Page 1

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

FOR

METER, AUDIO LEVEL TA-885/U

(HEWLETT-PACKARD MODEL 3555B)

(NSN 6625-00-255-1083)

TM 11-6625-2779-14&P

HEADQUARTERS, DEPARTMENT OF THE ARMY

11 MARCH 1980

Page 2

TM 11-6625-2779-14&P

This manual contains copyrighted material reproduced by permission of Hewlett-Packard Company. All rights are

reserved.

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY.

No. 11-6625-2779-14&P WASHINGTON, DC, 11 March 1980

OPERATOR'S, ORGANIZATIONAL, DIRECT SUPPORT AND GENERAL

SUPPORT MAINTENANCE MANUAL (INCLUDING REPAIR PARTS AND

SPECIAL TOOLS LISTS) FOR

METER, AUDIO LEVEL TA-885/U

(HEWLETT-PACKARD MODEL 3555B)

(NSN 6625-00-255-1083)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to

improve the procedures, please let us know. Mail your letter or DA Form 2028 (Recommended

Changes to Publications and Blank Forms), or DA Form 2028-2 located in back of this manual

direct to Commander, US Army Communications and Electronics Materiel Readiness Command,

ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703.

In either case, a reply will be furnished direct to you.

This manual is an authentication of the manufacturer's commercial literature which, through usage, has been found to

cover the data required to operate and maintain this equipment. The manual was not prepared in accordance with

military specifications; therefore, the format has not been structured to consider categories of maintenance.

SECTION 0. INTRODUCTION

Scope ...............................................................................................................................0-1 0-1

Indexes of Publications .....................................................................................................0-2 0-1

Maintenance forms, records, and reports...........................................................................0-3 0-1

Administrative storage.......................................................................................................0-4 0-2

Destruction of Army electronics materiel............................................................................0-5 0-2

Reporting of equipment improvements recommendations (EIR).........................................0-6 0-2

Items comprising an operable equipment ..........................................................................0-7 0-3

I. GENERAL INFORMATION

Introduction.......................................................................................................................1-1 1-1

Accessory equipment supplied..........................................................................................1-9 1-2

Instrument identification....................................................................................................1-11 1-2

150 BAL modification........................................................................................................1-13 1-2

II. INSTALLATION

Inspection.........................................................................................................................2-1 2-1

Warranty exception...........................................................................................................2-3 2-1

Power requirements..........................................................................................................2-5 2-1

Three-conductor power cable ............................................................................................2-7 2-1

Battery..............................................................................................................................2-10 2-1

Installation and removal of battery.....................................................................................2-12 2-2

Cover removal...................................................................................................................2-15 2-2

Repackaging for shipment.................................................................................................2-17 2-2

III. OPERATING INSTRUCTIONS

Introduction.......................................................................................................................3-1 3-1

Controls, connectors and indicators...................................................................................3-4 3-1

Operation..........................................................................................................................3-6 3-1

Battery..............................................................................................................................3-8 3-1

Level and noise measurements.........................................................................................3-12 3-5

Level measurements.........................................................................................................3-14 3-5

Noise measurements ........................................................................................................3-28 3-7

Recorder compatibility.......................................................................................................3-41 3-8

Applications......................................................................................................................3-45 3-8

Transmission loss measurements.....................................................................................3-48 3-10

Para Page

i

Page 3

SECTION III. OPERATING INSTRUCTIONS (Cont.). Para Page

Crosstalk measurements...................................................................................................3-53 3-10

Identifying noise characteristics.........................................................................................3-57 3-10

Measurements in DBC ......................................................................................................3-64 3-11

Measurement procedures..................................................................................................3-67 3-12

150 BAL conversion..........................................................................................................3-69 3-12

IV. THEORY OF OPERATION

Introduction.......................................................................................................................4-1 4-1

Block diagram description.................................................................................................4-7 4-1

Detailed circuit description.................................................................................................4-16 4-2

Range attenuator A2.........................................................................................................4-18 4-3

Input amplifier A3..............................................................................................................4-20 4-3

Filters................................................................................................................................4-25 4-4

Meter amplifier..................................................................................................................4-30 4-7

Detector............................................................................................................................4-32 4-7

Power supply and series regulator.....................................................................................4-37 4-8

V. MAINTENANCE

Introduction.......................................................................................................................5-1 5-1

Factory selected values.....................................................................................................5-4 5-1

150 BAL conversion..........................................................................................................5-6 5-1

Performance Checks.........................................................................................................5-7 5-2

Adjustment and calibration procedure................................................................................5-14 5-8

Assembly removal.............................................................................................................5-25 5-10

Troubleshooting procedures..............................................................................................5-27 5-10

Factory selected values.....................................................................................................5-39 5-15

VI. REPLACEABLE PARTS

Introduction.......................................................................................................................6-1 6-1

Ordering information.........................................................................................................6-4 6-1

VII. CIRCUIT DIAGRAMS

Introduction.......................................................................................................................7-1 7-1

Functional block diagrams.................................................................................................7-3 7-1

Schematic diagrams .........................................................................................................7-5 7-1

APPENDIX A. REFERENCES.................................................................................................................. A-1

APPENDIX B. MAINTENANCE ALLOCATION

SECTION I. Introduction....................................................................................................................... B-1

Il. Maintenance allocation chart for Meter, Audio Level TA-885/U........................................... B-3

III. Tool and test equipment requirements for Meter, Audio Level TA-883/U ............................ B-4

IV. Remarks (Not applicable)

APPENDIX C. MANUAL BACKDATING CHANGES.................................................................................. C-1

ii

Page 4

Model 3555B Table of Contents

LIST OF ILLUSTRATIONS

Number Page Number Page

1-1.Model 3555B Transmission and

Noise Measuring Set..................................1-1 4-7.Simplified Peak Detection................................4-7

2-1.Power Plugs.................................................2-1 5-1.Balanced BNC to 310 Plug..............................5-2

3-1.Front Panel Controls, Indicators, 5-2.Level Accuracy Check.....................................5-2

and Connectors.........................................3-2 5-3.+20dBm and +30dBm Level

3-2.Side Panel Controls and Connectors.............3-4 Accuracy Check............................................5-4

3-3.Impedance Matching 3555B to Recorder......3-8 5-4.Return Loss Test Set-Up..................................5-5

3-4.Recorder Compatibility Chart........................3-9 5-5.Filter Response Test Set-Up............................5-5

3-5.Simplified Send/Receive Test Set-Up...........3-9 5-6.Bridging Loss Test Set-Up...............................5-6

3-6.Typical Test Set-Up for Measuring 5-7.Input Balance Test Set-Up...............................5-7

Insertion Loss..........................................3-10 5-8.Troubleshooting Tree.....................................5-11

3-7.Test Set-Up for Measuring 7-1.Functional Block Diagram..........................7-3/7-4

Crosstalk Coupling Loss..........................3-11 7-2.A1 Function Assembly Schematic and

3-8.Simple Test for Inductive and Component Location...............................7-5/7-6

Capacitive Coupling.................................3-12 7-3.A2 Range Attenuator and A3 Input

4-1.Simplified Block Diagram..............................4-1 Amplifier Schematic and Component

4-2.Simplified DIAL BAT Function......................4-2 Location..................................................7-7/7-8

4-3.Simplified NG Function.................................4-3 7-4.A4 Filter Schematic and Component

4-4. Simplified Average Detection........................4-4 Location................................................7-9/7-10

4-5.3kHz FLAT and PROGRAM 7-5.A3 Meter Amplifier, Detector and Series

Weighting Curves......................................4-5 Regulator Schematic and Component

4-6.C-MSG and 15kHz FLAT Locations............................................7-11/7-12

Weighting Curves......................................4-6

LIST OF TABLES

Number Page Number Page

1-1 Specifications...............................................1-0 5-1 Required Test Equipment................................5-1

1-2 Accessory Equipment Supplied.....................1-2 5-2 75 UNBAL Carrier Accuracy Check..................5-3

2-1 Suitable Batteries Meeting 5-3 Carrier 600 BAL and 135 BAL Level

NEDA 202 Specifications...........................2-1 Accuracy Check............................................5-3

3-1 Front, Side and Rear Panel Controls, 5-4 VF/Nm Level Accuracy Checks 600 BAL

Indicators and Connectors...................3-3/3-5 and 900 BAL -80 dBm Through +30 dBm.....5-4

3-2 Crosstalk Correction Factor........................3-10 5-5 Filter Response Checks...................................5-6

3-3 Level Measurement....................................3-13 5-6 Front Panel Trouble Analysis.................5-12/5-13

3-4 Noise Metallic Measurements.....................3-13 5-7 Function Troubleshooting...............................5-14

3-5 Noise-to-Ground Measurements.................3-14 5-8 FUNCTION Switch Resistance Values...........5-15

3-6 Balance Measurement................................3-14 5-9 Range Attenuation and Amplifier Gain...........5-16

3-7 Recorder Calibration...................................3-14 5-10 Resistance Checks........................................5-16

3-8 Transmission Loss Measurement................3-14 5-11 Factory Selected Values................................5-16

4-1 Range Attenuation and Amplifier Gain..........4-4 6-1 Replaceable Parts...........................................6-2

6-2 Part Number-National Stock Number

Cross Reference Index...............................6-10

iii

Page 5

SECTION 0

INTRODUCTION

0-1. Scope

This manual contains instructions for the operation, organizational maintenance and general support maintenance of

Audio Level Meter TA-885/U. Throughout this manual, the equipment is referred to by its commercial designation of

Hewlett-Packard Model 3555B Transmission and Noise Measuring Set or simply as the 3555B. Appendix A of the

manual contains a list of references and appendix B contains the maintenance allocation chart (MAC).

NOTE

No direct support maintenance functions are authorized for this equipment.

0-2. Indexes of Publications

a. DA Pam 310-4. Refer to the latest issue of DA Pam 310-4 to determine if there are any new editions,

changes, or additional publications pertaining to this equipment.

b. DA Pam 310-7. Refer to DA Pam 310-7 to determine if there are any modification work orders (MWO's)

pertaining to this equipment.

0-3. Maintenance Forms, Records, and Reports

a. Reports of Maintenance and Unsatisfactory Equipment. Department of the Army forms and procedures

used for equipment maintenance will be those described by TM 38-750, The Army Maintenance Management System.

0-1

Page 6

b. Report of Packaging and Handling Deficiencies. Fill out and forward DD Form 6 (Packaging Improvement

Report) as prescribed in AR 700-58/NAVSUPINST 4030.29/AFR 71-13/MCO P4030.29A, and DLAR 4145.8.

c. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward Discrepancy in Shipment Report

(DISREP) (SF 361) as prescribed in AR 55-38/NAVSUPINST 4610.33B/AFR 75-18 MCO P4610.19C and DLAR 4500.15.

0-4. Administrative Storage

Before placing the TA-885/U in temporary storage (90 days), determine the serviceability of the equipment by

performing the checks in paragraphs 5-7 through 5-13.

0-5. Destruction of Army Electronics Materiel

Destruction of Army electronics materiel shall be in accordance with the instructions in TM 750-244-2.

0-6. Reporting Equipment Improvement Recommendations (EIR)

If your TA-885/U needs improvement, let us know. Send us an EIR. You, the user, are the only one who can tell

us what you don't like about your equipment. Let us know why you don't like the design. Tell us why a procedure is hard

to perform. Put it on an SF 368 (Quality Deficiency Report). Mail it to Commander, US Army Communications and

Electronics Materiel Readiness Command, ATTN: DRSEL-ME MQ, Fort Monmouth, New Jersey 07703. We'll send you

a reply.

0-2

Page 7

0-7. Items Comprising an Operable Equipment

Audio Level Meter TA-885/U includes the meter, with cover and a power cord. The power cord is stored inside

the cover of the set.

0-3

Page 8

Section I Model 3555B

Table 1-1. Specifications

VOICE FREQUENCY LEVEL MEASUREMENTS (20Hz balanced and 75 ohms unbalanced.

to 20kHz) Return loss: TERM ONLY

600 ohms: 26dB min 3kHz to 150kHz

Range: -91dBm to +31dBm 135 ohms: 26dB min to 600kHz

75 ohms: 30dB min to 3MHz

Level accuracy: 20Hz to 20kHz: +0.5dB Bridging loss: less than 0.05dB at 10kHz

40Hz to 15kHz: +-0.2dB Balance:

(Levels greater than -60dBm) greater than 70dB to 10kHz

Note: For levels greater than +1 dBm, level accuracy greater than 60dB to 100kHz

specification applies only for frequencies above greater than 40dB to 600kHz

100Hz.

GENERAL

Input: will terminate or bridge 600 ohms or 900 ohms Temperature range: 0°F to 120°F 0 to 95% relative

balanced. humidity

Bridging loss: less than 0.3 dB at 1kHz. The 3555B will operate at -40°F under reduced

Return loss: 30dB min. (50Hz to 20kHz) TERM specifications. At this temperature, attention

Return loss: 30dB min. (50Hz to 2kHz) TERM should be given to noting condition of battery as

only. indicated on Battery Test (DIAL/BAT).

Balance:

greater than 80dB at 60Hz Meter: linear dB scale indicates rms value of input

greater than 70dB to 6kHz signal. 12dB range.

greater than 50dB to 20kHz Meter response

Holding circuit: 700 ohms dc resistance, 60mA Normal: 200ms to indicate a reading to 0dBm on

max. loop current at 300Hz. With holding circuit meter.

in, above specs apply from 300Hz to 4kHz. Damp: 500ms to indicate a reading to 0dBm on

meter.

NOISE MEASUREMENTS

Maximum input voltage

Range: -1 dBm to +121dBm Tip to ring: 150V peak

Tip or ring to ground: 500V peak

Weighting filters: 3kHz flat, 15kHz flat, C-message, and (This is maximum instantaneous voltage. Input

program. Meets joint requirements of Edison circuit will withstand 48V dc CO battery with

Electric Institute and Bell Telephone System. superimposed 90V rms 20Hz ringing voltage or

±130V carrier supply.)

Input: same as for level measurements.

Maximum longitudinal voltage: 200V rms at 60Hz

Noise to ground:

80 kilohms across line AC Monitor: 0.27V rms for 0dBm on meter.

100 kilohms to ground R

-40dB relative to 600 ohms noise metallic at jacks. Sufficient to drive WE 1011B or 52 type

1kHz. headset.

DC Monitor: 1 volt for 0dBm on meter. R

CARRIER FREQUENCY LEVEL MEASUREMENTS kilohms. Jack accepts 310 plug (tip negative).

(30Hz to 3MHz)

Input jacks: will accept Western Electric (WE) 241,

Range: -61dBm to +11dBm 309, 310, 358 plugs. Binding posts accept banana

Level accuracy: Removable shorting bar between sleeve and

600 ohms balanced ground binding posts.

1kHz to 150kHz: ±0.5dB Dial/AC Monitor jacks: will accept WE 289, 310, 347

135 ohms balanced (or 150 ohms balanced) plugs. Accepts WE 1011B lineman's handset or

1kHz to 600kHz: ±0.5dB 52 type headset.

10kHz to 300kHz: ±0.2dB

75 ohms unbalanced Power requirements:

100Hz to 600kHz: ±0.2dB Internal battery: single NEDA 202 45V "B"

30Hz to 1MHz: ±0.5dB battery included. Expected battery life - 180

1MHz to 3MHz: ±0.5dB ±10% of meter reading hours at 4 hours per day at 70° F.

in dBm. AC: 115V or 230V, 48-440Hz, <1W

Input: will terminate or bridge 600 ohms or 135 ohms accepts 310 plug (tip negative) less than 15mA.

= 8 kilohms. Available at DIAL/AC MON

out

= 2

out

plugs, spade lugs, phone tips or bare wires.

External battery: 24V or 48V office battery; jack

1-0

Page 9

Model 3555B Section I

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION.

1-2. The Hewlett-Packard Model 3555 B

Transmission and Noise Measuring Set is a versatile set

designed for uses in testing telecommunications

equipment. The extreme sensitivity of this set, linked

with its wide and flat frequency response, make it

suitable for noise and level measurements at voice,

program and carrier frequencies. Levels from -80dBm

to +30dBm (10dBm to +120dBm) full-scale can be

measured and displayed on a meter calibrated to

indicate both in dBm for level measurements and in

dBm for noise measurements.

1-3. The set combines the features of a voice and

noise frequency measuring set and the features of a

carrier frequency measuring set. For voice and program

frequencies impedances of 900 ohms and 600 ohms are

provided, balanced or unbalanced, bridged or

terminated. For noise measurements a noise-to-ground

(Ng) function is provided which provides 40dB of

attenuation for longitudinal noise. For carrier

frequencies 600 ohm, 135 ohm and 75 ohm impedances

are provided. The 600 and 135 function can be either

balanced or unbalanced, bridged or terminated; The 75

function is unbalanced only. Bridging impedance is over

100 kilohms, allowing measurements with a bridging

loss of less than 0.05dB. The meter indicates in dBm

for any selected input impedance.

1-4. The 3555B includes a 3kHz flat, a C-Message, a

Program and a 15kHz flat filter, each easily selectable

by a front panel control. These filters conform to the

standards set up .by the Bell System and Edison Electric

Institute. Other filters are available upon request.

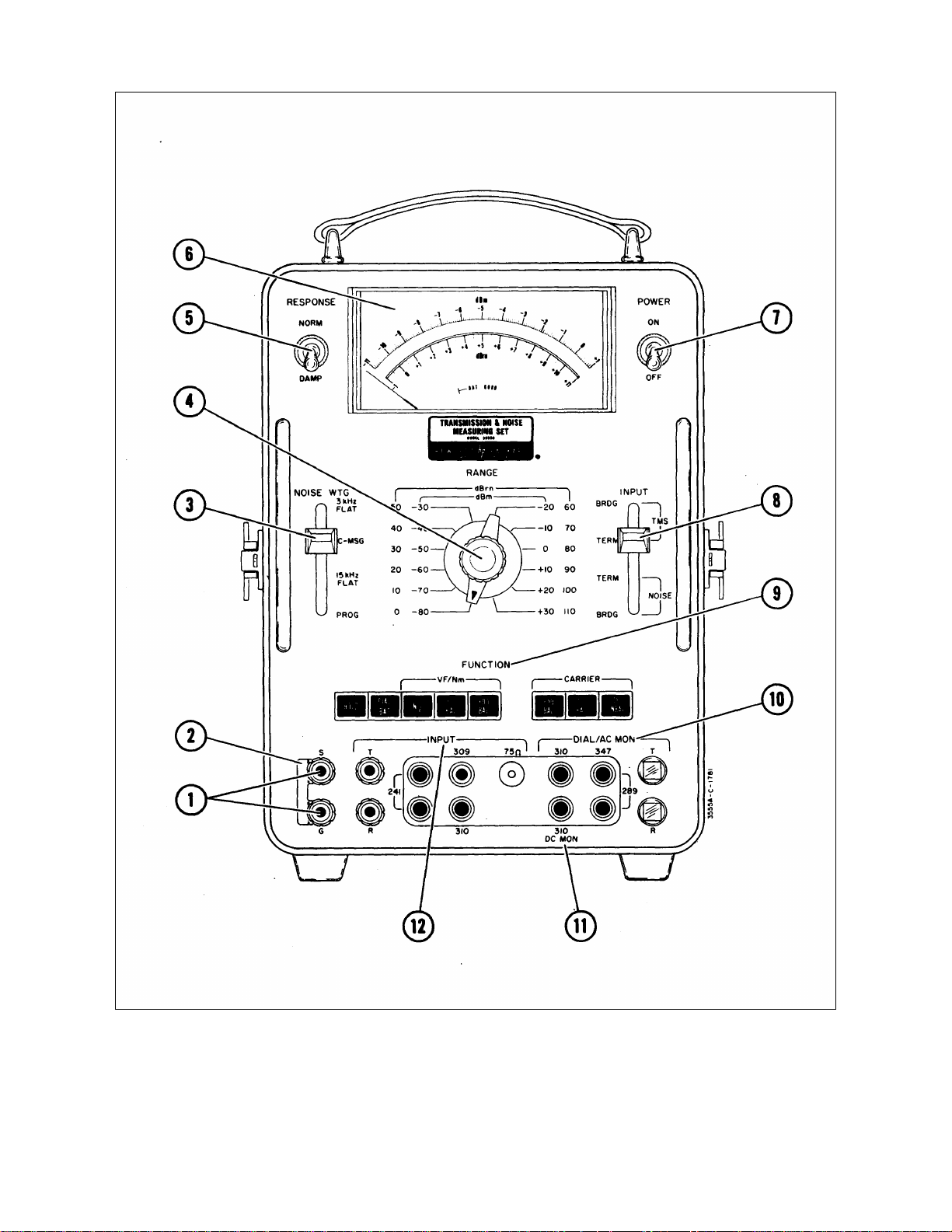

Figure 1-1. Model 3555B Transmission and Noise Measuring Set

1-1

Page 10

Section I Model 3555B

1-5. A noise-to-ground (Ng) function is included

which permits the measurement of longitudinal noise.

When making noise-to ground measurements the

impedance between INPUT terminals is greater than 80

kilohms and is 100 kilohms between each terminal and

ground. A HOLD function permits holding the line while

noise measurements are being made. The input

circuitry provides 40dB of longitudinal noise attenuation

when noise-to-ground measurements are being made.

1-6. A DIAL/BAT function permits connecting a

lineman's handset to the line for the purpose of dialing

and at the same time connects the front panel meter to

the power supply so that the battery voltage or

unregulated power supply voltage can be monitored.

1-7. Jacks accepting Western Electric type 241, 309,

310, 347, and 358 plugs are provided for INPUT

connections to the 3555B. Dual binding posts accept

banana plugs, wires, lugs or phone tips and a pair of

special connectors permit the attachment of clip leads

from a lineman's handset.

1-8. The Model 3555B can be operated from either

the internal 45V dry cell battery or from the ac line, 115

or 230Vac, 48Hz to 440Hz. A special device is included

in the cover to automatically turn the set off when the

cover is replaced. The set can also be operated from

the central office battery. A jack is provided on the side

of the set for this purpose.

1-9. ACCESSORY EQUIPMENT SUPPLIED.

1-10. The accessory equipment supplied with the

Model 3555B is listed in Table 1-2.

Table 1-2. Accessory Equipment Supplied

-hp- Part No. Description Quantity

8120-1348 Power Cord 1

1470-0026 Battery, 45 Volt dry cell 1

03555-26510 Test Board 1

5000-7135 Decal, 150 BAL 1

1-11. INSTRUMENT IDENTIFICATION.

1-12. Hewlett-Packard uses a two-section serial

number. The first section (prefix) identifies a series of

instruments. The last section (suffix) identifies a

particular instrument within the series. If a letter is

included with the serial number, it identifies the country

in which the instrument was manufactured. If the serial

prefix of your instrument differs from the one on the title

page of this manual, a change sheet will be supplied to

make this manual compatable with newer instruments or

the backdating information in Appendix C will adapt this

manual to earlier instruments. All correspondence with

Hewlett-Packard should include the complete serial

number.

1-13. 150 BAL MODIFICATION.

1-14. The Model 3555B is shipped from the factory

with a 135 BAL function. If a 150 BAL function is

desired instead of the 135 BAL function, the set can be

converted by simply clipping a shorting wire within the

set, applying a 150 BAL decal (supplied with the set)

over the 135 BAL decal and making only one

adjustment.

1-15. For detailed instructions on modification of the

set refer to Paragraph 5-6. If your set is known to be

within specification tolerances a simplified procedure

can be used to modify the set and is described in

Paragraph 3-69.

1-2

Page 11

Model 3555B Section II

SECTION II

INSTALLATION

2-1. INSPECTION.

2-2. The set was carefully inspected both

mechanically and electrically before shipment. It should

be physically free of mars or scratches and in perfect

electrical condition on receipt. To confirm this, the set

should be inspected for physical damage in transit, for

supplied accessories and for electrical performance.

Paragraph 5-7 outlines the electrical performance

checks using test equipment listed in Table 5-1. If there

is damage or deficiency, see the warranty in the front of

this manual.

2-3. WARRANTY EXCEPTION.

2-4. The battery supplied with the 3555B is

warranted for a period of 60 days, beginning at the time

of receipt of the set. This warranty is based on an

expected battery life of 180 hours at 4 hours per day at

700 F as specified in Table 1-1 in this Manual.

2-5. POWER REQUIREMENTS.

2-6. This set is designed to operate from an internal

45 volt dry cell battery, an external 24 to 48 volt CO

battery or from an ac power source (115/230V, 48 to

440Hz). The power source is selected by the AC/BAT

switch on the side of the, set. The line voltage is

selected by the 115/230 volt slide switch on the rear of

the set. The set is protected by a 0.1 5A slow-blow fuse.

Table 2-1. Suitable Batteries Meeting

NEDA 202 Specifications

Manufacturer Mfr. Part No.

Hewlett-Packard 1420-0026

Western Electric KS-14370

Military BA-59

Eveready 482

Burgess M-30

RCA VS013

Bright Star 3033-158, 30-33

Mallory M-202

Ray-O-Vac 202, P7830

Sears 6461

Wards 42

Wizard 3B6241

Zenith 2783

General W30B

Marathon 4202

National Carbon 482

2-10. BATTERY.

2-11. This set is operated from a single NEDA 202

45V dry cell internal battery or an external 48V CO

battery when the power selection switch, on the side of

the case, is in the DIAL/BAT position. Inserting a

Western Electric plug into the battery jack disconnects

the internal battery. (See Table 2-1 for batteries

suitable for use in this instrument.

2-7. THREE-CONDUCTOR POWER CABLE.

2-8. To protect operating personnel, the National

Electrical Manufacturers' Association (NEMA)

recommends that the panel and cabinet be grounded.

This set is equipped with a three-conductor power cable

which, when plugged into an appropriate receptacle,

grounds the set. The offset pin on the power cable

three-prong connector is the ground wire. This power

cable is detachable from the set and is stored inside the

front cover.

2-9. Figure 2-1 illustrates the standard power plug

configurations that are used throughout the United

States and in other countries. The -hp- part number

shown directly below each plug drawing is the part

number for a 3555B power cord equipped with the

proper plug. If the appropriate power cord is not

included with the instrument, notify the nearest HewlettPackard office and a replacement cord will be provided.

Figure 2-1. Power Plugs.

2-1

Page 12

Section II Model 355B

2-12. INSTALLATION AND REMOVAL OF

BATTERY.

2-13. To install or replace a battery, turn the four 1/4

turn fasteners on the battery cover on the rear of the

case counterclockwise to remove the cover. Lift off the

cover, lift the battery out of its recess and unplug the

three-prong connector.

2-14. Reverse the above procedure when installing a

new battery.

2-15. COVER REMOVAL.

2-16. To remove the cover from the instrument,

release the two spring latches on either side of the

instrument, then lift cover. When replacing the cover,

first check the latches for released position; then place

cover in position for latching. The power cord is stored

inside the cover by wrapping it around the retainer

fastened inside the cover.

CAUTION

DO NOT FORCE COVER INTO

PLACE. THERE IS A PROJECTION

ON THE COVER WHICH TURNS THE

POWER SWITCH TO THE OFF

POSITION TO PRESERVE BATTERY

LIFE. IF THIS IS NOT BINDING, THE

COVER FITS EASILY INTO PLACE.

2-17. REPACKAGING FOR SHIPMENT.

2-18. The following is a general guide for repackaging

at instrument for shipment. If you have any questions,

contact your local Sales and Service Office. (See

Appendix for locations.)

a. Place instrument in original container if

available. If not available, one can be

purchased from your nearest -hp- Sales

and Service Office.

b. Wrap instrument in heavy paper or plastic

before placing in inner container.

c. Use plenty of packing material around all

sides of instrument.

d. Use a heavy carton or wooden box to

house the instrument and inner container

and use strong tape or metal bands to seal

the shipping container.

e. Mark shipping container with "Delicate

Instrument" or "Fragile".

2-2

Page 13

Section III Model 3555B

SECTION III

OPERATING INSTRUCTIONS

3-1. INTRODUCTION.

3-2. The Model 3555B Transmission and Noise

Measuring Set is an extremely versatile transmission and

noise measuring set which satisfies many of the

requirements in testing telecommunications equipment.

The 3555B features a choice of 900 or 600 ohms bridging

or terminated for voice frequencies and 600, 135 or 75

ohms bridging or terminate for carrier frequencies. Noiseto-ground and noise Metallic may be measured with 3kHz

Flat, C-Message or 1 5kHz Flat weighting. A HOLD

function permits seizing the line while measurements are

being made at voice and program frequencies. The set is

portable and operates from the internal battery, office

battery or ac power source.

3-3. This section of the manual contains all the

information necessary in the operation of the 3555B along

with a description of all controls, connectors and

indicators.

3-4. CONTROLS, CONNECTORS AND

INDICATORS.

3-5. Figure 3-1, 3-2 and Table 3-1 illustrate and

describe the function of all front and side panel controls,

indicators and connectors.

3-6. OPERATION.

3-7. To operate the Model 3555B, refer to figure 3-1

and perform the following steps:

a. Before connecting the 3555B to an ac power

source, insure that the 115/230 volt switch is

positioned to indicate the line voltage to be

used. Some earlier instruments did not have

the 115/230 volt selector switch. To change

these instruments, jumper wires must be

changed on the power transformer. Refer to

Appendix C for a wiring diagram of the two

configurations.

b. If the set is to be operated from the internal

battery or from an external office battery,

place the AC/BAT switch (located on the side

of the set) to the BAT position, using a small

pointed object; if the set is to be operated

from the ac line, place the AC/BAT switch to

the AC position. For operation from a 24 or

48V office battery, connect a patch cord with

a Western Electric 310 plug to the battery

jack on the side of the case and then connect

the cord to the office battery on the test

board or bay. Inserting the plug disconnects

the internal battery. The office battery is

arranged for -48V or -24V ±2V with the

negative terminal of the battery connected to

the tip and the ground terminal connected to

the sleeve. Current consumption by the

3555B is approximately 15mA.

WARNING

DURING BATTERY OPERATION, THE

"G" BINDING POST MUST BE

CONNECTED TO EARTH GROUND.

CAUTION

THE CORD MUST BE CONNECTED TO

THE MEASURING SET BATTERY

JACK FIRST AND THEN PLUGGED

INTO THE BATTERY SUPPLY TO

AVOID SHORTING THE OFFICE

BATTERY TO GROUND.

c. Turn the POWER switch to ON and depress

the DIAL/BAT pushbutton on the FUNCTION

switch. The meter pointer should indicate in

the BAT GOOD area indicating that the

battery condition is good if the set is being

operated from the internal battery. The

meter will also monitor the ac supply voltage

or the external office battery voltage,

providing an indication of low voltage should

it exist. The voltage should cause meter

deflection above the lower end of the green

BAT GOOD area for proper set operation.

3-8. BATTERY.

3-9. The internal dry cell battery has a voltage range

between 45 volts when new to 24 volts at cut-off which is

the end of useful life. The cut-off voltage corresponds to

the left end of the green BAT GOOD area on the meter.

The condition of the battery and the approximate time to

cut-off can be estimated by observing the position of the

meter pointer in the BAT GOOD area.

3-10. The internal battery is of the carbon-zinc type with

its attendant limitations due to temperature. The service

obtained from carbon-zinc batteries depends on factors

such as current drain, discharge temperature, discharge

time and storage prior to use. The battery supplied with

the 3555B should provide in excess of 180 hours of

operation based on a 4 hours/day duty cycle at 77° F (25°

C). At other temperatures this time will change. At

temperatures above 131° F (55° C) the batteries may fail

suddenly while at temperatures below 40° F (-20° C), the

service life will be short.

3-1

Page 14

Section III Model 3555B

Figure 3-1. Front Panel Controls, Indicators, and Connectors

3-2

Page 15

Model 3555B Section III

Table 3-1. Front, Side and Rear Pane

(1) S and G Jacks: Binding posts accepting banana

plugs, spade lugs, phone tips or bare wires for

connection to the case ground (G) and sleeves (S)

of all INPUT jacks (12) and DIAL/AC MON jacks

(10) and (11).

(2) Shorting Strap: A swing-away shorting strap

connecting the S and G terminals together which

may be used to isolate the jack sleeves from case

ground. Not for use with type 347 plugs.

(3) WTG Switch: Selects weighting filters for noise

measurements. These filters are selectable only

when the INPUT switch is in one of the two NOISE

positions. The 3kHz FLAT, C-MSG, 15kHz FLAT

and PROG filters all conform to the standards set

up by the Bell System and Edison Institute for

measuring message circuit noise.

(4) RANGE SWITCH: Selects dBm or dBm ranges of

input sensitivity. The RANGE switch markings

correspond to the 0 markings on the meter scale

(6). The black markings are dBm for transmission

measurements and the blue markings are dBrn for

noise measurements.

(5) RESPONSE Switch: Selects NORM meter

response for transmission level measurements or

DAMP for noise measurements where noise is

impulsive in nature.

(6) Meter: A taut band individually calibrated meter

with shaped pole pieces to provide a linear dBm

indication with equal accuracy and resolution over

the entire meter scale. The dBm scale is marked

in black and has 0.1dB resolution for transmission

measurements. The 0 marking at the right end of

the scale corresponds to the black RANGE switch

setting. The dBm scale is marked in blue for noise

measurements. The 0 marking at the left end of

the scale corresponds to the blue RANGE switch

setting. The green arc marked BAT GOOD

corresponds to the green DIAL BAT pushbutton for

checking the power source. The left edge of the

arc corresponds to the battery cut-off voltage of 24

volts and the right edge (meter full-scale)

represents 60 volts which is the maximum voltage

that can be used to power the set without internal

damage.

(7) POWER ON/OFF Switch: turns on all power to the

set. The set operates from either 115 volts or 230

volts ac, the internal 45 volt dry cell battery or from

an external office battery supply.

(8) INPUT Switch: Selects TMS, either BRDG or

TERM for transmission measurements and NOISE,

either BRDG or TERM for noise measurements.

For noise measurements the switch must be in

Controls, Indicators and Connectors either the

NOISE BRDG or the NOISE TERM before the

NOISE WTG filters can be selected.

(9) FUNCTION Switch: A series of interlocking

pushbutton switches (with the exception of the

HOLD switch which is push-push type) with the

following functions:

a. VF/Nm

1. HOLD: Applies a dc holding bridge

across the metallic line for the NG, 900

and 600 functions. The HOLD

pushbutton is the push-push type, ie,

push to make and push to break. The

HOLD function cannot be

accomplished when any one of the

CARRIER pushbuttons is depressed.

2. DIAL/BAT: Connects the multiple

INPUT jacks in parallel with the

DIAL/AC MON jacks for the dial and

talk operation. The circuit is arranged

for loop dialing and the line under test

must supply talk battery. Connects the

meter circuit and a load to the internal

power supply to check the condition of

the battery, ac power or external office

battery as indicated on the green meter

scale. POWER (7) must be ON for the

battery test.

3. NG: Selects the noise-to-ground input

circuits for measuring longitudinal

noise. Attenuation of 40dB is inserted

by this circuit. Earth ground should be

connected to the black G binding post

(1)

4. 900: Selects the input circuitry for

balanced 900 ohm circuits. This

function selects a low frequency

transformer for voice frequencies.

Response of this transformer is 20Hz

to 20kHz.

5. 600: Selects the input circuitry for

balanced 600 ohm circuits. A low

frequency transformer is selected for

this function.

b. Carrier

1. 600: Selects the input circuitry for

balanced 600 ohm circuits. A high

frequency transformer is selected for

this function. Response of this

transformer is 1kHz to 600kHz. The

HOLD function is not operative in any

of the carrier functions.

3-3

Page 16

Section III Model 3555B

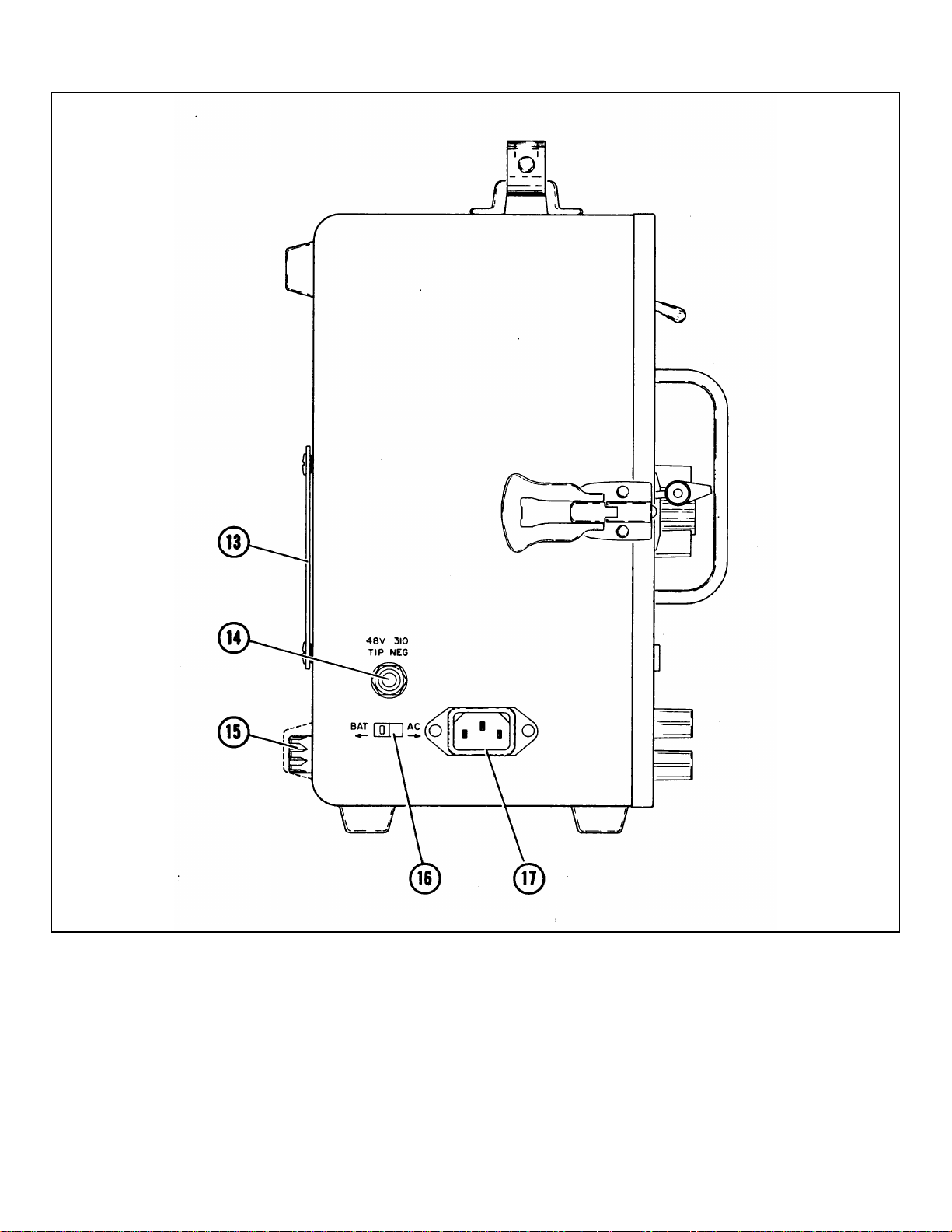

Figure 3-2. Side Panel Controls and Connectors

3-4

Page 17

Model 3555B Section III

Table 3-1. Front, Side and Rear Panel Controls, Indicators and Connectors (Cont’d)

2. 135: Selects the input circuitry for 135

ohm balanced circuits. A high

frequency transformer is selected for

this function.

3. 75: Selects the input circuitry for 75

ohm unbalanced operation. Only the

75 ohm jack can be used for this

function. This function does not utilize

an input transformer, therefore the

maximum bandwidth is available on

this function. This jack accepts a 358

plug.

(10) DIAL/AC MON: A set of multiple jacks accepting

Western Electric type 310 or 347 plugs, 289 dual

plugs and a pair of special clip posts marked T and

R which accept a Western Electric 1011IB

lineman's handset for the dial and talk operation

when the FUNCTION pushbutton marked

DIAL/BAT is depressed. Loop dialing is used and

the circuit must supply talk battery. When any

other FUNCTION pushbutton is depressed, the tip

and ring of these jacks are connected to the AC

MON output of the internal amplifiers for

monitoring purposes.

(11) DC MON: Accepts a Western Electric 310 or 347

plug for tip negative and sleeve connections to an

external dc recorder. Output voltage is

proportional to the input voltage on any one setting

of the RANGE switch.

(12) INPUT: A set of multiple jacks accepting Western

Electric 241 (or 289), 309, 310 and 358 plugs and a

pair of binding posts marked T and R for banana

plugs, spade lugs, phone tips or bare wires

providing connection to the input circuitry of the

measuring set. When the DIAL BAT pushbutton is

depressed, the INPUT jacks are connected in

parallel with the DIAL/AC MON jacks.

(13) Battery Cover: Removeable by four 1/4 turn screw

fasteners to expose the internal battery for

replacement.

(14) 48V 310: A jack accepting a Western Electric 310

plug with tip negative and sleeve ground to supply

external office battery power to the set. Insertion

of a 310 plug into this jack disconnects the internal

battery. The BAT-AC switch (16) must be set to

BAT for office battery operation.

CAUTION

WHEN OPERATING FROM AN EXTERNAL

BATTERY, CORD SHOULD BE CONNECTED

TO MEASURING SET FIRST, THEN PLUG

INTO BATTERY SUPPLY TO AVOID

SHORTING THE OFFICE BATTERY.

(15) 0.15A-SPARE Fuse: A 0.15A slo-blo fuse and a

spare for measuring set protection when operating

from AC power. Fuses are not used when the set

is battery powered.

(16) BAT-AC Switch: A slide switch for selecting the ac

power source or the internal battery and office

battery jack, (14), power source. The switch may

be operated by a small screwdriver or pointed tool

inserted into the slot in the switch.

(17) AC Power Receptacle: A 3 prong power receptacle

for the special power cord stored inside the front

cover. The BAT-AC switch (16), must be

positioned to AC for this power source.

3-11. High storage temperature is damaging to dry

cells and tends to reduce shelf life. Low storage

temperature is beneficial to battery life although the

battery should be warmed to room temperature prior to

use. Turning off the set when not in use and

consideration of the above factors will maximize battery

life. The instant turn characteristics of this set with no

warm-up time required allows turning off between

measurements.

NOTE

If the battery voltage indication drops below

the left end of the arc on the meter face the

set will not operate properly. This will be

noted by a slow oscillation of the meter. If

this symptom is encountered, depress the

DIAL/BAT pushbutton and check the battery

condition. If the indication is to the left of

the arc on the meter face, replace the

battery.

3-12. LEVEL AND NOISE MEASUREMENTS.

3-13. Since the 3555B is both a level measuring set

and a noise measuring set, the procedure for making

these measurements will be treated separately. Level

measurements can be made at voice frequencies and

carrier frequencies. Since the procedure for making

voice and Carrier level measurements are identical

except for the FUNCTION pushbutton utilized, only one

procedure will be described in detail.

3-14. LEVEL MEASUREMENTS.

3-15. The 3555B can be used as a wide range and

wide

3-5

Page 18

Section III Model 3555B

frequency Transmission Measuring Set (TMS) for voice,

program and carrier multiplex measurements. The set will

operate over a wide range of environmental conditions and

maintain a high degree of accuracy.

3-16. In general, transmission level measurements are

made by connecting the circuit under test to the INPUT

jacks with a suitable patch cord, selecting the proper

bridging or terminate condition and impedance, and then

operating the RANGE switch to provide an on-scale meter

indication. Transmission level measurements are made

with the INPUT switch in TMS position either bridging or

terminated. In this position, the set has its maximum

frequency range.

3-17. The multiple INPUT jacks and binding posts

accept the Western Electric 309, 310 and 358 single plugs

and the 241 or 289 twin plug. The two red binding posts

marked T (tip) and R (ring) will accept banana plugs,

spade lugs, phone tips or bare wires. These jacks and

binding posts are all connected in parallel and only one

should be used at a time. A patching cord such as the

Western Electric 3P12H, consisting of a cord with a 310

plug on one end and a 309 plug on the other end, should

be kept with the instrument as a universal patch cord. The

75 ohm jack accepts Western Electric type 358 plugs for

75 ohms. unbalanced carrier measurements.

3-18. The sleeves of all the INPUT and DIAL jacks are

connected together and to the black binding post marked

S. The binding post in turn, is connected through a swingaway shorting strap to a second black binding post marked

G. This binding post is the measuring set case ground.

When it is necessary to establish a battery or ground

connection on the sleeve for PBX test purposes, this

shorting strap may be disconnected by loosening the black

binding posts and swinging away the strap. A cord is then

connected to the S terminal and may be connected to the

battery or ground for the test. Type 347 plugs must not be

used when the shorting strap is removed.

3-19. The multiple jacks marked DIAL/AC MON are

connected in parallel and accept a 310 or a 347 single plug

or a 289 dual plug. A dial with the impulse springs

connected to the tip and ring of a 310 or 347 plug may be

used or a lineman's handset such as the Western Electric

1011 B may be connected to the two square clip posts for

the dialing and talk operation. When the FUNCTION

pushbutton marked DIAL/BAT is depressed, the DIAL

jacks are connected to the INPUT jacks and a number may

be dialed on the line connected to the INPUT jacks. The

circuit is arranged for loop dial operation and the circuit

under test must supply talk battery.

3-20. Once the switching equipment has been seized by

the dialing operation, the connection can be held by

depressing the HOLD pushbutton. This places a dc bridge

consisting of a high impedance retardation coil, across the

INPUT terminals. This coil has negligible effect on

measurements of voice frequencies. Once any other

pushbutton is depressed, the AC output of the internal

amplifier circuit is returned to the DIAL/AC MON jacks for

an external head Model 3555B phone which can be used

to monitor the noise or tones being measured. The

lineman's hand set which was used for the dialing

operation can be used for monitering by leaving it

connected to the clip posts. The jacks marked 310 will

accept a head phone or recorder connected to the tip and

ring of a 310 plug or tip and sleeve of a 347 plug. The

performance of the set is not affected by this output and

any impedance head-phone may be used.

3-21. The DIAL/BAT function also checks the power

source used. The green arc on the meter marked BAT

GOOD corresponding to the green BAT marking on the

pushbutton, indicates the range of voltages for proper

operation. Full scale corresponds to 60 volts and the left

end of the arc corresponds to the battery cut-off voltage of

24 volts. Thus the remaining battery life can be estimated

by noting the position of the pointer in the green arc.

Since the set POWER must be turned ON to perform this

check, the battery is properly loaded to give a true

indication of its condition. When operating from the

external office battery or AC power, the meter monitors

this voltage to indicate if it is the correct level to properly

power the set. The POWER switch turns OFF and ON all

power to the set.

3-22. The remaining FUNCTIONS are used to set up the

input conditions. The Ng function will be discussed under

the paragraph heading, "NOISE MEASUREMENTS". The

impedance of the set is selected by the pushbuttons

marked 900 and 600 for voice frequencies and 600, 135

and 75 for carrier frequencies. The 900 and 600 ohm

impedances are normally used for loop plant testing while

600, 135 and 75 ohms are usually reserved for carrier

system measurements. A bridged or terminated condition

is determined by the position of the INPUT switch. Using

this procedure, the meter will always indicate in dBm for

the impedance selected, bridging or terminated. The

terminations, when used, are provided with a dc blocking

capacitor. Accidental application of carrier or telegraph

battery, office battery or ringing voltage will not damage

the set. The pushbutton marked HOLD bypasses the

INPUT switch and terminates the circuit in addition to

placing the holding bridge across the line that is connected

to the INPUT. When the INPUT switch is in either of the

NOISE positions, weighting filters can be selected by the

NOISE WTG switch for noise measurements.

3-23. The RANGE switch selects the dBm range of the

meter. To avoid overloading the set, turn the RANGE

switch to +30dBm when connecting a circuit for testing.

Once the circuit connection is established turn the RANGE

switch counterclockwise until an on-scale indication is

obtained. The black dBm marking on the RANGE switch

identifies the input level required to deflect the meter to

the 0 mark on the black scale. The meter uses shaped

pole pieces to present linear dBm markings on the scale

with marks at 0.1 dBm increments. The accuracy and

resolution of this type of meter is the same at any point on

the scale and it is not necessary to keep the pointer in the

upper portion of the scale for maximum accuracy. The

accuracy of the set is not affected by the position of the

set. This type of meter will have the pointer off-scale to

the left

3-6

Page 19

Model 3555B Section III

when no input signal is present and a mechanical zero

adjust is not required. The actual input level to the set is

the algebraic sum of the black dBm meter scale and black

RANGE setting. For example, RANGE is set to 40dBm

and the meter indicates -6.3dBm. The input level is then (-

40) + (-6.3) = -46.3dBm. If the RANGE switch is at

+20dBm and the meter indication is 4.7dBm, the level is

(+20) + (4.7) = +15.3dBm.

3-24. All panel markings corresponding to the proper

dBm markings on the RANGE switch and meter face are in

black, as is the TMS position of the INPUT switch. The

blue markings correspond to the settings for noise

measurements as discussed in paragraph 3-28. The

response of the meter rectifier circuit is RMS which allows

the set to measure the true power of any arbitrary input

waveform provided the crest factor does not exceed 4:1.

Crest factor is defined as the ratio of the peak value of the

waveform to the RMS value of that waveform. In most

telephonic measurements, consideration of this crest

factor is not necessary.

3-25. The balanced input to the set is achieved through

the use of two repeat coils, one for voice frequencies from

20Hz to 20kHz and the other for carrier frequencies from

10kHz to 600kHz. The maximum high frequency range is

achieved through the use of the 75 ohm functions and the

75 ohm jack. This input bypasses both input repeat coils,

thus allowing measurements from 30Hz to 3MHz. This

high frequency range is limited to 600kHz on the +20 and

+30dBm ranges. The maximum longitudinal input voltage

is 150 volts peak between tip and ring and 200 volts rms at

60Hz between either tip or ring and ground.

3-26. The switch marked RESPONSE determines the

speed of the meter response and is usually left in the

NORM position for transmission measurements.

3-27. The jack marked DC MON accepts a Western

Electric 310 or 347 plug with connections to the tip and

sleeve. The dc voltage supplied by this jack can be used

to operate a dc potentiometric recorder requiring 1V or a

dc galvanometric recorder requiring 500uA. The dc output

is proportional to input level on any one range and not

meter deflection since the meter is logarithmically scaled.

Knowing the current required to drive the recorder full

scale and the input impedance of the recorder, enter these

numbers into the recorder compatability chart Figure 3-4 to

determine if the recorder is suitable for use with this set. If

these numbers do not fall within the compatability area,

refer to Paragraph 3-41. Connect an input voltage to the

set and adjust the RANGE switch until a near full scale

indication is observed on the meter. Connect the recorder

plug with the tip negative to the DC MON jack and adjust

the input level until the meter indicates 0dBm. Mark this

point, which should be near full scale, on the recorder

paper. Decrease the input level until the meter indicates 1dBm. Mark this point on the recorder paper. Continue

until the recorder has been calibrated for each major dBm

division on the meter. The actual input level to the set as

indicated on the recorder will be the algebraic sum of the

RANGE.

3-28. NOISE MEASUREMENT.

3-29. One of the primary functions of this set is to

measure message circuit noise, both metallic and noise-toground. The weighting filters built into this set are switch

selected and their characteristics conform to the standards

set up by the Bell System and Edison Electric Institute.

3-30. In general, noise-metallic measurements are made

by connecting the circuit under test to the INPUT jacks

with a suitable patch cord, selecting the proper bridging or

terminate condition and impedance, selecting the proper

weighting filter and operating the RANGE switch to provide

an on-scale meter indication. Noise measurements

involve many of the same operations as the level

measurements discussed in Paragraph 3-14 and only the

differences will be discussed.

3-31. Four filters are supplied for noise measurements;

C-MESSAGE and 3kHz FLAT for message circuit noise

measurement, a PROG and 15kHz FLAT for broadcast

studio-transmitter links and telephone company program

circuits. These filters are necessary to allow the

measuring set to approximate the response of the human

ear and give an indication representative of a person's

subjectiveness to noise. The frequency response of these

filters is shown in Figures 4-5 and 4-6.

3-32. Once a circuit has been connected, the RANGE

switch is adjusted until the noise fluctuations appear onscale on the meter with normal response, and a two-tothree minute observation of the pointer fluctuations is

made to establish the point at which the pointer appears

most of the time, disregarding the occasional high peaks.

For rapidly fluctuating noise such as atmospheric static or

switching noise, operate the RESPONSE switch to DAMP.

In this position of the switch, the level of the most

frequently occurring peaks should be read. Noise is

specified in dBm (decibels above reference noise) and the

type of filter used is noted, for example, dBmC meaning

C-message weighting is used.

3-33. The noise-metallic level is the algebraic sum of

the indication on the blue dBm meter scale and the blue

dBm RANGE switch setting. For example, RANGE is set

to 20dBm and the meter indicates +7dBm. The noisemetallic level is (20) + (+7) = +27dBm. The RANGE

switch marking indicates the level at the 0dBm mark on

the left end of the meter scale.

3-34. Occasionally other message circuit weightings

such as the older Bell System F1A weighting or the

International Telecommunication Union's CCITT or

psophometric weighting may be required. To convert from

C-message to F1A, subtract 6dBm from the C-message

indication. The units for F1A weighting are dBa, meaning

decibels adjusted. To convert from C-message to CCITT

or psophometric weighting, subtract 1dBm from the Cmessage level as read on the black dBm meter scale and

RANGE switch setting. This will give the noise level in

dBm which is acceptable for psophometric measurements.

3-7

Page 20

Section III Model 3555B

3-35. As an aid in identifying the source of noise, the

DIAL/AC MON jacks can be used with a monitoring

receiver to listen to the noise which will have

approximately the same quality as that heard by a

subscriber. Particular types of noise like power line

induction, switching noise, atmospheric static, crosstalk or

random noise may be identified by this listening test. To

aid in bringing up the level of the lower frequency power

line noise, the 3kHz flat weighting is used. A substantial

increase in meter indication with the 3kHz flat weighting

indicates the presence of low frequency noise and it will

also sound louder in the monitoring headphone.

3-36. In some cases recording of the noise during a

busy period is necessary. The recorder connections and

operation is discussed in Paragraph 3-27. The calibration

should be done using the dBm scale rather than the dBm

scale and it should be noted that the RESPONSE switch

also damps the recorder.

3-37. Noise-to-ground measurements are made by a

special input circuit arrangement which is used when

either the Ng or Ng HOLD pushbutton is depressed. Dial

and talk may be accomplished on the metallic circuit and

the metallic connection held by using the Ng HOLD

pushbutton. It is necessary to establish a good earth or

system ground and connect it to the black binding post

marked G. The noise-to-ground measurement is 40dB

less sensitive than the noise metallic measurement

because of the voltage divider in the input circuit. This

requires adding 40dB to the meter indication to arrive at

the correct noise-to-ground level. The level is the

algebraic sum of the blue RANGE switch setting and the

blue meter scale indication plus 40dB. For example,

RANGE is set to 20dBm and the meter indicates +3dBm.

3-40. Crosstalk measurements involve low level

measurements and part of the meter indication may be 38 Model 3555B caused by noise in addition to crosstalk.

The general technique is to measure with crosstalk and

noise present and then measure noise alone. A

correction factor must then be applied and can be found

in Table 3-2.

3-41. RECORDER COMPATIBILITY.

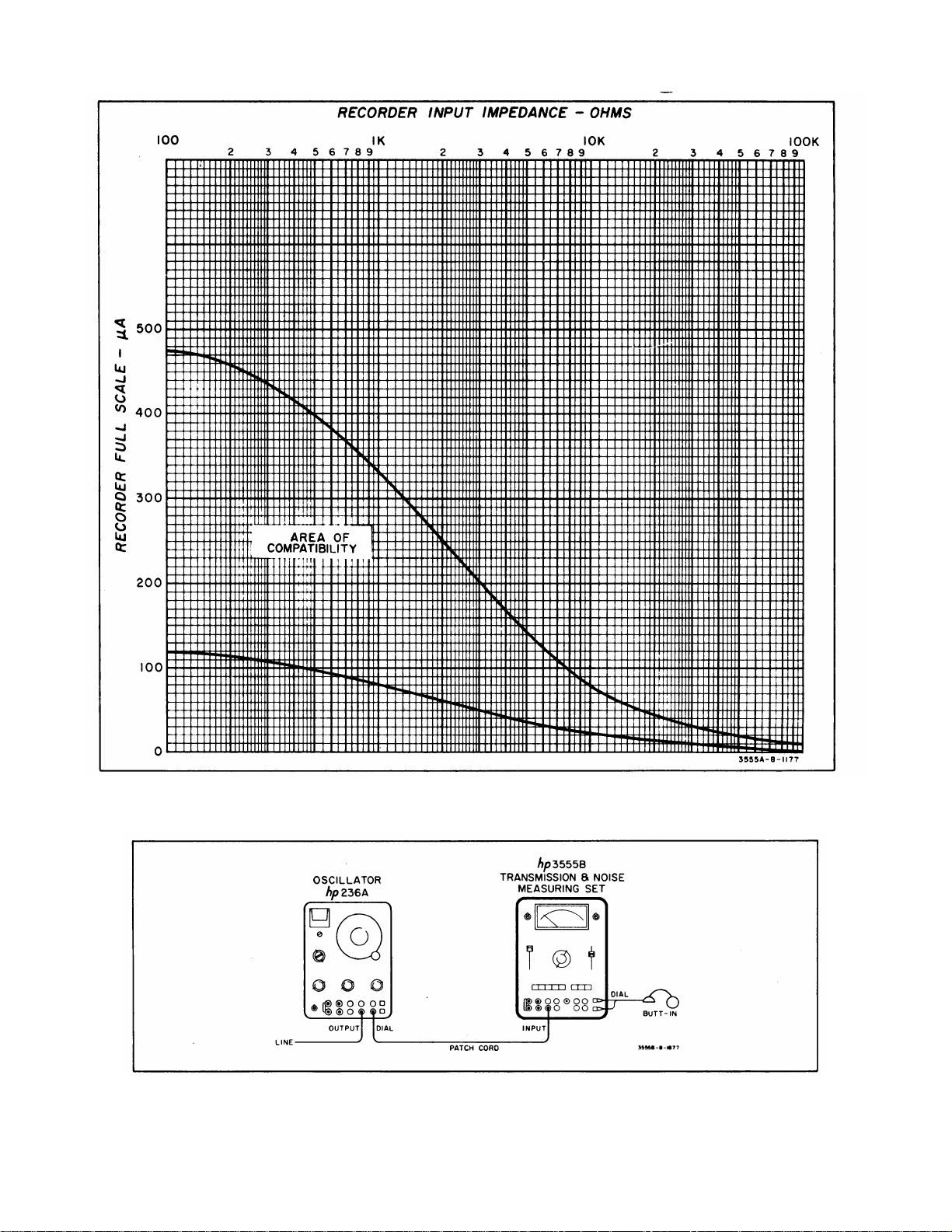

3-42. If an external recorder is to be used to monitor the

dc output of the 3555B, the Recorder Compatibility graph,

Figure 3-4 should be consulted to determine if your

particular recorder can be used. Recorders with input

characteristics that fall below the compatibility area can

be used provided a suitable resistor is used between the

3555B dc output and the recorder input.

3-43. To choose the value of this resistance, simply

follow the line designating the full scale current of your

recorder, horizontally until it intersects the top line in the

Recorder Compatibility graph. From this intersection

follow the vertical line to find the total impedance RT

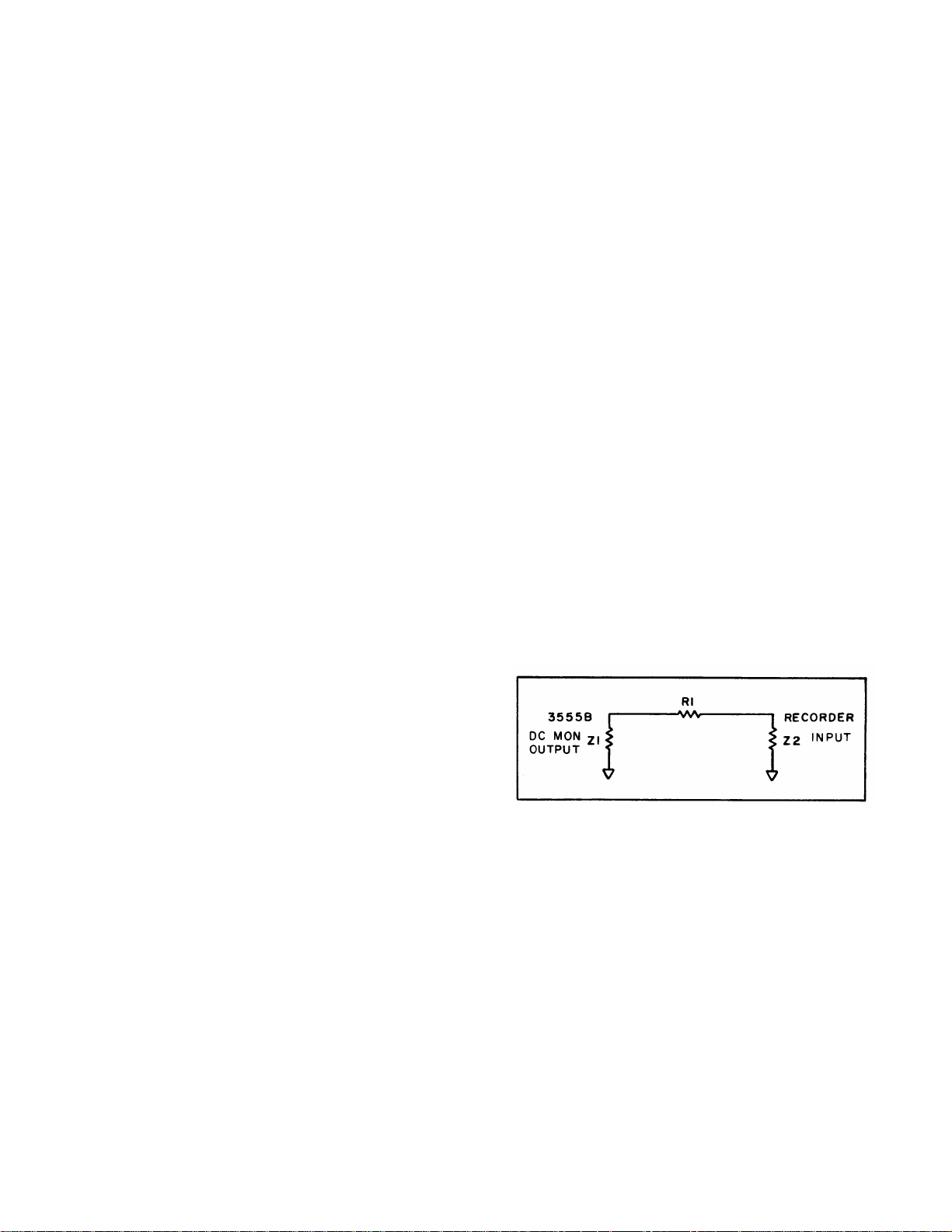

required for full scale deflection (see Figure 3-3). The

input impedance of the recorder should be subtracted

from this value RT to determine the value of R1. For

example, assume that your particular recorder has an

input impedance of 2000 ohms with a full scale sensitivity

of 20uA. Follow the 20uA line to the right until it

intersects the top line at 48 kilohms. The value of R1 will

then be 48 kilohms -2 kilohms input impedance = 46

kilohms.

3-44. Recorders with input characteristics that fall

above the compatibility area in Figure 3-4 cannot be used

to monitor the 3555B dc output since full scale deflection

of the recorder cannot be accomplished by the 3555B.

The noise-to-ground level is 20 + (+3) +40= 63dBm.

Some telephone company operating procedures disregard

the 40dB correction factor in which case the noise-toground level would be 20 + 3 = 23dBm.

3-38. The Nm and Ng indications can be used to

compute the balance of a facility since balance is defined

as the degree of rejection of longitudinal signals. The

degree of balance in dB where the major part of noisemetallic is due to noise-to-ground, is given by the

Figure 3-3. Impedance Matching 3555B to Recorder

equation, Balance in dB = Nm - Ng. For example, if the

noise-metallic level of a circuit is +26dBm and the noiseto-ground of the same circuit is +9OdBmC, the balance in

dB is (+26) - (+90) = 64dB. In the case mentioned above

where the 40dB correction factor is neglected, the balance

in dB = (Nm) (Ng + 40).

3-39. Other general purpose uses of the 3555B are

volume and crosstalk measurements. The ballistic

characteristics of the set make it approximately correct for

VU measurements. The RANGE switch should be

adjusted until the meter pointer fluctuations are on-scale

and should be observed for the maximum of the

frequently occurring peaks, disregarding the occasional

high peaks. The meter indication in dBm is equal to VU

(volume units.)

3-45. APPLICATIONS.

3-46. Sometimes it is necessary to transmit or send a

tone on a line and then measure the received signal

coming back on the same line. Rather than change

connections back and forth between the 3555B and 236A

Oscillator when changing from SEND to RECEIVE and

thus take a chance on dropping the line, it is much more

convenient to make one set of connections and then

select SEND or RECEIVE by means or a switch. Refer to

Figure 3-5.

3-47. By utilizing the test set-up shown in Figure 3-5,

send and receive can be accomplished with a minimum

number of operations. To dial, set both function switches

to DIAL and dial the desired line on the butt-in. To send,

change the

3-8

Page 21

Model 3555B Section III

Figure 3-4. Recorder Compatibility Chart

Figure 3-5. Simplified Send/Receive Test Set-up

3-9

Page 22

Section III Model 3555B

236A FUNCTION switch to 600 HOLD or 900 HOLD,

depending on the impedance required. To receive a

tone, set the 3555B FUNCTION switch to either 600

HOLD or 900 HOLD (whichever is appropriate) and

change the 236A FUNCTION switch to DIAL. To send

again, simply change the 236A to 600 HOLD or 900

HOLD. If holding is not required or dialing is not

required, simply select the impedance and switch back

and forth on the 236A FUNCTION switch.

3-48. TRANSMISSION LOSS MEASUREMENTS.

3-49. Transmission loss is defined as the ratio of

power from a transmission line by a receiving terminal

to the power available from the sending equipment and

is dependent on three factors; power dissipated by the

dc resistance of the line, power losses because of

impedance mismatch, power transferred to other circuits

by inductive or capacitive coupling. (See Figure 3-6).

3-50. These factors are difficult to measure

separately. Their sum, however, is relatively easy to

measure with the -hp- 236A/3555B combination.

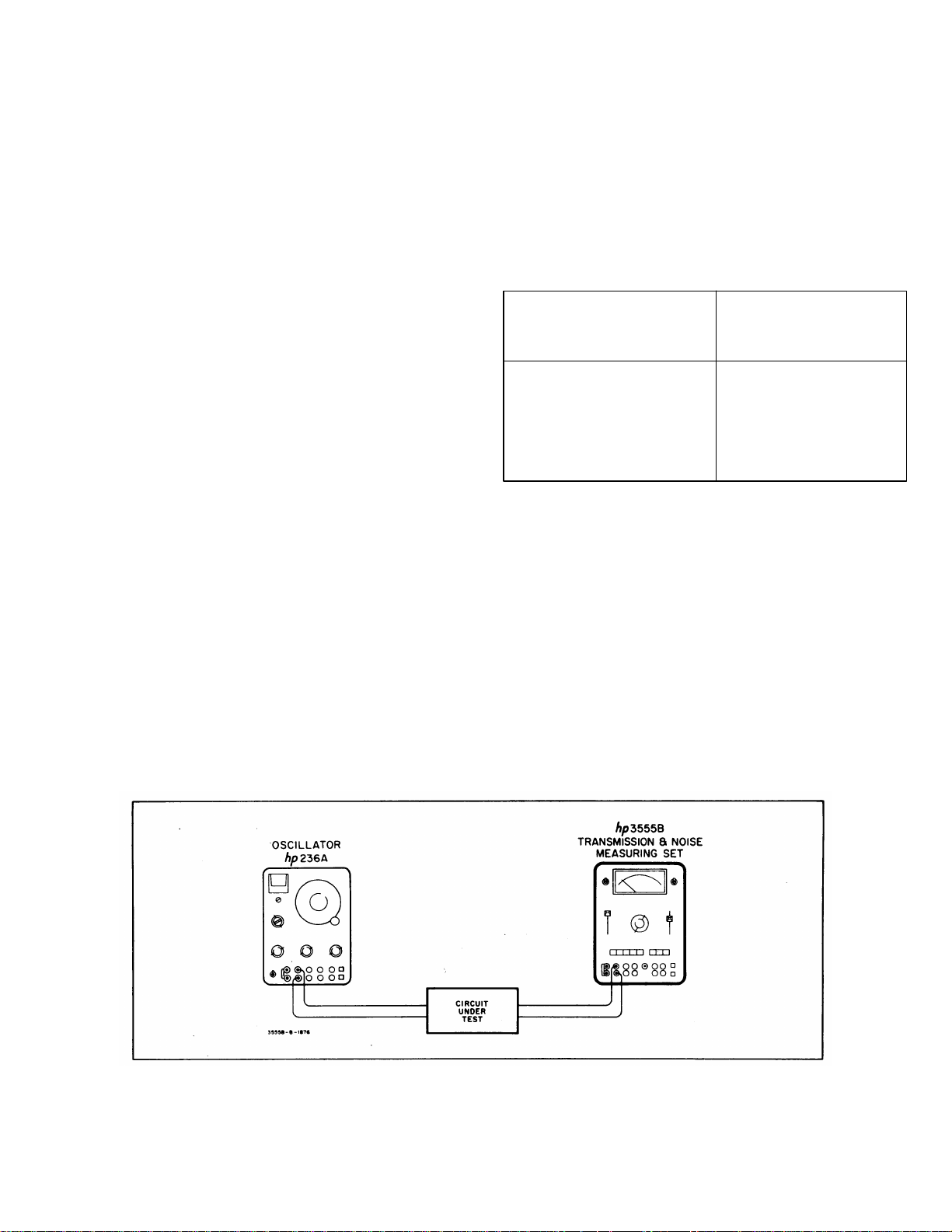

3-51. Figure 3-6 shows a typical transmission loss

measurement setup. The oscillator is adjusted for a

reference level and the signal is measured at the other

end of the line with a level meter. Loss measurements

are usually made at various frequencies to determine

the response of the line.

3-52. Ideally the man at each end of the line will have

both an oscillator and a Transmission Measuring Set

(TMS) so that the loss can be measured in both

directions, If the line that is being tested passes through

central office switching equipment, the oscillator or TMS

at the remote end is placed in the DIAL mode and the

lineman's handset connected to the DIAL posts,

permitting the repairman to bypass the instrument

circuitry and dial his test board at the central office.

Tests are then made in the 600 or 900 ohm HOLD

positions, which provide a dc path to hold the switching

relays.

3-53. CROSSTALK MEASUREMENTS.

3-54. Crosstalk is interference on a transmission line

caused by inductive and capacitive coupling between

pairs of transmission lines in close proximity. Crosstalk

can be classified as near-end and far-end. Far-end

crosstalk is interference at the end of the transmission

line opposite the , signal source while near-end crosstalk

is interference detected at the same end of the line as

the signal source.

Table 3-2. Crosstalk Correction Factor

dB Correction Factor

(Crosstalk + Noise) in dB Crosstalk in dB =

Minus Noise Alone in dB (Crosstalk + Noise)

Minus Correction Factor

1 7

2 4

3 3

4 to5 2

6 to 8 1

9 and above 0

3-55. Since different frequency bands are used for

each direction of transmission on two wire carrier

systems, near-end crosstalk cannot be detected. The

situation is quite different, however, for far-end crosstalk

since it is in the same frequency band as the desired

signal and can be detected.

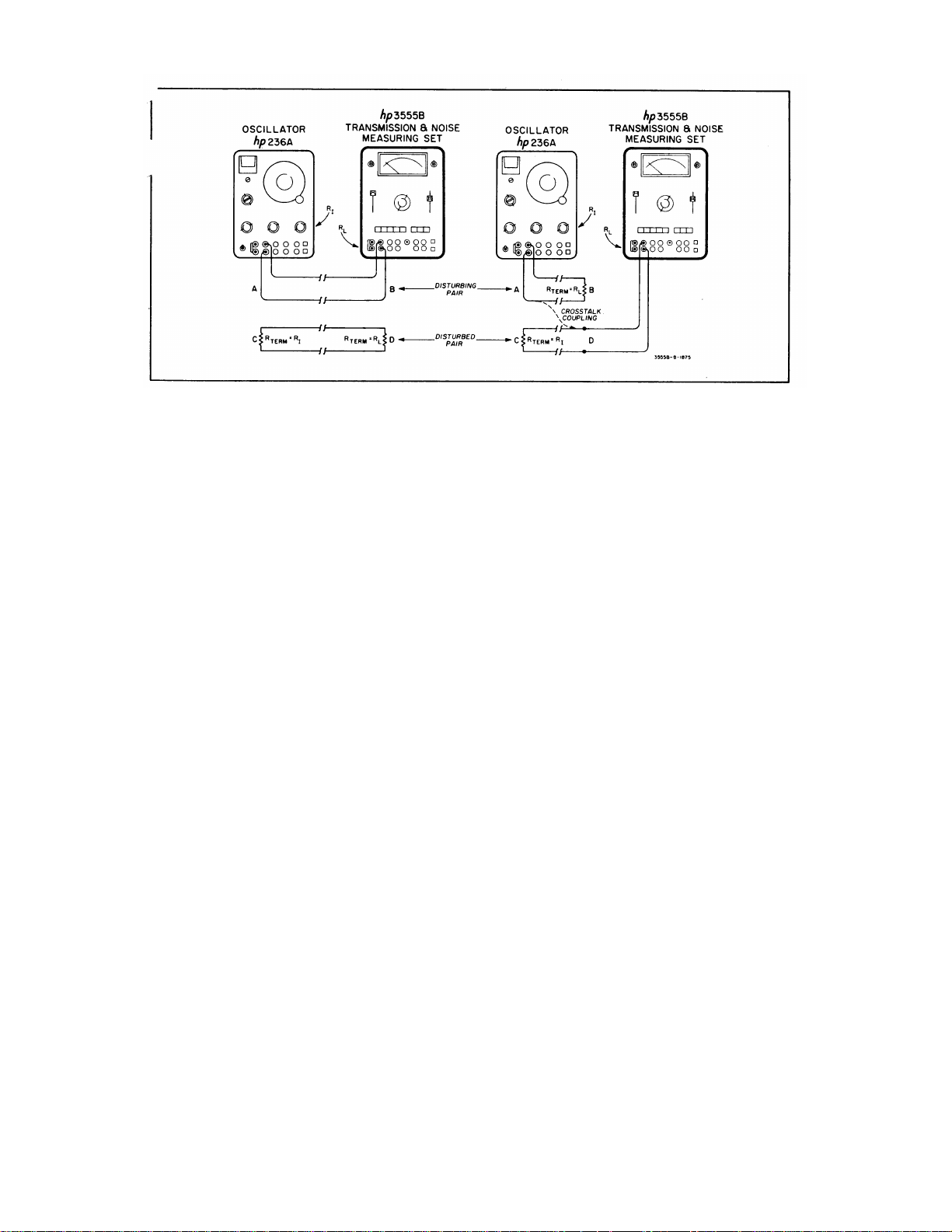

3-56. Referring to Figure 3-7, one line is designated

A-B and the other designated C-D with A and C

representing the near-end of one of the pairs, and band

D representing the far-end of the other pair. First

measure the transmission loss between A and B. Then

measure the transmission loss from A to D. The

crosstalk coupling loss in dBx is the difference in the

reading from A to B and the reading from Ato D.

3-57. IDENTIFYING NOISE CHARACTERISTICS.

Figure 3-6. Typical Test Setup for Measuring Insertion Loss

3-10

Page 23

Model 3555B Section III

Figure 3-7. Test Setup for Measuring Crosstalk Coupling Loss

3-58. Normally, a frequency selective voltmeter is

used to identify the characteristics of transmission line

interference in order to trace it down to its origin and

apply the appropriate corrective action. As an expedient

for troubleshooting, there are several subjective

measurements that the 236A/3555B can make to help

identify the interference characteristics.

3-59. Since power line noise is the most common

nuisance, a quick check with the 3555B should be made

first. By noting the difference in noise readings between

the 3kHz FLAT and C-message weighted modes, an

indication of line frequency disturbance can be

ascertained if the 3kHz flat mode shows a substantially

higher reading.

3-60. As a further aid in identifying noise, the

lineman's handset can be connected to the AC

MONITOR terminals and an aural analysis made.

Although the handset will not respond to 60Hz, line

interference is usually very rich in odd harmonics and

180Hz can easily be identified. This test also helps to

identify "babble" and other audio frequency interference.

3-61. Vagrant noise, such as atmospheric noise, can

be analyzed by connecting a strip chart recorder to the

DC MONITOR terminals. Long-term seasonal and

temperature effects can also be measured very

conveniently with a recorder.

3-62. Frequency of strong interfering periodic signals,

such as radio transmitters, can be roughly determined

with the 236A and 3555B. The 236A is connected to

one end of the line and the 3555B to the remote end, as

with transmission loss measurements. The oscillator

output is increased until the test meter barely indicates a

signal above the noise. The oscillator frequency is then

changed very slowly while the repairman observes the

3555B for a beat. By tuning for a beat, the frequency of

oscillator frequency dial to an accuracy of approximately

±3%. In practice, this measurement would probably be

made using a "loop around" technique. The oscillator

would be connected to a quiet line at the remote location

and this line would be tied to the noisy line back at the

central office. This permits one man to operate both the

oscillator and the test meter.

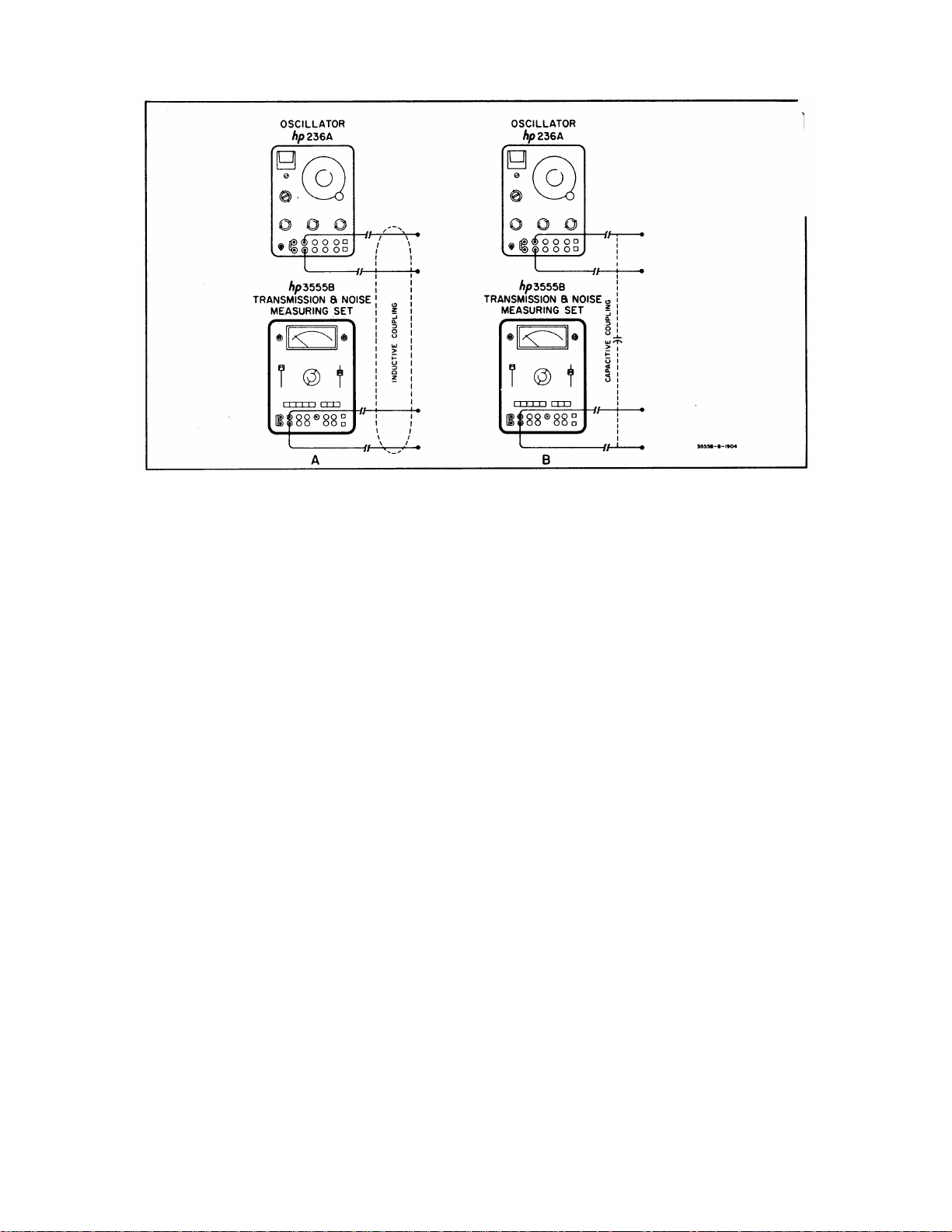

3-63. When a current flows through a conductor, it

sets up two distinct fields around the conductor - - the

electrostatic (capacitive) field and the magnetic

(inductive) field. Both are capable of inducing

longitudinal voltages in adjacent conductors, and both

increase in proportion to the power and frequency of the

current from which they result. They differ greatly,

however, in how they affect nearby circuits. The voltage

resulting from magnetic induction varies inversely-with

the impedance of the line. That is, the higher the line

impedance, the less voltage that can be induced by a

magnetic field. Capacitively coupled voltage, on the

other hand, increases in direct proportion to line

impedance-- the higher the impedance, the greater the

capacitive coupling. By means of a simple test, it is

possible to identify the coupling between two lines, as

shown in Figure 3-8. Since induced voltages are

inversely proportional to line impedance, the voltage

coupled from pair A into pair B (Figure 3-8a) will

increase as the impedance is lowered (i.e., shorted).

Conversely, since capacitively coupled voltages are

directly proportional to impedance, the coupled voltage

in Figure 3-8b would increase as the impedance is

increased (i.e., open circuited). Both tests in Figure 3-8

should be performed to correlate the result.

3-64. MEASUREMENTS IN DBC.

3-65. The term dBC means dB Collins and is defined

as

the interfering signal can be read directly off the

3-11

Page 24

Section III Model 3555B

Figure 3-8. Simple Test for Inductive and Capacitive Coupling

0dBC = 0.775V across any impedance as read on an

-hp- Model 400D AC Vacuum Tube Voltmeter. Thus,

the dBC is strictly a relative term.

3-66. Measurements can easily be made in dBC. by

utilizing the Model 3555B Telephone Test Meter. To

make these measurements, set FUNCTION to 600 and

the INPUT switch to TMS BRDG. Any termination

required other than 600 ohms must be provided

externally and connected across the two binding posts T

and R. Termination can also be made using a patch

cord and any one of the other INPUT jacks since all

INPUT jacks are connected in parallel. If a 600 ohm

termination is to be used, the internal termination can be

utilized by placing the INPUT switch to the TMS TERM

position.

3-67. MEASUREMENT PROCEDURES.

3-68. Tables 3-3 through 3-8 list the step by step

procedures for measuring levels and noise balance,

recorder calibration and transmission loss using the

3555B. For a more detailed discussion on level and

noise measurements refer to paragraphs 3-12 through

3-47.

3-69. 150 BAL CONVERSION.

3-70. The 3555B comes equipped with all the

necessary parts for converting the 135 BAL function to a

150 BAL function. The following is a simplified

procedure for making the modification.

a. Remove the set from the case and remove

the FUNCTION board. Clip the shorting

wire from across A1R17 (see Figure 7-2)

and reinstall the FUNCTION board. Leave

the set out of the case.

b. Set the 3555B controls as follows:

RANGE..........................................0dBm

FUNCTION................................135 BAL

INPUT ..................................TMS TERM

c. Remove the 150 BAL decal from the

envelope supplied with the set. Remove

the backing from the decal and place it

over the 135 BAL function pushbutton.

d. Connect a 150 ohm balanced source to the

input of the 3555B at a level of 0dBm

(387mV rms) at a frequency of 1kHz. Turn

the 3555B ON and adjust A3R24 (Figure 7-

3) for 0dBm indication on the 3555B meter.

e. Reinstall the set in its case.

3-12

Page 25

Model 3555B Section III

Table 3-3. Level Measurement

STEP PROCEDURE

1. Turn the 3555B/ON and depress the

DIAL/BAT pushbutton. The meter should

indicate in the green BAT GOOD area. If it

does not, replace the battery or check the

power source before attempting to make any

measurements. The battery test operates for

internal battery, office battery or ac power

source.

2. Select either TMS BRDG or TMS TERM,

depending on the measurement being made.

The weighting filters are not in the circuit at

this time.

3. Select the impedance (FUNCTION

pushbutton) to match the circuit to be tested.

Select either 900 BAL or 600 BAL (VF/Nm) for

frequencies between 20Hz and 20kHz. Select

600 BAL or 135 BAL (CARRIER) for balanced

measurements between 1 kHz and 600kHz.

Select 75 UNBAL for 75 ohm unbalanced

measurements between 30Hz and 3MHz.

4. Set the RANGE switch to +30dBm. Set the

RESPONSE switch to DAMP.

5. Connect the set to the line using a suitable

patch cord. For balanced measurements use

a cord having a 309 or 310 single plug, a 241

dual plug or banana plugs, bare wires or clip

leads. For unbalanced carrier measurements

(75 ohm only) use a cord having a 358 plug.

NOTE

Carrier measurements are

limited to the -50dBm RANGE

thru the +10dBm RANGE.

6. Down range the RANGE switch for an onscale indication. Level is equal to the

algebraic sum of the black RANGE setting

plus the black meter scale indication.

Table 3-4. Noise Metallic Measurements

STEP PROCEDURE

1. Turn the POWER switch to ON and depress

the DIAL/BAT pushbutton. The meter should

indicate in the green BAT GOOD area. If it

does not replace the battery or check the

power source. The battery test operates on

internal battery, office battery or ac power

source.

2. Select either NOISE TERM or NOISE BRDG,

depending on the measurement being made.

3. Select the impedance to match the circuit to

be tested using the FUNCTION pushbuttons.

The 900 BAL VF/Nm pushbuttons only should

be used for noise metallic measurements in

the frequency range of 20Hz to 20kHz. The

HOLD function can be used in NOISE TERM

if desired.

4. Select the appropriate weighting filters using

the NOISE WTG switch.

5. Set the RANGE switch to 110dBrn.

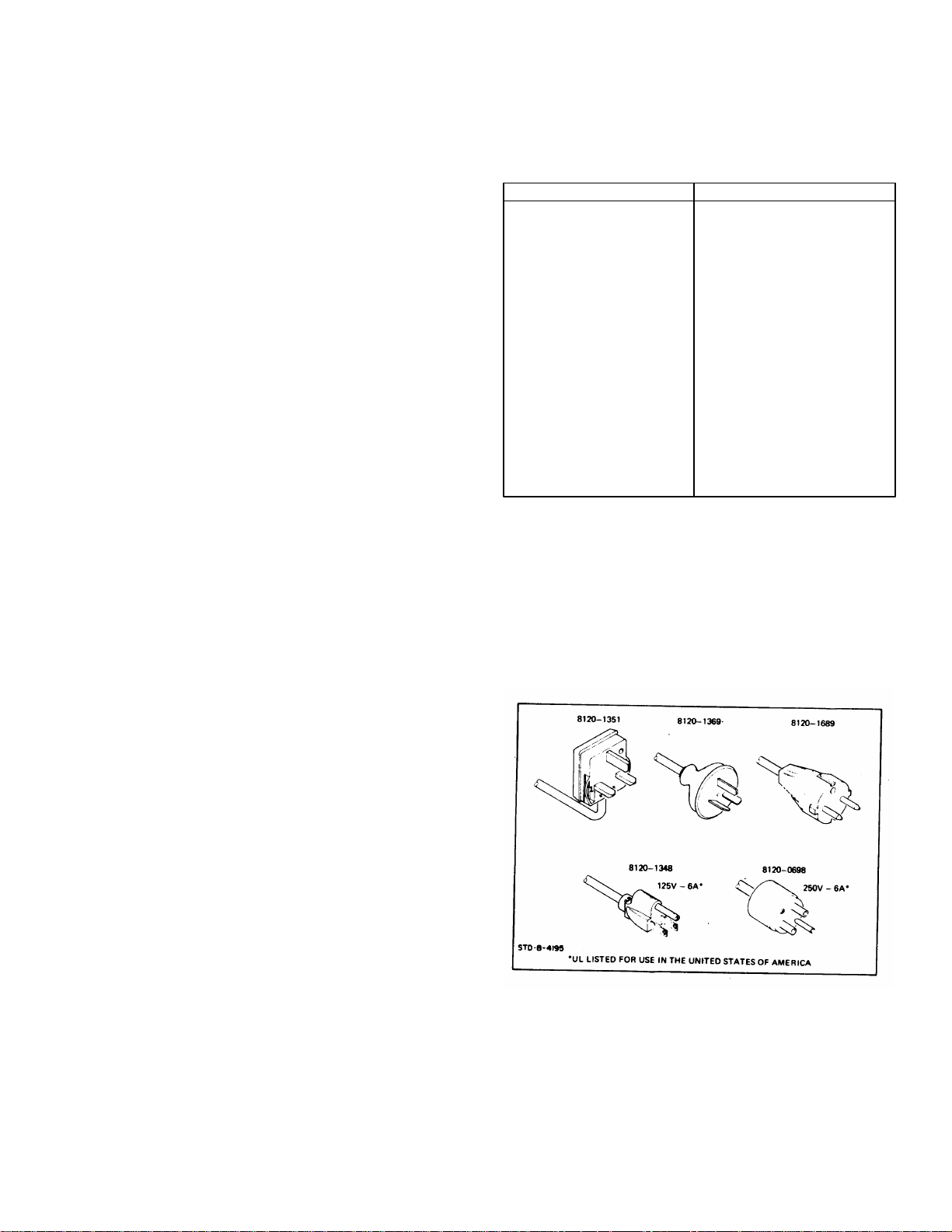

6. Connect the set to the circuit to be tested