HP StorageWorks

XP12000 Disk Array

site preparation guide

third edition (May 2005)

part number: AE002-96011

This guide contains site preparation information for the HP StorageWorks XP12000 Disk Array.

© 2004-2005, Hewlett-Packard Development Company, L.P. All rights reserved.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of

this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another language without the prior written consent of Hewlett-Packard. The

information contained in this document is subject to change without notice.

Product names mentioned herein may be trademarks of their respective companies.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein. The

information is provided “as is” without warranty of any kind and is subject to change without notice. The warranties for

Hewlett-Packard Company products are set forth in the express limited warranty statements accompanying such

products. Nothing herein should be construed as constituting an additional warranty.

Printed in the U.S.A.

HP StorageWorks XP12000 Disk Array Site Preparation Guide

third edition (May 2005)

part number: AE002-96011

2 HP StorageWorks XP12000 Disk Array Site Preparation Guide

About this guide 7

Related information 7

Document conventions and symbols 7

Getting help 8

HP technical support 8

HP storage web site 8

HP authorized reseller 9

Revision history 10

1 Site Prep Team and Tasks 11

The site prep team 12

HP representatives 12

Customer 12

Site prep tasks 13

Site prep checklist 13

Site prep time allowances 16

2 Site Requirements 17

Disk array physical specifications 18

Dimensions 19

Weights 19

Calculating the weight of your disk array configuration 22

Weight calculation example 24

General computer room requirements 25

Preventing electrostatic discharge 25

Safety requirements 27

Fire safety 27

Equipment servicing hazards 27

Contents

Contents 3

Raised floor requirements 28

Floor covering 29

Floor cutouts 29

Space planning requirements 32

The space planning process 32

Floor clearance 33

Environmental requirements 46

Altitude 46

Air conditioning 46

Temperature 47

Humidity 47

Mechanical vibration 48

Shock 49

Heat dissipation and power consumption 49

Acoustics 50

Dust and pollution control 50

Metallic particulate contamination 50

Data comm requirements 52

Electrical requirements 53

Line voltage 53

Branch circuit breakers 53

Frequency 54

Safety and dedicated ground 54

Grounding requirements 54

Receptacles 55

Power line transients 56

Maximum peak inrush and crest factor 57

Uninterruptible power supply (UPS) 58

Sources of electrical interference 59

Delivery space requirements 60

3 Delivery and Unpacking 61

Checking for shipping shortage and damage 62

Unpacking the equipment 63

Packaging configurations 63

Required personnel 63

Required tools 63

Unpacking process 64

4 HP StorageWorks XP12000 Disk Array Site Preparation Guide

A Electrical Specifications 69

AC line voltage requirements 70

50-amp, single-phase DKC 70

30-amp, single-phase DKC 70

30-amp, three-phase DKC 71

50-amp, single-phase DKU 71

30-amp, single-phase DKU 72

30-amp, three-phase DKU 72

Receptacle part numbers and ordering information 73

Three-phase cabling for the USA (60 Hz) 74

Connecting the external power-supply cords 74

Branch circuit requirements 75

Three-phase AC cabling for Europe (50 Hz) 76

Connecting the power-supply cords 76

Branch circuit requirements 77

Single-phase AC cabling for the USA 78

Connecting the power-supply cords 78

Branch circuit requirements 80

Single-phase cabling for Europe 81

Connecting the power-supply cords 81

Branch circuit requirements 82

Glossary 83

Index 95

Contents 5

6 HP StorageWorks XP12000 Disk Array Site Preparation Guide

About this guide

This guide is intended for anyone participating in preparing a site for the

installation of an HP StorageWorks XP12000 Disk Array.

Unless otherwise noted, the term disk array refers to the HP StorageWorks

XP12000 Disk Array.

Related information

For related product documentation, see the HP StorageWorks XP12000

Disk Array Owner’s Guide on the HP web site:

Document conventions and symbols

Table 1. Document conventions

Convention Element

Blue text (Figure 1) Cross-reference links

Bold Menu items, button names, key names, tab names, and group box names

www.hp.com

.

Italics Text emphasis and document titles

Blue underlined sans serif

font (www.hp.com

About this guide 7

)

Caution Failure to follow directions could result in hardware or software damage.

Web site addresses

Warning

Failure to follow directions could result in personal injury or death.

Getting help

If you have additional questions, contact your HP sales representative (HP

SR) or visit the HP web site:

HP technical support

In North America, call technical support at 1-800-652-6672, available 24

hours a day, 7 days a week.

Outside North America, call technical support at the location nearest you.

The HP web site lists telephone numbers for worldwide technical support:

www.hp.com/country/us/eng/support.html

Have the following information available before calling:

www.hp.com

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Applicable error messages

• Operating system type and revision level

.

.

• Detailed questions

For continuous quality improvement, calls may be recorded or monitored.

HP storage web site

For the most current information about HP StorageWorks XP products:

http://h18006.www1.hp.com/storage/arraysystems.html

8 HP StorageWorks XP12000 Disk Array Site Preparation Guide

.

HP authorized reseller

To obtain the name of your nearest HP authorized reseller:

United States 1-800-345-1518

Canada 1-800-263-5868

elsewhere See the HP web site for locations and telephone

numbers:

www.hp.com

About this guide 9

Revision history

September 2004 First edition

March 2005 Second edition

May 2005 Third edition

10 HP StorageWorks XP12000 Disk Array Site Preparation Guide

1

Site Prep Team and Tasks

The objective of a site prep is to prepare your site for the successful and

timely installation of the HP XP12000 disk array. Proper site preparation is

vital for the reliability of the disk array.

Site prep involves a careful balance of equipment design criteria, site

environmental variables, your business needs, and your budget constraints.

In addition to this guide, other site prep resources may be available to you.

The HP service organization is committed to making sure you receive

maximum benefit from your disk array. HP representatives will guide and

assist you throughout the site prep process.

Site Prep Team and Tasks 11

The site prep team

The site prep team plans, schedules, and completes all tasks necessary to

prepare your site for successful disk array installation.

The site prep team consists of HP representatives and you, the customer.

HP representatives

The HP team includes various HP representatives who have the training,

knowledge, experience, tools, and parts required to install and maintain XP

disk arrays. This team:

• Helps you to determine and implement the site requirements for your

specific site and array configuration

• Coordinates all HP resources to ensure successful delivery and

installation of the disk array

Your HP SR is your primary point of contact with HP during the site

preparation process.

Customer

As part of the site prep team, your responsibilities include planning and

preparing a suitable environment for the disk array, and scheduling

equipment delivery and installation. However, HP representatives are

available to help you throughout the site prep process. Your internal site

team may include personnel specializing in your site computer room, such

as your storage administrator and your site electrician.

12 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Site prep tasks

Contact your HP SR for assistance at any time during the site prep process.

1. If you have not printed a copy of this guide, HP recommends that you

print at least Chapter 2 and the “Site prep checklist” (page 13). Working

from printed copies makes it easier to use the tools provided and

provides hard copy documents that you can keep for your records.

2. Carefully review Chapter 2 to understand the site requirements for the

disk array. If you plan to connect additional external storage to the

XP12000, be sure to take the requirements of that storage into account.

See the documentation for the external system.

3. Use the information, instructions, and tools in Chapter 2 to determine

site requirements for the specific disk array components you ordered.

4. On the site prep checklist, answer each item “Yes” or “No” as it relates

to your site. The checklist includes references to the pages in this guide

where you can find more information on each item.

5. Checklist items that require a “Yes” answer are marked with asterisks

(*). If you answer “No” for any of these items, your site does not meet

site requirements for the disk array. Using the information in Chapter 2,

correct the site environment so that you can answer “Yes” for each of

these items.

6. When your site meets all site requirements, contact your HP SR to

coordinate delivery of the disk array equipment.

7. If you choose to unpack the equipment cartons without HP supervision,

follow the instructions in Chapter 3.

8. Contact the HP SR to schedule disk array installation and configuration.

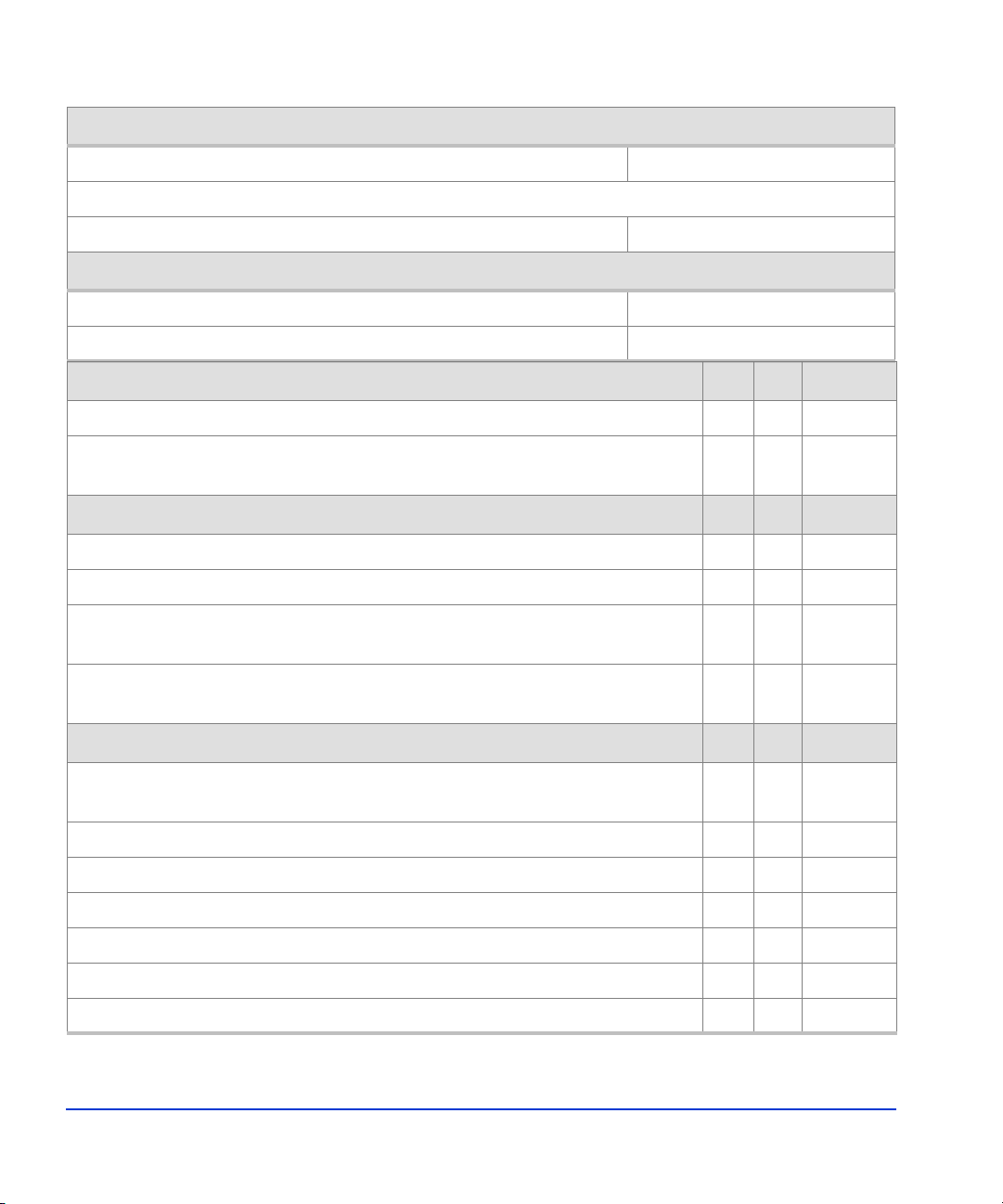

Site prep checklist

Checklist items that require a “Yes” answer are marked with asterisks (*).

The customer summary information is included for the benefit of HP

representatives, who will help you complete the checklist.

Site Prep Team and Tasks 13

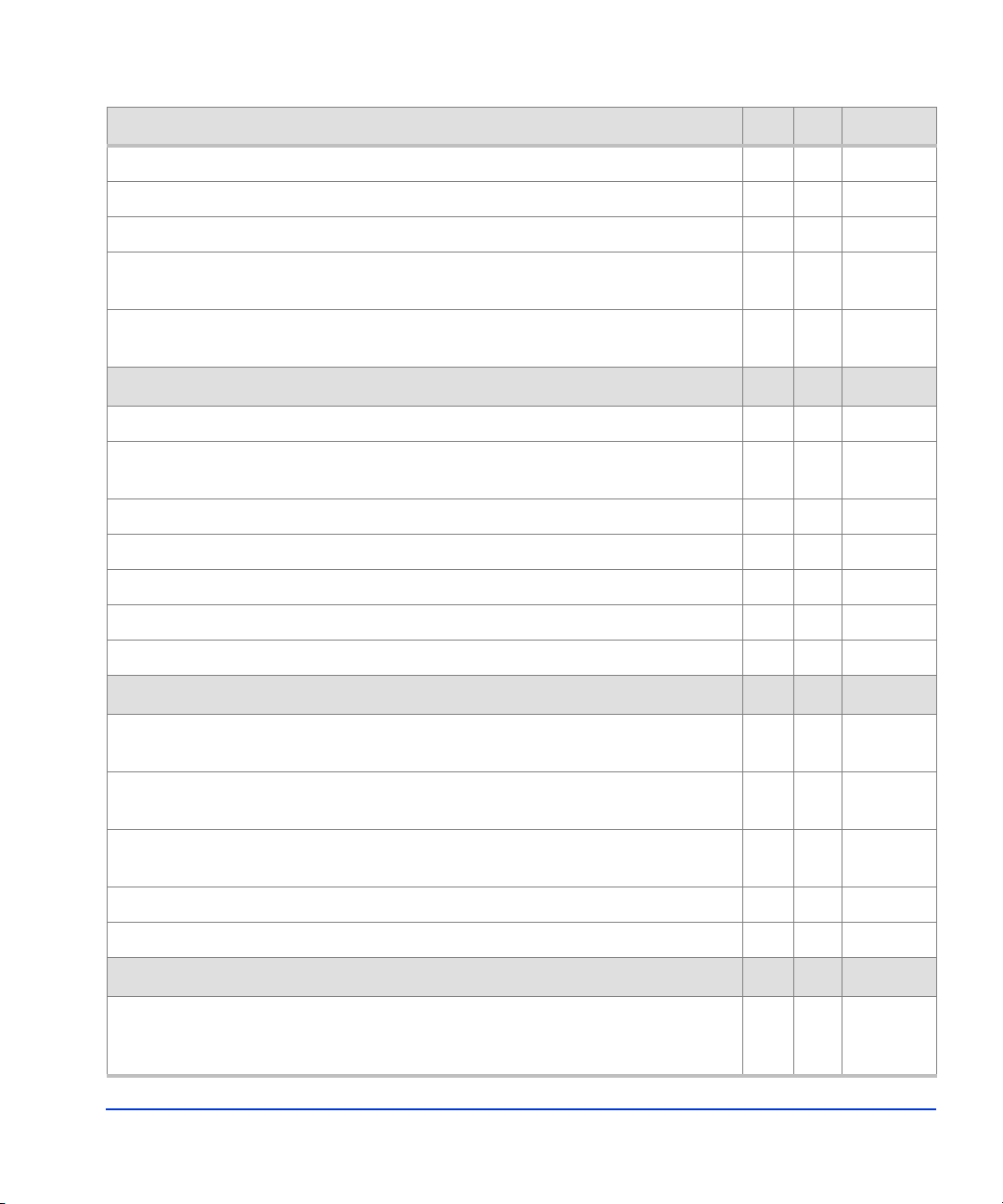

Customer summary

Customer: Date:

Address:

Contact: Phone:

HP summary

HP SR: Phone:

HP representative: Phone:

Safety Yes No Reference

Is there a fire protection system in the computer room? *❑❑page 27

Is the computer room free of any equipment servicing hazards (for example,

*❑❑page 27

electrical or data cables that obstruct access)?

Computer room space planning Yes No Reference

Is the existing floor plan documented? ❑❑page 32

Has a new floor plan been developed to include the new array? *❑❑page 32

Does the new floor plan include adequate space for airflow and servicing

*❑❑page 32

needs?

Does the new floor plan include the clearance required for the floor’s load

*❑❑page 33

rating?

Computer room infrastructure Yes No Reference

Is the computer room structurally complete (walls, floor, air conditioning

*❑❑Chapter 2

system, and so on)?

Is the raised floor adequate for the equipment load? *❑❑page 28

Is antistatic flooring or mats installed? *❑❑page 29

Are there cutouts or channels for cable routing? *❑❑page 29

Is there a dedicated analog telephone line for “phone home” configuration? *❑❑page 52

Is a telephone line available for HP representative use? *❑❑page 52

Is a private LAN available? *❑❑page 52

14 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Computer room environment Yes No Reference

Can the temperature be maintained between 16° and 32° C? *❑❑page 47

Can temperature changes be held to less than 10° C per hour? *❑❑page 47

Can the humidity level be maintained between 20% and 80%? *❑❑page 47

Is the computer room protected against dust, pollution, and metallic

*❑❑page 50

particulate contamination?

Does the computer room support other environmental considerations (such

as vibration and acoustics)?

Computer room electrical Yes No Reference

*❑❑page 48–

page 50

Are two AC outlets, on different lines, available for the equipment? *❑❑page 53

Does the input voltage correspond to the DKC and DKU equipment

*❑❑page 53

specifications?

Are the input circuit breakers adequate for equipment loads? *❑❑page 53

Does the input frequency correspond to equipment specifications? *❑❑page 54

Is an appropriate uninterruptible power supply (UPS) strategy in place? *❑❑page 58

If lightning arresters are recommended, are they installed? *❑❑page 59

Have all sources of electrical interferences been corrected? *❑❑page 59

Building access and security Yes No Reference

Does the customer site have access control (for example, HP representatives

❑❑NA

will need an escort)?

Does the computer room have access control (for example, HP

❑❑NA

representatives will need a security code)?

Are all floors, stairs, elevators, stairwalkers, lifts, ramps, or ladders needed

*❑❑page 60

to move the equipment adequate to support its weight and size?

Will the equipment fit through all doors and corridors and in lifts? *❑❑page 60

Does the building have a loading dock? Maximum access height is _____m. ❑❑NA

Additional equipment Yes No Reference

For any additional equipment required (for example, connectors,

*❑❑NA

receptacles, cables, and any equipment not supplied by HP), is the

equipment on site and ready for use?

Site Prep Team and Tasks 15

Site prep time allowances

The following site prep tasks may require several weeks:

• Acquiring required power connectors

• Arranging for an electrician

• Adding or modifying air conditioning systems

• Making building alterations

• Placing an order for data comm equipment

The time between placing an equipment order and actual delivery can vary.

Contact your HP representative to determine the best estimated delivery

dates.

16 HP StorageWorks XP12000 Disk Array Site Preparation Guide

2

Site Requirements

Your site must meet the following requirements before HP can deliver and

install the disk array:

• General computer room requirements, page 25

• Safety requirements, page 27

• Raised floor requirements, page 28

• Space planning requirements, page 32

• Environmental requirements, page 46

• Data comm requirements, page 52

• Electrical requirements, page 53

• Delivery space requirements, page 60

Site Requirements 17

Disk array physical specifications

Mini

Use the information in this section to determine the total dimensions and

weight for your specific array configuration. You will need these values to

complete other procedures in this chapter.

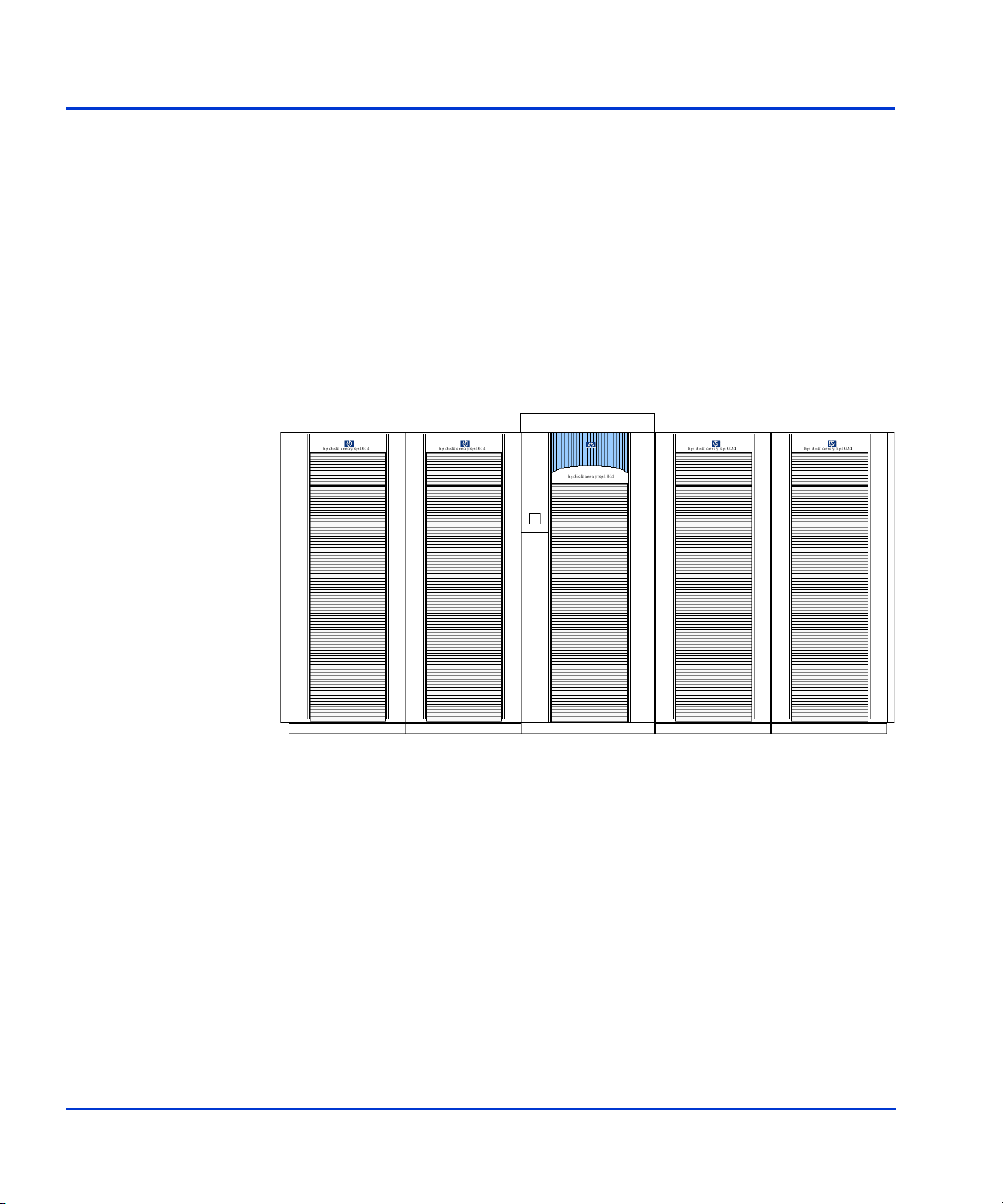

The disk array includes one disk controller frame (DKC), and zero to four

disk array frames (DKUs). The DKC contains the controller electronics for

the disk array and some hard disk drives. The DKUs contain additional

hard disk drives. Figure 1 shows a disk array with four DKUs.

mum disk subsystem

4th DKU (L2) 3rd DKU (L1) DKC 1st DKU (R1) 2nd DKU (R2)

Figure 1. Disk array minimum/maximum configuration

Supported configurations are:

• One DKC (minimum configuration)

• One DKC and one DKU (R1)

• One DKC and two DKUs (R1 and R2 or R1 and L1)

• One DKC and three DKUs (R1, R2, and L1 or R1, L1, and L2)

• One DKC and four DKUs (maximum configuration)

18 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Dimensions

Use the packaged values when determining delivery space requirements

(page 60), and unpackaged values during space planning (page 32).

Table 2. DKC and DKU dimensions

DKC Unpackaged DKC Packaged DKU Unpackaged DKU Packaged

Dimension

Width 78.2

cm in cm in cm in cm in

1

30.8 89 35.04 65 25.6 79 31.2

Depth 92.5 36.42 112.5 44.3 92.5 36.42 112.5 44.3

Height 186 73.23 202 79.52 186 73.23 202 79.52

1 Includes two side panels of 1.6 cm (0.63 in.) width each.

Weights

Use the approximate packaged weights when determining delivery space

requirements (page 60), and unpackaged weights to calculate the total

weight of your configuration (page 22).

Table 3 (page 20) provides the approximate weights for:

• Minimum configuration — base cabinet without additional product

components

• Maximum configuration — base cabinet fully populated with product

components

Site Requirements 19

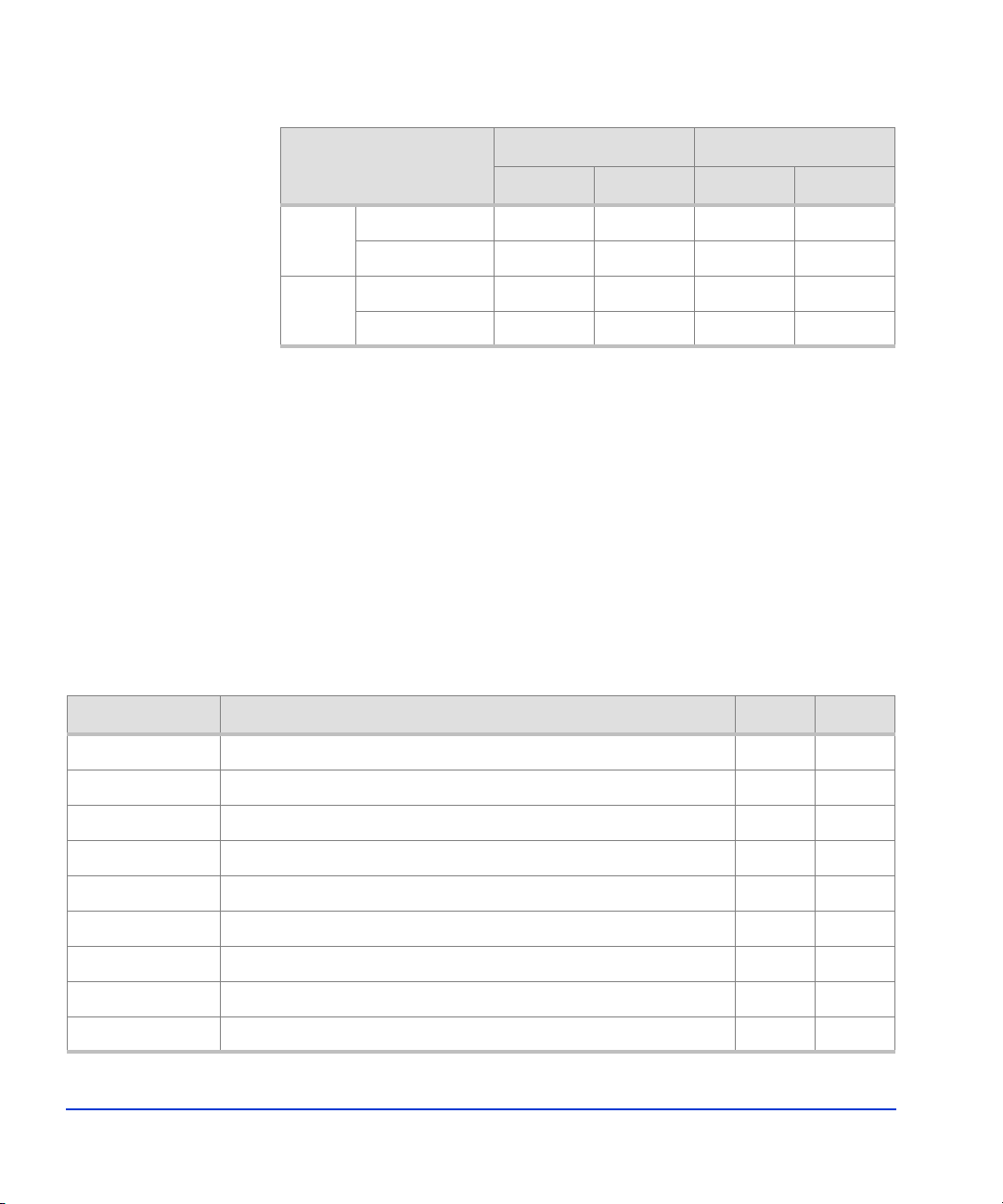

Table 3. DKC and DKU weights

Minimum configuration Maximum configuration

Cabinet

kg lb kg lb

Unpackaged 590 1300 875 1930

DKC

Packaged

1, 2

689 1518 989 2180

Unpackaged 429 945 739 1630

DKU

Packaged

1 For shipments from the USA to locations outside the USA and Canada, add 59 kg (130 lb)

for an international shipping crate.

2 Within the USA and Canada, most shipments use a special carrier process in which frames

are shipped without pallets, ramps, and cartons. In these cases, the packaged weight is the

unpackaged weight plus 23 kg (50 lb).

3 For upgrade DKU packaging (includes a ramp), add 29 kg (65 lb).

1, 3

499 1100 853 1880

The main factor that increases total weight is the number of disk drives.

The actual weight is the base cabinet weight plus the weight of all

additional components installed.

Table 4 provides the approximate weights of additional disk array

components when integrated into a DKC or DKU cabinet.

Table 4. Component weights

Product Description kg lb

AE002A #001 Three-phase 30A/60Hz for XP12000 DKC 22.6 50

AE002A #002 Three-phase 30A/50Hz for XP12000 DKC 20 44

AE002A #003 Single-phase 50A/60Hz for XP12000 DKC 21.3 47

AE002A #004 Single-phase 50A/50Hz for XP12000 DKC 17.2 38

AE002A #005 Single-phase 30A/60Hz for standard XP12000 DKC 20 44

AE002A #006 Single-phase 30A/50Hz for standard XP12000 DKC 18.6 41

AE002A #007 Single-phase 30A/60Hz for minimum XP12000 DKC 15.9 35

AE002A #008 Single-phase 30A/50Hz for minimum XP12000 DKC 15 33

AE003A XP12000 SVP High Reliability Support Kit 8.6 19

20 HP StorageWorks XP12000 Disk Array Site Preparation Guide

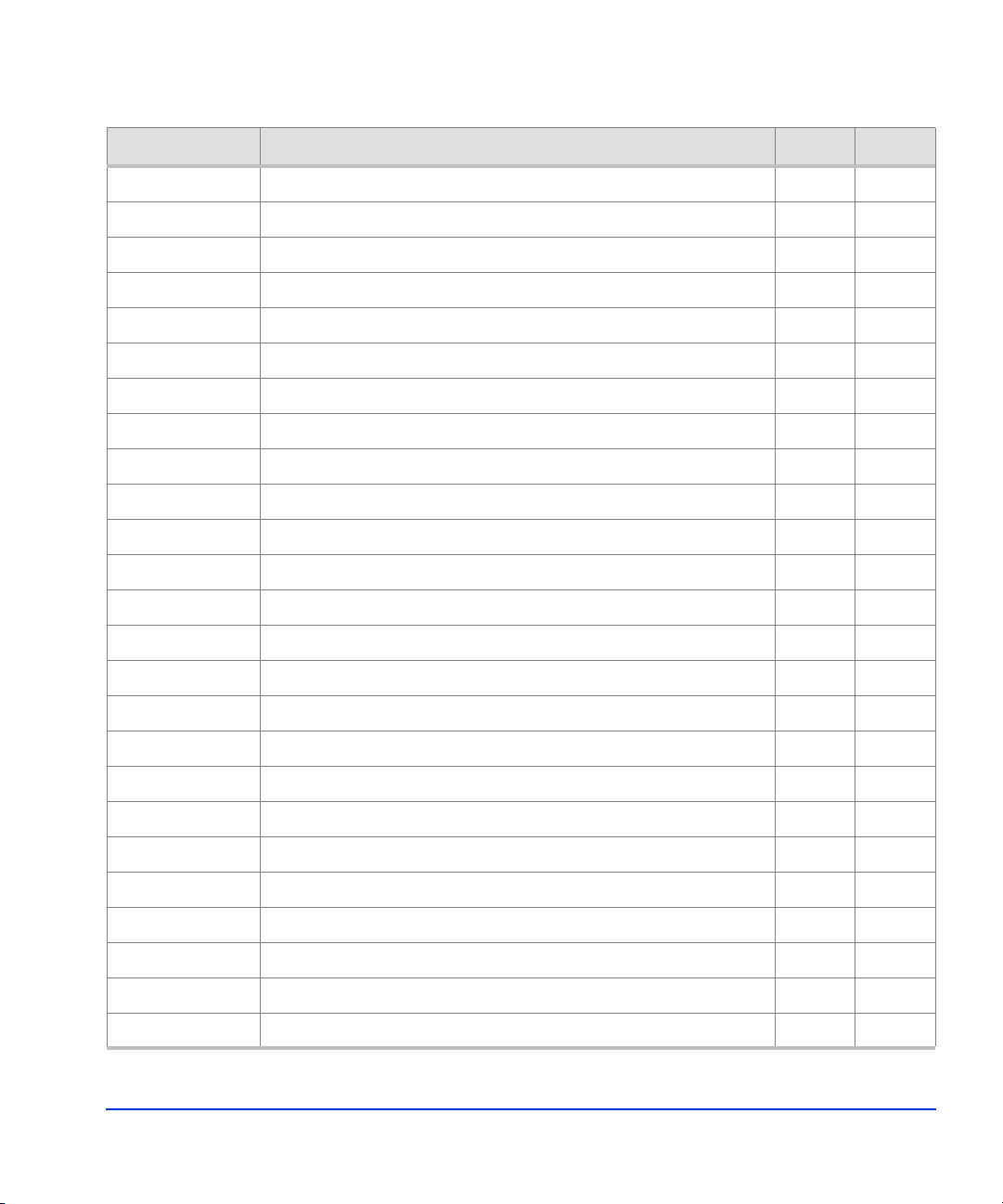

Table 4. Component weights (continued)

Product Description kg lb

AE004A XP12000 Power Control Interface Kit for Mainframe 0.5 1

AE006A XP12000 16-port 1–2 Gbps FC SW CHIP pair 5 11

AE007A XP12000 32-port 1–2 Gbps FC SW CHIP pair 5.9 13

AE008A XP12000 FC SFP Transceiver LW 0.03 0.05

AE013A XP12000 8-port 1–2 Gbps FICON SW CHIP pair 5.9 13

AE014A XP12000 8-port 1–2 Gbps FICON LW CHIP pair 5.9 13

AE017A XP12000 16-port EXSA CHIP pair 5.4 12

AE018A HP XP12000 8-Port 1 Gbps NAS SW CHIP 6.5 14

AE024A XP12000 DKC Power Supply 23.1 51

AE025A XP12000 4 GB Cache Memory Module 0.2 0.5

AE027A XP12000 Cache Platform Board 6.4 14

AE028A XP12000 DKC-DKU Battery 13.7 30

AE030A XP12000 1 GB Shared Memory Module 0.05 0.1

AE032A XP12000 Shared Memory Platform Board 2.3 5

AE033A XP12000 Cache Switch 3.6 8

AE034A XP12000 Standard Performance ACP pair 5 11

AE040A XP12000 Cable Set for DKU R1, basic 3.2 7

AE041A XP12000 Cable Set for DKU R1, high performance 4.1 9

AE042A XP12000 Cable Set for DKU L1, basic 4.1 9

AE043A XP12000 Cable Set for DKU L1, high performance 4.5 10

AE044A XP12000 Cable Set for DKU R2 or L2 2.3 5

AE045A #001 Three-phase 30A/60Hz for XP12000 DKU 22.6 50

AE045A #002 Three-phase 30A/50Hz for XP12000 DKU 20 44

AE045A #003 Single-phase 50A/60Hz for XP12000 DKU 21.3 47

AE045A #004 Single-phase 50A/50Hz for XP12000 DKU 17.2 38

Site Requirements 21

Table 4. Component weights (continued)

Product Description kg lb

AE045A #005 Single-phase 30A/60Hz for XP12000 DKU 20 44

AE045A #006 Single-phase 30A/50Hz for XP12000 DKU 18.6 41

AE046A XP12000 High Performance FC-AL Disk Path 6.8 15

AE050A XP12000 73 GB 15K rpm Array Group, four disks 4.5 10

AE050AS XP12000 73 GB 15K rpm Spare Disk 1.4 3

AE051A XP12000 146 GB 10K rpm Array Group, four disks 4.1 9

AE051AS XP12000 146 GB 10K rpm Spare Disk 0.9 2

AE053A XP12000 300 GB 10K rpm Array Group 4 9

AE053AS XP12000 300 GB 10K rpm Spare Disk 1 2

Calculating the weight of your disk array configuration

The total weight of your array configuration includes not just the DKC and

DKU(s), but also the number of disk drives in each cabinet and any

optional components. Your site must have adequate floor strength to

support the total weight of the array, from the delivery area to the computer

room.

Use the weight calculation worksheet (page 23) to calculate the total weight

of your unpackaged array configuration, in your preferred units (kg or lb).

See Table 6 (page 24) for an example of a completed worksheet.

Use the calculated total weight to estimate the required floor load rating for

the computer room (page 28).

22 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Table 5. Weight calculation worksheet

Units (kg or lb)

Part Number Description Weight1Quantity

x=

x=

x=

x=

x=

x=

x=

x=

x=

x=

Extended

weight

x=

x=

x=

x=

x=

x=

x=

Total weight of your configuration

1From Table3 (page 20) or Table 4 (page 20).

Site Requirements 23

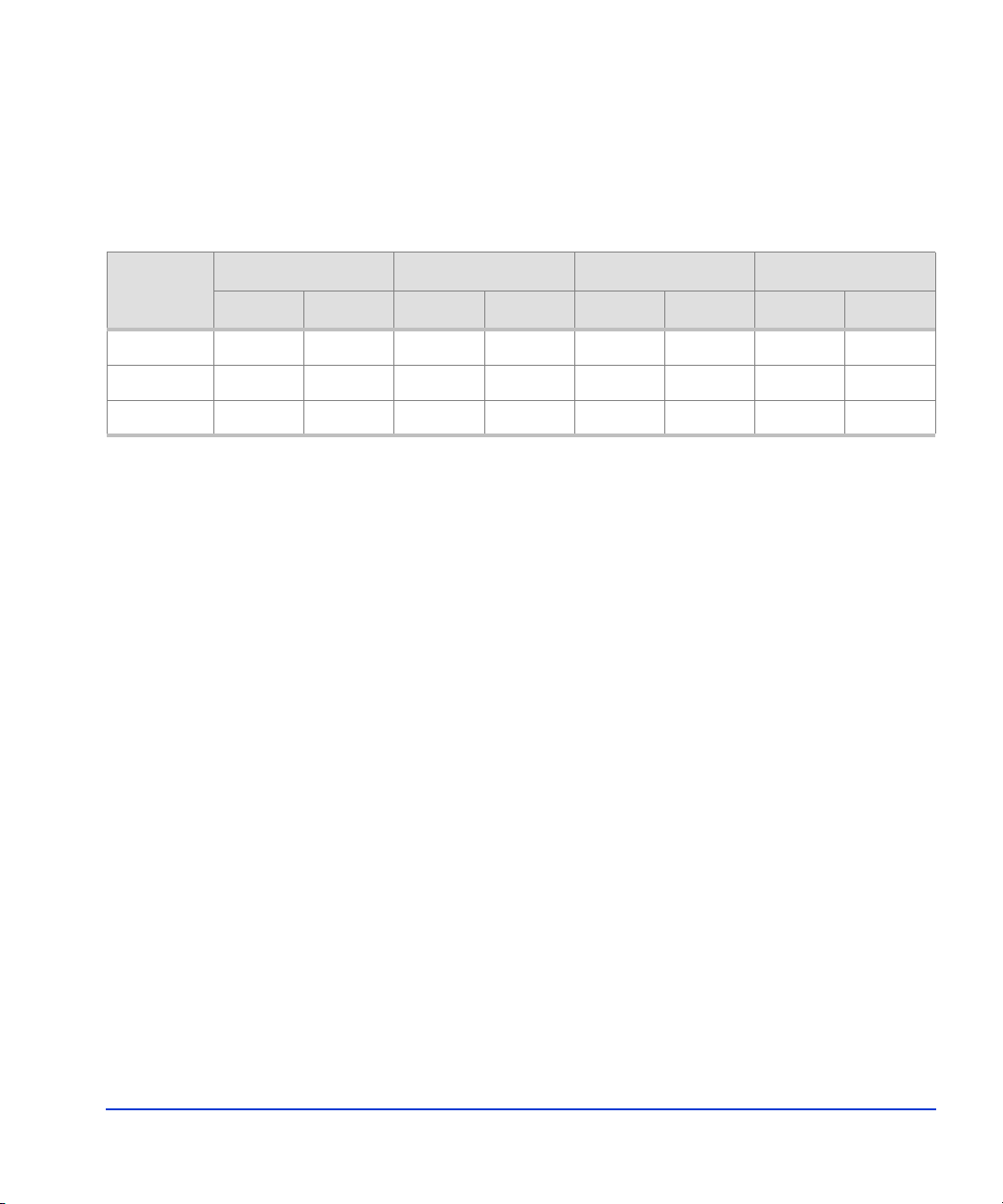

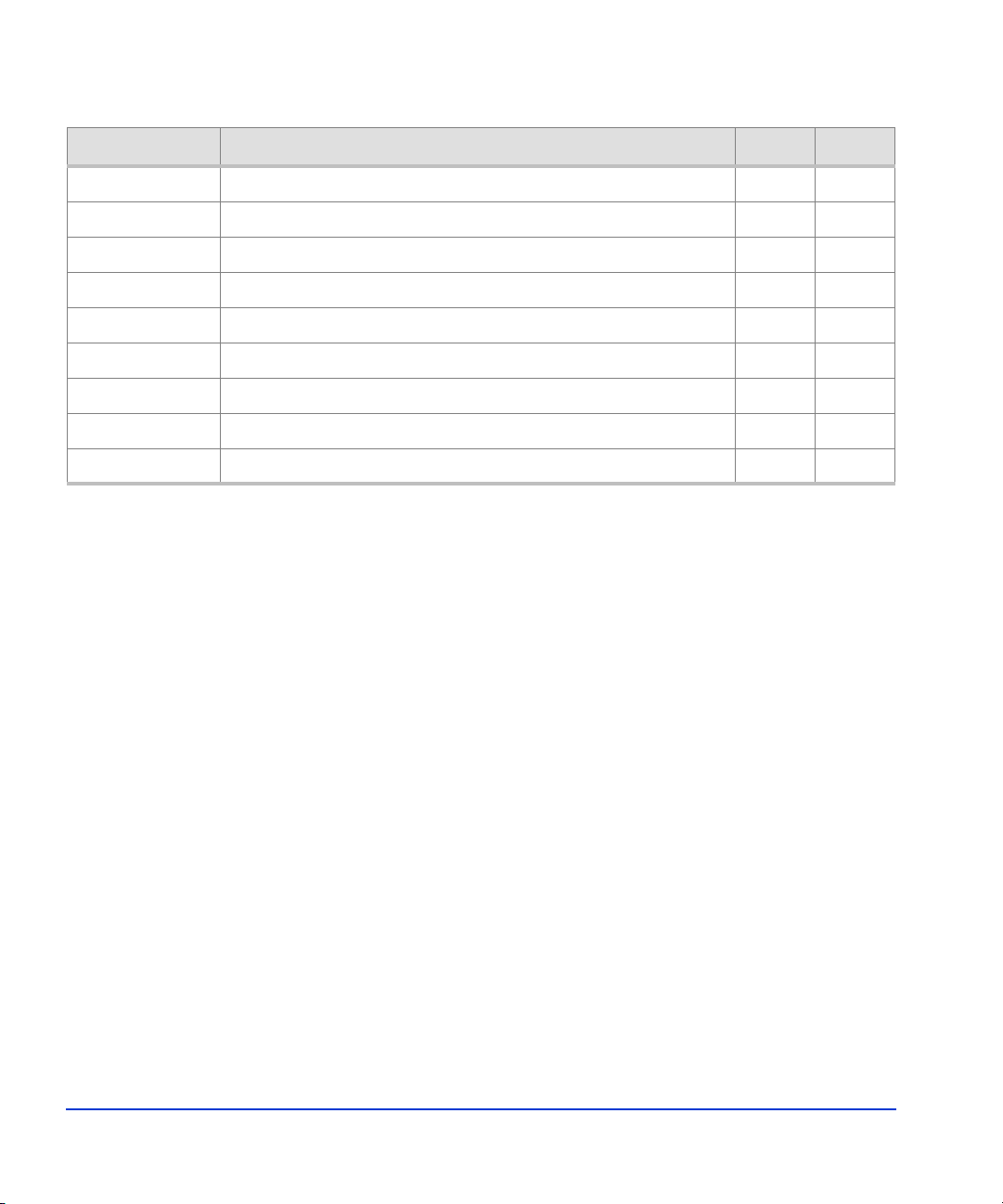

Weight calculation example

Table 6. Weight calculation worksheet example

Units (kg or lb)

Part Number Description Weight

Pounds (lb)

1

Quantity

Extended

weight

AE002A XP12000 Disk Control Frame (DKC) 1300 x 1 = 1300

AE002A #001 Three-phase 30A/60Hz for XP12000 DKC 50 x 1 = 50

AE007A XP12000 32-port 1–2 Gbps FC SW CHIP pair 13 x 2 = 26

AE013A XP12000 8-port 1–2 Gbps FICON SW CHIP pair 13 x 1 = 13

AE024A XP12000 DKC Power Supply 51 x 1 = 51

AE025A XP12000 4 GB Cache Memory Module 0.5 x 8 = 4

AE028A XP12000 DKC-DKU Battery 30 x 4 = 120

AE030A XP12000 1 GB Shared Memory Module 0.1 x 3 = 0.3

AE033A XP12000 Cache Switch 8 x 1 = 8

AE034A XP12000 Standard Performance ACP pair 11 x 2 = 22

AE040A XP12000 Cable Set for DKU R1, basic 7 x 1 = 7

AE041A XP12000 Cable Set for DKU R1, high performance 9 x 1 = 9

AE045A XP12000 Disk Array Frame (DKU) 945 x 1 = 945

AE045A #001 Three-phase 30A/60Hz for XP12000 DKU 50 x 1 = 50

AE046A XP12000 High Performance FC-AL Disk Path 15 x 1 = 15

AE051A XP12000 146 GB 10K rpm Array Group, four disks 9 x 70 = 630

AE051AS XP12000 146 GB 10K rpm Spare Disk 2 x 4 = 8

Total unpackaged weight of your configuration

1From Table3 (page 20) or Table 4 (page 20).

24 HP StorageWorks XP12000 Disk Array Site Preparation Guide

3258.3

General computer room requirements

The goal of a computer room is to maintain an ideal environment for

computer equipment, including XP disk arrays.

Make sure your computer room adheres to all national and local building

codes for a data center/computer room environment.

HP recommends that you follow these general guidelines:

• Locate the computer room away from exterior walls of the building to

avoid the heat gain from windows and exterior wall surfaces.

• When exterior windows are unavoidable, use windows that are double

or tripled glazed and shaded to prevent direct sunlight from entering

the computer room.

• Maintain the computer room at a positive pressure relative to the

surrounding spaces to reduce introduction of contaminants.

• Install a vapor barrier around the entire computer room envelope

(floors/walls/ceiling) to help keep moisture out of the room. This is

especially important if your computer room is located underground.

• Caulk and vapor-seal all pipes and cables that penetrate the computer

room envelope.

Preventing electrostatic discharge

Electrostatic discharge (ESD) can cause component damage during

servicing operations.

Static charges occur when objects are separated or rubbed together. The

voltage level of a static charge is determined by the following factors:

• Types of materials

• Relative humidity — low humidity contributes to undesirably high

levels of electrostatic charges, which increases the ESD voltage

potential.

Site Requirements 25

• Rate of change — a standard air conditioner both cools and removes

moisture from the air. The rate of change is how quickly the air in the

room is dried. The drier the air, the more static is generated. If you do

not use proper cooling equipment, air dryness can present problems.

• Separation — refers to the static discharge that can be generated when

two objects are separated. For example, printer paper is often stored in

cool dry conditions. If opened and used immediately, the act of

removing the paper from its box generates static. To allow the static to

discharge gradually over time, leave the box open in the computer

room for several hours before use.

Follow these precautions to minimize possible ESD-induced failures in

your computer room:

• Install conductive flooring (conductive adhesive must be used when

laying tiles).

• Use conductive wax if waxed floors are installed.

• Ensure that all equipment and flooring are properly grounded and are

at the same ground potential.

• Use conductive tables and chairs.

• Store spare electric parts in antistatic containers.

• Maintain recommended humidity level and airflow rates.

26 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Safety requirements

When making decisions concerning site safety, your first concern should be

the safety of your personnel and then the safety of your equipment.

Fundamental safeguards for disk arrays should include a site well away

from any sources of potential damage.

If you have any questions on site safety, consult your HP representative,

your insurance carrier, and local building inspectors for safety

recommendations.

Fire safety

Do not install or operate the disk array in an environment where there is a

risk of fire or explosion due to the presence of highly flammable gases,

volatile liquids, or combustible dust.

Consult your insurance carrier and local fire department for fire safety

suggestions. They can analyze your existing fire control systems and advise

you on any required changes. If you are building a new site or making

structural changes to an existing site, consult your local building codes for

fire prevention and protection guidelines.

Equipment servicing hazards

Your staff and HP service personnel require safe access to the disk array.

Running electrical and data communication cables underneath your

computer room’s raised floor is the best way to ensure that they do not

create a safety hazard.

Site Requirements 27

Raised floor requirements

The computer room floor must be able to support the total weight of the

equipment as well as localized weight at each caster or foot of the

equipment cabinets. A common method of preparing an adequate floor for

a computer room is to construct a raised floor over the building floor. A

raised floor:

• Allows weight to be spread evenly across the floor

• Provides an under-floor area for running interconnecting cables

conveniently and unobtrusively

• Allows optimum distribution of conditioned air

Warning

If metal is used in the construction of the raised floor, ensure that there is a

common ground connection between the raised floor and main floor to

avoid possible build up of different voltage potentials. Failure to comply

can result in serious injury to personnel and damage to equipment.

Requirements for raised floors:

• Raised floor access ramps must not exceed a 10

• Use a 10- to 12-inch raised floor system for the most favorable room

air distribution system.

• Grid panels must be at least 45 x 45 cm (17.72 x 17.72 in).

• The floor must have a load rating between 300 and 500 kg per square

meter (553 to 921.7 lb per square yard, or 61.4 to 102.4 lb per square

foot). The maximum point floor loading is 500 kg (1102.3 lb).

To estimate the load rating you need for your floor, consider the total

weight of all of these items:

• The disk array; see “Weights” (page 19)

• Other equipment

28 HP StorageWorks XP12000 Disk Array Site Preparation Guide

° slope.

Floor covering

Caution HP strongly discourages the use of carpeting, including antistatic varieties,

Caution If your computer room has carpeting, place static discharge mats where

• Furniture such as desks, chairs, and storage cabinets

• Computer room personnel

• Moving equipment such as forklifts, dollies, and similar items

The lower the floor load rating, the more clearance is required around the

array to distribute the equipment weight correctly. If your computer room is

too small to allow for minimum required clearance around the array, you

may need to increase the floor load rating. For more on required clearance,

see “Floor clearance” (page 33).

HP recommends the use of a tiled raised floor.

within 6.0 m (20 ft.) of the disk array. Over time, carpeting may shed dust

that can cause problems with the disk array.

personnel must walk across them before touching any part of the array.

Failure to comply with this precaution can result in equipment damage

through static discharge.

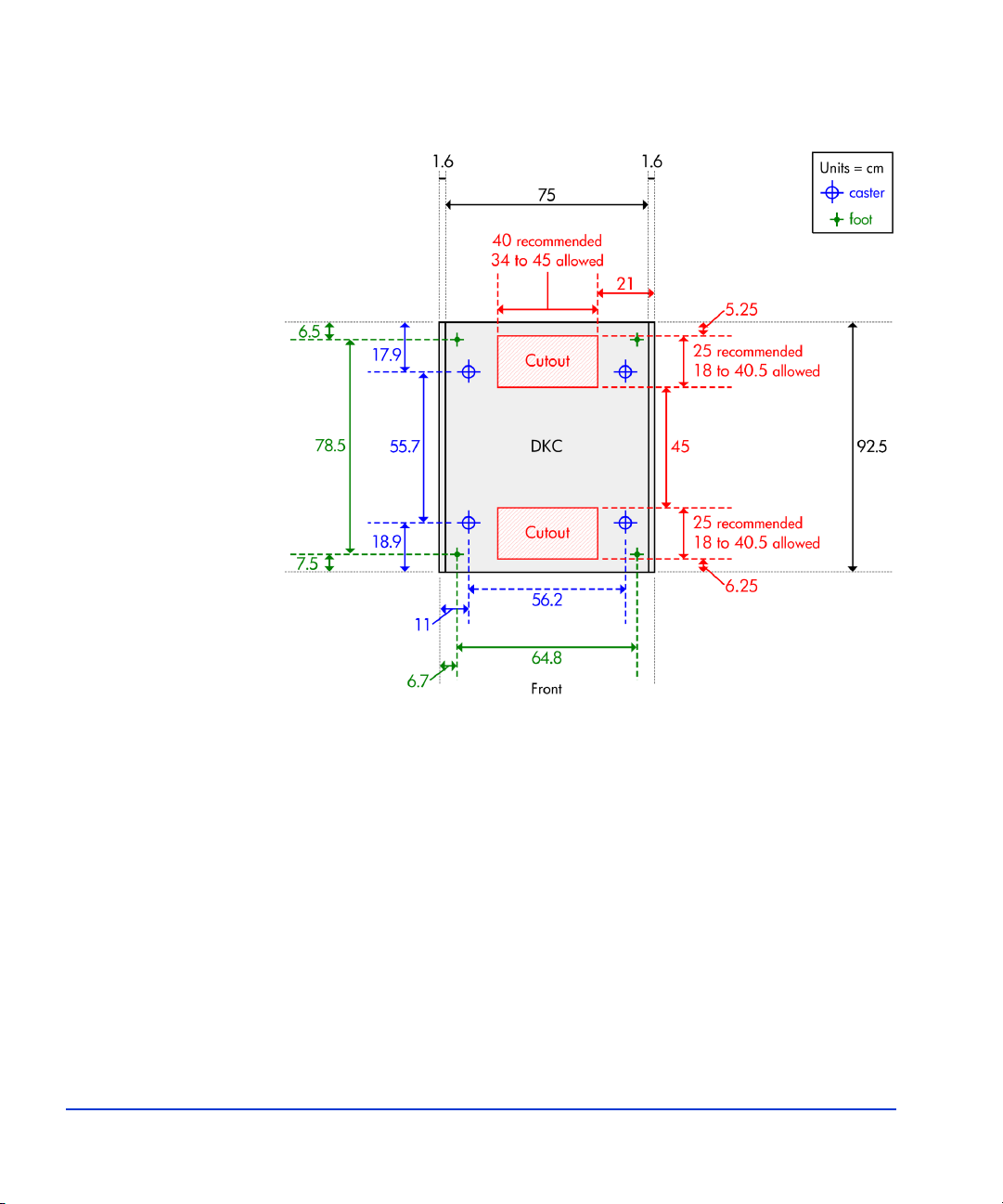

Floor cutouts

Figure 2 (page 30) and Figure 3 (page 31) show the locations of floor

cutouts under the DKC and DKU. Basically, position floor cutouts toward

the center of the cabinet. The position may be off-center as long as the

cutout is within the allowable range and allows smooth entrance of an

external cable (check the relationship between the position of the cutout

and the opening on the bottom of the cabinet).

Site Requirements 29

DKC floor cutouts

Figure 2. DKC floor cutouts

30 HP StorageWorks XP12000 Disk Array Site Preparation Guide

DKU floor cutout

Figure 3. DKU floor cutout

Site Requirements 31

Space planning requirements

Space planning involves making sure that your computer room:

• Is large enough to hold the new array and other equipment and

furniture

• Provides minimum clearance around the array for service access and

to ensure proper weight distribution on the computer room’s floor

• Includes correctly positioned floor cutouts for the array’s power and

data cables

The space planning process

1. Document your computer room’s existing floorplan, including the

locations of:

• Immovable objects, such as structural support columns

• Walls

• All equipment, furniture, cabinets, racks, data comm equipment,

and systems

• Floor cutouts

• Electrical outlets

• Interconnecting cables and power cords, including lengths

• Floor vents

2. Develop a new floorplan that includes the locations of:

• Immovable objects from your existing floorplan

• Walls

• The array with required clearance; see “Floor clearance” (page 33)

• All other equipment, furniture, cabinets, racks, data comm

equipment, and systems

• Floor cutouts; see “Floor cutouts” (page 29)

• Electrical outlets

32 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Floor clearance

• Interconnecting cables and power cords (keep cables away from

traffic areas to help prevent accidents and equipment failures)

• Floor vents

• Enough space and lighting for people to work effectively on a daily

basis and for periodic equipment servicing

• Flexibility to accommodate additional equipment as your

requirements increase

3. Implement the new floor plan, leaving empty space where the array will

be installed. If the new floorplan requires construction changes, consult

with local contractors and your HP representatives.

The total floor clearance required for the disk array includes:

• The actual space required by the equipment.

• Service clearance — the floor space required to access the disk array.

Never use this space for storage.

• Additional space required to properly distribute the equipment weight

on your computer room’s raised floor. The amount of additional space

required depends on your floor load rating.

To determine the floor clearance required for your disk array configuration:

1. Refer to the appropriate diagram for your array configuration:

• DKC only—Figure 4 (page 36)

• DKC with one DKU—Figure 5 (page 38)

• DKC with two DKUs—Figure 6 (page 40)

• DKC with three DKUs—Figure 7 (page 42)

• DKC with four DKUs—Figure 8 (page 44)

Site Requirements 33

2. In the floor clearance diagram:

• Clearance “A” is the space between the service clearance at the left

side of the array (10 cm for the kickplate) and any other object,

such as a desk or wall.

• Clearance “B” is the space between the service clearance at the

right side of the array (10 cm for the kickplate) and any other

object.

• Clearance “C” is the space between the service clearance at the

front of the array and any other object.

You use the value of C and your floor load rating to determine the

values for A and B.

3. Determine how much space you can assign to clearance C. For

maintenance purposes, try to make C larger (100 cm) rather than smaller

(0 cm). The smaller C is, the larger A and B must be.

4. In the table after the diagram, find the column for C. If your C value is

in between two table values, use the larger table value. Then, find the

row for your floor load rating. Where the column and row intersect is

the A+B value.

5. To determine clearance A and clearance B, divide the A+B value

between A and B. They do not need to be equal. For example, if the

A+B value from the table is 60 cm, then A can be 40 cm and B can be

20, or both A and B can be 30. However, if your configuration includes

only a DKC, or a DKC and one DKU, then A must be at least 28 cm

(11.1 in) to allow for opening the DKC front door.

34 HP StorageWorks XP12000 Disk Array Site Preparation Guide

6. Calculate the floor clearance for the array:

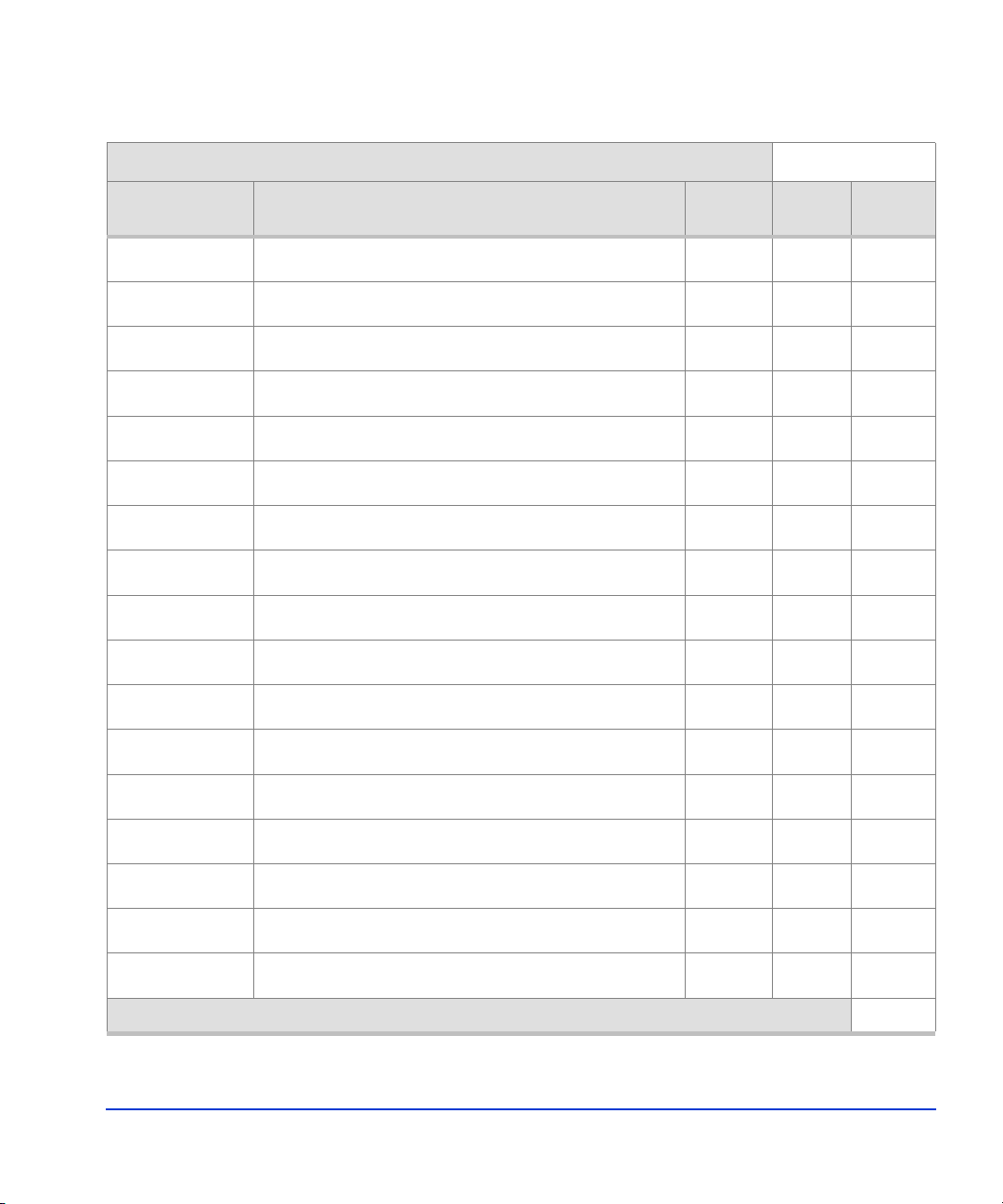

Table 7. Calculating floor clearance

Left Right Front Back

Clearance values

Minimum service clearance

Minimum floor clearance

A = _________+B = _________+C = _________+Not applicable

10 cm (3.94 in)=10 cm (3.94 in)=80 cm (31.5 in)=80 cm (31.5 in)

80 cm (31.5 in)

Site Requirements 35

Floor clearance — DKC only

Figure 4. Floor clearance — DKC only

For an explanation of this diagram, see step 2 (page 34).

36 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Table 8. A+B based on C and floor load rating — DKC only

Floor load

rating

(kg/m2)

C=0,

A+B must =

C=20 cm (7.9 in),

A+B must =

C=40 cm (15.8 in),

A+B must =

C=60 cm (23.6 in),

A+B must =

C=100 cm (39.4 in),

A+B must =

500 40 30 20 0 0

450 50 40 30 20 0

400 80 60 50 40 20

350 110 90 80 60 40

300 170 140 120 100 80

Site Requirements 37

Floor clearance — DKC and one DKU

Figure 5. Floor clearance — DKC and one DKU

For an explanation of this diagram, see step 2 (page 34).

38 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Table 9. A+B based on C and floor load rating — DKC and one DKU

Floor load

rating

(kg/m2)

C=0,

A+B must =

C=20 cm (7.9 in),

A+B must =

C=40 cm (15.8 in),

A+B must =

C=60 cm (23.6 in),

A+B must =

C=100 cm (39.4 in),

A+B must =

500 80 60 40 20 0

450 110 90 70 50 20

400 160 130 100 80 50

350 230 190 160 130 90

300 330 280 240 210 160

Site Requirements 39

Floor clearance — DKC and two DKUs

Figure 6. Floor clearance — DKC and two DKUs

For an explanation of this diagram, see step 2 (page 34).

40 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Table 10. A+B based on C and floor load rating — DKC and two DKU

Floor load

rating

(kg/m2)

C=0,

A+B must =

C=20 cm (7.9 in),

A+B must =

C=40 cm (15.8 in),

A+B must =

C=60 cm (23.6 in),

A+B must =

C=100 cm (39.4 in),

A+B must =

500 120 90 60 40 0

450 170 130 100 70 30

400 240 200 160 130 80

350 340 280 240 200 140

300 500 430 370 320 240

Site Requirements 41

Floor clearance — DKC and three DKUs

Figure 7. Floor clearance — DKC and three DKUs

For an explanation of this diagram, see step 2 (page 34).

42 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Table 11. A+B based on C and floor load rating — DKC and three DKUs

Floor load

rating

(kg/m2)

C=0,

A+B must =

C=20 cm (7.9 in),

A+B must =

C=40 cm (15.8 in),

A+B must =

C=60 cm (23.6 in),

A+B must =

C=100 cm (39.4 in),

A+B must =

500 160 120 80 50 0

450 230 180 140 100 50

400 320 260 210 170 100

350 460 380 320 270 190

300 660 570 490 420 320

Site Requirements 43

Floor clearance — DKC and four DKUs

Figure 8. Floor clearance — DKC and four DKUs

For an explanation of this diagram, see step 2 (page 34).

44 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Table 12. A+B based on C and floor load rating — DKC and four DKUs

Floor load

rating

(kg/m2)

C=0,

A+B must =

C=20 cm (7.9 in),

A+B must =

C=40 cm (15.8 in),

A+B must =

C=60 cm (23.6 in),

A+B must =

C=100 cm (39.4 in),

A+B must =

500 200 150 100 70 0

450 290 230 170 130 60

400 410 330 270 210 130

350 570 480 400 340 240

300 830 710 610 530 400

Site Requirements 45

Environmental requirements

The environmental specifications for operating your disk array must be

satisfied before installation.

Altitude

The maximum altitude for disk array operation is 3,000 meters. For

nonoperational or storage situations, the maximum altitude is 4,000 meters.

Air conditioning

Use separate computer room air conditioning duct work. If it is not separate

from the rest of the building, it might be difficult to control cooling and air

pressure levels. Duct work seals are important for maintaining a balanced

air conditioning system and high static air pressure. Adequate cooling

capacity means little if humidity levels increase when the ducts are exposed

to warm air, producing condensation. Condensation on any disk hardware

can damage the components.

Any questions regarding the adequacy of airflow construction should be

referred to and evaluated by a qualified structural engineer.

46 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Temperature

Table 13. Temperature specifications

Temperature range type Range

Recommended operating temperature range 21° to 24°C

70° to 75°F

Operating temperature 16° to 32°C

61° to 89°F

Nonoperating temperature range –10° to +43°C

14° to 109°F

Humidity

Shipping and storage temperature

(product packed in factory packing)

Temperature shock immunity

(maximum rate of temperature change)

Over-temperature warning At 40°C

Over-temperature shutdown At 60°C

Maintain proper humidity levels. High humidity levels cause galvanic

actions to occur between some dissimilar metals. This eventually causes a

high resistance between connections, leading to equipment failure.

Low humidity contributes to undesirably high levels of electrostatic

charges. This increases the electrostatic discharge (ESD) voltage potential.

ESD can cause component damage during servicing operations.

Low humidity levels are often the result of the facility heating system and

occur during the cold season. Most heating systems provide air with a low

humidity level, unless the system has a built-in humidifier.

–25° to +60°C

–13° to +140°F

10°C per hour

18°F per hour

At 104°F

At 140°F

Site Requirements 47

You should not see any condensation in or around the disk array under any

conditions. There is no procedure for recovery from moisture condensation.

Table 14. Humidity specifications

Noncondensing relative

Humidity range type

humidity (RH)

Recommended operating humidity range at 22° C (71° F) 50% to 55%

Operating humidity range at 22° C (71° F) 20% to 80%

Nonoperating humidity range 8% to 90%

Shipping and storage humidity range (product packed in factory packing) 5% to 95%

Operating maximum wet bulb temperature 26° C (79° F)

Nonoperating maximum wet bulb temperature 27° C (81° F)

Shipping and storage maximum wet bulb temperature 29° C (84° F)

Mechanical vibration

Continuous vibration can cause a slow degradation of mechanical parts

and, when severe, can cause data errors in disk drives. Mechanical

connections such as printed circuit assembly (PCA) conductors, cable

connectors, and processor backplane wiring can also be affected by

vibrations. Vibration specifications apply to all three axes.

Table 15. Mechanical vibration specifications

Condition Specification

Operating 0.25 mm, 5–10 Hz

0.05 G, 10–300 Hz

Nonoperating 2.5 mm, 5–10 Hz

0.5 G, 10–70 Hz

0.05 mm, 70–99 Hz

1.0 G, 99–300 Hz

1

Shipping and storage (product packed in factory packing) 0.5 G, 15 min.

at four most severe

resonances between 5–200 Hz

1 See ASTM D999-91 Standard Methods for Vibration Testing of Shipping Containers.

48 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Shock

Table 16. Shock specifications

Condition Specification

Operating None

Nonoperating 8 G, 15 ms

Shipping and storage (product packed in

factory packing)

Horizontal:

Incline impact: 1.22 m/s

1

1 See ASTM D5277-92 Standard Test Methods for Performing Programmed Horizontal

Impacts Using an Inclined Impact Tester.

2 See ASTM D1083-91 Standard Test Methods for Mechanical Handling of Unitized Loads

and Large Shipping Cases and Crates.

Heat dissipation and power consumption

Table 17 describes the heat dissipation and power consumption of the

XP12000 when fully loaded with the maximum number of disk drives.

Table 17. Heat dissipation and power consumption specifications

Parameter DKC Each DKU

Power consumption (kVA) 8.45 7.50 38.45

Heat dissipation (kW) 8.02 6.75 35.02

BTUs per hour 27370 23036 119514

kcal per hour 6897 5805 30117

Vertical:

2

Rotational edge: 0.1 m

Full array

(1 DKC and 4 DKUs)

Site Requirements 49

Acoustics

The acoustic emission specifications for the disk array are:

• 8.27 Bels (A) sound power

• 65 dB (A) sound pressure, operator position (1 meter from the floor

and surface of the cabinet)

You can reduce the ambient noise level caused by equipment and air

conditioning blowers in your computer room by:

• Installing a dropped ceiling covered in commercial-grade, fireresistant, acoustic-rated, fiberglass ceiling tile

• Covering the walls in sound-deadening material

• Installing foam rubber removable partitions

Dust and pollution control

Airborne contaminants and particles of a certain size and hardness can

damage the disk array. Some of the most common contaminants are dust,

smoke, ash, eraser debris, food crumbs, and salty air.

Mechanical filters on the disk array protect it by trapping large dust

particles. Smaller particles can pass through some filters, and can

eventually cause problems in mechanical parts. Prevent small dust particles

from entering the computer room by maintaining its air conditioning

system at a high static air pressure level.

Your HP representative can help you determine if you need to be concerned

about airborne contaminants.

Metallic particulate contamination

Metallic particulates can be especially harmful around electronic

equipment. This type of contamination may enter the data center

environment from a variety of sources, including but not limited to raised

floor tiles, worn air conditioning parts, heating ducts, rotor brushes in

50 HP StorageWorks XP12000 Disk Array Site Preparation Guide

vacuum cleaners, or printer component wear. Because metallic particulates

conduct electricity, they have an increased potential for creating short

circuits in electronic equipment.

Over time, very fine whiskers of pure metal can form on electroplated zinc,

cadmium, or tin surfaces. If these whiskers are disturbed, they may break

off and become airborne, possibly causing failures or operational

interruptions. For over 50 years, the electronics industry has been aware of

the relatively rare but possible threat posed by metallic particulate

contamination. During recent years, a growing concern has developed in

computer rooms where these conductive contaminants are formed on the

bottom of some raised floor tiles.

Although this problem is relatively rare, it may be an issue within your

computer room. Since metallic contamination can cause permanent or

intermittent failures on your electronic equipment, HP strongly

recommends that your site be evaluated for metallic particulate

contamination before installation of electronic equipment.

Site Requirements 51

Data comm requirements

Route data comm cables away from areas of high static electric fields

created by power transformers and heavy foot traffic. Use shielded data

comm cables that meet approved industrial standards to reduce the effects

of external fields.

For the XP disk array, you need:

Table 18. Computer room data comm requirements

Item Description

A dedicated analog

phone line

A twisted pair (Cat 5)

cable

An available LAN drop

on your Intranet

A public voice phone

line near the disk array

Needed for the HP StorageWorks Continuous

Track XP “phone home” feature, if you plan to

use it. An HP representative will configure

Continuous Track XP during installation. For

more information on Continuous Track XP, see

the HP StorageWorks XP12000 Disk Array

Owner’s Guide.

Needed to connect the XP12000 to an available

Ethernet port on your public LAN. To ensure

network security, consult with an HP

representative and your network administrator

before selecting the appropriate location of

your LAN drop.

Needed to allow your staff and HP

representatives to communicate inside and

outside your site.

52 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Electrical requirements

Line voltage

Line voltage (AC) at the wall power outlet is a function of the local power

utility and your building power distribution network. Voltages outside of

the operating range of the disk array can cause intermittent system errors or

a complete system shutdown. If required, an HP representative and your

electrician can determine the current line voltage and make

recommendations. See Appendix A for specific AC line voltage

requirements.

Avoid the use of a line voltage conditioner.

Make sure that a power distribution unit (if used) provides the correct

voltage to support your entire system.

Branch circuit breakers

See Appendix A for specific branch circuit requirements for your power

situation.

Three-phase branch circuit breakers

The power cords supplied with each DKC or DKU configured for

three-phase power are sized for connection to a 30-amp circuit.

Single-phase branch circuit breakers

The power cords supplied with each DKC or DKU configured for

single-phase power are sized for connection to a 30- or 50-amp circuit.

Note 30-amp, single-phase power is available by special order only.

Site Requirements 53

Frequency

Usually, AC line frequency is determined by your local power providers. In

some cases, electrical power is supplied by motor-generators. Shifts in AC

line frequency can cause system errors. An HP representative can monitor

the frequency of the input AC line power and make recommendations, if

necessary. The disk array requires that the line frequency be within 0.5 Hz

of the rated line frequency (50 Hz or 60 Hz).

See Appendix A for more information.

Safety and dedicated ground

The primary reason for grounding electrical systems is safety. The safety

ground is required by the National Electric Code (USA) and most other

local, regional, and national codes. In addition to safety ground, HP

requires that a dedicated (earth reference) ground be installed as a common

reference point for all system components. Consult with an HP

representative and your electrician to ensure that your electrical system

meets all local and national safety codes.

Grounding requirements

Your site’s electrical subsystem must meet all of the following conditions:

• Grounding as prescribed by your local country codes.

• An insulated grounding conductor that is identical in size and

insulation material and thickness to the ungrounded branch-circuit

supply conductors. It should be green, with or without yellow stripes,

and is to be installed as a part of the branch circuit that supplies the

unit or system. This means the ground conductor must be run in the

same conduit, armored cable, or other cable bundle as the phase wires.

• The grounding conductor should be grounded to earth at the service

equipment or other acceptable building earth ground such as the

building frames (in case of a high-rise steel-frame structure).

• IT-configured grounding systems are not certified for use with the disk

array as these grounding systems may not have solidly

54 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Receptacles

conductor-connected grounded power systems and/or they may have

resistive impedance inserted in ground and/or neutral lines. The disk

array requires a solidly conductor-connected ground and may require a

separate neutral in the case of WYE or STAR connections. For HP

disk arrays, TN grounding systems are preferred.

Each disk array cabinet has two or four separate connections to AC power.

• For disk array cabinets with two connections to AC power, each input

must be capable of supporting the entire current demand for the

cabinet.

• For disk array cabinets with four connections to AC power, the two

inputs to AC Box 1 or the two inputs to AC Box 2 must be capable of

supporting the entire current demand for the cabinet.

Figure 9 shows two examples of the fault-tolerant operation of the disk

array.

Figure 9. Examples of fault-tolerant power connections

Site Requirements 55

When receptacles are used to connect disk array components to AC power,

they must include a dedicated ground connection that is insulated from the

receptacle. It is important that the receptacle box be grounded with an

additional ground connection that is separate from the dedicated ground.

The additional ground can be hard conduit.

Specific power plugs and receptacles are required for the DKC and DKUs

depending on the power option you specify when ordering the HP XP12000

disk array. The power cords on 60 Hz cabinets are shipped with plugs

attached and connected. The power cords on 50 Hz cabinets are shipped

without plugs. You are responsible for having the correct plugs and

receptacles installed by an electrician in compliance with local electrical

requirements and practices.

Caution When installing the receptacles, the electrician must ensure that each

receptacle has its own neutral (if required) and ground. Using the same

neutral/ground for more than one circuit causes voltage loss and heat

problems and can create a fire hazard. A shared neutral conductor that

fails open-circuit can cause overvoltage damage to equipment.

See Appendix A for specific plug and receptacle part numbers and ordering

information.

Power line transients

Heavy electrical loads from nearby machinery or equipment (for example,

elevators or electric welders) can cause intermittent system problems with

sophisticated electronic equipment, even if that equipment is on a separate

circuit breaker. When faced with these conditions, provide a separate,

completely independent power panel with an isolated ground and circuit

breaker coming directly from the main building power source or secondary

power source.

If necessary, an HP representative can measure your power line noise level

and make appropriate recommendations concerning the use of line

treatment devices.

56 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Maximum peak inrush and crest factor

Table 19. Maximum peak inrush

Cabinet Power Single-phase Three-phase

DKC 30-amp 46 A 34 A

50-amp 60 A Not applicable

DKU 30-amp 34 A 26 A

50-amp 56 A Not applicable

1 50-amp power configurations are single-phase only.

Table 20. Crest factors

Cabinet Power Single-phase Three-phase

DKC 30-amp 1.68 1.67

50-amp 1.56 Not applicable

DKU 30-amp 1.65 1.53

50-amp 1.50 Not applicable

1 50-amp power configurations are single-phase only.

1

1

1

1

Site Requirements 57

Uninterruptible power supply (UPS)

Most disk array units are installed in data centers where a UPS strategy is

already in place. However, if you are making your first large disk array

purchase, you may need a separate UPS solution.

Caution This section discusses a product UPS. If you are planning or already have

a site-wide UPS, HP recommends against using a product UPS powered by

a site-wide UPS for the XP12000.

Make sure your UPS satisfies the requirements in Table 21. Table values

are based on a worst-case voltage (rated voltage –10 percent) and a

maximum configuration of DKC/DKUs. A phase imbalance of 15 percent

is also included in the calculation.

Table 21. Single secondary input (primary offline) power requirements

Single-phase 30A Single-phase 50A Three-phase 30A

Input (Vac)

DKC

Each additional

DKU

DKC

Each additional

DKU

Each additional

DKU

208 20.0 A 17.3 A 40.0 A 34.6 A 20.0 A

400

Not applicable Not applicable

Not applicable Not applicable

10.4 A

In a maximum disk array configuration (one DKC and four DKUs), the

array requires 31 kVA.

58 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Sources of electrical interference

Ensure that the disk array is protected from sources of electrical

interference:

Table 22. Sources of electrical interference

Potential source Description

Wall outlets Convenience power outlets for building maintenance

Lightning In geographical areas subject to lightning storms, it

equipment (such as vacuum cleaners and floor buffers)

must be wired from circuit breakers on a power panel

separate from the computer system panel. The ground

wires from these outlets must be connected to the

normal building distribution panel and not to the

system ground.

If a separate power source and separate ground are not

provided, operation of janitorial equipment can induce

electrical noise and cause abnormal operation of the

computer system. Your electrician can verify whether

or not maintenance outlets are on separate panels.

may by advisable to install lightning protection for

both personnel and computer systems. The principles

of lightning protection and personnel safety are

outlined in detail in the lightning protection code

contained in the National Fire Protection Association

(NFPA) Handbook.

Electromagnetic

interference

The disk array is specifically designed to reduce its

susceptibility to radiated and conducted interference.

Electromagnetic interference can cause a variety of

system problems. An HP representative can advise you

about the most common causes of electromagnetic

interference.

Site Requirements 59

Delivery space requirements

The delivery area must provide enough space and floor strength to support

the packaged equipment cartons for the disk array. Refer to the packaged

dimensions in “Dimensions” (page 19) and the packaged weights in

“Weights” (page 19).

Caution Make sure that your doorways and hallways provide enough clearance to

move the equipment safely from the delivery area to the computer room.

Permanent obstructions such as pillars or narrow doorways can cause

equipment damage. If necessary, plan for the removal of walls or doors.

Caution Make sure all floors, stairs, and elevators you use when moving the disk

array to the computer room can support the weight and size of the

equipment. Failure to do so could damage the equipment or your site.

60 HP StorageWorks XP12000 Disk Array Site Preparation Guide

3

Delivery and Unpacking

The disk array equipment is shipped directly from HP. If the disk array is

part of a system order, HP coordinates shipment from all HP locations so

that all of the equipment arrives at your site at approximately the same

time.

When your equipment ships, HP provides you with carrier information and

an expected delivery date. Factors beyond HP’s control can cause delivery

delays. If you have not received your equipment within two weeks of its

shipment from HP, contact your HP SR, who will trace your order and

expedite delivery.

Caution Before delivery, make sure your site meets “Delivery space requirements”

(page 60).

Delivery and Unpacking 61

Checking for shipping shortage and damage

Upon delivery of each equipment shipment:

1. Check the carrier’s bill of lading to ensure that the items listed match

the items delivered. Notify the carrier immediately if there are any

discrepancies or missing items.

2. Inspect all shipping containers for signs of damage, such as dents,

scratches, cuts, or water marks.

3. If you see any damage to the containers:

a. Note on the bill of lading that there is apparent damage, subject to

inspection.

b. Arrange for the carrier’s representative and an HP representative to

be present when the item in question is unpacked.

c. Contact your HP representative, who will make sure any damaged

components are replaced, regardless of the circumstances and

without waiting for any claim settlements.

62 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Unpacking the equipment

HP representatives will supervise the unpacking and moving of the disk

array equipment. It is your responsibility to provide the people, tools, and

equipment necessary to perform these tasks.

Packaging configurations

XP disk array cabinets are shipped in one of three standard packaging

configurations:

• Environmental pack — consists of stretch wrap over corner protectors.

No special tools or procedures are required to unpack shipments in this

form. This packaging is used for most shipments within the USA and

Canada that are direct from the factory to the customer. HP uses

special carriers with a dedicated fleet of trucks and specially trained

personnel.

• Full packaging — consists of a pallet, wooden loading ramp, inner

packaging, and outer corrugated carton assembly.

• Full packaging with wooden crate — consists of full packaging

encased in a wooden crate.

Required personnel

HP recommends that three physically able personnel be available to assist

with off-loading the disk array equipment from the pallet. Personnel must

be knowledgeable and experienced with the safe handling of large, heavy,

and sensitive computer equipment.

Required tools

• Claw hammer (if full packaging with wooden crate)

• Ratchet wrench or box-open end wrench sizes 11mm (7/16") and

19mm (3/4"), or adjustable end wrench

• 6mm hex wrench

Delivery and Unpacking 63

Unpacking process

• Scissors or box knife to cut polyester banding

• Safety glasses

• Short stepladder (helpful, but not required)

If you need to unpack the equipment without HP supervision, follow the

instructions in this section.

1. Following the steps “Removing packaging materials” (page 66), unpack

the DKC and DKU equipment cartons outside of the computer room to

avoid debris and possible contamination of the computer room

environment.

2. For software CDs, cables, and other installation hardware, leave the

sealed cartons or packages intact. HP representatives will unpack them

when they install and configure the disk array.

3. As you unpack the cartons, match the delivered items to the packing list

(invoice) for each carton. Contact your HP SR immediately if any items

are missing or are not the ones you ordered.

4. Move all equipment to the computer room before the installation date.

Safety precautions

Caution Be very careful when handling the equipment. Do not drop the equipment

from a height of more than 0.5 cm (0.2 in). Floor unevenness must be less

than 1 cm (0.4 in).

Warning

The DKC and DKU are very heavy. To avoid injury, use appropriate

lifting tools and have three people unpack and move the equipment.

64 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Caution Any movement of the equipment by forklift should be done prior to

unpacking. The carton assembly provides the most secure support of the

equipment during movement. Transporting the equipment by forklift after

the packaging carton has been removed is not advisable.

Caution DKCs and DKUs are top heavy and contain very sensitive electronic and

mechanical components.When moving on frame casters, the rolling surface

must be able to support the equipment weight and must be free of surface

conditions that could cause shock or vibration to the cabinet contents.

Warning

When using sharp objects or cutting tools, make sure that no part of your

body lies in the path of the blade bit or point.

Caution When detached from each other, DKCs and DKUs do not have side panels.

Exposed printed circuit boards (PCB) are present; however, normal

handling of the cabinet by the metal frames does not pose any ESD risks.

Caution When disk array equipment is not located in a data center or computer

room, it must be stored in a controlled area that meets environmental

requirements ((page 46).

Delivery and Unpacking 65

Removing packaging materials

Unpack the DKC first. DKC packaging contains a wooden ramp; standard

DKU packaging does not

1

. You will use the ramp to unload both the DKC

and DKUs.

1. If shipped in a wooden crate:

a. Using an 11mm (7/16") ratchet or wrench, remove the six lag screws

at the base of crate.

b. Using the claw end of a claw hammer, remove the crate clamps.

Warning

Crate clamps are under tension. Wear safety glasses and hold onto the

clamp with your free hand during removal.

c. Remove the crate panels.

1 DKUs shipped as upgrades (without a DKC) will contain a ramp.

66 HP StorageWorks XP12000 Disk Array Site Preparation Guide

P-fasteners

Polyester bands

Nails

Figure 10. Typical full frame outer packaging

2. Cut and remove the polyester bands.

3. Remove the nails attaching the carton to the pallet.

4. Remove the plastic carton fasteners (p-fasteners).

5. Remove the carton.

Delivery and Unpacking 67

Poly bag

Corner pads

Wooden ramp

Accessory box

Adapter plate

Figure 11. Typical full frame inner packaging with ramp

6. Remove the accessory boxes, ramp, and corner pads.

7. Using a 6mm hex and 19mm wrench, remove the adapter plates that

anchor the cabinet to the pallet.

8. Remove the poly bag covering the cabinet.

9. Following the instructions provided on the wooden ramp, attach the

ramp to the pallet and roll the cabinet onto the floor.

10. Visually check the unit for any damage.

68 HP StorageWorks XP12000 Disk Array Site Preparation Guide

A

Electrical Specifications

The detailed electrical specifications in this appendix are provided to help

your site electrician perform any necessary electrical work related to site

prep.

Electrical Specifications 69

AC line voltage requirements

50-amp, single-phase DKC

Table 23. 50-amp, 50 or 60 Hz, single-phase DKC operation

Nominal rated voltage (Vac)

Parameter 200 208

1

220 230 240

Minimum operating voltage (Vac) 184 191 202 212 221

Maximum operating voltage (Vac) 212 220 233 244 254

Rated line current per power cord (Arms) 22.6 21.7 20.5 19.6 18.8

Number of power cords 22222

Recommended circuit breakers 50A 50A 50A 50A 50A

Number of circuit breakers 22222

Dropout carry-through time at minimum line voltage (ms) 60 60 60 60 60

1 60 Hz only.

30-amp, single-phase DKC

Table 24. 30-amp, 50 or 60 Hz, single-phase DKC operation

Nominal rated voltage (Vac)

Parameter 200 208

Minimum operating voltage (Vac) 184 191 202 212 221

Maximum operating voltage (Vac) 212 220 233 244 254

1

220 230 240

Rated line current per power cord (Arms) 11.3 10.9 10.3 9.8 9.4

Number of power cords

2

44444

Recommended circuit breakers 30A 30A 30A 30A 30A

Number of circuit breakers 44444

Dropout carry-through time at minimum line voltage (ms) 60 60 60 60 60

1 60 Hz only.

2 Units with only two power cords require only two circuit breakers.

70 HP StorageWorks XP12000 Disk Array Site Preparation Guide

30-amp, three-phase DKC

Table 25. 30-amp, 50 or 60 Hz, three-phase DKC operation

Nominal rated voltage (Vac)

Parameter 200 208

1

220 230 240 380 400 415

Minimum operating voltage (Vac) 184 191 202 212 221 350 368 382

Maximum operating voltage (Vac) 212 220 233 244 254 403 424 440

Rated line current per power cord (Arms) 13 12.5 11.9 11.3 10.9 6.9 6.5 6.3

Number of power cords 2 2222222

Recommended circuit breakers 30A 30A 30A 30A 30A 30A 30A 30A

Number of circuit breakers 2 2222222

Dropout carry-through time at minimum

60 60 60 60 60 60 60 60

line voltage (ms)

1 60 Hz only.

50-amp, single-phase DKU

Table 26. 50-amp, 50 or 60 Hz, single-phase DKU operation

Nominal rated voltage (Vac)

Parameter 200 208

1

220 230 240

Minimum operating voltage (Vac) 184 191 202 212 221

Maximum operating voltage (Vac) 212 220 233 244 254

Rated line current per power cord (Arms) 18 17.3 16.4 15.7 15.0

Number of power cords 22222

Recommended circuit breakers 50A 50A 50A 50A 50A

Number of circuit breakers 22222

Dropout carry-through time at minimum line voltage (ms) 60 60 60 60 60

1 60 Hz only.

Electrical Specifications 71

30-amp, single-phase DKU

Table 27. 30-amp, 50 or 60 Hz, single-phase DKU operation

Nominal rated voltage (Vac)

Parameter 200 208

1

220 230 240

Minimum operating voltage (Vac) 184 191 202 212 221

Maximum operating voltage (Vac) 212 220 233 244 254

Rated line current per power cord (Arms) 9 8.7 8.2 7.8 7.5

Number of power cords 44444

Recommended circuit breakers 30A 30A 30A 30A 30A

Number of circuit breakers

2

44444

Dropout carry-through time at minimum line voltage (ms) 60 60 60 60 60

1 60 Hz only.

2 Units with only two power cords require only two circuit breakers.

30-amp, three-phase DKU

Table 28. 30-amp, 50 or 60 Hz, three-phase DKU operation

Nominal rated voltage (Vac)

Parameter 200 208

1

220 230 240 380 400 415

Minimum operating voltage (Vac) 184 191 202 212 221 350 368 382

Maximum operating voltage (Vac) 212 220 233 244 254 403 424 440

Rated line current per power cord (Arms) 10.4 10.0 9.4 9.0 8.7 5.5 5.2 5.0

Number of power cords 2 2222222

Recommended circuit breakers 30A 30A 30A 30A 30A 30A 30A 30A

Number of circuit breakers 2 2222222

Dropout carry-through time at minimum

60 60 60 60 60 60 60 60

line voltage (ms)

1 60 Hz only.

72 HP StorageWorks XP12000 Disk Array Site Preparation Guide

Receptacle part numbers and ordering information

Table 29 lists the plug and receptacle part numbers for 60 Hz

configurations of the XP12000 disk array.

Table 29. 60 Hz power plugs and receptacles

Power source Breaker rating Plug Receptacle

Single-phase 30 A Russellstoll 3750DP Russellstoll 3933 (alt. 9C33U0) or

3753 (alt. 9R33U0W)

50 A Russellstoll 9P53U2 Russellstoll 9C53U2 or 9R53U2W

Three-phase 30 A Russellstoll 3760PDG Russellstoll 3934 (alt. 9C34U0) or

3754 (alt. 9R34U0W)

Russellstoll connectors are available through most electrical distributors.

HP has arranged for the distributors listed below to stock these connectors.

These distributors are able to ship worldwide via your preferred carrier.

Beck Electrical Supply

2775 Goodrick Avenue

Richmond, CA 94801 USA

Telephone: (800) 466-4395

Fax: (800) 466-5442

Contact: Ken Mogan

casales@beckelectric.com

Source Research, Inc. (SRI)

2160 Sunnydale Boulevard

Clearwater, FL 33765-2108 USA

Telephone: (800) 356-0259

Contact: Erik Peterson, telephone extension 302

http://www.sourceresearch.com/index.cfm

Electrical Specifications 73

Three-phase cabling for the USA (60 Hz)

Each three-phase DKU has two main disconnect devices (two main

breakers for dual power lines) so that AC power to the unit can be supplied

from separate power distribution panels with two power-supply cords.

Caution An HP representative should be present whenever the disk array is being

connected to a new power source for the first time.

Connecting the external power-supply cords

The XP12000 disk array is factory-configured for 30-amp, three-phase

power.

When the disk array uses 30-amp, three-phase input power, the DKC and

DKUs have two power cords each.

Figure 12. 30-amp, three-phase power cords

If one power source malfunctions, the other power source assumes the total

load, providing uninterrupted operation. HP recommends that each power

74 HP StorageWorks XP12000 Disk Array Site Preparation Guide

cord have a separate electrical circuit as its source, in case of a circuit

failure. Each power-supply cord is supplied with an attachment plug type

Russellstoll 3760PDG.

Be sure to install Russellstoll 3934 (alternate, 9C34U0) or 3754 (alternate,

39R34U0W) socket receptacles between the power distribution panel of the

building and the power plugs for the unit.

The power cords provided with the disk array are nonshielded, type ST or

equivalent with four #8 AWG (minimum) conductors terminated at one end

with an assembled plug connector.

Branch circuit requirements

To protect the disk array, your building must be wired correctly. Each

supply (“hot”) conductor must be protected by a short-circuit protective

device and by an overcurrent protective device. Table 25 (page 71) and

Table 28 (page 72) provide specifications for the overcurrent protective

devices required for three-phase operation.

All protective devices must comply with national standards of the country

where the units are to be installed. If a protective device interrupts any

supply conductor, it must also interrupt all other supply conductors.

Overcurrent protection is not required for the neutral conductor of this unit.

Only 50 Hz, three-phase configurations have a neutral conductor.

Electrical Specifications 75

Three-phase AC cabling for Europe (50 Hz)

Each three-phase DKU has two main disconnect devices (two main

breakers for dual power lines) so that AC power to the unit can be supplied

from separate power distribution panels with two power-supply cords.

Caution An HP representative should be present whenever the disk array is being

connected to a new power source for the first time.

Connecting the power-supply cords

All 50 Hz, European XP12000 disk array cabinets are shipped with

unterminated power cords. Your electrician must select and install the

correct power plug. Be sure to prepare the socket receptacles and power

cords between the power distribution board of the building and the

attachment plugs for the unit. 30-amp power cords of type H07RN-F or

equivalent, with five 6 mm

unit.

Caution Be sure to connect the power cords to the distribution panel as shown in

Figure 13. Improper wiring of the neutral conductor may cause damage to

the disk array. To reduce the risk of a wrong connection, use a plug and

socket that are approved for this disk array. It is your electrician’s

responsibility to select and install the proper plug.

2

conductors per cord, are provided with the

Figure 13. Three-phase power connections for Europe

76 HP StorageWorks XP12000 Disk Array Site Preparation Guide

When connecting to 380 to 415 volt service, a WYE configuration with

neutral and ground conductors (in addition to the three-phase wires, for a

total of five wires) is required.

Warning

High leakage current can occur between the power supply and the unit. To

avoid electrical shock, be sure to make the protective earth connection

before the supply connections.

Branch circuit requirements

When the supplied line to line voltage is in the 380 to 415 volt range, the

connection must be a five-wire WYE or STAR connection.

To protect the disk array, your building must be wired correctly. Each

supply (“hot”) conductor must be protected by a short-circuit protective

device and by an overcurrent protective device. Table 25 (page 71) and

Table 28 (page 72) provide specifications for the overcurrent protective

devices required for three-phase operation.

All protective devices must comply with national standards of the country

where the units are to be installed. If a protective device interrupts a supply

conductor, it must also interrupt all other supply conductors.