Page 1

HP Designjet T1100- and T610-series Printers:

Productivity

Productivity and Image Quality.............................................................................................................. 2

In-printer Processing Architecture ........................................................................................................... 2

Image Processing Pipeline: T610-series .................................................................................................. 3

Image Processing Pipeline: T1100-series ................................................................................................ 4

Scalable Printing Technology and HP 72 Printheads ................................................................................ 6

For more information............................................................................................................................ 7

Page 2

HP Designjet T1100- and T610-series printers provide outstanding productivity and image quality with

powerful in-printer, hardware-based image processing that minimizes workstation computational load

and network traffic to deliver dependable printing results.

Productivity and Image Quality

On plain paper, HP Designjet T1100- and T610-series printers can produce a single A1/D-size color

line drawing in 35 seconds (Economode) and up to 52 prints per hour.

1

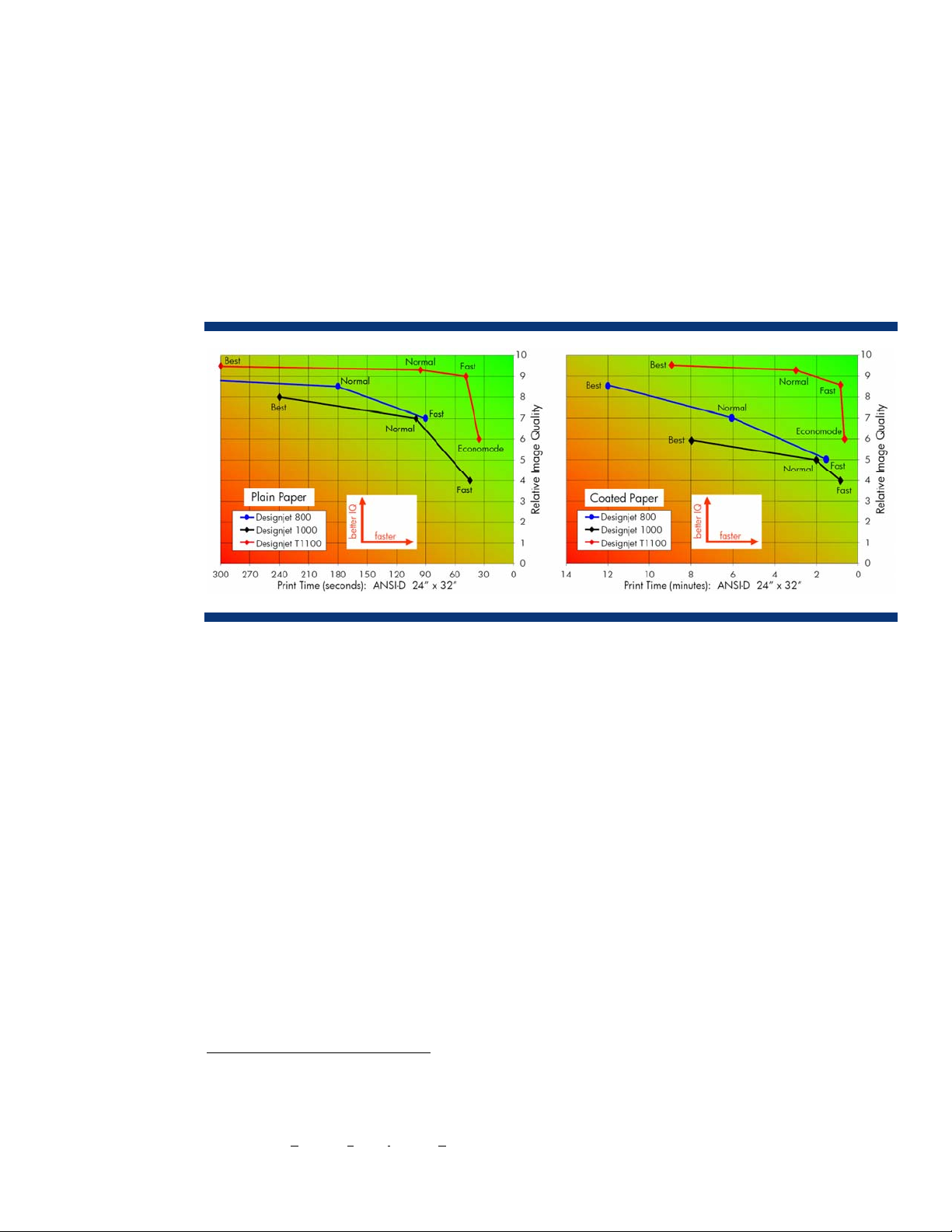

HP Designjet T1100- and T610-series printers deliver significantly higher image quality and at higher

productivity compared to the HP Designjet 800- and 1000-series. This is clearly seen in the

Productivity-Image Quality charts

2

in Figure 1, where faster mechanical printing times are shown from

left to right.

Figure 1. Relative Image Quality and Print Time: HP Designjet 800-, 1000-, and T1100-series printers

On plain paper, image quality in Fast mode on HP Designjet T1100- and T610-series printers was

ranked above all print modes on the 800- and 1000-series. Not only do HP Designjet T1100- and

T610-series printers have higher productivity than 800- and 1000-series Designjets, but they deliver

improved print quality as well. This is possible with a new writing system that has higher media

advance accuracy, better drop placement accuracy, and smaller drop volumes.

HP Designjet T1100- and T610-series printers produce very fine, sharp black lines

length accuracy

4

. With the capability for color emulation of HP Designjet 500-, 800-, and 1000-

3

with 0.1% line

series printers, HP Designjet T1100- and T610-series printers offer color consistency when printing

from popular applications like AutoCAD™ along with significantly higher levels of productivity and

quality.

In-printer Processing Architecture

HP Designjet T1100- and T610-series printers use an ASIC5 to perform fast, hardware-based color

processing, pixel scaling, and halftoning in the printer. The ASIC is a fully-custom design with

architecture and firmware developed by HP. It can process up to 50 million pixels per second and

can transfer up to 50 GB of data per second over its two 32-bit data busses.

1

Mechanical printing times, 24-inch and 42-inch T1100, T1100ps, and T610 printers.

2

For each printer and print mode, an internal HP print quality jury ranked prints in terms of relative image quality.

3

On matte film, line widths of 45.4um horizontal and 67um vertical can be obtained.

4

±0.1% of the specified vector length or ±0.2 mm (whichever is greater) at 23°C (73°F), 50-60% relative humidity, on E/A0-size roll feed HP

Matte Film in Best or Normal mode.

5

ASIC stands for Application-Specific Integrated Circuit

2

Page 3

How the workstation, network, and printer process large and multiple graphics pages has a

significant impact not only on overall printing speed but also on output quality and the productivity of

users and workgroups. Conversion of a page into a bitmap image can be done either in the user’s

workstation or in the printer.

• When print jobs are processed in the workstation, large bitmap image files are produced that must

be sent over the network to the printer.

6

In this case, the workstation and printer must be

synchronized, because delays in sending data (due to workstation or network load) can cause the

printer to stop and wait for data. This produces visible bands on the print because the ink dries

differently when the print carriage stops and waits compared to continuous printing. This effect is

called “wait-state banding”. When processing large and complex pages, and when sending

multiple bitmap image files over the network, dependable printing performance and print quality

can be compromised by workstation load and heavy network traffic.

• When print jobs are processed in the printer, the workstation sends only compact spool files

7

to the

printer. This data is converted to a bitmap image in the printer so that the large volume of bitmap

data is kept within the printer’s internal high-bandwidth image processing architecture. Situations

where the printer must stop and wait for incoming data are effectively eliminated, and workstation

and network loading are significantly reduced benefiting both individual users and network clients.

By processing images in the printer, HP Designjet T1100- and T610-series printers provide

dependable printing performance and productivity benefits to single users and workgroups.

Furthermore, real image quality benefits are realized because graphical elements, such as text and

lines, are recognized by HP’s embedded language processors.

8

This allows HP Designjet printers to

optimize bitmap image generation to produce crisp, clearly-readable text and sharp lines especially

when printed against colored or neutral backgrounds.

Image Processing Pipeline: T610-series

The image processing pipeline of HP Designjet T610-series printers is optimized for single-user

environments. Figure 2 shows the data paths from the printer’s I/O manager

9

through to pixel

instructions sent to the printheads. Internally, 24 bits per pixel (bpp) sRGB and device-dependent

RGB paths are supported along with a 32 bpp path for device-dependent CMYK. Processes are

color-coded in the figure to show whether they are performed in software (SW) or hardware (HW).

Figure 2. Image Processing Pipeline: HP Designjet T610-series Printers

Image processing in HP Designjet T610-series printers begins with interpreting the byte stream of

graphics data from the I/O manager. This is done by a Parser

6

From HP internal tests on a suite of A1 pages, the average size of bitmap image data files sent over the network was 206MB.

7

Spool files of HP-GL/2, RTL, PCL, and PostScript data are typically 10 to 100-times smaller than the bitmap image files they produce. Based on

internal HP tests on a suite of A1 pages, the average size of spool files sent over the network was 6MB compared to 206MB of bitmap image

data for the same pages.

8

HP-GL/2, RTL, and PCL3GUI processing is supported. HP Designjet T1100ps-series printers support PDF, JPEG, and TIFF formats and also

feature embedded PostScript.

9

The IO Manager handles data streams from the printer’s physical interfaces such as USB, Integrated LAN, and JetDirect EIO cards.

.

3

Page 4

For HP-GL/2 and RTL data, the Parser recognizes graphics instructions and their associated data10

and then creates an Object List

of graphical objects. The Object List defines shapes, lines, text, and

images in bands up to 256 rows high. These bands are stored in RAM in HP Designjet T610-series

printers, and they are ordered from the top to the bottom of the page. As the media is advanced

through the printer, bands in the Object List are fetched from memory by the Render

process to

produce a bitmap image in 24- or 32 bpp formats.

For PCL3GUI data, the Parser directly produces bitmap image data in 24- and 32 bpp formats.

HP Designjet T610-series printers feature embedded processing of HP-GL/2, RTL, and PCL3GUI

instructions using specialized algorithms running on high-performance hardware (the formatter). This

means compact spool files containing HP-GL/2, RTL, or PCL3GUI instructions are sent to the printer

from the workstation, and they are converted by the printer into the bitmap image. The large volume

of 24- or 32 bpp data produced by parsing, building object lists, and rendering is processed by HP’s

custom ASIC using the printer’s internal high-speed 32-bit data busses.

In the Color Pipeline

formats into values corresponding to the six (6) colors used in the writing system.

, the HP image processing ASIC converts pixel color data in RGB and CMYK

11

Using information

from HP’s Closed Loop Color Calibration process, this conversion takes into account the print mode

and the printheads, inks, and media loaded in the printer.

Scaling

(or pixel replication) converts pixels in the image file at the rendering resolution into pixels at

the printing resolution for the selected print mode.

Halftoning

produces the closest-match to the specified pixel color by choosing patterns of dots of the

appropriate ink colors. Halftoning gives smooth color transitions and maintains sharp edges in

graphic elements such as lines and text.

These processes produce a print mask with 1-, 2-, or 4-bit per (printed) pixel. The print mask instructs

each printhead where it will place drops of ink as the print carriage scans across the print.

Image Processing Pipeline: T1100-series

HP Designjet T1100-series printers have an image processing pipeline optimized for productivity in

workgroup environments. Shown below in Figure 3, some of the elements of the pipeline for HP

Designjet T1100-series printers can be recognized from the single-user pipeline of HP Designjet T610series printers: parsing, building object lists, and rendering into bitmap data, and converting that

data into print masks through the color pipeline, scaling, and halftoning processes.

Figure 3. Image Processing Pipeline: HP Designjet T1100- series Printers

10

For example, a vector HP-GL/2 instruction tells the printer to move the “pen” in relative or absolute page coordinates from its current position

with the pen “up” or “down”. The associated data

11

For HP Designjet T1100- and T610-series printers, these colors are cyan, magenta, yellow, photo black, matte black, and gray .

is the coordinates of the end-point of the move.

4

Page 5

The image processing pipeline for HP Designjet T1100-series printers features a 40GB hard disk

drive. This allows in-printer image processing to be segmented into three stages that can run

independently and simultaneously:

• parsing and building an Object List;

• rendering and storing a Virtual Page;

• composing and printing a page.

With this architecture, HP Designjet T1100-series printers can process up to three different jobs at the

same time to deliver high printing productivity for workgroups.

The three simultaneous processes are shown below in Figure 4 (a) through (c).

Figure 4. Three Simultaneous Processes in the Image Processing Pipeline for HP Designjet T1100-series Printers:

(a) parsing and building an Object List; (b) rendering and storing a Virtual Page; (c) composing and printing a page

In Figure 4a, HP Designjet T1100-series printers parse and build an Object List using essentially the

same process as HP Designjet T610-series printers. But, there are important differences: the Object

List is stored on the hard disk drive instead of RAM, and embedded PostScript processing is available

in HP Designjet T1100ps-series printers. The hard disk drive allows HP Designjet T1100-series

printers to process more complex pages than the HP Designjet T610-series, because the size of the

Object List is not limited by RAM.

In Figure 4b, the Object List produced by HP-GL/2, RTL, and PostScript parsers is fetched from the

hard disk drive and rendered. Note that PCL3GUI files are parsed and rendered directly as in HP

Designjet T610-series printers. The Virtual Page Storer

compresses the 24- or 32 bpp image data

using HP’s proprietary lossless algorithm. This algorithm is optimized for RGB and CMYK continuoustone data and allows more pages to be stored in the job queue without loss of quality. With 11GB

on the hard drive dedicated to job storage, the Virtual Page Store

can hold more than 11 A1 pages.

In Figure 4c, jobs are released from the top of the print queue when there is sufficient page data in

the Virtual Page Store to ensure that composing and printing the page can complete without running

out of data. This effectively prevents image quality problems from wait-state banding. The Virtual

Page Composer implements page nesting, crop marks, and other page layout features on the

compressed (virtual) page data. Then, the virtual page is decompressed by the ASIC and sent

through the Color Pipeline, Scaling, and Halftoning processes to produce print masks.

Also seen in Figure 4c is the direct writing path provided from the PCL3GUI Parser. The Parser can

produce halftoned print masks in 1-, 2-, or 4 bbp formats for each color of ink.

12

In this case, “N-channel” data shown in Figure 4c means 6-channels: one for each color printhead.

12

5

Page 6

Scalable Printing Technology and HP 72 Printheads

Using HP 72 printheads and HP Vivera inks, HP Designjet T1100- and T610-series printers produce

the fine and accurate lines and sharp text needed in technical graphics and business communication

applications. Consistently high print quality and faster printing speeds require precise drop ejection

characteristics, and these are determined by the design and construction of the printhead.

Figure 5. Detail of a Drop Generator on a Printhead built with HP Scalable Printing Technology

HP 72 Printheads are built with HP Scalable Printing Technology (SPT). SPT uses processes developed

for integrated circuit fabrication to form the printhead’s fluidic structures onto the silicon substrate that

contains the heaters (for drop ejection) and their control circuitry.

A cross-sectional detail of a single drop generator is shown in Figure 5. To get a sense of scale, the

entire fluidic structure (shown in a tan color) is about the thickness of a human hair.

Exposing and developing photo-sensitive epoxy materials (shown in a tan color in Figure 5) produces

ink channels and filters, drop generator chambers, and nozzles. These features are defined and

aligned together with sub-micron precision and become an integrated structure that is assembled inplace and without adhesives on the silicon substrate.

Because the SPT process can define and produce very small structures, a filter can be placed in the

ink supply for each drop generator (see the “pillars” in Figure 5). This improves printhead reliability

because microscopic particles are prevented from clogging the drop generators. And, SPT materials

are formulated to resist chemical interaction with Original HP inks to give long operational life.

SPT builds thousands of identical drop generators on a single silicon chip, and this ensures high print

quality with consistent drop volumes, drop speeds, and drop trajectories. With 1,200 nozzles per

inch, SPT-based HP 72 Printheads allow HP Designjet T1100- and T610-series printers to deliver high

productivity in all print modes and to produce very fine lines and crisp text.

HP Designjet T1100- and T610-series printers use three HP 72 Printheads for a total of 6,336 nozzles

in a 22.35mm (0.88 inch) print swath. Each HP 72 Printhead delivers two colors of ink (Gray/Photo

Black, Matte Black/Yellow, and Magenta/Cyan) with 1,056 nozzles per color.

When it is necessary, the user can remove and install an HP 72 Printhead in about a minute without

the expense, printer down-time, and inconvenience of a service call.

6

Page 7

For more information

To learn more about HP Designjet T1100- and T610-series printers and Original HP printing supplies,

visit

www.hp.com/go/designjet

© 2006 Hewlett-Packard Development Company, L.P. The information contained

herein is subject to change without notice. The only warranties for HP products and

services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or

omissions contained herein.

Itanium is a trademark or registered trademark of Intel Corporation or its

subsidiaries in the United States and other countries.

March 2007

Loading...

Loading...