Page 1

HP Smart Array 641/642 Controller

User Guide

Part Number 309311-001

November 2002 (First Edition)

Page 2

© 2002 Hewlett-Packard Development Company L.P.

Microsoft, Windows, and Windows NT are trademarks of Microsoft Corporation in the U.S.

and other countries.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions

contained herein. The information in this document is provided “as is” without warranty of

any kind and is subject to change without notice. The warranties for HP products are set forth

in the express limited warranty statements accompanying such products. Nothing herein

should be construed as constituting an additional warranty.

HP Smart Array 641/642 Controller User Guide

November 2002 (First Edition)

Part Number 309311-001

Page 3

Contents

About This Guide

Audience Assumptions..................................................................................................... vii

Important Safety Information ...........................................................................................vii

Symbols on Equipment..................................................................................................... vii

Symbols in Text...............................................................................................................viii

Related Documents............................................................................................................ ix

Getting Help....................................................................................................................... ix

Technical Support ....................................................................................................... ix

HP Website................................................................................................................... x

Authorized Reseller...................................................................................................... x

Reader’s Comments............................................................................................................ x

Chapter 1

Installation Overview

Procedure for a New System ...........................................................................................1-1

Procedure for a Preconfigured System ............................................................................1-2

Chapter 2

Installing the Hardware

Preparing the Server ........................................................................................................2-1

Installing the Smart Array Controller .............................................................................. 2-2

Connecting the Cables .....................................................................................................2-2

Internal Cabling.........................................................................................................2-2

External Cabling (Model 642 only)...........................................................................2-3

HP Smart Array 641/642 Controller User Guide iii

Page 4

Contents

Chapter 3

Updating the Firmware

Chapter 4

Setting the Controller Order

Using RBSU.................................................................................................................... 4-1

Using ORCA ................................................................................................................... 4-2

Chapter 5

Configuring an Array

Using ACU...................................................................................................................... 5-3

Using ORCA ................................................................................................................... 5-3

Using CPQONLIN .......................................................................................................... 5-4

Running CPQONLIN ............................................................................................... 5-5

Typical Manual Configuration Procedures in CPQONLIN...................................... 5-8

Chapter 6

Installing the Device Drivers and Management Agents

Installing the Device Drivers........................................................................................... 6-1

Updating the Management Agents.................................................................................. 6-1

Chapter 7

Upgrading or Replacing the Cache

Appendix A

Regulatory Compliance Notices

Federal Communications Commission Notice................................................................A-1

Class A Equipment ...................................................................................................A-2

Class B Equipment ...................................................................................................A-2

Declaration of Conformity for Products Marked with the FCC Logo,

United States Only....................................................................................................A-3

Modifications............................................................................................................A-3

Cables .......................................................................................................................A-3

Canadian Notice (Avis Canadien)...................................................................................A-4

Class A Equipment ...................................................................................................A-4

Class B Equipment ...................................................................................................A-4

Mouse Compliance Statement.........................................................................................A-4

iv HP Smart Array 641/642 Controller User Guide

Page 5

European Union Notice .................................................................................................. A-4

Japanese Notice ..............................................................................................................A-5

Taiwanese Notice............................................................................................................ A-5

Battery Replacement Notice........................................................................................... A-6

Appendix B

Electrostatic Discharge

Appendix C

Controller Specifications

Appendix D

Drive Arrays and Fault Tolerance

What Is a Drive Array?................................................................................................... D-1

Fault-Tolerance Methods................................................................................................ D-5

RAID 0—No Fault Tolerance.................................................................................. D-5

RAID 1+0—Drive Mirroring................................................................................... D-6

RAID 5—Distributed Data Guarding.......................................................................D-7

RAID ADG—Advanced Data Guarding.................................................................. D-9

Comparison of RAID Methods ..............................................................................D-10

Other Fault-Tolerance Options............................................................................... D-11

Contents

Appendix E

Hard Drive Installation and Replacement

General Information About Hard Drive Failure ............................................................. E-1

Recognizing Drive Failure ....................................................................................... E-2

Compromised Fault Tolerance ................................................................................. E-4

Automatic Data Recovery........................................................................................ E-5

General Aspects of Drive Replacement.......................................................................... E-6

Drive Failure During Rebuild .................................................................................. E-8

Moving Drives and Arrays ............................................................................................. E-9

Upgrading Hard Drive Capacity ............................................................................ E-10

Expanding and Extending Capacity....................................................................... E-11

HP Smart Array 641/642 Controller User Guide v

Page 6

Contents

Appendix F

Probability of Logical Drive Failure

Appendix G

Troubleshooting

Index

vi HP Smart Array 641/642 Controller User Guide

Page 7

This guide provides step-by-step instructions for installation, and reference

information for troubleshooting, for the HP Smart Array 641 and 642 Controllers.

Audience Assumptions

This guide is for the person who installs, administers, and troubleshoots servers. HP

assumes that you are qualified in the servicing of computer equipment and trained in

recognizing hazards in products with hazardous energy levels.

Important Safety Information

Before installing this product, read the Important Safety Information document

included with the server.

About This Guide

Symbols on Equipment

The following symbols may be placed on equipment to indicate the presence of

potentially hazardous conditions:

WARNING: This symbol, in conjunction with any of the following symbols,

indicates the presence of a potential hazard. The potential for injury exists if

warnings are not observed. Consult your documentation for specific details.

HP Smart Array 641/642 Controller User Guide vii

Page 8

About This Guide

This symbol indicates the presence of hazardous energy circuits or electric

shock hazards. Refer all servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure. Refer all maintenance, upgrades, and servicing to

qualified personnel.

This symbol indicates the presence of electric shock hazards. The area

contains no user or field serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure.

This symbol indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow the

surface to cool before touching it.

Symbols in Text

These symbols may be found in the text of this guide. They have the following

meanings.

WARNING: Text set off in this manner indicates that failure to follow directions

in the warning could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could

result in damage to equipment or loss of information.

IMPORTANT: Text set off in this manner presents essential information to explain a concept

or complete a task.

NOTE: Text set off in this manner presents additional information to emphasize or supplement

important points of the main text.

viii HP Smart Array 641/642 Controller User Guide

Page 9

Related Documents

For additional information on the topics covered in this guide, refer to the following

documentation:

• Array Configuration Utility User Guide, available on the software CD that is

provided with the server, or downloadable from the HP website.

• Servers Troubleshooting Guide, available on the Documentation CD that is

provided with the server.

• ROM-Based Setup Utility User Guide, available on the Documentation CD that is

provided with the server, or downloadable from the HP website.

Getting Help

If you have a problem and have exhausted the information in this guide, you can get

further information and other help in the following locations.

Technical Support

About This Guide

In North America, call the HP Technical Support Phone Center at 1-800-652-6672.

This service is available 24 hours a day, 7 days a week. For continuous quality

improvement, calls may be recorded or monitored. Outside North America, call the

nearest HP Technical Support Phone Center. Telephone numbers for worldwide

Technical Support Centers are listed on the HP website,

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

• Product serial number

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

HP Smart Array 641/642 Controller User Guide ix

www.hp.com.

Page 10

About This Guide

• Operating system type and revision level

HP Website

The HP website has information on this product as well as the latest drivers and flash

ROM images. You can access the HP website at

Authorized Reseller

For the name of your nearest authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• Elsewhere, see the HP website for locations and telephone numbers.

Reader’s Comments

HP welcomes your comments on this guide. Send comments and suggestions to

ServerDocumentation@hp.com.

www.hp.com.

x HP Smart Array 641/642 Controller User Guide

Page 11

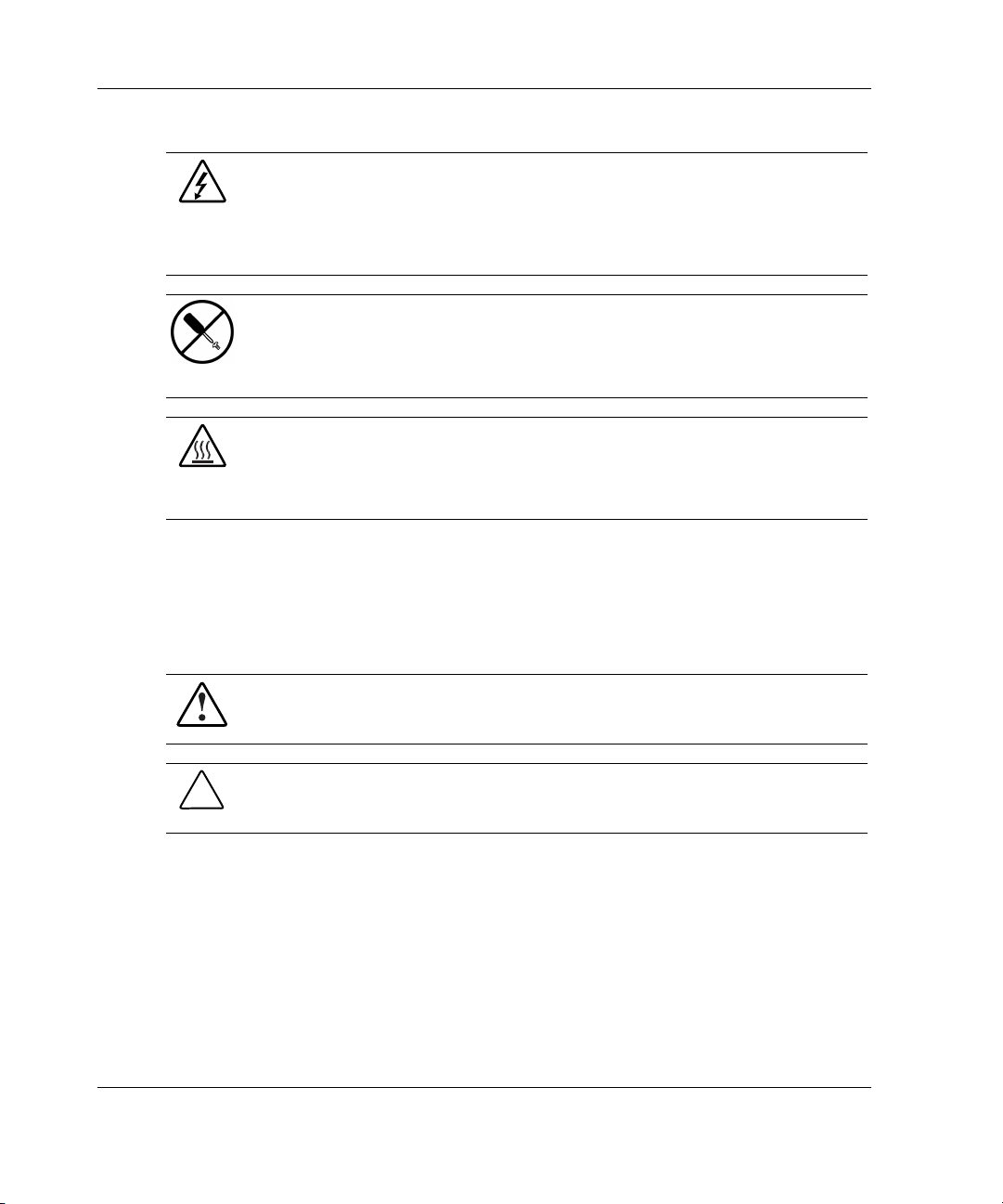

The details of the steps required to install the controller depend on whether the server

has an operating system installed and contains data. The flowcharts in Figure 1-1 and

Figure 1-2 summarize the installation procedures for the most common scenarios.

Procedure for a New System

Install the controller

1

hardware (Chapter 2), if

it is not preinstalled.

Set the boot controller

5

(Chapter 4).

Create at least one

6

logical drive and format

it (Chapter 5).

:

:

. . . . . . .

. . . . . . .

Installation Overview

Update the system

2

firmware (Chapter 3).

Update the controller

3

firmware (Chapter 3).

Configure the system

4

(Chapter 4).

:

:

1

Install the operating

7

system and device

drivers (Chapter 6).

Figure 1-1: Controller installation in a new system

HP Smart Array 641/642 Controller User Guide 1-1

. . . . . . .

Create and format

8

additional logical drives

if desired (Chapter 5).

Page 12

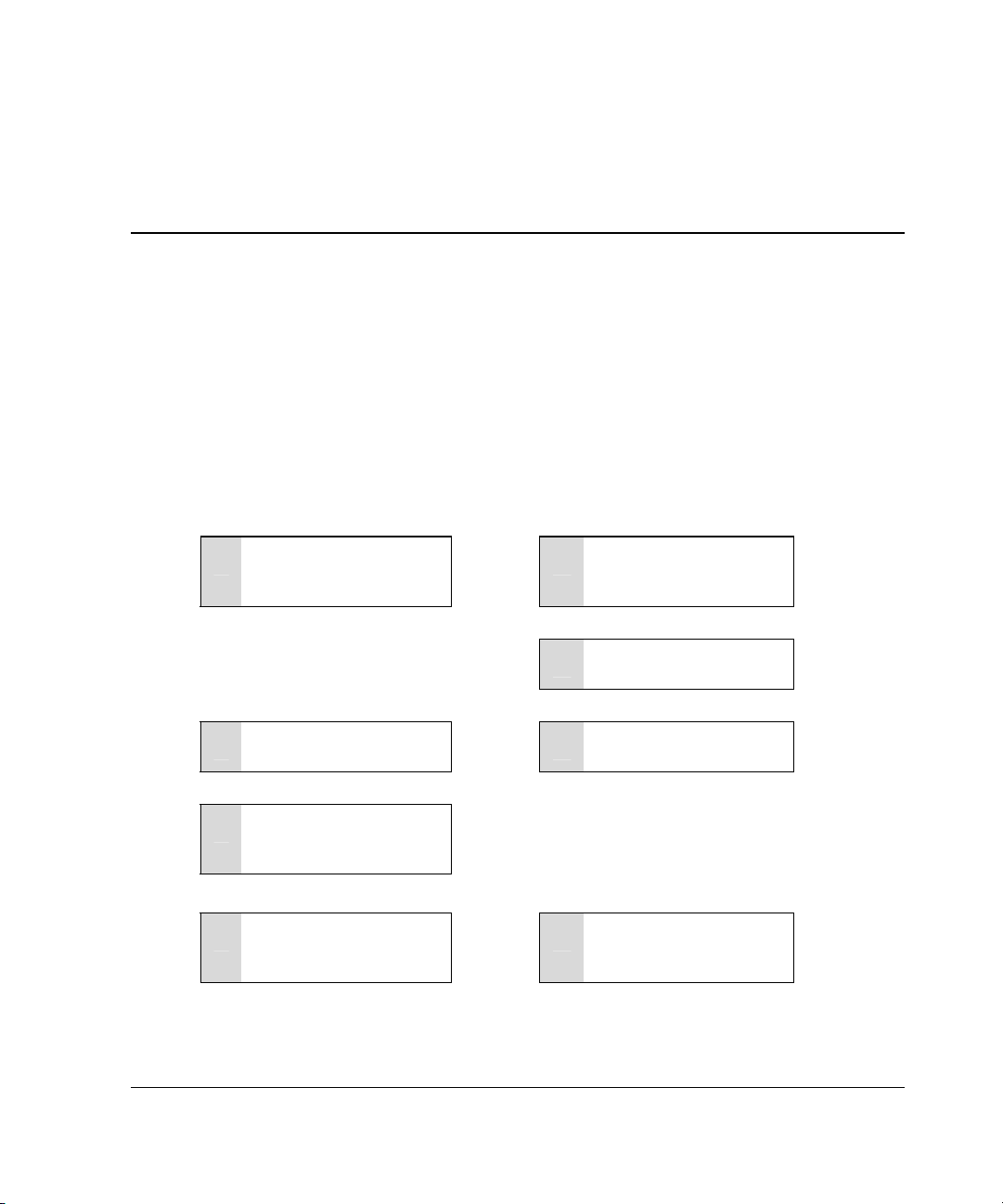

Installation Overview

Procedure for a Preconfigured System

Back up data (required if migrating

1

from a non-array controller).

Set the controller order (Chapter 4).

5

Update the controller firmware

6

(Chapter 3).

If using the System Configuration

7

Utility, update the system partition

(Chapter 3), and then check the

controller order (Chapter 4).

If migrating from a non-array

11

controller, restore data from backup.

:

:

- - - - -

- - - - -

- - - - -

- - - - -

Update the system firmware

2

(Chapter 3).

If the controller is to be the boot

3

device, install the device driver for

the operating system (Chapter 6).

Otherwise, continue with step 4.

Install the controller hardware

4

(Chapter 2).

If the controller is not to be the boot

8

device, install the device driver for

the operating system (Chapter 6).

Update the Management Agents if

9

new versions are available

(Chapter 6).

Create and format new logical

10

drives as desired (Chapter 5).

:

:

:

:

Figure 1-2: Controller installation in an already

configured system

1-2 HP Smart Array 641/642 Controller User Guide

Page 13

Preparing the Server

Before installing the controller in the server, back up all data. This step is mandatory

if you are moving non-arrayed SCSI drives to a Smart Array controller, because data

is not preserved during a move between array controllers and non-array controllers.

WARNING: To reduce the risk of personal injury or damage to the equipment,

consult the safety information and user documentation provided with the

computer before attempting the installation.

Many computers are capable of providing energy levels that are considered

hazardous, and are only intended to be serviced by qualified personnel trained

in dealing with these hazards. Do not remove enclosures or attempt to bypass

any interlocks that may be provided for the purpose of removing these

hazardous conditions.

2

Installing the Hardware

If the server supports hot-pluggable devices, go directly to the “Installing the Smart

Array Controller” section.

To prepare a server that does not support hot-pluggable devices:

1. Close all applications.

2. Power down the server.

CAUTION: In systems using external data storage, be sure that the server is the

first unit powered down and the last unit to be powered back up. This precaution

ensures that the system will not erroneously mark the drives as failed.

3. Power down any peripheral devices that are attached to the server.

HP Smart Array 641/642 Controller User Guide 2-1

Page 14

Installing the Hardware

4. Unplug the AC power cord from the outlet, and then from the server.

5. Disconnect any peripheral devices from the server.

Installing the Smart Array Controller

1. Remove or open the access panel.

2. Select an available 3.3-V PCI or PCI-X slot.

3. Remove the slot cover or open the hot-plug latch. Save the retaining screw, if one

is present.

4. Slide the controller board along the slot alignment guide, and press the board

firmly into the slot so that the contacts on the board edge are properly seated in

the system board connector.

5. Secure the controller board in place with the hot-plug latch or retaining screw.

6. Continue by following the instructions given in “Connecting the Cables.”

Connecting the Cables

Each peripheral that is connected to the server must have a unique SCSI ID value,

falling in the range from 0 to 15 (except ID 7, which is reserved for controller use).

The SCSI ID value determines the priority that is given to the device when it attempts

to use the SCSI bus.

On products that support hot-pluggable devices, the SCSI IDs for such peripherals

are automatically set. The IDs for non-hot-pluggable devices must be set manually by

using switches or jumpers on the device itself.

SCSI buses require termination on both ends to prevent signal degradation. In all

Compaq servers and storage systems, and the newer ProLiant systems, the controller,

SCSI cable, and backplane already provide this termination.

Internal Cabling

1. If the device is not hot pluggable, power down the system.

2-2 HP Smart Array 641/642 Controller User Guide

Page 15

Installing the Hardware

2. Install drives into the removable media bays on the server. (For additional

information about drive installation, consult the documentation that accompanied

the drives, and refer to Appendix E.)

NOTE: Drives that are to be grouped in the same array should have the same capacity.

— If the drives are hot pluggable, go to step 3.

— If the drives are not hot pluggable, go to step 4.

3. Attach the internal point-to-point SCSI cable (provided with the server) from the

internal connector of the controller to the hot-plug drive cage.

Installation of the hot-pluggable drives is complete.

4. For each SCSI bus, manually set the SCSI ID on each drive to a unique value in

the range of 0 to 15, except 7 (which is reserved for controller use). For detailed

instructions, consult the documentation that is provided with the drive.

5. Attach the multi-device SCSI cable from the internal connector of the controller

to the non-hot-pluggable hard drives.

The multi-device cable may have been provided with the server. If you need

additional cables, order the cable option kit, Part Number 166389-B21. This

cable is equipped to terminate Ultra2, Ultra160 (Ultra3), or Ultra320 (Ultra4)

drives.

CAUTION: Cable assembly 148785-001 is included in option kit 166389-B21

and is required with Ultra3 and Ultra4 drives. Failure to use this cable may result

in reduced performance, data loss, or both.

External Cabling (Model 642 only)

1. On the rear of the server, connect the cable to the VHDCI connector on the

controller, and then tighten the lock screws on the cable connector.

2. Attach the other end of the cable to the storage enclosure, and then tighten the

lock screws on the cable connector.

3. Replace the access panel and secure it with the thumbscrews, as required.

HP Smart Array 641/642 Controller User Guide 2-3

Page 16

Installing the Hardware

CAUTION: Do not operate the server with the access panel removed for

extended periods of time. This precaution protects thermally sensitive

components by ensuring the proper airflow through the server, and minimizes

personal contact with hazardous energy levels.

Table 2-1: External SCSI Cables for Storage Enclosures

Cable Type Length Option Kit Number Cable Assembly Number

VHDCI to VHDCI 1.8 m / 6 ft 341174-B21 313374-001

VHDCI to VHDCI

VHDCI to VHDCI 7.2 m / 24 ft 164604-B21 313374-004

VHDCI to VHDCI 11.7 m / 39 ft 150214-B21 313374-005

Note: If additional cables are required, order by the option kit number.

3.6 m / 12 ft

341175-B21 313374-002

2-4 HP Smart Array 641/642 Controller User Guide

Page 17

3

Updating the Firmware

You can update the firmware using the Smart Components, which are downloadable

from the HP website. Detailed instructions for using the Smart Components are given

on the Web page that contains the components.

NOTE: Some newer ProLiant servers automatically update the system and controller firmware

when they are powered up for the first time. To determine whether this situation is true for a

particular server, refer to the server-specific setup and installation guide.

Alternatively, if the server uses Microsoft Windows 2000 or Microsoft Windows NT

as the operating system, you can use one of the CDs that are supplied with the

controller to accomplish the firmware updates. Before using either CD, check the

Smart Components on the HP website to see whether newer versions of the firmware

upgrade files are available.

1. Insert the CD into the CD-ROM drive of the server.

— If the server was configured using the ROM-Based Setup Utility (RBSU),

use the SmartStart CD (version 6.0 or later).

— If the server did not use RBSU, use the Support Software CD.

If you want to run the firmware updates while offline, restart the server now, and

then wait for controller initialization to finish.

The ProLiant Storage Software license agreement page is displayed.

2. Click Agree.

The main ProLiant Storage Software screen is displayed.

3. Click ROM Update Utility.

4. Click the Updates tab.

HP Smart Array 641/642 Controller User Guide 3-1

Page 18

Updating the Firmware

5. Select Express or Custom mode, and follow the on-screen prompts and

instructions to update the firmware on the system and the controller.

If the server does not use RBSU, you now need to use the System Configuration

Utility (SCU) to update the system partition.

1. Locate the page on the HP website that contains SCU and follow the on-screen

instructions to create four SCU diskettes.

2. Insert SCU diskette #1 into the server diskette drive.

3. Restart the system.

4. Select System Configuration Utility from the menu or list of icons that is

displayed.

5. Follow the on-screen instructions to update or create and populate a system

partition.

6. Exit from SCU. If the server does not reboot or a CD error message is displayed,

press the Ctrl+Alt+Del keys to reboot the server manually.

3-2 HP Smart Array 641/642 Controller User Guide

Page 19

4

Setting the Controller Order

After installing the controller hardware and updating the firmware:

• Configure the server by using either RBSU or SCU. A brief description of the

procedure is given in this chapter; the server user guide provides more details.

IMPORTANT: When using SCU to reconfigure a system that uses a Smart Array 641 or

642 Controller as the boot controller, use ORCA immediately afterwards to check that

the controller order is unchanged. Reset the controller order if necessary.

NOTE: Some newer ProLiant servers configure themselves automatically when they are

powered up for the first time. To determine whether this situation is true for a particular

server, refer to the server-specific setup and installation guide.

• Set the boot controller by using RBSU or the Option ROM Configuration for

Arrays (ORCA) utility, as described in this chapter.

• Create at least one logical drive, as described in Chapter 5.

NOTE: Some newer ProLiant servers automatically create a logical drive and configure a

RAID level when they are powered up for the first time. For this sequence of events to

occur, the server must have fewer than seven internal hard drives, and the boot drive

must not have been written to. To determine whether this situation applies to a particular

server, refer to the server-specific setup and installation guide.

Using RBSU

RBSU is a system configuration utility that is embedded in the system ROM, and is

customized for the server that it is installed on.

HP Smart Array 641/642 Controller User Guide 4-1

Page 20

Setting the Controller Order

CAUTION: Not all servers support RBSU. Do not flash an RBSU-ROM image onto a

server that is already configured with SCU unless the update instructions specifically

state that upgrading from SCU to RBSU is supported. If the upgrade is not

supported, the consequences of upgrading are unpredictable and you may lose data.

To use RBSU:

1. Power up the server.

2. Press the F9 key when prompted during system startup.

The main RBSU screen is displayed.

3. Configure the system. (For detailed instructions, refer to the ROM-Based Setup

Utility User Guide.)

4. Select Boot Controller Order on the main RBSU screen and follow the

on-screen prompts to set the boot controller.

5. When you have finished using the utility, press the Esc key, and then press the

F10 key to confirm that you want to exit RBSU.

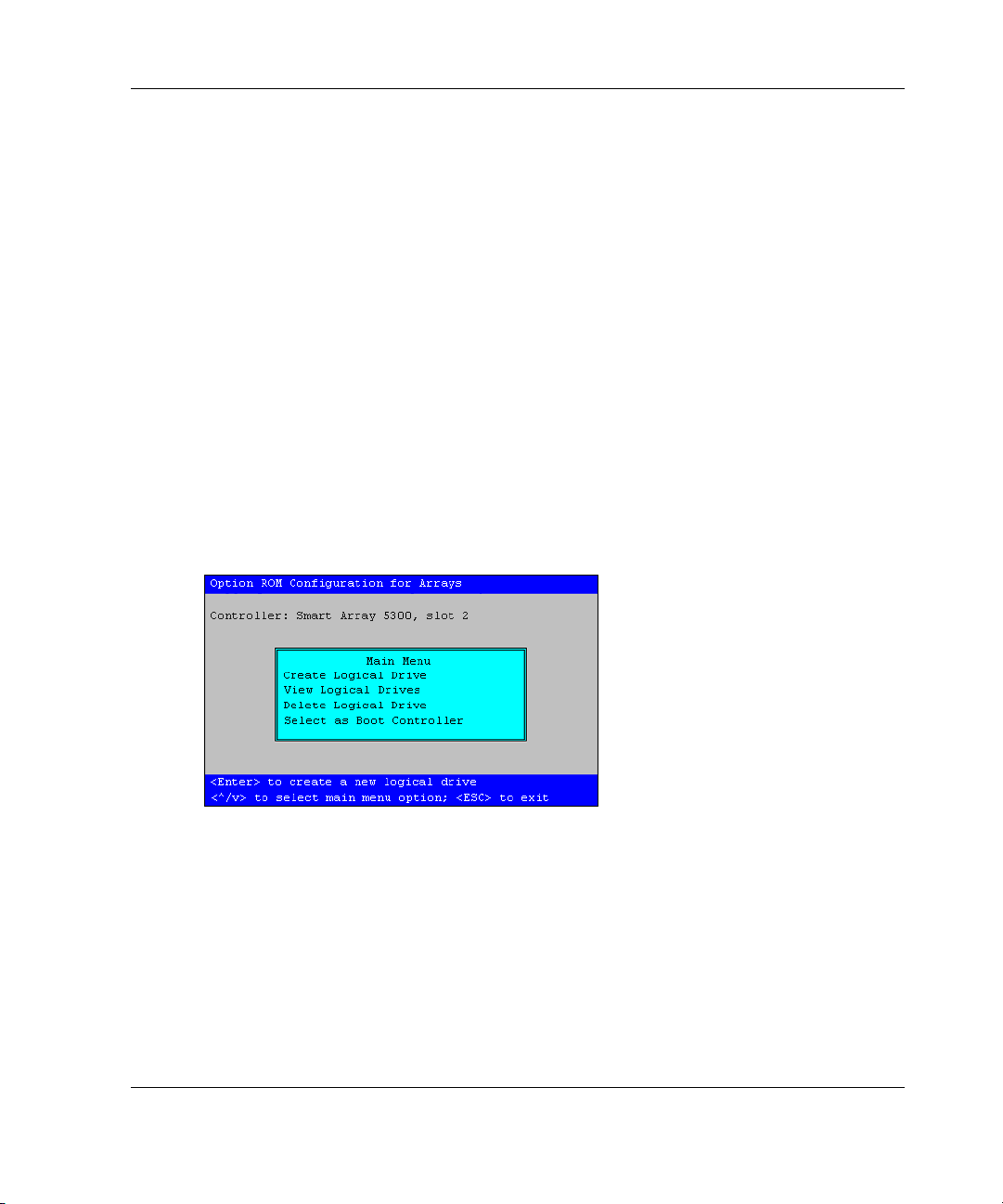

Using ORCA

Part of the startup sequence of a server is the Power-On Self-Test (POST). If the

array controller in the server supports ORCA, POST temporarily halts and an ORCA

prompt message is displayed for about five seconds. (If ORCA is not supported, the

prompt message is not displayed and the system continues with the startup sequence.)

1. Power up the server and let the system startup sequence begin.

2. While the prompt message is displayed, press the F8 key to start ORCA.

3. On the Main Menu screen, select Select as Boot Controller and follow the

prompts to set the boot controller for the system.

If you want to use ORCA to create logical drives, you do not need to exit the utility

yet. Continue using ORCA as described in Chapter 5.

4-2 HP Smart Array 641/642 Controller User Guide

Page 21

5

Configuring an Array

HP provides three utilities for manually configuring an array:

• Array Configuration Utility (ACU)—A versatile, browser-based utility that

provides maximum control over configuration parameters

• Option ROM Configuration for Arrays (ORCA)—A simple ROM-based

configuration utility that runs on all operating systems

• NetWare Online Array Configuration Utility (CPQONLIN)—A menu-driven

utility for NetWare

NOTE: If you want to copy a particular array configuration to several other servers on the

same network, use the Array Configuration Replicator (ACR) or the scripting capability of ACU.

ACR is provided in the SmartStart Scripting Toolkit, available at www.hp.com/servers/sstoolkit.

For background information about drive arrays and fault-tolerance (RAID) methods,

refer to Appendix D.

The following limitations apply to all configuration methods:

• For the most efficient use of drive space, do not mix drives of different capacity

within the same array. Each configuration utility treats all physical drives in an

array as if they have the same capacity as the smallest drive in the array. Excess

capacity of larger drives is wasted because it is unavailable for data storage.

• The probability that an array will experience a hard drive failure increases with

the number of hard drives in the array (for more detailed information, refer to

Appendix F). If you configure an array with RAID 5, keep the probability of

failure acceptably low by using no more than 14 drives.

HP Smart Array 641/642 Controller User Guide 5-1

Page 22

Configuring an Array

Table 5-1: Comparison of Utilities for Configuring an Array

ACU CPQONLIN ORCA

Uses a graphical interface + 0 0

Available in languages other than English + 0 0

Executable at any time + + 0

Available on CD + + 0

Uses a wizard to suggest the optimum

configuration for an unconfigured controller

Describes configuration errors + 0 0

Supports these operating systems:

Microsoft Windows 2000 + 0 +

Microsoft Windows NT + 0 +

Novell NetWare +* + +

Linux + 0 +

Allows these procedures:

Creation and deletion of arrays, logical drives + + +

Assignment of RAID level + + +

Sharing of spare drive among several arrays + + 0

Assignment of multiple spare drives per array + + 0

Setting of stripe size + + 0

Migration of RAID level or stripe size + + 0

Configuration of controller settings + + 0

Expansion of an array + + 0

Creation of multiple logical drives per array + + 0

Setting of boot controller 0 0 +

+ + 0

*NetWare can use ACU only when the system is offline.

5-2 HP Smart Array 641/642 Controller User Guide

Page 23

Using ACU

For detailed information about using ACU, refer to the HP Array Configuration

Utility User Guide.

Using ORCA

When a computer system is powered up, part of the startup sequence is the Power-On

Self-Test (POST). Any array controllers that are in the system are initialized while

POST is running. If the array controller supports ORCA, POST temporarily halts and

an ORCA prompt message is displayed for about five seconds. (If ORCA is not

supported, the prompt message is not displayed and the system continues with the

startup sequence.)

While the prompt is displayed, press the F8 key to start ORCA. The ORCA main

menu is displayed, allowing you to select the boot controller for the system, or to

create, view, or delete a logical drive.

Configuring an Array

Figure 5-1: ORCA main menu screen

NOTE: The maximum allowable boot drive size with ORCA is 4 GB.

To create a logical drive:

1. Select Create Logical Drive.

The screen displays a list of all available (unconfigured) physical drives and the

valid RAID options for the system.

HP Smart Array 641/642 Controller User Guide 5-3

Page 24

Configuring an Array

NOTE: You can create only one logical drive at a time.

2. Use the arrow keys, space bar, and tab key to navigate around the screen and set

up the logical drive, including a spare drive if required.

NOTE: ORCA allows only one array to use a given online spare.

3. Press the Enter key to accept the settings.

4. Press the F8 key to confirm the settings and save the new configuration.

After several seconds, the Configuration Saved screen is displayed.

5. Press the Enter key to continue.

You can now create another logical drive by repeating the previous steps.

NOTE: Raw logical drives are invisible to the operating system. To make the new logical

drives available for data storage, format the logical drive using the instructions given in the

operating system documentation.

Using CPQONLIN

The NetWare Online Array Configuration utility (CPQONLIN) lets you configure

drive arrays without shutting down the server. It also indicates when a drive attached

to the array controller has failed, is undergoing expansion, or is waiting (queued) for

expansion or rebuild.

IMPORTANT: The maximum logical drive size in CPQONLIN is 512 GB.

To install CPQONLIN:

1. Load CPQRAID.HAM from the SmartStart CD, or from the Controller Support

Software CD and diskettes. (Detailed instructions are given in the README file

on the CD.)

2. Load CPQONLIN.NLM from the same source.

3. Open CPQONLIN.NLM and follow the on-screen instructions.

5-4 HP Smart Array 641/642 Controller User Guide

Page 25

Running CPQONLIN

1. Enter cpqonlin at the console prompt.

2. Use the arrow keys to highlight Array Configuration Utility, and then press the

Enter key.

3. From the list of controllers that is presented, select the one that you want to

configure.

— If no logical drives are configured for the controller, the auto-configuration

wizard screen (Figure 5-2) is displayed.

— If logical drives are present on the controller, the manual configuration

screen (Figure 5-3) is displayed.

Press the F1 key for online help at any time on either screen.

Automatic Configuration

Configuring an Array

Figure 5-2: CPQONLIN auto-configuration wizard screen

1. If the proposed logical configuration shown on the wizard screen is acceptable,

highlight the fault-tolerance level that you want for the logical drive and press the

Enter key. Otherwise, select Custom Configuration and continue the procedure

as described in the “Manual Configuration” section.

2. Press the Esc key to save the changes and return to the controller selection

screen.

3. Restart the system to apply the changes.

HP Smart Array 641/642 Controller User Guide 5-5

Page 26

Configuring an Array

NOTE: Raw logical drives are invisible to the operating system. To make the new logical

drives available for data storage, format the logical drive using the instructions given in the

operating system documentation.

Manual Configuration

Figure 5-3: Main manual configuration screen

Highlight the controller, array, or logical drive that you want to configure, and then

press the Enter key. The menu options for that item are shown in the panel on the

right-hand side of the screen. Table 5-2 lists the menu options for each item in the

Logical Configuration View panel. If an option is not applicable in any particular

case, it is not displayed in the panel.

5-6 HP Smart Array 641/642 Controller User Guide

Page 27

Configuring an Array

Table 5-2: Menu Options in CPQONLIN

CONTROLLER OPTIONS Menu

Controller Settings Rebuild Priority

Expand Priority

Accelerator Ratio

Create New Array Create Array Assign Drive

Assign Array

Remove Drive

Accept Changes

Physical Drives (Panel shows spare drives and unassigned hard drives.)

New Array (Panel shows physical view of new array.)

ARRAY OPTIONS Menu

Expand Array Expand Array Assign Drive

Accept Changes

Physical Drives (Panel shows spare drives and unassigned hard drives.)

New Array (Panel shows physical view of new array.)

Assign Spare Assign Spare Assign Drive

Accept Changes

Physical Drives (Panel shows spare drives and unassigned hard drives.)

New Array (Panel shows physical view of new array.)

Delete Entire Array

LOGICAL DRIVE OPTIONS Menu

Drive Settings Enable / Disable Cache

Delete

Fault Tolerance

Stripe Size

HP Smart Array 641/642 Controller User Guide 5-7

Page 28

Configuring an Array

Typical Manual Configuration Procedures in CPQONLIN

Creating a Custom Configuration for a New Array

1. In the Logical Configuration View panel, highlight the controller that you want

to configure and then press the Enter key.

2. In the Controller Options panel, choose Create New Array, and then press the

Enter key.

The screen now displays three panels: Create Array, Physical Drives, and New

Array.

3. In the Create Array panel, choose Assign Drive, and then press the Enter key.

The highlight automatically moves to the Physical Drives panel.

4. Select a drive and then press the Enter key.

IMPORTANT: Do not assign a group of physical drives to the same array unless they are

of the same capacity. If the drives have different capacities, the excess capacity of the

larger drives cannot be used by the array and is wasted.

The New Array panel lists the added drive, and the highlight automatically

returns to the Create Array panel.

5. Repeat steps 3 and 4 until you have finished assigning drives to the array.

NOTE: You can add spare drives to the array only when all data storage drives have

been assigned.

6. Choose Accept Changes and press the Enter key.

The main manual configuration screen is displayed again.

5-8 HP Smart Array 641/642 Controller User Guide

Page 29

Adding Spare Drives

To add spare drives to an array, the array controller must have at least one attached

drive that is unassigned, or is assigned as a spare to another array.

You can:

• Assign a different online spare to each array on the controller.

• Share one online spare among several arrays on the same controller, for efficient

use of drive capacity.

• Assign several online spares to just one array.

• Share several online spares among several arrays; this method provides the

greatest amount of protection for the largest number of arrays.

IMPORTANT: Assigning several spares to an array lets you postpone replacement of faulty

drives, but it does not increase the fault-tolerance level of any logical drives in the array. For

example, a logical drive in a RAID 5 configuration suffers irretrievable data loss if two physical

drives fail simultaneously, regardless of the number of spare drives assigned.

Any drive that you assign as an online spare for an array operates as the spare for

every fault-tolerant logical drive within that array.

Configuring an Array

When you select Assign Spare, only drives that qualify are displayed; for example,

drives with too small a capacity are not listed. If a drive that you expect to see is not

listed, press the Tab key (to switch to the physical drive view) and check the capacity

of the drive.

To add a spare:

1. In the Logical Configuration View panel, highlight the array that needs a spare,

and then press the Enter key.

2. Choose Assign Spare in the Array Options menu, and then press the Enter key.

3. Select the drive that you want as the spare, and then press the Enter key.

4. Press the Esc key to accept the new configuration and return to the main manual

configuration screen.

HP Smart Array 641/642 Controller User Guide 5-9

Page 30

Configuring an Array

Configuring the New Logical Drive

1. In the Logical Configuration View panel, highlight the new logical drive that

you want to configure, and then press the Enter key.

2. Select Fault Tolerance in the Logical Drive Options menu, and then press the

Enter key.

3. Choose the RAID level that you want and then press the Enter key.

4. Choose Stripe Size and then press the Enter key.

5. Choose the stripe size that you want and then press the Enter key.

6. Press the Esc key to accept the settings and return to the main manual

configuration screen.

Configuring the Controller Settings

The Controller Settings option allows you to choose the drive rebuild priority,

expansion priority, and accelerator ratio for all arrays on the controller.

• With a low priority setting, a rebuild or expansion takes place only when the

array controller is not busy handling normal I/O requests. This setting has

minimal effect on normal I/O operations. However, there is an increased risk that

data will be lost if another physical drive fails while the rebuild is in progress.

• With a high priority setting, the rebuild or expansion occurs at the expense of

normal I/O operations. Although performance is affected, this setting provides

better data protection because the array is vulnerable to additional drive failures

for a shorter time.

• At the medium priority setting, expansion or rebuild occurs for half of the time,

and normal I/O requests are handled during the rest of the time.

NOTE: Logical drives can be rebuilt only if they have been configured for fault tolerance (that

is, any RAID level other than RAID 0). Drive rebuild begins automatically after you have

replaced a failed physical drive in the array.

The accelerator read/write ratio determines the amount of memory allocated to the

read and write caches on the array accelerator. Different applications have different

optimum settings. Some controllers (especially those without battery-backed write

cache) do not allow this ratio to be changed.

5-10 HP Smart Array 641/642 Controller User Guide

Page 31

Configuring an Array

1. In the Logical Configuration View panel, select the controller that you want to

configure, and then press the Enter key.

2. In the Controller Options panel, select Controller Settings, and then press the

Enter key. The Controller Settings screen is displayed.

Figure 5-4: Controller Settings screen

3. Alter the settings on this screen to meet your requirements.

4. Press the Esc key to save the new configuration.

5. Exit CPQONLIN, and then restart the system to apply the changes.

Expanding an Array

Performance may be degraded slightly during array expansion, depending on the

Expand Priority setting. To minimize any effect, expand the array during periods of

low server use.

NOTE: The expansion process takes about 15 minutes per gigabyte. The controller is not able

to expand or migrate any other logical drive during this time. Instead, further requests for

expansion or migration are queued.

1. Back up all data on the logical drive. Although array expansion is unlikely to

cause data loss, observing this precaution provides extra security.

2. Highlight the controller in the Logical Configuration View panel, and then press

the F3 key. Scroll down the screen until you reach the Array Accelerator

section. The condition of the battery and cache should both be OK.

HP Smart Array 641/642 Controller User Guide 5-11

Page 32

Configuring an Array

3. Exit from the previous screen, and then move the highlight to the logical drive. If

the controller has a battery-backed write cache, there should be an entry Disable

Cache in the right-hand panel, implying that the cache is enabled. If the entry is

Enable Cache, the cache is currently disabled; enable it.

4. In the Logical Configuration View panel, select the array that you want to

expand, and then press the Enter key.

5. Select Expand in the menu, and then press the Enter key.

6. Select the hard drive that you want to add to the array, and then press the Enter

key.

IMPORTANT: Do not assign a group of physical drives to the same array unless they are

of the same capacity. If the drives have different capacities, the excess capacity of the

larger drives cannot be used by the array and is wasted.

7. Repeat step 6 until you have finished adding drives.

8. Select Accept Changes, and then press the Enter key.

9. Press the Esc key to begin the array expansion.

You can see the progress of the expansion at any time by pressing the F3 key and

then scrolling to the progress bar near the bottom of the screen.

Migrating RAID Level or Stripe Size

Performance may be degraded slightly during migration, depending on the Expand

(or Rebuild) Priority setting. To minimize any effect, migrate during periods of low

server use.

NOTE: The migration process takes about 15 minutes per gigabyte. The controller is not able

to expand or migrate any other logical drive during this time. Instead, further requests for

expansion or migration will be queued.

1. Back up all data on the logical drive. Although migration is unlikely to cause

data loss, observing this precaution provides extra security.

2. Highlight the controller in the Logical Configuration View panel, and then press

the F3 key. Scroll down the screen until you reach the Array Accelerator

section. The condition of the battery and cache should both be OK.

5-12 HP Smart Array 641/642 Controller User Guide

Page 33

Configuring an Array

3. Exit from the previous screen, and then move the highlight to the logical drive. If

the controller has a battery-backed write cache, there should be an entry Disable

Cache in the right-hand panel, implying that the cache is enabled. If the entry is

Enable Cache, the cache is currently disabled; enable it.

4. In the Logical Configuration View panel, select the logical drive that you want

to migrate and then press the Enter key.

5. Select Drive Settings, and then press the Enter key.

6. Change the RAID level or stripe size shown on this screen.

Table 5-3: Supported Stripe Sizes for a Given RAID Level

Fault-Tolerance Level Supported Stripe Sizes (KB) Default (KB)

RAID 0, RAID 1+0 8, 16, 32, 64, 128, 256 128

RAID 5, RAID ADG* 8, 16, 32, 64 16

*Not all controllers support RAID ADG.

Table 5-4: Optimum Stripe Size for a Given Application

Type of Server Application Suggested Stripe Size Change

Mixed read/write Accept the default value

Mainly sequential read (such

as audio/video applications)

Mainly write (such as image

manipulation applications)

*Not all controllers support RAID ADG

Use larger stripe sizes for best performance

Use smaller stripes for RAID 5, RAID ADG*

Use larger stripes for RAID 0, RAID 1+0

7. Press the Esc key to accept the changes and begin migration.

You can check the progress of the migration at any time by pressing the F3 key

and then scrolling to the progress bar near the bottom of the screen.

HP Smart Array 641/642 Controller User Guide 5-13

Page 34

Installing the Device Drivers

and Management Agents

Installing the Device Drivers

The drivers for the controller are located on the Support Software CD and on the

SmartStart CD. Updates are posted to

Using the Support Software CD: Instructions for installing the drivers from the

Support Software CD are given in the leaflet that is supplied with the CD. Note that

the exact procedure depends on whether the server is new or already contains the

operating system and user data.

Using the SmartStart CD: If you used the SmartStart Assisted Installation path to

install the operating system on a new server, the drivers are automatically installed at

the same time. You can also use SmartStart to update the drivers manually on older

systems. For further information, refer to the SmartStart documentation.

www.hp.com.

6

Updating the Management Agents

If you used the SmartStart Assisted Installation path to install the operating system on

a new server, the Management Agents are automatically installed at the same time.

The Management Agents can also be manually updated using the SmartStart CD or

the Management CD. For the procedure, refer to the documentation on the

Management CD or on

HP Smart Array 641/642 Controller User Guide 6-1

www.hp.com/servers/manage.

Page 35

Installing the Device Drivers and Management Agents

You can obtain the Management CD from your local HP reseller or authorized

service provider. The latest versions of Insight Manager and Management Agents are

also available for download at

www.hp.com/servers/manage.

If the new agents do not function correctly, you may also need to update

Insight Manager.

6-2 HP Smart Array 641/642 Controller User Guide

Page 36

7

Upgrading or Replacing the Cache

WARNING: There is a risk of explosion, fire, or personal injury if the battery

pack is not properly handled. Refer to Appendix B and the Battery

Replacement Notice in Appendix A before installing or removing the cache.

To remove the cache module, open the DIMM ejector latches (1) on each side of the

DIMM connector, and then pull the cache out of the DIMM slot (2).

2

1

This drawing represents the Smart Array 642 Controller. The cache on the Smart

Array 641 Controller is removed in an identical manner.

To replace the cache module, reverse this procedure.

HP Smart Array 641/642 Controller User Guide 7-1

Page 37

Regulatory Compliance Notices

Federal Communications Commission Notice

Part 15 of the Federal Communications Commission (FCC) Rules and Regulations

has established Radio Frequency (RF) emission limits to provide an interference-free

radio frequency spectrum. Many electronic devices, including computers, generate

RF energy incidental to their intended function and are, therefore, covered by these

rules. These rules place computers and related peripheral devices into two classes, A

and B, depending upon their intended installation. Class A devices are those that may

reasonably be expected to be installed in a business or commercial environment.

Class B devices are those that may reasonably be expected to be installed in a

residential environment (for example, personal computers). The FCC requires

devices in both classes to bear a label indicating the interference potential of the

device as well as additional operating instructions for the user.

The rating label on the device shows the classification (A or B) of the equipment.

Class B devices have an FCC logo or FCC ID on the label. Class A devices do not

have an FCC logo or FCC ID on the label. After the Class of the device is

determined, refer to the corresponding statement in the following sections.

A

HP Smart Array 641/642 Controller User Guide A-1

Page 38

Regulatory Compliance Notices

Class A Equipment

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at personal expense.

Class B Equipment

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit that is different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio or television technician for help.

A-2 HP Smart Array 641/642 Controller User Guide

Page 39

Regulatory Compliance Notices

Declaration of Conformity for Products Marked with the FCC Logo, United States Only

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

For questions regarding your product, contact us by mail or telephone:

• Hewlett-Packard Company

P. O. Box 692000, Mail Stop 530113

Houston, Texas 77269-2000

• 1-800-652-6672 (For continuous quality improvement, calls may be recorded or

monitored.)

For questions regarding this FCC declaration, contact us by mail or telephone:

• Hewlett-Packard Company

P. O. Box 692000, Mail Stop 510101

Houston, Texas 77269-2000

• 1-281-514-3333

To identify this product, refer to the part, series, or model number found on the

product.

Modifications

The FCC requires the user to be notified that any changes or modifications made to

this device that are not expressly approved by Hewlett-Packard Company may void

the user’s authority to operate the equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI

connector hoods in order to maintain compliance with FCC Rules and Regulations.

HP Smart Array 641/642 Controller User Guide A-3

Page 40

Regulatory Compliance Notices

Canadian Notice (Avis Canadien)

Class A Equipment

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur

le matériel brouilleur du Canada.

Class B Equipment

This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur

le matériel brouilleur du Canada.

Mouse Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

European Union Notice

Products with the CE Marking comply with both the EMC Directive (89/336/EEC)

and the Low Voltage Directive (73/23/EEC) issued by the Commission of the

European Community.

Compliance with these directives implies conformity to the following European

Norms (the equivalent international standards are in parentheses):

• EN55022 (CISPR 22) – Electromagnetic Interference

A-4 HP Smart Array 641/642 Controller User Guide

Page 41

• EN55024 (IEC61000-4-2, 3, 4, 5, 6, 8, 11) – Electromagnetic Immunity

• EN60950 (IEC950) – Product Safety

Japanese Notice

Regulatory Compliance Notices

Taiwanese Notice

HP Smart Array 641/642 Controller User Guide A-5

Page 42

Regulatory Compliance Notices

Battery Replacement Notice

The battery-backed write cache uses a nickel metal hydride (NiMH) battery pack.

WARNING: There is a risk of explosion, fire, or personal injury if the battery

pack is not properly handled. To reduce this risk:

• Do not try to recharge the batteries if they are disconnected from the

controller.

• Do not expose the battery pack to water, or to temperatures higher than

60°C.

• Do not abuse, disassemble, crush, or puncture the battery pack.

• Do not short the external contacts.

• Replace the battery pack only with the designated HP spare.

Battery disposal should comply with local regulations. Alternatively, use

established parts return methods to return the battery pack to HP for disposal.

Batteries, battery packs, and accumulators should not be disposed of

together with the general household waste. To forward them to recycling or

proper disposal, use the public collection system or return them to HP, your

authorized HP Partners, or their agents.

For more information about battery replacement or proper disposal, contact your HP

authorized reseller or your authorized service provider.

A-6 HP Smart Array 641/642 Controller User Guide

Page 43

B

Electrostatic Discharge

To prevent damaging the system, be aware of the precautions you need to follow

when setting up the system or handling parts. A discharge of static electricity from a

finger or other conductor may damage system boards or other static-sensitive

devices. This type of damage may reduce the life expectancy of the device.

To prevent electrostatic damage, observe the following precautions:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free

workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or

assembly.

There are several methods for grounding. Use one or more of the following methods

when handling or installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or

computer chassis. Wrist straps are flexible straps with a minimum of 1 megohm

resistance in the ground cords. To provide proper ground, wear the strap snug

against the skin.

• Use heel straps, toe straps, or boot straps at standing workstations. Wear the

straps on both feet when standing on conductive floors or dissipating floor mats.

• Use conductive field service tools.

HP Smart Array 641/642 Controller User Guide B-1

Page 44

Electrostatic Discharge

• Use a portable field service kit with a folding static-dissipating work mat.

If you do not have any of the suggested equipment for proper grounding, have an HP

authorized reseller install the part.

NOTE: For more information on static electricity, or assistance with product installation,

contact your HP authorized reseller.

B-2 HP Smart Array 641/642 Controller User Guide

Page 45

Controller Specifications

Table C-1: Controller Specifications

Dimensions (PCB only) 28.7 cm × 10.8 cm × 1.6 cm (11.3 in × 4.3 in × 0.63 in)

Power required No more than 14 W for either model

PCI-X bus transfer rate Up to 1064 MB/s at 133 MHz (64-bit)

C

Temperature range

Relative humidity (noncondensing) Operating: 20% to 80%

RAID levels supported 0, 1+0, 5

SCSI Bus:

Number of channels 1 internal (641); 1 internal and 1 external (642)

Maximum number of drives per

channel

Connector type 68-pin Wide internal, VHDCI external

Termination Required, but provided on Compaq and newer HP systems

Transfer rate Up to 320 MB/s (80 MHz) per channel

Operating: 10° to 35°C (50° to 95°F)

Storage: –30° to 60°C (–22° to 140°F)

Storage: 5% to 90%

15 (14 in an external enclosure)

For more information about the controller features and specifications, refer to

www.compaq.com/smartarray.

HP Smart Array 641/642 Controller User Guide C-1

Page 46

Drive Arrays and Fault Tolerance

What Is a Drive Array?

The capacity and performance of a single physical (hard) drive is adequate for home

users. However, business users demand higher storage capacities, higher data transfer

rates, and greater protection against data loss when drives fail.

Connecting extra physical drives to a system increases the total storage capacity

(refer to Figure D-1), but has no effect on the efficiency of read/write (R/W)

operations. Data can still be transferred to only one physical drive at a time.

D

R/W

P1 P2 P3

Figure D-1: Physical drives added to system

HP Smart Array 641/642 Controller User Guide D-1

Page 47

Drive Arrays and Fault Tolerance

With an array controller installed in the system, the capacity of several physical

drives can be combined into one or more virtual units called logical drives (also

called logical volumes). Then, the read/write heads of all the constituent physical

drives are active simultaneously, reducing the total time required for data transfer.

P1 P2 P3

Figure D-2: Physical drives configured into a logical

drive (L1)

L1

Because the read/write heads are active simultaneously, the same amount of data is

written to each drive during any given time interval. Each unit of data is called a

block, and adjacent blocks form a set of data stripes across all the physical drives

that comprise the logical drive (refer to Figure D-3).

D-2 HP Smart Array 641/642 Controller User Guide

Page 48

Drive Arrays and Fault Tolerance

S1

S2

S3

S4

B1

B4

B7

B2

B5

B8

B11B10 B12

B3

B6

B9

Figure D-3: Data striping (S1-S4) of data blocks B1-B12

For data in the logical drive to be readable, the data block sequence must be the same

in every stripe. This sequencing process is performed by the array controller, which

sends the data blocks to the drive write heads in the correct order.

A natural consequence of the striping process is that each physical drive in a given

logical drive will contain the same amount of data. If one physical drive has a larger

capacity than other physical drives in the same logical drive, the extra capacity is

wasted because it cannot be used by the logical drive.

The group of physical drives containing the logical drive is called a drive array (or

just array). Since all the physical drives in an array are commonly configured into

just one logical drive, the term array is also often used as a synonym for logical drive.

However, an array can contain several logical drives, each of a different size (refer to

Figure D-4).

HP Smart Array 641/642 Controller User Guide D-3

Page 49

Drive Arrays and Fault Tolerance

A1

L1

L2

A2

L3

L4

L5

Figure D-4: Two arrays (A1, A2) containing five logical

drives spread across five physical drives

Each logical drive in an array is distributed across all of the physical drives within the

array. A logical drive can also extend across more than one port on the same

controller, but it cannot extend across more than one controller.

Drive failure, although rare, is potentially catastrophic. In Figure D-4, for example,

failure of any physical drive causes all logical drives in the same array to fail, and all

data on the drives is lost.

To protect against data loss due to physical drive failure, logical drives are

configured with fault tolerance. There are several fault-tolerance methods; those that

are described in this appendix are:

• RAID 0—Data Striping only (no fault tolerance)

• RAID 1+0—Drive Mirroring

• RAID 5—Distributed Data Guarding

• RAID ADG—Advanced Data Guarding

D-4 HP Smart Array 641/642 Controller User Guide

Page 50

For any configuration except RAID 0, further protection against data loss can be

achieved by assigning a drive as an online spare (or hot spare). This drive contains

no data and is connected to the same controller as the array. When any other physical

drive in the array fails, the controller automatically rebuilds information that was

originally on the failed drive to the online spare. The system is quickly restored to

full RAID-level data protection. (However, in the unlikely event that another drive in

the array fails while data is being rewritten to the spare, the logical drive will still

fail.)

When you configure an online spare, it is automatically assigned to all logical drives

in the same array. Additionally, you do not need to assign a separate online spare to

each array; you can configure one hard drive to be the online spare for several arrays,

as long as the arrays are all on the same controller.

Fault-Tolerance Methods

RAID 0—No Fault Tolerance

This configuration (refer to Figure D-3) provides data striping, but there is no

protection against data loss when a drive fails. However, it is useful for rapid storage

of large amounts of non-critical data (for printing or image editing, for example), or

when cost is the most important consideration.

Drive Arrays and Fault Tolerance

Advantages

• Highest performance method for writes

• Lowest cost per unit of stored data

• All drive capacity is used to store data (none needed for fault tolerance)

Disadvantages

• All data on the logical drive is lost if a physical drive fails

• Cannot use an online spare

• Can only preserve data by backing it up to external drives

HP Smart Array 641/642 Controller User Guide D-5

Page 51

Drive Arrays and Fault Tolerance

RAID 1+0—Drive Mirroring

In this configuration, data is duplicated to a second drive.

B1

B2

B3

B4

P1 P2

B1

B2

B3

B4

Figure D-5: Drive mirroring of P1 to P2

When the array has more than two physical drives, drives are mirrored in pairs.

S1

S2

B1

B5

P1

P5

B2

B6

P2

P6

B3

B7

P3

P7

B4

B8

P4

P8

S1

S2

B1

B5

B2

B6

B3

B7

B4

B8

Figure D-6: Mirroring with more than two physical

drives in the array

D-6 HP Smart Array 641/642 Controller User Guide

Page 52

In each mirrored pair, the physical drive that is not busy answering other requests

answers any read request sent to the array. (This behavior is called load balancing.)

If a physical drive fails, the remaining drive in the mirrored pair can still provide all

the necessary data. Several drives in the array can fail without incurring data loss, as

long as no two failed drives belong to the same mirrored pair.

This fault-tolerance method is useful when high performance and data protection are

more important than the cost of physical drives.

NOTE: When there are only two physical drives in the array, this fault-tolerance method is

often referred to as RAID 1.

Advantages

• Highest read and write performance of any fault-tolerant configuration

• No loss of data as long as no failed drive is mirrored to another failed drive (up to

half of the physical drives in the array can fail)

Disadvantages

• Expensive (many drives needed for fault tolerance)

Drive Arrays and Fault Tolerance

• Only half of total drive capacity usable for data storage

RAID 5—Distributed Data Guarding

By this method, a block of parity data is calculated for each stripe from the data that

is in all other blocks within that stripe. The blocks of parity data are distributed over

every physical drive within the logical drive (refer to Figure D-7). When a physical

drive fails, data that was on the failed drive can be calculated from the user data on

the remaining drives and the parity data. This recovered data is usually written to an

online spare in a process called a rebuild.

HP Smart Array 641/642 Controller User Guide D-7

Page 53

Drive Arrays and Fault Tolerance

Figure D-7: Distributed data guarding, showing parity

information (Px,y)

This configuration is useful when cost, performance, and data availability are equally

important.

Advantages

• High read performance

• No loss of data if one physical drive fails

• More drive capacity usable than with RAID 1+0—parity information requires

only the storage space equivalent to one physical drive

S1

S2

S3

S4

B1

B3

P5,6

B7

B2

P3,4

B5

B8

P1,2

B4

B6

P7,8

Disadvantages

• Relatively low write performance

• Loss of data if a second drive fails before data from the first failed drive is rebuilt

D-8 HP Smart Array 641/642 Controller User Guide

Page 54

RAID ADG—Advanced Data Guarding

NOTE: Not all controllers support RAID ADG.

RAID ADG is similar to RAID 5, because both methods generate and store parity

information to protect against data loss caused by drive failure. With RAID ADG,

however, two different sets of parity data are used, allowing data to still be preserved

if two drives fail. Each set of parity data uses up a capacity equivalent to that of one

of the constituent drives, as shown in Figure D-8.

Drive Arrays and Fault Tolerance

Figure D-8: Advanced data guarding (RAID ADG)

This method is most useful when data loss is unacceptable, but cost is also an

important factor. The probability that data loss will occur when arrays are configured

with RAID ADG is less than when they are configured with RAID 5 (for details,

refer to Appendix F).

Advantages

• High read performance

• High data availability—any two drives can fail without loss of critical data

• More drive capacity usable than with RAID 1+0—parity information requires

only the storage space equivalent to two physical drives

B1

B3

P5,6

Q7,8

B2

P3,4

Q5,6

B7

P1,2

Q3,4

B5

B8

Q1,2

B4

B6

P7,8

HP Smart Array 641/642 Controller User Guide D-9

Page 55

Drive Arrays and Fault Tolerance

Disadvantage

The main disadvantage of RAID ADG is a relatively low write performance (lower

than RAID 5), because of the need for two sets of parity data.

Comparison of RAID Methods

Table D-1 summarizes the important features of the different kinds of RAID methods

described here. The decision chart in Table D-2 may help you to determine which

option is best for your situation.

Table D-1: Summary of RAID Methods

RAID 0 RAID 1+0 RAID 5 RAID ADG*

Alternative name Striping (no

fault tolerance)

Usable drive space** 100% 50% 67% to 93% 50% to 96%

Usable drive space

formula

Minimum number of

physical drives

Tolerates failure of

one physical drive?

Tolerates

simultaneous failure

of more than one

physical drive?

Read performance High High High High

Write performance High Medium Low Low

Relative cost Low High Medium Medium

*Not all controllers support RAID ADG.

**Values for usable drive space are calculated with these assumptions: (1) all physical drives in the

array have the same capacity; (2) online spares are not used; (3) no more than 14 physical drives

are used per array for RAID 5; (4) no more than 56 drives are used with RAID ADG.

n n/2 (n-1)/n (n-2)/n

1 2 3 4

No Yes Yes Yes

No Only if no two

Mirroring Distributed

Data Guarding

No Yes

failed drives are

in the same

mirrored pair

Advanced Data

Guarding

D-10 HP Smart Array 641/642 Controller User Guide

Page 56

Table D-2: Choosing a RAID Method

Most Important Also Important Suggested RAID Level

Fault tolerance Cost effectiveness RAID ADG*

I/O performance RAID 1+0

Cost effectiveness Fault tolerance RAID ADG*

I/O performance

Fault tolerance RAID 1+0

*Not all controllers support RAID ADG.

I/O performance

Cost effectiveness

Other Fault-Tolerance Options

Your operating system may also support software-based RAID or controller

duplexing.

Drive Arrays and Fault Tolerance

RAID 5 (RAID 0 if fault

tolerance is not required)

RAID 5 (RAID 0 if fault

tolerance is not required)

• Software-based RAID resembles hardware-based RAID, except that the

operating system works with logical drives as if they were physical drives. To

protect against data loss caused by physical drive failure, each logical drive must

be in a different array from the others.

• Controller Duplexing uses two identical controllers with independent, identical

sets of drives containing identical data. In the unlikely event of a controller

failure, the remaining controller and drives will service all requests.

However, the hardware-based RAID methods described in this appendix provide a

much more robust and controlled fault-tolerant environment. Additionally, controller

duplexing and software-based RAID do not support online spares, auto-reliability

monitoring, interim data recovery, or automatic data recovery.

If you decide to use one of these alternative fault-tolerance options, configure your

arrays with RAID 0 for maximum storage capacity and refer to your operating system

documentation for further implementation details.

HP Smart Array 641/642 Controller User Guide D-11

Page 57

Hard Drive Installation and Replacement

Each drive on a SCSI bus must have a unique ID value in the range 0 to 15 (except

ID 7, which is reserved for controller use). This SCSI ID value is set automatically on

hot-pluggable drives in ProLiant servers and storage systems, but values for other

drives must be set manually.

• Do not terminate the drives. The internal cabling in ProLiant servers provides the

required termination of the SCSI bus.

• Do not use drives of different capacity in the same array. The excess capacity of

larger drives cannot be used by the array and is wasted.

• Do not use hot-pluggable drives on the same SCSI bus as non-hot-pluggable

drives.

Drives can be of the Ultra2, Ultra160 (Ultra3), or Ultra320 (Ultra4) type.

General Information About Hard Drive Failure

E

When a hard drive fails, all logical drives that are in the same array are affected. Each

logical drive in an array may be using a different fault-tolerance method, so each

logical drive can be affected differently.

• RAID 0 configurations cannot tolerate drive failure. If any physical drive in the

array fails, all non-fault-tolerant (RAID 0) logical drives in the same array will

also fail.

• RAID 1+0 configurations can tolerate multiple drive failures as long as no failed

drives are mirrored to one another.

• RAID 5 configurations can tolerate one drive failure.

HP Smart Array 641/642 Controller User Guide E-1

Page 58

Hard Drive Installation and Replacement

• RAID ADG configurations can tolerate simultaneous failure of two drives.

If more hard drives fail than the fault-tolerance method allows, fault tolerance is

compromised and the logical drive fails. In this case, all requests from the operating

system are rejected with unrecoverable errors. The “Compromised Fault Tolerance”

section discusses possible ways to recover from this situation.

Recognizing Drive Failure

The LEDs on the front of each hard drive are visible through the front of the server or

external storage unit. When a drive is configured as a part of an array and attached to