Page 1

HP DesignJet Z3200

User Report

by Julian Mussi

© Spectraow, Inc.

415-382-8681

Nov 2008

PREFACE

In this article I will be examining the HP Z3200, HP’s latest Large format printer. The Z3200 is essentially an update of the Z3100

released in late 2006. Externally the printer appears virtually identical to it’s predecessor, yet internally the printer has been revised and

upgraded. Perhaps the most obvious change Z3200 is the reformulated “Chromatic Red Type 73” cartridge which replaces the standard

“Red Type 70” of the Z3100. The Z3200 also benets from numerous tweaks to the drivers, hardware, and printer rmware that contribute to creating a noticeable better product. Due to the many shared similarities between the Z3100 and Z3200 many portions of this

review are borrowed directly from my original review of the Z3100, all sections have been updated, the screen shots are new, and the

conclusions has been rewritten to reect the most recent offerings from the competition.

PRINTER HARDWARE

INITIAL IMPRESSIONS AND SETUP

The Z3200 is a beautiful piece of machinery. If all it could do was toast bread it would still be an achievement in industrial design. Its

smooth black sloping lines give it an aerodynamic appearance, and I’m happy HP invested some time and energy into this aspect of their

product.

The box that the Z3200 ships in is identical to the Z3100 and HP again wins point in my book for best packaging design. The printer is

easily unpacked by one person with minimal difculty. The shipping crate’s top is removed revealing the printer, and all the components

Page 2

logically grouped together and easy to access. The stand, which is included for both 24” and 44” models, is sturdy and easy to constructs.

It is then screwed to the base of the printer (the printer is shipped upside down) and then easily ipped by two people. I actually managed

to unpack, assemble, and ip the 44” model myself.

Once the printer is assembled and plugged into a power source, you can then begin the somewhat lengthy setup process. Once the printer

is powered on you will be prompted to load the printers 12 cartridges, (1)photo black (2)matte black, (3)grey, (4)light grey, (5)light cyan,

(6)magenta, (7)light Magenta, (8)yellow, (9)(NEW)chromatic red, (10)green, (11)blue, and last but not least a (12)gloss enhancer. The 24”

Z3200 ships with 69mil cartridges while the 44” model ships with the standard 130mil carts. This means that the 44” Z3200 ships with

about $400.00 of extra ink, not a trivial sum. After the cartridges are installed the printer begins to charge the lines with ink, a process

that takes several minutes. When this process was completed, the ink levels for all of the inks were around 80% full on the smaller 69mil

tanks.

After the ink carts are loaded the print heads must be installed. HP uses what they refer to a semi-permanent print heads. What does this

mean exactly? By contrast Epson uses a different print head technology, micro piezo, allowing for permanent print heads. They are not

user replaceable, but are designed to last the life of the printer, if one does malfunction its replacement is a sizeable percentage of what

a new printer would cost. Both companies will argue for the relative superiority of the technology, and both have merit. Whatever the

system, clogged print heads will lead to banding and degradation in image quality, and must be remedied. Most Epson large formt print-

ers have additionally required users to clean the heads through an ink purge, which is both time consuming and expensive. Thermal print

heads by their very nature breakdown over time, which of course necessitates the use of replaceable heads. To avoid having to replace

the print head when only a small number of nozzles are bad, the printer maps defective nozzles and uses alternate nozzles to pick up the

slack. When too many of these nozzles become inoperable you will then have to replace the head. Since very little ink is purged through

the print heads the printer does not have a require large maintance tanks.

Changing heads in the Z3200 is a quick process, taking about a minute to remove the old head and install the new one. There is one head

for every two colors, at a cost of about $70 each (list). Each head is warranteed for 1000 mils of ink but is expected to push through 2500

mils of ink before it needs replacement. Since each cart contains 130mils of ink this means you will likely go through many complete

sets of ink before any of the heads will need to be replaced. Or viewed another way, about 20 tanks could be run through a head before

it is expected to fail. That’s a fair amount of ink.

After the heads have been installed the printer nishes it’s rather lengthy initialization process during which it buzzes and hums. This is

a good time to download the printer drivers on your system. After the printer nishes initializing, the basic hardware setup is nished.

You should then load the roll of paper that ships with the printer and run the paper feed and head alignment from the printer menu. This

is a crucial step, and will help avoid banding issues and ensure maximum image quality.

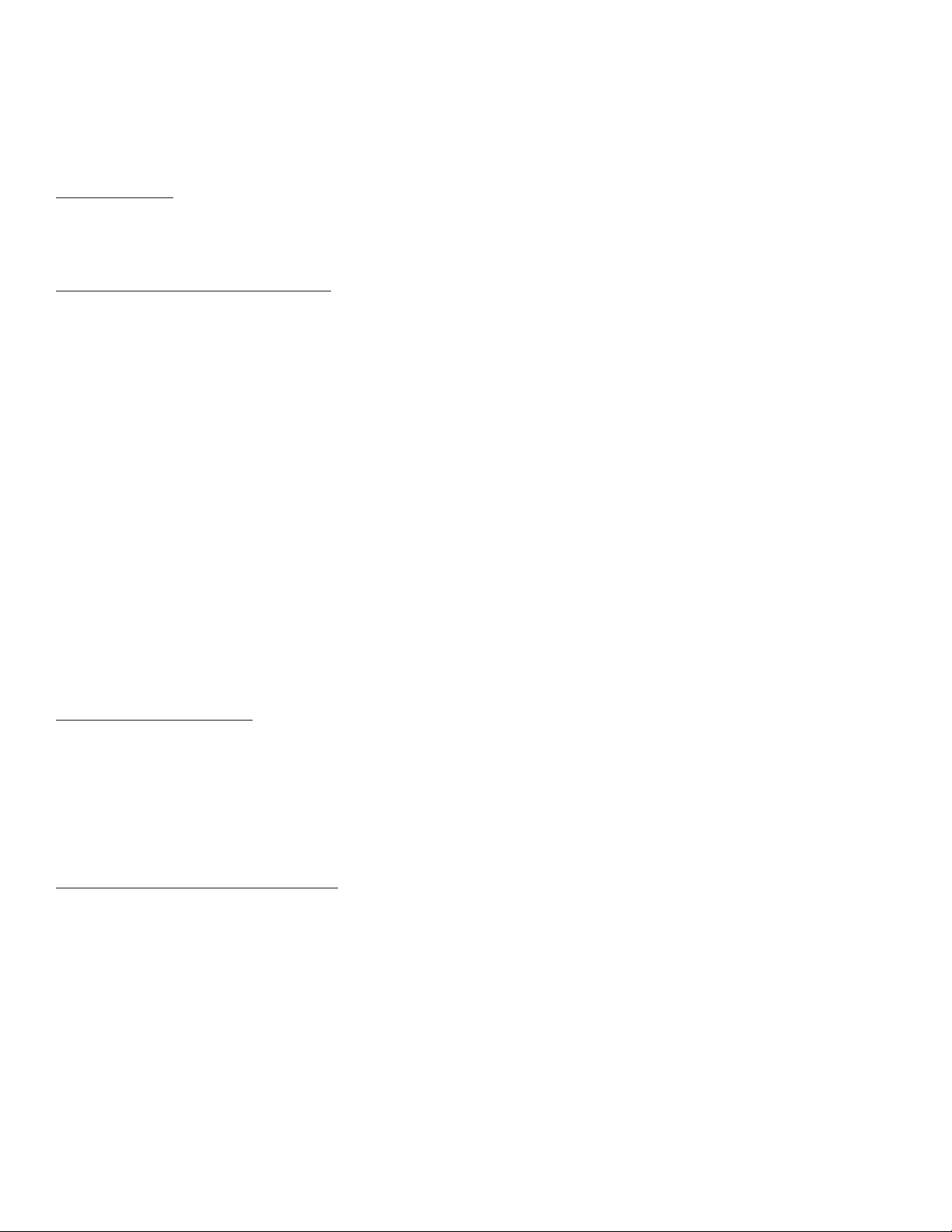

INK COSTS

Aside from the 69ml starter set on the 24” printer, all ink cartridges are 130 ml. The cartridges are available as a single cartridge or in

a twin pack. HP also charges less for the gloss optimizer, which as I’ll discuss later, is a good thing.

Assuming manufacture supplied list prices let’s look at some very basic ink set costs (though most suppliers, including Spectraow, sell for well below list prince).

HP DESIGNJET Z3200 EPSON STYLUS PRO

7/9880

Number of installed inks 11 colors

1 gloss enhancer (GE)

Ink cartridge size 130 ml 110/220 ml 150/350/700 ml

MSRP cost per cart $83 single / $62 GE

$132 double/$99 GE

($66 each)/($49.5 GE)

Total volume of ink in

printer

Cost per replacement set $975 single

1560 ml 880 (110 ml carts)

$1551 double

8 colors 11 colors

$70 for 110 ml

$112 for 220 ml

1760 (220 ml carts)

$560 for 110 ml

$896 for 220 ml

Epson 7/9900

$89.95 for 150 ml

$159.95 for 350 ml

$279.95 for 700 ml

3850 ml (300 ml carts)

7700 ml (700 ml carts)

$1759 for 350 ml tanks

$3079 for 700 ml tanks

Page 3

Cost per mil of ink $.62 for single

$.49 for double

One of the questions I get a lot has to do with how much does it cost to make a print on printer A as opposed to printer B. While it’s

easy enough to generate an estimate that will likely be correct within $ 0.10 eighty percent of the time on a letter size sheet, trying to

get any more exact is often an unrealistic goal. Many factors inuence the cost of a nal print: Driver vs. RIP, prole, media, quality

settings, ink waste, resolution. As you can see from the above chart the actual cost of the ink is fairly similar between the Z3200 and

the 7/9880, with the Epson 7/9900 coming in lower when the 700 ml carts are purchased. For the time being, however, let’s assume that

using the same media, at similar quality, using the OEM inks, that most of the printers will be fairly close to each other in the actual

cost of consumables it takes to make a print. Lets make this assumption so that we can for a moment look at some of the other issue that

affect the cost of a print.

One of the biggest ancillary costs is ink waste. Older Epson K3 printers used a lot of ink in the course of their standard duty cycle. One

of the biggest complaints with the Epson X600/X800/X880 series printers was the need to manually swap black inks when switching

between matte and photo papers. On a Epson 9880 changing from photo to matte black uses around 100 ml of ink. On the Z3200 matte

and photo black are loaded at all times, the printer knows what ink to use based on the settings in the driver or RIP, and no switching is

required. The new Epson Stylus Pro 7900 also has both blacks installed at the same time, but still has to switch between inks, requiring

a bout three minutes of time and a few ml of wasted ink. While this new system is MUCH better than the previous models it’s still not

as elegant as the HP method. A head cleaning cycle on the 7/9880 LF Epson printers will use around 10 mils of ink, the power cleaning

uses around 70mils of ink. The Z3100 in our ofces has been on almost continuously since it’s arrival more than a year ago, and aside

from an initial head cleaning, the printer has needed virtually no user initiated maintenance. HP has taken a very proactive approach

to maintaining the print system. First, at regular intervals the heads expel very very small amounts of ink (less than 1 ml) this keeps

the heads clean and helps to eliminate clogs. At the same time a sensor in the printer monitors what nozzles are ring and performs the

nozzle remapping when needed. I like the fact that this routine maintenance has been made completely transparent, meaning that the

printer is always in an optimal state, ready to use. If needed there is always the option of initiating maintenance tasks manually from

the control panel.

$.63 for 110 ml

$.51 for 220 ml

$.46 for 350 ml

$.40 for 700 ml

Because of the expanded color set the Z3200 is typically more effeciant in it’s use of ink than the Epson X880 series printers. Where a

typical eight color printer must mix cyan and yellow to produce a green the Z3200 can use a single drop of green. The gloss enhancer

being the notable exception. I think people are more tolerant of the ink cost when it ends up on paper, rather than wasted due to head

cleaning.

PAPER FEED

The Z3200 has a rear loading roll paper path and a top loading single sheet feeder. The sheet path is accessed by a sliding cover that

facilitates the loading of the paper and blends into the chassis of the printer when not in use. This mechanism has been slightly simplied

from the Z3100 but remains fundamentally the same. Once you get used to the way it works, feeding sheets is relatively easy, although I

do have a few complaints. The rst is that it is difcult to load smaller sheets (tabloid and smaller) without some degree of skew, requir-

ing the user to manually align the sheet to a blue line of the front of the printer. There is a very small raised guide to align the paper

against when feeding it into the printer, but it’s not quite enough. Also very thin sheets of paper or very heavy stocks are more difcult

to load correctly. For ne art paper with rough edges there is an option to bypass the skew check for sheets.

Roll paper is fed in a straight path from the rear of the printer. The plus side of this is that the paper path is both short and straight. Roll

paper is feed into the paper path until some resistance is felt, the printer then automatically advances the paper. The feeding mechanism

is somewhat picky, and unless the paper is fed perfectly straight you will be prompted to raise the paper lever so that an automatic paper

alignment correction can be done. If the automatic correction fails (as is often the case for thick media) you will be prompted to manually correct the skew, which requires aligning the paper to the blue line. With a little practice I can get the media to load automatically

about 80% of the time. Compared to the HP 5000 series printers this system is so much better that I would be hard pressed to complain.

Compared to the simple methods of loading on the Epson 9880 and the exceptional system on the Epson 7/9900 I nd the HP system

mildly frustrating.

Whenever a new type of paper is loaded, you will be prompted to select whether the media being loaded is sheet or roll, and the type

of paper being loaded. The paper type is selected from a list of media types arranged by category. It is important that the printer know

what type of media is loaded since the information is used to link the paper to a paper preset. The paper preset tells the printer what ICC

prole, calibration, ink type and amount to use.

Overall the paper feed system is well suited to the range of media used in the ne art and photographic markets. The system is not

without it’s frustrations and is not particularly well suited for super high volume production environments, or especially odd media types.

Page 4

The placement of the roll in the rear of the printer was not a good call. I understand the reasons for doing so, but the result is a loading

process that is annoying at best and for some it will be a major hassle. In almost all production environment’s printers are crammed

against walls in crowded small spaces. Another thing to note is that the HP does not use a vacuum system to keep the paper at when

moving under the print path, but instead uses a feed system that includes a star wheel system. On the Z3100 these occasionally produced

marks on the print. So far I have yet to see any marks from the star wheels on prints from the Z3200. My feeling is that the marks are a

non issues on HP branded media, or when time is taken to ensure the correct settings are used when creating a media set for a 3rd party

media. If the marks were a problem even after altering the print setting, you now have the option of lifting the rollers for specic media.

I’m fairly condent this will give users enough options at their disposal to allow better support for third party media.

PRINTER CONTROL PANEL

All the printer’s controls on the Z3200 are located on the front of printer, grouped around a large monochrome LCD panel. From here

you control all the standard functionality of the printer, such as loading and unloading paper, selecting media types, and performing

color calibration. I like detailed information accessible from the display. Everything from the warranty status of the inks, to the amount

of ink each head has red, to the rmware version and connectivity information is easily found and clearly displayed. It’s nice to have

this much functionality available without having to move to the computer interface. It’s easy to change and congure the IP address.

Even basic color management functionality can be controlled from this menu. I also like HP’s use of animations on the LCD panel to

walk you through simple tasks such as loading paper, and changing print heads. This makes the printer a little friendlier in multi-user

environments where many people may only have brief contact with the printer. Of course this sophistication comes at a cost, making

the printer much more computer like. Partly because of the integrated 80 gb hard drive it requires a bit more time to start-up and in my

experience is slightly more prone to “crashing”. This occurs more with third party RIP’s, but has happened a few times with the drivers.

In all the interface is easy to use and offers a great deal of control without having to retreat to the nearest console to see what’s going

on in the printer.

BUILD QUALITY

Over many years HP has established a track record of building reliable, often overbuilt, easily maintainable printers. Compared to the

HP4000 or Z6100, the Z3200 is a lightweight, and reects the design philosophy of a photo/ne art printer rather than a production

printer. When the Z3100 was released there were some problems. Quite a number of users, including Spectraow, had to have the paper

feed sensors replaced. Also some users were troubled by appearance of star wheel marks on their prints due to the roller system used.

Since the Z3200 is an evolution of the Z3100 platform, many of these issues have been addressed, and I would expect that this launch

will go much smoother. Most of the issues I encountered with Z3100 printers made themselves known very early on, were addressed,

and afterwards functioned reliably. The stand is very robust and assembly is elegantly simple. The outer case is almost entirely plastic

yet feels solid. The paper basket is also well thought out. This printer gives the impression of being well built, and after having spent

considerable time using the Z3100, I have no reason to think that the durability of the Z3200 will not be equaly good, or better.

HARDWARE SUMMARY

The HP Z3200 is a well designed, functional print platform. The hands off approach to maintenance is rst-rate, almost eliminating any

downtime, and reducing ink waste to the bare minimum. The placement of the roll is still one of the primary annoyances I have with the

unit. Paper loading over all is average, but should not pose any serious limitations for most users. Cost per print is quite good considering

the relatively small size of the cartridges. It would have been nice to see a larger size cartridge option.

Page 5

HP COLOR MANAGEMENT,

!

&

EMBEDDED SPECTROPHOTOMETER

INTRODUCTION

Arguably one of the most interesting and discussed features of the Z3100 and Z3200 is the embedded spectrophotometer (ESP). Previous HP printers have incorporated densitometers into the print head allowing the printer to perform basic calibrations. The Z family of

printers remain the rst and only line of commercially available printers to have a standard integrated spectrophotometer that allows

automated ICC prole creation at no additional cost. Announced around the same time as the Z3200 the Epson 7/9900 offers an optional

accessory spectrophotometer. It’s tempting to consider these as functioning in the same category but the Epson accessory is a very different beast. For starters the Epson SpectroProofer accessory adds $1500 MSRP to the 24” models base price and $2500 to the 44”. The

other difference is that the Epson accessory does not include a proling package for ICC creation, allowing only printer linearization

and creation of a measurement le to be used in conjunction with 3d party proling software. So at this time the HP still remains the

only printer to offer a truly turn key color manage-

ment solution.

HP COLOR CENTER

The color center functions as the control center for

all of the printers color related functionality. From

here you can modify the printer’s paper presets; performing paper color calibration, add custom papers,

as well as creating ICC proles. If you print most of

your work on HP media you will be required only

to do periodic calibrations of the media being used.

If you want to print on 3rd party media and don’t

plan on springing for the optional Advance Proling Solution( APS) then you will likely be spending

some time in the color center. Its interface is simple

enough that the technology wary users should feel

comfortable using it, which is the whole point of

having the ESP. If you’ve not yet begun to utilize

color management in a meaningful way, because it is a rather daunting thing to just jump into, then this is what you’ve been waiting for.

This printer offers the average user a simple way to take advantage of a fully color managed workow.

Adding a new paper preset is essentially a three step process. The rst step is to name the new paper preset, and choose an existing

media type that most closely matches the paper to be proled. This is a crucial step since the media type controls the ink limiting, and

number of passes in the printer. What I found in my testing was that settings that seemed to make sense (choosing photo matte paper for

Epson enhanced matte) didn’t always produce the best results when working with 3rd part media. So you may have to experiment with

different media types to nd the best match for your specic paper. New in the Z3200 is the option of adjusting the total ink limit and

the amount of gloss enhancer used. For thick papers prone to picking up star wheel marks there is also have the option of raising the star

wheels entirely.

After the paper is named the printer will run a calibration, a quick process, during which a small number of patches are printed and

then scanned. This is completely automated, and the calibration is automatically attached to the paper preset. The stability of the printer

over time should be as good as comparable printers however changing the print heads, or ink tanks will cause some degree of drift, and

the calibration process should be run each time a head is replaced. The calibration brings the printer back to it’s factory state, ensuring

consistency both from unit to unit and over long print runs. This feature should allow a Z3200 in San Francisco and New York to use

the same prole and produce identical output.

Page 6

The nal step of course will be to create the actual ICC paper prole. The whole process from start to nish takes about 40 minutes.

The easy ICC target uses 463 patches to build the ICC prole. Once completed the prole is saved to the computer, and uploaded to the

printer. Uploading makes it much easier to make sure paper proles are up-to-date in a multi user environment.

Let me say that the proles produced in the color center are quite good, but not quite on par with those produced using the best proling packages and larger number of measurement patches. The color center does however provide a simple and effective way to use third

party media in the printer and get good results. The supplied proles are also quite good, and when the printer is calibrated, should yield

good quality prints.

ADVANCED PROFILING SOLUTION

I think there will be a fair number of users who are very excited about the ESP, are ready to put it to good use, but are looking for a

little more functionality in the prole creation process. To target this market HP, in conjunction with X-Rite, is offering their advanced

proling solution (APS). The APS package retails for around $800 as an add on, but is included with the “PS” version of the Z3200. It

includes an Eye-One display for monitor calibration, and a streamlined version of GMB’s prole maker software. The interface is nicely

APS interface

designed and easy to use, however it you do lose some functionality compared to the full version of X-Rite’s full-featured ProleMaker

proling software.

The APS does offer several theoretical and a few real advantages over the basic package, the most notable of which is allowing the user

to print targets with more patches. There is actually much less of a correlation between patch count and prole quality than most people

think although the proles produced by the APS did differ lightly from those produced in the color center. I wont say that they are out-

right better, instead there are some subtly differences in transitions and how out of gamut colors are rendered. The APS is a nice solution

for people without any sort of monitor calibrator, since the package comes with an Eye-One display for monitor calibration. The APS

also allows you to build CMYK proles. This will be handy when used with the Postscript version of the Z3200, or you can use the APS

to build CMYK proles for other printers, or in conjunction with third party RIP’s. To do this you must rst save the targets and then

print them through your RIP or on the other printer. The targets can then be feed into the HP Z32000 and measured using the APS.

I like the APS’s centralized control of printer and monitor proling. The proling controls are decent enough, allowing for basic editing

to the printer and monitor proles, and there’s no doubt it offers a more complete and robust package than the color center alone. For

a certain segment, this package will offer the added features needed to make it cost effective. For others, the gains may not represent

enough of an increase in productivity to support the cost difference.

ESP QUALITY AND THIRD PARTY INTEGRATION

There are of course people who already own a spectrophotometer and proling package who will be purchasing a HP Z3200. The question then becomes what use is the Z3200’s ESP, and how does it compare to a professional color management solution?

Page 7

HP has made a point of advertising that the spectro found in the Z3200 is based on the Eye-One from X-Rite. There are some notable

differences however, perhaps the most signicant of which is the different light source found in the two units. The Standard Eye-One

uses a (UV ltered) tungsten light source, while the ESP illumination comes from an LED. The tungsten source on the Eye-One is UV

ltered, however the embedded spectro’s LED does not emit UV radiation and thus needs no ltration. It’s interesting to note that X-Rite

high-end Isis spectrophotometer also uses LED based illumination.

The HP ESP spectral range is also reduced to 400nm-700nm as opposed to the Eye-One’s 380nm-730nm. The spectral bandwidth is also

wider on the HP at 20nm as opposed to 10nm. Okay, enough geeking out, what does this mean in practice?

I conducted an informal test of the ESP’s by creating two proles. In the APS I choose to create an RGB prole and printed the 928

patch TC9.18 target from the APS. I used the printer to read the patches and exported the values to ProleMaker. Next I used the data set

from the APS target to generated a prole target for the DTP 70. I printed this from Photoshop and measured the patches on the DTP 70.

I used both sets of measurements to generate proles using the same settings in GMB Prole Maker 5.0.8. The results were essentially

identical, and both produced indistinguishable results with our test image. In all, I am satised that the measured data from the ESP is

reliable and accurate. Natrually, a tool such as an Isis, DTP70, or Spectroscan coupled with X-Rite Proler Platinum or GMB Prole

Maker will give you more exibility in creating and tweaking a prole. These tools also demand a several thousand dollar premium

above the cost of the printer, so one would expect better results.

The biggest drawback to the ESP is the size of the patch that is read, and the time required to read them. Each patch for the Z3200 is

about 15mm sq, compare this to the DTP70 with a patch size of only 6mm sq. What this means is that a device such as a DTP70 can

measure over a thousand patches on a tabloid sized sheet where as a similar target on the HP Z3200 uses a two foot square segment of

paper. With a DTP70 I can print and measure a target in under 10min. On the Z3200 this would require nearly 45min depending on

the media and quality settings. Despite the advantage of automation, this difference in time, paper and ink costs could add up if used

often. It is interesting to note that while the Epson SpectroProofer uses smaller patches, and is capable of reading up to 15 patches per

second, it takes the printer several seconds to advance the chart to the next line of patches, signicantly increasing the time to read a

chart. Considering that the HP ESP is nearly as fast as the Epson SpectroProofer, and included in the cost of the printer, the ESP offers

a lot of bang for the buck. One new feature that advanced users will appreciate is the ability to create, print, and then save a CGATS

measurement le that can be used by a third party proling package. This allows owners of Proler or Proler maker to essentially use

the Z3200 like any other spectrophotometer.

In addition to the color center and APS, a number of RIP’s are using the ESP. EFI and GMG are perhaps the current leader in utilization

the ESP, allowing the RIP to automate the base linearization process, prole creation and optimization down to a preset DE average. We

have performed remote calibrations of the Z3100 using the ESP with EFI’s Colorproof XF with very good results. There is also a print

verication system that works with the ESP allowing a user to verify the accuracy of any print produced by the system.

SU MM ARY

The Z3200’s ESP allows this printer unprecedented ease of access to accurate and reliable color with any media. The added functionality

presents a sort of color safety net that should allow even the most novice user to get good results. That said the implementation of this

technology will of course contribute to the cost of the printer, and some advanced users may question it’s usefulness. I like the idea of

being able to pop in any paper and within a few minutes generate a usable prole for that paper. For the more demanding user the ability

to use the ESP for more advanced prole creation is being limited by the functionality of the APS, not the hardware. There is a lot of

potential in this device and it will be interesting to see how it will be put to use. I have to hand it to HP, while the system is not perfect

they have really done a great job of making fairly complicated and time consuming tasks accessible to even the most inexperienced user.

At the same time the functionality should serve the needs of more advanced users as well.

Page 8

PRINT DRIVER, IMAGE QUALITY, AND COLOR GAMUT

INTRODUCTION

Judging the quality of a print means evaluating the interaction of the paper, ink, printer, and software. This makes comparisons

difcult.

HP DRIVER AND PRINTER UTILITIES

The software that accompanies the printer is quite robust., and consists of two main components, the driver and the HP Printer Utility.

The driver is fairly straightforward and well organized. The quality settings are simple though a bit ambiguous. There are three basic

options: Best, Normal, and Speed. Speed is only appropriate for draft level work. To guarantee high quality output the most appropriate

quality setting is Best. Assuming that the printer is free of head clogs and the paper advance has been calibrated, then you may be able

to use Normal on matte papers. I’ve been told by HP engineers that the printer was designed to work well with the Normal setting, but

my experience has been that this is not always the case. Looking at speed, the Best setting on glossy media is about the same speed as an

Epson 7880 at 1440 dpi unidirectional setting. The driver is also the place to choose if, and how much gloss enhancer to use. The driver

will also sync with Photoshop CS3, turning off printer color management when appropriate. Other functions such as setting custom page

size, orientation, and borderless options are all easy to use. Like Epson, HP offers a black and white mode that provides control over the

tone of a print.

The HP printer utility is also installed when the drivers are loaded, and is divided into several components. The “Overview” tab provides

the ability to monitor the status of the ink and print heads in detail. The “Color Center” has already been discussed and controls all of

the printer’s color management functions. On the raster (non-PS) version of the printer you have a “Job Accounting” tab. From here, a

list of all the jobs sent to the printer is shown, as well as the size, type of media and ink used for each print. You can even congure the

printer to email you this information at designated intervals. On the PS version of the Z3200 this tab becomes the “Job Center”. From

here you have the additional option of submitting jobs directly to the printer as well as creating job nests. The settings tab lets you cus-

tomize the default behavior of your printer. The “Support” tab, guides you through routine trouble shooting as well updating rmware

and drivers.

PRINT QUALITY SETTINGS

The Z3200 prints at 1200 dpi and varies the “quality” by adjusting the number of passes the head makes and whether it prints bidirectional or unidirectional. The number of passes for each quality setting is not xed and varies depending on the media type selected in

the printer. The “Max Detail” option will increase the rendered output resolution from a default 300 ppi to 600ppi, useful for printing

architectural renderings or other images with ne lines on photo paper. The “More Passes” option may yield a slight increase in quality

by reducing the chance of banding, but increases print times.

IMAGE QUALITY & GLOSS ENHANCER

To date the Z3200 produces the best overall image quality I’ve seen in a pigment based inkjet printer. Comparable printers from Epson

and Canon may edge out the Z3200 in some areas of the color gamut, and Epson’s new screening is incredibly good. Factoring in bronz-

ing, gloss differential, screening, and black and white output, the Z3200 sets the bar very high.

Bronzing on the HP Z3200 is virtually nonexistent. On very glossy paper there is the slightest hint of bronzing but it is so subtle as to

be unnoticeable at almost all angles. On most papers the gloss enhancer gives the print a perfectly uniform surface, producing a very

traditional photographic look. Print’s have a depth that is very appealing, and there are virtually no quality “tells” to identify the prints

as being from an inkjet.

All pigment based inks suffer from bronzing and gloss differential to some degree. Epson uses a process that coats the pigment particles,

signicantly reducing the degree to which bronzing is an issue. The HP Z3200’s ink set also suffers from bronzing, and left unaddressed

would limit it’s usefulness as a photographic printer. Rather than trying to alter the proprieties of the inks, HP added a Gloss Enhancer

to the ink set. The Gloss Enhancer (GE) is a clear “ink” that is printed in conjunction with the other colors, creating a more uniform

surface. Since bronzing is only an issue on glossy and satin papers, it is not applied to ne art, matte, or canvas media. The user also

Page 9

has the option of disabling the gloss enhancer, a cost saver for proong, or other work where bronzing is less of a concern. There is

also an “economy” mode that applies the GE only to needed imaged areas, rather than the default, which covers the whole page, paper

white included. I’ve found that this works well for properly prepared images. It will yield strange results on images that have specular

highlights or blown-out areas.

While the Gloss Enhance is clear, it does impact the printed image, and must be taken into consideration when building a prole. Printing an image using a prole built without GE, and then turning it on, will result in a slight but noticeable color shift. Therefore a media

will require one prole for when gloss enhancer is used, and another when it isn’t. Creating a prole for a photo paper using the color

center will automatically yield two sets of proles, one for use with GE and one for use without. It does this by automatically factoring

in the known impact the GE has on color. This works fairly well, but you will get better results by creating two separate proles.

One nal note about the gloss enhancer; the printer uses a lot of it. If the total ink used on a print without GE is 2 ml, turning GE on will

up the total to about 3 ml. In my testing I found that on glossy media, for full page coverage, the GE accounted for a third of the total

ink usage. Thankfully, the generous usage of the GE is offset by a lower cost for the GE ink cartridge. Even with the liberal use of this

“ink”, I think it’s a good solution. For those seeking the best nish for their images, the GE is a simple x compared to the cost, hassle,

and health concerns associated with spraying prints.

MONOCHROME OUTPUT

An area of printing that has been largely ignored (by the OEM drivers) until recently is black and white output. Epson has continued

to improve their Advanced Black and White mode to the point that I nd the result to be quite good. HP, like Epson, offers a Black and

White printing mode. HP, however does things a little differently.

The HP Z3200 ink set mirrors the Epson 7/9880 K3 and the 7/9900 HDR ink sets in terms of the black ink conguration, with a matte

and photo black, gray (light gray), and light gray (light light black). There are however some interesting differences. First, the Z3200

can use all four black inks when printing on certain ne art papers. In this conguration it uses the lower density of the photo black as

another gradation of gray ink. On glossy papers the printer uses the photo black, and the two grays. Perhaps the most interesting thing

about the monochrome output from the Z3200 is that the blacks are almost perfectly neutral. This means that the printer doesn’t have

to tone the black inks with color inks to get a neutral print. This has the added advantage of reducing metamerism, color shifting under

different light sources. Another interesting advantage to this system is that the HP automatically uses only black inks whenever R=G=B

in an RGB le. This means that you don’t have to use a special print mode to produce neutral black and white prints.

PRINT PERMANENCE

Lack of print permanence, also referred to as fade resistance, initially prevented inkjet prints from gaining acceptance in the ne art

world. Since then, most pigment printers offer archival rating that match or surpass traditional photographic process. The latest numbers

from Wilhlem Imaging Research (based on the Z3100) show prints from the HP Z3200 outlasting Epson K3 prints on comparable media

by a factor of two. Almost of all the numbers indicate that prints from this printer will last in excess of 200 years under glass, and over

100 years pinned to the wall. Compare these numbers to 40 years for Fuji’s crystal archive paper, one of the most common traditional

color photographic papers. While theses numbers are based on accelerated testing, Wilhelm’s methods have become industry standards.

The bottom line is that as of now the Z3200 produces some of the longest lasting prints available using any print process, traditional or

modern. Anyone involved in art reproduction or who sells their prints should give print permanence careful consideration.

11 COLOR INK SET

While it may seem that the 11 color ink set is pushing the envelope simply by merit of the number of colors used, the real innovation

is the way it balances color gamut, archival stability and print quality. Older dye-based printers offered the gamut and print quality but

lacked fade resistance. Early pigmented ink sets were very archival but sacriced both gamut and image quality and were highly metameric. While Canon, HP and Epson all now offer printers with 10+ color ink sets, they all have distinctly unique characteristic. I’ve

previously that the Z3200 has excellent image quality and print permanence. The last thing to consider then is the range of colors, or

gamut, that the printer can produce. Lets start by look at why there are so many ink cartridges.

For the most part inkjet printers use CMYK colored primaries. By mixing these inks, the secondary colors, red, green, and blue are

produced. Adding light inks allows for smoother transitions and improves the gamut and appearance of a continuous tone in the lighter

colors. Adding inks increases the complexity since the driver or RIP needs to control the transition between light and normal inks.

The Z3200 adds a newly developed red, green, and blue ink to the mix, while removing the “normal” cyan ink. These colors have been

Page 10

carefully developed to target a specic hue and increase the overall gamut of the printer. The additional hues make the translation of

CMYK (or RGB) data, to ink on paper a bit more complex. The problem is that there are now more ways to produce the same color using different mixes of ink. To produce a certain color of orange you could mix yellow and red, magenta and yellow, or some mix of all

three. To handle this HP embeds an “intelligence” they call multi-color separation technology (MCST) into the printer. Essentially a set

of screening tables, this system allows the print driver, as well as third part RIPs, to treat the printers as a large gamut RGB or CMYK

device. This is also what sometimes gets tweaked by rmware updates, resulting in changes to the color gamut of specic printers.

During the initial release period for the Z3100, rmware updates resulted in fairly drastic improvements to the printer’s performance

on matte paper. It is important to consider that if the color tables are altered in a meaningful way, then any calibration or ICC prole

will need to be redone. This applies to RIPs such as those from EFI’s Colorproof XF where calibrations build on the work done by the

MCST. Of course, there are RIPs that choose to bypass the MCST, requiring that user to control the 11 color ink limiting, and generate

a 7 color prole. While this offers maximum control over the printer, it requires a lot of work to achieve results that are as good as what

the MCST delivers. Balancing that many ink channels is not for the faint of heart. However an investment of time and resources could

potentially yield better results on oddball 3rd party papers.

COLOR GAMUT

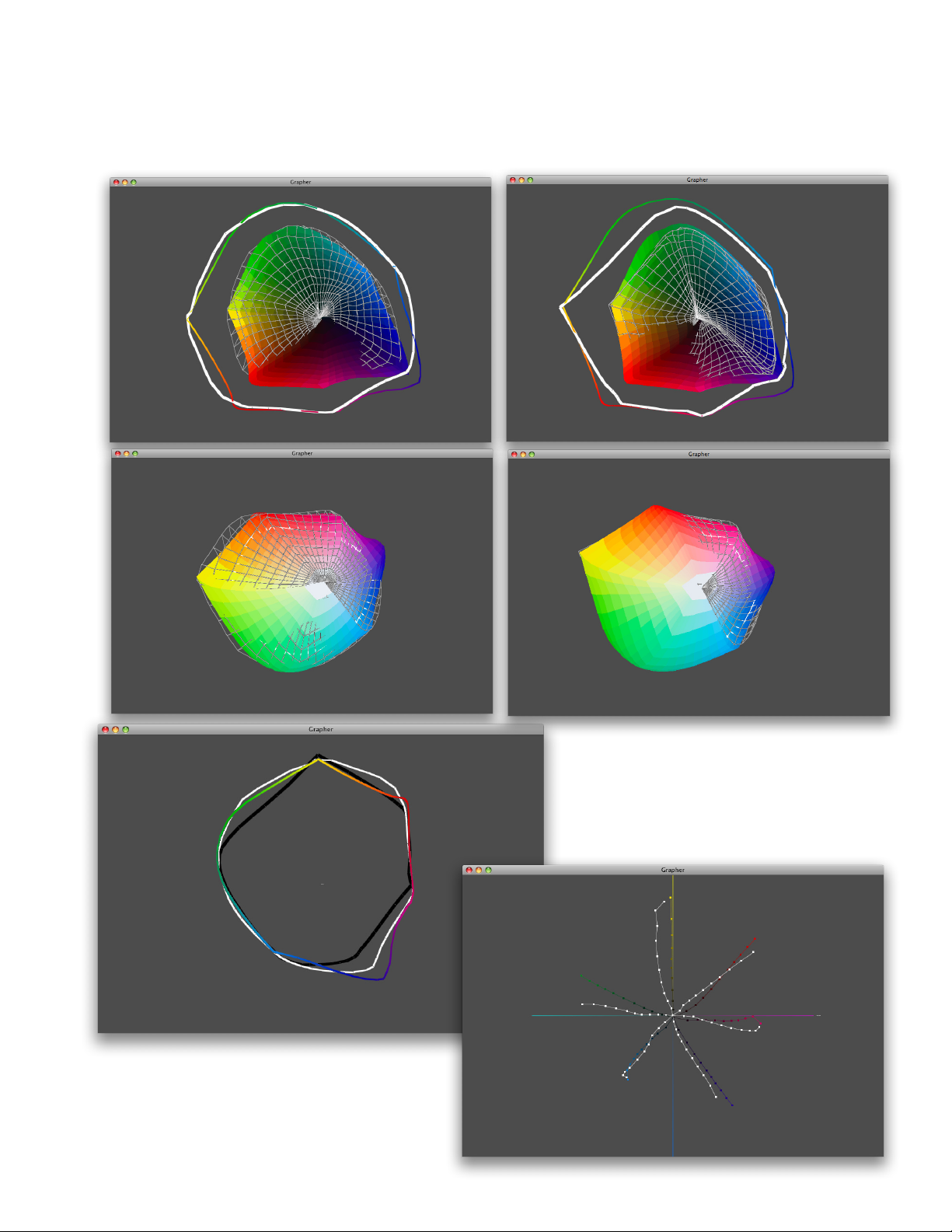

The Z3200 is able to produce an amazing range of colors. I spent a fair amount of time looking at gamut plots, 3d representations built

from the ICC proles that describe the range of colors a printer can produce. While they don’t always tell the whole story, they are useful

for comparing printer’s ink sets.

The rst set of gamut plots (in 2D) show the change in color gamut between the Z3100 and Z3200. The Z3100 produced excellent re-

sults on photographic media but showed a tendency to produce an undersaturated red on certain matte papers. The use of the Type 73

“Chromatic Red” on the Z3200 is designed to address this issue. You can see the red “bump” is most apparent on the matte paper, and

rightly so since this was the area that was lacking. The reformulation of the red resulted in a very slight reduction of orange in the midtone region but the improvement in red is seen all the way down into the shadows. In real world testing the Z3200 red produced greater

chroma, improved detail and contrast on matte papers, and subtly improved red on photo papers.

On luster/satin paper, the total gamut volume of the Z3200 is surpassed by the Epson 7/990 but is larger than the 7/9880. But this is a

somewhat poor criteria by which to judge the printer. Larger color gamuts are a good thing when utilized, and of no advantage when not

used. To support this point, there are colors that the Z3200 can produce that are outside the gamut of the large Adobe RGB color space,

meaning that you will actually under-utilize the printer’s true potential if you send sRGB or even Adobe RGB data. In the test I ran using a Z3200, Epson 7900 and Epson 7880 a few things became apparent. First, both the Z3200 and the 7900 produced prints with better

looking greens than the 7880. More people preferred the way the Z3200 rendered foliage than the 7900, but we we’re splitting hairs at

this point. The red on the Z3200 was undeniably preferred out of all of the printers, and interestingly the red/orange of the 7900 is very

similar to that of the Z3100. Blues were a bit harder to judge. Depending on the prole used, all three of the printers produced excellent

results with no clear winner. In general the Z3200 tended to produce the noticeable better results in lighter saturated greens and reds.

Dark saturated colors, aside from red, were slightly better on the Epson printers but by a small margin, showing another area of improvement in the Z3200 over the Z3100. The test on matte paper yielded the same conclusions as those on photo paper.

I think it’s safe to say that both the Z3200 and Epson 7900 are pushing the envelope of pigmented ink. To be honest the potential of either printer will only be realized by certain individuals with very demanding needs. Fine art reproduction and packaging

proong come to mind. HP now claims 95% pantone coverage, a really remarkable number. The differences in gamut will probably only

Z3200 Matte Litho paper - Full Color

Z3100 Matte Litho paper - White

CIE chromaticity diagram

Z3200 Matte Litho Paper - Full Color

Z3100 Matte Litho Paper - White

Z3100 (white) and Z2100 (color solid)

L*a*b* plot

Page 11

be noticeable on very specic images, and the advantages of one printer over the other will be fairly small at this point.

HP Z3200 Prem ID Satin - Solid Full Color

Epson 7900 Prem Luster 260 - White Wireframe

HP Z3200 Prem ID Satin - Solid Full Color

Epson 7880 Prem Luster 260 - White Wireframe

3d gamut - showing darker colors 3d gamut - showing darker colors

3d gamut - showing lighter colors

2D gamut

comparisons

HP Z3200 Prem ID Satin - Full Color

Epson 7900 Prem Luster 260 - White

Epson 7880 Prem Luster 260 - Black

3d gamut - showing lighter colors

Primaries and secondaries

HP Z3200 Prem ID Satin - Full Color

Epson 7900 Prem Luster 260 - White

Page 12

CONCLUSION

The Z3100 is an exception tool, and like any tool it should be evaluated based on how well it accomplishes what is designed to do. Compared to the other printers in the HP Designjet line it’s obvious that the Z3200 is designed from the ground up to be a “Photo Printer”,

meaning that the emphasis is on quality not quantity. In this capacity the printer is ideal for anyone looking to produce high quality color

critical work, this primarily includes photographic, ne art, graphic design, 3d renderings, proong and packaging.

For the photographer and graphic designer looking for consistent high quality output, this will be an enormously appealing product. For

color work the prints are as good as anything I’ve seen. The vibrant reds and greens are quite impressive and add to the realism and appeal of color photographs. For black and white work, there is little question in my mind that the Z3200 produces the best output from any

OEM ink set in production. The Z3100 makes monochrome printing easy, as well as elevating the quality of the output to the point where

lingering traditionalists may now want to reevaluate their stance on digital printing. HP has a massive selection of papers that should

fulll the needs of most photographers and designers. The improvements to the Z3200 should also improve the printers’s ability to use

3rd party and speciality media. HP has also integrated all the tools necessary for managing color, ensuring that good accurate color is

easily achievable. This solution oriented philosophy will hopefully allow users to spend more time employed in creative pursuits.

For the proong market, color accuracy and speed are often the driving issues. The large gamut easily allows SWOP and GRACoL

proofs, but the real advantage should be in spot color matching. The pantone emulation built into the PS version of the printer is quite

good. While the need to prole a wide verity of media may not be used as often in the proong world, the Z3100’s ability to perform

routine calibrations should offer an even more exacting degree of uniformity between units, aiding remote proong workows as well

as validating the accuracy of proofs. The drivers also provide excellent job accounting and consumables monitoring, which should allow

the units to function well in multi-printer and corporate environments.

Dissected into it’s many components there are a number of minor and a few fairly major improvements incorporated into the Z3200.

What is truly impressive however is the end result. Not everything about it is perfect. It frustrates me every time I have to move the

printer away from the wall to load a roll, or the loud BEEP the printer emits when a sheet is loaded crooked. I dislike it when the printer

crashes and the amount of time required to re-start. Despite these few shortcomings, the HP Z3200 is a great printer for its intended

market. The Z3200 has addressed all of the major headaches associated with digital printing, while pushing the envelope in terms of

quality, ease of use and archival stability. I considered the Z3100 somewhat of a milestone product, and the Z3200 build on that legacy.

It has all of the advantages of a V2 product, meaning that the things that didn’t work were mostly addressed and the things that did work

still do. Color gamut has surpassed virtually any other printing method. The stability of the prints exceed that of a typical human life and

should now be the standard against which all other processes are compared. Monochrome output, once the entry point into photographic

printing, has once again been made accessible to amateurs and experts alike. Color management has also been simplied to the point of

being accessible for the vast majority of users. All of these features have been brought together with the end goal of allowing the user to

focus as much energy as possible on the nished output, a major advance if there ever was one.

STRENGTHS

Hands-Off Maintenance - Printer is always ready to go

Low Ink Waste - No need to swap black, no maintenance tanks

Color Gamut - About as good as it gets for pigment inks

Black and White Print Quality - Neutral black and white, low metamerism

Print Quality - Gloss enhancer virtually eliminates bronzing and gloss differential

Good Drivers - Easy to use, allows for easy job tracking

On-Board Spectrophotometer - Allows automated ICC creation, proling system is easy and well designed

V2 Product - Building on lessons learned from Z3100, the Z3200 is a more rened product

Firmware Upgrades - Add functionality and evolve color gamut

WEAKNESSES

Speed - Quality over quantity

Ink Tank Size - Limited to 130 ml tanks

Paper Feed System - Rear loading system is a hassle, can not handle media over .8mm thick

Paper Advance - Roller system not as elegant as vacuum system

Firmware Upgrades - Large updates that have required reproling media at times

Startup time - Takes a long time to restart

Loading...

Loading...