Page 1

Technical Reference Guide

HP workstation c8000

Document Part Number: 5969-3188

Second Edition

July 2004

This manual contains an overview of system specifications, instructions

for removing and replacing system components, information on

configuring your system using the included tools and interfaces, and

detailed troubleshooting information.

Page 2

© Copyright 2004 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

® and Itanium® are registered trademarks of Intel Corporation in the U.S. and other countries and are used

Intel

under license.

NVIDIA and NVIDIA Quadro are registered trademarks or trademarks of NVIDIA Corporation in the United

States and/or other countries.

All other product names mentioned herein may be trademarks of their respective companies.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this material. The

information in this document is provided “as is” without warranty of any kind, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose, and is subject to change without notice.

The warranties for HP products are set forth in the express limited warranty statements accompanying such

products. Nothing herein should be construed as constituting an additional warranty.

This document contains proprietary information that is protected by copyright. No part of this document may be

photocopied, reproduced, or translated to another language without the prior written consent of Hewlett-Packard

Company.

WARNING: Text set off in this manner indicates that failure to follow directions could result in

Å

bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could result in

Ä

damage to equipment or loss of information.

Technical Reference Guide

HP workstation c8000

Second Edition (July 2004)

Document Part Number: 5969-3188

Page 3

Important Safety Warnings

WARNING: Avoid Electrical Shocks. To avoid electrical shock, do not open the power supplies. There

Å

are no user-serviceable parts inside.

To avoid electrical shock and harm to your eyes by laser light, do not open the DVD laser module. The

laser module should be serviced by service personnel only. Do not attempt to make any adjustment to the

laser unit. Refer to the label on the DVD for power requirements and wavelength. This product is a class I

laser product.

WARNING: Removing and Replacing the Cover. For your safety, never remove the system side cover

Å

without first disconnecting the power cord from the power outlet and removing any connection to a

telecommunications network. If a Power Protection Device is fitted to your system, you must shut down

your computer using its on/off switch, then remove the power cord before removing the system’s side

cover. Remove the Power Protection Device cables before any servicing operation. Always replace the

side cover before switching the system on again.

WARNING: Battery Safety Information. There is a danger of explosion if the battery is incorrectly

Å

installed. For your safety, never attempt to recharge, disassemble, or burn an old battery. Replace the

battery with the same or equivalent type, as recommended by the manufacturer.

The battery in this system is a lithium battery that does not contain any heavy metals. However, to protect

the environment, do not dispose of batteries in household waste. Return used batteries either to the shop

from which you bought them, to the dealer from whom you purchased your system, or to HP so that they

can either be recycled or disposed of in the correct way. Returned batteries will be accepted free of

charge.

WARNING: Metallic particulates can be especially harmful around electronic equipment. This type of

Å

contamination may enter the data center environment from a variety of sources, including, but not limited

to, raised floor tiles, worn air conditioning parts, heating ducts, rotor brushes in vacuum cleaners or

printer component wear. Because metallic particulates conduct electricity, they have an increased

potential for creating short circuits in electronic equipment. This problem is exaggerated by the

increasingly dense circuitry of any electronic equipment.

Over time, very fine whiskers of pure metal can form on electroplated zinc, cadmium, or tin surfaces. If

these whiskers are disturbed, they may break off and become airborne, possibly causing failures or

operational interruptions. For over 50 years, the electronics industry has been aware of the relatively rare,

but possible, threat posed by metallic particulate contamination. During recent years, a growing concern

has developed in computer rooms where these conductive contaminants are formed on the bottom of

some raised floor tiles.

Although this problem is relatively rare, it may be an issue within your computer room. Since metallic

contamination can cause permanent or intermittent failures on your electronic equipment,

Hewlett-Packard strongly recommends that your site be evaluated for metallic particulate contamination

before installation of electronic equipment.

WARNING: Avoid Burn Injuries. Some parts inside the computer will be hot. Turn off and unplug the

Å

system, then wait approximately three to five minutes for them to cool down before opening the system

access panels or touching internal components.

Page 4

CAUTION: Avoid Static Electricity. Static electricity can damage electronic components. Turn OFF all

Ä

equipment and disconnect the power cable before installing an accessory card. Don’t let your clothes

touch any accessory card. To equalize the static electricity when replacing an accessory card, rest the

accessory card bag on top of the system unit while you are removing the card from the bag. Handle the

card as little as possible and with care.

CAUTION: Information on Ergonomic Issues. It is strongly recommended that you read the ergonomics

Ä

information, available in the “Working In Comfort” section of this manual, before using your system. You

can access more extensive ergonomics information at: www.hp.com/ergo

NOTE: Recycling Your System. HP has a strong commitment toward the environment. Your HP

system has been designed to respect the environment as much as possible. HP can also take back

your old system for recycling when it reaches the end of its useful life. HP has a product

take-back program in several countries. The collected equipment is sent to an HP recycling

facilities in Europe or the U.S.A. As many parts as possible are reused. The remainder is

recycled. Special care is taken for batteries and other potential toxic substances, these are

reduced into non-harmful components through special chemical processes. If you require more

details about the HP product take-back program, contact your local dealer or your nearest HP

Sales Office.

Page 5

Contents

Important Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i–iii

Product Information

System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Power Consumption and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

System Configuration

Boot Console Handler (BCH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Accessing the BCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Paths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

BCH Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Baseboard Management Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Installing or Replacing Parts

Locating System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Location of Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Exploded View of Main System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

System Board Components and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Tools and Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Removing and Replacing Access Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Removing the Main System Access Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Removing the Front Access Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Removing and Replacing Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Airflow Guide and Memory Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

Memory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

PCI and AGP Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–12

Optical Drives (CD or DVD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–17

Hard Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–19

External SCSI Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–23

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–25

Hard Drive and Chassis Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–27

Front Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–29

Replacing the Processor or Installing an Additional Processor. . . . . . . . . . . . . . . . . . . . . . . . . 3–32

System Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–39

System Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–41

Technical Reference Guide 1

Page 6

Contents

Troubleshooting

E-Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Troubleshooting Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Identifying and Diagnosing Hardware Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

BCH Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

Displaying PIM Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

Clearing the FPL and SEL Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

Troubleshooting the VGA Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–13

Troubleshooting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–14

Running HP Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

Resetting the BMC Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–17

Ultra ATA / IDE Guidelines

Ultra ATA Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Ultra ATA Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Cable Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Drive Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Device Classes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Attach Sequence Rules by Class Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Attach Sequence Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

Additional Drive Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

SMART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

CD-ROM or DVD-ROM Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

SCSI Guidelines

Self Monitoring Analysis and Reporting Technology (SMART) . . . . . . . . . . . . . . . . . . . . . . . . . . B–2

Cable Pin-Outs

Enhanced Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

Mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

Ethernet RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

Microphone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

Headphone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

Line-in Audio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

Line-out Audio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

Ultra SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–3

Monitor (VGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–4

Monitor (DVI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–5

ATA/ATAPI (IDE) Standard Drive Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–6

Accelerated Graphics Port (AGP Pro) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–7

24-pin Power (Main) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–9

6-pin Power (Auxiliary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–10

Hard Drive Activity Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–10

PCI 3.3V Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–11

2 Technical Reference Guide

Page 7

Index

Contents

Technical Reference Guide 3

Page 8

Contents

4 Technical Reference Guide

Page 9

This chapter provides an overview of the HP workstation c8000, including:

■ System Features, page 1-1

■ Physical Characteristics, page 1-4

■ Power Specifications, page 1-5

■ Front Panel, page 1-7

■ Rear Panel, page 1-9

System Features

The HP workstation c8000 is available in several different configurations. To obtain more

information for your system, see one of the following:

■ Boot Console Handler (BCH) Information menu (page 2-6).

■ Features and overview at: http://www.hp.com/workstations/risc/c8000

1

Product Information

■

Supported accessories and components at: http://partsurfer.hp.com

Feature Description

Processor One or two HP PA-8800 processor modules

Firmware 8 MB flash EEPROM

Configured using Boot Console Handler (BCH)

Operating system HP-UX 11i v1

Main memory Capacity:

• Minimum 1 GB (2 x 512 MB)

• Supports up to 32 GB (8 x 4 GB)

Type: PC2100 ECC registered DDR266 DIMMs

Slots: Eight DIMM slots

Peak bandwidth: up to 8.5 GB/sec

For memory loading order and detailed memory installation instructions,

see “Memory Modules” on page 3-10.

Hard drive(s) May include the following internal drives:

• Up to two Ultra ATA-133 IDE hard drives

• Up to four LVD Ultra 320 SCSI hard drives with 68-pin interface

connector plus four-pin standard power connector

Technical Reference Guide 1–1

Page 10

Product Information

Feature Description

Optical drive(s) Model with IDE hard drives may include up to two optical drives.

SCSI controller Two-channel Ultra 320 SCSI controller on system board

Model with SCSI hard drives may include up to three optical drives.

The following optical drives are supported:

•48X CD-RW

•16X DVD-ROM

•4X DVD+RW

External SCSI connector (option)

• 68-pin standard, high density SCSI connector

• Requires cables designated as U320-capable with U320 devices

• Supports LVD devices (Ultra320, Ultra 160, Ultra2)

• Legacy SE devices

• SE, narrow devices with appropriate conversion hardware

• Does not support HVD

•80-pin SCA connector not supported

IDE controller Ultra ATA-133 capable controller supporting two IDE buses and a total of

four IDE devices:

• Up to three front-access optical drives, or

• Up to two front-access optical drives and two internal hard drives

Graphics controller 1 AGP 8X Pro 110 slot (150 W max power including auxiliary power

connector)

Accessory card slots Seven slots total:

• One AGP 8X Pro 110W 32-bit slot

• Two half-length 3.3V 32-bit 33 MHz PCI slots

• One full-length 3.3V 64-bit 33 MHz PCI slot

• Two full-length 3.3V 64-bit 66 MHz PCI-X slots

• One full-length 3.3V 64-bit 133 MHz PCI-X slot

I/O connectors • 10/100/1000 LAN connector

• Two 9-pin serial connectors:

•UART 16550 buffered

• RS-232-C

• Five USB 2.0 480 Mb/s connectors:

•Two front-access

•Three rear-access

1–2 Technical Reference Guide

Page 11

Feature Description

Input devices USB keyboard and mouse:

• HP 104/105 key keyboard, available in 13 localized layouts

• HP three-button mouse, standard or scroll-wheel

Audio (option) May include:

• PCI Audio card

• Front-access mic and headphone connectors

• Line in, line out, microphone in (on audio card)

Product Information

Technical Reference Guide 1–3

Page 12

Product Information

Physical Characteristics

Characteristic HP workstation c8000

Weight

1

Tower system Minimum: 22.5 kg (49.5 lb)

Maximum: 26.6 kg (58.6 lb)

Rack system Minimum: 20.5 kg (45.2 lb)

Maximum: 24.7 kg (54.4 lb)

Dimensions

Tower system Height: 490.2 mm (19.3 in.)

Depth: 571.4 mm (22.5 in.)

Chassis Width: 203.2 mm (8.0 in.)

Pedestal Width: 287.0 mm (11.3 in.)

Rack system Chassis Height: 203.2 mm (8.0 in.)

Front Panel Height: 219.0 mm (8.6 in.)

Depth: 568.9 mm (22.4 in.)

Chassis Width: 424.2 mm (16.7 in.)

Front Panel Width: 482.6 mm (19.0 in.)

Footprint, tower system

Space requirement, rack system

1. Excludes keyboard, mouse and display.

0.16 m

5 units (5U)

2

(1.77 sq ft)

1–4 Technical Reference Guide

Page 13

Power Specifications

Parameter Total Rating PCI Slots AGP Slots

Input voltage (wide-range) 100 – 127VAC

Product Information

200 – 240VAC

Max input current

1

8.7A at 100VAC

4.4A at 200VAC

Input frequency 50 – 60 Hz

Max output power

2

700W 6 slots available

Max current at +12V -- combined 50A

Max current at +12V -- CPU0 15A

Max current +12V -- CPU1 15A

I/0 12V 15A

AGP 12V 15A

Max current at +3.3V 34A

Max current at +5V 25A

Max current at –12V 0.5A

Max current at +5V -- Standby 2A

at 15W/slot

Total of 90W

1 slot available

at 110W/slot

1. The worst case/highest current given the lowest input voltage and the maximum input power.

2. Corresponds to the maximum DC power the power supply can provide to the system.

The power supply has Active Power Factor Correction (APFC) that meets EN61000-3-2 over the

range of 88-265 VAC rms.

Technical Reference Guide 1–5

Page 14

Product Information

Power Consumption and Cooling

This information is based on primary power consumptions.

Components Power Consumption

Workstation: typical configuration

maximum configuration

Processor 130W 443.6 Btu/h

IDE hard disk drive with I/O access 23W 78.4 Btu/h

IDE hard disk without I/O access (idle) 16W 54.5 Btu/h

PCI card 10W to 25W 34.12 Btu/h to 85.30 Btu/h

AGP card 110W maximum

1. A typical configuration includes: 1 CPU, 4 GB RAM (4 x 1 GB), 700W power supply, 2 hard drives, 1

medium power AGP, and 1 optical drive.

2. A maximum configuration (fully loaded) includes: 2 CPUs, 32 GB RAM (8 x 4 GB), 700W power supply,

4 hard drives, 1 high end AGP, and 3 optical drives.

1

2

Environmental Specifications

410W 1399 Btu/h

871W 2973 Btu/h

170.6 Btu/h

(150W possible with

optional power

dongle)

Environmental Specifications (System Processing Unit with Hard Disk)

Operating temperature +5° C to +35° C (+41° F to +95° F)

Storage temperature -20° C to +70 C (-4° F to +158° F)

Over-temperature shutdown +38° C (+100° F)

Operating humidity 15% to 80% relative (non-condensing)

Storage humidity 8% to 80% relative (non-condensing)

Operating altitude 0 – 3000 m (0 – 10,000 ft.)

Storage altitude (long-term) 0 – 4600 m (0 – 15,000 ft.)

Operating temperature and humidity ranges may vary depending on the installed mass storage

devices. High humidity levels can cause improper disk operation. Low humidity levels can

aggravate static electricity problems and cause excessive wear of the disk surface.

1–6 Technical Reference Guide

Page 15

Front Panel

The HP workstation c8000 front panel has the features identified in the following figures.

■ A pull-out information card containing the product and serial numbers is on the side of the

system.

■ For more information about the system LEDs, see “LAN LEDs (Front and Rear Panel)” on

page 4-3.

Product Information

Front panel, tower configuration

1 System speaker 6 LAN activity LED

2 Three optical drive bays 7 Two USB connectors

3 System status LED 8 Headphone (option)

4 Power button

5 Disk activity LED

Microphone (option)

9

IEEE-1394 FireWire (not supported)

-

Technical Reference Guide 1–7

Page 16

Product Information

Front panel, rack-mount configuration

-

1 System speaker 6 LAN activity LED

2 Three optical drive bays 7 Two USB connectors

3 System status LED 8 Headphone (option)

4 Power button

5 Hard Disk activity LED

Microphone (option)

9

IEEE-1394 FireWire (not supported)

-

1–8 Technical Reference Guide

Page 17

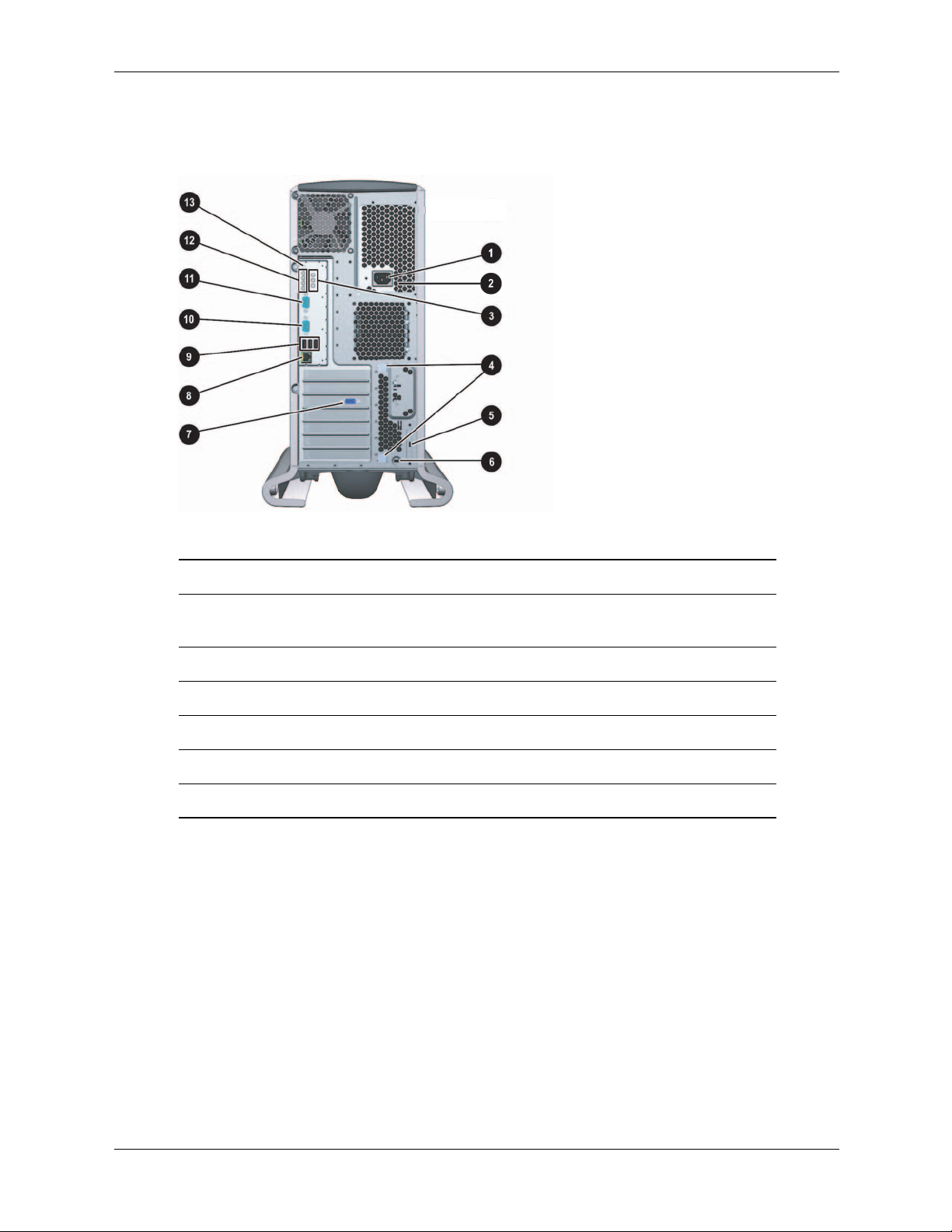

Rear Panel

The HP workstation c8000 rear panel has the following connectors and features:

Product Information

Rear panel, tower configuration

1 Power cord connector 8 LAN connector and LEDs

2 Built-In Self Test LED (power supply

9 Three USB connectors

LED behind ventilation holes)

3 On-board diagnostic LEDs - Serial connector B

4 PCI/AGP retention release ; Serial connector A

5 External SCSI connector (option) < Diagnostic LEDs

6 Security cable slot = Transfer-of-control (TOC) button

7 Monitor connector (on graphics card)

Technical Reference Guide 1–9

Page 18

Product Information

Rear panel, rack-mount configuration

1 Power cord connector 8 LAN connector and LEDs

2 Built-In Self Test LED (power supply

9 Three USB connectors

LED behind ventilation holes)

3 On-board diagnostic LEDs - Serial connector B

4 PCI/AGP retention release ; Serial connector A

5 External SCSI connector (option) < Diagnostic LEDs

6 Security cable slot = Transfer-of-control (TOC) button

7 Monitor connector (on graphics card)

1–10 Technical Reference Guide

Page 19

You will typically alter the system configuration only if you want to change the boot device or

change the console. This chapter covers:

■ “Boot Console Handler (BCH)” on page 2-1

■ “Firmware Upgrades” on page 2-9

Boot Console Handler (BCH)

You can configure the HP workstation c8000 system with The Boot Console Handler (BCH), the

user interface to the system firmware. The BCH:

■ Lets the bootstrap code know which path (that is, which device) to boot from.

■ Allows you to view and modify a set of specific system parameters.

■ If you are satisfied with your system configuration, you do not need to perform any system

configuration.

2

System Configuration

Accessing the BCH

You can access the BCH through either:

■ your system’s USB keyboard and graphics monitor by interrupting the normal boot process

■ a serial console connection and terminal emulator.

Access via Keyboard and Graphics Monitor

When you boot your system, the boot process pauses and gives you 10 seconds to interrupt the

normal boot process. Perform the specified action to access the BCH. When you are finished,

reboot your system.

Access via Serial Console Connection

To access the BCH through a serial connection:

1. With the workstation turned off, connect the serial cable provided with your system or a

compatible cable to Serial Port A on the rear panel of the workstation, and to your remote

device.

NOTE: If your system has a plug-in serial card (installed in slot 6), connect to the card’s serial

port instead of to Serial Port A.

2. Disconnect all USB keyboards from the system.

Technical Reference Guide 2–1

Page 20

System Configuration

3. Configure the terminal emulation software with these settings:

❏ Baud rate: 9600

❏ Bits: 8

❏ Parity: None

❏ Stop Bits: 1 (one)

❏ Flow Control: XON/XOFF

4. Using the terminal emulation software, connect to the workstation with a direct connection.

5. Turn on the workstation. The system display is redirected to the serial console device.

Paths

All devices in the HP workstation c8000 are represented by paths in the BCH. To identify the

correct slot or disk drive, use the following tables.

Accessory Card Slots

Slot Path

1 PCI (33 MHz, 32 bit, half-length) 0/3/5/0

2 PCI (33 MHz, 32 bit, half-length) 0/3/4/0

3 AGP 8X 32 bit 0/4/0/0

4 PCI (33 MHz, 64 bit) 0/3/6/0

5 PCI-X (66 MHz, 64 bit) 0/2/2/0

6 PCI-X (66 MHz, 64 bit) 0/2/3/0

7 PCI-X (133 MHz, 64 bit) 0/0/1/0

IDE Drives

Drive Path Hardware Connection

IDE hard drive 1 (or optical drive 3) 0/3/2/0.0.0 IDE 0, master

IDE hard drive 2 0/3/2/0.0.1 IDE 0, slave

IDE optical drive 1 0/3/2/0.1.0 IDE 1, master

IDE optical drive 2 0/3/2/0.1.1 IDE 1, slave

2–2 Technical Reference Guide

Page 21

SCSI Drives

Drive Path

SCSI hard drive on channel A 0/2/1/0.<scsi_ID>

SCSI hard drive on channel B 0/2/1/1.<scsi_ID>

Network

Device Path

Built-in LAN 0/3/3/0

System Configuration

Technical Reference Guide 2–3

Page 22

System Configuration

BCH Commands

The interactive portion of BCH includes the following five main commands, which are available

on the Main Menu and all submenus.

Command Description

BOot [PRI

DIsplay Redisplay the current menu

HElp [<menu>

RESET Restart the system

MAin Return to the Main Menu

Main Menu

The following commands are available in the main menu.

--- Main Menu ---------------------------------------------------------------

Command Description

------- -----------

BOot [PRI|ALT|<path>] Boot from specified path

PAth [PRI|ALT|CON|KEY] [<path>] Display or modify a path

SEArch [DIsplay|IPL] [<path>] Search for boot devices

COnfiguration menu Displays or sets boot values

INformation menu Displays hardware information

SERvice menu Displays service commands

DIsplay Redisplay the current menu

HElp [<menu>|<command>] Display help for menu or command

RESET Restart the system

|ALT|<path>] Boot from a specified path

|<command> Display help for menu or command

2–4 Technical Reference Guide

Page 23

System Configuration

Configuration Menu

The following commands are available in the configuration menu.

----------------------------------------------------------------------------------

Main Menu: Enter command or menu > co

--- Configuration Menu ------------------------------------------------------

Command Description

------- -----------

AUto [BOot|SEArch|STart] [ON|OFF] Display or set specified flag

BootID [<proc> [<bootid>]] Display or set Boot Identifier

BootINfo Display boot-related information

BootTimer [0 - 200] Seconds allowed for boot attempt

CPUconfig [<proc> [ON|OFF]] Config/Deconfig processor

DEfault Set the system to predefined values

FastBoot [ON|OFF] Display or set boot tests execution

LanConfig [<config type>] Display or set LAN configuration

MOnitor [LIST|<type>] Display or set the current monitor type

PAth [PRI|ALT|CON|KEY [<path>]] Display or change a path

PoWerRestore [ON|OFF|LAST] Display or set the Power Restore Policy

ResTart [ON|OFF] Display or set the System Restart Policy

SEArch [DIsplay|[[IPL] [<path>]]] Search for boot devices

SECure [ON|OFF] Set/show security mode

TIme [c:y:m:d:h:m[:s]] Read or set the real time clock in GMT

BOot [PRI|ALT|<path>] Boot from specified path

DIsplay Redisplay the current menu

HElp [<command>] Display help for specified command

RESET Restart the system

----------------------------------------------------------------------------------

The configuration default command sets the following values:

Primary boot path: scsiA.0 (core SCSI)0

Alternate boot path: lan.0.0.0.0 (core LAN)

Console path: graph3 (AGP Graphics Slot 3)

Keyboard path: usb0 (core USB)

Autoboot: ON

Autosearch: ON

Autostart: OFF

BootTimer 0

Technical Reference Guide 2–5

Page 24

System Configuration

Information Menu

The following commands are available from the information menu:

----------------------------------------------------------------------------------

Main Menu: Enter command or menu > in

---- Information Menu --------------------------------------------------------

Command Description

------- -----------

ALL Display all system information

BootINfo Display boot-related information

CAche Display cache information

ChipRevisions Display revisions of major VLSI

COprocessor Display coprocessor information

FRU Display FRU information

FwrVersion Display firmware version

* IO Display I/O interface information

LanAddress Display Core LAN station address

MEmory Display memory information

PRocessor Display processor information

** WArnings Display selftest warning messages

BOot [PRI|ALT|<path>] Boot from specified path

DIsplay Redisplay the current menu

HElp [<command>] Display help for specified command

RESET Restart the system

MAin Return to Main Menu

----------------------------------------------------------------------------------

* The PCI device information displayed includes Description, Path, VendorID, DeviceID,

Slot#, and bus#.

** Any warnings that apply are displayed.

2–6 Technical Reference Guide

Page 25

System Configuration

The Info PR command displays processor information on the console. For example:

----------------------------------------------------------------------------------

Main Menu: Enter command or menu > in pr

Model: hp workstation c8000 (model string 9000/785/c8000)

PROCESSOR INFORMATION

HVERSION SVERSION Processor

Processor Speed HVERSION SVERSION CVERSION Processor

--------- -------- -------- -------- -------- ---------0 1000 MHz 0x088b 0x0491 3.1 Active

1 1000 MHz 0x088b 0x0491 3.1 Idle

2 1000 MHz 0x088b 0x0491 3.1 Idle

3 1000 MHz 0x088b 0x0491 3.1 Idle

Central Bus Speed (in MHz) : 200

Software ID (dec) : 1704034802

Software ID (hex) : 0x659181f2

Software Capability : 0x01f0

----------------------------------------------------------------------------------

Model Model/Op State

Technical Reference Guide 2–7

Page 26

System Configuration

Service Menu

The following commands are available from the Service menu.

------------------------------------------------------------------------------------

Main Menu: Enter command or menu > ser

---- Service Menu ------------------------------------------------------------

Command Description

------- -----------

ChassisCodes [<proc>|ON|OFF] Display/enable/disable chassis codes

CLeaRLogs Clear SEL and FPL logs

CLEARPIM Clear (zero) the contents of PIM

MemRead <address> [<len>] Read memory and I/O locations

PDT [CLEAR] Display or clear the PDT

PIM [<proc>] [HPMC|LPMC|TOC]] Display PIM information

ScRoll [ON|OFF] Display or change scrolling ability

SCSI [<path> [<option> [<val>]]] Display or set SCSI controller values

SErial [ON|OFF] [A/B] Display/enable/disable core serial ports

------------------------------------------------------------------------------------

The SCSI command is for displaying/setting the SCSI controller parameters like initiator ID and

speed. These parameters are used by the OS device drivers to program the controller(s).

The serial port command automatically resets the system. When the serial ports are enabled, the

ports can be used with HP-UX.

NOTE: If the HP-UX version was released prior to June 2004, the system might not boot if the

✎

serial ports are enabled.

Baseboard Management Controller

The Baseboard Management Controller (BMC) supports the industry-standard Intelligent

Platform Management Interface (IPMI) specification. The management features have been built

into the system board and include diagnostics (local and remote), console support, configuration

management, hardware management, and troubleshooting.

2–8 Technical Reference Guide

Page 27

Firmware Upgrades

To update the system and BMC firmware:

System Configuration

1. Download the firmware update from

http://www.hp.com/bizsupport.

Follow the menu prompts to navigate to the support page:

a. Select

b. Enter the product name in the search field (

download drivers/software.

HP workstation c8000).

c. Select the search result.

d. Choose the firmware release you need to download.

e. Click the release notes for instructions on how to download, unpack, and install the

firmware upgrade.

2. Download, unpack, and install the firmware upgrade.

3. Execute the

in FwrVersion BCH command to confirm that the upgrade was successful.

Technical Reference Guide 2–9

Page 28

System Configuration

2–10 Technical Reference Guide

Page 29

Installing or Replacing Parts

This chapter contains the following sections:

■ Locating System Components, page 3-1

■ Tools and Safety, page 3-5

■ Removing and Replacing Access Panels, page 3-6

■ Removing and Replacing Internal Components, page 3-8

Locating System Components

This section contains diagrams to help you locate system components. The diagrams in this

section include only the most frequently accessed components and connectors. For

comprehensive component and system board diagrams, see the label on the inside of the main

access panel.

■ Location of Internal Components, page 3-2

■ Exploded View of Main System Components, page 3-3

3

■ System Board Components and Connectors, page 3-4

For the location of items on the front and rear panel of the system, see:

■ Front Panel, page 1-7

■ Rear Panel, page 1-9

Technical Reference Guide 3–1

Page 30

Installing or Replacing Parts

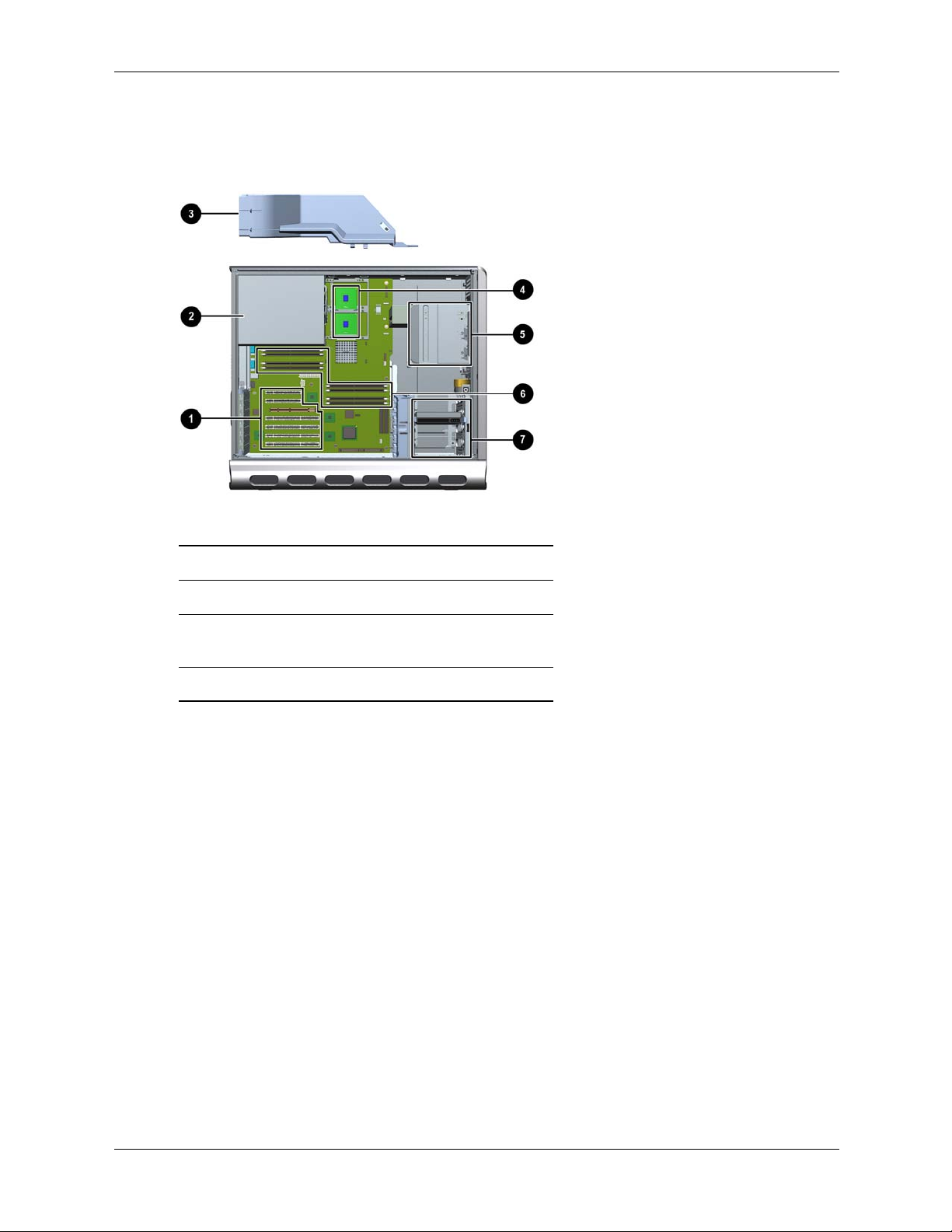

Location of Internal Components

This diagram identifies main system components. For a comprehensive component diagram, see

the label on the inside of the main access panel.

Location of internal components

1 PCI and AGP slots 5 Optical drive bays

2 Power supply 6 Memory slots

3 Air flow guide and

memory fan

4 CPU sockets

7 Hard drive bays

3–2 Technical Reference Guide

Page 31

Exploded View of Main System Components

This diagram identifies main system components. For a comprehensive component diagram, see

the label on the inside of the main access panel.

Installing or Replacing Parts

Exploded view of system components

1 Power supply : Hard drive fan

2 CPU0 and CPU1 with power modules ; AGP retainer

3 Chassis fan < System board

4 Airflow guide and memory fan = AGP graphics card

5 Top panel > Memory module

6 Optical drive ? Hard drive with rails

7 Chassis @ Front access panel (rack-mount)

8 Front access panel (tower) A Main (side) access panel

9 Pedestal

Technical Reference Guide 3–3

Page 32

Installing or Replacing Parts

System Board Components and Connectors

This diagram identifies main system board components and connectors. For a comprehensive

system board diagram, see the label on the inside of the main access panel.

System board connectors and slots

1 Slot 7 PCI-X connector

(133 MHz 64 Bit)

2 Slot 6 PCI-X connector

(66 MHz 64 Bit)

3 Slot 5 PCI-X connector

(66 MHz 64 Bit)

4 Slot 4 PCI connector

(33 MHz 64 Bit)

5 Slot 3 AGP Pro

8X connector

6 Slot 2 PCI connector

(half-length 33 MHz 32 Bit)

7 Slot 1 PCI connector

(half-length 33 MHz 32 Bit)

8 LAN connector 18 Processor power

9 Rear USB

connectors (3)

10 Serial B connector 20 Processor—CPU 0 30 Memory module

11 Serial A (console)

connector

12 Diagnostic LEDs 22 Processor fan

13 Transfer of Control

(TOC) button

14 On-board LEDs 24 Processor fan

15 Chassis fan connector 25 Front control panel

16 Input power

connector—CPU 1 (option)

17 Input power

connector—CPU 0

module—CPU 0

19 Processor power

module—CPU 1(option)

21 Processor—CPU 1 (option) 31 Primary IDE 0

connector—CPU 0

23 Battery connector 33 Front panel USB

connector—CPU 1

connector

26 Memory fan

connector

27 Main power

connector

28 Auxiliary power

connector

29 System board

tray release

connectors

connector

32 Secondary IDE 1

connector

connector

34 Hard drive fan

connector

35 SCSI A

connector

36 SCSI B

connector

Hard drive activity

LED connector

3–4 Technical Reference Guide

Page 33

Tools and Safety

Most hardware replacement tasks do not require any tools. However, to prevent possible damage

from static electricity, you will need:

■ Static-free mat

■ Static strap

These tasks require tools:

■ If you are adding or replacing a processor, you will need the special processor tool that is

provided with the new processor.

■ If you are removing or replacing the front control module, you will need a T-15 Torx driver.

WARNING: For hardware installation procedures, you must power off the system, unplug the power

Å

cord from the outlet, and wait for all LEDs to turn off.

WARNING: If you have any doubt that you can lift the system or monitor safely, do not try to move them

Å

without help.

NOTE: To maintain FCC/EMI (Electromagnetic Interference) compliance, replace all covers

and make sure all screws are properly seated after you replace components.

Installing or Replacing Parts

To prevent damage to this system, observe all of the following ESD precautions while

performing the system parts removal/replacement procedures:

■ Work on a static-free mat.

■ Wear a static strap to ensure that any accumulated electrostatic charge is discharged from

your body to ground.

■ Create a common ground for the equipment you are working on by connecting the static-free

mat, static strap and peripheral units to that piece of equipment.

■ Keep uninstalled printed circuit boards in their protective antistatic bags.

■ Handle printed circuit boards by their edges, once you have removed them from their

protective antistatic bags.

Technical Reference Guide 3–5

Page 34

Installing or Replacing Parts

Removing and Replacing Access Panels

To upgrade, remove or replace system components, you need to remove one or both access

panels from the system chassis.

WARNING: Never remove the system access panel(s) without first turning the system off and

Å

unplugging the power cord from the back of the system. Always replace the cover(s) before turning the

workstation on.

Removing the Main System Access Panel

To remove or install most components, you only need to remove the main system access panel.

NOTE: The front system access panel only needs to be removed when removing the “Front

✎

Control Module” on page 3-29 or the “Optical Drives (CD or DVD)” on page 3-17.

1. Unlock the panel if it is locked 1.

2. Pull out on the latch to release it 2.

3. Rotate the panel 3, pull up 4, and lift it away 5.

Removing the main system access panel

3–6 Technical Reference Guide

Page 35

Removing the Front Access Panel

To install or replace the “Front Control Module” on page 3-29 or the “Optical Drives (CD or

DVD)” on page 3-17, you need to remove the front access panel.

1. If you have already connected and turned on the system, turn off the system and disconnect

all cables.

2. Remove the main system access panel:

a. Unlock the panel if it is locked 1

b. Pull out on the latch to release it 2

c. Rotate the panel 3 and lift it off 4

3. Remove the front system access panel:

a. Depress the clips on the inside of the case to release the front panel 5

b. Rotate the panel and lift it off 6

Installing or Replacing Parts

Removing the system access panels

Technical Reference Guide 3–7

Page 36

Installing or Replacing Parts

Removing and Replacing Internal Components

This section includes instructions for removing and replacing the following components:

■ Airflow Guide and Memory Fan, page 3-9

■ Memory Modules, page 3-10

■ PCI and AGP Cards, page 3-12

■ Optical Drives (CD or DVD), page 3-17

■ Hard Drives, page 3-19

■ External SCSI Devices, page 3-23

■ Power Supply, page 3-25

■ Hard Drive and Chassis Fans, page 3-27

■ Front Control Module, page 3-29

■ Replacing the Processor or Installing an Additional Processor, page 3-32

■ System Board, page 3-39

■ System Battery, page 3-41

Instructions for the following procedures are included with kits containing the parts:

■ Processor Replacement and Installation

■ Tower-to-Rack Conversion

■ Rack-to-Tower Conversion

3–8 Technical Reference Guide

Page 37

Airflow Guide and Memory Fan

The system airflow guide and memory fan must be removed to access several other components.

To remove the airflow guide and fan:

1. Turn off the system, disconnect the power cable, and remove the system access panel.

2. Unplug the memory fan connector from the system board 1.

3. Grasp the airflow guide 2 and lift it out of the system 3.

Installing or Replacing Parts

Removing the airfllow guide and fan

To replace the airflow guide and fan:

1. Insert the airflow guide into the system and press until it snaps into place.

2. Plug the memory fan connector into the system board.

Technical Reference Guide 3–9

Page 38

Installing or Replacing Parts

Memory Modules

The HP workstation c8000 has eight memory slots for Dual Inline Memory Modules (DIMMs).

These modules can be:

■ 256 MB

■ 512 MB

■ 1 GB

■ 2 GB

■ 4 GB

DIMMs must be installed in matched pairs of equal size. You can install a minimum of 512 MB

and a maximum of 32 GB of memory.

■ To obtain detailed configuration information for your system, use the BCH Information

menu (see page 2-6).

■ For a list of approved memory modules, see:

http://partsurfer.hp.com

Removing Memory Modules

1. Turn off the system, disconnect all cables, and remove the main access panel and airflow

guide.

WARNING: To ensure that memory modules are not damaged during removal or installation, power off

Å

the workstation and unplug the power cord from the AC power outlet. Wait until the power supply LED

(page 1-7) turns off before removing or installing memory.

2. Press downward and outward on the memory module retainer clips, then lift the DIMM out

of the slot by its edges.

Removing DIMMs

3. If the removed memory is functional, store it in a static-free container for future use.

4. Replace the airflow guide and system access panel, reconnect all cables, and turn on the

system.

5. Check the configuration using the BCH

Information menu (page 2-6).

3–10 Technical Reference Guide

Page 39

Installing Memory Modules

1. Turn off and unplug the system, disconnect the power cable, and remove the system access

panel and airflow guide.

WARNING: To ensure that memory modules are not damaged during removal or installation, power off

Å

the workstation and unplug the power cord from the AC power outlet. Wait until all LEDs on the system

board turn off before removing or installing memory.

2. Holding the DIMM by its left and right edges, insert it into the slot. Make sure DIMMs are

inserted fully and that the side clips fully clasp the DIMM edges.

CAUTION: The memory modules are keyed and can only be inserted in one direction. Do not try to

Ä

force a DIMM into a slot backwards. When the module is correctly seated, the retainer clips will return to

their fully upright position. Snap the clips firmly into place to ensure that the DIMMs are seated properly.

3. Replace the airflow guide and system access panel, reconnect all cables, and turn on the

system.

Installing or Replacing Parts

4. Check the memory configuration using the BCH

DIMM Installation Guidelines

The HP workstation c8000 has eight memory DIMM slots organized as four a/b pairs: 0a and 0b,

1a and 1b, 2a and 2b, 3a and 3b.

❏ The DIMM in each a slot must match the DIMM in the corresponding b slot.

❏ DIMMs match if they have the same HP part number. (Two empty slots also match.)

❏ For maximum system performance, install DIMMs so that the even pairs match the odd

pairs: 0a and 0b match 1a and 1b; 2a and 2b match 3a and 3b.

❏ Matched pairs should be loaded in this order:

1 slots 0A and 0B

2 slots 1A and 1B

3 slots 2A and 2B

4 slots 3A and 3B

Information menu (page 2-6).

DIMM slots

Technical Reference Guide 3–11

Page 40

Installing or Replacing Parts

PCI and AGP Cards

This section explains how to:

■ access the AGP and PCI slots, and

■ remove and replace AGP graphics and PCI accessory cards.

Removing PCI or AGP Card

1. Turn off the system, disconnect all cables, and remove the main access panel.

2. Remove the AGP retainer if it is blocking the card you wish to access:

a. Press in on the release snaps on the AGP retainer 1.

b. Rotate the retainer outwards 2 and lift it out of the system.

Removing the AGP retainer

3–12 Technical Reference Guide

Page 41

Installing or Replacing Parts

3. Open the PCI/AGP retainer clip:

❏ Push in on the two blue levers at the ends of the PCI/AGP retainer clip 1 then rotate the

clip into the open position 2.

Opening the PCI/AGP retainer clip

4. Remove the card:

a. If the card is an audio card, unplug the connectors attached to the front control panel (see

figure on page 3-29).

b. If the card is a full length card, push the card edge stop to the side to allow the card to

slide out of the guide.

Full-length AGP or PCI card

Technical Reference Guide 3–13

Page 42

Installing or Replacing Parts

c. Grasp the card at the edges 1 and lift it out of the slot 2.

Removing an AGP or PCI card

5. If you are not installing a new card in the same slot, insert a filler blank. If you are installing

a new card in the same slot, see page 3-15.

6. Close the PCI/AGP retainer clip and press the two blue release snaps on the rear panel of the

system to lock it in place. (See figure on page 3-13).

7. Replace the AGP retainer if you removed it.

a. Insert the tab on the retainer securely into the slot on the rear edge of the system

chassis 1 and rotate the retainer until it snaps into place 2.

b. Make sure the retainer 3 is securely holding the AGP card in place.

Replacing the AGP retainer

8. Replace the main access panel, reattach the power cable and any external cables attached to

the PCI/AGP cards, and turn on the system.

3–14 Technical Reference Guide

Page 43

Installing or Replacing a PCI or AGP Card

NOTE: For specifications on your graphics card, visit the manufacturer’s web site or refer to the

graphics documentation included in the acccessory kit.

To install an accessory or graphics card:

1. Remove the existing card or bulkhead blank that is in the slot you want to use.

a. From the inside of the case, push on the two blue release snaps at the ends of the

PCI/AGP retainer clip 1 then rotate the clip into the open position 2.

b. If the slot has a card installed, remove it (page 3-12).

c. If the slot is empty, pull the filler blank out of the system 3.

Installing or Replacing Parts

Removing the existing card or bulkhead blank

Technical Reference Guide 3–15

Page 44

Installing or Replacing Parts

2. Install the card:

a. Grasp the edges of the new card and insert it into the slot.

b. If the card has a power connector, plug it in.

Plugging in a PCI or AGP card power connector

c. If the card is a full length card, the end of the card will automatically snap into place (not

shown).

3. Close the PCI/AGP retainer clip and press the two blue release snaps on the rear panel of the

system to lock it in place. (See the figure on page 3-13).

4. Replace the AGP retainer and system access panel and reconnect all cables.

5. Turn on the system and check the configuration using the BCH

Information menu

(page 2-6).

3–16 Technical Reference Guide

Page 45

Optical Drives (CD or DVD)

Removing an Optical Drive

1. Turn off the system, disconnect all cables, and remove the system access panel and front

panel.

2. Disconnect the audio 1, IDE 2, and power 3 cables from the optical drive.

3. Pull outward on the lever to release the optical drives from the bay 4.

Installing or Replacing Parts

Disconnecting an optical drive

4. Grasp the optical drive firmly and slide it forward to pull it out of the drive bay.

Removing an optical drive from tower and rack-mounted systems

5. If you are not replacing the optical drive with a new drive, install a blank in the drive bay

opening and a plastic filler in the front panel.

Technical Reference Guide 3–17

Page 46

Installing or Replacing Parts

Installing an Optical Drive

1. Turn off the system, disconnect all cables, and remove the system access panels.

2. Pull the release handle on the optical drive bay, and slide the optical drive into the bay until it

stops and snaps into place. Verify that the drive is properly installed by checking that the

small alignment holes on the side of the drive bay are aligned with the holes on the drive

(4 below).

If you need help performing these steps, refer to “Removing an Optical Drive” on page 3-17.

3. Connect the power and audio cables to the optical drive.

4. Connect the IDE cable to the optical drive:

The system has two IDE cables:

❏ If you have IDE hard drives installed, one cable is used to connect the hard drives, the

other to connect up to two optical drives.

❏ If you have SCSI hard drives installed, two optical drive IDE cables are available to

connect up to three optical drives.

To connect the IDE cable:

a. Locate the IDE cable(s) connected to the secondary IDE connector on the system

board 1 and route the cable(s) 2 to the optical drives. If you have three optical drives,

connect the third drive to the cable connected to the primary IDE connector.

b. Plug the cable in to the connector on the optical drive 3.

Connecting an optical drive

NOTE: The black connector on each cable is for the master device; the gray connector is for the

slave device. Make sure the jumper on the optical drive is set to cable select (CSEL), not to

master (M) or slave (S). See the documentation provided with your drive for help locating the

jumper.

3–18 Technical Reference Guide

Page 47

5. Replace the access panels and reconnect all cables.

Installing or Replacing Parts

6. Turn the system on, then check the configuration using the BCH

(page 2-6).

Hard Drives

Removing a Hard Drive

1. Turn off the system, disconnect all cables, and remove the system access panel.

2. Disconnect the hard drive IDE or SCSI cable 1 and power connector 2.

3. Squeeze inward on the blue release clips located on the sides of the drive 3. Then, pull

outward to remove the drive from the system 4.

Information menu

Removing a hard drive

Technical Reference Guide 3–19

Page 48

Installing or Replacing Parts

Replacing a Hard Drive

1. Review “Hard Drive Installation Guidelines” on page 3-21 for instructions on configuring

drives and installing drives in the correct bays.

2. Select a drive bay in which to install the drive. Squeeze inward on the blue release clips

located on the sides of the tray with attached drive rails. Pull forward to remove the tray from

the empty bay (see step 3 in figure of removing a drive on page 3-19).

3. Snap the drive inside the drive tray to attach rails to the hard drive. Pull outwards on the drive

rails 1, then place the tray onto the drive 2. Align the pins on the tray wtih the holes on the

drive and let the rails snap into place 3.

1

2

Attach the rails

4. Push the drive into the bay until it snaps into place 1. Then attach the power 2 and IDE or

SCSI cable 3 to the drive.

Installing a hard drive

5. Replace the system access panel and cables.

6. Turn the system on, then check the configuration using the BCH

Information menu

(page 2-6).

3–20 Technical Reference Guide

Page 49

Hard Drive Installation Guidelines

The system supports either IDE or SCSI hard drives, but not both in the same system.

IDE Drives

The HP workstation c8000 supports up to two IDE hard drives, attached to the primary IDE

cable.

NOTE: For additional information on configuring IDE drives, see Appendix A, “Ultra ATA /

IDE Guidelines.”

❏ The system has two IDE cables — one for connecting hard drives, and the other for

connecting optical drives. Locate the IDE cable connected to the primary IDE connector

on the system board 1 and attach the cable 2 to the hard drive.

❏ The black connector on each cable is for the master device 3; the gray connector is for

the slave device 4. Make sure the jumper on the hard drive is set to cable select (CSEL),

not to master (M) or slave (S). See the documentation provided with your drive for help

locating the jumper.

❏ Install the first drive in the top bay 3. Install the second drive in the bay above the

bottom bay 4.

Installing or Replacing Parts

IDE hard drive locations

NOTE: The Disk Activity LED automatically communicates with IDE and SCSI drives

connected to the built-in controllers.

To get this functionality with an SCSI or IDE controller card, connect the card with an LED

activity cable to the hard drive activity LED connector on the system board.

Refer to “System Board Components and Connectors” on page 3-4 for a picture showing where

on the system board to connect the LED activity cable (item 36).

Technical Reference Guide 3–21

Page 50

Installing or Replacing Parts

SCSI Drives

The HP workstation c8000 supports up to four SCSI hard drives attached to the SCSI A

connector.

1. Set the SCSI ID on your drive(s):

❏ Drive 1 ID=3

❏ Drive 2 ID=4

❏ Drive 3 ID=5

❏ Drive 4 ID=6

See the label on the hard drive or documentation provided with the drive for instructions on

setting SCSI IDs. These instructions should include a diagram of the jumper block and

jumper settings for each SCSI ID.

NOTE: See Appendix B, “SCSI Guidelines” for more information on configuring SCSI drives.

2. Locate the SCSI cable connected to the SCSI A connector on the system board 1 and attach

the cable 2 to the hard drive(s).

3. Install drives in bays in the following order 3:

❏ Use bay 3d for Drive 1

❏ Use bay 3b for Drive 2

❏ Use bay 3c for Drive 3

❏ Use bay 3a for Drive 4

NOTE: There is no need to terminate the SCSI chain. The supported SCSI cable includes an

attached hardware terminator.

SCSI hard drive locations

3–22 Technical Reference Guide

Page 51

NOTE: The Disk Activity LED automatically communicates with IDE and SCSI drives

connected to the built-in controllers.

To get this functionality with an SCSI or IDE controller card, connect the card with an LED

activity cable to the hard drive activity LED connector on the system board.

Refer to “System Board Components and Connectors” on page 3-4 for a picture showing where

on the system board to connect the LED activity cable (item 36).

External SCSI Devices

You can add an external SCSI connector (U320 SCSI port) to the on-board SCSI controller or to

an optional PCI SCSI controller card.

Note that:

■ You can connect up to 15 devices at any SCSI ID, except SCSI ID 7 which is used by the host

controller.

■ The bus should be terminated as normal if you use external devices. No termination is

necessary if there are no devices connected.

Installing or Replacing Parts

■ SCSI IDs are set by jumpering pins on the disk drive.

■ If you are adding a SCSI hard drive to your system, you may need to change the SCSI ID of

the new hard drive so that all SCSI devices have unique IDs. If two devices use ID 0, the

system will not boot.

■ If you are replacing a SCSI hard drive, you can use the SCSI ID number of the current hard

drive for the replacement hard drive.

To install the external connector:

1. Remove the knockout panel in the chassis using a regular screwdriver. Insert a flat-head

screwdriver into the rectangular hole and twist the metal until the panel comes out.

Remove knockout panel

Technical Reference Guide 3–23

Page 52

Installing or Replacing Parts

2. Plug the cable into the connector 1 and route as shown.

Installing external connector

3. Peel the release liner off of the pad on the cable and press the pad against the chassis wall 2

to secure.

4. Thread the jackscrews through the rear chassis wall and into the connector 3.

3–24 Technical Reference Guide

Page 53

Power Supply

Before replacing the power supply, you can use the Built-In Self-Test (BIST) feature to find out if

the power supply still works. Refer to Chapter 4, “Troubleshooting”, for more information.

Removing the Power Supply

1. Turn off the system, disconnect all cables, and remove the system access panel and airflow

guide.

2. Unplug the power supply power connectors from all components 1, including the:

❏ hard drives

❏ optical drives

❏ graphics card

❏ system board

NOTE: Use caution when lifting the power supply because there are cables below the power

supply (illustrated on the next page) that must be removed before completely removing the

power supply from the chassis.

3. Loosen the thumbscrew that secures the power supply to the rear panel 2.

Installing or Replacing Parts

4. While supporting the power supply weight with your hand 3, reach inside the system chassis

and pull the lever that locks the power supply in place 4.

5. Slide the power supply toward the front of the chassis 5 and toward the PCI slots 6, then lift

it out 7.

6. Unplug the power supply cables that connect to the power module(s) 8.

2

3

5

6

7

4

8

Removing the power supply

NOTE: For information on testing the power supply, refer to “Troubleshooting the Power

✎

Supply” on page 4-14.

Technical Reference Guide 3–25

Page 54

Installing or Replacing Parts

Replacing the Power Supply

1. Before inserting the power supply, reconnect the processor power module cable(s) from the

power supply to the power modules on the system board.

NOTE: The power cables connecting to the power modules are interchangeable. The cables are

different colors but all are designed for the same purpose.

2. Align the tabs on the power supply with the mounting holes on the system chassis.

3. Insert the new power supply into the system chassis. Push the power supply up and slide it

toward the back of the chassis until it snaps into place.

4. Tighten in the thumbscrew that secures the power supply to the rear panel.

5. Connect the remaining power supply power cables to all system components, including the

hard drives, optical drives and system board. Be sure the cables are routed properly, so they

do not block the airflow guide or interfere with the heatsinks on the processors.

3–26 Technical Reference Guide

Page 55

Hard Drive and Chassis Fans

In addition to the fan attached to the airflow guide (page 3-9), two cooling fans are mounted at

the front and rear of the system.

Removing the Hard Drive and Chassis Fans

1. Turn off the system, disconnect the power cable, and remove the system access panel and

airflow guide.

2. To remove the hard drive fan:

a. Unplug the fan power cable from the system board.

b. Push in on the snap on the side of the fan 1. Then rotate the fan towards the rear of the

chassis 2 and lift it out of the system 3.

Installing or Replacing Parts

Removing hard drive fan

Technical Reference Guide 3–27

Page 56

Installing or Replacing Parts

3. To remove the chassis fan:

a. Unplug the fan power cable 1.

b. Remove the push rivets holding the fan in place 2 then slide the fan towards the front of

the chassis and lift the fan out of the system 3.

Removing the chassis fan

Replacing the Hard Drive and Chassis Fans

1. Grasp the replacement fan module firmly and insert it into same location from which you

removed the old fan.

❏ If you are replacing the chassis fan, install the push rivets.

2. Re-attach the fan cable.

3. Replace the access panel and reconnect all cables.

4. Turn the system on, then check that the fans have been properly installed by verifying that

none of the Diagnostic LEDs on the rear panel of the system are lit.

3–28 Technical Reference Guide

Page 57

Front Control Module

The front control module contains these connectors and components:

■ Front-access USB connector

■ Microphone and headphone connectors (optional)

■ IEEE-1394 FireWire connector (not supported)

■ Power button

■ System status LED

■ Temperature sensor

■ Chassis intrusion switch

■ Disk activity LED

■ LAN activity LED

Removing the Front Control Module

1. Turn off the system, disconnect all cables, and remove the system access panels.

2. Disconnect the front control module cables.

Installing or Replacing Parts

Location of front control module cables and connections

1 Power 4 Audio (plugged into optional PCI card)

• Microphone (a)

• Headphone (b)

2 USB 5 Temperature sensor

3 Chassis speaker 6 Chassis intrusion switch

Technical Reference Guide 3–29

Page 58

Installing or Replacing Parts

3. Remove the chassis intrusion switch and temperature sensor:

a. Slide the switch out of the slot by pushing it in the direction shown 1.

b. Pull the switch out of the opening 2.

c. Pull up on the head of the plastic push rivet and remove it, then remove the sensor from

the system 5.

Removing the chassis intrusion switch

4. Remove the panel from the system:

a. Use a Torx T-15 or slot screwdriver to remove the screws holding the front control

module in place 1 2 3.

Unscrewing the front control module

3–30 Technical Reference Guide

Page 59

b. Remove the module, carefully extracting the attached cables through the opening on the

chassis.

Disconnecting the front control module

Replacing the Front Control Module

1. Insert the cables connected to the module through the opening in the system chassis and

route them to the appropriate connectors.

Installing or Replacing Parts

2. Reconnect the chassis intrusion switch:

a. Insert the new switch housing into the system chassis.

b. Insert the switch into the housing and slide in until it snaps into place.

3. Replace the temperature sensor and attach it with a plastic push rivet.

4. Replace the I/O panel in the system and use a Torx T-15 or slot screwdriver to attach the

mounting screws.

Replacing the front control module

5. Route the cables attached to the module to the appropriate components and connectors and

reconnect all cables (page 3-29).

6. Replace the system access panels and reconnect all power cables and turn on the system.

Verify that the System Status LED is working.

Technical Reference Guide 3–31

Page 60

Installing or Replacing Parts

Replacing the Processor or Installing an Additional Processor

To replace an existing processor or install a new one in the HP workstation c8000, follow these

steps.

Read Cautions and Warnings

For your safety, you must read the “Important Safety Warnings” at the beginning of this guide

and the “Tools and Safety” section at the beginning of this chapter before proceeding.

Remove the System Access Panel

1. Turn off the system and disconnect the power cable.

2. Place the unit on its side with the pedestal hanging over the edge of a table.

3. Remove the access panel (page 3-8).

Remove the Airflow Guide

1. Unplug the memory fan connector from the system board 1.

2. Grasp the airflow guide 2 and lift it out of the system 3.

Removing the airflow guide and fan

Remove the Power Supply

Follow the steps in “Removing the Power Supply” on page 3-25 to remove the power supply.

3–32 Technical Reference Guide

Page 61

Remove the Processor (for Replacement)

CAUTION: You must follow these steps exactly and in the correct sequence to avoid serious

Ä

damage to the system.

1. Remove the processor power module (CPU0 is shown):

a. Use the special processor tool (included with your processor kit) to remove the two

screws 1 from the processor power module.

b. Slide the processor power module towards the rear of the system until it stops, then lift it

out of the system.

Installing or Replacing Parts

Removing a processor power module

Technical Reference Guide 3–33

Page 62

Installing or Replacing Parts

2. Remove the processor:

a. Using the Torx driver end of the special processor tool, loosen the four screws on the

processor assembly until they pop up into the released position 1.

b. Insert the other end of the special processor tool into the slot on the side of the heatsink

and rotate the processor locking mechanism 180 degrees counter-clockwise to unlock

it 2.

Removing the processor

3. Lift the processor out of the system.

3–34 Technical Reference Guide

Page 63

Install the Processor

1. Prepare the CPU socket:

a. If you are adding a second CPU, remove the plastic film covering the socket.

b. Verify that the CPU locking mechanism is in the unlocked position.

Verifying unlocked position

Installing or Replacing Parts

The special processor tool rotates this lock

1

Unlocked

2

3 Locked

Technical Reference Guide 3–35

Page 64

Installing or Replacing Parts

2. Install the processor power module and the CPU:

a. Insert the processor into the socket.

b. Insert the allen wrench end of the special processor tool into the hole that runs down the

side of the heatsink. Engage the socket 1, and rotate it clockwise 180 degrees to lock the

processor in place. Remove the tool.

c. Using the other end of the special processor tool, tighten the four screws on the processor

assembly 2.

NOTE: If you are installing a new additional processor, the second power module shown in the

figure below will not be present.

Using the special processor tool

CAUTION: While carefully holding the system board back against the rear of the chassis, screw

Ä

in the four processor screws slowly, making sure to tighten all the screws evenly. Tighten one pair

of diagonally opposite screws 1 until the screw shank settles on the system board, then tighten

the remaining pair 2. Do not fully tighten one screw, then move on to the next. Tighten all of the

screws a little at a time, making sure the processor remains level.

3–36 Technical Reference Guide

Page 65

d. Insert the shims provided with the kit 1.

Installing or Replacing Parts

e. Insert the processor power module into the system

2 and slide it into the processor until

it stops.

f. Tighten the two screws from the processor power module firmly using the special

processor tool provided with the new processor 3.

Installing the processor power module

g. Plug in the fan connector 1.

1

Connecting fan connector

3. Replace the power supply (see “Replacing the Power Supply” on page 3-26) and reconnect

all power cables.

Technical Reference Guide 3–37

Page 66

Installing or Replacing Parts

Replace the Power Supply

Using the figure on page 3-34 as a guide:

1. Before inserting the power supply, be sure to re-connect the two processor power module

cables (from the power supply) to the power modules (on the system board).

2. Align the tabs on the power supply with the mounting holes on the system chassis.

3. Insert the new power supply into the system chassis. Push the power supply up and slide it

towards the back of the chassis until it snaps into place.

4. Connect the remaining power supply power cables to all system components, including the

hard drive(s), optical drive(s) and system board. Make sure the cables are routed properly, so

they do not block the airflow guide or interfere with the heatsinks on the processors.

Replace the Airflow Guide

Using the figure on page 3-38 as a guide:

1. Insert the airflow guide into the system and press until it snaps into place.

2. Plug the memory fan connector into the system board.

Replace the System Access Panel

Using the figure on page 3-8 as a guide:

1. Replace the system access panel.

2. Plug in the power cable and start the system to verify that it boots properly with the new

processor.

3–38 Technical Reference Guide

Page 67

System Board

Removing the System Board

1. Turn off the system, disconnect all external cables, and remove the system access panel.

Disconnect all devices attached to the system. Place the system on its side.

2. Disconnect the system board connectors (page 3-4) and remove all components except the

CPU(s).

❏ Power supply and all power cables connected to system board

❏ Airflow guide and memory fan

❏ Hard drive fan

❏ DIMMs

❏ AGP retainer

❏ Accessory and graphics cards