Page 1

HP ProLiant BL495c Generation 5 Server Blade User Guide

Part Number 491030-003

April 2009 (Third Edition)

Page 2

© Copyright 2008, 2009 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, Windows NT, and Windows Server are U.S. registered trademarks of Microsoft Corporation.

AMD Athlon is a trademark of Advanced Micro Devices, Inc.

Intended audience

This guide is for an experienced service technician. HP assumes you are qualified in the servicing of

computer equipment and trained in recognizing hazards in products with hazardous energy levels and

are familiar with weight and stability precautions for rack installations.

Page 3

Contents

Component identification............................................................................................................... 6

Front panel components ............................................................................................................................. 6

Front panel LEDs ....................................................................................................................................... 7

System board components.......................................................................................................................... 8

Mezzanine connector definitions ....................................................................................................... 8

System maintenance switch............................................................................................................... 9

System maintenance switch procedures .............................................................................................. 9

HP c-Class Blade SUV Cable..................................................................................................................... 10

Operations................................................................................................................................. 11

Power up the server blade........................................................................................................................ 11

Power down the server blade.................................................................................................................... 11

Remove the server blade .......................................................................................................................... 12

Remove the access panel.......................................................................................................................... 12

Install the access panel............................................................................................................................. 13

Setup......................................................................................................................................... 14

Overview ...............................................................................................................................................14

Installing an HP BladeSystem c-Class enclosure ...........................................................................................14

Installing server blade options................................................................................................................... 14

Installing interconnect modules.................................................................................................................. 14

Interconnect bay numbering and device mapping.............................................................................. 15

Connecting to the network........................................................................................................................ 17

Installing a server blade ........................................................................................................................... 17

Completing the configuration.................................................................................................................... 18

Hardware options installation....................................................................................................... 19

Introduction ............................................................................................................................................ 19

Hard drive option.................................................................................................................................... 19

Memory option ....................................................................................................................................... 20

Advanced ECC memory .................................................................................................................21

DIMM installation guidelines........................................................................................................... 21

DIMM population order.................................................................................................................. 21

Installing DIMMs ........................................................................................................................... 21

Processor option...................................................................................................................................... 23

Mezzanine card option............................................................................................................................ 28

Cabling ..................................................................................................................................... 30

Hard drive cabling .................................................................................................................................. 30

Using the HP c-Class Blade SUV Cable ...................................................................................................... 30

Connecting locally to a server blade with video and USB devices.................................................................. 30

Accessing a server blade with local KVM .........................................................................................31

Accessing a server blade with local media devices ............................................................................ 31

Software and configuration utilities ............................................................................................... 33

Server blade deployment tools .................................................................................................................. 33

RBSU requirement for Linux deployment............................................................................................ 33

Software drivers and additional components..................................................................................... 33

Contents 3

Page 4

HP BladeSystem c-Class Advanced management ............................................................................... 34

Network-based PXE deployment ...................................................................................................... 34

Deployment methods...................................................................................................................... 36

Configuration tools.................................................................................................................................. 39

SmartStart software........................................................................................................................ 39

HP ROM-Based Setup Utility............................................................................................................ 40

Array Configuration Utility.............................................................................................................. 42

Option ROM Configuration for Arrays .............................................................................................42

Re-entering the server serial number and product ID........................................................................... 43

Management tools................................................................................................................................... 43

Automatic Server Recovery .............................................................................................................43

ROMPaq utility.............................................................................................................................. 44

iLO 2 technology........................................................................................................................... 44

Erase Utility ..................................................................................................................................44

StorageWorks library and tape tools................................................................................................ 44

HP Systems Insight Manager........................................................................................................... 45

Management Agents...................................................................................................................... 45

HP ProLiant Essentials Virtualization Management Software ................................................................45

HP ProLiant Essentials Vulnerability and Patch Management Pack ........................................................45

HP Insight Server Migration software for ProLiant...............................................................................46

HP ProLiant Essentials Performance Management Pack .......................................................................46

HP Insight Control Environment Suites............................................................................................... 47

HP Insight Control Linux Edition ....................................................................................................... 47

Redundant ROM support ................................................................................................................ 47

USB support and functionality ......................................................................................................... 48

Diagnostic tools ...................................................................................................................................... 49

HP Insight Diagnostics.................................................................................................................... 49

HP Insight Diagnostics survey functionality ........................................................................................49

Integrated Management Log ...........................................................................................................49

Array Diagnostic Utility ..................................................................................................................50

Remote support and analysis tools............................................................................................................. 50

HP Insight Remote Support software ................................................................................................. 50

Keeping the system current ....................................................................................................................... 50

Drivers ......................................................................................................................................... 50

ProLiant Support Packs ................................................................................................................... 51

Operating system version support.................................................................................................... 51

System Online ROM flash component utility ......................................................................................51

Change control and proactive notification ........................................................................................ 51

Care Pack ....................................................................................................................................52

Troubleshooting.......................................................................................................................... 53

Troubleshooting resources ........................................................................................................................53

Pre-diagnostic steps ................................................................................................................................. 53

Important safety information............................................................................................................ 54

Symptom information ..................................................................................................................... 55

Prepare the server for diagnosis ......................................................................................................55

Service notifications................................................................................................................................. 56

Loose connections ...................................................................................................................................56

Troubleshooting flowcharts .......................................................................................................................56

Start diagnosis flowchart ................................................................................................................57

General diagnosis flowchart ........................................................................................................... 58

Server blade power-on problems flowchart .......................................................................................60

POST problems flowchart ............................................................................................................... 62

OS boot problems flowchart ...........................................................................................................64

Contents 4

Page 5

Server fault indications flowchart ..................................................................................................... 66

POST error messages and beep codes....................................................................................................... 68

Battery replacement .................................................................................................................... 69

Regulatory compliance notices ..................................................................................................... 70

Regulatory compliance identification numbers............................................................................................. 70

Federal Communications Commission notice............................................................................................... 70

FCC rating label............................................................................................................................ 70

Class A equipment......................................................................................................................... 70

Class B equipment......................................................................................................................... 70

Declaration of conformity for products marked with the FCC logo, United States only....................................... 71

Modifications.......................................................................................................................................... 71

Cables................................................................................................................................................... 71

Canadian notice (Avis Canadien).............................................................................................................. 72

European Union regulatory notice .............................................................................................................72

Disposal of waste equipment by users in private households in the European Union......................................... 72

Japanese notice ...................................................................................................................................... 73

BSMI notice............................................................................................................................................ 73

Korean notice ......................................................................................................................................... 73

Laser compliance .................................................................................................................................... 74

Battery replacement notice........................................................................................................................ 74

Taiwan battery recycling notice................................................................................................................. 75

Electrostatic discharge................................................................................................................. 76

Preventing electrostatic discharge.............................................................................................................. 76

Grounding methods to prevent electrostatic discharge.................................................................................. 76

Specifications............................................................................................................................. 77

Environmental specifications ..................................................................................................................... 77

Server blade specifications....................................................................................................................... 77

Technical support........................................................................................................................ 78

Before you contact HP.............................................................................................................................. 78

HP contact information............................................................................................................................. 78

Customer Self Repair ...............................................................................................................................78

Acronyms and abbreviations........................................................................................................ 86

Index......................................................................................................................................... 89

Contents 5

Page 6

Component identification

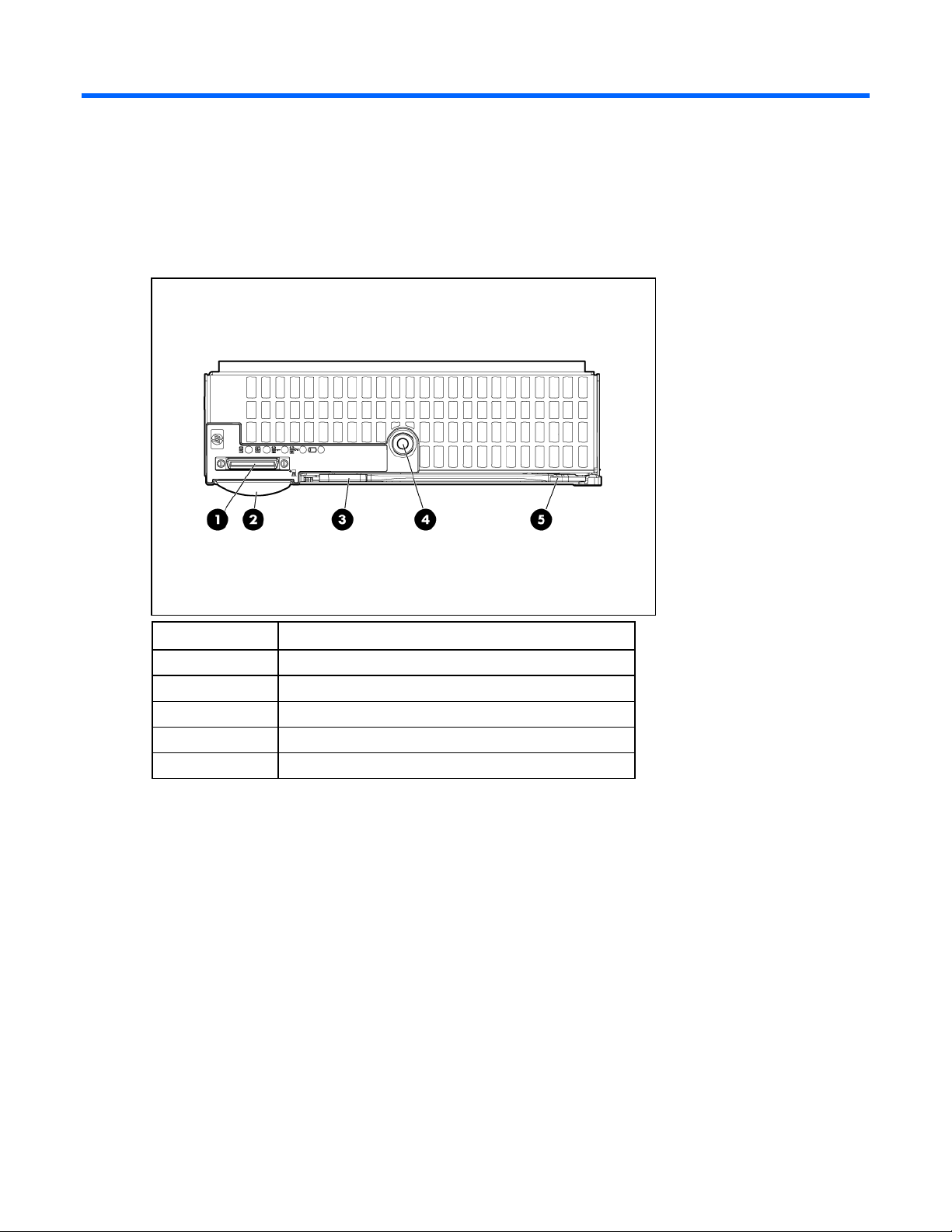

Front panel components

Item Description

1 Local I/O connector

2 Serial label pull tab

3 Server blade handle button

4 Power On/Standby button

5 Server blade handle

Component identification 6

Page 7

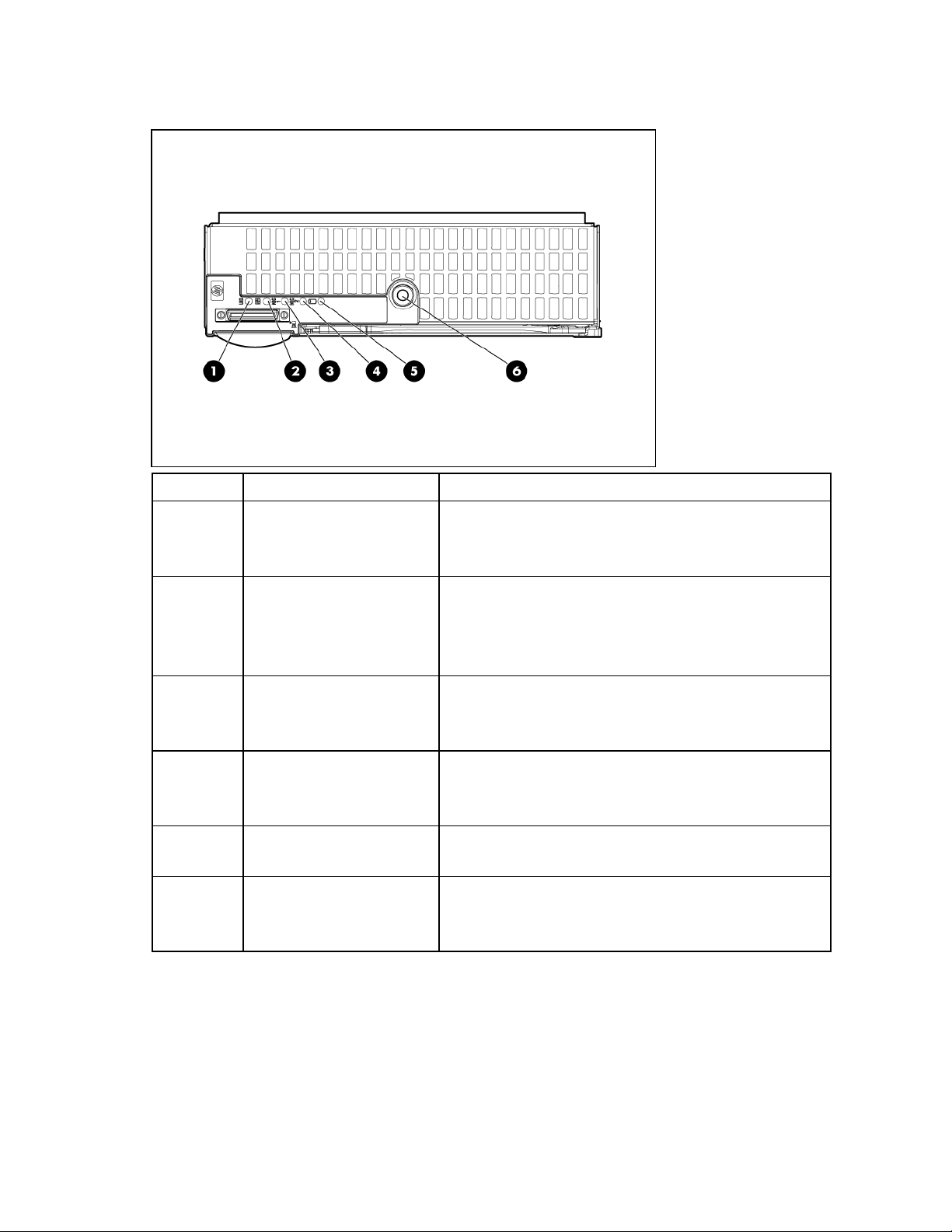

Front panel LEDs

Item Description Status

1 UID LED Blue = Identified

Blue flashing = Active remote management

Off = No active remote management

2 Internal health LED Green = Normal

Flashing = Booting

Amber = Degraded condition

Red = Critical condition

3 Flex10 1 LED Green = Network linked

Green flashing = Network activity

Off = No link or activity

4 Flex10 2 LED Green = Network linked

Green flashing = Network activity

Off = No link or activity

5 Hard drive activity LED Green = Activity

Off = No activity

6 Power On/Standby button

and system power LED

Green = On

Amber = Standby (auxiliary power available)

Off = Off

Component identification 7

Page 8

System board components

Item Description

1 DIMM slots

2 Hard drive data connector 2

3 Hard drive data connector 1

4 Hard drive power connector 1

5 Hard drive power connector 2

6 Internal USB connector

7 System battery

8 Enclosure connector

9 Battery tray

10 Mezzanine connector 1 (Type I only)

11 Mezzanine connector 2 (Type I or Type II)

12 System maintenance switch

13 Processor socket 1

14 Processor socket 2

Mezzanine connector definitions

Item Connector Card support

Mezzanine connector 1 PCIe x8 Type I mezzanine card only

Mezzanine connector 2 PCIe x8 Type I or II mezzanine card

Component identification 8

Page 9

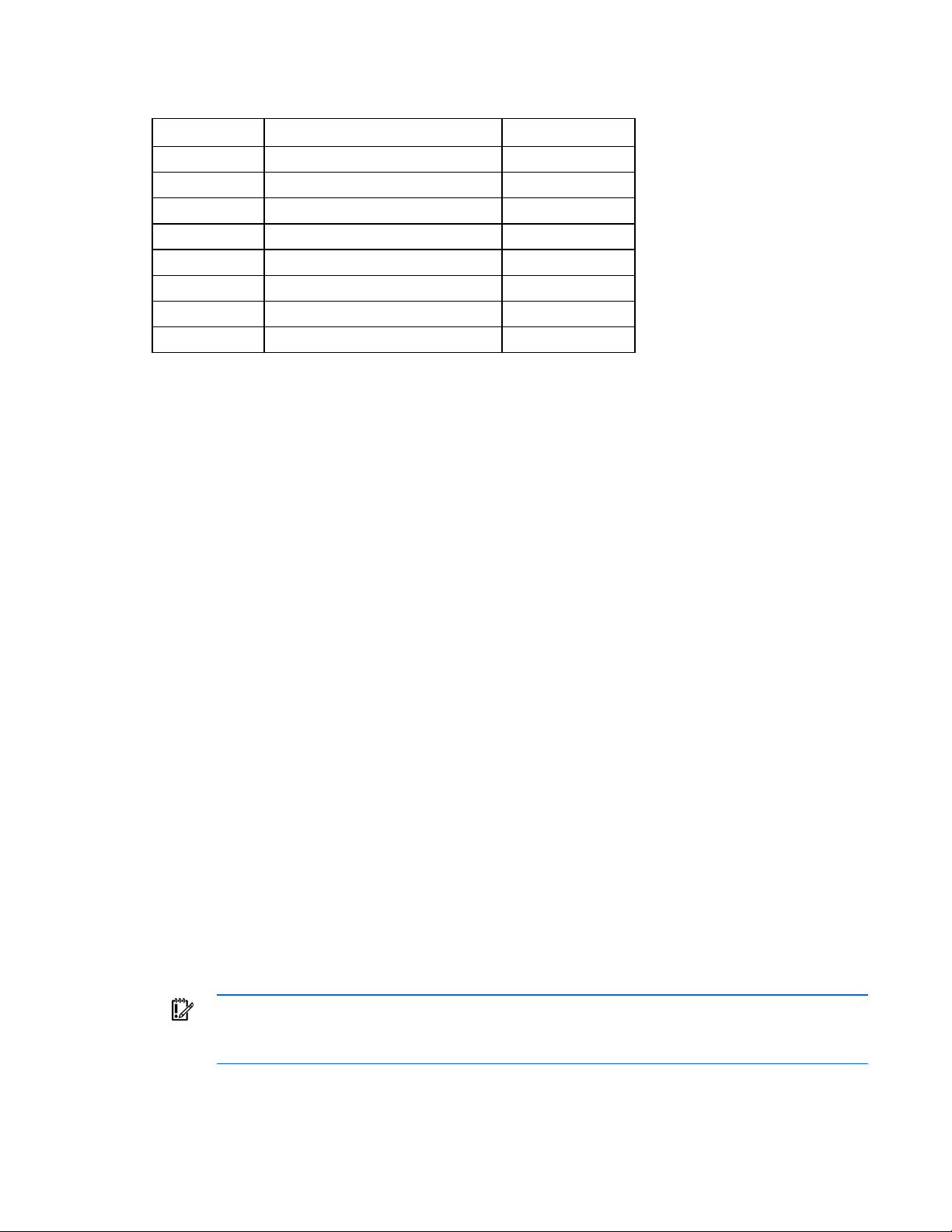

System maintenance switch

Position Function Default

1* iLO 2 security override Off

2 Configuration lock Off

3 Reserved Off

4 Reserved Off

5* Password disabled Off

6* Reset configuration Off

7 Reserved Off

8 Reserved Off

*To access redundant ROM, set S1, S5, and S6 to ON.

System maintenance switch procedures

When you perform troubleshooting steps, this guide may instruct you to perform the following procedures:

• Clear the system configuration ("Clearing the system configuration" on page 9).

• Access the redundant ROM ("Accessing the redundant ROM" on page 10).

To complete these procedures, you must change physical settings on the system maintenance switch.

Clearing the system configuration

RBSU can be used to restore the factory default configuration. For more information, see "HP ROM-Based

Setup Utilit

system configuration:

1. Power down the server blade (on page 11).

2. Remove the server blade (on page 12).

3. Remove the access panel (on page 12).

4. Change position 6 of the system maintenance switch to on.

5. Install the access panel (on page 13).

6. Install the server blade in the enclosure and power up the server blade.

7. Wait for the POST message that prompts you to change the switch setting:

8. Repeat steps 1 through 3.

9. Change position 6 of the system maintenance switch to off.

10. Repeat steps 5 through 7.

y (on page 40)." If the system is unable to boot into RBSU, use the following steps to clear the

Maintenance switch detected in the "On" position.

Power off the server and turn switch to the "Off" position.

IMPORTANT: When the server blade boots after NVRAM is cleared, a delay of up to 2

minutes is normal. During this delay, the system appears non-functional. Do not attempt any

procedures during the delay.

Component identification 9

Page 10

Accessing the redundant ROM

If the system ROM is corrupted, the system automatically switches to the redundant ROM in most cases. If

the system does not automatically switch to the redundant ROM, perform the following steps:

1. Power down the server blade (on page 11).

2. Remove the server blade (on page 12).

3. Remove the access panel (on page 12).

4. Change positions 1, 5, and 6 of the system maintenance switch to on.

5. Install the access panel (on page 13).

6. Install the server blade in the enclosure and power up the server blade.

7. After the system beeps, repeat steps 1 through 3.

8. Change positions 1, 5, and 6 of system maintenance switch to off.

9. Repeat steps 5 and 6.

If both the current and backup versions of the ROM are corrupt, return the system board for a service

replacement.

To switch to the backup ROM when the System ROM is not corrupt, use RBSU.

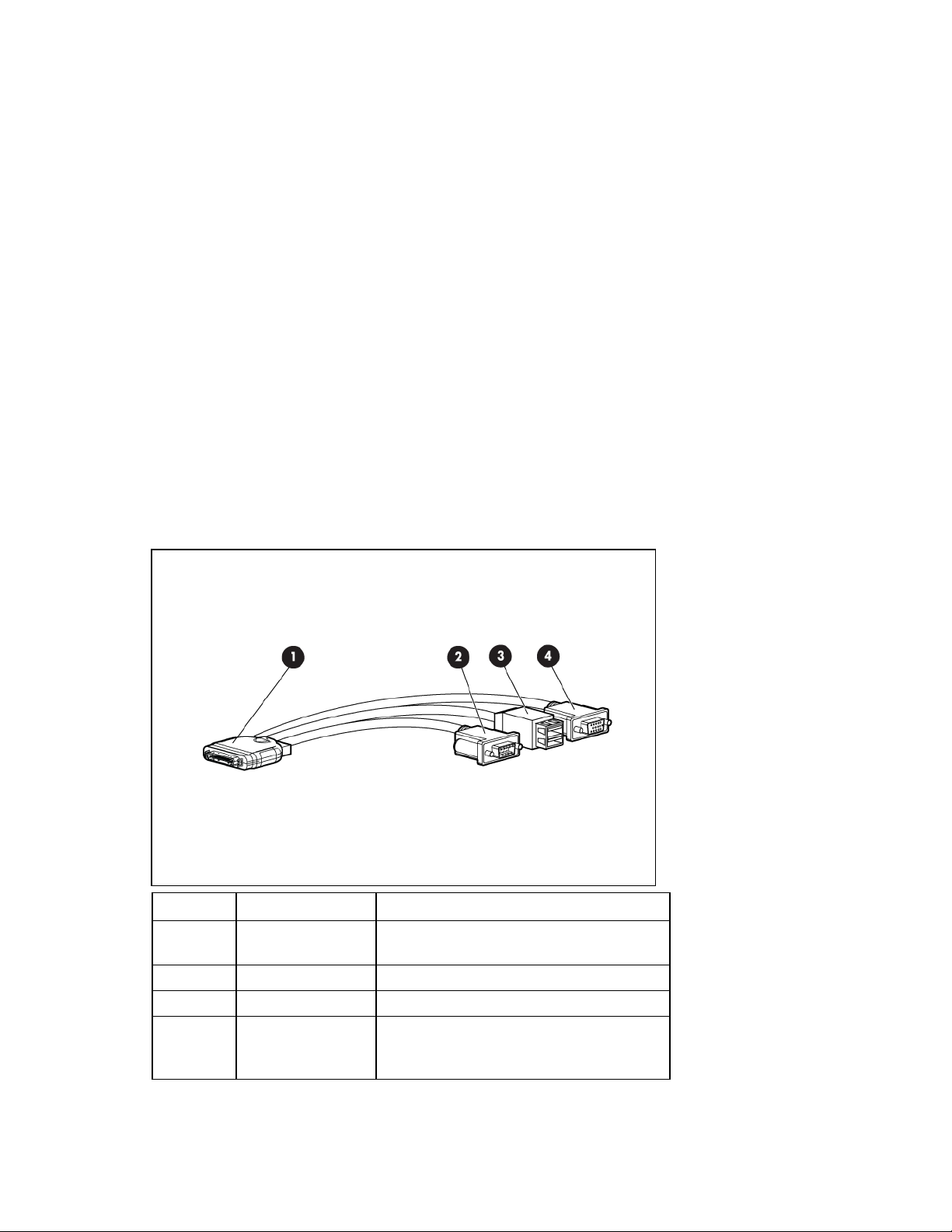

HP c-Class Blade SUV Cable

Item Connector Description

1 Server blade For connecting to the SUV connector on the

server blade front panel

2 Video For connecting a video monitor

3 USB For connecting up to two USB devices

4 Serial For trained personnel to connect a null modem

serial cable and perform advanced diagnostic

procedures

Component identification 10

Page 11

Operations

Power up the server blade

The enclosure initiates an automatic power-up sequence when the server blade is installed. If the default

setting is changed, use one of the following methods to power up the server blade:

• Use a virtual power button selection through iLO 2.

• Press and release the Power On/Standby button.

When the server blade goes from the standby mode to the full power mode, the system power LED

changes from amber to green.

For more information about the enclosure, see the enclosure setup and installation guide

website

For more information about iLO 2, see "iLO 2 technology."

(http://www.hp.com/support).

Power down the server blade

Before powering down the server blade for any upgrade or maintenance procedures, perform a backup

of critical server data and programs.

Depending on the enclosure configuration, use one of the following methods to power down the server

blade:

• Use a virtual power button selection through iLO 2.

This method initiates a controlled remote shutdown of applications and the OS before the server

blade enter standby mode.

• Press and release the Power On/Standby button.

This method initiates a controlled shutdown of applications and the OS before the server blade enter

standby mode.

• Press and hold the Power On/Standby button for more than 4 seconds to force the server blade to

enter standby mode.

This method forces the server blade to enter standby mode without properly exiting applications and

the OS. It provides an emergency shutdown method in the event of a hung application.

on the HP

• Execute one of the following c

eroff server all

pow

or

poweroff server all force

The first command initiates a controlled shutdown of applications and the OS before the server blade

enter standby mode. The second form of the command forces the server blade to enter standby mo

without exiting applications a

event of a hung application.

ommands using the enclosure CLI:

nd the OS. This is an emergency method to force a shutdown in the

Operations 11

de

Page 12

•

Use the enclosure GUI to initiate a shutdown:

a. Select the Enclosure Information tab, then select th

b.

Initiate a shutdown from the Virtual Power menu:

— Select Momentary Press to initiate a controlled shutdown of applications and the OS.

—

Select Press and Hold to initiate an emergency shutdown of applications and the OS.

IMPORTANT: When the server blade are in standby mode, auxiliary power is still being

provided. To

enclosure.

remove all power from the server blade, remove the server blade from the

After initiating a virtual power down command, be sure that the server blade go into standby mode by

observing that the system power LED is amber

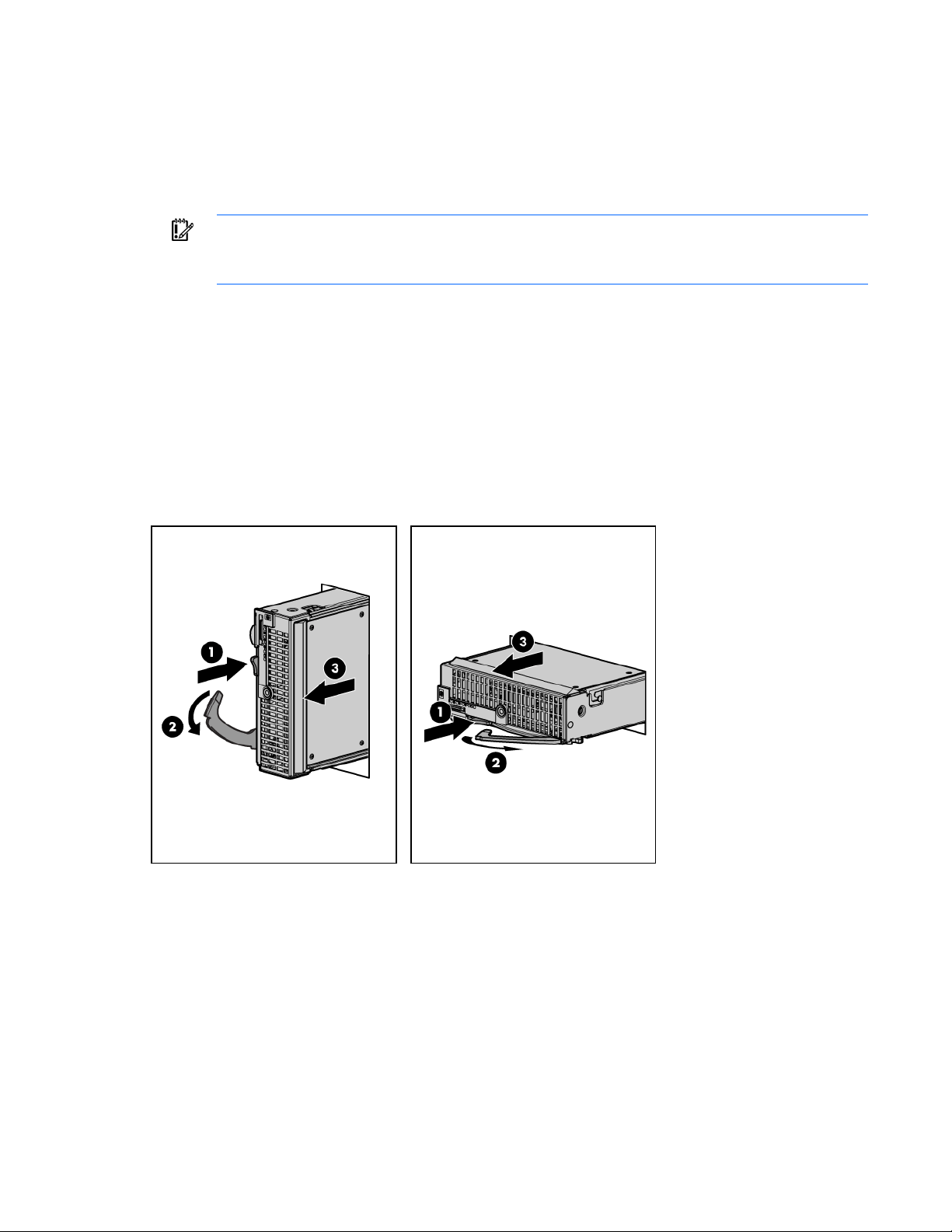

Remove the server blade

To remove the component:

1. Identify the proper server blade.

2. Power down the server bla

3. Remove the server blade.

de (on page 11).

e Overall checkbox in the Device Bays item.

.

4. Place the server blade on a flat, level work

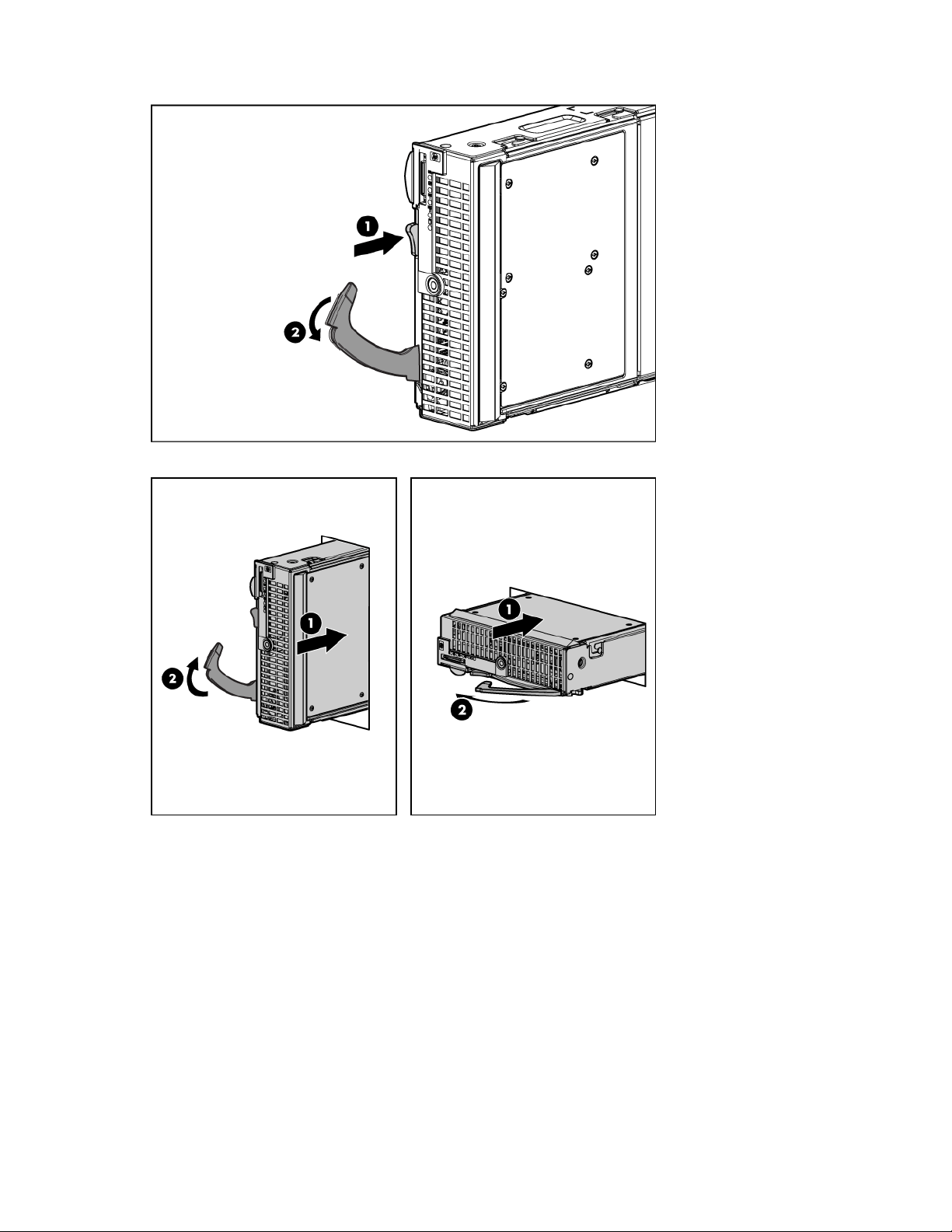

Remove the access panel

To remove the component:

1. Power down the server blade (on page 11

2. Remove the server blade (on page 12).

3. Press the access panel release button.

4. Slide the access panel towards the rear of the server blade, and then lift to remove the panel.

surface.

).

Operations 12

Page 13

Install the access panel

1. Place the access panel on top of the server blade.

2. Slide the access panel forward until it clicks into place.

Operations 13

Page 14

Setup

Overview

Installation of a server blade requires the following steps:

1. Install and configure an HP BladeSystem c-Class enclosure.

2. Install any server blade options.

3. Install interconnect modules in the enclosure.

4. Connect the interconnect modules to the network.

5. Install a server blade.

6. Complete the server blade configuration.

Installing an HP BladeSystem c-Class enclosure

Before performing any server blade-specific procedures, install an HP BladeSystem c-Class enclosure.

The most current documentation for server blades and other HP BladeSystem components is available at

HP website (http://www.hp.com/go/bladesystem/documentation).

the

Documentation is also available in the following locations:

• Documentation CD that ships with the enclosure

• HP Business Support Center website (http://www.hp.com/support)

• HP Technical Documentation website (http://docs.hp.com)

Installing server blade options

Before installing and initializing the server blade, install any server blade options, such as an additional

processor, hard drive, or mezzanine card. For server blade options installation information, see the

ProLiant BL495c Generation 5 Server Blade User Guide

http://www.hp.com/go/bladesystem/documentation).

(

on the HP website

HP

Installing interconnect modules

For specific steps to install interconnect modules, see the documentation that ships with the interconnect

module.

Setup 14

Page 15

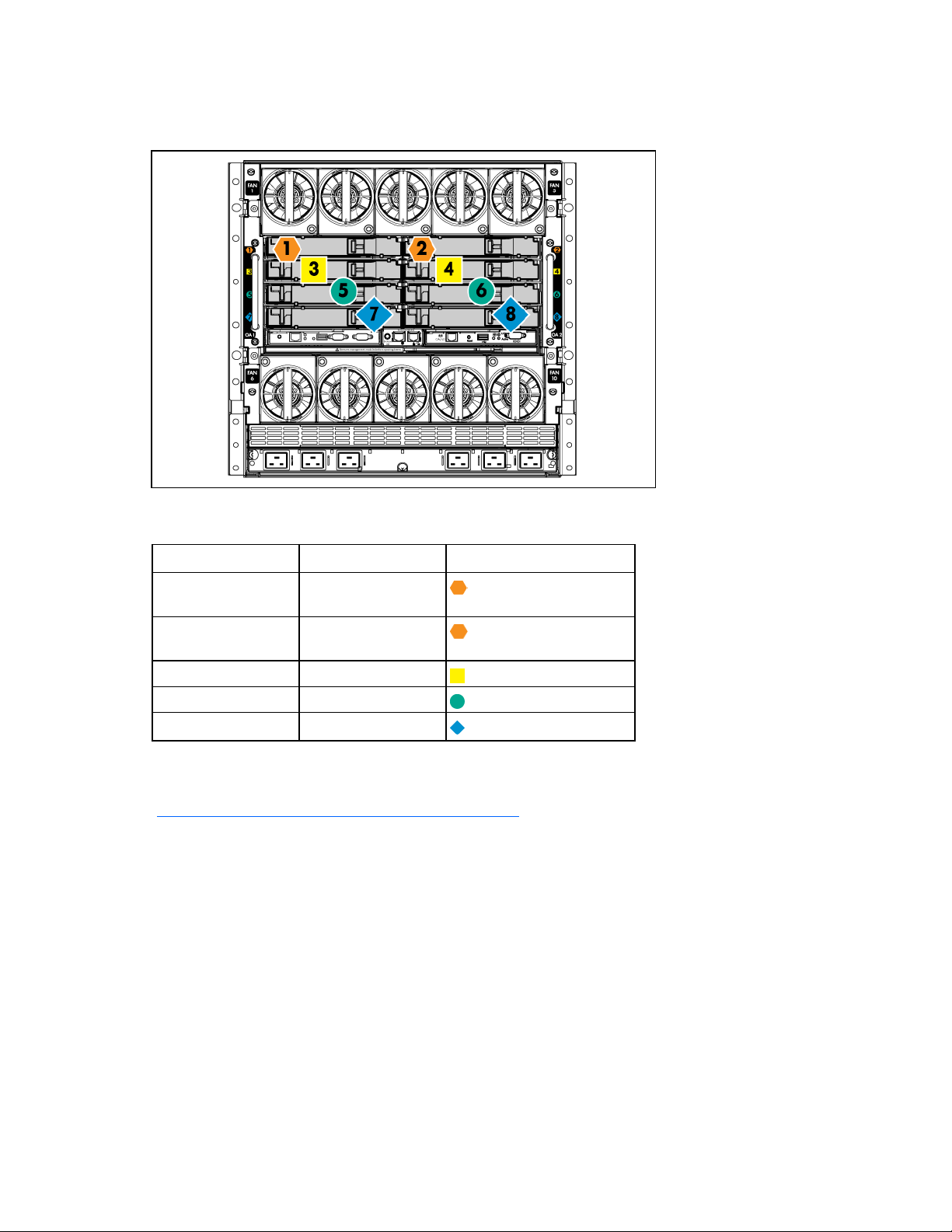

Interconnect bay numbering and device mapping

• HP BladeSystem c7000 Enclosure

To support network connections for specific signals, install an interconnect module in the bay

corresponding to the embedded NIC or mezzanine signals.

Server blade signal Interconnect bay Interconnect bay labels

Flex-10 NIC 1

(embedded)

Flex-10 NIC 2

(embedded)

Mezzanine 1 3 and 4

Mezzanine 2 5 and 6

1

2

7 and 8

For detailed port mapping information, see the HP BladeSystem enclosure installation poster or the

HP BladeSystem enclosure setup and installation guide on the

http://www.hp.com/go/bladesystem/documentation).

(

HP website

Setup 15

Page 16

• HP BladeSystem c3000 Enclosure and Tower Enclosure

Server blade signal Interconnect bay

number

Flex-10 NIC 1, 2

(embedded)

Mezzanine 1 2

Mezzanine 2 3,4

1

Interconnect bay

label

Notes

—

Four port cards connect to bay 2

• Four port cards

• Ports 1 and 3 connect to bay 3

• Ports 2 and 4 connect to bay 4

For detailed port mapping information, see the HP BladeSystem enclosure installation poster or the

HP BladeSystem enclosure setup and installation guide on the

http://www.hp.com/go/bladesystem/documentation).

(

HP website

Setup 16

Page 17

Connecting to the network

To connect the HP BladeSystem to a network, each enclosure must be configured with network

interconnect devices to manage signals between the server blades and the external network.

Two types of interconnect modules are available for HP BladeSystem c-Class enclosures: Pass-thru modules

and switch modules. For more information about interconnect module options, see the

http://www.hp.com/go/bladesystem/interconnects).

(

HP website

Installing a server blade

CAUTION: To prevent improper cooling and thermal damage, do not operate the enclosure

1. Remove the device bay blank.

2. Remove the enclosure connector cover.

unless all bays are populated with a component or a blank.

Setup 17

Page 18

3.

Prepare the server blade for installation.

4. Install the server blade.

Completing the configuration

To complete the server blade and HP BladeSystem configuration, see the overview card that ships with the

enclosure.

Setup 18

Page 19

Hardware options installation

Introduction

If more than one option is being installed, read the installation instructions for all the hardware options

and identify similar steps to streamline the installation process.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server before

beginning any installation procedure. Improper grounding can cause electrostatic discharge.

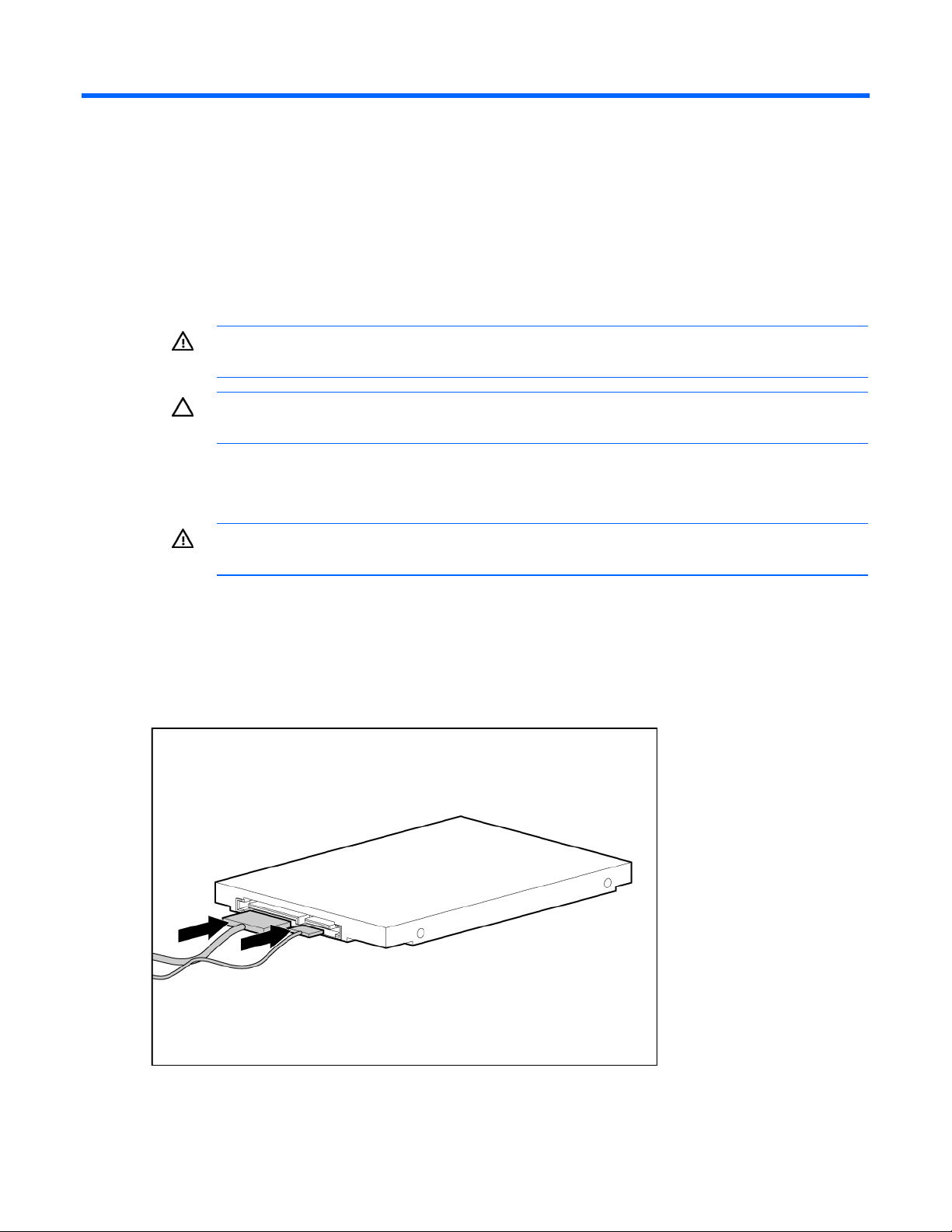

Hard drive option

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

To install the component:

1. Power down the server blade (on page 11).

2. Remove the server blade (on page 12).

3. Remove the access panel (on page 12).

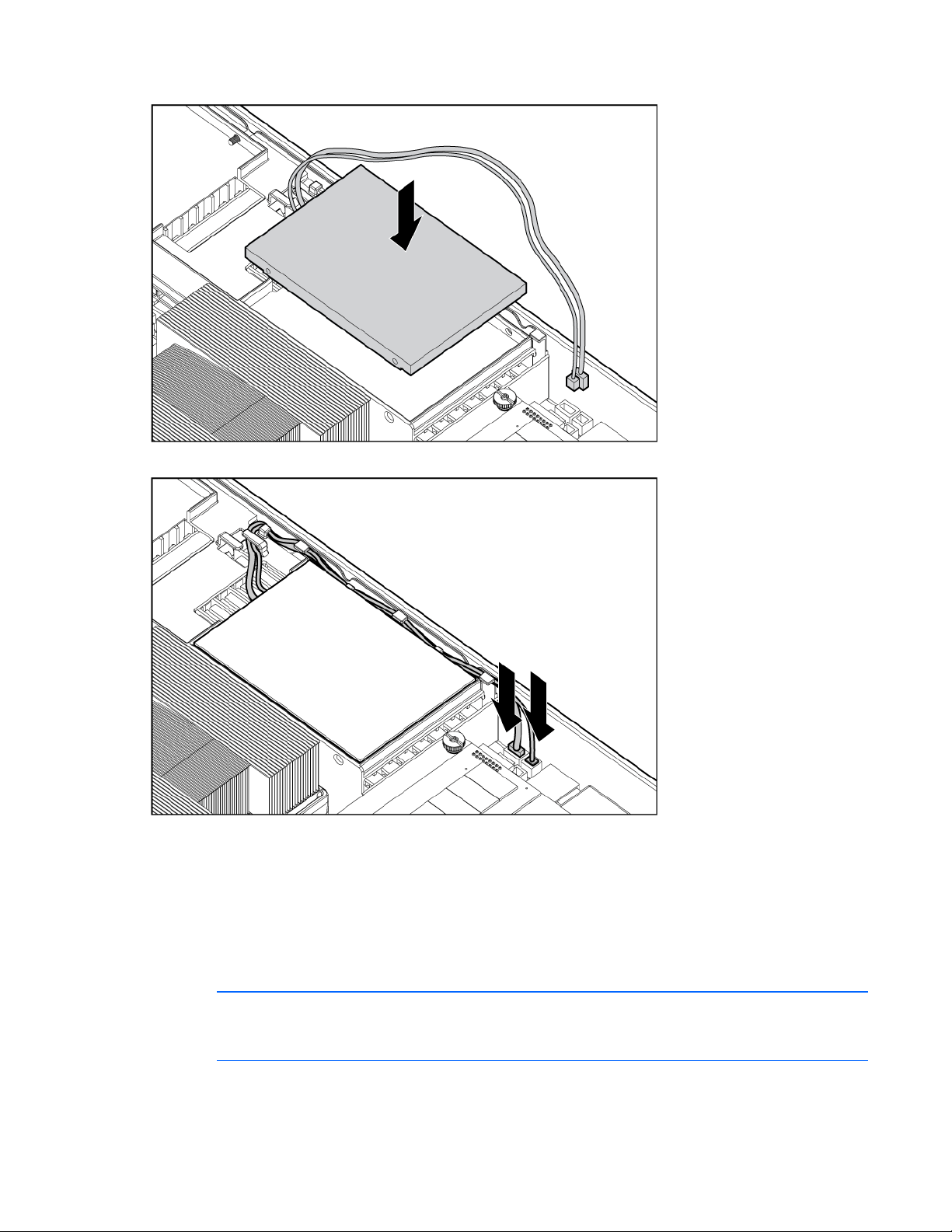

4. Connect the cables to the hard drive.

internal system components to cool before touching them.

5. Install the hard drive.

Hardware options installation 19

Page 20

For hard drive connector locations, see "System board components (on page 8)."

6. Connect and route the cables.

7. Install the access panel (on page 13).

8. Install the server blade ("Installing a server blade" on page 17).

Memory option

You can expand server memory by installing PC2-5300 Registered DDR2 SDRAM DIMMs. The server

supports up to 128 GB of memory using 16 8-GB DIMMs (eight DIMMs per processor).

NOTE: The Advanced Memory Protection option in RBSU provides additional memory

protection beyond Advanced ECC. By default, the server is set to

For DIMM slot locations and bank assignments, see "System board components (on page 8)."

more information, refer to "

Advanced ECC Support. For

HP ROM-Based Setup Utility (on page 40)."

Hardware options installation 20

Page 21

Advanced ECC memory

Advanced ECC memory is the default memory protection mode for this server blade. In Advanced ECC,

the server blade is protected against correctable memory errors. The server blade provides notification if

the level of correctable errors exceeds a pre-defined threshold rate. The server blade does not fail

because of correctable memory errors. Advanced ECC provides additional protection over Standard ECC

because it is possible to correct certain memory errors that would otherwise be uncorrectable and result in

a server blade failure.

Whereas standard ECC can correct single-bit memory errors, Advanced ECC can correct single-bit

memory errors and multi-bit memory errors if all failed bits are on the same DRAM device on the DIMM.

DIMM installation guidelines

CAUTION: Always wear an antistatic wrist strap when working inside the server.

Observe the following guidelines when installing additional memory:

• Install only ECC PC2-5300 Registered DDR2 SDRAM DIMMs

• Always install DIMMs in sequence (1A, 2A, 3B, 4B).

• DIMMs must always be installed in pairs.

• HP recommends installing DIMMs with the greatest capacity in the banks farthest from each

populated processor first.

• mber. DIMMs installed in the same memory bank must have the same part nu

• DIMMs installed in different banks can be of different sizes.

For DIMM slot locations, see "

Each server supports multiple memory modes, based on DIMM population. The system will default to

combined chan

on page 40).

nel mode and Advanced ECC. To select a mode, use

System board components (on page 8)."

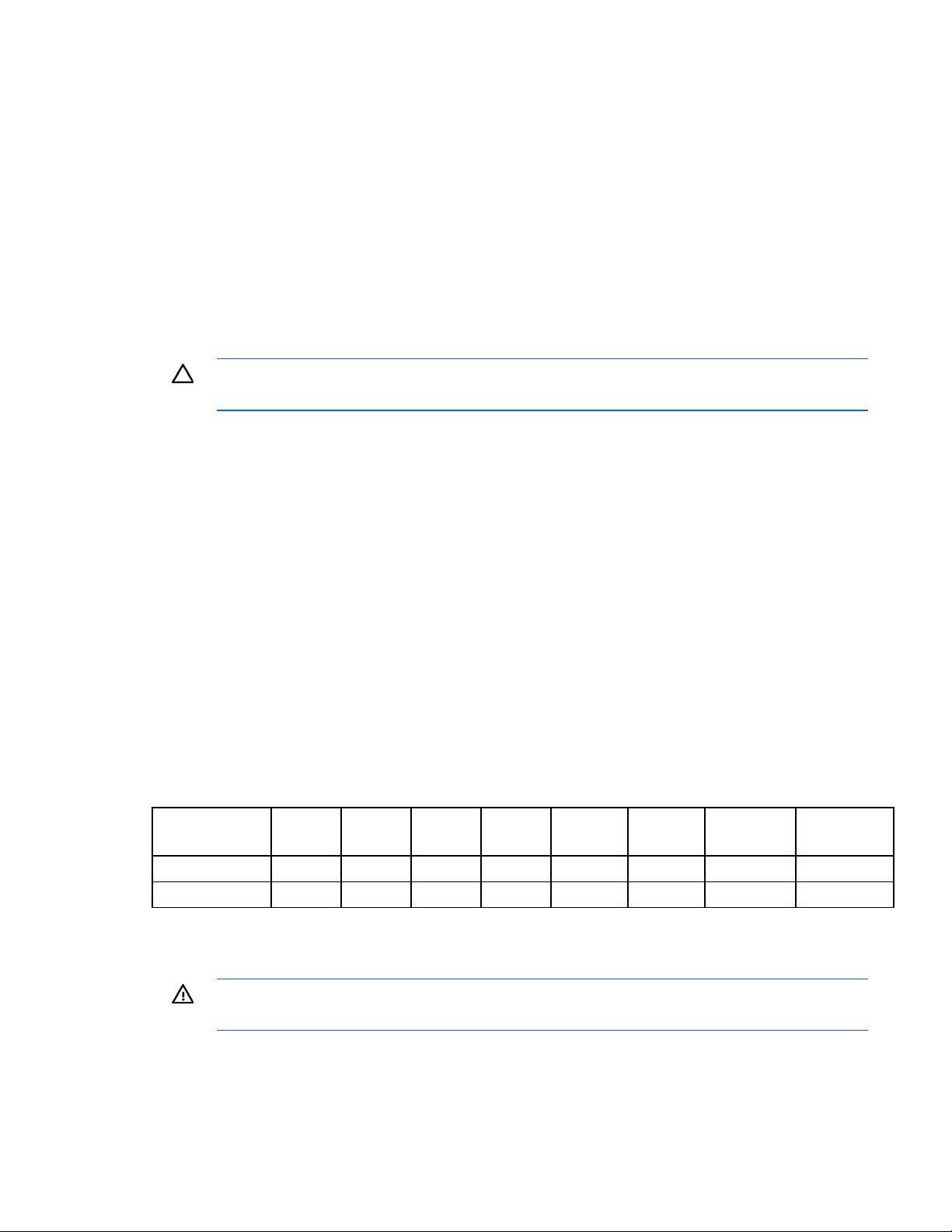

DIMM population order

Bank A

1A, 2

Single processor 1st 2nd 3rd 4th — — — —

Two processors 1st 3rd 5th 7th 2nd 4th 6th 8th

Bank B

A D 2F 14G H, 16H

3B, 4B

Bank C

5C, 6C

Bank D

7D, 8

Bank E

9E, 10E

RBSU ("HP ROM-Based Setup Utility"

Bank F

11F, 1

Bank G

13G,

Bank H

15

Installing DIMMs

WARNING: To reduce the risk of personal injury from hot

To install the component:

1. Power down the server blade (on page 11).

internal system components to cool before touching them.

surfaces, allow the drives and the

Hardware options installation 21

Page 22

2.

Remove the server blade (on page 12).

3. Remove the access panel (on page 12).

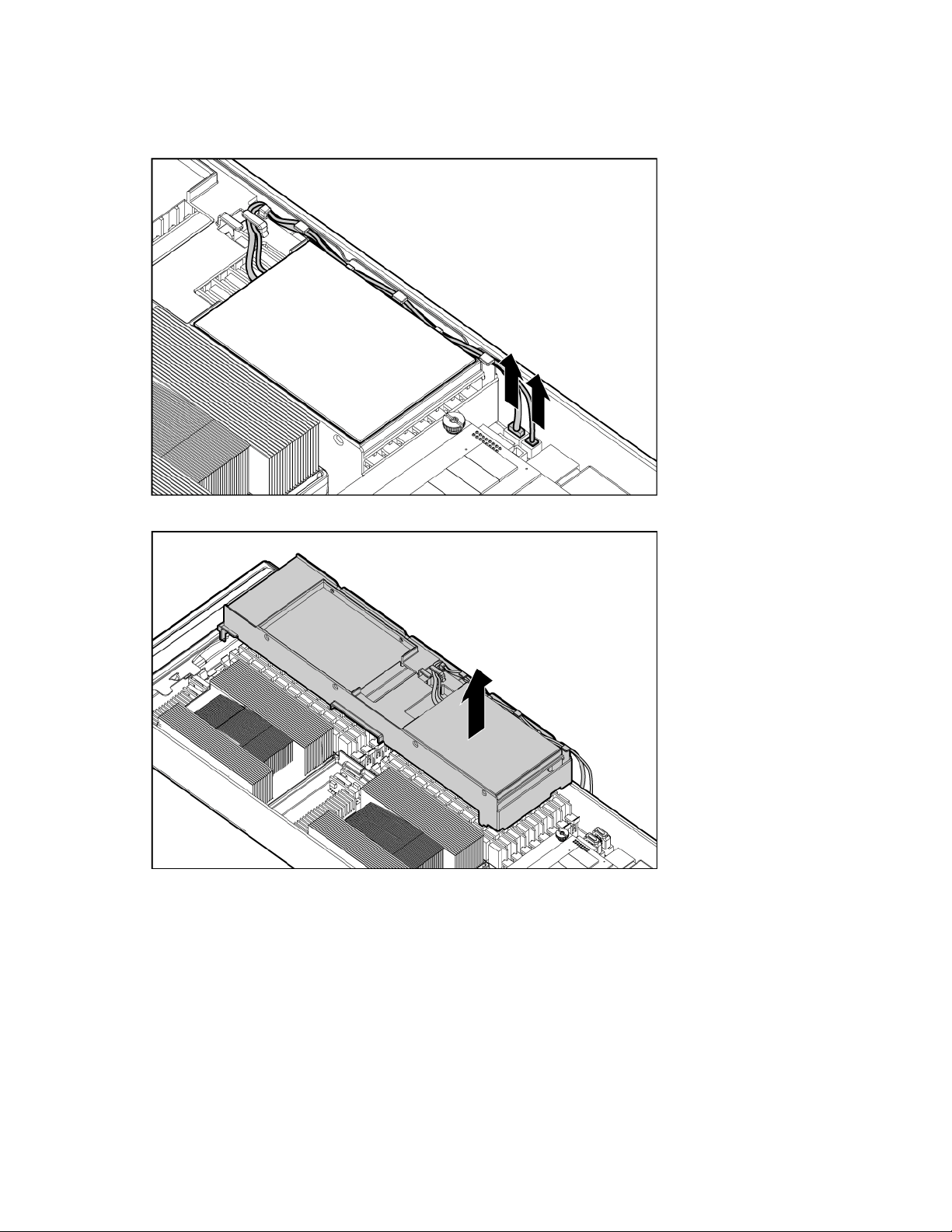

4. Disconnect the hard drive cables.

5. Remove the DIMM baffle with the hard drives and cables in place.

6. Open the DIMM slot latches.

Hardware options installation 22

Page 23

7.

Install the DIMM.

8. Install the DIMM baffle.

9. Connect the hard drive cables.

10. Install the access panel (on page 13).

11. Install the server blade ("Installing a server blade" on page 17).

Processor option

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

CAUTION: To avoid damage to the system board:

• Do not touch the processor socket contacts.

• Always install the processor socket cover after removing the processor from the socket.

• Do not tilt or slide the processor when lowering the processor into the socket.

CAUTION: To avoid damage to the processor:

• Handle the processor only by the edges.

• Do not touch the bottom of the processor, especially the contact area.

CAUTION: The heatsink thermal interface media is not reusable and must be replaced if the

heatsink is removed from the processor after it has been installed.

IMPORTANT: Processor socket 1 must be populated at all times or the server blade does not

function.

To install a processor:

1. Update the system ROM.

Hardware options installation 23

Page 24

Locate and download the latest ROM version from the HP website (http://www.hp.com/support).

Follow the instructions on the website to update the system ROM.

2. Power down the server blade (on page 11).

3. Remove the server blade (on page 12).

4. Remove the access panel (on page 12).

5. Remove the heatsink blank. Retain the heatsink blank for future use.

CAUTION: The pins on the processor socket are very fragile. Any damage to them may

require replacing the system board.

6. Remove the processor socket protective cover. Retain the cover for future use.

CAUTION: Failure to completely open the processor retaining latch prevents the processor

from seating during installation, leading to hardware damage.

Hardware options installation 24

Page 25

7.

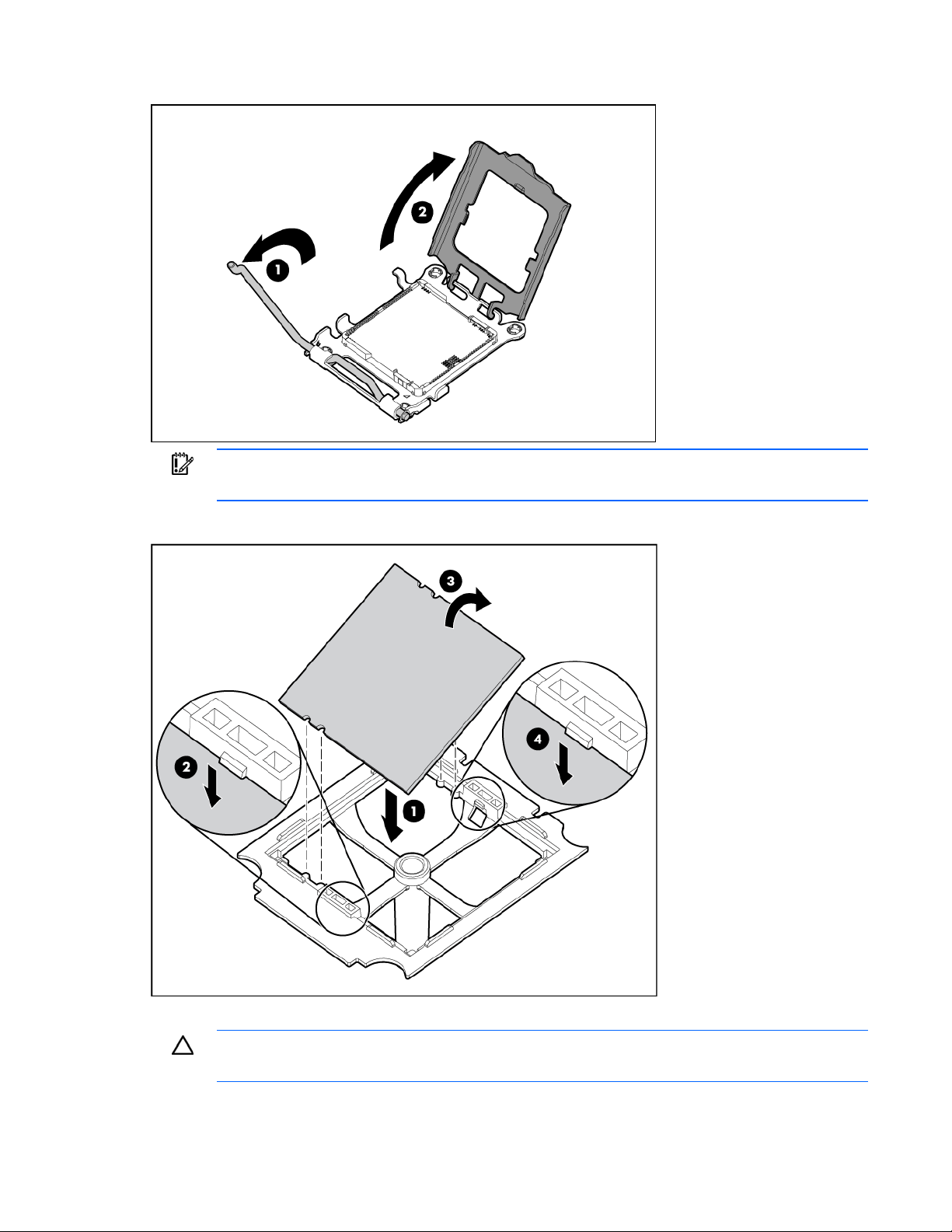

Open the processor retaining latch and the processor socket retaining bracket.

IMPORTANT: Be sure the processor remains inside the processor installation tool.

8. If the processor has separated from the installation tool, carefully re-insert the processor in the tool.

9. Align the processor installation tool with the socket and install the processor.

CAUTION: The processor is designed to fit one way into the socket. Use the alignment guides

on the processor and socket to properly align the processor with the socket.

Hardware options installation 25

Page 26

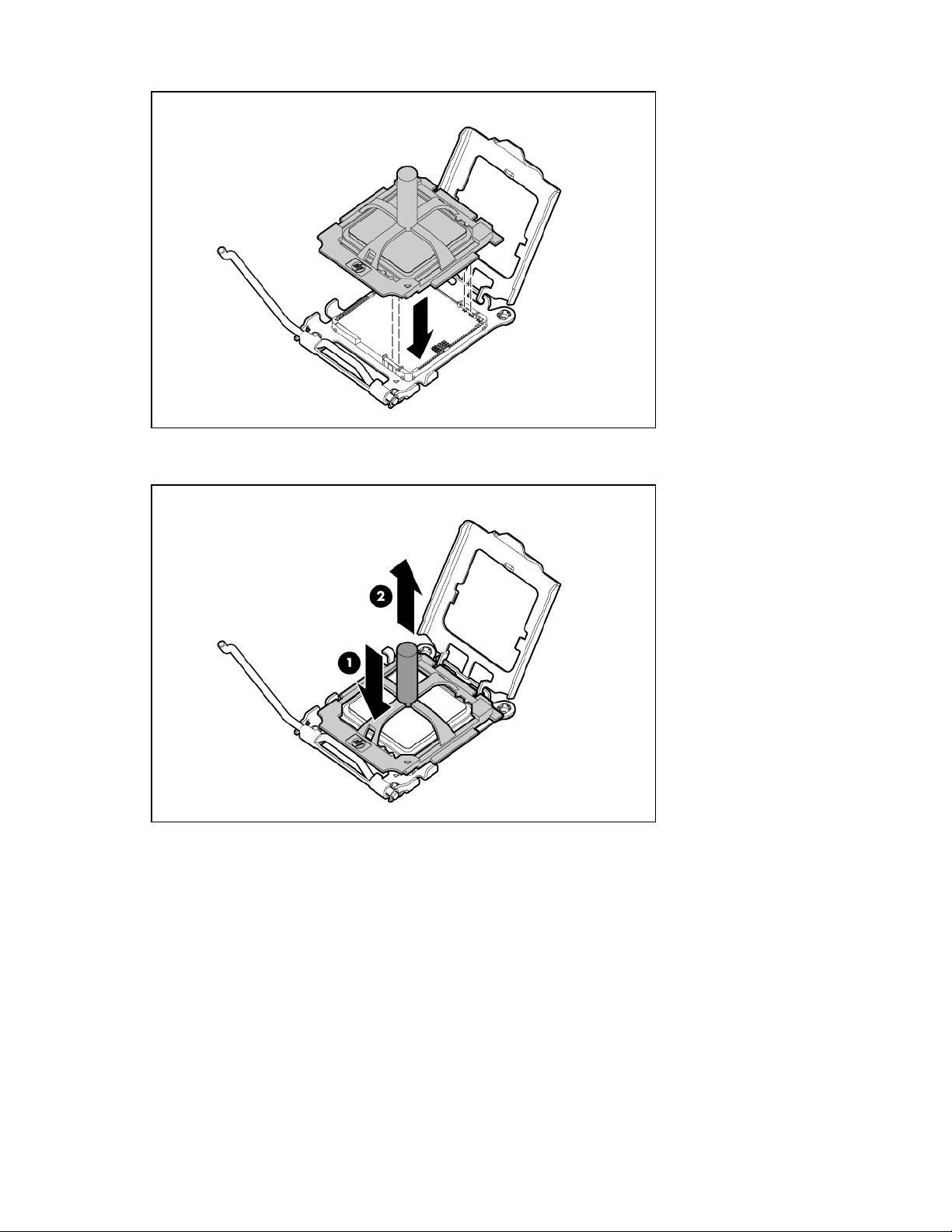

10. Press down firmly until the processor installation tool clicks and separates from the processor, and

then remove the processor installation tool.

Hardware options installation 26

Page 27

11.

Close the processor retaining bracket and the processor retaining latch.

12. Remove the thermal interface protective cover from the heatsink.

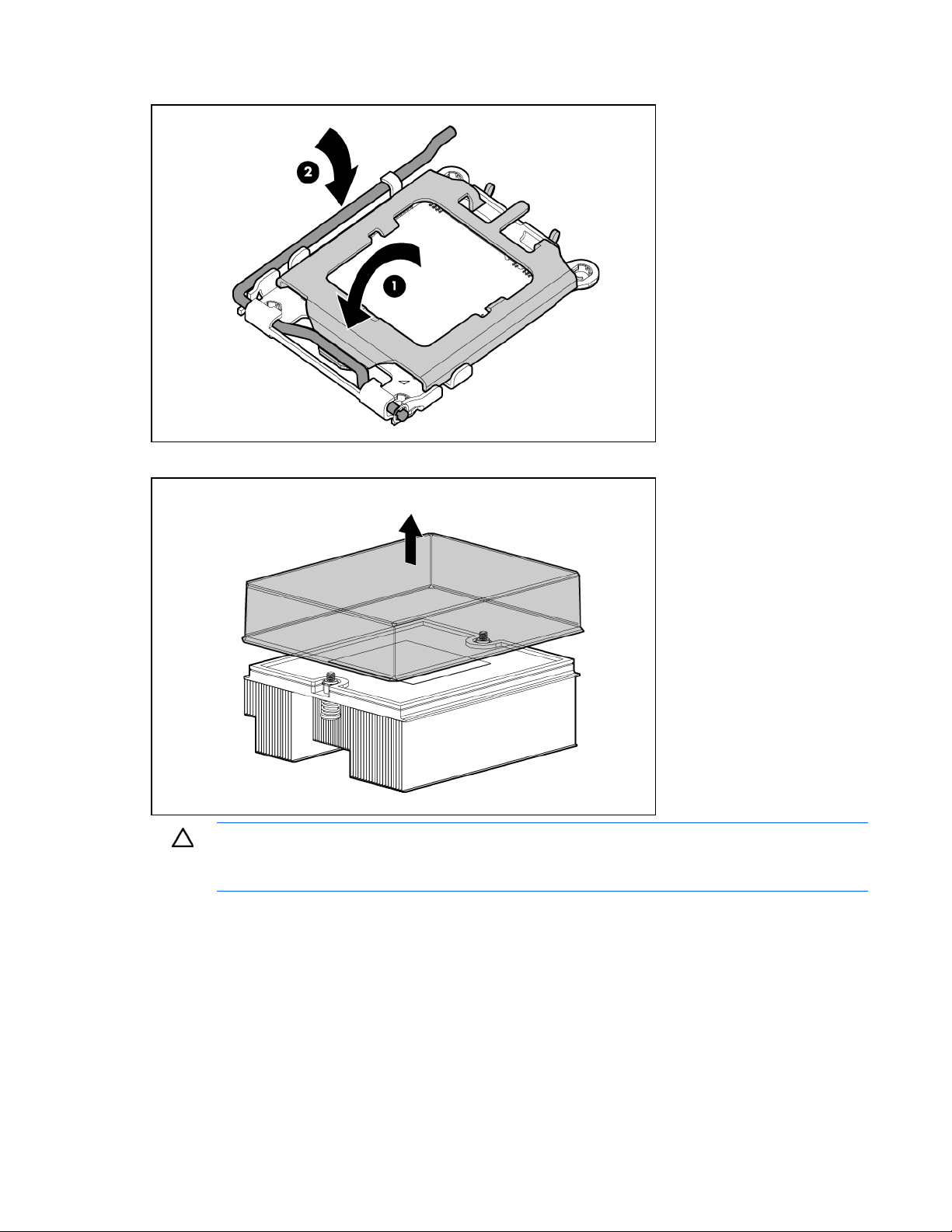

CAUTION: To avoid damage to the system board, processor socket, and screws, do not

overtighten the heatsink screws. Use the wrench supplied with the system to reduce the

possibility of overtightening the screws.

Hardware options installation 27

Page 28

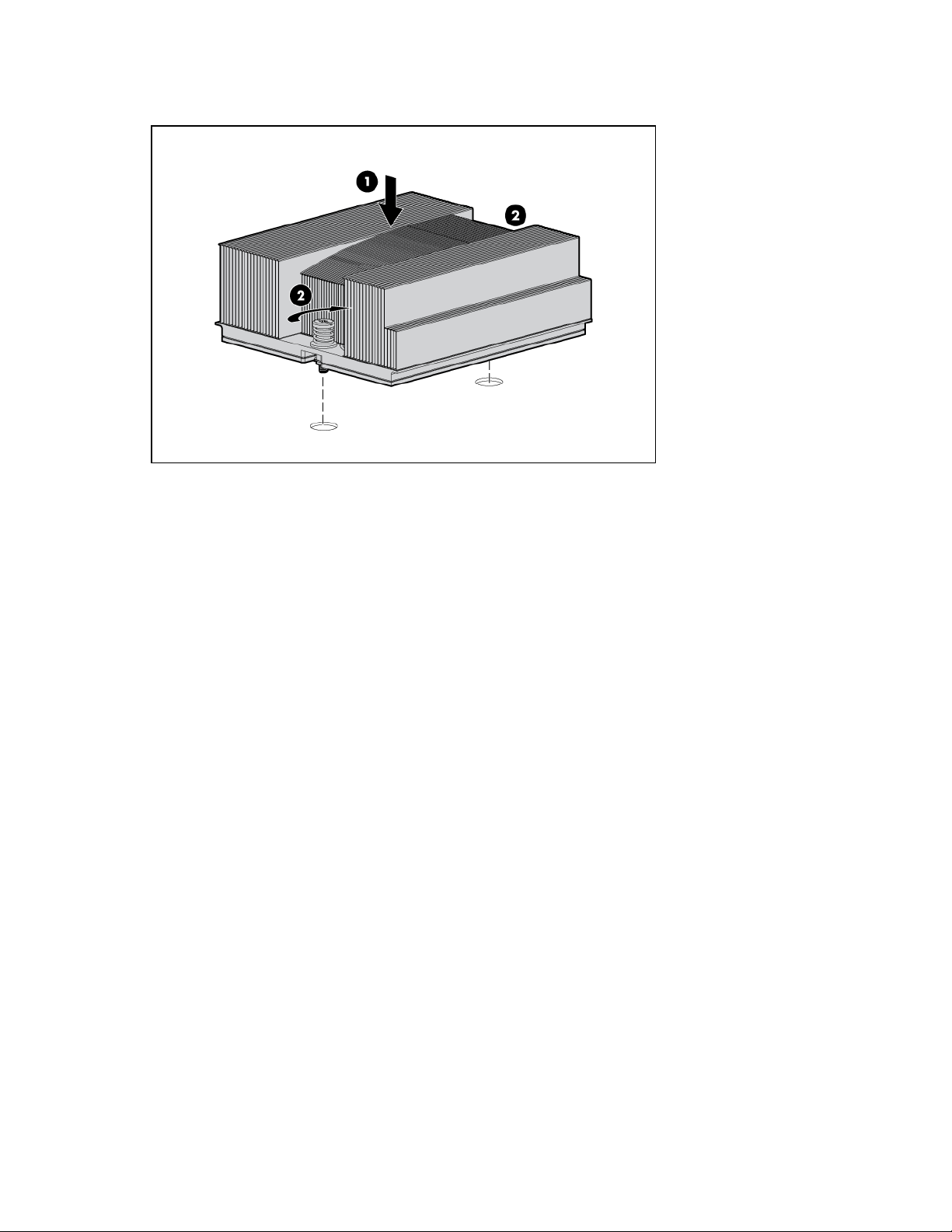

13.

Install the heatsink. Insert both screws, and then alternate tightening until the heatsink is seated

properly.

14. Install the access panel (on page 13).

15. Install the server blade ("Installing a server blade" on page 17).

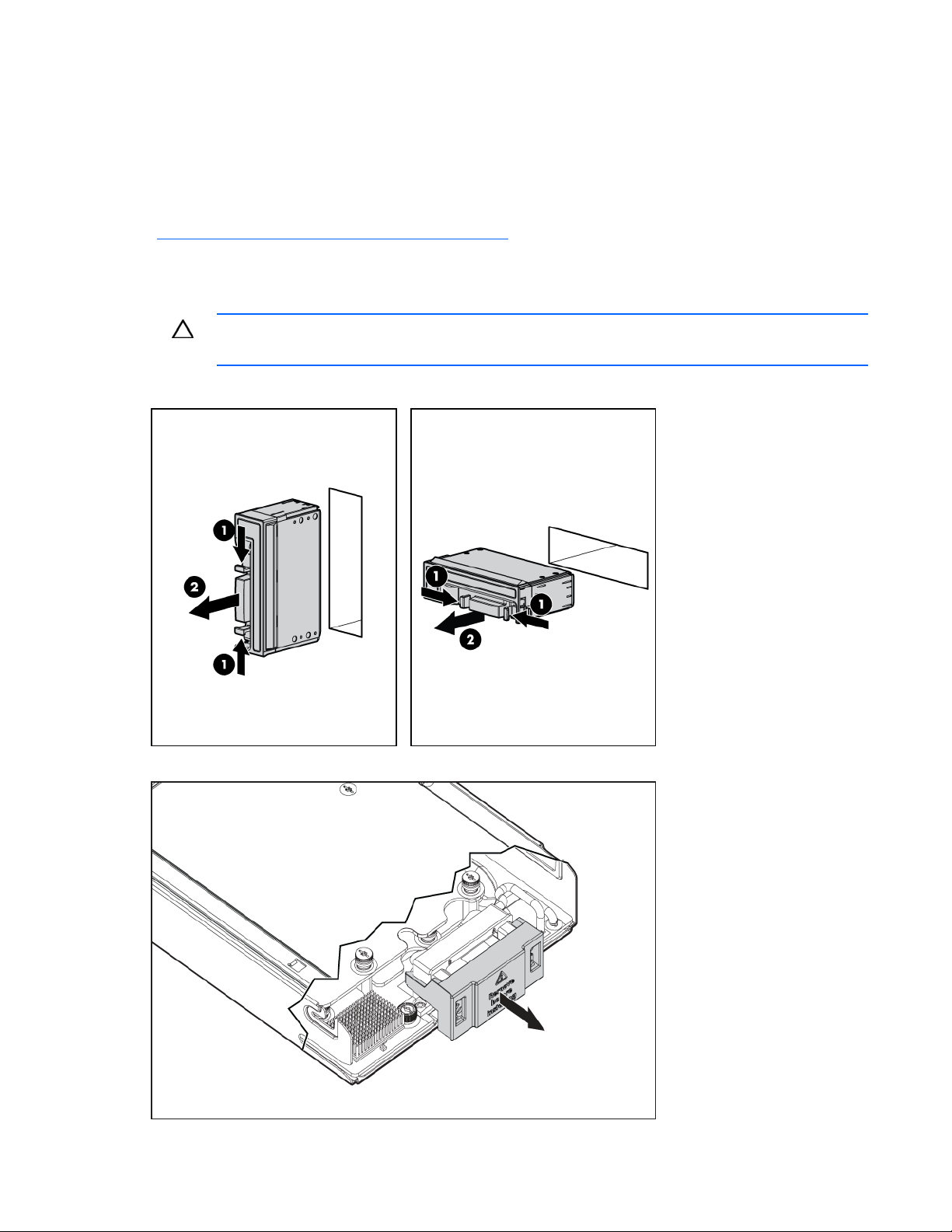

Mezzanine card option

Optional mezzanine cards are classified as Type I mezzanine cards and Type II mezzanine cards. The

card type determines where it can be installed in the server blade.

• Install Type I mezzanine cards on either mezzanine 1 connector or mezzanine 2 connector.

• Install Type II mezzanine cards only on mezzanine 2 connector.

Optional mezzanine cards enable network connectivity and provide Fibre Channel support. For

mezzanine card locations, see the

For mezzanine card signal mapping, see the

Instructions

that ship with this server blade.

To install the component:

1. Power down the server blade (on page 11).

2. Remove the server blade (on page 12).

3. Remove the access panel (on page 12).

system board components (on page 8).

HP ProLiant BL495c Generation 5 Server Blade Installation

Hardware options installation 28

Page 29

4.

Remove the mezzanine connector cover.

5. Install the mezzanine card. Press down on the connector to seat the board.

6. Install the access panel (on page 13).

7. Install the server blade ("Installing a server blade" on page 17).

Hardware options installation 29

Page 30

Cabling

Hard drive cabling

CAUTION: When routing cables, always be sure that the cables are not in a position where

they can be pinched or crimped.

Using the HP c-Class Blade SUV Cable

The HP c-Class Blade SUV Cable enables the user to perform server blade administration, configuration,

and diagnostic procedures by connecting video and USB devices directly to the server blade. For SUV

cable connectors, see "

HP c-Class Blade SUV Cable (on page 10)."

Connecting locally to a server blade with video and USB devices

Use the SUV cable to connect a monitor and any of the following USB devices:

• USB hub

• USB keyboard

• USB mouse

• USB CD/DVD-ROM drive

• USB diskette drive

Cabling 30

Page 31

Numerous configurations are possible. This section offers two possible configurations. For more

information, see "

USB support and functionality (on page 48)."

Accessing a server blade with local KVM

For this configuration, a USB hub is not necessary. To connect additional devices, use a USB hub.

CAUTION: Before disconnecting the SUV cable from the connector, always squeeze the

release buttons on the sides of the connector. Failure to do so can result in damage to the

1. Connect the SUV cable to the server blade.

2. Connect the video connector to a monitor.

3. Connect a USB mouse to one USB connector.

4. Connect a USB keyboard to the second USB connector.

equipment.

Item Description

1 Monitor

2 USB mouse

3 HP c-Class Blade SUV Cable

4 Server blade

5 Video connector

6 USB keyboard

Accessing a server blade with local media devices

Use the following configuration when configuring a server blade or loading software updates and

patches from a USB CD/DVD-ROM or a USB diskette.

Use a USB hub when connecting a USB diskette drive and/or USB CD-ROM drive to the server blade. The

USB hub provides additional connections.

Cabling 31

Page 32

1.

Connect the SUV cable to the server blade.

2. Connect the video connector to a monitor.

3. Connect a USB hub to one USB connector.

4. Connect the following to the USB hub:

o USB CD/DVD-ROM drive

o USB keyboard

o USB mouse

o USB diskette

Item Description

1 Monitor

2 USB mouse

3 HP c-Class Blade SUV Cable

4 Server blade

5 USB hub

6 USB keyboard

7 USB CD/DVD-ROM drive or diskette drive

Cabling 32

Page 33

Software and configuration utilities

Server blade deployment tools

RBSU requirement for Linux deployment

To properly install some versions of the Linux x64 operating system, the Linux x64 HPET Workaround

selection in RBSU must be enabled. If this step is not performed, a kernel panic can occur during boot.

The following operating systems are affected:

• Red Hat Enterprise Linux 4 Update 3 x86_64

• Red Hat Enterprise Linux 4 Update 4 x86_64

• SUSE SLES9 SP3 x86_64

To avoid the kernel panic issue with these operating systems, perform the following steps:

1. Access RBSU ("Using RBSU" on page 40).

2. Select the Advanced Options menu.

3. Set the Linux x64 HPET Workaround selection to Enabled.

4. Save the changes and exit the utility.

HP is working with Linux providers to address this problem in future revisions of these operating systems.

This option may not be required with newer revisions of Red Hat Enterprise Linux or SUSE Linux Enterprise

Server.

Software drivers and additional components

HP offers the following additional software components for server blades:

• Health and Wellness driver and IML viewer

• iLO 2 Management interface driver

• Rack infrastructure interface service

For Microsoft® Windows® OS users, these items are included in the HP ProLiant

Edition, available from the

Linux OS users can download these components

http://www.hp.com/products/servers/linux

(

HP website (http://www.hp.com/servers/lights-out

from the

).

HP website

iLO 2 Standard Blade

).

ebsite

For information on how to use these components with a Linux OS, see the

http://h18000.www1.hp.com/products/servers/linux/documentation.html

(

HP w

).

Software and configuration utilities 33

Page 34

HP Bl

adeSystem c-Class Advanced management

iLO 2 is a standard component of ProLiant c-Class server blades that provides server health and remote

server blade manageability. Its features are accessed from a network client device using a supported we

browser. In addition to other features, iLO 2 provides keyboard, mouse, and video (text and graphics)

capability for a server blade, regardless of the

iLO 2 includes an intelligent microprocessor, secure memory, and a dedicated network interface. This

sig

de n makes iLO 2 independent of the host server blade and its OS. iLO 2 provides remote access to

any ides other server blade management functions.

authorized network client, sends alerts, and prov

Using a supported web browser, you can:

• tely access the console of the host server blade, including all text mode and graphics mode

Remo

screens with full keyboard and mouse controls.

• Remotely power up, power down, or reboot the host server blad

• Remotely boot a host server blade to a virtual media image to perform a ROM upgrade o

OS.

• state of the host server blade.

Send alerts from iLO 2 regardless of the

• Access advanced troubleshooting features provided by iLO 2.

• Launch a web browser, use SNMP alerting, and diagno

• Configure static IP bay settings for the dedicated iLO 2 management NICs on each server blade in

an enclosure for faster deployment.

state of the host OS or host server blade.

e.

r install an

se the server blade with HP SIM.

b

To connect to the server blade using iLO 2, install the server blade in an enclosure. enclosure assigns an

IP address to enable iLO 2 connectivity to

The c-Class tab enables you to control specific se

based status for the HP BladeSystem configuratio

For detailed information about iLO 2, refer to the

http://www.hp.com/servers/lights-out).

(

the server blade.

Network-based PXE deployment

PXE is a component o

execute an NBP from a PXE server and to execute a pre-configured image. The image can be an OS

image created by software utilities or a boot diskette image. This feature enables a user to configure a

Deploym ov

server blade and install an OS over a network.

ent erview

When a PXE-enabled target server blade boots, it ob

server blade obtains the name of the NBP from the appropriate boot server. Then, the target server blade

uses TFTP to download the NBP from the boot server and executes the image.

IMPORTANT: To connect to a network with a Pass-Thru module, always connect the Pass-Thru

module to a network device that supports Gigabit speed.

f the Intel® WfM specification. The PXE model enables server blades to load and

ttings for the HP BladeSystem. iLO 2 also provides webn.

HP Integrated Lights-Out User Guide on the HP website

tains an IP address from a DHCP server. The target

For each s

The server blade defau nctions to NIC 1, but any of the NC series NICs in the server blade can

erver blade being deployed, the PXE server must be connected to the NIC designated for PXE.

lts PXE fu

Software and configuration utilities 34

Page 35

be designated for PXE in RBSU. For NIC connector locations, refer to the documentation included with the

server blade.

NOTE: Actual N

IC numeration depends on several factors, including the OS installed on the

server blade.

o deploy an OS to multiple server blades, install a PXE deployment server on a network.

T

Deployment infrastructure

IMPORTANT: To connect to a network with a Pass-Thru module, always connect the Pass-Thru

module to a network device that supports Gigabit speed.

To es d PXE deployment infrastructure, provide the following software and minimum

tablish a network-base

hardware:

• e

Cli nt PC (administrative workstation)

o AMD Athlon™ XP processor (700 MHz or gr

or Intel® Pentium® III or higher processor (700 MHz or greater recommended)

o 128 MB of RAM

o Microsoft® Windows® 2000 Professional or Microsoft® Wi

o Microsoft® Internet Explorer 5.5 or above with 128-bit encr

o C with 10/100 RJ-45 connector

Ethernet NI

o orking and an IP address compatible with one of the following: the iLO 2 Diagnostic

TCP/IP netw

Port IP address or an assigned DHCP or static

o drive

CD-ROM drive, CD/DVD-ROM drive, and/or diskette

o e Environment versions:

Any of the following Java™ Runtim

1.3.1_02

eater recommended), AMD Athlon™ 64 processor,

ndows® XP OS

yption

IP address

1.3.1_07

1.3.1_08

1.4.1 for Windows® users only

1.4.2 for Linux users only

Access the Java™

http://java.sun.com/products/a ).

(

• ment)

DHCP server (IP address assign

o AMD Athlon™ XP processor (700 MHz or

Runtime Environment versions at the

rchive/index.html

greater recommended), AMD Athlon™ 64 processor,

or Intel® Pentium® or Pentium® II 200-MHz or faster processor

o

64 MB of RAM

o 64 MB of free har

o 10-Mb/s network adapter

• E ver (storing boot images)

PX deployment ser

o AMD Athlon™ XP processor (700 MHz or greater recommen

d drive space

or Intel® Pentium® III or higher processor (500 MHz recomm

o 256 MB of RAM

HP website

ded), AMD Athlon™ 64 processor,

ended)

Software and configuration utilities 35

Page 36

o

10-Mb/s network adapter

o CD-ROM drive

•

Windows® repository server (Windows® or Linux deployment)

o d

Windows® 2000 or Windows Server® 2003 OS installe

o Network connection

o CD-ROM drive

o vailable disk space

1.5 GB of a

o orking and an IP address compatible with one of the following: the iLO 2 Diagnostic

TCP/IP netw

Port IP add

o ive

CD-ROM drive and/or diskette dr

o Runtime Environment versions:

Any of the following Java™

ress or an assigned DHCP or static IP address

1.3.1_02

1.3.1_07

1.3.1_08

Deplo m

y ent methods

ree ed:

Th primary deployment methods are support

• PXE deployment (on page 36)

• CD-ROM deployment (on page 37)

• Diskette image deployment (on page 38)

PXE deployme

PXE enables server blades to load an image over the network from a PXE server, and then execute it in

memory. The first NIC on the server blade is the default PXE boot NIC, bu

NICs can be configured to boot PXE. For more information, refer to "

page 34)."

NOTE: Actual NIC numeration depends on several factors, including the OS installed on the

1.4.1 for Windows®

users only

1.4.2 for Linux users only

Access the Java™ Runtime Environment ver

h

ttp://java.sun.com/products/archive/index.html).

(

sions at the

HP website

ork server with an OS in• Netw stalled

IMPORTANT: To deploy a server blade without the RDP, create a bootable diskette or image

of a

bootable diskette.

nt

t any of the other NC series

Network-based PXE deploy

server blade.

ment (on

HP recommends using one of the following methods for PXE deployment:

• HP ProLiant Essentials RDP ("HP ProLiant Essentials R

apid Deployment Pack" on page 37)

• SmartStart Scripting Toolkit (on page 37)

Software and configuration utilities 36

Page 37

A nu ber

m of third-party PXE deployment tools are available for Windows® and Linux. For additional

informatio

ftp://ftp.compaq.com/pub/products/servers/management/pxe_wp.pdf

(

HP ProLiant Essentials Rapid Deployment Pack

n, refer to the

HP website

).

NOTE: To deploy server blades in an existing server blade enclosure, always use the most

recent version of RDP available at the

HP website (http://www.hp.com/servers/rdp).

The RDP software is the preferred method for rapid, high-volume server deployments. The RDP software

integrates two powerful products: Altiris Deployment Solution and the HP ProLiant Integration Module.

The intuitive graphical user interface of the Altiris Deployment Solution console provides simplified point-

ations that enable you to deploy target servers, including server blades, and-click and drag-and-drop oper

remotely. It enables you to perform imaging or scripting functions and maintain software images.

For more information about the RDP, refer to the HP ProLiant Essentials Rapid Deployment Pack CD or

refer to the

HP website (http://www.hp.com/servers/rdp).

SmartStart Scripting Toolkit

The SmartStart Scripting Toolkit is a server deployment product that delivers an unattended autom

installation for high-volume server deployments. The SmartStart Scripting Toolkit is designed to support

ProLiant BL, ML, and DL servers. The toolkit includes a modular set of utilities and imp

ortant documentation

that describes how to apply these new tools to build an automated server deployment process.

Using SmartStart technology, the Scriptin

g Toolkit provides a flexible way to create standard server

configuration scripts. These scripts are used to automate many of the manual steps in the server

configuration process

. This automated server configuration process cuts time from each server deployed,

making it possible to scale server deployments to high volumes in a rapid manner.

For more information, and to download the SmartStart Scripting Toolkit, refer to the

http://www.hp.com/servers/sstoolkit).

(

HP website

ated

CD-RO oyme

M depl nt

CD-ROM ootable CD that executes scripts to configure the hardware and

install the OS.

deployment involves using a b

After the OS is configured, the server blade can access the network to locate the scripts

and files necessary for deployment. Before beginning t

the network.

NOTE: For more informa

that ship with the enclosure.

Two methods are available for CD-ROM deployment:

• iLO virtual CD-ROM (on page

•

USB CD-ROM (on page 38)

iLO t

vir ual CD-ROM

To deploy with a boot CD:

1. Do one of the following:

o Insert the boot CD into the client PC using the iLO 2 Remote Console.

he deployment process, connect the server blade to

tion about hardware and cabling configurations, see the documents

37)

Software and configuration utilities 37

Page 38

o

Use iLO 2 to create an image file of the boot CD.

o Copy the image of the boot C

2. Remotely access the server blade through iLO 2. See "HP BladeSystem c-Class advanced

on page 34)."

management

3. Click the Virtual Media tab.

4. Select the Virtual Media applet.

Use the Virtual Media applet to select the local CD or image file and connect the Virtual CD to the

5.

server blade.

6. Use the iLO 2 Virtual Power Button feature to reboot the server blade.

7. After the server blade boot

(

D to a location on the network or the client PC hard drive.

s, follow the normal network installation procedure for the OS.

USB CD-ROM

This art also allows for manual

method uses SmartStart to facilitate loading the OS. However, SmartSt

loading of the OS and drivers.

d

To eploy with a boot CD:

1. Use the local I/O cable to connect a USB CD-ROM drive to the server blade. Refe

locally to a server blade with video and USB devices

2. Insert the boot CD into the USB CD-ROM drive.

3. Rebo

ot the server blade.

(on page 30)."

r to "Connecting

Diskette

4. After the server blade boots, follow the normal installation procedure for an OS.

Windows Server® 2003 cannot be installe

completely blank (no partitions defined). To install Windows Server® 2003

meth

ods:

• e a partition on the hard drive that Windows Server® 2003 will be loaded on.

Mak

• Use the SmartStart CD 7

.60 or later.

d from a USB CD-ROM on the I/O cable if the hard drive is

, use one of the following

• Use the Rapid Deployment Pack. For instructions, see the HP website

http://h18013.www1.hp.com/products/servers/management/rdp.html?jumpid=reg_R1002_USE

(

N).

image deployment

To deploy with a diskette imag

executes a script that configures the hardware and installs the OS. The diskette enables the s

to access the required deployment scripts and files on the network.

This metho

server, Mi e, or a Linux file share. For more information, refer to "

infrastructure

Before beginning the deployment process, connect the server blade to the network.

d implies a deployment infrastructure that may include an administrator workstation, PXE

crosoft® Windows® file shar

(on page 35)."

NOTE: For more information abo

that ship with the enclosure.

e, the user creates a DOS-based network-enabled boot diskette that

erver blade

ut hardware and cabling configurations, see the documents

Deployment

Two methods are available for diskette image deployment:

Software and configuration utilities 38

Page 39

• iLO virtual floppy (on page 39)

• PXE ("PXE deployment" on

page 36)

iLO virtual floppy

To d o

epl y with a boot diskette:

1.

Do one of the following:

o Insert the boot diskette into the client PC using the iLO 2 Remote Console.

o Use iLO 2 to create an ima

o Copy the image of the bo

2. Remotely access the server blade

management

3. edia tab.

Click the Virtual M

4. Select the Virtual Media applet.

5. Use the Virtual Media applet to select the local diskette or image file and connect the Virtu

the server blade.

6. Use the iLO 2 Virtual Pow

7. After the server blade boots, follow the normal network installation procedure for the OS.

(on page 34)."

ge file of the boot diskette.

ot diskette to a location on the network or the client PC hard drive.

through iLO 2. See "HP BladeSystem c-Class advanced

al CD to

er Button feature to reboot the server blade.

Creating a boot diskette

The SmartStart Scripting Toolkit provides the tools and information for creating a boot diskette. For deta

refer to the

HP website (http://www.hp.com/servers/sstoolkit).

the

As an alternative method, configure the hardware manually with RBSU and the iLO 2 remote cons

With this method, the disk is more generic and integrates with an existing network OS installation

process. For more information, refer to "

To operate properly, the server bla

supported OS, refer to the

SmartStart Scripting Toolkit User Guide and download the latest version of the software

Configuration too

Smar

tStart software

SmartStart is a collection of software that optimizes single-server setup, providing a simple and consistent

way to dep

resulting in proven, reliable configurations.

SmartStart assists the deployment process by performing a wide range of configuration activities,

lu

inc ding:

• re using embedded configuration utilities, such as RBSU and ORCA

loy server configuration. SmartStart has been tested on many ProLiant server products,

Configuring hardwa

HP BladeSystem c-Class advanced management (on page 34)."

de must have a supported OS. For the latest information on a

HP web ).

site (http://www.hp.com/go/supportos

ls

ils,

from

ole.

• Preparing the system for installing "off-the-shelf" versions of leading operating system software

• Installing optimized server drivers, management agents, and utilities automatically with every

assisted installation

Software and configuration utilities 39

Page 40

• Testing server hardware using the Insight Diagnostics Utility ("HP Insight Diagnostics" on page 49)

Installing software drivers directly from t• he CD. With systems that have internet connection, the

SmartStart Autorun Menu provides access to a complete list of ProLiant system software.

• Enabling access to the Array Configuration Utility (on page 42), Array Diagnostic Uti

SmartStart is included in the HP ProLiant E

SmartStart software, refer to the HP ProLia

(

HP RO

RBSU is a configuration utility embedded in Pr

activities that can include the followi

• Configuring system devices and instal

• Enabling and disabling system

• Displaying system in

• Selecting the primary boot controller

• Configuring memory options

• Lan

For more information on RBSU, see the

or the

50), and

http://h18013.www1.hp.com/products/servers/management/smartstart/index.html).

Erase Utility (on page 44)

ssentials Foundation Pack. For more information about

nt Essentials Foundation Pack or the

HP website

M-Based Setup Utility

oLiant servers that performs a wide range of configuration

ng:

led options

features

formation

guage selection

HP ROM-Based Setup Utility User Guide on the Documentation CD

HP website (http://www.hp.com/support/smartstart/documentation).

lity (on page

Using R SU

B

s

To u e RBSU, use the following keys:

To ac

• cess RBSU, press the F9 key during power-up when prompted.

• na

• To m

• To access Help for a highlighted configuration option, press the F1 key.

Default configuration settings are applied to the server at one of the following times:

• Upon the first system po

• After defaults have been re

Default configuration settings are sufficient for proper typical server operation, but configuration settings

Auto-co

can be modified using R

nfiguration process

The ORCA utility is supported when using an optional Smart Array con

attac

vigate the menu system, use the arrow keys.

ake selections, press the ToEnter key.

IMPORTANT: RBSU automatically saves settings when you press the Enter key. The utility does

not prompt you for confirmati

setting, you must select a different setting

wer-up

stored

BSU. The system will prompt you for access to RBSU with each power-up.

h storage blade.

on of settings before you exit the utility. To change a selected

and press the

Enter key.

troller mezzanine card or a direct-

Software and configuration utilities 40

Page 41

The auto-c e first time. During the

onfiguration process automatically runs when you boot the server for th

power-up sequence, the system ROM automatically configures the entire system without needing any

intervent

defa lt se

ion. During this process, the ORCA utility, in most cases, automatically configures the array to a

u tting based on the number of drives connected to the server.

NOTE: The server may not support all the following examples.

NOTE: If th oot drive is not empty or has been written to in the past, ORCA does not

automatically configure the arra ust run ORCA to configure the array settings.

e b

y. You m

Drives installed Drives used RAID level

1 1 RAID 0

2 2 RAID 1

3, 4, 5, or 6 3, 4, 5, or 6 RAID 5

More than 6 0 None

To change any ORCA default settings and override the auto-configuration process, press the F8 key w

hen

prompted.

By default, the auto-configuration process configures the system for the English language. To change any

default settings in the auto-configuration process (such as the settings for langu

primary boot controller), execute RBSU by pressing the

selected,

exit RBSU and allow the server to reboot automatically.

F9 key when prompted. After the settings are

age, operating system, and

For more information on RBSU, see the

or the

Boot options

Near the end of the boot process, the boot options screen is displayed. This screen is visible for severa

s co oot from a supported boot device. During this time, you can do

e nds before the system attempts to b

the following:

• Access RBSU by pressing the F9 key.

• Access the Syst

Inspect) by pressing the

BIOS S

• Force a PXE Network boot by pressing the F12 key.

erial Console

BIOS Serial Console allows you to configure the serial port to view POST error messages and run

remotely through a serial connection to the server COM port. The server that you are remotely configuring

does not require a keyboa

For more information about BIOS Serial Console, see the

Documentation CD or the

HP ROM-Based Setup Utility User Guide on the Documentation C

HP website (http://www.hp.com/support/smartstart/documentation).

em Maintenance Menu (which enables you to launch ROM-based Diagnostics or

F10 key.

rd and mouse.

BIOS Serial Console User Guide on the

HP website (http://www.hp.com/support/smartstart/documentation).

D

l

RBSU

Software and configuration utilities 41

Page 42

Configu n

ri g AMP modes

Not

supp U enables the following advanced

mem

• Advanced ECC Mode—Provides memory protection beyond Standard ECC. All single-bit failures

• is set

• Mirrored Memory Mode—Provide

• RAID Memory Mode—Provides protection levels similar to Mirrored Memory Mode, and it requires

all ProLiant servers support all AMP modes. RBSU provides menu options only for the modes

orted by the server. Advanced memory protection within RBS

ory.

and some multi-bit failures can be corrected without resulting in system downtime.

Online Spare Mode—Provides protection against failing or degraded DIMMs. Certain memory

aside as spare, and automatic failover to spare memory occurs when the system detects a degraded

DIMM. DIMMs that are likely to receive a fatal/uncorrectable memory error are removed from

operation automatically, resulting in less system downtime.

See the server-specific user guide for DIMM po

s protection against uncorrectable memory errors that would

otherwise result in system failure. I

uncorrectable memory error occur

mirrored copy. The system continues to operate norma

supports hot-plug memory, the failed memory c

less memory allocation than fu

n this mode, the system maintains two copies of all data. If an

s, the system automatically retrieves the good data from the

ll redundancy.

pulation requirements.

lly without any user intervention. If the system

an be replaced while the system continues to operate.

Array o

C nfiguration Utility

ACU is a browser-based utility with the following features:

• Runs as a local application or remote service

• Supports online array capacity expansion, logical drive extension, assignment of online spares,

RAID or stripe size migration

• Suggests the optimum configuration for an unconfigured system

• Provides different operating modes, enabling faster configuration or greater control over the

configuration options

•

Remains available any time that the server is on

• Displays on-screen tips for individual steps of a configu

For optimum performance, the minimum display settings are 800 × 600 resolution and 256 colors.

Servers running Micros

For Linux servers, refer to the README.TXT file for additional browser and support information.

For more information, refer to the

the Documentation CD or the

oft® operating systems require Internet Explorer 5.5 (with Service Pack 1) or later.

Configuring Arrays on

HP website (http://www.hp.co ).

HP Smart Array Controllers Reference Guide on

Option ROM Configuration for Arrays

and

ration procedure

m

e O n optional Smart Array controller mezzanine card or a direct-

Th RCA utility is supported when using a

ac

att h storage blade.

Before installing an operating system, you can use the ORCA utility to create the fi

RAID levels, and establish online spare configurations.

The utility also provides support for the following functions:

Software and configuration utilities 42

rst logical drive, assign

Page 43

• Reconfiguring one or more logical drives

• Viewing the current logical drive configuration

• Deleting a logical drive configuration

• Setting the controller to be the boot controller

If you do not use the utility, ORCA will default to the standard configuration.

For more information regarding array controller configuration, refer to the controller user guide.

For more information regarding the default configurations that ORC

up

Set Utility User Guide

Re-enteri

After you replace the system board, you must r

1. During the server startup sequence, press the F9 k

2. Select the System O

3. Select Serial Number. The following warning i

4. Press the Enter key to clear the warning.

5. Enter the serial number and

6. Select Product ID.

7. Enter the product ID and press the

8. Press the Esc key to close the menu

9. Press the Esc key to exit RBSU.

10. Press the F10 key to confirm exiting RBSU. The server will automatically reboot.

A uses, refer to the

on the Documentation CD.

HP ROM-Based

ng the server serial number and product ID

e-enter the server serial number and the product ID.

ey to access RBSU.

ptions menu.

s displayed:

WARNING! WARNING! WARNING!

during the manufacturing process and should NOT be modified. This option

should only be used by

always match the serial number sticker located on the chas

press the Enter key.

The serial number is loaded into the system

qualified service personnel. This value should

sis.

Enter key.

.

Man

Autom

agement tools

atic Server Recovery

ASR is a feature that caus

as a blue screen, ABEND, or panic. A system fail-safe timer, the ASR timer, starts when the System

Management drive

functioning properl

the timer expires and restarts the server.

ASR increases server availability by restarting the server within a specified time after a system hang or

shutdown. At the same time, the HP SIM console notifies you by sending a message to a designated

pager number that ASR has restarted the system. You can disable ASR from the HP SIM console or

through RBSU.

es the system to restart when a catastrophic operating system error occurs, such

r, also known as the Health Driver, is loaded. When the operating system is

y, the system periodically resets the timer. However, when the operating system fails,

Software and configuration utilities 43

Page 44

ROMPaq utility

The ROMPaq utility enables you to upgrade the system firmware (BIOS). To upgrade the firmware, insert

a ROMPaq diskette into the diskette drive or ROMPaq USB Key into an available USB port and boot the

system. Online versions of the ROMPaq utility are also available for updating the system firmware.

The ROMPaq utility checks the system and provides a choice (if more than one exists) of available

firmware revisions.

iLO 2 ec

For more information about the ROMPaq utility, see the

t hnology

e i vides server health and

Th LO 2 subsystem is a standard component of selected ProLiant servers that pro

o essor, secure memory,

rem te server manageability. The iLO 2 subsystem includes an intelligent microproc

and a dedicated network interface. This design makes iLO 2 independent of the host server and its

operating system. The iLO 2 subsystem provides remote access to any authorized network client, sends

alerts, and provides other server managem

Using iLO 2,

• Remotel

• nd

Se alerts from iLO 2 regardless of the state of the host server.

• Acce

• Diag and SNMP alerting.

For more information about iLO 2 features (which may require an iLO Advanced Pack or i

for BladeSystem license), see the iLO 2 documentation on the Documentatio

http://www.hp.com/servers/lights-out).

(

ss advanced troubleshooting features through the iLO 2 interface.

nose iLO 2 using HP SIM through a web browser

Erase Utility

CAUTION: Perform a bac

to its original factory state, deletes the current h

array setup and disk partitioning, and erases al

instructions for using this utility.

HP website (http://www.hp.com/go/support).

ent functions.

you can:

y power up, power down, or reboot the host server.

kup before running the System Erase Utility. The utility sets the system

ardware configuration information, including

l connected hard drives completely. Refer to the

n CD or on the

LO Advanced

HP website

Run the Erase Utility if you must erase the system for the following reasons:

• You want to install a new operating system on a server with an existing operating system.

• You encounter an error when completing the steps of a factory-installed operating syste

The Erase Utility can be accessed from the

software

" on page 39).

Maintenance Utiliti

StorageWorks library and tape tools

HP StorageWorks L&TT provides functionality for firmware downloads, verification of device operation,

maintenance procedures, failure analysis, corrective service actions, and some utili

pr s s at

ovider eamless integration with HP hardware support by generating and emailing support tickets th

delive a s

napshot of the storage system.

m installation.

es menu of the SmartStart CD ("SmartStart

ty functions. It also

Software and configuration utilities 44

Page 45

For more information, and to download the utility, refer to the StorageWorks L&TT website

http://h18006.www1.hp.com/products/storageworks/ltt).

(

HP Systems Insight Ma

HP SIM is a web-based application that allows system administrators to accomplish normal ad

tasks from any remote location, using a web browser. HP SIM provides device management capabiliti

that consolidate and integrate management data from HP and third-party devices.

IMPORTANT: You must install and use HP SIM to benefit from the Pre-Failure Warranty for