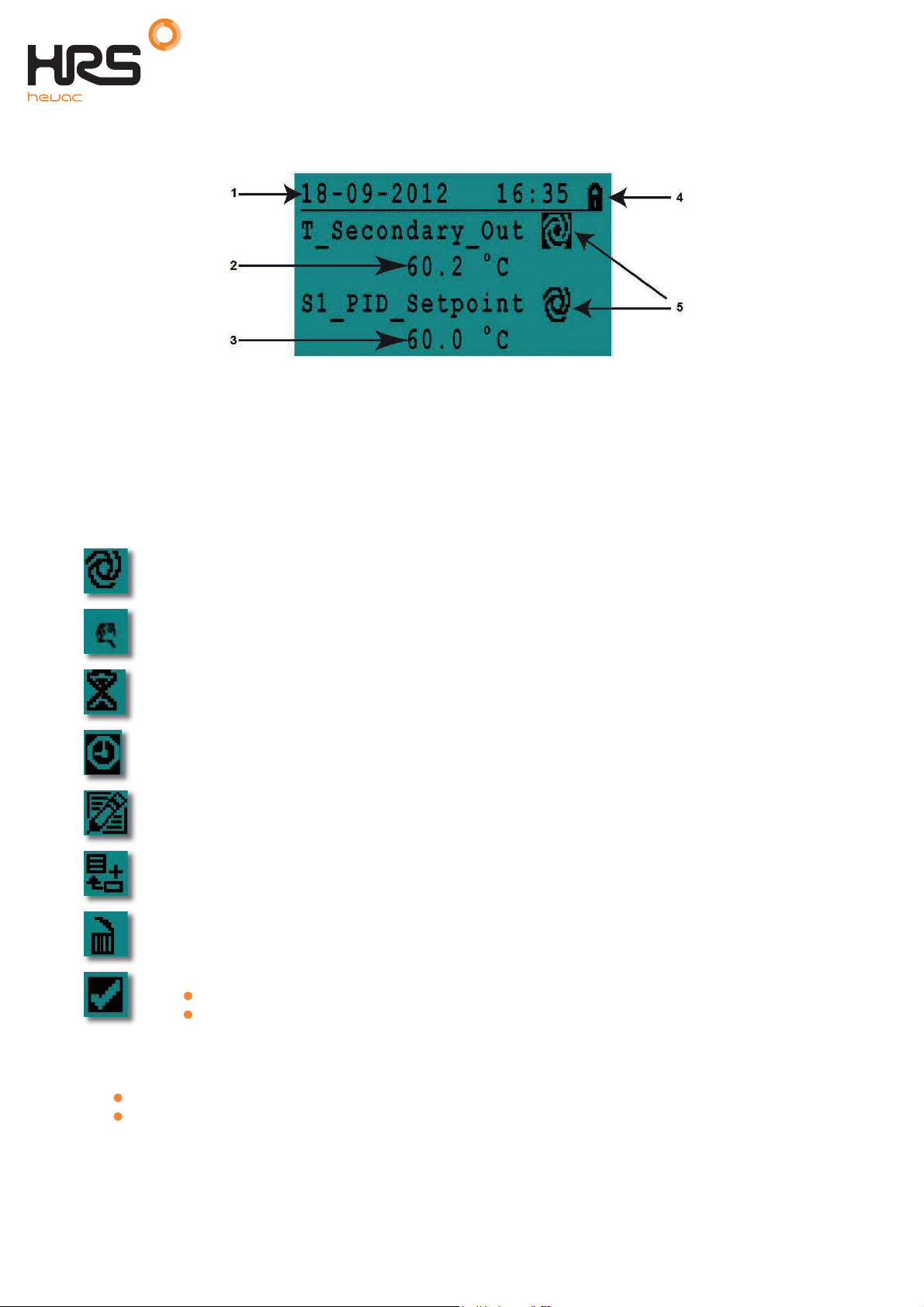

7.2 Home screen

When starting up the Micro 3000 controller this menu displays on them screen. The menu is called the Home

screen.

1 Date / hour 4 Access level:

Locked=restricted /

Key= total (3333)

2 DHW Temperature 5 Command symbols

3DHW Set point

: if there is an ongoing alarm when starting up the controller AquaSave, an alarm text will be

NOTE

displayed on the screen. Press the House button to enter the Home screen.

7.3 Command symbols

Auto

Datapoint is in automatic operation and can be switched into manual operation.

Manual

Datapoint in manual operation and can be switched into automatic operation.

Today function

Datapoint value can be overridden for a particular time period within the next 24 hours.

Datapoint must have a daily time program assigned.

Time Program

Datapoint has a daily time program assigned. Daily time program can be selected and edited.

Edit

Item (datapoint, time program etc.) can be edited.

Add

Item (datapoint, time program etc.) can be added to a list e.g. datapoint can be put to a list of

trended datapoints.

Deleted

Item can be deleted

Enable/disable

Checked: item is enabled

Unchecked: item is disabled

7.4 Password and login

The controller has password protection, allowing accesses to different menus.

End user level

Technician level

- requires no login. Marked with a locker in the upper right corner.

- access to all menus requires login. Marked with a key in the upper right corner.

t.01923 232335 www.hrshevac.co.uk 17 of 58

HRS Hevac Ltd AquaSave A6 Range

Installation, Operating & Instruction Manual

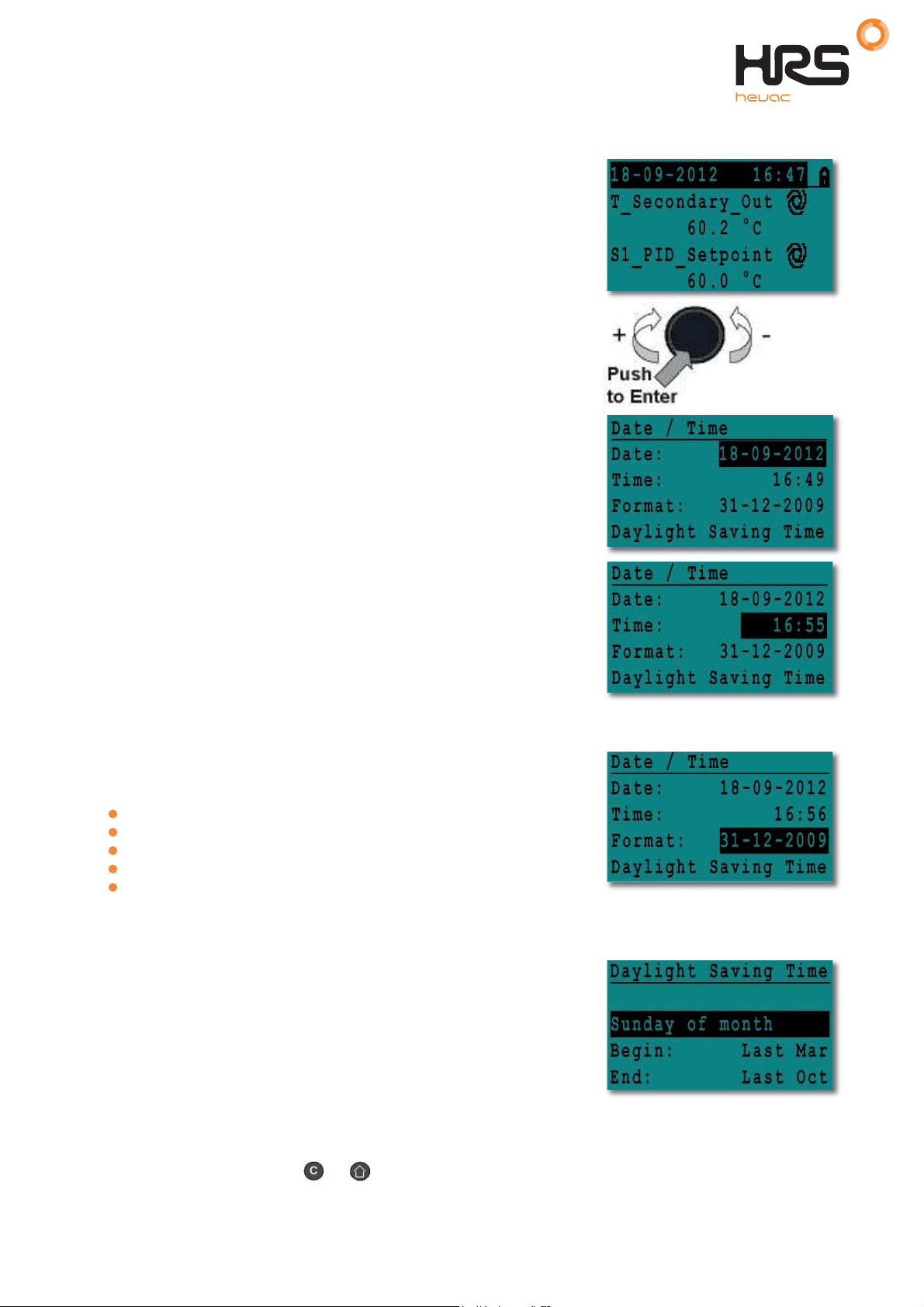

7.5 Setting the time and date

1. Turn the wheel anticlockwise to highlight the line with time and

date at the top of the screen. Press the wheel to enter the

Date/Time menu.

2. Press the wheel to change the first variable, the year.

3. When the year flashes, increase or reduce the set value by

rotating the wheel.

Once the right value is displayed, press the wheel to confirm the

setting. Next parameter to change starts to flash.

4. Proceed in the same way to set the month, date

and time (hour: minute).

7.6 Changing the date format

In the Date/Time menu the date format can be changed.

Choose between the following formats:

yyyy-mm-dd

mm-dd-yyyy

dd-mm-yyyy

dd.mm.yyyy

dd/mm/yyyy

7.7 Setting the daylight saving time

Summer time

Changing between summer/winter time can be automatic or turned off.

You can also define the dates for changes if they are altered.

The default settings for summertime is:

Last Sunday in March to last Sunday in October.

7.8 Saving changes

Once a value has been changed and confirmed by pressing the wheel, the corresponding change will be

immediately updated. Press the or to return to the home screen.

18 of 58 t.01923 232335 www.hrshevac.co.uk

Loading...

Loading...