HP StorageWorks Director 2/64 Installation Manual

Installation

Guide

hp StorageWorks

Director 2/64

Product Version: FW v06.xx/HAFM SW v08.02.00

Fourth Edition (July 2004)

Part Number: AA–RSNGD–TE/958–000289–002

This guide provides procedures for setting up, configuring, and managing the HP

StorageWorks Director 2/64.

© Copyright 2001–2004 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another language without the prior written consent of Hewlett-Packard.

The information contained in this document is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial

errors or omissions contained herein.

IBM® and AIX are trade marks or registered trade marks of IBM.

Intel® is a U.S. registered trademark of Intel Corporation.

Intel® is a trademark or registered trademark of Intel Corporation in the U.S. and other countries and are used under

license.

Java is a trademark of Sun Microsystems, Inc

Linux is a U.S. registered trademark of Linus Torvalds.

Microsoft®, Windows 98®, Windows 2000®, Windows 2003®, Windows XP®, Windows ME®, and

Windows NT® are U.S. registered trademarks of Microsoft Corporation.

Red Hat is a registered trademark of Red Hat, Inc.

Sun, Sun Microsystems, the Sun Logo, and Solaris are trademarks or registered trademarks of Sun Microsystems, Inc.

UNIX® is a registered trademark of The Open Group.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein. The

information is provided “as is” without warranty of any kind and is subject to change without notice. The warranties

for Hewlett-Packard Company products are set forth in the express limited warranty statements for such products.

Nothing herein should be construed as constituting an additional warranty.

Printed in the U.S.A.

Director 2/64 Installation Guide

Fourth Edition (July 2004)

Part Number: AA–RSNGD–TE/958–000289–002

Contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Intended audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Related documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Text symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Equipment symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rack stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Getting help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HP technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HP storage web site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HP authorized reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Director Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Director Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Error-Detection, Reporting, and Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Zoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Multi-Switch Fabrics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

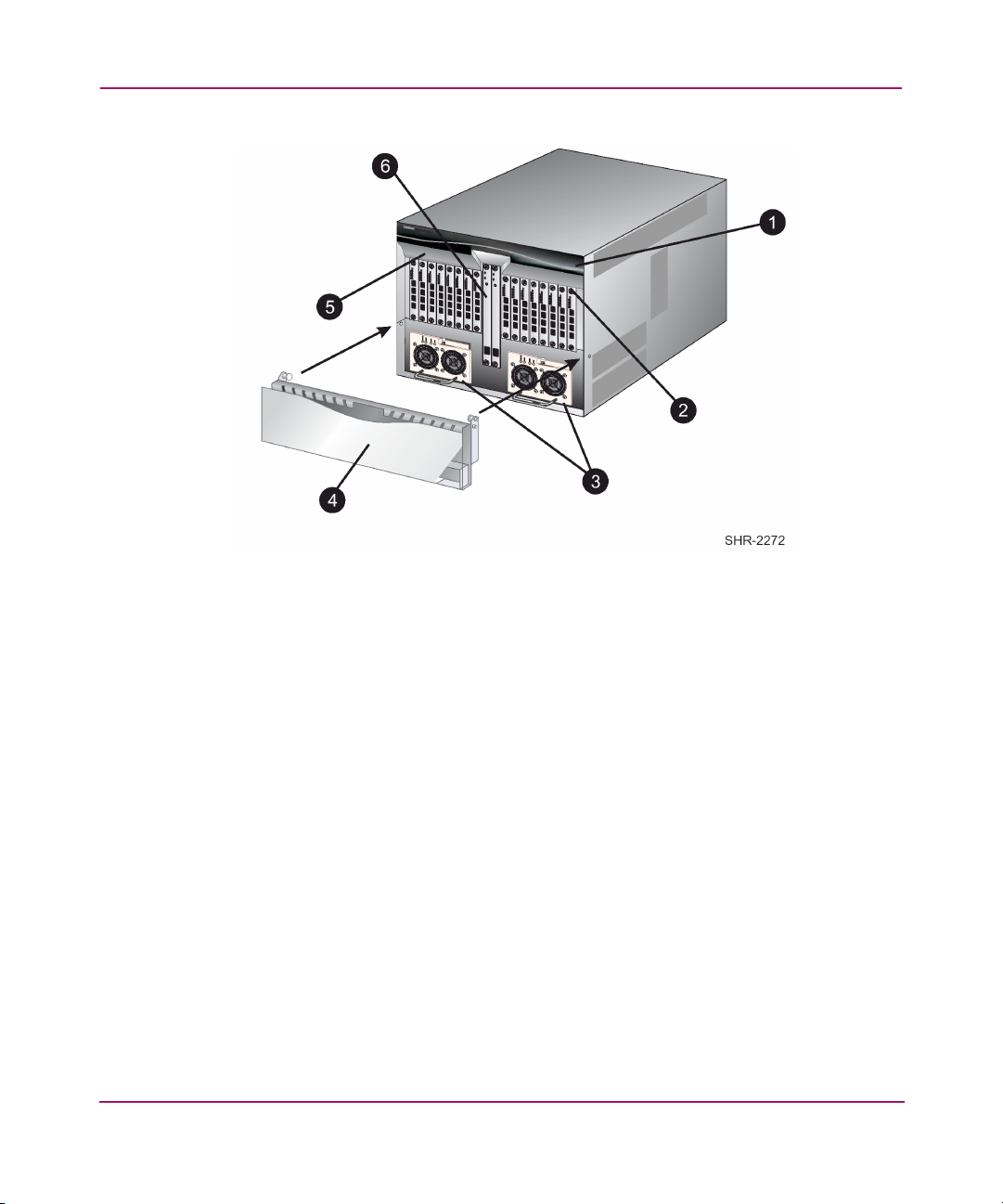

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CTP2 Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cable Management Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

UPM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fan Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Contents

3Director 2/64 Installation Guide

Contents

SBAR Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Module Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tools Supplied with the Director. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tools Supplied by Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Optional Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2 Installing and Configuring the Director. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Installation Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Review Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Items Required for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Select an Operating Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cooling and Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Unpack and Inspect the Director . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Install the Director in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Tips for Installing More than One Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Transfer the Director to the Lift Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

HP 9000, HP 10000, and HP 11000 Series Rack Installation . . . . . . . . . . . . . . . . . . . . . 47

Install the Shelf Brackets in a HP 9000, HP 10000, and HP 11000 Series Rack . . . 47

Prepare the Switch for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Secure the Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Insert the Cage Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Insert the Front Cage Nuts in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Insert the Rear Cage Nuts in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Finalize the Rack-Mounting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

HP System/e and Industry-Standard 19-inch Rack Installation. . . . . . . . . . . . . . . . . . . . 54

Install the Anti-tip Feet on an HP System/e Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Install Mounting Bracket Hardware in the Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Prepare the Front and Rear Rack Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Prepare the Switch for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Finalize the Rack-Mounting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Sliding Shelf Installation—For an HAFM Appliance only. . . . . . . . . . . . . . . . . . . . 64

Recommended Cable Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configure Director Network Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Changing the Director’s IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

LAN-Connect the Director . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4 Director 2/64 Installation Guide

Contents

HAFM Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Element ManagerEnabling HAFM to Manage the Director . . . . . . . . . . . . . . . . . . . . . . 78

Verify Communication Between the Director and HAFM Appliance. . . . . . . . . . . . . . . 79

Set Director Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Set Date and Time Manually. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Synchronize Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Frequently Used HAFM Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Setting the Director Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Setting the Director Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configuring Director Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configuring Director Management Style. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Configuring Switch Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Switch Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Domain ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Preferred . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Insistent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Rerouting Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Domain RSCNs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Suppress RSCN’s on Zone Set Activations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Director Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Configuring Fabric Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Fabric Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

BB_Credit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

R_A_TOV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

E_D_TOV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Switch Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Interop Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configuring Preferred Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configuring Switch Binding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configuring Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configuring Port Addresses (FICON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Configuring SNMP Trap Message Recipients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Configuring and Enabling E-mail Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Configuring and Enabling Call-Home Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Configuring and Enabling Ethernet Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Configuring Threshold Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Creating New Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Modifying Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5Director 2/64 Installation Guide

Contents

Activating or Deactivating Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Deleting Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Backing Up HAFM Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuring Open Systems Management Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuring FICON Management Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuring Feature Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuring Open Trunking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Enabling Embedded Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Enabling Telnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Connecting Cables to the Fibre Channel Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Connecting the Director to a Fabric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Unpacking, Inspecting, and Installing the Ethernet Hub (Optional) . . . . . . . . . . . . . . . . . . 111

Using HAFM from a Remote Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Remote Workstation Minimum Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Installing HAFM Client on a Remote Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Launching HAFM from the Remote Client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3 Managing Firmware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Determining a Director Firmware Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Adding a Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Modifying a Firmware Version Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Deleting a Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Downloading a Firmware Version to a Director . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Backing Up the Director’s Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

A Regulatory Compliance Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Regulatory Compliance ID Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Federal Communications Commission Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Class A Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Class B Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Declaration of Conformity for Products Marked with FCC Logo—United States Only 129

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Network and Serial Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

IEC EMC Statement (Worldwide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Spécification ATI Classe A (France) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Canadian Notice (Avis Canadien) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Class A Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Class B Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

European Union Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

6 Director 2/64 Installation Guide

Contents

Japanese Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Harmonics Conformance (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

German Noise Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Certification and Classification Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

B Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Physical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Operating Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Laser Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

C Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Precautions Against Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Grounding Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Figures

1 Director components—front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 UPM card LEDs and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3 Director components—rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4 Torque tool and hex adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 Loopback plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 Fiber-Optic protective plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Null modem cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8 Carton contents for a Director 2/64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 Carton contents for an HP 9000, HP 10000, and HP 11000 Series Rack . . . . . . . . . . . . 42

10 Carton contents for a HP system/e or industry-standard 19-in rack installation . . . . . . . 44

11 Securing shelf brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12 Securing the two mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13 Aligning the switch in the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

14 Securing the rear angle brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15 AC power connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

16 Mounting anti-tip feet for a HP system/e rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

17 Rail tray mounting location requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

18 Attaching a rear rail tray bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7Director 2/64 Installation Guide

Contents

19 Installing a Tinnerman nut on the rack-front rail in U1. . . . . . . . . . . . . . . . . . . . . . . . . . 57

20 Inserting the rail tray in the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

21 Preparing the front rack columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

22 Preparing the rear rack columns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

23 Installing the rack-mounting brackets on the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

24 Positioning the switch in the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

25 Securing the switch to the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

26 AC power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

27 Installing the sliding shelf brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

28 Positioning the sliding shelf bracket on a rail rear slot . . . . . . . . . . . . . . . . . . . . . . . . . . 66

29 Positioning the sliding shelf bracket at the rack front . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

30 Recommended cable management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

31 Connecting the null modem cable between the director and a workstation. . . . . . . . . . . 72

32 Connection Description dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

33 Connect To dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

34 COMn Properties dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

35 HyperTerminal window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

36 HyperTerminal dialog box (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

37 HyperTerminal dialog box (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

38 LAN-connect the director . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

39 Discover Setup dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

40 Domain Information dialog box (IP Address page). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

41 Hardware View page (with FRU failures) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

42 Configure Date and Time dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

43 Date and Time Synced dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

44 Configure Identification dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

45 Configure Switch Parameters dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

46 Configure Fabric Parameters dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

47 Configure Ports check boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

48 Configure SNMP dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

49 E-Mail Event Notification Setup dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

50 HAFM 8 Server Users dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

51 Define Filter dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

52 Configure Ethernet Event dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

53 Configure Threshold Alerts dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

54 New Threshold Alerts dialog box—first screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

55 New Threshold Alerts dialog box—second screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

56 New Threshold Alerts dialog box—third screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8 Director 2/64 Installation Guide

Contents

57 New Threshold Alerts dialog box—summary screen . . . . . . . . . . . . . . . . . . . . . . . . . . 105

58 Configure Threshold Alerts dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

59 Connect the Fibre Channel cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

60 Port Properties dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

61 HAFM remote client install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

62 HAFM 8 Log In dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

63 View All - HAFM 8 window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

64 Director Firmware Library dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

65 New Firmware Version dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

66 New Firmware Description dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

67 Backup and Restore Configuration dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Tables

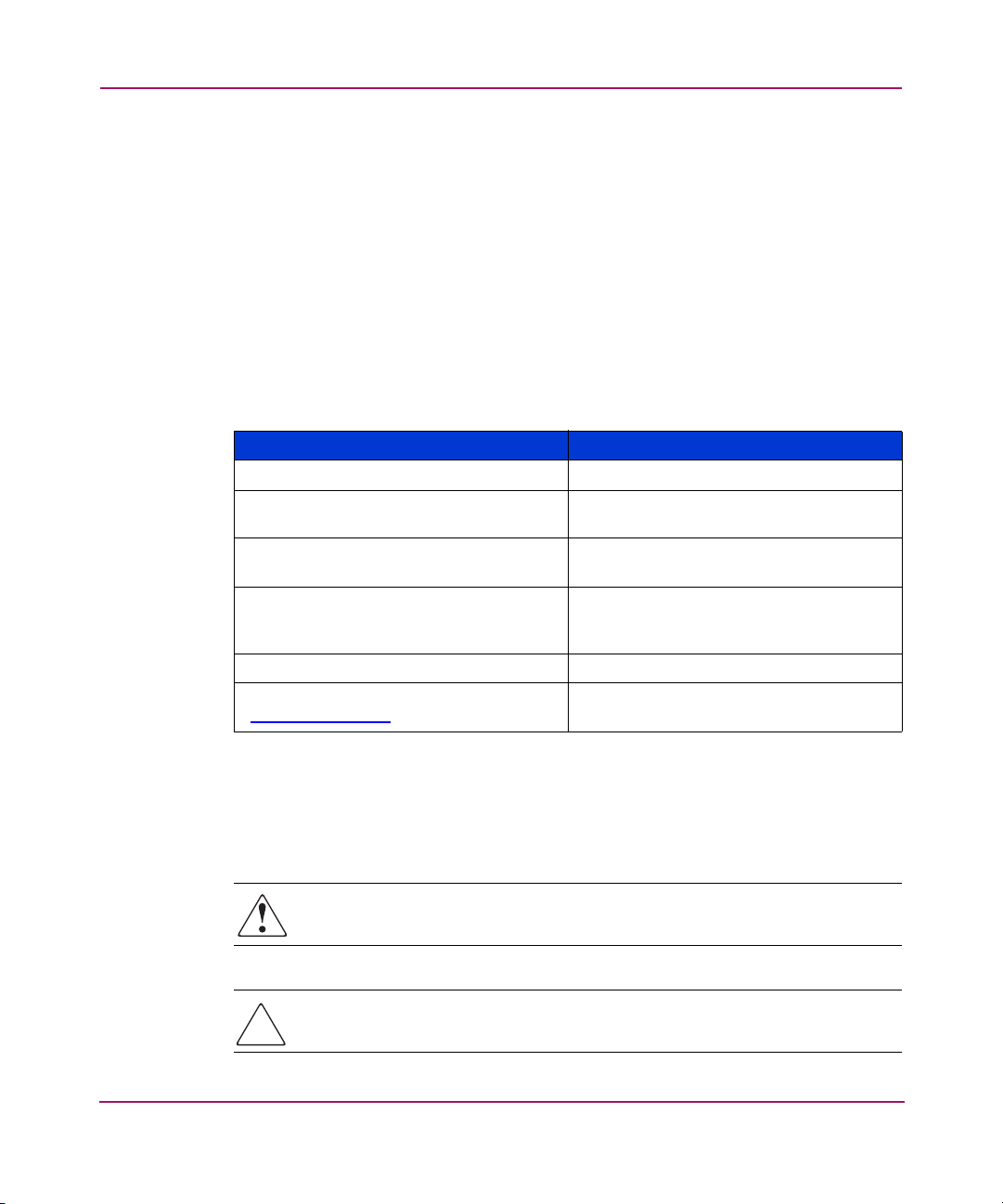

1 Document conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Director Optional Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3 Shipping Carton Contents for a Director 2/64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Shipping Carton Contents for an HP 9000, HP 10000, and HP 11000 Series Rack . . . . 42

5 Parts for Installing in an HP System/e and Industry-Standard 19-inch Rack . . . . . . . . . 45

6 Director Operational States and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

8 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

9 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10 Operating Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11 Laser specs - 2 Gb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9Director 2/64 Installation Guide

Contents

10 Director 2/64 Installation Guide

About this

Guide

This guide provides information on installing, configuring, managing, and

verifying operation of the HP StorageWorks Director 2/64. The Director switch

connects storage devices, hosts, and servers in a SAN. The director is easily

managed and configured to optimize the performance of your SAN.

“About this Guide” topics include:

■ Overview, page 12

■ Conventions, page 13

■ Rack stability, page 15

■ Getting help, page 16

About this Guide

About this Guide

11Director 2/64 Installation Guide

About this Guide

Overview

This section covers the following topics:

■ Intended audience

■ Related documentation

Intended audience

This guide is part of a documentation set that supports the Director. It is intended

for use by trained service and installation representatives experienced with the

SAN technology and Fibre Channel technology.

Related documentation

For a list of corresponding documentation included with this product, see the

Related Documents section of the HP StorageWorks Director 2/64 Release Notes.

For the latest information, documentation, and firmware releases, please visit the

HP StorageWorks website:

http://h18006.www1.hp.com/storage/s an in frastructure.html

For information about Fibre Channel standards, visit the Fibre Channel Industry

Association website located at

12 Director 2/64 Installation Guide

http://www.fibrechanne l.org

.

Conventions

Conventions consist of the following:

■ Document conventions

■ Text symbols

■ Equipment symbols

Document conventions

This document follows the conventions in Tab le 1.

Table 1: Document conventions

Blue text: Figure 1 Cross-reference links

Bold Menu items, buttons, and key, tab, and

Italics

Monospace font User input, commands, code, file and

Monospace, italic font Command-line and code variables

Blue underlined sans serif font text

(

http://www.hp.com

About this Guide

Convention Element

box names

Text emphasis and document titles in

body text

directory names, and system responses

(output and messages)

Web site addresses

)

Text symbols

The following symbols may be found in the text of this guide. They have the

following meanings:

WARNING: Text set off in this manner indicates that failure to follow

directions in the warning could result in bodily harm or death.

Caution: Text set off in this manner indicates that failure to follow directions

could result in damage to equipment or data.

Director 2/64 Installation Guide

13

About this Guide

Tip: Text in a tip provides additional help to readers by providing nonessential or

optional techniques, procedures, or shortcuts.

Note: Text set off in this manner presents commentary, sidelights, or interesting points

of information.

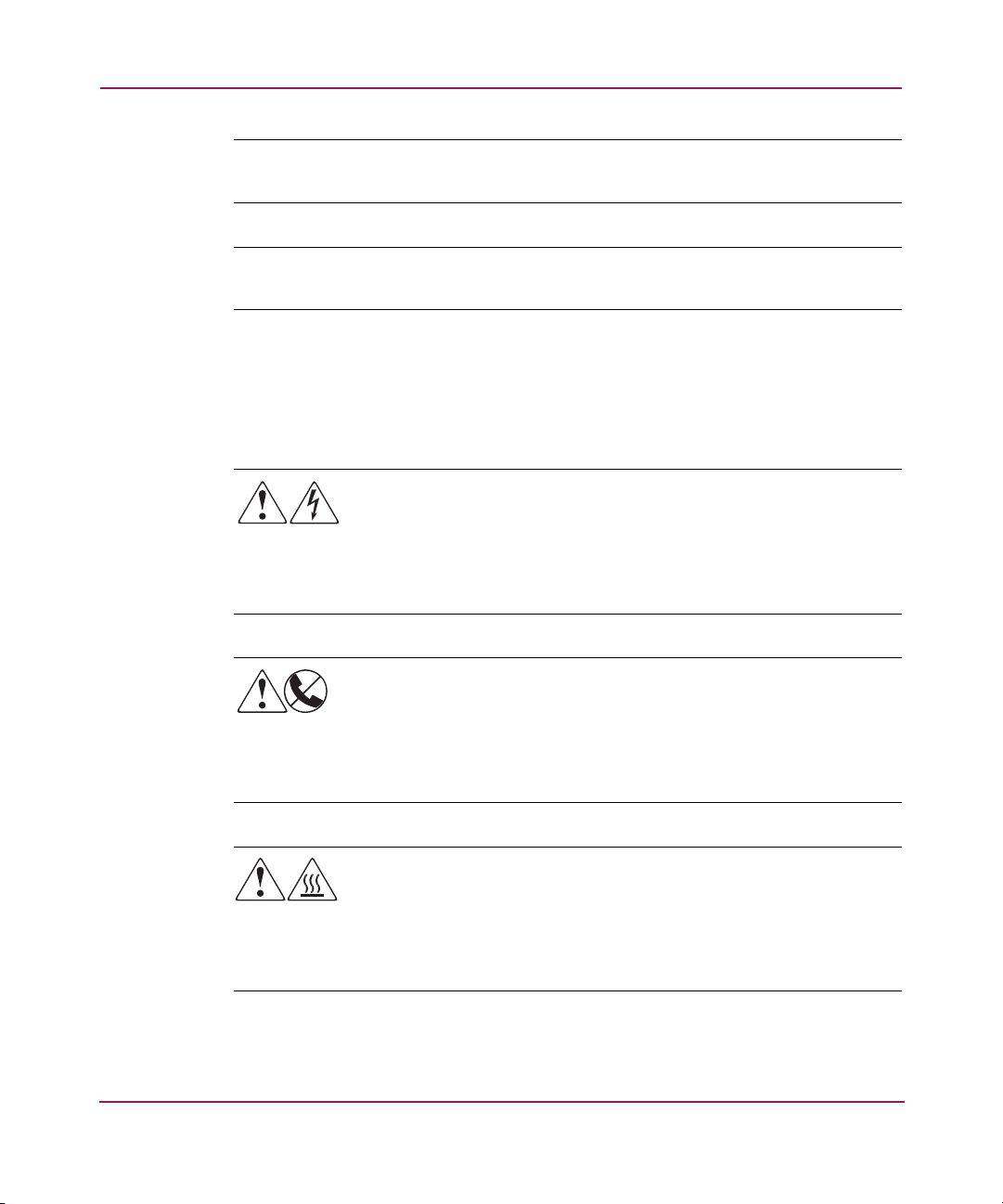

Equipment symbols

The following equipment symbols may be found on hardware for which this guide

pertains. They have the following meanings:

Any enclosed surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards. Enclosed

area contains no operator serviceable parts.

WARNING: To reduce the risk of personal injury from electrical shock

hazards, do not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network

interface connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to

the equipment, do not plug telephone or telecommunications

connectors into this receptacle.

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. Contact with

this surface could result in injury.

WARNING: To reduce the risk of personal injury from a hot

component, allow the surface to cool before touching.

14 Director 2/64 Installation Guide

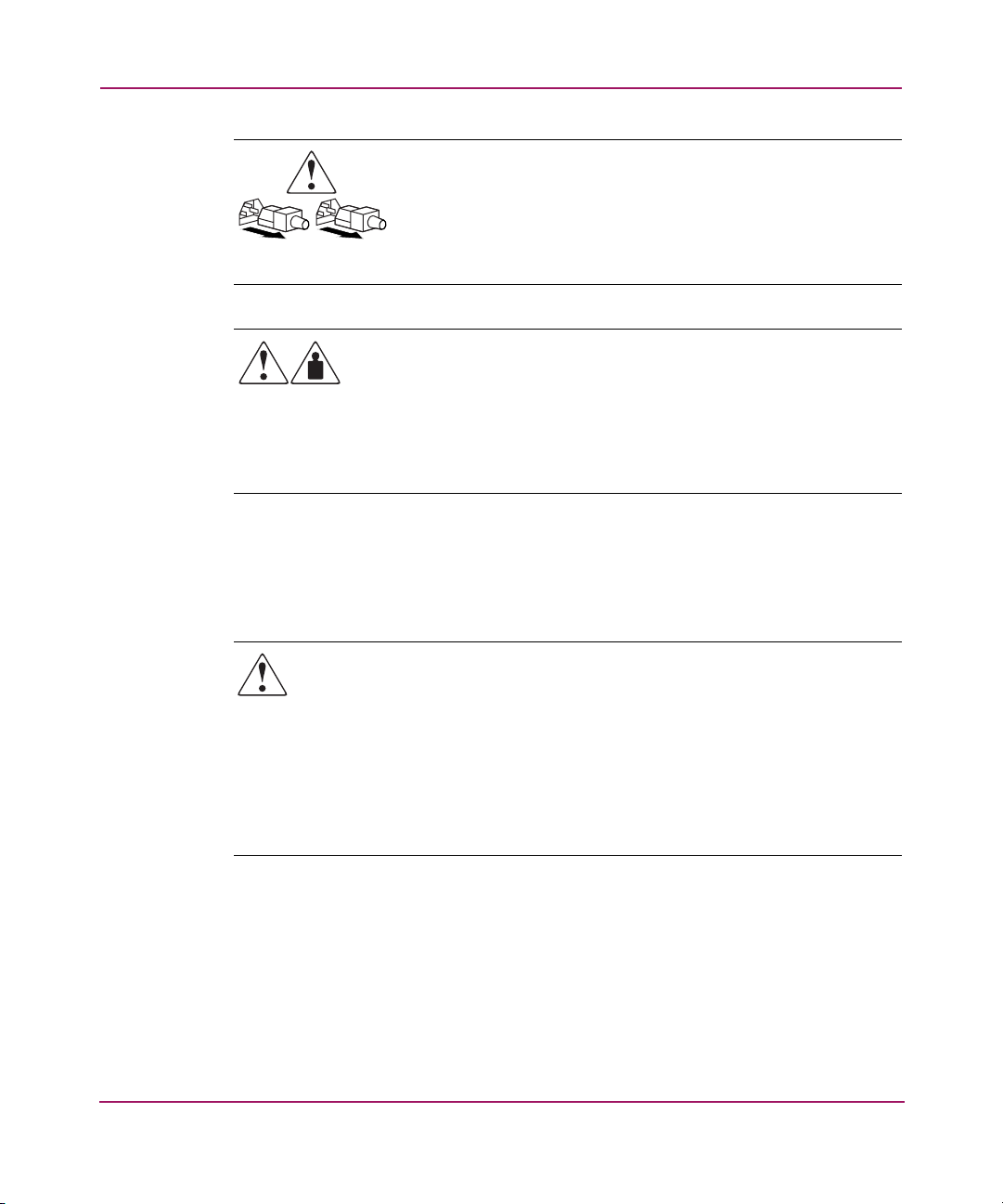

Rack stability

Rack stability protects personnel and equipment.

About this Guide

Power supplies or systems marked with these symbols indicate

the presence of multiple sources of power.

WARNING: To reduce the risk of personal injury from electrical

shock, remove all power cords to completely disconnect power

from the power supplies and systems.

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to

handle safely.

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manually handling material.

WARNING: To reduce the risk of personal injury or damage to the

equipment, be sure that:

■ The leveling jacks are extended to the floor.

■ The full weight of the rack rests on the leveling jacks.

■ In single rack installations, the stabilizing feet are attached to the rack.

■ In multiple rack installations, the racks are coupled.

■ Only one rack component is extended at any time. A rack may become

Director 2/64 Installation Guide

unstable if more than one rack component is extended for any reason.

15

About this Guide

Getting help

If you still have a question after reading this guide, contact an HP authorized

service provider or access our web site:

HP technical support

Telephone numbers for worldwide technical support are listed on the following

HP web site:

of origin.

Note: For continuous quality improvement, calls may be recorded or monitored.

Be sure to have the following information available before calling:

■ Technical support registration number (if applicable)

■ Product serial numbers

■ Product model names and numbers

■ Applicable error messages

http://www.hp.com

http://www .hp.com/support/

.

. From this web site, select the country

■ Operating system type and revision level

■ Detailed, specific questions

HP storage web site

The HP web site has the latest information on this product, as well as the latest

drivers. Access storage at:

storage.html

. From this web site, select the appropriate product or solution.

http://www .hp.com/country/us/eng/prodserv/

HP authorized reseller

For the name of your nearest HP authorized reseller:

■ In the United States, call 1-800-345-1518

■ In Canada, call 1-800-263-5868

■ Elsewhere, see the HP web site for locations and telephone numbers:

http://www .hp .com

16 Director 2/64 Installation Guide

.

Overview

This chapter contains the following HP StorageWorks Director 2/64 information:

■ Director Description, page 18

■ Features, page 18

■ Hardware Components, page 24

■ Tools and Test Equipment, page 31

■ Optional Kits, page 34

1

17Director 2/64 Installation Guide

Overview

Director Description

The director is a second-generation, 64-port product that provides dynamic

switched connections between Fibre Channel servers and devices in a SAN

environment. Directors are managed and controlled through an High Availability

Fabric Manager (HAFM) appliance with HAFM and Director 2/64 Element

Manager installed. The HAFM appliance is a 1U rack-mount appliance that

provides a central point of control for up to 48 directors and/or edge switches.

Multiple directors and the HAFM appliance communicate through the customer’s

local area network (LAN).

Features

Features of the Director 2/64 include:

■ Scalable from 32 to 64 User ports (with optional UPM 2 Gb add-on)

■ 100% dynamic non-blocking, cut through switching with congestion queuing

■ Online error detection, error isolation, and error recovery

■ Redundant, hot-pluggable components

■ Full duplex 200 MB/sec per port performance

■ Less than 2-µs average switch latency

■ 100-km distance support (60 buffers), with use of repeaters

■ Small form factor, hot-pluggable optical transceivers, auto configure G_ports

■ Combination short-wave or long-wave laser transceivers

■ Redundant power supplies and fan modules

■ Online product repair for Field Replaceable Units (FRUs)

■ Periodic health check and enhanced system monitoring

■ Non-disruptive firmware load and update

18 Director 2/64 Installation Guide

Director Management

The director is managed and controlled through:

■ The HAFM application. This graphical user interface (GUI) resides on the

HAFM appliance and provides a single point of management for all directors,

and a launching point for the Director 2/64 Element Manager.

■ Simple network management protocol (SNMP). A SNMP agent is

implemented through the HAFM application that allows administrators on

SNMP management workstations to access director management information

using any standard network management tool. Administrators can assign

internet protocol (IP) addresses and corresponding community names for up

to 12 SNMP workstations functioning as SNMP trap message recipients.

Refer to the HP StorageWorks SNMP Reference Guide for Directors and

Edge Switches for more information.

■ The Internet using the Embedded Web Server (EWS) interface installed on

the director. This interface supports configuration, statistics monitoring, and

basic operation of the director, but does not offer all the capabilities of the

Director 2/64 Element Manager. Administrators launch the EWS interface

from a remote PC by entering the director’s IP address as the internet URL,

then entering a user name and password at a login screen. The PC browser

then becomes a management console.

Overview

Note: The default user name for the right to view status and other information is

“operator.” The default user name for the right to modify configuration data,

perform maintenance tasks, or perform other options is “Administrator.” The

default password for both user names is “password.”

■ The command line interface (CLI). The CLI allows you to access many

HAFM and Element Manager functions while entering commands during a

telnet session with the director. The primary purpose of the CLI is to automate

management of a large number of directors using scripts. The CLI is not an

interactive interface; no checking is done for pre-existing conditions and no

prompts display to guide users through tasks. Refer to the HP StorageWorks

CLI Reference Guide for Directors and Edge Switches for more information.

■ A customer-supplied PC or UNIX-based platform with the HAFM appliance

and client HAFM and Director Element Manager installed.

■ A customer-supplied remote workstation communicating with the HAFM

appliance through a corporate intranet.

19Director 2/64 Installation Guide

Overview

■ A customer-supplied PC platform with a network connection to the EWS

interface installed on the director.

■ A customer-supplied server platform communicating with the switch through

a LAN or corporate intranet. The HAFM applications are ordered and

installed on the server by the customer.

Error-Detection, Reporting, and Serviceability

The director provides the following error-detection, reporting, and serviceability

features:

■ Light-emitting diodes (LEDs) on director FRUs and the front bezel that

provide visual indicators of hardware status or malfunctions.

■ System and threshold alerts, event logs, audit logs, link incident logs,

threshold alert logs, and hardware logs that display director, Ethernet link, and

Fibre Channel link status at the HAFM appliance, remote workstation, or

EWS.

■ Diagnostic software that performs power-on self-tests (POSTs) and port

diagnostics (internal loopback, external loopback, and Fibre Channel (FC)

wrap tests). The FC wrap test applies only when the director is configured to

operate in FICON management style.

■ An internal modem for use by support personnel to dial in to the HAFM

appliance for event notification and to perform remote diagnostics.

■ Automatic notification of significant system events (to support personnel or

administrators) through e-mail messages or the call-home feature at the

HAFM appliance.

Note: The call-home feature is not available through the EWS interface.

■ An RS-232 maintenance port at the rear of the director (port access is

password-protected) that enables installation or service personnel to change

the director’s internet protocol (IP) address, subnet mask, and gateway

address.

■ Redundant FRUs—logic cards, power supplies, and cooling fans—that are

removed or replaced without disrupting director or Fibre Channel link

operation.

20 Director 2/64 Installation Guide

Overview

■ A modular design that enables quick removal and replacement of FRUs

without tools or equipment.

■ Concurrent port maintenance—UPM cards are added or replaced and

fiber-optic cables are attached to ports without interrupting other ports or

director operation.

■ Beaconing to assist service personnel in locating a specific port, FRU, or

director in a multi-switch environment. When port beaconing is enabled, the

amber LED associated with the port flashes. When FRU beaconing is

enabled, the amber (service required) LED on the FRU flashes. When unit

beaconing is enabled, the system error indicator on the front bezel flashes.

Beaconing does not affect port, FRU, or director operation.

■ Data collection through the Element Manager on the HAFM appliance to help

isolate system problems. The data includes a memory dump file and audit,

hardware, and engineering logs.

■ Status monitoring of redundant FRUs and alternate Fibre Channel data paths

to ensure continued director availability in case of failover. The HAFM

application queries the status of each backup FRU daily. A backup FRU

failure is indicated by an illuminated amber LED.

■ SNMP management using the Fibre Alliance management information base

(MIB) Version 3.1, that runs on the HAFM appliance. Up to 12 authorized

management workstations can be configured through the HAFM application

to receive unsolicited SNMP trap messages. The trap messages indicate

operational state changes and failure conditions.

■ SNMP management using the Fibre Channel Fabric Element MIB (Version

1.1), transmission control protocol/internet protocol (TCP/IP) MIB-II

definition (RFC 1213), or a product-specific MIB that runs on each director.

Up to six authorized management workstations can be configured through the

Element Manager on the HAFM appliance to receive unsolicited SNMP trap

messages. The trap messages indicate operational state changes and failure

conditions.

Note: For more information about SNMP support provided by HP products, refer

to the

HP StorageWorks SNMP Reference Guide for Directors and Edge Switches

.

21Director 2/64 Installation Guide

Overview

Zoning

The director supports a name server zoning feature that partitions attached devices

into restricted-access groups called zones. Devices in the same zone can recognize

and communicate with each other through switched port-to-port connections.

Devices in separate zones cannot communicate with each other.

Zoning is configured by authorizing or restricting access to name server

information associated with device N_Ports that attach to director fabric ports

(F_Ports). A zone member is specified by the port number to which a device is

attached, or by the eight-byte (16-digit) World Wide Name (WWN) assigned to

the host bus adapter (HBA) or Fibre Channel interface installed in a device. A

device can belong to multiple zones.

Caution: If zoning is implemented by port number, a change to the director

fiber-optic cable configuration disrupts zone operation and may incorrectly

include or exclude a device from a zone.

If zoning is implemented by WWN, removal and replacement of a device

HBA or Fibre Channel interface (thereby changing the device WWN) disrupts

zone operation and may incorrectly include or exclude a device from a zone.

In Open Fabric mode, only zoning by WWN is supported. Zoning by port

numbers is not supported.

Zones are grouped into zone sets. A zone set is a group of zones that is enabled

(activated) or disabled across all directors and edge switches in a multi-switch

fabric. Only one zone set can be enabled at one time.

Multi-Switch Fabrics

A Fibre Channel topology that consists of one or more interconnected directors or

switch elements is called a fabric. Operational software provides the ability to

interconnect directors (through expansion port (E_Port) connections) to form a

multi-switch fabric. The data transmission path through the fabric is typically

determined by fabric elements and is user-transparent. Subject to zoning

restrictions, devices attached to any interconnected director can communicate

with each other through the fabric.

Because a multi-switch fabric is typically complex, maintenance personnel should

be aware that several factors can degrade fabric performance or cause

connectivity failures. These factors include:

22 Director 2/64 Installation Guide

Overview

■ Domain ID assignment—Each director in a fabric is identified by a unique

domain ID that ranges from 1 through 31. A domain ID of 0 is invalid. If two

operational fabrics join, they determine if any domain ID conflicts exist

between the fabrics. If one or more conflicts exist, the E_Ports that form the

interswitch link (ISL) segment to prevent the fabrics from joining.

■ Zoning—In a multi-switch fabric is configured on a fabric-wide basis, and a

change to the zoning configuration is applied to all directors and switch

elements in the fabric. To ensure zoning is consistent across a fabric, the

following rules are enforced when two fabrics (zoned or unzoned) join:

— Fabric A unzoned and Fabric B unzoned—The fabrics join

successfully, and the resulting fabric remains unzoned.

— Fabric A zoned and Fabric B unzoned—The fabrics join successfully,

and fabric B automatically inherits the zoning configuration from

fabric A.

— Fabric A unzoned and Fabric B zoned—The fabrics join successfully,

and fabric A automatically inherits the zoning configuration from

fabric B.

— Fabric A zoned and Fabric B zoned—The fabrics join successfully only

if the zone configurations can be merged. If the fabrics cannot join, the

connecting E_Ports segment and the fabrics remain independent.

Zone configurations for two fabrics are compatible (the zones can join) if the

active zone set name is identical for each fabric, and if zones with the same

name have identical elements.

■ Port segmentation—When an ISL activates, directors exchange operating

parameters to determine if they are compatible and can join to form a single

fabric. If they are incompatible, the connecting E_Port at each director

segments to prevent the creation of a single fabric. A segmented link transmits

only Class F traffic; the link does not transmit Class 2 or Class 3 traffic. The

following conditions cause ports to segment:

— Incompatible operating parameters—Either the resource allocation

timeout value (R_A_TOV) or error detect timeout value (E_D_TOV) is

inconsistent between directors. To prevent E_Port segmentation, the same

E_D_TOV and R_A_TOV must be specified for each director.

— Duplicate domain IDs—One or more domain ID conflicts are detected.

— Incompatible zoning configurations—Zoning configurations for the

directors are not compatible.

23Director 2/64 Installation Guide

Overview

— Build fabric protocol error—A protocol error is detected during the

process of forming the fabric.

— No principal switch—No director in the fabric is capable of becoming

the principal switch.

— No response from attached switch—After a fabric is created, each

director in the fabric periodically verifies operation of all attached

switches and directors. An ISL segments if a switch or director does not

respond to a verification request.

— ELP retransmission failure timeout—A director that exhibits a

hardware failure or connectivity problem cannot transmit or receive Class

F frames. The director did not receive a response to multiple exchange

link protocol (ELP) frames, did not receive a fabric login (FLOGI) frame,

and cannot join an operational fabric.

Hardware Components

The Director provides a modular design that enables quick removal and

replacement of FRUs. The following sections define Director 2/64 main

components.

Front View

Figure 1 shows Director 2/64 components accessible from the front of the

Director. Component descriptions follow the figure.

24 Director 2/64 Installation Guide

Overview

CTP2 Card

1 Power and system error LEDs

2 UPM cards

3 Power sup plies

1. Provided in rack-mount kits HP 9000, HP 10000, and HP 11000 Series

only.

4 Cable management assembly

5 Front bezel

6 CTP2 cards

1

Figure 1: Director components—front

The Director 2/64 ships with two Control Processor (CTP2) cards. The active

CTP2 card initializes and configures the director after power on, and contains the

microprocessor and associated logic that coordinate director operation. The

second CTP2 card serves as a backup. A CTP2 card provides an Initial Machine

Load (IML) button on the faceplate. When the button is pressed and held for three

seconds, the director reloads firmware and resets the CTP2 card without switching

off power or affecting operational fiber-optic links.

Each CTP2 card also provides a 10/100 megabit per second (Mbps) RJ-45 twisted

pair connector on the faceplate that attaches to an Ethernet Local Area Network

(LAN).

25Director 2/64 Installation Guide

Overview

Each CTP2 card provides System Services Processor (SSP) and Embedded Port

(EP) subsystems. The SSP subsystem runs director applications, communicates

with director ports, and controls the RS-232 maintenance port and 10/100 Mbps

ethernet port. The EP subsystem provides Class F processing, and manages frame

transmission to and from the Serial Crossbar Assembly (SBAR). In addition,

CTP2 cards provide non-volatile memory for storing firmware director

configuration information, persistent operating parameters, and memory dump

files. Director firmware is upgraded concurrently (without disrupting operation).

Each card faceplate contains a green light emitting diode (LED) that turns O

the card is operational and active, and an amber LED that turns O

fails. The LEDs are O

beaconing is enabled.

Front Bezel

The bezel at the front of the Director includes two indicator LEDs. The green

power LED turns O

turns O

FF, a facility power source, alternating current (AC) power cord, or director

power distribution failure is indicated.

The amber system error LED turns O

requiring immediate operator attention, such as an FRU failure. The LED remains

illuminated as long as an event is active. The LED F

enabled.

Cable Management Assembly

The cable management assembly positioned at the front of the director provides

routing for Ethernet cables attached to CTP2 cards and fiber-optic cables attached

to director ports. The assembly rotates up to provide front access to the redundant

power supplies.

The cable management assembly is supplied with rack-mount kits for the

HP 9000, HP 10000, and HP 11000 Series racks only

N if

N if the card

FF on the backup CTP2. The amber LED FLASHES if

N when the director is powered on and operational. If the LED

N when the director detects an event

LASHES if unit beaconing is

Power Supplies

The Director 2/64 uses redundant, load-sharing power supplies which step down

and rectify facility input power to provide 48-VDC power to Director FRUs. The

power supplies also provide over-voltage and over-current protection. Either

power supply can be replaced while the switch is powered on and operational.

Each power supply has a separate backplane connection to allow for different AC

power sources.

26 Director 2/64 Installation Guide

UPM Card

Overview

The power supplies are input rated at 85 to 264 VAC. The faceplate of each power

supply provides the following status LEDs:

■ A green PWR OK LED turns ON if the power supply is operational and

receiving AC power.

■ An amber FAU LT LED turns ON if the power supply fails.

■ An amber TEMP LED turns ON if the power supply shuts down due to an

over temperature condition.

■ An amber I LIM LED turns ON if the power supply is overloaded and

operating at the current limit (15.6 A).

Power supply requirements are listed in Appendix B.

Each Universal Port Module (UPM) card provides four full-duplex generic ports

(G_Ports) that transmit or receive data at 1.063 or 2.125 gigabits per second

(Gbps). G_Port functionality depends on the type of cable attachment. UPM cards

use Non-Open Fiber Control (NOFC) Class 1 laser transceivers that comply with

Section 21 of the Code of Federal Regulations (CFR), Subpart J as of the date of

manufacture.

Depending on device connections, G_Ports work as follows:

■ If the G_Port is attached to a Fibre Channel device, the port functions as a

fabric port (F_Port). An F_Port is the interface on a director that connects to a

device N_Port.

■ If the G_Port is attached to another director to form an Interswitch Link (ISL),

the port functions as an expansion port (E_Port). A multi-switch fabric is

formed through multiple directors and ISLs.

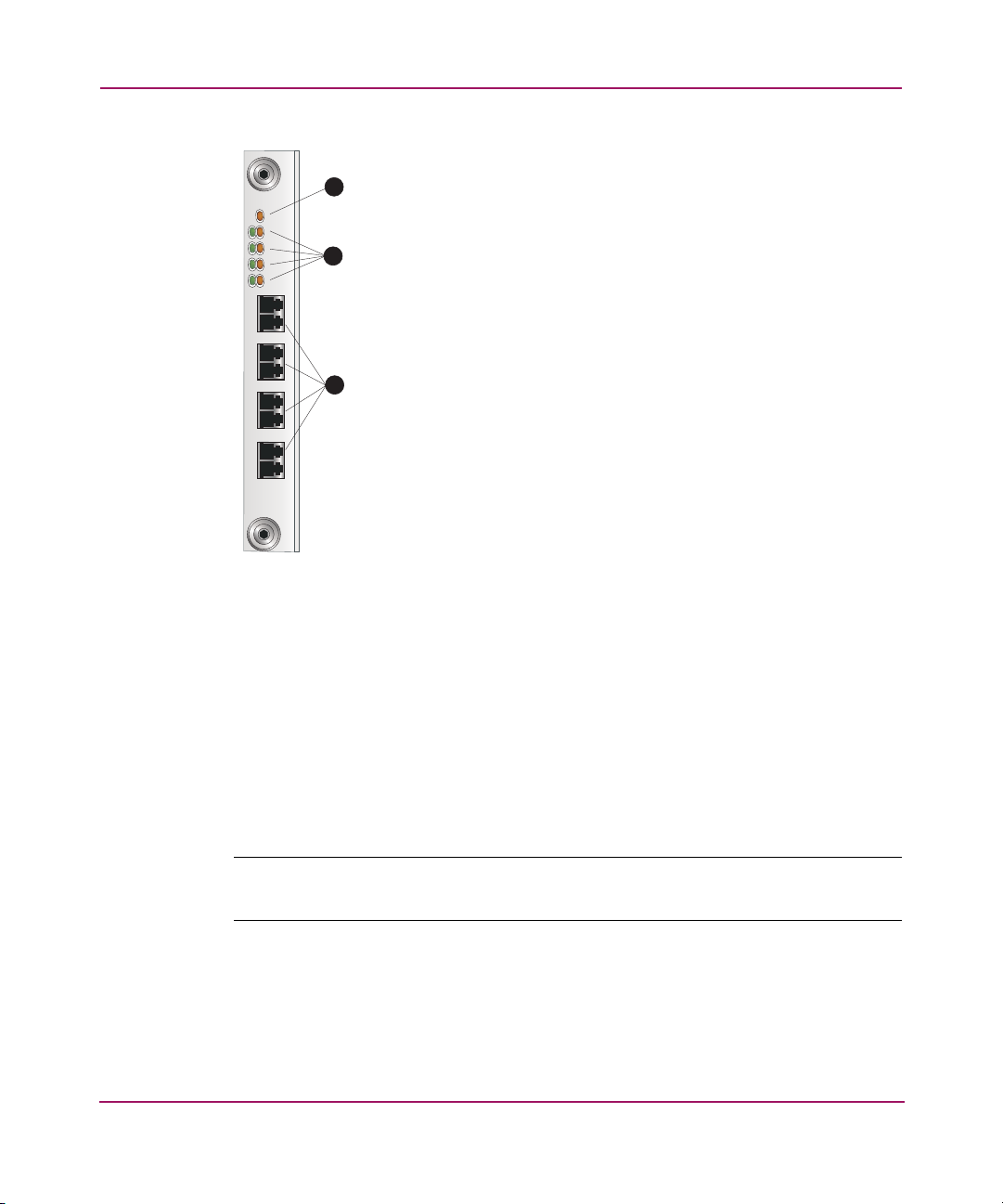

Figure 2 shows the faceplate of an UPM.

27Director 2/64 Installation Guide

Overview

2

UPM

1

2

1 Card LED

2 Port LEDs

3

3 Port Connectors

(G_Ports)

SHR-

Figure 2: UPM card LEDs and connectors

Single-mode or multi-mode fiber-optic cables attach to UPM cards through small

form factor pluggable (SFP) optic transceivers. The fiber-optic transceivers

provide duplex connectors, and can be detached from UPM cards (through a

10-pin interface) for easy replacement. Three fiber-optic transceiver types are

available:

■ Short-wave Laser—Short-wave laser transceivers provide connections for

transferring data over short distances (2 to 500 meters) through 50-µm (500

meters) or 62.5-µm (200 meters) multi-mode fiber.

Note: Hewlett-Packard recommends 50-µm fiber-optic cable for any new

installation requiring multi-mode fiber.

■ Long-wave Laser—Long-wave laser transceivers provide connections for

transferring data over long distances (up to 10 kilometers) through 9-µm

single-mode fiber.

28 Director 2/64 Installation Guide

Rear View

Overview

■ Extended reach long-wave Laser—Long-wave laser transceivers that

provide connections for transferring data over extended long distances (up to

35 kilometers) through 9-µm single-mode fiber.

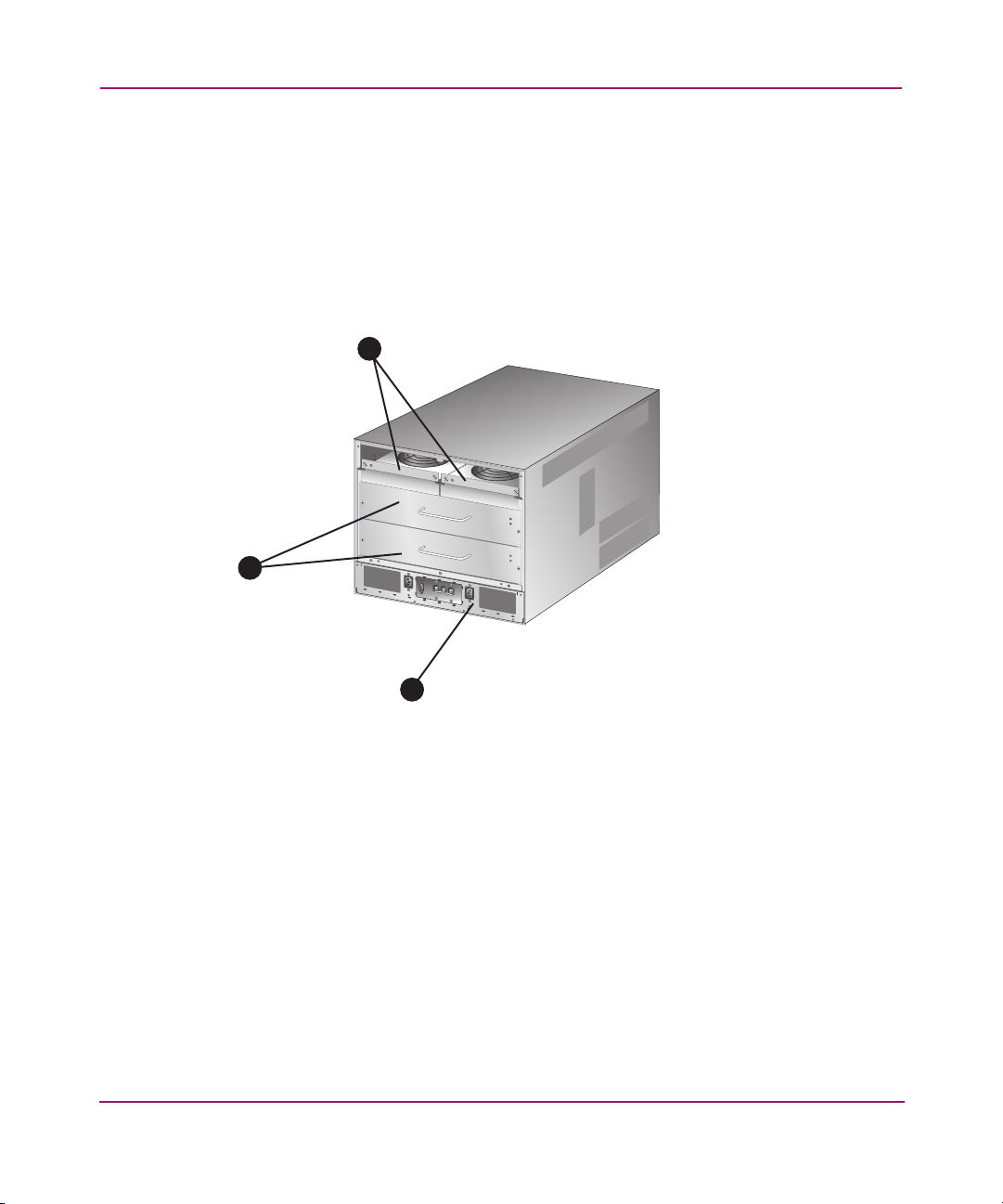

Figure 3 shows the components accessible from the rear of the Director2/64.

3

2

Fan Modules

1

SHR-2309

1 Power module assembly

2 SBAR assemblies

Figure 3: Director components—rear

3 Fan modules

Two fan modules, each containing three fans (six fans total), provide cooling for

director FRUs, as well as providing redundancy for continued operation if a fan

fails.

The fan module can be replaced while the director is powered on and operating,

provided the module is replaced within 10 minutes (after which software powers

off the director). An amber LED for each fan module turns O

N if one or more fans

fail or rotate at insufficient velocity.

29Director 2/64 Installation Guide

Overview

SBAR Assembly

The director ships with two SBAR assemblies. The active SBAR is responsible for

Fibre Channel frame transmission from any director port to any other director

port. Connections are established without software intervention. The assembly

accepts a connection request from a port, determines if a connection can be

established, and establishes the connection if the destination port is available. The

assembly also stores busy, source connection, and error status for each director

port.

The backup SBAR takes over operation if the active assembly fails, and provides

the ability to maintain connectivity and data frame transmission without

interruption. The transition to the backup assembly is transparent to attached

devices.

Each SBAR assembly consists of a card and steel carriage that mounts flush on

the backplane. The carriage provides protection for the back of the card,

distributes cooling airflow, and assists in aligning the assembly during installation.

The rear of the carriage contains a green LED that turns O

operational and active, and an amber LED that turns O

amber LED F

Power Module Assembly

N if the assembly is

N if the assembly fails. The

LASHES if FRU beaconing is enabled.

The power module assembly is located at the bottom rear of the director. The

module provides the following.

■ Two single-phase AC power connectors. Each connector is input rated at 85 to

264 VAC.

■ A power switch (circuit breaker) that controls AC power distribution to both

power supplies. The breaker is set manually, or is automatically tripped by

internal software if thermal sensors indicate the director has overheated.

■ A 9-pin maintenance port that provides a connection for a local terminal or

dial-in connection for a remote terminal.

30 Director 2/64 Installation Guide

Loading...

Loading...