Page 1

HP StorageWorks

9000–series Virtual Library System User Guide

This document describes the HP StorageWorks VLS9000 systems to facilitate their installation, operation, and

maintenance. This document is intended for system administrators who are experienced with setting up and

managing large storage systems.

*AG306-96027*

Part number: AG306-96027

Eighth edition: March 2010

Page 2

Legal and notice information

© Copyright 2007, 2010 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set

forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as

constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Page 3

Contents

1 Introduction ..................................................................................... 17

VLS9000-series Components ...................................................................................................... 17

2 Hardware Installation ....................................................................... 21

Preparing for the Installation ....................................................................................................... 21

Tools for Installation ............................................................................................................ 21

Taking ESD Precautions ....................................................................................................... 21

Grounding Methods to Prevent Electrostatic Discharge ............................................................. 21

Unpacking ............................................................................................................................... 22

Removing the Packing Materials .................................................................................................. 22

Rack Planning Resources ............................................................................................................ 22

Rack Requirements .................................................................................................................... 23

Rack Warnings ......................................................................................................................... 23

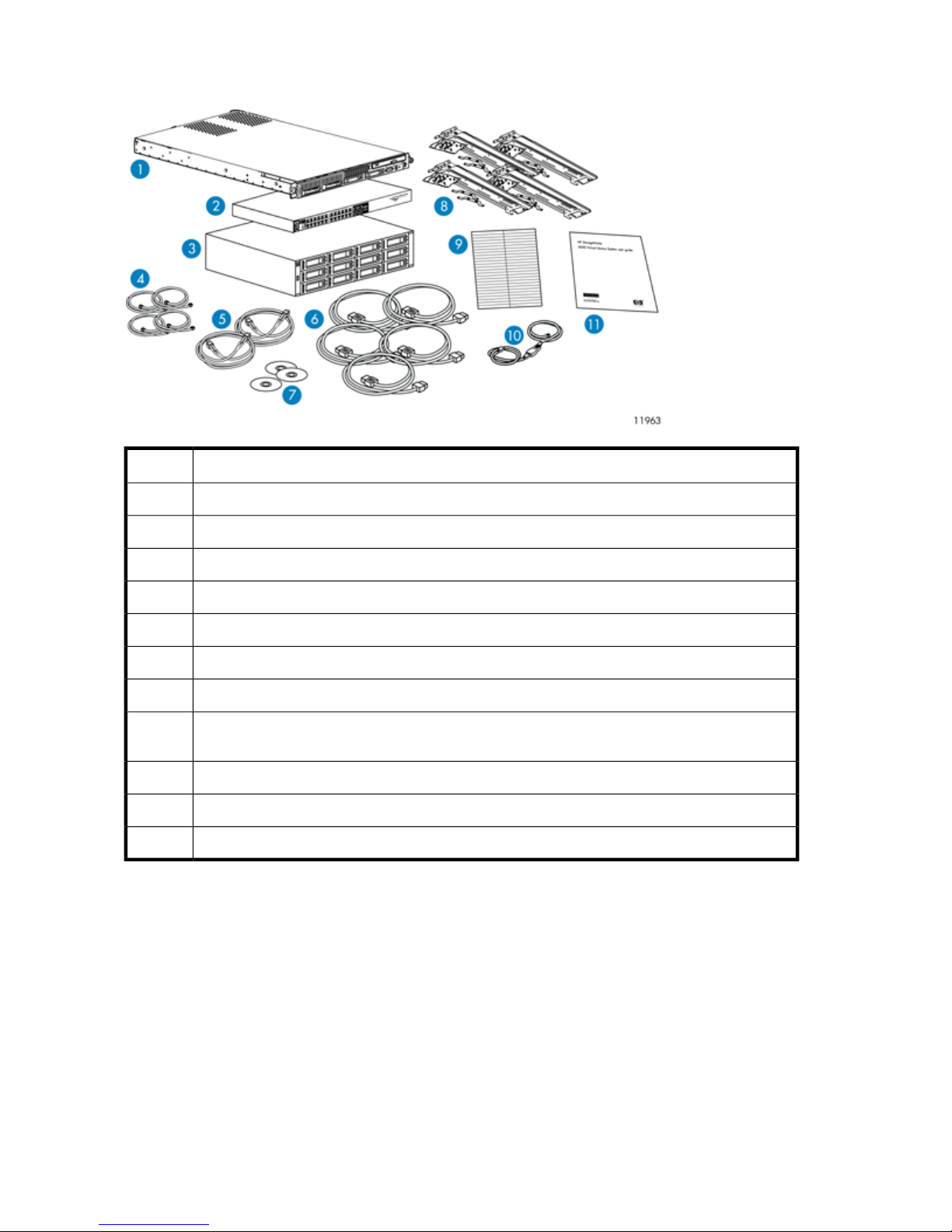

Identifying the VLS Shipping Carton Contents ............................................................................... 23

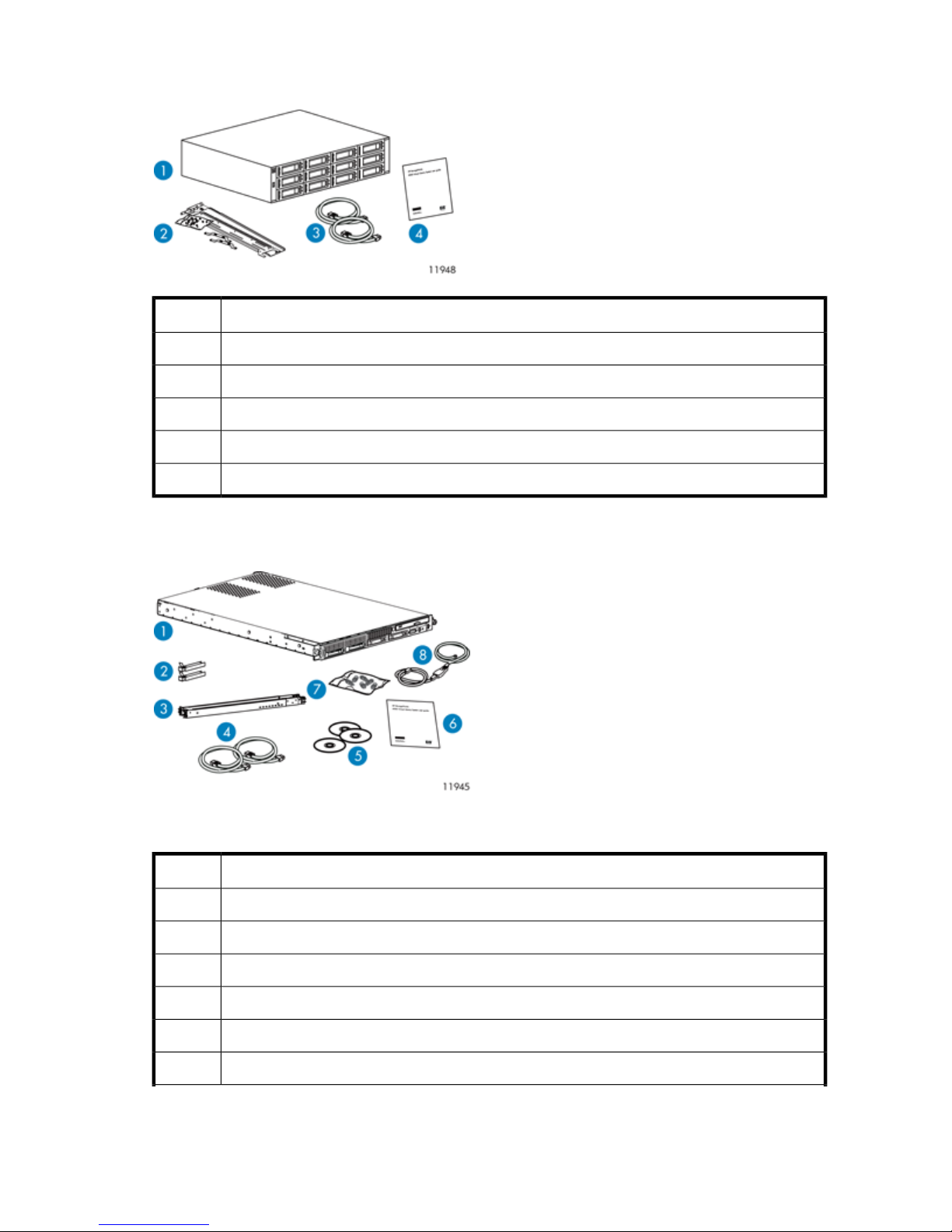

VLS9000 7.5 TB and 10 TB Systems Shipping Carton ............................................................. 24

VLS9000 Single Expansion Disk Array Enclosure Shipping Carton ............................................ 25

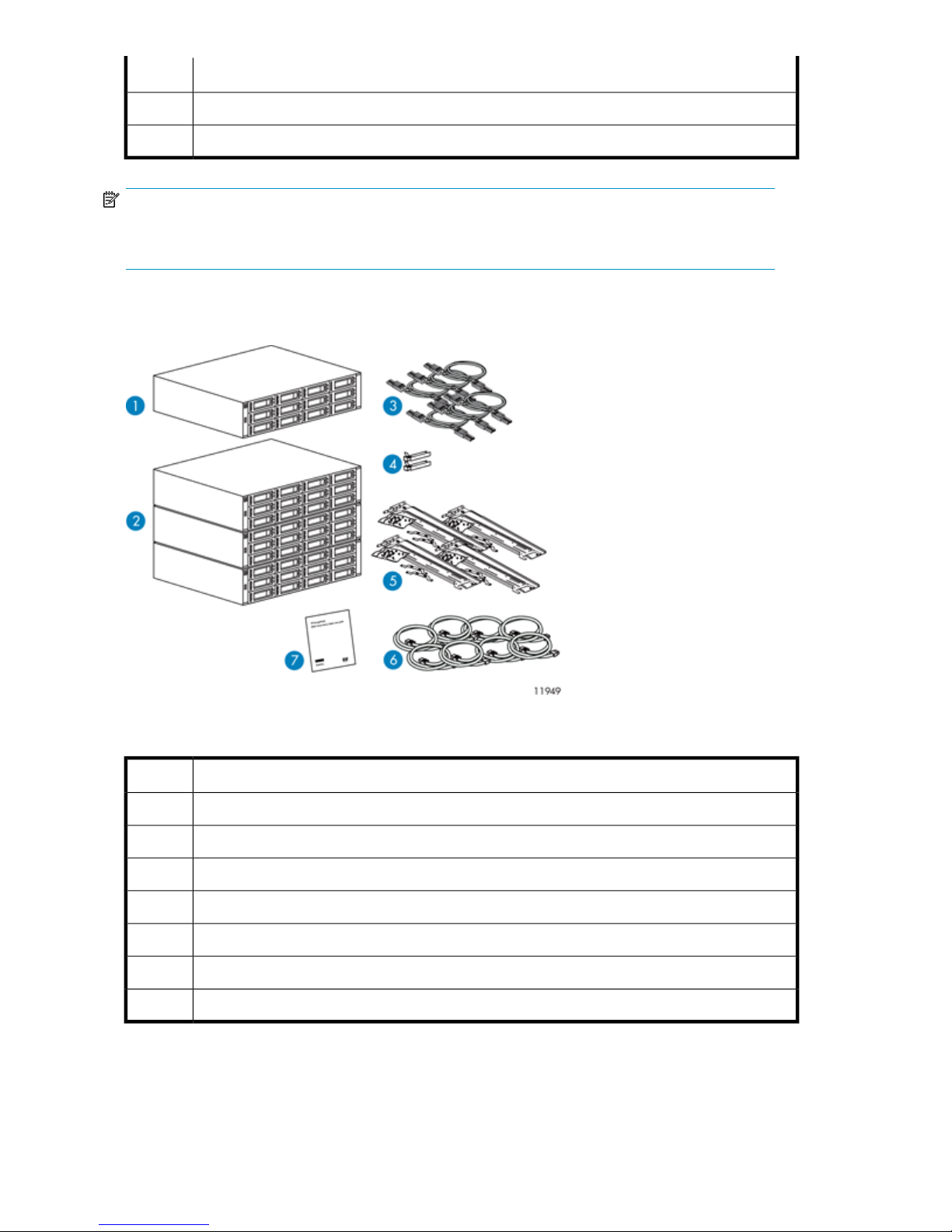

VLS9000 Node Shipping Carton ......................................................................................... 25

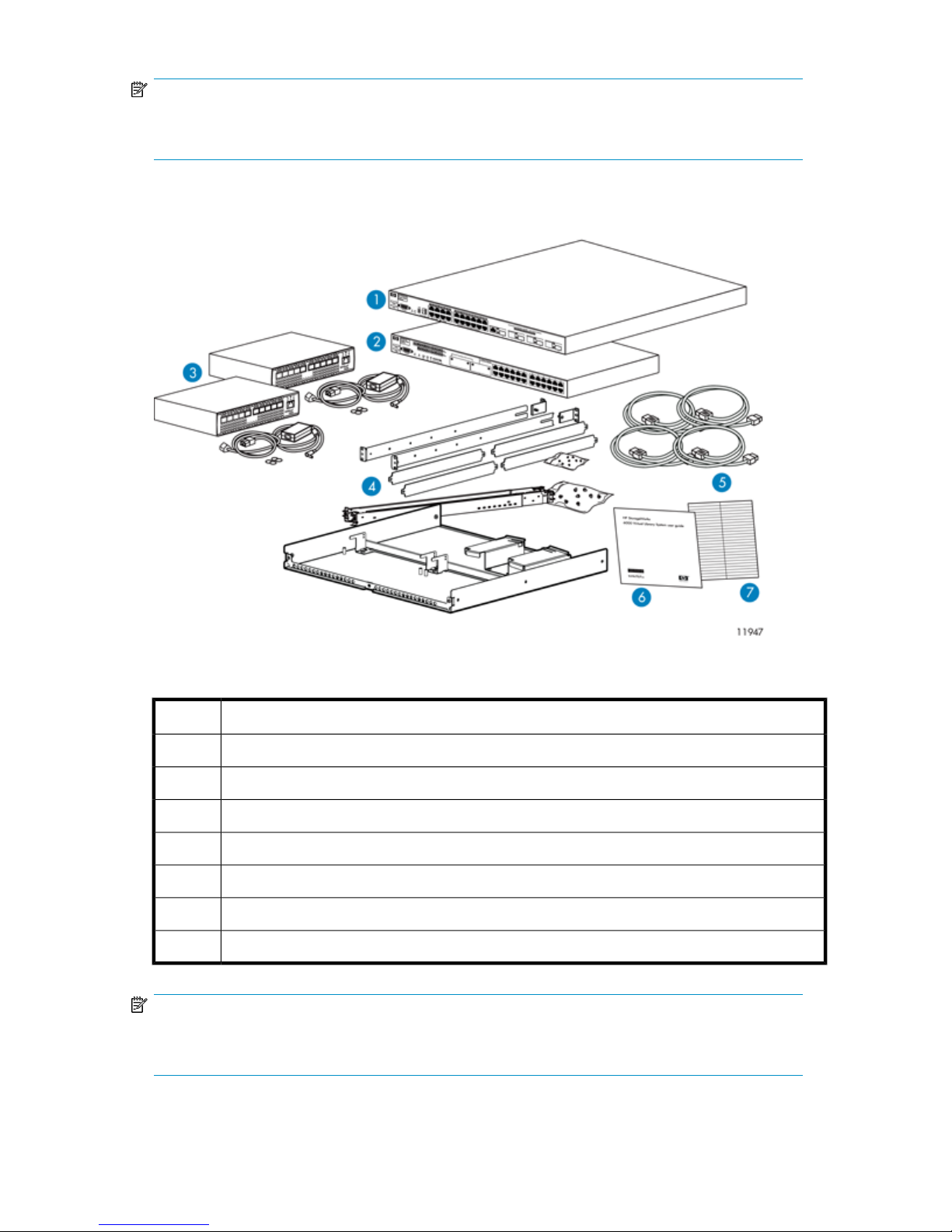

VLS9000 Array Shipping Carton .......................................................................................... 26

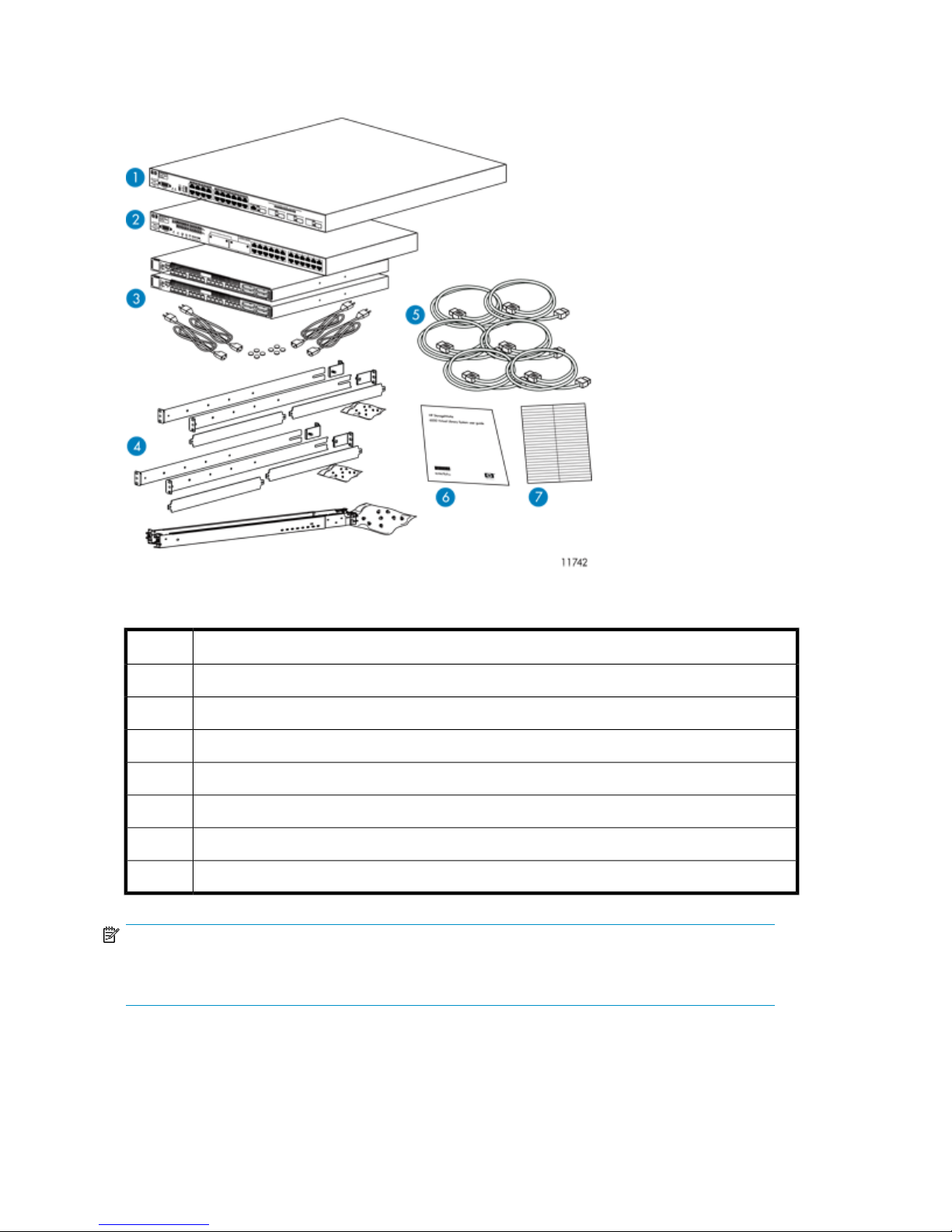

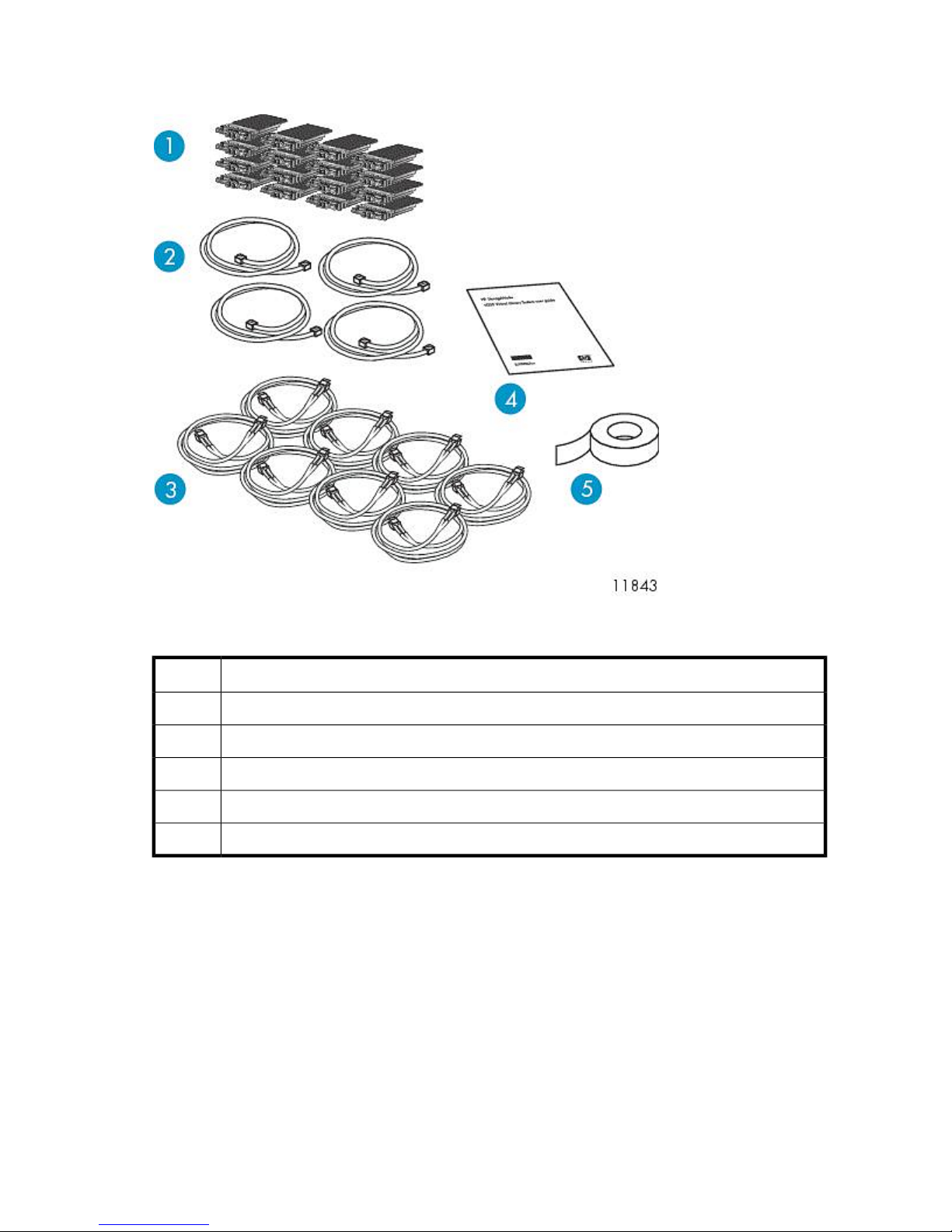

VLS9000 20-port Connectivity Kit Shipping Carton ................................................................ 27

VLS9000 32-port Connectivity Kit Shipping Carton ................................................................. 28

VLS9000 Interswitch Link Kit Shipping Carton ........................................................................ 29

VLS9000-series Hardware Installation Overview ........................................................................... 29

Installing the VLS9000 7.5 TB and 10 TB Systems ......................................................................... 31

Installing PDUs ......................................................................................................................... 32

Installing the VLS9000 Node into a Rack ..................................................................................... 34

Installing Fibre Channel Switches 4/10q onto Racking Shelf ........................................................... 42

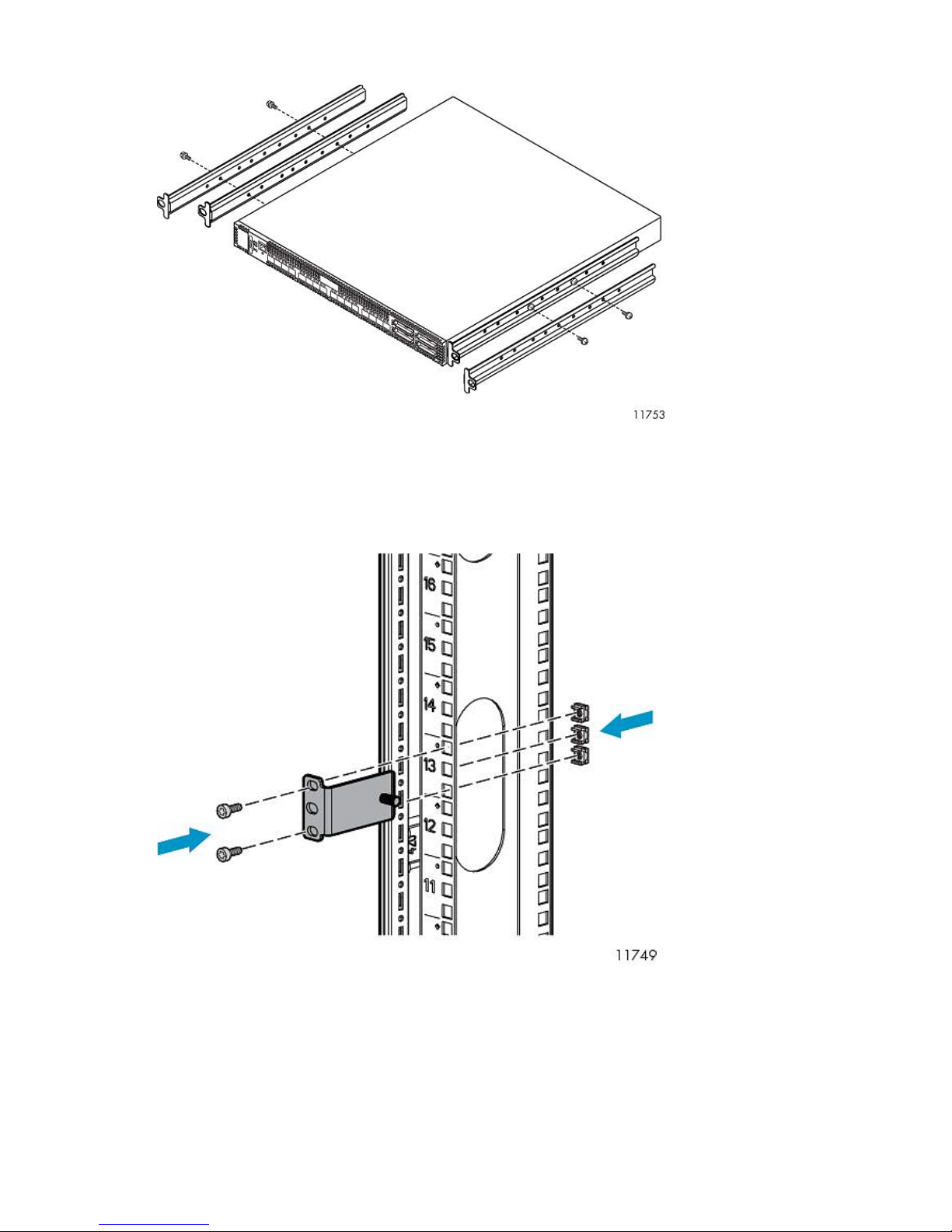

Attaching Rails to Fibre Channel Switches 4/16q ......................................................................... 43

Racking Fibre Channel Switches 4/10q or 4/16q ........................................................................ 44

Installing the 1 Gb Ethernet Switch 2810–24G into a Rack ............................................................ 46

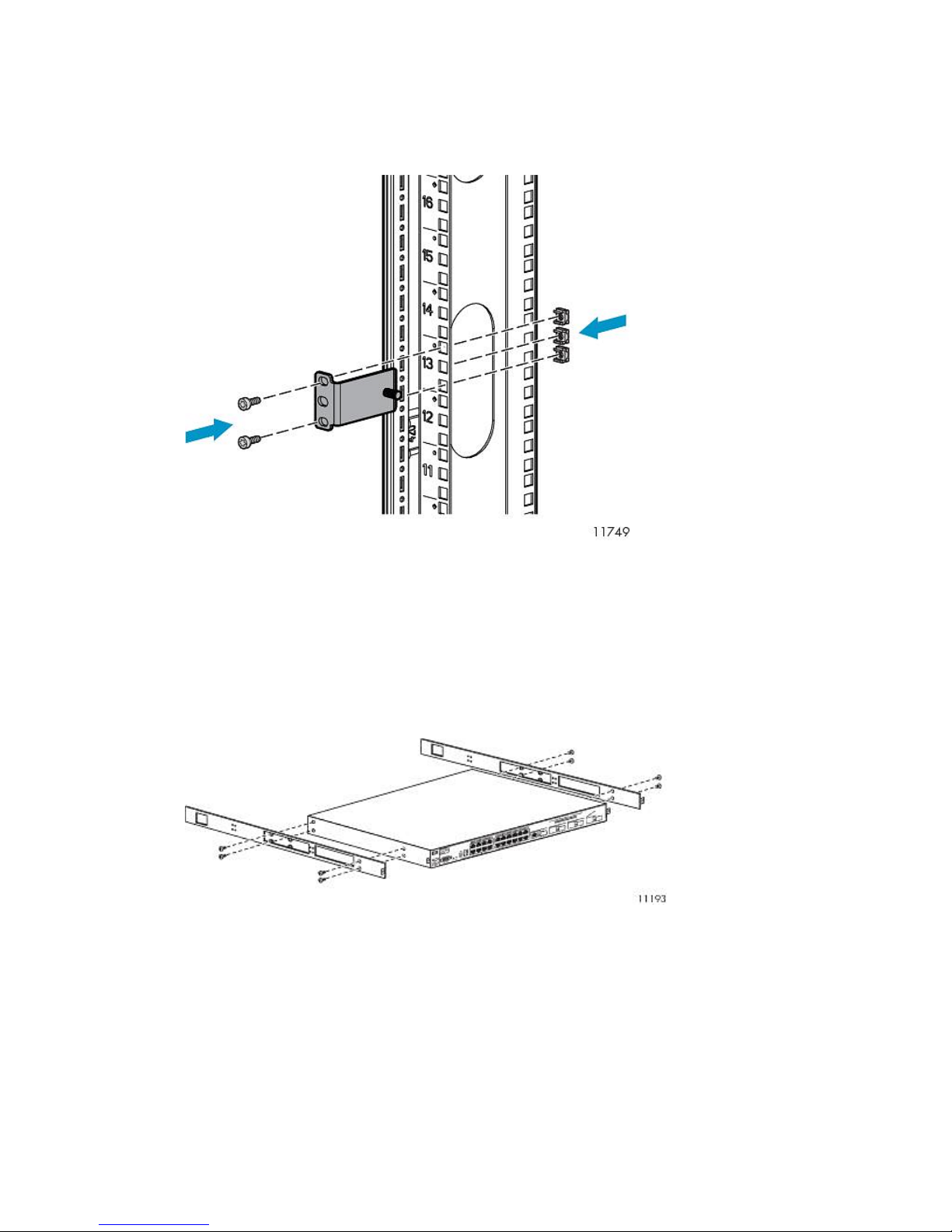

Installing Cage Nuts and Rail Flanges in the Rack .................................................................. 47

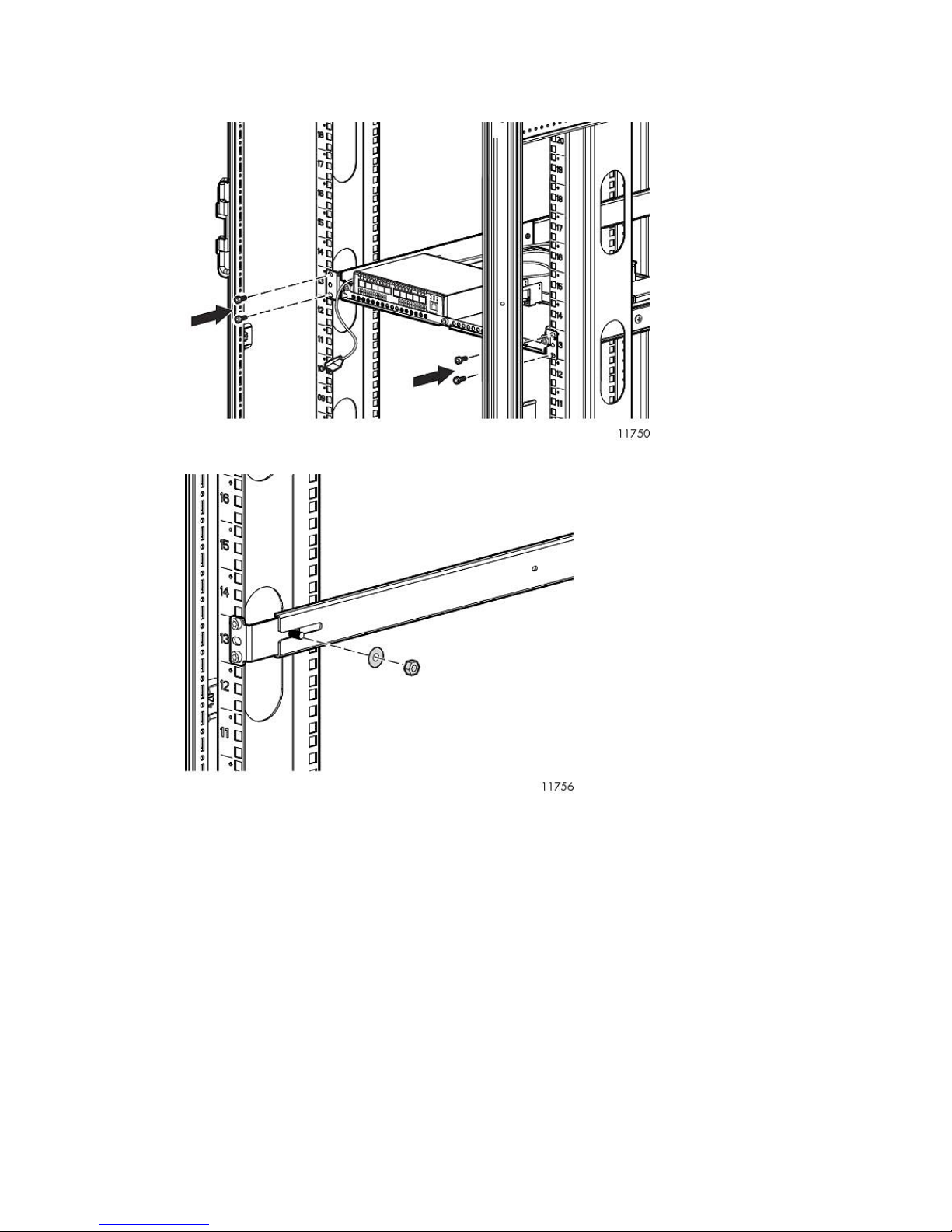

Attaching Rails to the Ethernet Switch 2810-24G .................................................................... 47

Installing Ethernet Switch 2810-24G in Rack .......................................................................... 48

Installing the 100 Mb Ethernet Switch 2510–24 into a Rack ........................................................... 49

Installing the Disk Array Enclosures into a Rack ............................................................................. 50

Rack Mounting Requirements ............................................................................................... 50

Mounting a Disk Array Enclosure into a Rack ......................................................................... 52

Installing Power Cables ....................................................................................................... 57

Installing VLS9000 Cables ......................................................................................................... 58

Cabling the Nodes ............................................................................................................. 58

Cabling Disk Array Enclosures ............................................................................................. 60

Cabling Ethernet Switch 2510–24 ........................................................................................ 61

Cabling Ethernet Switch 2810–24G ..................................................................................... 62

Cabling Fibre Channel Switch 4/10q ................................................................................... 63

Cabling Fibre Channel Switch 4/16q ................................................................................... 64

Management Ports and External Connections ......................................................................... 66

HP StorageWorks 3

Page 4

Installing VLS9000–series Interswitch Link Kit ................................................................................ 66

Reconfiguring Fibre Channel Switches 4/16q ........................................................................ 67

Reconfiguring Ethernet Switches ........................................................................................... 68

Installing XPAK Transponders ............................................................................................... 68

Applying Labels ................................................................................................................. 70

Installing Interswitch Fibre Channel Cables ............................................................................ 70

Installing Interswitch Ethernet Cables ..................................................................................... 71

3 Multi-node Setup ............................................................................. 73

Configuring Primary Node 0 ...................................................................................................... 73

Configuring the Secondary Nodes 1 through 7 ............................................................................ 73

4 Storage Configuration ...................................................................... 75

Managing VLS9000–series Capacity .......................................................................................... 75

Adding a VLS9000 Capacity Kit .......................................................................................... 75

Removing a VLS9000 Capacity Kit ....................................................................................... 76

Configuring the Storage Pool Policy ...................................................................................... 77

Viewing the Storage Pool .............................................................................................. 77

Rebuilding all Storage Pools .......................................................................................... 77

Rebuilding a Storage Pool ............................................................................................. 78

Installing Additional Licenses ...................................................................................................... 79

5 Automigration/Replication ................................................................ 81

Understanding Automigration Concepts ....................................................................................... 82

Echo Copy Concepts .......................................................................................................... 82

Smart Copy Concepts ......................................................................................................... 83

Replication Concepts .......................................................................................................... 83

Tape Initialization ............................................................................................................... 84

Connecting a Destination Library ................................................................................................ 85

Supported Destination Library Configurations ......................................................................... 85

Connecting a Destination Library to a VLS9000 ..................................................................... 85

Managing and Unmanaging a Destination Library ........................................................................ 85

Managing a SAN Library .................................................................................................... 86

Managing a LAN/WAN Replication Library .......................................................................... 86

Unmanaging a SAN or LAN/WAN Library ........................................................................... 87

Echo Copy Pool Operations ....................................................................................................... 88

Creating an Echo Copy Pool ................................................................................................ 89

Creating Virtual Tapes ........................................................................................................ 94

Restoring from a SAN Physical Cartridge ............................................................................... 94

Restoring from a LAN/WAN Virtual Cartridge ....................................................................... 95

Loading Blank Media into an Echo Copy Pool ........................................................................ 95

Loading Media into an Echo Copy Pool for Overwrite ............................................................. 96

Restarting a Broken Mirror ................................................................................................... 96

Viewing Cartridges in Automigration Source Libraries ............................................................. 97

Viewing Automigration Cartridges in the Firesafe .................................................................... 97

Smart Copy Pool Operations ...................................................................................................... 97

Editing SMI-S Settings ......................................................................................................... 97

Creating a Smart Copy Pool ................................................................................................ 98

Changing the Number of Drives in a Smart Copy Pool ............................................................ 99

Loading Blank Media into a Smart Copy Pool ........................................................................ 99

Loading Media into a Smart Copy Pool for Overwrite ............................................................. 99

Editing Copy Pools .................................................................................................................. 100

Moving a Copy Pool ......................................................................................................... 100

4

Page 5

Changing the Slot Mapping for a SAN Library .................................................................... 100

Changing the Slot Mapping for a LAN/WAN Library ........................................................... 102

Editing the SAN or LAN/WAN Policy ................................................................................. 103

Editing the SAN or LAN/WAN Availability Windows ........................................................... 103

Deleting a Copy Pool ........................................................................................................ 103

SAN Destination Library Operations .......................................................................................... 103

Monitoring Destination Library Status .................................................................................. 104

Cartridge Status and Slot Details ................................................................................. 104

Advanced Search for Slots .......................................................................................... 107

Mailslot Details ......................................................................................................... 107

Copy Pool Details ...................................................................................................... 107

Import/Export Pool Details .......................................................................................... 107

Tape Drive Details ...................................................................................................... 108

Forcing a Replication Job .................................................................................................. 108

Placing a Library Offline or Online ..................................................................................... 108

Moving Media from One Slot to Another ............................................................................. 109

Ejecting Media from a Slot into an Empty Mailslot ................................................................ 109

Ejecting Media from a Drive into an Empty Mailslot .............................................................. 110

Restarting Automigration/Replication Services ...................................................................... 110

Scanning a SAN Destination Library ................................................................................... 110

Editing the Management URL ............................................................................................. 111

Uploading SAN Destination Library or Tape Drive Firmware ................................................... 111

Deploying SAN Destination Library or Tape Drive Firmware ................................................... 111

Generating a SAN Destination Library Support Ticket ............................................................ 112

Generating a SAN Destination Library Drive Support Ticket ................................................... 112

Running a SAN Destination Library Assessment Test .............................................................. 112

Running a SAN Destination Library Drive Assessment Test ...................................................... 113

LAN/WAN Destination Library Operations ................................................................................ 113

Exporting Data to Physical tapes for Tape Initialization .......................................................... 113

Stopping a Tape Export .................................................................................................... 114

Importing Data from Physical Tapes for Tape Initialization ...................................................... 114

Forcing Non-Deduplicated Replication ................................................................................ 115

LAN/WAN Replication Target Operations ................................................................................. 115

Creating a LAN/WAN Replication Target ........................................................................... 115

Viewing the Replication Target Slot Details ........................................................................... 117

Setting the Global LAN/WAN Replication Target Configuration Settings ................................. 118

Editing a LAN/WAN Replication Target .............................................................................. 118

Deleting a LAN/WAN Replication Target ............................................................................ 119

Changing the LAN/WAN Replication Target Password ......................................................... 119

Clearing the Source VLS from the LAN/WAN Replication Target ............................................ 120

Automigration/Replication Reporting ......................................................................................... 120

Cartridge Status ............................................................................................................... 120

Configuring the Cartridge Summary ............................................................................. 121

Viewing the Current Status ................................................................................................. 122

Configuring Automigration Job Reports ............................................................................... 122

Viewing the Job History ..................................................................................................... 123

Exporting the Job History to a CSV File ......................................................................... 124

Viewing the Job Summary ................................................................................................. 124

6 Deduplication ................................................................................ 125

Understanding Accelerated Deduplication .................................................................................. 125

How it Works .................................................................................................................. 126

Getting Deduplication Running on the VLS ................................................................................. 126

Considerations ................................................................................................................. 126

HP StorageWorks 5

Page 6

Installing the Firmware ...................................................................................................... 126

Installing the Deduplication Licenses ................................................................................... 127

Configuring Deduplication Options ........................................................................................... 127

Editing the Data Protector Configuration .............................................................................. 128

Viewing Deduplication Statistics and Reports .............................................................................. 129

Deduplication Summary .................................................................................................... 129

Deduplication Backup Report ............................................................................................. 129

Deduplication Cartridge Report .......................................................................................... 131

Deduplication System Capacity .......................................................................................... 131

7 Operation ..................................................................................... 133

Powering on VLS9000 Arrays ................................................................................................... 133

Powering on the VLS9000–series System .................................................................................... 136

Rebooting the System .............................................................................................................. 137

Powering Off the System .......................................................................................................... 138

Powering Off VLS9000 Arrays .................................................................................................. 139

8 User Interfaces ............................................................................... 141

User Interface Requirements ..................................................................................................... 141

Command View VLS ............................................................................................................... 141

Window Regions ............................................................................................................. 142

Opening a Command View VLS Session from a Web Browser ............................................... 143

Opening a Command View VLS Session from Command View TL ........................................... 144

Installing the SSL Certificate into your Web Browser .............................................................. 144

Restarting Command View VLS .......................................................................................... 145

Closing a Command View VLS Session ............................................................................... 146

Secure Shell and Serial User Interfaces ...................................................................................... 146

Opening a Secure Shell Session ......................................................................................... 146

Closing a Secure Shell Session ........................................................................................... 147

Opening a Serial Session .................................................................................................. 147

Closing a Serial Session .................................................................................................... 147

9 Configuration ................................................................................ 149

Setting the Network Settings ..................................................................................................... 149

Setting the Network Settings using the VLS Discovery Utility ................................................... 149

Setting the Network Settings using the CLI Command Set ...................................................... 151

Setting the Network Settings using Command View VLS ........................................................ 153

Setting the User Preferences ..................................................................................................... 154

Editing the Default Fibre Channel Host Port Settings ..................................................................... 155

Managing Oversubscription ..................................................................................................... 156

Enabling and Disabling Oversubscription ............................................................................ 157

Shutdown at 98% Capacity ............................................................................................... 157

Reclaiming Storage Space .......................................................................................... 158

Managing Virtual Device LUNs ................................................................................................. 158

Default LUN Numbering .................................................................................................... 159

Operating System LUN Requirements and Restrictions ............................................................ 159

LUN Masking .................................................................................................................. 160

LUN Masking (v3.x) ................................................................................................... 160

LUN Masking (v2.x) ................................................................................................... 160

LUN Mapping ................................................................................................................. 161

LUN Mapping (v3.x) .................................................................................................. 161

LUN Mapping (v2.x) .................................................................................................. 167

Dual Port Virtual Devices ................................................................................................... 168

6

Page 7

Creating a Virtual Library ........................................................................................................ 169

Editing a Virtual Library's Slots and Drives ................................................................................. 171

Creating Tape Drives ............................................................................................................... 171

Creating Cartridges ................................................................................................................ 173

Destroying a Virtual Library ...................................................................................................... 176

Destroying a Tape Drive ........................................................................................................... 176

Destroying Cartridges .............................................................................................................. 177

Adding and Removing Barcode Templates ................................................................................. 179

10 Management ............................................................................... 181

Changing the Account Passwords ............................................................................................. 181

Managing High Availability ..................................................................................................... 182

Array Dual Pathing ........................................................................................................... 182

Load Balancing ......................................................................................................... 182

LUN Path Failover ...................................................................................................... 182

Private LAN Dual Pathing .................................................................................................. 183

Managing Disk Arrays ............................................................................................................ 184

Viewing the Virtual Disk Status ........................................................................................... 184

Deleting Unused Virtual Disks ............................................................................................ 185

Clearing the Leftover Disks ................................................................................................. 185

Updating the Disk Firmware ............................................................................................... 186

Managing Cartridges .............................................................................................................. 186

Unloading a Cartridge from a Drive .......................................................................................... 186

Freeing up Storage Space ........................................................................................................ 187

Restarting VLS Device Emulations .............................................................................................. 187

Updating the Firmware ............................................................................................................ 188

Saving Configuration Settings ................................................................................................... 189

11 Monitoring .................................................................................. 191

Status Information in the Status Pane .......................................................................................... 191

Status Icons ............................................................................................................................ 191

Device Status Icon ............................................................................................................ 191

Navigation Tree Icon ........................................................................................................ 192

Notification Alerts ................................................................................................................... 192

Command View VLS ......................................................................................................... 193

E-mail Notification ............................................................................................................ 194

Editing the Email Server Settings .................................................................................. 194

Edit the Email Settings ................................................................................................ 194

SNMP Notification ........................................................................................................... 195

Editing the SNMP Settings .......................................................................................... 196

SMI-S Support .................................................................................................................. 197

Trace Log Files ........................................................................................................................ 198

Viewing Trace Log Files ..................................................................................................... 198

Saving a Trace Log File ..................................................................................................... 198

Creating a Support Ticket .................................................................................................. 198

Performance and Storage Use Reports ....................................................................................... 199

Exporting CSV Data ......................................................................................................... 199

Configuring Performance Reports and Notifications .............................................................. 199

Current Status Tab ...................................................................................................... 199

Performance History Tab ............................................................................................. 200

SAN Health Tab and Notifications ............................................................................... 200

Physical Capacity Notifications .................................................................................... 200

Logical Capacity Notifications ..................................................................................... 200

Current Status .................................................................................................................. 201

HP StorageWorks 7

Page 8

Performance History ......................................................................................................... 201

Logical Capacity .............................................................................................................. 202

Physical Capacity ............................................................................................................. 203

SAN Health ..................................................................................................................... 203

Workload Assessment ....................................................................................................... 205

Running a Workload Assessment Simulation .................................................................. 205

Using the Workload Assessment Templates ................................................................... 205

Editing the Notification Alerts ...................................................................................... 206

Replication History ........................................................................................................... 206

Receiving Automated Reports ............................................................................................. 206

Stress Testing Hard Disks ......................................................................................................... 208

Configuring the Storage Exerciser ....................................................................................... 208

Storage Exerciser CLI Commands ................................................................................. 209

Starting and Reviewing Read-only Jobs ................................................................................ 209

Starting and Reviewing Background Jobs ............................................................................. 210

Log Monitor Summary ................................................................................................ 211

Log File Fields .................................................................................................................. 211

12 CLI Command Set ........................................................................ 213

Commands ............................................................................................................................ 213

Conventions .................................................................................................................... 213

CLI-only Commands ................................................................................................................ 213

Connection Commands ..................................................................................................... 213

Output Commands ........................................................................................................... 214

VLS Commands ...................................................................................................................... 214

Network Settings Configuration Commands ......................................................................... 214

Configuration Commands .................................................................................................. 215

Management Commands .................................................................................................. 223

Monitoring Commands ..................................................................................................... 224

13 Component Identification .............................................................. 227

VLS9000 Node Components, LEDs, and Buttons ......................................................................... 227

Front Panel Components .................................................................................................... 227

Front Panel LEDs and Buttons ............................................................................................. 228

Rear Panel Components .................................................................................................... 229

Rear Panel LEDs and Buttons .............................................................................................. 230

System Board Components ................................................................................................ 231

Accessing the HP Systems Insight Display ............................................................................ 232

HP Systems Insight Display and LEDs ................................................................................... 233

HP Systems Insight Display LEDs and Internal Health LED Combinations ................................... 233

Hard Drive LEDs ............................................................................................................... 235

Hard Drive LED Combinations ............................................................................................ 235

Fan Locations ................................................................................................................... 236

Fibre Channel Switch 4/10q Components, LEDs, and Buttons ....................................................... 236

Front Panel Components .................................................................................................... 236

Front Panel LEDs and Buttons ............................................................................................. 237

Heartbeat LED Blink Patterns ....................................................................................... 238

Fibre Channel Switch 4/16q Components, LEDs, and Buttons ....................................................... 238

Front Panel Components .................................................................................................... 238

Front Panel LEDs and Buttons ............................................................................................. 239

Rear Panel Components .................................................................................................... 240

Rear Panel LEDs and Buttons .............................................................................................. 240

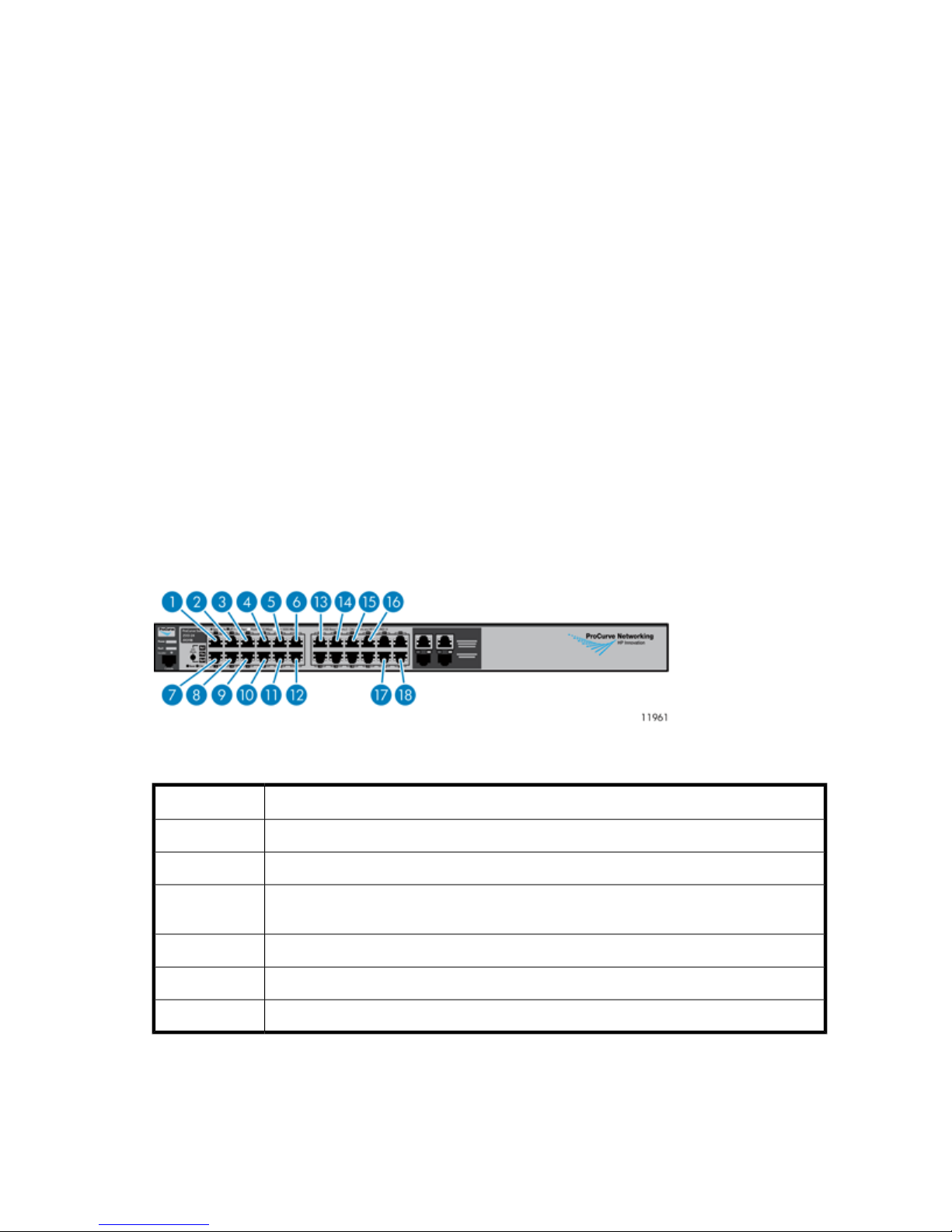

Ethernet Switch 2510–24 Components, LEDs, and Buttons ............................................................ 241

Front Panel Components .................................................................................................... 241

8

Page 9

Front Panel LEDs and Buttons ............................................................................................. 241

Ethernet Switch 2810–24G Components, LEDs, and Buttons ......................................................... 243

Front Panel Components .................................................................................................... 243

Front Panel LEDs and Buttons ............................................................................................. 244

USB LAN Adapter Components ................................................................................................ 246

VLS9000–series Disk Array Components, LEDs, and Buttons ......................................................... 246

Front Panel Components .................................................................................................... 246

Front Panel LEDs ............................................................................................................... 247

Rear Panel Components .................................................................................................... 248

Base Disk Array Enclosure ........................................................................................... 248

Expansion Disk Array Enclosure ................................................................................... 248

Rear Panel LEDs and Buttons .............................................................................................. 249

Base Disk Array Enclosure ........................................................................................... 249

Expansion Disk Array Enclosure ................................................................................... 250

14 Component Replacement .............................................................. 253

Safety Considerations .............................................................................................................. 253

Preventing Electrostatic Discharge ....................................................................................... 253

Grounding Methods to Prevent Electrostatic Damage ............................................................. 253

Warnings and Cautions .................................................................................................... 254

Preparation Procedures ............................................................................................................ 254

Extending a VLS9000 Node from the Rack .......................................................................... 255

Removing a VLS9000 Node from the Rack .......................................................................... 255

Removing the VLS9000 Node Access Panel ......................................................................... 255

Installing the VLS9000 Node Access Panel .......................................................................... 256

VLS9000 Node Component Replacement .................................................................................. 256

SATA Hard Drive .............................................................................................................. 256

DVD-CD Drive .................................................................................................................. 258

Power Supply ................................................................................................................... 259

Fan Module ..................................................................................................................... 260

FBDIMM ......................................................................................................................... 262

Replacing a Primary Node ....................................................................................................... 263

Replacing a Secondary Node .................................................................................................. 264

Fibre Channel Switch 4/10q Replacement ................................................................................. 265

Fibre Channel Switch 4/16q Replacement ................................................................................. 266

Fibre Channel Transceiver Replacement ..................................................................................... 266

Ethernet Switches .................................................................................................................... 267

USB LAN Adapter Replacement ................................................................................................ 267

VLS9000–series Disk array Component Replacement ................................................................... 268

Hard Drive ...................................................................................................................... 268

Power Module ................................................................................................................. 269

RAID or Expansion Controller ............................................................................................ 271

15 Disaster Recovery ......................................................................... 273

Recovering from Operating System Failure ................................................................................. 273

Restoring the Configuration Settings .................................................................................... 274

Restoring the Virtual Library Configuration from a Configuration File ................................. 274

Rebuilding the Virtual Library Configuration .................................................................. 275

Re-installing the VLS Licenses .............................................................................................. 276

Warm Failover ................................................................................................................. 276

Recovering from a VLS9000 Disk Array RAID Volume Failure ........................................................ 276

Recovering from a Node RAID Volume Failure ............................................................................ 277

HP StorageWorks 9

Page 10

16 Support and Other Resources ........................................................ 279

Related Information ................................................................................................................. 279

Documents ...................................................................................................................... 279

Websites ......................................................................................................................... 279

Document Conventions and Symbols ......................................................................................... 280

Rack Stability ......................................................................................................................... 281

Contacting HP ........................................................................................................................ 282

Before you Contact HP ...................................................................................................... 282

HP Contact Information ..................................................................................................... 282

Subscription Service ................................................................................................................ 282

Customer Self Repair ............................................................................................................... 283

Product Warranties ................................................................................................................. 283

Documentation Feedback ......................................................................................................... 283

A Troubleshooting ............................................................................. 285

VLS Common Issues ................................................................................................................ 285

Automigration/Replication Issues .............................................................................................. 292

Destination library status icon ............................................................................................ 292

Replacing a library ........................................................................................................... 292

Deduplication Issues ................................................................................................................ 293

B Specifications ................................................................................ 295

VLS9000 Node ...................................................................................................................... 295

VLS9000–series Disk Array Enclosure ........................................................................................ 295

Fibre Channel Switch 4/10q .................................................................................................... 296

Fibre Channel Switch 4/16q .................................................................................................... 297

Ethernet Switch 2510–24 ......................................................................................................... 299

Ethernet Switch 2810–24G ...................................................................................................... 300

Environmental Specifications .................................................................................................... 301

C Regulatory Compliance Notices ....................................................... 303

Regulatory Compliance Identification Numbers ........................................................................... 303

Federal Communications Commission Notice ............................................................................. 303

FCC rating label .............................................................................................................. 303

Class A equipment ..................................................................................................... 303

Class B equipment ..................................................................................................... 304

Declaration of Conformity for products marked with the FCC logo, United States only ............... 304

Modification .................................................................................................................... 304

Cables ............................................................................................................................ 304

Canadian Notice (Avis Canadien) ............................................................................................ 304

Class A Equipment ........................................................................................................... 304

Class B Equipment ............................................................................................................ 305

European Union Notice ........................................................................................................... 305

Japanese Notices ................................................................................................................... 305

Japanese VCCI-A Notice ................................................................................................... 305

Japanese VCCI-B Notice ................................................................................................... 305

Japanese Power Cord Statement ......................................................................................... 305

Korean Notices ...................................................................................................................... 306

Class A Equipment ........................................................................................................... 306

Class B Equipment ............................................................................................................ 306

Taiwanese Notices .................................................................................................................. 306

BSMI Class A Notice ........................................................................................................ 306

Taiwan Battery Recycle Statement ....................................................................................... 306

10

Page 11

Laser Compliance Notices ....................................................................................................... 307

English Laser Notice ......................................................................................................... 307

Dutch Laser Notice ........................................................................................................... 307

French Laser Notice .......................................................................................................... 308

German Laser Notice ........................................................................................................ 308

Italian Laser Notice .......................................................................................................... 308

Japanese Laser Notice ...................................................................................................... 309

Spanish Laser Notice ........................................................................................................ 309

Recycling Notices ................................................................................................................... 309

English Notice ................................................................................................................. 309

Bulgarian Notice .............................................................................................................. 310

Czech Notice .................................................................................................................. 310

Danish Notice ................................................................................................................. 310

Dutch Notice ................................................................................................................... 310

Estonian Notice ............................................................................................................... 311

Finnish Notice ................................................................................................................. 311

French Notice .................................................................................................................. 311

German Notice ................................................................................................................ 311

Greek Notice ................................................................................................................... 312

Hungarian Notice ............................................................................................................ 312

Italian Notice ................................................................................................................... 312

Latvian Notice ................................................................................................................. 312

Lithuanian Notice ............................................................................................................. 313

Polish Notice ................................................................................................................... 313

Portuguese Notice ............................................................................................................ 313

Romanian Notice ............................................................................................................. 313

Slovak Notice .................................................................................................................. 314

Spanish Notice ................................................................................................................ 314

Swedish Notice ................................................................................................................ 314

Turkish Notice .................................................................................................................. 314

Battery Replacement Notices .................................................................................................... 315

Dutch Battery Notice ......................................................................................................... 315

French Battery Notice ....................................................................................................... 316

German Battery Notice ..................................................................................................... 316

Italian Battery Notice ........................................................................................................ 317

Japanese Battery Notice ................................................................................................... 317

Spanish Battery Notice ..................................................................................................... 318

Glossary .......................................................................................... 319

Index ............................................................................................... 325

HP StorageWorks 11

Page 12

Figures

Racked VLS9000 system (32-port connectivity kit shown) .............................................. 181

Identifying contents of the VLS9000 node shipping carton ........................................... 252

Identifying contents of the VLS9000 array shipping carton ........................................... 263

Identifying contents of the VLS9000 20-port connectivity kit shipping carton ................... 274

Identifying contents of the VLS9000 32-port connectivity kit shipping carton ................... 285

Identifying contents of the VLS9000 interswitch link kit shipping carton .......................... 296

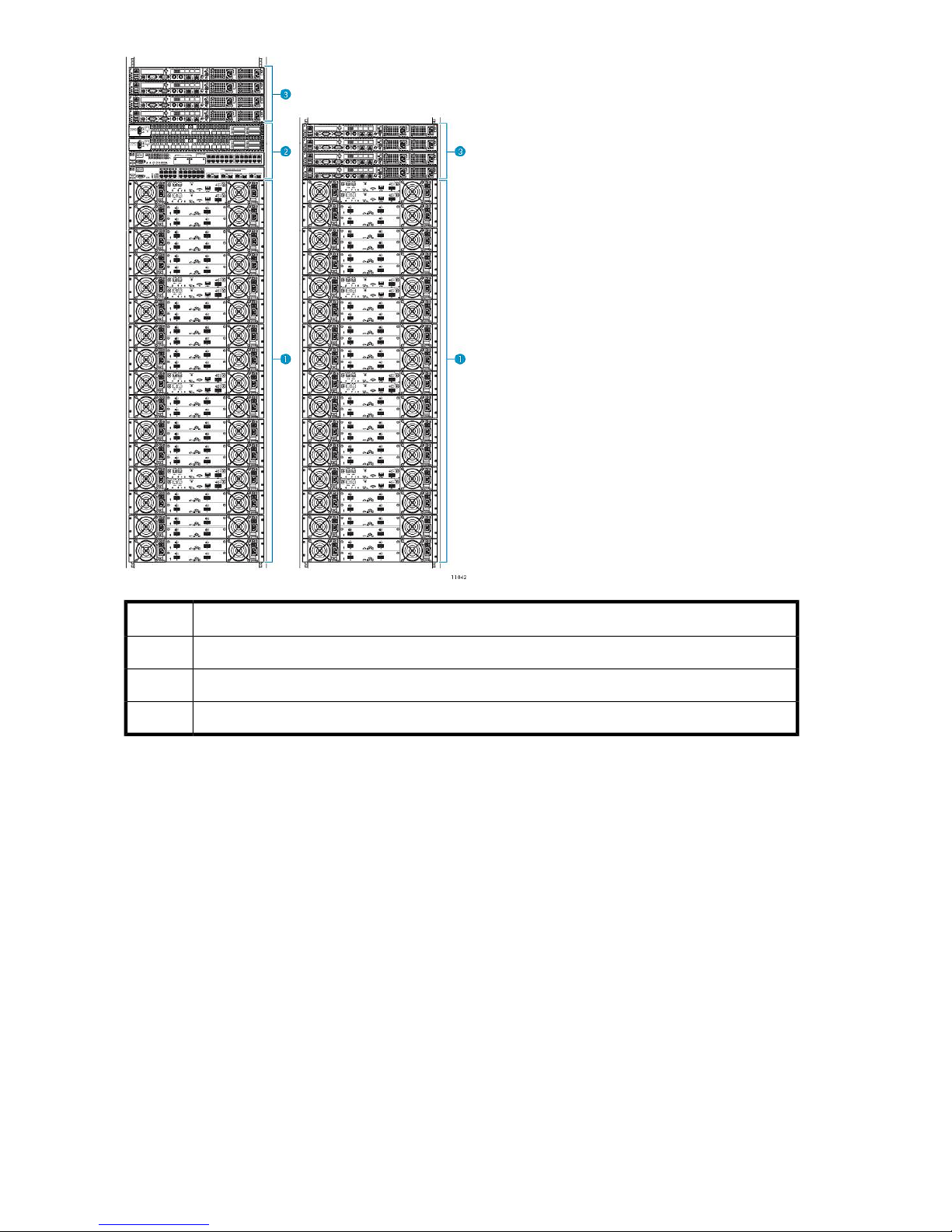

VLS9000-series two-rack configuration ....................................................................... 307

VLS9000–series four-rack configuration, Racks 1–4 (left to right) .................................... 318

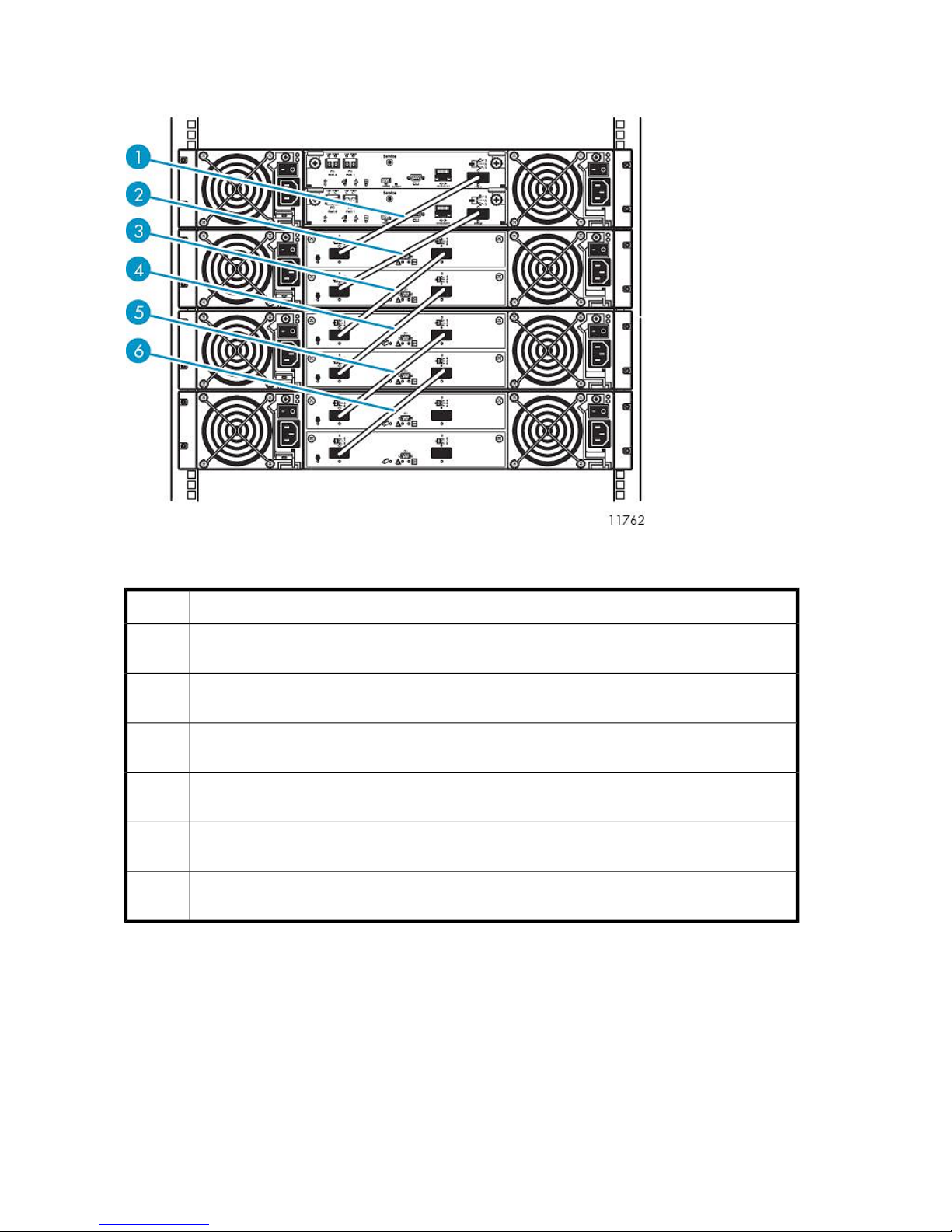

PDU and PDM locations ........................................................................................... 339

Rack one recommended rack configuration (32-port connectivity kit shown) .................... 3510

Rack two recommended rack configuration ................................................................ 3711

Rack three recommended rack configuration ............................................................... 3912

Rack four recommended rack configuration ................................................................ 4013

VLS9000 array rack configuration ............................................................................. 5114

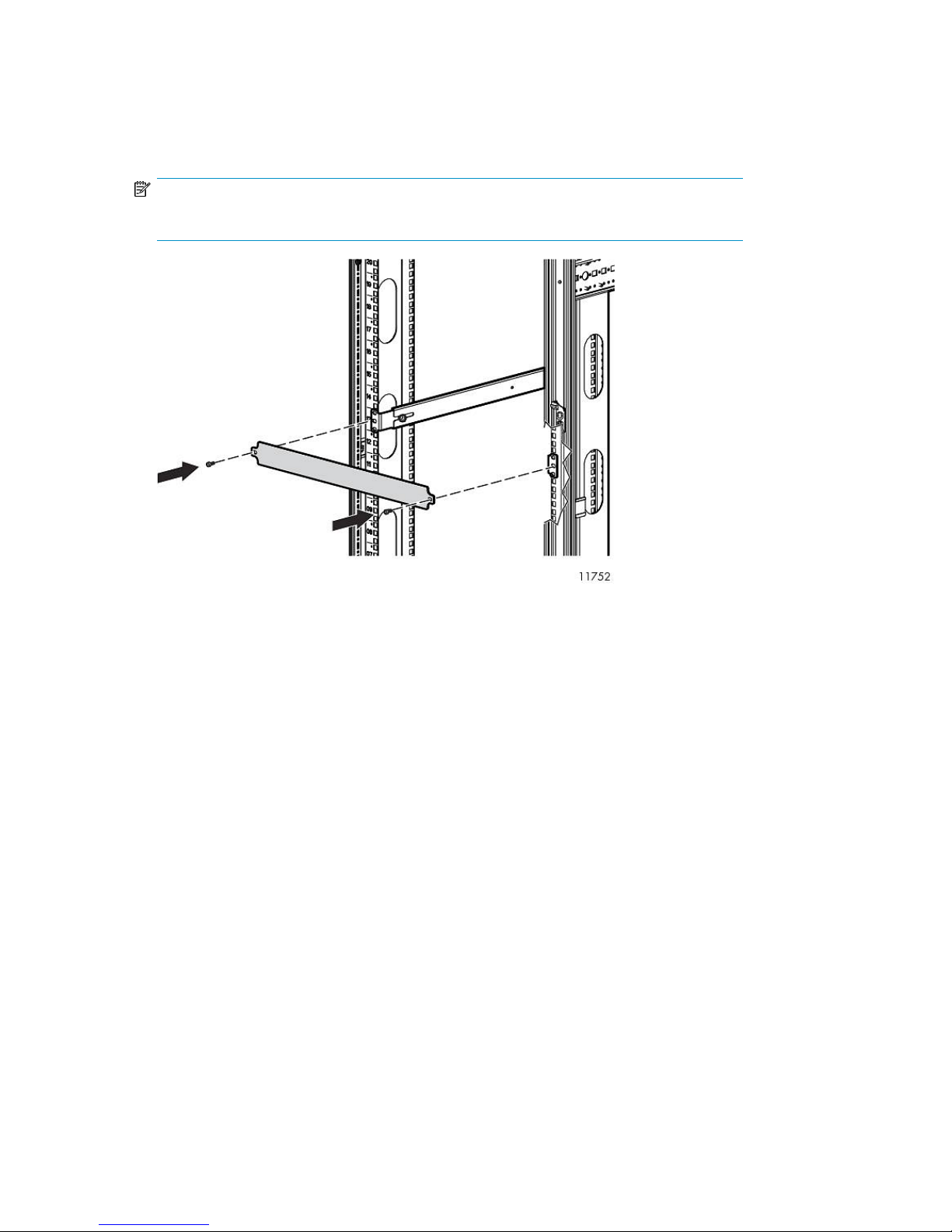

Installing the cage nuts ............................................................................................ 5315

Nodes port cabling ................................................................................................. 5816

Disk array enclosure SAS port cabling ....................................................................... 6017

Ethernet Switch 2510–24 port cabling ....................................................................... 6118

Ethernet Switch 2810–24G port cabling .................................................................... 6219

Fibre Channel Switch 4/10q port cabling .................................................................. 6320

Fibre Channel Switch 4/16q port cabling .................................................................. 6421

Inter-rack connected VLS9000 ................................................................................. 6722

Fibre Channel Switch 4/16q 10Gb ports ................................................................. 6923

Installed XPAK transponders ..................................................................................... 6924

Interswitch Fibre Channel cables ............................................................................... 7025

Ethernet Switch 2510–24 ......................................................................................... 7126

Ethernet Switch 2810-24G ....................................................................................... 7127

Creating an echo copy pool (LAN/WAN shown) ........................................................ 8928

Setting the echo copy pool policies (LAN/WAN shown) .............................................. 9129

Setting up the availability windows (LAN/WAN shown) .............................................. 9330

Creating a new smart copy pool (with sample slot range error message) ........................ 9831

Creating a LAN/WAN replication target ................................................................. 11632

12

Page 13

Adding policy windows to a new LAN/WAN replication target .................................. 11733

Setting the global LAN/WAN replication target settings ............................................ 11834

Editing a LAN/WAN replication target's availability windows .................................... 11935

Changing the job history options ............................................................................ 12436

Configuring deduplication options .......................................................................... 12837

Disk array front panel LED status during normal operation .......................................... 13438

Base disk array rear panel LED status during normal operation ................................... 13539

Expansion disk array rear panel LED status during normal operation ........................... 13640

VLS9000 node LED status during normal operation ................................................... 13741

VLS discovery utility — main window ...................................................................... 15042

VLS discovery utility – Device Configuration window .................................................. 15143

Set Network Configuration Wizard window ............................................................. 15344

User Preferences window ....................................................................................... 15445

Fibre Channel Host Ports window ............................................................................ 15646

Host LUN Mapping Mode window .......................................................................... 16147

LUN Mapping Device View window ........................................................................ 16348

LUN Mapping Host View window ........................................................................... 16449

LUN Mapping Host Setup window .......................................................................... 16650

Library Parameters – Map LUNs window .................................................................. 16851

Create Virtual Library Wizard window (1 of 12) ....................................................... 16952

Create Virtual Library Wizard window (2 of 12) ....................................................... 17053

Create Virtual Library Wizard window (5 of 12) ...................................................... 17254

Create Virtual Library Wizard window (6 of 12) ....................................................... 17355

Create Virtual Library Wizard window (8 of 12) ....................................................... 17456

Create Virtual Library Wizard window (9 of 12) ....................................................... 17557

Create Virtual Library Wizard window (10 of 12) ..................................................... 17558

Cartridges details window ..................................................................................... 17859

Cartridges parameters window ............................................................................... 17960

Add/Remove Barcode Templates window ................................................................ 18061

Edit Accounts window ........................................................................................... 18162

Device status icon in the status banner ..................................................................... 19263

Navigation tree icon ............................................................................................. 19264

Notification alert examples .................................................................................... 19365

Edit Email Settings window .................................................................................... 19566

Edit SNMP Settings window ................................................................................... 19667

CSV data fields for VLS performance reports ............................................................ 20168

SAN Health tab .................................................................................................... 20469

HP StorageWorks 13

Page 14

Extending the HP Systems Insight Display ................................................................. 23270

Rotating the HP Systems Insight Display .................................................................... 23271

Removing a node hard drive .................................................................................. 25772

Preparing the node hard drive ................................................................................ 25773

Installing the node hard drive ................................................................................. 25774

Pressing ejector button ........................................................................................... 25875

Installing the DVD-CD drive .................................................................................... 25976

Removing a node power supply .............................................................................. 25977

Installing a node power supply ............................................................................... 26078

Placing the power cord in the strain relief clip ........................................................... 26079

Removing the node power supply air baffle .............................................................. 26180

Removing the node fan module 1 ............................................................................ 26181

Removing the node fan module 2 or 3 ..................................................................... 26282

Installing the node FBDIMM ................................................................................... 26383

Rail release bracket ............................................................................................... 26484

Removing a disk array hard drive ............................................................................ 26885

Removing a disk array power module ...................................................................... 27086

Disengaging the disk array controller ...................................................................... 27187

Installing the disk array controller ............................................................................ 27288

14

Page 15

Tables

VLS9030 capacity (with 2:1 data compression) .......................................................... 191

VLS9040 capacity (with 2:1 data compression) .......................................................... 202

VLS user interface requirements ............................................................................... 1413

CLI connection commands ...................................................................................... 2134

CLI output commands ............................................................................................ 2145

CLI network settings configuration commands ........................................................... 2156

CLI configuration commands .................................................................................. 2167

CLI management commands .................................................................................. 2238

CLI monitoring commands ...................................................................................... 2249

Document Conventions .......................................................................................... 28010

HP StorageWorks 15

Page 16

16

Page 17

1 Introduction

The HP StorageWorks virtual library system (VLS) family consists of RAID disk-based SAN backup

devices that emulate physical tape libraries, allowing you to perform disk-to-virtual tape (disk-to-disk)

backups using your existing backup applications. The VLS family includes different series of models

that vary in storage capacity and performance.

The VLS emulates a variety of physical tape libraries, including the tape drives and cartridges inside

the libraries. You determine the number and types of tape libraries a VLS emulates, and the number

and types of tape drives and cartridges included in each tape library to meet the needs of your

environment. You configure the size of the virtual cartridges in your VLS, which provides even more

flexibility.

The VLS automigration features allow you to establish data pools to create and manage mirror (echo

copy) or snapshot (smart copy) replication of data for additional protection against data loss.

Deduplication provides the functionality in which only a single copy of a data block is stored on a

device. Duplicate information is removed, thereby reducing the amount of storage used by a given

data block.

The VLS accommodates mixed IT platform and backup application environments, allowing all your

servers and backup applications to access the virtual media simultaneously. You can specify which

servers are allowed to access each virtual library and tape drive you configure. You can change the

default LUNs assigned to the virtual library and tape drives for each host as needed to accommodate

different operating system requirements and restrictions.

Data stored on a VLS is easily cloned to physical tape for off-site disaster protection or long-term

archival using a backup application.

This section describes the HP StorageWorks 9000–series virtual library system models.

VLS9000-series Components

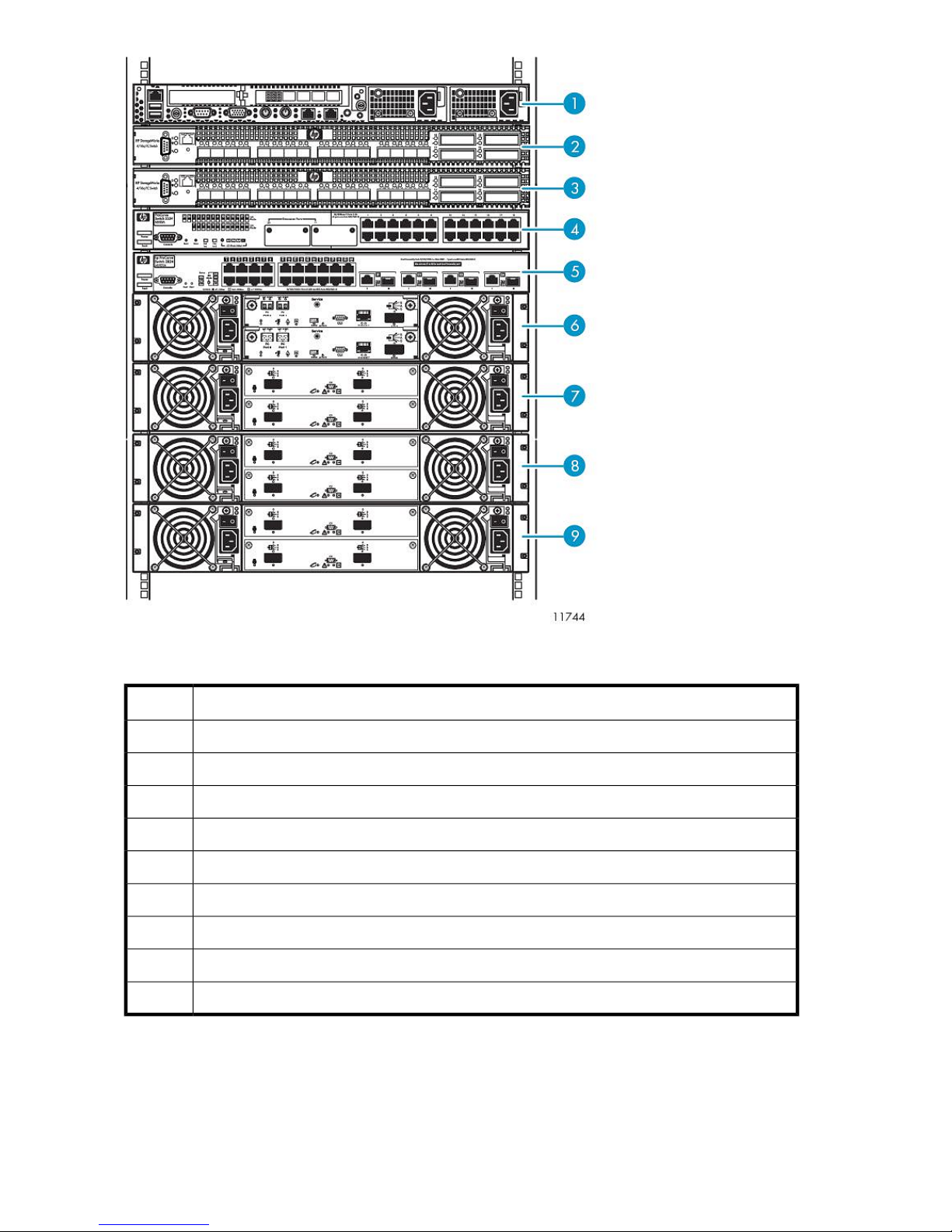

A typical VLS9000-series system consists of at least one VLS9000 node, at least one VLS9000 array

(one base disk array enclosure and three expansion disk array enclosures), and one VLS9000

connectivity kit (two Ethernet switches for internal inter-node connections and two Fibre Channel

switches for disk storage connections). See the drawing of a racked system below. The VLS9000 7.5

TB and 10 TB systems consist of one node, one Ethernet switch, one base disk array enclosure, and

up to three expansion disk array enclosures.

Each VLS9000 node contains hardware data compression, dual processors, one 4 Gb quad port

Fibre Channel HBA, eight 2048 MB memory modules (for a total of 16 GB), and two 120 GB SATA

hard drives.

HP StorageWorks 17

Page 18

Figure 1 Racked VLS9000 system (32-port connectivity kit shown)

.

DescriptionItem

Node 0, primary node1

FC switch 02

FC switch 13

Ethernet Switch 2510–24 (100 Mb)4

Ethernet Switch 2810–24G (1 Gb)5

Base disk array enclosure6

Expansion disk array enclosure7

Expansion disk array enclosure8

Expansion disk array enclosure9

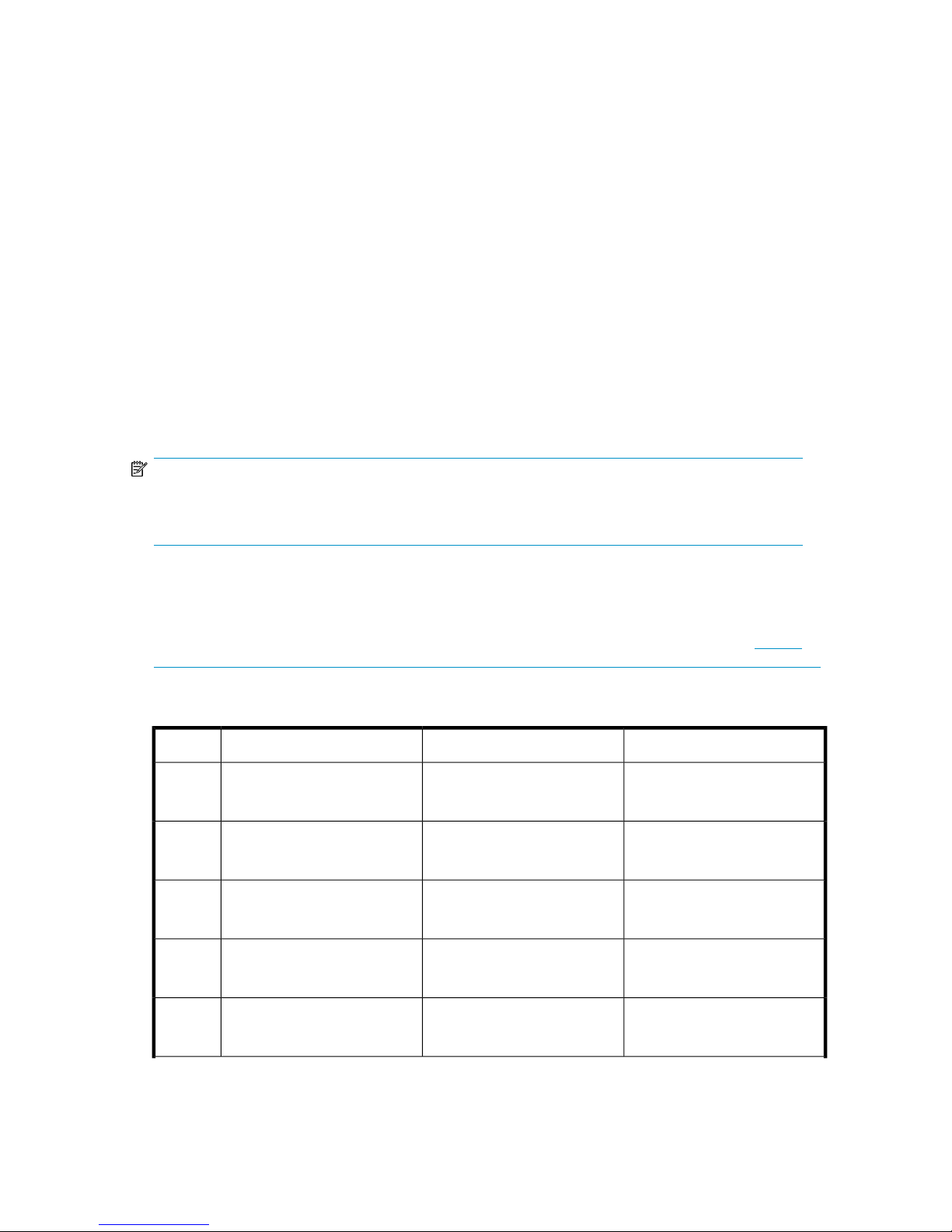

You can install either the VLS9000 20-port or 32-port connectivity kit with the VLS9000-series. (The

VLS9000 7.5 TB and 10 TB systems omit the connectivity kit.) The 20-port connectivity kit includes

two 10-port Fibre Channel switches and two Ethernet switches. The 32-port connectivity kit includes

Introduction18

Page 19

two 16-port Fibre Channel switches and two Ethernet switches. The number of Fibre Channel ports

available determines the number of arrays and nodes that can be installed. The 32-port connectivity

kit allows you to install more VLS9000 nodes and VLS9000 arrays in your VLS9000-series system

than the 20-port connectivity kit.

VLS9000–series scalability considerations:

• Two Fibre Channel ports (one Fibre Channel port on each Fibre Channel switch) are required for

each VLS9000 node

• Two Fibre Channel ports (one Fibre Channel port on each Fibre Channel switch) are required for

each VLS9000 array

• Up to two VLS9000 arrays may be installed for every VLS9000 node in a VLS9000-series system

• Adding nodes and arrays increases the VLS9000-series storage capacity

• Adding nodes to a system that has more than one array installed for every node increases perform-

ance

If you have a 20–port connectivity kit, you can install a total of ten devices, consisting of a combination

of arrays and nodes. If you have a 32–port connectivity kit, you can install a total of 16 devices.

By interconnecting two 32–port connectivity kits with an interswitch link kit, you can further expand

the scalability of VLS9000–series. See Table 1 and Table 2 for configuration options.

NOTE:

For maximum performance, install one VLS9000 array for every VLS9000 node installed.

For maximum capacity, install two VLS9000 arrays for every VLS9000 node installed.

To add a VLS9000 array, purchase a VLS9000 capacity kit. A VLS9000 capacity kit includes one

VLS9000 array and one capacity license for the VLS9000 array. If you have a 7.5 TB or 10 TB

system, you can add expansion disk array enclosures individually.

See the HP StorageWorks VLS9000 Virtual Library System Quickspec on the HP web site (http://

h18004.www1.hp.com/storage/disk_storage/disk_to_disk/vls/index.html?jumpid=reg_R1002_USEN)

for performance data.

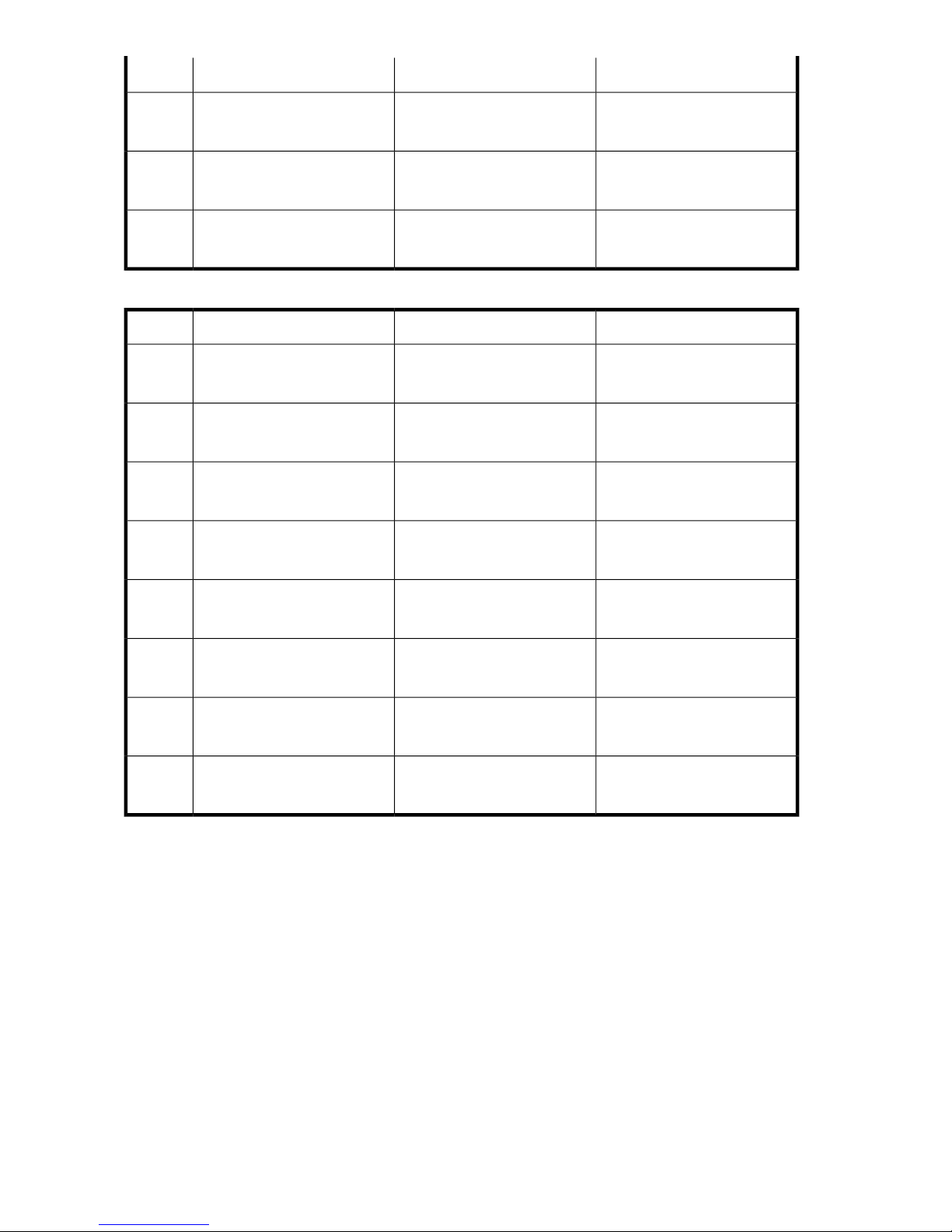

Table 1 VLS9030 capacity (with 2:1 data compression)

2x32-port connectivity kit32-port connectivity kit20-port connectivity kitNodes

1

2

3

4

5

60 TB — 120 TB

(1 — 2 arrays)

120 TB — 240 TB

(2 — 4 arrays)

180 TB — 360 TB

(3 — 6 arrays)

240 TB — 360 TB

(4 — 6 arrays)

300 TB

(5 arrays)

60 TB — 120 TB

(1 — 2 arrays)

120 TB — 240 TB

(2 — 4 arrays)

180 TB — 360 TB

(3 — 6 arrays)

240 TB — 480 TB

(4 — 8 arrays)

300 TB — 600 TB

(5 — 10 arrays)

60 TB — 120 TB

(1 — 2 arrays)

120 TB — 240 TB

(2 — 4 arrays)

180 TB — 360 TB

(3 — 6 arrays)

240 TB — 480 TB

(4 — 8 arrays)

300 TB — 600 TB

(5 — 10 arrays)

HP StorageWorks 19

Page 20

2x32-port connectivity kit32-port connectivity kit20-port connectivity kitNodes

N/A6

N/A7

N/A8

360 TB — 600 TB

(6 — 10 arrays)

420 TB — 540 TB

(7 — 9 arrays)

480 TB

(8 arrays)

Table 2 VLS9040 capacity (with 2:1 data compression)

1

2

3

4

80 TB – 160 TB

(1 – 2 arrays)

160 TB – 320 TB

(2 – 4 arrays)

240 TB – 480 TB

(3 – 6 arrays)

320 TB – 480 TB

(4 – 6 arrays)

80 TB – 160 TB

(1 – 2 arrays)

160 TB – 320 TB

(2 – 4 arrays)

240 TB – 480 TB

(3 – 6 arrays)

320 TB – 640 TB

(4 – 8 arrays)

360 TB — 720 TB

(6 — 12 arrays)

420 TB — 840 TB

(7 — 14 arrays)

480 TB — 960 TB

(8 — 16 arrays)

2x32–port connectivity kit32-port connectivity kit20-port connectivity kitNodes

80 TB – 160 TB

(1 – 2 arrays)

160 TB – 320 TB

(2 – 4 arrays)

240 TB – 480 TB

(3 – 6 arrays)

320 TB – 640 TB

(4 – 8 arrays)

5

400 TB

(5 arrays)

N/A6

N/A7

N/A8

400 TB – 800 TB

(5 – 10 arrays)

480 TB – 800 TB

(6 – 10 arrays)

560 TB – 720 TB

(7 – 9 arrays)

640 TB

(8 arrays)

400 TB – 800 TB

(5 – 10 arrays)

480 TB – 960 TB

(6 – 12 arrays)

560 TB – 1120 TB

(7 – 14 arrays)

640 TB – 1280 TB

(8 – 16 arrays)

Introduction20

Page 21

2 Hardware Installation

This section details the steps to install the VLS hardware from installation preparation to final cabling.

Preparing for the Installation

Tools for Installation

• Two people

• #1 and #2 Phillips screwdriver

• Standard screwdriver

• Allen wrench (provided; used with 6-mm screws and #12-24 x 3/8-inch sockethead screws)

• #3 Pozidrive screwdriver

• 7/16 inch wrench

• Box cutting knife

CAUTION:

Do not use any power tools. They could strip or damage connections.

Taking ESD Precautions

To prevent damaging the system, be aware of the precautions you need to follow when setting up

the system or handling parts. A discharge of static electricity from a finger or other conductor may

damage system boards or other static-sensitive devices. This type of damage may reduce the life

expectancy of the device.

To prevent electrostatic damage: