HP Pro 3080, Pro 3005 Disassembly Instructions Manual

Product Category: Personal Computers

Marketing Name / Model

[List multiple models if applicable.]

HP Pro 3080 Microtower Business PC

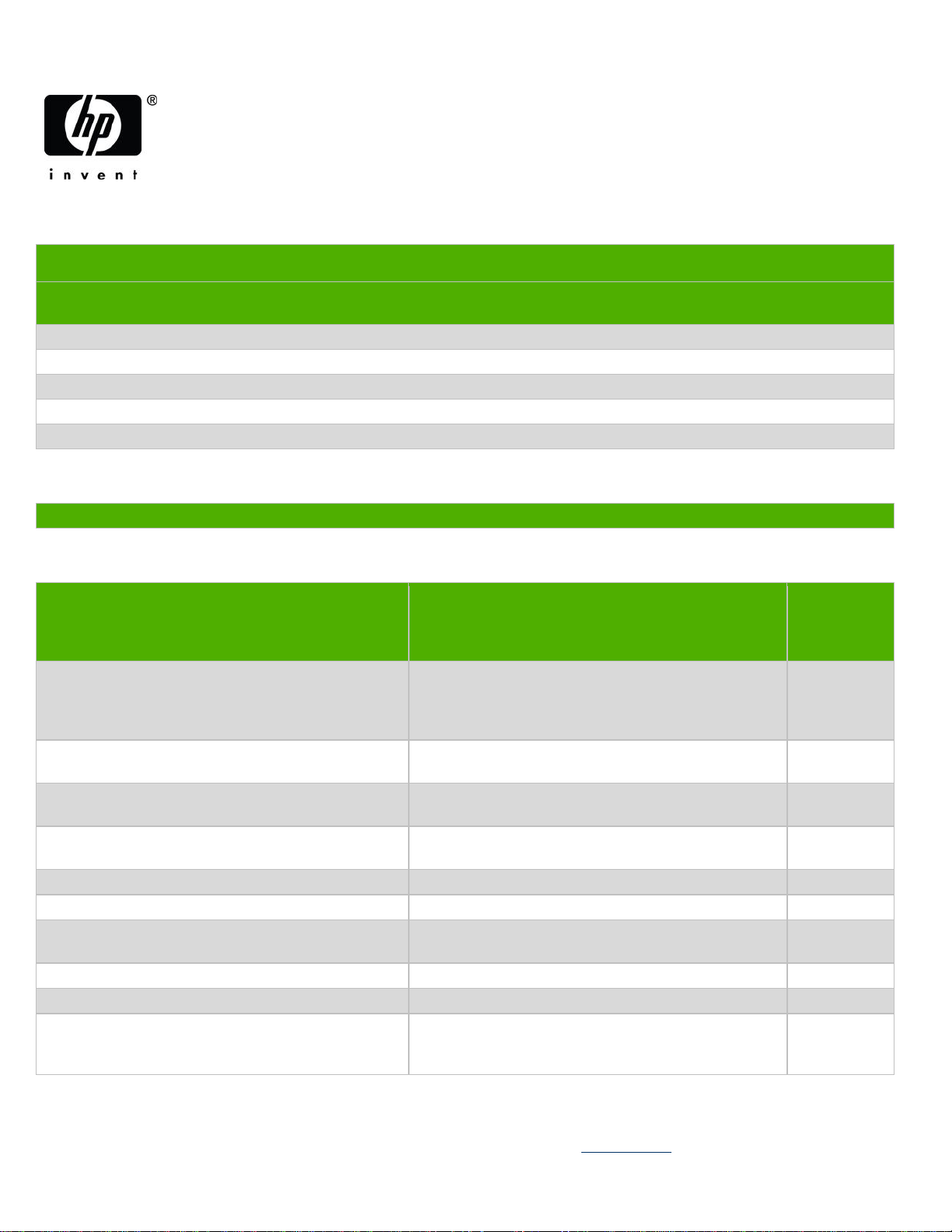

1.0 Items Requiring Selective Treatment

Item Description

Notes

Quantity of

items

included in

product

Printed Circuit Boards (PCB) or Printed Circuit

Assemblies (PCA)

With a surface greater than 10 sq cm

2(1 sys

board,

1 P/S

board)

Batteries

All types including standard alkaline and lithium coin

or button style batteries

1

Mercury-containing components

For example, mercury in lamps, display backlights,

scanner lamps, switches, batteries

0

Liquid Crystal Displays (LCD) with a surface

greater than 100 sq cm

Includes background illuminated displays with gas

discharge lamps

0

Cathode Ray Tubes (CRT)

0

Capacitors / condensers (Containing PCB/PCT)

0

Electrolytic Capacitors / Condensers measuring

greater than 2.5 cm in diameter or height

6( P/S board

Capacitors,)

External electrical cables and cords

0

Gas Discharge Lamps

0

Plastics containing Brominated Flame Retardants

weighing > 25 grams (not including PCBs or PCAs

already listed as a separate item above)

Fans

3

Product End-of-Life Disassembly Instructions

Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions

for the disassembly of HP products to remove components and materials requiring selective treatment, as defined by EU

directive 2002/96/EC, Waste Electrical and Electronic Equipment (WEEE).

1.1 Items listed below are classified as requiring selective treatment.

1.2 Enter the quantity of items contained within the product which require selective treatment in the right column, as

applicable.

EL-MF877-00 Page 1

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Components and parts containing toner and ink,

including liquids, semi-liquids (gel/paste) and toner

Include the cartridges, print heads, tubes, vent

chambers, and service stations.

0

Components and waste containing asbestos

0

Components, parts and materials containing

refractory ceramic fibers

0

Components, parts and materials containing

radioactive substances

0

1.3 Markings for plastic parts greater than 25 grams

Plastic Part Name

Plastic Part

Description

Weight

(grams)

ISO 11469:2000 Plastic Part

Mark

Optional:

Photo

Pine China Main Bezel

Main front bezel piece

150

>ABS<

Pine China Bezel

Frame

Front bezel frame

194

>ABS<

System Fan Frame

Fan Frame

40

>PBT-GF30-FR(17)<

CPU Heatsink Fan

Frame

Fan Frame

28

>PBT-GF30-FR(17)<

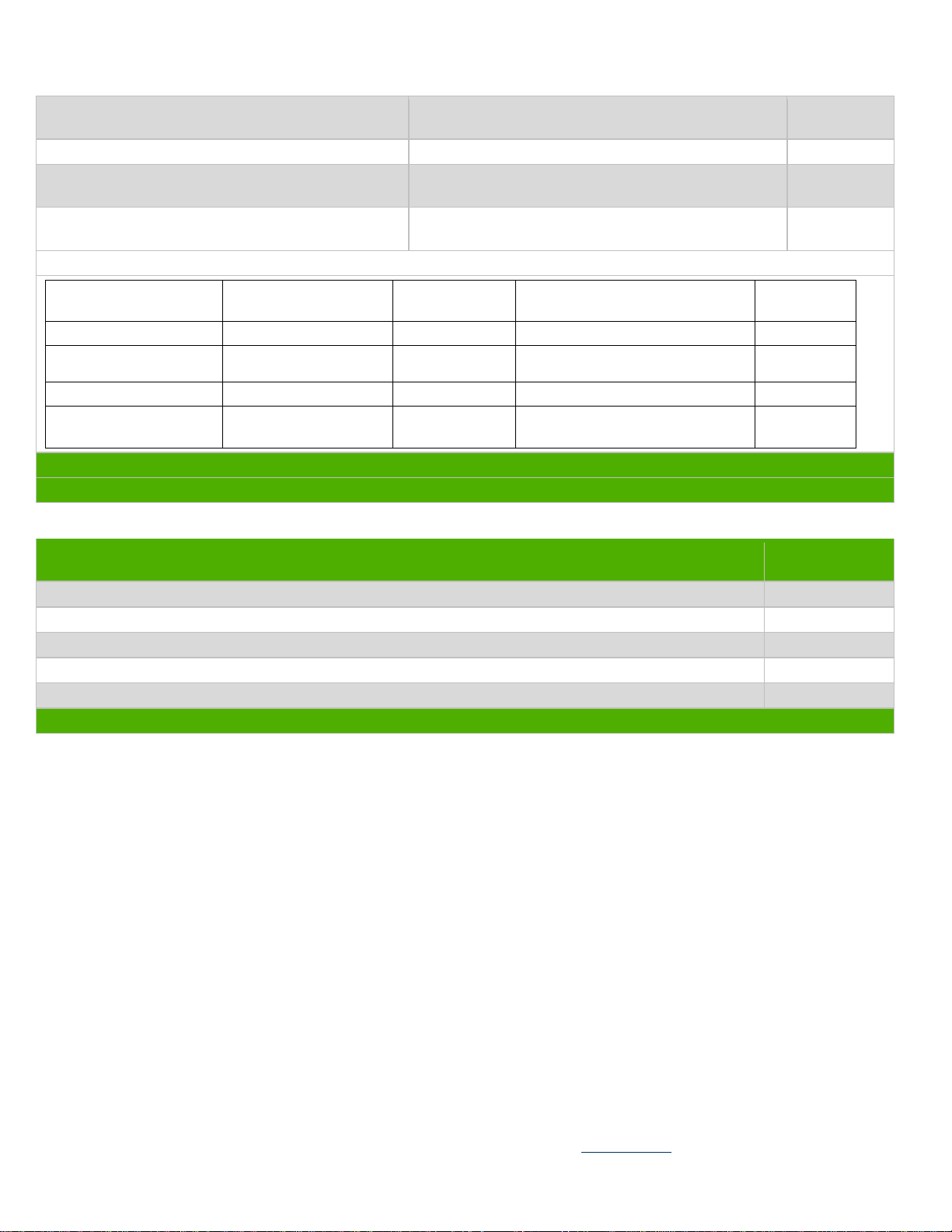

2.0 Tools Required

Tool Description

Tool Size (if

applicable)

Description #1 Torx screwdriver

T15

Description #2 Phillips screwdriver

175mm

Description #3 Diagonal cutters (dikes)

165mm

Description #4

Description #5

3.0 Product Disassembly Process

List the type and size of the tools that would typically be used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

1. SYSTEM BOARD:

(1). Remove the access panel: (a)Remove the one screws that secure the access panel to the computer chassis. (see

Figure 1 below) (b)Pull the Access Panel to rear side and take off the Access Panel. (see Figure 2 below)

(2). Remove the front bezel: (see Figure 3 below) a) Release the 3 front bezel snaps on the top side of the bezel. b)

Rotate the front bezel and take off.

( 3). Disconnect the power, and data cables from the back of all installed drives.

(4). Disconnect all cables from the system board.

( 5). Remove the heatsink from the system board: (see Figure 4 below) (a)Disconnect the heatsink control cable from the

system board. (b)Loosen the four captive screws that secure the heatsink to the system board. (c)Lift the heatsink from

atop the processor and set it on its side to keep from contaminating the work area with thermal grease.

EL-MF877-00 Page 2

Template Revision B

PSG instructions for this template are available at EL-MF877-01

( 6). Remove the system board: (see Figure 5 below) (a)Remove the 8 screws that secure the system board to the chassis.

(b) Lift the system board and depart form stand-off. (c) Slide the system board towards the front of the chassis then

remove it.

NOTE: The system board in the computer may look slightly different from the one shown here.

2. POWER SUPPLY PRINTED CIRCUIT ASSEMBLY:

(1). Remove the power supply: (see Figure 6 below) (a) Remove all cables connected to all devices in the chassis. (b)

Using a phillips screwdriver, remove the four screws that secure the power supply to the chassis. (c)Slide the power supply

toward the front of the computer, and then lift it out of the chassis.

(2). Remove the cover from the power supply: (a) Using a phillips screwdriver, remove the 4 screws that secure the cover

to the PSU chassis. (see Figures 7 & 8 below) (b) Using diagonal cutters (dikes), cut the plastic cable clamp that secures

the cables to the PSU chassis. (see Figure 9 below) (c) Remove the screws of fan and AC Inlet from the PSU

case.(fan:4pcs,AC Lnlet:2pcs) (see Figure 10 below) d) Lift the cover off the power supply.

(3). Remove the power supply PCA: (a) Remove the 4 screws that secure the power supply PCA and 1screw of AC Inlet to

the PSU chassis.(see Figure 11 below) (b) Using diagonal cutters (dikes), cut all cables connected to the PCA. (2 to fan, 2

to AC inlet,2 to LED,PSU plug) (see Figure 12 below) (c) Remove the power supply PCA from the power supply chassis.

(4). Remove the Electrolytic Capacitors: (a) Using Soldering Iron, heat the solder of Electrolytic Capacitors. (see Figure 13

& 14 below) (b) Remove the Electrolytic Capacitors. (see Figure 15 below)

3. BATTERY: Locate the battery and battery holder on the system board. Depending on the type of battery holder on the

system board, follow the instructions below to remove the battery:

(1). TYPE 1 BATTERY HOLDER (see Figure 16 below) Lift the battery out of the holder.

(2). TYPE 2 BATTERY HOLDER (see Figure 17 below) To release the battery from its holder, squeeze the metal clamp

that extends above one edge of the battery. When the battery pops up, lift it out.

(3). TYPE 3 BATTERY HOLDER (see Figure 18 below) Pull back on the clip that holds the battery in place, and then

remove the battery.

4.

5.

6.

7.

8.

3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items

contained in the product that require selective treatment (with descriptions and arrows identifying locations).

EL-MF877-00 Page 3

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Loading...

Loading...