Page 1

HP StorageWorks

Director blade i

nstallation

instructions

Overview

Read these installation instructions if you have purchased one of the

optional Director blades listed in Table 1. Install the Director blades in

compatible models only.

NOTE:

This document refers to blades by their short names.

Table 1 Director blades

© Copyright 2008 Hewlett-Packard Development Company, L.P.

First edition: March 2008

The information in thi s document is subject to change without

notice.

Printed in the U.S.

www.hp.com

Model

HP

StorageWorks

SAN Director

16 Po r t , 4G b

FC blade

HP

StorageWorks

SAN Director

32 Port, 4Gb

FC blade

HP

StorageW

SAN Direc

48 Port, 4

FC blade

HP

StorageWorks

SAN Director

16 Po rt 8 Gb

FC blade

HP

StorageWorks

SAN Director

32 Port 8Gb

FC blade

HP

StorageWorks

SAN Director

48 Port 8Gb

FC blade

orks

tor

Gb

Short name

(imprinted on

blade)

FC4-16 A7990A

FC4-32 A7991A

FC4-48 AG561A

FC8-16

FC8-32

FC8-48 AK860A

Part number

AK858A

AK859A

Compatible

Director

models

2/128 SAN

Director or

4/256 SAN

Director

4/256 SAN

Director

4/256 SAN

Director

4/256 SAN

Director or

nl

DC SAN

Backbon

Directo

DC SAN

Backbone

Director

DC SAN

Backbone

Director

e

r

K858-96001*

*A

Page 1

HP

StorageWorks

SAN Director 6

Por t 10Gb FC

blade

HP

StorageWorks

B-Series iSCSI

Director blade

HP

StorageWorks

B-Series

Multi-protocol

(MP) Router

blade

FC10-6

FC4-16IP AG671A

FR4-18i AG461A

AK861A

4/256

Dire

nl

DC SAN

Backbone

Director

4/256 SAN

Director

4/256 SAN

Director or

nl

DC SAN

Backbone

Director

SAN

ctor or

Page 2

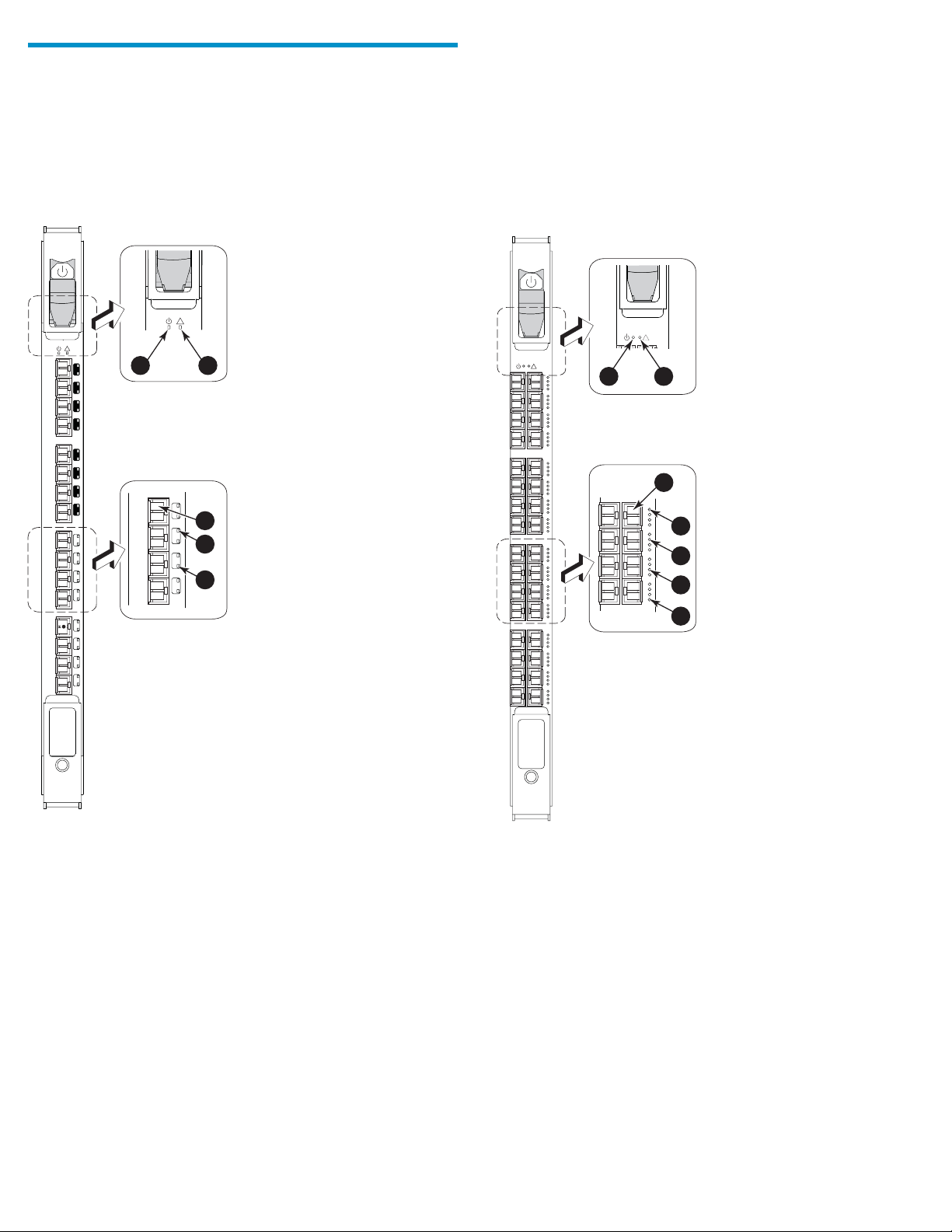

Identifying blade components

The following sections illustrate Director blade compon ents.

FC4-16 components

Figure 1 identifies FC4-16 components. Ports are numbered 0 through

15,frombottomtotop.

!

!

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1

2

7

3

6

4

5

5

4

FC4-32 components

Figure 2 identifies FC 4-32 components.

!

!

1

2

3

4

5

6

7

FC4

16

Figure1FC4-16blade

1. Power LED

2. Status LED

3. FC port

25363a

4. Port speed LED

5. Por t status LED

FC4

32

Figure2FC4-32blade

1. Power LED

2. Status LED

3. FC port

4. Port speed LED (left port)

25364a

5. Port status LED ( left port)

speed LED (right port)

6. Port

7. Port status LED (righ t port)

Page 2

Page 3

FC4-48 components

FC8-16 componen

ts

Figure 3 identifi

!

es FC4-48 components.

47

23

46

22

45

21

44

20

43

19

42

18

41

17

40

16

39

15

38

14

37

13

36

12

35

11

34

10

33

9

32

8

31

7

30

6

29

5

28

4

27

3

26

2

25

1

24

0

1

!

35

11

34

10

33

9

32

8

Figure3FC4-48blade

1. Power LED

2. Status LED

2

3

4

25365a

3. FC port

4. Port status LED

Figure 4 identifies FC8-16 components.

1

2

3

4

25362a

Figure 4

1. Power LED

2. Statu

FC8-16 blade

sLED

3. FC port

4. Port stat us LED

Page 3

Page 4

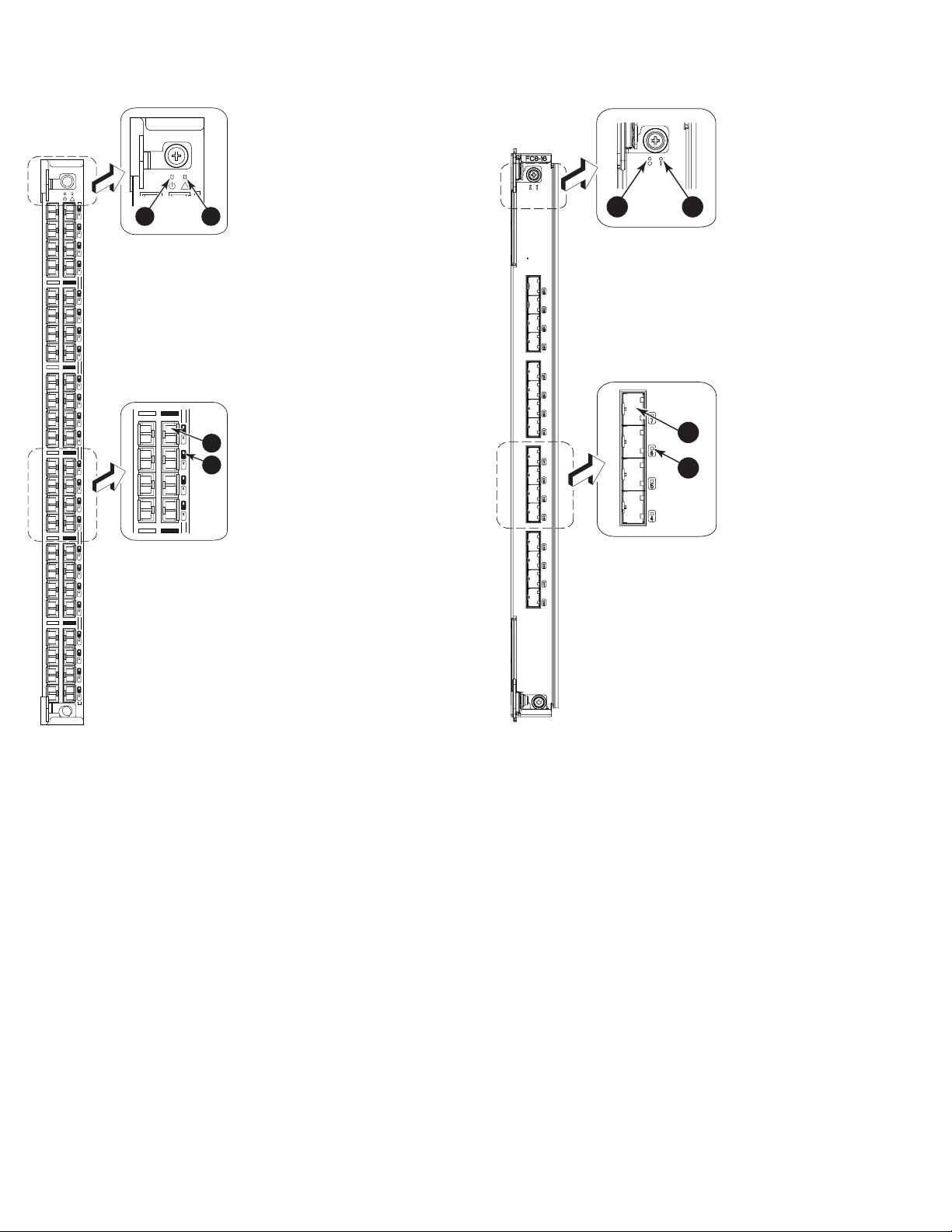

FC8-32 componen

ts

FC8-48 components

Figure 5 identifies FC8-32 components.

1

Figure 5 FC8-32 blade

1. Power LED

2. Status LED

3. FC port

4. Port status LED

2

3

4

25367a

Figure 6 identifi

es FC8-48 components.

!

47

23

46

22

45

21

44

20

43

19

42

18

41

17

40

16

39

15

38

14

37

13

36

12

35

11

34

10

33

9

32

8

31

7

30

6

29

5

28

4

27

3

26

2

25

1

24

0

1

Figure6FC8-48blade

1. Power LED

2. Status LED

35

11

34

10

33

9

32

8

!

47

2

3

4

25366a

3. FC port

4. Port stat us LED

Page 4

Page 5

FC10-6 componen

ts

FC4-16IP components

Figure 7 identifies FC10-6 components.

1

2

3

4

Figure 8 identifi

!

7

6

5

4

GE

3

2

1

0

7

6

5

4

FC

3

2

1

0

es FC4-16IP components.

!

1

FC

2

7

3

6

4

5

4

Figure 7 FC10-6 blade

1. Power LED

2. Status LED

25368a

3. FC port

4. Port s

tatus LED

FC4

16IP

Figure 8 FC4-16IP blade

1. Power LED

2. Status LED

25358a

3. FC port

4. Port stat us LED

Page 5

Page 6

FR4-18i components

Figure 9 identifi

!

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

GE0

GE1

es FR4-18i components.

!

1

2

7

3

6

4

5

4

Verifying installation requirements

The installation takes less t han 10 minutes. Obtain the following items:

• Replacement Director blade

• Replacement filler panel for each empty slot (ships with the Director

blade)

• Electrostatic discharge (ESD) grounding strap

• Workstation computer

• Phillips screwdriver

• Small form-factor pluggable (SFP) transceivers, as needed

• Extended form-factor pluggable (XFP) transceivers, as needed (for

the FC10-6 Director b lad e only)

• Optical cables, as needed

IMPORTANT:

Order SFP transceivers separately. The HP DC SAN Backbone

Director 8Gb port blades support HP transceivers labeled

“B-Series FC SFP" only. Check h

ttp://www.hp.com for more

information on supported transceivers.

Removing the filler panel

Remove the filler panel, if installed. There are three filler panel types

(Figure 10).

FR4

18 i

Figure 9 FR4-18i blade

1. Power LED

2. Status LED

25359a

3. FC port

4. Port s

tatus LED

IMPORTA

NT:

Remove a filler panel only when installing or replacing a new

Director blade. Any slot that is not occupied by a Director blade

requires a filler panel to ensure correct cooling of the chassis

and protection from dust.

Page 6

Page 7

!

Determining the ejector type

!

6

5

4

3

2

1

200-240 VA

!

56

-0

0

005

9

0

-0

1

R

e

v

A

!

!

5

1

4

1

I O I O I RS - 232

3

1

I O I O I RS - 232

2

1

1

1

0

1

s

k

/

b

in

L

M

0

0

1

/

0

1

9

P

s

k

/

C

n

e

b

Li

iv

M

t

c

0

A

0

/1

8

0

1

P

C

e

tiv

c

A

7

6

5

4

3

2

1

0

CP4

CP4

FC4

16

200-240 VA

0-60 Hz

C 12A 5

10

9

8

7

56

-

0

0

0059

0

-01

R

e

v

A

!

5

1

14

3

1

2

1

1

1

10

9

8

7

6

5

4

3

2

1

0

FC4

16

C 12A 50-60 Hz

4

Y

L

P

P

U

S

R

E

W

O

P

3

Y

L

P

P

U

S

R

E

W

O

P

!

!

2

Y

L

P

P

U

S

R

E

W

O

P

!

!

1

1

LY

LY

P

P

P

P

U

U

S

S

R

R

E

E

W

W

O

O

P

P

2

1

3

Installation procedures differ depending on the ejector mechanism on

the Director blade. Read the following sections to identify your blade’s

ejector type.

Director blade

swithejectorsandslider

switches

The following Director blades use both ejectors and slider switches:

• FC4-16

• FC4-32

• FC10-6

• FC4-16IP

• FR4-18i

Director blades with ejectors

Figure 10

Removing three different filler panel types

1. Filler panel with handle

rpanelwithhandle

2. Fille

captive

screws (2)

8

5. Ejectors (2)

6. Fille

captive

6

7

5

r panel with pull tabs

screws (2)

3. Handle 7. Pull tabs (2)

4. Filler panel with ejectors 8. Filler panel with pull tabs

To remove a filler panel with a handle:

1. Unscrew the two captive screws securing the filler panel.

2. Grasp the handle and remove the filler panel.

To remove a filler panel with ejectors:

1. Push in the yellow tab on each ejector.

2. Open both ejectors and remove the filler panel from the chassis.

To remove a filler panel with pull tabs:

1. Unscrew the top and bottom captive screws on the filler panel.

2. Graspthetopandbottompulltabsandremovethefiller panel.

4

25043b

The followi

ng Director blades use ejectors only:

• FC8-16

• FC8-32

• FC8-48

• FC4-48

Installing the Director blade

To install the Director blade:

CAUTION

Wear a grounded ESD strap when handling the Director blade.

The Director chassis provides a grounding connection above the

power connectors.

1. Identi

"Deter

2. Locate an appropriate slot. Slots are numbered from left to right

when f

For the 4/256 SAN Director Switch: Install Director blades in slots

1through4and7through10.

FortheDCSANBackboneDirectorSwitch: Install Director blades

in slots 1 through 4 and 9 through 12.

3. Ori

(aw

bla

:

fy the ejector type for your blade, as described in

mining the ejector type".

acing the port side of the chassis.

ent the Director blade so that the blade’s ports face outward

ay from the slot), and the flat (non-component) side of the

de is on the left.

Page 7

Page 8

4. Go to Step 5 if you

installing uses

ForDirectorbla

ejectors only. See "Determining the ejec tor type".

des with both ejectors and slider switches:

a. Open the ejecto

side of the Director blade inside the upper and lower rail

guides in the slot, and slide the Director blade into the slot,

with slight pr

2

1

Figure 11 Removing and repl acing a Director blade

with e jectors and slider switches (FC4-16 shown)

have determined that the Director blade you are

rs to approximately 45 degrees, align the flat

essure to the left (Figure 11).

1

3

200-240 VA

1

R

e

v

A

4

5

6

-

0

0

0

05

9

0

-0

!

5

1

4

1

3

1

2

1

1

1

0

1

9

8

7

6

5

4

3

2

1

0

FC4

16

C 12A 50-60 Hz

!

!

8

7

6

5

5

6

-

0

0

0

0

5

9

0

-0

1

Re

v

A

!

5

1

4

1

3

1

!

2

!

I O I O I RS - 232

k

Lin

10/100 Mb/s

Active CP

CP4

1

1

1

0

1

I O I O I RS - 232

9

8

7

6

k

Lin

5

10/100 Mb/s

4

Active CP

3

2

1

0

FC4

32

FC4

16

CP4

C 12A 50-60 Hz

0 VA

-24

200

!

!

10

9

FC4

32

PLY 4

ER SUP

W

PO

!

!

WER SUPPLY 3

PO

!

!

2

ER SUPPLY

W

PO

!

!

WER SUPPLY 1

WER SUPPLY 1

PO

PO

2

5

6

-

0

0

0

0

5

9

0

-0

1

R

e

v

A

!

5

1

4

1

3

1

2

1

1

1

0

1

9

8

7

6

5

4

3

2

1

0

FC4

16

4

3

25217a

1

!

!

8

7

6

5

56

-

0

0

0

0

59

0

-01

Rev A

4

3

2

1

-0

00

0

590

-

0

1

R

e

v

A

!

5

1

4

1

13

2

1

1

1

0

1

9

8

7

6

5

4

3

2

1

0

FC

16

0 VAC

-24

200

!

5

1

4

1

3

1

!

56

4

12A

2

1

!

1

1

0

1

I O I O I RS - 232

9

8

I O I O I RS - 232

7

6

s

k

Lin

5

100 Mb/

10/

s

k

Lin

4

Active CP

100 Mb/

10/

Active CP

3

2

1

0

4

FC

16

P4

C

P4

C

50-60

AC 12A

0 V

200-24

50-60 Hz

!

!

0

1

9

4

FC

32

FC4

32

Hz

Y 4

L

PP

ER SU

W

PO

!

!

Y 3

PPL

SU

ER

OW

P

!

!

LY 2

SUPP

ER

OW

P

!

!

Y 1

Y 1

PL

PL

POWER SUP

POWER SUP

2

3

!

7

4

3

2

6

4

2

2

5

4

1

2

4

4

0

2

3

4

9

1

2

4

8

1

1

4

7

1

0

4

6

1

9

3

5

1

8

3

4

1

7

3

3

1

6

3

2

1

5

3

1

1

4

3

0

1

3

3

9

2

3

8

1

3

4

7

0

3

6

9

2

5

8

2

4

7

2

3

6

2

2

5

2

1

4

2

0

25223a

Figure 12 Removing and replacing a Director blade

with ejectors only (FC4-48 shown)

1. 4/256 SAN Director

chassis

2. FC4-48

3. Upper ejector

4. Lower ejector

d. Close the ejectors.

6. Verify that the power LED on the Director blade is displaying a

steady green light and that the Director blade is seated firmly.

7. Install the SFP or XFP (FC10-6 only) transceivers and cables.

1. 4/25

chassi

2. FC4-16

b. Close

6SANDirector

s

3. On/Off slider switch

4. Ejector

the ejectors by pushing the handles toward the center

of the blade until the ejectors lock. The levering action of the

handles seats the blade in the slot.

c. Tighten the thumb screw inside each handle using the Phillips

screwdriver.

d. Turn the blade on by sliding the slider switch in the top ejector

up, covering the thumb screw.

e. Go to Step 6.

5. For Director blades with ejectors:

a. Open the ejectors.

b. Align the flat side of the Director blade inside the upper and

lower rail guides in the slot.

c. SlidetheDirectorbladeintotheslotuntilitisfirmly seated

(Figure 1 2).

For mo

This do

re configuration information

cument provides initial setup and configuration procedures only.

See the following documents for more comprehensive configuration

dures (including mixed blade configurations):

proce

• HP St

orageWorks SAN Director hardware reference guide or HP

StorageWorks DC SAN Backbone Director hardware reference

guide

• HP StorageWorks Fabric OS 6.x administrator guide

• iSCSI Gateway Service administrator guide

the latest documentation and firmware releases, go to

For

ttp://www.hp.com/go/san.

h

Page 8

Loading...

Loading...