HP ProLiant ML310 Generation 2 Server

Maintenance and Service Guide

August 2005 (Third Edition)

Part Number 378290-003

© Copyright 2005 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

Microsoft, Windows, and Windows NT are U.S. registered trademarks of Microsoft Corporation.

Linux is a U.S. registered trademark of Linus Torvalds.

August 2005 (Third Edition)

Part Number 378290-003

Audience assumptions

This document is for the person who installs, administers, and troubleshoots servers and storage

systems. HP assumes you are qualified in the servicing of computer equipment and trained in

recognizing hazards in products with hazardous energy levels.

3

Contents

Illustrated parts catalog 5

Customer self repair.............................................................................................................................5

Mechanical components.......................................................................................................................6

System components..............................................................................................................................7

Removal and replacement procedures 11

Required tools.................................................................................................................................... 11

Safety considerations ......................................................................................................................... 12

Preventing electrostatic discharge ..........................................................................................12

Server warnings and cautions................................................................................................. 12

Warnings and cautions............................................................................................................13

Preparation procedures.......................................................................................................................15

Powering down the server ......................................................................................................15

Removing the server from the rack.........................................................................................15

Unlocking the bezel................................................................................................................ 16

Bezel ..................................................................................................................................................17

Hot-plug SCSI hard drive ..................................................................................................................17

Hot-plug SATA/SAS hard drive........................................................................................................ 18

Access panel.......................................................................................................................................20

PCI expansion board..........................................................................................................................21

Battery................................................................................................................................................ 21

DIMM ................................................................................................................................................23

DIMM installation guidelines................................................................................................. 24

Air baffle............................................................................................................................................25

Fan .....................................................................................................................................................25

Power supply......................................................................................................................................27

Processor assembly............................................................................................................................27

Diskette drive..................................................................................................................................... 30

CD-ROM/DVD-ROM drive ..............................................................................................................31

Installing a full-height tape drive option............................................................................................32

Full-height tape drive......................................................................................................................... 34

Power button/LED board ................................................................................................................... 35

Hard drive (non-hot-plug)..................................................................................................................37

Hot-plug SCSI backplane...................................................................................................................38

Hot-plug SATA or SAS backplane.................................................................................................... 40

System board......................................................................................................................................42

4 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Server cabling 45

Hot-plug SCSI cabling.......................................................................................................................45

Hot-plug SATA cabling.....................................................................................................................46

Non-hot-plug SCSI cabling................................................................................................................ 46

Non-hot-plug SATA cabling.............................................................................................................. 47

SAS cabling .......................................................................................................................................48

Diagnostic tools 49

Survey Utility..................................................................................................................................... 49

Array Diagnostic Utility.....................................................................................................................49

HP Insight Diagnostics.......................................................................................................................50

Integrated Management Log ..............................................................................................................50

Server component identification 53

Front panel components..................................................................................................................... 53

Front panel LEDs and buttons............................................................................................................54

Rear panel components...................................................................................................................... 55

Rear panel LEDs and buttons.............................................................................................................56

System board components .................................................................................................................57

System maintenance switch....................................................................................................57

System board LEDs ...........................................................................................................................59

System LEDs and internal health LED combinations........................................................................ 60

SCSI IDs ............................................................................................................................................62

Hot-plug SCSI hard drive LEDs........................................................................................................ 62

Hot-plug SCSI hard drive LED combinations ................................................................................... 63

Hot-plug SATA or SAS IDs ..............................................................................................................64

SATA or SAS hard drive LEDs.........................................................................................................65

Fan locations...................................................................................................................................... 66

Specifications 67

Server specifications ..........................................................................................................................67

Environmental specifications............................................................................................................. 68

Hot-plug power supply calculations...................................................................................................68

1.44-MB diskette drive specifications................................................................................................68

CD-ROM drive specifications............................................................................................................69

Acronyms and abbreviations 73

Index 77

5

Illustrated parts catalog

In this section

Customer self repair........................................................................................................................5

Mechanical components .................................................................................................................6

System components ........................................................................................................................7

Customer self repair

What is customer self repair?

HP's customer self-repair program offers you the fastest service under either

warranty or contract. It enables HP to ship replacement parts directly to you so

that you can replace them. Using this program, you can replace parts at your own

convenience.

A convenient, easy-to-use program:

• An HP support specialist will diagnose and assess whether a replacement

part is required to address a system problem. The specialist will also

determine whether you can replace the part.

• Replacement parts are express-shipped. Most in-stock parts are shipped the

very same day you contact HP. You may be required to send the defective

part back to HP, unless otherwise instructed.

• Available for most HP products currently under warranty or contract. For

information on the warranty service, refer to the HP website

(http://h18004.www1.hp.com/products/servers/platforms/warranty/index.htm

l).

For more information about HP's customer self-repair program, contact your

local service provider. For the North American program, refer to the HP website

(http://www.hp.com/go/selfrepair

).

Customer replaceable parts are identified in the following tables.

6 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Mechanical components

Item Description Assembly

part number

1 Bezel (w/o bezel key) 383678-001 382979-001 Yes

2 Access panel – – –

3 Air baffle 385712-001 385758-001 Yes

4 PCI retainer clips – – Yes

5 Release lever, full height drive bay – – Yes

6 Fan holder – – Yes

7 PCI expansion board guide – – Yes

8 Feet (4) – – Yes

9 Hot-plug SATA hard drive cage 346078-001 345640-001 Yes

10 Non-hot-plug SATA/SCSI hard drive cage 346079-001 382992-001 Yes

11 Hot-plug SCSI hard drive cage* 384522-001 384756-001 Yes

12 Bezel key* – 399394-001 Yes

Plastics kit

– 382978-001 Yes

Spare part

number

Customer self

repair

Illustrated parts catalog 7

* not shown

System components

Item Description Assembly

part number

1 System fan module 381458-001 382109-001 Yes

2 Processor heatsink/cooling fan assembly 379265-001 382110-001 No

3

Processor

a) Intel® Celeron® D 2.8-GHz/533-MHz FSB/256KB L2 cache

b) Intel® Pentium® 4 3.0-GHz/800-MHz FSB/1-MB

L2 cache*

c) Intel® Pentium® 4 3.2-GHz/800-MHz FSB/1-MB

L2 cache*

d) Intel® Pentium® 4 3.4-GHz/800-MHz FSB/1-MB

L2 cache*

e) Intel® Pentium® 4 3.2-GHz/800-MHz FSB/2-MB

L2 cache*

367744-001 382232-001 No

390592-001 366643-001 No

384930-001 366644-001 No

384931-001 367415-001 No

391817-001 384786-001 No

Spare part

number

Customer

self repair

8 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Item Description Assembly

part number

d) Intel® Pentium® 4 3.4-GHz/800-MHz FSB/2-MB

L2 cache*

4

Memory

a) 256-MB PC-3200 unbuffered DDR DIMM 326315-441 382202-001 Yes

b) 512-MB PC-3200 unbuffered DDR DIMM* 326316-441 351657-005 Yes

c) 1-GB PC-3200 unbuffered DDR DIMM* 326317-451 351658-001 Yes

Boards

5 System board with tray 326513-001 382202-001 Yes

6 Hot-plug SCSI hard drive backplane board 382118-001 385597-001 Yes

7 Hot-plug SATA hard drive backplane board 379271-001 382985-001 Yes

8 SCSI controller card 332541-001 366651-001 Yes

9 Power button/LED board 383680-001 385744-001 Yes

Mass storage devices

10 IDE CD-ROM drive (48X) 266072-001 288894-005 Yes

11 Non-hot-plug 36-GB SCSI hard drive 357014-001 372659-005 Yes

12 Non-hot-plug 80-GB SATA hard drive 332649-003 373315-001 Yes

398344-001 384787-001 No

Spare part

number

Customer

self repair

Power

13 350-W power supply unit with cable assembly 377580-001 382097-001 Yes

14 3-V 200-mAh internal lithium battery for system

board

Cable assembly

15 IDE CD-ROM drive cable assembly* 385482-001 382972-001 Yes

16 SCSI drive cable assembly* 302377-001 384753-001 Yes

17 Non-hot-plug SATA cable assembly* 384735-001 389309-001 Yes

18 Hot-plug SATA/SAS cable assembly* 361316-009 386754-001 Yes

19 Power button/LED board cable assembly* 382630-001 382982-001 Yes

20 Front USB connector cable assembly* 382631-001 382984-001 Yes

- 234556-001 Yes

Illustrated parts catalog 9

Item Description Assembly

part number

21 Return kit* - 382204-001 Yes

* Not shown

Spare part

number

Customer

self repair

11

Removal and replacement procedures

In this section

Required tools...............................................................................................................................11

Safety considerations....................................................................................................................12

Preparation procedures .................................................................................................................15

Bezel.............................................................................................................................................17

Hot-plug SCSI hard drive.............................................................................................................17

Hot-plug SATA/SAS hard drive...................................................................................................18

Access panel .................................................................................................................................20

PCI expansion board.....................................................................................................................21

Battery ..........................................................................................................................................21

DIMM...........................................................................................................................................23

Air baffle ......................................................................................................................................25

Fan ................................................................................................................................................25

Power supply ................................................................................................................................27

Processor assembly.......................................................................................................................27

Diskette drive................................................................................................................................30

CD-ROM/DVD-ROM drive.........................................................................................................31

Installing a full-height tape drive option ......................................................................................32

Full-height tape drive....................................................................................................................34

Power button/LED board..............................................................................................................35

Hard drive (non-hot-plug) ............................................................................................................37

Hot-plug SCSI backplane.............................................................................................................38

Hot-plug SATA or SAS backplane ..............................................................................................40

System board ................................................................................................................................42

Required tools

You need the following items for some procedures:

• T-15 Torx screwdriver

• HP Insight Diagnostics software ("Array Diagnostic Utility" on page 49

Insight Diagnostics" on page 50

, "HP

)

12 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Safety considerations

Before performing service procedures, review all the safety information.

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you need to follow

when setting up the system or handling parts. A discharge of static electricity

from a finger or other conductor may damage system boards or other staticsensitive devices. This type of damage may reduce the life expectancy of the

device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe

containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-

free workstations.

• Place parts on a grounded surface before removing them from their

containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or

assembly.

Server warnings and cautions

Before installing a server, be sure that you understand the following warnings

and cautions.

WARNING: To reduce the risk of electric shock or damage to

the equipment:

Removal and replacement procedures 13

• Do not disable the power cord grounding plug. The grounding

plug is an important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet

that is easily accessible at all times.

• Unplug the power cord from the power supply to disconnect

power to the equipment.

• Do not route the power cord where it can be walked on or

pinched by items placed against it. Pay particular attention to

the plug, electrical outlet, and the point where the cord extends

from the server.

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the drives and the internal system components to

cool before touching them.

CAUTION: Do not operate the server for long periods with the

access panel open or removed. Operating the server in this manner

results in improper airflow and improper cooling that can lead to thermal

damage.

Warnings and cautions

WARNING: To reduce the risk of personal injury or damage to

the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack

installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become

unstable if more than one component is extended for any

reason.

WARNING: To reduce the risk of personal injury or equipment

damage when unloading a rack:

14 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

• At least two people are needed to safely unload the rack from

the pallet. An empty 42U rack can weigh as much as 115 kg

(253 lb), can stand more than 2.1 m (7 ft) tall, and may become

unstable when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp

from the pallet. Always handle the rack from both sides.

WARNING: When installing a server in a telco rack, be sure

that the rack frame is adequately secured to the top and bottom of

the building structure.

WARNING: This server is very heavy. To reduce the risk of

personal injury or damage to the equipment:

• Observe local occupational health and safety requirements and

guidelines for manual material handling.

• Get help to lift and stabilize the product during installation or

removal, especially when the product is not fastened to the

rails. When the server weighs more than 22.5 kg (50 lb), at least

two people must lift the server into the rack together. A third

person may be required to help align the server if the server is

installed higher than chest level.

• Use caution when installing the server in or removing the

server from the rack; it is unstable when not fastened to the

rails.

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the drives and the internal system components to

cool before touching them.

WARNING: To reduce the risk of personal injury, electric

shock, or damage to the equipment, remove the power cord to

remove power from the server. The front panel Power On/Standby

button does not completely shut off system power. Portions of the

power supply and some internal circuitry remain active until AC

power is removed.

CAUTION: Protect the server from power fluctuations and

temporary interruptions with a regulating uninterruptible power supply

(UPS). This device protects the hardware from damage caused by

power surges and voltage spikes and keeps the system in operation

during a power failure.

Removal and replacement procedures 15

CAUTION: Do not operate the server for long periods with the

access panel open or removed. Operating the server in this manner

results in improper airflow and improper cooling that can lead to thermal

damage.

Preparation procedures

List of topics:

Powering down the server ............................................................................................................15

Removing the server from the rack ..............................................................................................15

Unlocking the bezel......................................................................................................................16

Powering down the server

WARNING: To reduce the risk of personal injury, electric

shock, or damage to the equipment, remove the power cord to

remove power from the server. The front panel Power On/Standby

button does not completely shut off system power. Portions of the

power supply and some internal circuitry remain active until AC

power is removed.

IMPORTANT: If installing a hot-plug device, it is not necessary to

power down the server.

1. Shut down the OS as directed by the OS documentation.

2. Press the Power On/Standby button to place the server in standby mode.

When the server enters standby power mode, the system power LED changes

to amber.

3. Disconnect the power cords.

The system is now without power.

Removing the server from the rack

If the server is installed with an optional rack enabling kit, remove the server

from the rack before beginning any service procedures.

1. Power down the server ("Powering down the server" on page 15

).

16 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

2. Disconnect peripheral device and power cables.

3. Release the server from the tray.

4. Extend the server from the rack.

5. Remove the server from the tray and place it on a flat work surface.

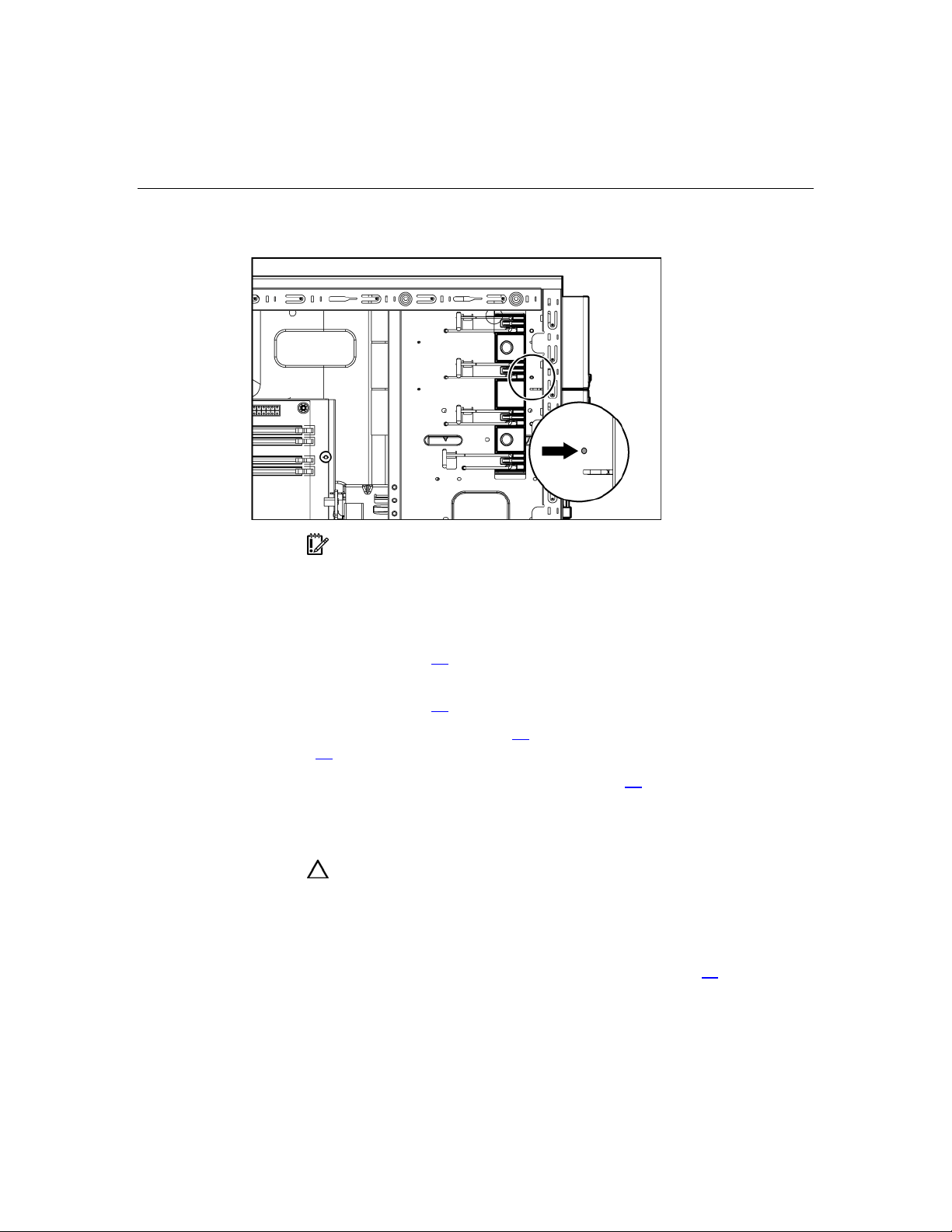

Unlocking the bezel

Unlock and open the bezel before accessing the hard drive cage and before

removing the access panel. Close and lock the bezel during normal server

operations to ensure proper cooling airflow.

Removal and replacement procedures 17

Bezel

To remove the component:

To replace the component, reverse the removal procedure.

Hot-plug SCSI hard drive

CAUTION: To prevent improper cooling and thermal damage, do

not operate the server unless all bays are populated with either a

component or a blank.

To remove the component:

1. Determine the status of the hard drive from the hot-plug hard drive LEDs

("Hot-plug SCSI hard drive LED combinations" on page 63

hard drive LEDs" on page 62

2. Unlock and open the bezel ("Unlocking the bezel" on page 16

, "Hot-plug SCSI

).

).

18 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

3. Remove the hard drive.

To replace the component:

1. Slide the drive into the cage until it clicks, locking the drive into place.

2. Close the lever.

IMPORTANT: When the drive is inserted, the drive LEDs flash for

2 seconds to indicate that the drive is seated properly and receiving

power.

3. As the drive begins to spin, be sure that the drive LEDs illuminate one at a

time and then turn off together to indicate that the system has recognized the

new drive.

In fault-tolerant configurations, allow the replacement drive to be

reconstructed automatically with data from the other drives. While

reconstruction is in progress, the online LED flashes.

Hot-plug SATA/SAS hard drive

Hot-plug SATA and hot-plug SAS hard drives can be used interchangeably when

a SAS controller is installed. The embedded SATA controller supports only

SATA drives.

Removal and replacement procedures 19

CAUTION: To prevent improper cooling and thermal damage, do

not operate the server unless all bays are populated with either a

component or a blank.

To remove the component:

1. Determine the status of the hard drive from the hot-plug hard drive LEDs

("Hot-plug SCSI hard drive LED combinations" on page 63

hard drive LEDs" on page 62

IMPORTANT: When hot-plug SATA hard drives are installed,

SATA LED functionality and full SATA hot-plug capability are not

supported with the embedded controller. For full LED and hot-plug

support, an optional SATA RAID or SAS controller must be installed.

).

, "Hot-plug SCSI

2. Unlock and open the bezel ("Unlocking the bezel" on page 16).

3. Remove the hard drive.

To replace the component:

1. Slide the drive into the cage until it clicks, locking the drive into place.

2. Close the lever.

IMPORTANT: When the drive is inserted, the drive LEDs flash for

2 seconds to indicate that the drive is seated properly and receiving

power.

20 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

3. As the drive begins to spin, be sure that the drive LEDs illuminate one at a

time and then turn off together to indicate that the system has recognized the

new drive.

In fault-tolerant configurations, allow the replacement drive to be

reconstructed automatically with data from the other drives. While

reconstruction is in progress, the online LED flashes.

NOTE: The SATA RAID feature supports the use of two hard

drives. When the feature is enabled on a system with three or more

drives installed, the system only recognizes the two drives with the

lowest drive numbers.

Access panel

WARNING: To reduce the risk of personal injury from hot

surfaces, allow the drives and the internal system components to

cool before touching them.

CAUTION: Do not operate the server for long periods with the

access panel open or removed. Operating the server in this manner

results in improper airflow and improper cooling that can lead to thermal

damage.

1. Power down the server ("Powering down the server" on page 15).

2. Remove the bezel ("Bezel" on page 17

).

3. Remove the access panel.

Removal and replacement procedures 21

To replace the component, reverse the removal procedure.

PCI expansion board

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

).

3. Remove the access panel ("Access panel" on page 20).

4. Remove the expansion board from the slot.

To replace the component, reverse the removal procedure.

).

Battery

If the server no longer automatically displays the correct date and time, you may

need to replace the battery that provides power to the real-time clock. Under

normal use, battery life is 5 to 10 years.

WARNING: The computer contains an internal lithium

manganese dioxide, a vanadium pentoxide, or an alkaline battery

pack. A risk of fire and burns exists if the battery pack is not

properly handled. To reduce the risk of personal injury:

22 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

• Do not attempt to recharge the battery.

• Do not expose the battery to temperatures higher than

60°C (140°F).

• Do not disassemble, crush, puncture, short external contacts,

or dispose of in fire or water.

• Replace only with the spare designated for this product.

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

).

).

4. Remove the battery.

To replace the component, reverse the removal procedure.

IMPORTANT: After replacing the battery, the server is

automatically configured with the default settings. The user can update

these settings using RBSU.

).

For more information about battery replacement or proper disposal, contact an

authorized reseller or an authorized service provider.

Removal and replacement procedures 23

DIMM

You can expand server memory by installing PC-3200 DDR SDRAM DIMMs

with Advanced ECC. The system supports up to four DIMMs for a maximum of

4 GB.

Refer to "System Board Components (on page 57

)" for DIMM slot locations and

bank assignments.

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

).

).

4. Remove the DIMM.

).

IMPORTANT: DIMMs do not seat fully if turned the wrong way.

To replace the component, reverse the removal procedure.

For DIMM configuration information, refer to DIMM installation guidelines (on

page 24

).

24 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

DIMM installation guidelines

Observe the following guidelines when installing additional memory:

• DIMMs installed in the server must be Unbuffered DDR DRAM, 2.5 volts,

64 bits wide, and ECC.

• If only a single DIMM is installed, it must be installed in slot 1A.

• All DIMMs installed must be the same speed.

BIOS detects the DIMM population and sets the system as follows:

• Single-channel mode: DIMMs installed in one channel only.

• Dual-channel asymmetric mode: DIMMs installed in both channels but of

unequal capacities per channel.

• Dual-channel interleaved mode: DIMMs installed in both channels with

equal channel capacities.

The following table lists some, but not all, possible configurations. For best

performance, HP recommends dual-channel interleaved mode configurations.

Slot 1A Slot 2A Slot 3B Slot 4B Total memory Mode

128 MB — — — 128 MB Single-channel

128 MB — 128 MB — 256 MB Dual-channel interleaved

128 MB 128 MB 128 MB — 384 MB Dual-channel

asymmetric

128 MB 128 MB 128 MB 128 MB 512 MB Dual-channel interleaved

256 MB — — — 256 MB Single-channel

256 MB — 256 MB — 512 MB Dual-channel interleaved

512 MB — — — 512 MB Single-channel

512 MB — 512 MB — 1 GB Dual-channel interleaved

1 GB — — — 1 GB Single-channel

1 GB — 1 GB — 2 GB Dual-channel interleaved

1 GB 1 GB 1 GB — 3 GB Dual-channel

asymmetric

Removal and replacement procedures 25

Slot 1A Slot 2A Slot 3B Slot 4B Total memory Mode

1 GB 1 GB 1 GB 1 GB 4 GB Dual-channel interleaved

Air baffle

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

).

).

4. Remove the air baffle.

To replace the component, reverse the removal procedure.

).

Fan

To remove the component:

1. Power down the server ("Powering down the server" on page 15

).

26 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

2. Remove the bezel ("Bezel" on page 17).

3. Remove the access panel ("Access panel" on page 20

4. Remove the air baffle ("Air baffle" on page 25

).

5. Remove the fan assembly.

6. Remove the fan from the holder.

).

To replace the component, reverse the removal procedure.

Removal and replacement procedures 27

Power supply

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

4. Remove the air baffle ("Air baffle" on page 25

).

).

).

5. Disconnect the power and data cables.

6. Remove the power supply.

).

To replace the component, reverse the removal procedure.

Processor assembly

IMPORTANT: To avoid damage to the processor and system

board, only authorized technicians trained by HP should attempt to

replace or install the processor in this server.

To remove the component:

1. Power down the server ("Powering down the server" on page 15).

28 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

2. Remove the bezel ("Bezel" on page 17).

3. Remove the access panel ("Access panel" on page 20

4. Disconnect the fan cable from the system board.

5. Remove the heatsink fan assembly

CAUTION: Heatsink retaining screws should be removed in

diagonally opposite pairs (in an "X" pattern).

CAUTION: The pins on the processor socket are very fragile. Any

damage to them may require replacing the system board.

).

Removal and replacement procedures 29

6. Remove the processor.

To replace the component:

1. Install the processor.

CAUTION: To prevent possible server malfunction or damage to

the equipment, be sure to align the processor pins with the

corresponding holes in the socket.

CAUTION: To prevent possible server malfunction or damage to

the equipment, be sure to completely close the processor locking lever.

30 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

2. Prepare the heatsink for installation:

– If reusing the heatsink, clean the bottom of the heatsink with the provided

alcohol pad, then apply a thin layer of thermal grease to the top of the

processor.

– If installing a new heatsink, remove the protective covering.

3. Install the heatsink fan assembly.

CAUTION: Heatsink retaining screws should be tightened in

diagonally opposite pairs (in an "X" pattern).

4. Connect the fan cable to the system board.

5. Install the access panel.

6. Install the bezel.

Diskette drive

not operate the server unless all bays are populated with either a

component or a blank.

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

CAUTION: To prevent improper cooling and thermal damage, do

).

).

Removal and replacement procedures 31

3. Remove the access panel ("Access panel" on page 20).

4. Disconnect the power and data cables.

5. Remove the diskette drive.

To replace the component, reverse the removal procedure.

CD-ROM/DVD-ROM drive

CAUTION: To prevent improper cooling and thermal damage, do

not operate the server unless all bays are populated with either a

component or a blank.

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

4. Disconnect the power and data cables.

).

).

).

32 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

5. Remove the CD-ROM or DVD-ROM drive.

To replace the component, reverse the removal procedure.

Installing a full-height tape drive option

1. Power down the server ("Powering down the server" on page 15).

2. Remove the bezel ("Bezel" on page 17

page 12

).

3. Remove the access panel ("Access panel" on page 20

4. Remove the media bay blanks ("Front panel components" on page 53

, "Server warnings and cautions" on

).

).

Removal and replacement procedures 33

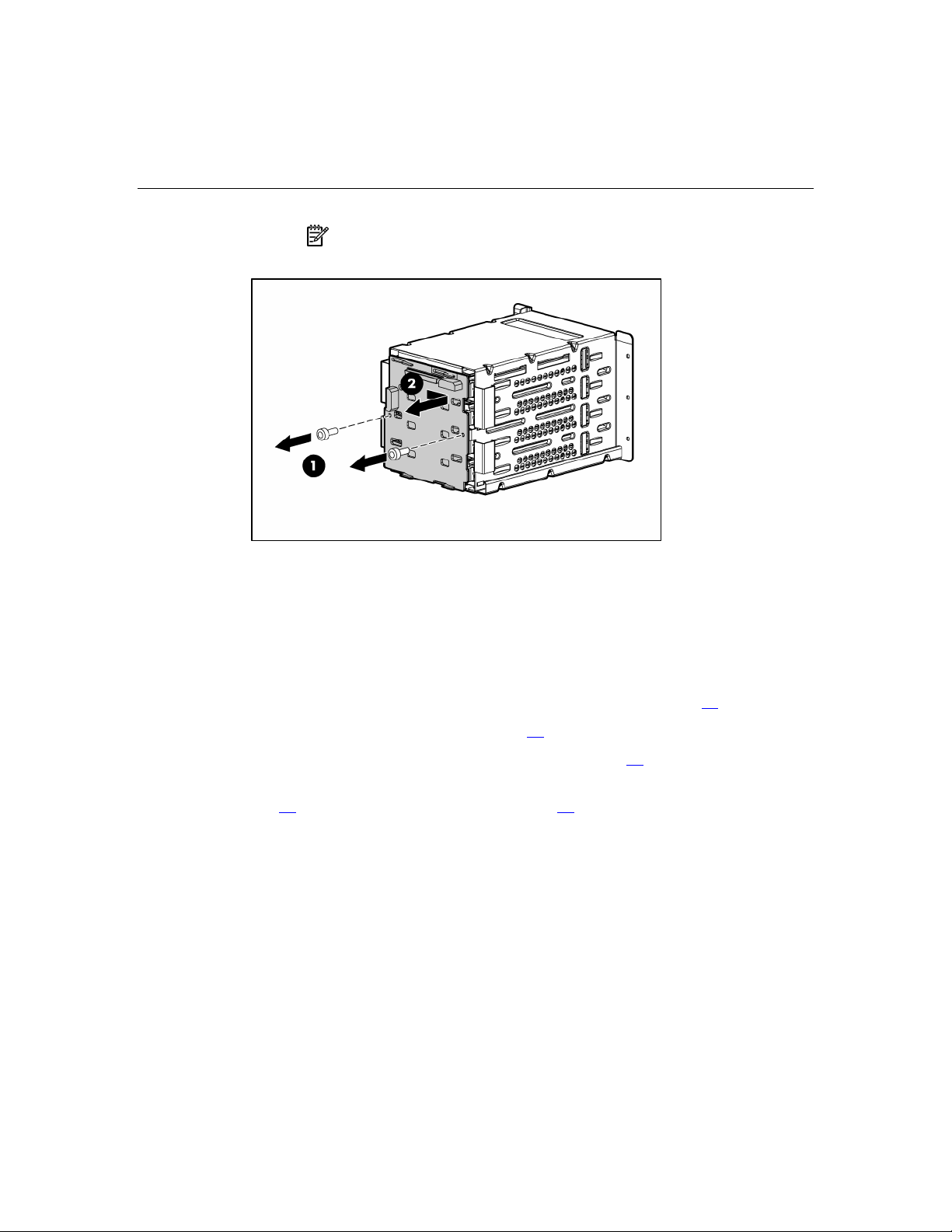

5. Use a screwdriver to disengage the two wire supports inside the full-height

drive bays.

6. Install the tape drive.

34 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

7. Install the retaining screw.

IMPORTANT: HP recommends installing the tape drive on a

separate SCSI cable to avoid a decrease in performance on other SCSI

devices.

8. Connect the data and power cables to the back of the tape drive.

9. Connect the data cable into a SCSI controller channel ("System board

components" on page 57

10. Remove the applicable bezel blanks from the bezel ("Front panel

components" on page 53

11. Install the bezel ("Bezel" on page 17

page 12

12. Replace the access panel ("Access panel" on page 20

).

Full-height tape drive

CAUTION: To prevent improper cooling and thermal damage, do

not operate the server unless all bays are populated with either a

component or a blank.

To remove the component:

1. Power down the server ("Powering down the server" on page 15

).

).

, "Server warnings and cautions" on

).

).

Removal and replacement procedures 35

2. Remove the bezel ("Bezel" on page 17).

3. Remove the access panel ("Access panel" on page 20

4. Disconnect the power and data cables.

5. Remove the tape drive.

To replace the component, reverse the removal procedure.

Power button/LED board

).

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

).

).

).

4. Disconnect the power and data cables.

36 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

5. Remove the front panel assembly.

6. Remove the power button/LED board.

To replace the component, reverse the removal procedure.

Removal and replacement procedures 37

Hard drive (non-hot-plug)

This procedure applies to non hot-plug drives only. If the server is equipped with

hot-plug hard drives, refer to the hot-plug hard drive removal procedures ("Hotplug SATA/SAS hard drive" on page 18

17

).

To remove the component:

, "Hot-plug SCSI hard drive" on page

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

4. Disconnect the power and data cables.

5. Remove the hard drive cage.

).

).

).

38 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

6. Remove the hard drive.

To replace the component, reverse the removal procedure.

Hot-plug SCSI backplane

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

).

).

).

4. Remove all hot-plug hard drives ("Hot-plug SATA/SAS hard drive" on page

, "Hot-plug SCSI hard drive" on page 17).

18

5. Disconnect the power and data cables.

Removal and replacement procedures 39

6. Remove the hard drive cage.

7. Remove the SCSI backplane.

40 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

NOTE: If replacing only the hard drive cage, retain the backplane

for use with the replacement hard drive cage.

To replace the component, reverse the removal procedure.

Hot-plug SATA or SAS backplane

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

).

).

).

4. Remove all hot-plug hard drives ("Hot-plug SATA/SAS hard drive" on page

, "Hot-plug SCSI hard drive" on page 17).

18

5. Disconnect the power and data cables.

Removal and replacement procedures 41

6. Remove the hard drive cage.

7. Remove the SATA or SAS backplane.

42 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

NOTE: If replacing only the hard drive cage, retain the backplane

for use with the replacement hard drive cage.

To replace the component, reverse the removal procedure.

System board

To remove the component:

1. Power down the server ("Powering down the server" on page 15

2. Remove the bezel ("Bezel" on page 17

3. Remove the access panel ("Access panel" on page 20

4. Remove the air baffle ("Air baffle" on page 25

).

).

).

).

5. Disconnect all cabling.

Removal and replacement procedures 43

6. Remove the system board.

To replace the component, reverse the removal procedure.

After you replace the system board, you must re-enter the server serial number

and the product ID.

1. During the server startup sequence, press the F9 key to access RBSU.

2. Select the Advanced Options menu.

3. Select Serial Number. The following warning is displayed:

Warning: The serial number should ONLY be modified by

qualified service personnel. This value should always

match the serial number located on the chassis.

4. Press the Enter key to clear the warning.

5. Enter the serial number.

6. Select Product ID. The following warning is displayed.

Warning: The Product ID should ONLY be modified by

qualified service personnel. This value should always

match the Product ID located on the chassis.

7. Enter the product ID and press the Enter key.

8. Press the Esc key to close the menu.

9. Press the Esc key to exit RBSU.

44 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

10. Press the F10 key to confirm exiting RBSU. The server will automatically

reboot.

45

Server cabling

In this section

Hot-plug SCSI cabling..................................................................................................................45

Hot-plug SATA cabling................................................................................................................46

Non-hot-plug SCSI cabling ..........................................................................................................46

Non-hot-plug SATA cabling ........................................................................................................47

SAS cabling..................................................................................................................................48

Hot-plug SCSI cabling

Item Cable description

1 Power cable

2 SCSI cable

46 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Hot-plug SATA cabling

Item Cable description

1 Power cable

2 SATA cable

Non-hot-plug SCSI cabling

Server cabling 47

Item Cable description

1 SCSI cable

2 Power cable

Non-hot-plug SATA cabling

Item Cable description

1 SATA cable

2 Power cable

48 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

SAS cabling

Item Cable description

1 Power cable

2 SAS cable

49

Diagnostic tools

In this section

Survey Utility ...............................................................................................................................49

Array Diagnostic Utility ...............................................................................................................49

HP Insight Diagnostics .................................................................................................................50

Integrated Management Log.........................................................................................................50

Survey Utility

Survey Utility, a feature within HP Insight Diagnostics ("Array Diagnostic

Utility" on page 49

information on ProLiant servers.

This utility supports operating systems that may not be supported by the server.

For operating systems supported by the server, refer to the HP website

(http://www.hp.com/go/supportos

, on page 50), gathers critical hardware and software

).

If a significant change occurs between data-gathering intervals, the Survey

Utility marks the previous information and overwrites the Survey text files to

reflect the latest changes in the configuration.

Survey Utility is installed with every SmartStart-assisted installation or can be

installed through the HP PSP.

Array Diagnostic Utility

ADU is tool that collects information about array controllers and generates a list

of detected problems. ADU can be accessed from the SmartStart CD or

downloaded from the HP website (http://www.hp.com

).

50 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

HP Insight Diagnostics

HP Insight Diagnostics is a proactive server management tool, available in both

offline and online versions, that provides diagnostics and troubleshooting

capabilities to assist IT administrators who verify server installations,

troubleshoot problems, and perform repair validation.

HP Insight Diagnostics Offline Edition performs various in-depth system and

component testing while the OS is not running. To run this utility, launch the

SmartStart CD.

HP Insight Diagnostics Online Edition is a web-based application that captures

system configuration and other related data needed for effective server

management. Available in Microsoft® Windows® and Linux versions, the utility

helps to ensure proper system operation.

For more information or to download the utility, refer to the HP website

(http://www.hp.com/servers/diags

).

Integrated Management Log

The IML records hundreds of events and stores them in an easy-to-view form.

The IML timestamps each event with 1-minute granularity.

You can view recorded events in the IML in several ways, including the

following:

• From within HP SIM ("HP Insight Diagnostics" on page 50

• From within Survey Utility (on page 49

• From within operating system-specific IML viewers

– For NetWare: IML Viewer

– For Windows®: IML Viewer

– For Linux: IML Viewer Application

• From within HP Insight Diagnostics ("Array Diagnostic Utility" on page 49

on page 50

)

)

)

,

Diagnostic tools 51

For more information, refer to the Management CD in the HP ProLiant Essentials

Foundation Pack.

53

Server component identification

In this section

Front panel components................................................................................................................53

Front panel LEDs and buttons......................................................................................................54

Rear panel components.................................................................................................................55

Rear panel LEDs and buttons .......................................................................................................56

System board components............................................................................................................57

System board LEDs......................................................................................................................59

System LEDs and internal health LED combinations ..................................................................60

SCSI IDs.......................................................................................................................................62

Hot-plug SCSI hard drive LEDs...................................................................................................62

Hot-plug SCSI hard drive LED combinations..............................................................................63

Hot-plug SATA or SAS IDs.........................................................................................................64

SATA or SAS hard drive LEDs ...................................................................................................65

Fan locations.................................................................................................................................66

Front panel components

54 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Item Description

1 Media bays (bezel blanks)

2 Power On/Standby button

3 Hard drive bays

4 USB connectors (2)

5 Bezel lock

6 CD-ROM drive

Front panel LEDs and buttons

Item Description Status

1 CD-ROM drive ejector

button

2 Power On/Standby button N/A

3 Power on/Standby LED Amber = System has AC power and is in standby mode

N/A

Green = System has AC power and is functioning

Off = System has no AC power

Server component identification 55

Item Description Status

4 Hard drive activity LED (for

non-hot-plug)

Green = Hard drives are properly connected and functioning

Off = No hard drive activity

5 NIC link/activity LED Green = Linked to network

Flashing green = Linked with activity on the network

Off = No network connection

6 Internal system health

LED

Green = Normal (system on)

Amber = System health is degraded

Red = System health is critical

Off = Normal (system off)

7 CD-ROM drive indicator

N/A

LED

Rear panel components

Item Description

1 Power cord connector

2 Mouse connector

3 Keyboard connector

56 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Item Description

4 Serial connector

5 Video connector

6 USB connectors (2)

7 RJ-45 Ethernet connector

8 Parallel connector

Rear panel LEDs and buttons

Item Description Status

1 10/100/1000 NIC link LED On = Link

Off = No link

2 10/100/1000 NIC standby LED Flashing =

Activity

Off = No activity

Server component identification 57

System board components

Item Description Item Description

1 Mouse/keyboard connectors 10 Diskette drive connector

2 Processor power connector 11 RILOE connector

3 Power supply connector 12 32-bit PCI slot

4 DIMM slot 4 (B) 13 PCI Express x4 slot *

5 DIMM slot 3 (B) 14 PCI-X slot 2

6 DIMM slot 2 (A) 15 PCI-X slot 1

7 DIMM slot 1 (A) 16 RJ-45 connector

8 IDE connector 17 USB connectors (2)

9 SATA connector 18 Serial/video/parallel ports

* x8 PCI Express cards are supported, but will run at x4 speeds.

System maintenance switch

Position Default Function

S1 Off Reserved

58 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Position Default Function

S2 Off Off = System configuration can

be changed

On = System configuration is

locked

S3 Off Reserved

S4 Off Reserved

S5 Off Off = No function

On = Clears power-on password

and administrator password

S6 Off Off = Normal

On = ROM treats system

configuration as invalid

When the system maintenance switch position 6 is set to the On position, the

system is prepared to erase all system configuration settings from both CMOS

and NVRAM.

CAUTION: Clearing CMOS and/or NVRAM deletes configuration

information. Be sure to properly configure the server or data loss could

occur.

Server component identification 59

System board LEDs

Item LED description Status

1 PPM failure Off = Normal

Amber = PPM failed or missing

2 Multibit error Off = Normal

Amber = A multibit error has occurred

3 Single bit error Off = Normal

Amber = Single bit error limit has been

exceeded

4 DIMM 4 failure Off = Normal

Amber = DIMM 4 has failed or is missing

5 DIMM 3 failure Off = Normal

Amber = DIMM 3 has failed or is missing

6 DIMM 2 failure Off = Normal

Amber = DIMM 2 has failed or is missing

7 DIMM 1 failure Off = Normal

Amber = DIMM 1 has failed or is missing

60 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Item LED description Status

8 Power good Off = Normal

Green = Power failed

9 Processor failure Off = Normal

Amber = Processor has failed

10 System temperature

alert

11 System fan failure Off = Normal

12 Processor fan failure Off = Normal

Off = Normal

Amber = System temperature has exceeded

OS cautionary level

Amber = System fan has failed or is missing

Amber = Processor fan has failed or is missing

System LEDs and internal health LED combinations

When the internal health LED on the front panel illuminates either amber or red,

the server is experiencing a health event. Combinations of illuminated system

LEDs and the internal health LED indicate system status.

NOTE: The system management driver must be installed in order

for the internal health LED to provide pre-failure and warranty

conditions.

The front panel health LEDs indicate only the current hardware status. In some

situations, HP SIM may report server status differently than the health LEDs

because the software tracks more system attributes.

System LED and

color

Internal health

LED color

Status

Processor failure,

socket X (Amber)

Amber Processor in socket X is in a pre-failure condition.

Red One or more of the following conditions may exist:

• Processor in socket X has failed.

• Processor X is not installed in the socket.

• ROM detected a failed processor during POST.

Server component identification 61

System LED and

color

PPM failure, slot X

(Amber)

Internal health

Status

LED color

Red • PPM in slot X has failed.

• PPM is not installed in slot X, but the corresponding

processor is installed.

DIMM failure, slot X

(Amber)

Red • DIMM in slot X has failed.

• DIMM has experienced a multi-bit error.

Amber • DIMM in slot X has reached single-bit correctable

error threshold.

• DIMM in slot X is in a pre-failure condition.

DIMM bank error (all

slots in one bank,

Red The bank is not populated entirely or DIMMs do not all

match within the bank.

Amber)

DIMM failure (all

slots, Amber)

System temperature

alert (Amber)

Red • No valid or usable memory is installed in the system.

• The banks are not populated in the correct order.

Red System temperature has exceeded OS cautionary level

or critical hardware level.

Fan (Amber) Red A required fan has failed.

Power supply

Amber A redundant fan has failed.

Red The power supply backplane has failed.

backplane failure

(Amber)

62 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

SCSI IDs

Hot-plug SCSI hard drive LEDs

Server component identification 63

Item LED description Status

1 Activity status On = Drive activity

Flashing = High activity on the drive or

drive is being configured as part of an

array.

Off = No drive activity

2 Online status On = Drive is part of an array and is

currently working.

Flashing = Drive is actively online.

Off = Drive is offline.

3 Fault status On = Drive failure

Flashing = Fault-process activity

Off = No fault-process activity

Hot-plug SCSI hard drive LED combinations

Activity

LED (1)

Online

LED (2)

Fault LED

(3)

Interpretation

On, off, or

On or off Flashing A predictive failure alert has been received for this drive.

flashing

On, off, or

On Off The drive is online and is configured as part of an array.

flashing

On or

Flashing Off

flashing

On Off Off

Replace the drive as soon as possible.

If the array is configured for fault tolerance and all other drives in

the array are online, and a predictive failure alert is received or a

drive capacity upgrade is in progress, you may replace the drive

online.

Do not remove the drive. Removing a drive may terminate the

current operation and cause data loss.

The drive is rebuilding or undergoing capacity expansion.

Do not remove the drive.

The drive is being accessed, but (1) it is not configured as part of an

array; (2) it is a replacement drive and rebuild has not yet started; or

(3) it is spinning up during the POST sequence.

64 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Activity

LED (1)

Flashing Flashing Flashing

Online

LED (2)

Fault LED

(3)

Interpretation

Do not remove the drive. Removing a drive may cause data

loss in non-fault-tolerant configurations.

Either (1) the drive is part of an array being selected by an array

configuration utility; (2) Drive Identification has been selected in

HP SIM; or (3) drive firmware is being updated.

Off Off On The drive has failed and has been placed offline.

You may replace the drive.

Off Off Off Either (1) the drive is not configured as part of an array; (2) the

drive is configured as part of an array, but it is a replacement drive

that is not being accessed or being rebuilt yet; or (3) the drive is

configured as an online spare.

If the drive is connected to an array controller, you may replace the

drive online.

Hot-plug SATA or SAS IDs

Server component identification 65

SATA or SAS hard drive LEDs

Item LED description Status

1 Fault/UID status Amber = Drive failure

Flashing amber = Fault-process activity

Blue = Unit identification is active

Off = No fault-process activity

2 Online/Activity status Green = Drive activity

Flashing green = High activity on the

drive or drive is being configured as part

of an array

Off = No drive activity

IMPORTANT: When hot-plug SATA hard drives are installed,

SATA LED functionality and full SATA hot-plug capability are not

supported with the embedded controller. For full LED and hot-plug

support, an optional SATA RAID or SAS controller must be installed.

66 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Fan locations

Item Description

1 System fan

2 Processor fan

67

Specifications

In this section

Server specifications.....................................................................................................................67

Environmental specifications .......................................................................................................68

Hot-plug power supply calculations.............................................................................................68

1.44-MB diskette drive specifications ..........................................................................................68

CD-ROM drive specifications......................................................................................................69

Server specifications

Specification Value

Dimensions

Height 43 cm (16.93 in)

Depth (w/o bezel) 50 cm (19.69 in)

Depth (w bezel) 54 cm (21.26 in)

Width 20 cm (7.87 in)

Weight (maximum) 22 kg (47.41 lb)

Weight (no drives installed) 16.5 kg (36.24 lb)

Input Requirements

Rated input voltage 100 VAC to 240 VAC *

Rated input frequency 47 Hz to 63 Hz

Rated input current 10 A (100 V) to 5 A (200 V)

Rated input power 1000 W

BTUs per hour 2730

Power Supply Output

Rated steady-state power 320 W

Maximum peak power 350 W

68 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

*10 A is required for 100 to 127 VAC; 5 A is required for 200 to 240 VAC.

Environmental specifications

Specification Value

Temperature range*

Operating

Shipping

Maximum wet bulb temperature

Relative humidity

(noncondensing)**

10°C to 35°C (50°F to 95°F)

-10°C to 60°C (14°F to 140°F)

28°C (82.4°F)

Operating 20% to 80%

Non-operating 20% to 90%

* All temperature ratings shown are for sea level. An altitude derating of 1°C per 300 m

(1.8°F per 1,000 ft) to 3048 m (10,000 ft) is applicable. No direct sunlight allowed.

** Storage maximum humidity of 95% is based on a maximum temperature of 45°C

(113°F). Altitude maximum for storage corresponds to a pressure minimum of 70 KPa.

Hot-plug power supply calculations

For power supply specifications and calculators to determine electrical and heat

loading for the server, refer to the HP Enterprise Configurator website

(http://h30099.www3.hp.com/configurator/

).

1.44-MB diskette drive specifications

Specification Value

Dimensions

Height 12.7 mm (0.5 in)

Width 96 mm (3.8 in)

Specifications 69

Specification Value

Depth 130 mm (5.1 in)

LEDs (front panel) Green = On

Read/write capacity per

diskette

High density 1.44 MB

Low density 720 KB

Drives supported 1

Drive height One-third height

Drive rotation 300 rpm

Transfer rate

High 500 Kb/s

Low 250 Kb/s

Bytes/sector 512

Sectors per track (high/low) 18/9

Tracks per side (high/low) 80/80

Access times

Track-to-track (high/low) 3 ms/6 ms

Average (high/low) 169 ms/94 ms

Setting time 15 ms

Latency average 100 ms

Cylinders (high/low) 80/80

Read/write heads 2

CD-ROM drive specifications

Specification Value

Disk formats CD-ROM (modes 1 and 2); mixed mode (audio and data combined); CD-DA;

Photo CD (single/multiple-session), CD-XA ready; CDi ready

70 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

Specification Value

Capacity 550 MB (mode 1, 12 cm)

Block size 2368, 2352 bytes (mode 0)

Dimensions

Height 12.7 mm (0.50 in)

Depth 132.08 mm (5.20 in)

Width 132.08 mm (5.20 in)

Weight 0.34 kg (0.75 lb)

Data transfer rate

Sustained 150 KB/s (sustained 1X), 1500/3600 KB/s (10X to 24X)

Burst 16.6 MB/s

Access times

(typical)

Full stroke 300 ms

Random 140 ms

Diameter 12 cm, 8 cm (4.70 in, 3.15 in)

Thickness 1.2 mm (0.05 in)

640 MB (mode 2, 12 cm)

2352, 2340, 2336, 2048 bytes (mode 1)

2352, 2340, 2336, 2048 bytes (mode 2)

Track pitch 1.6 µm (6.3 × 10-7 in)

Cache/buffer 128 KB

Startup time < 10 s

Stop time < 5 s (single); < 30 s (multisession)

Laser parameters

Type Semiconductor laser GaAs

Wave length 700 ± 25 nm

Divergence angle 53.5° ± 1.5°

Output power 0.14 mW

Specifications 71

Specification Value

Operating conditions

Temperature 5°C to 45°C (41°F to 118°F)

Humidity 5% to 90%

73

Acronyms and abbreviations

ABEND

abnormal end

ACU

Array Configuration Utility

ASR

Automatic Server Recovery

DDR

double data rate

DIMM

dual inline memory module

ECC

error checking and correcting

HBA

host bus adapter

IEC

International Electrotechnical Commission

74 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

iLO

Integrated Lights-Out

IML

Integrated Management Log

IPL

initial program load

IRQ

interrupt request

LDAP

Lightweight Directory Access Protocol

MPS

multi-processor specification

NEMA

National Electrical Manufacturers Association

NFPA

National Fire Protection Association

NIC

network interface controller

NMI

non-maskable interrupt

Acronyms and abbreviations 75

NVRAM

non-volatile memory

PCI-X

peripheral component interconnect extended

PDU

power distribution unit

POST

Power-On Self Test

PPM

Processor Power Module

PSP

ProLiant Support Pack

PXE

preboot eXecution environment

RAID

redundant array of inexpensive (or independent) disks

RBSU

ROM-Based Setup Utility

RILOE II

Remote Insight Lights-Out Edition II

76 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

SAS

serial attached SCSI

SATA

serial ATA

SCSI

small computer system interface

SDRAM

synchronous dynamic RAM

SIM

Systems Insight Manager

TMRA

recommended ambient operating temperature

UID

unit identification

VHDCI

very high density cable interconnect

WOL

Wake-on LAN

77

expansion slots 55

Index

F

fan assembly 25

A

AC power supply 27, 56

access panel 20

ADU (Array Diagnostic Utility) 49

air baffle 25

ASR (Automatic Server Recovery) 73

Automatic Server Recovery (ASR) 73

fan LED 62

fan zones 63

fans 25, 66

fans, replacing 25

front panel components 53

front panel LEDs 54

H

B

battery 21

bezel, removing 17

buttons 53

C

cabling 45, 46, 47, 48

CD-ROM drive 31, 69

components 53

connectors 53

CSR (customer self repair) 5

customer self repair 5

D

DC power supply 56

diagnostic tools 49, 50

diagnostics utility 50

DIMM slot locations 57

DIMMs 23

diskette drive 30, 68

drive LEDs 62, 63

DVD-ROM drive 31

E

electrostatic discharge 12

expansion boards 21

hard drive LEDs 62, 63

hard drive, replacing 17, 18, 37

hard drives 62, 63

hard drives, determining status of 62, 63

hard drives, removing 17, 18, 37

health LEDs 62

HP Insight Diagnostics 50

I

illustrated parts catalog 5

iLO (Integrated Lights-Out) 55

IML (Integrated Management Log) 50

Insight Diagnostics 50

K

keyboard connector 55

L

LEDs 53, 62, 63

LEDs, hard drive 62, 63

M

management tools 49

memory slot LEDs 60

memory slots 57

mouse connector 55

78 HP ProLiant ML310 Generation 2 Server Maintenance and Service Guide

N

network connector LEDs 56

NIC (network interface controller) 74

NIC LEDs 60

O

overtemperature LED 60, 63

P

parallel connector 55

power button/LED board 35

power cord connector 55

power supplies 27, 55, 56

power supply LEDs 56, 60

powering down 15

PPM failure LEDs 60, 63

preparation procedures 15

processor failure LEDs 60

processor fan assembly, removing 27

processor module 27

R

rear panel components 55

rear panel connectors 55

rear panel LEDs 56

RJ-45 connectors 55

RJ-45 network connector LEDs 56

specifications 67, 68

specifications, environmental 68

specifications, server 67

static electricity 12

Survey Utility 49

switches 57

system board 42, 57, 59

system board battery 21

system board LEDs 59

T

temperature, overtemperature LED 60, 63

tools 49, 55

U

UID LEDs 55, 56

USB connectors 55

utilities 49, 50

V

video connector 55

W

warnings 12, 13

S

safety considerations 12

SAS backplane 40

SAS cabling 48

SAS hard drive cabling 48

SAS-SATA hard drive cage 40

SATA backplane 40

SATA drives 64

SCSI backplane 38

serial connector 55

serial number 55

spare part numbers 6, 7

Loading...

Loading...