Page 1

HP ProLiant DL145 Generation 3 Server

Maintenance and Service Guide

Part number: 430047-004

Fourth Edition: April 2007

Page 2

Legal notices

© Copyright 2006, 2007 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

AMD, AMD Opteron, and combinations thereof are trademarks of Advanced Micro Devices, Inc.

Printed in the US

Part number: 430047-004

Fourth Edition: April 2007

2

Page 3

Contents

Illustrated parts catalog

Customer self-repair (CSR)......................................................................................................................... 4

Mechanical parts exploded view ............................................................................................................... 5

System components exploded view ............................................................................................................ 6

HP contact information ............................................................................................................................. 7

Before you contact HP .............................................................................................................................. 7

Removal and replacement procedures

Hardware configuration tools .................................................................................................................... 9

Hardware configuration warnings.............................................................................................................. 9

Symbols on equipment......................................................................................................................... 9

Rack warnings.................................................................................................................................. 10

Server warnings and precautions ........................................................................................................ 11

Hardware configuration information......................................................................................................... 11

Electrostatic discharge information ...................................................................................................... 11

Pre-installation procedures.................................................................................................................. 11

Post-installation procedures................................................................................................................. 12

Powering down the server....................................................................................................................... 12

Opening and closing the server ............................................................................................................... 12

Drive bay configuration .......................................................................................................................... 14

Cable routing diagrams ..................................................................................................................... 14

Optical drive .................................................................................................................................... 18

Hard drives ...................................................................................................................................... 20

System board ........................................................................................................................................ 29

Removing a system board .................................................................................................................. 29

Installing a system board.................................................................................................................... 30

System board configuration..................................................................................................................... 32

Processor ......................................................................................................................................... 32

Memory........................................................................................................................................... 38

Expansion boards ............................................................................................................................. 41

System battery .................................................................................................................................. 48

System fans ...................................................................................................................................... 50

Power supply unit (PSU) ..................................................................................................................... 54

Diagnostic tools

Overview of available diagnostic tools ..................................................................................................... 61

Connectors, buttons, and LEDs

Connectors and components ................................................................................................................... 62

Front panel components ..................................................................................................................... 62

Rear panel components ..................................................................................................................... 62

System board components.................................................................................................................. 63

Front panel board components ................................................................................................................ 65

Front panel board cable routing.......................................................................................................... 66

Status LED indicators .............................................................................................................................. 67

Front panel LED indicators.................................................................................................................. 67

Rear panel LED indicators .................................................................................................................. 68

System board LED indicators .............................................................................................................. 69

Physical and operating specifications

System unit............................................................................................................................................ 70

Memory................................................................................................................................................ 72

Processor .............................................................................................................................................. 72

Gigabit Ethernet controller ...................................................................................................................... 72

Index

Contents 3

Page 4

Illustrated parts catalog

This chapter provides the illustrated parts breakdown and spare parts lists for the HP ProLiant DL145 Generation

3 server. Information for contacting HP is also provided.

Customer self-repair (CSR)

What is customer self-repair?

HP's customer self-repair program offers you the fastest service under either warranty or contract. It enables HP to

ship replacement parts directly to you so that you can replace them. Using this program, you can replace parts at

your own convenience.

A convenient, easy-to-use program:

• An HP support specialist will diagnose and assess whether a replacement part is required to address a

system problem. The specialist will also determine whether you can replace the part.

• Replacement parts are express-shipped. Most in-stock parts are shipped the very same day you contact HP.

You may be required to send the defective part back to HP, unless otherwise instructed.

• Available for most HP products currently under warranty or contract. For information on the warranty

service, refer to the HP website

(http://h18004.www1.hp.com/products/servers/platforms/warranty/index.html

For more information about HP's customer self-repair program, contact your local service provider. For the North

American program, refer to the HP website (http://www.hp.com/go/selfrepair

Table 1 and Table 2 show the customer replaceable parts under the CSR program.

).

).

NOTE: Table items marked with an asterisk (*) are not shown in the figures.

Illustrated parts catalog 4

Page 5

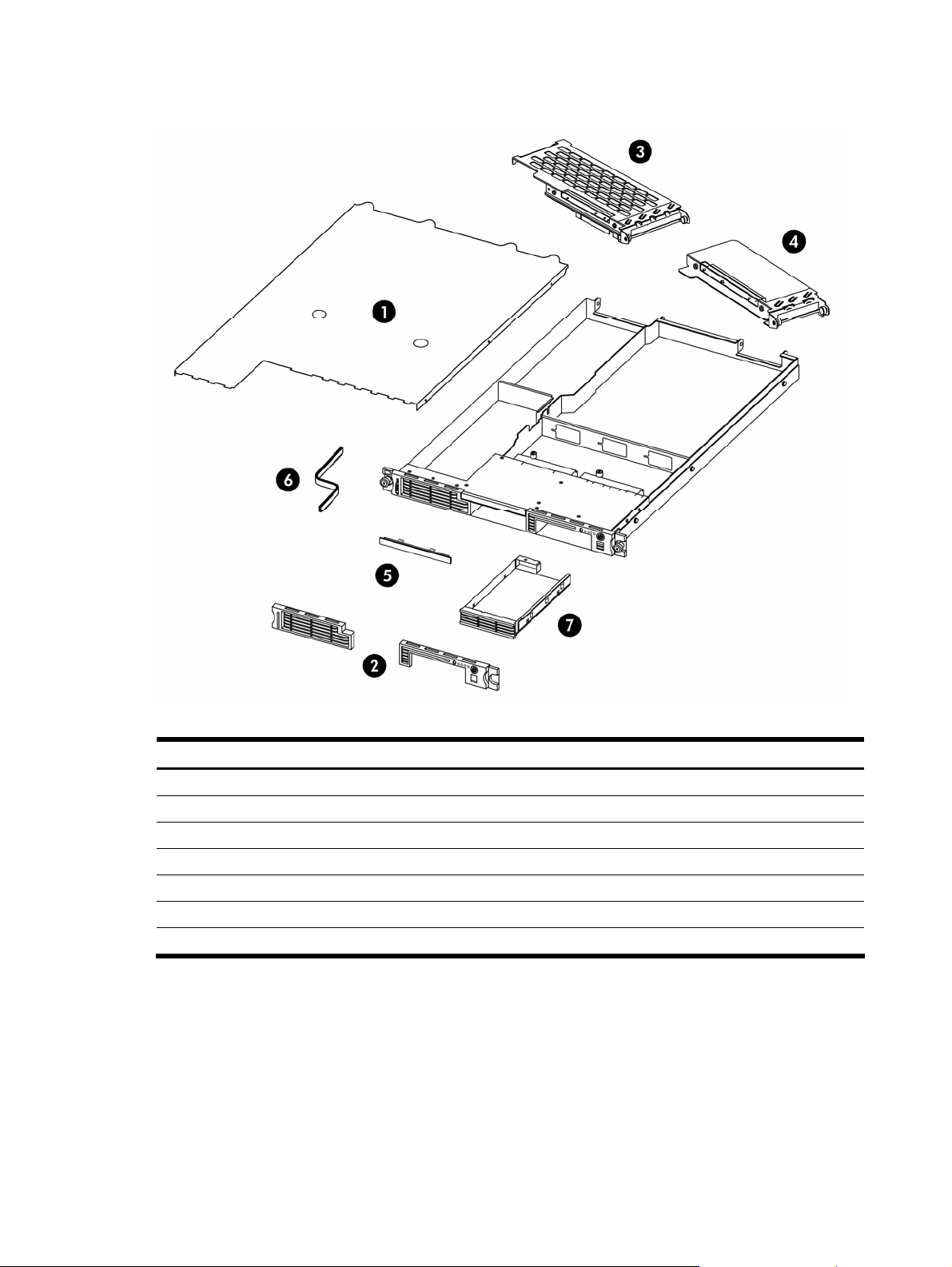

Mechanical parts exploded view

Figure 1 Mechanical parts exploded view

Table 1 Mechanical spare parts list

Item Description Spare Part Number Customer Self Repair

1 Top cover 434437-001 Mandatory

2 Front bezel 434423-001 Mandatory

3 Full-sized riser board assembly 434459-001 Mandatory

4 Low-profile riser board assembly 434458-001 Mandatory

5 Optical drive bay bezel 434436-001 Mandatory

6 Air baffle 434424-001 Mandatory

7 Non-hot-plug hard disk drive (HDD) carrier 434425-001 Mandatory

Illustrated parts catalog 5

Page 6

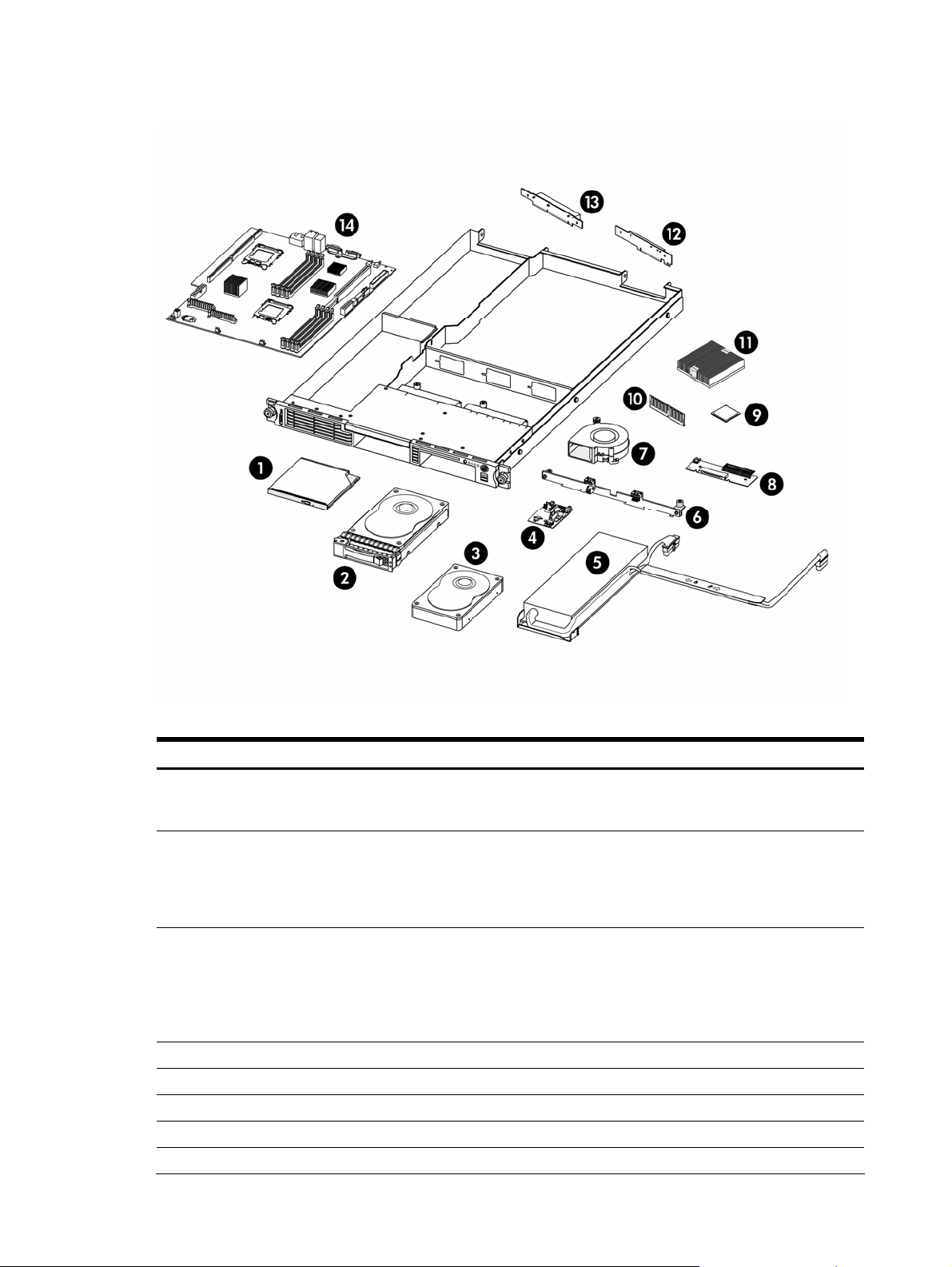

System components exploded view

Figure 2 System components exploded view

Table 2 System components spare parts list

Item Description Spare Part Number Customer Self Repair

1 Optical drive

a) DVD ROM drive

b) DVD/CD RW combo drive

2 Hot-plug SAS hard drive

a) 36 GB

b) 72 GB

c) 146 GB

d) 300 GB

3 Non-hot-plug SATA hard drive

a) 80 GB

b) 160 GB

c) 250 GB

d) 500 GB

e) 750 GB

4 Front panel board 434428-001 Mandatory

5 650 W power supply unit 434418-001 Mandatory

6 Hot-plug SATA/SAS backplane 434432-001 Mandatory

7 System fan module 434417-001 Mandatory

8 Optical drive docking board 434430-001 Mandatory

436951-001

436952-001

376593-001

376594-001

376595-001

432147-001

373311-001

399968-001

399969-001

404654-001

397377-001

Mandatory

Mandatory

Mandatory

Illustrated parts catalog 6

Page 7

Table 2 System components spare parts list

Item Description Spare Part Number Customer Self Repair

9 Processor

a) 1.8 GHz, 68W AMD Opteron

b) 1.8 GHz, 95W AMD Opteron

c) 2.2 GHz, 68W AMD Opteron

d) 2.4 GHz, 68W AMD Opteron

e) 2.4 GHz, 95W AMD Opteron

f) 2.6 GHz, 95 W AMD Opteron

g) 2.8 GHz, 95 W AMD Opteron

10 Memory

a) 512 MB PC2-5300 DIMM

b) 1 GB MB PC2-5300 DIMM

c) 2 GB MB PC2-5300 DIMM

11 Processor heat sink 434433-001 Optional

12 Low-profile riser board

a) PCI Express x4 riser board

b) PCI-X riser board

13 Full-sized riser board

a) PCI Express x16 riser board

b) HTX riser board

14 System board 434426-001 Optional

PCI-X SATA/SAS controller board 403053-001 Mandatory

IDE data cable 434421-001 Mandatory

SATA data cable (long) 434461-001 Mandatory

SATA data cable (short) 434462-001 Mandatory

SAS cable assembly 385840-001 Mandatory

Front panel board LED cable assembly 434420-001 Mandatory

Front panel USB port 2.0 cable assembly 434419-001 Mandatory

Drive power cable assembly (non-hot-plug) 436538-001 Mandatory

Drive power cable assembly (hot-plug) 436539-001 Mandatory

3V 200-mAh internal lithium battery for system board 234556-001 Mandatory

434949-001

419473-001

419477-001

419479-001

419478-001

419480-001

439749-001

416355-001

416356-001

416357-001

434429-001

434434-001

434431-001

434435-001

Optional

Mandatory

Mandatory

Mandatory

HP contact information

For the name of the nearest HP authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• In other locations, refer to the HP website at www.hp.com.

For HP technical support:

• In North America:

• Call 1-800-HP-INVENT (1-800-474-6836). This service is available 24 hours a day, 7 days a week.

For continuous quality improvement, calls may be recorded or monitored.

• If you have purchased a Care Pack (service upgrade), call 1-800-633-3600. For more information

about Care Packs, refer to the HP website at www.hp.com.

• Outside North America, call the nearest HP Technical Support Phone Center. For telephone numbers for

worldwide Technical Support Centers, refer to the HP website at www.hp.com

Before you contact HP

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

.

Illustrated parts catalog 7

Page 8

• Product serial number

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

Illustrated parts catalog 8

Page 9

Removal and replacement procedures

This chapter provides subassembly and module-level removal and replacement procedures for the HP ProLiant

DL145 Generation 3 server.

Review the specifications of a new component before installing it to make sure it is compatible with the server.

When you integrate new components into the system, record its model and serial number and any other pertinent

information for future reference. After completing any removal or replacement procedure, run the diagnostics

program to verify that all components operate properly.

Hardware configuration tools

When performing any hardware configuration procedure, you may need the following tools:

• T-15 Torx screwdriver

• Flat-blade screwdriver

• L-shaped wrench (ships with the server)

The following references and software tools may also be used:

• HP ProLiant DL145 Generation 3 Server Support CD

• IPMI Event Log

• Diagnostics software

NOTE: The figures used in this chapter to illustrate procedural steps are labeled numerically (1, 2, 3, and

so on). When these figures are used in substep items, the alphabetically labeled instructions correspond

to the numbered labels on the related figure (label 1 corresponds to step a, label 2 corresponds to step

b, and so on).

The procedures described in this chapter assume that the server is out of the rack and is positioned on a flat,

stable surface.

Hardware configuration warnings

Read the following sections before performing any servicing or troubleshooting procedure.

WARNING! Only authorized technicians trained by HP should attempt to repair this equipment. Because of the

complexity of the individual boards and subassemblies, no one should attempt to make repairs at the

component level or to make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

CAUTION: Whenever installing hardware or performing maintenance procedures requiring access to internal

components, it is recommended that all server data be backed up to avoid loss.

Symbols on equipment

These symbols may be located on equipment in areas where hazardous conditions may exist.

WARNING! This symbol, in conjunction with any of the following symbols, indicates the presence of a

potential hazard. The potential for injury exists if warnings are not observed. Consult your documentation for

specific details.

This symbol indicates the presence of hazardous energy circuits or electric shock hazards. Refer all servicing to

qualified personnel.

WARNING! To reduce the risk of injury from electric shock hazards, do not open this enclosure. Refer all

maintenance, upgrades, and servicing to qualified personnel.

This symbol indicates the presence of electric shock hazards. The area contains no user or field serviceable

Removal and replacement procedures 9

Page 10

parts. Do not open for any reason.

WARNING! To reduce the risk of injury from electric shock hazards, do not open this enclosure.

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING! To reduce the risk of electric shock, fire, or damage to the equipment, do not plug telephone or

telecommunications connectors into this receptacle.

This symbol indicates the presence of a hot surface or hot component. If this surface is contacted, the potential

for injury exists.

WARNING! To reduce the risk of injury from a hot component, allow the surface to cool before touching.

These symbols, on power supplies or systems, indicate that the equipment is supplied by multiple

sources of power.

WARNING! To reduce the risk of injury from electric shock, remove all power cords to completely

disconnect power from the system.

This symbol indicates that the component exceeds the recommended weight for one individual to handle safely.

WARNING! To reduce the risk of personal injury or damage to the equipment, observe local occupational

health and safety requirements and guidelines for manual material handling.

Rack warnings

WARNING! To reduce the risk of personal injury or damage to equipment, always ensure that the rack is

adequately stabilized before extending a component outside the rack. A rack may become unstable if more

than one component is extended for any reason. Extend only one component at a time.

WARNING! To reduce the risk of personal injury or damage to the equipment, be sure that:

WARNING! When installing the server in a Telco rack, make certain that the rack frame is adequately secured

to the building structure at the top and bottom.

WARNING! To reduce the risk of personal injury or damage to the equipment, at least two people are needed

to safely unload the rack from the pallet. An empty 42U rack weighs 115 kg (253 lb), is more than 2.1 m (7 ft)

tall, and may become unstable when being moved on its casters. Do not stand in front of the rack as it rolls

down the ramp from the pallet. Handle the rack from both sides.

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizers are attached to the rack, if it is a single rack installation.

• The racks are coupled together in multiple rack installations.

CAUTION: This ProLiant server is intended for rack-mount operation. The server bezel is made from glossy

material. For safety purposes, do not place the server in the visual field of users to prevent any accidents

arising from light bouncing off the bezel’s surface.

ACHTUNG: Entsprechend der Bildschirmabeitsplatzverordnung, darf das Gerät nicht im Gesichtsfeld des

Bedieners aufgestellt werden, da das Gehäuse eine glänzende Front aufweist.

Removal and replacement procedures 10

Page 11

Server warnings and precautions

WARNING! Hazardous voltages are present inside the server. Always disconnect AC power from the server

and other associated assemblies while working inside the unit. Serious injury may result if this warning is not

observed.

WARNING! To reduce the risk of personal injury from hot surfaces, allow the hot-plug drives and the internal

system components to cool before touching them.

WARNING! To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Disconnect all power cords to completely remove power from the system.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a regulating

uninterruptible power supply (UPS). This device protects the hardware from damage caused by power surges

and voltage spikes and keeps the system in operation during a power failure.

CAUTION: The server must always be operated with the system top cover closed. Proper cooling is not

achieved if the system top cover is removed.

Hardware configuration information

Electrostatic discharge information

Proper packaging and grounding techniques are necessary precautions to prevent damage. To prevent

electrostatic damage, observe the following precautions:

• Transport products in static-safe containers such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

• Cover workstations with approved static-dissipating material. Use properly grounded (earthed) tools and

equipment and a wrist strap connected to the work surface.

• Keep the work area free of nonconductive materials, such as ordinary plastic assembly aids and foam

packing.

• Make sure that you are always properly grounded (earthed) when touching a static-sensitive component or

assembly.

• Avoid touching pins, leads, or circuitry.

• Always place drives with the Printed Circuit Board (PCB) assembly-side down.

• Use conductive field service tools.

Pre-installation procedures

Perform the steps below before you open the server or before you remove or replace any component:

WARNING! Failure to properly turn off the server before you open the server or before you start removing or

installing hardware components may cause serious damage as well as bodily harm.

1. Turn off the server and all the peripherals connected to it.

Refer to the “Powering down the server” section on page 12 for detailed instructions on how to completely

power down the server.

2. Disconnect the AC power cord from the power supply cable socket located on the server rear panel to

eliminate the risk of electrical shock.

Removal and replacement procedures 11

Page 12

3. Remove the top cover by following the procedure described in the “Opening and closing the server”

section on page 12.

4. Follow the ESD precautions listed in the “Electrostatic discharge information” section on page 11 when

handling a server component.

IMPORTANT: To streamline the configuration process, read through the entire installation and removal

procedures first and make sure you understand them before you before you begin.

Post-installation procedures

Perform the steps below after installing or removing a server component:

1. Be sure all components are installed according to the described step-by-step instructions.

2. Check to make sure you have not left loose tools or parts inside the server.

3. Reinstall any expansion boards, riser board assemblies, peripherals, board covers, brackets, and system

cables that you have removed.

4. Reinstall the top cover by following the procedure described in the “Opening and closing the server”

section on page 12.

5. Connect all external cables and the AC power cord to the system.

Route the cables properly through the available cable management arrangement.

6. Press the power button on the front panel to turn on the server.

Powering down the server

The server does not completely power down when the power button is pressed. The power button toggles

between On and Standby. The standby position removes power from most electronics and the drives, but some

internal circuitry remains active. To completely remove all power from the system, disconnect all power cords

from the server.

To power down the server:

1. Shut down server as directed by the operating system documentation.

2. Press the power button to toggle to Standby.

This places the server in standby mode and changes the power LED indicator to amber. In this mode, the

main power supply output is disabled. Standby does not completely disable or remove power from the

system.

3. Disconnect the AC power cord from the AC outlet and then from the server.

4. Be sure that the power LED indicator is turned off and that the fan noise has stopped.

5. Disconnect all external peripheral devices from the server.

Opening and closing the server

The top cover is detachable. You need to remove this cover before you can remove or replace a server

component.

To open the server:

1. Perform steps 1 and 2 of the pre-installation procedures on page 11.

2. Detach the top cover from the chassis:

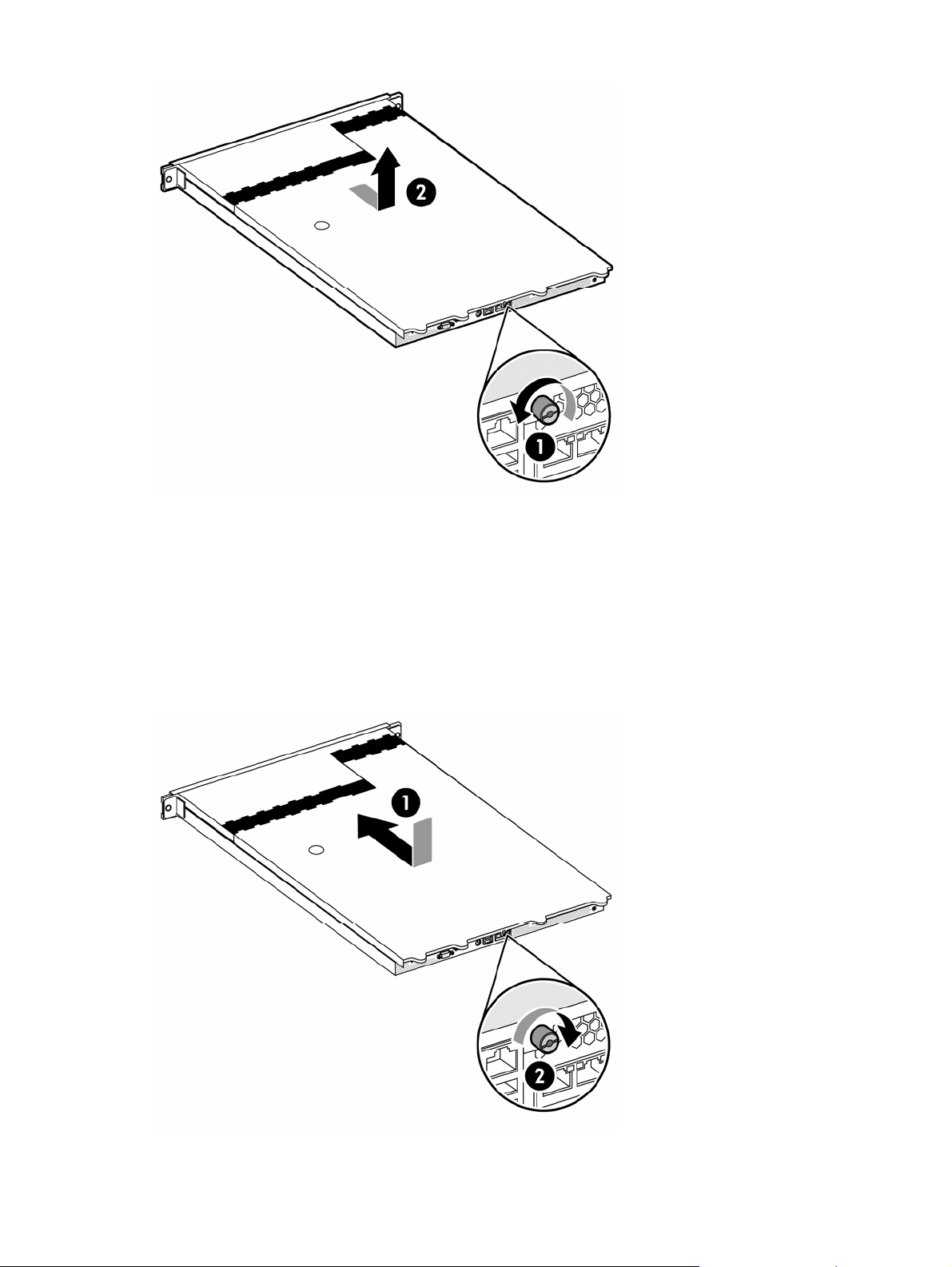

a. Loosen the captive screw on the rear panel.

To loosen the screw, HP recommends using the L-shaped wrench that ships with the server.

b. Slide the cover approximately 1.25 cm (0.5 in) toward the rear of the unit, then lift the cover away

from the chassis.

You can use the two circular grips on the top cover to help you slide the cover more easily.

Removal and replacement procedures 12

Page 13

Figure 3 Removing the top cover

3. Place the top cover in a safe place for reinstallation later.

To reinstall the top cover:

1. Perform steps 1 to 3 of the post-installation procedures described on page 12.

2. Reinstall the top cover:

a. Place the cover on the chassis approximately 1.25 cm (0.5 in) toward the rear of the unit, then slide the

cover forward into place.

b. Tighten the captive screw on the rear panel.

To tighten the screw, HP recommends using the L-shaped wrench that ships with the server.

Figure 4 Reinstalling the top cover

3. Perform steps 5 and 6 of the post-installation procedure on page 12.

Removal and replacement procedures 13

Page 14

Drive bay configuration

The server supports three drive bays — two drive bays for hard disk drives and one drive bay for a 9.5-mm

optical drive.

Go to the HP website at http://www.hp.com/

information on supported hard drives and optical drives.

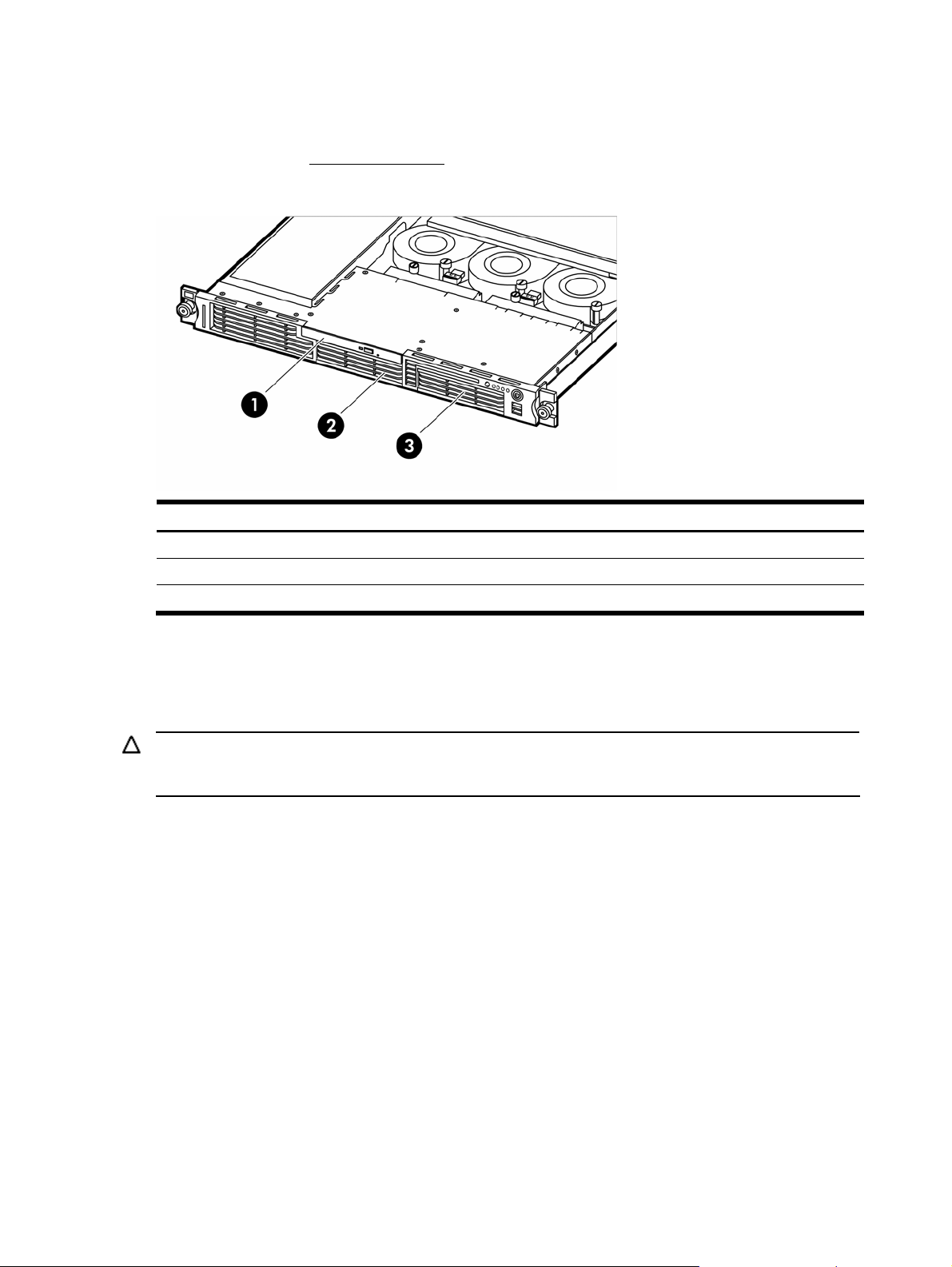

Figure 5 Drive bay configuration

and refer to the options list for this server model for the latest

Item Description

1 Optical drive bay

2 Hard disk drive (HDD) bay 1

3 HDD bay 2

Cable routing diagrams

Figure 6 to Figure 8 show the cable routing for the optical drive as well as the SATA and SAS hard drives. For

detailed cable routing procedures for each type of drive, refer to the corresponding steps in the drive

configuration sections later in this chapter.

CAUTION: Route the drive cables neatly. If possible, follow the pre-installed cable bundles in the chassis. The

cables should be routed in a position where they will not be pinched or crimped by the top cover, and they

should not hamper proper airflow inside the chassis.

Removal and replacement procedures 14

Page 15

Optical drive cable routing

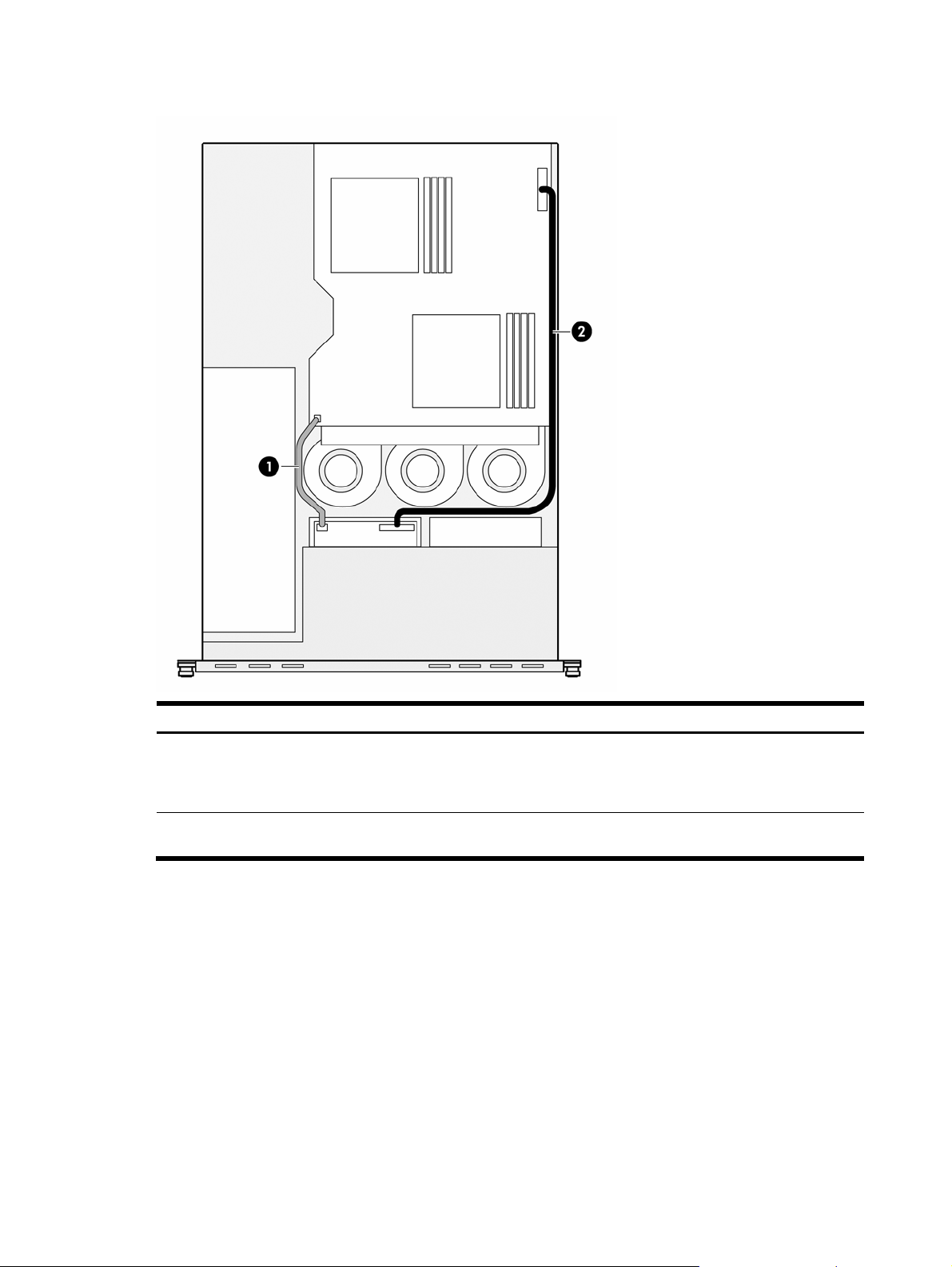

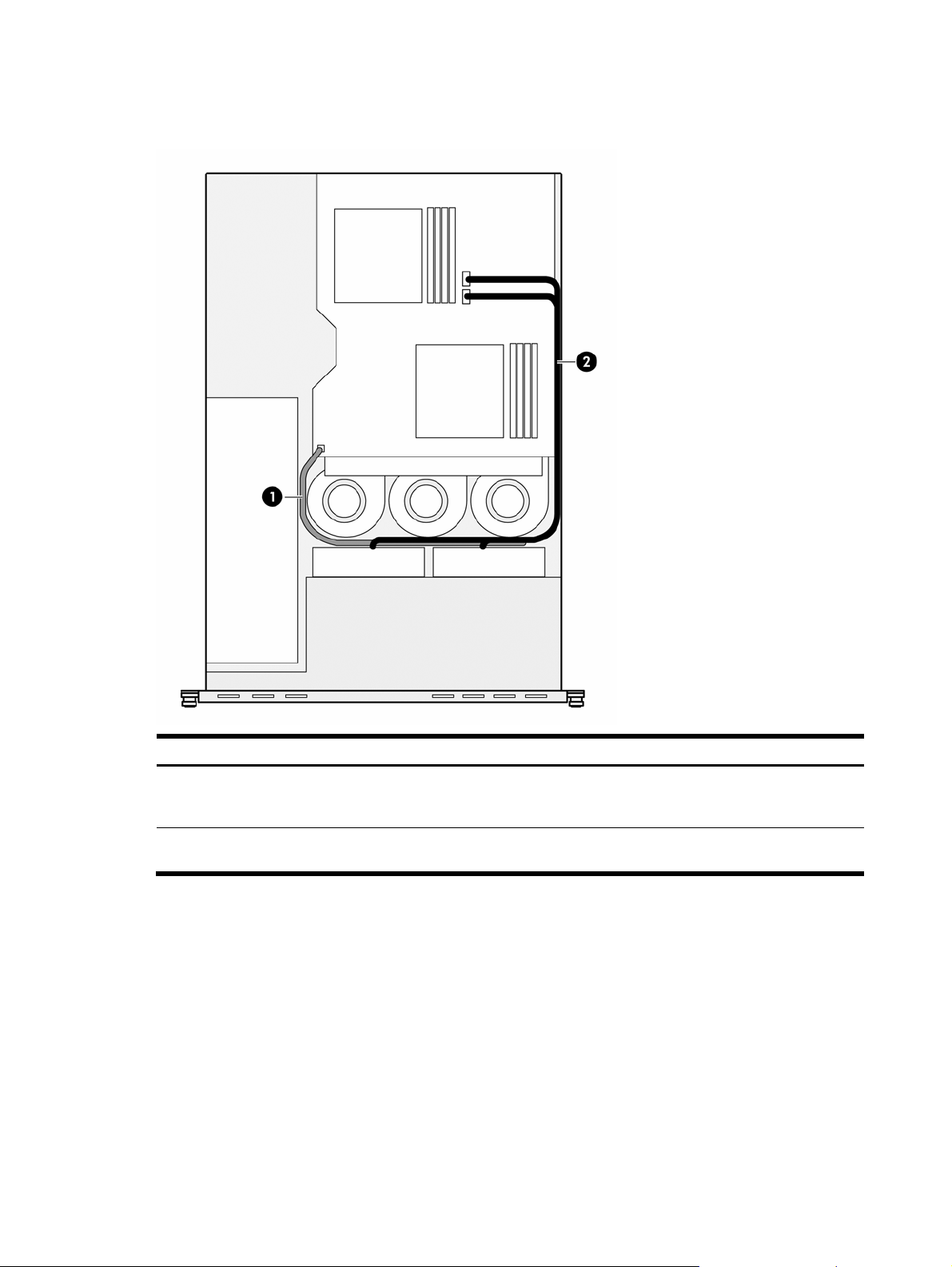

Figure 6 Optical drive cable routing

Item Description Connections

1 Drive power cable • P41 on the system board

• Power connector on the optical drive docking board

• Power connectors on any installed non-hot-plug SATA hard drives or the

hot-plug SATA/SAS backplane, if installed

2 IDE data cable • J7 on the system board

• Data connector on the optical drive docking board

Removal and replacement procedures 15

Page 16

Hard drive cable routing

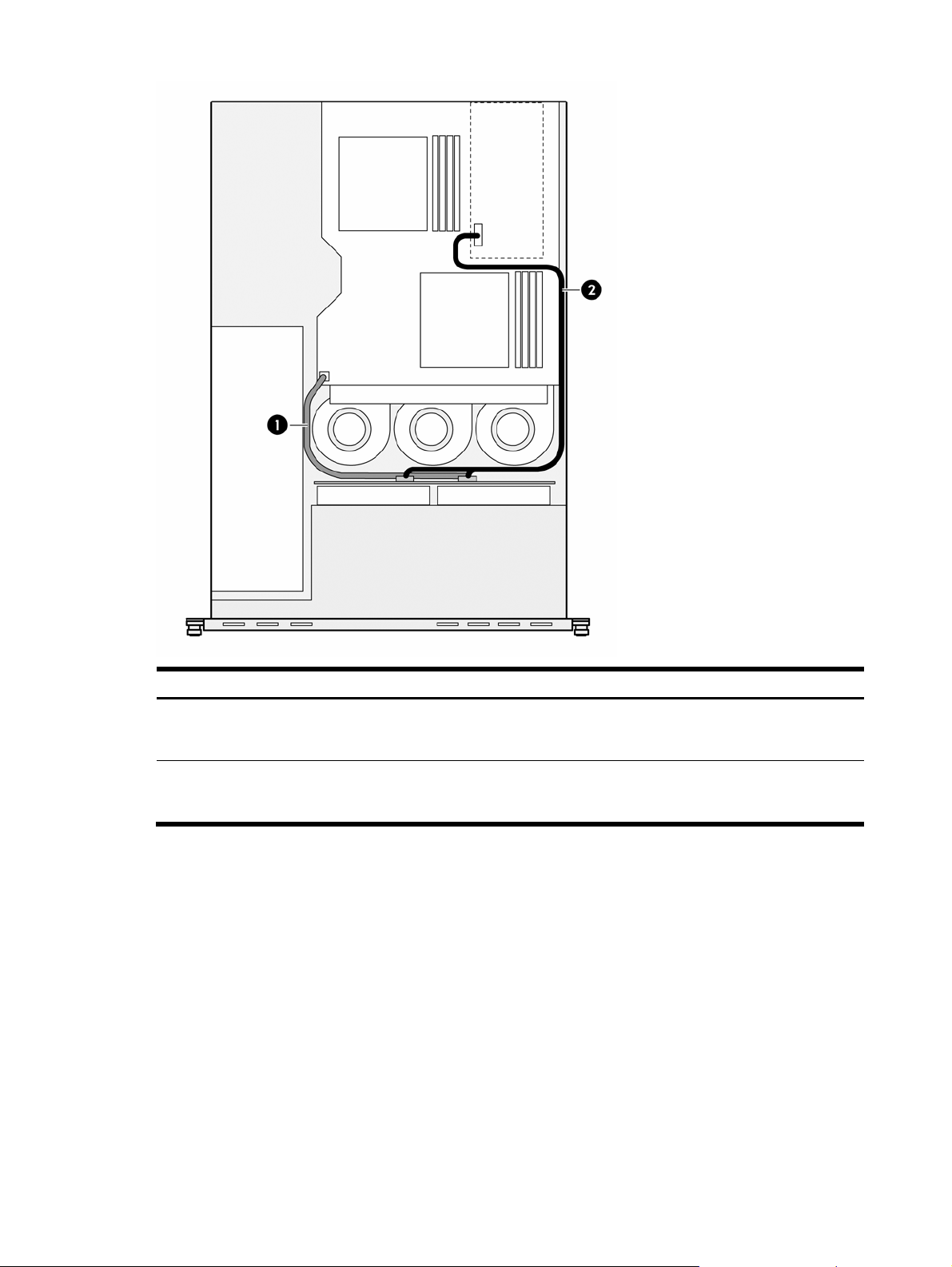

Non-hot-plug SATA hard drive cable routing

Figure 7 Non-hot-plug SATA hard drive cable routing

Item Description Connections

1 Drive power cable • P41 on the system board

• Power connector on each installed non-hot-plug SATA hard drive

• Power connector on the optical drive docking board, if installed

2 SATA data cables • P19 or P23 on the system board

• Data connector on each installed non-hot-plug SATA hard drive

Hot-plug SATA/SAS hard drive cable routing

Figure 8 shows the hot-plug hard drive cable routing when the server has a low-profile PCI Express x4 or PCI-X

hot-plug SATA/SAS controller board installed. Figure 9 shows the hard drive cable routing when the server has a

full-sized PCI Express x16 hot-plug SATA/SAS controller board installed.

Removal and replacement procedures 16

Page 17

Figure 8 Hot-plug SATA/SAS hard drive cable routing with a low-profile controller board

Item Description Connections

1 Hot-plug SATA/SAS backplane power

cable

• P41 on the system board

• Power connectors on the hot-plug SATA/SAS backplane

• Power connector on the optical drive docking board, if installed

2

Hot-plug SATA/SAS cable assembly

• Data connector on the hot-plug SATA/SAS controller board

• Data connectors and the LED connector on the hot -plug SATA/SAS

backplane

Removal and replacement procedures 17

Page 18

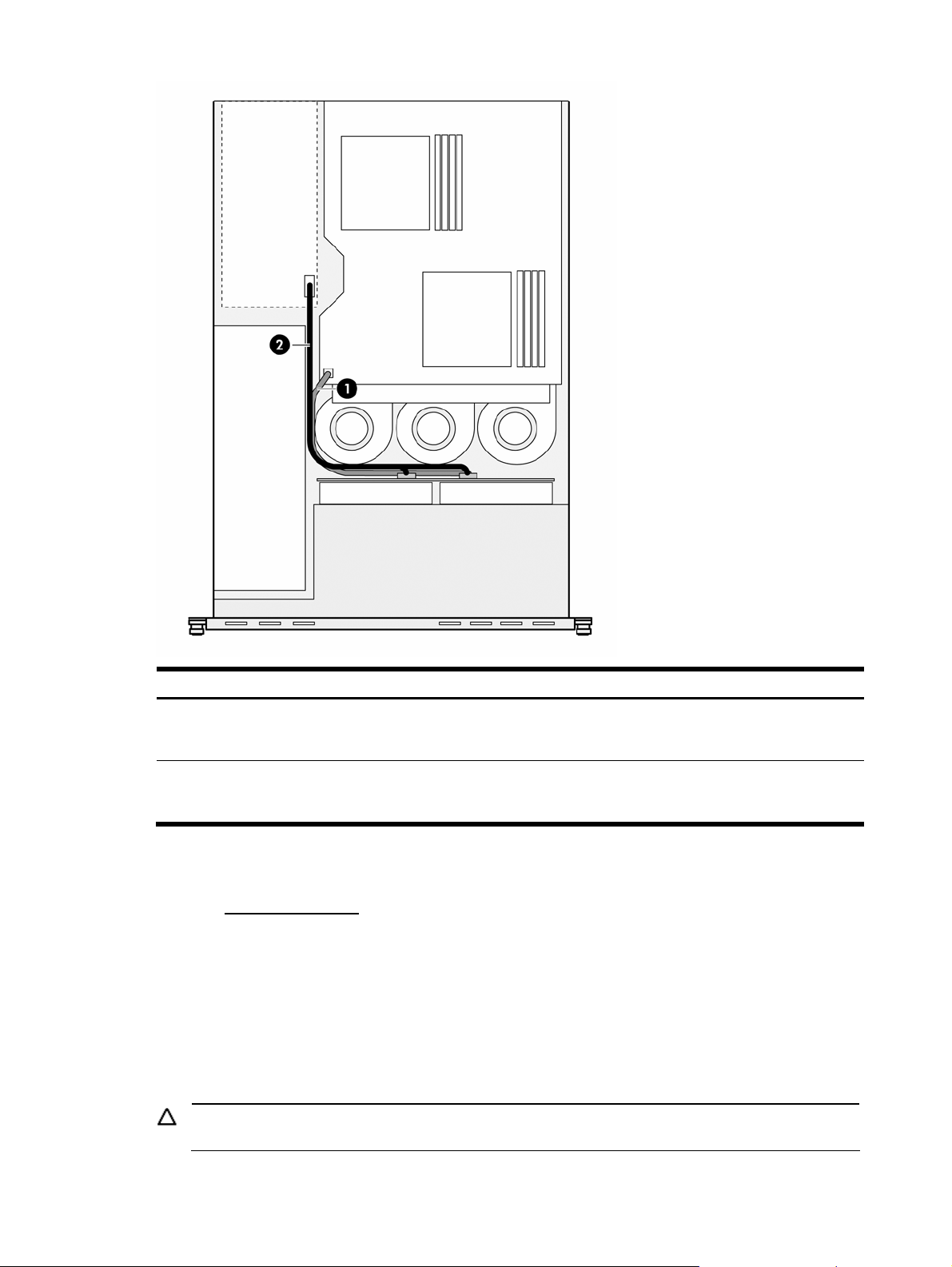

Figure 9 Hot-plug SATA/SAS hard drive cable routing with a full-sized controller board

Item Description Connections

1 Hot-plug SATA/SAS backplane power

2

Optical drive

The optical drive bay supports the installation of a 9.5-mm CD-ROM or CD/DVD combo drive. Go to the HP

website at http://www.hp.com/

drives.

To install a CD-ROM or CD/DVD combo drive:

1. Perform the pre-installation procedures described on page 11.

2. Remove the optical drive bay bezel from the chassis:

a. Push down on the two bezel tabs above the optical drive bay on the non-removable section of the

b. Remove the bezel from the optical drive bay.

cable

Hot-plug SATA/SAS cable assembly

and refer to the options list for this server model for a list of supported optical

chassis top cover.

Store the bezel for reassembly later.

• P41 on the system board

• Power connectors on the hot-plug SATA/SAS backplane

• Power connector on the optical drive docking board, if installed

• Data connector on the hot-plug SATA/SAS controller board

• Data connectors and the LED connector on the hot-plug SATA/SAS

backplane

CAUTION: Do not discard the bezel. If the optical drive is removed in the future, this bezel must be

reinstalled in the chassis for the proper cooling of the system.

Removal and replacement procedures 18

Page 19

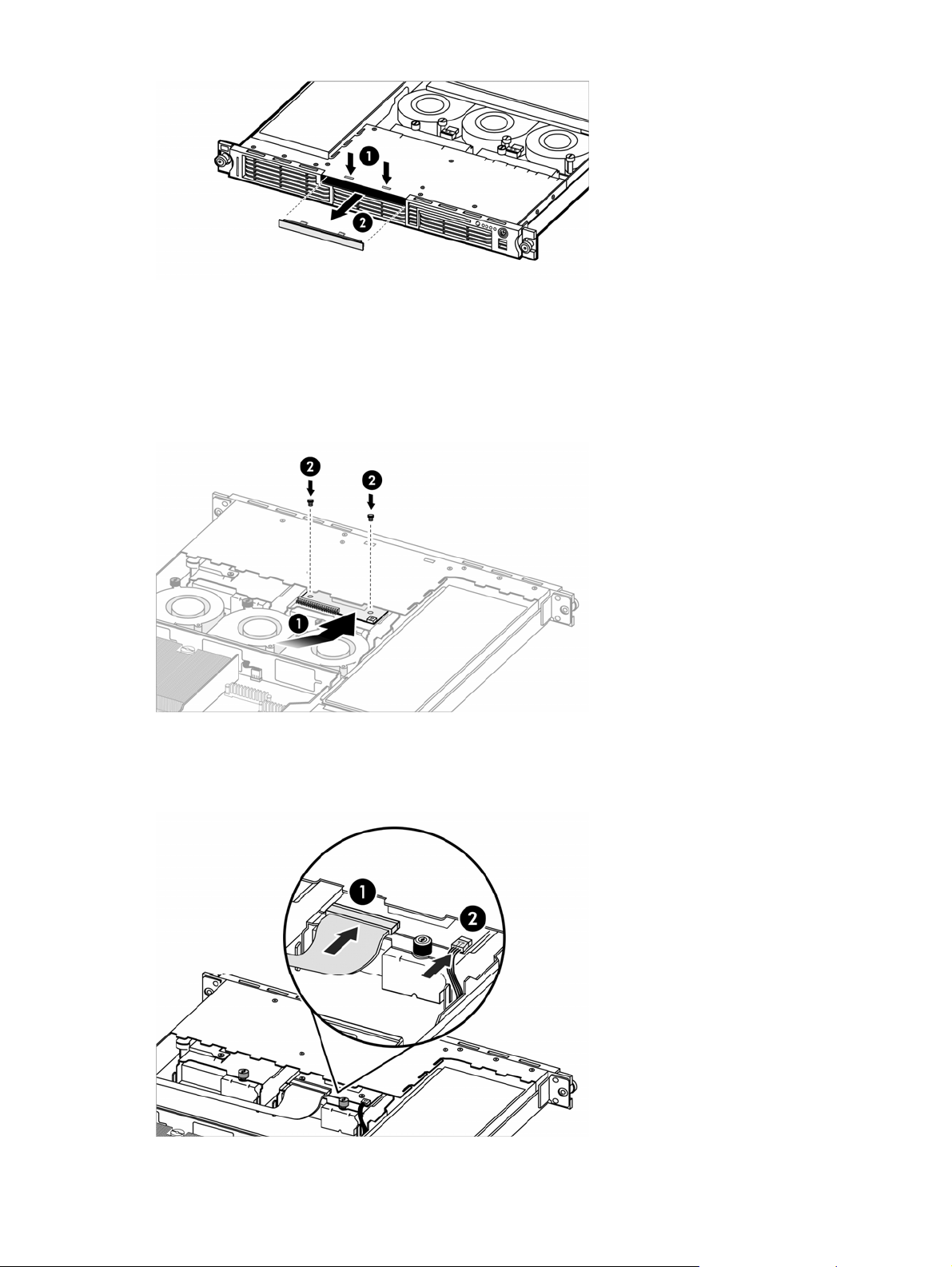

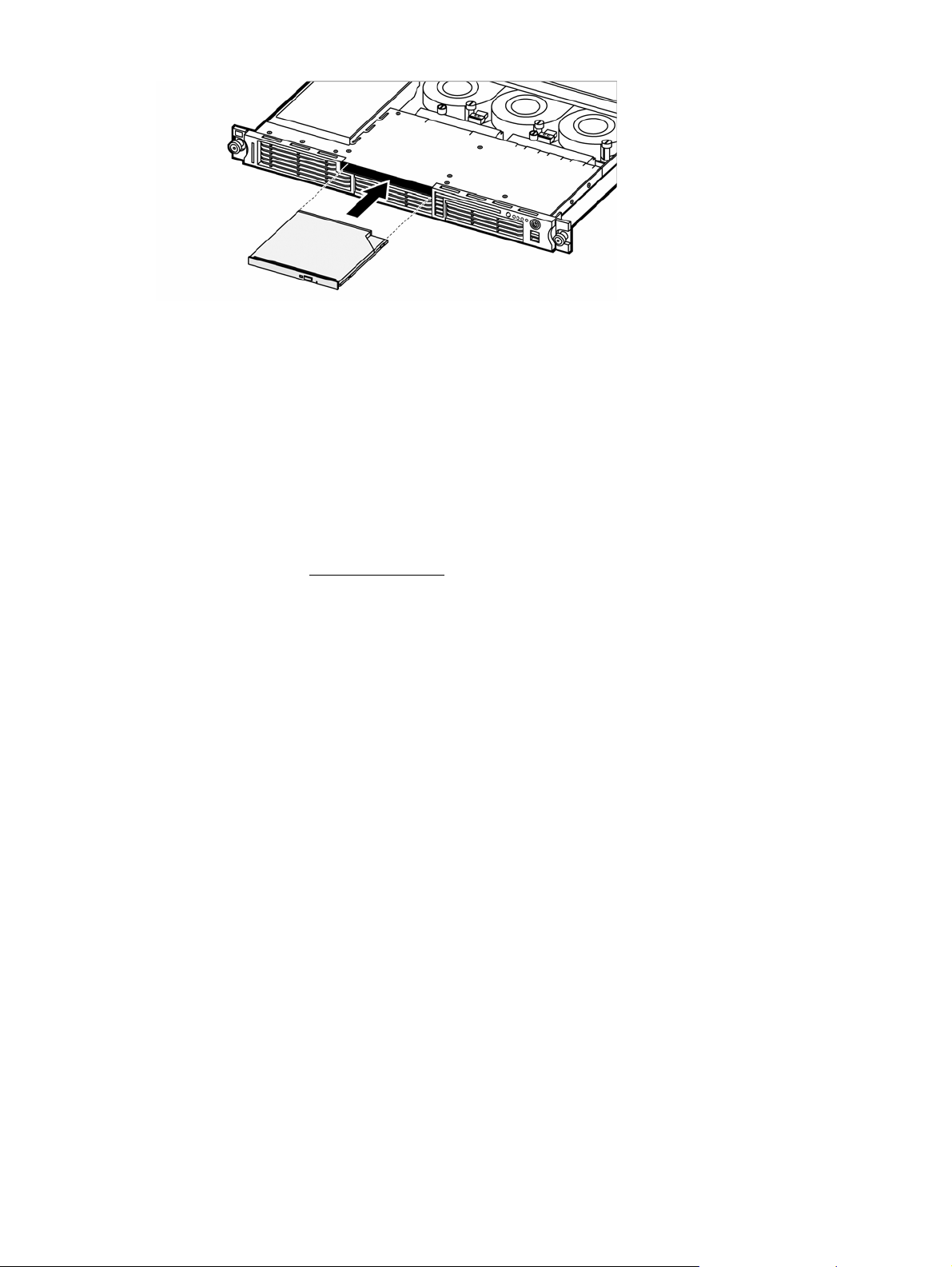

Figure 10 Removing the optical drive bay bezel

3. Install the optical drive docking board:

a. Hold the docking board at a slight angle to the chassis, then carefully slide it into place under the non-

removable section of the chassis top cover and on top of the optical drive bay.

Be sure not to scratch any docking board components on the non-removable section of the chassis top

cover or on the captive thumbscrew on HDD bay 1 beneath the optical drive bay.

b. Attach the docking board to the chassis with the two screws included in the option kit.

Figure 11 Installing the optical drive docking board

4. Connect the IDE data cable and the small drive power cable to the docking board.

Both cables are already connected to the system board and routed to the optical drive bay within the

chassis.

Figure 12 Connecting the optical drive cables

5. Remove the new optical drive from its protective packaging.

6. Align the optical drive with the optical drive bay, then push the drive fully into the drive bay.

Make sure the drive is not upside down.

Removal and replacement procedures 19

Page 20

Figure 13 Installing an optical drive

7. Perform the post-installation procedures described on page 12.

Hard drives

The server has two HDD bays that support both non-hot-plug SATA hard drives and hot-plug SATA or SAS hard

drives. You can add a hard drive to an empty HDD bay by installing an appropriate drive option; servers

configured as non-hot-plug systems cannot use hot-plug hard drives, and servers configured as hot-plug systems

cannot use non-hot-plug hard drives.

The non-hot-plug SATA drive options include only the hard drive. Install these drive options using the HDD

carriers and mounting screws included with a server configured for non-hot-plug drives.

The hot-plug SATA and SAS drive options are pre-installed in hot-plug HDD carriers. Use these hot-plug drive

assemblies to replace any installed hardware in an HDD bay of a server configured for hot-plug drives. A hotplug HDD bay may contain a blank drive carrier or a hot-plug drive assembly.

Go to the HP website at http://www.hp.com/ and refer to the options list for this server model for the latest

information on supported hard drives.

Hard drive installation guidelines

Observe the following important guidelines when installing hard drives:

• Install only hard drive models specified for your ProLiant server. Installing unsupported hard drives may

damage the system by consuming power and generating heat in excess of the operating tolerance of the

server. This condition may result in a loss of system and/or data integrity.

• Install non-hot-plug SATA hard drives in the HDD carriers included with the server. Use four of the six HDD

screws pre-installed in each of the two HDD carriers.

Removal and replacement procedures 20

Page 21

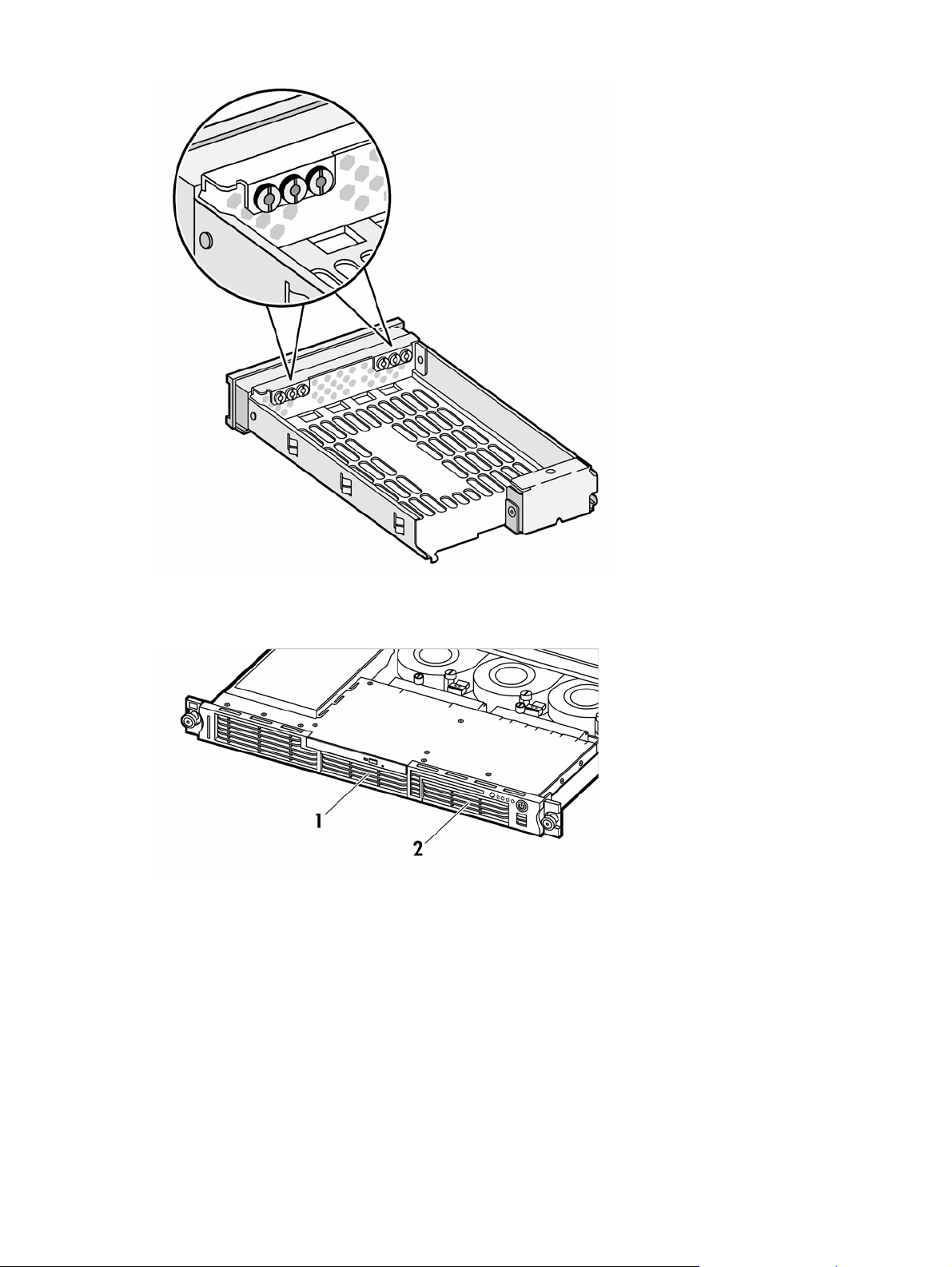

Figure 14 Pre-installed screw locations in the non-hot-plug HDD carrier

• Hard drives installed in the server are labeled as drive 1 and drive 2 from left to right when viewed from

the front of the server.

Figure 15 HDD bay locations

Removing a non-hot-plug SATA hard drive

If you intend to replace a non-hot-plug SATA hard drive with another non-hot-plug SATA hard drive, use the HDD

carrier and screws you remove from the old drive to install the new drive.

To remove a non-hot-plug SATA hard drive:

1. Perform the pre-installation procedures described on page 11.

2. Disconnect the data and power cables from the rear of the hard drive.

3. Remove the HDD carrier from the chassis:

a. Loosen the screw that secures the HDD carrier to the chassis.

b. Push the HDD carrier toward the front of the chassis, then slide it out completely.

Removal and replacement procedures 21

Page 22

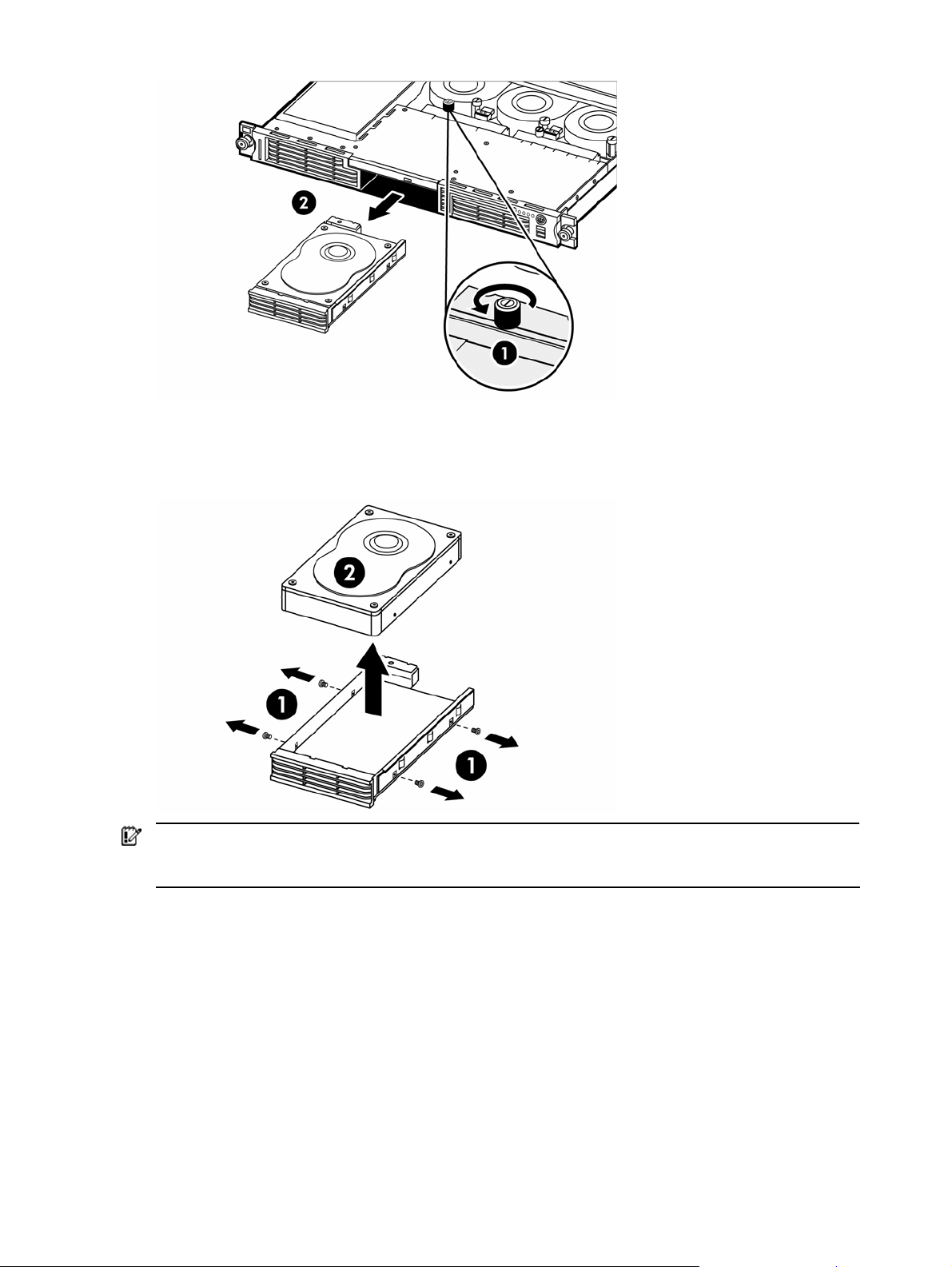

Figure 16 Removing a non-hot-plug SATA hard drive from the chassis

4. Remove the hard drive from the HDD carrier:

a. Remove the four mounting screws that secure the hard drive to the HDD carrier.

b. Remove the hard drive from the HDD carrier.

Figure 17 Removing a non-hot-plug SATA hard drive from the HDD carrier

IMPORTANT: If you remove a hard drive and do not plan to install a new one immediately, you must reinstall

the mounting screws at their pre-installed location for future use, then reinstall the HDD carrier in the chassis to

ensure the proper cooling of the system. Then perform the post-installation procedures described on page 12.

Installing a non-hot-plug SATA hard drive

1. Perform the pre-installation procedures described on page 11.

2. Select a drive bay for the new hard drive.

If the drive bay is occupied, remove the currently installed drive by following the procedures described in

the “Removing a non-hot-plug SATA hard drive” section on page 21.

If the drive bay is empty, perform step 3 in the “Removing a non-hot-plug SATA hard drive” section

described on page 21, then remove four mounting screws from the HDD carrier. You will use these screws

to install the new drive.

3. Install the new hard drive in the HDD carrier:

a. Align the new hard drive on the HDD carrier.

If you are installing the new drive in a previously occupied drive bay, use the HDD carrier and

mounting screws you removed from the old drive.

Removal and replacement procedures 22

Page 23

If you are installing the new drive in an empty drive bay, use the HDD carrier and mounting screws you

removed from that drive bay.

b. Secure the hard drive to the HDD carrier with the four mounting screws.

c. Slide the hard drive assembly into the chassis.

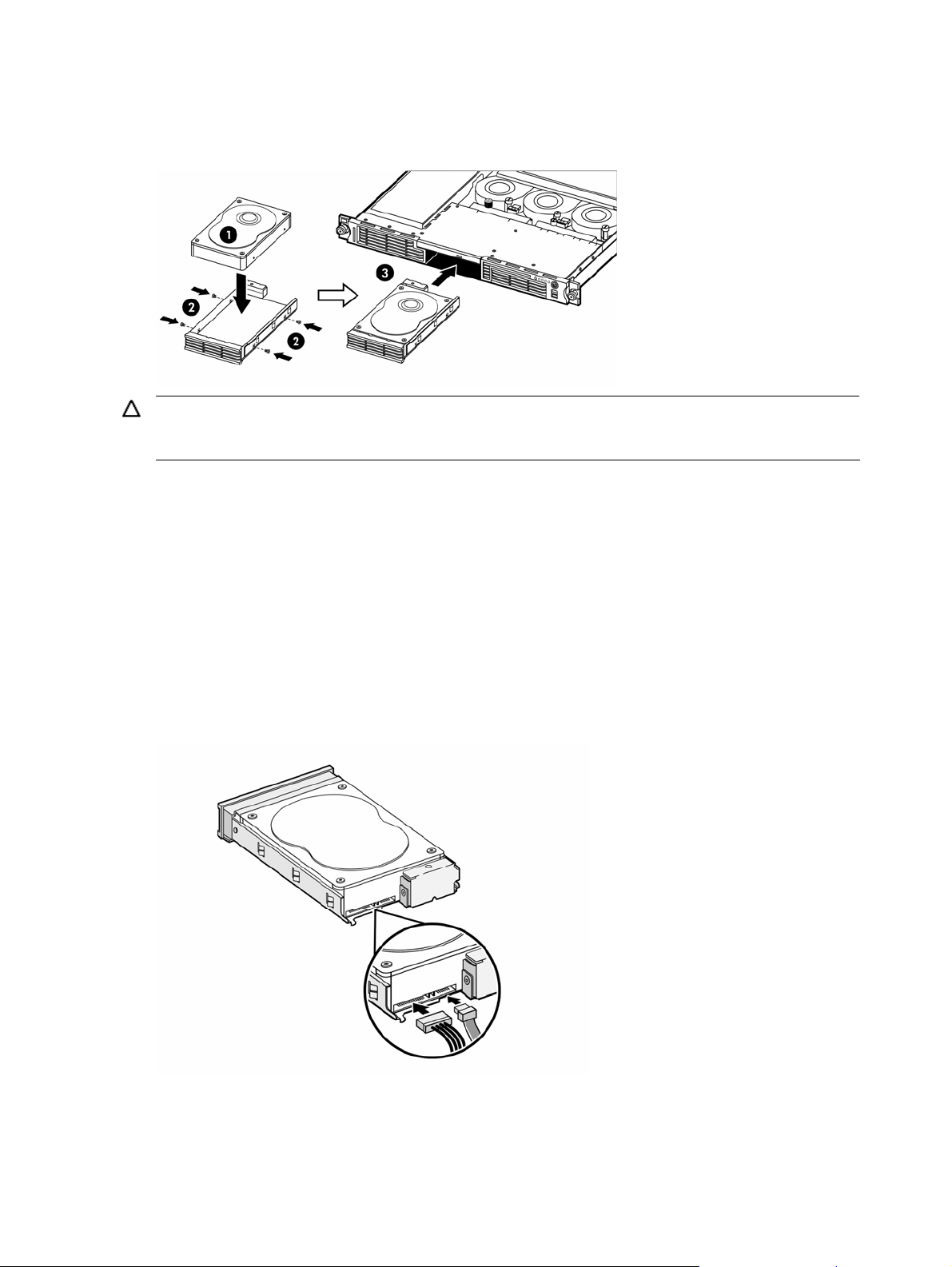

Figure 18 Installing a non-hot-plug SATA hard drive in the HDD carrier and chassis

CAUTION: Route the SATA data cables neatly. Follow the bundle of cables along the right side of the chassis.

The cables should be routed in a position where they will not be pinched or crimped by the top cover, and

they should not hamper proper airflow inside the chassis.

4. Route the SATA data cable:

a. Connect the SATA data cable to an open SATA connector on the system board (P19 or P23) if it is not

already connected.

b. Route the SATA data cable between the processor 2 socket DIMM slots and the PCI Express x4 slot to

the right edge of the chassis (as viewed from the front of the server).

c. Route the SATA data cable toward the front of the chassis, following the bundled cables.

d. Route the SATA data cable between the drive bays and the system fans.

5. Connect the SATA data and power cables to their corresponding connectors on the rear of the new drive.

If necessary, you can remove the system fans to allow easier access to the drive connectors. Perform steps 2

to 4 in the “Removing a system fan” section described on page 51 to remove each system fan, then

continue with this procedure.

Figure 19 Connecting the SATA data and power cables to a non-hot-plug hard drive

6. Check that all cables are clear of the HDD carrier and are properly routed to their corresponding

connectors, then tighten the screw that secures the hard drive assembly to the chassis.

If you removed the system fans in the previous step, perform steps 1 to 3 in the “Installing a system fan”

section described on page 53.

7. Perform the post-installation procedures described on page 12.

Removal and replacement procedures 23

Page 24

8. Set up the SATA configuration.

For detailed procedures, refer to the Server Support CD or to the operating system documentation.

Removing a hot-plug SATA/SAS drive assembly

This procedure assumes the hot-plug SATA/SAS backplane is already installed. See the “Installing the hot-plug

SATA/SAS backplane” section described on page 26 for more details.

To remove a hot-plug SATA/SAS drive assembly from the server:

1. Push the button on the front of the HDD carrier you want to remove to release the carrier latch, then pull the

carrier latch to its open position.

2. Remove the hot-plug drive assembly from the chassis.

Installing a hot-plug SATA/SAS drive assembly

This procedure assumes the hot-plug SATA/SAS backplane is already installed. See the “Installing the hot-plug

SATA/SAS backplane” section described on page 26 for more details.

To install a hot-plug SATA/SAS drive assembly in the server:

1. Prepare the HDD bay for installation:

• If you are replacing a currently installed hot-plug drive with a hot-plug drive option pre-installed in an

HDD carrier, perform the procedure in the “Removing a hot-plug SATA/SAS drive assembly” section on

page 24.

Because the new hot-plug hard drive is pre-installed in an HDD carrier, you do not need to reuse the

HDD carrier that you are removing from the server.

• If you are replacing a currently installed hot-plug drive with a SATA or SAS drive that is not pre-

installed in an HDD carrier, perform the procedure in the “Replacing a hot-plug SATA or SAS hard

drive” section on page 25.

• If the HDD bay contains a blank drive carrier, squeeze the two center tabs on the bezel toward each

other, then remove the carrier from the chassis.

2. If the carrier latch on the HDD carrier you want to install is not already open, push the button on the front of

the HDD carrier, then pull the carrier latch to its open position.

3. Align the hot-plug drive assembly with the open drive bay and push the assembly into the drive bay until it

stops.

Figure 20 Installing a hot-plug SATA/SAS drive assembly

The metal tab at the front of the HDD bay should fit inside the notch in the hinge of the carrier latch.

Removal and replacement procedures 24

Page 25

Figure 21 Aligning the latch on a hot-plug SATA/SAS drive assembly

4. Press the HDD carrier latch inward until it clicks.

The latch should pull the hot-plug drive assembly fully into the chassis. The carrier latch should pull against

the metal tab on the HDD bay only, not on the front bezel on the chassis.

Figure 22 Closing the latch on a hot-plug SATA/SAS drive assembly

Replacing a hot-plug SATA or SAS hard drive

This procedure assumes the hot-plug SATA/SAS backplane is already installed. See the “Installing the hot-plug

SATA/SAS backplane” section described on page 26 for more details.

To replace a hot-plug SATA or SAS hard drive:

1. Perform the procedure in the “Removing a hot-plug SATA/SAS drive assembly” section on page 24 to

remove the appropriate hot-plug drive assembly.

2. Remove the hard drive from the hot-plug HDD carrier:

a. Remove the four mounting screws that secure the hard drive to the hot-plug HDD carrier.

b. Remove the hard drive from the hot-plug HDD carrier.

3. Install the new drive in the hot-plug HDD carrier:

a. Align the hard drive in the HDD carrier.

b. Secure the hard drive to the HDD carrier with the four mounting screws.

Removal and replacement procedures 25

Page 26

Figure 23 Installing a SATA or SAS hard drive in the hot-plug HDD carrier

4. Perform the procedure in the “Installing a hot-plug SATA/SAS drive assembly” section on page 24 to

reinstall the hot-plug drive assembly in the chassis.

Installing the hot-plug SATA/SAS backplane

To enable hot-plug SATA/SAS drive functionality, you must install a hot-plug SATA/SAS controller board and

cabling in addition to the hot-plug backplane. See the “Installing a hot-plug SATA/SAS controller board” section

on page 28 for more details.

To install the hot-plug SATA/SAS backplane board:

1. Perform the pre-installation procedures described on page 11.

2. Perform steps 2 to 4 in the “Removing a system fan” section described on page 51 to remove each system

fan.

3. Disconnect the drive power and SATA data cables:

a. Disconnect the power cable from each hard drive installed in the server.

b. Disconnect the power cable from the optical drive docking board, if installed.

Figure 24 Disconnecting the optical drive power cable

c. Disconnect the drive power cable from the connector on the system board (P41).

d. Disconnect all SATA data cables from the hard drives and at the system board connectors (P19 and

P23).

4. Perform step 3 of the “Removing a non-hot-plug SATA hard drive” section described on page 21 for each

HDD bay to remove both non-hot-plug HDD carriers from the chassis.

5. Install the hot-plug backplane:

Removal and replacement procedures 26

Page 27

a. Align the hot-plug backplane between the drive bays and the system fans.

The data cable connectors on the backplane should face the rear of the chassis.

b. Attach the backplane to the chassis with the screws on each end.

Figure 25 Installing the hot-plug backplane

6. Connect and route the new drive power cable included with the option kit:

NOTE: Do not reuse the power cable you removed in step 3.

a. Connect the square 4-pin end of the drive power cable to the drive power connector on the system

board (P41).

b. Route the power cable between the drive bays and the system fan locations.

c. Connect the small power connector to the optical drive docking board, if installed.

d. Connect the square 4-pin power connector to the hot-plug backplane.

Figure 26 Connecting the power connector to the hot-plug backplane

7. Perform steps 1 to 3 in the “Installing a system fan” section described on page 53 to reinstall the three

system fans you removed earlier.

Removal and replacement procedures 27

Page 28

8. Perform the post-installation procedures described on page 12.

Installing a hot-plug SATA/SAS controller board

To enable hot-plug SATA/SAS drive functionality, you must install the hot-plug SATA/SAS backplane in addition

to a hot-plug SATA/SAS controller board and cabling. This procedure assumes the backplane is already

installed. See the “Installing the hot-plug SATA/SAS backplane” section described on page 26 for more details.

To install a hot-plug SATA/SAS controller board:

1. Perform the procedure in the “Removing a riser board assembly” section on page 42 to remove the

appropriate riser board assembly.

If the hot-plug controller board you want to install is a PCI-X or PCI Express x4 board, remove the low-

profile assembly. If the hot-plug controller board you want to install is a PCI Express x16 board, remove the

full-sized assembly.

2. Prepare the assembly:

• If no riser board is installed in the assembly, perform the procedure in the “Installing a riser board”

section on page 45 to install the correct riser board for the controller board you want to install.

• If the riser board installed in the assembly is not the correct type, perform the procedures in the

“Removing a riser board” section on page 43 and the “Installing a riser board” section on page 45 to

replace the riser board.

• If the correct riser board is installed in the assembly but an expansion board is installed, perform the

procedure in the “Removing an expansion board” section on page 46.

• If the correct riser board is installed in the assembly and no expansion board is installed, continue to

the next step.

3. Perform steps 2 to 6 in the “Installing an expansion board” section described on page 46 to install the hotplug controller board in the assembly.

4. Connect the wide connector on one end of the hot-plug SATA/SAS cable assembly to the data connector

on the hot-plug controller board.

5. Perform step 1 of the “Installing a riser board assembly” section on page 43 to reinstall the assembly in the

server.

6. For a low-profile controller board, route the hot-plug SATA/SAS cable assembly as follows:

a. From the controller board, route the cable assembly between the processor 2 socket DIMM slots and

the PCI Express x4 slot to the right edge of the chassis (as viewed from the front of the server).

b. Route the cable assembly toward the front of the chassis, following the bundled cables.

c. Route the cable assembly between the drive bays and the system fans.

7. For a full-sized controller board, route the hot-plug SATA/SAS cable assembly as follows:

a. From the controller board, route the cable assembly toward the front of the server between the power

supply and the system fan closest to the power supply.

b. Route the cable assembly between the drive bays and the system fans.

8. Connect the hot-plug SATA/SAS cable assembly to the hot-plug backplane:

a. Connect the longer SATA/SAS data cable to the data connector on the backplane farthest from the

controller board.

b. Connect the LED cable to the connector on the backplane beneath the HDD bay 1 data connector.

c. Connect the shorter SATA/SAS data cable to the data connector on the backplane closest to the

controller board.

Removal and replacement procedures 28

Page 29

Figure 27 Connecting the hot-plug SATA/SAS cable assembly to the hot-plug backplane

9. Perform the post-installation procedures described on page 12.

System board

Refer to the following sections for instructions about how to remove or replace a system board.

Removing a system board

A server’s system board attaches to the floor of the unit and provides connectivity for all inside components.

1. Perform the pre-installation procedures described on page 11.

2. Follow the instructions for Removing a riser board assembly on page 42 to remove the full-length riser and

the low-profile riser assemblies.

3. Follow the instructions for Removing a memory module on page 40 to remove the DIMMs.

4. Remove the air deflector.

a. Unplug the backplane power cable from the system board.

b. Pull both air deflector mounting tabs away from each side of the heat sink for CPU1.

c. Lift the air deflector off of the system board.

5. Unplug the power supply cables, USB cable, OP panel cable, IDE cable, SATA data cables, and fan cables

from the system board.

6. Follow the instructions for Removing a processor on page 34 to remove the heat sinks, but leave the

processors until the new system board is mounted to the chassis.

7. Remove the eleven system board mounting screws.

Removal and replacement procedures 29

Page 30

Figure 28 Removing the mounting screws from the system board

8. Remove the system board by lifting the end closest to the fans enough to clear the fan bracket and gently

sliding the system board toward the front of the chassis.

Figure 29 Removing the system board from the chassis

Installing a system board

This section assumes that the components or cables that would prevent a system board installation are removed

or disconnected.

1. Install the system board.

a. Lay the back end on the floor of the chassis, holding the front end up enough to clear the

fan bracket.

Removal and replacement procedures 30

Page 31

Figure 30 Placing the system board on the floor of the chassis

b. Slide the system board toward the back of the chassis lowering the front end as it clears the

fan bracket.

Figure 31 Sliding the system board into the chassis

c. Position the system board so that all switches function freely and all connectors seat

properly.

Figure 32 Positioning the system board connector

2. Install the eleven system board mounting screws.

Removal and replacement procedures 31

Page 32

Figure 33 Installing mounting screws on the system board

3. Follow the instructions for Removing a processor on page 34 and Installing a processor on page 35 to

transfer the CPUs from the old system board to the new system board.

4. Reconnect the power supply cables, USB cable, OP panel cable, IDE cable, SATA data cables, and fan

cables to the system board.

5. Install the air deflector.

a. Place the front edge against the fan bracket.

b. Lay the air deflector lengthwise along the section of the unit containing the power supply

and full-length riser assembly.

c. Pull both air deflector mounting tabs away from the heat sink for CPU1 and release the tabs

around the heat sink guide.

d. Reconnect the backplane power cable to the system board.

6. Follow the instructions for Installing a memory module on page 39 to re-install the DIMMs.

7. Follow the instructions for Installing a riser board assembly on page 43 to re-install the full-length riser and

the low-profile riser assemblies.

8. Perform the post-installation procedures described on page 12.

System board configuration

Refer to the following sections for instructions on how to remove or replace the processors, the memory modules,

the expansion boards, and the system battery.

Processor

The dual 1207-pin processor sockets on the system board support single core, 64-bit AMD Opteron processors

with 1 GHz HT bus and 1 MB on-die L2 cache. Figure 34 shows the two processor sockets (U42 and U55).

Removal and replacement procedures 32

Page 33

Figure 34 Processor sockets

Item Component Code Component

1 U42 AMD Opteron 1207-pin processor 1 socket

2 U55 AMD Opteron 1207-pin processor 2 socket

Processor installation guidelines

Observe the following important guidelines before performing any of the installation steps listed in the next

section:

• The processor 1 socket (U42) must always be populated. If no processor is installed in this socket, the

system fails to boot, halts during POST, and does not function properly.

• Handle the processor and heat sink with care. Damage to either may affect processor performance.

• The processor socket pins are very fragile. Do not bend or damage them.

• Be sure that the server has the most recent ROM version. If the ROM is not the most recent version, failure to

flash the ROM before installing a processor can cause a system failure.

• HP does not recommend using a processor in the processor 2 socket (U55) when all processor 2 socket

DIMM slots (DIMM5 to DIMM8) are empty. Populate at least the DIMM7 and DIMM8 slots when you install

a second processor.

CAUTION: To prevent the heat sink from tilting to one side during installation or removal procedures, HP

recommends that you alternate tightening or loosening each screw a little at a time. Do not tighten or

loosen one screw completely before tightening or loosening the other.

CAUTION: To help avoid damage to the processor and system board, do not install the processor without

using the processor installation tool.

NOTE: The heat sink may differ slightly in appearance from the design shown in this document. This does not

affect the installation or removal procedures.

Removal and replacement procedures 33

Page 34

Removing a processor

1. Perform the pre-installation procedures described on page 11.

2. Locate the processor you want to remove.

3. Remove the heat sink:

a. Loosen the two spring-loaded screws a few threads, alternating back and forth between each screw, to

release the heat sink from the processor base.

b. Rotate the heat sink back and forth within the available space to break the hold of the thermal grease,

then lift the heat sink away from the system board.

Figure 35 Removing a heat sink

4. Remove the processor:

a. Disengage the socket retention lever from the processor base.

b. Lift up the socket retention bracket.

c. Grasp the processor by the edges and lift it out of the socket.

Removal and replacement procedures 34

Page 35

Figure 36 Removing a processor

5. Place the processor on a static-dissipating work surface or inside an anti-static bag.

6. If you are replacing the processor, continue with the procedure in the “Installing a processor” section

described next. Otherwise, protect the empty socket:

a. Place the socket retention bracket over the socket.

b. Push the socket retention lever back into place.

c. Attach the socket cover to the socket retention bracket.

d. Perform the post-installation procedures described on page 12.

Installing a processor

1. Perform the pre-installation procedures described on page 11.

2. Locate the processor socket on which you want to install the processor.

3. If the processor socket you want to use is not empty, perform the procedure in the “Removing a processor”

section on page 34 to remove the installed processor. Then skip to step 5 in this procedure.

4. If the processor socket is empty, prepare the socket for installation:

a. Remove the socket cover.

NOTE: Do not discard the socket cover. If the processor is removed and not replaced with another

processor in the future, the socket cover must be reinstalled to prevent damage to the socket pins.

Figure 37 Removing a socket cover

b. Disengage the socket retention lever from the processor base.

c. Lift up the socket retention bracket.

5. If the processor has separated from the installation tool, carefully reinsert the processor in the installation

tool.

IMPORTANT: Be sure the processor remains inside the processor installation tool.

Removal and replacement procedures 35

Page 36

Figure 38 Inserting a processor in the processor installation tool

6. Use the processor installation tool to install the new processor into the socket:

a. Align the processor installation tool with the processor socket and install the processor.

CAUTION: Make sure that the processor is properly aligned in the socket. The corner of the

processor marked with a gold triangle should align with the corner of the socket marked on the

system board with a triangular symbol.

b. Press down firmly until the installation tool clicks and separates from the processor, and then remove the

installation tool.

Figure 39 Installing a processor

7. Secure the processor in the socket:

a. Place the socket retention bracket over the processor.

b. Push the socket retention lever back into place.

Removal and replacement procedures 36

Page 37

Figure 40 Securing a processor

8. If the heat sink is new, remove the protective cover on the bottom of the heat sink.

9. Install the heat sink:

a. Align the heat sink over the processor, then place the heat sink on top of the processor and the heat

sink guide rails.

CAUTION: Do not overtighten the two spring-loaded screws or they may break off. A maximum

torque of 8-in-lb is set for the system.

b. Tighten the two spring-loaded screws a few threads, alternating between each screw. Then tighten the

screws completely to secure the heat sink to the processor base.

To tighten the screws, HP recommends using the L-shaped wrench that ships with the server.

IMPORTANT: If the heat sink is removed for any reason, it is critical that you apply more thermal

interface material to the integrated heat spreader on the processor to ensure proper thermal bonding

between the processor and the heat sink. Clean the contact surface of both the processor and heat

sink with an alcohol pad, then re-apply an HP-approved thermal interface material before re-installing

the processor. Use a pattern of five dots when applying the thermal interface material—one dot in the

center, and one dot at each corner. HP recommends using Shin-Etsu X23-7783D thermal grease

compound for your ProLiant server.

Removal and replacement procedures 37

Page 38

Figure 41 Installing a heat sink

10. Perform the post-installation procedures described on page 12.

Memory

The system has eight DIMM slots that support up to 16 GB maximum system memory (2 GB in each of the eight

DIMM slots).

Removal and replacement procedures 38

Page 39

Figure 42 DIMM slot locations

Memory installation guidelines

Observe the following important guidelines when installing memory modules:

• Use only HP-supported PC2-5300 DDR2 (667 MHz) registered ECC DIMMs in 512 MB, 1 GB, or 2 GB

capacities.

• The processor 2 socket (U55) must be populated before you can install memory modules in the DIMM5 to

DIMM8 slots.

• If a second processor is installed, HP does not recommend leaving all processor 2 socket DIMM slots

(DIMM5 to DIMM8) empty. Populate at least the DIMM7 and DIMM8 slots when the server uses a second

processor.

• Memory modules must be installed in pairs of the same size in the sequence listed below:

• For the processor 1 socket DIMM slots: Populate DIMM3 and DIMM4 first, then DIMM1 and DIMM2.

• For the processor 2 socket DIMM slots: Populate DIMM7 and DIMM8 first, then DIMM5 and DIMM6.

• Memory modules in DIMM1 and DIMM2 should not be larger in capacity than the modules in DIMM3 and

DIMM4; similarly, the modules in DIMM5 and DIMM6 should not be larger than the modules in DIMM7

and DIMM8.

Installing a memory module

1. Perform the pre-installation procedures described on page 11.

2. If necessary, remove any accessory boards or cables that prevent access to the DIMM slots.

3. Locate an empty DIMM slot on the system board.

4. If necessary, open the holding clips of the selected DIMM slot.

5. Remove the memory module from its protective packaging, handling it by the edges. Do not touch any

components on the module or the gold connectors on the bottom edge.

6. Install the memory module:

a. Align the notch on the bottom edge of the module with the keyed surface of the DIMM slot, and then

press the module fully into the slot.

Removal and replacement procedures 39

Page 40

The DIMM slots are designed to ensure proper installation. If you insert a memory module but it does

not fit easily into the slot, you may have inserted it incorrectly. Reverse the orientation of the module

and insert it again.

b. Firmly press the holding clips inward to secure the memory module in place.

If the holding clips do not close, the module is not inserted correctly.

Figure 43 Installing a memory module

7. Perform the post-installation procedures described on page 12.

Removing a memory module

1. Perform the pre-installation procedures described on page 11.

2. If necessary, remove any accessory boards or cables that prevent access to the DIMM slots.

3. Locate the memory module you want to remove.

4. Remove the selected memory module:

a. Completely open the holding clips securing the module.

This forces the module up in the slot and makes it easier to remove.

b. Gently pull the memory module upward to remove it from its slot.

Figure 44 Removing a memory module

5. Place the memory module on a static-dissipating work surface or inside an anti-static bag.

Removal and replacement procedures 40

Page 41

6. Perform the post-installation procedures described on page 12.

Expansion boards

System board expansion slots

There are four expansion slots on the system board that support four different PCI riser boards.

Figure 45 Expansion slots

Item Component Function

1 HTX slot Supports a full-sized 1 GHz, 16x16 HTX expansion board installed on an HTX riser

2 PCI Express x16 slot Supports a full-sized PCI Express x16 expansion board installed on a PCI Express

3 PCI-X slot Supports a low-profile 64-bit, 133 MHz PCI-X expansion board installed on a PCI X

4 PCI Express x4 slot Supports a low-profile PCI Express x4 expansion board installed on a PCI Express

Riser board assemblies

The server supports up to two expansion boards installed on riser boards. With the appropriate riser boards, the

two riser board assemblies that come with the server convert the expansion slots on the system board to slots that

are positioned at a 90° angle from the system board. You can then install expansion boards in a position

parallel to the system board.

The system comes with one full-sized assembly and one low-profile assembly. The full-sized assembly supports

either an HTX riser board or a PCI Express x16 riser board. The low-profile assembly supports either a PCI

Express x4 riser board or a PCI-X riser board.

NOTE: Some full-size expansion boards may not be supported due to a small blockage caused by the molded

connector on the end of the AC power cable. The connector molding reduces the overall component space

near the end of full-size expansion boards.

board

x16 riser board

riser board

x4 riser board

Removal and replacement procedures 41

Page 42

NOTE: You cannot install the PCI Express x4 and PCI-X riser boards at the same time. You also cannot install

the HTX and PCI Express x16 riser boards at the same time.

Expansion board installation guidelines

Use only HP-supported expansion boards that meet the following specifications:

• HTX: Full-sized, 1 GHz, 16x16

• PCI Express x4: Low-profile

• PCI Express x16: Full-sized

• PCI-X: Low-profile, 64-bit, 3.3 V, 133 MHz

For ease of reading, the riser board assembly will be referred to as the “assembly” in the following sections.

Also, in some figures, the plane section of the assembly is dimmed out for clarity.

Removing a riser board assembly

1. Perform the pre-installation procedures described on page 11.

2. Locate the assembly you want to remove:

• To install, remove, or replace an HTX or PCI Express x16 expansion board or riser board, remove the

full-sized assembly.

• To install, remove, or replace a PCI-X or PCI Express x4 expansion board or riser board, remove the

low-profile assembly.

3. If an expansion board is installed in the assembly, disconnect any cables that connect the expansion board

to the system board.

4. Remove the appropriate assembly:

a. Loosen the two captive thumbscrews that secure the assembly to the chassis.

b. Lift the assembly away from the chassis.

If you are removing the full-sized assembly, first lift the assembly from the end with the captive

thumbscrews to disconnect the riser board from the expansion slot on the system board. Slide the

assembly approximately 1.25 cm (0.5 in) toward the rear of the chassis, then lift the assembly away

from the chassis.

Removal and replacement procedures 42

Page 43

Figure 46 Removing the full-sized assembly

Figure 47 Removing the low-profile assembly

Installing a riser board assembly

1. Install the assembly in server:

a. Align the assembly with the correct slot on the system board and firmly press the assembly into the slot.

If you are reinstalling the full-sized assembly, slide the front of the assembly into place with the three

retaining tabs on the chassis. The front edge of the assembly should slide underneath the middle

retaining tab. The corners of the assembly should rest on top of the left and right retaining tabs. Then,

align the riser board connector with the expansion slot on the system board and firmly press the

assembly into the slot.

b. Tighten the two captive thumbscrews that secure the assembly to the chassis.

Removal and replacement procedures 43

Page 44

Figure 48 Installing the full-sized assembly

Figure 49 Installing the low-profile assembly

2. Perform the post-installation procedures described on page 12.

Removing a riser board

1. Perform the procedure described in the “Removing a riser board assembly” section on page 42 to remove

the appropriate assembly.

2. If an expansion board is installed in the assembly, perform the procedure in the “Removing an expansion

board” section on page 46.

3. Remove the installed riser board from the assembly:

NOTE: Keep the two screws you remove in this step for installing the new riser board later.

a. Remove the two screws securing the riser board to the assembly.

b. Remove the riser board from the assembly.

Removal and replacement procedures 44

Page 45

Figure 50 Removing a full-sized riser board

Figure 51 Removing a low-profile riser board

Installing a riser board

1. Perform the procedure described in the “Removing a riser board assembly” section on page 42 to remove

the appropriate assembly.

2. Prepare the assembly for the new riser board:

• If no riser board is installed on the assembly, remove the two screws installed on the inside of the

vertical side of the assembly.

• If a riser board is already installed on the assembly, perform the procedure in the “Removing a riser

board” section on page 44 to remove the riser board and expansion board, if any.

NOTE: Keep the two screws you remove in this step for installing the new riser board later.

3. Install the new riser board on the assembly:

a. Align the back of the riser board with the mounting posts and screw holes on the inside of the

assembly.

The slot on the riser board should face the inside of the assembly.

b. Secure the riser board to the assembly using the two screws you removed in step 2.

Removal and replacement procedures 45

Page 46

Figure 52 Installing a full-sized riser board

Figure 53 Installing a low-profile riser board

4. Continue with the procedure in the “Installing an expansion board” section on page 46 or the “Installing a

riser board assembly” section on page 43 as appropriate.

Removing an expansion board

1. Perform the procedure in the “Removing a riser board assembly” section on page 42 to remove the

appropriate assembly.

2. Hold the expansion board by the edges and pull it out of the riser board slot.

3. Place the expansion board on a static-dissipating work surface or inside an anti-static bag.

4. If you are not installing another expansion board, reinstall the slot cover on the assembly.

5. Continue with the procedure in the “Installing an expansion board” section on page 46, the “Removing a

riser board” section on page 44, or the “Installing a riser board assembly” section on page 43 as

appropriate.

Installing an expansion board

1. Perform the procedure in the “Removing a riser board assembly” section on page 42 to remove the

appropriate assembly.

2. Remove the slot cover on the assembly if it is installed.

Store it for reassembly later.

CAUTION: Do not discard the slot cover. If the expansion board is removed in the future, the slot cover

must be reinstalled to maintain proper cooling.

Removal and replacement procedures 46

Page 47

Figure 54 Removing the full-sized riser board assembly slot cover

Figure 55 Removing the low-profile riser board assembly slot cover

3. If an expansion board is installed in the assembly, perform the procedure in the “Removing an expansion

board” section on page 46.

4. Remove the expansion board from its protective packaging, handling it by the edges.

5. Verify that the size of the expansion board and its connector are compatible with the assembly.

If necessary, perform the procedures in the “Removing a riser board” section on page 44 and the

“Installing a riser board” section on page 45 to install the correct riser board.

6. Slide the expansion board into the riser board slot.

Press the board firmly to seat it properly in the slot.

Removal and replacement procedures 47

Page 48

Figure 56 Installing a full-sized HTX or PCI Express x16 expansion board

Figure 57 Installing a low-profile PCI-X or PCI Express x4 expansion board

7. Connect any necessary cables to the expansion board.

Refer to the documentation that came with the board.

8. Continue with the procedure in the “Installing a riser board assembly” section on page 43.

System battery

The HP ProLiant server uses nonvolatile memory that requires a battery to retain system information when power

is removed. The battery, a 3 V 200-mAh internal lithium battery, is located on the system board (XBAT1).

Removal and replacement procedures 48

Page 49

Figure 58 System battery location

If the server no longer automatically displays the correct date and time, the system battery that provides power to

the real-time clock may need to be replaced. Under normal use, the battery life is 5 to 10 years.

WARNING! Note the following warnings when replacing the system battery.

• Replace the battery with the same type as the battery recommended by HP. Use of another

battery may present a risk of fire or explosion.

• A risk of fire and chemical burn exists if the battery is not handled properly. Do not

disassemble, crush, puncture, or short external contacts, or expose the battery to temperatures

higher than 60° C (140° F).

• Do not dispose of the used battery in water or fire. Dispose of used batteries according to

manufacturer's instructions.

CAUTION: Loss of BIOS settings occurs when the battery is removed. BIOS settings must be reconfigured

whenever the battery is replaced.

Replacing the system battery

1. If necessary, remove any accessory boards or cables that prevent access to the battery socket.

2. Remove the installed battery:

IMPORTANT: Do not bend the spring latch during battery replacement. For proper operation, the latch

must maintain a position of contact with the battery.

a. Insert a small flat-blade screwdriver or a similar tool between the battery and spring latch to dislodge

the battery from its socket.

b. Lift up the old battery to remove it.

Removal and replacement procedures 49

Page 50

Figure 59 Removing the system battery

3. Insert a new battery with the positive polarity (+ side) facing up, and ensure that it is seated completely.

Ensure the spring latch is in place, and that it holds the battery firmly.

Figure 60 Installing the system battery

4. Perform the post-installation procedures described on page 12.

System fans

The server has three system fans located behind the drive bays. Figure 61 shows the locations of these system

fans and the connections to the system board.

Removal and replacement procedures 50

Page 51

Figure 61 System fans

If a system fan becomes defective, you must replace the fan to allow the server to operate properly.

Removing a system fan

1. Perform the pre-installation procedures described on page 11.

2. Disconnect the 14-pin power cable from the connector on the system board (P22).

3. Remove the power cable guide above the system fans:

a. Slide the power cable guide away from the power supply.

b. Pull the power cable guide toward the front of the server and place it out of the way.

Removal and replacement procedures 51

Page 52

Figure 62 Removing the power cable guide

4. Remove the system fan you want to replace:

a. Disconnect the power cable of the fan from the system board and slide the cable out of the notch in the

chassis partition wall.

The fan closest to the power supply connects to P47. The middle fan connects to P48. The fan farthest

from the power supply connects to P49.

b. Loosen the screw holding the fan to the chassis.

c. Lift the fan away from the chassis.

Removal and replacement procedures 52

Page 53

Figure 63 Removing a system fan from the chassis

Installing a system fan

1. Install the new system fan:

a. Place the fan in an open fan location in the chassis.

b. Connect the fan power cable to the connector on the system board, and slide the power cable into the

notch in the chassis partition wall.

The fan closest to the power supply connects to P47. The middle fan connects to P48. The fan farthest

from the power supply connects to P49.

c. Tighten the screw holding the fan to the chassis.

Figure 64 Installing a system fan

2. Reinstall the power cable guide above the system fans:

a. Insert the power cable guide into the slots in the rail above the system fans.

b. Slide the power cable guide toward the power supply.

Removal and replacement procedures 53

Page 54

Figure 65 Installing the power cable guide

3. Connect the 14-pin power cable to the connector on the system board (P22).

4. Perform the post-installation procedures described on page 12.

Power supply unit (PSU)

Located on the rear panel of the server is a single standard autoranging 650-watt PSU. Figure 66 shows the

location of the PSU.

Removal and replacement procedures 54

Page 55

Figure 66 Power supply unit

The PSU power cables connect to the P34 and P22 connectors on the system board. Figure 67 shows the PSU

power cable routing.

Removal and replacement procedures 55

Page 56

Figure 67 Power supply cable routing

WARNING! Take note of the following reminders to reduce the risk of personal injury from electric shock

hazards and/or damage to the equipment.

• Installation of power supply units should be referred to individuals who are qualified to service

server systems and are trained to deal with equipment capable of generating hazardous

energy levels.

• DO NOT open the power supply unit. There are no serviceable parts inside.

Replacing the power supply unit

1. Perform the pre-installation procedures described on page 11.

2. Perform the procedure in the “Removing a riser board assembly” section on page 42 to remove the full-

sized riser board assembly.

3. Remove the power cable guide above the system fans:

a. Slide the power cable guide away from the power supply.

b. Pull the power cable guide toward the front of the server and place it out of the way.

Removal and replacement procedures 56

Page 57

Figure 68 Removing the power cable guide

4. Disconnect both power supply cables from the system board (P22 and P34).

5. Remove the PSU:

NOTE: Keep the two screws you remove in this step for installing the new PSU later.

a. Disconnect the AC power cable from the rear of the PSU.