Page 1

getting started guide

hp surestore

fc 1Gb/2Gb entry switch 8B

and fc 1Gb/2Gb switch 8B

www.hp.com

Page 2

Notice

Safety notices

© Hewlett-Pack a rd C om pa n y, 2001. All rights rese r v ed .

Part number: A7346-96002

Edition: E1201

Hewlett-Packard Company makes no warranty of any

kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and

fitness for a particular purpose. Hewlett-Packard shall not

be liable for errors contained herein or for incidental or

consequential damages in c o nn ectio n with the furnish in g,

performance, or use of this material.

This document conta in s p rop rie ta ry info rm at ion , whic h is

protected by copyr ight. No part of this document may be

photocopie d, reproduced, or translated into another

language without the prior written consent of

Hewlett-Packard. The i nformation contained in this

document is subject to change without notice.

Use, duplication, or disclosure by government is subject

to restrictions as set forth in subdivision (c) (1) (ii) of the

Rights in Technical Data and Computer Software Clause

at DFARS 252.227.7013.

Any servicing , adjustme nt, mainte nance, or re pair must be

performed only by authorized service-trained personnel.

Format convention s

variable Indicates that you must supply a value.

output Denotes text displayed on the screen.

[ ] Indicates that the enclo sed element is

optional and may be left out.

{ } Indicates that you must specify one of the

listed options.

| Separates alternatives.

. . . Indicates a repetition of the precedi ng

parameter.

Tip Denotes ideas for enhanced product usage.

Note De no te s significa nt con cep ts or operat ing

instructions.

Warranty

If you have any ques tions about the warranty for this

product, contact your dealer or local Hewle t t-P ackard

sales representative.

Trademarks

BROCADE, the Brocade B weave logo, Brocade: the

Intelligent Platform for Networking Sto rag e, Silk Worm,

and SilkWorm Express, are trademarks or registered

trademarks of Brocade Communications Systems, Inc. or

its subsidiaries in the United States and/or in other

countries.

All other brands, product or service names are or may be

trademarks or service marks of, and are used to identify

products of servi ces of their respe c tive owners.

CAUTION Denotes a hazard that can cause hardware or

software damage.

WARNING Denotes a hazard that ca n cause personal

injury or death.

Page 3

CONTENTS

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

1 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the Switch as a Stand-Alone Unit . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the Switch in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SFP Media Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fan Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fabric Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SFPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fibre Channel Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configuring and Connecting the Switch . . . . . . . . . . . . . . . . . . . . . . . . . 23

Saving the System Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Backing up the Switch Configuration Settings . . . . . . . . . . . . . . . . . 28

Restoring the System Configuration Settings . . . . . . . . . . . . . . . . . . 29

iii

Page 4

Next Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting QuickLoop Mode on Ports . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting Up Speed Negotiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuring Supported Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Switch Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

LEDs on the SFP Media Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LEDs on the Fan Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Maintenance and Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Getting Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Additional Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Product Regulatory Information . . . . . . . . . . . . . . . . . . . 49

iv Getting Started Guide

Page 5

Revision History

December 2001 First release.

Updates

For the most current information about the HP Surestore FC 1Gb/2Gb

Entry Switch 8B and FC 1Gb/2Gb Switch 8B, visit the support Web site

located at

For information ab out produ ct avai labil ity, configurat ion, and co nnecti vity,

consult your HP account representative.

Related Publications

Related product information can be found in the following publications.

Those publications with part numbers are provided as printed copies with

your product. The FC Entry Switch 8B and FC Switch 8B Documentation

CD contains all publications listed in the table below and is also provided

with your product. These publications are also available at

http://www.hp.com/support/fc8B.

http://www.hp.com/support/fc8B.

Title Part Number

HP Surestore FC 1Gb/2Gb Entry Switch 8B and FC

1Gb/2Gb Switch 8B Getting Started Guide

HP Surestore FC 1Gb/2Gb Entry Switch 8B and FC

1Gb/2Gb Switch 8B Documentation CD

HP Surestore FC 1Gb/2Gb Entry Switch 8B and FC

1Gb/2Gb Switch 8B Installation and Reference Guide

Fabric OS Reference Manual, version 3.0 Available on CD

Fabric OS Procedures Guide, version 3.0 Available on CD

Fabric OS Version 3.0.1b Release Notes Available on CD

Fabric Watch User’s Guide, version 3.0 Available on CD

QuickLoop User’s Guide, version 3.0 Available on CD

A7346-96002

A7346-11001

Available on CD

v

Page 6

Title Part Number

Web Tools User’s Guide, version 3.0 Available on CD

Distributed Fabrics User’s Guide, version 3.0 Available on CD

Zoning User’s Guide, version 3.0 Available on CD

MIB Reference Manual, version 3.0 Available on CD

ISL Trunking User’s Guide, version 3.0 Available on CD

Advanced Performance Monitoring User’s Guide,

Available on CD

version 3.0

Merging Heterogeneous Fabrics Instructions Available on CD

For information about Fibre Channel standards, visit the Fibre Channel

Association Web site, located at

http://www.fibrechannel.com.

vi Getting Started Guide

Page 7

Product Description

The FC Entry Switch 8B and FC Switch 8B products are 8-port Fibre

Channel gigabit switches that support link speeds up to 2 Gbps. Each port

automatically negotiates to the highest common speed of all devices

connected to the port. The ports are compatible with SFPs (small form

factor pluggable medi a), are universa l and self-con figuring, and ar e capable

of individually becoming an F_Port (fabric enabled), FL_Port (fabric loop

enabled), or an E_Port (expansion port).

The base product, FC Entry Switch 8B (A7346A/AZ), includes a single

E_Port, Fabric OS version 3.0.1b or later, QuickLoop, and Web Tools.

Zoning may be purchased as a licensed upgrade. The FC Entry Switch 8B

can also be upgraded to a full fabric switch, the FC Switch 8B by

purchasing a license.

1

INSTALLING THE SWITCH

The FC Switch 8B (A7347A/AZ) includes full switch interconnect (eight

E_Ports), Fabric OS version 3.0.1b or later, QuickLoop, Web Tools,

Zoning, Fabric Watch, and free licenses for Extended Fabrics and Remote

Switch. ISL Trunking and Advanced Performance Monitoring can be

purchased as optional licensed upgrades.

1

Page 8

Safety Guidelines

Follow these safety guidelines to ensure successful and safe operation of

the switch:

• The supply circuit, line fusing, and wire size must conform to the

• The ambient air temper ature ne ar the swit ch must not e xceed 40 degr ees

• The volume of air flow available to the switch must be at least 50 cubic

Follow these safety guidelines for a rack-mount installation:

• The rack space should be 1U high, 19 inches wide, and 26 inches deep.

• All equipment install ed in the rac k shou ld hav e a rel ia ble branch circuit

• The additional weight of the switch should not unbalance the rack or

electrical rating on the switch nameplate.

Celsius. This is particularly impo rtant to ver ify if the switch is installed

in a closed or multi-rack assembly.

feet per minute, and all air vents should have a minimum of 1.5 inches

of airspace.

ground connection. Do not rely on a secondary connection to a branch

circuit, such as a power strip.

exceed the rack’s weight limits.

• The rack should be mechanically secured to insure stability in the event

of an earthquake.

WARNING For safety reasons, when installing this product in an

equipment rack, you must consider rack stability against tipping. Please

refer to the Hewlett-Packard Rack System/E User's Manual provided with

the equipment rack to determine rack stability (also available in electronic

format through the HP Web site at

http://www.hp.com/racksolutions/). If the

necessary stability is not achieved, through the placement of additional

equipment or ballast, the equipment rack must be anchored to the building

structure before operation.

2 Getting Started Guide

Page 9

Package Contents

The major items included in the shipping carton(s) include the following

items:

• One FC Entry Switch 8B or FC Switch 8B

• One 10 ft. RS-232 serial cable (convertible to an RJ-45 connector by

removing the adapter on the end of the cable)

• One grounded 6 ft. power cord

• Rubber mounting feet (used only for setting up the switch as a

stand-alone unit)

• Two rails and one bag of rail mounting hardware (required if the switch

is to be installed in a r ack)

• One plenum

• HP Surestore FC 1Gb/2Gb Entry Switch 8B and FC 1Gb/2Gb Switch

8B Getting Started Guide

• HP Surestore FC 1Gb/2Gb Entry Switch 8B and FC 1Gb/2Gb Switch

8B Documentation CD

Installing the Switch as a Stand-Alone Unit

This section provi de s i nstructions for setting up the swi tch as a st and-alone

unit on a flat surface. The following items are required:

• FC Entry Switch 8B or FC Switch 8B

• Power cord

• Rubber mounting feet

To set up the switch as a stand-alone unit:

1. Check contents of th e shipp ing carton to verif y all the r equired p arts and

hardware are available.

2. Apply the rubber feet by completing the following steps:

CAUTION Installing the rubber feet on the switch is recommended to help

prevent the switch from accidentally sliding off the supporting surface.

Installing the Switch 3

Page 10

a. Clean the four depressions on each bottom corner of the switch to

ensure they are free of dust.

b. Place a rubber foot in each depression with the adh esi ve side against

the chassis and press into place.

3. Place the switch with the bottom side down on a flat, sturdy surface.

4. Provide power to the swit ch by connecting the power cord to the swi tc h

power supply and to a power outlet. Ensure the power cord is routed so

that it is not expose d to str ess. Power is supplied t o the switch a s soon as

the cord is connected. The switch runs POST (power on self-test) by

default each time it is turned on.

Note Do not connect the switch to the network until the IP address is

correctly set. For instructions on how to set the IP address, see

“Configuring and Connecting the Switch” on page 23.

Installing the Switch in a Rack

This section provides instructions for installing the FC Entry Switch 8B or

FC Switch 8B in an HP or Compaq/Rittal rack.

Figure 1. FC Entry Switch 8B and FC Switch 8B Rack-Mounted Switch

4 Getting Started Guide

Page 11

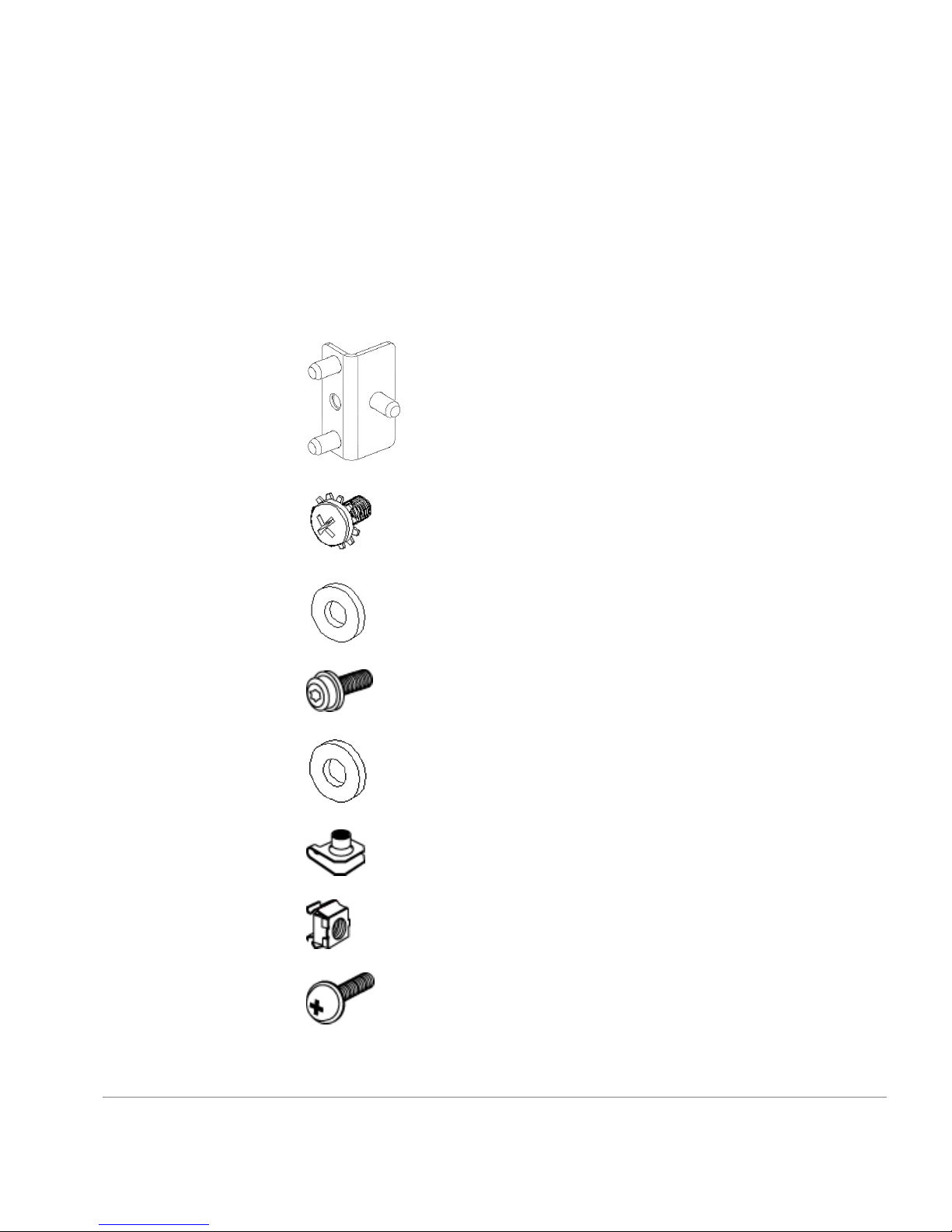

The following items are required to install the switch in a rack:

• FC Entry Switch 8B or FC Switch 8B

• Power cable

• #2 Phillips and T25 Torx screwdrivers

•Plenum

• Rails and rail mounting hardware:

(2) Rear mounting bracket

(8) #8-32 x 5/16 Phillips pan-head screw with captive star

lock wash er

(8) #8 Flat washer

(6) M5 Torx head screw with captive lock washer

(2) Rubber washer

(4) M5 U-type Tinnerman clip (HP rack only)

(4) #10-32 square Tinnerman nut (Compaq/Rittal rack only)

(4) #10-32 x 5/8 Phi ll ip s pan-head screw with attached lo ck

washer (Compaq/Rittal rack only)

Installing the Switch 5

Page 12

(6) Spacer (Compaq/Rittal rack only)

(4) M5 flat washer (Compaq/Rittal rack only)

CAUTION For proper airflow, the SFP media side of the FC Entry Switch

8B or FC Switch 8B faces the rear of the rack. This mounting allows air to

enter the front of the rack through the plenum and to exhaust at the rear of

the rack, s imilar to other rack-mou nted equipm ent. This pr events switch

overheatin g that may cause it to fail.

To install the switch in an HP rack:

1. Check contents of th e shipp ing carton to verif y all the r equired p arts and

hardware are available.

2. Choose a mounting location in the rack for the switch.

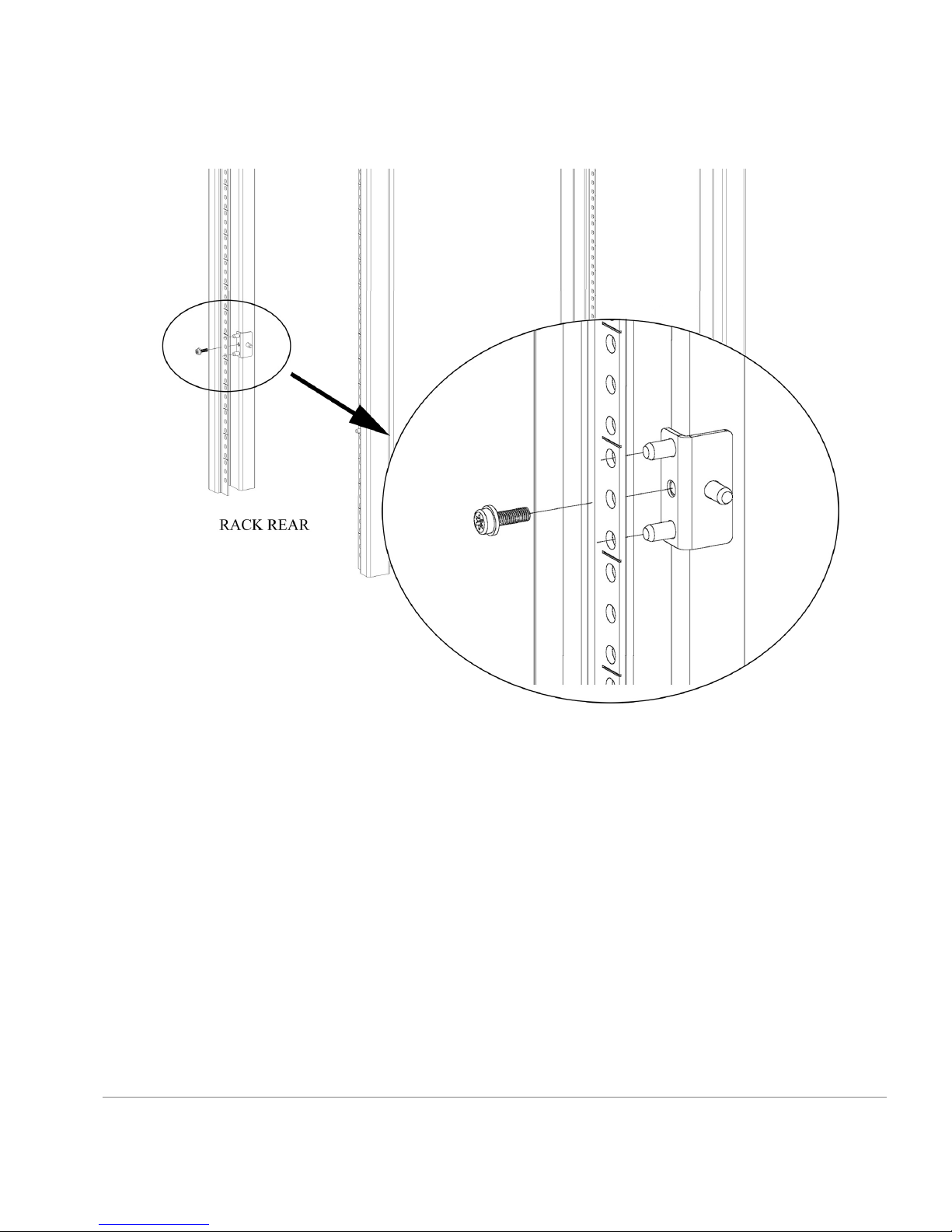

3. Attach the rear rail-tray brackets to the rear rack uprights by installing

each of the two mounting brackets with one M5 Torx head screw with

captive l ock washer as shown in Figure 2.

6 Getting Started Guide

Page 13

Figure 2. Installing the Rear Rail-Tray Brackets

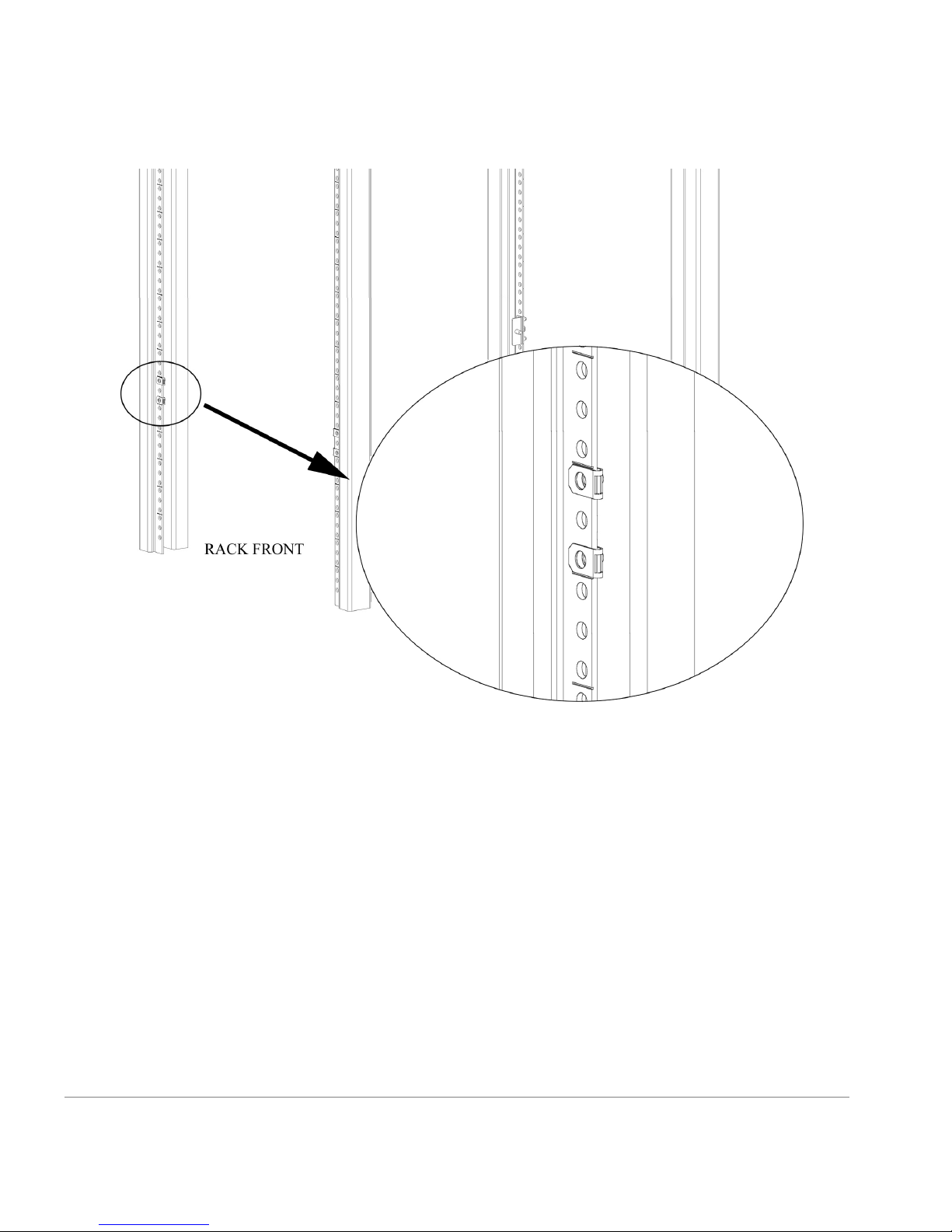

4. Install two M5 U-type Tinnerman clips for each of the front columns of

the rack in the t op a nd bottom positions of the three-ho le EIA pattern as

shown in Figure 3.

Installing the Switch 7

Page 14

Figure 3. Installing the Tinnerman Clips

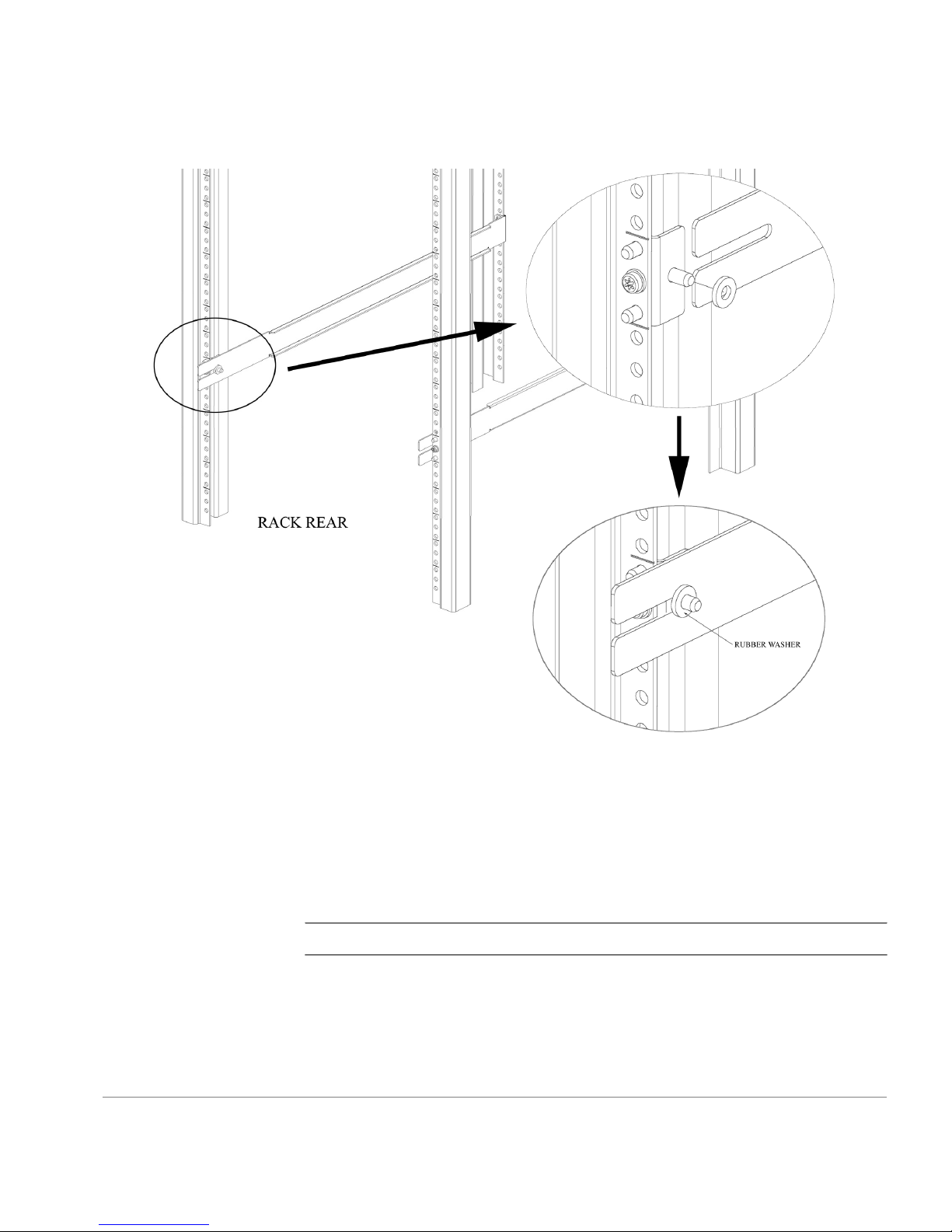

5. Assemble the outer rails by completing the followin g steps:

a. As an aid in asse mbly , two rub ber washers have been included to h elp

keep the rear slotted portion of the outer rail flush against the rear

rail-tray brackets. Install them as shown in Figure 4.

8 Getting Started Guide

Page 15

Figure 4. Installing the Rubber Washers

b. Insert the alignment pins attached to the outer rail front flange into the

center opening in the rack.

c. Install one M5 Torx screw in the upper hole location of the right rail.

Then, install one M5 T orx screw in the lower location of the left rail.

See Figure 5.

Note Do not install the upper left and lower right screws until later.

Installing the Switch 9

Page 16

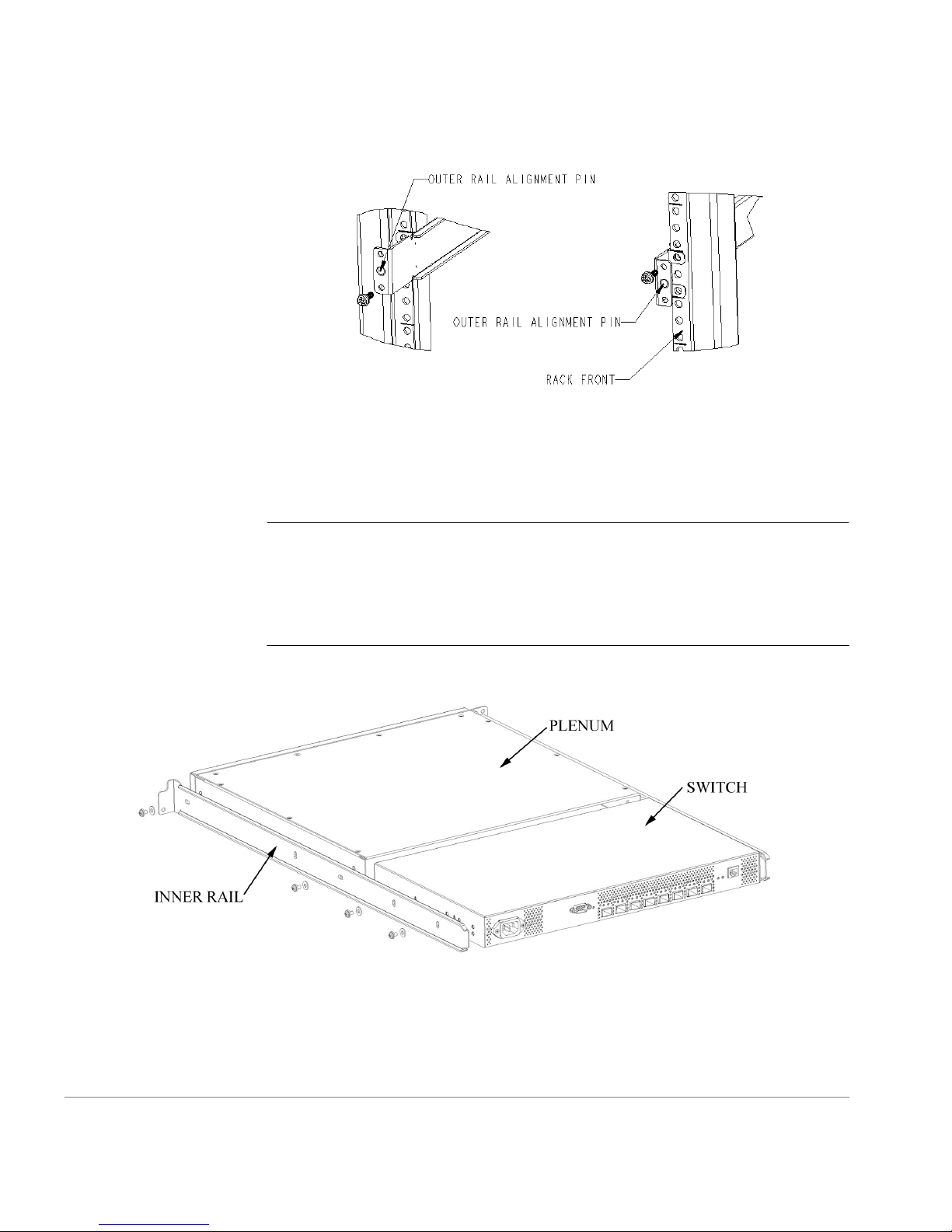

Figure 5. Assembling the Outer Rails

6. Assemble each of th e two i nne r rails (o ne on e ach si de of t he swi tch an d

plenum) using eight #8- 32 x 5/16 Phillips pan-head screws (wit h attached

star lock washers) and eight #8 flat washers as shown in Figure 6.

CAUTION Do not use any other screws other than the eight that are

provided. Use of any longer lengths can cause damage to internal

components of the switch. Be sur e t o install the flat washers along with the

pan-head screws. Before tightening screws, make sure that the rails are

centered to the overall height of the switch.

Figure 6. Assembling the Inner Rails

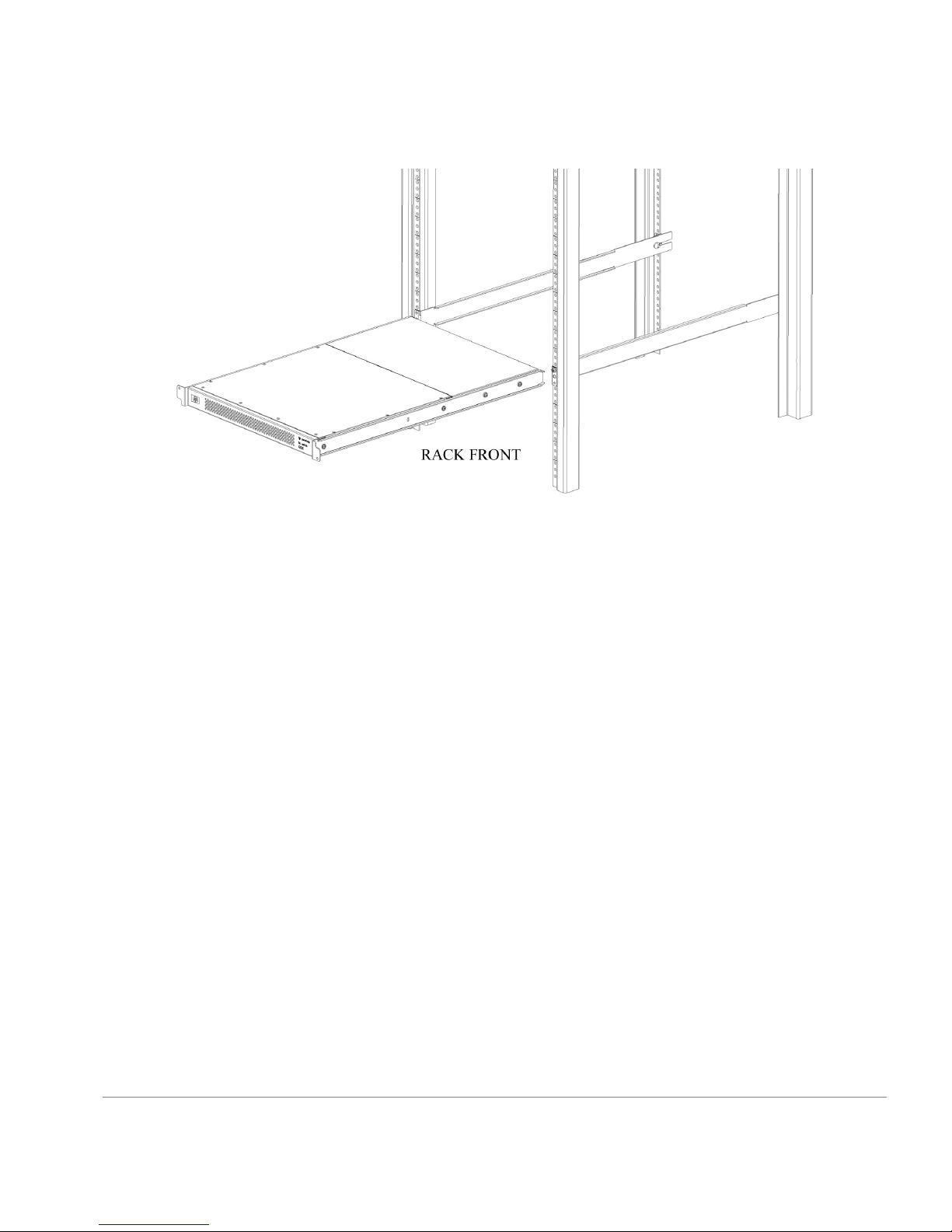

7. Insert the switch with the attached inne r rails into the out er rails as shown

in Figure 7.

10 Getting Started Guide

Page 17

Figure 7. Installing the Switch into an HP Rack

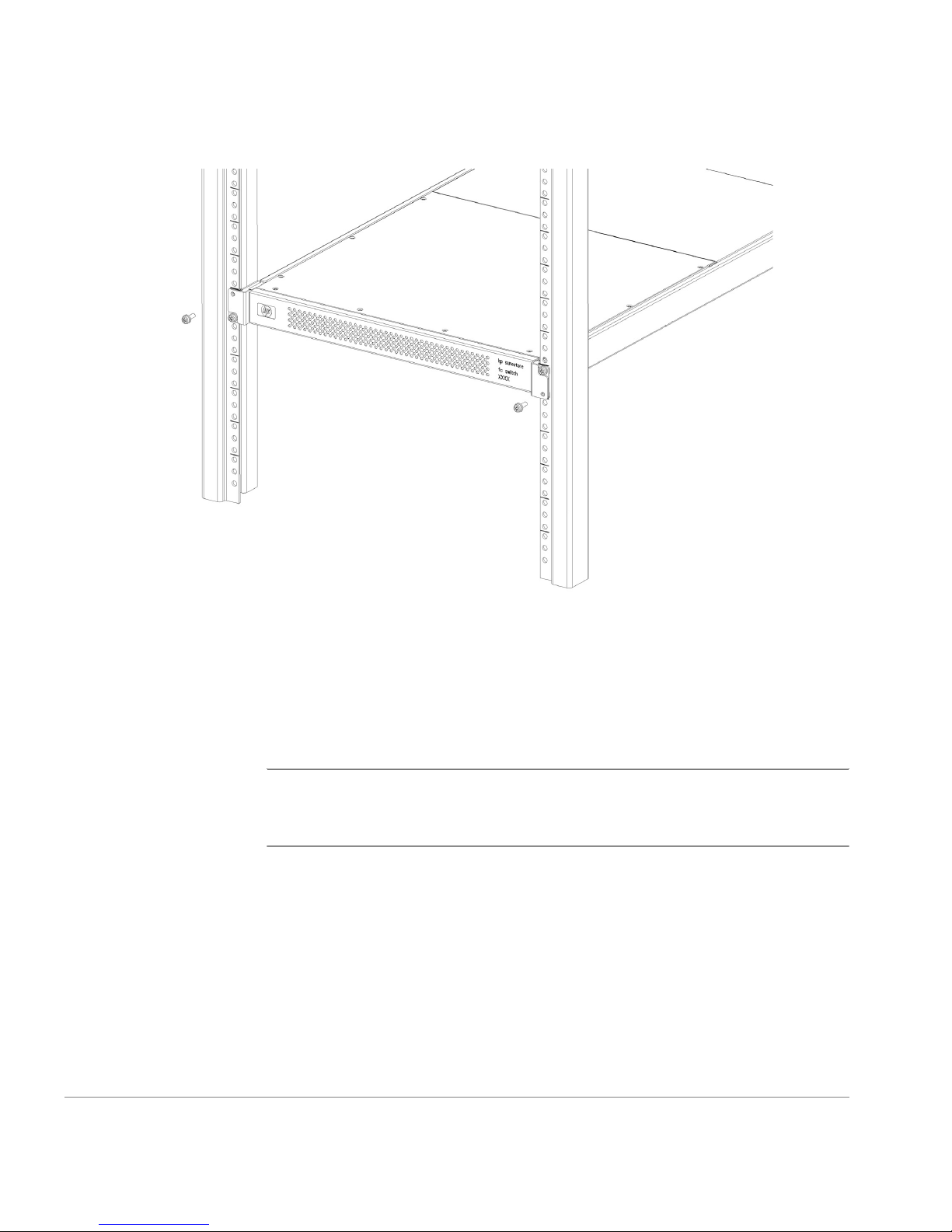

8. Install the two remaining M5 Torx screws into the upper left and lower

right holes to complete the installation. See Figure 8.

Installing the Switch 11

Page 18

Figure 8. Securing the Switch

9. Provide power to the swit ch by connecting the power cord to the swi tc h

power supply and to a power outlet. Ensure the power cord is routed so

that it is not expose d to str ess. Power is supplied t o the switch a s soon as

the cord is connected. The switch runs POST (power on self-test) by

default each time it is turned on.

Note Do not connect the switch to the network until the IP address is

correctly set. For instructions on how to set the IP address, see

“Configuring and Connecting the Switch” on page 23.

To install the switch in a Compaq/Rittal rack:

1. Check contents of th e shipp ing carton to verif y all the r equired p arts and

hardware are available.

2. Choose a mounting location in the rack for the switch.

12 Getting Started Guide

Page 19

3. Attach the rear rai l-tr ay brack ets to t he re ar rac k uprigh ts by asse mbli ng

each of the two bracke ts with two spacers, t wo M5 flat wa shers, and o ne

M5 Torx head screw with captive lock washer as shown in Figure 9.

Note The alignment pins will be resting on the top surfaces of the spacers.

Figure 9. Installing the Rear Rail-Tray Brackets

4. Install two #10-32 square Tinnerman nuts for each of the front columns

Installing the Switch 13

of the rack in the top an d bottom posit ions of the three-hole EI A pattern.

Also install one spacer in the center position for each column on the front

of the rack. See Figure 10.

Page 20

Figure 10. Installing the Tinnerman Nuts and Spacers

5. Assemble the outer rails by completing the followin g steps:

a. As an aid in asse mbly , two rub ber washers have been included to h elp

keep the rear slotted portion of the outer rail flush against the rear

rail-tray brackets. Install them as shown in Figure 11.

14 Getting Started Guide

Page 21

Figure 11. Instal l ing the Rubber Washers

b. Insert the alignment pins attached to the outer rail front flange into the

center opening in the rack.

Note The alignment pins will be resting on the top surfaces of the spacers.

c. Install one #10-32 x 5/8 Phillips pan-head screw in the upper hole

location of the right rail. Then, install one #10-32 x 5/8 Phillips

pan-head screw in the lower locatio n of the left rail as shown in

Figure 12.

Note Do not install the upper left and lower right screws until later.

Installing the Switch 15

Page 22

Figure 12. Assembling the Outer Rack

6. Assemble each of th e two i nne r rails (o ne on e ach si de of t he swi tch an d

plenum) using eight #8- 32 x 5/16 Phillips pan-head screws (wit h attached

star lock washers) and eight #8 flat washers as shown in Figure 13.

CAUTION Do not use any other screws other than the eight that are

provided. Use of any longer lengths can cause damage to internal

components of the switch. Be sur e t o install the flat washers along with the

pan-head screws. Before tightening screws, make sure that the rails are

centered to the overall height of the switch.

16 Getting Started Guide

Page 23

Figure 13. Assembling the Inner Rails

7. Insert the switch with the attached inne r rails into the out er rails as shown

in Figure 14.

Figure 14. Installing the Switch into a Compaq/Rittal Rack

8. Install the re maining #10-32 x 5/8 Phillips pan-head screws into the upper

Installing the Switch 17

left and low er right holes to complete the installa tion. See Figure 15.

Page 24

Figure 15. Securing the Switch

9. Provide power to the swit ch by connecting the power cord to the swi tc h

power supply and to a power outlet. Ensure the power cord is routed so

that it is not expose d to str ess. Power is supplied t o the switch a s soon as

the cord is connected. The switch runs POST (power on self-test) by

default each time it is turned on.

Note Do not connect the switch to the network until the IP address is

correctly set. For instructions on how to set the IP address, see

“Configuring and Connecting the Switch” on page 23.

18 Getting Started Guide

Page 25

System Components

The FC Entry Switch 8B or FC Switch 8B consists of the following

components:

• A chassis designed to be mounted in a 1U rack space, w ith forced -air

cooling that flows fr om the fan side of the switch to the cable side.

• Eight optical ports, compatible with SFP (small form factor pluggable)

media.

• One RS-232 serial port (DB9 connector) on the SFP media side.

2

SETUP

• One IEEE compliant RJ-45 connector on the SFP media side for use

• Human-readable labels (including IP address label) and bar code labels

• A total of 20 LEDs:

with 10/100 Mbps Ethernet or in-band.

on the top of the switch.

– One LED on the SFP media side to indic at e the overall switch status.

– Two LEDs for each of the eight ports to indicate port status and link

speed information.

– Two LEDs for t he Ether net po rt to indi cate port s tatus and l ink s peed

information.

19

Page 26

SFP Media Side

– One LED in the center of the fan side to indicate the overall switch

status.

• One universal input power supply.

•Five fans:

– Two dedicated to cooling the power supply, three dedicated to

cooling the motherboard.

– Air is pulled in through the rear intake and pushed out through the

vents in the SFP media side.

• Three digital thermometers, capable of sensing a temperature range

from -55°C to +125°C, in 0.5°C increments.

• A real-time clock (RTC) with a 10-year battery and 56 bytes of

NVRAM.

Figure 16 shows the SFP media side of the switch, which contains the

power connector, IP label, serial port, switch status LED, fiber optic ports

and their corresponding LEDs, and the Ethernet port and its corresponding

LEDs.

Figure 16. The SFP Media Side of the FC Entry Switch 8B and FC Switch 8B

The switch ports are col or-coded into two groups of four, to indicate which

ports can be used in the same ISL Trunking group.

20 Getting Started Guide

Page 27

Fan Side

Note ISL Trunking is a Fabric OS feature that enables distribution of

traffic over the combined bandwidth of up to four ISLs between two

directly adjacent switches, while preserving in-order delivery. For

information about ISL Trunking, refer to the ISL Trunking User’s Guide.

Figure 17 shows the fan side of the switch, which contains the fa ns an d the

switch status LED.

Figure 17. The Fan Side of the FC Entry Switch 8B and FC Switch 8B

Power Supply

The power supply is universal and capable of functioning worldwide

without using voltage jumpers or switches. It meets IEC 61000-4-5 surge

voltage requirements and is autoranging in terms of accommodating input

voltages and line fre quencies. The power supply has its own built -in fan for

cooling, pushing the air towards the SFP media side of the switch. See

“Power Supply” on page 47 for a list of power supply specifications.

To turn the FC Entry Switch 8B or FC Switch 8B on, connect the power

cable to the power connector on the switch and to a power source. The

switch takes approximately 4.5 minutes to boot after it is turned on.

To turn the switch off, disconnect the power cable from the power source.

Setup 21

Page 28

Note Rem oving all power from th e switch tri ggers a system reset. When

power is restored, all devices are returned to the initial state and the switch

runs POST, a system check that lasts approximately 2.5 minutes.

POST can be skipped by using the fastboot command. For more

information abo ut thi s command, re fer to th e Fabric OS Refer enc e Manual.

A fast boot requires approximately two minutes to complete.

Fabric Operating System

Included with the switch is the Fabric OS. The system provides a large

number of commands and libraries to manage real-time tasks. See the

Fabric OS Reference Manual and the Fabric OS Procedures Guide for

details.

SFPs

The FC Entry Switch 8B or FC Switch 8B accommodates up to 8 SFPs

(small form factor pluggable media). The SFPs supported are the SWL

(short wavelength) and LWL (long wavelength) fibre-optics. Shortwave

SFPs have black dots visible from the fr ont. Longwave SFPs have blue dots

visible from the front. The SFPs qualified by HP are 1Gb/2Gb capable.

To install an SFP, position the SFP so that the key (the tab near the

cable-end of the SFP) is on top and insert the SFP into the port until it is

firmly seated and the latching mechanism clicks. For more specific

instructions, refer to the SFP manufacturer’s documentation.

Note The SFP is keyed so that it can only be inserted with the correct

orientation into the port. If the SFP does not slide in easily, ensure it is

correctly oriented.

Fibre Channel Cable Connections

LC cables are used to plug into SFPs. The cables required for the

HP/Brocade 2400 and 2800 switches have SC connectors and connect into

GBIC optic modules. LC to SC cables or adapters are required to connect

the cables together.

22 Getting Started Guide

Page 29

To connect an SC cable to the FC Entry Switch 8B or FC Switch 8B, use

the HP C7540A - 2M LC male - SC male cable adapter.

Connect inter switch links (ISLs) between two FC Entry Switch 8B or FC

Switch 8B products using an LC to LC cable.

Table 1. Cables Used with the FC Entry Switch 8B or FC Switch 8B

LC - SC Cable Connectors

Product

Number

Part

Number Description

C7534A 5183-2684 SC female - SC female adapter

C7540A N/A 2M LC male - SC male adapter kit -

contains both C7534A (adapter) and

C7529A (2 m eter cable)

C7529A 5065-5106 2m FC Cable LC-SC duplex M/M

C7530A 5065-5107 16m FC Cable LC-SC duplex M/M

LC - LC Cables

Product

Number

Part

Number Description

C7524A 5065-5101 2m FC Cable LC duplex M/M

C7525A 5065-5102 16m FC Cable LC duplex M/M

C7526A 5065-5103 50m FC Cable LC duplex M/M

C7527A 5065-5104 200m FC Cable LC duplex M/M

Configuring and Connecting the Switch

This procedure provides instructions for configuring and con necting the FC

Entry Switch 8B or FC Switch 8B for use in a network and fabric.

The following items are required to configure and connect the FC Entry

Switch 8B or FC Switch 8B:

• The FC Entry Switch 8B or FC Switch 8B installed and connected to a

Setup 23

power source

Page 30

• Workstation that has a terminal emula tor applica tion (such as

HyperTerminal)

• Serial cable provided with the switch for connecting the switch to the

workstation

• An unused IP address

• Ethernet cable for connecting the switch to the workstation or to a

network containing the workstation

• SFPs and FC cables as required to connect the switch to the fabric

To configure the switch and connect it to a fabric:

1. Replace the factory IP address and related inform ation with the IP

information provided by your network administrator by completing the

following steps:

a. Remove the shipping plug from the serial port and insert the serial

cable provided with the switch.

b. Connect the other end of the serial cable to an RS-232 serial port on

the workstation. If no RS-232 serial port is available on the

workstation, the ad apter on the end of the serial cable ca n be removed

to use the RJ-45 connector to create a serial connection.

c. V erify t hat the switch has power and POST is compl eted (LED display

has returned to a standard healthy state).

d. Disable any serial communication programs running on the

workstation.

e. Open a terminal emulator application (such as HyperTerminal on a

PC, or TERM in a Unix environment), and configure as follows:

– In a Windows 95, 98, 2000, or NT environment:

Parameter Value

Bits per second: 9600

Databits: 8

Parity: None

Stop bits: 1

Flow control: None

24 Getting Started Guide

Page 31

– In a UNIX environment, enter the following string at the prompt:

tip /dev/ttyb -9600.

f. From the terminal emulator application, lo g on to the switch with

administrative privileges through the serial connection. The default

administrative logon is admin and the default password is

password.

CAUTION Do not change the default password unless local administration

policy requires it.

g. Enter the following at the terminal emulator application prompt:

ipAddrSet.

h. Enter th e requested information at the prompts:

– Ethernet IP Address [10.77.77.77]:

Enter the new Etherne t IP address.

– Ethernet Subnetmask [0.0.0.0]:

Enter the new Ethernet subnetm ask.

– Fibre Channel IP Address [none]:

Enter the new Fibre Ch annel IP ad dress if des ired.

– Fibre Channel Subnetmask [none]:

Enter the new Fibre Channel subnet mask if de sired.

– Gateway Address [172.17.1.1]:

Enter the new gateway address.

– Set IP address now? [y = set now, n = next

reboot]:

Enter “y” to set now.

i. Optional: Verify the address was correctly set by entering the

following: ipAddrShow.

j. Record the IP address on the label provided for this purpose on the

switch.

k. Once the IP address is verified as correct, remove the serial cable and

replace the shipping plug in the serial port.

Setup 25

Page 32

Note The serial port is intended only for use during the initial setting of

the IP address and fo r serv ice pu rpo ses. Usi ng the seria l port duri ng normal

switch operation or for regular maintenance is not recommended.

2. Connect the switch to the workstation computer by Ethernet cable (can

be a direct connection or through a network).

a. Remove the shipping plug from the Ethernet port.

b. Insert one end of an Ethernet cable in the Ethernet port.

c. Connect the oth er end of the Ethernet cable to the workst ation (use a

cross-over Ethernet cable and the default IP address [10.77.77.77]

when connecting directl y to the workstation) or to an Ethe rnet network

containing the work station (us e a straight -through Ethe rnet cable a nd

the assigned IP address from Step 1 above).

Note The switch can now be accessed remotely, using telnet (although

only one telnet session can be active at a time) or Web Tools. Ensure that

the switch is not being modified from any other connections during the

remaining steps.

3. Log on to the switch with administrative privileges by telnet. The default

administrative logon is admin and the default password is password.

CAUTION Do not change the default password unless local administration

policy requires it.

4. Modify the domain IDs if desired by completing the following steps:

Note The default domain ID is 1. If the defau lt domain I D is alrea dy in use

when the switch is connected to the fabric, the domain ID for the new

switch is automatically reset to a unique value. The domain IDs that are

currently in use can be determined using the telnet command

fabricShow.

a. Disable the switch by entering the following: switchDisable.

26 Getting Started Guide

Page 33

b. Then enter the following to display the configuration prompts:

configure.

c. Enter “y” after the pr ompt “Fabric parameters”. For example:

Fabric parameters (yes, y, no, n): [no] y

d. Enter a unique domain ID: Domain: (1..239) [1] 3.

e. Complete the remaining prom pts or press CTRL+D to accept the

remaining settings without completing all the prompts.

f. Re-enable the swi t ch by entering the following: switchEnable.

5. Optional: Specify a ny custom status policies for the fabric by comple ting

the follow ing steps:

a. Enter th e following at the prompt: switchStatusPolicySet.

b. Customize the status pol icies as desired. T o comple tely deactivate the

alarm for a particular condition, enter “0” at the prompt for that

condition.

6. If necessary, install or change the SFPs (small form factor pluggable

media) by completing the following steps:

Note The ports selected for use in trunking groups must meet specific

requirements. For a list of these requirements, refer to the ISL Trunking

User’s Guide.

a. Remove the shipping plugs from the ports to be used.

b. Position the SFP so tha t the key (the tab near the cable-end of the SFP)

is on top and insert the SFP into the port until it is firmly seated and

the latching mechanism clicks. For instructions specific to the SFP

type, refer to the SFP manufacturer’s documentation.

Note The SFP is keyed so that it can only be inserted with the correct

orientation into the port. If the SFP does not slide in easily, ensure it is

correctly oriented.

7. Connect the cables to the SFPs as appropriate to the fabric topology.

Position each cable so that the key (the ridge on one side of the cable

connector) is align ed with the slot in the SFP. Then, insert the cable into

Setup 27

Page 34

the SFP un til it is firml y seated and the latchi ng mechanism clicks. For

instructions specific to the cable type, refer to the cable manufacturer’s

documentation.

Note The cables used in trunking groups must meet specific re quirements .

For a list of these requiremen ts , refer to the ISL Trunking User’s Guide.

The cable is keyed so that it can only be inserted correctly into the SFP. If

the cable does not slide in easily, ensure it is correctly oriented.

8. Optional: Verify the correct operation of the switch by entering the

following command from a workstatio n: switchShow. This command

provides informat ion about the status of t he switch and the ports. For more

information about this and other commands, refer to the Fabric OS

Procedures Guide.

Use the cfgSave and cfgEnable commands to save any zone

configurations before the switch is powered off. The saved

configuration is automatically reloaded by the switch on power up. If a

configuration was enabled at the time it was saved, the same

configuration is reinstalled with an automati c cfgEnable command.

Saving the System Configuration Files

Upload the switch configuration file for disaster recovery and keep it in a

safe place where it can be easily found. Backing up the configuration after

the initial configuration changes and periodically thereafter is strongly

recommended.

Backing up the Switch Configuration Settings

FTP must be used on Windows workstations to backup the system

configuration. The FTP server must be r unning be fore a n upload can o ccur.

Use the RSHD service or FTP on a UNIX machine.

Note The two supplied utilities, RSHD.EX E and CAT.EXE currently do

not support uploads for Windows, only downloads. These utilities are

available from the support Web site: http://www.hp.com/support/fc8B.

28 Getting Started Guide

Page 35

1. Verify that the RSHD service (on a UNIX machine) or the FTP service

(on a Windows machine) is running on the host workstation.

2. Log on to the switch as the admin user.

3. At the command line enter the following command:

configUpload "hostIPaddr", "user",

"path_filename","password"

where hostIPaddr is th e IP address of the host computer, user is the

User ID used to log into t his computer,

location and filename of the configuration file, and

password for the user ID specified. If only

path_filename is the path

password is the

configUpload is entered

the system prompts you for each parameter.

Example:

switch:admin> configupload

Server Name or IP Address [host]: 123.45.678.901

User Name [user]: kelev

File Name [config.txt]: switch1

Protocol (RSHD or FTP) [rshd]: ftp

Password:

upload complete

Restoring the System Configuration Settings

To restore the system configuration settings from a backup:

1. Verify that the RSHD service or the FTP service is runni ng on the hos t

workstation (Windows or UNIX).

2. Login to the switch as the admin user.

3. Shut down the switch by entering the following command:

switchDisable

4. At the command line enter the following command:

configDownload "hostIPaddr", "user",

"path_filename","password"

where hostIPaddr is the IP address of the host computer containing

the configuration file,

computer,

Setup 29

path_filename is the path location and filename of the

user is the User ID used to log into this

Page 36

system configuration f ile, and password is the password for the user ID

specified.

Note The password operand is only required if you are using FTP.

5. Reboot the switch by entering the following command:

fastBoot

Next Steps

Specific tasks re main to be com plet ed befo re th e swit ch is f ully op era tiona l

and manageable in your network with your equipment. These tasks and the

associated tools are descri bed in t he remai ning doc uments sh ipped wit h the

product on the Document ation CD. This sect ion provid es spec ific guidanc e

for completing tasks that many users may need to do.

Setting QuickLoop Mode on Ports

The default configuration for a port is fabric mode. QuickLoop is used to

connect private host s to private storage usi ng the Fibre Chann el network. A

QuickLoop zone, connecting two switches, may be used to expand the

number of private hosts and stora ge connected. An entire switch can be set

to operate in QuickLoop mode using the

port on a switch operating in Mixed mode can be set to or removed from

QuickLoop using the telnet commands

qlPortDisable. See the QuickLoop User’s Guide for more de tails.

qlEnable telnet co mmand. A

qlPortEnable and

Setting Up Speed Negotiation

There are two methods for confi guring t he ports o n the FC Entr y Switch 8B

and FC Switch 8B. The po rt can be set to auto-sensing mode, whi ch al lows

the port to automatically be configured to the highest speed. Ports can also

be set to a fixed speed of either 1 or 2 Gbps.

To display the configuration settings of the ports on a switch, use the

portCfgShow. The port speed is displayed as 1G (f ixed speed of 1

Gbps), 2G ( fi xed speed of 2 Gbps), or AN ( auto-n egoti ate). To set the speed

level for all the ports on a switch, use the telnet command

30 Getting Started Guide

Page 37

switchCfgSpeed. To set the speed level for a single port, use the

portCfgSpeed.

Depending on your environment you may need to force a port to use a

specific speed level. Auto negotiation may not be supported by the device.

Check the configuration information for your network components for

specific requirements. See the Fabric OS Reference Manual for a detailed

command description.

Configuring Supported Devices

HP Surestore Director FC-64 Switch

The FC Entry Switch 8B or FC Switch 8B switch can be used with the HP

Surestore Director FC-64 switch. Specific configurations must be set on

both devices to make this work.

On the FC Entry Switch 8B or FC Switch 8B, log on to the switch with

administrative privileges and enter the following telnet commands:

1. switchDisable

2. interopMode 1

3. switchEnable

On the Dire ctor FC-64 switch, the following steps must be completed to

configure the switch f or interoperability:

Step 1: Verify Unique Domain IDs

Step 2: Select a Single Surestore FC-64 Director as Principal Switch

Step 3: Verify Unique Zone Names

Step 4: Verify Brocade Product Zoning Configurations

Step 5: Verify Zone Naming Conventions

Step 6: Verify Operating Mode

Step 7: Verify Surestore FC-64 Director Switches’ Operating

Parameters

Step 8: Verify Firmware Versi on

Step 9: Verify EFC Manager Version

Step 10: Verify Private Loop Targets on Brocade Products are

Translated to Fabric

Step 11: Add Switches to Fabric

Setup 31

Page 38

Step 12: Complete Zoning Activities

Step 13: Save Active Zone Set

For complete inst ructi ons on con figuring the HP Dir ector FC-64 s witch see

“Checklist for Merging Fabrics” in the Merging Heterogeneous Fabrics

Instructions white paper on the FC Entry Switch 8B or FC Switch 8B

Documentation CD.

HP Surestore VA 7400

The FC Entry Switch 8B or FC Switch 8B also can support a 2Gb

connection to an HP Surestore Virtual Array 7400. Set the port speed to

2Gb using the telnet command

portCfgSpeed.

Use the V i rtual Fr ont Panel ( VFP) on the VA 7400 and configure the de vice

as follows:

1. Change the controller port data rate to 2 Gbits/s

a. T o change the port data rate to 2 gigabi ts/second for contro ller 1, enter:

vfpmgr -S 2 -c 1

When prompted to reset, enter no.

b. To change the port data rate for controller 2, enter:

vfpmgr -S 2 -c 2

When prompted to reset, enter no if additional settings must be

changed. If all changes have been made, enter

yes to reset the array.

2. Change the controller port topology.

a. To change the port topology for controller 1 enter the following

command, selecting

vfpmgr -t 4 -c 1

4 for Direct Fabric Attach:

When prompted to reset, enter no.

b. To change the port topology for controller 2 enter the following

command, using the same topology value used for controller 1:

vfpmgr -t 4 -c 2

When prompted to reset, enter no if additional settings must be

changed. If all changes have been made, enter

yes to reset the array.

32 Getting Started Guide

Page 39

Private Loop Devices

To work with private loop devices such as the FC 60, the FC 10, or the

SCSI bridge FC 4/2, set th e FC Entry Switch 8 B or FC Swit ch 8B por t as an

L_PORT. See the telnet command

portCfgLport.

Setup 33

Page 40

34 Getting Started Guide

Page 41

Switch Status Indicators

System activity and status can be determined through the activity of the

LEDs on the switch .

Note The LEDs may flash yellow during diagnostic tests, and green,

yellow, or orange during POST. This is normal, and does not indicate a

problem unless the LEDs do not display a he althy patt ern after POST or t he

other diagnostic tests are complete.

3

DIAGNOSTICS

The orange light may be referred to as “amber” in other documentation.

The switch includes the following LEDs:

• Eight port status LEDs on the SFP media side (above and to the left of

• Eight port speed LEDs on t he SFP media side (above and to the right o f

• One switch status LED on the SFP media side and one on the fan side,

each port) to indicate the status of each port.

each port) to indicate the current link speed of each port.

to indicate whether the switch is on and has successfully booted, and

whether any of the ports are faulty.

35

Page 42

• Two Ethernet port LEDs, one to show link speed and one to show link

status.

LEDs on the SFP Media Side

Figure 18 shows the SFP media side of the swit ch with the LEDs id entifie d.

Figure 18. The SFP Media Side of the FC Entry Switch 8B and FC Switch 8B

Note The LEDs may flash different colors during diagnostic tests and

POST. This does not indicate a problem unless the LEDs do not display a

healthy pattern after POST or the other diagnostic tests are complete.

The following table describes the switch status LED located to the right of

the serial port on the SFP media side of the switch.

Color of LED Status of Hardware Recommended Action

No light Either the switch is off, or boot

is not complete, or boot has

failed.

Verify that the switch

is on and boot has had

time to complete. If

there is still no light,

contact HP support.

Steady green Switch is on and all ports are

No action required.

ready for use.

36 Getting Started Guide

Page 43

Color of LED Status of Hardware Recommended Action

Steady yellow One or more ports are not ready

for use. Switch may be booting

or disabled, or one or more

ports may be faulty.

Verify that the switch

has completed

booting and is not

disabled. If the light

is still yellow, check

the port status LEDs.

Slow-flashing

yellow

One or more ports are faulty. Check the port status

LEDs. Also, any

errors are listed in the

error log. For more

information about t he

error log, refer to the

Fabric OS

Procedures Guide.

The following ta bl e de scr ib es t h e por t s tat us LEDs located above each port

on the left.

Color of LED Status of Hardware Recommended Action

No light No light or signal carrier

(media or cable) is detected.

Steady green Port is online (connected to an

external device) but has no

traffic.

Slow-flashing

green (on 1

second; off 1

Port is online but segmented,

indicating a loopback cable or

incompatible switc h.

second)

Fast-flashing

green (on 1/4

The port is in intern al loopba ck

(diagnostic).

second; off 1/4

second)

Verify that media and

cable are both firmly

seated an d functiona l.

No action required.

Verify correct device

is connected to port.

No action required.

Diagnostics 37

Page 44

Color of LED Status of Hardware Recommended Action

Flickering green Port is online, with traffic

No action required.

flowing through port.

Steady orange Port is receiving light or signal

No action required.

carrier, but is not yet online.

Slow-flashing

orange (on 1

second; off 1

The port is disabled

(result of diagnostics or

portDisable command).

Reset the port from a

management station.

second)

Fast-flashing

orange (on 1/4

second; off 1/4

The port is faulty. Reset the switch from

a management

station.

second)

Alternating green

and yellow

Port is bypassed. Reset the port from a

management station.

The following ta bl e de scr ib es the port speed LEDs located above each port

on the right.

Color of LED Status of Hardware Recommended Action

No light The port is

No action required.

transmitting/receiving at

1 Gbps.

Steady green The port is

No action required.

transmitting/receiving at

2 Gbps.

No light The port is

No action required.

transmitting/receiving at

10 Mbps.

Steady green The port is

No action required.

transmitting/receiving at

100 Mbps.

38 Getting Started Guide

Page 45

Color of LED Status of Hardware Recommended Action

No light No Ethernet traffic is flowing

Steady green Ethernet traffic is flowing

LEDs on the Fan Side

Figure 19 shows the fan side of the switch with the LED identified.

through the RJ-45 port.

through the RJ-45 port.

Verify that the switch

has power and the

Ethernet cable is

firmly seated.

No action required.

Figure 19. The Fan Side of the FC Entry Switch 8B and FC Switch 8B

Note The LEDs may flash different colors during diagnostic tests and

POST. This does not indicate a problem unless the LEDs do not display a

healthy pattern after POST or the other diagnostic tests are complete.

Diagnostics 39

Page 46

The following table describes the switch status LED on the fan side of the

switch.

Color of LED Status of Hardware Recommended Action

No light Either the switch is off, or boot

is not complete, or boot has

failed.

Steady green Switch is on and all ports are

ready for use.

Steady yellow One or more ports are not rea dy

for use. Switch may be booting

or disabled, or one or more

ports may be faulty.

Slow-flashing

One or more ports are faulty. Check the port status

yellow

Verify that the switch

is on and boot has had

time to complete. If

there is still no light,

contact HP support.

No action required.

Verify that the switch

has completed

booting and is not

disabled. If the light

is still yellow, check

the port status LEDs.

LEDs. Also, any

errors are listed in the

error log. For more

information about t he

error log, refer to the

Fabric OS

Procedures Guide.

Maintenance and Diagnostic Tests

Neither the FC Entry Switch 8B nor FC Switch 8B requires any regular

physical maintenance and is designed to minimize the chance of failure.

Diagnostic tests are provided to help troubleshoot the hardware and the

firmware. The diagnostic tests provided on the switch include tests of

internal connections and circuitry, fixed media, and any SFP modules and

fiber optic cables in use. The tests are implemented by command, either

through a telnet session or thr ough a terminal set up for a serial connection

to the switch. Some tests require the ports to be connected by external

40 Getting Started Guide

Page 47

cables, to al low dia gnostics to verify the seri ali ze r/ deserializer interface, as

well as the attached SFP and cable.

All diagnostic tests are run at link speeds of both 1 Gbps and 2 Gbps. For

detailed information about the specific diagnostic tests and how to run

them, refer to the Fab ric OS Procedures Gu ide.

Note The transmit and receive speed of the links may be temporarily

locked to a specific speed during diagnostic testing.

Test Command Description

Error Log errDump Displays the error log without

page breaks.

Switch Offline switchDisable Sets the switch to offline state

necessary to run certain switch

diagnostics.

Memory Test ramTest Checks CPU RAM memory. Run

offline or online.

Port Register

Test

Central Memo ry

Test

Control Message

Interface (CMI)

Conn Test

Content

Addressable

Memory (C AM)

Test

portRegTest Checks that the registers and stat ic

memory in each ASIC can be

successfully accessed. Run

offline.

centralMemoryTest Checks that the c entral me mory in

each ASIC can be successfully

accessed. Run offline.

cmiTest Verifies that control mess age s c an

be sent from ASIC to ASIC.

Run offline.

camTest Verifies CAM functionality. Run

offline.

Diagnostics 41

Page 48

Test Command Description

Port Loopback

Test

portLoopbackTest Checks all switch main board

hardware. Frames transmitted are

looped back and received. Run

offline.

Cross Port Test crossPortTest Checks all switch paths. Frames

transmitted by port M are looped

back via external cable and

received at port N. Run offline or

online.

Spin Silk Test spinSilk Checks all switch paths at the

maximum speed of 1 Gbps.

Frames transmitted by port M are

looped back via external cables

and when received by port N are

sent again by port M in an

external loop. Run offline.

SRAM Data

Retention Test

sramRetentionTest Verifies that data written into

ASIC memories is retained. Runs

offline.

CMem Data

Retention Test

CmemRetentionTest Verifies that data written into

ASIC SRAMs is retained. Runs

offline.

Switch Online switchEnable Returns switch to online state.

Error Messages

To analyze error messages, access the error message log via a Telnet

session using the

power from the switch; error messages are stored in RAM and are lost

when power is removed. See the Fabric OS Reference Manual for a

detailed description of each message.

42 Getting Started Guide

errDump command. Note any messages befor e removi ng

Page 49

Getting Support

Service and Support

There are no customer servicea ble parts in the FC Entr y Switch 8B or FC

Switch 8B. For the most current technical support information for the FC

Entry Switch 8B and FC Switch 8B, visit the HP Web site at

http://www.hp.com/support/fc8B.

Additional Licenses

For information on obtaining license keys visit the HP Web site at

http://www.hp.com/support/fc8B.

Diagnostics 43

Page 50

44 Getting Started Guide

Page 51

General

4

SPECIFICATIONS

The following ta bl e l is ts the general specifications f or t he FC Entry Switch

8B and FC Switch 8B.

Specification Description

Fabric

initialization

IP over Fibre

Channel

(FC-IP)

System

architecture

System

processor

Number o f

Fibre Channel

ports

Fibre Channel

port speed

Complies with FC-SW 5.0

Complies with FC-IP 2.3 of the FCA profile

Non-blocking shared-memory switch

Intel 80960VH, 100MHz CPU

8 SFP ports

1 or 2 Gbps, full duplex

45

Page 52

Specification Description

Modes of

Fibre Channel Class 2 and Class 3

operation

Aggregate

32 Gbps if all 8 ports running at 2 Gbps, full duplex

switch I/O

bandwidth

Frame buffers 27 buffers per E_Port and 16 buffers per F_Port at 2112

bytes per frame

Port to port

latency

Data

transmission

range

Less than 2 microseconds with no contention (destination

port is free)

With 50 u cable at 2 Gbps:

Up to 300 m (984 ft.) for short-wavelength optical link

Up to 10 km (6.2 mi.) for long-wavelength optical link

With 62.5 u cable at 2 Gbps:

Up to 150 m (492 ft.) for short-wavelength optical link

Up to 10 km (6.2 mi.) for long-wavelength optical link

Chassis type Forced-air cooling that fl ows from the fan side to the SFP

media side

Environmental

The following table lists the acceptable environmental ranges.

Condition Acceptable Range

Temperature (operating) 10°C to 40°C

Temperature (non-operating) -35°C to 65°C

Humidity (operating) 20% to 85% RH non-condensing, at 40° C

Humidity (non-operating) 85% RH non-conducting, at 70°C

Altitude (operating) 0 to 3 kilometers above sea level

Altitude (non-operating) 0 to 12 kilometers above sea level

Shock (operating) 4 G, 11 MS duration, half sine

46 Getting Started Guide

Page 53

Dimensions

Condition Acceptable Range

Shock (non-operating) 20 G, 11 MS duration, sq. wave

Vibration (operating) 5 G, 0-3 kHz at 1.0 octave/minute

Vibration (non-operating) 10 G, 0-5 kHz at 1.0 octave/minute

The following table li sts t he dimensi ons of th e FC Entry Swit ch 8B and FC

Switch 8B.

Dimension Value

Height 1.69 inches (4.2 cm)

Depth 10.4 inches (26.4 cm)

Width 16.9 inches (42.8 cm)

Weight 8.0 lbs (3.6 kg)

Power Supply

The following table lists the power supply specifications.

Specification Value

Maximum output 75 watts

Maximum system power

50 watts

consumption

Input voltage 90 - 264 VAC

Input line frequency 47 - 63 Hz

Harmonic distortion Active power factor correction per

IEC1000-3-2

BTU rating 60 Watts x 3.412 BTU/Hr /Watts = 204.72

BTU/hr

Specifications 47

Page 54

48 Getting Started Guide

Page 55

PRODUCT REGULATORY INFORMATION

FCC EMC Statement (USA)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency ener gy and, if n ot installed an d used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense. The end u ser of this pro duct sho uld be aware that any changes or

modifications made to this equipment without the approval of Hewlett-Packard

could result in the product not meeting the Class A limits, in which case the FC C

could void the user's authority to operate the equipment.

EMC Statement (Canada)

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A respecte toutes les exigences du Règlement

sur le matériel brouilleur du Canada.

EMC Statement (European Union)

This is a Class A product. In a domestic environment this product may cause r a dio

interference, in which case the user may be required to take adequate measures.

Spécification ATI Classe A (France)

DECLARATION D'INSTALLATION ET DE MISE EN EXPLOITATION d'un

matériel de traitement de l'information (ATI), classé A en fonction des niveaux de

perturbations radioélectriques émis, définis dans la norme européenne EN 55022

concernant la Compatibilité Electromagnétique.

49

Page 56

Germany Noise Declaration

Schalldruckpegel Lp = 46.1 dB(A)

Am Arbeitsplatz (op erator position)

Normaler Betrieb (normal operation)

Nach ISO 7779:1999 (Typprüfung)

VCCI EMC Statement (Japan)

Harmonics Conformance (Japan)

BSMI EMC Statement (Taiwan)

RRL EMC Statement (Korea)

50 Getting Started Guide

Page 57

Laser Safety

A. Certification and Classification Information

When equipped with native Fibre Channel adapters, this product contains a laser

internal to the small form factor pluggable (SFP) transceiver modules.

In the USA, the SFP module is certified as a Class 1 Laser product, conforming to

the requirements contained in Department Of Health and Human Services (DHHS)

regulation 21 CFR, Subchapter J. The certification is indicated by a label on the

metal SFP housing.

Outside the USA, the SFP is certified as a Class 1 Laser product conform ing to

requirements contained in IEC 825-1:1993 and EN60825-1:1994, including

Amendment 11:1 996 .

The SFP includes the following certifications:

• UL Recognized Component (USA)

• CSA Certified Component (Canada)

• TUV Certified Component (European Union)

• CB Certificate (Worldwide)

The following figure shows the Class 1 information label that appears on the metal

housing of the SFP.

CLASS 1 LASER PRODUCT 21 CFR(J)

B. Product Information

Each communications port consists of a transmitter and receiver optical

subassembly. The transmitter subassembly contains internally a semiconductor

laser diode in the wavelength of either 850 nanometers (shortwave laser) or 1310

nanometers (longw ave laser).

Class 1 Laser products are not considered hazardous.

WARNING There are no user maintenance operations, service operations, or

adjustments to be performed on the SFP module.

C. Usage Restrictions

Failure to comply with these usage restrictions may result in incorrect operation of

the system and points of access may emit laser radiation above the Class 1 limits

established by the IEC and U.S. DHHS.

Product Regulatory Information 51

Page 58

Declaration of Conformity

Manufacturer's Name:

Network Storage Solutions Organization

Manufacturer's Address:

Roseville, CA 95747

USA

declares, that the product

Product Name:

Model Number(s):

Product Options:

conforms to the following Product Specifications:

Safety: IEC 60950:1991 + A1, A2, A3, A4 / EN 60950:1992 + A1, A2, A3, A4, A11

GB 4943-1995

IEC 60825-1:1993 / EN 60825-1:1994 + A11, Class 1 (Laser/LED)

EMC: CISPR 22:1997 / EN 55022:1998 Class A

CISPR 24:1997 / EN 55024:1998

IEC 61000-3-2:1995 / EN 61000-3-2:1995 +A14

IEC 61000-3-3:1994 / EN 61000-3-3:1995

A7346A, A7346AZ, A7347A, A7347AZ

All

GB 9254-1988

DECLARATION OF CONFORMITY

accordin g to ISO/ IEC Gui de 22 and EN 4501 4

Hewlett-Packard Company

8000 Foothills Blvd.

hp surestore fc 1Gb/2Gb entry switch 8B

hp surestore fc 1Gb/2Gb switch

8B

1

Supplementary Information

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC and carries the CE marking accordingly.

1) The Product was tested in a worst-case test configuration which maximizes RFI emissions.

Roseville, CA

October 15, 2001

European Contact: You r local Hewlett-Pac kard Sales and Servic e Office or Hewlett-Pac kard GmbH, Departm ent HQTRE, Herrenberger Straße 130, D-71034 Böblingen (FAX: + 49-7031-14-3143)

:

52 Getting Started Guide

Page 59

Page 60

Technical information in this document

is subject to change without notice.

© Copyright Hewlett-Packard Company 2001.

All right reserved.

Reproduction, adaptation, or translation

without prior written permission is pro hibited

except as allowed under the copyright laws.

Printed in U.S.A.

E1201

Manual Part Number

A7346-96002

*A7346-96002*

Loading...

Loading...