HP SureStore DLT Autoloader

Models 418, 718 & 818

User’s Guide

Edition 1

Manufacturing Part Number: C6282-90009

September 1999

Printed in: Greeley, CO USA

© Copyright 1999 Hewlett-Packard Company

Notice

This document contains information that is protected by copyright. All

rights are reserved. No part of this document may be photocopied,

reproduced, or translated to another language. The information

contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

printed material, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance,

or use of this material.

See Appendix B for important safety and regulatory information.

Warranty

NOTE See Appendix A for more information about support and service.

HP PRODUCT: HP SureStore DLT Autoloader Models 418, 718, and 818

DURATION OF LIMITED WARRANTY: 3 years

1. HP warrants HP hardware, accessories, and supplies against defects

in materials and workmanship for the period specified above. If

Hewlett-Packard receives notice of such defects during the warranty

period, Hewlett-Packard will, at its option, either repair or replace

products which prove to be defective. Replacement products may be

either new or like-new.

2. HP warrants that HP software will not fail to execute its

programming instructions, for the period specified above, due to

defects in material and workmanship when properly installed and

used. If HP receives notice of such defects during the warranty period,

HP will replace software media that does not execute its

programming instructions due to such defects.

ii

3. HP does not warrant that the operation of HP products will be

uninterrupted or error free. If HP is unable, within a reasonable time,

to repair or replace any product to a condition as warranted, customer

will be entitled to a refund of the purchase price upon prompt return

of the product.

4. HP products may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of

installation if installed by HP. If customer schedules or delays HP

installation more than 30 days after delivery, warranty begins on the

31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or

inadequate maintenance or calibration, (b) software, interfacing,

parts or supplies not supplied by HP, (c) unauthorized modification or

misuse, (d) operation outside of the published environmental

specifications for the products, or (e) improper site preparation or

maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE

WARRANTIES ARE EXCLUSIVE AND NO OTHER WARRANTY

OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED

OR IMPLIED AND HP SPECIFICALLY DISCLAIMS ANY IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY,

SATISFACTORY QUALITY, AND FITNESS FOR A PARTICULAR

PURPOSE.

8. HP will be liable for damage to tangible property per incident up to

the greater of $300,000 or the actual amount paid for the product that

is the subject of the claim, and for damages for bodily injury or death,

to the extent that all such damages are determined by a court of

competent jurisdiction to have been directly caused by a defective HP

product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN

THIS WARRANTY STATEMENT ARE THE CUSTOMER’S SOLE

AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE,

IN NO EVENT WILL HP OR ITS SUPPLIERS BE LIABLE FOR

LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR

OTHERWISE.

iii

Printing History

New editions of this manual incorporate all material updated since the

previous edition. The manual printing date and part number indicate the

current edition. The printing date changes when a new edition is printed.

(Minor corrections and updates incorporated at reprint do not change

this date.)

Edition 1: September 1999: Initial printing

iv

Typographical Conventions and Terms

The following typographical conventions are used in this manual:

Italic font: Denotes important information.

Keycap : Keys on the Autoloader.

Computer Output: Information displayed in the control panel and screen menu items that you select.

Menu Path: Series of menus that you need to enter to access the menu currently being described.

WARNING Warnings call attention to a procedure or practice that could

result in personal injury if not correctly performed. Do not

proceed until you fully understand and meet the required

conditions.

CAUTION Cautions call attention to an operating procedure or practice that could

damage the product if not correctly performed. Do not proceed until

understanding and meeting these required conditions.

NOTE Notes provide information that can be helpful in understanding the

operation of the product.

v

In This Manual

In this manual, the following areas are described:

Chapter 1 Getting Started: Describes how to install, connect,

power on, and move the Autoloader.

Chapter 2 Operating the Autoloader: Describes how to operate

the control panel, set administrative options, and

troubleshoot.

Chapter 3 Using and Maintaining Tapes: Describes how to use

and care for tapes.

Appendix A Support and Customer Service: Describes how to get

support for the Autoloader and how to order parts.

Appendix B Safety and Regulatory: Describes safety and regulatory

information for the Autoloader.

Appendix C TapeAlert Messages: Describes the TapeAlert

messages.

Appendix D Installing an Autoloader Into a Non-HP Rack:

Describes how to install the Autoloader into a non-HP

rack.

vi

Contents

1. Getting Started

Chapter Overview................................................................................. 1-2

Product Components ............................................................................ 1-3

Installation Overview...........................................................................1-4

Autoloader Rear Panel................................................................... 1-5

Choosing a Location.......................................................................1-6

Mounting the Autoloader in a Rack..............................................1-7

Tools and Components.............................................................1-7

Mounting the Autoloader ........................................................ 1-8

Connecting the Autoloader...................................................................1-15

T

a

b

l

e

o

f

C

o

n

t

e

n

t

s

Powering on the System....................................................................... 1-18

Installing the SCSI Bus Adapter ......................................................... 1-19

Moving or Shipping the Autoloader.....................................................1-20

Moving the Autoloader...................................................................1-20

Shipping the Autoloader................................................................ 1-22

2. Operating the Autoloader

Chapter Overview................................................................................. 2-2

Loading/Unloading Tapes.....................................................................2-3

Inserting and Removing Tapes with Software ............................. 2-3

Opening the Door ........................................................................... 2-3

Alternate Door Open Method.................................................. 2-3

Removing the Magazine .......................................................... 2-4

Inserting the Magazine ........................................................... 2-5

Loading Tapes .......................................................................... 2-5

Unloading Tapes ......................................................................2-7

Autoloader Control Panel..................................................................... 2-8

vii

Contents

Understanding Control Panel Messages............................................. 2-9

Tape Status .................................................................................... 2-9

Drive/Autoloader Status................................................................ 2-10

Autoloader Display Menu Tree............................................................ 2-11

Top-Level Menu Options...................................................................... 2-12

Password-Protected Functions...................................................... 2-15

Entering the Administration Menu Password.................................... 2-17

Changing the Administration Menu Password .................................. 2-18

Setting or Viewing SCSI IDs ............................................................... 2-19

Setting SCSI IDs............................................................................ 2-19

Viewing SCSI IDs .......................................................................... 2-20

Cleaning the Autoloader Tape Drive................................................... 2-21

Drive Cleaning Errors.......................................................................... 2-23

Configuring the Autoloader ................................................................. 2-24

Retrieving Autoloader Information..................................................... 2-27

Running an Internal Test .................................................................... 2-28

Upgrading Firmware............................................................................ 2-33

Upgrading Drive Firmware from Tape ......................................... 2-33

Troubleshooting.................................................................................... 2-34

Understanding Error Messages........................................................... 2-42

3. Using and Maintaining Tapes

Chapter Overview ................................................................................ 3-2

Labeling Tape Cartridges ................................................................... 3-3

Labeling the Magazine......................................................................... 3-4

viii

Contents

Write-Protecting Tape Cartridges ....................................................... 3-5

Maintaining Tape Cartridges............................................................... 3-6

Do Not:............................................................................................ 3-6

Do: ................................................................................................... 3-6

Inspecting Tape Cartridges.................................................................. 3-7

DO NOT Use Cartridges:............................................................... 3-8

A. Support and Customer Service

Supplies and Accessories......................................................................A-2

Hewlett-Packard Customer Support ...................................................A-3

T

a

b

l

e

o

f

C

o

n

t

e

n

t

s

Information Needed for Support ...................................................A-3

Faxback Services ............................................................................ A-4

Hewlett-Packard Web Site............................................................. A-4

Telephone Support During Warranty............................................A-5

North and South America ....................................................... A-5

European Customer Support Centers .................................... A-5

Asia Pacific Customer Support Centers ................................. A-7

Elsewhere................................................................................. A-7

Telephone Support After Warranty............................................... A-8

US and Canada ........................................................................ A-8

Europe ...................................................................................... A-8

Elsewhere................................................................................. A-8

HP Reseller Locator Numbers ................................................ A-8

B. Safety and Regulatory

Chapter Overview................................................................................. B-2

Regulatory Information........................................................................ B-3

United Kingdom Telecommunications Act 1984 ..........................B-4

ix

Contents

Herstellerbescheinigung................................................................ B-4

English Translation of German Sound Emission Directive ........ B-4

Japanese Harmonics Statement ................................................... B-5

Japanese VCCI Class B Statement............................................... B-5

English Translation ................................................................ B-5

Taiwan Class A Warning Statement............................................. B-6

For HP DLT Library Model 718 (C6282L, C6280J, A5501A) B-6

Taiwan Class A Warning Statement............................................. B-6

For HP DLT Library Model 418 (C6280F and C6280H) ....... B-6

C. TapeAlert Messages

Overview............................................................................................... C-2

TapeAlert Messages and Descriptions ................................................ C-3

D. Installing an Autoloader into a Non-HP Rack

Mounting the Autoloader in a Non-HP Rack...................................... D-2

Tools and Components................................................................... D-2

Mounting the Autoloader .............................................................. D-3

Cable Management........................................................................ D-9

x

Figures

Figure1-1.RearPanelFeatures...............................1-5

Figure1-2.RackKitParts ...................................1-7

Figure1-3.ClipnutandScrewInstallation......................1-8

Figure1-4.InstallationWithSpaceAboveBezel .................1-9

Figure1-5.InstallationWithoutSpaceAboveBezel...............1-9

Figure1-6.ShelfInstallation................................1-10

Figure 1-7. Filler Panel Installation...........................1-11

Figure1-8.RemovingtheCoverandFeet......................1-12

Figure1-9.SecuringtheAutoloader ..........................1-13

T

a

b

l

e

o

f

C

o

n

t

e

n

t

s

Figure1-10.CableManagement..............................1-14

Figure1-11.AutoloaderastheOnlyPeripheral .................1-16

Figure1-12.AutoloaderwithOtherPeripherals.................1-17

Figure1-13.UnboltingtheAutoloader ........................1-21

Figure2-1.RemovingtheMagazine............................2-4

Figure2-2.LoadingTapesintotheMagazine....................2-5

Figure2-3.LoadingInternalSlots.............................2-6

Figure3-1.LabelPosition....................................3-3

Figure3-2.MagazineLabelPosition ...........................3-4

Figure3-3.Write-ProtectButtonSettings.......................3-5

Figure3-4.LeaderBucklingLoop .............................3-7

FigureD-1.RackKitParts...................................D-2

FigureD-2.ClipnutandScrewInstallation......................D-3

FigureD-3.CustomizingtheShelfDepth .......................D-4

xi

Figures

FigureD-4.ShelfInstallation................................ D-5

FigureD-5.TightentheScrews............................... D-6

Figure D-6. Filler Panel Installation. . ......................... D-7

FigureD-7.SecuringtheAutoloader .......................... D-8

FigureD-8.CableManagement .............................. D-9

xii

Table s

Table 1-1. Components Provided .......................................................1-3

Table 1-2. Location Criteria ...............................................................1-6

Table 1-3. Technical Specifications....................................................1-6

Table 2-1. Top-Level Menus...............................................................2-12

Table 2-2. Admin Menu Options........................................................2-15

Table 2-3. Drive Cleaning Troubleshooting ......................................2-23

Table 2-4. Configuration Options ......................................................2-24

Table 2-5. Information Logs...............................................................2-27

Table 2-6. Tests Available from the Control Panel...........................2-28

T

a

b

l

e

o

f

C

o

n

t

e

n

t

s

Table 2-7. Troubleshooting Table ...................................................... 2-32

Table 2-8. Common Error Codes........................................................2-41

Table C-1. TapeAlert Tape Drive Error Messages............................C-3

Table C-2. TapeAlert Tape Library Error Messages ........................C-7

xiii

Table s

xiv

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1GettingStarted

1-1

Getting Started

Chapter Overview

Chapter Overview

This chapter explains the following:

• Identifying product components

• Choosing a location

• Installing the Autoloader

• Connecting the Autoloader

• Powering on the system

• Installing the SCSI bus adapter

• Moving the Autoloader

• Shipping the Autoloader

1-2 Chapter 1

Product Components

Table 1-1 describes the parts that are provided with the Autoloader.

Table 1-1 Components Provided

Product Name Description

SCSI cables Connects the Autoloader to the host. Cable

length is 2 meters.

SCSI terminator 68-pin terminator terminates power at the end

of a SCSI chain.

SCSI jumper cable Connects the drive and SCSI controller board.

SCSI bus adapter Matches the interface type of the Autoloader.

Power cord Localized power cord supplies power.

Data cartridges Five type IV DLTtape

backup.

Getting Started

Product Components

Ô

cartridges for data

G

e

t

t

i

n

g

S

t

a

r

t

e

d

Cleaning cartridge One cartridge included for cleaning the tape

drive head.

Installation poster Displays simplified installation instructions.

Live trial software One shrink-wrapped package for trial use.

Contact software vendor for licensing

information.

User’s Guide Contains installation, operation, and

troubleshooting information.

SureStore Tape CD-ROM

Contains diagnostic utilities, backup software

information, and localized versions of the user’s

guide and installation poster.

Chapter 1 1-3

Getting Started

Installation Overview

Installation Overview

Before installing the Autoloader:

• Make sure you have the components listed in Table 1-1 on page 1-3.

• Become familiar with the back of the Autoloader, as shown in

Figure 1-1 on page 1-5.

Installing the Autoloader requires:

1. Choosing a suitable location.

2. Mounting the Autoloader in a rack (rackmount configuration only).

3. Connecting the Autoloader.

4. Powering on the system.

These steps are explained in this chapter.

NOTE After unpacking the Autoloader, save the shipping carton and accessory

kit carton. These items may be reused if future shipping becomes

necessary.

1-4 Chapter 1

Getting Started

Installation Overview

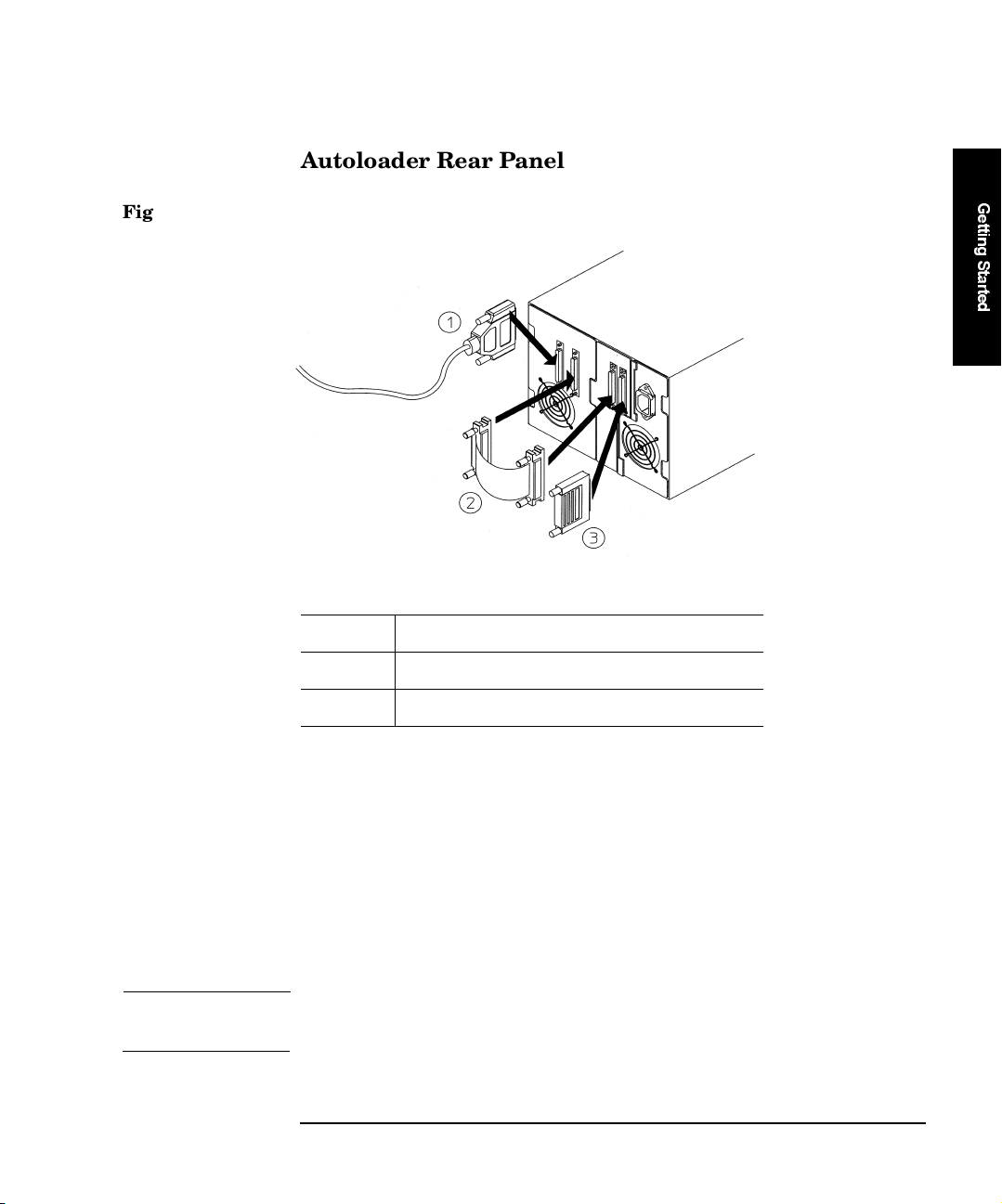

Autoloader Rear Panel

Figure 1-1 Rear Panel Features

1 SCSI cable connector to host SCSI port

2SCSIjumpercable

G

e

t

t

i

n

g

S

t

a

r

t

e

d

3SCSIterminator

The Autoloader can be connected to the host system in one of two configurations:

Standard

configuration: Connects the drive and the Autoloader with an

external jumper cable on one SCSI bus, as shown in

Figure 1-1.

Advanced configuration: Connects the drive and autoloader controller to the

host using separate SCSI buses.

NOTE The advanced configuration requires an additional terminator that is not

provided.

Chapter 1 1-5

Getting Started

Installation Overview

Choosing a Location

Choose a location that meets the following criteria:

Table 1-2 Location Criteria

Room temperature 50–104° F (10–40 C)

Power source AC power voltage: 100–127V or 200–240V

Air quality Minimal particulate contamination. Avoid areas

Auto Ranging

Current Rating: 100–127V, 1.8A, 50/60 HZ,

220–240V, .9A, 50/60 HZ Auto Ranging

Maximum Watts: 100 Watts, 100-127V (60 HZ)

Maximum Watts: 90 Watts, 200-240V (50 HZ)

near frequently used doors and walkways,

stacks of supplies that collect dust, smoke-filled

rooms, large or high-speed printers. Do not use

filters.

Caution: Excessive dust and debris can damage

the tapes and the tape drive.

Adequate clearance

Table 1-3 Technical Specifications

Dimensions Height: 7.35 inches (18.7 cm)

Acoustics 58 Decibels Sound Pressure

1-6 Chapter 1

Desktop configuration—free standing:

Back 6 inches/ 15 cm

Front 8 inches/ 20 cm

Sides 1 inch/ 2.5 cm

Rackmount configuration—requires 5 EIA units

inarack(1EIA=1.75inchesor4.5mm)

Width: 8.9 inches (22.6 cm)

Depth: 22 inches (55.9 cm

Weight: 31.5 pounds (14.3 kg)

Getting Started

Installation Overview

Mounting the Autoloader in a Rack

NOTE For instructions on installing the Autoloader into a non-HP rack, refer to

“Installing an Autoloader into a Non-HP Rack” on page D-1.

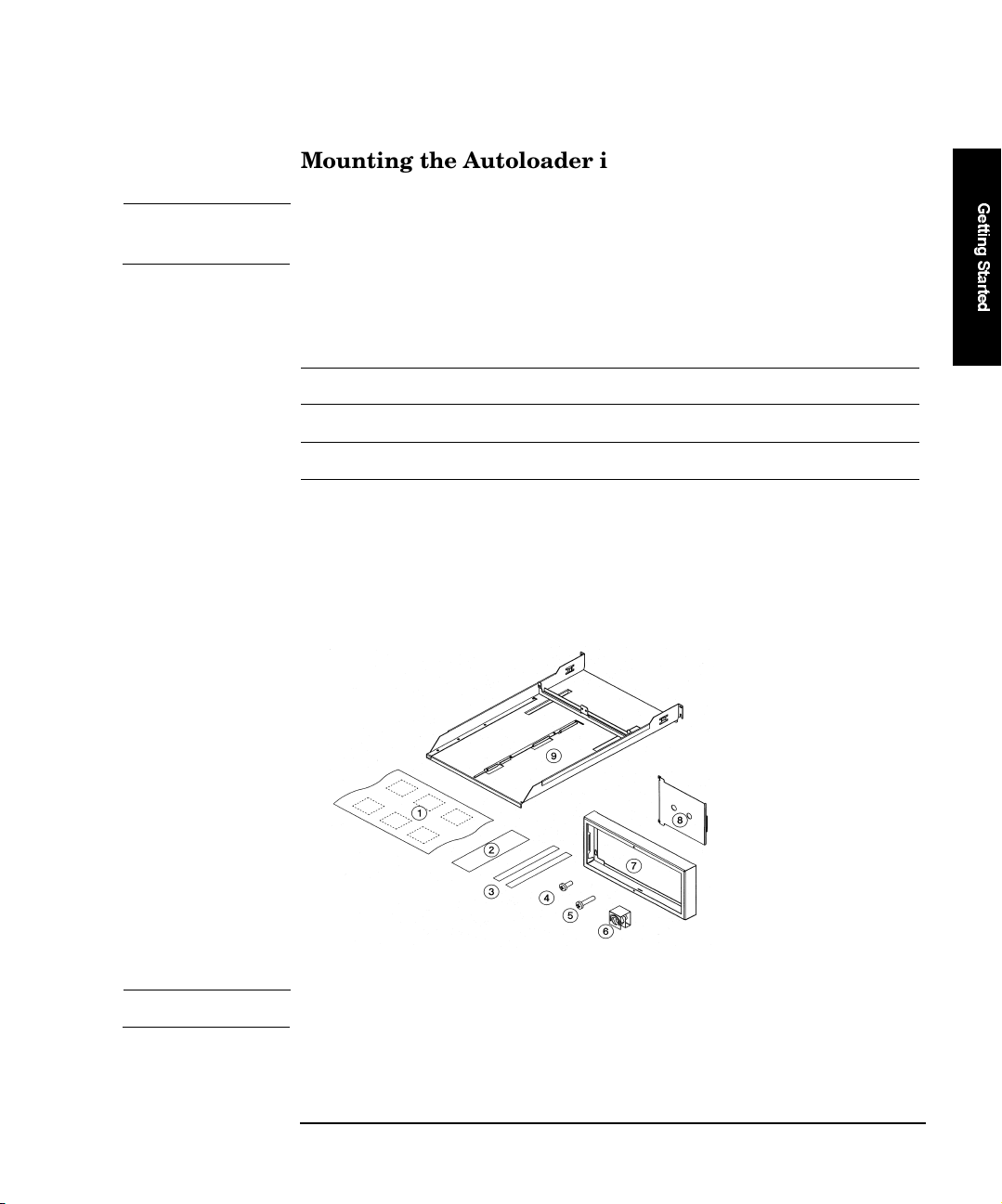

Too ls and Comp onen t s

Beforeyoubegin,makesureyouhavethefollowing:

Too ls :

#2 Phillips screwdriver

Kit Components (parts are labeled for easy identification):

1. Installation poster (Qty 1)

2. Template (Qty 2)

3. Cable ties (Qty 2)

4. M4 x 10 mm pan phillips (Qty 4)

5. 10-32 x 5/8 pan phillips (Qty 8)

Figure 1-2 Rack Kit Parts

6. 10-32 clipnuts (Qty 8)

7. Support bezel (Qty 1)

8. Filler panel (Qty 1)

9. Shelf (Qty 1)

G

e

t

t

i

n

g

S

t

a

r

t

e

d

NOTE The rack kit may contain extra parts.

Chapter 1 1-7

Getting Started

Installation Overview

Mounting the Autoloader

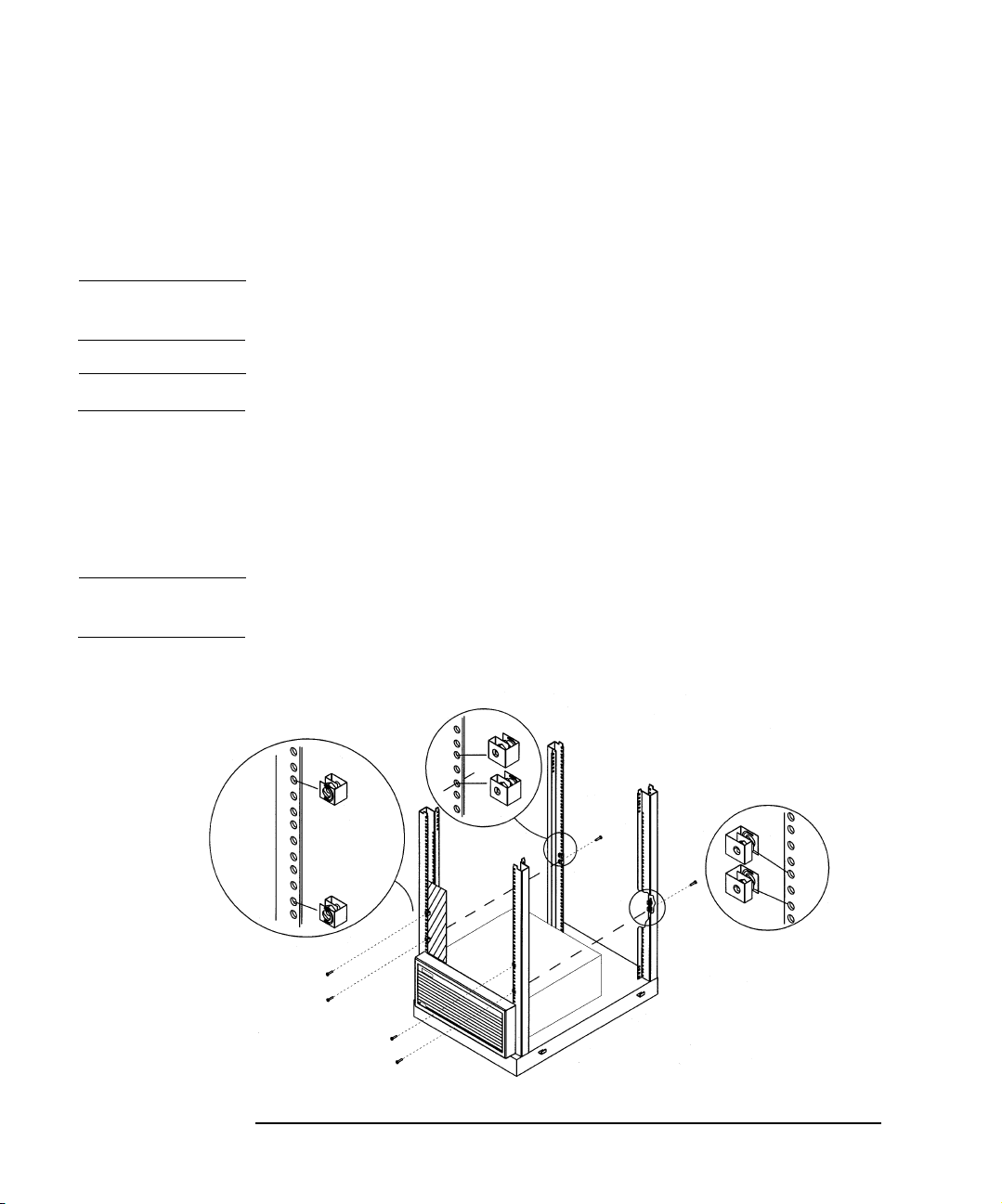

1. Facing the front of the rack and using the template as a guide, install

four clipnuts (two in each rail) above any existing products

(Figure 1-3).

TIP For a level shelf, ensure that the screws are in the same position on the

right and left rail.

NOTE Your rack might look different from the illustrations.

2. Using the template as a guide, install two clipnuts into each back rail

of the rack. The back lower clipnuts should be located in the same

position as the lower clipnuts in the front of the rack (Figure 1-3).

3. Using six 10-32 screws (four in the front and two in the back lower

clipnuts), start a screw into each clipnut and turn 2-3 times.

NOTE If you are installing the unit flushed to the top of the rack, do not install

screws at this time. Instead, proceed to the next step.

Figure 1-3 Clipnut and Screw Installation

1-8 Chapter 1

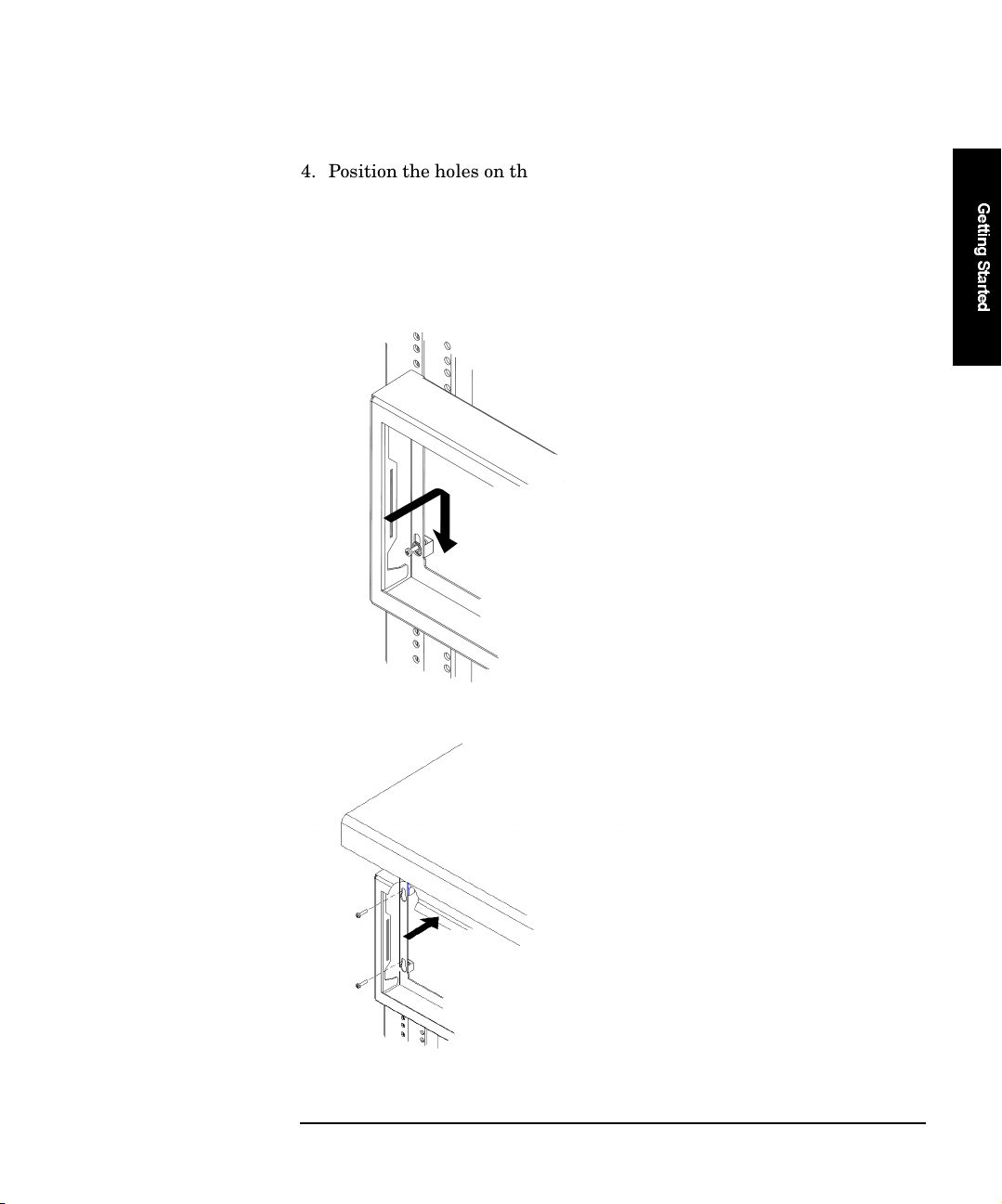

4. Position the holes on the support bezel over the screws on the clipnut,

and slide downward, securing the bezel into place (Figure 1-4). If you

are installing the Autoloader flushed to the top of the rack, hold the

bezel in place, then install the screws (Figure 1-5). Tighten screws

when complete.

Figure 1-4 Installation With Space Above Bezel

Getting Started

Installation Overview

G

e

t

t

i

n

g

S

t

a

r

t

e

d

Figure 1-5 Installation Without Space Above Bezel

Chapter 1 1-9

Getting Started

Installation Overview

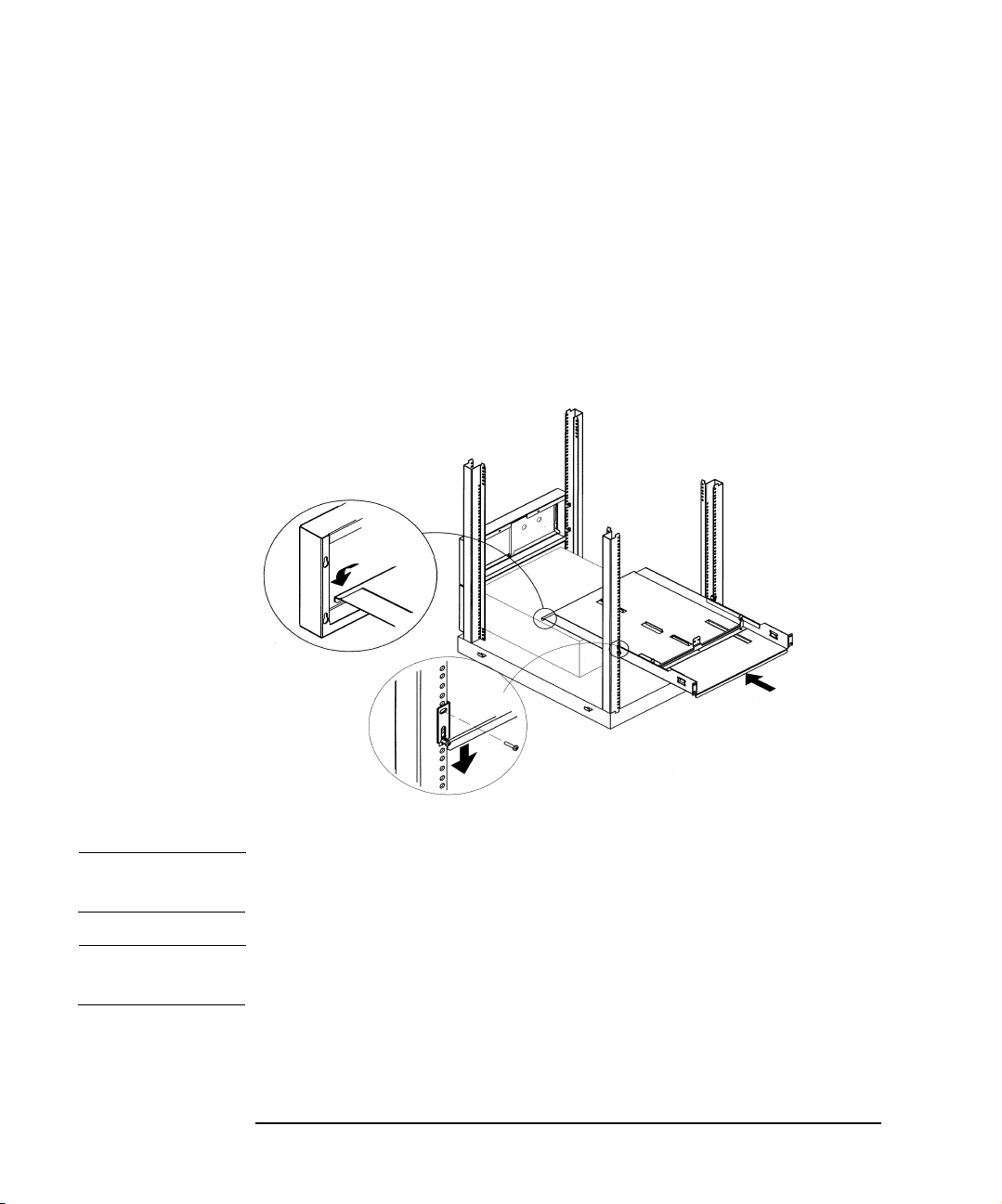

5. Slide the shelf through the back of the rack until the front lip is over

the bezel and the rear portion of the shelf slides over the back screws

(Figure 1-6).

a. Lower the shelf into place, and tighten the screws in the bottom

clipnuts.

b. Insert and tighten two additional screws into the top clipnuts to

secure the shelf.

Figure 1-6 Shelf Installation

NOTE Have a second person stand at the front of the rack to help guide the

front lip of the shelf between the slots on the bezel.

CAUTION Ensure that installation in your rack cabinet does not create an unstable

condition.

1-10 Chapter 1

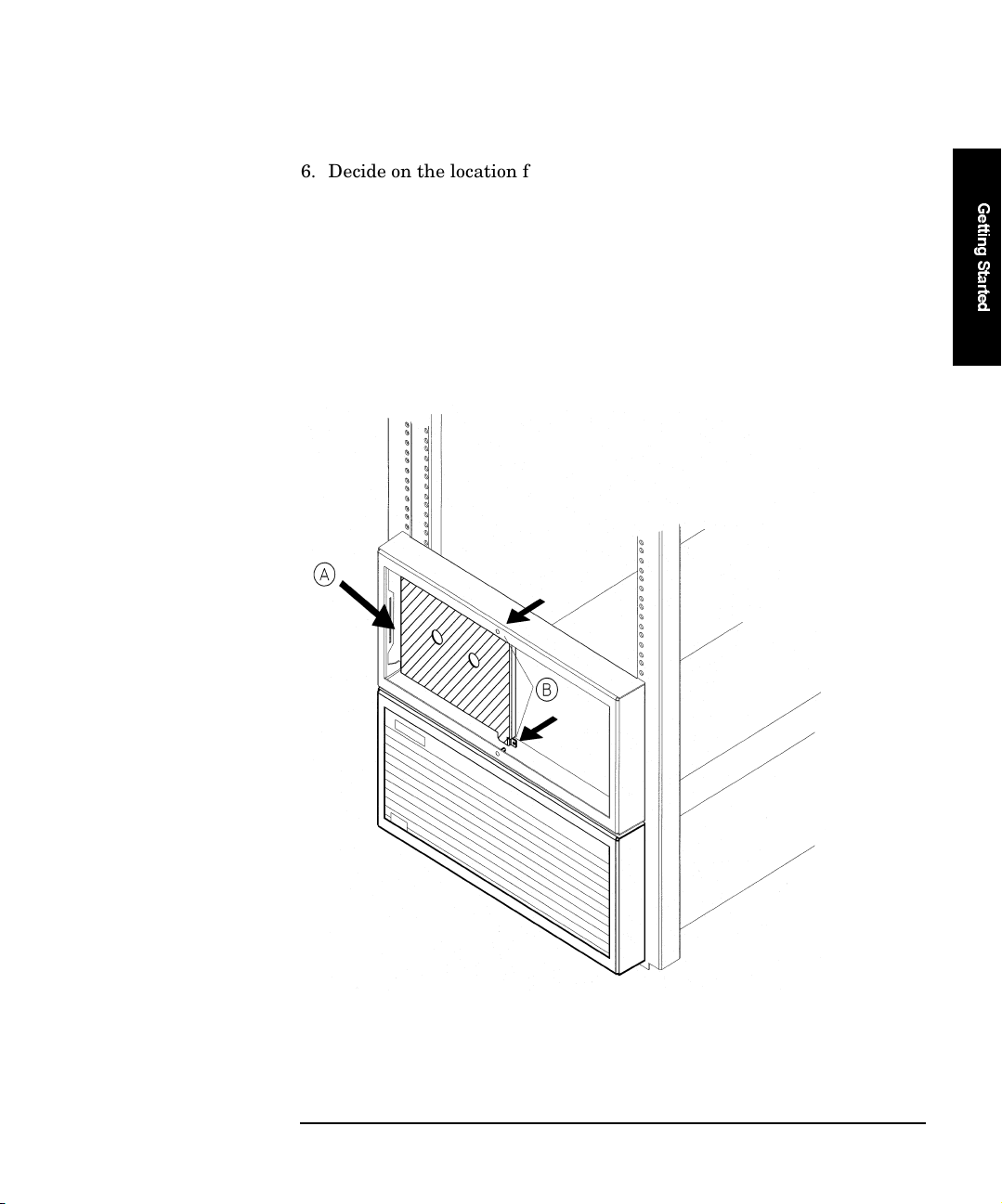

6. Decide on the location for the Autoloader. The filler panel will be

installed on the other side if you are only installing one Autoloader

(Figure 1-7).

a. Reach inside the bezel and insert the filler panel into the slot on

the bezel.

b. Pull the filler panel forward to the inside face of the bezel until it

snaps into position.

Figure 1-7 Filler Panel Installation

Getting Started

Installation Overview

G

e

t

t

i

n

g

S

t

a

r

t

e

d

Chapter 1 1-11

Getting Started

Installation Overview

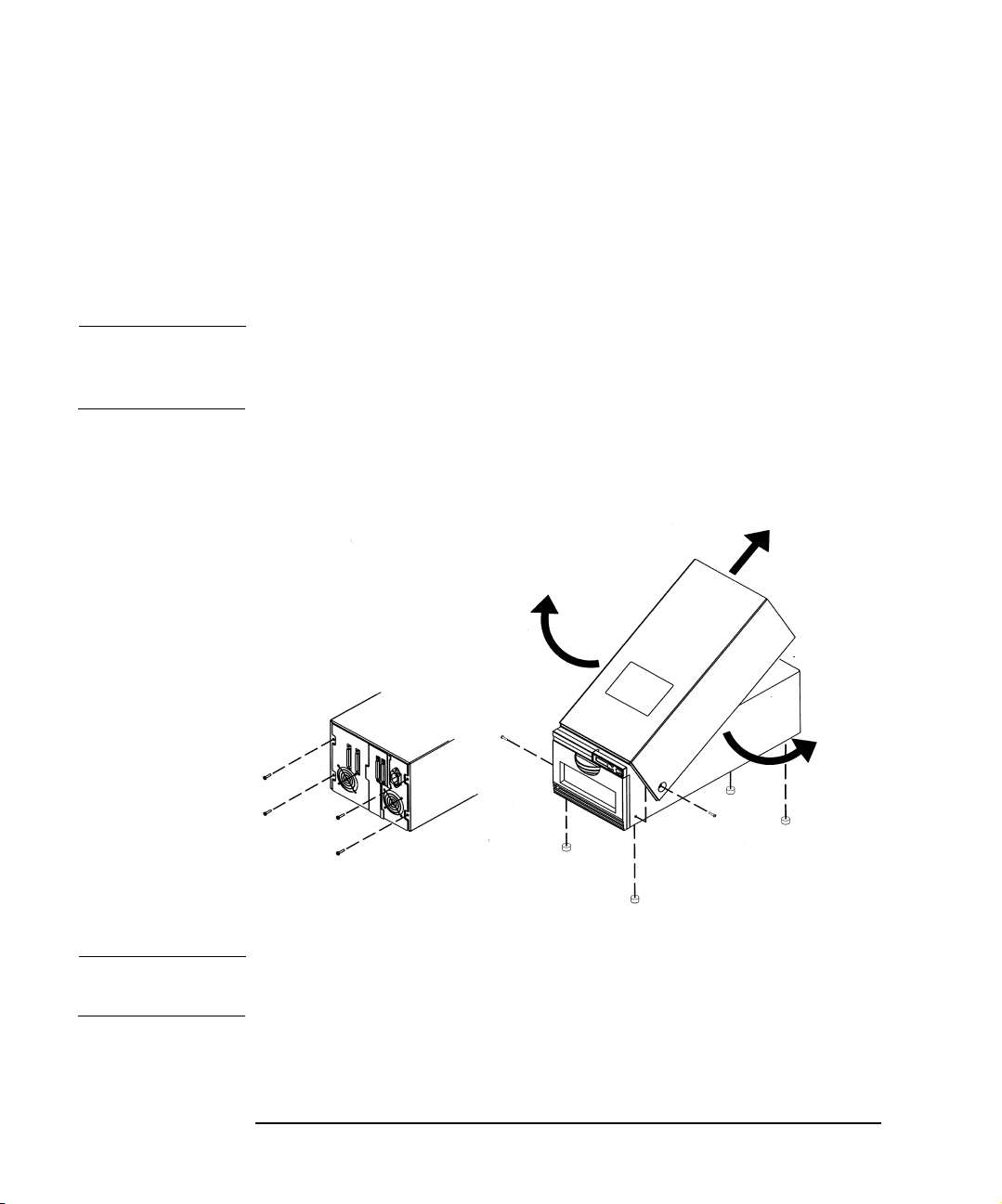

7. Remove the cover and feet on the Autoloader.

a. Remove the four screws on the back of the cover and the two

screws on the side of the cover (Figure 1-8).

b. Remove the cover by pulling the sides of the cover out and lifting it

up.

NOTE The cover may fit tightly near the control panel. If the cover is not easily

removed, pull the sides out near the control panel while lifting up on the

back end of the cover.

c. Unscrew and remove the four feet. You may lay the unit on its side

to remove the feet.

Figure 1-8 Removing the Cover and Feet

NOTE If it later becomes necessary to ship the Autoloader, reattach the cover

and feet before shipping.

8. From the front of the bezel, slide the Autoloader into the shelf until it

rests firmly against the support bracket.

1-12 Chapter 1

Getting Started

Installation Overview

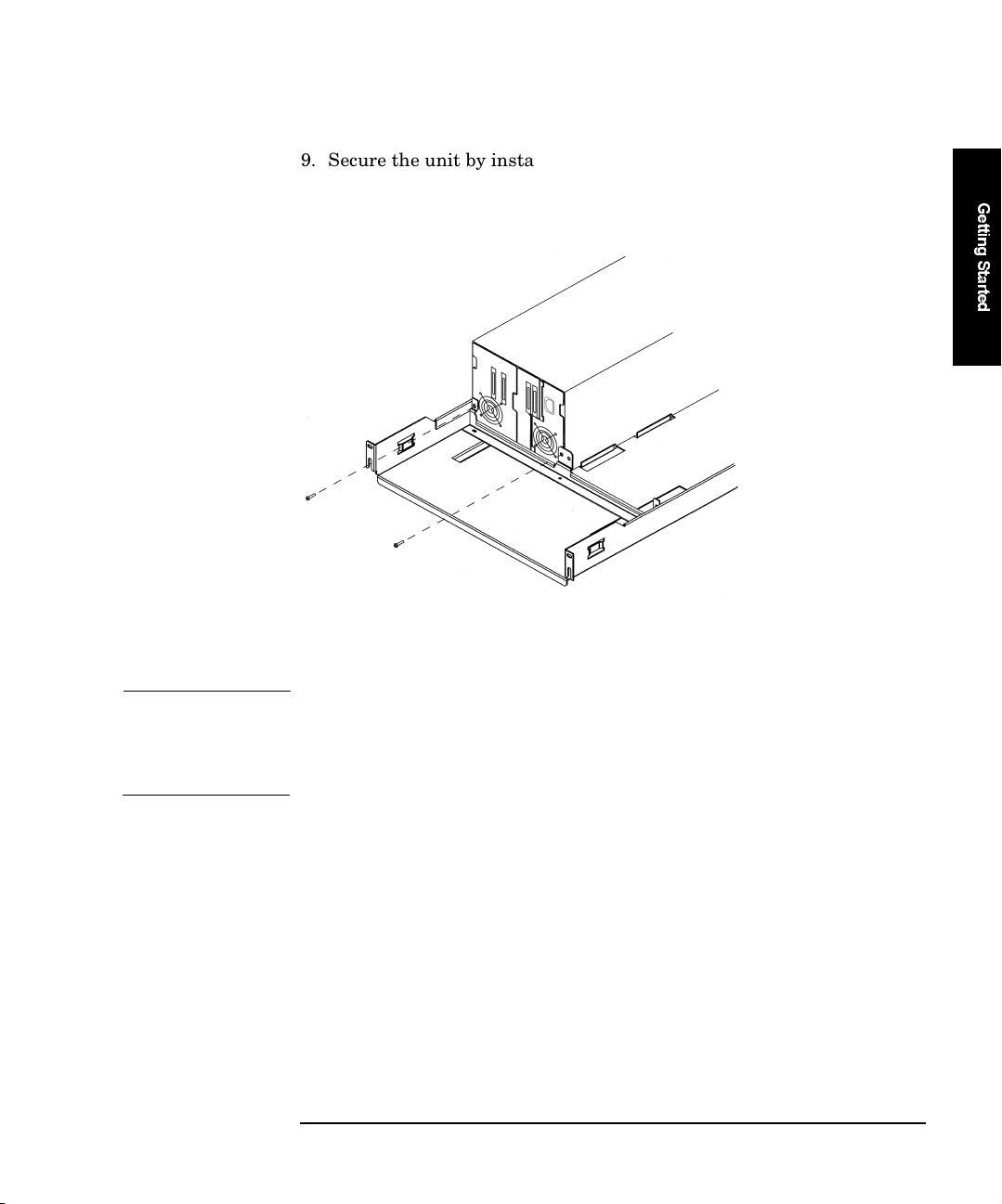

9. Secure the unit by installing two M4x10 mm screws through the

support bracket and into the rear panel (Figure 1-9).

Figure 1-9 Securing the Autoloader

10.After connecting the external cables, secure the cables to the side of the rack.

G

e

t

t

i

n

g

S

t

a

r

t

e

d

CAUTION Ensure that the SCSI and power cables are properly routed and secured

on rackmounted Autoloaders so that they do not interfere with other

moveable rackmounted products. Failure to properly route cables could

damage them.

a. After connecting external cables described in “Connecting the

Autoloader” on page 1-15, thread one cable tie through the cable

tie mount on the shelf (Figure 1-10 on page 1-14).

b. Gently pull the cables toward the cable tie to secure them to the

back of the shelf.

c. Route the cables through the rack so that they do not interfere

with other rackmounted products.

Chapter 1 1-13

Getting Started

Installation Overview

Figure 1-10 Cable Management

NOTE Save the remaining screws for a possible second Autoloader installation.

CAUTION Be certain that the temperature of the rack cabinet does not exceed the

maximum temperature of 104oF or 40C.

1-14 Chapter 1

Getting Started

Connecting the Autoloader

Connecting the Autoloader

1. Properly shut down all peripheral devices connected to the host

computer.

If the host computer is connected to a network, check with the system

administrator before switching off power.

2. Shut down the host.

If the host does not already have a SCSI bus adapter with a matching

interface type, install the supplied adapter. See “Installing the SCSI

Bus Adapter” on page 1-19 for more information.

3. Connect the long SCSI cable from the Autoloader to the host.

NOTE For maximum performance, do not connect the Autoloader to the same

SCSI bus as the hard drive, another tape drive, or a SCSI RAID

controller.

G

e

t

t

i

n

g

S

t

a

r

t

e

d

4. Connect the SCSI jumper cable to the two inside connectors on the Autoloader.

To install the Autoloader as the only device on the SCSI bus, connect

the cables and terminator as shown in Figure 1-11 on page 1-16.

To install the Autoloader in the middle of a SCSI bus, connect the

cables and terminator as shown in Figure 1-12 on page 1-17.

NOTE If using a single-ended Autoloader with an HVDS host, you must use a

single-ended to wide differential converter, such as HP part number

C4316A converter. To install, connect a wide SCSI cable from the host

differential SCSI port to the differential fast/wide input of the converter.

Connect the single-ended output of the converter to the Autoloader.

Any converter used must be fully SCSI compliant.

Chapter 1 1-15

Getting Started

Connecting the Autoloader

Figure 1-11 Autoloader as the Only Peripheral

1 SCSIcabletohostSCSIport

2SCSIjumpercable

3 SCSI 68-pin terminator

1-16 Chapter 1

Figure 1-12 Autoloader with Other Peripherals

Getting Started

Connecting the Autoloader

G

e

t

t

i

n

g

S

t

a

r

t

e

d

1SCSIcabletohostSCSIport

2 SCSI jumper cable

3 SCSI cable to SCSI port

4 SCSI 68-pin terminator

5. Verify the standby switch on the autoloader control panel is switched

off. Connect the socket end of the power cord into the power port on

the autoloader rear panel.

6. If you are mounting the unit in a rack, secure the cables to the side of

the rack as shown in Figure 1-10 on page 1-14.

7. To power on the unit, see the instructions in “Powering on the

System” on page 1-18.

Chapter 1 1-17

Getting Started

Powering on the System

Powering on the System

WARNING To disconnect primary power, remove the power cord from the

wall receptacle. The standby switch on the front of the unit shuts

down secondary circuits only.

CAUTION Make certain that reliable earth grounding of the rackmounted

equipment and the power tap is maintained.

CAUTION Be certain that the total current of the rack components does not exceed

the current rating of the power tap or outlet receptacle.

1. Power off the host and other peripherals.

2. Connect the power cord into a grounded outlet.

3. If the standby switch is turned off, use a pencil eraser or other similar

tool to switch it on (see “Autoloader Control Panel” on page 2-8).

Initially the messages NOT READY/SELF TEST, NOT READY/INVENTORY CHECK,andNOT READY/CHECK DRIVE will display on the front control panel. After the power-on test completes (approximately 30 seconds), the drive status information appears in the display window.

NOTE If you have problems powering on the unit see “Troubleshooting” on page

2-32.

4. Turn on any other peripherals.

5. Turn on the host.

1-18 Chapter 1

Getting Started

Installing the SCSI Bus Adapter

Installing the SCSI Bus Adapter

Refer to the host computer user’s guide and the card installation

instructions for information on installing the SCSI bus adapter.

Follow these guidelines:

• Make sure that the host has a PCI expansion slot available.

• Power off the host before installation.

• For maximum performance, do not connect other peripherals to the sameSCSIbusastheharddrive.

• If you are using a SCSI bus adapter other than the one provided,

ensure that it matches the Autoloader interface type as shown below.

Model Part Number Interface

418 C6280F Single-Ended SCSI

718 C6280J Single-Ended SCSI

G

e

t

t

i

n

g

S

t

a

r

t

e

d

818 C6282NB

C6282RA

Low Voltage Differential SCSI (LVDS) High Voltage Differential SCSI (HVDS)

CAUTION Do not connect an HVDS Autoloader on a single-ended SCSI bus.

LVDS Autoloaders require an LVDS terminator and can be used on a

single-ended or low voltage differential SCSI bus.

The SCSI specification defines maximum cable lengths for LVDS as:

• 3 meters in single-ended fast/wide mode

• 6 meters in single-ended slow mode

• 12 meters in LVDS mode

• 1.5 meters if a single-ended ultra SCSI device is on the same bus

Chapter 1 1-19

Getting Started

Moving or Shipping the Autoloader

Moving or Shipping the Autoloader

Moving the Autoloader

1. Verify that a tape is not in the drive.

• If the drive is loaded with a tape, unload it before moving the

Autoloader. Refer to the backup software documentation, or use

the UNLOAD menu option (see “Top-Level Menu Options” on page

2-12).

2. Shut down the host if necessary.

CAUTION Notify the system administrator before shutting down the host.

3. Remove the power cord and the host SCSI cable from the autoloader rear panel.

• If the Autoloader is a stand-alone unit, place it onto a cart and

wheel it to its new location. Go to step 5.

• If the Autoloader is rackmounted, follow these steps:

a. Remove the two screws that secure the back of the Autoloader

to the shelf (Figure 1-13 on page 1-21).

b. Remove the filler panel (if necessary), and slide the Autoloader

out of the rack.

c. Move the Autoloader to its new destination.

4. Reinstall the Autoloader into the rack using the rackmount kit

instructions in “Mounting the Autoloader” on page 1-8.

NOTE You will need the rack kit equipment to reinstall the unit into another

rack (Figure 1-2 on page 1-7).

1-20 Chapter 1

Getting Started

Moving or Shipping the Autoloader

Figure 1-13 Unbolting the Autoloader

G

e

t

t

i

n

g

S

t

a

r

t

e

d

5. Reconnect the power cord and SCSI cables. See “Connecting the

Autoloader” on page 1-15.

Chapter 1 1-21

Getting Started

Moving or Shipping the Autoloader

Shipping the Autoloader

1. Verify that a tape is not in the drive.

• If the drive is loaded with a tape, unload it before moving the

Autoloader. Refer to the backup software documentation, or use

the UNLOAD menu option. See “Top-Level Menu Options” on page

2-12.

2. Remove all tape cartridges from the magazine and internal slots, and

return the magazine to the Autoloader.

3. Shut down the host if necessary.

CAUTION Notify the system administrator before shutting down the host.

4. Remove the power cord and the host SCSI cable from the rear panel.

• If the Autoloader is a desktop unit, go to step 5.

• If the Autoloader is rackmounted, follow these steps:

a. Remove the two screws that attach the Autoloader to the shelf

(Figure 1-13 on page 1-21).

b. Remove the filler panel (if necessary), and slide the Autoloader

out of a rack.

NOTE You will need the rack kit equipment to reinstall the unit into another

rack (Figure 1-2 on page 1-7).

5. Repackage the Autoloader in the original packing materials.

If the original packaging materials are not available, contact your

service representative for packaging materials.

CAUTION The Autoloader can be seriously damaged if it is not shipped using

appropriate shipping materials.

1-22 Chapter 1

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

2 Operating the Autoloader

2-1

Operating the Autoloader

Chapter Overview

Chapter Overview

This chapter explains how to:

•Loadandremovetapes

• Load and remove the magazine

• Operate the control panel

• Interpret control panel messages

• Enter and change an administration menu password

•ViewandsetSCSIIDs

• Clean the tape drive

• Interpret drive cleaning errors

• Configure the Autoloader

• Retrieve Autoloader information

•Runinternaltests

• Upgrade firmware

•Troubleshoot

• Interpret common error messages

2-2 Chapter 2

Loading/Unloading Tapes

Operating the Autoloader

Loading/Unloading Tapes

Inserting and Removing Tapes with Software

If you are using a software application to manage tapes in the

Autoloader, check the software documentation for instructions on

inserting and removing them.

Opening the Door

1. Press the NEXT button until RELEASE DOOR is displayed in the control panel.

2. Press

3. Gently open the front access door by pulling down the handle.

ENTER.

• If the drive is empty, the door will release.

• If a tape is loaded in the drive, EMPTY DRIVE NO is displayed. If the

Autoloader is controlled with host software, press

CANCEL to abort. Use the host software to unload the drive.

•Otherwise,press

displayed, and then press

NEXT or PREV until EMPTY DRIVE YES is

ENTER.

ENTER or

UNLOADING DRIVE will be displayed for up to two minutes, followed by DOOR RELEASED.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Alternate Door Open Method

1. Press and hold the

CANCEL button for three to five seconds.

2. After hearing a “click,” pull on the door handle to open.

Chapter 2 2-3

Operating the Autoloader

Loading/Unloading Tapes

Removing the Magazine

1. Swing the magazine handle forward until it is perpendicular with the

magazine (Figure 2-1).

2. Pull the magazine straight out.

Figure 2-1 Removing the Magazine

NOTE Remove the magazine to load tapes. If tapes are loaded while the

magazine is in the autoloader, tapes may not be secured inside the slot.

2-4 Chapter 2

Operating the Autoloader

Loading/Unloading Tapes

Inserting the Magazine

1. With the magazine handle facing out the front of the Autoloader, slide

the magazine into the Autoloader until it “clicks” into place

(Figure 2-1 on page 2-4).

2. Swing the magazine handle to the left to store.

3. Gently shut the front access door.

NOTE The INVENTORY CHECK runs whenever the front access door closes so that

an inventory of storage slot locations can be stored into memory. This

process takes approximately thirty seconds. The inventory check will not

run if the door is not completely shut, or if magazine is not completely

inserted.

Loading Tapes

The Autoloader has two internal storage slots inside the unit (slot

numbers 7 and 8) and six storage slots in the removable magazine (slot

numbers 1-6).

1. With the write-protect switch facing out and at the top, load tapes

into the magazine by pushing the tape in until it “clicks.” If the tape

does not “click” into place and the magazine is inside the autoloader,

remove the magazine to load the tape. A metal tab should release to

lockthetapeintoplace(Figure2-2).

Figure 2-2 Loading Tapes into the Magazine

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Chapter 2 2-5

Operating the Autoloader

Loading/Unloading Tapes

CAUTION Discharge static by touching the internal sheet-metal panel on the left

side of the unit. Take care not to touch internal electronics.

NOTE If the metal tab is already in the “Up” position, place the corner of the

tape on the tab, and slide the tape into the slot. The latching mechanism

will not click since the tab is already engaged. When tapes are “locked”

into the magazine, the tapes will not fall out if the magazine is turned.

2. With the write-protect switch facing out of the Autoloader and at the

top, load internal slots by pushing the tape in until it “clicks.”

NOTE Themagazinemustberemovedtoloadtheinternalslots(Figure2-3).

Figure 2-3 Loading Internal Slots

3. With the magazine handle facing out the front of the Autoloader, slide

the magazine into the Autoloader until it “clicks” into place

(Figure 2-1 on page 2-4).

4. Swing the magazine handle to the left to store.

5. Gently shut the front access door.

2-6 Chapter 2

Operating the Autoloader

Loading/Unloading Tapes

NOTE The INVENTORY CHECK runs whenever the front access door closes so that

an inventory of storage slot locations can be stored into memory. This

process takes approximately thirty seconds. The inventory check will not

run if the door is not completely shut.

Unloading Tapes

1. Remove the magazine by following the steps under “Opening the

Door” on page 2-3 and “Removing the Magazine” on page 2-4.

2. Unload tapes from the magazine by pressing the tape in until it clicks

and releases. Remove it after it partially ejects.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Chapter 2 2-7

Operating the Autoloader

Autoloader Control Panel

Autoloader Control Panel

1 Control panel

keys

PREV: Scrolls the control panel choice backward by one.

NEXT: Scrolls the control panel choice forward by one.

ENTER: Selects the option currently being displayed.

CANCEL: Cancels the current selection or steps you back to the

previous menu.

2 Activity light Steady green: Power is on.

Flashing green: A tape is being accessed.

Amber: An error occurred (see “Troubleshooting” on page 2-32).

3Twoline,

16-character

display

Displays the current operation or drive status. An asterisk (*)

indicates a submenu for that task. Press

ENTER on the control panel

to access that menu.

4 Standby switch Puts the unit’s power in standby mode. Turns off secondary circuits

only.

2-8 Chapter 2

Operating the Autoloader

Understanding Control Panel Messages

Understanding Control Panel Messages

The control panel window is a two-line display with 16 characters per

line that shows the status of the Autoloader or the current function.

Tape Status

The following example shows the display when the Autoloader is in the ready state.

The numbers on the top line show that slots 1, 2, 3, 5, and 8 contain

tapes, tape 4 is in the drive, and slots 6 and 7 are empty.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

• A blinking number indicates that the tape is being moved from a slot or the drive.

• If a tape is in the drive, the number remains lit and is underlined (tape4inthefigureabove).

• If the Autoloader is empty, the top line reads STATUS EMPTY.Onthe bottom line, the display will read LOADER READY or a drive activity message and can include one of these indicators (represented by the shaded boxes above):

C is always displayed if the drive needs cleaning. If the drive is not

active, CLEAN DRIVE will also display.

WP is displayed if a tape is write protected.

NOTE In a menu option (other than a test menu), the Autoloader defaults to the

drive status display when there has been no user interaction for three

minutes.

Chapter 2 2-9

Operating the Autoloader

Understanding Control Panel Messages

Drive/Autoloader Status

The top display line normally shows the slot status or the current menu.

The bottom display line shows the drive/loader activity unless a control

panel menu has been selected. See “Top-Level Menu Options” on

page 2-12.

The status of the drive and Autoloader is indicated by the following:

• LOADER READY

• LOADER ACTIVE

• DRIVE IDLE

• CLEANING

• WRITING

• READING

• REWINDING

• SEEKING

• ERASING

• LOADING

• UNLOADING

• NO DRIVE (Displays if the drive isn’t functioning properly)

2-10 Chapter 2

Autoloader Display Menu Tree

Autoloader Display Menu Tree

Operating the Autoloader

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Chapter 2 2-11

Operating the Autoloader

Top-Level Menu Options

Top-Level Menu Options

NOTE To move through the menus, use the control panel keys. If a menu

selection is flashing, press

indicates sub-level menus.

ENTER to select that option. An asterisk (*)

The top-level menu contains the options listed in Table 2-1. Press

or NEXT when the Autoloader is not performing power-on self tests to

view these menus:

Tab l e 2-1 To p- L e v el M enus

Option Function

RELEASE DOOR * Unlocks the access door. See “Opening the Door” on page 2-3

LOAD TAPE * Moves a tape from a slot to the drive.

• The second line displays FROM SLOT with the slot number.

•Press

•Press

The first full slot is the default slot. Only slots containing tapes can be selected.

UNLOAD TAPE * Unloads a tape from the drive to the slot it came from.

ADMIN * All functions under this menu option are password protected. See

“Password-Protected Functions” on page 2-15.

NEXT until the desired slot number displays.

ENTER to select the slot number.

PREV

2-12 Chapter 2

Tab l e 2-1 To p- L e v el M enus

Option Function

Operating the Autoloader

Top-Level Menu Options

OPERATING MODE *

(There are three operating modes.)

• AUTODETECT MODE (default mode): Operates as if in

Stacker mode until receiving a SCSI changer command. It then

operates in Random mode until power cycled. (See descriptions

of Random and Stacker modes that follow.)

Changer commands are: INITIALIZE ELEMENT STATUS, READ ELEMENT STATUS, POSITION TO ELEMENT, MOVE MEDIA, and EXCHANGE MEDIA. After receiving one of these commands, the

Autoloader operates as if in Random mode.

• RANDOM MODE: Allows random access to tapes.

Mode: In Random mode, the drive and the autoloader controller

canbeaccessedviatheSCSIbus.Allstackerfeaturesare

disabled after selecting Random mode. Tape cartridges can only

be moved by using host SCSI commands to the Autoloader or by

using the LOAD/UNLOAD front panel menu.

Operation: The SCSI interface for the Autoloader in Random

mode conforms to the SCSI-2 command specification for tape

changer devices.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Chapter 2 2-13

Operating the Autoloader

Top-Level Menu Options

Tab l e 2-1 To p- L e v el M enus

Option Function

OPERATING MODE *

(continued)

• STACKER MODE: Loads each tape sequentially after each drive unload request.

Mode: When in Stacker mode, the autoloader controller will not

use an ID and cannot be accessed from the SCSI bus. Only the

drive ID is available. In this mode, the jumper cable may be

removed from the back of the Autoloader, but it will not impact

the system to leave it connected.

Operation: An autoload option and circular mode option is available under the CONFIG menu.

If the autoload option is selected, the first available tape loads

into an empty drive at power up. By default, autoload is off so

that the user must use the front-panel LOAD command to load

tape cartridges. When the host issues a SCSI unload command

to the drive, the Autoloader automatically removes the tape

cartridges from the drive and inserts the next available tape.

If the circular mode option has been selected in CONFIG,the Autoloader will reload the first tape cartridge. If circular is disabled and the last tape cartridge has been unloaded, the Autoloader stops operating until the user loads more tape cartridges.

While in Stacker Mode, if the Autoloader encounters a cleaning

cartridge during the cycle, it will be loaded into the drive as

normal, but will be automatically unloaded after the cleaning

cycle. If the user indicates which slot contains the cleaning

cartridge via the clean drive menu, the Autoloader will skip that

slot.

2-14 Chapter 2

Password-Protected Functions

All ADMIN * functions are password protected.

1. Before accessing the following options, enter the password. (See page 2-17.)

A default password of 000-000-000 is set at the factory. Change this

password when first using the Autoloader if it is in an unsecured

location. (See page 2-18.) Ensure that you document this new

password and keep it safe.

Tab l e 2-2 Admi n M enu Options

Option Function

INFO * Retrieves performance information stored

CLEAN DRIVE * Allows the user to clean the drive.

SCSI IDs * Displays or sets the SCSI addresses for the

Operating the Autoloader

Top-Level Menu Options

in the Autoloader.

autoloader controller and drive.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

CONFIG * Customizes the autoloader functions. See

“Configuring the Autoloader” on page 2-24.

UPDATE DRIVE FW * Allowstheusertoupdatethefirmwarein

the drive. See “Upgrading Firmware” on

page 2-31.

TEST * Runs internal autoloader tests. See

“Running an Internal Test” on page 2-28.

OVERRIDE DOOR Emergency door release that does not check

the internal state of the Autoloader.

2. When a changeable menu selection is flashing, press the option, or press

PREV or NEXT to display other available options.

ENTER to select

Chapter 2 2-15

Operating the Autoloader

Top-Level Menu Options

3. Press ENTER to select the flashing item.

The “Autoloader Display Menu Tree” on page 2-11 shows the

autoloader menu options available throughout the control panel. To

select the functions listed below the shaded boxes:

a. Press

b. Press

ENTER when that option is displayed.

PREV or NEXT to scroll through the list.

c. To perform the displayed operation, press

ENTER.

2-16 Chapter 2

Operating the Autoloader

Entering the Administration Menu Password

Entering the Administration Menu Password

A numeric password is required to access functions within the ADMIN * menu. A default password of 000-000-000 is set at the factory, which can be used when the Autoloader is powered on for the first time.

1. Starting at the top-level menu, press display window.

2. Press

ENTER.

The default password displays, and the first set of zeros flashes.

3. Press

ENTER to accept the first set of flashing zeros or NEXT/PREV to

change the values.

NEXT until ADMIN * is in the

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

4. Press

ENTER to accept the second set of flashing zeros or NEXT/PREV

to change the values.

5. Press

ENTER to accept the last set of flashing zeros or NEXT/PREV to

change the values.

INFO * displays.

6. Press

PREV or NEXT until the desired function displays, then press

ENTER.

Chapter 2 2-17

Operating the Autoloader

Changing the Administration Menu Password

Changing the Administration Menu Password

ADMIN * / CONFIG*/NEWPASSWORD

Change the password so that only authorized persons can access the

Autoloader and change operation settings.

NOTE Be sure you document a new password and keep it safe. If you forget the

password, only a service representative can restore the default password.

1. Complete steps 1 through 6 in “Entering the Administration Menu

Password” on page 2-17.

2. Press

3. Press

NEXT until CONFIG * displays, and press ENTER.

NEXT or PREV until NEW PASSWORD displays, and press ENTER.

NEW 000 000 000 displays, and the first set of zeros flashes.

4. Press

NEXT or PREV until the new number for the first part of the

password displays, then press

ENTER to select.

The second set of zeros flashes.

5. Press

NEXT or PREV until the new number for the second part of the

password displays, then press

ENTER to select.

The last set of zeros flashes.

6. Press

NEXT or PREV until the new number you wish to assign to the

third part of the password displays, and press

ENTER to select.

PASSWORD CHANGED displays, which indicates that the password has

been saved to non-volatile RAM.

7. Press

CANCEL three times to return to the ready state.

NOTE After changing the password, you can save the new password to flash

ROM by power cycling the Autoloader, which allows the password to be

recovered if the Autoloader is powered off for more than ten days. If this

step is not completed, the password changes may be lost.

Consult your system administrator before power cycling.

2-18 Chapter 2

Operating the Autoloader

Setting or Viewing SCSI IDs

Setting or Viewing SCSI IDs

ADMIN * / SCSI IDs *

NOTE If other peripherals are on the same SCSI bus, check to see which IDs are

available.

When you choose SCSI IDs, you have two options:

• SET IDs * assigns a SCSI ID to the autoloader controller and a SCSI

ID to the drive.

• VIEW IDs * displays the autoloader controller and drive settings.

Device Default SCSI IDs

Autoloader ID 1

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Drive ID 0

Setting SCSI IDs

ADMIN * / SCSI IDs * / SET IDs *

1. When SET IDs * is displayed, press ENTER.

• AUTOLOADER ID #, DRIVE ID #,orUPDATE IDS NOW (use this last

function after changing IDs to save) is displayed.

• AUTOLOADER ID # stands for the current SCSI ID of the autoloader

controller. DRIVE ID # is the current SCSI ID of the drive.

2. Press

3. Press

Chapter 2 2-19

NEXT until the setting that you want to change is displayed,

and then press

NEXT or PREV until the new SCSI address is displayed, and

then press

ENTER. The current SCSI address flashes.

ENTER.

Operating the Autoloader

Setting or Viewing SCSI IDs

4. Press NEXT until UPDATE IDs NOW is displayed, and press ENTER.

One of the following messages is displayed:

• If the drive and controller are set to the same ID, CONFLICT-ABORTED displays, followed by SET IDs *.

• If the new settings are accepted, IDs SAVED then SCSI IDs * is displayed.

• If a drive serial communications error is detected while trying to set the SCSI IDs, DRV CONNECT ERR displays, followed by IDs NOT

CHANGED. Any changes entered are lost, returning you to the SCSI

IDs * menu.

5. Press

CANCEL three times to return to the ready state.

NOTE After changing an address, you may need to reboot the host for it to

recognize the new SCSI IDs. Consult the system administrator and

operating system documentation for the correct procedure for your

system.

After changing the settings, you can save the new settings to flash ROM

by power cycling the Autoloader, which allows the settings to be

recovered if the Autoloader is powered off for more than ten days. If this

step is not completed and the Autoloader is turned off for more than 10

days, the new settings may be lost.

Viewing SCSI IDs

ADMIN * / SCSI IDs * / VIEW IDs *

1. Enter the SCSI IDs * menu, which is under the ADMIN * menu.

2. Press

3. AUTOLOADER ID # or DRIVE ID # is displayed. (AUTOLOADER ID # stands

NEXT until VIEW IDs * is displayed. Press ENTER.

for the current SCSI ID of the autoloader controller, and DRIVE ID # is

the current SCSI ID setting for the drive.)

4. Press

5. Press

NEXT or PREV to view the other ID.

CANCEL three times to return to the ready state.

2-20 Chapter 2

Operating the Autoloader

Cleaning the Autoloader Tape Drive

Cleaning the Autoloader Tape Drive

ADMIN * / CLEAN DRIVE *

NOTE Useacleaningcartridgetocleanthedrive.Thedrivemechanismshould

only be cleaned if the clean drive status indicator displays (see

“Understanding Control Panel Messages” on page 2-9). Excessive use of

the cleaning cartridge can cause unnecessary wear on the drive head.

The cleaning cartridge needs to be replaced after 20 cleaning cycles.

1. Starting at the top-level menu, press the control panel and then press

2. Enter the password. INFO * displays.

NEXT until ADMIN * appears in

ENTER.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

3. Press

NEXT until CLEAN DRIVE * is displayed, and press ENTER.

• If the autoloader power has been turned off or the front access

door has been opened since a cleaning cartridge location has been

selected, SET CLEAN CART * is displayed. Press

ENTER and select a

slot location.

• If the autoloader power has not been turned off or the front access

door has not been opened since a cleaning cartridge location has

been selected, CLN CART LOC # displays. (The number that flashes

indicates the storage location of the cleaning cartridge.) If the

storage slot location is correct, press

select a different slot location, press

correct slot location is displayed, press

ENTER andgotostep4.To

NEXT or PREV until the

ENTER,andgotostep4.

Chapter 2 2-21

Operating the Autoloader

Cleaning the Autoloader Tape Drive

4. If a tape is in the drive, a message will display to indicate that the

drivemustbeemptiedbeforecleaning.

• If the slot location chosen in step 3 did not contain a cleaning

cartridge, NOT CLEAN CART displays briefly and then CLEAN FAIL #

displays. Press

CANCEL twicetoreturntothereadystate.Locate

the cleaning cartridge. If no cleaning cartridge is present, insert

oneintoanavailableslot.

• In the event of a drive error, FAILED displays and then the CLEAN

DRIVE menu appears.

5. Press

CANCEL two times to return to the ready state.

2-22 Chapter 2

Operating the Autoloader

Drive Cleaning Errors

Drive Cleaning Errors

Table 2-3 describes situations that can cause drive cleaning errors. The

message CLEAN DRIVE is displayed when a tape cartridge may be at

fault.

For drive cleaning instructions, refer to “Cleaning the Autoloader Tape

Drive” on page 2-21.

NOTE If the drive cleaning problems persists, call an authorized service

provider.

Table 2-3 Drive Cleaning Troubleshooting

If this happens . . . The reason is . . . So you need to . . .

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

A brand new tape is used and a drive cleaning message is received.

An older, frequently-used tape is loaded and a drive cleaning message is received.

An older, frequently-used tape causes a cleaning message to be displayed for the second time.

Debris from the tape manufacturing process was deposited on the drive head.

Dust from frequent

tape loads and

unloads has

probably built up on

the tape cartridge

and deposited on the

drive head.

The cleaning

cartridge needs to be

replaced or the tape

is probably

damaged. (Damaged

tapes can result in

unnecessary use of

the cleaning

cartridge.)

• Clean the drive using the tape drive

cleaning procedure in “Cleaning the

Autoloader Tape Drive” on page 2-21.

• If the message is displayed again within a short amount of time, replace the tape.

• Clean the outside of the tape cartridge using a damp cloth.

• Clean the tape drive using the tape drive

cleaning procedure found in “Cleaning

the Autoloader Tape Drive” on page 2-21.

• Verify the tape is readable by clearing the error message.

• Try reading the tape again.

• If the tape can be read, back up data

from the damaged tape to another tape

cartridge, and discard the damaged one.

• Replace the cleaning cartridge.

Chapter 2 2-23

Operating the Autoloader

Configuring the Autoloader

Configuring the Autoloader

ADMIN * / CONFIG *

1. In the CONFIG * menu, press NEXT or PREV until the desired operation is displayed, then press

If the option has multiple settings, the current setting flashes. Press

NEXT or PREV until the desired setting is displayed.

ENTER.

2. Press

3. Press

4. Press

NEXT or PREV to change the setting.

ENTER to select the setting. OPTION SAVED is displayed.

CANCEL two times to return to the ready state.

Table 2-4 Configuration Options

Config Name Description Default

RECOVERY ON/OFF

If set to ON, the Autoloader attempts

to recover from errors. If set to OFF

the Autoloader stops moving if an

error occurs. Recovery should remain

ON under normal conditions.

RESTORE DEFAULTS

CLEAR ODOMETERS

Sets all autoloader configuration options to their default settings.

Used by service personnel only. Sets all autoloader odometers to zero.

NEW PASSWORD Allowsthepasswordtobechanged. —

SCSI LOG ON/OFF

Used by service personnel only. Tracks internal SCSI states and saves the information to a log.

ON

—

—

OFF

SECURE ON/OFF When set to ON, the RELEASE DOOR

OFF

option will not unlock the door. When

set to OFF, the door can be released.

2-24 Chapter 2

Table 2-4 Configuration Options

Config Name Description Default

Operating the Autoloader

Configuring the Autoloader

POWER SECURE ON/OFF

REP RECOVERED ON/OFF

AUTOLOAD ON/OFF

COMPRESSION ON/OFF

When set to ON, the SECURE ON/OFF

setting is retained in the event of a

power outage. When set to OFF, the

Autoloader returns to its default

setting of SECURE OFF when power is

restored.

When set to ON, recovered errors are

reported; when set to OFF, the

recovered errors are not reported.

When set to OFF in the Stacker

mode, a tape must be loaded into the

drive using the front panel. When set

to ON, the first available tape is

loaded when the unit is powered on

and the drive is empty. This option is

only used when the operation mode

is set to Stacker mode.

Displays the current setting of drive

compression.WhensettoON,the

drive will compress data unless the

host turns it off. When set to OFF,

the drive will not compress data,

unless requested by the host.

OFF

ON

OFF

ON

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Note:Whenthedriveisempty,the

display will always read that

compression is OFF.

CIRCULAR ON/OFF

WhensettoON,thefirsttapeis

reloaded after the last tape unloads.

OFF

This option only functions in Stacker

or Autodetect mode.

Caution: Data overwrite can occur

since the loader will reload the first

tape after unloading the last tape.

Chapter 2 2-25

Operating the Autoloader

Configuring the Autoloader

Table 2-4 Configuration Options

Config Name Description Default

INQ TOGGLE WhensettoON,theinquirystring

for the product family is reported to

the SCSI bus. When set to OFF, the

inquiry string for this autoloader

model is reported to the SCSI bus.

Note: In most cases, the product

family and model inquiry strings will

be the same.

OFF

2-26 Chapter 2

Retrieving Autoloader Information

ADMIN * / INFO *

Information logs describing the autoloader operation are displayed in the INFO * menu. The information logs are described in Table 2-5.

1. When INFO * displays, press

2. Press

3. Press

Tab l e 2-5 Inform a ti o n Logs

Log Name Description

LOADER FW # Displays the autoloader’s firmware revision

DRIVE FW # Displays the drive’s firmware revision number.

NEXT until the desired log name displays and then press ENTER.

CANCEL two times to return to the ready state.

Operating the Autoloader

Retrieving Autoloader Information

ENTER.

number.

The drive firmware number will look similar to

this: DRV FW (183C) 60 where 18 is the build

code, 3C is the hex value, and 60 is the decimal

value.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

MECH FW # Displays the internal mechanism’s firmware

revision number.

LIB ODOMETERS * Press

ENTER to select the odometer logs for

power-on hours, moves, and drive loads.

HARD ERRORS *

(see “Understanding

Error Messages” on

page 2-40)

Displays a log of commands with unrecoverable

errors. Returns either NO HARD ENTRIES or

ENTRY #.Press

currently displayed error. Press

ENTER to view the log for the

NEXT to view

the next error.

SOFT ERRORS *

(see “Understanding

Error Messages” on

page 2-40)

Displays a log of commands with recovered

errors. After an error, returns either NO SOFT

ENTRIES or ENTRY #.Press

log for the currently displayed error. Press

ENTER to view the

NEXT

to select the next error.

Chapter 2 2-27

Operating the Autoloader

RunninganInternalTest

Running an Internal Test

ADMIN * / TEST *

1. When TEST * is displayed, press ENTER.

2. Press

3. Press

NOTE Press CANCEL at any time to abort a test. The last test cycle will

complete before cancelling. TEST CANCEL - WAIT is displayed while the

last test cycle completes.

Descriptions of the internal tests available from the control panel are in

Tab le 2-6.

Table 2-6 Tests Available from the Control Panel

Test N ame Description

EMPTY DRIVE Do not run this test if the drive contains a tape

REWIND MEDIA Do not run this test if the Autoloader contains a

NEXT until the desired test is displayed, and press ENTER.

NUM LOOPS 1 is displayed, where the 1 is flashing.

NEXT until the number of desired test loops displays (1, 10, 100,

1000, or forever) then press

cartridge with data. Moves a tape out of the drive

mechanism and returns it to its home storage slot

if the location is known, otherwise the tape is

placed into the first available storage slot.

tape cartridge with data. Rewinds the tape in the

drive and opens the solenoid in the drive handle.

Use the OPEN DRV HANDLE test to open the drive

and remove the tape.

ENTER to select.

LOAD/UNLOAD Selects a random full slot and moves the tape to

the drive. After the tape loads, the transport

moves to another slot and then returns to the

drive, unloading the tape to its original location.

2-28 Chapter 2

Table 2-6 Tests Available from the Control Panel

Test N ame Description

DRIVE IO Moves a tape from the drive to the transport or

from the storage slot to the transport. This tape is

then moved from the transport to the drive and

then back to the transport the selected number of

test loops. When complete, the tape is returned to

the original location.

SLOT IO Moves a tape from a random full slot to the

transport. The tape is then moved back to its

original location.

Operating the Autoloader

Running an Internal Test

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

CLOSE DRV HANDLE

OPEN DRV HANDLE

Closes the drive handle. Only one operation is performed, regardless of the loop count chosen.

Use this test after performing the REWIND MEDIA

test to manually remove tapes. Opens the drive

handle. Only one operation is performed,

regardless of the loop count chosen.

EXERCISE

Closes then opens the drive handle.

HANDLE

INIT MECHANICS Performs the power on self-test. Each test is run

one time per test loop.

CHECK INVENTORY

Functions the same as the SCSI Initialize

Element Status command. This test physically

scans the entire unit to determine which storage

slots contain tape cartridges and if the drive

contains a tape.

Note: This test will appear as INVENTORY TST in

all control panel error messages.

EXERCISE MECH Runs the TRANSLATE TEST, IO MAGAZINE, and

IO DRIVE tests. Each test is run one time per test

loop.

EMPTY TRANSPORT

Moves the media in the transport back to the

original slot. The test passes if the transport is

empty.

Chapter 2 2-29

Operating the Autoloader

RunninganInternalTest

Table 2-6 Tests Available from the Control Panel

Test N ame Description

TRANSPORT

Runs the motor in the transport back and forth.

MOTOR

PLUNGE TEST Runs the tape pusher back and forth.

TRANSLATE TEST Translates from side to side. No tape cartridge is

required.

DOOR LOCK Locks the door.

DOOR UNLOCK Unlocks the door.

EXERCISE LOCK Locks then unlocks the door.

DOOR SENSOR Displays if the door is open or not.

PUSH SENSOR 1 Displays the value of transport sensor 1.

PUSH SENSOR 2 Displays the value of transport sensor 2.

DOOR LOCK

Displays the current value of the door lock sensor.

SENSOR

DRV HNDL OPEN SENSOR

DRV HNDLE CLOSE SENSOR

Displays the current value of the drive handle open sensor.

Displays the current value of the drive handle close sensor.

T MAG SENSOR Displays the current value of the magazine side

transport sensor.

T DRIVE SENSOR Displays the current value of the drive side

transport sensor.

MAG PRESENT SENSOR

Displays the current value of the magazine present sensor.

CaPUSH SENSOR Displays the current value of the cartridge push

sensor.

DRIVE SENSOR

Displays the current value of the drive side transport position sensor.

2-30 Chapter 2

Upgrading Firmware

Operating the Autoloader

Upgrading Firmware

Upgrading Drive Firmware from Tape

1. Callyourservicerepresentativetogetthedriveupgradetape.

2. Ensure that the drive is empty.

If a tape is in the drive, use the front panel display to return the tape

to a storage slot. See “Loading/Unloading Tapes” on page 2-3.

3. Load the drive upgrade tape into the Autoloader. See “Loading/Unloading Tapes” on page 2-3. Make a note of the slot in which you place the drive upgrade tape.

4. From the Admin * menu, select Update Drive FW.Press

5. Select the slot number that contains the firmware upgrade tape.

Enter.

Press

6. Watch the upgrade status on the control panel.

NOTE Error messages will only display for a few seconds after a failure. Always

check the firmware level from the INFO * menu after an update to ensure

the update was successful.

Enter.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i

o

n

Chapter 2 2-31

Operating the Autoloader

Troubleshooting

Troubleshooting

Before calling for service, locate the serial and model numbers for your

Autoloader. The serial and models numbers are located inside the

Autoloader under the magazine.

For problems that may be related to the host or application software,

refer to the host system documentation or to the application software

instructions.

CAUTION Do not cycle power while the device is active on the SCSI bus. Cycling

power when the SCSI bus is active can cause data loss and/or problems

with the SCSI interface.

Table 2-7 Troubleshooting Table

Problem What to do

Autoloader will not power on or no display messages appear.

Power on self-test

failed. DEVICE

FAILED is displayed

in the control panel

with an error code on

the next line.

• Check the power cord connections.

• Make sure the standby switch is on.

• Makesurethereispowertotheoutlet.

• Replace the power cord with a known good one.

• If the Autoloader still won’t power on, call a service representative.

• Remove all tapes and the magazine, then

cycle power. If self-test passes, reload tapes

and magazine.

• If the power-on test fails again, note the error code, and call a service representative.

2-32 Chapter 2

Table 2-7 Troubleshooting Table

Problem What to do

Operating the Autoloader

Troubleshooting

Host unable to communicate.

The Autoloader’s

power failed while a

tape was in the drive

and did not return to

the ready state after

the power came on.

• Verify that SCSI bus adapter and terminator types match (HVDS, LVDS, or Single-Ended).

• Check cable and terminator for correct connections to the host and Autoloader.

• Checkforbentorbrokenpinsoncables and terminators.

• Replace cable and terminator with known good components.

• Check to see if operating mode is set to

stacker (see “Top-Level Menu Options” on

page 2-12).

Caution: Unit may not meet EMI regulatory specifications if proper cable is not used.

• Press the standby switch off and then on again to run the power-on inventory test.

• If the power-on test is unsuccessful, switch

off the power and call a service

representative for assistance.

A

u

t

o

l

o

a

d

e

r

O

p

e

r

a

t

i