HP ProLiant DL120 G7 User Manual

HP ProLiant DL120 G7 Server

tended for experienced

setup experience. HP assumes you are qualified in the servicing of computer equipment and

Part Number: 638025-003

User Guide

Abstract

This document is for the person who installs, administers, and troubleshoots servers and storage systems. This document is in

IT professionals or end-users with no or prior hardware

trained in recognizing hazards in products with hazardous energy levels.

September 2012

Edition: 3

© Copyright 2011, 2012 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation. Bluetooth® is a trademark owned by its proprietor and used

by Hewlett-Packard Company under license.

Contents

Component identification ............................................................................................................... 7

Front panel components ............................................................................................................................. 7

Front panel LEDs ....................................................................................................................................... 8

Rear panel components .............................................................................................................................. 8

Rear panel LEDs ........................................................................................................................................ 9

PCIe expansion slot definitions .................................................................................................................. 10

System board components ........................................................................................................................ 10

System board LEDs ........................................................................................................................ 11

System maintenance switch ............................................................................................................. 11

NMI functionality ........................................................................................................................... 12

DIMM slot locations ....................................................................................................................... 12

SAS and SATA device numbering ............................................................................................................. 13

SAS and SATA drive LEDs ........................................................................................................................ 13

BBWC module LEDs ................................................................................................................................ 14

Fan locations .......................................................................................................................................... 15

T-10/T15 Torx screwdriver ....................................................................................................................... 16

Operations ................................................................................................................................. 17

Power up the server ................................................................................................................................. 17

Power down the server ............................................................................................................................. 17

Remove the server from the rack ................................................................................................................ 17

Remove the access panel.......................................................................................................................... 18

Install the access panel............................................................................................................................. 18

Remove the PCIe riser cage ...................................................................................................................... 18

Install the PCIe riser cage ......................................................................................................................... 19

Remove the air baffle ............................................................................................................................... 19

Install the air baffle .................................................................................................................................. 20

Setup ......................................................................................................................................... 22

Optional installation services .................................................................................................................... 22

Rack planning resources........................................................................................................................... 22

Optimum environment .............................................................................................................................. 22

Space and airflow requirements ...................................................................................................... 23

Temperature requirements ............................................................................................................... 23

Power requirements ....................................................................................................................... 24

Electrical grounding requirements .................................................................................................... 24

Rack warnings ........................................................................................................................................ 24

Identifying the contents of the server shipping carton .................................................................................... 25

Installing hardware options ....................................................................................................................... 25

Installing the server into the rack ................................................................................................................ 25

Powering up and configuring the server ..................................................................................................... 26

Installing the operating system................................................................................................................... 26

Registering the server ............................................................................................................................... 27

Hardware options installation ....................................................................................................... 28

Introduction ............................................................................................................................................ 28

Memory options ...................................................................................................................................... 28

Contents 3

Memory subsystem architecture ....................................................................................................... 28

Single-rank and dual-rank DIMMs .................................................................................................... 28

DIMM identification ....................................................................................................................... 29

UDIMM maximum memory configurations ......................................................................................... 29

Memory configuration .................................................................................................................... 30

General DIMM slot population guidelines ......................................................................................... 30

Installing a DIMM .................................................................................................................................... 30

Drive options .......................................................................................................................................... 31

Drive guidelines ............................................................................................................................ 31

Removing a drive blank .................................................................................................................. 31

Removing a drive .......................................................................................................................... 32

Installing a hot-plug drive ................................................................................................................ 33

Optical drive option ................................................................................................................................ 33

Dedicated iLO management port module option .......................................................................................... 35

Expansion board option ........................................................................................................................... 36

Storage controller option .......................................................................................................................... 37

BBWC module and battery pack option ..................................................................................................... 38

Redundant hot-plug power supply option (with cage) ................................................................................... 40

HP Trusted Platform Module option ............................................................................................................ 44

Installing the Trusted Platform Module board ..................................................................................... 45

Retaining the recovery key/password .............................................................................................. 46

Enabling the Trusted Platform Module ............................................................................................... 46

Cabling ..................................................................................................................................... 48

Cabling overview .................................................................................................................................... 48

Server cabling ........................................................................................................................................ 48

Non redundant power supply 400 W cabling ............................................................................................ 48

RPS cabling ............................................................................................................................................ 49

Internal USB cabling ................................................................................................................................ 49

BBWC battery cabling ............................................................................................................................. 50

ODD cabling .......................................................................................................................................... 51

SATA cabling ......................................................................................................................................... 51

SAS cabling ........................................................................................................................................... 52

Configuration and utilities ............................................................................................................ 54

Configuration tools .................................................................................................................................. 54

SmartStart software ........................................................................................................................ 54

HP ROM-Based Setup Utility ............................................................................................................ 54

Array Configuration Utility .............................................................................................................. 56

Option ROM Configuration for Arrays ............................................................................................. 57

Re-entering the server serial number and product ID ........................................................................... 57

Management tools ................................................................................................................................... 58

Automatic Server Recovery ............................................................................................................. 58

ROMPaq utility .............................................................................................................................. 58

Integrated Lights-Out 3 technology ................................................................................................... 58

Erase Utility .................................................................................................................................. 59

USB support .................................................................................................................................. 59

Diagnostic tools ...................................................................................................................................... 59

HP Insight Diagnostics .................................................................................................................... 59

HP Insight Diagnostics survey functionality ........................................................................................ 60

Integrated Management Log ........................................................................................................... 60

Remote support and analysis tools ............................................................................................................. 60

HP Insight Remote Support software ................................................................................................. 60

Keeping the system current ....................................................................................................................... 61

Contents 4

Drivers ......................................................................................................................................... 61

Version control .............................................................................................................................. 61

ProLiant Support Packs ................................................................................................................... 62

Operating System Version Support .................................................................................................. 62

Firmware ...................................................................................................................................... 62

HP Smart Update Manager ............................................................................................................. 62

Change control and proactive notification ........................................................................................ 63

Care Pack .................................................................................................................................... 63

Troubleshooting .......................................................................................................................... 64

Pre-diagnostic steps ................................................................................................................................. 64

Important safety information ............................................................................................................ 64

Symptom information ..................................................................................................................... 66

Prepare the server for diagnosis ...................................................................................................... 66

Loose connections ................................................................................................................................... 68

Service notifications ................................................................................................................................. 68

Server health LEDs ................................................................................................................................... 68

Troubleshooting flowcharts ....................................................................................................................... 69

Start diagnosis flowchart ................................................................................................................ 69

General diagnosis flowchart ........................................................................................................... 70

Server power-on problems flowchart ................................................................................................ 72

POST problems flowchart ............................................................................................................... 75

OS boot problems flowchart ........................................................................................................... 77

Server fault indications flowchart ..................................................................................................... 78

POST error messages and beep codes ....................................................................................................... 80

Battery ....................................................................................................................................... 82

Regulatory compliance notices ..................................................................................................... 83

Regulatory compliance identification numbers ............................................................................................. 83

Federal Communications Commission notice ............................................................................................... 83

FCC rating label ............................................................................................................................ 83

FCC Notice, Class A Equipment ...................................................................................................... 83

Declaration of conformity for products marked with the FCC logo, United States only ....................................... 84

Modifications .......................................................................................................................................... 84

Cables ................................................................................................................................................... 84

Canadian notice (Avis Canadien) .............................................................................................................. 84

European Union regulatory notice ............................................................................................................. 84

Disposal of waste equipment by users in private households in the European Union ......................................... 85

Japanese class A notice ........................................................................................................................... 85

BSMI notice ............................................................................................................................................ 86

Korean class A notice .............................................................................................................................. 86

Chinese notice ........................................................................................................................................ 86

Laser compliance .................................................................................................................................... 86

Battery replacement notice ........................................................................................................................ 87

Taiwan battery recycling notice ................................................................................................................. 87

Power cord statement for Japan ................................................................................................................. 87

Electrostatic discharge ................................................................................................................. 88

Preventing electrostatic discharge .............................................................................................................. 88

Grounding methods to prevent electrostatic discharge .................................................................................. 88

Specifications ............................................................................................................................. 89

Environmental specifications ..................................................................................................................... 89

Mechanical specifications ........................................................................................................................ 89

Contents 5

Power supply specifications ...................................................................................................................... 89

Support and other resources ........................................................................................................ 91

Before you contact HP .............................................................................................................................. 91

HP contact information ............................................................................................................................. 91

Customer Self Repair ............................................................................................................................... 91

Acronyms and abbreviations ........................................................................................................ 99

Documentation feedback ........................................................................................................... 102

Index ....................................................................................................................................... 103

Contents 6

Component identification

Serial label pull tab

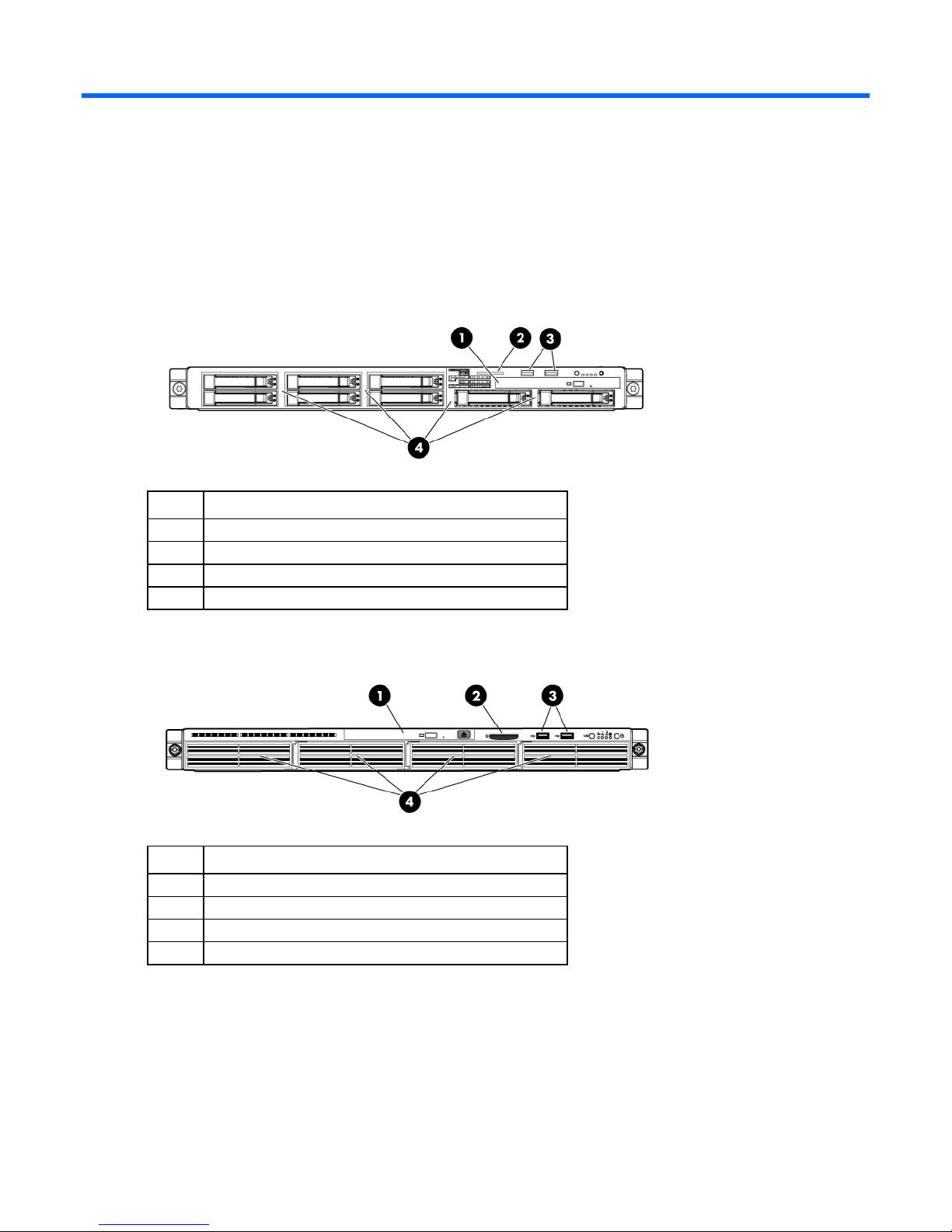

Front panel components

• SFF model

Item Description

1

2

3

4

Optical drive

Serial label pull tab

USB connectors (2)

Drive bays

• LFF model

Item Description

1

2

3

4

Optical drive

USB connectors (2)

Drive bays

Component identification 7

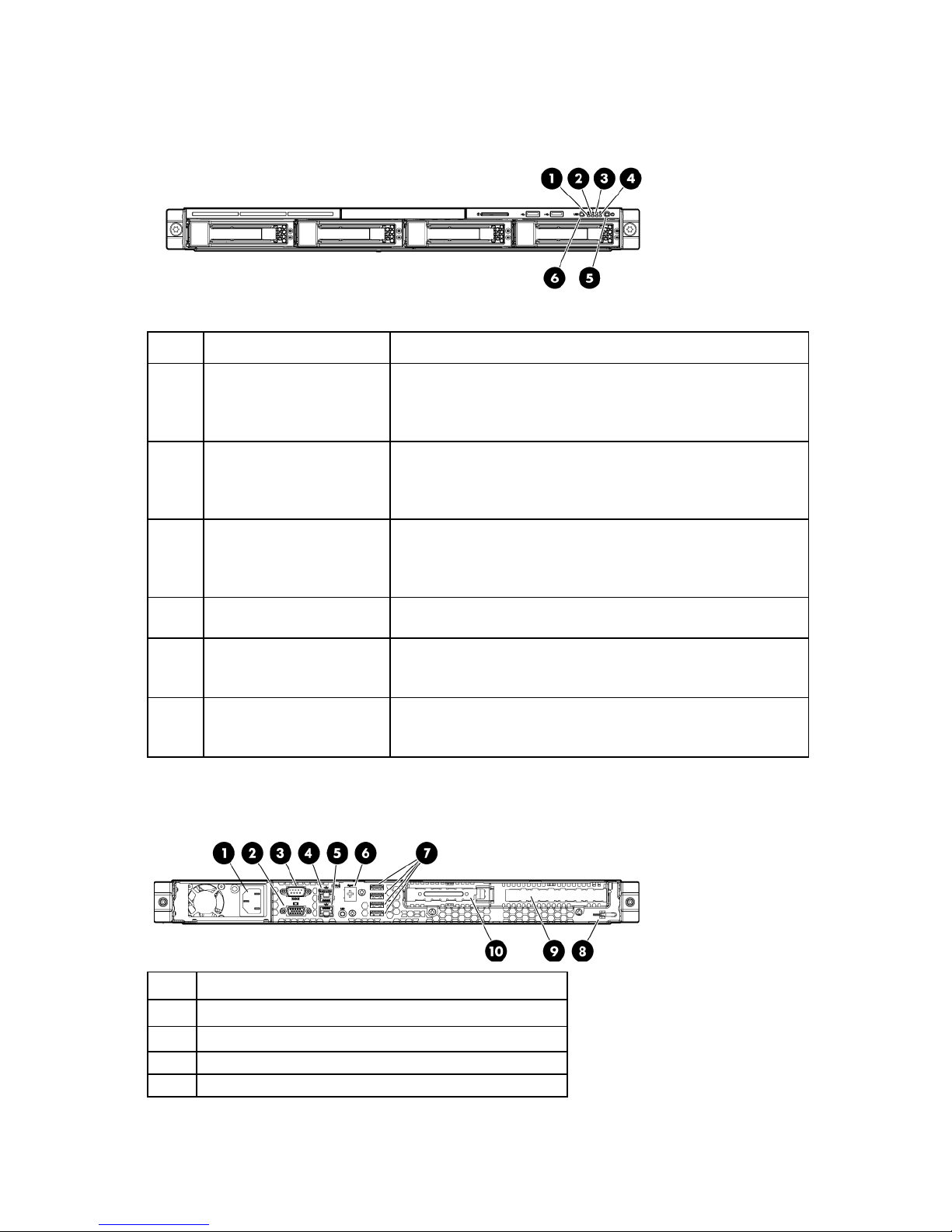

Front panel LEDs

Power On/Standby button

Green = Normal (system on)

Item Description Status

1

2

3

4

5

6

Internal health LED Green = Normal

Amber = System degraded

Red = System critical

Off = Normal (when in standby mode)

NIC 1 link/activity LED Green = Network link

Flashing green = Network link and activity

Off = No network link

If the power is off, view the LEDs on the RJ-45 connector.

NIC 2 link/activity LED Green = Network link

Flashing green = Network link and activity

Off = No link to network

If the power is off, view the LEDs on the RJ-45 connector.

Drive activity LED Green = Drive active

Off = No drive activity

and system power LED

UID button/LED Blue = Activated

Amber = System in standby, but power is still applied

Off = Power cord not attached or the power supply failed

Flashing blue = System being managed remotely

Off = Deactivated

Rear panel components

Item Description

1

2

3

4

Power cord connector

Video connector

Serial connector

10/100/1000 NIC 2 connector

Component identification 8

Item Description

5

6

7

8

9

10

10/100/1000 NIC 1 connector/ shared iLO management

port

HP dedicated iLO management port (optional)

USB connectors (4)

T10/T15 tool

Slot 1 PCIe2 x16 (16, 8, 4, 1)

Slot 2 PCIe2 x8 (4, 1)

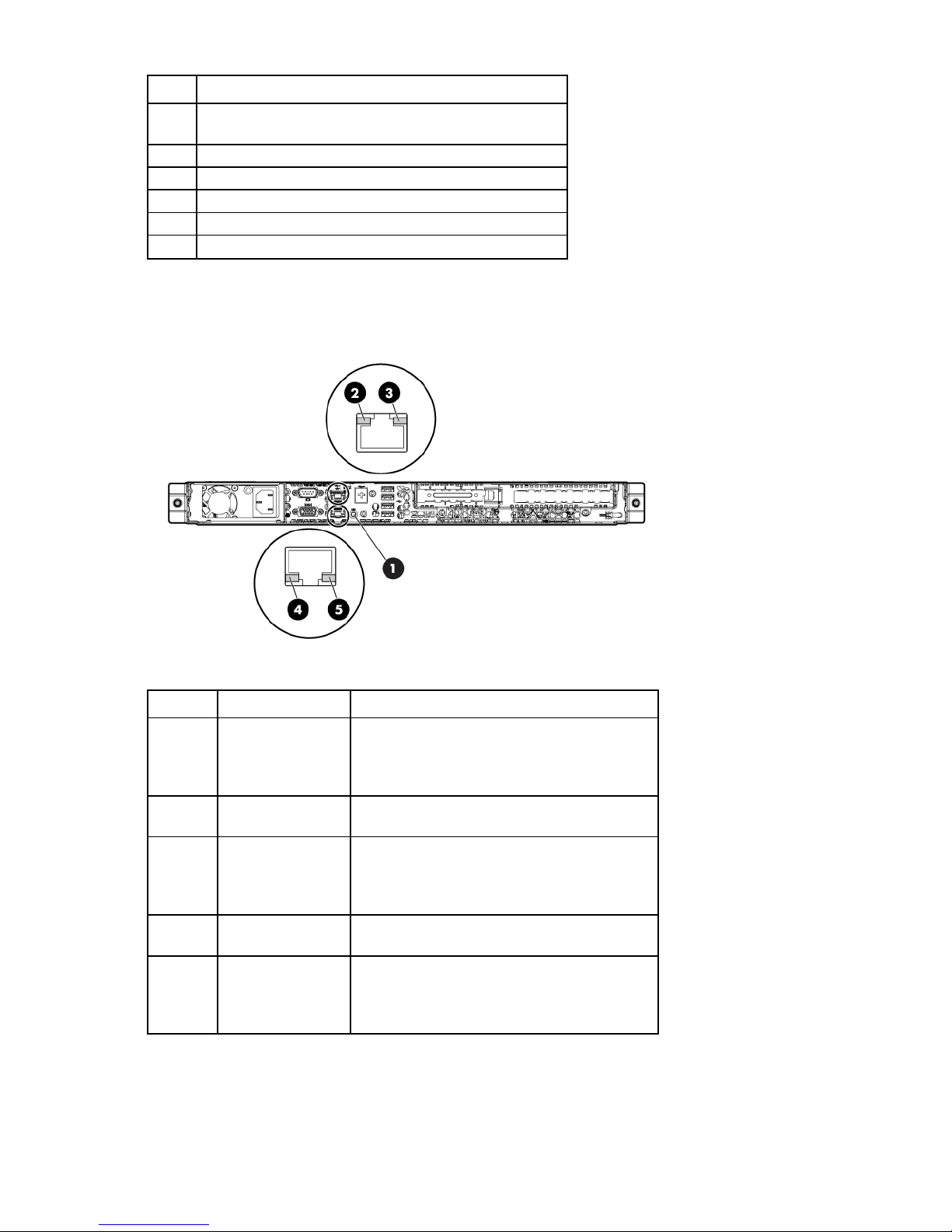

Rear panel LEDs

Item Description Status

1

2

3

4

5

UID button/LED Blue = Identification

Flashing blue = System is being managed

remotely

Off = Off

NIC2 link LED Green = 10M/100M/1G link speed

Off = No connection

NIC2 activity LED Green = Linked to the network

Flashing green = Linked and activity on the

network

Off = No network activity

NIC1 link LED Green = 10M/100M/1G link speed

Off = No connection

NIC1 activity LED Green = Linked to the network

Flashing green = Linked and activity on the

network

Off = No network activity

Component identification 9

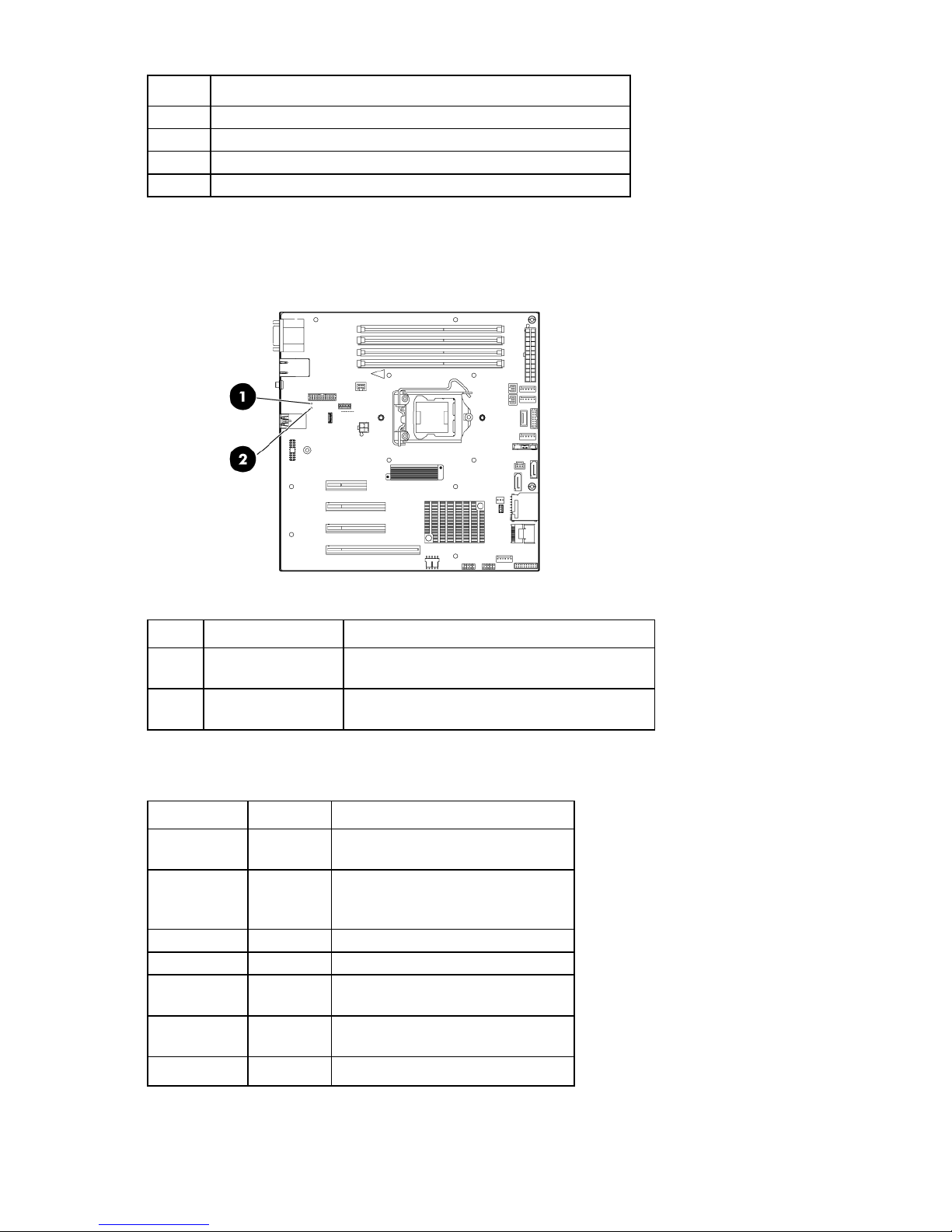

PCIe riser board connectors

PCIe expansion slot definitions

Slot Type Length Connector Interconnect

1

2

PCIe2 Full x16 x16

PCIe2 Half x8 x4

System board components

Item Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

DIMM slots 1-4

Processor socket

System power connector (24 pin)

Fan connector 7 (Reserved)

Fan connector 8 (Reserved)

Fan connector 3

Fan connector 4

RPS connector

Fan connector 5

System battery

2

C cable connector

I

SATA connectors

SD card slot

Mini-SAS connector

Front panel connector

Fan connector 6

Front USB connectors

Internal USB connector

Reserved

Component identification 10

Item Description

21

22

23

24

TPM connector

Power supply connector (4 pin)

System maintenance switch

HP dedicated iLO management connector

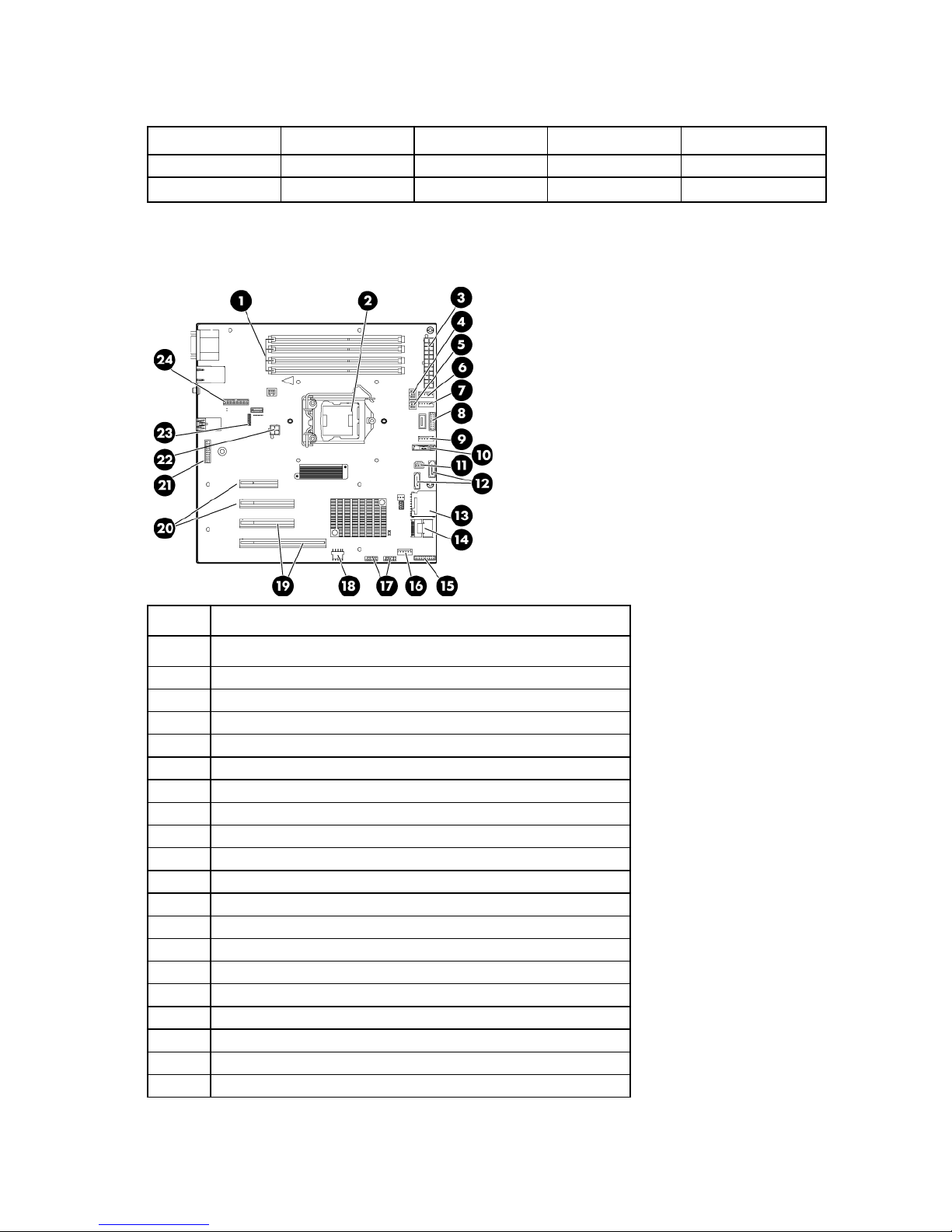

System board LEDs

Item LED description Status

1

Power supply 1

failure

2

Power supply 2

(redundant) failure

Red = Power supply 1 failed

Off = Normal

Red = Power supply 2 failed

Off = Normal

System maintenance switch

Position Default Function

1

2

3

4

5

6

7

Off Off = iLO 3 security is enabled

On = iLO 3 security is disabled

Off Off = System configuration can be

changed

On = System configuration is locked

Off Reserved

Off Reserved

Off Off = Password is enabled

On = Password is disabled

Off Off = No function

On = Clear NVRAM

Off Reserved

Component identification 11

Position Default Function

8

Off Reserved

9

10

Off Reserved

Off Reserved

When the system maintenance switch position 6 is set to the On position, the system is prepared to erase all

system configuration settings from both CMOS and NVRAM.

CAUTION: Clearing CMOS and/or NVRAM deletes configuration information. Be sure to

properly configure the server or data loss could occur.

NMI functionality

An NMI crash dump enables administrators to create crash dump files when a system is hung and not

responding to traditional debug mechanisms.

Crash dump log analysis is an essential part of diagnosing reliability issues, such as hangs in operating

systems, device drivers, and applications. When crashes freeze a system, administrators must cycle the

system power. Resetting the system erases any information that support issue analysis, but the NMI feature

preserves that information by performing a memory dump before a hard reset.

The administrator must use the iLO Virtual NMI feature to force the OS to invoke the NMI handler and

generate a crash dump log.

For additional information, see the HP website

(http://h20000.www2.hp.com/bc/docs/support/SupportManual/c00797875/c00797875.pdf).

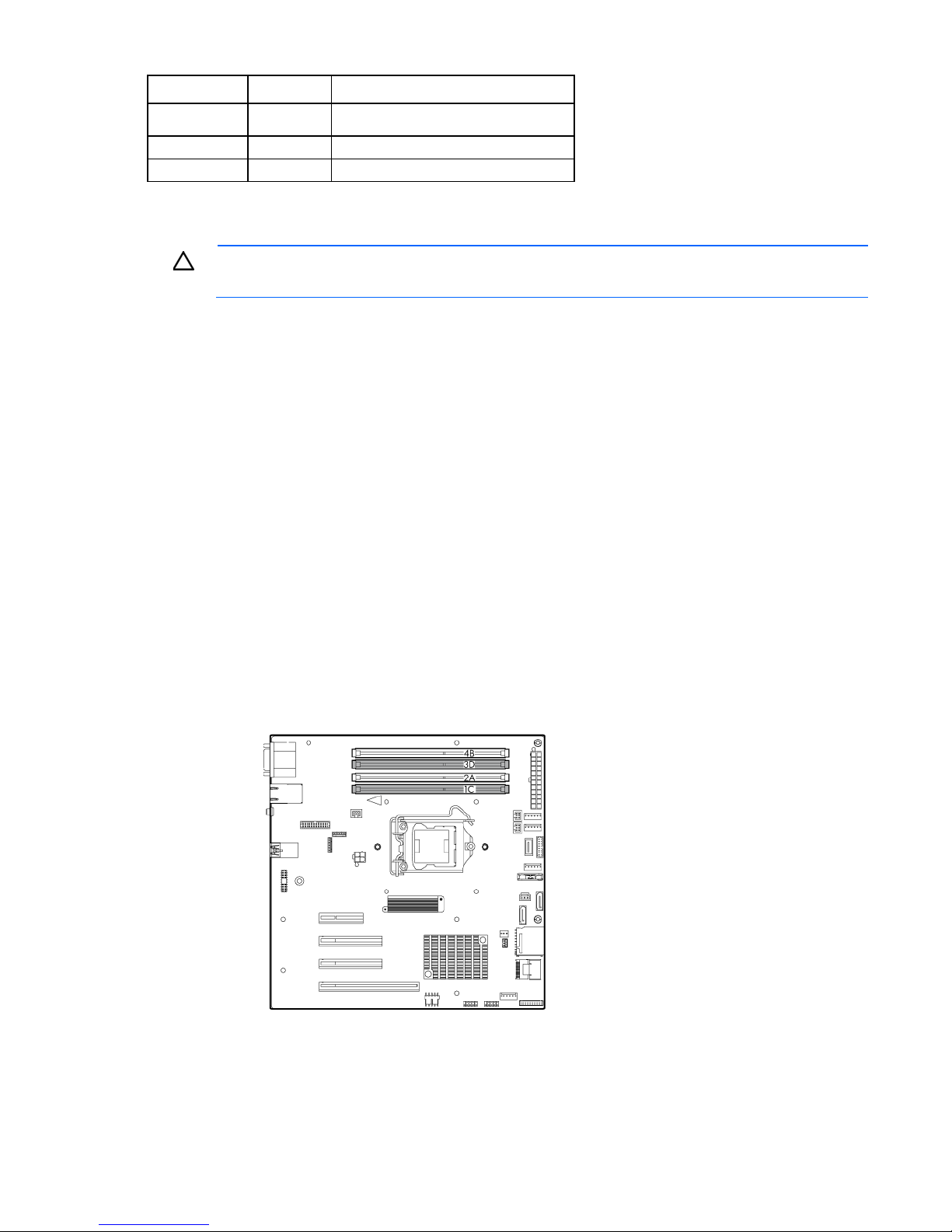

DIMM slot locations

DIMM slots are numbered sequentially for the processor.

Populate the DIMM slots in the following sequence:

• 1 DIMM: 2A

Component identification 12

• 2 DIMMs: 2A+4B

• 3 DIMMs: 2A+4B+1C

• 4 DIMMs: All DIMMs

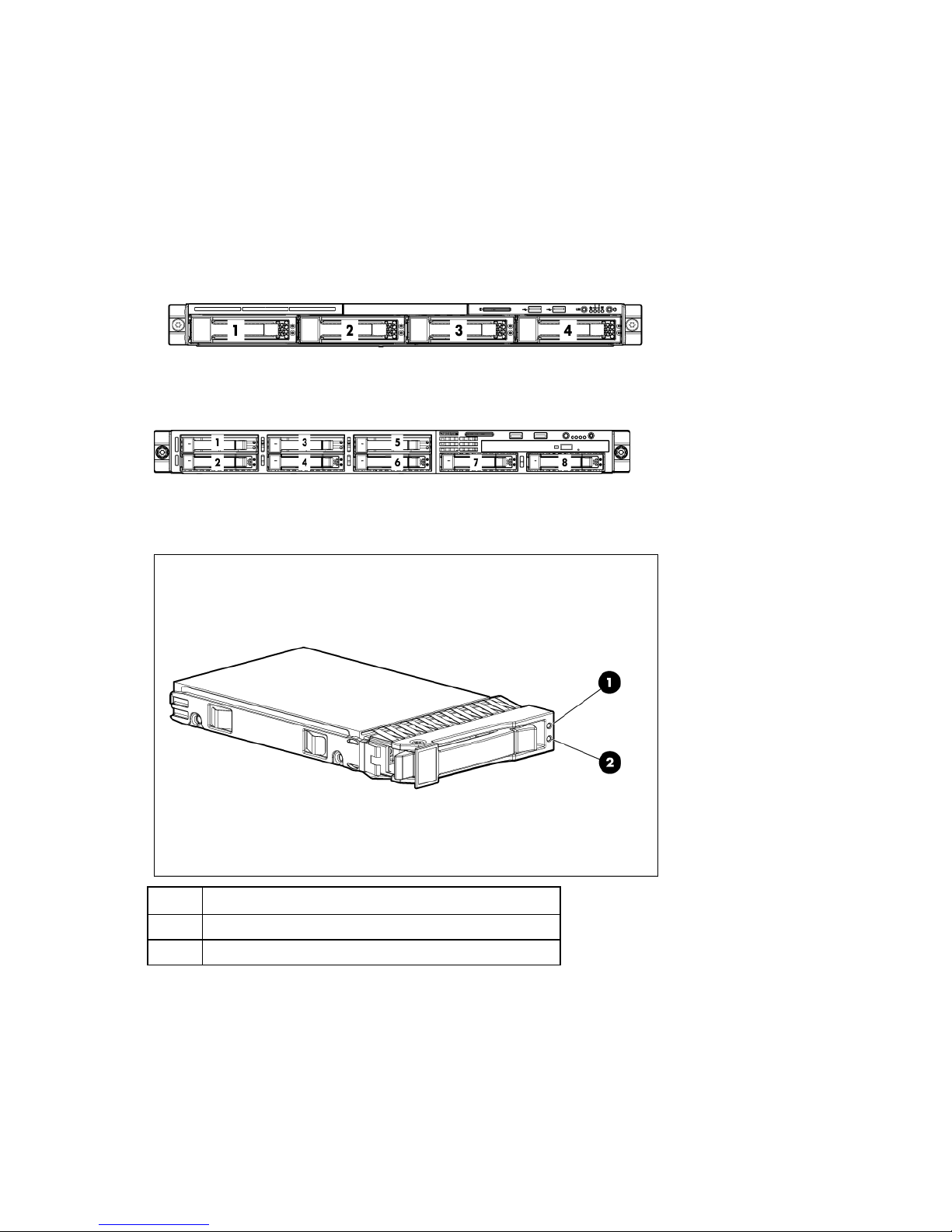

SAS and SATA device numbering

• LFF device bay numbering

• SFF device bay numbering

SAS and SATA drive LEDs

Item Description

1

2

Fault/UID LED (amber/blue)

Online LED (green)

Component identification 13

BBWC module LEDs

3.3 V auxiliary power is available, as indicated by LED 2, then data

Item ID Color Description

1

2

3

4

Green System Power LED. This LED illuminates steadily when the

system is powered up and 12-V system power is available.

This power supply is used to maintain the battery charge

and provide supplementary power to the cache

microcontroller.

Green Auxiliary Power LED. This LED illuminates steadily when 3.3

V auxiliary voltage is detected. The auxiliary voltage is used

to preserve BBWC data and is available any time that the

system power cords are connected to a power supply.

Amber Battery Health LED. To interpret the illumination patterns of

this LED, see the following table.

Green BBWC Status LED. To interpret the illumination patterns of

this LED, see the following table.

LED3 pattern LED4 pattern Interpretation

—

—

One flash every

two seconds

Double flash, then

pause

The system is powered down, and the cache contains data that has not

yet been written to the drives. Restore system power as soon as

possible to prevent data loss.

If

preservation time is extended. If no auxiliary power is available, only

battery power preserves the data. A fully-charged battery can

normally preserve data for at least two days.

The battery lifetime also depends on the cache module size. For more

information, see the controller QuickSpecs on the HP website

(http://www.hp.com).

The cache microcontroller is waiting for the host controller to

communicate.

Component identification 14

An alternating green and amber blink pattern indicates that the cache

pack. BBWC features are disabled until the battery pack is replaced.

pack. BBWC features are disabled until the battery pack is replaced.

LED3 pattern LED4 pattern Interpretation

—

One flash per

second

—

—

One flash per

second

Steady glow

One flash per

Steady glow The battery pack is fully charged, and posted write data is stored in the

Off The battery pack is fully charged, and write data is not posted in the

One flash per

second

— There is a short circuit across the battery terminals or within the battery

— An open circuit is across the battery terminals or within the battery

second

The battery pack is below the minimum charge level and is being

charged. Features that require a battery (such as write cache, capacity

expansion, stripe size migration, and RAID migration) are temporarily

unavailable until charging is complete. The recharge process takes

between 15 minutes and 2 hours, depending on the initial capacity of

the battery.

cache.

cache.

microcontroller is executing from within its boot loader and receiving

new flash code from the host controller.

The life expectancy of a battery pack is typically more than three

years.

The life expectancy of a battery pack is typically more than three

years.

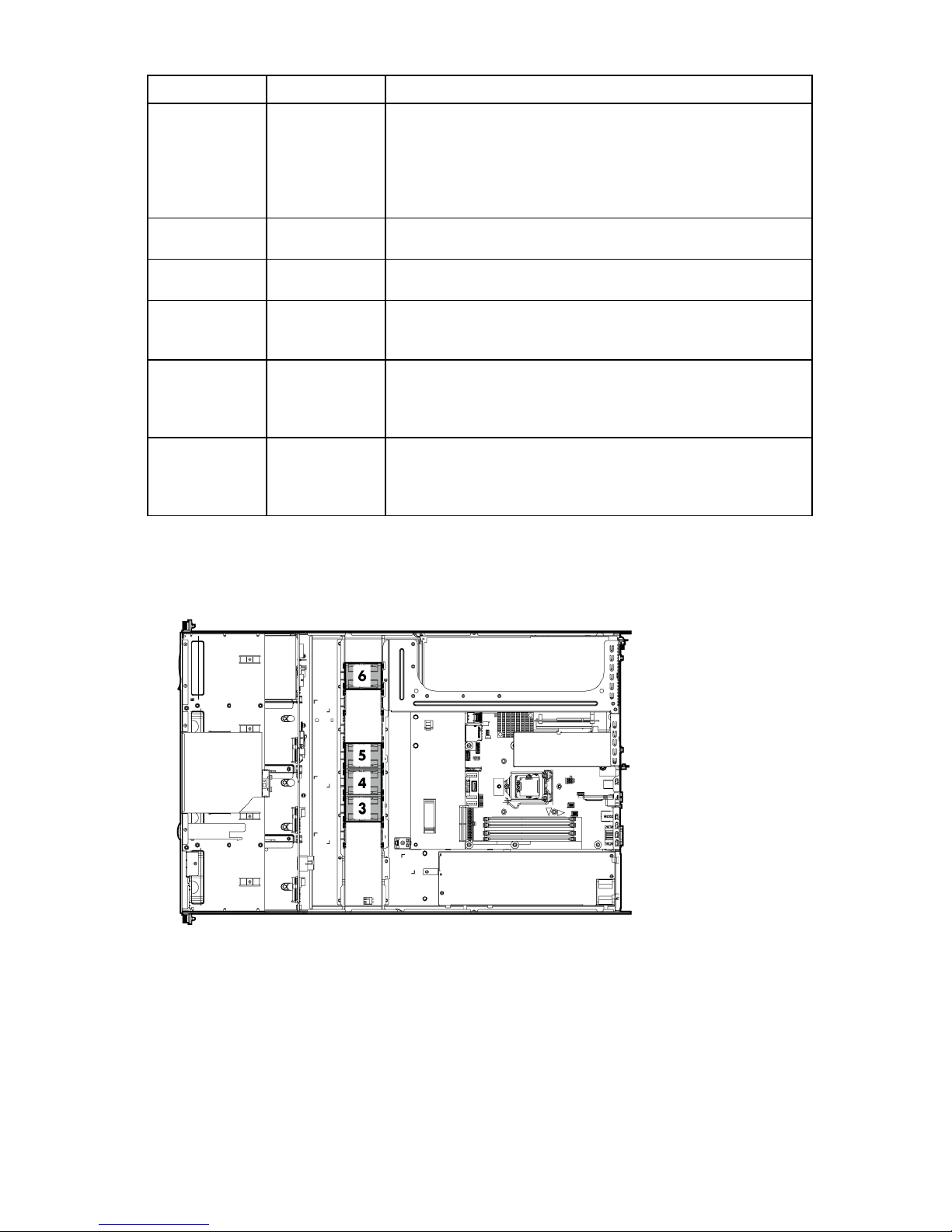

Fan locations

Component identification 15

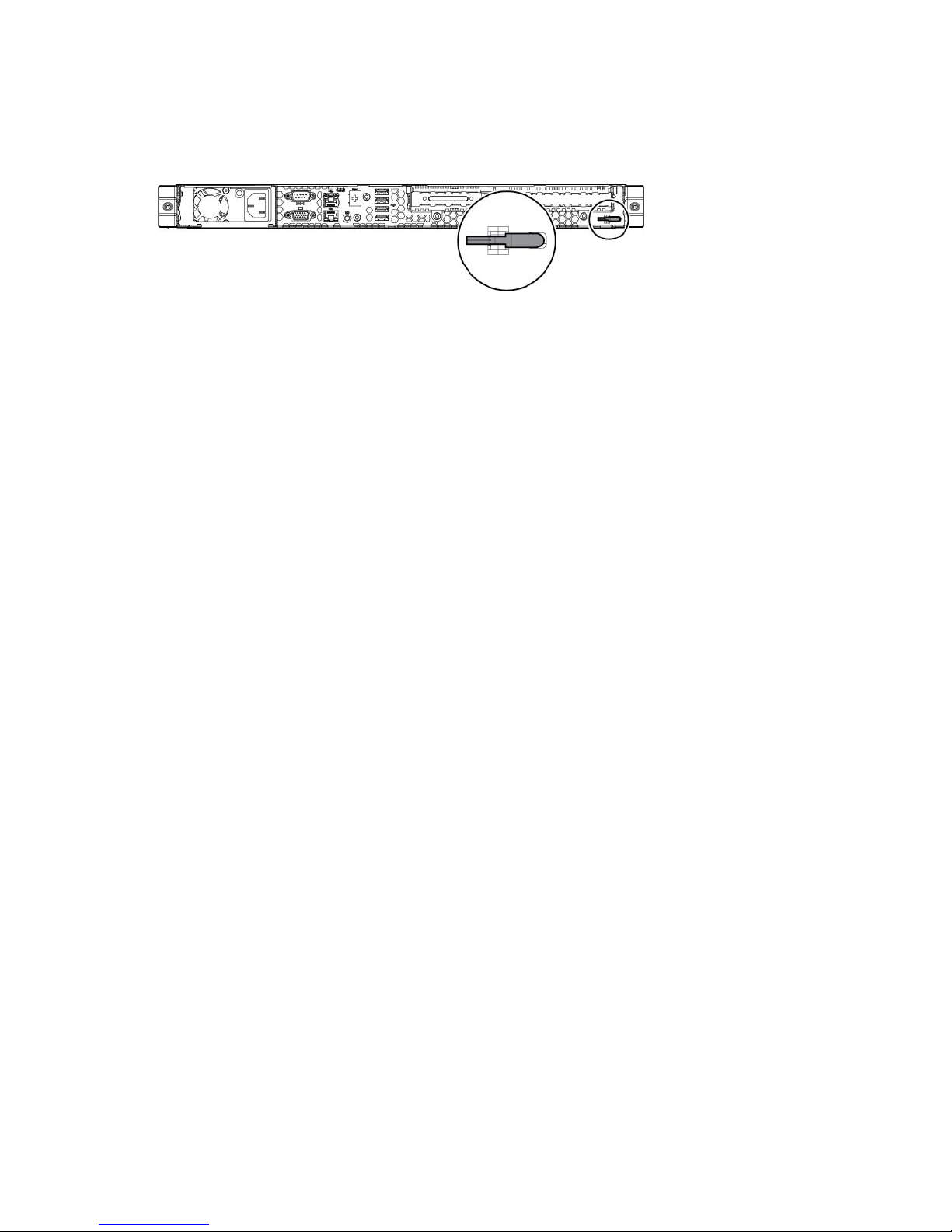

T-10/T15 Torx screwdriver

The server includes a T-10/T-15 Torx screwdriver located on the rear panel of the server. Use the screwdriver

to loosen screws during hardware configuration procedures.

Component identification 16

Operations

Power up the server

1. Connect each power cord to the server.

2. Connect each power cord to the power source.

3. Press the Power On/Standby button.

The server exits standby mode and applies full power to the system. The system power LED changes

Power down the server

from amber to green.

Before powering down the server for any upgrade or maintenance procedures, perform a backup of critical

server data and programs.

WARNING: To reduce the risk of personal injury, electric shock, or damage to the equipment,

remove the power cord to remove power from the server. The front panel Power On/Standby

button does not completely shut off system power. Portions of the power supply and some internal

circuitry remain active until AC/DC power is removed.

IMPORTANT: When the server is in standby mode, auxiliary power is still being provided to the

system.

To power down the server, use one of the following methods:

• Press and release the Power On/Standby button.

This method initiates a controlled shutdown of applications and the OS before the server enters standby

mode.

• Press and hold the Power On/Standby button for more than 4 seconds to force the server to enter

standby mode.

This method forces the server to enter standby mode without properly exiting applications and the OS.

If an application stops responding, you can use this method to force a shutdown.

• Use a virtual power button selection through iLO 3.

This method initiates a controlled remote shutdown of applications and the OS before the server enters

standby mode.

Before proceeding, verify the server is in standby mode by observing that the system power LED is amber.

Remove the server from the rack

WARNING: The server is not attached to the rack mounting rails. To avoid potential damage to

the server and personal injury, always support the server with both hands when removing it from

the rack.

Operations 17

To remove the server from an HP, Compaq branded, TELCO, or third-party rack:

1. Power down the server (on page 17).

2. Disconnect all peripheral cables and power cords from the server rear panel.

3. Loosen the thumbscrews that secure the server faceplate to the front of the rack.

4. Remove the server from the rack. For more information, see the documentation that ships with the rack

mounting option.

5. Place the server on a sturdy, level surface.

Remove the access panel

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

CAUTION: For proper cooling, do not operate the server without the access panel, baffles,

expansion slot covers, or blanks installed. If the server supports hot-plug components, minimize

1. Power down the server (on page 17).

2. Remove the server from the rack (on page 17).

3. Press the hood latch button, slide the access panel to the rear of the chassis, and then remove the access

the amount of time the access panel is open.

panel.

If the access panel is locked, use a T-10 Torx screwdriver to unlock the hood lock screw.

Install the access panel

1. Place the access panel on top of the server. Allow the panel to extend past the rear of the server

approximately 1.25 cm (0.5 inch).

2. Slide the panel to the front of the chassis until it is well engaged with the hard drive cage.

3. Use the T-10 Torx screwdriver attached to the rear of the server to tighten the hood lock screw on the

hood.

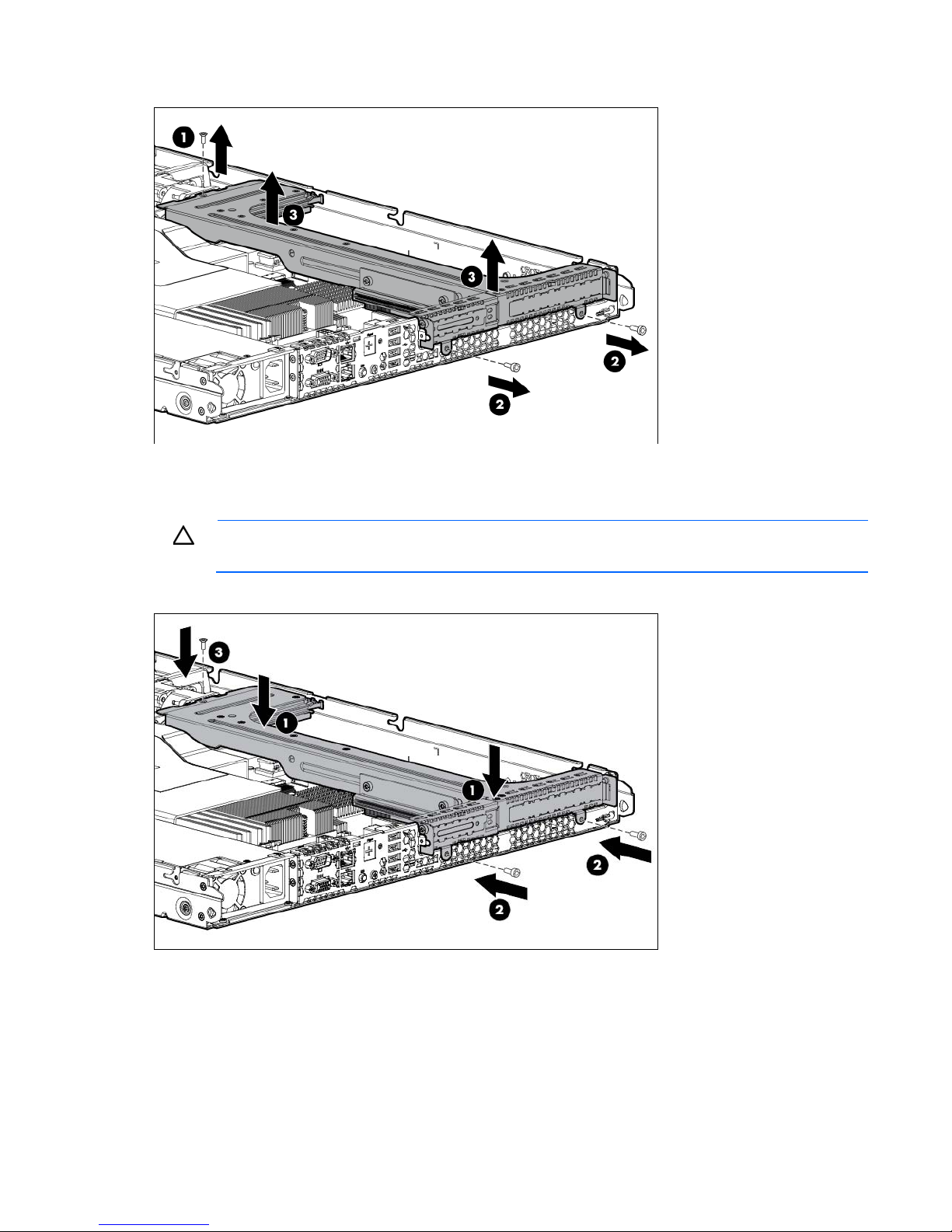

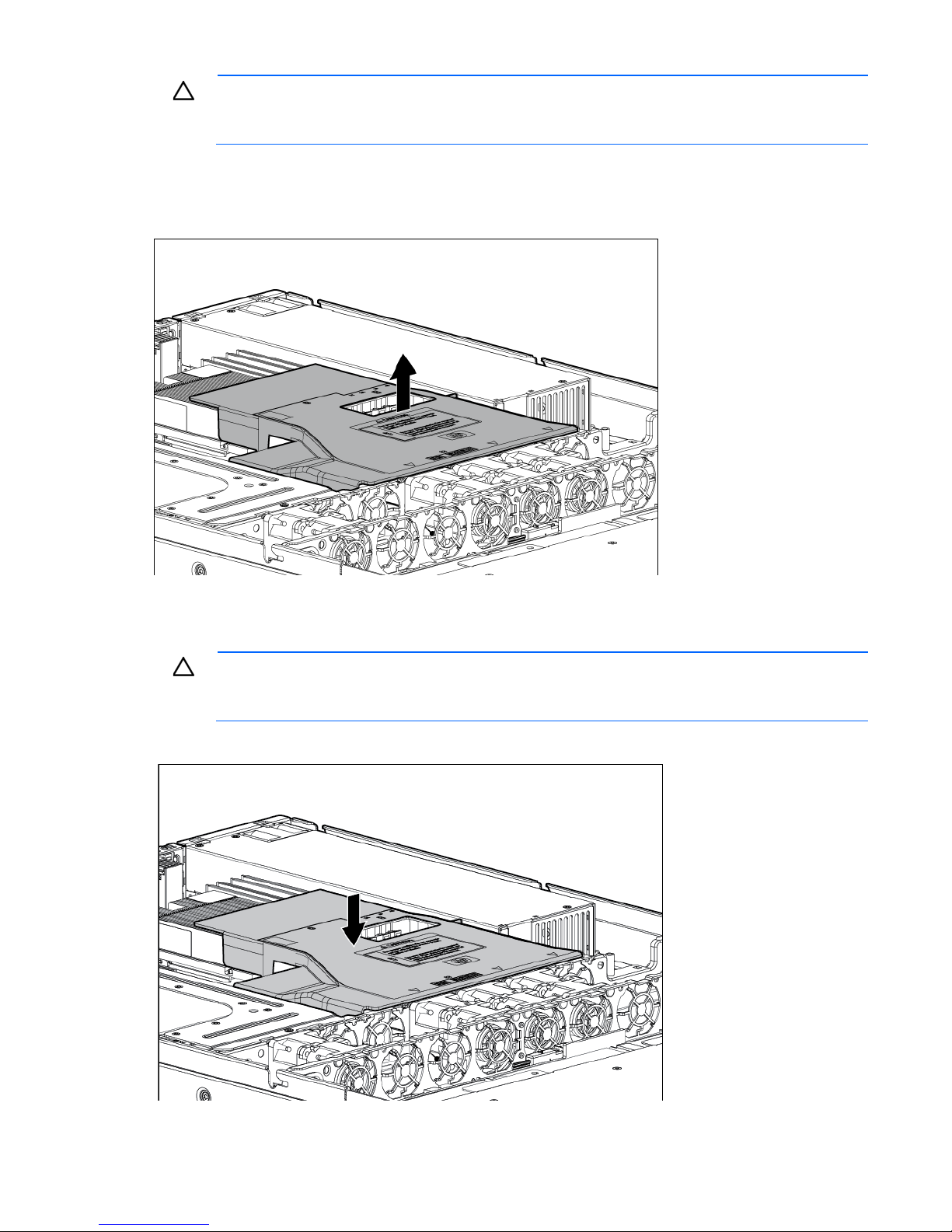

Remove the PCIe riser cage

CAUTION: To prevent damage to the server or expansion boards, power down the server and

1. Power down the server (on page 17).

2. Remove the server from the rack (on page 17).

3. Remove the access panel (on page 18).

4. Disconnect all internal cables connected to existing expansion boards.

5. Remove the PCIe riser cage:

remove all AC power cords before removing or installing the PCIe riser board assembly.

a. Remove the T-10 screw.

b. Remove the T-15 screws.

Operations 18

c.

Remove the riser cage.

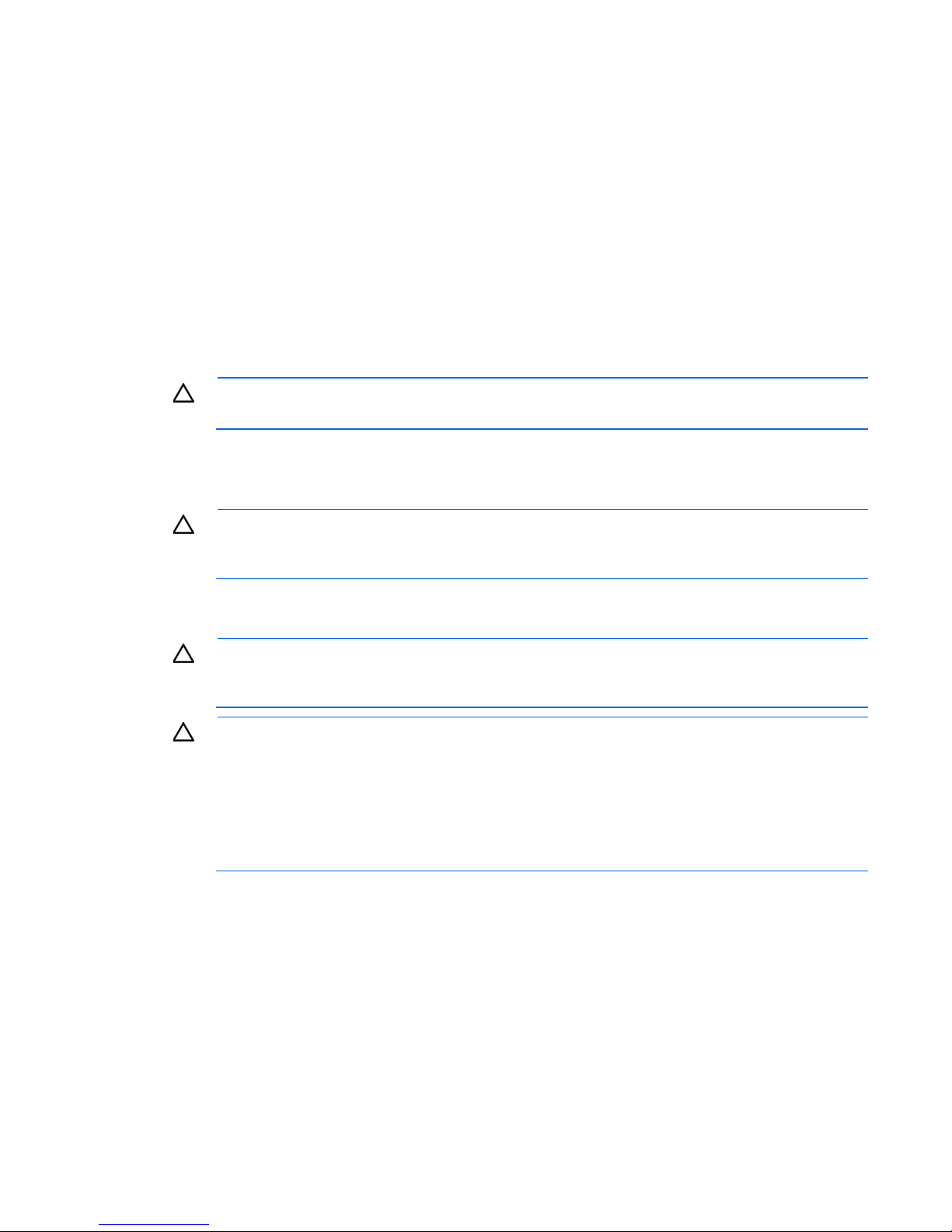

Install the PCIe riser cage

CAUTION: To prevent damage to the server or expansion boards, power down the server and

1. Install the PCIe riser cage.

remove all AC power cords before removing or installing the PCIe riser board assembly.

2. Connect any internal cables for expansion boards.

3. Install the access panel (on page 18).

4. Install the server into the rack ("Installing the server into the rack" on page 25).

Remove the air baffle

Operations 19

CAUTION: For proper cooling, do not operate the server without the access panel, baffles,

expansion slot covers, or blanks installed. If the server supports hot-plug components, minimize

1. Power down the server (on page 17).

2. Remove the access panel (on page 18).

3. Remove the air baffle.

the amount of time the access panel is open.

Install the air baffle

CAUTION: For proper cooling, do not operate the server without the access panel, baffles,

expansion slot covers, or blanks installed. If the server supports hot-plug components, minimize

1. Install the air baffle.

the amount of time the access panel is open.

Operations 20

2.

Install the access panel (on page 18).

3. Power up the server (on page 17).

Operations 21

Setup

Optional installation services

Delivered by experienced, certified engineers, HP Care Pack services help you keep your servers up and

running with support packages tailored specifically for HP ProLiant systems. HP Care Packs let you integrate

both hardware and software support into a single package. A number of service level options are available

to meet your needs.

HP Care Pack Services offer upgraded service levels to expand your standard product warranty with

easy-to-buy, easy-to-use support packages that help you make the most of your server investments. Some of

the Care Pack services are:

• Hardware support

o 6-Hour Call-to-Repair

o 4-Hour 24x7 Same Day

o 4-Hour Same Business Day

• Software support

o Microsoft® operating systems

o Linux operating systems

o HP ProLiant Essentials (HP SIM and RDP)

• Integrated hardware and software support

o Critical Service

o Proactive 24

o Support Plus

o Support Plus 24

• Startup and implementation services for both hardware and software

For more information on HP Care Pack Services, see the HP website

(http://www.hp.com/services/carepack).

Rack planning resources

The rack resource kit ships with all HP branded or Compaq branded 9000, 10000, and H9 series racks. For

more information on the content of each resource, see the rack resource kit documentation.

Optimum environment

When installing the server in a rack, select a location that meets the environmental standards described in

this section.

Setup 22

Space and airflow requirements

ensures proper airflow. Using a rack without blanking panels results in improper cooling that can

party rack is used, observe the following additional requirements to ensure

Rack server

To allow for servicing and adequate airflow, observe the following space and airflow requirements when

deciding where to install a rack:

• Leave a minimum clearance of 63.5 cm (25 in) in front of the rack.

• Leave a minimum clearance of 76.2 cm (30 in) behind the rack.

• Leave a minimum clearance of 121.9 cm (48 in) from the back of the rack to the back of another rack

or row of racks.

HP servers draw in cool air through the front door and expel warm air through the rear door. Therefore, the

front and rear rack doors must be adequately ventilated to allow ambient room air to enter the cabinet, and

the rear door must be adequately ventilated to allow the warm air to escape from the cabinet.

CAUTION: To prevent improper cooling and damage to the equipment, do not block the

When vertical space in the rack is not filled by a server or rack component, the gaps between the

components cause changes in airflow through the rack and across the servers. Cover all gaps with blanking

panels to maintain proper airflow.

ventilation openings.

CAUTION: Always use blanking panels to fill empty vertical spaces in the rack. This arrangement

lead to thermal damage.

The 9000 and 10000 Series Racks provide proper server cooling from flow-through perforations in the front

and rear doors that provide 64 percent open area for ventilation.

CAUTION: When using a Compaq branded 7000 series rack, install the high airflow rack door

insert (PN 327281-B21 for 42U rack, PN 157847-B21 for 22U rack) to provide proper

front-to-back airflow and cooling.

CAUTION: If a third-

adequate airflow and to prevent damage to the equipment:

• Front and rear doors—If the 42U rack includes closing front and rear doors, you must allow

5,350 sq cm (830 sq in) of holes evenly distributed from top to bottom to permit adequate

airflow (equivalent to the required 64 percent open area for ventilation).

• Side—The clearance between the installed rack component and the side panels of the rack

must be a minimum of 7 cm (2.75 in).

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the system in a well-ventilated,

climate-controlled environment.

The maximum recommended ambient operating temperature (TMRA) for most server products is 35°C

(95°F). The temperature in the room where the rack is located must not exceed 35°C (95°F).

Setup 23

CAUTION: To reduce the risk of damage to the equipment when installing third-party options:

• Do not permit optional equipment to impede airflow around the server or to increase the

internal rack temperature beyond the maximum allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of information technology equipment by licensed electricians. This equipment is designed to

operate in installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992

(code for Protection of Electronic Computer/Data Processing Equipment). For electrical power ratings on

options, refer to the product rating label or the user documentation supplied with that option.

WARNING: To reduce the risk of personal injury, fire, or damage to the equipment, do not

overload the AC supply branch circuit that provides power to the rack. Consult the electrical

When installing more than one server, you may need to use additional power distribution devices to safely

provide power to all devices. Observe the following guidelines:

authority having jurisdiction over wiring and installation requirements of your facility.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

regulating uninterruptible power supply. This device protects the hardware from damage caused

by power surges and voltage spikes and keeps the system in operation during a power failure.

• Balance the server power load between available AC supply branch circuits.

• Do not allow the overall system AC current load to exceed 80 percent of the branch circuit AC current

rating.

• Do not use common power outlet strips for this equipment.

• Provide a separate electrical circuit for the server.

Electrical grounding requirements

The server must be grounded properly for proper operation and safety. In the United States, you must install

the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article 250, as well as

any local and regional building codes. In Canada, you must install the equipment in accordance with

Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries, you must

install the equipment in accordance with any regional or national electrical wiring codes, such as the

International Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you must be sure

that all power distribution devices used in the installation, such as branch wiring and receptacles, are listed

or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple servers connected to the same power

source, HP recommends the use of a PDU that is either permanently wired to the building’s branch circuit or

includes a nondetachable cord that is wired to an industrial-style plug. NEMA locking-style plugs or those

complying with IEC 60309 are considered suitable for this purpose. Using common power outlet strips for

the server is not recommended.

Rack warnings

Setup 24

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

WARNING: To reduce the risk of personal injury or equipment damage when unloading a rack:

• At least two people are needed to safely unload the rack from the pallet. An empty 42U rack

can weigh as much as 115 kg (253 lb), can stand more than 2.1 m (7 ft) tall, and might

become unstable when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp from the pallet. Always handle

the rack from both sides.

Identifying the contents of the server shipping carton

Unpack the server shipping carton and locate the materials and documentation necessary for installing the

server. All the rack mounting hardware necessary for installing the server into the rack is included with the

rack or the server.

The contents of the server shipping carton include:

• Server

• Power cord

• Hardware documentation, Documentation CD, and software products

• Rack-mounting hardware

In addition to the supplied items, you might need:

• Operating system or application software

• Hardware options

Installing hardware options

Install any hardware options before initializing the server. For options installation information, refer to the

option documentation. For server-specific information, refer to "Hardware options installation (on page 28)."

Installing the server into the rack

CAUTION: Always plan the rack installation so that the heaviest item is on the bottom of the rack.

1. Install the server into the rack. For more information, see the installation instructions that ship with the 1U

Install the heaviest item first, and continue to populate the rack from the bottom to the top.

Quick Deploy Rail System.

2. Connect peripheral devices to the server. For more information, see "Rear panel components (on page

8)."

Setup 25

WARNING: To reduce the risk of electric shock, fire, or damage to the equipment, do not plug

Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

telephone or telecommunications connectors into RJ-45 connectors.

3. Connect the power cord to the rear of the server.

4. Install power cord anchors.

5. Connect the power cord to the AC power source.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

•

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it.

Pay particular attention to the plug, electrical outlet, and the point where the cord extends from

the server.

Powering up and configuring the server

To power up the server, press the Power On/Standby button.

While the server boots, RBSU and the ORCA utility are automatically configured to prepare the server for

operating system installation.

To configure these utilities manually:

• Press the F8 key when prompted during the array controller initialization to configure the array

controller using ORCA.

• Press the F9 key when prompted during the boot process to change the server settings using RBSU. The

system is set up by default for the English language.

For more information on the automatic configuration, refer to the HP ROM-Based Setup Utility User Guide

located on the Documentation CD.

Installing the operating system

To operate properly, the server must have a supported operating system installed. For the latest information

on supported operating systems, see the HP website (http://www.hp.com/go/supportos).

Methods to install an operating system on the server include:

• SmartStart assisted installation—Insert the SmartStart CD into the DVD-ROM drive and reboot the

server.

• Manual installation—Insert the operating system CD into the DVD-ROM drive and reboot the server. You

might have to obtain additional drivers from the HP website (http://www.hp.com/support).

For more information, see the SmartStart installation poster in the HP ProLiant Essentials Foundation Pack

included with the server.

Setup 26

Registering the server

To register the server, refer to the HP Registration website (http://register.hp.com).

Setup 27

Hardware options installation

Introduction

If more than one option is being installed, read the installation instructions for all the hardware options and

identify similar steps to streamline the installation process.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

Memory options

internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server before

beginning any installation procedure. Improper grounding can cause electrostatic discharge.

The server memory subsystem supports only UDIMMs.

The server supports dual-rank, PC3-10600E (DDR3) DIMMs operating at a speed of 1,333 MHz.

Depending on the processor model and the number of DIMMs installed, the memory clock speed might be

reduced to 1,066 or 800 MHz. For more information, see "General DIMM slot population guidelines (on

page 30)."

Memory subsystem architecture

The memory subsystem in this server is divided into channels. The processor supports two channels, and each

channel supports two DIMM slots, as shown in the following table.

Channel Slot Slot number

A

B

This server supports only UDIMMs.

DIMM slots in this server are identified by number and by letter. Letters identify the slots to populate for

specific memory modes. Slot numbers are reported by ROM messages during boot and for error reporting.

C

A

D

B

1

2

3

4

Single-rank and dual-rank DIMMs

DIMM configuration requirements are based on these classifications:

• Single-rank DIMM—One set of memory chips that is accessed while writing to or reading from the

memory.

• Dual-rank DIMM—Two single-rank DIMMs on the same module, with only one rank accessible at a time.

Hardware options installation 28

The server memory control subsystem selects the proper rank within the DIMM when writing to or reading

from the DIMM.

Dual-rank DIMMs provide the greatest capacity with the existing memory technology. For example, if current

DRAM technology supports 2-GB single-rank DIMMs, a dual-rank DIMM would be 4 GB.

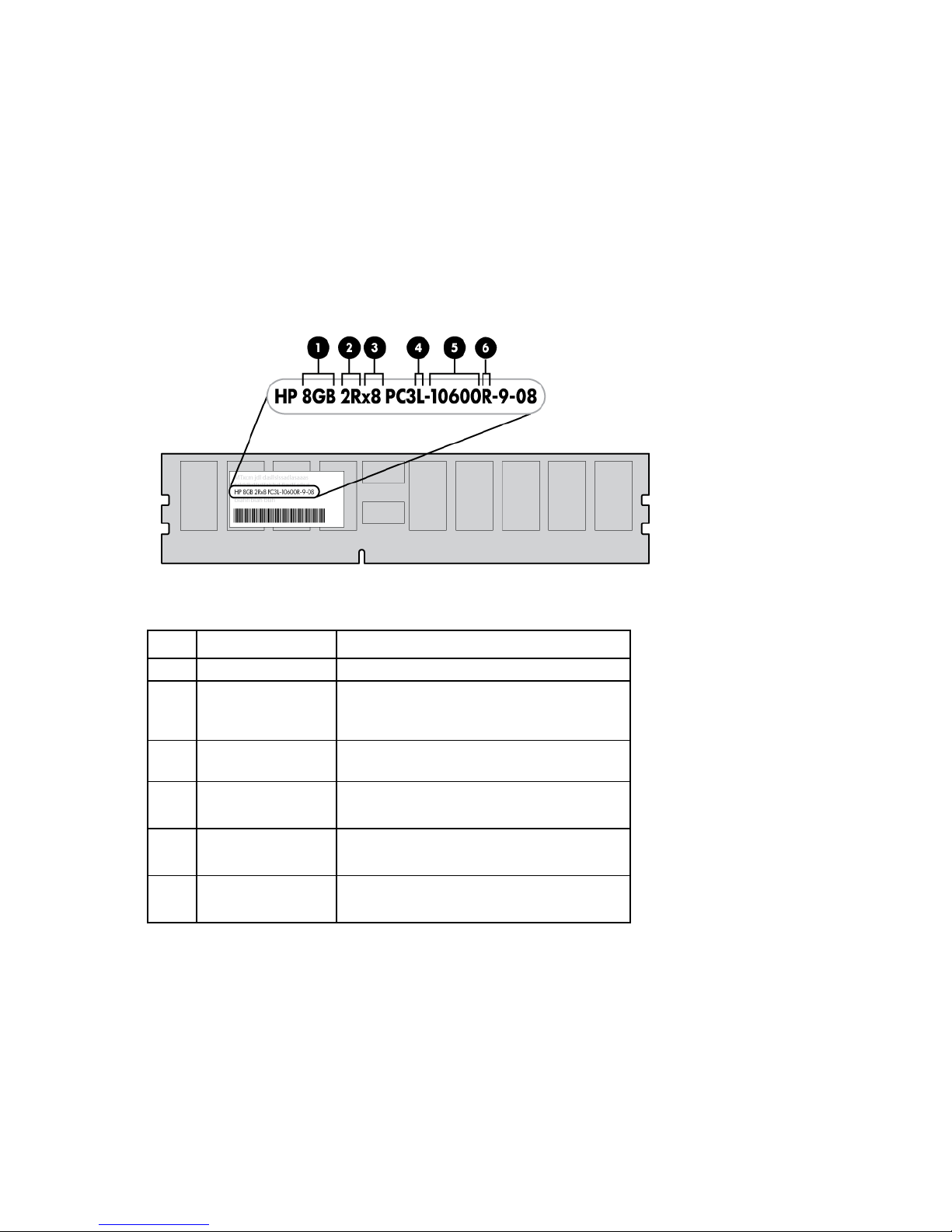

DIMM identification

To determine DIMM characteristics, use the label attached to the DIMM and the following illustration and

table.

Item Description Definition

1

2

3

4

5

6

For the latest supported memory information, see the QuickSpecs on the HP website (http://www.hp.com).

Size —

Rank 1R = Single-rank

2R = Dual-rank

4R = Quad-rank

Data width x4 = 4-bit

x8 = 8-bit

Voltage rating L = Low voltage (1.35v)

Blank or omitted = Standard

Memory speed 10600 = 1333-MHz

8500 = 1066-MHz

DIMM type R = RDIMM (registered)

E = UDIMM (unbuffered with ECC)

UDIMM maximum memory configurations

The server supports a maximum of 32 GB, using 1-GB, 2-GB, 4-GB and 8-GB single-rank or dual-rank

UDIMMs.

Hardware options installation 29

Memory configuration

To optimize server availability, the server supports ECC memory. ECC memory provides the greatest memory

capacity for a given DIMM size, while providing single-bit memory error corrections, depending on the

specific DIMM type. This mode is the default option for this server.

For the latest memory configuration information, see the QuickSpecs on the HP website

(http://www.hp.com).

ECC memory configuration

ECC memory is the default memory protection mode for this server. Standard ECC can correct single-bit

memory errors and detect multi-bit memory errors. When multi-bit errors are detected by using Standard

ECC, the error is sent to the server and causes the server to halt.

General DIMM slot population guidelines

• The server has four memory slots.

• The server supports two channels with two UDIMM slots per channel.

• Memory channel A consists of the two UDIMMs that are closest to the processor.

• Memory channel B consists of the two UDIMMs that are located farthest from the processor.

• Different types of processors have different types of memory support.

• The server supports dual-rank, 1,333 MT/s ECC UDIMMs.

• The server supports up to 32 GB (4x8-GB) for UDIMMs.

• The server does not support:

o LV-DIMMs

o RDIMMs

o Non-ECC UDIMMs

• When installing DIMMs:

o If the processor is not installed, then do not install DIMMs.

o Populate DIMMs from heaviest load (double-rank) to lightest load (single-rank).

o Use HP-qualified UDIMMs.

o The DIMM farthest from the processor (either CHA or CHB) must be populated first.

Installing a DIMM

NOTE: The server does not support Elpida UDIMM memory.

1. Power down the server (on page 17).

2. Remove the access panel (on page 18).

3. Remove the air baffle (on page 19).

4. Open the DIMM slot latches.

Hardware options installation 30

Loading...

Loading...