HP ProLiant Cluster F500 DT Installation Guide

September 2006 (Second Edition)

Part Number 364780-002

© Copyright 2004, 2006 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, and Windows NT are U.S. registered trademarks of Microsoft Corporation. Windows Server 2003 is a trademark of

Microsoft Corporation. Intel, Pentium, and Itanium are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries. UNIX is a registered trademark of The Open Group.

September 2006 (Second Edition)

Part Number 364780-002

Audience assumptions

This document is for the person who installs, administers, and troubleshoots servers and storage systems.

HP assumes you are qualified in the servicing of computer equipment and trained in recognizing hazards

in products with hazardous energy levels.

Contents

HP ProLiant Cluster F500 DT for Enterprise Virtual Array overview...................................................... 5

HP ProLiant Cluster F500 for EVA introduction .............................................................................................. 5

Disaster tolerance for EVA..........................................................................................................................5

HP ProLiant Cluster F500 for EVA overview ..................................................................................................5

EVA basic DT configuration ........................................................................................................................ 6

EVA bidirectional DT configuration .............................................................................................................. 7

EVA maximum DT configuration .................................................................................................................. 8

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array......................................................... 9

Required materials..................................................................................................................................... 9

Continuous access..................................................................................................................................... 9

Installing the hardware............................................................................................................................... 9

Preparing the F500 for continuous access EVA hardware installation ...................................................10

Setting up the servers ..................................................................................................................... 10

Setting up the storage subsystem .....................................................................................................10

Setting up the Fibre Channel adapters.............................................................................................. 10

Setting up the Fibre Channel switches at both locations, if applicable................................................... 11

Connecting the controllers to the switches ......................................................................................... 11

Connecting the host to the switches.................................................................................................. 13

Zoning recommendations ...............................................................................................................13

Setting up a bidirectional solution.................................................................................................... 13

Configuring the software.......................................................................................................................... 13

Preparing the F500 for continuous access EVA software installation ..................................................... 14

Logging on to the SAN management appliance................................................................................. 15

Entering a license key .................................................................................................................... 15

Initializing the source site................................................................................................................ 15

Naming the site............................................................................................................................. 15

Creating the VD folders..................................................................................................................16

Creating the VDs........................................................................................................................... 16

Creating the host folder.................................................................................................................. 17

Adding a host............................................................................................................................... 17

Presenting the VDs to the host.......................................................................................................... 17

Discovering the devices.................................................................................................................. 18

Creating the DR groups..................................................................................................................18

Creating the copy sets.................................................................................................................... 18

Creating the managed sets ............................................................................................................. 19

Pre-presenting the destination VDs to cluster nodes....................................................................................... 19

HP ProLiant Cluster F500 for MA8000 Enhanced DT overview ........................................................ 20

HP ProLiant Cluster F500 for MA8000 introduction .....................................................................................20

Disaster tolerance for MA8000................................................................................................................. 20

HP ProLiant Cluster F500 for MA8000 overview ......................................................................................... 20

MA8000 basic DT configuration............................................................................................................... 21

MA8000 bidirectional DT configuration..................................................................................................... 22

MA8000 maximum DT configuration.........................................................................................................23

Setting up the ProLiant Cluster F500 for MA8000........................................................................... 24

Required materials................................................................................................................................... 24

Data Replication Manager........................................................................................................................ 24

Installing the hardware............................................................................................................................. 24

Setting up the servers for MA8000 .................................................................................................. 25

Contents 3

Setting up the storage subsystem .....................................................................................................25

Setting up the host bus adapters ...................................................................................................... 25

Designating the server as a maintenance terminal.............................................................................. 25

Setting up the Fibre Channel switches at both locations ...................................................................... 25

Configuring DRM .................................................................................................................................... 25

Configuring the controllers at the target site ......................................................................................26

Configuring the storage at the target site .......................................................................................... 29

Connecting fiber optic cables between the controllers and switches ..................................................... 29

Connecting the target site to the external fiber link ............................................................................. 29

Connecting the target site to the ATM link......................................................................................... 30

Configuring the host at the target site............................................................................................... 30

Configuring the controllers at the initiator site.................................................................................... 31

Configuring the storage at the initiator site........................................................................................ 34

Connecting fiber optic cables between the controllers and switches ..................................................... 34

Connecting the initiator site to the external fiber link........................................................................... 35

Connecting the initiator site to the ATM link ......................................................................................35

Creating remote copy sets ..............................................................................................................35

Creating log units and association sets (optional)............................................................................... 36

Configuring the Host at the Initiator Site ........................................................................................... 37

Installing Microsoft Cluster Server.............................................................................................................. 39

Documenting the configuration.................................................................................................................. 39

Saving controller information .......................................................................................................... 39

Installing bidirectional storage .................................................................................................................. 40

Adding clusters ....................................................................................................................................... 40

Installing server options .................................................................................................................. 41

Configuring the host at the target site............................................................................................... 41

Configuring the host at the initiator site............................................................................................. 41

Disaster recovery ........................................................................................................................ 42

HP ProLiant Cluster F500 DT for EVA ......................................................................................................... 42

Managing continuous access .......................................................................................................... 42

Failure scenarios ........................................................................................................................... 42

EVA storage failback procedure ...................................................................................................... 45

ISL failback procedure.................................................................................................................... 46

HP ProLiant Cluster F500 DT for MA8000 .................................................................................................. 46

Managing Data Replication Manager .............................................................................................. 47

F500 DT for MA8000 failure scenarios............................................................................................47

Zoning worksheets...................................................................................................................... 51

Site A zoning worksheet........................................................................................................................... 51

Site B zoning worksheet ........................................................................................................................... 51

Connection naming worksheet...................................................................................................... 53

Connection naming worksheet .................................................................................................................. 53

Technical support........................................................................................................................ 54

Before you contact HP.............................................................................................................................. 54

HP contact information............................................................................................................................. 54

Acronyms and abbreviations........................................................................................................ 55

Glossary.................................................................................................................................... 58

Index......................................................................................................................................... 60

Contents 4

HP ProLiant Cluster F500 DT for Enterprise

Virtual Array overview

In this section

HP ProLiant Cluster F500 for EVA introduction ............................................................................................. 5

Disaster tolerance for EVA......................................................................................................................... 5

HP ProLiant Cluster F500 for EVA overview................................................................................................. 5

EVA basic DT configuration....................................................................................................................... 6

EVA bidirectional DT configuration............................................................................................................. 7

EVA maximum DT configuration................................................................................................................. 8

HP ProLiant Cluster F500 for EVA introduction

This guide provides supplemental information for setting up an HP ProLiant Cluster F500 Disaster Tolerant

for EVA configuration using HP StorageWorks Continuous Access EVA software. This guide serves as a

link between the various clustering guides needed to complete a DT cluster installation. Other guides

include:

•

HP ProLiant Cluster F500 Installation Guide

•

Best Practices Guide — ProLiant Cluster HA/F500 for Enterprise Virtual Array (HSV100/HSV110)

Using Microsoft Windows 2000 Advanced Server and Microsoft Windows Server 2003, Enterprise

Edition

•

HP StorageWorks Continuous Access EVA Design Reference Guide

For the latest version of the reference guide and other Continuous Access EVA documentation, access the

HP storage website (http://h18006.www1.hp.com/storage/index.html).

Disaster tolerance for EVA

Disaster-tolerant solutions provide high levels of availability with rapid data access recovery, no single

point of failure, and continued data processing after the loss of one or more system components in a

cluster configuration. Data is simultaneously written to both local and remote sites during normal

operation. The local site is known as the source site because it is in control of the operation. The remote

site is known as the destination site because it is where the information is copied.

Copied data resides at both the source and destination sites. However, in base DT cluster configurations

under normal conditions, host data access occurs only through the source site. Processing will migrate to

the destination site and continue normal operation if a component failure or a catastrophe occurs at the

source site.

HP ProLiant Cluster F500 for EVA overview

The HP ProLiant Cluster F500 DT for EVA configuration is a two-node cluster for Microsoft® Windows®

2000 Advanced Server or a two-to-eight-node cluster for Microsoft® Windows® Server 2003, Enterprise

HP ProLiant Cluster F500 DT for Enterprise Virtual Array overview 5

Edition. The DT configurations use HP ProLiant servers, HP StorageWorks storage subsystems, HP

StorageWorks Continuous Access software, HP OpenView software, and HP StorageWorks Secure Path

software.

This solution combines the failover functionality of Microsoft® Cluster Server with the remote data

mirroring functionality of Continuous Access. This solution also allows for a distance of up to 100 km

between a primary (local) external storage subsystem and a mirrored (remote) external storage subsystem.

The server-to-storage connection is based on a Fibre Channel switch, using a shortwave connection, and

server-to-server communication, using Ethernet over FDDI or FCIP connections. The extended Continuous

Access EVA-over-IP configuration is similar to the simple Continuous Access EVA configuration except for

the use of Fibre Channel-to-IP gateways. Two gateways are required at each site, one per fabric, for a

total of four per solution, dedicated to that solution. When multiport gateways become available, each

port must be dedicated to another single port.

The ProLiant server nodes in the cluster are connected or stretched over a distance. Up to two storage

subsystems for FCIP connections and four storage subsystems for non-FCIP connections can be used at one

site. These storage subsystems act as the source sites for the Continuous Access software and process disk

subsystem requests for all nodes in the cluster. The storage subsystems are connected to the server nodes

by means of redundant Fibre Channel connections that are managed by Secure Path. Additionally, the

source storage subsystems are connected by means of redundant longwave fiber/FCIP connections to the

destination site. As with standard ProLiant clusters using Microsoft® operating systems, MSCS manages

failovers at the server and application levels.

The Continuous Access software functions at the redundant storage controller level in each of the storage

subsystems and performs synchronous mirroring from the source site to the destination site, creating an

exact copy of the cluster-shared disk. A manual recovery process performed at the destination site enables

access to the mirrored data in the event of a disaster at the source site. The cluster is functional again

within minutes, and application processing can continue.

The F500 DT for EVA cluster requires two types of links: network and storage. The first requirement is at

least two network links between the servers. MSCS uses the first network link as a dedicated private

connection to pass heartbeat and cluster configuration information between the servers. The second

network link is a public network connection that clients use to communicate with the cluster nodes. The DT

cluster configuration can use any network card that is supported by Microsoft® operating systems.

However, MSCS requires that the dedicated private link and public link between the servers be located

on different TCP/IP subnets.

Because typical network topologies, such as 100-Mb Ethernet, cannot normally meet this criterion over the

longer distances used in a DT cluster, another topology, such as FDDI or FCIP, must be used. FDDI

network cards can be used in each server in place of the standard Ethernet NICs, or standard Ethernet

NICs can be used to connect to an FDDI concentrator/FCIP switch that will connect the two sites.

The second requirement is the storage link between the storage subsystems. The servers are connected to

the local storage systems, using multimode fiber optic cable. Each storage subsystem is connected to two

Fibre Channel switches at each site in a redundant path configuration using multimode fiber optic cable.

The switches at one site are connected to the switches at the other site by means of single-mode fiber optic

or FCIP connections.

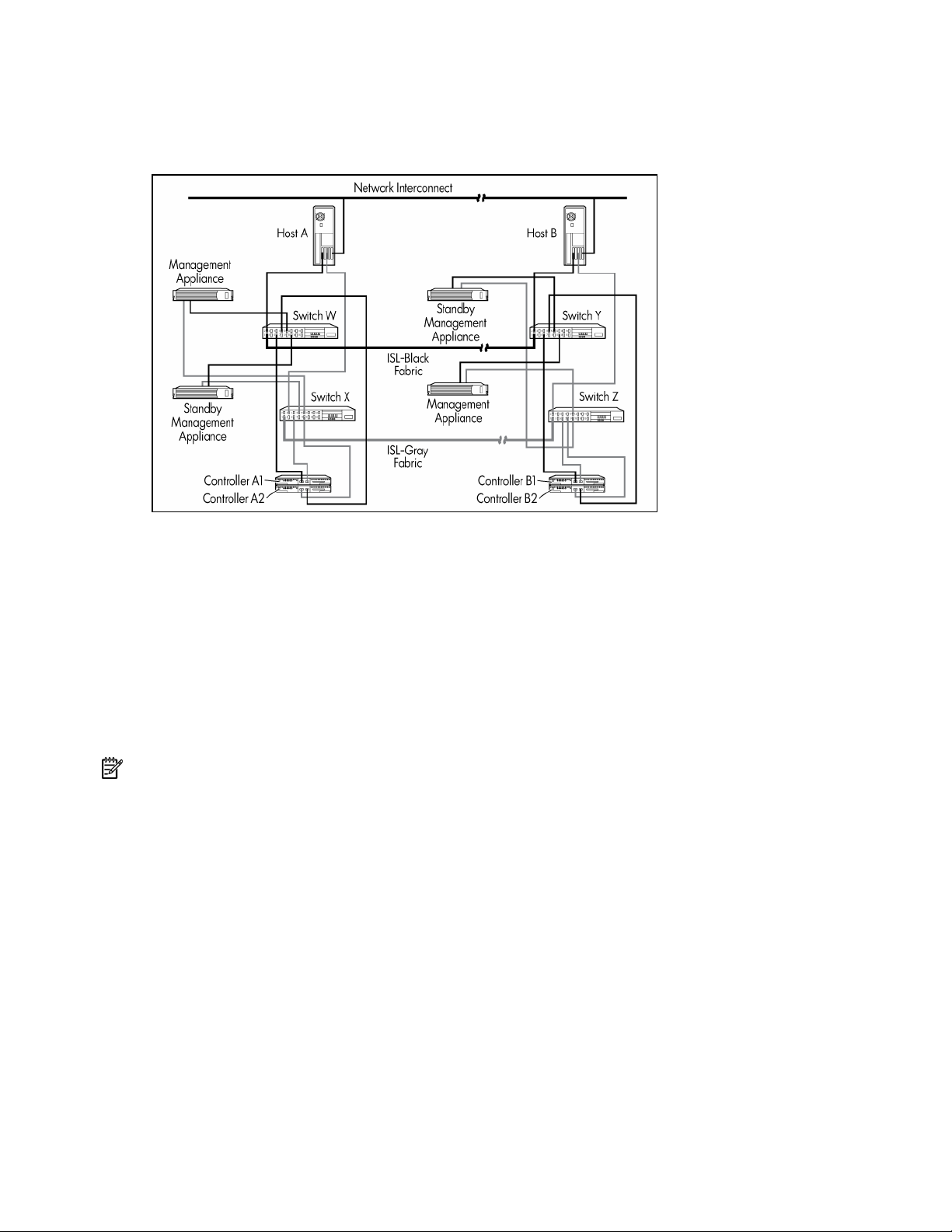

EVA basic DT configuration

The basic DT configuration includes a second destination storage subsystem that mirrors the data on the

source storage subsystem. The basic DT configuration consists of:

•

Two ProLiant servers as cluster nodes

•

Two storage subsystems

•

Four HP StorageWorks Fibre Channel SAN switches (for a current list of supported switches, refer to

the High Availability website) (http://www.hp.com/servers/proliant/highavailability

)

HP ProLiant Cluster F500 DT for Enterprise Virtual Array overview 6

Two FCAs in each server

•

•

Two storage management appliances, at least one for each site

A basic DT cluster configuration consists of two separated nodes. The two nodes, plus the source storage

subsystem, form an MSCS cluster.

EVA bidirectional DT configuration

The bidirectional DT configuration enables a source subsystem to also be configured as a destination

subsystem. The bidirectional DT configuration consists of:

•

Two ProLiant servers as cluster nodes

•

Two storage subsystems

•

Four HP StorageWorks Fibre Channel switches

•

Two FCAs in each server

•

Two SMAs, at least one for each site

NOTE: Refer to the HP StorageWorks Continuous Access EVA Design Reference Guide for complete lists of

supported equipment.

HP ProLiant Cluster F500 DT for Enterprise Virtual Array overview 7

A bidirectional DT configuration consists of two separated nodes. As in the basic DT configuration, data

at the first site is mirrored on a second storage subsystem at the second site. Two storage systems can

communicate bidirectionally, meaning that a storage system can be used as the primary source for data

and as a destination for data replication. By providing redundant systems and software, as well as

alternate paths for data flow, high availability and disaster tolerance is achieved with no single point of

failure.

EVA maximum DT configuration

Refer to the High Availability website (http://www.hp.com/servers/proliant/highavailability) or HP

StorageWorks Continuous Access EVA Design Reference Guide for maximum configuration information.

HP ProLiant Cluster F500 DT for Enterprise Virtual Array overview 8

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array

In this section

Required materials.................................................................................................................................... 9

Continuous access.................................................................................................................................... 9

Installing the hardware ............................................................................................................................. 9

Configuring the software......................................................................................................................... 13

Pre-presenting the destination VDs to cluster nodes ..................................................................................... 19

Required materials

To configure an F500 DT cluster for Continuous Access, you will need any applicable documents listed in

the "Related Documents" section of the HP Continuous Access EVA Getting Started Guide. Many of the

referenced documents will be online.

The following is a short list of essential documents.

•

HP Continuous Access EVA Getting Started Guide

•

HP ProLiant Cluster F500 Installation Guide

•

HP StorageWorks Continuous Access EVA Design Reference Guide

•

HP StorageWorks Continuous Access User Interface Installation Guide

•

HP StorageWorks Continuous Access User Interface Release Notes

•

HP StorageWorks Command View EVA documentation, including online help

•

HP StorageWorks Continuous Access Management User Interface online help

•

HP StorageWorks Secure Path for Windows installation guide

•

Fibre Channel SAN Switch installation and hardware guide

Continuous access

Refer to the HP StorageWorks Continuous Access EVA Operations Guide for detailed information on

Continuous Access, including any restrictions.

Installing the hardware

Depending on the size of your SAN and the considerations used in designing it, many different hardware

configurations are possible. Refer to the HP StorageWorks Continuous Access Enterprise Virtual Array

Design Reference Guide for a detailed description of various hardware configurations.

Set up the cluster using the following procedures:

1.

"Preparing the F500 for continuous access EVA hardware installation (on page 10)"

2.

"Setting up the servers (on page 10)"

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 9

"Setting up the storage subsystem (on page 10)"

3.

4.

"Setting up the Fibre Channel adapters (on page 10)"

5.

"Setting up the Fibre Channel switches at both locations, if applicable (on page 11)"

6.

"Connecting the controllers to the switches (on page 11)"

7.

"Connecting the host to the switches (on page 13)"

8.

"Zoning recommendations (on page 13)"

9.

"Setting Up a Bidirectional Solution (on page 13)"

Preparing the F500 for continuous access EVA hardware installation

Task Reference document

Set up EVA storage system hardware. HP StorageWorks Enterprise Virtual Array User Guide

Make fabric connections:

• Connect GBICs or small form factor pluggables

to switch ports.

• Connect HSV controller pair, SMA, and hosts to

Fibre Channel fabrics.

• HP StorageWorks Continuous Access EVA

Operations Guide

• Compaq SANworks Management Appliance

Getting Started Guide

• Test intersite links.

Install intersite links and connect to switches with

GBICs or SFPs.

Install host kits and device drivers, if required.

Upgrade drivers if necessary.

HP StorageWorks SAN Extension Using FCIP

Configuration Guide

OS-specific kit version 3.x for EVA installation and

configuration guide

Install Fibre Channel adapters. FCA documentation

Create separate management zones for any HSG80

HP StorageWorks SAN Design Reference Guide

systems in your SAN.

Plan and populate layout of one or more physical

disk groups.

Power up storage systems and SMAs.

HP StorageWorks Continuous Access EVA Operations

Guide

• HP ProLiant Cluster F500 Installation Guide

• Compaq SANworks Management Appliance

Getting Started Guide

Setting up the servers

To prepare the Continuous Access solution for setup, refer to the ProLiant cluster documentation. Follow

the installation instructions in the ProLiant server documentation.

Setting up the storage subsystem

Refer to the documentation that was shipped with the storage subsystem for detailed installation

instructions.

Setting up the Fibre Channel adapters

Two FCAs must be installed on each host. For detailed installation instructions, refer to the documentation

that comes in the host kit or with your adapter.

Locate and record the World Wide Names of each FCA on the zoning worksheet. Keep a copy of the

worksheets at all your sites. In addition, record the WWNs for the EVA and the SMAs for each site.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 10

NOTE: The WWN can be found on the bottom of the adapter board. Look for a small bar code label with

an IEEE precursor. A WWN example is 1000-0000-C920-A5BA.

Setting up the Fibre Channel switches at both locations, if applicable

NOTE: Both Fibre Channel switches can be configured from the same site.

Your Fibre Channel switches must be installed and configured with two working redundant fabrics before

you connect the remaining Continuous Access EVA components to your fabrics. For information on the

specific switches used and GBICs needed, refer to the HP website

(http://h18006.www1.hp.com/storage/saninfrastructure.html

).

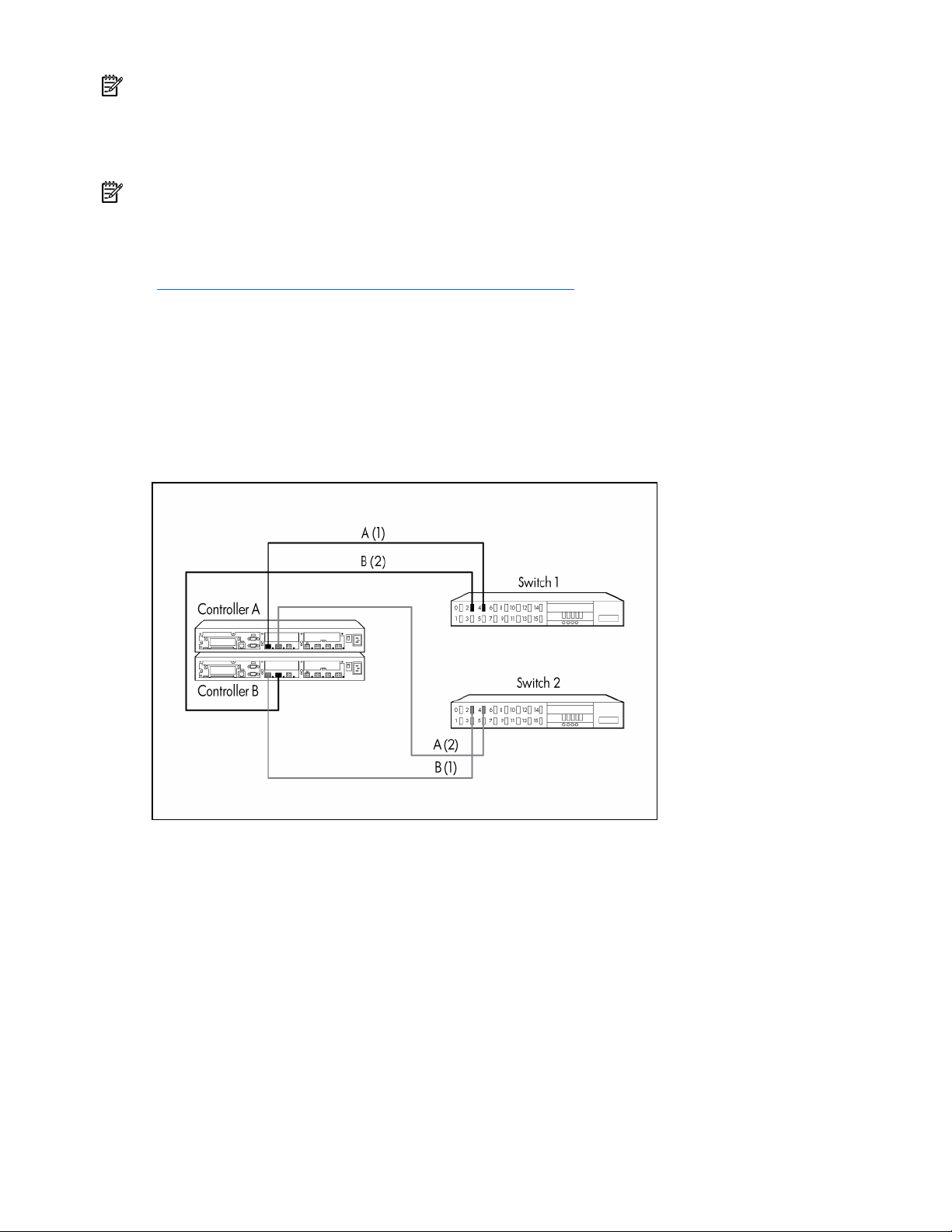

Connecting the controllers to the switches

Before connecting fiber optic cables between storage components, HP recommends that you tag each end

to identify switch names, port numbers, controller names, and so on.

Four fiber optic cable connections are required for each controller pair. The only supported connection

scheme is shown below. Connect the fiber optic cable such that port 1 of controller A and controller B go

to different fabrics. Connect port 2 of controller A and controller B to separate fabrics that are the fabric

opposite from port 1 on that controller.

The basic rule is that the first or left-hand port on the top controller is cabled to the first fabric and the

other port of the same controller is cabled to the other fabric. The other (bottom) controller is cabled such

that the left-hand port is attached to the second fabric, while the second port is cabled to the first fabric,

the opposite of the first (top) controller. Even though it does not matter which switch ports are used,

symmetry is recommended.

Either controller can be controller A or controller B. In a storage system that has not been configured, the

first controller that powers up and passes a self-test becomes controller A. Also, under certain conditions,

controller A and controller B can have their designations reversed.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 11

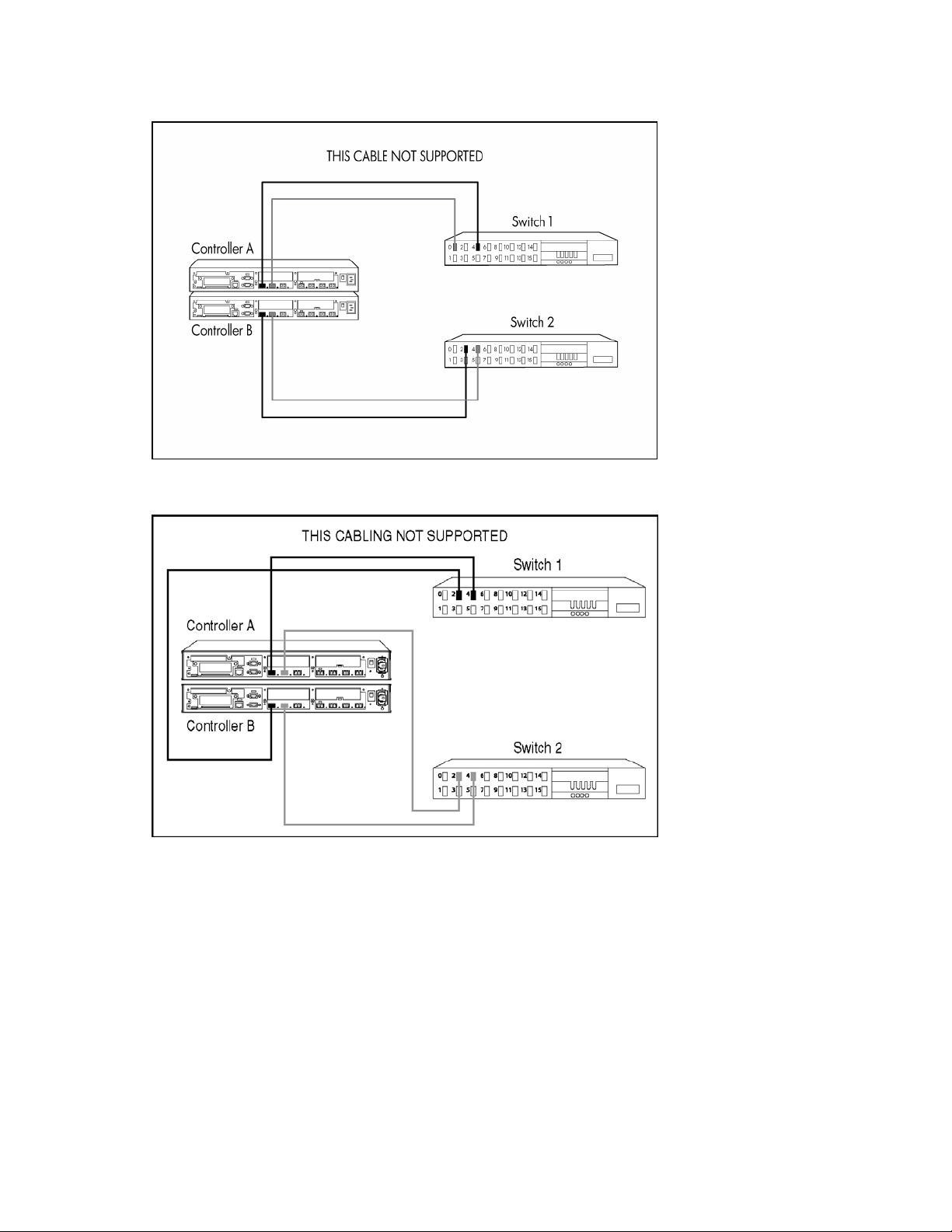

Any other controller-to-fabric cabling scheme is not supported. The cabling in the following example is not

supported because both port 1s share the same fabric and both port 2s share the same fabric.

The cabling in the following example is not supported because both ports of a controller are on the same

fabric, limiting failover options when there is a fabric issue.

You can control the power sequence of the controllers in your storage system, thereby forcing a controller

designation. To guarantee that a particular controller is designated controller A:

1.

Uninitialize the storage system. If it is a new storage system that has never been initialized, this step

is not necessary.

2.

Power off both controllers.

3.

Pull out and reseat the cache batteries on the controller you want to designate controller A. This

procedure clears the cache.

4.

Power up that controller.

5.

After controller A passes the self-test, power up the other controller.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 12

Connecting the host to the switches

Tag each end of your fiber optic cable to identify switch names, port numbers, host names, and so on.

Two fiber optic connections are required for each host. Connect the fiber optic cable such that

connections to the two FCAs go to two separate switches (fabrics).

Zoning recommendations

Having both fabrics in place and operational is necessary before you even begin any other equipment

installation. For information on fabric topologies, fabric design rules, and switch zoning, refer to the HP

StorageWorks SAN Design Reference Guide.

For Continuous Access-specific guidelines, refer to the HP StorageWorks Continuous Access EVA

Operations Guide.

Zoning is a logical grouping of end-to-end Fibre Channel connections, implemented by switches, to create

a barrier between different environments and allow for finer segmentation of the fabric. Switch ports that

are members of a zone can communicate with each other but are isolated from ports in other zones.

Because the SMA and hosts in a Continuous Access EVA environment can conflict with each other, they

must reside in separate zones.

NOTE: If any HSG80 controllers with DRM reside within the SAN, they must be zoned out of an EVA

fabric.

Setting up a bidirectional solution

You can configure data replication groups to replicate data from storage system A to storage system B

and other unrelated data replication groups to replicate data from storage system B back to storage

system A. This feature, called bidirectional replication, enables a storage system to have both source and

destination virtual disks, where these Vdisks belong to separate Data Replication groups. This setup has

no effect on normal operation or failover policy and has the advantage of allowing for the destination

storage system to be actively used while also providing a disaster-tolerant copy of the other site's data. If

the business needs require bidirectional data transfers, you must determine the effect on the links.

Refer to the Continuous Access EVA Design Reference Guide for more information.

Configuring the software

The storage system must be initialized before it can be used. This process binds the controllers together as

an operational pair and establishes preliminary data structures on the disk array.

Initialization is performed through the use of the Command View EVA. This procedure is documented in

the HP StorageWorks Command View EVA Getting Started Guide. HP StorageWorks Command View

EVA maintains a database that resides on the management appliance and is accessible only by the

element manager for each storage system.

The Command View EVA software can be installed on more than one management appliance in a fabric.

Each installation of the Command View EVA software is a management agent. The client for the agent is

a standard browser.

To begin the configuration process, create, or initialize, the storage system. When you first view the EVA

from the Command View EVA software, the storage pool is presented as "uninitialized storage."

Before the host servers can use the virtual disks, you must:

•

Initialize the storage systems at both the source and destination. The storage pool is "uninitialized

storage" at the outset.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 13

Add hosts to the storage system.

•

•

Create and present virtual disks to hosts.

Configure the software using the following procedures:

1.

"Preparing the F500 for Continuous Access EVA Software Installation (on page 14)"

2.

"Logging On to the SAN Management Appliance (on page 15)"

3.

"Entering a License Key (on page 15)"

4.

"Initializing the Source Site (on page 15)"

5.

"Naming the Site (on page 15)"

6.

"Creating the VD Folders (on page 16)"

7.

"Creating the VDs (on page 16)"

8.

"Creating the Host Folder (on page 17)"

9.

"Adding a Host (on page 17)"

10.

"Presenting the VDs to the Host (on page 17)"

11.

"Discovering the Devices (on page 18)"

12.

"Creating the DR Groups (on page 18)"

13.

"Creating the Copy Sets (on page 18)"

14.

"Creating the Managed Sets (on page 19)"

15.

"Pre-presenting the Destination VDs to Cluster Nodes (on page 19)"

Preparing the F500 for continuous access EVA software installation

Task Reference document

Install latest version of system software:

• HP OpenView Storage Management

Appliance Software

• HP StorageWorks Virtual Controller Software

Install HP StorageWorks Secure Path for

Windows® for your platform.

Install HP StorageWorks Continuous Access User

Interface.

Enter storage system WWN into controller using

the Operator Control Panel.

Configure one switch zone encompassing the

active SMA and all storage systems.

Configure one switch zone for each operating

system/host and the storage systems.

Install Command View EVA and set up agents and

user options.

HP OpenView Storage Management Appliance Software

User Guide

EVA Read Me First

EVA Release Notes

HP StorageWorks system software for EVA installation

card

HP StorageWorks upgrade instructions for EVA

HP StorageWorks Secure Path for Windows® platform-

specific installation guide

HP StorageWorks Continuous Access User Interface

Installation Guide

HP ProLiant Cluster F500 DT Installation Guide

HP StorageWorks SAN Design Reference Guide, 4th

Edition

Compaq StorageWorks Switch Zoning Reference Guide

HP StorageWorks SAN Design Reference Guide, 4th

Edition

Compaq StorageWorks Switch Zoning Reference Guide

HP StorageWorks Command View EVA Getting Started

Guide

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 14

Logging on to the SAN management appliance

1.

Log on to the management appliance by opening a browser and accessing the management

appliance remotely by entering the IP address (or the network name if a DNS is configured) as the

URL. The logon screen opens.

2.

Click anonymous.

3.

Log in as administrator.

4.

Enter the password for the account.

5.

Click OK. The hp openview storage management appliance window displays.

Entering a license key

You must enter a license key encoded with the WWN of the storage system before you initialize the

storage system.

Follow the "Obtaining a License Key" instructions in the HP StorageWorks Enterprise Virtual Array

Licensing Guide.

Each license key belongs to a specific WWN, so enter a license key that matches the WWN of the

storage system. You can enter the license keys for all storage systems that this management agent will

control at the same time.

NOTE: The WWN number must be entered exactly as it appears on the label. This field is case-sensitive.

License keys require an ASCII text editor to ensure their format.

To enter a license key:

1.

Click Agent Options in the Session pane. The Management Agent Options window displays.

2.

Click Licensing Options. The Licensing Options window displays.

3.

Click Enter new license key. The Add a License window displays.

4.

Enter the license key.

You must enter the license key exactly as it was in the e-mail you received from the license key

fulfillment website. If possible, copy the license key from the e-mail and paste it into the text field.

5.

Click Add license. The license key is added.

6.

To enter additional license keys, repeat steps 4 and 5.

Initializing the source site

The procedures to initialize the source site are as follows:

Using the Command View EVA

•

Naming the site

•

Creating the VD folder

•

Creating the Host folder

•

Creating the Disk group folder

Using the Continuous Access GUI

•

Creating the DR Group folder

Naming the site

In the hp openview storage management appliance window:

1.

Click Devices. The Devices window displays.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 15

Click command view eva. The HSV Storage Network Properties window displays. You can now

2.

browse the EVAs in the Uninitialized Storage System in the navigation panel.

3.

Determine which site is to be designated Site A and which is to be designated Site B by selecting

Hardware>Controller Enclosure. The Initialize an HSV Storage System window displays.

4.

Enter any requested license key information. Refer to "Entering a license key (on page 15)."

5.

In the Step 1: Enter a Name field, enter the site name.

6.

In the Step 2: Enter the number of disks field, enter the maximum number of disks (minimum of eight

in a disk group) or the number of disks you will use in the default disk group.

NOTE: You must determine if you will configure your storage in a single disk group or multiple disk groups.

CAUTION: Do not use the browser Back button because you will undo the previous operation.

7.

Select Advanced Options to set up the clock.

IMPORTANT: Set up the clock on both EVAs to pull time from the same source.

8.

Click Next. Request a disk failure protection level.

NOTE: HP recommends selecting double for disk failure protection.

9.

Click Finish, and then click OK (if the operation was successful).

NOTE: If the operation is not successful, it typically is caused by a communication problem. Verify the SAN

connection, fix the problem, and begin again at step 1.

Creating the VD folders

1.

In the Command View EVA navigation pane, click Virtual Disks. The Create a Folder window

displays.

2.

In the Step 1: Enter a Name field, enter the folder name (use the cluster name).

3.

In the Step 2: Enter comments field, enter any additional information.

4.

Select Finish>OK.

Creating the VDs

You are given the opportunity to select a preferred path during the creation of a Vdisk. This means that

host I/O to a Vdisk will go to the controller you designate as preferred, as long as the paths to that

controller are available. There are five possible preferred path settings. However, the Windows®

environment enables only those shown in the bulleted list, as Secure Path is responsible for supporting

failback capability.

NOTE: For path A and B, all members of a DR group must have the same preferred path.

•

None (not recommended)

•

Path A—Failover only

•

Path B—Failover only

1.

In the Command View EVA navigation pane, click the new VD folder. The Create a Vdisk Family

window displays.

2.

In the Vdisk name: field, enter the VD name.

3.

In the Size: field, enter the size in gigabytes.

4.

In the Preferred path/mode: dropdown menu, make a selection (for load balancing).

NOTE: All members of DR group must have same setting.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 16

Click Create More and repeat steps 2 through 4 for each VD you create.

5.

6.

Select Finish>OK.

NOTE: The Continuous Access software will create the Site B VDs.

Creating the host folder

Create a host folder for each cluster to enable ease of administration.

1.

Click Create Folder. The Create a Folder window displays.

2.

In the Step 1: Enter a Name field, enter SiteA or any name up to 32 characters long.

3.

In the Step 2: Enter comments field, enter any additional information, up to 64 characters long.

4.

Select Finish>OK.

5.

Repeat steps 1 through 4 for all remaining clusters.

Adding a host

NOTE: If the SAN appliance cannot see the host WWNs, perform steps 1 and 2. Otherwise, begin at step

3.

1.

Reboot the SAN appliance.

2.

Access the Command View EVA application.

3.

Click the desired host in the navigation pane. The Add a Host window displays.

4.

In the Host name: field, enter the host name.

5.

In the Host IP address: dropdown menu, select the appropriate scheme or enter the IP address if it is

a static IP address.

6.

In the Port WW Name: dropdown menu, select a port WWN for the first FCA.

7.

Click Add Host, and then click OK. The Add a Host Port window displays.

8.

For each FCA:

a.

In the Click to select from list dropdown menu, select the appropriate FCA.

b.

Click Add port.

9.

Select the Ports tab (which displays only after selecting to add the port) and verify the ports are

correctly assigned.

10.

Repeat the procedure for Site B.

Presenting the VDs to the host

CAUTION: Shut down all the nodes. Only one node should see the drives at one time.

1.

In the Command View EVA navigation pane, click the first new VD. The Vdisk Active Member

Properties window displays.

2.

Click Presentation. The Vdisk Active Member Properties window displays.

3.

Click Present. The Present Vdisk window displays.

4.

Select both hosts, and then click Present Vdisk.

5.

Click OK. You are returned to the Vdisk Active Members Property window.

6.

Select the Presentation tab to verify that both hosts are on the same LUN. The Vdisk Active

Members Property window displays.

7.

Repeat steps 1 through 6 for each VD.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 17

Power on Node 1.

8.

9.

Log on to the domain.

10.

Wait until all the VDs are discovered.

11.

Open the operating system Device Manager and look at that disk drive.

12.

Go to the operating system Disk Manager and select Initialize, do not upgrade to dynamic

disk.

13.

Format the disk and label the volumes.

14.

Install MSCS on Node 1. Refer to the appropriate documentation.

15.

Repeat steps 8 through 14 for Node 2.

16.

Join Node 2 to the cluster.

Discovering the devices

You will be creating the copy sets and DR groups in the same sequence.

1.

In the HP OpenView Storage Management Appliance window, click Tools.

2.

Click continuous access. The Continuous Access Status window displays. The window is empty.

NOTE: You are now working in the Continuous Access user interface, not the Command View EVA.

3.

Click Refresh>Discover. A pop-up window informs you that the discovery process could be

lengthy.

After the system has discovered the devices, you will create the DR groups and copy sets.

NOTE: You must plan how to separate managed sets and copy sets. Refer to the HP StorageWorks

Continuous Access EVA Operations Guide.

Creating the DR groups

You can create the DR groups first or create the initial copy set, which forces the DR group creation

process.

The following procedure is for creating the DR groups before the copy sets.

1.

On the Continuous Access window, select the site from the navigation pane.

2.

Click Create>DR Group. The Create a new DR Group window opens.

3.

In the DR Group: field, enter the name.

4.

In the Destination Storage System: dropdown list, select the destination site.

5.

In the Comments: field, enter any comments.

6.

Click Next.

7.

Select Finish>OK.

8.

Repeat the procedure for each DR group.

Creating the copy sets

NOTE: Entering the first copy set will force the DR group creation sequence if no DR Group has yet been

created.

1.

On the Continuous Access window, select the site from the navigation pane.

2.

Click Create>Copy Set. The Create a new Copy Set window opens.

3.

In the DR Group: dropdown list, select the DR group to which the copy set will belong.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 18

In the Copy Set: field, enter the copy set name.

4.

5.

Select the source VD from the Source Virtual Disk: dropdown list.

6.

Enter the DR Group.

7.

Select the destination from the Destination Storage System: dropdown list (Site B, if you have

followed suggested naming conventions).

8.

Click Finish.

Creating the managed sets

A managed set is a folder created to hold DR groups. One or more DR groups can be combined to create

a managed set.

1.

Choose Create>Managed Sets. The Edit or create a Managed Set window displays.

2.

In the Managed Set Name: field, enter the name.

3.

Click Finish.

4.

Repeat the procedure for each managed set to create.

5.

In the navigation pane, select the first DR group to be part of a managed set.

6.

In the Configuration dropdown menu, select Edit. The Edit an existing DR Group window displays.

7.

Select a managed set from the Managed Set list, and then click Finish.

8.

Repeat steps 5 through 7 for each DR group to add.

Pre-presenting the destination VDs to cluster nodes

1.

In the hp openview storage management appliance window, select Devices. The Devices window

displays.

2.

Click command view eva. The command view eva Properties window opens.

3.

In the navigation pane, select the destination subsystem, and then click Virtual Disks.

4.

Select the virtual disk to present on the destination subsystem.

5.

Select Active. The Vdisk Active Member Properties window displays.

6.

Select the Presentation tab, and then click Present. The Present Vdisk window opens.

7.

Select the VDs, and then click Present Vdisk.

8.

Click OK.

9.

Repeat for each VD to present.

10.

Verify the disks are properly presented.

a.

In the navigation pane, select the host to verify.

b.

Select the Presentation tab. The Host Properties window displays.

c.

Verify that each VD is presented to a unique LUN.

The configuration is complete.

Setting up the ProLiant Cluster F500 for Enterprise Virtual Array 19

HP ProLiant Cluster F500 for MA8000 Enhanced DT overview

In this section

HP ProLiant Cluster F500 for MA8000 introduction.................................................................................... 20

Disaster tolerance for MA8000................................................................................................................ 20

HP ProLiant Cluster F500 for MA8000 overview........................................................................................ 20

MA8000 basic DT configuration.............................................................................................................. 21

MA8000 bidirectional DT configuration.................................................................................................... 22

MA8000 maximum DT configuration........................................................................................................ 23

HP ProLiant Cluster F500 for MA8000 introduction

This guide provides supplemental information for setting up an HP ProLiant Cluster F500 DT for MA8000

configuration, and it is a link between the various clustering guides needed to complete a DT cluster

installation. These guides include the following:

•

Data Replication Manager HSG80 ACS operations guide

•

StorageWorks HSG80 Array Controller ACS configuration guide

•

StorageWorks HSG80 Array Controller CLI reference guide

•

HP ProLiant Cluster F500 Installation Guide

This guide includes additional installation instructions and references to these guides to complete the setup

of an F500 DT for MA8000 cluster.

Disaster tolerance for MA8000

Disaster-tolerant solutions provide high levels of availability with rapid data access recovery, no single

point of failure, and continued data processing after the loss of one or more system components in a

cluster configuration. Data is simultaneously written to both local and remote sites during normal

operation. The local site is known as the initiator site because it is in control of the operation. The remote

site is known as the target site because it is where the information is copied.

Copied data resides at both the initiator and target sites. However, in base DT cluster configurations

under normal conditions, host data access occurs only through the initiator site. Processing will migrate to

the target site and continue normal operation if a component failure or a catastrophe occurs at the

initiator site.

HP ProLiant Cluster F500 for MA8000 overview

The HP ProLiant Cluster F500 DT for MA8000 configuration is a two-node cluster for Windows® 2000

Advanced Server. The DT configurations use HP ProLiant servers, StorageWorks storage subsystems,

StorageWorks Data Replication Manager software, and StorageWorks Secure Path software.

HP ProLiant Cluster F500 for MA8000 Enhanced DT overview 20

This solution combines the failover functionality of Microsoft® Cluster Server with the remote data

mirroring functionality of DRM. This solution also allows for a distance of up to 100 km between the

server nodes and between a primary (local) external storage subsystem and a mirrored (remote) external

storage subsystem. The server-to-storage connection is based on a Fibre Channel switch using a

shortwave connection and server-to-server communication using Ethernet over FDDI or ATM connections.

The HP ProLiant server nodes in the cluster are connected or stretched over a distance. Up to two storage

subsystems for ATM connections and four storage subsystems for non-ATM connections can be used at

one site. These storage subsystems act as the initiator sites for the DRM software and process disk

subsystem requests for all nodes in the cluster. The storage subsystems are connected to the server nodes

by means of redundant Fibre Channel connections that are managed by Secure Path. Additionally, the

initiator storage subsystems are connected by means of redundant longwave fiber/ATM connections to

the target site. As with standard HP ProLiant Clusters using Microsoft® operating systems, MSCS manages

failovers at the server and application levels.

The DRM software functions at the redundant storage controller level in each of the storage subsystems

and performs synchronous mirroring from the initiator site to the target site, creating an exact copy of the

cluster-shared disk. A manual recovery process performed at the target site enables access to the mirrored

data in the event of a disaster at the initiator site. The cluster is functional again within minutes, and

application processing can continue.

The F500 DT for MA8000 cluster requires two types of links: network and storage. The first requirement is

for at least two network links between the servers. MSCS uses the first network link as a dedicated private

connection to pass heartbeat and cluster configuration information between the servers. The second

network link is a public network connection that clients use to communicate with the cluster nodes. The DT

cluster configuration can use any network card that is supported by Microsoft® operating systems.

However, MSCS requires that the dedicated private link and public link between the servers be located

on the same TCP/IP subnet.

Because typical network topologies, such as 100 Mb Ethernet, cannot normally meet this criterion over

the longer distances used in a DT cluster, another topology, such as FDDI or ATM must be used. FDDI

network cards can be used in each server in place of the standard Ethernet NIC cards, or standard

Ethernet NICs can be used to connect to an FDDI concentrator/ATM switch that will connect the two sites.

This type of configuration supports the longer distances used in a DT cluster and meets the requirement for

keeping the servers on the same TCP/IP subnet.

The second requirement is the storage link between the storage subsystems. The servers are connected to

the local storage systems using multimode fiber optic cable. Each storage subsystem is connected to two

Fibre Channel switches at each site in a redundant path configuration using multimode fiber optic cable.

The switches at one site are connected to the switches at the other site by means of single-mode fiber optic

or ATM connections.

MA8000 basic DT configuration

The basic DT configuration includes a second target storage subsystem that mirrors the data on the

initiator storage subsystem. The basic DT configuration consists of:

•

Two HP ProLiant servers as cluster nodes

•

Two storage subsystems

•

Four StorageWorks Fibre Channel SAN Switch 8/8-EL or SAN Switch 16/16-EL switches

•

Two host bus adapters in each server

•

Two storage controllers in each storage subsystem

HP ProLiant Cluster F500 for MA8000 Enhanced DT overview 21

A basic DT configuration consists of two separated nodes. The two nodes plus the initiator storage

subsystem form an MSCS cluster.

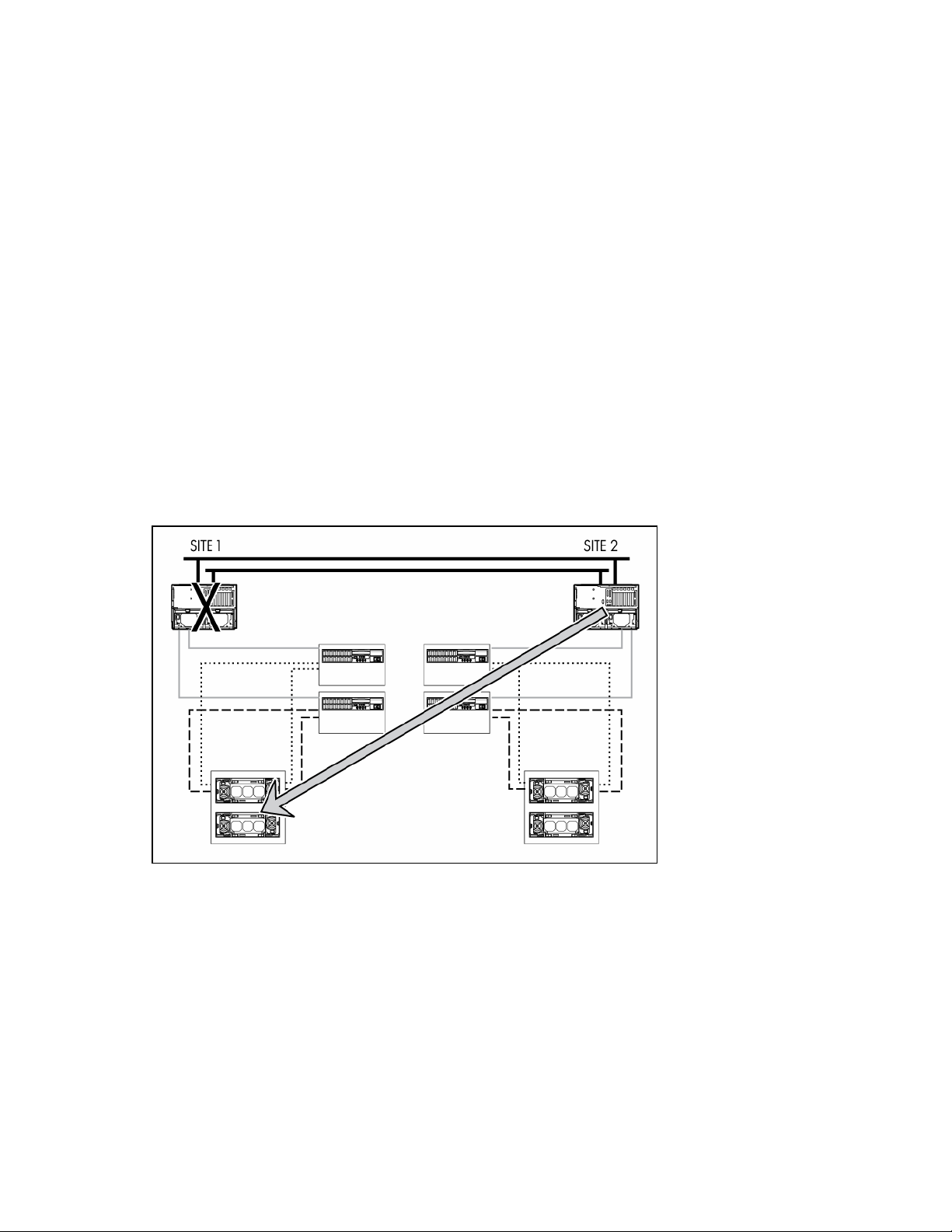

MA8000 bidirectional DT configuration

The bidirectional DT configuration adds two storage subsystems to the basic DT configuration. The

bidirectional DT configuration consists of:

•

Two HP ProLiant servers as cluster nodes

•

Four storage subsystems

•

Four StorageWorks Fibre Channel SAN Switch 8/8-EL or SAN Switch 16/16-EL switches

•

Two host bus adapters in each server

•

Two storage controllers in each storage subsystem

HP ProLiant Cluster F500 for MA8000 Enhanced DT overview 22

A bidirectional DT configuration consists of two separated nodes. As in the basic DT configuration, data

at the first site is mirrored on a second storage subsystem at the second site. The bidirectional DT solution

adds an initiator storage subsystem at the second site. This storage subsystem is mirrored at the first site

on a fourth storage subsystem (a target site). The first initiator-target pair of storage subsystems mirrors

data from the first site to the second site, while the second initiator-target pair of storage subsystems

mirrors data from the second site to the first site.

MA8000 maximum DT configuration

Refer to the High Availability website (http://www.hp.com/servers/proliant/highavailability) for

maximum configuration information.

HP ProLiant Cluster F500 for MA8000 Enhanced DT overview 23

Setting up the ProLiant Cluster F500 for MA8000

In this section

Required materials.................................................................................................................................. 24

Data Replication Manager ...................................................................................................................... 24

Installing the hardware ........................................................................................................................... 24

Configuring DRM ................................................................................................................................... 25

Installing Microsoft Cluster Server............................................................................................................. 39

Documenting the configuration................................................................................................................. 39

Installing bidirectional storage ................................................................................................................. 40

Adding clusters ...................................................................................................................................... 40

Required materials

To configure an F500 DT cluster for DRM, you will need the following guides:

•

HP ProLiant Cluster F500 Installation Guide

•

Data Replication Manager HSG80 ACS operations guide

•

StorageWorks HSG80 Array Controller ACS configuration guide

•

StorageWorks HSG80 Array Controller ACS maintenance and service guide

•

StorageWorks HSG80 Array Controller ACS CLI reference guide

•

StorageWorks Command Console getting started guide

•

StorageWorks Secure Path for Windows installation guide

•

Fibre Channel SAN Switch installation and hardware guide

Data Replication Manager

Refer to the Data Replication Manager HSG80 ACS operations guide for detailed information on the

Data Replication Manager including any restrictions.

Installing the hardware

Set up the cluster using the following procedures:

1.

"Setting up the servers for MA8000 (on page 25)"

2.

"Setting up the storage subsystem (on page 10)"

3.

"Setting up the host bus adapters (on page 25)"

4.

"Designating the server as a maintenance terminal (on page 25)"

5.

"Setting up the Fibre Channel switches at both locations (on page 25)"

Setting up the ProLiant Cluster F500 for MA8000 24

Setting up the servers for MA8000

Refer to the Data Replication Manager HSG80 ACS operations guide for DRM installation information

needed to get the DRM solution ready for setup.

Follow the installation instructions in the HP ProLiant server documentation to set up each server as a

stand-alone server, and then follow the instructions in the following sections to configure the cluster.

Setting up the storage subsystem

Refer to the documentation that was shipped with the storage subsystem for detailed installation

instructions.

Setting up the host bus adapters

Install two host bus adapters into the host server to run the DRM solution. Refer to the host bus adapter

guide for detailed information on this hardware.

Locate and record the WWN of each host bus adapter on the Connection naming worksheet (on page

53). This number will be needed when renaming the host connections later in the installation process.

NOTE: The WWN can be found on the bottom of the adapter board. Look for a small bar code label with

an IEEE precursor. A WWN example is 1000-0000-C920-A5BA.

Designating the server as a maintenance terminal

A server must be connected to the storage controller to provide a maintenance terminal.

NOTE: Only one server should be designated as the maintenance terminal. It is recommended that a

separate stand-alone server that is not part of the cluster be designated as the maintenance server.

1.

Connect the RJ-12 connector on the communications cable to the maintenance port on the storage

controller.

2.

Connect the 9-pin serial connector on the communications cable to either the COM1 or COM2 port

on the server.

NOTE: Record which serial port is used. This information will be needed when setting up the

communications program and configuring the controller.

Setting up the Fibre Channel switches at both locations

Refer to the documentation that was shipped with the switches for detailed switch installation instructions.

To set up the Fibre Channel switches at both locations:

1.

Turn on the AC power for each switch.

2.

Enter the IP addresses and subnet masks for each switch. Each switch must have a different IP

address.

Configuring DRM

A command line interface must be present on both the target and initiator sites before you begin the

configuration process. Refer to the Data Replication Manager HSG80 ACS operations guide for detailed

DRM configuration instructions.

Set up DRM using the following procedures:

Setting up the ProLiant Cluster F500 for MA8000 25

"Configuring the Controllers at the Target Site (on page 26)"

1.

2.

"Configuring the Storage at the Target Site (on page 29)"

3.

"Connecting Fiber Optic Cables Between the Controllers and Switches (on page 29)"

4.

"Connecting the Target Site to the External Fiber Link (on page 29)"

5.

"Connecting the Target Site to the ATM Link (on page 30)"

6.

"Configuring the Host at the Target Site (on page 30)"

7.

"Configuring the Controllers at the Initiator Site (on page 31)"

8.

"Configuring the Storage at the Initiator Site (on page 34)"

9.

"Connecting Fiber Optic Cables Between the Controllers and Switches (on page 29)"

10.

"Connecting the Initiator Site to the External Fiber Link (on page 35)"

11.

"Connecting the Initiator Site to the ATM Link (on page 35)"

12.

"Creating Remote Copy Sets (on page 35)"

13.

"Creating Log Units and Association Sets (Optional) (on page 36)"

14.

"Configuring the Host at the Initiator Site (on page 37)"

Configuring the controllers at the target site

Before configuring the controllers at the target site:

•

Identify the WWN on each host bus adapter and document it on the Connection Naming Worksheet

for later use.

•

Establish the name for the target site. Use a naming convention that is meaningful, such as building

or city names (for example, SiteA for the initiator site and SiteB for the target site).

To get the DT system up and running you must first set up and configure the controllers. To set up and

configure the controllers:

1.

Power off all the storage subsystems, Fibre Channel switches, PDUs, and the main power supply.

2.

Plug all cabinet PDU power cords into the main power receptacles.

3.

Apply power to the main power source.

NOTE: Be sure that there is a serial connection to each of the controllers.

4.

Turn on all PDUs.

5.

Be sure that the Fibre Channel switches are powered up but not cabled.

6.

Power on the storage subsystems. (This refers to RA8000/ESA12000 storage subsystems.)

NOTE: The controllers will boot when the storage subsystems are powered up if the PCMCIA program

cards are already installed. If there are no cards in the controller slots, insert them now, and press the reset

button. Refer to the StorageWorks HSG80 Array Controller ACS maintenance and service guide for

complete instructions on properly seating the controller cards.

7.

Establish a local connection to the controller. Refer to the StorageWorks HSG80 Array Controller

ACS maintenance and service guide for instructions.

8.

Verify that all controllers are turned on and functional by looking for the CLI prompt on the

maintenance port terminal.

NOTE: All operations can be conducted from either controller.

9.

Enter the following command:

SHOW THIS_CONTROLLER

Setting up the ProLiant Cluster F500 for MA8000 26

Verify that the storage subsystem WWN, also called the NODE_ID, is set. The WWN is not set if

10.

zeros are displayed. Go to step 14 if the WWN is set. If the WWN has not been assigned to the

controller, obtain the WWN and continue with step 11.

CAUTION: Data corruption occurs if two subsystems are set to the same WWN.

NOTE: The storage subsystem WWN and checksum can be found on a sticker located on top of the frame

that houses the controllers, EMU, PVA, and cache modules. This sticker also includes a checksum that

verifies that the WWN is valid. Contact a customer service representative for assistance if the sticker is

missing. Refer to the StorageWorks HSG80 Array Controller ACS configuration guide for more information

on WWNs. Each subsystem WWN begins with 5000 and ends in zero, for example 5000-1FE1-FF0CEE00. The controller port IDs are derived from the WWN.

11.

Assign the WWN to the controller by entering the following command:

SET THIS NODE_ID=node_ID checksum

12.

Restart the controller by entering the following command:

RESTART THIS_CONTROLLER

NOTE: A series of %LFL, %CER, and %EVL messages are displayed when the controller restarts. These

messages indicate a Last Failure Log, a CLI Event Report, and an Event Log. Refer to the StorageWorks

HSG80 Array Controller ACS maintenance and service guide for a complete explanation of these event

messages.

13.

Use a SHOW THIS command to verify that the WWN has been set.

14.

Configure the controllers for multibus failover mode by entering the following command:

SET MULTIBUS_FAILOVER COPY=THIS_CONTROLLER

This command automatically restarts the other controller. A series of %LFL and %EVL messages are

displayed. Refer to the StorageWorks HSG80 Array Controller ACS maintenance and service guide

for more details on these messages.

15.

Be sure that the setting from step 14 has been applied by entering the following command:

SHOW THIS_CONTROLLER FULL

The output shows that the controllers have been configured to support multibus failovers.

NOTE: The multibus failover settings are automatically applied to controller B.

16.

Verify that the settings have been accepted on controller B by entering the following command:

SHOW OTHER_CONTROLLER FULL

17.

Change the controller prompts to help identify which controller is in use by entering the following

commands:

SET THIS_CONTROLLER PROMPT="TargetControllerNameTop"

SET OTHER_CONTROLLER PROMPT="TargetControllerNameBottom"

NOTE: The commands used in this step assume the maintenance cable is connected to the top controller

port.

18.

Verify the SCSI Version and the Command Console LUN settings by entering the following

command:

SHOW THIS_CONTROLLER

It is recommended to use SCSI-3 so that the CCL is always enabled. The CCL is required for scripting

failover and failback procedures. For more information on scripting, refer to the Data Replication

Manager HSG80 ACS scripting user guide.

Set the SCSI Version to SCSI-3 by entering the following command:

SET THIS_CONTROLLER SCSI_VERSION=SCSI-3

19.

Verify that the settings established for controller A have been applied to controller B by entering the

following command:

SHOW OTHER_CONTROLLER

Setting up the ProLiant Cluster F500 for MA8000 27

Check to see if the mirrored write-back cache is enabled by entering the following command:

20.

SHOW THIS_CONTROLLER

If the mirrored write-back cache is not enabled, enter the following command:

SET THIS_CONTROLLER MIRRORED_CACHE

The controllers will restart after the mirrored write-back cache has been set, and you will see a series

of %LFL and %EVL messages.

21.

Confirm that the mirrored write-back cache is enabled (after the controllers restart) by entering the

following command:

SHOW THIS_CONTROLLER

Notice that the mirrored write-back cache is now set. It is not necessary to repeat this step on

controller B.

NOTE: It might take up to five minutes after the controller restarts to complete the cache check. The

controllers will reject this command until the cache check is complete. Do not restart the controllers if this

command is rejected. Wait a few minutes and then retry.

The storage subsystem is ready to operate when the Reset LED indicator on the storage controller

flashes at a rate of one time per second.

22.

Set the time on the storage subsystems by entering the following command:

SET THIS_CONTROLLER TIME=DD-MMM-YYYY:HH:MM:SS

23.

Set both of the cache battery expiration dates. Perform the following:

a.

While connected to the top controller, type in run frutil and press Enter.

b.

Type Y and press Enter when the prompt to replace this controller cache battery displays.

c.

Ignore the instructions to replace the battery and press Enter.

d.

Connect the maintenance cable to the bottom controller.

e.

Type in run frutil and press Enter.

f.

Repeat steps b and c for the bottom controller. Both cache battery expiration dates are now set.

g.

Connect the maintenance port to the top controller and press Enter to display a prompt.

24.

Set the fabric topology for each port on both controllers by entering the following commands:

SET THIS_CONTROLLER PORT_1_TOPOLOGY=FABRIC

SET THIS_CONTROLLER PORT_2_TOPOLOGY=FABRIC

SET OTHER_CONTROLLER PORT_1_TOPOLOGY=FABRIC

SET OTHER_CONTROLLER PORT_2_TOPOLOGY=FABRIC

25.

Verify that the topology is set correctly by entering the following commands:

SHOW THIS_CONTROLLER

SHOW OTHER_CONTROLLER

26.

Enable the DRM by entering the following command:

SET THIS_CONTROLLER REMOTE_COPY=TargetNodeName

NOTE: Specify a meaningful NodeName, such as a name that reflects the site location. Do not use "local"

and "remote;" these are reserved keywords. The name can be up to eight characters and must be unique to

all your controllers. Refer to the StorageWorks HSG80 Array Controller ACS configuration guide for naming

guidelines.

A series of %LFL and %EVL messages are displayed, and the controllers automatically restart after

entering the CLI command.

27.

Verify that these settings are correct by entering the following command:

SHOW THIS_CONTROLLER

Setting up the ProLiant Cluster F500 for MA8000 28

Configuring the storage at the target site

Add disks, create the storagesets, and create units before configuring the storage for DRM. Refer to the

StorageWorks HSG80 Array Controller ACS configuration guide for instructions. Keep in mind the

restrictions specific to this installation where noted.

IMPORTANT: The target site and the initiator site must have exactly the same storageset and unit

configuration.

NOTE: If using SWCC, at least one LUN defined on the storage subsystem that is not part of a remote copy

set is required.

To configure the storage after all the units have been created:

1.

Disable access on all units by entering the following command:

SET UnitNumber DISABLE_ACCESS_PATH=ALL

2.

Verify that the access on each unit is set to None by entering the following command:

SHOW UNITS FULL

3.

Repeat steps 1 and 2 for each unit.

4.

Verify that the unit settings are correct by entering the following command:

SHOW UNITS FULL

5.

Enter the following commands to distribute the units by setting their preferred path:

SET UnitNumber PREFERRED_PATH=THIS_CONTROLLER

SET UnitNumber PREFERRED_PATH=OTHER_CONTROLLER

Connecting fiber optic cables between the controllers and switches

To establish fiber optic connections:

1.

Connect a multimode fiber optic cable from port 1 of the top controller to port 2 of the top Fibre

Channel switch.

2.

Connect a second multimode fiber optic cable from port 2 of the top controller to port 4 of the top

Fibre Channel switch.

3.

Connect a third multimode fiber optic cable from port 1 of the bottom controller to port 2 of the

bottom Fibre Channel switch.

4.

Connect a fourth multimode fiber optic cable from port 2 of the bottom controller to port 4 of the

bottom Fibre Channel switch.

IMPORTANT: If "PORT_1_TOPOLOGY = FABRIC (point-to-point)" is displayed, it indicates a switch

configuration error. Consult the switch documentation to correct this problem.

NOTE: A green LED indicator on the switch illuminates as soon as the cable is inserted at both ends. This

verifies that there is a good connection.

Connecting the target site to the external fiber link

Locate the connection points linking the target site to the initiator site. Look for either a fiber optic cable

connector or a patch panel to insert the cable.

To connect the target site to the external fiber link:

1.

Connect a single-mode fiber optic cable pair from port 6 of the top switch to one connection point.

2.

Connect another single-mode fiber optic cable pair from port 6 of the bottom switch to the other

connection point.

The target site is now physically linked to the initiator site.

Setting up the ProLiant Cluster F500 for MA8000 29