Page 1

HP ProLiant DL580 Generation 2 Server

Maintenance and Service Guide

January 2004 (Fifth Edition)

Part Number 230828-005

Page 2

© Copyright 2003 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and

services are set forth in the express warranty statements accompanying such products and services. Nothing herein

should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors

or omissions contained herein.

Microsoft, Windows, and Windows NT are U.S. registered trademarks of Microsoft Corporation. Intel, Pentium,

and Itanium are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States

and other countries. UNIX is a registered trademark of The Open Group. Linux is a U.S. registered trademark of

Linus Torvalds.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

January 2004 (Fifth Edition)

Part Number 230828-005

Page 3

Contents

About This Guide

Audience Assumptions.................................................................................................................................ix

Technician Notes..........................................................................................................................................ix

Where to Go for Additional Help..................................................................................................................x

Integrated Management Log...................................................................................................................x

Telephone Numbers................................................................................................................................x

Chapter 1

Illustrated Parts Catalog

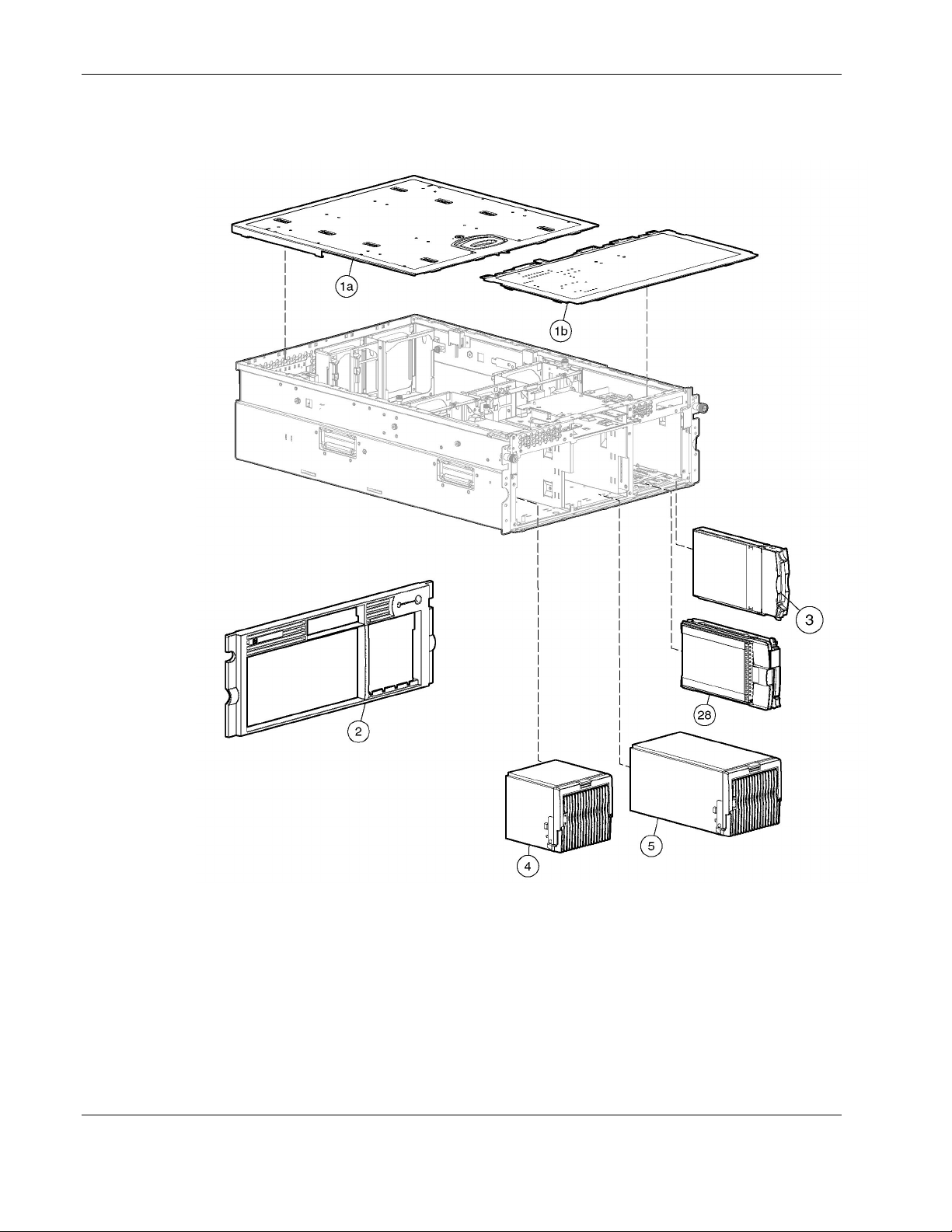

Mechanical Components Exploded View ................................................................................................. 1-2

Mechanical Components Spare Parts List................................................................................................. 1-3

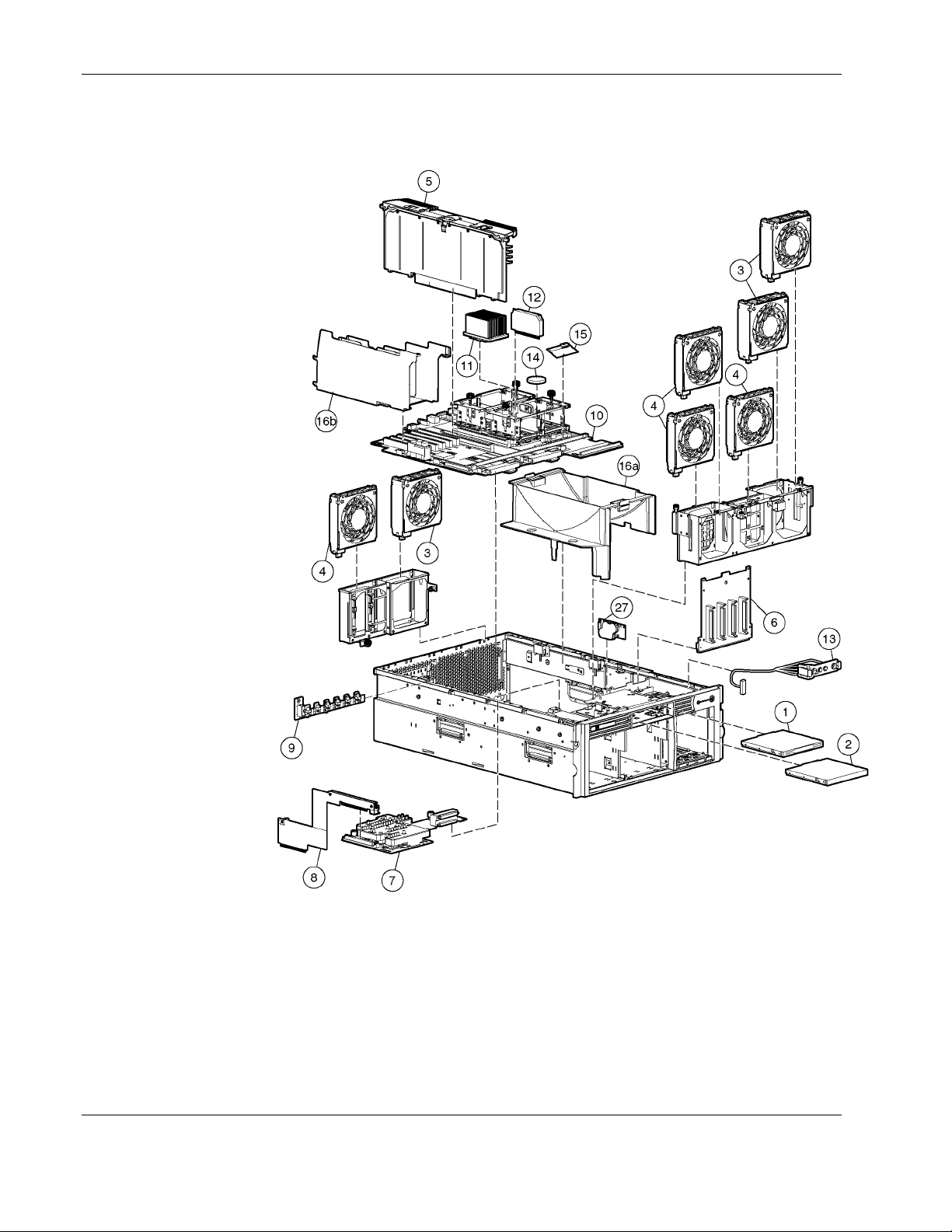

System Components Exploded View ........................................................................................................ 1-4

System Components Spare Parts List........................................................................................................ 1-5

Chapter 2

Removal and Replacement Procedures

Safety Considerations................................................................................................................................ 2-1

Electrostatic Discharge ....................................................................................................................... 2-1

Symbols on Equipment....................................................................................................................... 2-2

Rack Warnings and Cautions.............................................................................................................. 2-2

Server Warnings and Cautions............................................................................................................ 2-3

Preparation Procedures.............................................................................................................................. 2-4

Locating and Removing the Torx T-15 Tool...................................................................................... 2-5

Extending the Server from the Rack................................................................................................... 2-6

Opening and Removing the Rear Access Panel.................................................................................. 2-8

Removing the Front Access Panel .................................................................................................... 2-10

Replacing the Access Panels............................................................................................................. 2-11

Powering Down the Server ............................................................................................................... 2-13

Removing the Server from the Rack................................................................................................. 2-13

Memory ................................................................................................................................................... 2-15

Memory Replacement Guidelines..................................................................................................... 2-15

Memory Board Slot Locations.......................................................................................................... 2-16

Parts of the Memory Board............................................................................................................... 2-17

Memory Board LEDs and Icons ....................................................................................................... 2-18

DIMM Installation Requirements..................................................................................................... 2-22

Removing a Memory Board.............................................................................................................. 2-23

Removing a DIMM........................................................................................................................... 2-25

Installing a DIMM ............................................................................................................................ 2-26

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide iii

Page 4

Contents

Installing a Memory Board................................................................................................................2-27

Configuring the Memory...................................................................................................................2-28

Hot-Plug Procedures ................................................................................................................................2-30

Hard Drive Blanks.............................................................................................................................2-30

Hot-Plug SCSI Hard Drives ..............................................................................................................2-31

Power Supply Blank..........................................................................................................................2-33

Hot-Plug Power Supplies ..................................................................................................................2-34

PCI and PCI-X Hot Plug Expansion Boards .....................................................................................2-35

Performance Balancing .....................................................................................................................2-39

Hot-Plug Fans....................................................................................................................................2-40

Non-Hot-Plug Procedures........................................................................................................................2-41

Slimline Drives..................................................................................................................................2-42

Front Bezel ........................................................................................................................................2-43

Power Button/LED assembly ............................................................................................................2-45

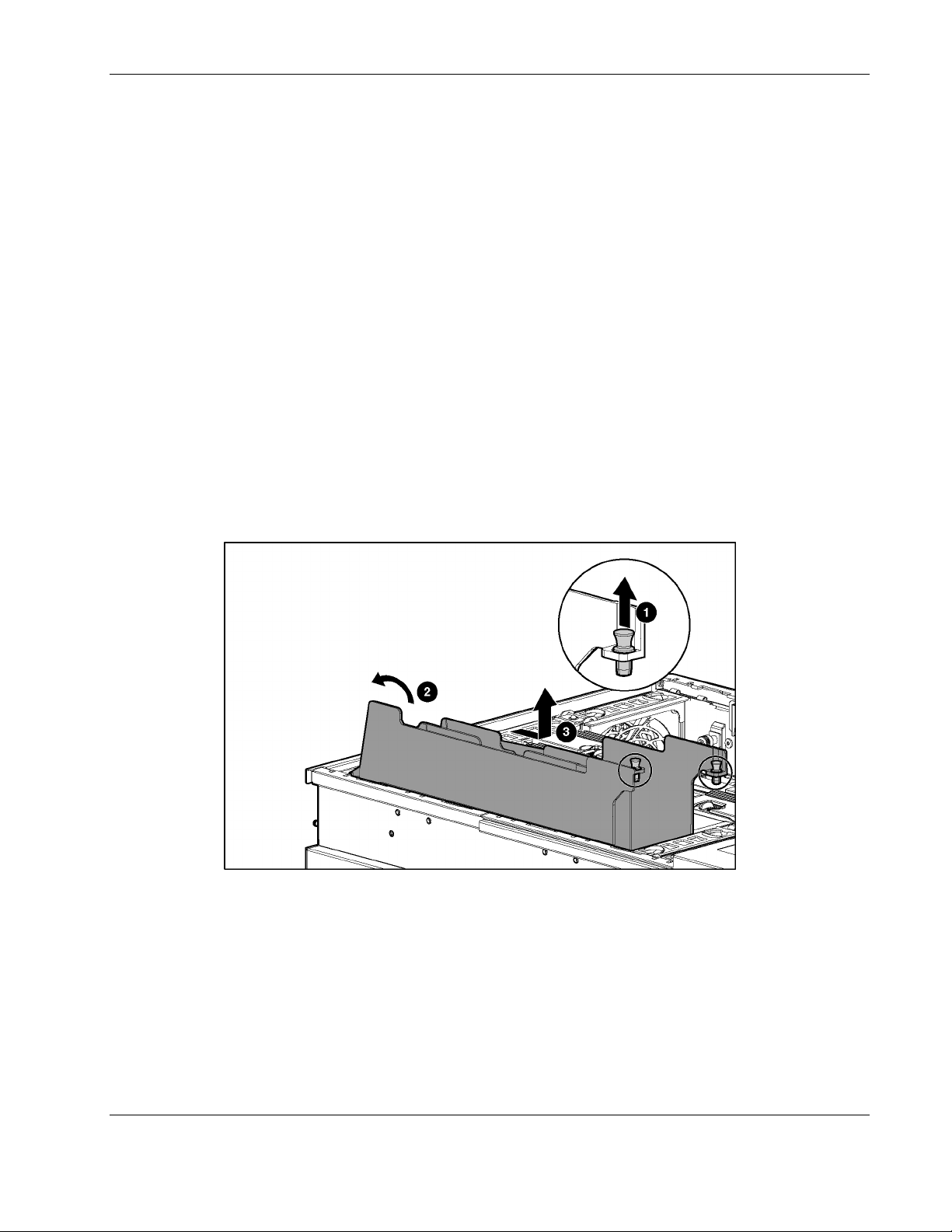

Processor Air Baffle ..........................................................................................................................2-46

Processor Power Modules .................................................................................................................2-47

Processors..........................................................................................................................................2-49

Non-Hot-Plug PCI-X Expansion Boards...........................................................................................2-51

PCI-X Expansion Board Basket ........................................................................................................2-53

PCI-X Hot Plug Board ......................................................................................................................2-54

SCSI Cables.......................................................................................................................................2-55

Front Fan Cage ..................................................................................................................................2-56

Pass-Through Board..........................................................................................................................2-57

Diagnostics Display Board and Lightpipe.........................................................................................2-58

Rear Fan Cage ...................................................................................................................................2-59

Battery-Backed Write Cache Assembly............................................................................................2-60

SCSI Backplane.................................................................................................................................2-62

System Battery ..................................................................................................................................2-63

System Board ....................................................................................................................................2-65

AC Filter Cable Assembly.................................................................................................................2-68

Re-entering the Server Serial Number.....................................................................................................2-71

Chapter 3

Diagnostic Tools

Chapter 4

Connectors, LEDs, and Switches

Connectors .................................................................................................................................................4-1

Rear Panel............................................................................................................................................4-2

System Board ......................................................................................................................................4-3

SCSI Backplane Board........................................................................................................................4-4

Memory Board ....................................................................................................................................4-5

LEDs ..........................................................................................................................................................4-6

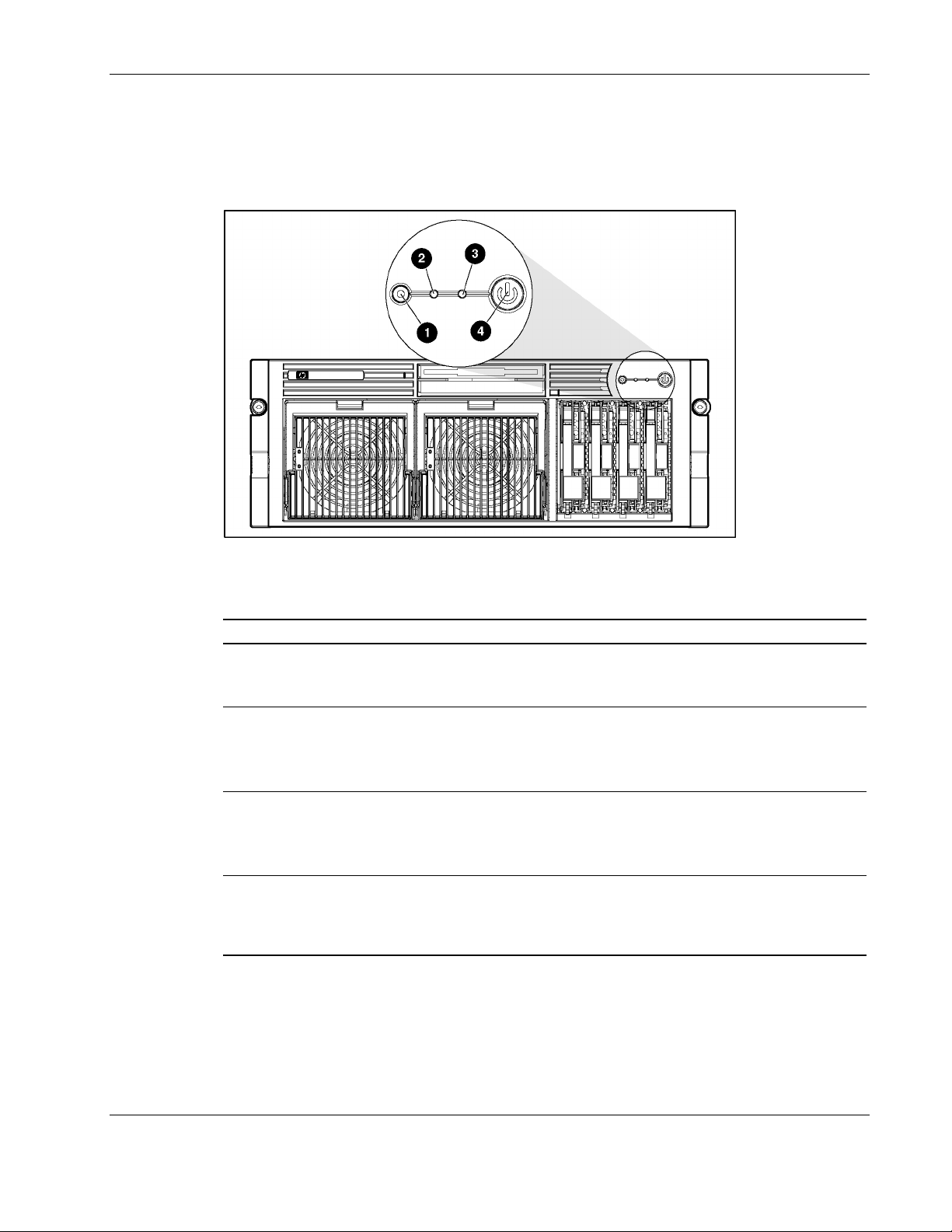

Front Panel ..........................................................................................................................................4-7

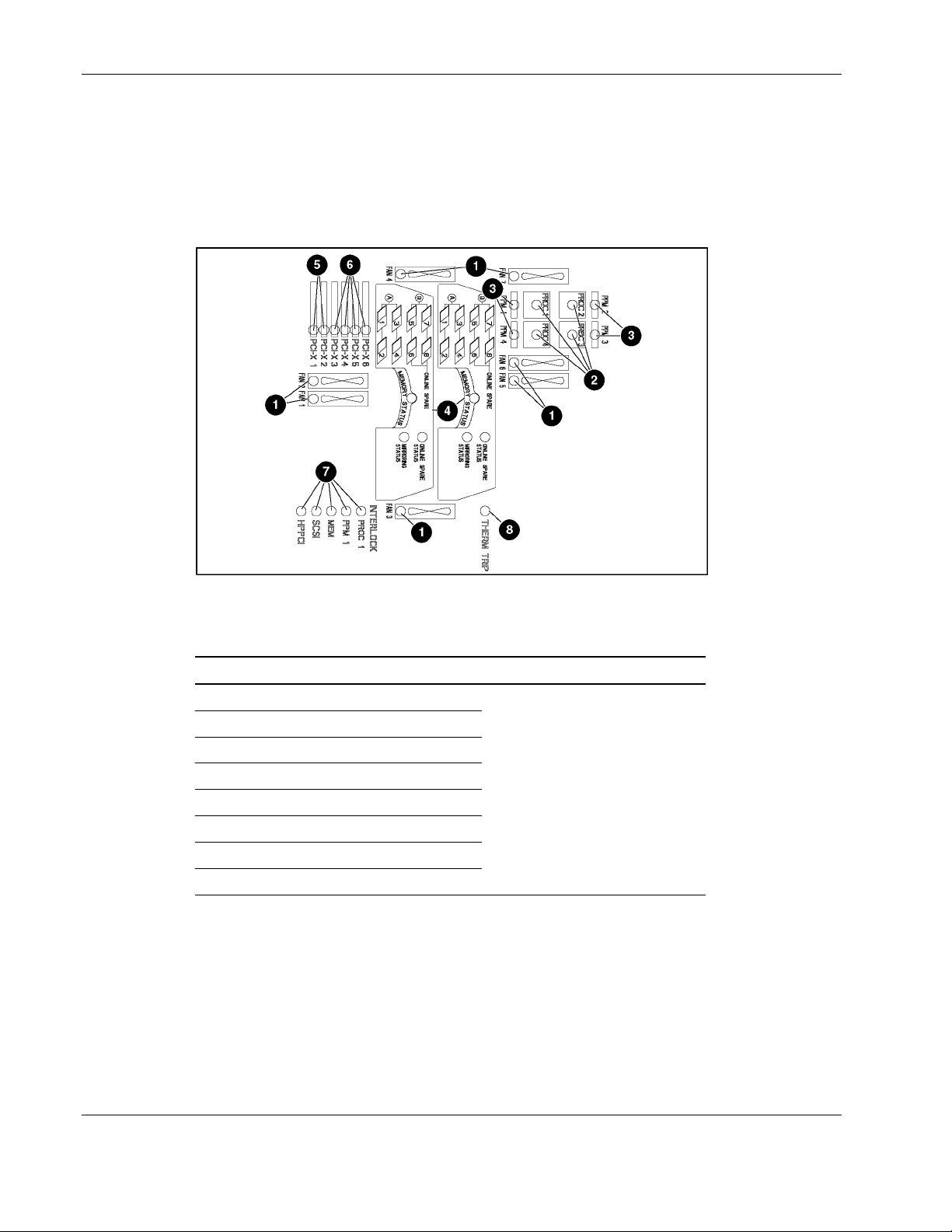

QuickFind Diagnostic Display ............................................................................................................4-8

Interlock Status....................................................................................................................................4-9

Hot-Plug SCSI Hard Drive................................................................................................................4-10

Hot-Plug Fan .....................................................................................................................................4-12

Hot-Plug Power Supplies ..................................................................................................................4-13

iv HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 5

PCI-X Hot Plug................................................................................................................................. 4-14

Network Interface Controller............................................................................................................ 4-15

Battery-Backed Write Cache Enabler ..................................................................................................... 4-17

Memory Board.................................................................................................................................. 4-18

Internal Diagnostic Display .............................................................................................................. 4-22

System Board Switches........................................................................................................................... 4-23

System Maintenance Switch (SW4) .................................................................................................4-24

System ID Switch (SW7).................................................................................................................. 4-26

iLO/Spread Spectrum Switch (SW8)................................................................................................4-27

Non-Maskable Interrupt (NMI) Switch ............................................................................................ 4-28

Rear Unit Identification LED Switch...................................................................................................... 4-29

NC7770 PCI-X Gigabit Server Adapter Jumper ..................................................................................... 4-30

Chapter 5

Troubleshooting

When the Server Does Not Start ............................................................................................................... 5-2

Diagnostic Steps........................................................................................................................................ 5-4

Problems After Initial Boot ....................................................................................................................... 5-9

ROMPaq Disaster Recovery.................................................................................................................... 5-11

Other Information Resources .................................................................................................................. 5-12

Contents

Chapter 6

Specifications

Index

List of Figures

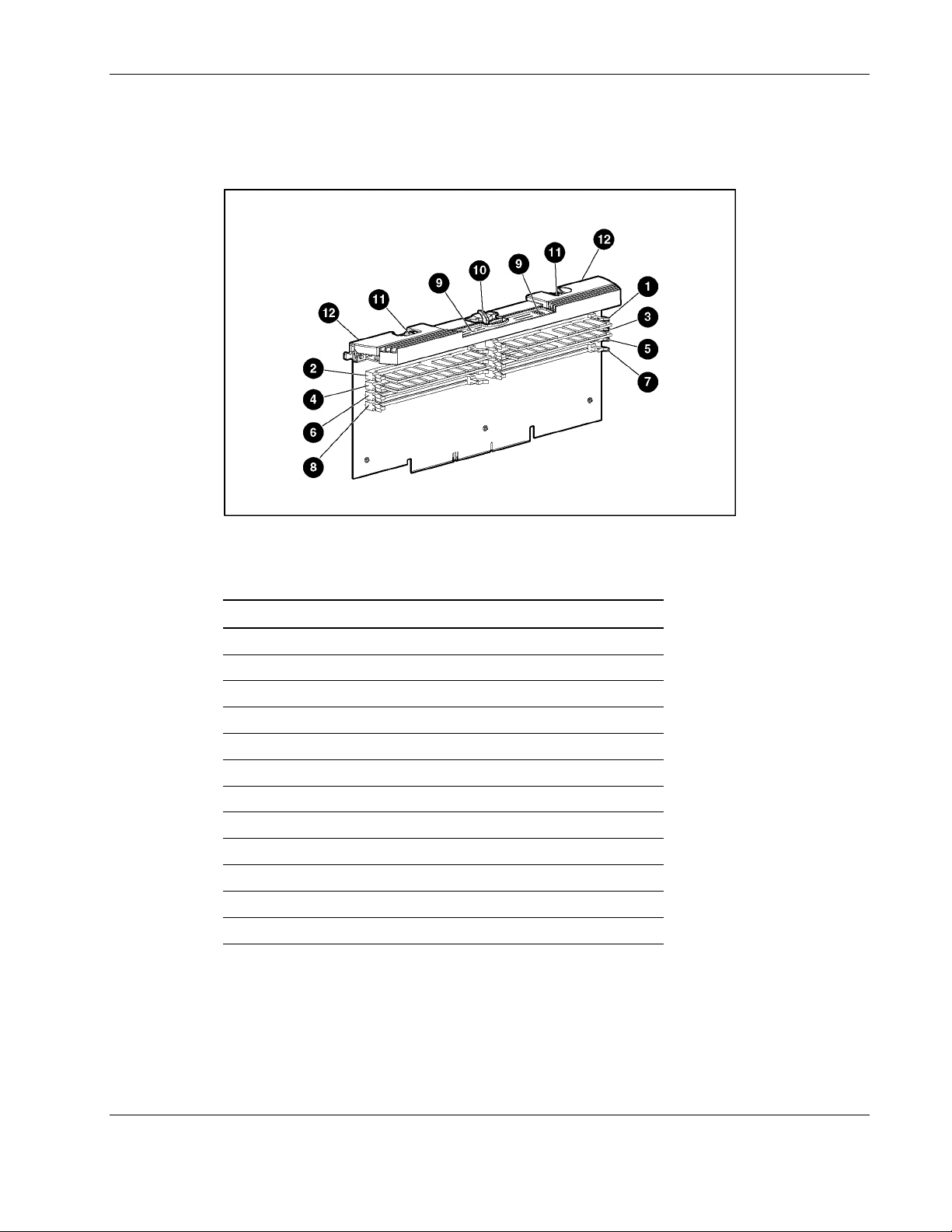

1-1 Mechanical components exploded view ............................................................................................. 1-2

1-2 System components exploded view .................................................................................................... 1-4

2-1 Locating and removing the Torx T-15 tool......................................................................................... 2-5

2-2 Loosening the front panel thumbscrews ............................................................................................. 2-6

2-3 Extending the server from the rack..................................................................................................... 2-6

2-4 Returning the server back into the rack .............................................................................................. 2-7

2-5 Unlocking and sliding the rear access panel open .............................................................................. 2-8

2-6 Opening the rear access panel............................................................................................................. 2-9

2-7 Removing the rear access panel.......................................................................................................... 2-9

2-8 Removing the front access panel ...................................................................................................... 2-10

2-9 Replacing the front access panel....................................................................................................... 2-11

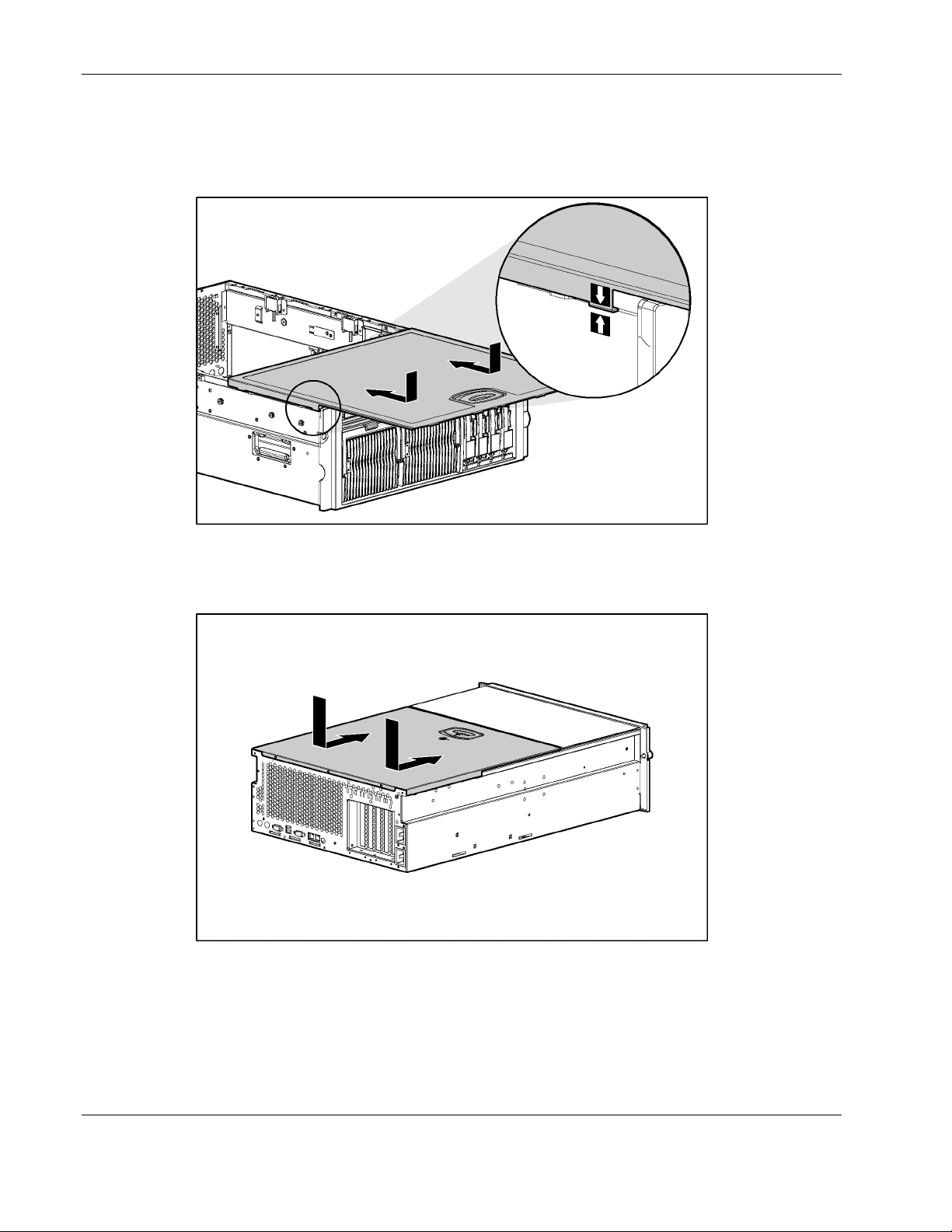

2-10 Lining up the guide marks ................................................................................................................ 2-12

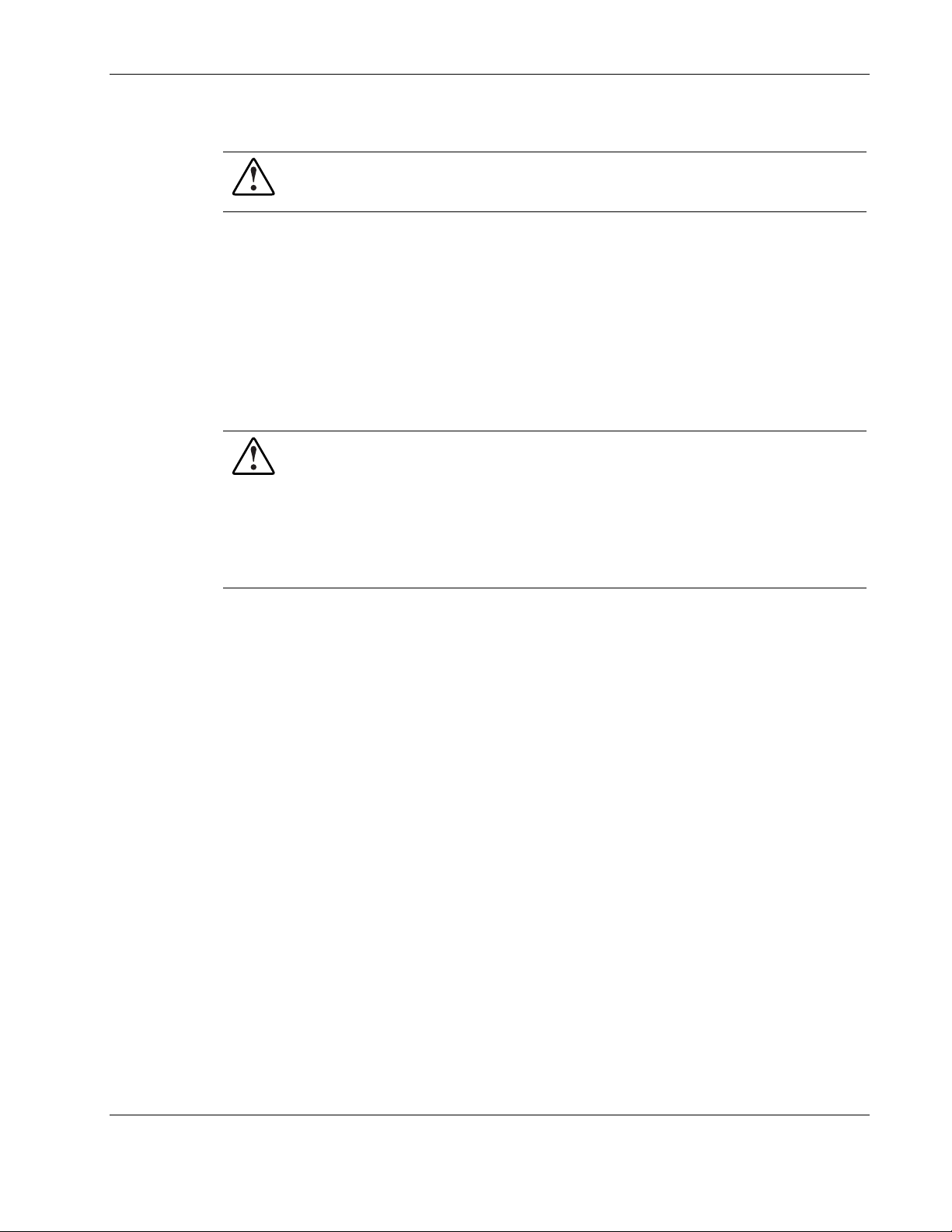

2-11 Installing the rear access panel ......................................................................................................... 2-12

2-12 Removing the server from the rack................................................................................................... 2-14

2-13 Memory board slots .......................................................................................................................... 2-16

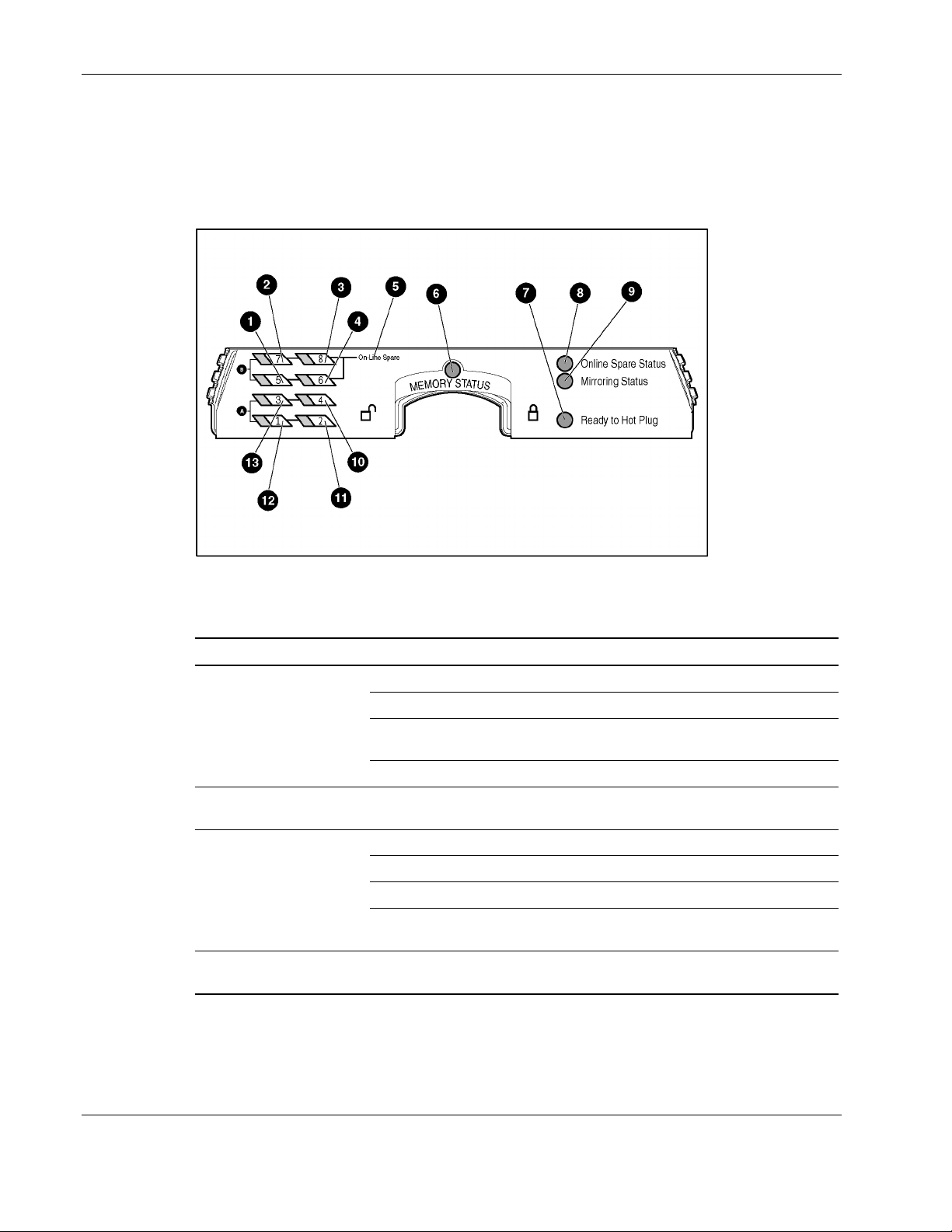

2-14 Parts of the memory board................................................................................................................ 2-17

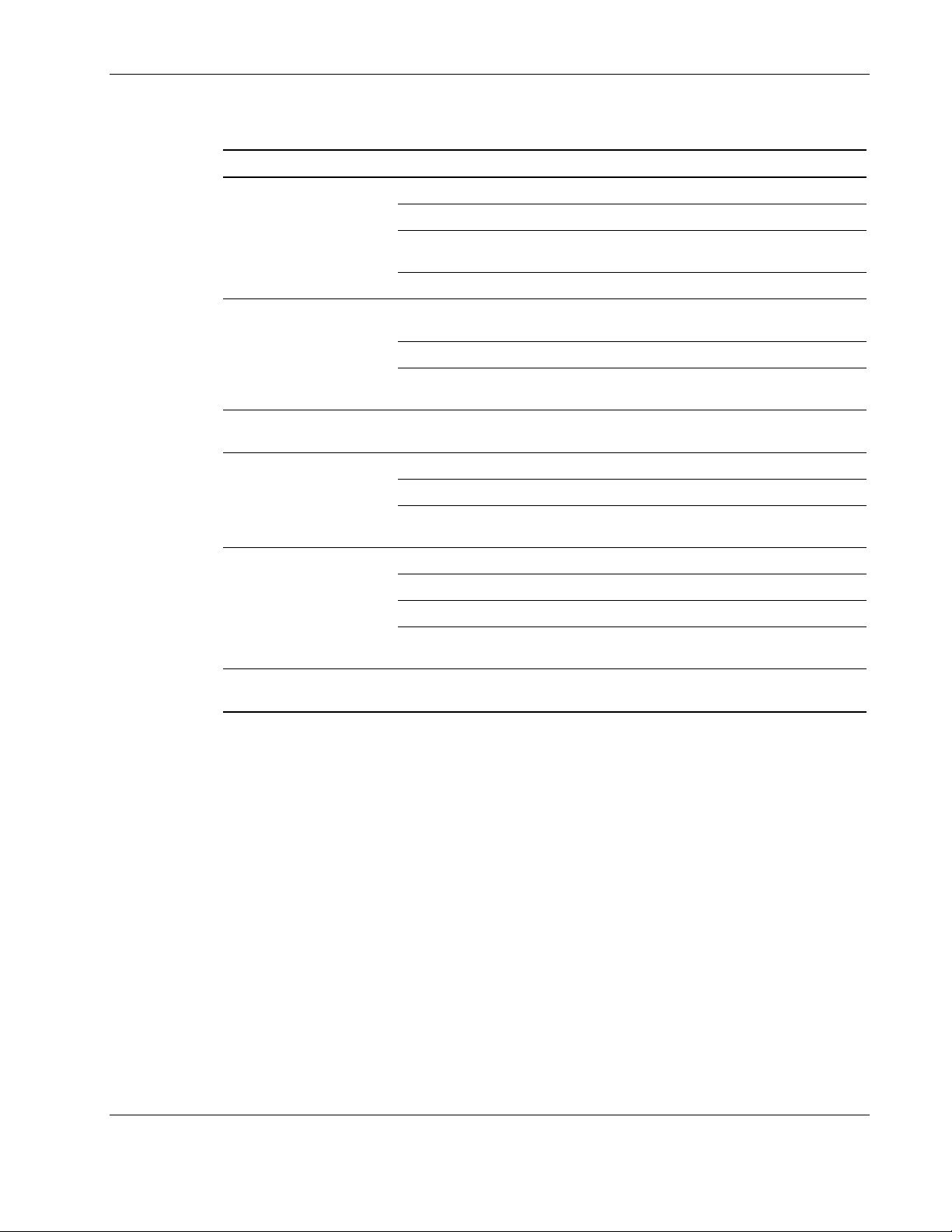

2-15 Memory board LEDs and icons ........................................................................................................ 2-18

2-16 Removing a memory board............................................................................................................... 2-24

2-17 Removing a DIMM........................................................................................................................... 2-25

2-18 Installing a DIMM ............................................................................................................................ 2-26

2-19 Installing a memory board ................................................................................................................ 2-27

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide v

Page 6

Contents

2-20 Removing a drive blank ....................................................................................................................2-30

2-21 Removing a hot-plug SCSI hard drive ..............................................................................................2-32

2-22 Removing a power supply blank .......................................................................................................2-33

2-23 Removing a hot-plug power supply ..................................................................................................2-34

2-24 PCI-X slot locations ..........................................................................................................................2-36

2-25 PCI-X Hot Plug button......................................................................................................................2-37

2-26 Pressing the PCI-X retaining clip......................................................................................................2-37

2-27 Removing a PCI-X Hot Plug expansion board..................................................................................2-38

2-28 Removing a hot-plug fan...................................................................................................................2-40

2-29 Removing a drive from a slimline drive bay .....................................................................................2-42

2-30 Removing the exterior and interior chassis screws ...........................................................................2-43

2-31 Disengaging the locking tabs and removing the front bezel .............................................................2-44

2-32 Removing the power button/LED assembly......................................................................................2-45

2-33 Removing the processor air baffle.....................................................................................................2-46

2-34 Opening the processor retaining bracket ...........................................................................................2-47

2-35 Removing a PPM...............................................................................................................................2-48

2-36 Opening the processor retaining bracket ...........................................................................................2-49

2-37 Removing the processor/heatsink assembly......................................................................................2-50

2-38 Pressing the PCI-X retaining clip......................................................................................................2-51

2-39 Removing an expansion board from a non-hot-plug slot ..................................................................2-52

2-40 Removing the expansion board basket..............................................................................................2-53

2-41 Removing the PCI-X Hot Plug board................................................................................................2-54

2-42 Disconnecting SCSI cables from the backplane and expansion boards ............................................2-55

2-43 Removing the front fan cage .............................................................................................................2-56

2-44 Removing the pass-through board.....................................................................................................2-57

2-45 Removing the removable media board..............................................................................................2-58

2-46 Removing the rear fan cage...............................................................................................................2-59

2-47 Removing the BBWC enabler and 5i Plus Memory Module ............................................................2-61

2-48 Removing the SCSI backplane..........................................................................................................2-62

2-49 Locating the battery on the system board..........................................................................................2-63

2-50 Removing the battery from the system board....................................................................................2-64

2-51 Unscrewing the thumbscrews and sliding the system board .............................................................2-66

2-52 Removing the system board from the chassis ...................................................................................2-67

2-53 Cutting the cable tie-wraps................................................................................................................2-69

2-54 Removing the cable clips...................................................................................................................2-69

2-55 Removing the power supply connectors............................................................................................2-70

2-56 Removing the AC filters....................................................................................................................2-70

4-1 Rear panel components .......................................................................................................................4-2

4-2 System board connectors.....................................................................................................................4-3

4-3 SCSI backplane board connectors.......................................................................................................4-4

4-4 Memory board connectors and DIMM banks......................................................................................4-5

4-5 Front panel LEDs ................................................................................................................................4-7

4-6 QuickFind Diagnostic Display LEDs..................................................................................................4-8

4-7 Interlock LEDs ....................................................................................................................................4-9

4-8 Hot-plug SCSI hard drive LEDs........................................................................................................4-10

4-9 Hot-plug fan LED..............................................................................................................................4-12

4-10 Hot-plug power supply LEDs............................................................................................................4-13

4-11 External PCI-X Hot Plug LEDs ........................................................................................................4-14

4-12 Network Interface Controller LEDs ..................................................................................................4-15

vi HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 7

Contents

4-13 Internal PCI Hot Plug LEDs and button ........................................................................................... 4-16

4-14 Battery-Backed Write Cache Enabler LEDs..................................................................................... 4-17

4-15 Memory board LEDs ........................................................................................................................ 4-18

4-16 Internal diagnostic display LEDs and switches ................................................................................ 4-22

4-17 System maintenance switch (SW4) .................................................................................................. 4-24

4-18 System ID switch (SW7) .................................................................................................................. 4-26

4-19 iLO/Spread Spectrum switch (SW8) ................................................................................................ 4-27

4-20 Non-Maskable Interrupt (NMI) switch............................................................................................. 4-28

4-21 Rear Unit Identification LED switch ................................................................................................ 4-29

4-22 NC7770 PCI-X Gigabit Server Adapter jumper settings.................................................................. 4-30

List of Tables

1-1 Mechanical Components Spare Parts List .......................................................................................... 1-3

1-2 System Components Spare Parts List ................................................................................................. 1-5

2-1 Memory Board Slots......................................................................................................................... 2-16

2-2 Parts of the Memory Board............................................................................................................... 2-17

2-3 Advanced ECC (Standard) Memory LEDs....................................................................................... 2-18

2-4 Online Spare Memory LEDs ............................................................................................................ 2-19

2-5 Single-Board Mirrored Memory LEDs............................................................................................. 2-20

2-6 Hot-Plug Mirrored Memory LEDs ................................................................................................... 2-21

2-7 Memory Board Icons ........................................................................................................................ 2-21

2-8 Memory LED States on a Properly Configured Memory Board ...................................................... 2-28

2-9 ProLiant DL580 Generation 2 PCI-X Expansion Slots and Buses................................................... 2-36

2-10 Recommended PCI-X Expansion Slot Population Order ................................................................. 2-39

3-1 Diagnostic Tools................................................................................................................................. 3-2

4-1 Rear Panel Components...................................................................................................................... 4-2

4-2 System Board Connectors................................................................................................................... 4-3

4-3 SCSI Backplane Board Connectors .................................................................................................... 4-4

4-4 Memory Board Connectors and DIMM Banks................................................................................... 4-5

4-5 Front Panel LEDs................................................................................................................................ 4-7

4-6 QuickFind Diagnostic Display LEDs ................................................................................................. 4-8

4-7 Interlock LEDs.................................................................................................................................... 4-9

4-8 Hot-Plug SCSI Hard Drive LEDs..................................................................................................... 4-10

4-9 Hot-Plug SCSI Hard Drive LED Combinations ............................................................................... 4-11

4-10 Hot-Plug Power Supply LEDs.......................................................................................................... 4-13

4-11 External PCI-X Hot Plug LEDs........................................................................................................ 4-14

4-12 Network Interface Controller LEDs.................................................................................................. 4-15

4-13 Internal PCI Hot Plug LEDs and Button........................................................................................... 4-16

4-14 Battery-Backed Write Cache Enabler LEDs..................................................................................... 4-17

4-15 Advanced ECC (Standard) Memory LEDs....................................................................................... 4-18

4-16 Online Spare Memory LEDs ............................................................................................................ 4-19

4-17 Single-Board Mirrored Memory LEDs............................................................................................. 4-20

4-18 Hot-Plug Mirrored Memory LEDs ................................................................................................... 4-21

4-19 Internal diagnostic display switches ................................................................................................. 4-22

4-20 System Maintenance Switch (SW4) ................................................................................................. 4-25

4-21 System ID Switch (SW7).................................................................................................................. 4-26

4-22 iLO/Spread Spectrum Switch (SW8)................................................................................................ 4-27

5-1 Diagnostic Steps ................................................................................................................................. 5-4

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide vii

Page 8

Contents

5-2 Is the System Power LED Off? ...........................................................................................................5-5

5-3 Is the System Power LED Green?.......................................................................................................5-6

5-4 Is the External Health LED Green?.....................................................................................................5-6

5-5 Is the Internal Health LED Green?......................................................................................................5-7

5-6 Is the Monitor Displaying Information?..............................................................................................5-8

5-7 Problems After Initial Boot .................................................................................................................5-9

5-8 Troubleshooting Resources ...............................................................................................................5-12

6-1 System Unit Specifications..................................................................................................................6-1

viii HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 9

This maintenance and service guide can be used for reference when servicing the HP

ProLiant DL580 Generation 2 server.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, only authorized service technicians should attempt to repair this

equipment. Improper repairs can create conditions that are hazardous.

Audience Assumptions

This guide is for service technicians. HP assumes you are qualified in the servicing of

computer equipment and trained in recognizing hazard in products with hazardous energy

levels and are familiar with weight and stability precautions for rack installations.

Technician Notes

WARNING: Only authorized technicians trained by HP should attempt to repair this

equipment. All troubleshooting and repair procedures are detailed to allow only

subassembly/module-level repair. Because of the complexity of the individual boards

and subassemblies, no one should attempt to make repairs at the component level or

to make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, do not exceed the level of repairs specified in these procedures.

Because of the complexity of the individual boards and subassemblies, do not attempt

to make repairs at the component level or to make modifications to any printed wiring

board. Improper repairs can create conditions that are hazardous.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Disconnect power from the system by unplugging all power cords from the power

supplies.

• Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

CAUTION: To properly ventilate the system, you must provide at least 7.6 cm (3.0 in) of

clearance at the front and back of the server.

About This Guide

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide ix

Page 10

About This Guide

CAUTION: The computer is designed to be electrically grounded (earthed). To ensure proper

operation, plug the AC power cord into a properly grounded AC outlet only.

NOTE: Any indications of component replacement or printed wiring board modifications may void any

warranty.

Where to Go for Additional Help

In addition to this guide, the following information sources are available:

• User documentation

• Service Quick Reference Guide

• Service training guides

• Service advisories and bulletins

• QuickFind information services

• Insight Manager software

• HP Servers Troubleshooting Guide

Integrated Management Log

The server includes an integrated, nonvolatile management log that contains fault and

management information. The contents of the Integrated Management Log (IML) can be

viewed with Insight Manager.

Telephone Numbers

For the name of the nearest HP authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

For HP technical support:

• In the United States and Canada, call 1-800-652-6672.

• Outside the United States and Canada, refer to

www.hp.com

x HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 11

1

Illustrated Parts Catalog

This chapter provides the illustrated parts breakdown and spare parts lists for the HP ProLiant

DL580 Generation 2 server. Refer to Tables 1-1, 1-2, and 1-3 for the names of referenced

spare parts.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 1-1

Page 12

Illustrated Parts Catalog

Mechanical Components Exploded View

Figure 1-1: Mechanical components exploded view

1-2 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 13

Mechanical Components Spare Parts List

Table 1-1: Mechanical Components Spare Parts List

Item Description Spare Part Number

Illustrated Parts Catalog

1 Access panels

a) Rear

b) Front

2 Front bezel 243669-001

3 SCSI hard drive blank 122759-001

4 Power supply blank 267133-001

5 Power supply, 800 W, hot-plug 192201-001

6 Cable management arm* 295792-001

7 Power cord retainer kit* 313825-001

* Not shown.

240241-001

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 1-3

Page 14

Illustrated Parts Catalog

System Components Exploded View

Figure 1-2: System components exploded view

1-4 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 15

System Components Spare Parts List

Table 1-2: System Components Spare Parts List

Item Description Spare Part Number

Illustrated Parts Catalog

Media Storage Devices

1 Diskette drive, 12.7 mm, multibay 267132-001

2 CD-ROM drive, 24X, multibay 228508-001

Fans

3 Fan assembly, hot-plug, 120 × 38 mm 240243-001

4 Fan assembly, hot-plug, 120 × 25 mm 240244-001

Boards

5 Memory board 231126-001

6 SCSI backplane 231128-001

7 Diagnostic display board and lightpipe 249105-001

8 Pass-through board 249106-001

9 PCI-X Hot Plug board 231127-001

9a NIC, 10/100/1000 controller* 284848-001

9b NIC, Dual PCI-X NC7170* 313586-001

10 System board 231125-001

11 Processors

a) Processor, Xeon MP, 1.4-GHz/512 KB L3

b) Processor, Xeon MP, 1.6-GHz/1 MB L3*

c) Processor, Xeon MP, 1.5 GHz/1 MB L3*

d) Processor, Xeon MP, 1.9 GHz/1 MB L3*

e) Processor, Xeon MP, 2.0 GHz/2 MB L3*

f) Processor, Xeon MP, 2.0 GHz/1-MB L3*

g) Processor, Xeon MP, 2.5 GHz/1-MB L3*

h) Processor, Xeon MP, 2.8 GHz/2-MB L3*

i) Processor, Xeon MP, 2.2 GHz/2-MB L3*

j) Processor, Xeon MP, 2.7 GHz/2-MB L3*

k.) Processor, Xeon MP, 3.0 GHz/4-MB L3*

IMPORTANT: Mixing processor speeds and cache

sizes is not supported.

12 Processor power module (PPM) 266655-001

13 Power switch assembly 243670-001

272935-001

272936-001

309617-001

311277-001

309618-001

327839-001

327840-001

327841-001

352311-001

352312-001

352313-001

* Not shown

continued

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 1-5

Page 16

Illustrated Parts Catalog

Table 1-2: System Components Spare Parts List continued

Item Description Spare Part Number

14 Battery, system, 3 V 153099-001

15 5i Plus memory module 260741-001

16 Plastics kit*

17 AC power cord, 15 A, 125 V* 237457-001

18 AC power cord, 10A, C14-C19* 311582-001

19 AC power cord, 16A, C19-C20* 295508-001

20 AC power cord, 20 A, 250 V* 237458-001

21 Rack-mounting hardware kit (company rack)* 313215-001

22 Rack-mounting hardware kit (third-party)* 291895-001

23 Cable kit, AC Power* 243671-001

24 Torx screwdriver, T-15* 199630-001

25 Country kit* 231091-001

26 Return kit* 279645-001

26a Hardware mounting kit, 4U* 286221-001

26b Cable Kit, Signal* 243670-001

27 Battery-Backed Write Cache Module, 4.8 V 260740-001

28 18.2-GB SCSI hard drive, hot-plug 10 K RPM 152190-001

28a 18.2-GB SCSI hard drive, universal, hot-plug, 15 K

28b 18.2-GB SCSI hard drive, U320, hot-plug, 15K 289240-001

28c 36.4-GB SCSI hard drive, hot-plug, 10 K RPM* 177986-001

28d 36.4-GB WUS, 1-inch hot-plug,15 K RPM* 233350-001

28e 36.4-GB SCSI Hard drive, U320, hot-plug, 10K 289041-001

28f 36.4-GB SCSI Hard drive, U320, hot-plug, 15K 289241-001

28g 72.8-GB WUS, 1-inch hot-plug, 10 K RPM* 233345-001

28h 72.8-GB SCSI hard drive, U320, hot-plug, 10K 289042-001

28i 72.8-GB SCSI hard drive, U320, hot-plug, 15K 289243-001

28j 146.8-GB SCSI hard drive, U320, hot-plug, 10K 289044-001

31 8X DVD-ROM drive* 268795-001

a) Processor air baffle

b) PCI Expansion board basket

Options

RPM*

243672-001

189395-001

continued

1-6 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 17

Illustrated Parts Catalog

Table 1-2: System Components Spare Parts List continued

Item Description Spare Part Number

Memory

32 256-MB DIMM (DDR SDRAM) 249674-001

33 512-MB DIMM (DDR SDRAM) 249675-001

34 1-GB DIMM (DDR SDRAM) 249676-001

35 2-GB DIMM (DDR SDRAM) 265791-001

* Not shown

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 1-7

Page 18

Removal and Replacement Procedures

This chapter provides subassembly/module-level removal and replacement procedures for

ProLiant DL580 Generation 2 servers. After completing all necessary removal and

replacement procedures, run the Diagnostics Utility to be sure that all components operate

properly.

You need the following items for some procedures:

Torx T-15 tool

•

Flathead screwdriver

•

Diagnostics Utility on the HP SmartStart CD

•

Safety Considerations

Before performing service procedures, review the following safety information.

2

Electrostatic Discharge

A discharge of static electricity can damage static-sensitive devices or micro-circuitry. Proper

packaging and grounding techniques are necessary precautions to prevent damage. To

prevent electrostatic damage:

•

Transport products in static-safe containers such as conductive tubes, bags, or boxes.

•

Keep electrostatic-sensitive parts in their containers until they arrive at static-free

stations.

•

Cover workstations with approved static-dissipating material. Use a wrist strap connected

to the work surface and properly grounded (earthed) tools and equipment.

•

Keep work area free of nonconductive materials such as ordinary plastic assembly aids

and foam packing.

•

Be sure that you are properly grounded (earthed) when touching a static-sensitive

component or assembly.

•

Avoid touching pins, leads, or circuitry.

•

Use nonconductive field service tools.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-1

Page 19

Removal and Replacement Procedures

Symbols on Equipment

These symbols may be located on equipment in areas where hazardous conditions may exist.

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment,

observe local occupational health and safety requirements and guidelines for

manual material handling.

Any surface or area of the equipment marked with these symbols indicates the

presence of a hot surface or a hot component.

WARNING: To reduce the risk of injury from a hot component, allow the surface

to cool before touching it.

Any surface or area of the equipment marked with these symbols indicates the

presence of electric shock hazards. The enclosed area contains no operator

serviceable parts.

WARNING: To reduce the risk of injury from electric shock hazards, do not open

this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network interface

connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the equipment,

do not plug telephone or telecommunications connectors into this receptacle.

Rack Warnings and Cautions

WARNING: To reduce the risk of personal injury or damage to the equipment,

adequately stabilize the rack before extending a component outside the rack. Extend

only one component at a time. A rack may become unstable if more than one

component is extended.

WARNING: To reduce the risk of personal injury or damage to the equipment:

• Extend the leveling jacks to the floor.

• Rest the full weight of the rack on the leveling jacks.

• Attach the stabilizers to the rack if it is a single rack installation.

• Couple the racks together in multiple rack installations.

WARNING: When installing the server in a telco rack, adequately secure the rack frame

to the building structure at the top and bottom.

WARNING: To reduce the risk of personal injury or damage to the equipment, use two

or more people to safely unload the rack from the pallet. An empty 42U rack weighs

115 kg (253 lb), is over 2.1 m (7 ft) tall, and may become unstable when moved on its

casters. Handle the rack from both sides as it rolls down the ramp from the pallet. Do

not stand in front of the rack.

2-2 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 20

CAUTION: Always begin by mounting the heaviest item on the bottom of the rack. Continue

to populate the rack from the bottom to the top.

Server Warnings and Cautions

WARNING: Do not exceed the level of repair specified in the procedures in the product

documentation. All troubleshooting and repair procedures are detailed to allow only

subassembly or module-level repair. Because of the complexity of the individual

boards and subassemblies, do not attempt to make repairs at the component level or to

make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the hot-plug

drives and the internal system components to cool before touching.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the AC power cord grounding plug. The grounding plug is an

important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

Removal and Replacement Procedures

• Unplug the power cord from each power supply to disconnect power to the

equipment.

WARNING: The installation of internal options and routine maintenance and service of

this product should be performed by individuals who are knowledgeable about the

procedures, precautions, and hazards associated with equipment containing

hazardous energy levels.

WARNING: Do not use conductive tools that could bridge live parts. Remove all

watches, rings, or loose jewelry when working in hot-plug areas of an energized server.

WARNING: Do not replace non-hot-plug components while power is applied to the

product. First, shut down the product and disconnect all AC power cords.

WARNING: Be sure that the AC power supply branch circuit that provides power to the

rack is not overloaded. Maintaining a low electrical current draw reduces the risk of

personal injury, fire, or damage to the equipment. The total rack load should not

exceed 80 percent of the branch circuit rating. Consult the electrical authority having

jurisdiction over your facility for wiring and installation requirements.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

regulating uninterruptible power supply (UPS). This device protects the hardware from

damage caused by power surges and voltage spikes and keeps the system in operation

during a power failure.

CAUTION: Do not operate the server for extended periods without the access panel.

Operating the server without the access panel results in improper airflow and improper cooling

that can lead to thermal damage.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-3

Page 21

Removal and Replacement Procedures

CAUTION: Reinstall each hard drive into the specific slot from which it was removed. Mixing

the hard drives adversely affects the system drive configuration.

Preparation Procedures

To access some components and perform certain service procedures, you must do one or

more of the following:

•

Extend the server from the rack.

If you are performing service procedures in an HP, Compaq branded, or third-party rack

cabinet, you can use the locking feature of the rack rails to support the server and gain

access to internal components.

•

Access internal components.

If you need to access internal components for removal or replacement, you can remove

the front and rear access panels without removing the server from the rack.

•

Power down the server.

If you must perform a non-hot-plug replacement procedure, power down the server.

•

Remove the server from the rack.

If the rack environment, cabling configuration, or the server location in the rack creates

awkward conditions, remove the server from the rack. If the server is installed in a telco

rack, you must remove the server from the rack to access internal components.

WARNING: Before lifting the server, remove all hot-plug power supplies and hard

drives to reduce the weight.

2-4 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 22

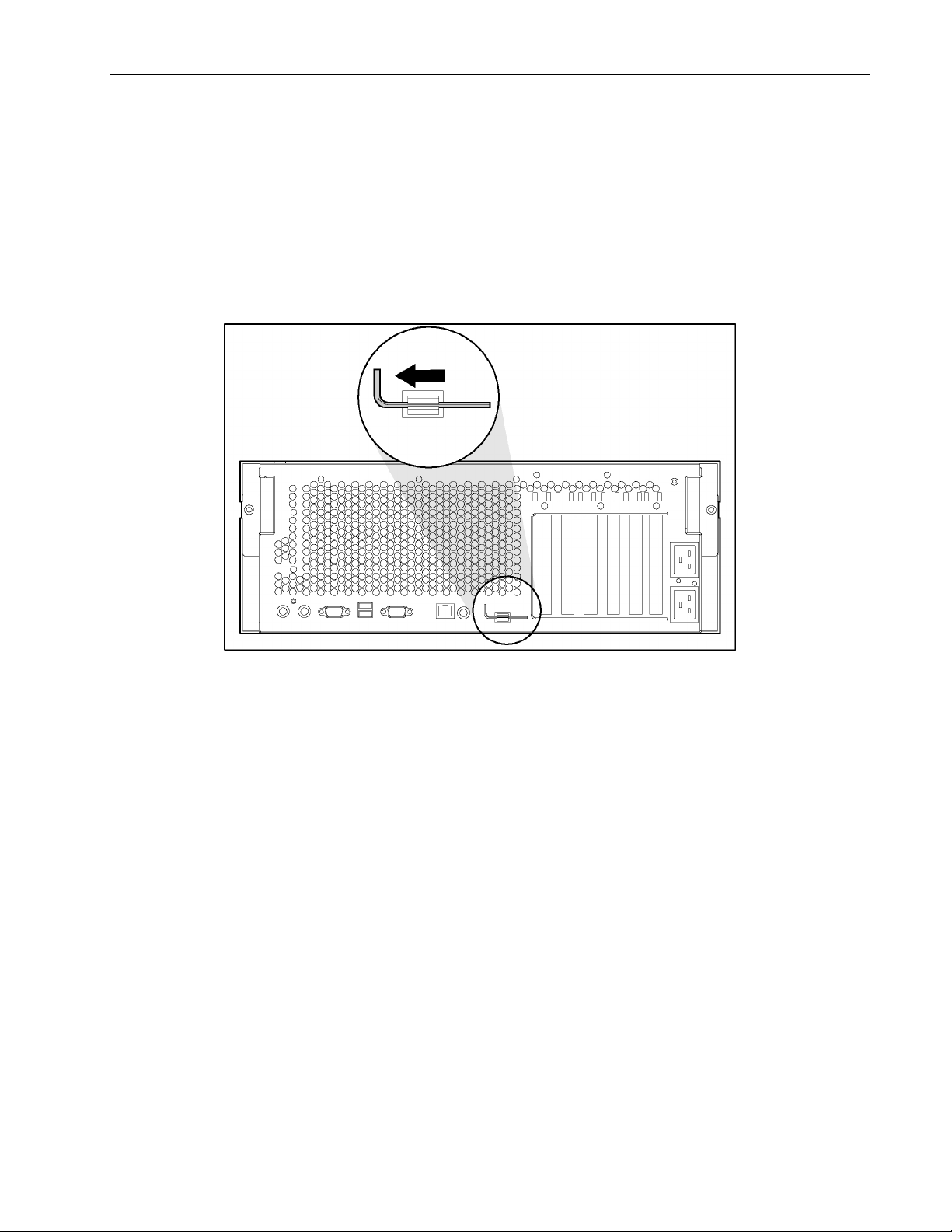

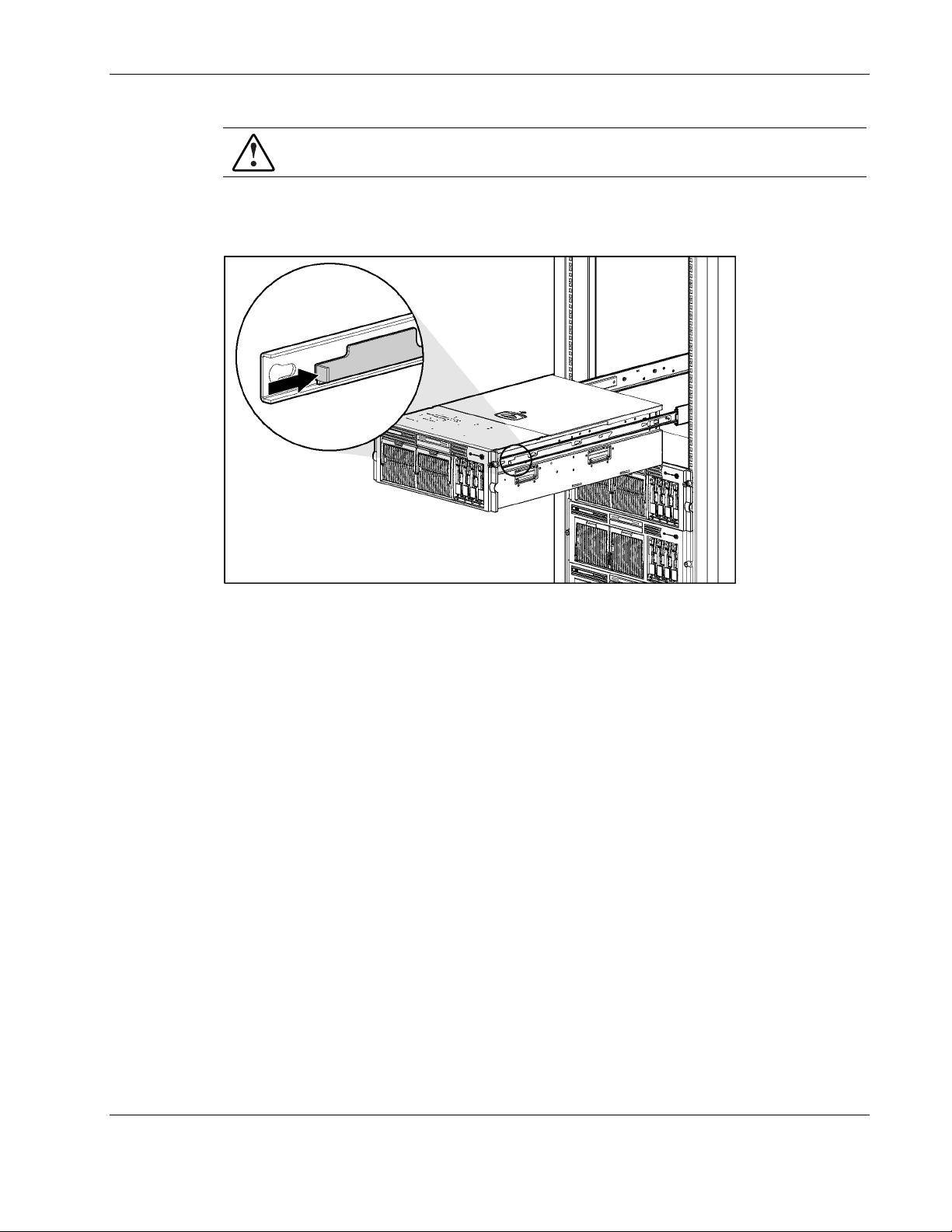

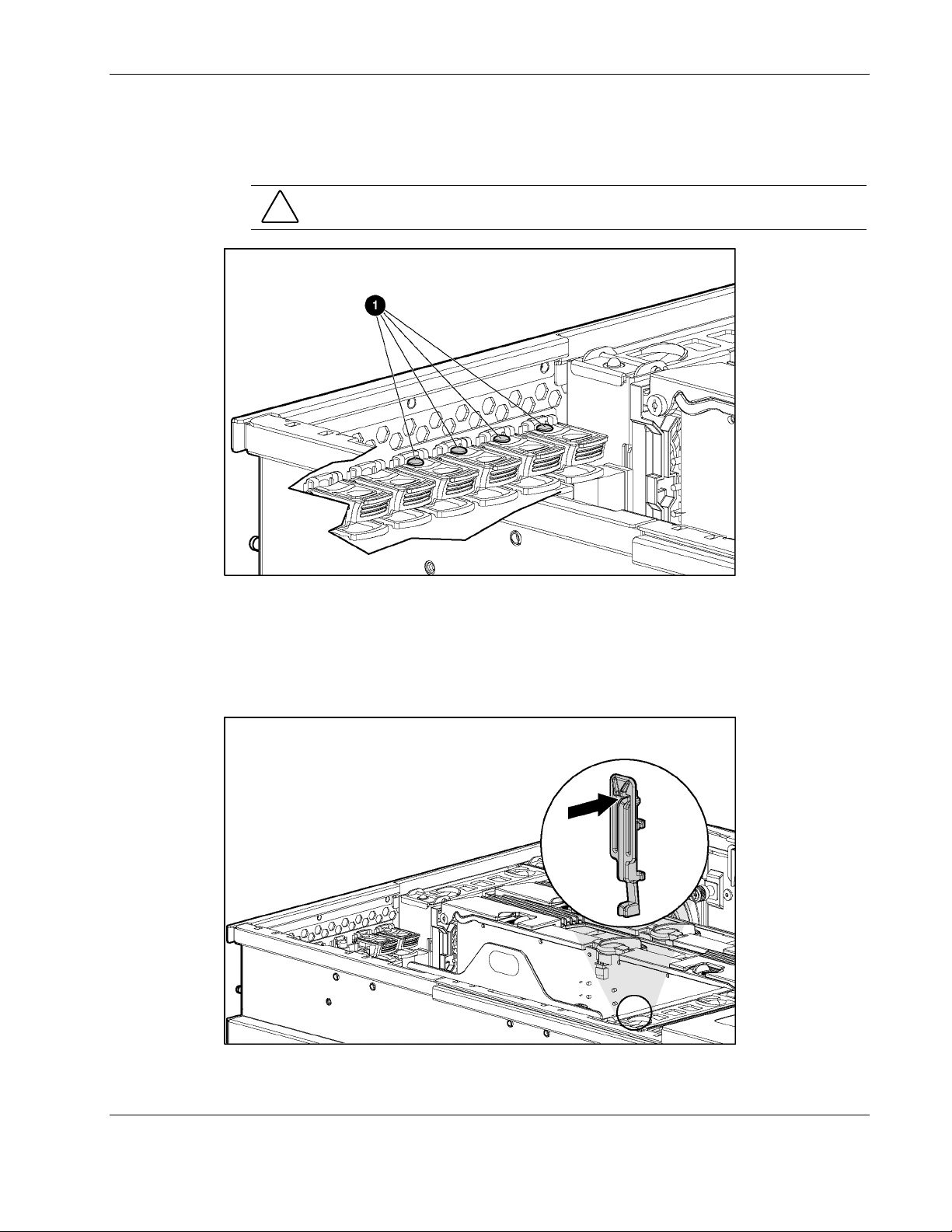

Locating and Removing the Torx T-15 Tool

Many hardware procedures in the ProLiant DL580 Generation 2 server are toolless, but a few

require the removal of Torx T-15 screws that have been installed for shipping or security

reasons. A Torx T-15 tool ships with the server for the removal of these screws.

To locate and remove the Torx T-15 tool:

1. Locate the Torx T-15 tool on the back of the server. It is next to PCI-X slot 6.

2. Slide the tool out of the retaining clips.

Removal and Replacement Procedures

Figure 2-1: Locating and removing the Torx T-15 tool

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-5

Page 23

Removal and Replacement Procedures

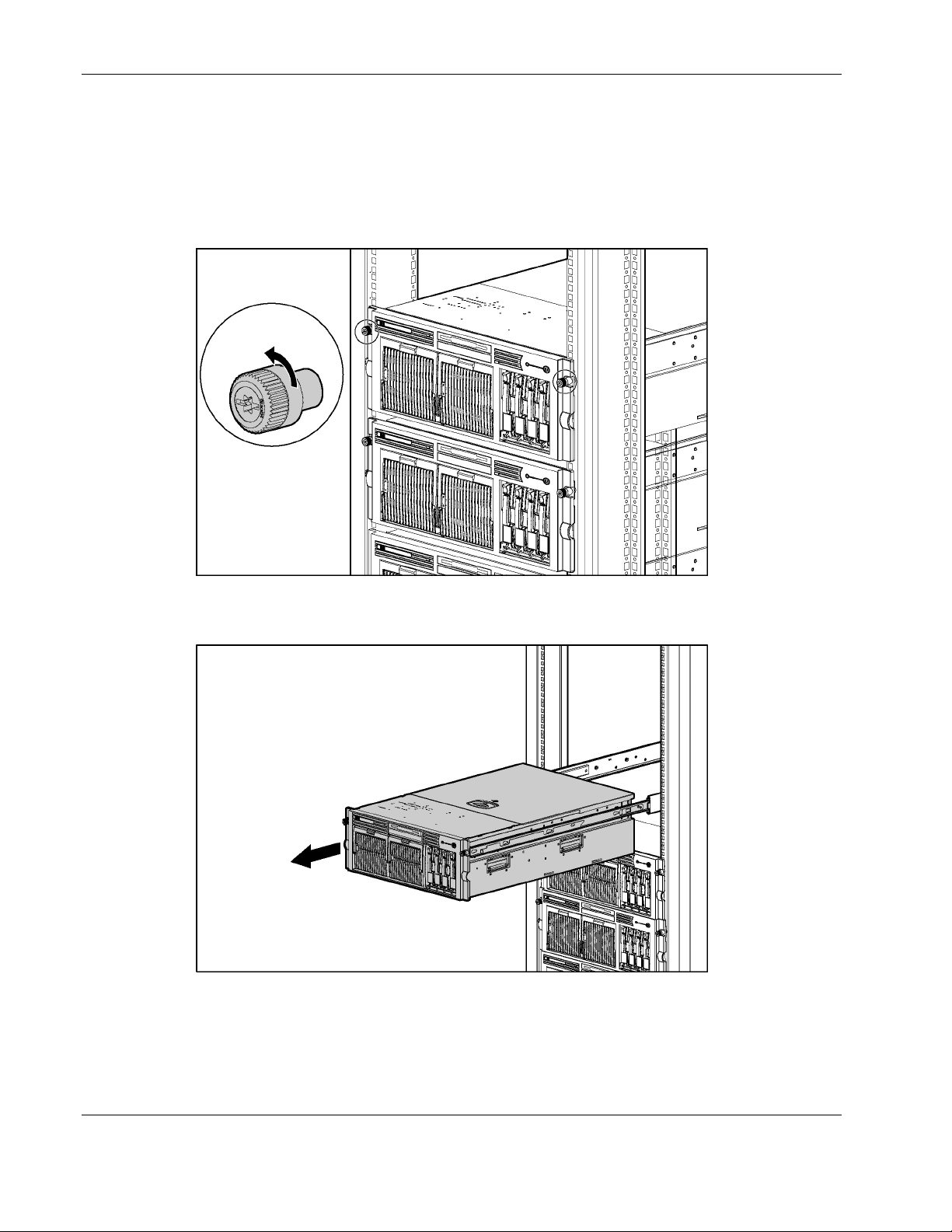

Extending the Server from the Rack

To perform service procedures, you must extend the server from the rack.

To extend the server from the rack:

1. Loosen the thumbscrews that secure the server to the front of the rack.

Figure 2-2: Loosening the front panel thumbscrews

2. Extend the server on the rack rails until the server rail-release latches engage.

Figure 2-3: Extending the server from the rack

2-6 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 24

Removal and Replacement Procedures

WARNING: Be careful when pressing the rail-release levers and sliding the component

into or out of the rack. The sliding rails could pinch your fingertips.

3. To return the server to the rack, reach around the front of the server to press the

rail-release levers at the front of both server rails and continue to slide the server into the

rack.

Figure 2-4: Returning the server back into the rack

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-7

Page 25

Removal and Replacement Procedures

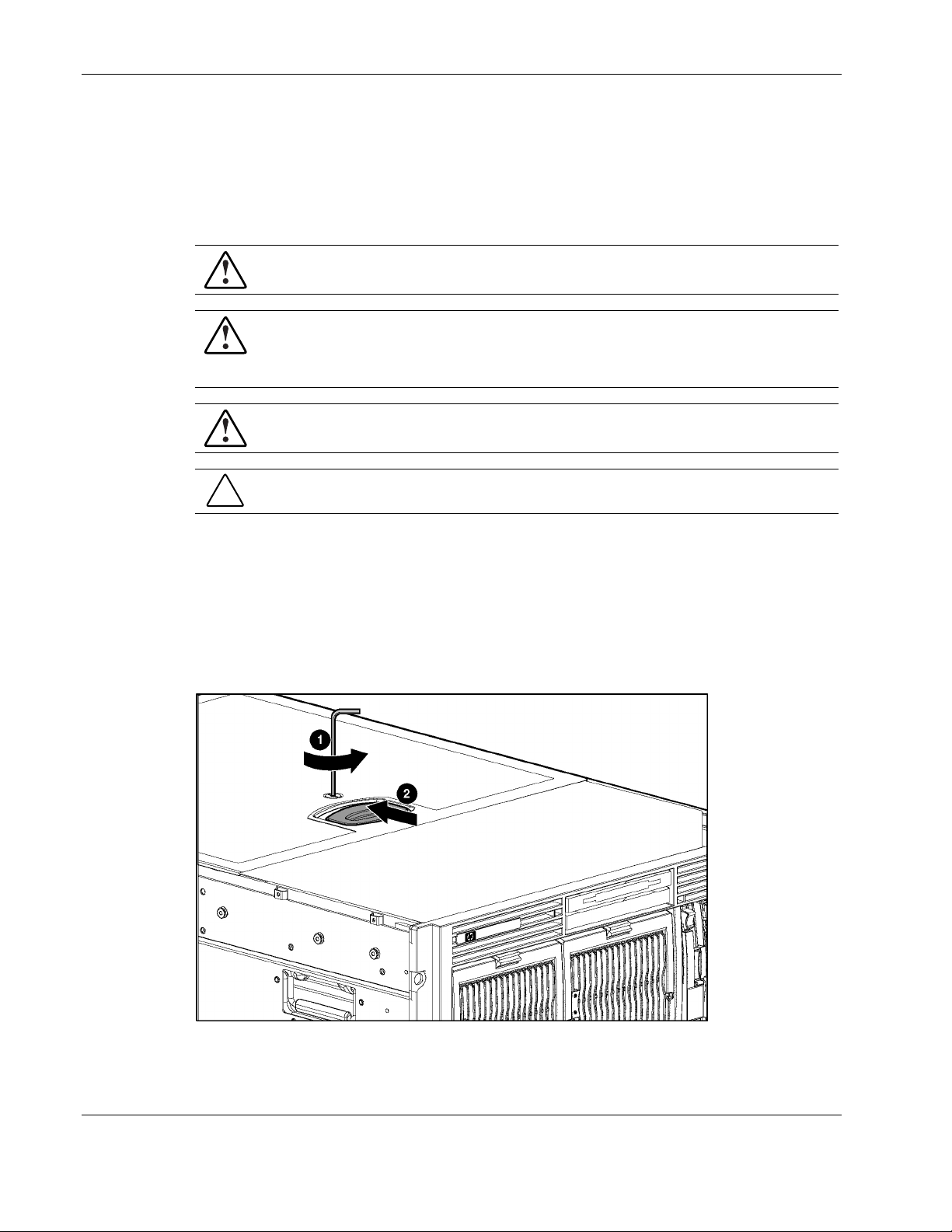

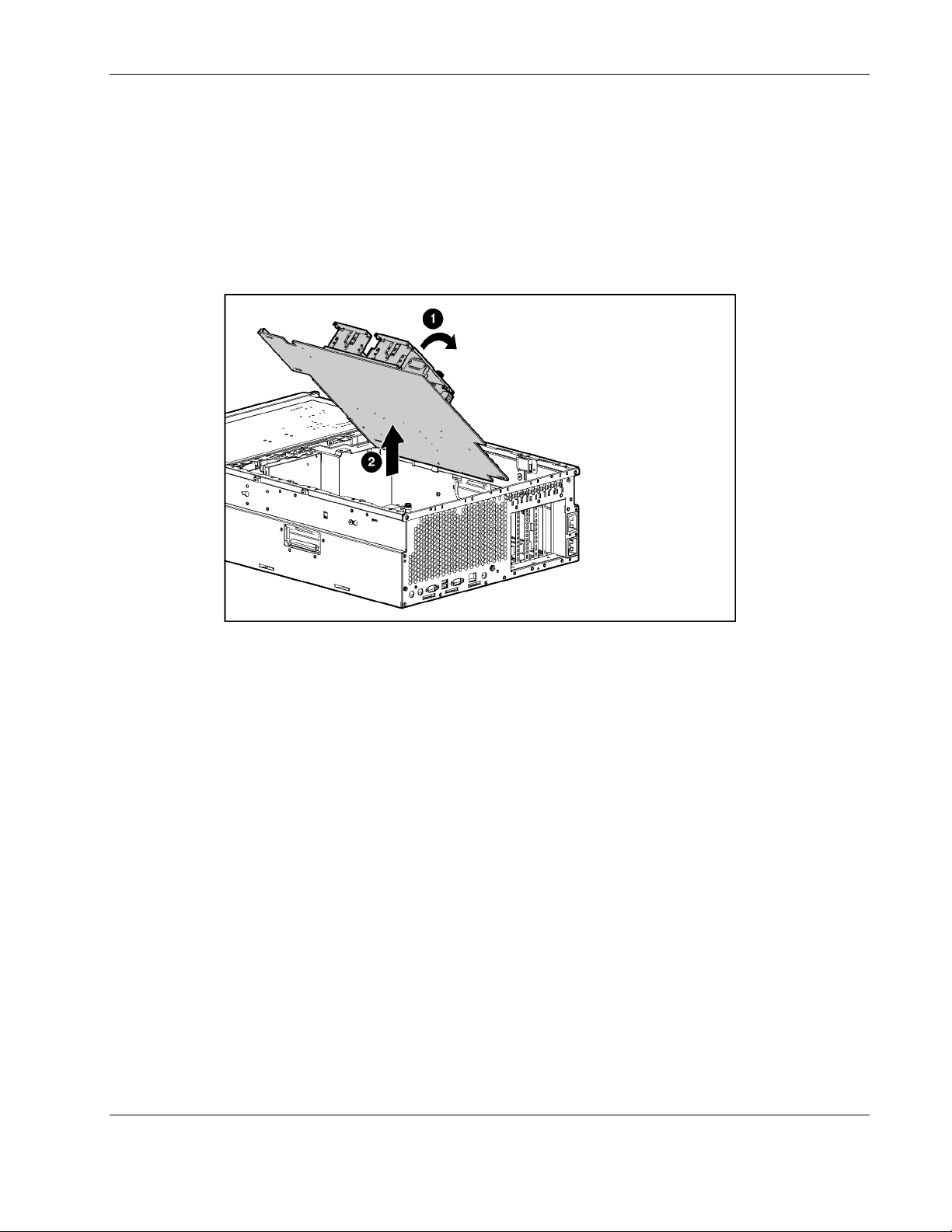

Opening and Removing the Rear Access Panel

The ProLiant DL580 Generation 2 server has front and rear access panels that may need to be

opened and removed to access the system board, processors, memory slots, expansion slots,

and other internal components. Observe the following warnings and cautions when removing

the access panels.

WARNING: Before removing the access panels for non-hot-plug hardware options, be

sure that the power cords are disconnected from the electrical outlet.

WARNING: Pressing the Power On/Standby button sets the server to the standby

position, which removes power from most areas of the server. However, portions of the

power supply and some internal circuitry remain active until the AC power cord is

removed.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

system components to cool before touching.

CAUTION: Electrostatic discharge can damage electronic components. Properly ground

yourself before beginning any installation procedure.

To open the rear access panel:

1. Extend or remove the server from the rack. Refer to “Extending the Server from the

Rack” in this chapter.

2. Disengage the lock on the rear panel using the Torx T-15 tool (1).

3. Using the handle on the rear access panel, slide the rear access panel toward the rear of

the unit (2). The springs raise the rear access panel.

Figure 2-5: Unlocking and sliding the rear access panel open

2-8 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 26

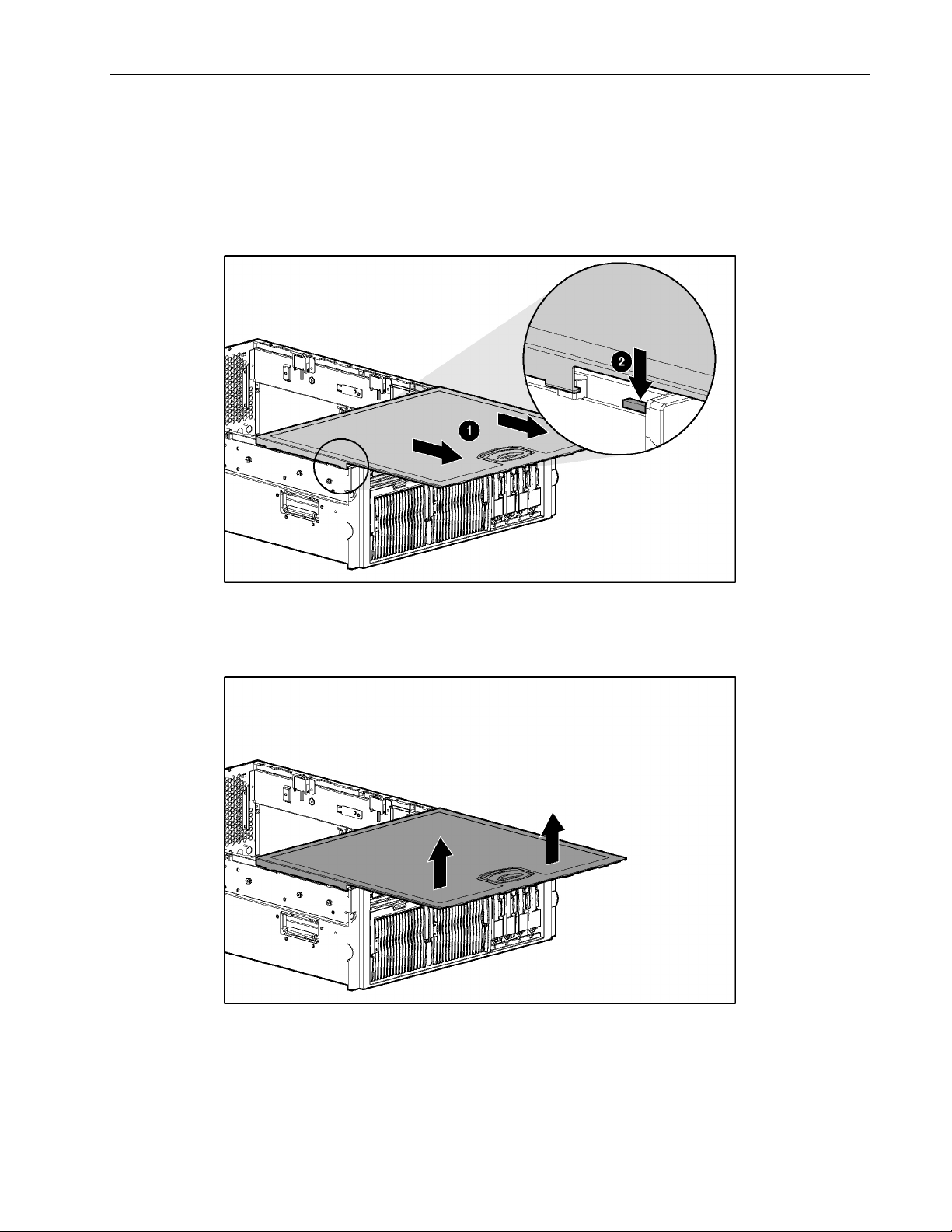

Removal and Replacement Procedures

4. Slide the rear access panel toward the front of the server (1).

5. Push and hold the access panel release lever down (2) while sliding the rear access panel

forward about 2.54 cm (1 in).

IMPORTANT: The guide marks on the rear access panel and the server must line up before

proceeding to the next step.

Figure 2-6: Opening the rear access panel

6. Align the guide marks on the rear access panel and the chassis, and lift the rear access

panel from the server.

Figure 2-7: Removing the rear access panel

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-9

Page 27

Removal and Replacement Procedures

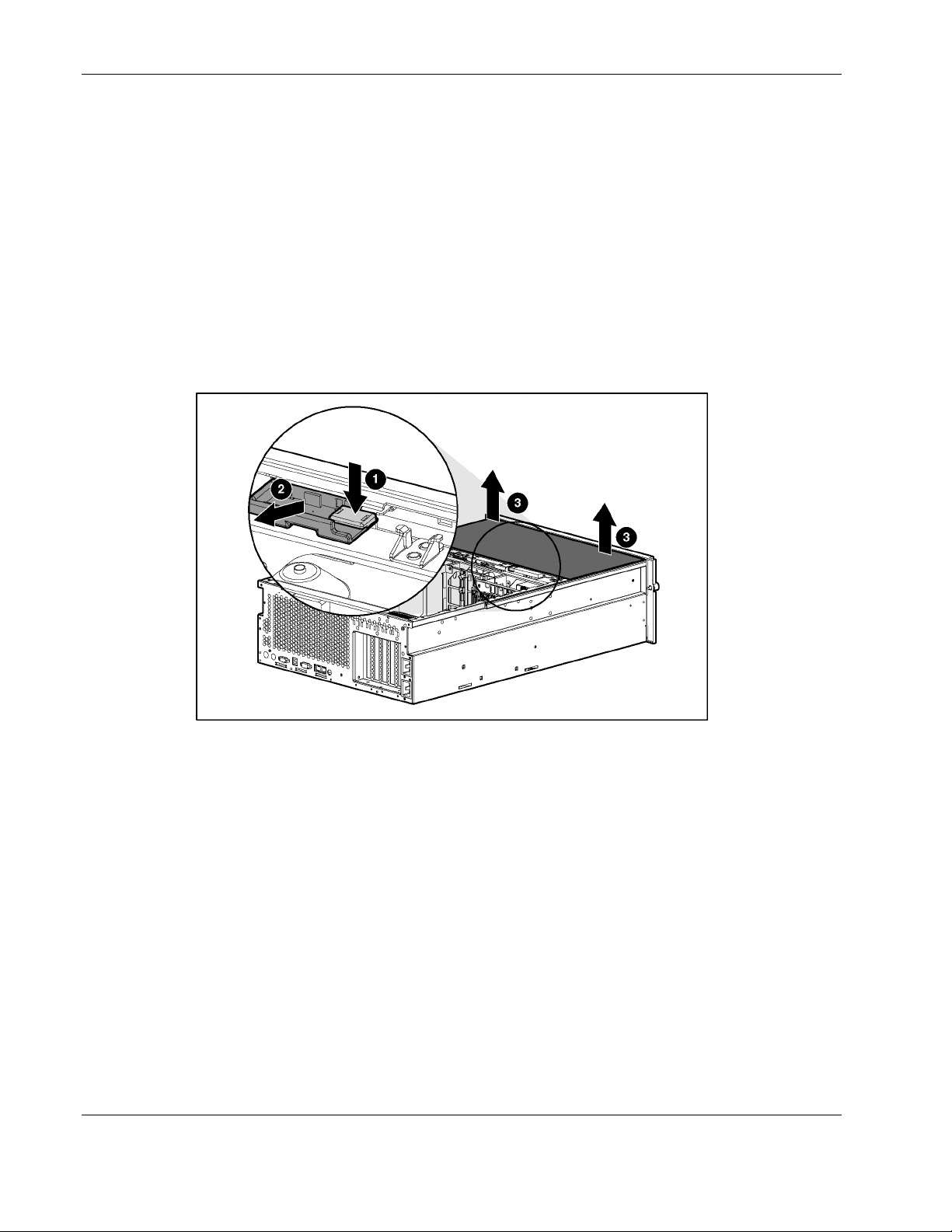

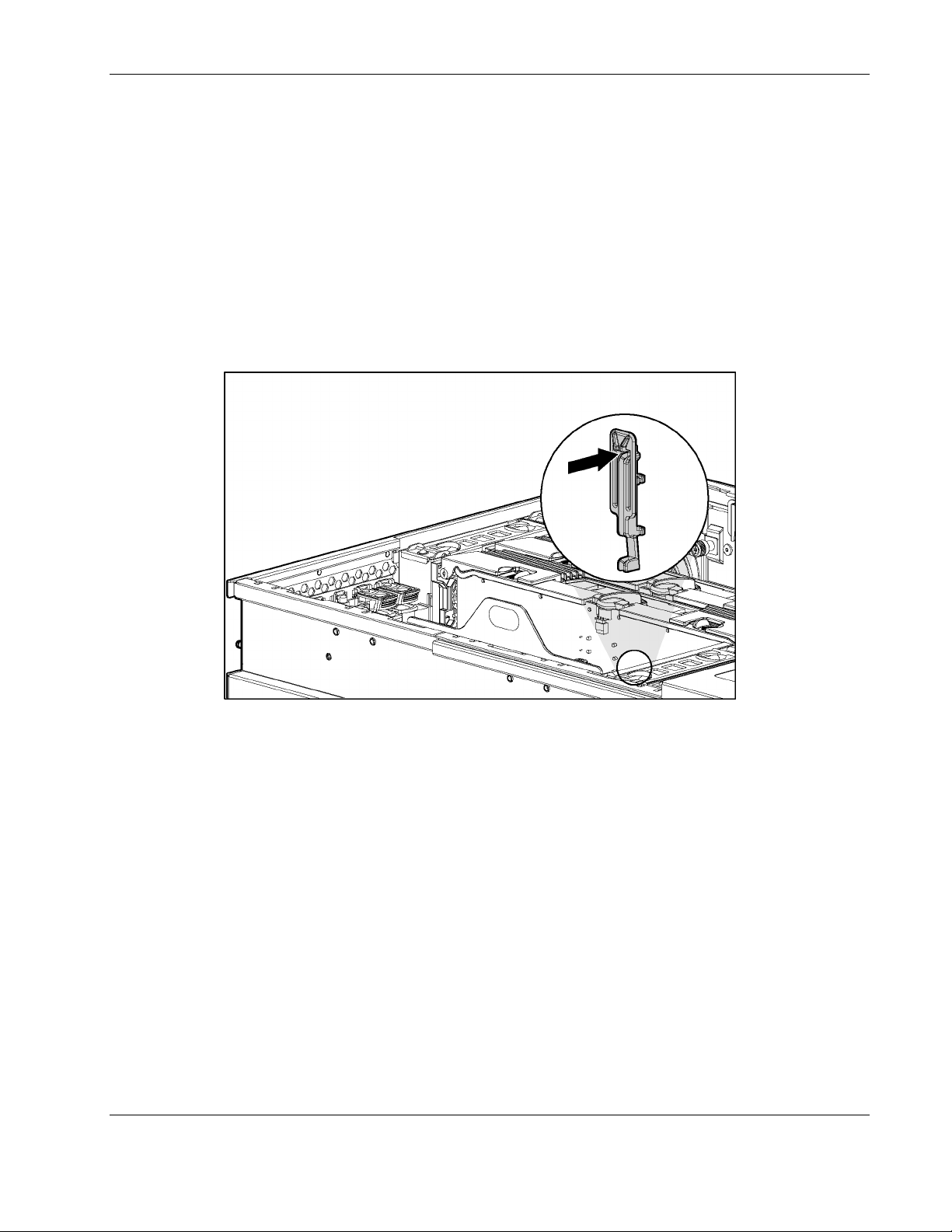

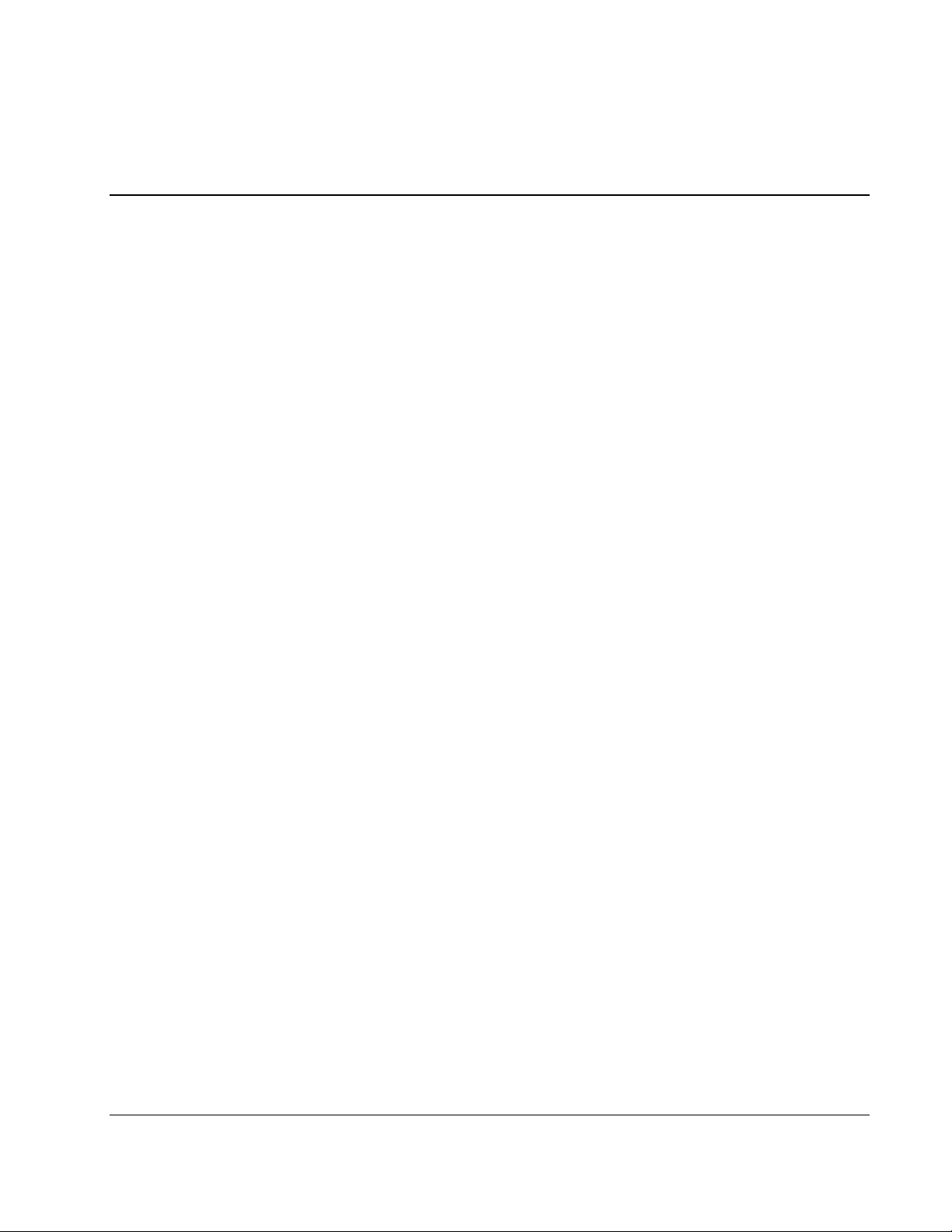

Removing the Front Access Panel

To remove the front access panel:

1. Extend or remove the server from the rack. Refer to “Extending the Server from the

Rack” in this chapter.

2. Remove the rear access panel. Refer to “Opening and Removing the Rear Access Panel”

in this chapter.

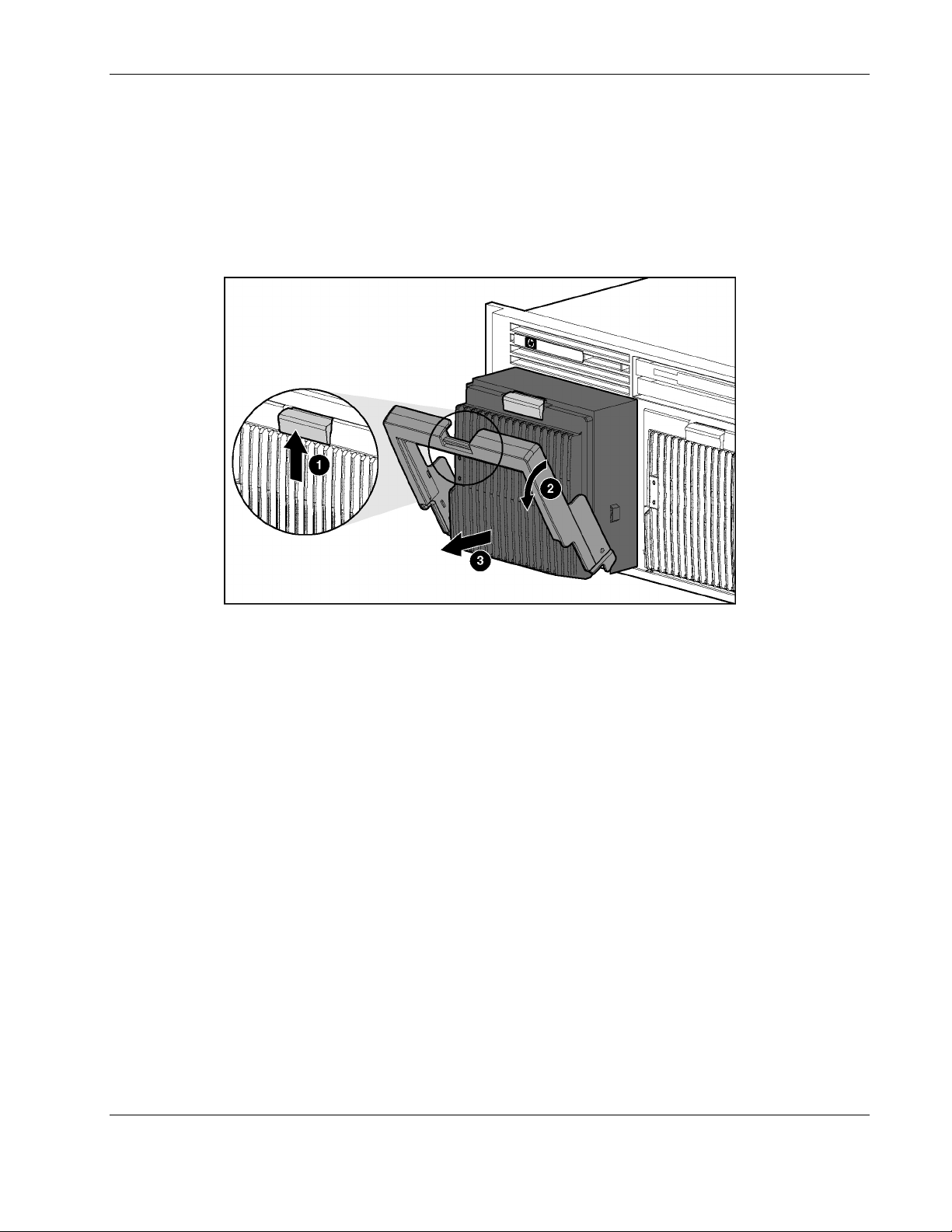

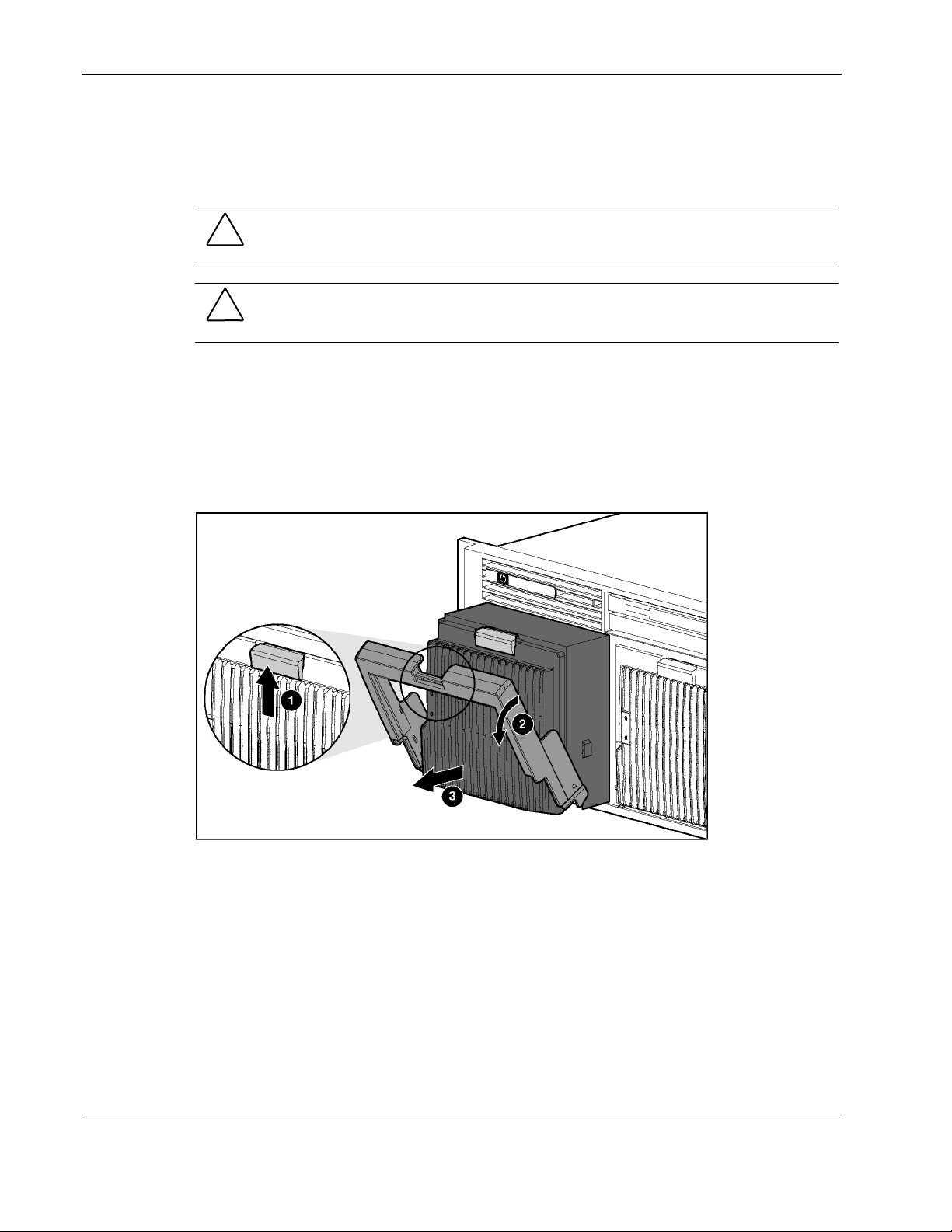

3. Remove the front access panel:

a. Press the release button located on the inside rear of the front access panel (1).

b. Slide the front access panel toward the rear of the server (2).

c. Remove the access panel (3).

Figure 2-8: Removing the front access panel

2-10 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 28

Replacing the Access Panels

To replace the access panels:

1. Place the front access panel on top of the server, and line up the guide marks on the front

access panel with the corresponding server guide marks.

2. With even pressure, push the front access panel down and slide it toward the front of the

server into the fitted slots.

Removal and Replacement Procedures

Figure 2-9: Replacing the front access panel

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-11

Page 29

Removal and Replacement Procedures

3. Place the rear access panel on top of the server and line up the guide marks on the rear

access panel with the corresponding server guide marks.

4. Slide the rear access panel toward the back of the server until it stops.

Figure 2-10: Lining up the guide marks

5. With even pressure, push the rear access panel down and slide it toward the front of the

server until it seats.

Figure 2-11: Installing the rear access panel

6. Use the Torx T-15 tool to turn the locking screw clockwise to lock the latch.

2-12 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 30

Powering Down the Server

WARNING: It is necessary to be knowledgeable of electrostatic discharge information

before preparing the server. For electrostatic discharge information, refer to

“Electrostatic Discharge ” in this chapter.

For all non-hot-plug procedures, you must power down the server. To power down the server:

1. Press the Power On/Standby button.

2. Be sure that the front panel power LED indicator is amber and that the fans are off.

3. Disconnect all AC power cords from the server.

4. Disconnect all external peripheral devices from the server.

Removing the Server from the Rack

WARNING: The server is very heavy, up to 44.5 kg (98 lb). To reduce the risk of

personal injury or damage to the equipment:

• Remove all hot-plug power supplies to reduce the weight of the server before

lifting it.

• Observe local occupational health and safety requirements and guidelines for

material handling.

• Get help to lift and maneuver the server.

Removal and Replacement Procedures

To remove the server from the rack:

1. Power down the server. Refer to “Power ing Down the Server” in this chapter.

2. Loosen the front panel thumbscrews that secure the server faceplate to the front of the

rack.

3. Extend the server from the rack. Refer to “Extending the Server from the Rack” i n this

chapter.

4. Remove the cables from the cable management arm and unplug the cables from the rear

of the server.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-13

Page 31

Removal and Replacement Procedures

5. Press the rail release levers on the rails and slide the server off the rack rails.

Figure 2-12: Removing the server from the rack

6. Place the server on a sturdy, level surface.

Reverse steps 1 through 4 to install the server into the rack.

2-14 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 32

Memory

Removal and Replacement Procedures

This section provides the following information about the memory components and

procedures in the ProLiant DL580 Generation 2 server:

Memory replacement guidelines

•

Memory board slot locations

•

Parts of the memory board

•

Memory board LEDs and icons

•

DIMM installation requirements

•

Removing a memory board

•

Removing a DIMM

•

Installing a DIMM

•

Installing a memory board

•

Configuring the memory

•

Memory Replacement Guidelines

DIMM and memory board installation, removal, and replacement procedures can be either

hot-plug or non-hot-plug procedures, depending on how the server is configured.

•

You cannot perform hot-plug procedures when the system is configured for:

— Advanced ECC memory

— Online spare memory

— Single-board mirrored memory

•

You can only perform a hot-plug replacement procedure:

— When the server is configured for hot-plug mirrored memory, enabling you to replace

failed or degraded DIMMs without powering down the server

— When the server is configured for Hot-Add functionality, enabling you to upgrade the

amount of memory without powering down the server

For more information about requirements and procedures for using Hot-Add functionality,

refer to the HP ProLiant DL580 Generation 2 and HP ProLiant ML570 Generation 2 Server

Hot-Add Memory booklet on the Documentation CD or the Compaq Reference Library on

www.hp.com.

The replacement procedures in this section apply to both hot-plug and non-hot-plug memory

replacement, except as noted.

CAUTION: Be sure to power down the server when performing these procedures in a server

that is not configured for hot-plug mirrored memory or Hot-Add functionality.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-15

Page 33

Removal and Replacement Procedures

Observe the following warnings when performing a hot-plug replacement procedure.

WARNING: Always comply with all electrostatic and thermal guidelines to prevent

bodily injury and ensure a properly functioning system when performing hot-plug

operations. For detailed information, refer to “Abou t this Guide” i n this guide.

WARNING: The rear access panel provides access to hazardous energy circuits. To

avoid risk of injury or damage to the equipment from hazardous energy, be sure the

door remains locked during normal operation or install the server in a controlled

access location.

WARNING: To reduce the risk of personal injury from hazardous energy or damage to

the equipment when working on energized servers:

• Remove all watches, rings, and any other loose fitting jewelry.

• Avoid the use of conductive tools inside the server that could bridge live parts.

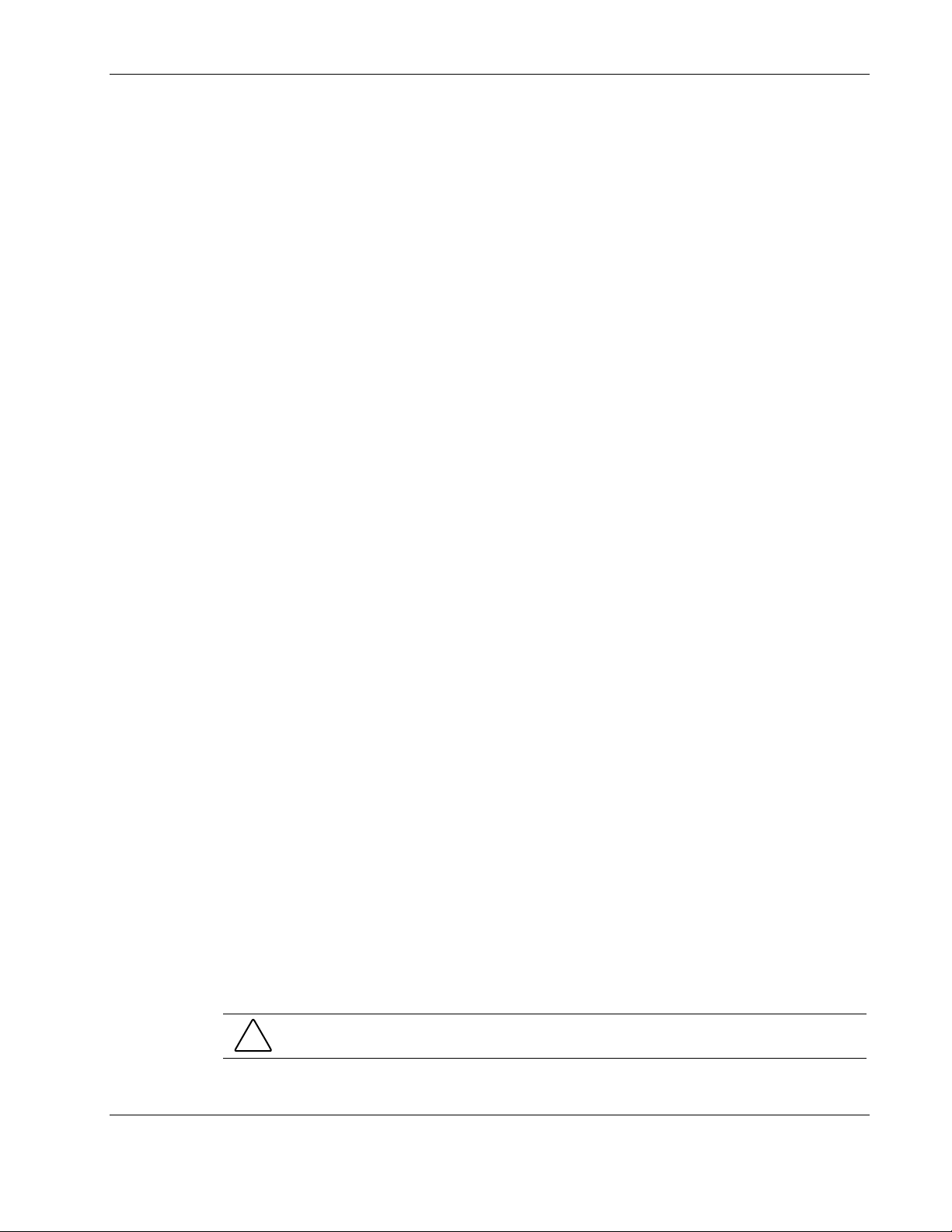

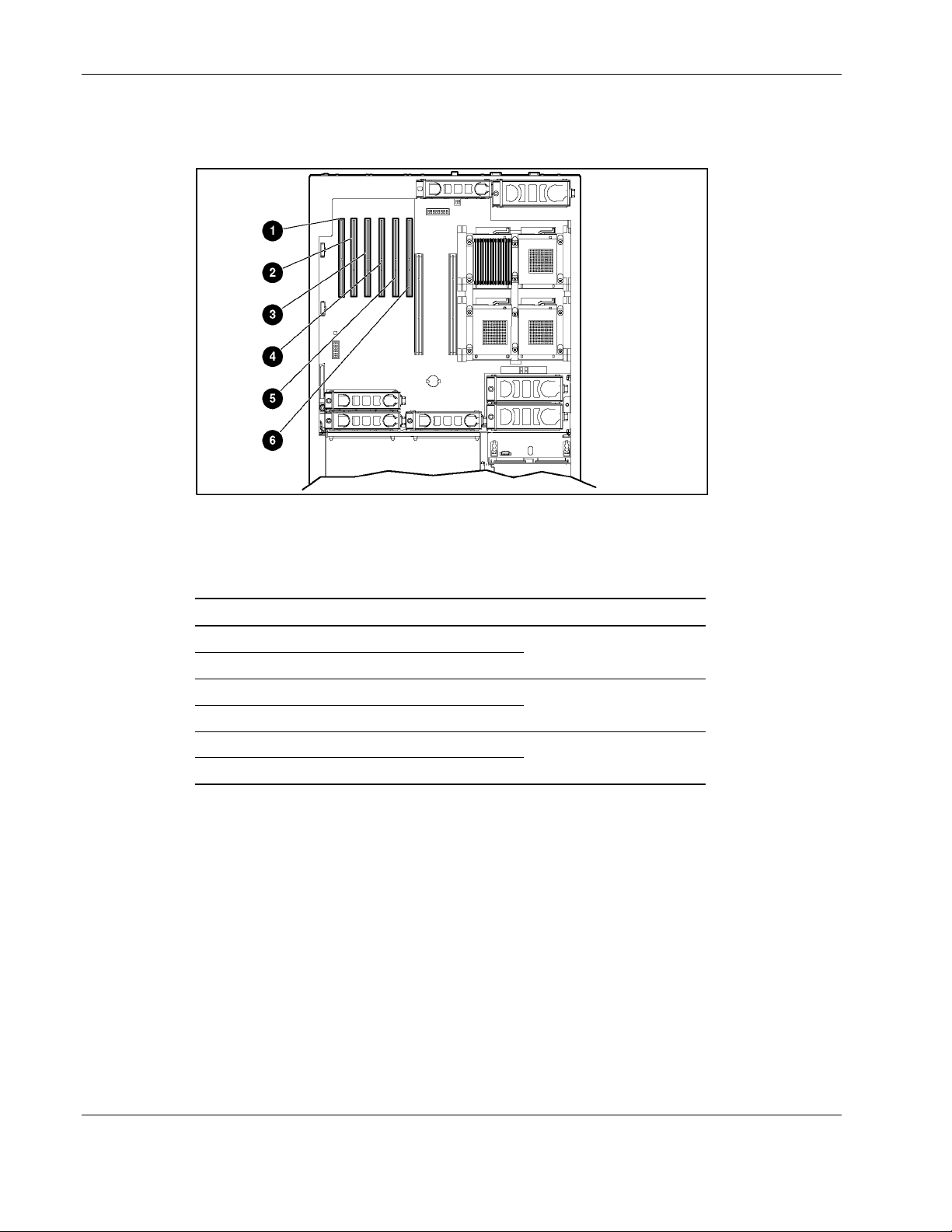

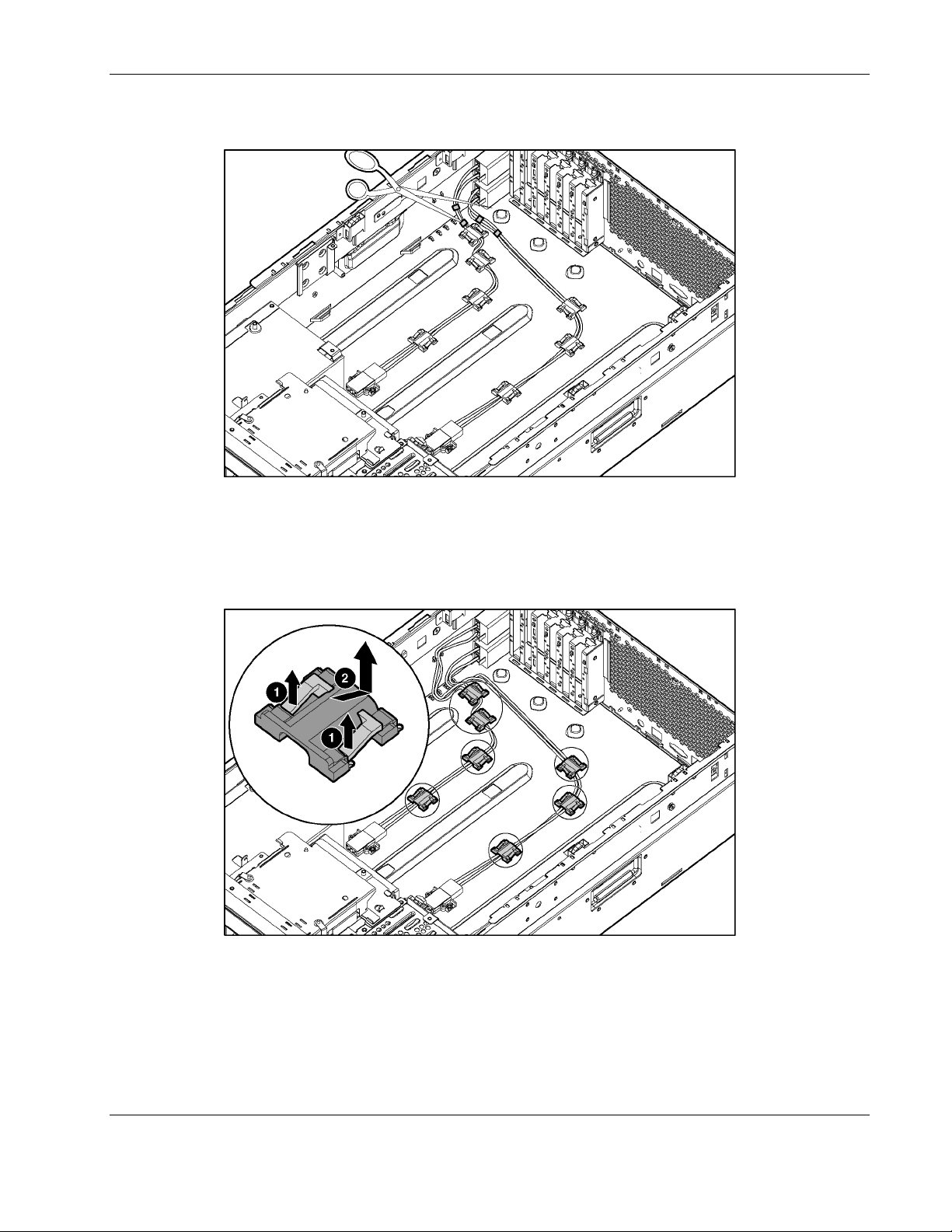

Memory Board Slot Locations

Use Figure 2-13 and Table 2-1 to identify the memory board slots on the system board.

Figure 2-13: Memory board slots

Table 2-1: Memory Board Slots

Item Description

1 Memory board slot 1

2 Memory board slot 2

2-16 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 34

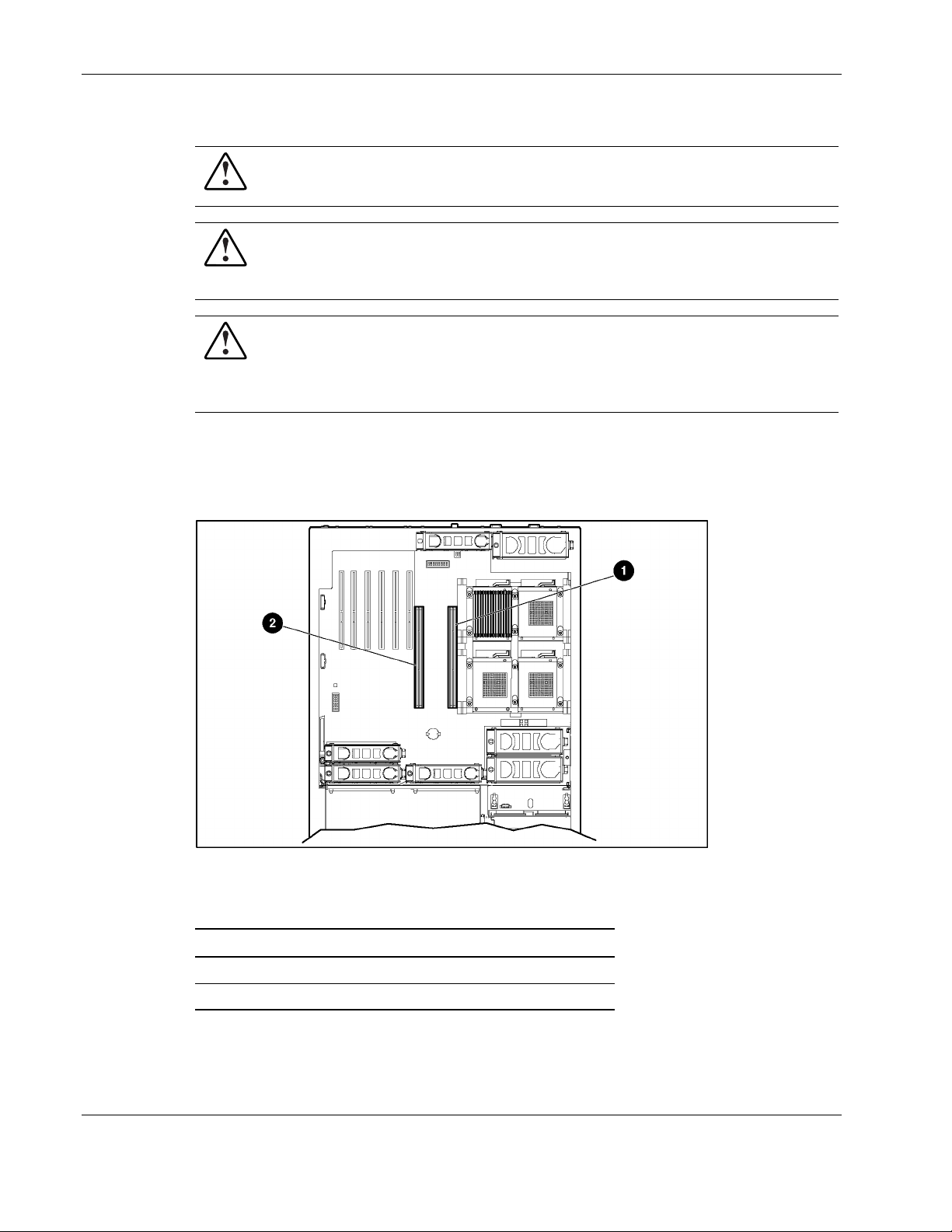

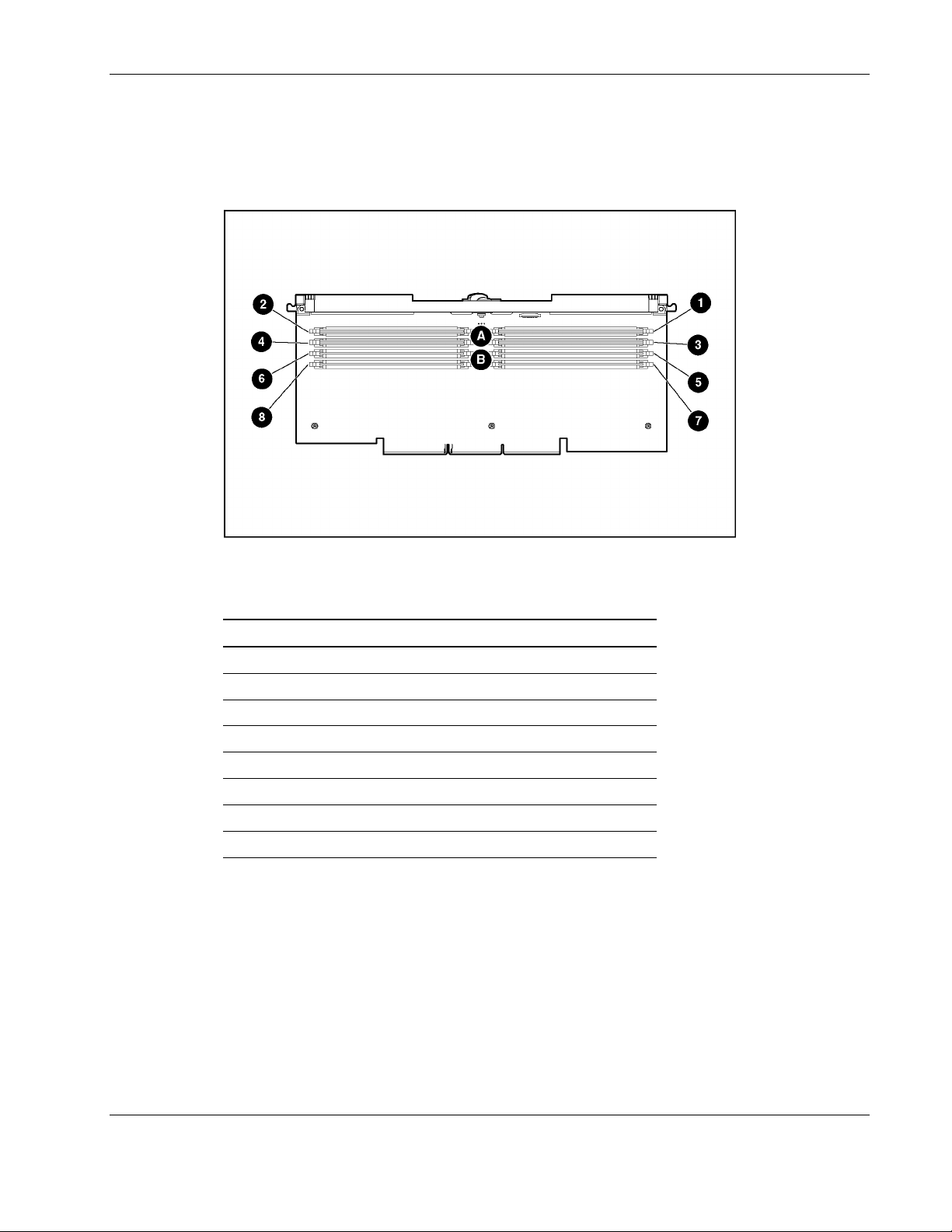

Parts of the Memory Board

Use Figure 2-14 and Table 2-2 to identify the parts of the memory board.

Figure 2-14: Parts of the memory board

Removal and Replacement Procedures

Table 2-2: Parts of the Memory Board

Item Description

1 DIMM slot 1, bank A (populated)

2 DIMM slot 2, bank A (populated)

3 DIMM slot 3, bank A (populated)

4 DIMM slot 4, bank A (populated)

5 DIMM slot 5, bank B

6 DIMM slot 6, bank B

7 DIMM slot 7, bank B

8 DIMM slot 8, bank B

9 LEDs

10 Locking switch

11 Release latches

12 Ejector levers

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-17

Page 35

Removal and Replacement Procedures

Memory Board LEDs and Icons

Use Figure 2-15 and Table 2-3 through 2-7 to identify icons and LEDs and their status on the

memory board. Each table represents the LEDs for a specific memory mode. Be sure you are

referring to the correct table for the specific mode.

Figure 2-15: Memory board LEDs and icons

Table 2-3: Advanced ECC (Standard) Memory LEDs

Item Description Indicator Status

6 Memory

Status

7 Ready to

Hot Plug

1-4

and

10-13

DIMMs 1-8

status

All LEDs Flashing

Off Memory board is offline.

Green Memory board is online.

Flashing

green

Amber Memory error has occurred on this memory board.

Off Do not remove memory board. Advanced ECC

Off DIMM is not installed.

Green DIMM is installed.

Amber Memory error has occurred on this DIMM.

Flashing

amber

amber

Memory board is busy.

memory does not support hot-removal of boards.

Configuration error has occurred.

CAUTION: Memory board is in use; relock it

immediately.

2-18 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 36

Table 2-4: Online Spare Memory LEDs

Item Description Indicator Status

Removal and Replacement Procedures

6 Memory

Status

8 Online Spare

Status

7 Ready to

Hot Plug

5 Online Spare

text

1-4

and

10-13

All LEDs Flashing

DIMMs 1-8

status

Off Memory board is offline.

Green Memory board is online.

Flashing

green

Amber Memory error has occurred on this memory board.

Off Memory board is not configured for online spare

Green Online spare memory is functioning properly.

Amber Memory error has occurred and system has failed over

Off Do not remove memory board. Online spare memory

Off Bank is not configured as an online spare bank.

Green Bank is configured as an online spare bank.

Flashing

green

Off DIMM is not installed.

Green DIMM is installed.

Amber Memory error has occurred on this DIMM.

Flashing

amber

amber

Memory board is busy.

memory.

to the online spare bank.

does not support hot-plug capability.

Failure has occurred and online spare bank is active.

Configuration error has occurred.

CAUTION: Memory board is in use; relock it

immediately.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-19

Page 37

Removal and Replacement Procedures

Table 2-5: Single-Board Mirrored Memory LEDs

Item Description Indicator Status

6 Memory Status

Off Memory board is offline.

Green Memory board is online.

Flashing green Memory board is busy.

Amber Memory error has occurred on this memory

9 Mirroring Status

Off Memory board is not configured for mirrored

Green Single-board mirrored memory is functioning

Amber Memory error has occurred and system has

7 Ready to

Off Do not remove memory board. Single-board

Hot Plug

1-4 and

10-13

DIMMs 1-8

status

Off DIMM is not installed.

Green DIMM is installed.

Amber Memory error has occurred on this DIMM.

Flashing amber Configuration error has occurred.

All LEDs Flashing amber

board.

memory.

properly.

failed over to the mirrored bank(s).

mirrored memory does not support hot-plug

capability.

CAUTION: Memory board is in use; relock it

immediately.

2-20 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 38

Removal and Replacement Procedures

Table 2-6: Hot-Plug Mirrored Memory LEDs

Item Description Indicator Status

6 Memory Status

Off Memory board is offline.

Green Memory board is online.

Flashing green Memory board is busy.

Amber Memory error has occurred on this

memory board.

9 Mirroring Status

Off Memory board is not configured for

mirrored memory.

Green Hot-plug mirrored memory is functioning

properly.

Amber Memory error has occurred and system

has failed over to the mirrored board.

Off Do not remove memory board. 7 Ready to Hot Plug

Green Memory board can be hot-plugged.

1-4 and

10-3

DIMMs 1-8 status

Off DIMM is not installed.

Green DIMM is installed.

Amber Memory error has occurred on this

DIMM.

Flashing amber Configuration error has occurred.

All LEDs Flashing amber

CAUTION: Memory board is in use;

relock it immediately.

Table 2-7: Memory Board Icons

Description Status

Lock Memory board is locked and cannot be removed.

Unlock Memory board is unlocked, and is only hot-pluggable if the Ready to Hot Plug

LED is on.

Note: The icon at which the memory board switch is pointed indicates whether the memory board is

locked or unlocked.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-21

Page 39

Removal and Replacement Procedures

DIMM Installation Requirements

Observe the following DIMM configuration requirements when installing DIMM:

Use only industry-standard PC1600 registered DDR SDRAM DIMMs in 256-MB,

•

512-MB, 1-GB, and 2-GB capacities, and that support Error Checking and Correcting

(ECC).

Install DIMMs in groups of four, one bank at a time.

•

Groups of four DIMMs must be identical. Installing DIMMs of different capacities into

•

the same bank can degrade memory performance.

Bank A must always be populated. To ease subsequent DIMM installations, install the

•

DIMMs in sequential order.

IMPORTANT: HP recommends that you use only HP DIMMs. Third-party DIMMs may have additional

installation requirements. For information about third-party DIMM installation requirements, refer to the

Advanced Memory Protection white paper on the ProLiant website at www.hp.com.

IMPORTANT: You must power down the server before installing additional DIMMs. Follow all DIMM

configuration requirements carefully. If the DIMMs are not configured properly, you receive an error

message during POST.

Additional Requirements for Online Spare Memory Technology

In addition to the DIMM configuration requirements for advanced ECC memory, observe the

following DIMM configuration requirements when installing DIMMs for online spare

memory:

•

Memory board slot 1 must be populated.

•

Bank B on the memory board in slot 1 is always the online spare bank, even if two

memory boards are installed, and must be populated when the server is configured for

online spare memory.

•

DIMMs installed in the online spare bank must be of equal or greater capacity than each

of those in the remaining banks on both memory boards.

IMPORTANT: If memory board slot 1 Bank B is not populated, the system automatically switches to

advanced ECC memory and displays an error message during POST.

NOTE: When configured for online spare memory, the memory board has no hot-plug capabilities.

2-22 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 40

Removal and Replacement Procedures

Additional Requirements for Single-Board Mirrored Memory Technology

In addition to the DIMM configuration requirements for advanced ECC memory, observe the

following DIMM configuration requirements when installing DIMMs for single-board

mirrored memory:

Install only one board. The board must be installed in memory board slot 1.

•

Bank B of memory board 1 is the mirrored bank.

•

DIMMs in the mirrored bank must be configured identically to the bank they are

•

mirroring. Both banks must be populated with DIMMs of the same capacity.

IMPORTANT: If memory board slot 1 Bank B is not populated, the system automatically switches to

advanced ECC memory and displays an error message during POST.

NOTE: When configured for single-board mirrored memory, the system has no hot-plug capabilities.

Additional Requirements for Hot-Plug Mirrored Memory Technology

In addition to the DIMM configuration requirements for advanced ECC memory, observe the

following DIMM configuration requirements when installing DIMMs for hot-plug mirrored

memory:

Two memory boards must be installed.

•

Both memory boards must be configured identically. Corresponding banks (for instance,

•

bank A on the memory board in slot 1 and bank A on the memory board in slot 2) must

be populated with DIMMs of the same size and type.

Observe the following DIMM configuration requirements when performing a hot-plug

replacement:

Do not remove the memory board unless the Ready to Hot Plug LED is green.

•

If you replace a DIMM, the DIMM must be a PC1600 DDR SDRAM DIMM of the same

•

capacity as the DIMM you are replacing.

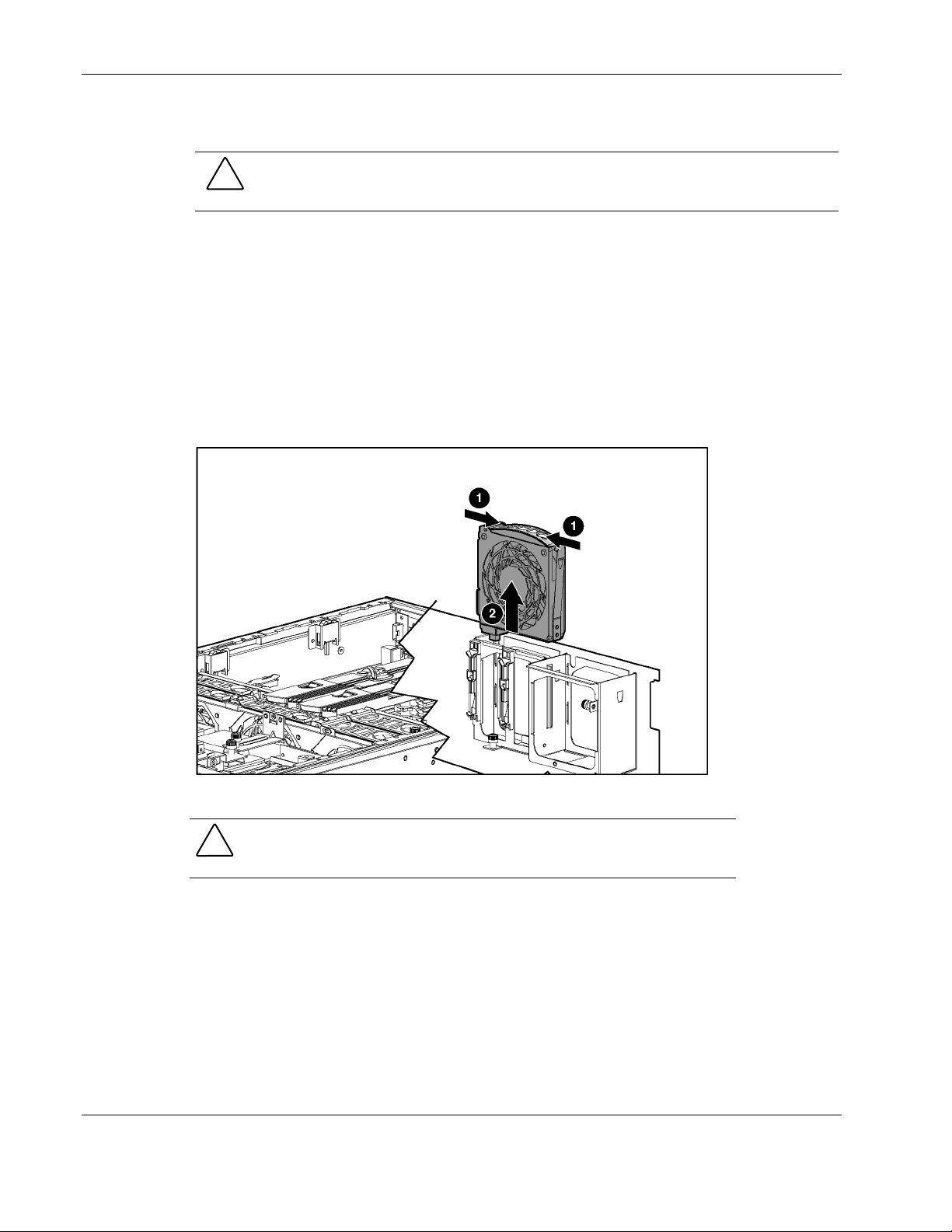

Removing a Memory Board

CAUTION: Electrostatic discharge can damage electronic components. Be sure you are

properly grounded before beginning any installation procedure.

To remove a memory board:

1. If the server is not configured for hot-plug mirrored memory, you must power down the

server. Refer to “Powering Down the Server” in this chapter.

Hot-plug replacement procedure: If the server is configured for hot-plug mirrored

memory, skip to step 2.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-23

Page 41

Removal and Replacement Procedures

2. Open the rear access panel. Refer to “Op ening and Removing the Rear Access Panel” in

this chapter.

Hot-plug replacement procedure: Determine which memory board contains the failed

DIMM by locating the memory board with an amber memory status LED and one or

more amber DIMM status LEDs. The Ready to Hot Plug LED must be green, indicating

that you can perform a hot-plug procedure.

NOTE: If the Ready to Hot Plug LED is off on both boards, you must power down the server

before replacing DIMMs.

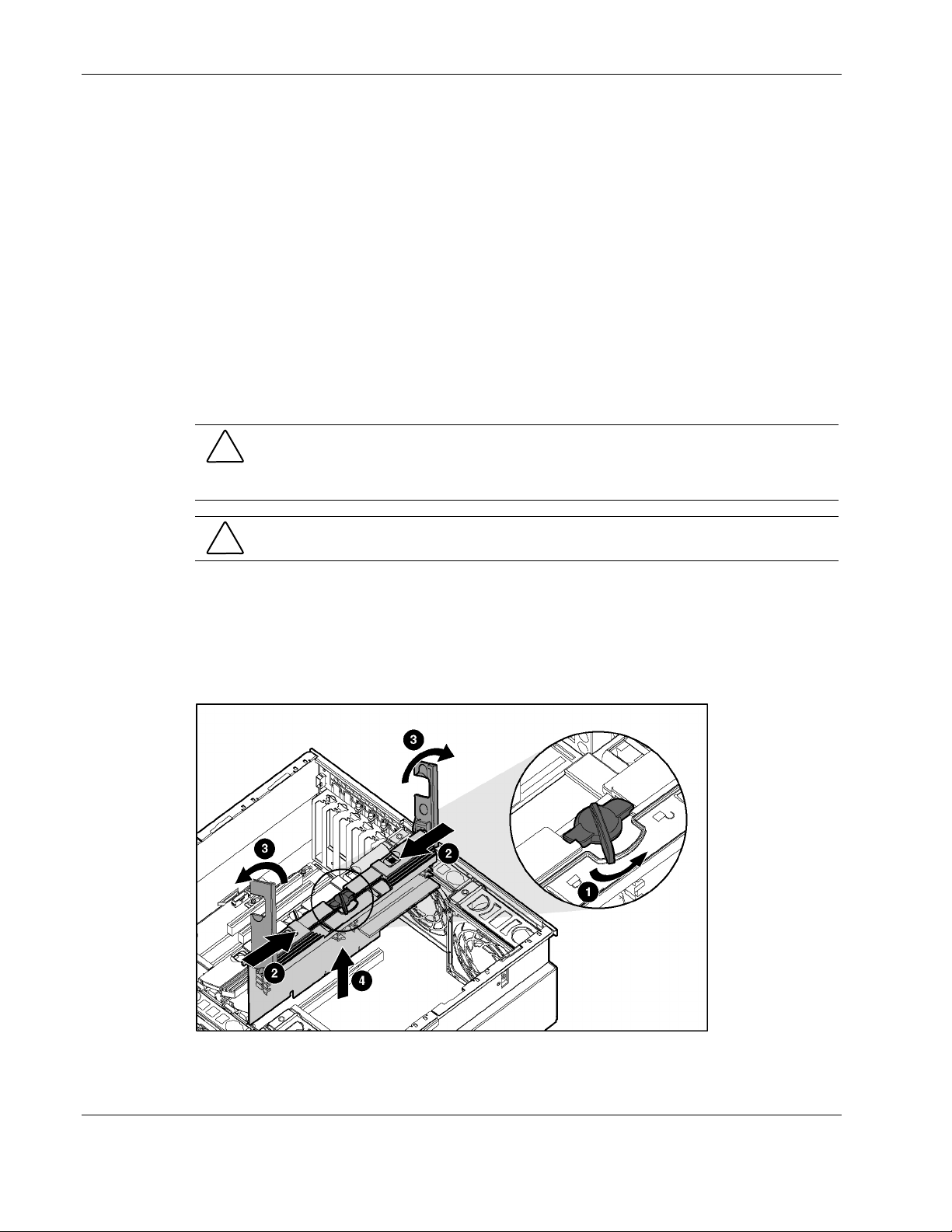

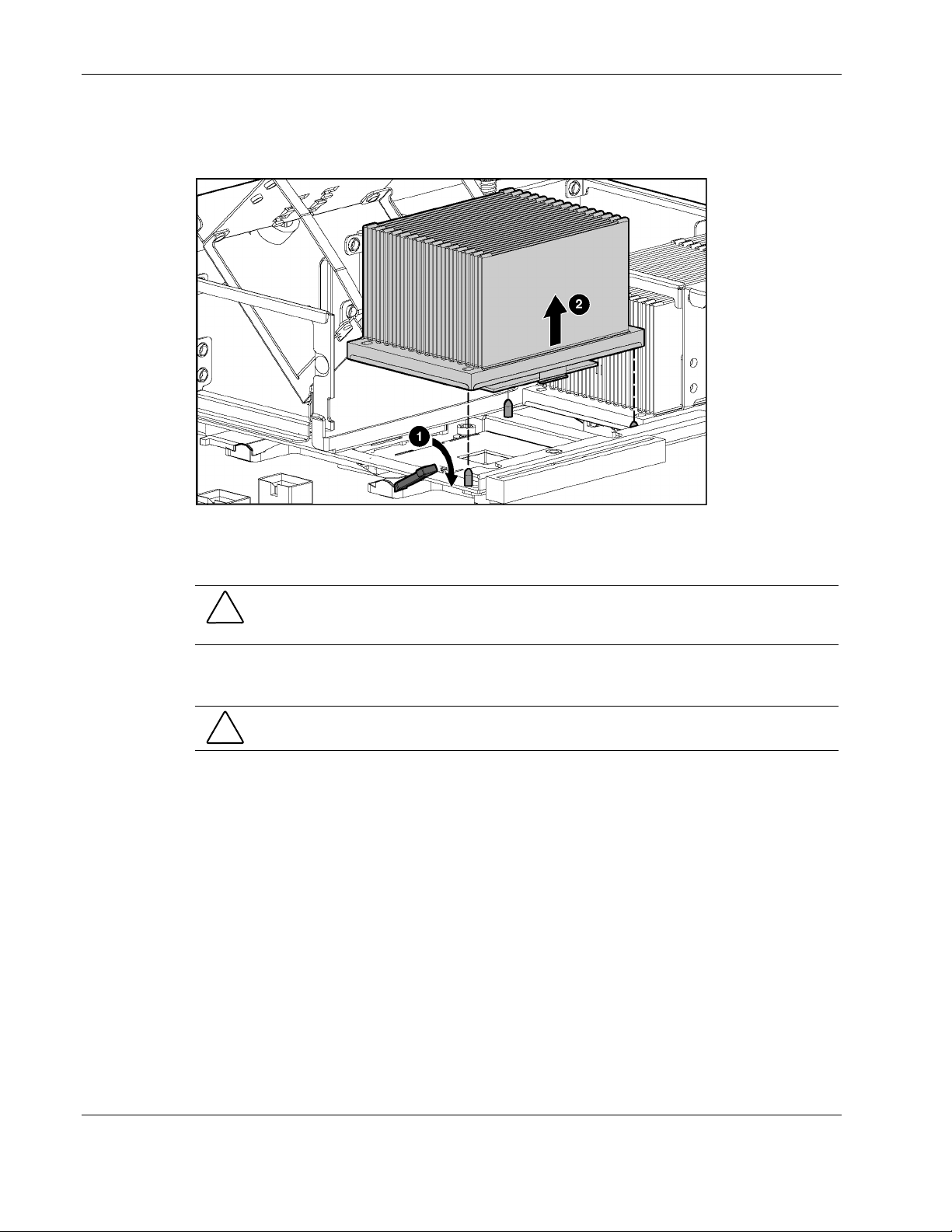

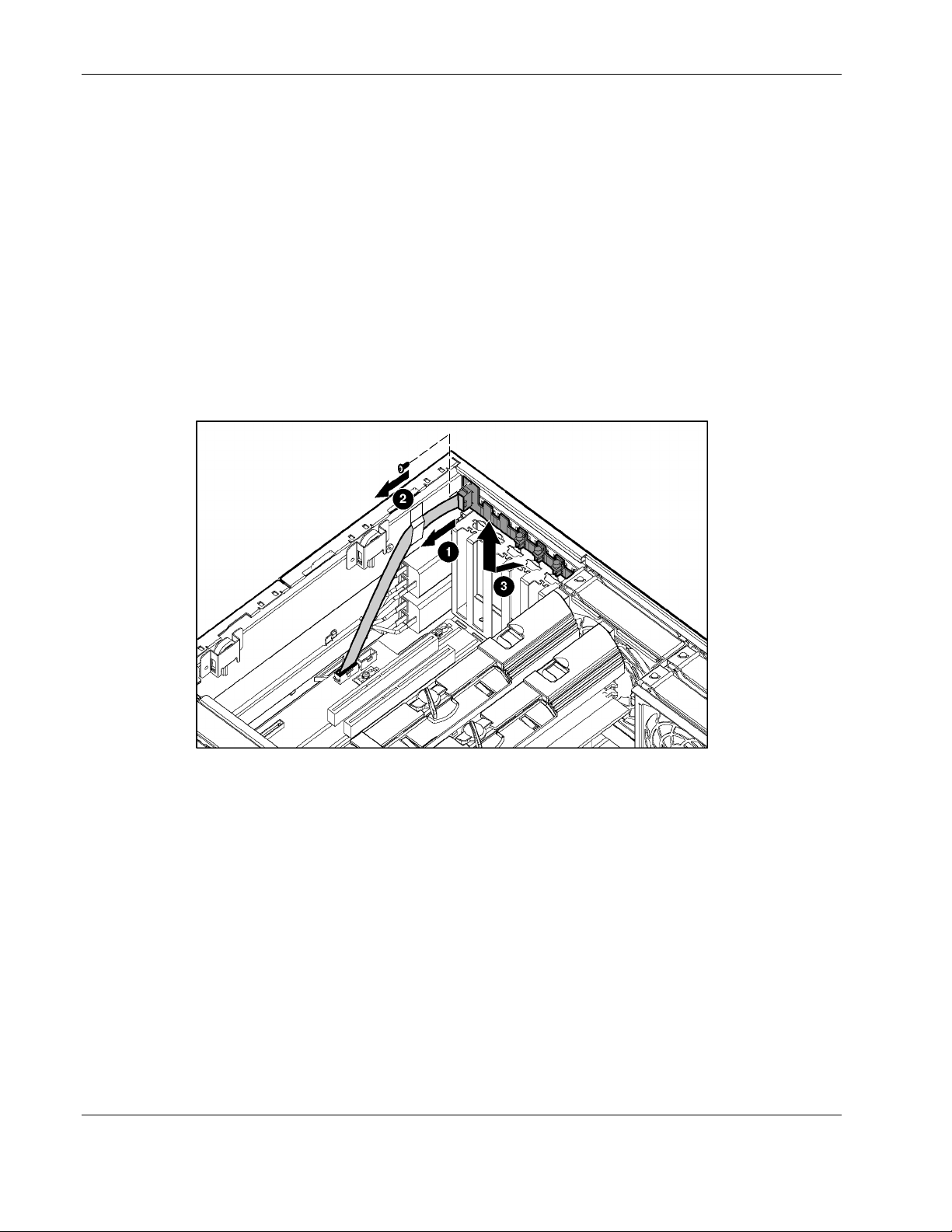

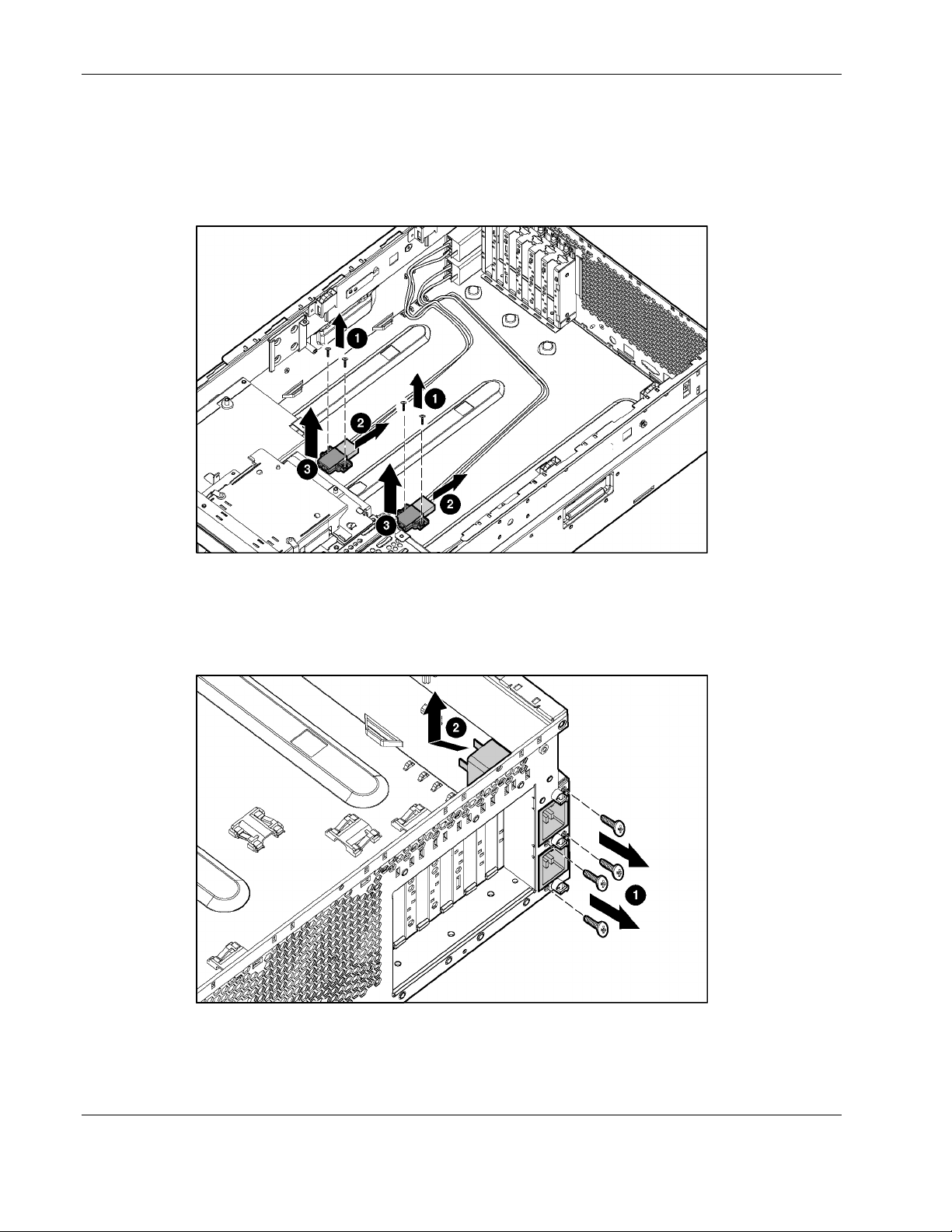

3. Disengage the locking switch (1).

Hot-plug replacement procedure: After turning the locking switch to the unlock

position, the LEDs turn off, except the amber LEDs. Wait until all green LEDs are off

before proceeding. Make note of which DIMM status LED remains illuminated amber,

indicating the DIMM you need to replace.

CAUTION: Do not attempt to unlock the memory board in an operational server when the

Ready to Hot Plug LED is not green. This will generate an audible alarm and cause the

memory board LEDs to flash amber. Proceeding to remove the memory board after the

audible and visible alarms causes system failure.

CAUTION: To prevent system failure, do not remove the memory board from the server until

the memory status LED stops blinking.

4. Press the release latches inward (2).

5. Pull the memory board up out of the server (3).

Hot-plug replacement procedure: While the memory board with the failed or degraded

DIMM is being replaced, the system continues to read and write from the operational

memory board.

Figure 2-16: Removing a memory board

2-24 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 42

Removing a DIMM

To remove a DIMM:

1. Remove the memory board. Refer to “Rem oving a Memory Board” in this chapter.

2. Place the memory board on a level, nonconductive surface.

3. Open the DIMM slot latches (1).

4. Remove the DIMM from the DIMM slot (2).

Removal and Replacement Procedures

Figure 2-17: Removing a DIMM

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-25

Page 43

Removal and Replacement Procedures

Installing a DIMM

To install a DIMM:

1. Align the keyed portion of the bottom edge of the DIMM with the tab in the DIMM slot.

IMPORTANT: The bottom edge of the DIMM is keyed to fit into the DIMM slot only one way.

2. Press the DIMM firmly into the slot (1).

3. Push the latches into place (2).

Figure 2-18: Installing a DIMM

2-26 HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide

Page 44

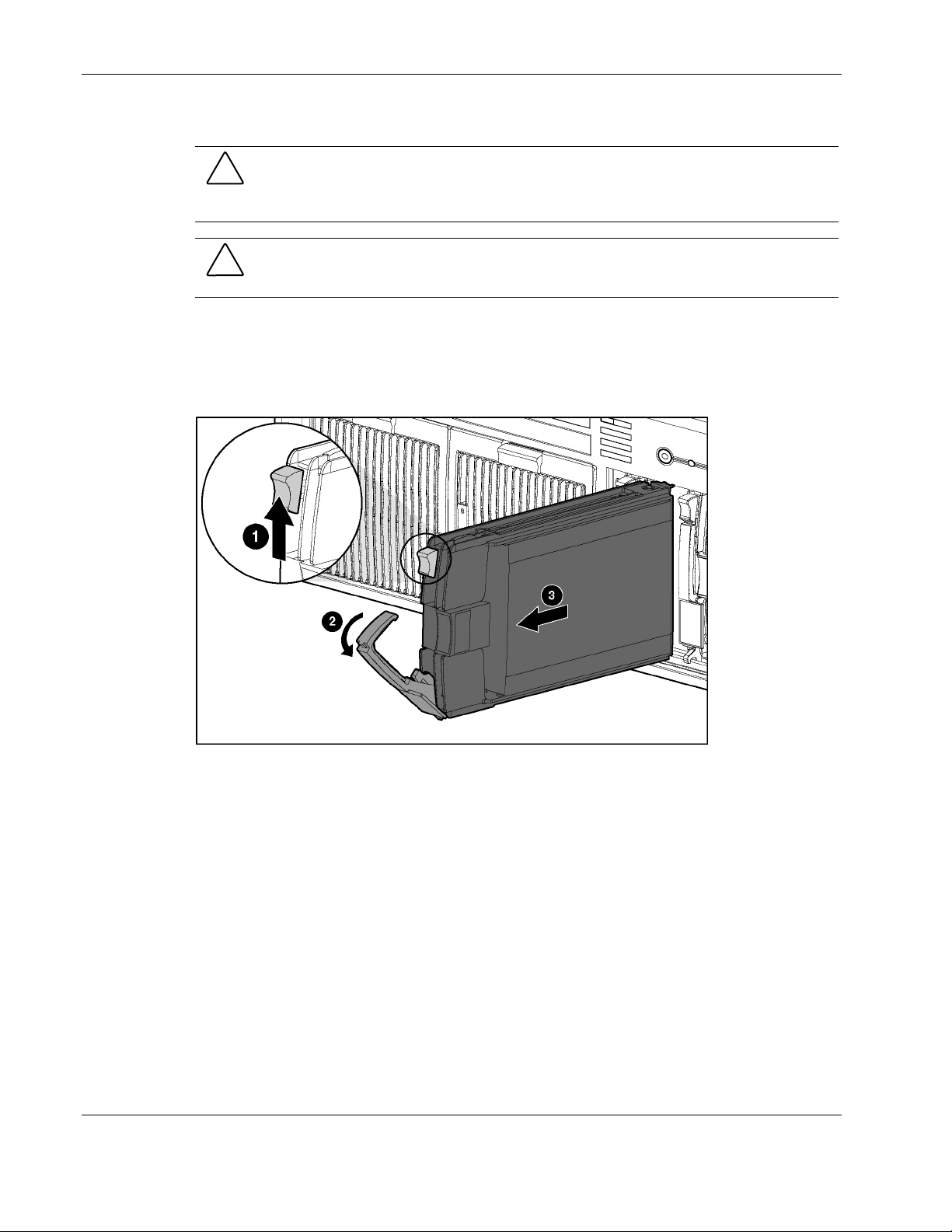

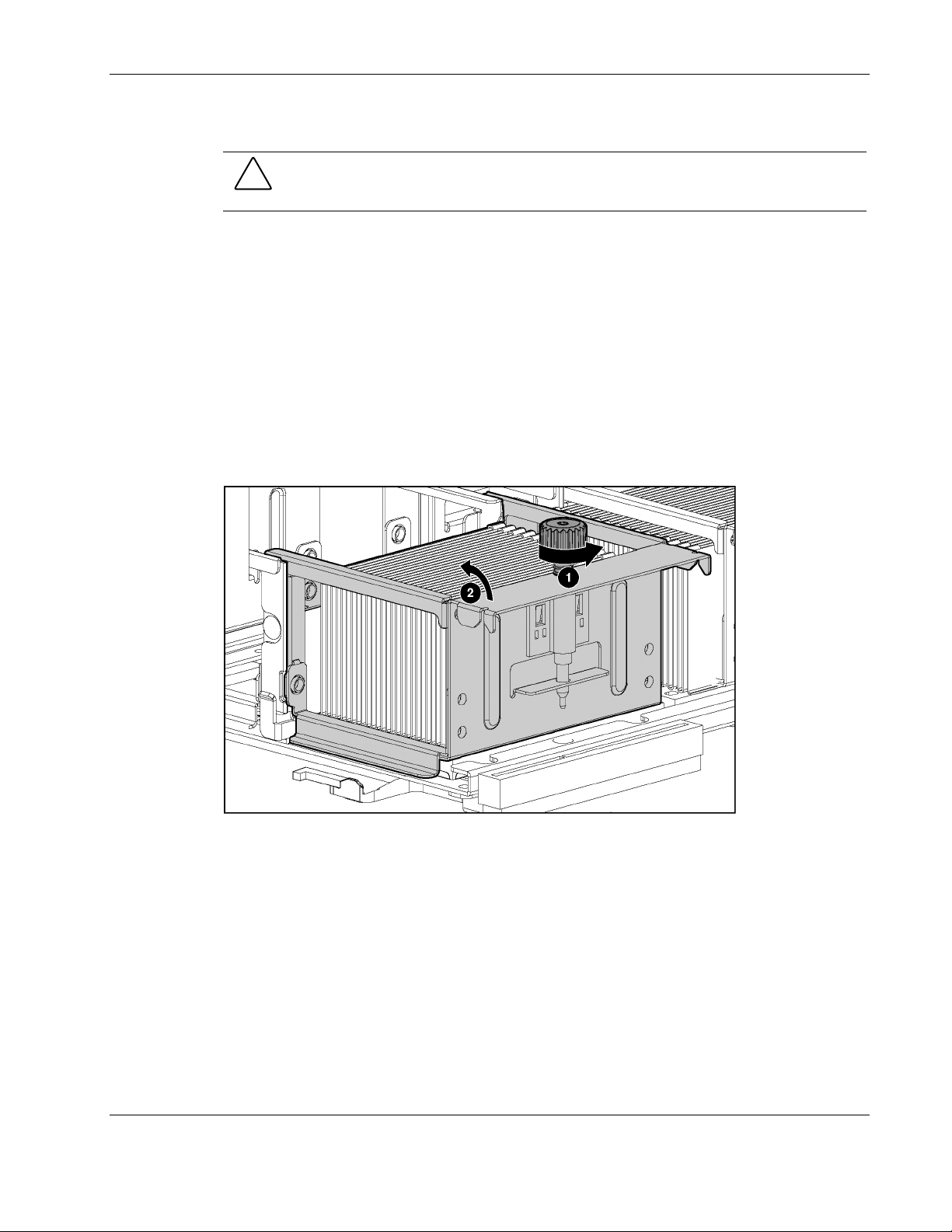

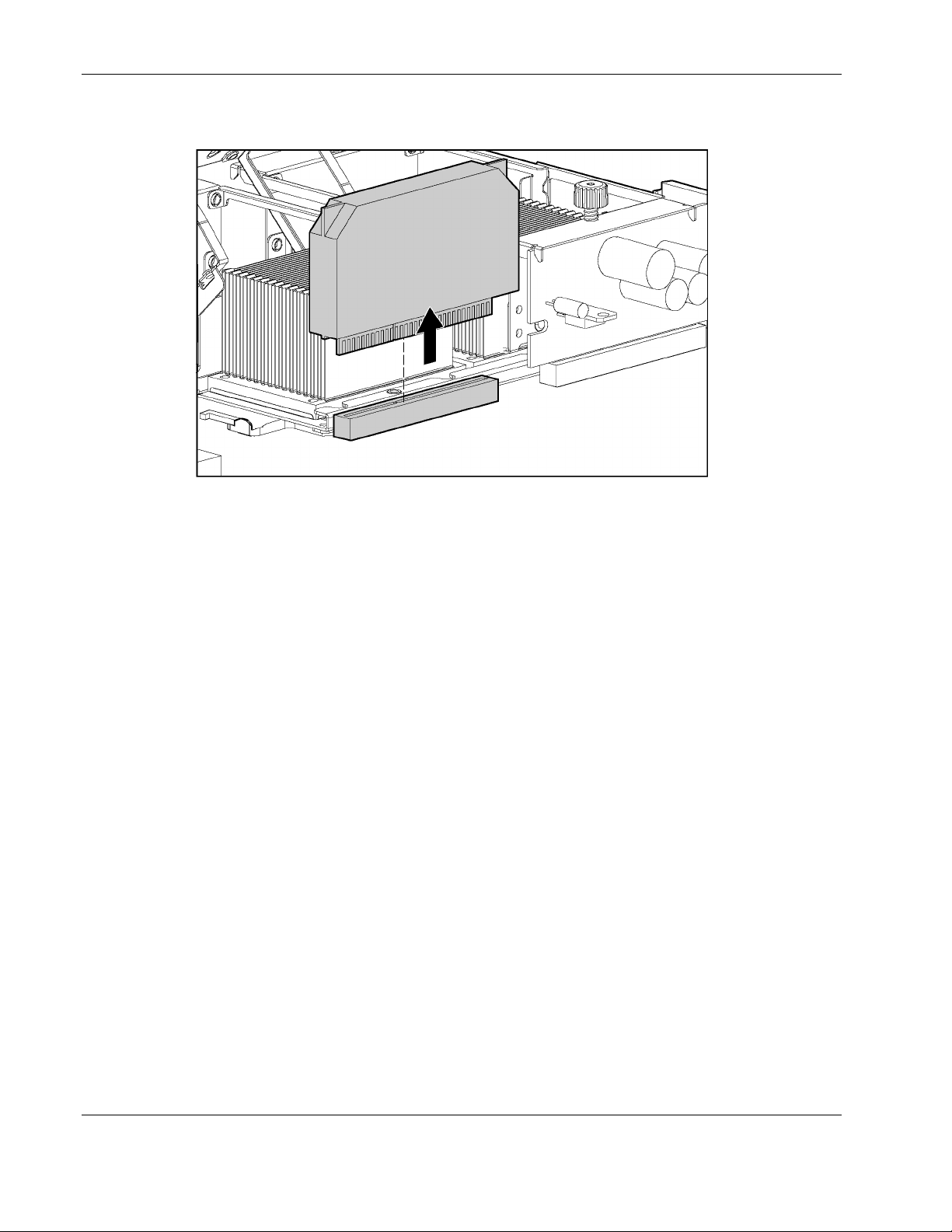

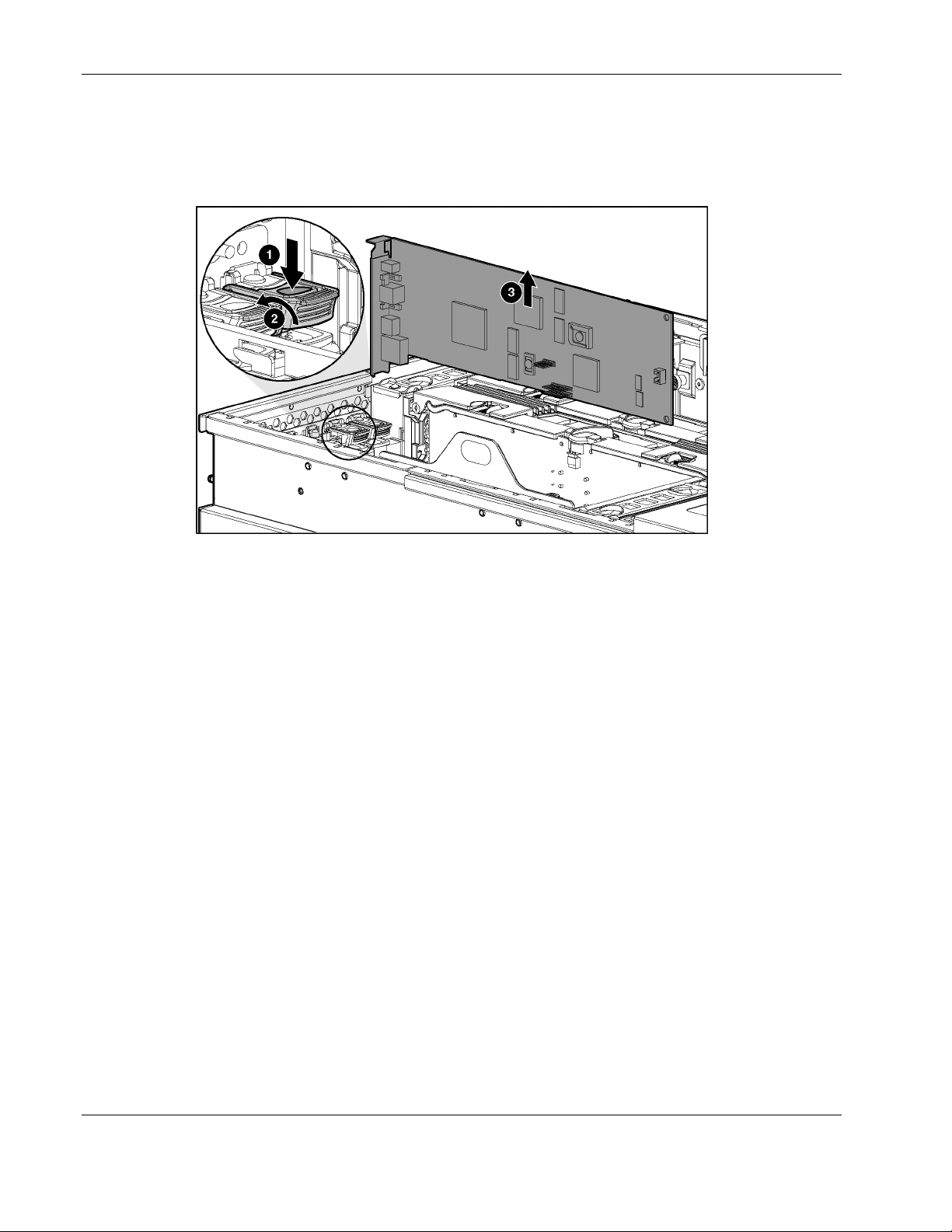

Installing a Memory Board

To install a memory board:

1. Align the memory board with the memory slot and memory board guide clips.

2. Slide the memory board into the server (1), and close the ejector levers to seat the

memory board firmly (2).

Hot-plug procedure: Any LEDs that were amber when the board was removed from the

server now illuminate amber again.

IMPORTANT: The LEDs relight amber during this step to enable you to verify again which DIMM

failed. If you have already replaced the failed DIMM, disregard the amber LEDs. The LEDs change

back to green after the locking switch is engaged, and the memory copy is complete.

3. Engage the locking switch (3).

Hot-plug procedure: All LEDs now turn off except the memory status LED, which

flashes green while data is copied from one memory board to the other. This process may

take up to a minute to complete. When the copying process is complete, the other LEDs

will re-illuminate as described in Table 2-11.

CAUTION: Do not remove the memory board while the memory status LED is flashing.

When the memory status LED is flashing, the memory board is transferring data.

Removing the memory board during data transfer may cause system failure.

Removal and Replacement Procedures

Figure 2-19: Installing a memory board

4. If the server is not currently configured for hot-plug mirrored memory, power up the

server. Refer to “ Powering Down the Server” in this chapter.

Hot-plug procedure: If the server is configured for hot-plug mirrored memory or Hot-

Add functionality, skip to step 7.

5. Configure the memory. Refer to “Conf iguring the Memory” in this chapter.

HP ProLiant DL580 Generation 2 Server Maintenance and Service Guide 2-27

Page 45

Removal and Replacement Procedures

6. Reference the LEDs on the top of the memory board to be sure that the memory is

functioning properly. The following table describes the LEDs for each memory

configuration when the DIMMs and memory board are installed and functioning

properly. For more information on LEDs, refer to Chapter 4 “Conn ectors, LEDs, and

Switches.”

Table 2-8: Memory LED States on a Properly Configured Memory Board

Memory Status Green Green Green Green

DIMMs 1-8, if

populated

Online Spare

Status

Mirroring Status Off Off Green Green

Online Spare

text*

Ready to Hot

Plug

*If two memory boards are installed, the online spare text is only illuminated for the memory board in

slot 1.

Memory Configuration LED

Advanced ECC