Page 1

Reference

Guide

hp StorageWorks

DLT VS80 Tape Drive

Third Edition (November 2003)

Part Number: 289067-003

This guide is to be used as step-by-step instructions for installation and as a reference for

operation, troubleshooting, and future upgrades.

Page 2

© Copyright 2002-2003 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another language without the prior written consent of Hewlett-Packard.

The information contained in this document is subject to change without notice.

Compaq Computer Corporation is a wholly-owned subsidiary of Hewlett-Packard Company.

Adobe® and Acrobat® are trademarks of Adobe Systems Incorporated.

Intel® and Celeron® are U.S. registered trademarks of Intel Corporation.

Intel® and Itanium® are trademarks or registered trademarks of Intel Corporation in the U.S. and other countries

and are used under license.

Intel® Itanium™ Processor Family is a trademark in the U.S. and other countries and is used under license.

Microsoft®, MS-DOS®, MS Windows®, Windows®, and Windows NT® are U.S. registered trademarks of

Microsoft Corporation.

Oracle® is a registered U.S. trademark of Oracle Corporation, Redwood City, California.

UNIX® is a registered trademark of The Open Group.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein. The

information is provided “as is” without warranty of any kind and is subject to change without notice. The warranties

for Hewlett-Packard Company products are set forth in the express limited warranty statements for such products.

Nothing herein should be construed as constituting an additional warranty.

DLT VS80 Tape Drive Reference Guide

Third Edition (November 2003)

Part Number: 289067-003

Page 3

contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Text Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rack Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HP Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HP Storage Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HP Authorized Reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Previously Recorded Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Software Included. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data Compression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 External Tape Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unpacking the Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Selecting an Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the SCSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting a Single Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terminating the Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Verifying the Tape Drive Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using Library and Tape Drive Tools to Verify Physical Installation . . . . . . . . . . . . . . . 26

Contents

3DLT VS80 Tape Drive Reference Guide

Page 4

Contents

Completing the Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 Internal Tape Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unpacking the Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setting the SCSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Terminating the Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the Internal Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Verifying the Tape Drive Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Using Library and Tape Drive Tools to Verify Physical Installation . . . . . . . . . . . . . . . 34

Completing the Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 Operating System Device Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Device Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing Drivers on Windows NT 4.0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installing Drivers on Windows 2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installing Drivers on Advanced Server 2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Novell NetWare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ASPI Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

HP Tru64 UNIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DDR Recognition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Turning Compression On or Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Example 1 - Turning Compression On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Example 2 - Turning Compression Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Red Hat Linux. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

SuSe Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 Operating the DLT VS80 Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Front Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Using Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Inserting a Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removing a Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Write-Protecting a Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Caring for Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using the Cleaning Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Troubleshooting and Upgrading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 DLT VS80 Tape Drive Reference Guide

Page 5

Contents

Upgrading the Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A Regulatory Compliance Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Federal Communications Commission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Class A Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Class B Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Declaration of Conformity for products marked with the FCC logo -

United States only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Canadian Notice (Avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Class A Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Class B Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

European Union Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

BSMI Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Japanese Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

B Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Grounding Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

C Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Acoustic Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Temperature and Humidity Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Airflow Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5DLT VS80 Tape Drive Reference Guide

Page 6

Contents

6 DLT VS80 Tape Drive Reference Guide

Page 7

About This

Guide

This reference guide provides information to help you:

■ Install the DLT VS80 tape drive

■ Install the software drivers

■ Operate the DLT VS80 tape drive

■ Troubleshoot the DLT VS80 tape drive

About this Guide

About this Guide

Update the firmware on the DLT VS80 tape drive

“About this Guide” topics include:

■ Overview, page 8

■ Conventions, page 9

■ Rack Stability, page 11

■ Getting Help, page 12

7DLT VS80 Tape Drive Reference Guide

Page 8

About this Guide

Overview

This section covers the following topics:

■ Intended Audience

■ Prerequisites

■ Related Documentation

Intended Audience

This book is intended for use by technicians who are experienced with installing

and operating HP tape drives.

Prerequisites

Before you install the DLT VS80 tape drive, make sure you consider the items

below.

■ Review the installation instructions and gather all required tools.

■ Review the installation instructions to be sure your installation location meets

the required environmental conditions.

Related Documentation

In addition to this guide, HP provides corresponding information:

■ HP StorageWorks DLT VS80 External Tape Drive Installation Instructions

■ HP StorageWorks DLT VS80 Internal Tape Drive Installation Instructions

8 DLT VS80 Tape Drive Reference Guide

Page 9

Conventions

Conventions consist of the following:

■ Document Conventions

■ Text Symbols

■ Equipment Symbols

Document Conventions

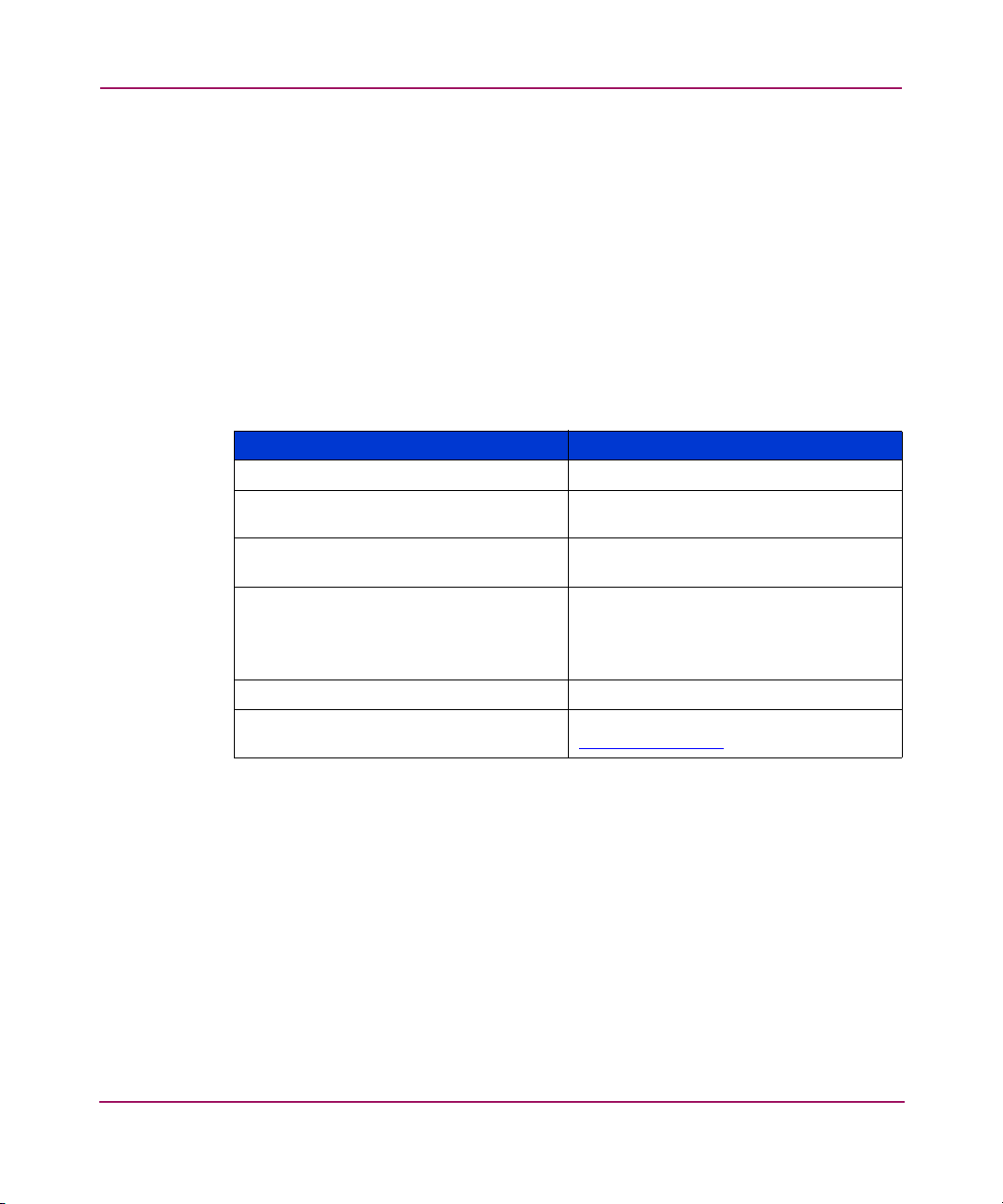

The document conventions included in Tab le 1 apply in most cases.

Table 1: Document Conventions

Cross-reference links Figure 1

Key and field names, menu items,

buttons, and dialog box titles

File names, application names, and text

emphasis

User input, command and directory

names, and system responses (output

and messages)

Variables <monospace, italic font>

Website addresses Underlined sans serif font text:

About this Guide

Element Convention

Bold

Italics

Monospace font

COMMAND NAMES are uppercase

monospace font unless they are case

sensitive

http://www.hp.com

DLT VS80 Tape Drive Reference Guide

9

Page 10

About this Guide

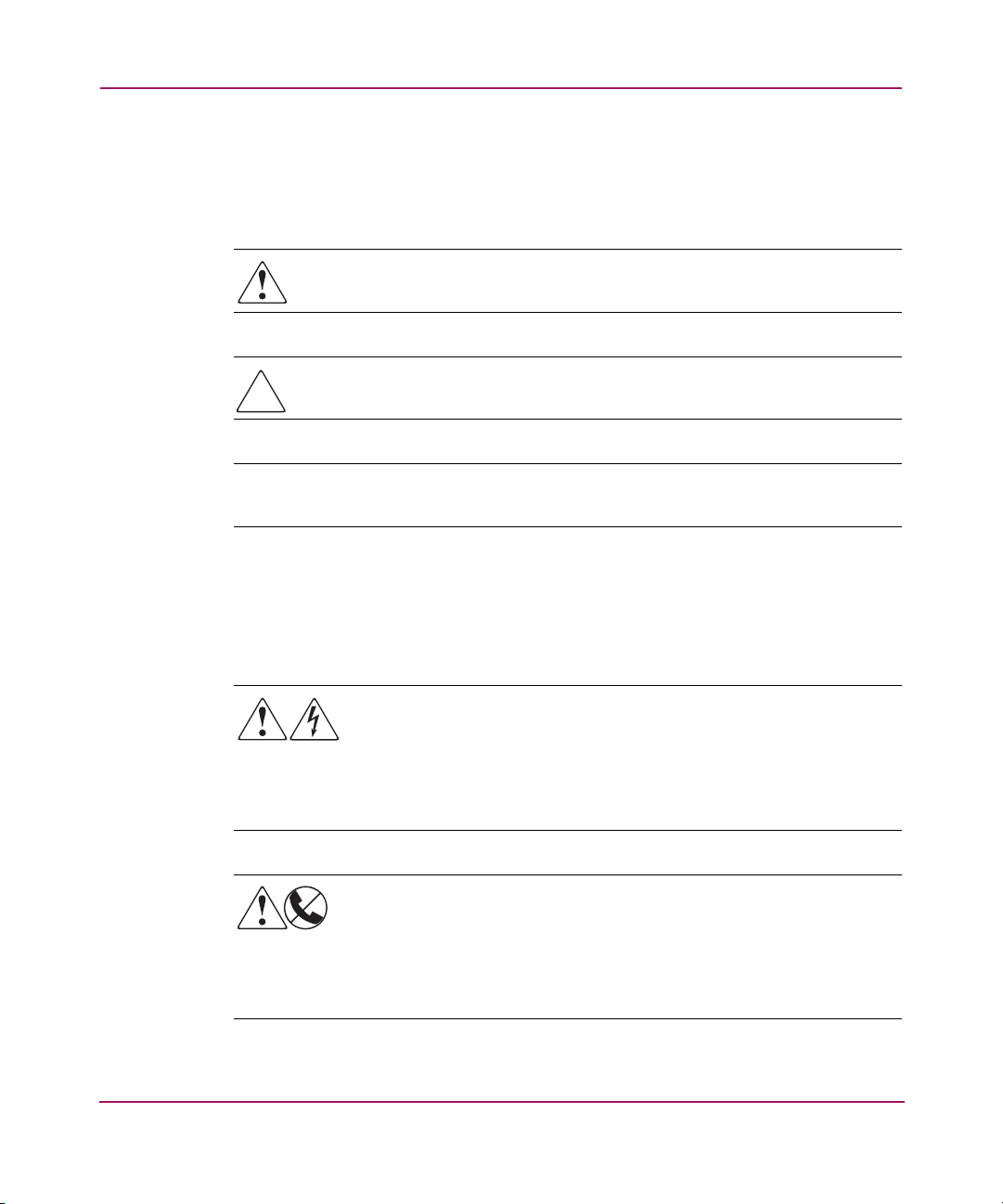

Text Symbols

The following symbols may be found in the text of this guide. They have the

following meanings.

WARNING: Text set off in this manner indicates that failure to follow

directions in the warning could result in bodily harm or death.

Caution: Text set off in this manner indicates that failure to follow directions

could result in damage to equipment or data.

Note: Text set off in this manner presents commentary, sidelights, or interesting points

of information.

Equipment Symbols

The following equipment symbols may be found on hardware for which this guide

pertains. They have the following meanings.

Any enclosed surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards. Enclosed

area contains no operator serviceable parts.

WARNING: To reduce the risk of personal injury from electrical shock

hazards, do not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network

interface connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors

into this receptacle.

10 DLT VS80 Tape Drive Reference Guide

Page 11

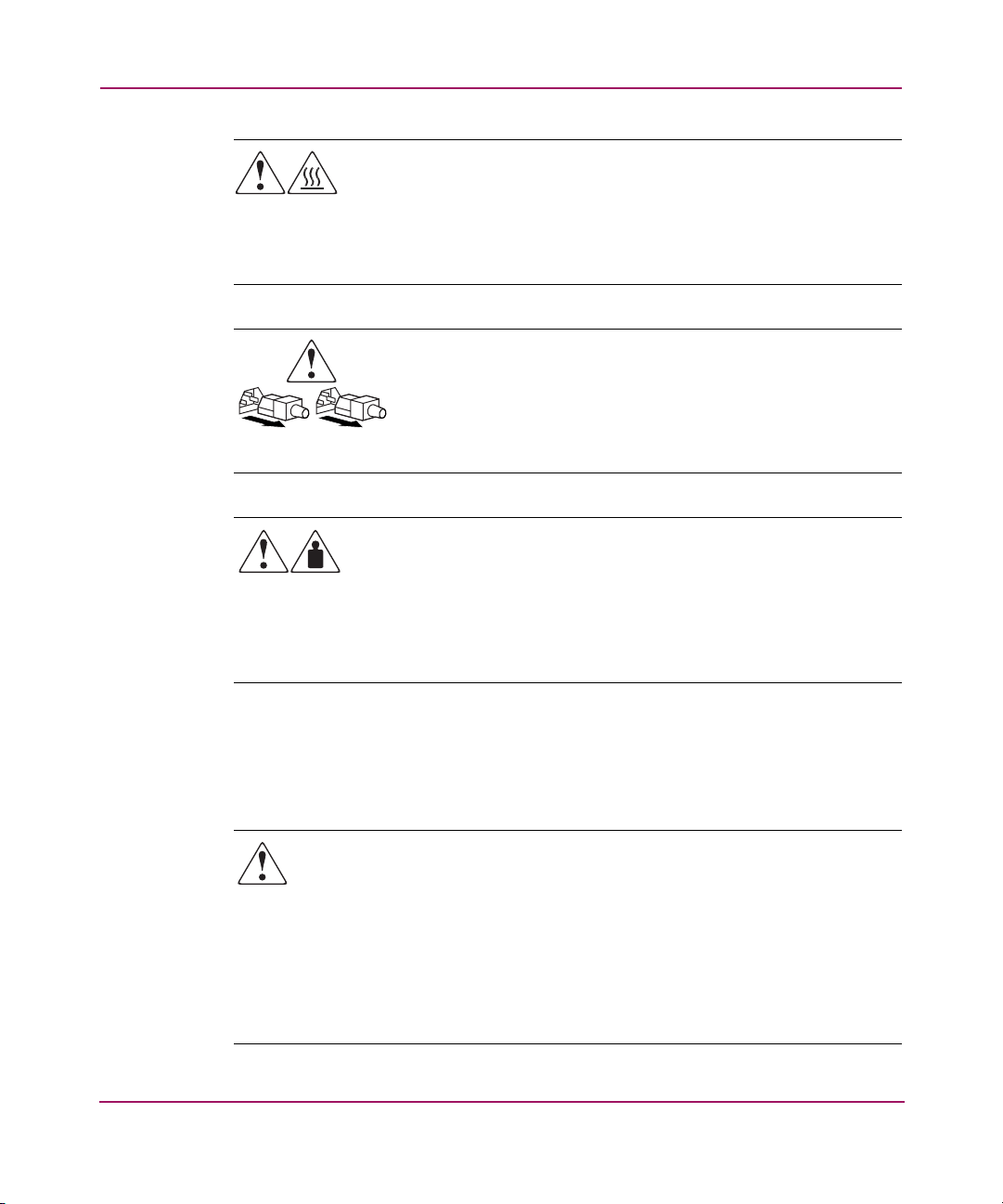

About this Guide

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. Contact with

this surface could result in injury.

WARNING: To reduce the risk of personal injury from a hot component,

allow the surface to cool before touching.

Power supplies or systems marked with these symbols indicate the

presence of multiple sources of power.

WARNING: To reduce the risk of personal injury from electrical

shock, remove all power cords to completely disconnect power

from the power supplies and systems.

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to

handle safely.

Rack Stability

Rack stability protects personnel and equipment.

WARNING: To reduce the risk of personal injury or damage to the

equipment, be sure that:

■ The leveling jacks are extended to the floor.

■ The full weight of the rack rests on the leveling jacks.

■ In single rack installations, the stabilizing feet are attached to the rack.

■ In multiple rack installations, the racks are coupled.

■ Only one rack component is extended at any time. A rack may become

unstable if more than one rack component is extended for any reason.

DLT VS80 Tape Drive Reference Guide

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manually handling material.

11

Page 12

About this Guide

Getting Help

If you still have a question after reading this guide, contact an HP authorized

service provider or access our website:

HP Technical Support

Telephone numbers for worldwide technical support are listed on the following

HP website:

of origin.

Note: For continuous quality improvement, calls may be recorded or monitored.

Be sure to have the following information available before calling:

■ Technical support registration number (if applicable)

■ Product serial numbers

■ Product model names and numbers

■ Applicable error messages

http://www .hp.com

http://www.hp.com/support/

.

. From this website, select the country

■ Operating system type and revision level

■ Detailed, specific questions

HP Storage Website

The HP website has the latest information on this product, as well as the latest

drivers. Access storage at:

http://www.hp .com/products1/storage

. From this

website, select the appropriate product or solution.

HP Authorized Reseller

For the name of your nearest HP authorized reseller:

■ In the United States, call 1-800-345-1518

■ In Canada, call 1-800-263-5868

■ Elsewhere, see the HP website for locations and telephone numbers:

http://www .hp .com

12 DLT VS80 Tape Drive Reference Guide

.

Page 13

Introduction

The HP StorageWorks DLT VS80 Tape Drive is a value-priced, high-capacity

streaming cartridge tape drive designed for use with HP systems. The drive has a

dual-channel read/write head, Lempel-Ziv (DLZ) high-efficiency data

compression, and tape-mark directory to achieve fast data throughput and access

times.

1

Figure 1: DLT VS80 tape drive

Previously Recorded Media

The DLT VS80 can read DLTtape™IV media previously recorded using a DLT

20/40 format. The DLT VS80 can only write to brand new DLTtapeIV media or

media previously recorded using a DLT I or DLT VS80 tape drive. See “Using

Cartridges” in Chapter 5 for additional information.

13DLT VS80 Tape Drive Reference Guide

Page 14

Introduction

Software Included

The DLT VS80 tape drive ships with a CD that contains Microsoft certified

drivers that support the Microsoft Windows NT, Windows 2000, or Windows

Advanced Server 2003 operating systems. Multiple software utilities are also

available to customers through the HP website and can be downloaded free of

charge.

System Requirements

Your DLT VS80 tape drive requires a wide, SCSI-2, Low Voltage Differential

(LVD) or Single-Ended (SE) SCSI bus. The following controller types are

supported:

■ Fast SCSI-2 (Wide)

■ Wide-Ultra SCSI

■ Ultra2 SCSI

■ Ultra3 SCSI

Note: The DLT VS80 tape drive does not support High Voltage Differential (HVD)

controllers.

Install and configure the controller before beginning the drive installation, using

the documentation included with the controller. If you connect your DLT VS80

tape drive to an SE SCSI bus, drive performance is limited to the maximum data

transfer speed of the SE bus.

If connected to an Ultra2 or Ultra3 controller, data transfer is limited to the

maximum transfer rate of the Wide-Ultra interface on the DLT VS80 tape drive.

14 DLT VS80 Tape Drive Reference Guide

Page 15

Data Compression

The DLT VS80 tape drive offers a formatted, native cartridge capacity of 40 GB

(80 GB assuming a 2:1 compression ratio) and a sustained user data transfer rate

of 3 MB/s (up to 6 MB/s with 2:1 compression).

Note: Capacity may vary based upon actual stored data. Data transfer rate can vary

depending on actual data.

The DLT VS80 tape drive ships from the factory with data compression enabled

for writing. In this mode, data is always compressed when writing to the tape, but

the drive is capable of reading both compressed and uncompressed tapes. For the

drive to write uncompressed data, the data compression setting must be changed

through the software. To change it, consult the backup application software

documentation for the data compression enabling and disabling procedure.

Introduction

15DLT VS80 Tape Drive Reference Guide

Page 16

Introduction

16 DLT VS80 Tape Drive Reference Guide

Page 17

External Tape Drive Installation

Installing the DLT VS80 external tape drive requires no special tools. You will

need a ballpoint pen to change the SCSI ID switch on the rear panel of the drive.

WARNING: Risk of electric shock. Do not attempt to open this product. There

are no user-serviceable parts inside. Refer all service to an HP authorized

service provider.

Installation Overview

1. Unpack the drive and check for shipping damage.

2. Select a location near the server that is to be the host for the DLT VS80 tape

drive.

3. Set the SCSI ID, if necessary.

4. Shut down and turn off the server that is to host the tape drive. Remove the

power cable from the selected server. Turn off and remove the power cables

from all devices attached to the selected server.

5. Install an LVD/SE SCSI host adapter in the server that is to be the host for the

drive, if necessary.

2

6. Attach the SCSI cable to the tape drive and SCSI host adapter.

7. Install the terminator on the tape drive if it is the last or only device on the

SCSI bus.

8. Attach the power cables to the tape drive, server, and all attached devices.

Plug in the power cable to the nearest power outlet, and turn on all devices.

9. Install software drivers, if necessary.

10. Verify that the tape drive is working properly.

17DLT VS80 Tape Drive Reference Guide

Page 18

External Tape Drive Installation

Unpacking the Tape Drive

Caution: If the room where you are unpacking the drive differs from the

temperature at which the tape drive was shipped or stored by 30º F (15º C) or

more, let the drive acclimate to the surrounding environment for at least 12

hours before opening the shipping carton.

Unpack and inspect the tape drive for shipping damage:

1. Inspect the shipping box for damage. If you notice any damage, report it to the

shipping company immediately.

2. Open the shipping box and remove the accessories package. Open the

accessories package; you will need these items during installation.

3. With the drive still in the shipping box, reach under and around the drive.

Carefully lift it out of the shipping box and place it on the work surface, top

facing up. Do not stand the drive on either end.

4. Carefully remove the drive from the protective bag.

Note: Save the packing materials in case you need to move or ship the drive in the

future. You must ship the DLT VS80 tape drive in the original or equivalent packing

materials to preserve your warranty.

18 DLT VS80 Tape Drive Reference Guide

Page 19

Selecting an Installation Location

Select an installation location that is flat, sturdy, level, and close to the host server.

A desk or table top is most suitable. Regardless of the location you choose for the

external DLT VS80 tape drive, make sure the environment is free from dust and

excessive temperature and humidity. See Appendix C, “Specifications,” for

acceptable operating temperature and humidity limits.

Be sure to follow these additional guidelines:

■ Allow at least 6 inches (15.3 cm) behind the drive for proper cooling.

■ Avoid locations near printers or photocopy machines, both of which produce

paper fiber and other types of dust and airborne contaminants.

■ Do not place your drive on the floor.

■ Avoid locations near generators, electric motors, audio speakers, or other

sources of magnetic fields. Magnetic fields can adversely affect your drive

and media.

External Tape Drive Installation

19DLT VS80 Tape Drive Reference Guide

Page 20

External Tape Drive Installation

Setting the SCSI ID

Each SCSI device attached to the server that is to be the host for the DLT VS80

tape drive must have a unique SCSI ID. Check the SCSI IDs on all other devices

attached to the selected SCSI bus, including the SCSI host adapter itself, on the

selected server and select an unused SCSI ID for the tape drive. If the drive factory

default SCSI ID 6 is not being used by another device on the same SCSI bus, you

do not need to change the SCSI ID.

Note: You can use Library and Tape Tools (L&TT) to check the SCSI IDs on the other

devices. See Chapter 6, “Troubleshooting,” for complete information on L&TT.

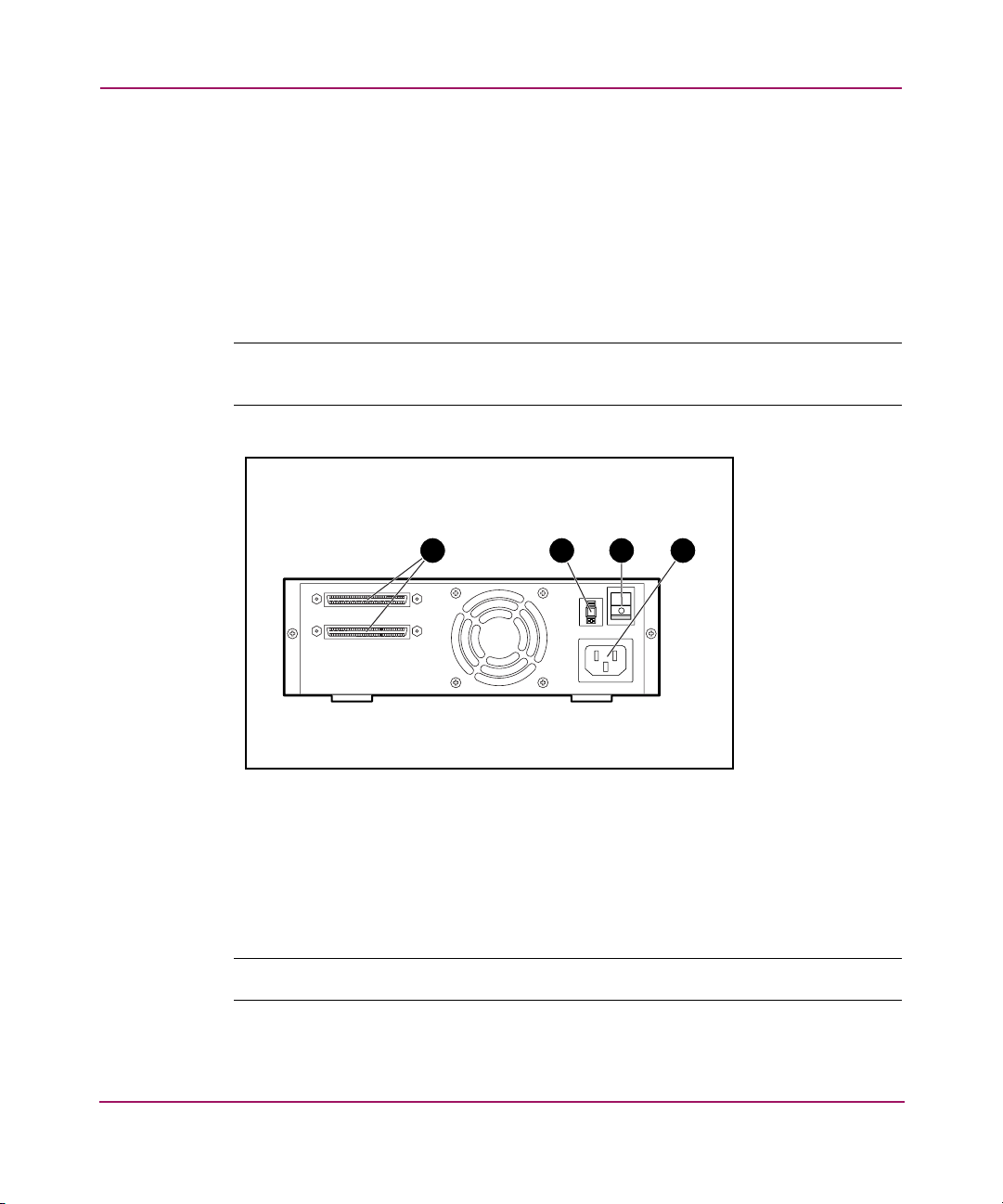

1 2 3 4

Figure 2: Rear view of tape drive

1 68-pin SCSI connectors

2 SCSI ID display

3 Power switch

4 Power cable connector

Note: If the tape drive is attached to a narrow SCSI bus, only IDs 0 through 7 are valid.

20 DLT VS80 Tape Drive Reference Guide

Page 21

External Tape Drive Installation

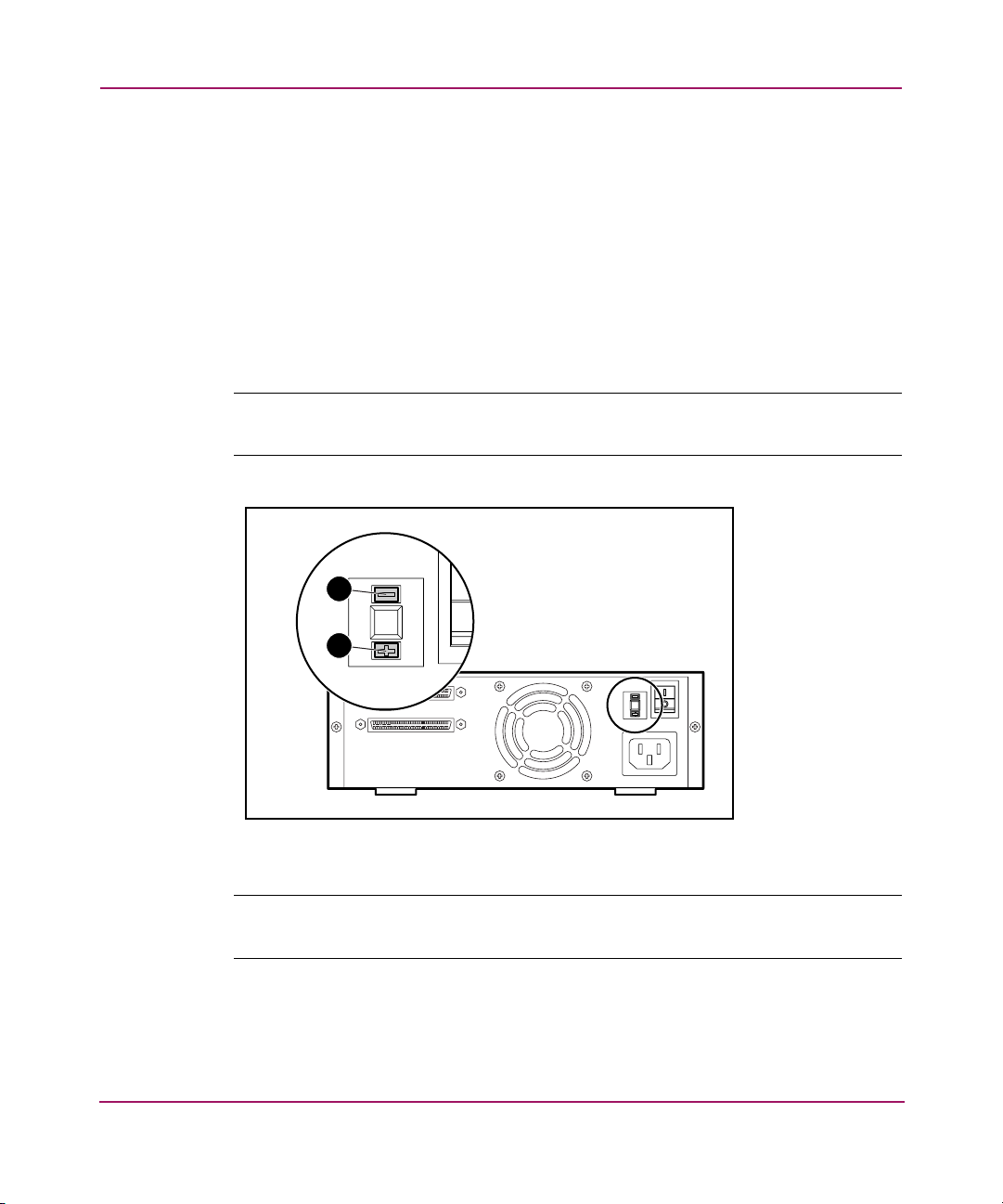

To set the SCSI ID use a small screwdriver or ballpoint pen to press the button

above or below the SCSI ID display.

■ Press the button above the SCSI ID display 1 to select the next lower SCSI

ID.

■ Press the button below the SCSI ID display 2 to select the next higher SCSI

ID.

Each time you press one of these buttons, the SCSI ID decreases or increases by

one. Press the appropriate button until the desired SCSI ID appears on the switch

display.

Note: SCSI ID 7 is reserved for the controller. The SCSI ID can be set up to 15, but a

SCSI ID above 6 is not recommended.

1

2

Figure 3: SCSI ID switch

Note: If the drive is powered on when you change the SCSI ID, you must power the

drive off and on again for the new SCSI ID to take effect.

21DLT VS80 Tape Drive Reference Guide

Page 22

External Tape Drive Installation

Connecting a Single Drive

If the selected server does not already have an LVD/SE SCSI host adapter

installed, install one now.

To connect the SCSI and power cables:

1. Shut down the operating system and power off the selected server. Turn off all

attached peripherals such as printers and other SCSI devices. Remove the

power cable from the host server and all attached peripherals.

Caution: Failure to follow these instructions could result in damage to the DLT

VS80 tape drive or other devices.

2. Remove the SCSI cable from the accessories package and locate the external

SCSI port on the rear of the server.

Note: The SCSI cable included with the DLT VS80 tape drive allows connection to a

68-pin VHDCI HBA, which will accommodate most servers. If your HBA does not have

a 68-pin VHDCI connector, you will need to purchase a separate cable. Refer to the

Quick Specs at

http://www.hp.com

for cable option part numbers.

Note: Your server may differ from the following illustrations; refer to the documentation

included with your server.

22 DLT VS80 Tape Drive Reference Guide

Page 23

External Tape Drive Installation

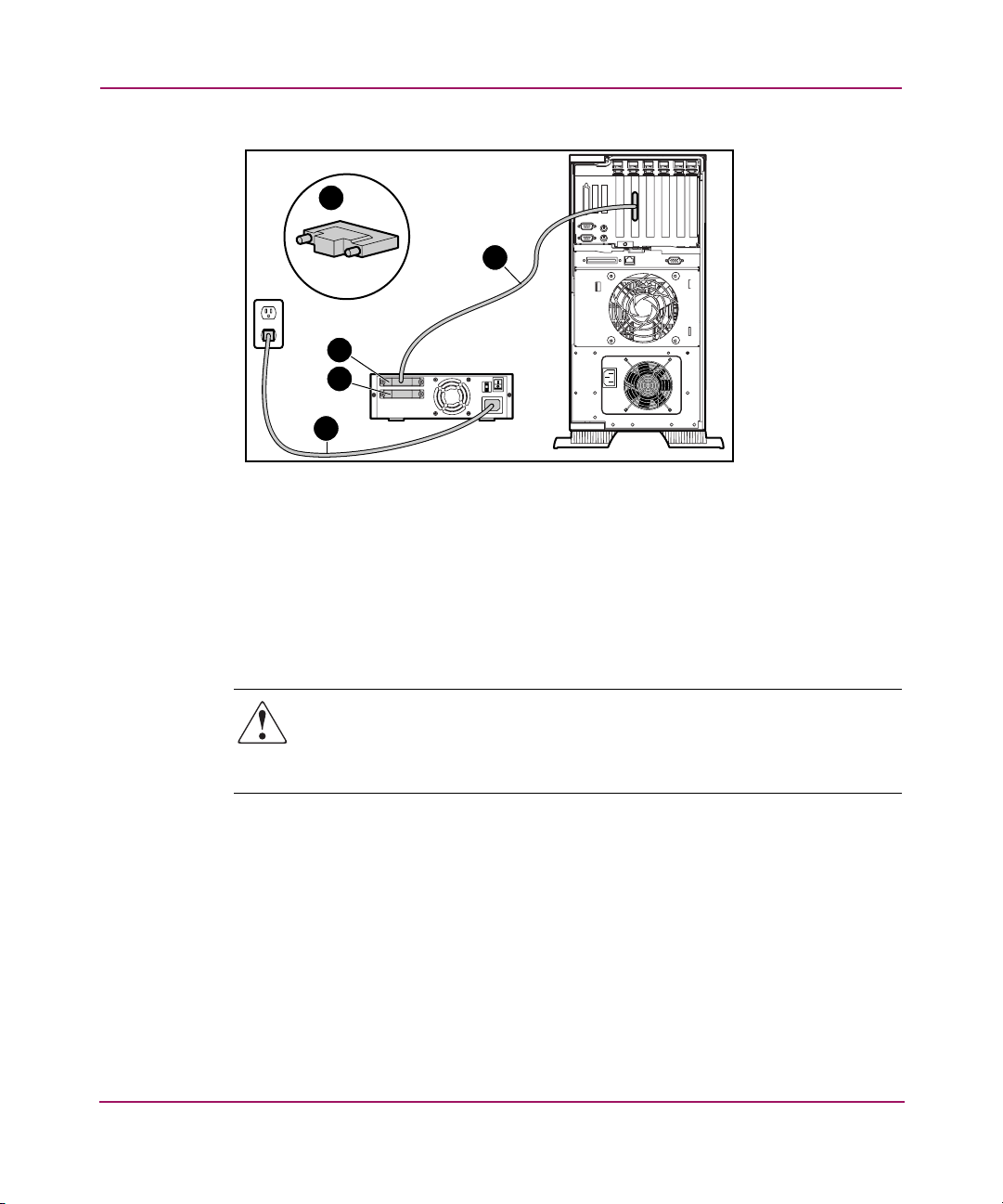

3

1

2

3

4

Figure 4: Connecting a single external drive

3. Attach the SCSI signal cable 1 to the SCSI connector 2 location on the rear

panel of the DLT VS80 tape drive and then to the external SCSI-2 port on the

server.

4. Tighten the thumbscrews to secure the cable to the connector.

5. Attach the terminator 3 to the SCSI connector.

WARNING: To reduce the risk of electric shock or damage to your equipment,

do not disable the power cord grounding feature. This equipment is designed

for connection to a grounded (earthed) power outlet. The grounding plug is an

important safety feature.

6. Plug the drive AC power cord 4 into the drive, then into a grounded AC

outlet.

7. Plug in the AC power cords for any remaining peripheral devices and power

all of them on.

8. Plug in the AC power cord for the server and power it on.

See Figure 5 if you want to daisy-chain several drives.

23DLT VS80 Tape Drive Reference Guide

Page 24

External Tape Drive Installation

Note: To daisy-chain, you must purchase additional cables. Refer to the Quick Specs at

http://www.hp.com

1

2

Figure 5: Daisy-chaining several external drives

for cable option part numbers.

1 To SCSI host adapter

2 Terminator

Note: Each tape drive in the daisy-chain must have a unique SCSI ID. See “Setting the

SCSI ID” in this chapter.

24 DLT VS80 Tape Drive Reference Guide

Page 25

Terminating the Tape Drive

If the DLT VS80 tape drive is the only SCSI device – other than the SCSI host

adapter – on the selected server, it must be terminated. Likewise, if the DLT VS80

tape drive is the last device on the selected server SCSI bus, it must be terminated.

If the DLT VS80 tape drive is at the end of the SCSI cable, it is the last device on

the SCSI bus.

To terminate the DLT VS80 tape drive, locate the terminator in the accessories

package and press it firmly into either of the two SCSI connectors on the rear

panel of the drive. Secure the terminator by tightening the screws until snug.

1

2

2

External Tape Drive Installation

Figure 6: Terminating the tape drive

1 To SCSI host adapter

2 Terminator

25DLT VS80 Tape Drive Reference Guide

Page 26

External Tape Drive Installation

Verifying the Tape Drive Installation

Every time the DLT VS80 tape drive is powered on, it conducts a Power-On

Self-Test (POST) to ensure that the drive is working properly and ready to use.

While POST is in progress, watch the front panel LEDs to see the progress and

results of the test. During POST, the following actions take place:

1. The LEDs turn on all at once and then turn off.

2. The Ready (green) LED blinks during initialization and remains illuminated

after POST.

3. The drive emits a buzzing sound as the drive calibrates the read/write head's

position.

POST is complete only after the buzzing sound stops. POST takes several seconds

to complete.

Using Library and Tape Drive Tools to Verify Physical Installation

You can use the HP Library and Tape Tools (L&TT) to verify the physical

installaion of the tape drive. Complete instructions and download of L&TT are

available at:

http://www.hp.com/support/tapetools

Completing the Installation

You may need to install a device driver for your operating system to correctly

communicate with your tape device. Proceed to Chapter 4, “Operating System

Device Drivers.”

26 DLT VS80 Tape Drive Reference Guide

Page 27

Internal Tape Drive Installation

The following items may be required for DLT VS80 tape drive installation:

■ Torx T-15 screwdriver

■ Type 1A, Phillips screwdriver

Installation Overview

1. Unpack the drive and check for shipping damage.

2. Select a server that is to be the host for the DLT VS80 tape drive.

3. Set the SCSI ID, if necessary.

4. Shut down and turn off the server that is to host to the tape drive. Remove the

power cable from the selected server. Turn off and remove the power cables

from all devices attached to the selected server.

5. Remove the cover from the selected server as explained in the server manuals.

6. Install an LVD/SE SCSI host adapter in the server that is to be the host for the

drive, if necessary.

7. If necessary, attach the drive rails that ship with the drive.

3

Note: Your server may supply rails in the drive bay. Refer to your server user guide for

information on the correct rails to use with your server.

8. Install the DLT VS80 tape drive into an open drive bay.

9. Attach the SCSI ribbon cable to the tape drive and SCSI host adapter.

10. If necessary, install a terminator on the SCSI ribbon cable if the tape drive is

the last or only device on the SCSI bus.

11. Attach a power cable to the internal DLT VS80 tape drive.

27DLT VS80 Tape Drive Reference Guide

Page 28

Internal Tape Drive Installation

12. Secure the tape drive in the selected server.

13. Replace the server cover, attach power cables to all devices, power on the

server and other devices.

14. Install software drivers, if necessary.

15. Verify that the tape drive is working properly.

Unpacking the Tape Drive

Caution: If the room where you are unpacking the drive differs from the

temperature at which the tape drive was shipped or stored by 30º F (15º C) or

more, let the drive acclimate to the surrounding environment for at least 12

hours before opening the shipping carton.

Unpack and inspect the tape drive for shipping damage:

1. Inspect the shipping box for damage. If you notice any damage, report it to the

shipping company immediately.

2. Open the shipping box and remove the accessories package. Open the

accessories package; you will need these items during installation.

3. With the drive still in the shipping box, reach under and around the drive.

Carefully lift it out of the shipping box and place it on the work surface, top

facing up. Do not stand the drive on either end.

4. Carefully remove the drive from the protective bag.

Note: Save the packing materials in case you need to move or ship the drive in the

future. You must ship the DLT VS80 tape drive in the original or equivalent packing

materials to preserve your warranty.

28 DLT VS80 Tape Drive Reference Guide

Page 29

Setting the SCSI ID

Each SCSI device attached to the server that is to be the host for the DLT VS80

tape drive must have a unique SCSI ID. Check the SCSI IDs on all other devices

attached to the selected SCSI bus, including the SCSI host adapter itself, on the

selected server and select an unused SCSI ID for the tape drive. If the drive factory

default SCSI ID 6 is not being used by another device on the same SCSI bus, you

do not need to change the SCSI ID.

Note: You can use Library and Tape Tools (L&TT) to check the SCSI IDs on the other

devices. See Chapter 6, “Troubleshooting,” for complete information on L&TT.

Internal Tape Drive Installation

1 2 3

Figure 7: Rear view of internal tape drive

1 68-pin SCSI connector

2 Power connector

3 SCSI ID jumpers

Note: If the tape drive is attached to a narrow SCSI bus, only IDs 0 through 7 are valid.

29DLT VS80 Tape Drive Reference Guide

Page 30

Internal Tape Drive Installation

Locate the SCSI ID jumpers on the rear panel of the drive as shown in Figure 7.

Use Figure 8 to select the desired SCSI ID.

SCSI ID 0 1 2 3 4 5 6

Jumper

Block

Figure 8: SCSI ID settings

Note: SCSI ID 7 is reserved for the controller. The SCSI ID can be set up to 15, but a SCSI ID

above 6 is not recommended.

Terminating the Tape Drive

If the DLT VS80 tape drive is the only SCSI device – other than the SCSI host

adapter – on the selected server, it must be terminated. Likewise, if the DLT VS80

tape drive is the last device on the selected server SCSI bus, it must be terminated.

The DLT VS80 tape drive ships with a ribbon cable that is already terminated as

shown in Figure 9. If you use a cable other than the one provided, be sure that the

cable is terminated at each end.

30 DLT VS80 Tape Drive Reference Guide

Page 31

Figure 9: Ribbon cable with terminator

Installing the Internal Tape Drive

Internal Tape Drive Installation

Caution: Electrostatic discharge (ESD) can damage electronic components. Be

sure you are properly grounded before beginning this procedure. See

Appendix B, “Electrostatic Discharge,” for additional information.

1. Shut down the operating system and power off the selected server. Turn off all

attached peripherals such as printers and other SCSI devices. Remove the

power cable from the host server and all attached peripherals.

Caution: Failure to follow these instructions could result in damage to the DLT

VS80 tape drive or other devices.

2. Remove the cover from the host server to allow access to the desired drive

bay.

31DLT VS80 Tape Drive Reference Guide

Page 32

Internal Tape Drive Installation

Note: Your server may differ from the following illustrations; refer to the documentation

included with your server.

Figure 10: Installing an internal drive

T

C

E

L

E

S

T

C

E

J

E

R

E

T

N

E

3. Install an LVD/SE SCSI host adapter in the server that is to be the host for the

drive, if necessary.

4. If necessary, attach the drive rails that ship with the drive.

Note: You may need to use the rails that ship with your server. Refer to your server user

guide for information on the correct rails to use.

5. Insert the drive into an available 5 1/4-inch drive bay.

Note: You may need to remove the front cover from the drive bay. Refer to the

documentation included with your server.

6. Secure the tape drive into the server according to the documentation included

with the server.

7. Connect an available power cable and the wide SCSI signal cable.

32 DLT VS80 Tape Drive Reference Guide

Page 33

Internal Tape Drive Installation

1

2

Figure 11: Connecting the power and signal cable

1 Signal cable

2 Power cable

8. Attach the other end of the SCSI ribbon cable to the SCSI host adapter.

9. Replace the cover on the server.

10. Plug in the AC power cords for any peripheral devices and power all of

them on.

11. Plug in the AC power cord for the server and power it on.

33DLT VS80 Tape Drive Reference Guide

Page 34

Internal Tape Drive Installation

Verifying the Tape Drive Installation

Every time the DLT VS80 tape drive is powered on, it conducts a Power-On

Self-Test (POST) to ensure that the drive is working properly and ready to use.

While POST is in progress, watch the front panel LEDs to see the progress and

results of the test. During POST, the following actions take place:

1. The LEDs turn on all at once and then turn off.

2. The Ready (green) LED blinks during initialization and remains illuminated

after POST.

3. The drive emits a buzzing sound as the drive calibrates the read/write head's

position.

POST is complete only after the buzzing sound stops. POST takes several seconds

to complete, after which the drive is ready to use.

Using Library and Tape Drive Tools to Verify Physical Installation

You can use the HP Library and Tape Tools (L&TT) to verify the physical

installaion of the tape drive. Complete instructions and download of L&TT are

available at:

http://www.hp.com/support/tapetools

Completing the Installation

You may need to install a device driver for your operating system to correctly

communicate with your tape device. Proceed to Chapter 4, “Operating System

Device Drivers.”

You can use the HP Library and Tape Tools (L&TT) to verify the physical

installaion of the tape drive. Complete instructions and download of L&TT are

available at:

http://www.hp.com/support/tapetools

34 DLT VS80 Tape Drive Reference Guide

Page 35

Operating System Device Drivers

The following operating systems support the HP StorageWorks DLT VS80 tape

drive:

■ Microsoft® Windows NT 4.0

■ Microsoft Windows 2000

■ Microsoft Windows Advanced Server 2003

■ Novell NetWare

■ HP Tru64 UNIX

■ Red Hat Linux

■ SuSe Linux

For an updated list of supported operating systems, refer to:

http://www .hp.com.

Device Drivers

Windows Operating System device drivers for Intel-based systems are available

on the documentation CD that shipped with your product or can be downloaded

from the HP website.

4

To download the drivers from the HP website go to:

http://welcome.hp.com/cou ntry/us/eng/software_drivers.htm

1. Type DLT VS80 in the enter product model number field.

2. Select the HP StorageWorks DLT VS80 tape drive.

3. Select your operating system.

4. Download the driver for the HP StorageWorks DLT VS80 tape drive.

35DLT VS80 Tape Drive Reference Guide

Page 36

Operating System Device Drivers

Installing Drivers on Windows NT 4.0

These instructions apply to the Windows NT Backup Utility and other

applications that don't provide their own drivers.

Note: Before starting the driver installation, verify that your tape drive is properly

connected. Windows NT 4.0 only allows you to install tape device drivers sequentially.

If you have other tape devices installed without drivers, install those drivers before

attempting the following procedure, or click Cancel to bypass each tape device.

1. Click Start > Settings > Control Panel to open the Windows Control Panel.

2. Double-click the Tape Devices icon.

3. The Tape Devices dialog box is displayed and indicates that the driver for the

new tape drive is not loaded. If the system does not automatically scan for

new devices, select Detect. This scanning process creates a list of device

drivers available for installation.

4. In the Install Driver dialog box, click Have Disk. The Install From Disk dialog

box is displayed.

5. In the Copy manufacturer's files from field, type the driver path as shown

below, and then select OK. Substitute the correct drive letter for your CD

ROM drive.

For Intel systems:

E:drivers\nt4\

6. In the Install Driver dialog box, select the appropriate driver for your tape

drive and click OK.

7. In the New SCSI Tape Device Found dialog box, click OK.

8. In the Tape Devices dialog box, click OK. This step completes the driver

installation. Remove the CD and restart your system.

36 DLT VS80 Tape Drive Reference Guide

Page 37

Installing Drivers on Windows 2000

These instructions apply to the Windows Backup Utility.

1. Right-click the My Computer icon and select Manage.

2. Select Device Manager on the left panel to display all the devices on the right

panel on the Computer Management console. Make all subsequent selections

from the devices shown in the right panel.

3. If the tape drive has not yet been installed, connect the device and select Scan

for hardware changes to detect the device. At first, the device might be

displayed in the “other device” category under the ? icon. After the correct

driver is installed the device will be correctly displayed in the tape drives

category.

To install the DLT VS80 tape driver, select the tape drive under device manager

and do the following:

1. Right click the drive and select Properties.

2. Select the Driver tab.

3. Click Update Driver to launch the Update Device Driver Wizard.

4. When prompted, select the option to display a list of known drivers.

5. Click Have Disk and select the CD ROM drive.

Operating System Device Drivers

6. Navigate to the \Drivers\win2000 directory.

7. Select the .inf file and click OK.

8. The wizard displays a list of the drives available in this directory.

9. Select the item that describes your drive and then click OK to install the

driver.

37DLT VS80 Tape Drive Reference Guide

Page 38

Operating System Device Drivers

Installing Drivers on Advanced Server 2003

These instructions apply to the Windows Backup Utility.

1. Right-click the My Computer icon and select Manage.

2. Right-click on the device in the list and select Update Driver.

3. If the tape drive has not yet been installed, connect the device and select Scan

for hardware changes to detect the device. At first, the device might be

displayed in the “other device” category under the ? icon. After the correct

driver is installed the device will be correctly displayed in the tape drives

category.

4. When prompted, select the option to display a list of known drivers.

5. Click Have Disk and select the CD ROM drive.

6. Navigate to the \Drivers\AS2003 directory.

7. Select the .inf file and click OK.

8. The wizard displays a list of the drives available in this directory.

9. Select the item that describes your drive and then click OK to install the

driver.

38 DLT VS80 Tape Drive Reference Guide

Page 39

Novell NetWare

The tape device driver is located with the operating system. Refer to the backup

application installation guide for more information regarding additional software

that might be needed.

Table 2 provides a list of supported controllers and where to get information about

the software driver:

Table 2: Novell NetWare

Wide-Ultra SCSI

Ultra-2 SCSI

Be sure to load the appropriate drivers in accordance with the controller being

used. There are additional driver considerations if you want to use applications

requiring the Advanced SCSI Programming Interface (ASPI) support. For more

information, see the “ASPI Support” section.

ASPI Support

Operating System Device Drivers

Controller Software Driver Information

Run the

Software Support Diskettes (NSSD) for driver

installation instructions.

Readme.com

file on any of the Novell

The Readme.com file on the Novell Software Support Diskette (NSSD) outlines

the specific drivers you need to support ASPI tape backup applications.

If you are using a tape backup application that uses ASPI, such as ARCserve

provided by Computer Associates or VERITAS BackupExec, refer to the

information provided with the application NLM to determine whether it uses

ASPI.

The ASPI drivers, Cpqsaspi.nlm Device Driver Functional Specification (DDFS)

and Nwaspi.nlm NetWare Peripheral Architecture (NWPA), provide ASPI support

for the SCSI architecture for applications that require this interface.

Note: Some ISPs such as VERITAS use their own ASPI drivers. Please read the ISV

documentation before loading nwaspi.

All required drivers for ASPI tape support are provided on the NSSD. The NSSD

ships with each server or can be downloaded from the HP website at:

http://welcome.hp.com/cou ntry/us/eng/software_drivers.htm

The Scsi.rdm file on the NSSD gives complete instructions on how to load these

drivers and troubleshoot any problems.

39DLT VS80 Tape Drive Reference Guide

Page 40

Operating System Device Drivers

HP Tru64 UNIX

The HP Tru64 UNIX operating system uses Dynamic Device Recognition (DDR)

which allows the operating system to recognize the DLT VS80 tape drive.

If the Tru64 UNIX system does not have a DDR entry to identify the DLT VS80

tape drive, the system defaults to a generic SCSI device and to the default settings

of the tape drive.

DDR Recognition

Note: Starting with UNIX 5.1, the syntax for tape related commands changed. The

examples included below show the new syntax.

The DLT VS80 tape drive provides compression so that the storage capability for

tapes can be effectively be doubled. This is known as hardware compression.

Hardware compression should be used instead of the software compression, which

is sometimes provided by software products. The drive is instructed by the user to

turn off hardware compression through use of switches in utilities such as tar.

(Additional information is available online. See the man pages for tz, file,

tar, dump and cpio. Additionally the man page for ddr.dbase can be useful. It

is the derivation for the integers associated with compression below).

The drive defaults to implement hardware compression. In some very limited

cases the drive performance can be improved by turning off hardware

compression.

40 DLT VS80 Tape Drive Reference Guide

Page 41

Turning Compression On or Off

The following sections give two examples of turning compression on or off using

the tar command.

Example 1 - Turning Compression On

An example to turn on compression using a tar command is:

$tar cvf /dev/tape/tape5_d? filename.txt

Where:

■ tape5 = the tape device as known by the system (shown in the file command,

in this case, tape unit 5).

■ ? = 1, 3, 5 or 7 will turn hardware compression on.

Example 2 - Turning Compression Off

The following command turns hardware compression off:

$tar cvf /dev/tape/tape5 filename.txt

Where:

■ tape5 = the tape device as known by the system (shown in the file command,

in this case, tape unit 5).

Operating System Device Drivers

■ ? = 0, 2, 4 or 6 will turn hardware compression off (see the DLT VS80 drive

description in the ddr.dbase file online).

DDR tables are part of the UNIX patches. For the latest UNIX patches refer to:

http://welcome.hp.com/cou ntry/us/eng/software_drivers.htm.

41DLT VS80 Tape Drive Reference Guide

Page 42

Operating System Device Drivers

Red Hat Linux

Red Hat Linux provides native drive recognition. Drive files are located in the /dev

directory. Supplemental drivers are not required. The operating system defaults to

a generic SCSI device and to the default settings of the tape drive.

Table 3: Typical Native OS Commands

Task Command

Tar Write tar cvf /dev/st0 ./largefile

Tar Read tar xvf /dev/st0

DD Write dd if=./largefile of=//dev/st0 bs=51

DD Read dd if=//dev/st0 of=./largefile bs=512

SuSe Linux

SuSe Linux provides native drive recognition. Drive files are located in the /dev

directory. Supplemental drivers are not required. The operating system defaults to

a generic SCSI device and to the default settings of the tape drive.

Table 4: Typical Native OS Commands

Task Command

Tar Write tar cvf /dev/st0 ./largefile

Tar Read tar xvf /dev/st0

DD Write dd if=./largefile of=/dev/st0 bs=512

DD Read dd if=/dev/st0 of=./largefile bs=512

42 DLT VS80 Tape Drive Reference Guide

Page 43

Operating the DLT VS80 Tape Drive

This chapter describes:

■ Front Panel Controls and Indicators

■ Using Cartridges

— Inserting a cartridge

— Removing a cartridge

— Write-Protecting a cartridge

— Caring for cartridges

— Using the cleaning cartridge

5

43DLT VS80 Tape Drive Reference Guide

Page 44

Operating the DLT VS80 Tape Drive

Front Panel Controls and Indicators

Every time the DLT VS80 tape drive is powered on, it conducts a Power-On

Self-Test (POST) to ensure that the drive is working properly and ready to use.

While POST is in progress, watch the front panel LEDs to see the progress and

results of the test. During POST, the following actions take place:

1. The LEDs turn on all at once and then turn off.

2. The Ready (green) LED blinks during initialization and remains illuminated

after POST.

3. The drive emits a buzzing sound as the drive calibrates the read/write head's

position.

POST is complete only after the buzzing sound stops. POST takes several seconds

to complete, after which the drive is ready to use.

1 2 3 4 5 6

Figure 12: Front panel components

1 External power LED 4 Clean/Media LED

2 Drive error LED 5 Cartridge door

3 Ready LED 6 Unload button

44 DLT VS80 Tape Drive Reference Guide

Page 45

Operating the DLT VS80 Tape Drive

Tabl e 5 describes the meaning of the front panel LEDs.

Table 5: Indicator Activity

Indicator State Operating Condition

Drive error (amber) Blinking An unrecoverable drive error or a

POST error has occurred. Call

Technical Support.

Off No drive errors.

Ready (green) On Power to the drive.

Off No power to the drive.

Blinking (constant

period & duty cycle)

Clean/Media (amber) Blinking

Off Cleaning is not required.

All three LEDs On POST is starting.

Blinking Firmware upgrade in progress.

External power LED On Power to the drive.

Off No power to the drive.

Tape is in motion.

■ A hard read/write error that

is probably recoverable has

occurred. Clean the drive.

The LED is off after

completing a cleaning cycle

with a DLT1/DLT VS

Cleaning Cartridge after

loading a properly formatted

data cartridge into the drive.

Cycling the power on the

drive also turns off the LED.

■ An inappropriate tape has

been loaded into the drive.

The tape should

automatically eject.

■ The drive has exceeded 150

tape motion hours. The drive

must be cleaned. Cycling the

power on the drive does not

turn off the LED.

45DLT VS80 Tape Drive Reference Guide

Page 46

Operating the DLT VS80 Tape Drive

Using Cartridges

The DLT VS80 tape drive uses only DLTtape™IV cartridges. The DLT VS80 tape

drive automatically unloads any other cartridge types and any cartridges whose

format it cannot read. Make sure all cartridges that you want to use for writing are

either unformatted or have been formatted with the DLT VS80 tape drive before

loading them.

The DLT VS80 tape drive can use previously written media that has been

degaussed. DLTtape™IV media is rated at 1850 oersteds. Typical handheld

degaussers do not have the rating to completely degauss DLTtape™IV media. To

completely degauss, the degausser used must be rated at at least 1850 oersteds,

although a value two to three times greater than 1850 oersteds is preferred.

Note: If you use an outside vendor to degauss your media, be sure their equipment

meets this criteria.

The DLT VS80 tape drive can read (but not write to) DLTtape™IV cartridges that

have been written using a DLT 20/40 tape drive.

Table 6: Media Compatibility

DLT VS80 Can

Cartridge

DLTtape IV written to by DLT VS80 Yes Yes

DLTtape IV written to by DLT1 Yes Yes

DLTtape IV written to by DLT 20/40 Yes No

DLTtape IV written to by DLT 35/70 No No

DLTtape IV written to by DLT 40/80 No No

DLTtape III No No

46 DLT VS80 Tape Drive Reference Guide

Read

DLT VS80 Can

Write

Page 47

Inserting a Cartridge

To load a cartridge into the DLT VS80 tape drive:

1. Insert the DLTtape IV cartridge into the cartridge slot after the drive

completes POST. See Figure 13.

2. Gently push the cartridge into the drive until it stops.

Operating the DLT VS80 Tape Drive

Figure 13: Inserting a DLTtape IV cartridge

47DLT VS80 Tape Drive Reference Guide

Page 48

Operating the DLT VS80 Tape Drive

Removing a Cartridge

Caution: To avoid damage to the cartridge or the tape drive, remove the

cartridge from the DLT VS80 tape drive before turning off the drive. Leaving a

cartridge in the drive when power is off can result in cartridge and drive

damage and may cause data loss because the header/catalog data may not

be properly written before the drive loses power.

To remove a cartridge:

1. Press the Unload button or use the backup software to unload the cartridge.

The Ready LED blinks while the drive rewinds the tape. When the drive has

rewound the tape it ejects the cartridge.

2. Remove the cartridge from the drive.

Figure 14: Removing a DLTtape IV cartridge

3. Return the cartridge to its storage case.

48 DLT VS80 Tape Drive Reference Guide

Page 49

Write-Protecting a Cartridge

All DLTtape IV cartridges have a write-protect switch to prevent accidental

erasure of data. Before loading the cartridge into the drive, position the

write-protect switch on the front of the cartridge. By moving the switch to the left

1, the cartridge is write-protected. By moving the switch to the right 2, the

cartridge is write-enabled.

Operating the DLT VS80 Tape Drive

1

2

Figure 15: Cartridge write-protect switch

Caring for Cartridges

To ensure longer life of recorded or unrecorded cartridges, follow these

guidelines:

■ Use cartridges in temperatures between 16ºC and 32ºC (60.8ºF to 89.6ºF).

When stored at these conditions cartridges have a life expectancy of 20 years.

■ Do not expose cartridges to direct sunlight or sources of heat, including

portable heaters and heating ducts.

■ If the cartridge has been exposed to extreme heat or cold, stabilize the

cartridge at room temperature for the same amount of time it was exposed —

up to 24 hours.

■ Do not place cartridges near electromagnetic interference sources, such as

terminals, motors, and video or X-ray equipment. Data on the cartridge can be

altered.

49DLT VS80 Tape Drive Reference Guide

Page 50

Operating the DLT VS80 Tape Drive

■ Store cartridges in a dust-free environment where the relative humidity is

between 20% and 80% (noncondensing). For longer cartridge life, store the

cartridge at 20% to 80% relative humidity.

■ Store cartridges in their storage cases.

■ Do not drop or strike a cartridge. Excessive shock can displace the tape leader,

making the cartridge unusable and possibly damaging your DLT VS80 tape

drive.

■ Place identification labels only in the slide-in slot on the front of the cartridge.

■ Never use any type of adhesive labels on the cartridges.

■ Never stack cartridges more than five high.

Condensation

Condensation can be a problem for tape drives and cartridges. To minimize the

chance of condensation, stay within the specifications above for using and storing

cartridges and observe the following guidelines:

■ Position the drive where the temperature is relatively stable - away from open

windows, heat sources, and doors.

■ Avoid leaving cartridges in severe temperature conditions, for example, in a

car standing in bright sunlight.

■ Avoid transferring data (reading from and writing to cartridges) when the

temperature is changing by more than 10ºC (18ºF) per hour.

■ If you bring a cold tape drive or cartridge into a warm room, allow time for it

to warm to room temperature before using it. For example, if you have moved

the drive from a cold car to a warm room, allow time for the drive to reach

room temperature (up to 24 hours if the temperature change is extreme.)

50 DLT VS80 Tape Drive Reference Guide

Page 51

Using the Cleaning Cartridge

When the Clean/Media LED is on, the DLT VS80 tape drive read/write head may

need to be cleaned.

Insert the cleaning cartridge as you would a data cartridge. See “Inserting a

Cartridge.” Cleaning typically takes several minutes during which the Ready LED

blinks.

You should only use DLT 1/DLT VS Cleaning Cartridges, which are a smoky-gray

color. Inappropriate cleaning tapes are immediately ejected.

Caution: Do not use a DLT Cleaning Tape III, which is a cream color

(p/n 199704-001 or C5142A).

Use only HP-approved DLT 1/DLT VS Cleaning Cartridges (p/n 279839-B21

or C7998A). Use of any other type of cleaning cartridge can damage the tape

drive read/write head.

Each cleaning cartridge has a useful life of 20 cleanings. The cleaning cartridge

includes a label with 20 small boxes printed on it. Always place a check mark in a

box each time you use the cartridge to clean the drive. Replace the cleaning

cartridge when all boxes are checked.

When the cleaning cartridge has cleaned the read/write head, the Clean/Media

LED turns off and the drive ejects the cleaning cartridge.

Operating the DLT VS80 Tape Drive

Note: If any LEDs blink or if the Clean/Media LED is illuminated again when you

insert another cartridge immediately after cleaning, see Table 5 for more information.

Proceed to the trouble shooting section in Chapter 6, if necessary.

51DLT VS80 Tape Drive Reference Guide

Page 52

Operating the DLT VS80 Tape Drive

52 DLT VS80 Tape Drive Reference Guide

Page 53

Troubleshooting and Upgrading the Firmware

Troubleshooting

The HP Library and Tape Tool (L&TT) is a tape management and diagnostic tool.

In addition to the diagnostic and troubleshooting ability of L&TT, it offers useful

information about your products and provides automated firmware update checks

from the Internet, with the ability to retrieve the latest firmware versions.

Use L&TT to perform a first level failure analysis. If you are unable to solve the

issue by running L&TT and referring to Tab le 7, use L&TT to generate a support

ticket before calling HP support,

Complete instructions and download of L&TT are available at:

http://www.hp.com/support/tapetools

Use Table 7 to locate drive problems and the suggested solutions.

6

53DLT VS80 Tape Drive Reference Guide

Page 54

Troubleshooting and Upgrading the Firmware

Table 7: Troubleshooting

Symptom Problem Solution

None of the drive’s

LEDs illuminate.

All of the LEDs on the

front panel blink

continually.

The host server does

not recognize your DLT

VS80 tape drive.

The drive is not

receiving power.

An internal drive fault

has occurred.

The drive SCSI ID

might not be unique.

The SCSI host adapter

might be incorrectly

configured.

The SCSI cable might

be loose.

Check the drive’s power cable.

If an external drive, check the

power cable connections. Plug

the power cable into a

different power outlet.

1. Press and hold the Unload

button for 6 seconds or

until all three LEDs are

illuminated to reset the

drive. Release the Unload

button when the reset

process begins.

2. Turn the drive off and then

on again. If it is an

internal drive, shut down

and turn off the host

server, then turn it back on

and allow it to boot.

3. Call technical support if

POST continues to fail.

1. Change the drive’s SCSI

ID. Shut down and turn off

the host server; turn off the

desktop drive. Change the

drive SCSI ID. Turn on the

host server and desktop

drive.

2. Ensure that all devices on

the SCSI bus are SE or

LVD.

Check the SCSI host adapter

configuration. Refer to the SCSI

host adapter documentation

for instructions.

Check both ends of the SCSI

cable, both for external and

internal drives.

54 DLT VS80 Tape Drive Reference Guide

Page 55

Table 7: Troubleshooting

Symptom Problem Solution

The host server does

not recognize your DLT

VS80 tape drive.

(continued)

Troubleshooting and Upgrading the Firmware

The SCSI terminator

might be loose or

missing.

The SCSI bus might be

improperly terminated.

The SCSI terminator

might not be at the end

of the SCSI bus or

more than two

terminators might be

present on the SCSI

bus.

The SCSI host adapter

might be in a defective

expansion slot.

1. Make sure the terminator

is properly seated on the

open SCSI connector on

the rear panel of the

desktop drive or on the

last device on the SCSI

bus.

2. Make sure an LVD/SE

terminator is in place on

the end of the SCSI ribbon

cable for the internal

drive.

1. If the DLT VS80 tape drive

is the last or only device

on the SCSI bus, make

sure the drive is properly

terminated.

2. If the DLT VS80 tape drive

is not the last or only

device on the SCSI bus,

check all SCSI cable

connections and make

sure the last device on

each end of the SCSI bus

is terminated. The SCSI

host adapter must usually

be terminated.

Make sure the terminators are

placed only at each end of the

SCSI bus – one at the host

adapter and one on the last

device on the bus, both

internal and external.

Move the SCSI host adapter to

a different expansion slot.

55DLT VS80 Tape Drive Reference Guide

Page 56

Troubleshooting and Upgrading the Firmware

Table 7: Troubleshooting

Symptom Problem Solution

The host server does

not recognize your DLT

VS80 tape drive.

(continued)

There are fatal or

non-fatal errors for

which you cannot find

the cause.

The SCSI bus might be

too long.

The SCSI bus might be

improperly terminated.

The AC power source

may not be properly

grounded (external

drive only).

Make sure the total length of

the SCSI bus does not exceed

the ANSI SCSI standard of 40

feet (12.2 meters) for an LVD

SCSI bus with multiple devices,

82 feet (25 meters) for an LVD

SCSI bus with a single device,

or 10 feet (3.05 meters) for a

Fast SCSI-2 or Ultra SCSI-1SE

bus.

1. If the DLT VS80 tape drive

is the last or only device

on the SCSI bus, make

sure the drive is properly

terminated. Make sure

only the last device is

terminated.

2. If the DLT VS80 tape drive

is not the last or only

device on the SCSI bus,

check all SCSI cable

connections and make

sure the last device on the

SCSI bus is terminated.

1. Plug the tape drive power

cable into a power outlet

on the same circuit as the

host server.

2. Plug the DLT VS80

external tape drive power

cable into a different

power outlet.

56 DLT VS80 Tape Drive Reference Guide

Page 57

Table 7: Troubleshooting

Symptom Problem Solution

Drive will not read or

write to media.

Troubleshooting and Upgrading the Firmware

Media or format not

supported by tape

drive.

1. DLT IV cartridge contains

data written by a DLT

20/40 drive. Tape drive

cannot overwrite tape with

DLT 20/40 data. You must

degauss the media to be

able to write VS80

formatted data onto tape.

See Table 6 for media

compatibility.

2. DLT IV cartridge contains

format that cannot be read

by the VS80 drive. See

Table 6 for media

compatibility.

57DLT VS80 Tape Drive Reference Guide

Page 58

Troubleshooting and Upgrading the Firmware

Table 7: Troubleshooting

Symptom Problem Solution

Drive will not eject a

DLTtape IV cartridge

Drive has

malfunctioned or the

cartridge is physically

stuck.

1. Allow sufficient time for

the drive to complete any

operations such as POST,

reset, load, unload,

rewind, and so on. For

example, when powering

up the drive with the tape

positioned at Physical End

of Media, recovery could

take up to ten minutes.

2. Allow sufficient time for

the backup applications to

release any hold it may

have on the drive. This

could take up to ten

minutes.

3. Try a software eject (via

the backup application) as

well as a hardware eject

(manually press the eject

button) allowing sufficient

time for the command to

execute. Depending on

where the media is

positioned, either of these

actions could take up to

ten minutes.

4. If the tape still will not

eject, power down the

drive and remove all

connectors except power

from the rear of the tape

drive. Apply power to the

drive and allow it to come

to read. Try a hardware

eject, allowing sufficient

time (up to ten minutes) for

the command to execute.

5. If the tape is not

successfully ejected using

these steps, contact HP

technical support.

58 DLT VS80 Tape Drive Reference Guide

Page 59

Upgrading the Firmware

The HP Library and Tape Tool (L&TT) is a tape management and diagnostic tool

to help you install and support your HP storage product. In addition to the

diagnostic and troubleshooting ability of L&TT, it offers useful information about

your products and provides automated firmware update checks from the Internet,

with the ability to retrieve the latest firmware versions.

Complete instructions and download of L&TT are available at:

http://www.hp.com/support/tapetools.

Troubleshooting and Upgrading the Firmware

59DLT VS80 Tape Drive Reference Guide

Page 60

Troubleshooting and Upgrading the Firmware

60 DLT VS80 Tape Drive Reference Guide

Page 61

Regulatory Compliance

Notices

Federal Communications Commission Notice

Part 15 of the Federal Communications Commission (FCC) Rules and

Regulations has established Radio Frequency (RF) emission limits to provide an

interference-free radio frequency spectrum. Many electronic devices, including

computers, generate RF energy incidental to their intended function and are,

therefore, covered by these rules. These rules place computers and related

peripheral devices into two classes, A and B, depending upon their intended

installation. Class A devices are those that may reasonably be expected to be

installed in a business or commercial environment. Class B devices are those that

may reasonably be expected to be installed in a residential environment (personal

computers, for example). The FCC requires devices in both classes to bear a label

indicating the interference potential of the device as well as additional operating

instructions for the user.

The rating label on the device shows which class (A or B) the equipment falls into.

Class B devices have an FCC logo or FCC ID on the label. Class A devices do not

have an FCC logo or FCC ID on the label. Once the class of the device is

determined, refer to the following corresponding statement.

A

Class A Equipment

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

personal expense.

61DLT VS80 Tape Drive Reference Guide

Page 62

Regulatory Compliance Notices

Class B Equipment

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

■ Reorient or relocate the receiving antenna.

■ Increase the separation between the equipment and receiver.

■ Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

■ Consult the dealer or an experienced radio or television technician for help.

Modifications

The FCC requires the user to be notified that any changes or modifications made

to this device that are not expressly approved by Hewlett-Packard Company may

void the user's authority to operate the equipment.

Cables

Connections to this device must be made with shielded cables with metallic

RFI/EMI connector hoods in order to maintain compliance with FCC Rules and

Regulations.

Declaration of Conformity for products marked with the FCC logo United States only

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

62 DLT VS80 Tape Drive Reference Guide

Page 63

For questions regarding your product, contact:

Hewlett-Packard Company

P. O. Box 692000, Mail Stop 530113

Houston, Texas 77269-2000

Or, call

1-800- 652-6672