Page 1

Agilent TS-5000

Functional Test System

System Software User’s

Guide

Agilent Technologies

Page 2

Notices

Caution

!

WARNING

© Agilent Technologies, Inc. 1999 - 2012

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Documentation History

All Editions and Updates of this manual and

their creation date are listed below. The

first Edition of the manual is Edition 1. The

Edition number increments by 1 whenever

the manual is revised. Updates, which are

issued between Editions, contain replacement pages to correct or add additional

information to the current Edition of the

manual. Whenever a new Edition is created, it will contain all of the Update information for the previous Edition. Each new

Edition or Update also includes a revised

copy of this documentation history page.

Edition 1 (E8770-90000) July 1999

Edition 2 (E8770-90023) September 2000

Edition 3 (E8770-90033) January 2004

Edition 4 (E8770-90033) January 2006

Edition 4 (E8770-90033) April 2010

Edition 5 (E8770-90033) May 2011

Edition 6 (E8770-90033) August 2011

Edition 7 (E8770-90033) December 2012

Manual Part Number

E8770-90033

Printed in Malaysia

Agilent Technologies Microwave Products

(Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone

11900 Penang, Malaysia

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection

with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of

a U.S. Government prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

A Caution notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

Caution notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and met.

Page 3

Safety Summary

!

WARNING

!

WARNING

The following general safety

precautions must be observed

during all phases of operation

of this system. Failure to

comply with these precautions

or with specific warnings

elsewhere in this manual

violates safety standards of

design, manufacture, and

intended use of the system.

Agilent Technologies, Inc.

assumes no liability for the

customer's failure to comply

with these requirements.

General

This product is provided with

a protective earth terminal.

The protective features of this

product may be impaired if it

is used in a manner not

specified in the operation

instructions.

Cleaning Instructions

Clean the system cabinet using

a soft cloth dampened in

water.

DO NOT REMOVE ANY SYSTEM

COVER

Operating personnel must not

remove system covers. Component

replacement and internal adjustments must be made only by qualified service personnel. Equipment

that appears damaged or defective

should be made inoperative and

secured against unintended operation until they can be repaired by

qualified service personnel.

Environmental Conditions

DO NOT OPERATE IN AN EXPLOSIVE

ATMOSPHERE

Do not operate the system in the

presence of flammable gases or

flames.

If the equipment in this system

is used in a manner not

specified by Agilent

Technologies, the protection

provided by the equipment

may be impaired.

Unless otherwise noted in the

specifications, this system is

intended for indoor use in an

installation category II,

pollution degree 2

environment. It is designed to

operate at a maximum relative

humidity of 80% and at

altitudes of up to 2000 meters.

Refer to the specifications

tables for the ac mains voltage

requirements and ambient

operating temperature range.

Before applying power

Verify that all safety

precautions are taken. Note the

external markings described in

“Safety Symbols and

Regulatory Markings”on

page 4.

Safety and Support Information 3

Page 4

Ground the System

!

WARNING

To minimize shock hazard, the

instrument chassis and cover

must be connected to an

electrical protective earth

ground. The instrument must

be connected to the ac power

mains through a grounded

power cable, with the ground

wire firmly connected to an

electrical ground (safety

ground) at the power outlet.

Any interruption of the

protective (grounding)

conductor or disconnection of

the protective earth terminal

will cause a potential shock

hazard that could result in

personal injury.

The power cable ground wire must

be connected to an electrical ground

(safety ground) at the power outlet.

Any interruption of the protective

grounding will cause a potential

shock hazard that could result in

personal injury.

Fuses

Use only fuses with the

required rated current, voltage,

and specified type (normal

blow, time delay). Do not use

repaired fuses or

short- circuited fuse holders. To

do so could cause a shock or

fire hazard.

CANNOT BE OPERATOR

ACCESSIBLE: Cables and

connectors are considered

inaccessible if a tool (e.g.,

screwdriver, wrench, socket,

etc.) or a key (equipment in a

locked cabinet) is required to

gain access to them.

Additionally, the operator

cannot have access to a

conductive surface connected

to any cable conductor (High,

Low or Guard).

ASSURE THE EQUIPMENT

UNDER TEST HAS

ADEQUATE INSULATION

BETWEEN THE CABLE

CONNECTIONS AND ANY

OPERATOR- ACCESSIBLE

PARTS (DOORS, COVERS,

PANELS, SHIELDS, CASES,

CABINETS, ETC.): Ve r i fy

there are multiple and

sufficient protective means

(rated for the voltages you are

applying) to assure the

operator will NOT come into

contact with any energized

conductor even if one of the

protective means fails to work

as intended. For example, the

inner side of a case, cabinet,

door, cover or panel can be

covered with an insulating

material as well as routing the

test cables to the module’s

front panel connectors through

non- conductive, flexible

conduit such as that used in

electrical power distribution.

Operator Safety Information

MODULE CONNECTORS AND

TEST SIGNAL CABLES

CONNECTED TO THEM

4 Safety and Support Information

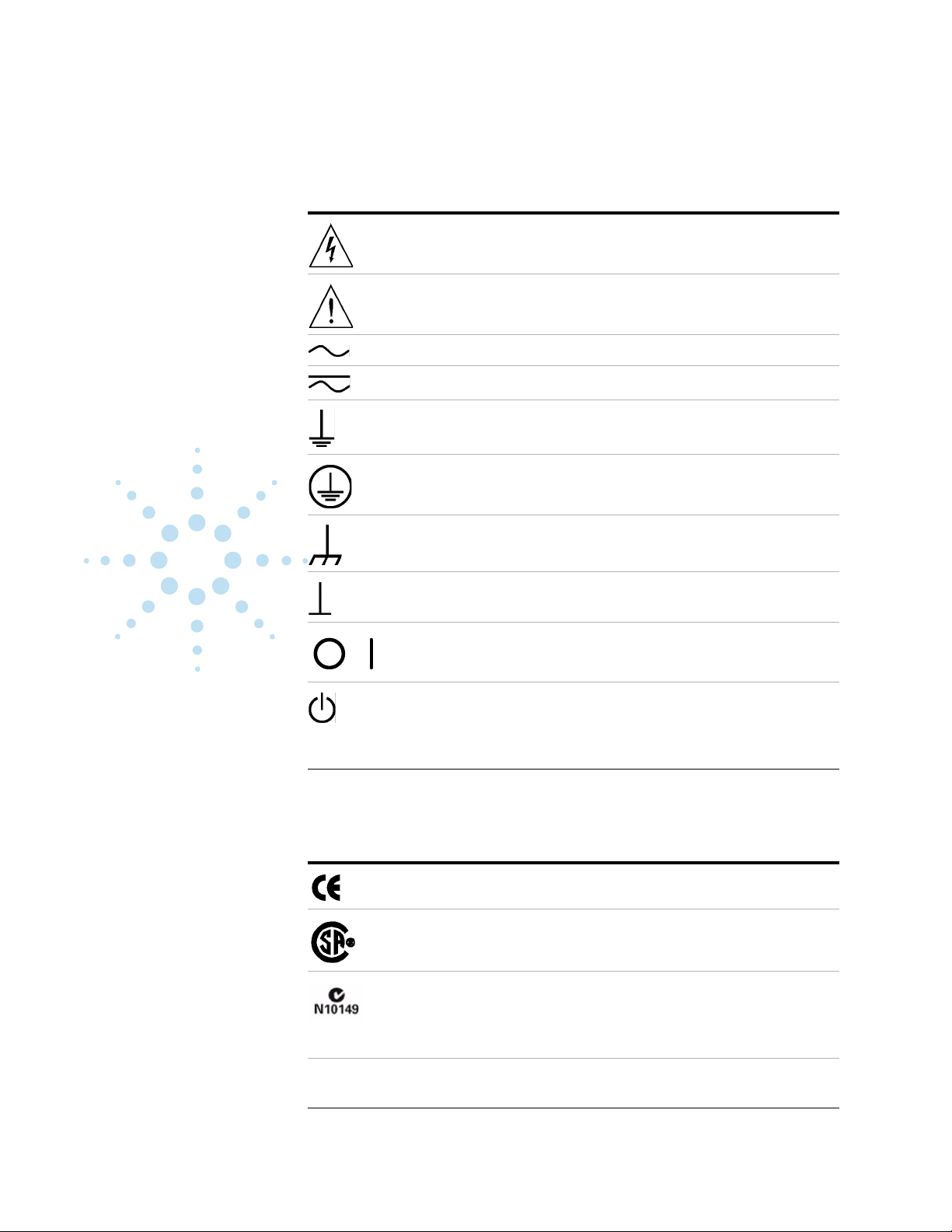

Safety Symbols and Regulatory Markings

Symbols and markings on the

system, in manuals and on

instruments alert you to

Page 5

potential risks, provide

information about conditions,

and comply with international

Tab l e 1 Safety Symbols and Markings

Warning: risk of electric shock.

Caution: refer to accompanying documents.

Alternating current.

Both direct and alternating current.

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

regulations. Table 1 and

Table 2 define the symbols and

markings you may encounter.

Terminal is at earth potential. Used for measurement and control

circuits designed to be operated with one terminal at earth potential.

Switch setting indicator. O = Off, | = On.

Standby (supply); units with this symbol are not completely

disconnected from ac mains when this switch is off. To completely

disconnect the unit from ac mains, either disconnect the power cord, or

have a qualified electrician install an external switch.

Tab l e 2 Regulatory Symbols Markings

The CE mark is a registered trademark of the European Community.

The CSA mark is a registered trademark of the Canadian Standards

Association.

The C-tick mark is a registered trademark of the Spectrum Management

Agency of Australia. This signifies compliance with the Australian EMC

Framework regulations under the terms of the Radio Communications

Act of 1992.

ISM 1-A This text indicates that the product is an Industrial Scientific and

Medical Group 1 Class A product (CISPR 11, Clause 4).

Safety and Support Information 5

Page 6

Service and Support

Tab l e 2 Regulatory Symbols Markings

This product complies with the WEEE Directive (2002/96/EC) marking

requirement. The affixed product label (see above) indicates that you

must not discard this electrical/electronic product in domestic

household waste.

Product Category: With reference to the equipment types in the WEEE

directive Annex 1, this product is classified as a “Monitoring and

Control instrumentation” product.

Do not dispose in domestic household waste

To return unwanted products, contact your local Agilent office, or see

http://www.agilent.com/environment/product for more information.

Any adjustment, maintenance,

or repair of this product must

be performed by qualified

personnel. Contact your

customer engineer through

your local Agilent Technologies

Service Center.

http://www.agilent.com

Click the link to Te s t &

Measurement. Select your

country from the drop- down

menus. The Web page that

appears next has contact

information specific for your

country.

Agilent on the Web

You can find information about

technical and professional

services, product support, and

equipment repair and service

on the Web:

Tab l e 3 Agilent Call Centers and Regional Headquarters

United States: Test and Measurement Call Center

(800) 829 4444(toll-free in US)

Canada: (877) 894 4414

Agilent by Phone

If you do not have access to

the Internet, call one of the

numbers in Table 3.

Europe: (41 22) 780 8111

Japan: Measurement Assistance Center

Latin America: 305 269 7500

Asia-Pacific: (85 22) 599 7777

6 Safety and Support Information

0120 (421) 345

Page 7

Contents

Chapter 1

System Software Overview ........................................................................................... 9

Agilent TestExec SL..................................................................................................... 9

Testplans ..................................................................................................................... 10

Testgroup ............................................................................................................. 10

List of Statements ................................................................................................ 10

Test ...................................................................................................................... 10

Switching Action ................................................................................................. 10

Action .................................................................................................................. 10

Actions ........................................................................................................................ 11

System.ust File............................................................................................................ 11

Aliases ................................................................................................................. 12

Wires ................................................................................................................... 12

Modules ............................................................................................................... 12

System Configuration Editor ...................................................................................... 14

Chapter 2

How to Use the System Software ................................................................................ 15

Chapter Contents......................................................................................................... 15

Required Computer Hardware and Software..............................................................15

System Software Description...................................................................................... 16

Selecting Agilent TestExec SL ................................................................................... 17

Loading a Testplan...................................................................................................... 17

Creating a Testplan ..................................................................................................... 18

Using TS-5000 Supplied Actions ............................................................................... 19

Standard Action Types ........................................................................................ 20

Example Testplans .............................................................................................. 20

Adding an Action to a Testplan ........................................................................... 20

Using Software Debug Features ................................................................................. 23

Looping ............................................................................................................... 23

Single Stepping ................................................................................................... 24

Action Debug Messages ...................................................................................... 25

Watch Window .................................................................................................... 25

Instrument Debug Front Panels ........................................................................... 28

Fast Connection Selection ................................................................................... 40

Viewing Waveforms ........................................................................................... 45

Instrument Handlers.................................................................................................... 48

Using the Action Wizard To Develop ........................................................................ 49

Multithreading ............................................................................................................ 50

How Multithreading is working on a Testplan? .................................................50

Opening System Configuration Editor ....................................................................... 56

Adding an IVI-COM Module in System Configuration Editor.................................. 57

Contents 7

Page 8

Adding a .Net Module in System Configuration Editor ............................................. 59

Chapter 3

Using the DMM and ARB ........................................................................................... 61

Chapter Contents......................................................................................................... 61

Triggered Voltage Measurement ................................................................................ 62

How to Trigger the DMM ................................................................................... 62

Using the Agilent E6173A Arbitrary Waveform Generator....................................... 65

Arbitrary Waveform Generator Description ....................................................... 65

How the Arb Generates Waveforms ................................................................... 65

Generating Arb Waveforms ................................................................................ 66

Memory Requirements for Downloading Waveforms ........................................ 86

Agilent E6173A Arbitrary Waveform Generator Error Messages ...................... 86

Chapter 4

Action Summary .......................................................................................................... 87

Index .............................................................................................................................. 177

8 Contents

Page 9

This chapter contains a detailed overview of the system software. Chapter

contents are:

Agilent TestExec SL

The Agilent TS-5000 System uses Agilent TestExec SL and system specific

software to test the Unit Under Test (UUT). Agilent TestExec SL is a test

executive designed for high-volume, high-throughput functional test

applications. The other system specific software provides the

communications between the test executive and system instruments.

Chapter 1

System Software Overview

• Agilent TestExec SL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

• Testplans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

• Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

• System.ust File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

• System Configuration Editor . . . . . . . . . . . . . . . . . . . . . . . . page 14

Agilent TestExec SL uses testplans (see “Testplans”) and actions (see

“Actions”) to perform the tests. The actions are the building blocks from

which the tests are created. The actions are called from a test which are

executed in a testplan. The switching actions makes the connections from

the system instruments, and/or loads on the load cards to the Unit Under Test

(UUT). The switching actions are built into Agilent TestExec SL.

Both actions and switching actions are used in a testplan to run the tests. The

testplan automatically closes the appropriate pin matrix and load card

switches to make the connections, setup and execute the appropriate sources

and detectors, and return any test results.

The switching information and the instrument types used in the system are

located in the system.ust file (see

information). This file is generated at the factory and is custom for each

system. It has the necessary information for the switching actions to close

the appropriate switches and for the other actions to communicate with the

system instruments. Instrument data in the system.ust file can be generated

and/or modified using the System Configuration Editor (see

Configuration Editor” on page 14).

“System.ust File” on page 11 for more

“System

System Software Overview 9Chapter 1

Page 10

Testplans

Start of

Program

Test

End of Testgroup

Testgroup

Statement

Switching Action

Action

Te s t N a m e

Test Description

(required if using a “Testgroup”)

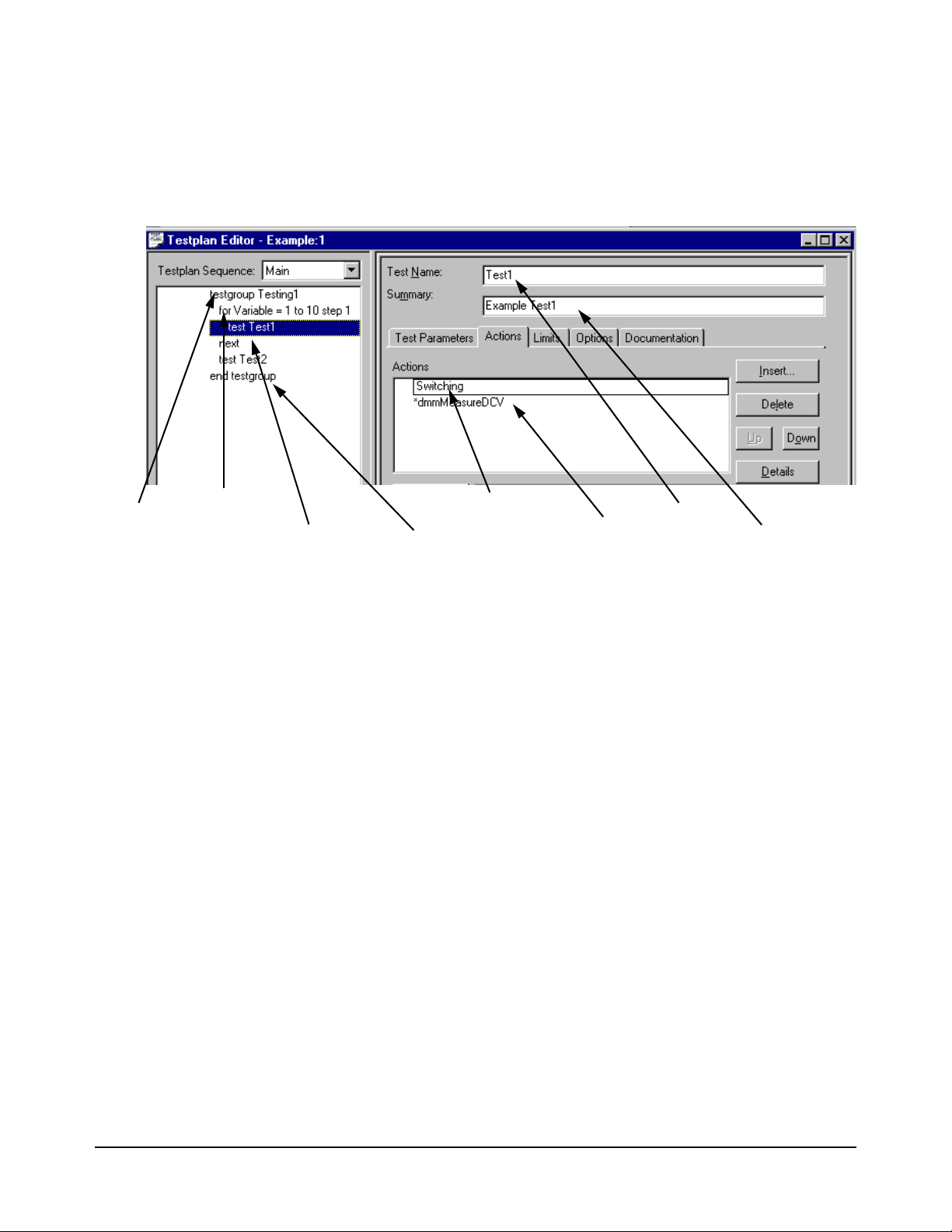

Figure 1-1 shows a testplan and some of its components; an explanation

follows the figure (see Loading a Testplan for an explanation on how to load

a testplan).

Figure 1-1. Typical Testplan Components

Testgroup A named block of tests that can be executed in a predefined order. Each

testgroup in a testplan must have a unique name; no duplicate names are

allowed.

List of Statements Test or flow control statements executed in the order shown.

Test A named series of actions that can be executed as a group. A test can contain

actions and switching actions. A test can have limit checking capabilities to

determine if a test passes or fails. A test must have a unique name; no

duplicate names are allowed.

Switching Action Actions that make connections from the instrument and loads to the Unit

Under Test. These actions are internal to Agilent TestExec SL. The

switching information in these actions are determined by the data in the

'system.ust' file and the user-generated fixture.ust and uut.ust files.

Action The smallest component in a test or testgroup that can be called to perform

functions such as setting up an instrument, making measurements and

prompting the user.

10 System Software Overview Chapter 1

Page 11

Actions

The system comes with a set of supplied actions. These actions are used for

such things as configuring instruments, making measurements and

prompting users for inputs. You can also generate custom actions using the

Action Wizard and an application program such as Visual C/C++.

The action directory path is:

C:\Program Files\Agilent\TS-5000 System

Software\actions

Actions are located in the following sub-directories:

Sub-Directory Action Type

arb Arbitrary Waveform Generator Actions

counter Counter Actions

dac D/A Converter Actions

dgn Diagnostics Actions

digitizer Digitizer Actions

dio Digital I/O Actions

dmm Digital Multimeter Actions

dso Digital Storage Oscilloscope

event Event Detector Actions

generic Miscellaneous Actions

mcm Measurement Control Module Actions

power Power Supply Actions

serial Serial Interface Actions

SerialProtocol Automotive Serial Protocol Actions

switch SLU and Switching Actions

vi Voltage / Current Source Actions

daq Data Acquisition Actions

esa Spectrum Analyzer Actions

esg Signal Generator Actions

System.ust File

The 'system.ust' file is created at the factory with the appropriate

module/instrument and wiring data according to the system option. The file

can be edited using the System Configuration Editor (see

System Software Overview 11Chapter 1

“System

Page 12

Configuration Editor” on page 14) or the Topology Editor in Agilent

Alias Name

Alias Description

Reference Node

TestExec SL.

The data in the 'system.ust' file consists of modules/instruments and

instrument nodes (i.e., connections at the 32-Pin Matrix and Instrument

Multiplexer Module), and other nodes (connections at the 32-Pin Matrix

Modules and load cards) using the Aliases, Wires, and Modules

designations. The Module designations are used to determine the

modules/instruments installed in the system, and the Aliases and Wires are

used to generate switch paths.

A typical 'system.ust' file contains Aliases, Wires and Modules.

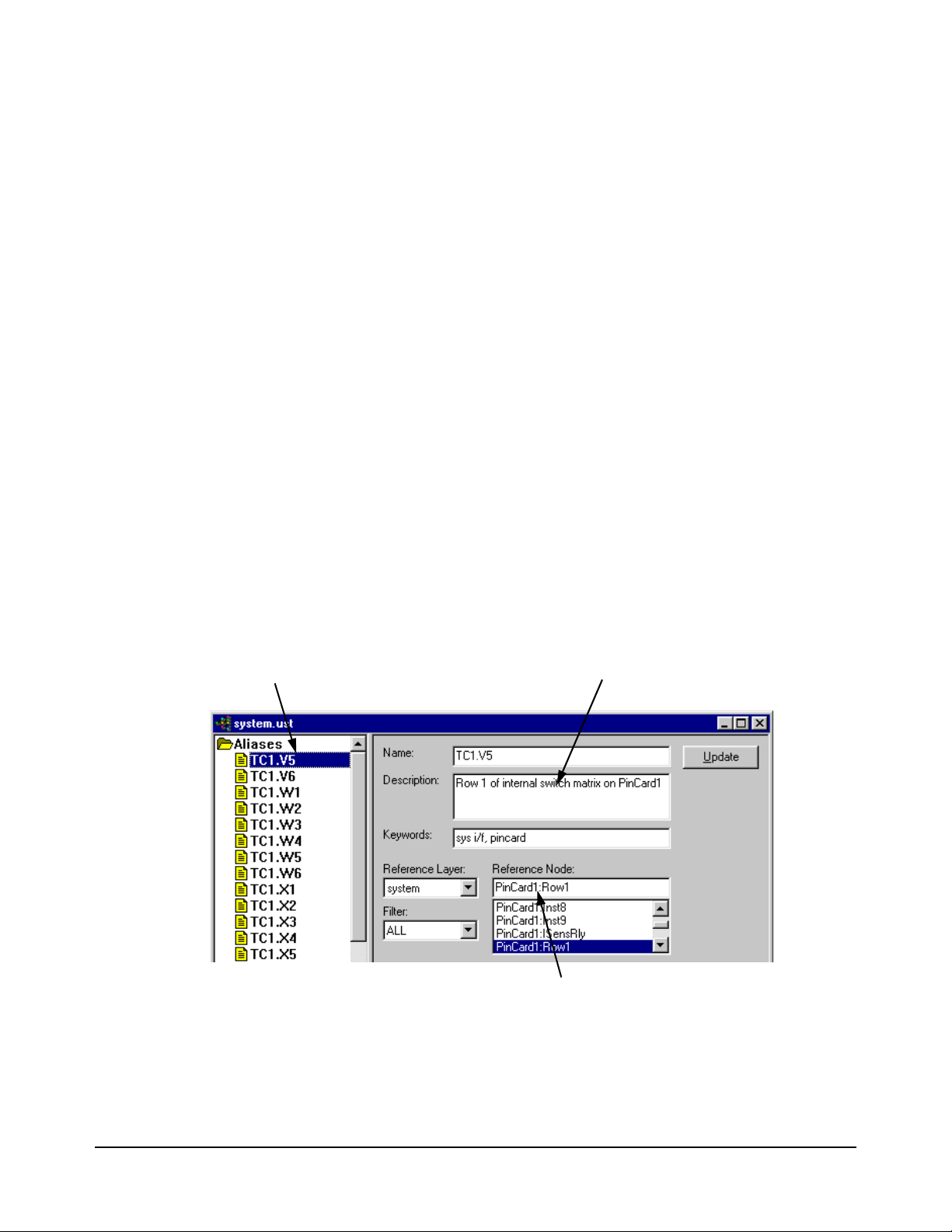

Aliases These are alternate names for reference nodes. The names are descriptive in

nature to easily identify the node. For example, the node name for the high

current output of the Agilent 34401 or E1411 Digital Multimeter is called

"IsrcHi".

Figure 1-2 shows typical Aliases in the 'system.ust' file.

Wires These are names for wires that connect to or between nodes. In some cases,

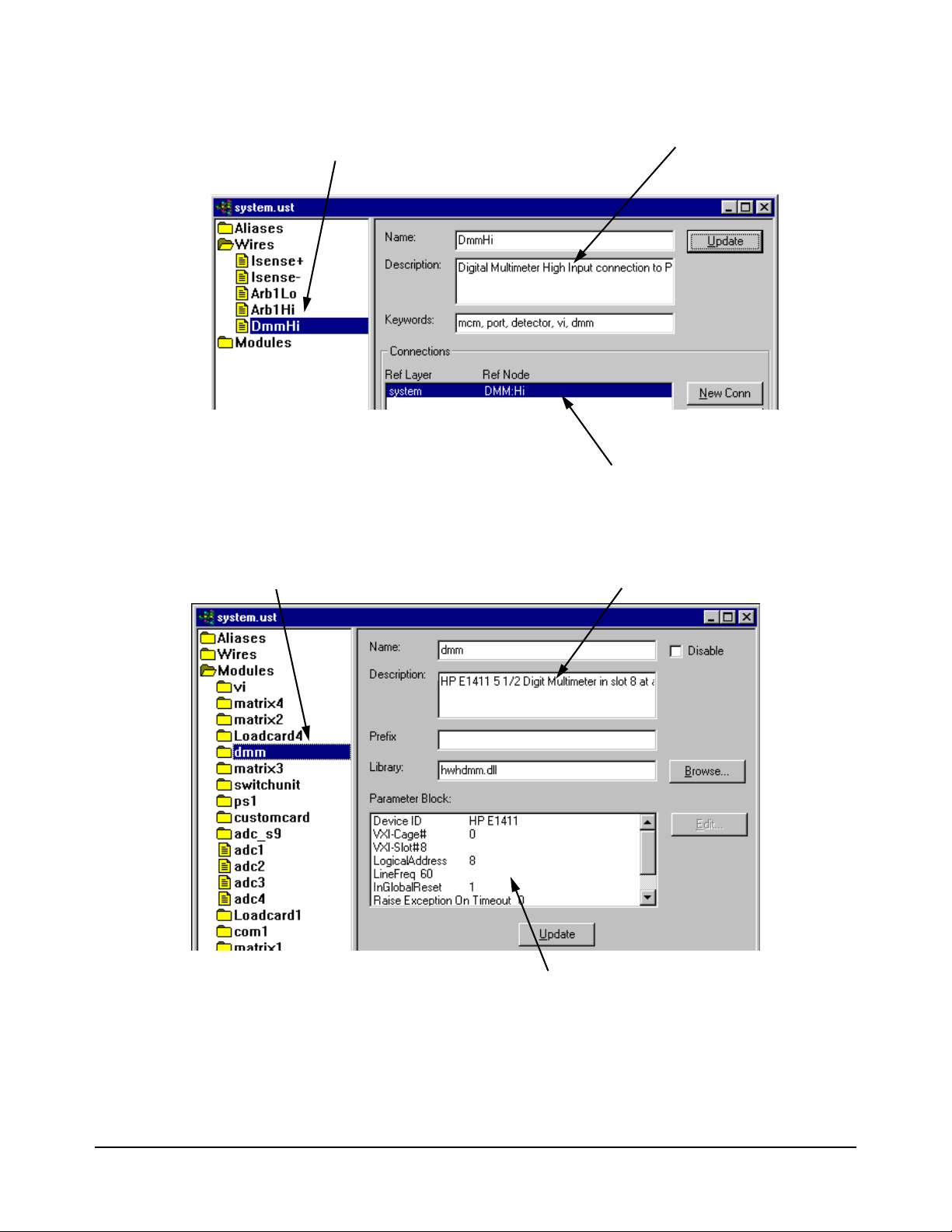

these names are the same aliases used for nodes. For example, the alias

called "DVMIsrcHi" is often used for the wire name that connects to that

Figure 1-3 shows typical wires in the 'system.ust' file.

node.

Modules These are the names of the instruments in the system. For example, the name

"MCM" indicates that there is an Agilent E6171B Measurement control

module in the system. The

'system.ust' file.

Figure 1-2. Typical Aliases

Figure 1-4 shows a few typical modules in the

12 System Software Overview Chapter 1

Page 13

Figure 1-3. Typical Wires

Wire Name

Wire Description

Reference Node

Module Name

Module Description

Module Related Data

Figure 1-4. Typical Modules/Instruments

System Software Overview 13Chapter 1

Page 14

System Configuration Editor

This editor can be used to add new modules/instruments or delete old

modules/instruments to/from the system.ust file (see

page 11 for information). It can add/delete any supported GPIB or VXI

instruments, Pin Matrix Modules, and/or load cards.

The editor has the following functions:

• Shows all supported modules/instruments.

• Automatically detects all modules/instruments currently in the system

• Able to add new custom modules/instruments to the system.ust file

• Able to edit module/instrument parameters

Any of the supported and custom modules/instruments can be added to the

system.ust file. Dependent on the system type and option (e.g., Test System

Interface vs. Mass Interconnect), the System Configuration Editor

automatically generates the appropriate wires and aliases (see

File” on page 11 for information). The wiring, etc. data is located in a

spreadsheet that is specifically generated for your system type and option.

The System Configuration Editor is available from the TestExec SL Toolbar

or from a shortcut in the Desktop on the system PC controller. Refer to the

System Configuration Editor’s online help for more details.

“System.ust File” on

“System.ust

14 System Software Overview Chapter 1

Page 15

How to Use the System Software

Chapter Contents

Chapter 2

This chapter lists the needed software to run the system and shows some

system specific software operation. The chapter is separated as follows:

• Required Computer Hardware and Software . . . . . . . . . . . . page 15

• System Software Description . . . . . . . . . . . . . . . . . . . . . . . . page 16

• Selecting Agilent TestExec SL . . . . . . . . . . . . . . . . . . . . . . . page 17

• Loading a Testplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

• Creating a Testplan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

• Using TS-5000 Supplied Actions . . . . . . . . . . . . . . . . . . . . . page 19

• Using Software Debug Features . . . . . . . . . . . . . . . . . . . . . . page 23

• Instrument Handlers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

• Using the Action Wizard To Develop. . . . . . . . . . . . . . . . . . page 49

• Multithreading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 50

Required Computer Hardware and Software

The following is a list of the computer hardware and software needed to run

the Agilent TS-5000 Test System. All necessary software was factory

installed on your system:

• IBM-compatible PC (at least a Pentium) with 256 MB of RAM,

1024x768 graphics, 100 MB of free disk space (20 MB for Agilent

TestExec SL software).

• Microsoft

• Agilent TestExec SL software, Version 5.1 or later.

• Agilent TS-5000 Software version 5.1 or later.

Note For more detailed information about using the Agilent TestExec SL

software, refer to the software documentation

®

Windows® XP or 7 Microsoft® Windows® 64-Bit

How to Use the System Software 15Chapter 2

Page 16

System Software Description

The Agilent TS-5000 System uses Agilent TestExec SL and system specific

software to test the Unit Under Test. Agilent TestExec SL is a test executive

designed for high-volume, high-throughput functional test applications. The

other system specific software provides the communications between the

test executive and system instruments.

Agilent TestExec SL uses testplans and actions to perform the tests. The

actions are the building blocks from which the tests are created. The actions

are called from a test which are executed in a testplan. The switching actions

makes the connections from the system instruments, and/or loads on the load

cards to the Unit Under Test. The switching actions are built into Agilent

TestExec SL.

Both actions and switching actions are used in a testplan to run the tests. The

testplan automatically closes the appropriate pin matrix and load card

switches to make the connections, setup and execute the appropriate sources

and detectors, and return any test results.

The switching information and the instrument types used in the system are

located in the

custom for each system. It has the necessary information for the switching

actions to close the appropriate switches and for the other actions to

communicate with the system instruments. Instrument data in the

system.ust file can be generated and/or modified using the System

Configuration Editor (see

“TS-5000 System Integrator’s Manual”

system.ust file. This file is generated at the factory and is

“Using the System Configuration Editor” in the

).

16 How to Use the System Software Chapter 2

Page 17

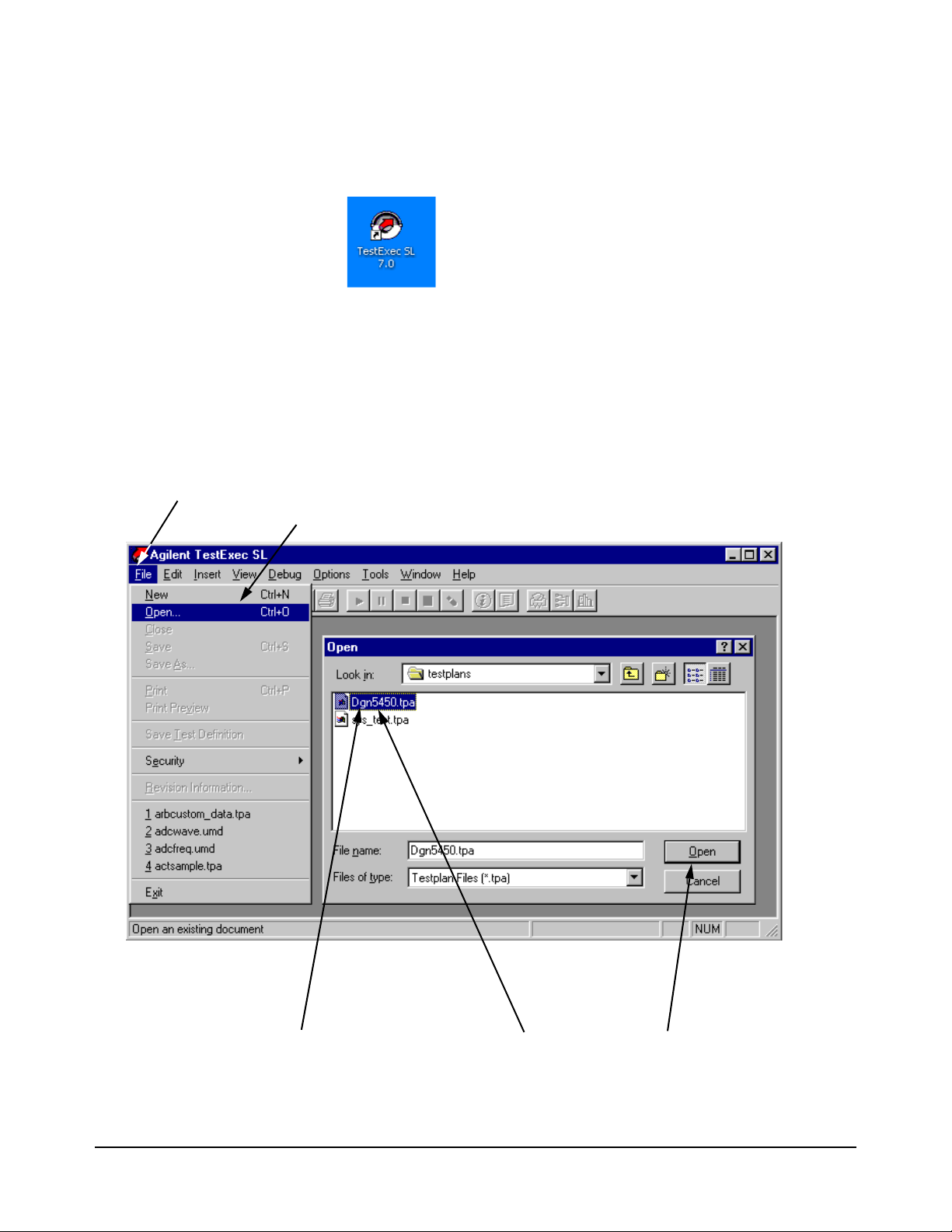

Selecting Agilent TestExec SL

3. Double Click on File Name or Select File Name and click on “Open”

1. Select “File” menu

2. Select “Open” Menu Item or press “Ctrl+O” buttons

The Agilent TestExec SL software is pre-installed on your PC controller’s

hard drive. Start TestExec SL from this icon in the PC desktop:

You can also run TestExec SL by clicking:

Start | Programs | Agilent TestExec SL 7.0 | TestExec SL 7.0

Loading a Testplan

Figure 2-1. Agilent TestExec SL Main Screen and File Open Box

How to Use the System Software 17Chapter 2

Page 18

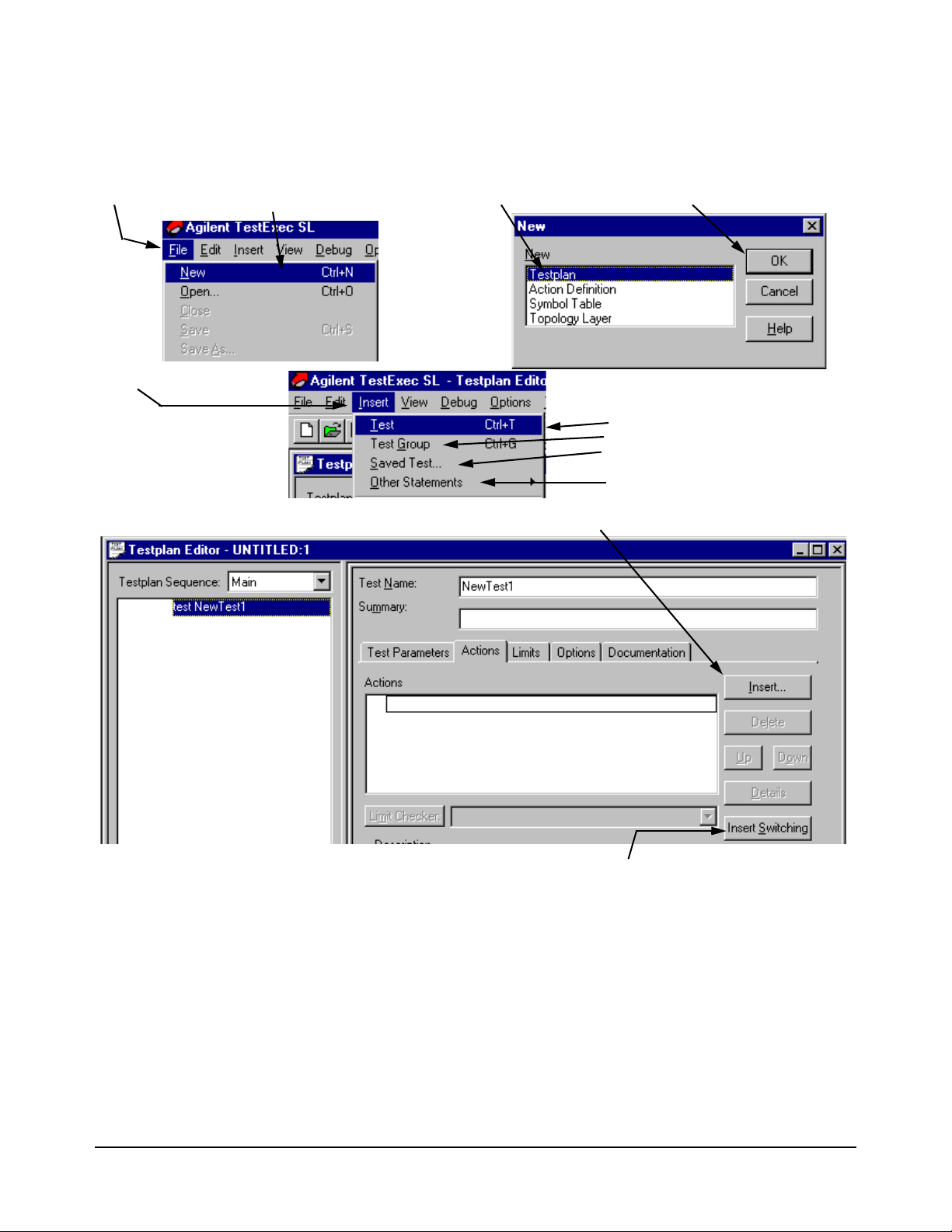

Creating a Testplan

1. Click on “File” menu

2. Click on “New” menu item

3. Click on “Testplan” 4. Click on “OK”

5. Click on “Insert” menu

6. Click on one of the following:

Test - inserts a new test

Test Group - inserts a new testgroup

Saved Test - inserts a test from a

previously saved test library

Other Statements - inserts a program

statement

7A. Click to insert action

7B. Click to insert switching action

Figure 2-2 shows how to create a testplan.

Figure 2-2. Creating a Testplan

18 How to Use the System Software Chapter 2

Page 19

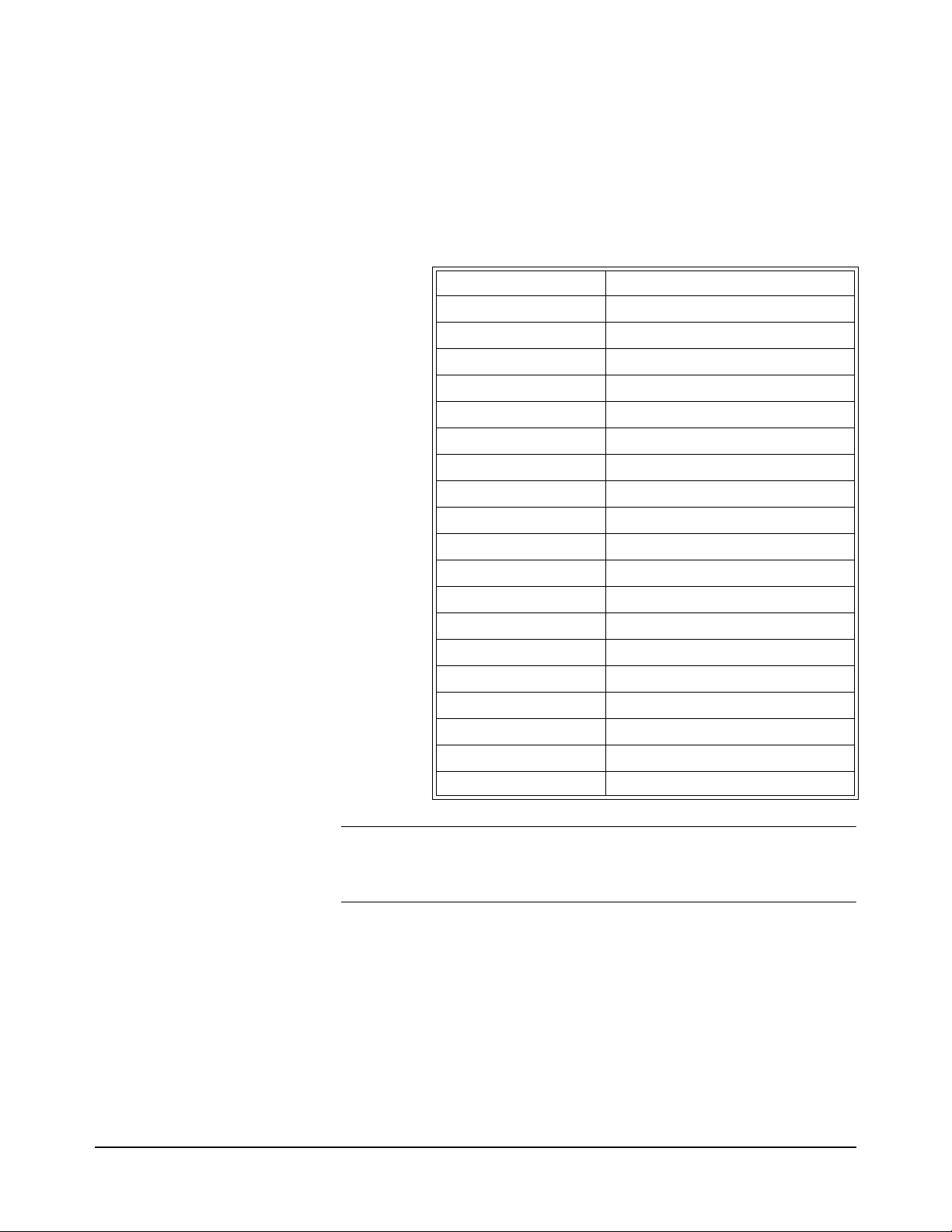

Using TS-5000 Supplied Actions

The Agilent TS-5000 System with a set of standard actions supplied with the

system. The action directory path is:

C:\Program Files\Agilent\TS-5000 System Software\actions

Actions are located in the following sub-directories:

Sub-Directory Action Type

arb Arbitrary Waveform Generator Actions

counter Counter Actions

dac D/A Converter Actions

dgn Diagnostics Actions

digitizer Digitizer Actions

dio Digital I/O Actions

dmm Digital Multimeter Actions

dso Digital Storage Oscilloscope Actions

event Event Detector Actions

generic Miscellaneous Actions

mcm Measurement Control Module Actions

power Power Supply Actions

serial Serial Interface Actions

SerialProtocol Automotive Serial Protocol Actions

switch SLU and Switching Actions

vi Voltage / Current Source Actions

daq Data Acquisition Actions

esa Spectrum Analyzer Actions

esg Signal Generator Actions

Note The actions are summarized in Chapter 4 of this manual. The actions are

documented in detail in the TS-5000 online help which is available from

the TestExec SL Help menu.

How to Use the System Software 19Chapter 2

Page 20

Standard Action

Types

The standard actions are generally organized around a specific instrument or

module in the system. The actions are also separated into the types discussed

below.

High-Level Actions These are actions that usually perform complete tests, such as setting up a

source and then making a measurement. These actions normally, but not

always, use one or more of the Low-Level Actions.

Low-Level Actions These actions perform specific configuration or measurement function on a

particular instrument. The low-level actions give you more flexibility in

configuring instruments and making the measurements than do the

high-level actions. Low-Level actions are organized by instrument type and

function. For example, an action that is to set up triggering for a voltmeter

is a low-level action.

Example Testplans Example testplans to show how to use the actions are in the following

directory:

C:\Program Files\Agilent\TS-5000 System

Software\testplan\examples

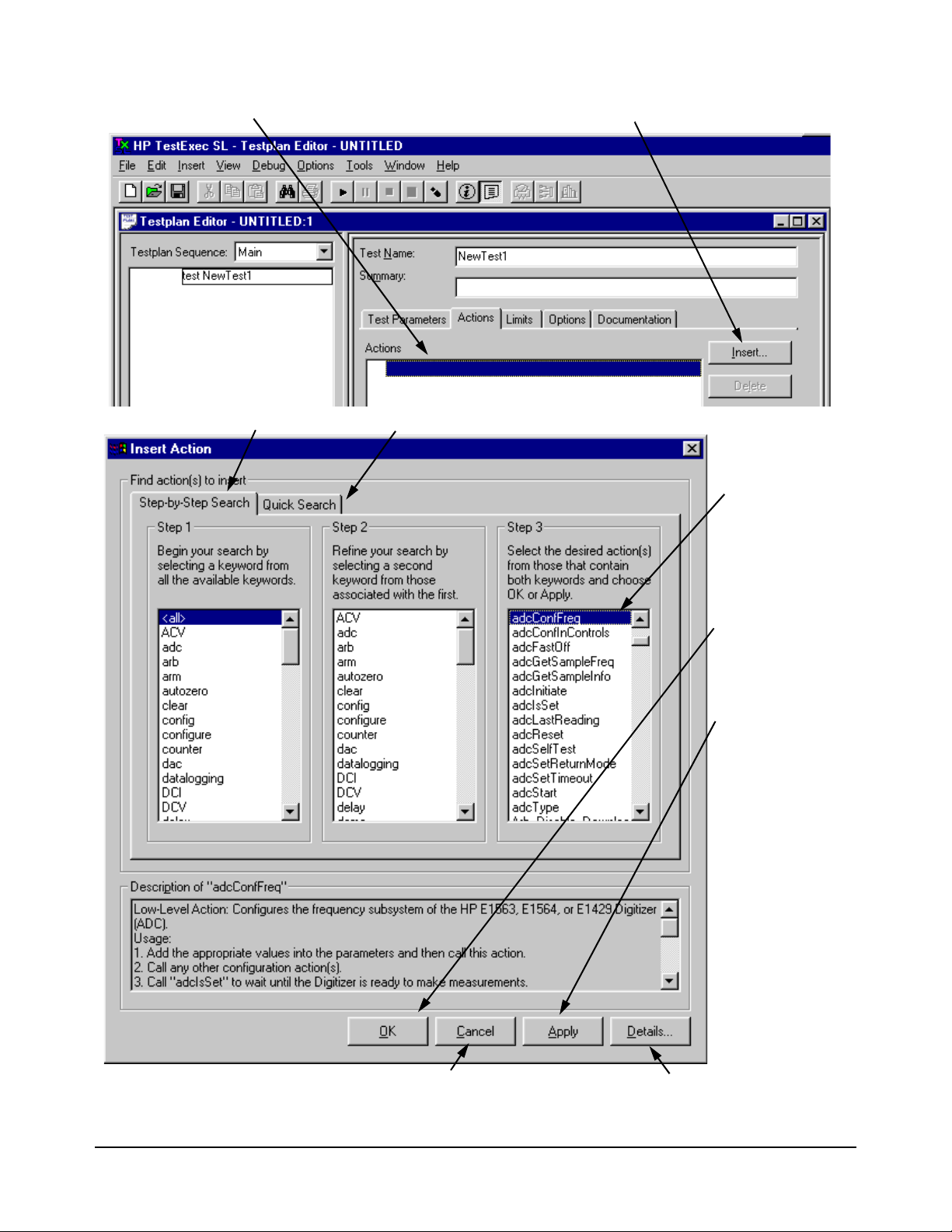

Adding an Action to

a Testplan

Do the following:

1. Open Agilent TestExec SL using the procedure in “Selecting Agilent TestExe c SL” on page 17.

2. Either create a new or open an old testplan, using the procedure in “Loading a Testplan” on page 17 or “Creating a Testplan” on page 18, respectively.

3. If using a new testplan, do the procedure in Figure 2-2 on page 18 to add a test. If using an old testplan, select the test into which you wish to add an action and continue with step 4.

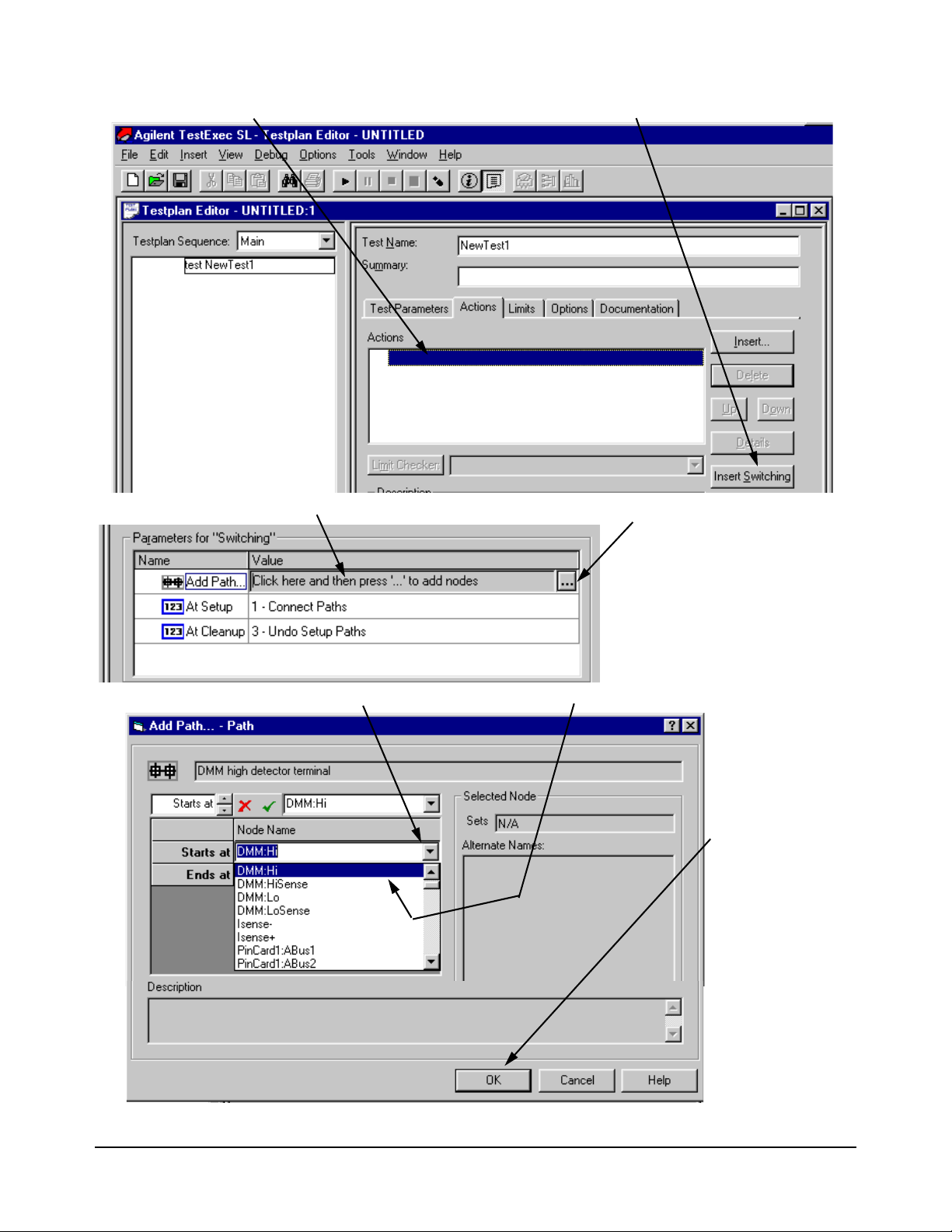

4. Add an action to the test, as shown in Figure 2-3 and Figure 2-4.

There are two different actions that can be added, a regular action and

a switching action.

Figure 2-4 shows how to add a switching action.

Figure 2-3 shows how to add a regular action and

20 How to Use the System Software Chapter 2

Page 21

1. Select the place to add the action

2. Click on “Insert”

3. Either click on “Step-by-Step Search” or “Quick Search” (“Quick Search” shows all actions in a column)

4. Select the action

5. Click on “OK” to

Or

click on “Apply” to

Click on “Cancel” to close Click on “Detail” to open

add the action and

close the window

add the action, but

keep window open

to add more actions

window without adding action Action Definition Editor

Figure 2-3. Adding an Action

How to Use the System Software 21Chapter 2

Page 22

6. Select the place to add the switching action

8. Click on the “Value” field to view button with the three dots (. . .)

7. Click on “Insert Switching”

9. Click on the three dots

10. Click on arrow to view “Node Names”, then click on name to select it

11. Click on “OK” to

12. Repeat steps

select the node; use

the same procedure

for the “Ends At”

nodes

8 to 11 to add

other nodes

Figure 2-4. Adding a Switching Action

22 How to Use the System Software Chapter 2

Page 23

Using Software Debug Features

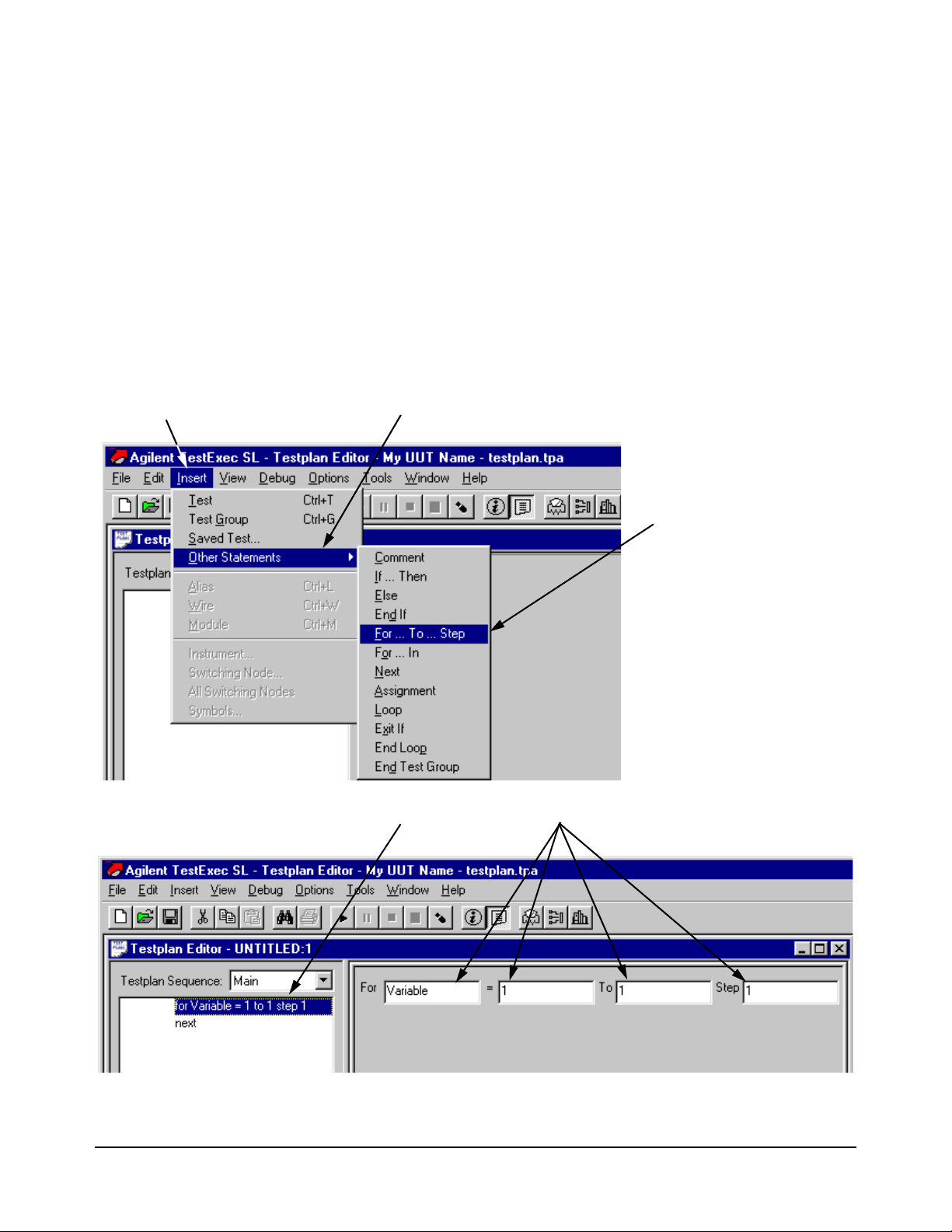

1. Click on “Insert” Menu

2. Click on “Other Statements” menu item

3. Click on looping

or other statement

4. Statement has been added; make any necessary changes

This section describes specific software features, unique to the Agilent

TestExec

debugging your tests and testplans. To enable Agilent TestExec

procedure in

Looping The loop constructs are FOR / NEXT sequencer statements. For example, a

testplan developer would stop a testplan (if one is running), add

NEXT lines to the testplan and then restart the testplan from the beginning.

Refer to the Agilent TestExec SL documentation for additional information.

Figure 2-5 shows how to select and insert the looping statements into a

testplan.

SL version 2.0 and later, that you will find helpful in creating and

“Selecting Agilent TestExec SL” on page 17, if not enabled.

SL, use the

FOR and

Figure 2-5. Selecting Looping and Other Statements

How to Use the System Software 23Chapter 2

Page 24

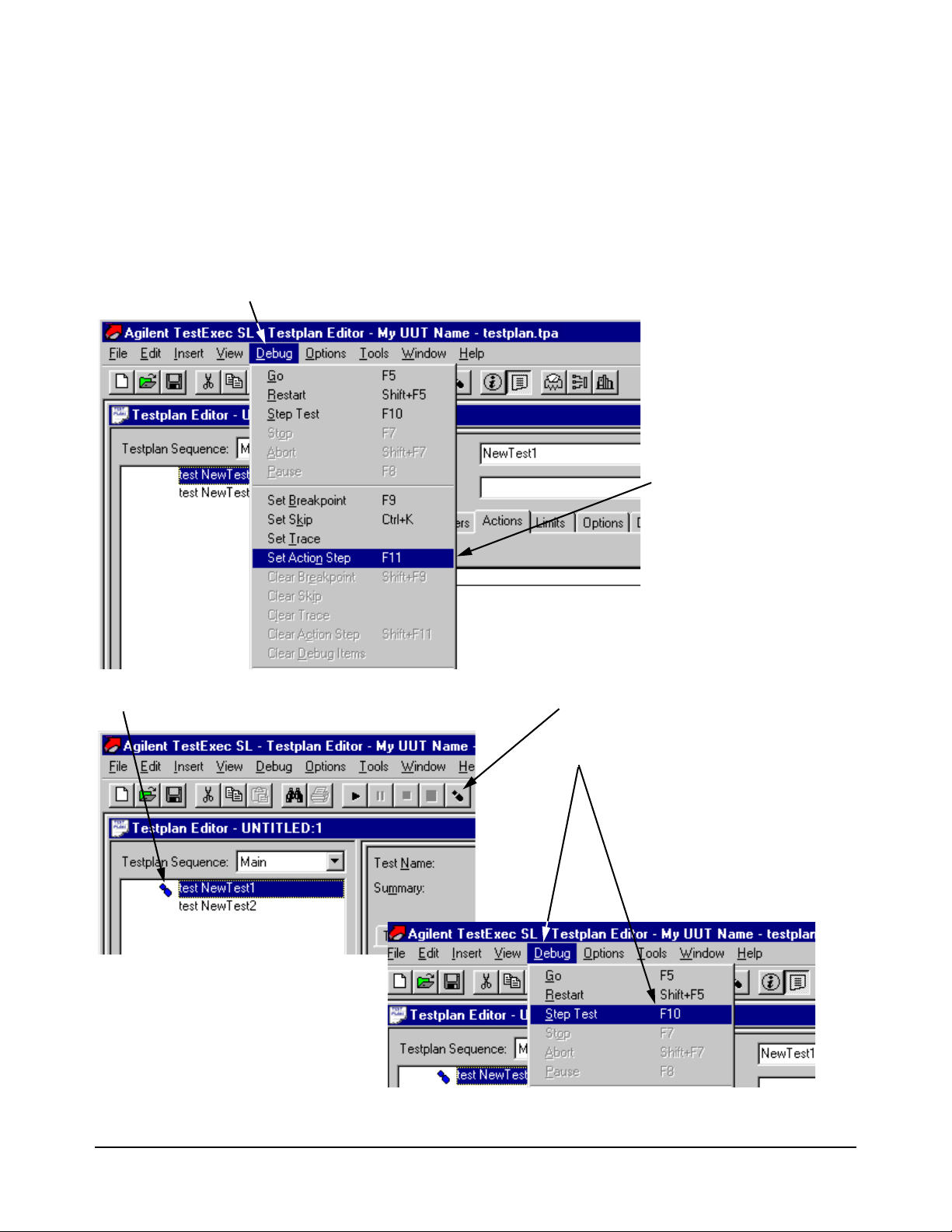

Single Stepping Agilent TestExec SL adds the ability to single step the execution of the

1. Click on “Debug” menu.

2. Click on “Set Action Step”

menu item

3. Foot symbol indicates that this step is to be paused

4. Click here to advance the test

Or

Click on “Debug” and “Step Test” to

advance the test

operations that make up a test. When stepping through the actions of a test,

the system pauses at entry point calls for each action routine. Action

stepping can be performed any time testplan execution is paused (as a result

of operator pause or test breakpoint). The action step which is currently

paused is listed in the trace window. Refer to the Agilent TestExec SL

documentation for additional information.

Figure 2-6 shows how to select the single stepping

Figure 2-6. Selecting Action Stepping

24 How to Use the System Software Chapter 2

Page 25

Action Debug

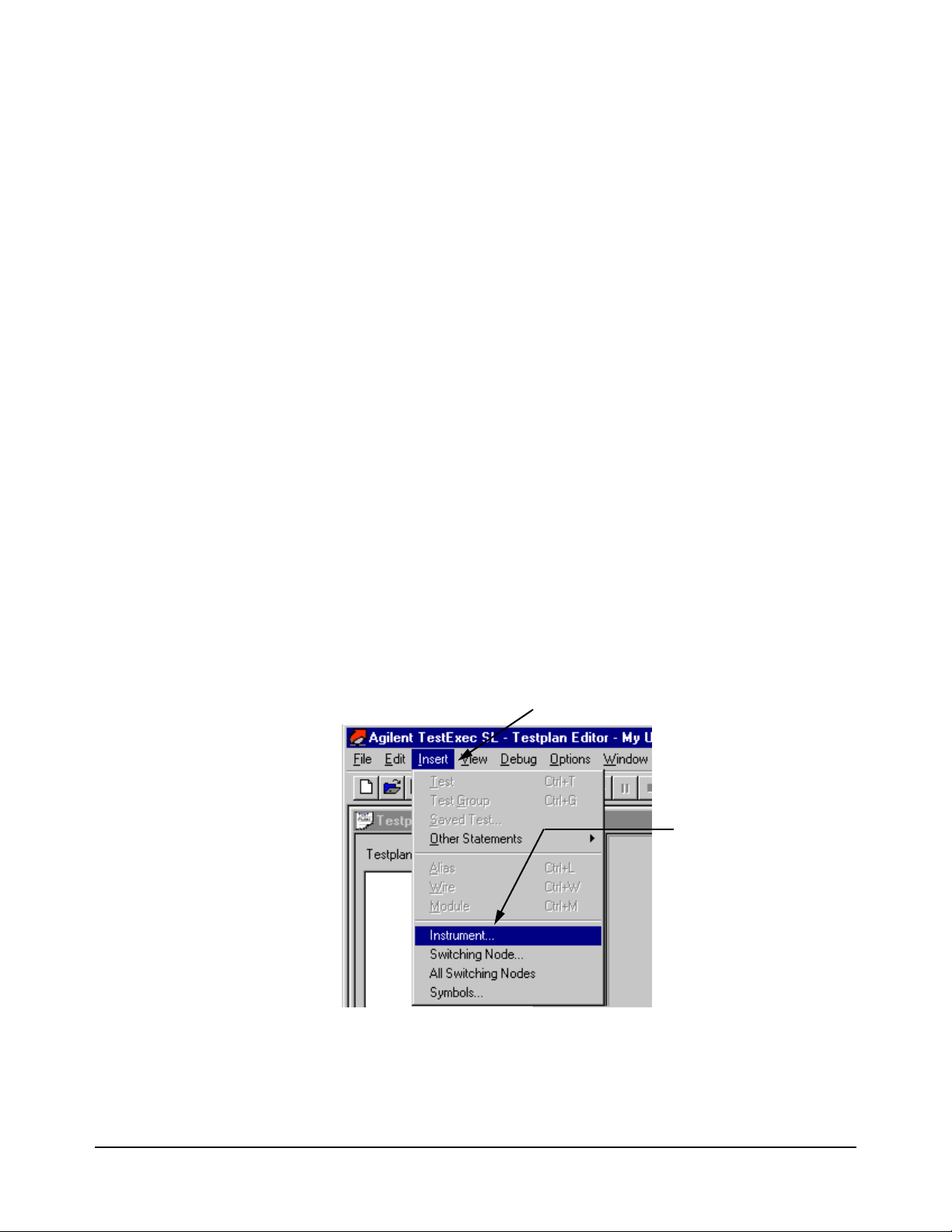

1. Click on “Insert” Menu.

2. Click on “Instrument”

menu item (or a

different item, if so

desired)

Messages

Agilent TestExec SL allows action routines to send strings to the same

debug window that the system uses for the test trace output. Use the

following API:

• UtaTrace (MessageString, MessageID)

-- MessageString is a string that will be sent to the trace window.

-- MessageID is an optional string that allows the messages to be

group (as identified by MessageID). Note: currently, this parameter

does not provide any functionality.

Watch Window Watch windows provide the ability to select ‘objects’ to dynamically

monitor as a testplan executes. Select an item to watch from a list, the item

is added to the watch window list and is updated each time the testplan

pauses. Items can be added or deleted at any time (as long as the testplan is

not running).

The watch window can monitor 4 types of objects:

• Instruments

• Switching Node

• All Switching Nodes

• Symbols

Watch Window Menu

Selections

The following shows some typical example of the window.

Watch Window Menu Selections shows how to select one of the four Watch

Window objects. The object to be selected, as shown in the figure, is the

‘instrument’ object. (The selection of the other objects is the same.)

Figure 2-7. Watch Window Menu Selections

How to Use the System Software 25Chapter 2

Page 26

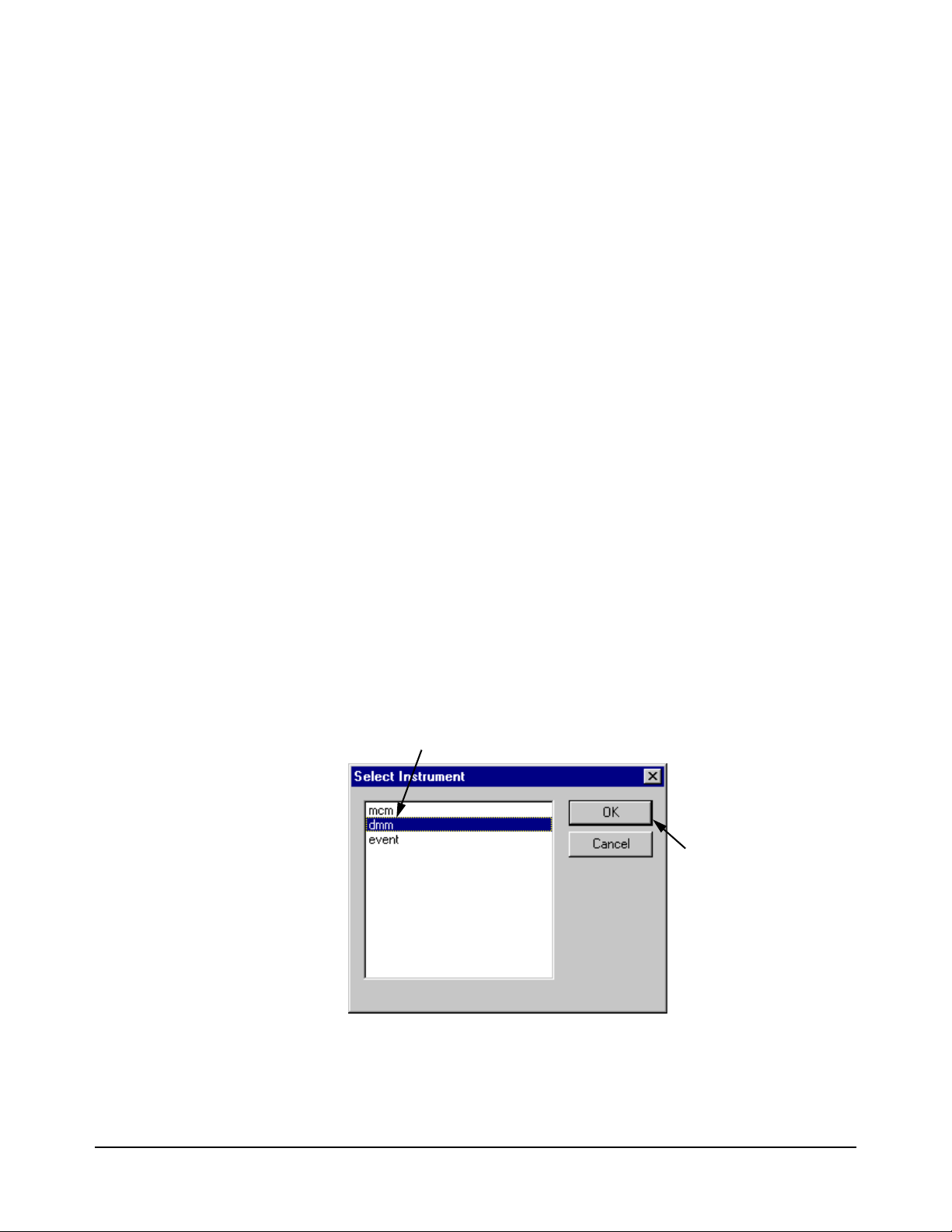

Watch Window

1. Click on the “dmm”, or a different, instrument to be watched

2. Click “OK” to enable

the Watch Window

Instrument Status

Watch windows are available for many of the instruments in an Agilent

TS-5000 system. The instruments that can be monitored are:

• Agilent E1328A or E1418A Digital to Analog Converter Module

(DAC)

• Agilent E1333A Counter Module

• Agilent E1411 Digit Multimeter Module (DMM)

• VXI Technology E1563A Analog to Digital Converter Module (ADC)

• Agilent E6171B Measurement Control Module (MCM)

• Agilent E6174A 32-Channel Event Detector Module

• Agilent 6642A, 6643A, 6652A, 6653A, 6673A Power Supplies

The displayed instrument states match the parameters of the instrument

handler routines. For example the Agilent E1411 Digital Multimeter has the

following routines which affect the state of the module:

• dmmConfFunction (dmm, Func, Range, Aperture);

• dmmConfCal (dmm, Linefreq, Autozero);

• dmmConfTrigIn (dmm, Trigselect, Trigcount, Delay);

• dmmConfSample (dmm, Sampsrc, Count, Period);

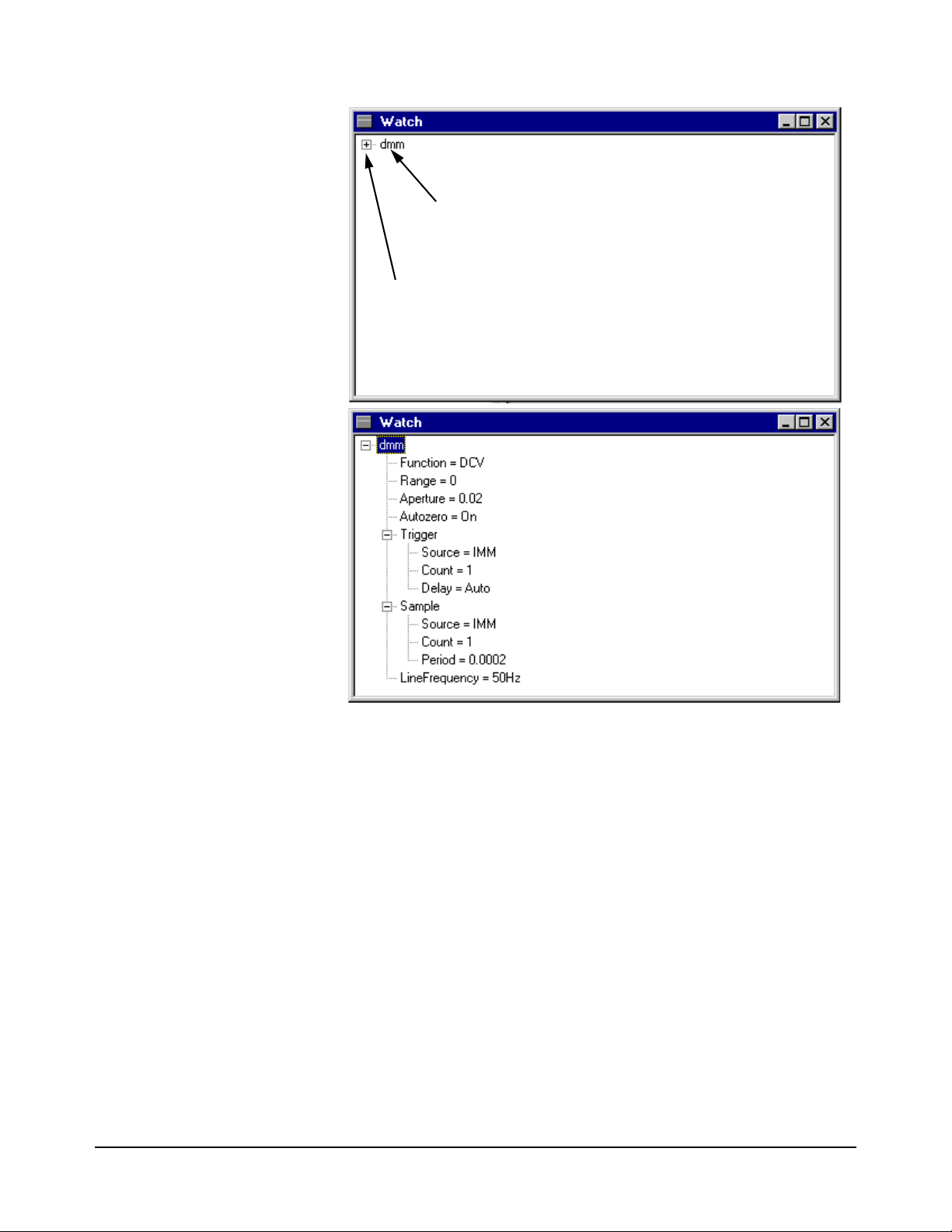

Figure 2-8 shows the menu box to select the instrument to be watched. The

figure shows how to select the Digital Multimeter (dmm).

To add an instrument to the Watch Window, select the instrument type and

press “OK”, as shown in

as shown in Figure 2-9.

Figure 2-9 also shows the expanded tree view that shows the status of the

‘dmm’ parameters. The instruments display their state in a tree view. This

allows a logical grouping of states and reduces the amount of data displayed

by placing less important states in lower levels of the tree.

Figure 2-8. The Watch Window is then displayed,

Figure 2-8. Selecting an Instrument to be Watched

26 How to Use the System Software Chapter 2

Page 27

Shows that the “dmm” is watched

Click here to see the expanded view of the parameters (see below)

This is an expanded view of the dmm

(Agilent E1411 Digital Multimeter)

parameters

Figure 2-9. Agilent E1411B Digital Multimeter Watch Window with

Parameters

How to Use the System Software 27Chapter 2

Page 28

Instrument Debug

Front Panels

Agilent TestExec SL provides a series of debug instrument front panels for

the Agilent TS-5000 system instruments. The debug panels provide two

main features:

• The ability to interactively view the current Unit Under test (UUT)

state

• The ability to interactively view the current state of points within the

system.

Debug Panel Types The following debug panels are supplied with the system, dependent on the

modules/instrument currently installed in the system.

• Agilent E1411B Digital Multimeter . . . . . . . . . . . . . . . . . . . page 30

• Agilent E1328A & E1418A Digital to Analog Converter . . page 32

• Agilent E1333A Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

• VXI Technology E1563A Digitizer . . . . . . . . . . . . . . . . . . . page 35

• Agilent E6171B Measurement Control Module . . . . . . . . . . page 36

• Agilent E6174A Event Detector . . . . . . . . . . . . . . . . . . . . . . page 37

• Agilent E6198A Switch/Load Unit. . . . . . . . . . . . . . . . . . . . page 38

• Agilent 6642A, 6643A, 6652A, 6653A, 6673A Power Supplies

page 39

Debug Panel Features All of the debug panels provide the following features:

• Changes on the instrument front panel are not made until either:

-- you initiate a measurement (for detectors) or

-- you press the “Apply” button (for sources)

The instrument state memory is modified in the instrument handler at

this time (since this is when the instrument handler is called;

Instrument Handlers on page 48 for information about handlers).

See

• If the instrument is connected in the Agilent TS-5000 system through

switching, the front panel provides a section which allows you to

define the switching path. Either select a UUT pin to connect to

directly or define a custom switch path.

Connecting to the UUT pin is the easiest way to select a switch path;

you select an ABus pin and the UUT pin. If the instrument has both the

high and low terminals connected to the switch matrix, then both pins

need to be defined. The low terminal is connected to UUTCommon by

default and does not need to be selected, if you use the default. The

UUT option is available if you have defined a UUT switching

configuration file. In addition to the UUT pins, the system

automatically adds the option to measure an ABus pin only. This will

allows you to inject a signal on the front of the system and measure it

using the instrumentation within the system.

• The state of the system is saved upon entering a pause state and is

restored when entering the run state. This allows the panels to be used

28 How to Use the System Software Chapter 2

Page 29

without affecting the testplan.

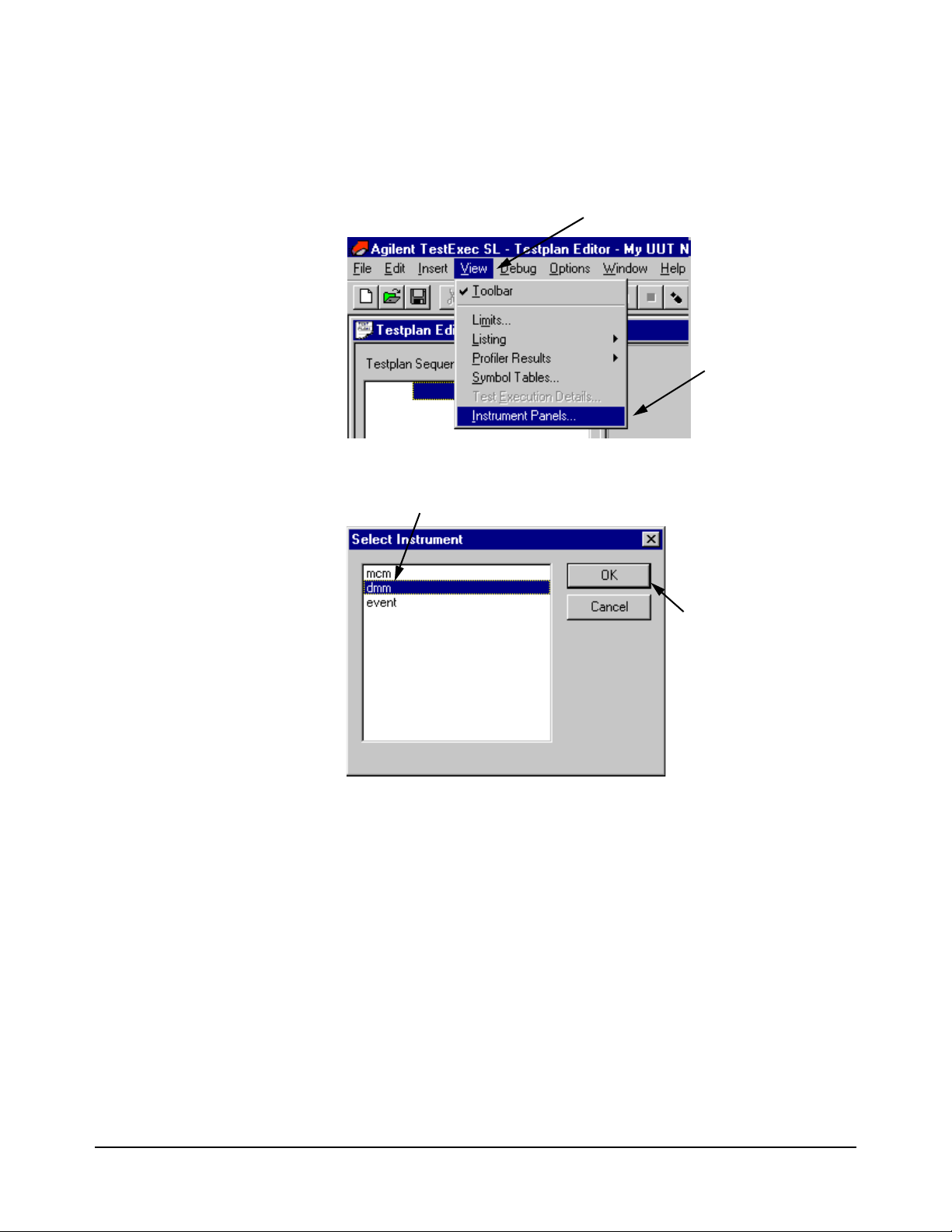

1. Click on “View” menu

2. Click “Instrument”

menu item

1. Select the Instrument of which the Debug Panel is to be displayed

2. Click “OK” to enable

the Debug Panel

Selecting the Debug

Panel

Debug Front Panel Selection and Select an Instrument from the Debug Front

Panel Selection show how to enable the debug instrument front panels.

Figure 2-10. Debug Front Panel Selection

Figure 2-11. Select an Instrument from the Debug Front Panel Selection

The following sections show and explain the different debug instrument

panels.

How to Use the System Software 29Chapter 2

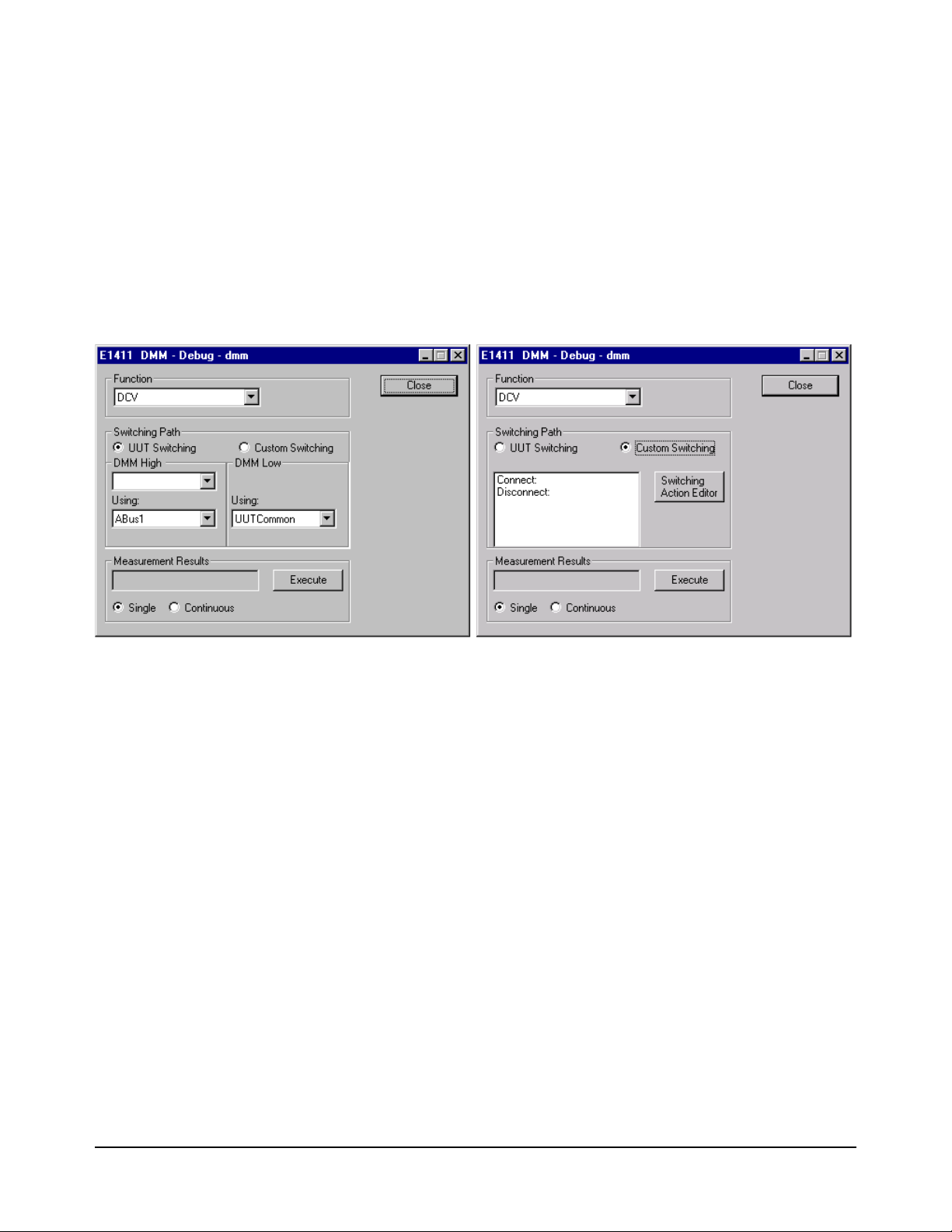

Page 30

Agilent E1411B Digital

A

B

B

Multimeter

An instrument box which connects to the Agilent E6171 Measurement

Control Module, such as the Agilent E1411 DMM, usually has two different

dialog boxes which depend on the type of path selected (as shown in

Agilent

E1411 DMM Debug Front Panel (showing Path Selection)A and Agilent

E1411 DMM Debug Front Panel (showing Path Selection)B). This allows

you to either connect to the pin on the UUT (Agilent E1411 DMM Debug

Front Panel (showing Path Selection)A) or select any point within the

system by defining a custom switching path (Agilent E1411 DMM Debug

Front Panel (showing Path Selection)B). The custom switching is applied on

top of the current switching state, so to undo a switching path you need to

define a ‘disconnect’ path.

Figure 2-12. Agilent E1411 DMM Debug Front Panel (showing Path Selection)

The debug panel boxes and buttons do the following:

Function:

Choose ACV, DCV, Ohms, Ohms - Offset Compensated

The measurement is made in auto range and medium resolution.

Switching Path:

The debug panel supports the selection of the switching path. The

panel switches both high and low connections of voltage sense and the

high and low connection of the current terminals. The sense

connections are connected in parallel with the high and low terminals.

You specify the high or low terminal and the system automatically

connects the associated sense terminal.

Measurement Results:

Press the “Single” button to initiate a single measurement; press the

“Continuous” button to initiate a series of measurements. The

continuous button is modified to a “Stop” button once pressed. When

the dialog box is brought up, the measurement results box is blank.

Switching Action Editor:

This button enables the editor to select the switching paths for the

30 How to Use the System Software Chapter 2

Page 31

Digital Multimeter. See “Fast Connection Selection” on page 40 for a

description on how to use the editor.

Execute:

This button starts a measurement.

Close:

This button closes the debug panel.

System Interface

The setting of the Digital Multimeter function uses the following actions:

dmmMeasureDCV, dmmMeasureACV, dmmMeasureOhms

The above actions also return the results of a measurement.

How to Use the System Software 31Chapter 2

Page 32

Agilent E1328A &

E1418A Digital to Analog

Converter

Agilent E1328A and E1418A DAC Debug Front Panel shows the dialog box

for controlling the Agilent E1328/E1418 Digital-to-Analog Converter

(DAC) Module.

Figure 2-13. Agilent E1328A and E1418A DAC Debug Front Panel

The debug panel boxes and buttons do the following:

Voltage or Current:

You have the option to specify the output voltage or current for each

channel of the DAC. The ‘Type’ selection sets the voltage or current

mode and defines contents of the input field.

Dependent on the type selected, enter the voltage value/current value

into the Voltage/Current field.

(Note the E1328A cannot programmatically select the voltage or

current option.)

Update Output:

This button changes the output setting.

Close:

This button closes the debug panel.

System Interface

The setting of the DAC uses the following action routine:

dac16i_setup

32 How to Use the System Software Chapter 2

Page 33

Agilent E1333A Counter Agilent E1333 Counter Debug Front Panel shows the dialog box for Agilent

E1333A Counter. Only the UUT connection screen is shown. The custom

path selection is the same used by the Digital Multimeter (see

on page 30).

Figure 2-12

Figure 2-14. Agilent E1333 Counter Debug Front Panel

The debug panel boxes and buttons do the following:

Function:

Choose Frequency, Period, Positive Pulse Width, Negative Pulse

Width, Totalize

Input, Coupling, Input Impedance:

Allows you to set input functions. The setting of each function is sent

before a measurement is made.

Switching Path:

The counter panel supports the selection of a switching path. The

counter switches only the high connections of the output. The low

connections are automatically connected to system ground.

How to Use the System Software 33Chapter 2

Page 34

Measurement Results:

Select the “Single” button to initiate a single measurement or the

“Continuous” button to initiate a series of measurements. The

continuous button is changed to a “Stop” button, once pressed.

Note that when the dialog box is brought up, the measurement results

box is blank.

Execute:

This button starts a measurement.

Close:

This button closes the debug panel.

System Interface

The setting of the counter function will use the following action routines:

ctrMeasureFrequency, ctrMeasurePeriod, ctrMeasurePulseWidth,

ctrMeasureTimeInterval, ctrMeasureTotalize

The measurement uses the level trigger specified in the dialog box (using the

slider control), a default range and default resolution.

The input section uses the following action routine:

ctrMeasureInControls

34 How to Use the System Software Chapter 2

Page 35

VXI Technology E1563A

Digitizer

Figure 2-15 shows the debug front panel for the VXI Technology E1563A

Digitizer. Only the UUT connection screen is shown. The custom path

selection is the same as for the Agilent E1411B Digital Multimeter (see

“Agilent E1411B Digital Multimeter” on page 30).

Figure 2-15. VXI Technology E1563A Digitizer Debug Front Panel

The debug panel boxes and buttons do the following:

Time Base and Range:

The range and timebase can be modified by selecting the “arrow” keys

on the side and bottom of the waveform. To update the display, take a

new measurement.

The time base allows the following range of selections:

50 nS to 20 Sec in 1, 2, 5 steps

the range has the following selections:

0.1 to 100 volts in 1, 2, 5 steps.

When the dialog box is brought up, the combo box contains the current

time base and range. All of the setting for the digitizer are saved until

an actual sweep is initiated.

Input and Triggering:

These two sections allow you to set a variety of input and trigger

functions. The setting of each function is sent when a measurement is

made.

Switching Path:

The debug panel supports the selection of a switching path. The

digitizer switches both the high and low connections of the output.

How to Use the System Software 35Chapter 2

Page 36

Waveform Display:

Select the “Single” button to generates a single waveform display or

the “Continuous” button to generate a continuous update of

waveforms. The display updates at a rate of >10

Close:

This button closes the debug panel.

System Interface

The setting of the digitizer function will use the following action

routines:adcConfArm, dcConfFreq, adcConfInControls, adcIsSet,

adcGetResults

update/sec.

Agilent E6171B

Measurement Control

Module

Figure 2-16. Agilent E6171B Measurement Control Module Debug Front Panel

Agilent E6171B Measurement Control Module Debug Front Panel shows

the dialog box for controlling the Agilent E6171B Measurement Control

Module.

The debug panel boxes and buttons do the following:

Voltage or Current:

You have the option to specify the output voltage or current for each

channel of the MCM. The ‘Type’ selection sets the voltage or current

mode.

Dependent on the type selected, enter the voltage value or current

value into the Voltage or Current field, respectively.

Expected Current (when enabled by the Type-Current):

Defines the expected current of the MCM (or VI, i.e., Voltage/Current)

source.

Update Output:

This button changes the output source of the MCM.

Close:

This button closes the debug panel.

System Interface

The setting of the counter function will use the following action routines:

viSetSourceDCI, viSetSourceDCV, viSet

36 How to Use the System Software Chapter 2

Page 37

Agilent E6174A Event

Detector

Agilent E6174A Event Detector Debug Front Panel shows the dialog box for

controlling the Event Detector Module.

Figure 2-17. Agilent E6174A Event Detector Debug Front Panel

The debug panel boxes and buttons do the following:

Clock Frequency:

Select the clock rate of the event detector module.

Edge Trigger, External Gating and Number of Events:

Specifies the type of edge triggering to be used and external gating.

The text box defines the number of events to be logged before a

measurement is complete.

Event Display:

The event detector can generate either a single display or a continuous

update of events. The table provides a simple list view of the event and

it’s time stamp. The column width can be adjust by dragging the line

which separates the titles.

Execute:

This button starts a measurement.

Close:

This button closes the debug panel.

System Interface

The setting of the event detector will use the following action routines:

eventMeasure

How to Use the System Software 37Chapter 2

Page 38

Agilent E6198A

Switch/Load Unit

Agilent E6198A Switch/Load Unit Debug Front Panel shows the dialog box

for controlling the Switch/Load Unit.

Figure 2-18. Agilent E6198A Switch/Load Unit Debug Front Panel

The debug panel boxes and buttons do the following:

Digital I/O Read:

Reads a value from the Agilent E6198 switch/load unit digital input

ports. Fixture ID is value from Fix_ID(0..7) of access connector J104

and Spare is value from Spare_DigIn(0..7) of access connector J104.

Digital I/O Write:

Write a value to the Agilent E6198 switch/load unit digital output

ports. Open Collector writes to output port on the switch/load unit

backplane. Spare writes to output Spare_DigOut(0..7) on backplane

connector J104.

Digital to Analog Converter DAC #1/DAC #2:

Change the voltage, gain, and offset values used to set the DAC

voltage in the switch/load unit for both DAC #1 and DAC #2.

System Interface

The setting of the switch/load unit will use the following action routines:

digitalWriteSU, digitalReadSU, dacSetDCVSU, dacSetGainOffsetSU

38 How to Use the System Software Chapter 2

Page 39

Agilent 6642A, 6643A,

6652A, 6653A, 6673A

Power Supplies

Power Supply Debug Front Panel shows the dialog box for controlling the

Agilent 6642A, 6643A, 6653A, 6673A Power Supplies. You can specify the

output voltage or current for each channel of the Power Supply. You must

specify a protection voltage greater than the voltage setting.

Figure 2-19. Power Supply Debug Front Panel

The debug panel boxes and buttons do the following:

Voltage/Current:

Specifies the output voltage or current for each channel of the power

supplies. The ‘Type’ selection sets the voltage or current mode.

Dependent on the type selected, enter the voltage value or current

value into the Voltage or Current field, respectively.

Update Output:

This button changes the power supply output.

Close:

This button closes the debug panel.

System Interface

The setting of the counter function uses the following action routines:

psConfVI, psSet, psIsSet, psConnect, psDisconnect

How to Use the System Software 39Chapter 2

Page 40

Fast Connection

Selection

You can select a switching path to a module/instrument either by selecting

pins on the Unit Under Test (UUT) (see “Switching Path” box in

E1411 DMM Debug Front Panel (showing Path Selection)A on page 30) or

by creating a custom path using the Switching Action Editor (see “Switching

Action Editor” button in

Path Selection)B on page 30).

Agilent E1411 DMM Debug Front Panel (showing

Agilent

Specifying Unit Under

Test Pin s

Creating a User Defined

Switching Path

When selecting UUT pins, you normally specify from 1 to 4 connections,

depending on the module/instrument. For example, for the Digital

Multimeter (DMM), you define these four connections: high, low, high

current sense, and low current sense. The Counter only has only a high

connection.

The software works backwards though the switching configuration and

generates a switching path which connects to ABusx, depending on the

option selected. For example, a typical connection from ABus1 to the high

input of the Digital Multimeter would be: [DVMHi ABus1 VISrcHi]

User defined switching paths are created using the “Select Switching Path”

screen which is enabled by the “Switching Action Editor” button (see

Agilent E1411 DMM Debug Front Panel (showing Path Selection)B on page

30). The “Select Switching Path” screen shows two different fields, the

‘Connect’ and ‘Disconnect’ fields. All paths added or listed in the ‘Connect’

field are always connected. All paths added or listed in the ‘Disconnect’

field are always disconnected. Note that the fields are blank, if no paths have

previously been added.

To add/edit/delete a path, first enable the “Select Switching Path” screen

using an appropriate instrument panel, as shown in

uses the Agilent E1411B Digital Multimeter instrument panel.

The following shows how to add/edit/delete a path.

Figure 2-20. The figure

40 How to Use the System Software Chapter 2

Page 41

Figure 2-20. Enabling the “Select Switching Path” Screen

1. Select “Custom Switching” radio button

2. Click on “Switching Action Editor”

to select the next “Select Switching

Path” window

Adding a New Path

To add a new path, first determine the end nodes or points in the path. Then

use the “Switching Action Editor” to find a path using the intermediate

nodes between the end notes or points.

For example, to connect the Hi input of the Agilent E1411B Digital

Multimeter (DMM) to the Hi output of the Agilent E6171 Measurement

Control Module (MCM), you must know the node names for these

connections. Also, since the DMM has no direct connections to the VI

source or MCM, it must connect using ABusx. Thus, the nodes for this path

would be: [DVMHi

ABus1 VISrcHi].

Before adding a new path, first use the procedure in Figure 2-20 to enable

the “Select Switching Path” screen. Then use the procedure in Figure 2-21

to add the path.

Editing a Switching Path

To edit a path, first use the procedure in Figure 2-20 to enable the “Select

Switching Path” screen, if the screen is not enabled. Then use the procedure

Figure 2-22 to edit the path.

in

Deleting a Path

To delete a path, first use the procedure in Figure 2-20 to enable the “Select

Switching Path” screen, if the screen is not enabled. Then use the procedure

Figure 2-23 to delete the path.

in

How to Use the System Software 41Chapter 2

Page 42

2. Choose a node name to be used in the path

3. Click “Select” to select the node; perform

4. Click on “OK” to add the node and close

5. Click on “OK” to return to the instrument

To add another path, click “Add Path” again,

This is the newly added path

1. Click to add a path to the “Connect” field

to enable the “Switching Path Editor”

Or

Click to add a path to the “Disconnect” field

to enable the “Switching Path Editor”

(e.g., “DVMHi”)

step B and this step to select all nodes used

in the path

the “Switching Path Editor”

before clicking on “OK”

panel

Figure 2-21. Adding a New Switching Path

42 How to Use the System Software Chapter 2

Page 43

1. Click on the Switch Path to be edited

2. Click the “Edit Path” button.

3. Select the Node to be changed by

4. Click on “OK” to make the changes and

5. Click one “OK” to return to the instrument

clicking on “Back Up” until the node to be

changed has been deleted; then click on

“Select” to add the new node and continue

adding the previously deleted nodes you

wish to keep

panel

close the “Switching Path Editor”

Figure 2-22. Editing a Switching Path

How to Use the System Software 43Chapter 2

Page 44

Figure 2-23. Deleting a Switching Path

1. Click on the Path to be deleted

2. Click on “Delete Path” to delete the path

3. Click on “OK” to return to the instrument

panel

44 How to Use the System Software Chapter 2

Page 45

Viewing Waveforms A ‘Waveform’ data type is available in the “ADC_Analyze_Wave”

Click on the parameter value to select it

then click on the dots (...) to enable the

waveform editor

High-Level Action. This data type includes a graphical viewer for data.

Sample Testplan Showing Waveform Data Type shows a sample testplan

using the “ADC_Analyze_Wave” Action with the Waveform parameter.

Range Data on the Waveform Display Graphical Editor and Sample

Waveform Display show the waveform editor, and Figure 2-27 shows the

waveform display.

Figure 2-24. Sample Testplan Showing Waveform Data Type

How to Use the System Software 45Chapter 2

Page 46

Figure 2-25. Range Data on the Waveform Display Graphical Editor

Set Start and Stop

Set the number of

time value for

waveform

points on the

waveform

Click to add range data

Click to add amplitude data

Add amplitude data here

Click to view waveform (see next figure)

46 How to Use the System Software Chapter 2

Figure 2-26. Amplitude Data on the Waveform Display Graphical Editor

Page 47

Figure 2-27. Sample Waveform Display

Click on “OK” to store waveform

How to Use the System Software 47Chapter 2

Page 48

Instrument Handlers

User Actions

Instrument Handler

Driver

Instrument Handlers are a layer of software between Agilent TestExec SL

and standard instrument drivers (see

Handlers are designed to be called from C/C++ code action.

Instrument handlers contain functions written in C code that are organized

by instrument type and function, and require parameters relevant to the

function. For example, the call to set up triggering for a voltmeter is:

Figure 2-28). In general, Instrument

Figure 2-28. Software Layers

Note Instrument handlers are maintained constant in different TS-5000 software

dmmConfTrigIn (dmm, trigselect, count, delay);

Function dmmConfTrigIn accepts four parameters: dmm, trigselect, count,

and delay. The generic name of the function is

of the instrument, in this case

specific name of the function.

releases, which is not the case with the drivers. Thus, use instrument

handlers for actions whenever possible.

dmm, is added as a prefix to form the full,

ConfTrigIn, and the name

48 How to Use the System Software Chapter 2

Page 49

Using the Action Wizard To Develop

1. Click on “Tools” menu

2. Click on “Action Wizard” menu item.

The Agilent TestExec SL application used in the TS-5000 System comes

with a program called Action Wizard to develop actions. The Action Wizard

automatically runs through the steps necessary to develop an action. The

wizard also includes a help file with more detailed instructions and

information on how to use the wizard.

To run the “Action Wizard”, use the procedure in Figure 2-29.

Note Actions are the smallest components of a test and are used to setup and

execute instruments, perform cleanup functions, and to make

measurements.

Figure 2-29. Selecting and Running the Action Wizard

How to Use the System Software 49Chapter 2

Page 50

Multithreading

Multithreading is an execution model which allows multiple threads to exist

within a single process. It contains more than one unit of execution in a

single process. In the context of TestExec SL, multithreading is the

capability of running more than one thread. These threads share the process's

resources but are able to execute independently.

A thread is a basic unit of execution. A single thread executes a series of

application instructions, following a single path of logic through the

application. All applications have at least one thread, but you can design

your applications to use multiple threads, with each thread executing

separate logic.

This capability becomes useful when a process thread stalls due to necessary

data that are not yet available or when switching to another thread will yield

a better result. In a single threaded program, once the main execution thread

is blocked the whole application comes to a standstill. However, with

multithreading, blocked programs can be moved from the main execution to

a separate thread and can be concurrently executed with the main execution.

This allows the application to stay responsive while executing tasks in the

background. Multithreading can lead to improved performance as many

threads are executed concurrently.

However, there are always disadvantages to complex application like this.

Executing a multithreaded test can be more difficult than a typical test as

there can be time related defects. In order for the operating system to track

a large number of threads, it is going to consume processor time. If there are

too many threads, then each thread may not be given enough time to execute

during its time slice. In addition, each thread is scheduled for execution less

frequently due to the volume and time slice committed to each thread.

How Multithreading

is working on a

Testplan?

50 How to Use the System Software Chapter 2

a. Creating a Thread Safe Action

Thread safe is a concept that can be applied in multithreading. A piece of

code is thread-safe, if it functions correctly during simultaneous execution

in multiple threads. By using thread-safe routines, the risk that one thread

will interfere and modify data elements of another thread is eliminated by

circumventing potential data race situations with coordinated access to

shared data.

For a thread to be thread-safe, it first must behave correctly in a

single-threaded environment. Furthermore, for a thread to be thread-safe, it

must continue to behave correctly when accessed from multiple threads,

regardless of the scheduling or interleaving of the execution threads by the

runtime environment and without any additional synchronization on the part

of the calling code. The effect is that operations on a thread-safe object will

appear in a fixed, globally consistent order to all threads.

The thread safe declaration is introduced as an indicator. By default, an

action is not thread safe and is indicated by a visual cue.

Page 51

Figure 2-30. Symbol of thread safe declaration

If you do not wish to see a visual cue next to non-thread safe action, click

Options | Testplan Options and in the Threading tab, uncheck the Mark

non-thread-safe action checkbox.

Note: If check “Force testplan to run in sequential mode” checkbox, all

testplans will run in sequential mode. For multithreading mode, the

checkbox must be unchecked.

Figure 2-31. Testplan Option for Mark non-thread-safe action

To create a thread safe action,

1. Double-click an action and the Action Definition Editor window will appear.

2. Enter "thread_safe" under Keywords.

3. Click Add.

You should now be able to see thread_safe in the right column. Take note of

the highlighted areas.

How to Use the System Software 51Chapter 2

Page 52

Figure 2-32. Action Defination Editor

4. The visual cue will disappear once the action has been declared as thread safe.

Figure 2-33. Disappear Thread Safe’s symbol

b. Settings for a Threaded Test

To thread a test, select the Threading tab and check the Thread This Test

checkbox. A threaded visual cue will appear next to the test once the test has

been threaded, as shown below.

52 How to Use the System Software Chapter 2

Page 53

Figure 2-34. Thread This Test

c. Using Resource Locking

Resource locking is the process of protecting data in a multiprocessing

environment. It means at the same point of time only one thread can access

to this method of created object. Unless the lock is released after completion

of the code, the next routine or iteration cannot enter the block. In the context

of TestExec SL, resources that can be locked are switching paths, instrument

handlers, action access, and reference parameters.

TestExec SL supports two types of resource locking which are full locking

and partial locking. By implementing multithreaded tests and choosing the

correct resource locking that fits your test, you can easily control the sharing

of instruments and synchronize multiple UUTs. In full locking mode,

TestExec SL will automatically perform locking on all objects underneath

the test objects which are switching paths, instrument handlers, action

access, and reference parameters. In partial locking mode, TestExec SL

allows you to manually apply one or more of the above mentioned locks to

the object(s).

Resource locking can be applied to each of the containing objects under the

test object. Tests can be manually locked by selecting the Threading tab.

Click the Lock All Test Objects checkbox for a full lock or click an

individual lock to choose your preferred lock. The visual cues for full

locking and partial locking slightly differ in color.

How to Use the System Software 53Chapter 2

Page 54

Figure 2-35. Lock All Test Objects

Figure 2-36. Lock Test Objects partially

d. Using the Wait Thread Statement

One way to think of the wait thread statement is to imagine an item of data

such as an integer variable as if it were a field in a database. If you do not

have some locking mechanism in the database you stand a chance of

corruption to the data.

Thus, one user might retrieve the data and perform a calculation and write

back the data. If in the meantime someone else has retrieved the data,

performed the calculation and written it back, the second user's calculations

will be lost when the first person writes back to the database. In the way that

a database has to handle updates at unpredictable times, so a multithreaded

program has to cater for this possibility. TestExec SL has a wait thread

statement especially to resolve matters like this.

54 How to Use the System Software Chapter 2

Page 55

The Wait Thread statement allows you to block remaining statements from

execution prior to completion of threaded tests statement in the Wait For

column.

To insert a Wait Thread statement, click Insert | Wait Thread in TestExec

SLs menu bar. The maximum timeout value is used to specify the maximum

duration a Wait Thread statement would need to wait for the threads. A

timeout of 0 ms means the program will wait forever until all the waited

threaded tests have completed execution.

The below testplan shows that NewWaitthread needs to wait for NewTest1

to complete execution.

Figure 2-37. Wait Thread statment

Using Wait Thread Statement in Loop, For...In and For...To...Step

Statements

It is recommended to insert Wait Thread statement right before Next

statement in Loop, For...In and For...To...Step statements if threaded tests

exists within these statements. The Wait Thread statement needs to wait for

all threaded tests within the Loop and For Loop statements, otherwise, the

results might be unexpected.

Using Wait Thread Statement for Throughput Multiplier Threaded

Test Statement

It is also recommended to insert Wait Thread statement after a throughput

multiplier threaded test statement to wait for all the threads running for all

the UUTs to complete execution before proceeding on with next statement.

How to Use the System Software 55Chapter 2

Page 56

Using Wait Thread Statement in Testgroup Statement

A Wait Thread statement should be inserted right before end testgroup

statement if threaded tests exist within the testgroup statement. The Wait

Thread statement needs to wait for all threaded tests within the testgroup,

otherwise, the results might be unexpected.

Using Wait Thread Statement in Sequence Library

A Wait Thread statement should be inserted as the last statement of a

sequence library (local or external) if threaded tests exist in the sequence

library. The Wait Thread statement is to ensure all the threaded tests in the

sequence library have completed their execution before returning to Main

sequence. If the Wait Thread statement is not inserted, threads in the

sequence library might be still running upon returning to Main sequence.

e. Using Timeout

A specified period of time that will be allowed to elapse in a system before

a the next specified event is to take place. TestExec SL allows you to specify

a timeout value as well as the behavior of the timeout. The timeout value is

set in the Wait Thread statement while it's behavior is set in Testplan

Options.

In Options | Testplan Options, a new Threading tab has been added to allow

users to specify the behavior of the timeout. There are three options you can

choose from:

• Generate exception

• Generate error message on report window and continue execute

• Prompt timeout dialog

Threaded objects are killed when timeout is exceeded. This timeout feature

is the simplest method of preventing of deadlocks.

Opening System Configuration Editor

1. Start System Configuration Editor from this icon on the PC desktop:

You can also run System Configuration Editor by clicking:

Start | All Programs | Agilent TS-5000 System Software 7.1.2

56 How to Use the System Software Chapter 2

Page 57

Adding an IVI-COM Module in System Configuration Editor