Page 1

hp LaserJet printer family

print media guide

Page 2

Contents

Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How HP LaserJet printers work . . . . . . . . . . . . . . . . . . . . . . . . . .4

Alternate sources of information . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General Information

Guidelines for purchasing and using print media . . . . . . . . . . . . . .5

Types of print media to avoid . . . . . . . . . . . . . . . . . . . . . . . . . .6

Testing small amounts of print media . . . . . . . . . . . . . . . . . . .7

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Adhesive labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Overhead transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Conditioning print media . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Opening and loading paper . . . . . . . . . . . . . . . . . . . . . . . . . .21

Printing on both sides of the paper. . . . . . . . . . . . . . . . . . . . .21

Preparing laser-printed mailings . . . . . . . . . . . . . . . . . . . . . .22

Purchasing HP print media . . . . . . . . . . . . . . . . . . . . . . . . .24

Guidelines for shipping and storing print media . . . . . . . . . . . . . .32

Shipping media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Storing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Troubleshooting checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Paper problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Frequent paper jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Frequent multiple paper feeds . . . . . . . . . . . . . . . . . . . . . . . .39

Reducing post-image curl . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Envelope problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Frequent envelope jams . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Gray areas on envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Wrinkling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Technical specification tables

U.S. paper grades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Contents i

Page 3

Common paper grades and basis weights . . . . . . . . . . . . . . .44

Weight equivalence table . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Print media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

What the specifications mean. . . . . . . . . . . . . . . . . . . . . . . . .46

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Envelopes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Adhesive labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Overhead tranparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Standard media sizes used in laser printers . . . . . . . . . . . . . . . .54

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Card stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Comparisons of paper smoothness . . . . . . . . . . . . . . . . . . . . . . .56

Glossary

Index

ii Contents

Page 4

Overview

Introduction

HP LaserJet printers quickly and quietly produce documents with

excellent print quality. A variety of print media, including paper,

envelopes, labels, and overhead transparencies can be used in your

HP LaserJet printer. However, to ensure consistent performa nce and

long-term reliability, the print media must be designed for use with

laser printers. There are many choices of high-quality print media

available to laser printer users.

This guide provides useful guidelines for selecting and using print

media that will give you the best performance with most HP LaserJet

printers. It also contains information to help troubleshoot HP LaserJet

printer problems that may be caused by poor-quality print media.

Note This document does not support HP LaserJet 2686A, HP LaserJet

Plus, HP LaserJet 500, or HP LaserJet 2000 printers. See the user

guide for each printer for informat ion about pri nt media specifica tions.

Note When HP LaserJet printers are discussed in this guide, the infor mation

pertains to both HP Monochrome LaserJet printers and HP Color

LaserJet printers unless otherwise noted.

Chapter – Overview 3

Page 5

How HP LaserJet printers work

HP LaserJet printers use laser and e lectrophotographic technologies.

To print a page in a laser printer, the print media must b e picked from

the input tray one sheet at a time and transported through the paper

path. While passing through the paper path, a scanning laser beam

writes an electrostatic image onto a rotating photosensitive drum. As

this image passes the developing station, a dry, powdery toner is

attracted to the imaged areas. In an HP Color LaserJet printer, this

process is repeated for each of the four toner colors.

The developed image then advances to the tr ansfer station where the

drum contacts the paper or other print media and the toner image is

electrostatically transferred onto the paper. After transfer, the print

media passes through the fuser where heat is app lied and the toner

fuses (melts) onto the print media. The print media is then delivered

to the output bin, ready for use.

To summarize, to create the printed image the print media must be

transported through the printer, charged electrostatically, and heated .

This is why print media properties such as electrical resistivity,

caliper, finish, moisture content, and stiffness can affect the print

quality and media-handling performance of your HP LaserJet printer.

Alternate sources of information

The media manufacturer and vendor can provide you with information

about the suitability of print media for an HP LaserJet printer.

If you have tried the suggestions outlined in this document and in

your user guide and you still need assistance, call the dealer from

whom you purchased your printer. You can also obtain support

through the worldwide network of HP Sales and Service Offices. (See

the sales and service listings located in any HP LaserJet printer user

guide.)

Visit HP’s website at http://www.hp.com

HP printer and HP print media.

4 How HP LaserJet printers work

to find out more about your

Page 6

General Information

Guidelines for purchasing and using print media

HP LaserJet printers are designed to be flexible in the types of print

media they can use. However, it is advisable to use good quality

media, and specifically, HP paper that is designed to work with your

HP LaserJet printers (see "Purchasing HP print media"). This section

is designed to help you select media that works best with your HP

LaserJet printer.

Note Properties of print media are subject to change. Hewlett-Packar d has

no control over such changes. The customer assumes all responsibility

for the quality and performance of media. Although testing media helps

to characterize its performance, long-term satisfaction requires

process quality control by the manufacturer and proper handling and

storage by the customer.

Chapter – General Information 5

Page 7

Types of print media to avoid

The following characteristics can affect the performa nce of your HP

LaserJet printer unless the paper or o ther print media you are using is

specifically designed to work with your HP LaserJet printer.

l Print media that is very rough, highly textured, or he avily

embossed.

l Print media with multipart forms.

l Print media that offsets or discolors.

l Print media that is damaged, curled, wrinkled, or irregularly

shaped.

l Paper that is extremely shiny or glossy.

l Paper, labels, envelopes, media coatings, dyes, or inks that

produce undesirable emissions or melt when exposed to a fu sing

temperature of 205° C (401° F) for 0.1 second (0.2 second for

HP Color LaserJet printers).

l Overhead tranparency material that produces undesirable

emissions or melt when exposed to a fusing temperature of

205° C (401° F) for 0.1 second (0.4 second fo r HP Color LaserJet

printers).

l Envelopes that have an open flap with the adhesive exposed so

that closing the flap seals the envelope.

l Envelopes with clasps, snaps, tie strings, windows, or synthetic

materials. These materials can severely damage the printer.

l Envelopes that are not square, straight, or constructed correctly

(see "Envelope construction").

l Envelopes with a basis weight less than 60 g /m

than 105 g/m

l Envelopes with baggy construction or folds that are not sh arply

2

(28 lb).

creased.

2

(16 lb) or greater

6 Guidelines for purchasing and using print media

Page 8

Testing small amounts of print media

If you are planning a large purchase of print media, first print a small

quantity in your printing environment. Subject the print media to the

temperature, humidity, and printing applications in which the print

media will be used. Hewlett-Packard recommends that you ask your

print media vendor for a guarantee that its print media will perform

satisfactorily in your HP LaserJet printer and that the vendor will

assume responsibility for the replacement of any print media that

does not print acceptably.

Note HP recommends testing print media before purchasing large

quantities.

Chapter – General Information 7

Page 9

Paper

“Plain paper” is a misnomer. All papers are designed and

manufactured for a specific use. Papers designed for the

electrophotographic process used by laser prin ter and copy machines

are usually called laser, photocopy, or xerographic grade papers.

High quality laser and photocopy papers ar e usually made from 100%

chemical wood pulp and are characterized by a smooth surface,

controlled electrical properties, heat stability, and cleanliness. These

characteristics ensure good image transfer, fusing without excessive

curl, and reliable printer operation.

Use conventional white photocopy paper for most printing. The pap er

should be high quality and free of the following:

l cuts

l tears

l grease spots

l loose particles

l dust

l wrinkles voids

l curled or bent edges

Some print jobs require a paper with a more prestigious look or feel.

Bond papers generally have a watermark and often use cotton fiber.

These papers tend to have a rougher surface, and their properties

might not be controlled like those of photocopier papers. Your

HP LaserJet printer will print black satisfactorily on many of these

bond papers. Using this type of paper with an HP Color LaserJet

printer can degrade color print quality. However, paper manufacturers

are now making laser-grade bond papers, which have properties

optimized for laser printing.

Note Paper can meet the general specifications listed in "Print media

specifications" and still not print satisfactorily because of the printing

environment or other variables over which HP has no control.

This section contains the following two topics:

l "Reading a ream label"

l "Paper types"

8 Guidelines for purchasing and using print media

Page 10

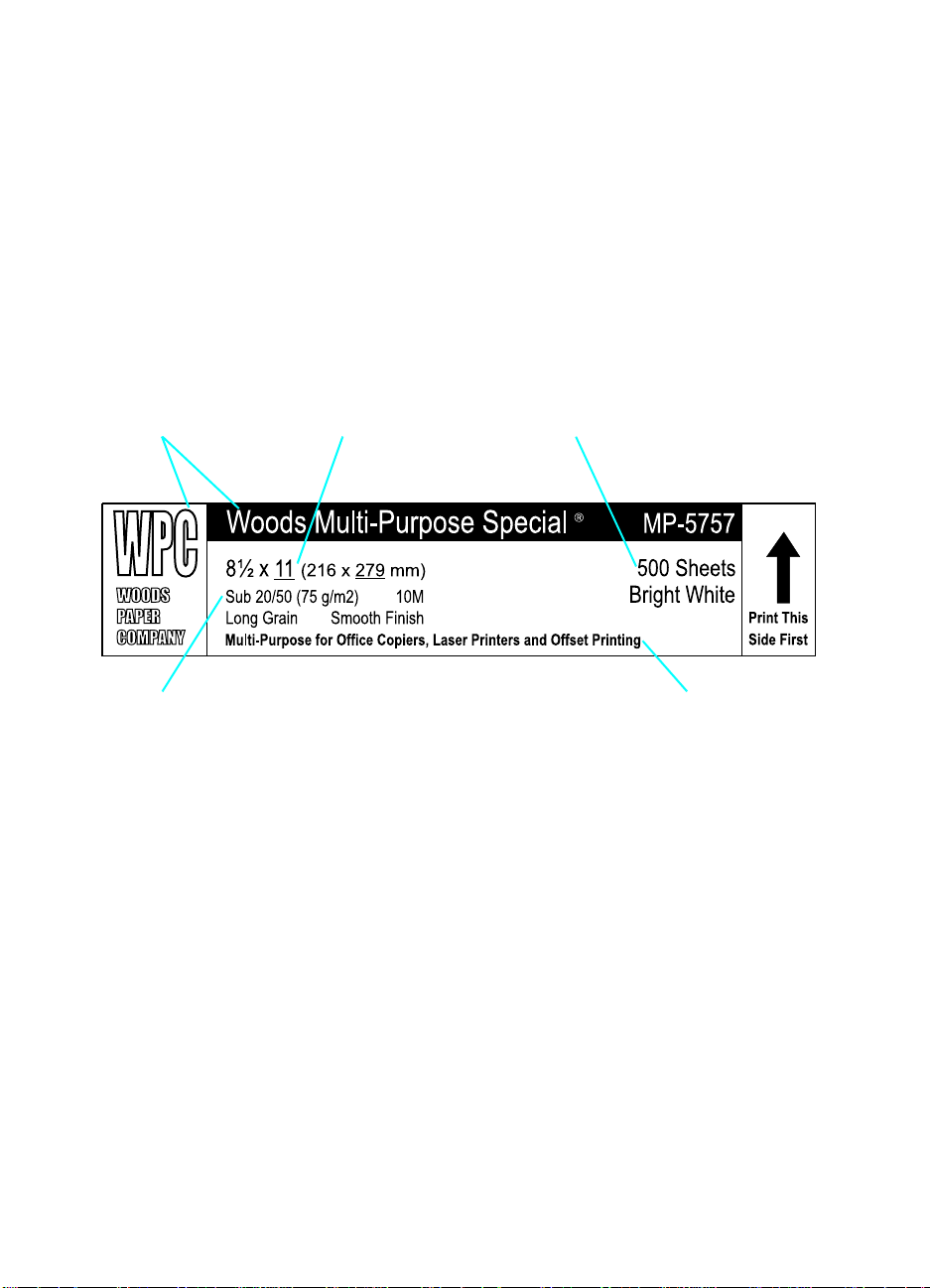

Reading a ream label

A ream label is placed on the outside of the paper wrapping. The

ream label usually indicates basis weight, size, number of sheets,

grain direction, and grade. T he pr int ing sur face of the p ape r migh t be

indicated by an arrow on the ream label, although some

manufacturers do not specify a print side. Paper should be loaded

into the printer so that the surface indicated by the arrow will be the

printing surface. The printing surface might be facing up or down in

the input tray, depending on the printer model and the paper-feeding

source.

Manufacturer name Paper size

Basis weight Paper type

Quantity

Chapter – General Information 9

Page 11

Paper types

This section describes the following paper types:

l Recycled paper l Specialty or converted paper

l Archival paper l Preprinted forms and letterhead

l Colored paper l Embossed and debossed paper

l Coated paper

Recycled paper

Recycled paper is a combination of unused fibers and pre- and postconsumer waste paper. Printed waste paper is usually washed to

remove most of the inks and other contaminants. A recycled sheet of

paper might contain dark specks or appear gray or dir ty. Choose

recycled paper that meets the same specifications as standard paper

(see "Print media specifications") and that has an appearance

suitable for your needs. HP recommends that recycled paper contain

no more than 5% groundwood.

Archival paper

Paper used for archiving must meet the same specifications as

standard paper; however, the pH should be no less than 7.0. Some

archival demands are more stringent than others, requir i ng a sp ecif ic

degree of alkalinity and chemical stability. Toner is chemically stable

and should last as long as the paper does. Toner can be degraded by

petroleum-based solvents or p lasticizers, such as those found in vinyl

folders.

Avoid folding archival documents across printed areas or handling

archival documents roughly. Discuss archival requirements with your

paper supplier.

Colored paper

You can use colored paper in your HP LaserJet printer as long as

the paper meets the same specifications as standard paper

(see "Print media specifications").

The HP Color LaserJet printers are optimal when printin g on white

paper. You also can use an HP Color LaserJet printer to print on

colored paper that meets all the specifications listed in this guide.

However, colored paper can change the appearance of the printed

colors. This is because HP Color LaserJet printers create colors by

printing a pattern of dots, overlaying and varying their spacing to

produce various colors. When these colors are printed on colored

media, the shade or color of the media will vary the shades of your

printed colors. Because the printer cannot sense what color paper

10 Guidelines for purchasing and using print media

Page 12

you are using, it cannot adjust the output color s for color ed paper . To

manually adjust the output colors, see the service manual for your

printer.

Coated paper

Clay or other pigment-coated papers must be specifically designed

for laser printers. The electrical prope rties must be contro lled and the

surface designed not to blister during fusing, and the coa ting must not

flake or shed particles that can contaminate the printer.

Some chemically coated papers such as carbonless pa per can cause

swelling of rollers, damage to the paper path, or buildup on the fuser,

and can produce undesirable emissions. These papers can result in

unsatisfactory performance and poor reliability, and their use is not

recommended.

Specialty or converted paper

Paper that undergoes converting processes before being used in

your laser printer must be properly designed and manufactured to

ensure acceptable performance. Converting processes include

preprinting, engraving, die-cutting, perforating, folding, gluing,

embossing, and debossing. These processes use many different

inks, materials, tools, and techniques and it is recommend that you

make sure your converter or supplier knows that the media will be

used in a laser printer. Ask for a guarantee of acceptable

performance.

Media that have perforations or cutouts can be printed successfully

on your HP LaserJet printer. However, these media must be properly

designed and manufactured to avoid feed o r contamination problems.

Chapter – General Information 11

Page 13

Cutout: The area where material has been removed by punching or

die-cutting. Cutouts can interact with paper path sensors or can

result in contamination from toner if printing is too close to a cutout

location.

Perforations: A series of holes or slits made in media to provide a

controlled tear for separating one port ion of the sheet fro m another. It

is recommended that micro-perfs be used, as they provide better

strength and reduce nesting, debris, and dusting.

The following guidelines should be considered when working with a

knowledgeable vendor in developing media that will have perforations

or die-cuts:

l Punch cutouts and perforations from the side to be pr inted so that

edge trimmings will not scratch the photosensitive drum.

l Round all corners of a cutout to prevent snagging or, in the case

of labels, peeling.

l Ensure that die-cutting of labels does not penetrate t he liner

sheet.

l Ensure that cutouts are not made at a position where paper path

sensors are located.

l Do not print closer than 10 mm (0.394 in) to a cutout edge or

perforation to avoid toner contamination.

l All cuts should be clean (no burrs) with no edge rollover to

prevent nesting, poor feeding, or contaminat ion.

l Orient perforations in the direction of paper feeding to minimize

tenting or feeding problems from reduced stiffness.

l Do not run perforations closer than 2 mm (0.0788 in) from the

paper edge or 25 mm (0.985 in) from the leading edge, or

jamming and feeding problems can result.

12 Guidelines for purchasing and using print media

Page 14

Preprinted forms and letterhead

To avoid multiple-feed and jamming problems when us ing preprinted

forms, embossed paper, and letterhead paper, observe the following

guidelines:

l Avoid using low-temperature inks (the kind used with some types

of thermography).

l Use forms and letterhead paper printed by offset lithography or

engraving.

l Print forms with heat-resistant inks that will not melt, vaporize, or

release undesirable emissions when heated to 205° C (401° F)

for 0.1 second (0.2 second for HP Color LaserJet printers).

Typically, oxidation-set or oil-based inks meet this requirement .

l When the form is preprinted, be careful not to change the

moisture content of the paper, and do not us e ma te ria ls th at

change the paper’s electrical or handling properties. Seal the

forms in moisture-proof wrap to prevent moistu re change s dur ing

storage.

l Avoid processing preprinted forms with a finish or coating.

l Avoid using heavily embossed or raised-letterhead papers.

l Avoid papers with heavily textured surfaces.

l Avoid using offset powders or other materials to prevent printed

forms from sticking together.

Embossed and debossed paper

Avoid heavily embossed or debossed papers because multiple sheet

feeding can occur from nesting. Do not print closer than 1 5 mm

(0.591 in) from the embossment to prevent poor print quality and

fusing (toner adhesion). The fuser can tend to iron flat the embossed

or debossed images.

Chapter – General Information 13

Page 15

Envelopes

CAUTION HP Color LaserJet and HP Color LaserJet 5 printers do not support

envelopes. Printing envelopes can damage the printer. See the user

guide that came with your printer for detailed instructions about printing

envelopes.

You can print many sizes and styles of envelopes on most

HP LaserJet printers by using manual fe ed, a multipurpo se (MP) tray,

an optional envelope tray, or an optional envelope feed er. Whicheve r

input method you use, envelopes should meet all specifications

discussed in this document. Your envelope vendor should provide

you with a satisfactory envelope that complies with the specifications

listed in "Print media specifications". However, folding inconsistencies

or other process control problems can result in some envelopes

feeding well and others jamming. Purchase envelopes that have the

quality and consistency your printer requires.

Note Envelopes can meet the general specifications listed in "Print media

specifications" and still not print satisfactorily because of the printing

environment or other variables over which HP has no control.

CAUTION Envelopes containing windows, clasps, or snaps can cause severe

damage to the printer. See the printer user guide before using

envelopes in your HP LaserJet printer.

This section contains the following two topics:

l "Envelope construction"

l "Results of envelope testing"

14 Guidelines for purchasing and using print media

Page 16

Envelope construction

Because of their construction, some envelopes will not feed through

the printer dependably. Observe the following guidelines when

purchasing and using envelopes:

l Make sure the envelope’s leading edge, which enters the printer

first, is straight, with a sharp, well-creased fold that has no more

than two thicknesses of paper. Envelopes that exceed 90 g/m

(24 lb) basis weight can cause jamming.

l Avoid using flimsy envelopes with thick or curved leading edges;

they will not feed reliably.

l Envelopes should lie flat and should not be wrinkled, nicked, or

otherwise damaged.

l Avoid envelopes with baggy construction; they might wrinkle

while going through the printer’s fuser assembly.

l Make sure that the adhesive labels used on envelopes will not

scorch, melt, offset, or release undesirable emissions when

heated to 205° C (401° F) for 0.1 second (0.2 second for HP

Color LaserJet printers).

l Avoid using envelopes with encapsulated adhesives that do not

require moistening, but rely instead on pressure to seal them.

l Do not use envelopes with clasps, snaps, tie strings, transparent

windows, holes, perforations, or cutouts.

l Do not use envelopes that have any adhesive surfaces exposed

to the printer.

l Finishes such as wove or smooth are recommended to ensure

good toner adhesion on envelopes.

2

Chapter – General Information 15

Page 17

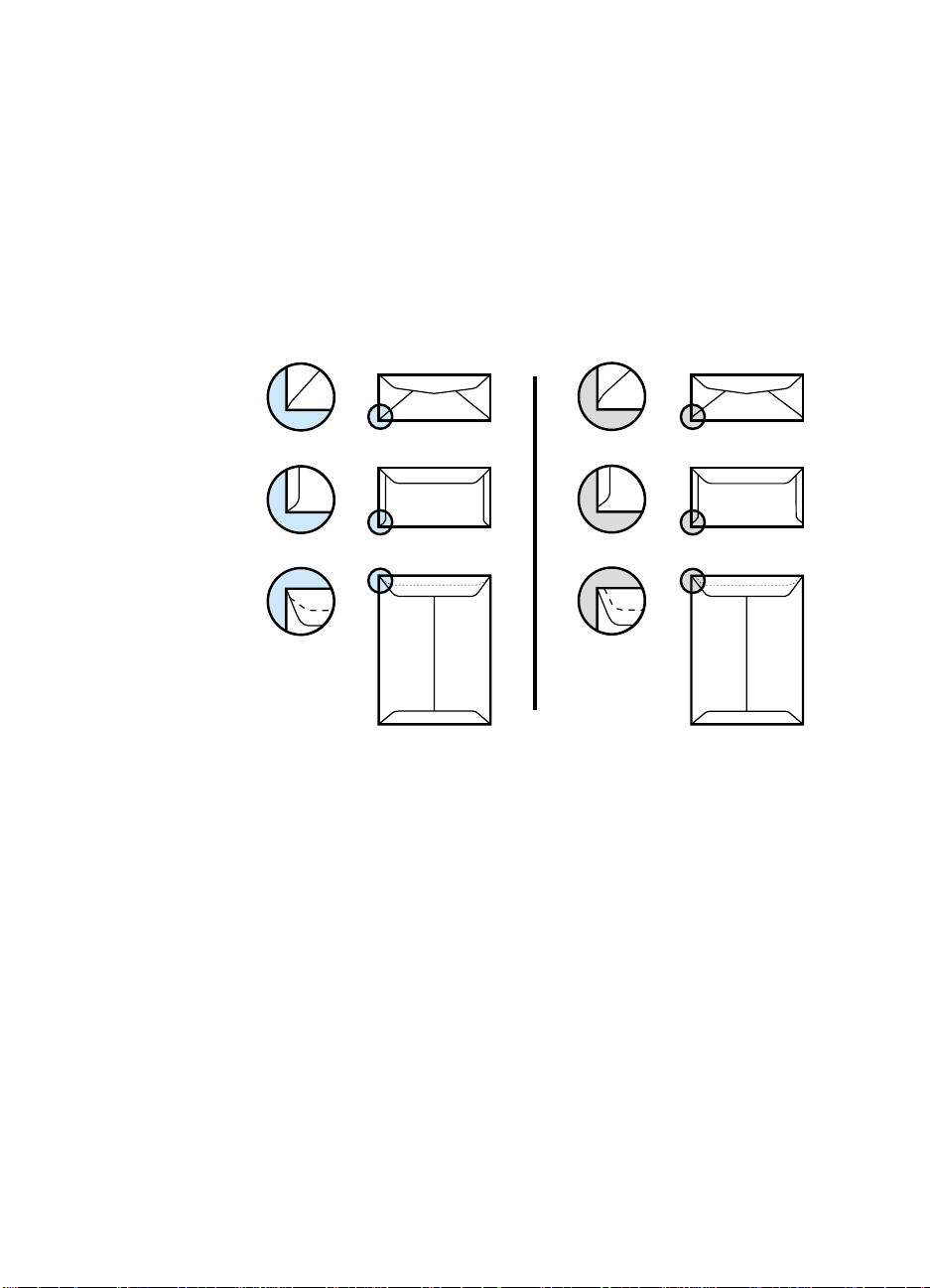

Many envelopes will feed through your HP LaserJet printer without

problems. However, some envelope constructions (as shown in the

figure below) will not feed reliably. Problems can occur when the

envelopes are folded more tightly than normal, causing a thick

leading edge near a corner. Folding inconsistencies at the

manufacturer can cause some envelopes to feed well and others to

jam. Purchase envelopes with the quality and consistency that you

require.

Good construction Bad construction

16 Guidelines for purchasing and using print media

Page 18

Results of envelope testing

HP tests many types of envelopes to determine which on e s prin t

acceptably in an HP LaserJet printer. Some of the test results are

listed below.

l Commercial or Official envelopes (also called Business or

Regular), with diagonal seams and standard gum m e d flap s,

performed the most reliably.

l Envelopes with double-sided seam construction, which have

vertical seams at both ends of the envelope instead of diagonal

seams, tend to be more flimsy than diagonal-seam envelopes.

Double-side seam envelopes tend to jam or wrinkle unless the

edges are thin and sharply creased. However, a variety of

double-sided seam envelopes have performed accepta bly during

testing.

l Envelopes with a peel-off adhesive strip, or with more than one

flap that folds over for sealing, must use adhesives compatible

with the heat and pressure of the printer’s fusing process. Many

varieties of this type of envelope performed satisfactorily in HP

testing; however, the extra flaps and strips can r esult in increased

jamming or wrinkling.

l Generally, feeding problems increase with envelope size. Larger

envelope sizes (C5, B5) cannot have a basis weight greater t ha n

105 g/m

l Rougher finishes such as laid, linen, or cockle can result in poor

fusing due to poor contact between the hot fusing roll and the

bumpy surface.

2

(28 lb).

Chapter – General Information 17

Page 19

Adhesive labels

Labels are multiple-layer media typically consisting of a face sheet

(the printable surface), pressure-sensitive adhesive, and a liner (a

carrier sheet coated with a release agent). Labels used in your HP

LaserJet printer must be specifically designed for laser printers. If

labels other than those compatible with laser printers are used, there

is a significant risk of labels peeling or adhesive contamination that

can severely damage your printer. All materials in laser label stock

must be compatible with the heat and pressure of the fusing process,

and must not melt or release undesirable emissions when heated to

205° C (401° F) for 0.1 second (0.2 second for HP Color LaserJet

printers).

CAUTION Not all HP Color LaserJet printers support printing on labels. Refer to

your user guide to determine if your printer supports labels.

Consider the information in this section when choosing label stock.

Face sheet

The face sheet is the printable surface on a sheet of adhesive labels

and can be made from different materials including paper, polyester,

and vinyl. It is common for a face sheet to be die-cut so that

individual shapes can be removed after printing. Polyester and vinyl

labels require a topcoat to provide the proper electr ical and toner

adhesion properties. It is important to purchase labels from a

knowledgeable converter who familiar with these processes and laser

printing.

Adhesives

Different adhesives can provide removable, permanent, or semipermanent fixturing of the face sheet onto the item being labeled.

Generally, acrylic-based adhesives are preferred for laser printing

because they can be applied in very thin layers to prevent oozing and

contamination, and can be made compatible with the heat and

pressure of fusing. Improved processes are being developed to

minimize adhesive contamination such as zone coating or stripped

matrix. Zone coating recesses the adhesive around the border of a

die-cut, and stripped matrix prevents adhesive from oozing between

the die-cut labels. The adhesive and liner must provide adequate

release strength so that labels will not peel during printing.

18 Guidelines for purchasing and using print media

Page 20

Liner

The liner is the carrier sheet for the label material. This must provide

stability for the reliable pick-up and transport of the label stock

through the printer.

Recommendations

l Regularly inspect your labels after printing for any indication of

label edges lifting or adhesive contamination on t he print surface.

If either of these problems are observed, it is recommended that

you discontinue use of that box or lot number and discuss the

problem with your label supplier.

l If many sheets of labels are being continuously run, periodically

run several sheets of paper through the printer to clean any

contamination on label stock that might have deposited.

l Run full sheets of labels. Reprinting unused portions can

increase the risk of label peeling and adhesive cont am in atio n .

Chapter – General Information 19

Page 21

Overhead transparencies

Overhead transparency film must be designed specifically for use

with laser printers. Photocopy transparency film might not be

compatible with laser printers because of higher temperature and

stiffness requirements. Color laser printers also require different film

than monochrome printers for proper color reproduction and fusing

needs.

Overhead transparency film is very smooth and must have a topcoat

to provide the proper electrical and toner adhesion properties. A

transparency that is made of poor material s or that is too thin c an

easily melt in the fuser and damage your printer. The thickness

requirement for monochrome overhead transparency film is 0.10 to

0.11 mm (4.1 to 4.3 mils) and for color is 0.12 to 0.13 mm (4.8 to

5.2 mils).

Overhead transparency materials must be compatible with the heat

and pressure of the fusing process. Materials must not discolor,

offset, or release undesirable emissions when heated to 205° C

(401° F) for 0.1 second (0.4 second for HP Color LaserJet printers).

See your HP LaserJet printer user guide for detailed instructions on

using overhead transparencies. See "Overhead tranparen cies" in th e

"Print media specifications" section for mor e info rm a tio n.

See "HP LaserJet Black & White Transparency" or "HP Color

LaserJet Transparency" for informa tio n ab o ut or de r ing

HP transparencies.

20 Guidelines for purchasing and using print media

Page 22

Conditioning print media

After purchasing print media, you might have to prepare it for usage.

Print media needs some time to stabilize in a new environment. To

prepare print media, keep it in its protective packagin g an d sto re it in

the environment in which it will be used. For small quantities, such as

one or two reams, store the print media for one to two days. For

larger quantities or if the change in the environment is large, a week

or more may be needed.

If print media is not properly prepared, the ed ge s in the re am can

become wavy or the sheets can curl soon after opening the package.

Opening and loading paper

Follow this suggested process when opening and loading paper:

1 Place the ream of paper on a flat surface with the seam side up.

2 Read the ream label located on the outside of the paper wrapping

and note the direction of the arrow that indicates the preferred

print side (if there is one). See "Reading a ream label".

3 Open the paper wrapping and inspect for any damage to the

sheets such as bent corners, wrinkles, nicked edges, or glue

contamination. Discard any damaged sheets.

4 Handle the stack of paper as little as possible before loading it as

a single stack. (Fanning the paper or separating the paper into

several stacks creates air pockets between sheets that may

cause multi-feeds.)

Printing on both sides of the paper

Two-sided printing, also known as duplex printing can be either an

automatic or a manual process.

Note The print quality for color duplex printing has been optimized for 90 g/

m2 (24 lb) and heavier paper.

Automatic duplexing

Automatic duplexing requires an HP LaserJet printer designed

especially for duplex printing. For example, when duplexing on the

Color LaserJet 8500 printer, 90 g/m

media is recommended. Adhesive labels, envelopes, and overhead

tranparencies cannot be duplexed.

2

to 105 g/m2 (24 lb to 28 lb)

Chapter – General Information 21

Page 23

Manual duplexing

Manual duplex printing, in which sheets that already have been

printed are refed into the printer, requ ires b ot h opera to r an d softwar e

intervention. (See the software application user guide for more

information.) Hewlett-Packard recommends manually refeeding

sheets only through the manual feed slot, the MultiPurpose (MP)

tray, or tray 1. Do not refeed sheets from the paper cassette trays.

Using the paper cassette trays can cause jams, misfeeds, and printquality problems.

Preparing laser-printed mailings

Laser printing technology is being used by more and more postal

customers to prepare their mailings. Laser printers produce

high-quality images; offer advantages in speed, flexibility, and size;

and are the printers of choice for smaller co mpanies and in-home

businesses.

Unlike offset printers, in which the ink is absorbed into the paper,

laser printers use heat to fuse a plastic toner to the surface of the

paper. Because of this difference, Hewlett -Packard recommends that

our customers use the following guidelines to produce quality

laser-printed products for mailings:

1 Ensure that the manufacturer’s recommen de d to ne r is use d fo r

the laser printer. Many aftermarket toners do not comply with the

manufacturer’s original specifications. Hewlett-Packard cannot

predict or guarantee the performance of non-HPconsumables in

HP products.

2 Paper selection is critical. Several manufacturers have papers

that are specifically formulated for their printers. Good laser

printer papers have the following properties:

• Basis weight of 24 lb (90 g/m

• Thickness from 4 mils to 4.7 mils (0.004 in to 0.0047 in)

• Smoothness from 100 to 150 Sheffield

In our testing and in the United States Postal Service (USPS)

testing, the new HP LaserJet Paper has been found to be one of

the best of the commodity-grade papers available. The only

comparably performing papers we tested were specialty papers

not usually suited to standard business use.

3 Avoid preparing las er -p rin te d sh ee ts as fold ed self-m aile rs. Th e

laser-printed sheets should be mailed in envelopes. The

envelopes should have an edge or end seam and a minimum

basis weight of 24 lb (90 g/m

22 Guidelines for purchasing and using print media

2

).

2

)

Page 24

4 Pre-bar code and presort all envelopes. Meter the envelopes or

use precanceled stamps. (In addit ion to he lpin g in the overall

performance of the laser-printed document, bar coding and

presorting can offer advantageous postal charges. Please

contact your USPS business office to find out more about this.)

5 Avoid text-on-text contact. This can be avoided by printing

single-sided, and then folding the document with the fold to the

outside. Text will contact only the inside of the envelope or the

back side of the printed sheets. If text-on-text contact cannot be

avoided, use a thin insert such as onion skin to separate the

printed sheets.

6 Ensure that all mailpieces placed in a tray and presented at the

retail window or Bulk Mail Acceptance Unit (BMAU). Avoid

placing laser-printed mail into collection boxes or chutes.

Chapter – General Information 23

Page 25

Purchasing HP print media

In the United States you can purchase HP Paper and Tranparencies

through HP’s website at http://www.hp.com/ljsupplies/

local reseller. To order outside of the U.S., please contact your local

sales office.

This section lists the current HP papers and tranparencies available:

l HP LaserJet Black & White Transparency

l HP Color LaserJet Transparency

l HP LaserJet Soft Gloss Paper

l HP Premium Choice LaserJet Paper

l HP LaserJet Paper

l HP Printing Paper

l HP MultiPurpose Paper

l HP Office Paper

l HP Office Recycled Paper

HP LaserJet Black & White Transparency

Type: 4.3 mm (0.169 in) thickness

Compatible with: HP LaserJet black and white printers

or contact your

Suggested use: Overhead presentations, and report and manual

covers

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

A4

210 by 297 mm

(8.3 by 11.7 in)

50 sheets per box 92296T

50 sheets per box 92296U

HP Color LaserJet Transparency

Type: 5 mm (0.197 in) thickness

Compatible with: HP Color LaserJet printers

Suggested use: Overhead presentations, and report and manual

covers

Size Quantity HP part number

24 Guidelines for purchasing and using print media

Page 26

Letter 50 sheets per box C2934A

A4

210 by 297 mm

(8.3 by 11.7 in)

50 sheets per box C2936A

HP LaserJet Soft Gloss Paper

Type: 32 lb weight, coated paper

Compatible with: HP Color LaserJet printers and HP LaserJet black

and white printers

Suggested use: Documents with photographic images or graphics

and charts, engineering designs, brochures, sales material,

pamphlets, and calendars

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

A4

210 by 297 mm

(8.3 by 11.7 in)

50 sheets per box C4179A

50 sheets per box C4179B

HP Premium Choice LaserJet Paper

Type: 32 lb weight / 98 brightness

Compatible with: HP Color LaserJet printers, HP LaserJet black

and white printers, and color copiers

Suggested use: Hardcopy presentations, business plans, reports,

proposals, data sheets, price lists, and newsletters

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

Tabloid

279 by 432 mm

(11 by 17 in)

A4

210 by 297 mm

(8.3 by 11.7 in)

500 sheets per ream

10-ream carton

250 sheets per ream

6-ream carton

500 sheets per ream

4-ream carton

HPU1132

HPU1732

CHP410

Chapter – General Information 25

Page 27

A4

210 by 297 mm

(8.3 by 11.7 in)

A3

297 by 420 mm

(11.7 by 16.5 in)

250 sheets per ream

8-ream carton

500 sheets per ream

4-ream carton

CHP415

CHP420

26 Guidelines for purchasing and using print media

Page 28

HP LaserJet Paper

Type: 24 lb weight / 96 brightness

Compatible with: HP Color LaserJet printers and HP LaserJet black

and white printers

Suggested use: Letterhead, high-value memos, legal documents,

and direct mail or correspondence

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

Letter

216 by 279 mm

(8.5 by 11 in)

Letter, three hole

216 by 279 mm

(8.5 by 11 in)

Legal

216 by 356 mm

(8.5 by 14 in)

Tabloid

279 by 432 mm

(11 by 17 in)

A4

210 by 297 mm

(8.3 by 11.7 in)

500 sheets per ream

10-ream carton

200 sheets per ream

12-ream carton

500 sheets per ream

10-ream carton

500 sheets per ream

10-ream carton

500 sheets per ream

5-ream carton

500 sheets per ream

5-ream carton

HPJ1124

HPJ200C

HPJ113H

HPJ1424

HPJ1724

CPH310

Chapter – General Information 27

Page 29

HP Printing Paper

Type: 22 lb weight / 92 brightness

Compatible with: HP Color LaserJet printers, HP LaserJet black

and white printers, and HP InkJet printers

Suggested use: Correspondence, and all documents printed with

HP LaserJet and InkJet technology

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

Tabloid

279 by 432 mm

(11 by 17 in)

A4

210 by 297 mm

(8.3 by 11.7 in)

A3

297 by 420 mm

(11.7 by 16.5 in)

500 sheets per ream

10-ream carton

500 sheets per ream

10-ream carton

500 sheets per ream

5-ream carton

500 sheets per ream

5-ream carton

HPP1122

HPP1722

CHP210

CHP220

28 Guidelines for purchasing and using print media

Page 30

HP MultiPurpose Paper

Type: 20 lb weight / 90 brightness

Compatible with: HP Color LaserJet printers, HP LaserJet black

and white printers, copiers, and fax machines

Suggested use: Copier and fax needs, correspondence, drafts,

memos, and e-mails

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

Letter

216 by 279 mm

(8.5 by 11 in)

Letter

216 by 279 mm

(8.5 by 11 in)

Letter, three-hole

216 by 279 mm

(8.5 by 11 in)

Legal

216 by 356 mm

(8.5 by 14 in)

Tabloid

279 by 432 mm

(11 by 17 in)

500 sheets per ream

10-ream carton

500 sheets per ream

5-ream carton

250 sheets per ream

12-ream carton

500 sheets per ream

10-ream cartons

500 sheets per ream

10-ream carton

500 sheets per ream

5-ream carton

HPM1120

HPM115R

HP25011

HPM113H

HPM1420

HPM1720

Chapter – General Information 29

Page 31

HP Office Paper

Type: 20 lb weight / 84 brightness

Compatible with: All office equipment, such as laser and inkjet

printers, copiers, and fax machines

Suggested use: Copier and fax needs and high volume printing

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

Letter, three hole

216 by 279 mm

(8.5 by 11 in)

Letter

216 by 279 mm

(8.5 by 11 in)

Legal

216 by 356 mm

(8.5 by 14 in)

Tabloid

279 by 432 mm

(11 by 17 in)

A4

210 by 297 mm

(8.3 by 11.7 in)

A3

297 by 420 mm

(11.7 by 16.5 in)

500 sheets per ream

10-ream carton

500 sheets per ream

10-ream carton

Quick Pack

2,500 sheets per carton

500 sheets per ream

10-ream carton

500 sheets per ream

5-ream carton

500 sheets per ream

5-ream carton

500 sheets per ream

5-ream carton

HPC8511

HPC3HP

HP2500S

HPC8514

HPC1117

CHP110

CHP120

30 Guidelines for purchasing and using print media

Page 32

HP Office Recycled Paper

Type: 20 lb weight / 84 brightness

Compatible with: All office equipment, such as Laser and inkjet

printers, copiers, and fax machines

Suggested use: Copier and fax needs and high volume printing

Size Quantity HP part number

Letter

216 by 279 mm

(8.5 by 11 in)

Letter, three hole

216 by 279 mm

(8.5 by 11 in)

Legal

216 by 356 mm

(8.5 by 14 in)

500 sheets per ream

10-ream carton

500 sheets per ream

10-ream carton

500 sheets per ream

10-ream carton

HPE1120

HPE113H

HPE1420

Chapter – General Information 31

Page 33

Guidelines for shipping and storing print media

The performance of HP LaserJet printers depends on the condition of

the print media used. This section contains rec om m e nd at ion s for

shipping and storing media, and provides information about

environmental effects on media.

Shipping media

When shipping print media through different environments, use

plastic wrap to wrap all cartons on the shipping pallet. When shipping

media across bodies of water, also wrap individu al carto n s.

Packaging must protect the media from physical damage.

Storing media

Follow these guidelines when stacking and storing print media:

l DO NOT store cartons or reams directly on the floor; place

cartons on a pallet or on shelves.

l DO NOT store individual reams in a manner that will result in

curling or warping.

l Rewrap partially used packages of media before storing.

l DO NOT stack more than six cartons on top of each other.

l Stack each carton squarely on top of the one underneath.

l Stack each carton upright.

l DO NOT place anything on top of media, regardless of whethe r

the paper is packaged or unpackaged.

l Store envelopes in a protective box to avoid damaging the

envelope edges.

l Keep stored media away from extremes in temperature and

humidity.

l DO NOT store printed documents in vinyl folders (which can

contain plasticizers) and do not expose the documents to

petroleum-based solvents.

32 Guidelines for shipping and storing print media

Page 34

Environmental considerations

HP LaserJet printers are designed to operate in a wide range of

environmental conditions. For best performance, store and use media

at 20° to 24° C (68° to 75° F), with a relative humidity of 45 to 55

percent. Follow these guidelines when media is used in an

environment outside those temperature and humidity ranges:

l DO NOT expose the media to extremes in humidity or

temperature. If media is left unwrapped or in the printer input tr ay,

extreme changes in the environment will cause the media

assume unwanted characteristics.

l In the case of extreme humidity, keep paper and envelopes

tightly wrapped in plastic.

If a significant temperature difference occurs between the media

storage area and the printer’s opera ting environment, allow the media

time to adjust to the temperature in the printer’s operating

environment before unwrapping it. The greater the temperature

difference and the greater the amo un t of me d i a to ac clim at e, the

longer this time period should be. Allow one day for every 10° C

(20° F) difference in temperature between storage environment and

printing environment.

Chapter – General Information 33

Page 35

34 Guidelines for shipping and storing print media

Page 36

Troubleshooting

Introduction

Print-quality and media-handling problems usually result from print

media that does not meet the specifications described in this guide,

has been stored improperly, or is not in good condit ion .

The following sections further explain the possible causes of and

solutions to print media problems.

Chapter – Troubleshooting 35

Page 37

Troubleshooting checklist

Ask the following questions to determine if the print media is causing

print-quality problems:

l Does your media meet the specifications outlined in this

document? (See "Types of print media to avoid" and "Print media

specifications".)

l Is the media in good condition? Is the media bent or wrinkled?

l Are you using the printing procedures outlined in the printer user

guide?

l Are you observing correct practices when handlin g media? (See

the guidelines in your printer user guide for loading media.)

l Are your print-quality problems isolated to a specific type of

media?

l Did you check the following aspects of the environment in which

the printer operates? See "Environmental considerations".

• temperature

• humidity

• exposure to sunlight

• cleanliness

36 Troubleshooting checklist

Page 38

Basic troubleshooting

If you cannot determine the cause of your print de fe cts by using

information from the previous section, try the following procedures:

1 Try print media from another lot or from a different manufacturer.

2 Flip the paper over in the input tray, or turn it from front to rear

(both, if necessary).

3 If you have an envelope print-quality problem, print a sheet of

paper to determine if the problem is caused by the variable

thickness of your envelope.

• If the paper’s print quality is good, re-examine your envelope

and see "Envelope construction" for more information.

• If the paper’s print quality is poor, you might have a printer

problem. See the documentation that came with your printer

for further troubleshooting.

4 Read the rest of this Troubleshooting section for further

troubleshooting information, pe rf or m the maintenance

procedures recommended in your printer user guide, or see the

troubleshooting section in your printer user guide.

Chapter – Troubleshooting 37

Page 39

Paper problems

This section provides information about conditions that ca n indicate

paper problems. These conditions include high occurrences of jams,

high numbers of multiple feeds, and post-image curl.

CAUTION Do not reuse jammed paper. Doing so can damage the printer.

Frequent paper jams

The following table lists possible causes of frequent paper jams and

suggested actions.

Note To recover from a paper jam, follow the directions listed in your

HP LaserJet printer user guide.

Cause Action(s)

Paper is too stiff or heavy. Heavy

or stiff paper might not be able to

negotiate the paper path or be

picked up from the input tray.

Paper is too smooth or too rough.

Paper is not cut to specification.

This can cause poor print

alignment, misstacking, improper

fit in the input tray, or difficulties

for the paper sensors.

Paper is too light or too flimsy.

Paper adjustments are set

incorrectly in the printer.

l Make sure the paper does not

exceed the basis weight listed for

your printer as specified in the user

documentation for your printer.

l Manually feed the paper into the

printer.

l Use the correct output bin, as shown

in your printer user guide.

l Use a lighter-weight paper.

l Change the paper type or manually

feed the paper into the printer. See

your printer user guide for the correct

output tray selection.

l Change the paper type or try another

ream of paper.

l Make sure the paper meets the

specifications listed for basis weight

in "Print media specifications".

l Make sure all paper adjustments

have been set correctly. See the user

documentation for your printer for

more information.

38 Paper problems

Page 40

Frequent multiple paper feeds

The following table lists possible causes of frequent multiple paper

feeds and suggested actions.

Cause Action(s)

Paper is added in small amounts

to the input tray.

Paper is too dry, not moist

enough. (Insufficient moisture

makes paper less conductive

and creates static buildup.

Paper is too light or too thin.

Paper is too smooth or too rough.

Surfaces tend to interlock or stick

together.

Paper is embossed or has raised

letterhead.

Paper adjustments are set

incorrectly.

Paper sticks together at the

edges (edgeweld). Edgeweld is

caused by the use of dull cutting

blades during the manufacturing

process.

l Add only large amounts of paper to

the input tray, and avoid mixing paper

types in the input tray.

l Try another ream of paper.

l Change the paper type.

l Make sure that the paper is properly

acclimated (see "Conditioning print

media").

l Change the paper type.

l Change the paper type.

l Change the paper type.

l Make sure all paper adjustments

have been set correctly. See the user

documentation for your printer for

more information.

l Bend the paper in an upside-down “u”

shape to break the weld.

l Try a different ream of paper.

l Try a different paper manufacturer.

Chapter – Troubleshooting 39

Page 41

Reducing post-image curl

When an HP LaserJet printer prints a sheet of paper, the sheet

develops a curvature called post-image curl. Gene rally, the higher the

moisture content of the paper, the greater the curl.

Both the paper and the printer affect th e amount of post-image curl. In

the papermaking process, stresses that can cause curl are

manufactured into the paper, so different papers will have differing

amounts of post-image curl. In the printing process, the paper is

subjected to the heat and pressure of the fusing assembly as well as

to the contours of the paper path.

Cause Action(s)

Paper is too moist, resulting in

waviness or curl.

l Print to the face-up output bin. (This

option is not available with some

printers.)

l Turn the paper stack over or turn it

around in the input tray to reverse the

direction of the paper.

l Change to a different type or brand of

paper.

l You may need to acclimate the paper

to your environment to diminish

differences in heat and moisture. See

"Conditioning print media".

l Follow the storage and handling

specifications in this document. (See

"Guidelines for shipping and storing

print media".)

l On HP Color LaserJet printers,

reduce toner coverage by using

dither patterns rather than solid fill.

l The grain of the paper can affect the

curl of the paper. Therefore, if you are

feeding the paper in landscape mode

(horizontally) and are experiencing

curl, try feeding the paper in portrait

mode (vertically).

40 Paper problems

Page 42

Envelope problems

High rates of jams, gray areas printing on envelopes, or wrinkling can

indicate problems with envelopes.

Frequent envelope jams

Overfilling the envelope tray and misadjusting its guides are the most

common causes of jams. However, if the envelope tray is properly

loaded, the envelopes might be causing the problems.

To recover from an envelope jam, follow the directions listed in your

HP LaserJet printer user guide.

CAUTION Do not reuse jammed envelopes. Doing so can damage the printer.

Cause Action(s)

Envelopes are poorly

manufactured.

Envelopes are not creased

sufficiently to have sharp edges.

Envelopes are wrinkled, bent, or

curled.

Envelopes are too stiff or heavy.

Stiff or heavy envelopes cannot

negotiate the paper path or be

picked up from the envelope tray.

Envelopes are too smooth (not

enough friction for transport) or

too rough

Envelope is inserted too far into

the manual feed slot.

l Make sure the leading edge is

straight, with a sharp, well-creased

fold. The envelope must not have

more than two thicknesses of paper

along any leading edge. The folded

layers of paper should form a point at

the leading-edge corners (see the

figure in "Envelope construction").

l Purchase envelopes that are

manufactured correctly, or run the

side of a pen or pencil over the

envelope edges to flatten them.

l Crease the leading edge of the

envelope with the side of a pen or

pencil, or change to a different type or

brand.

l Use envelopes with edges that are

thin and sharply creased.

l Use a lighter-weight envelope. Do not

exceed 105 g/m2 (28 lb).

l Change to a different type of

envelope.

l Insert the envelope only until you feel

a slight resistance.

Chapter – Troubleshooting 41

Page 43

Gray areas on envelopes

Cause Action(s)

Envelope has seams or multiple

layers.

The toner density setting in the

printing software might be too

light.

l Avoid printing over seams or other

multiple layer areas.

l Reduce background (gray shading in

non-imaged areas) by adjusting the

toner density setting of the print to a

darker setting. See the

documentation that came with your

printer.

Wrinkling

Wrinkles that form in envelopes after printing usually are caused by

the following envelope conditions:

Cause Action(s)

Loose envelope construction. l Try different envelopes that are better

constructed. See "Envelope

construction" for characteristics of

good envelope construction.

Folds are not sharply creased.

Low weight/low strength paper

used in envelope construction.

High moisture content.

l Try different envelopes that are better

constructed. See "Envelope

construction" for characteristics of

good envelope construction.

l Try different envelopes that are better

constructed. See "Envelope

construction" for characteristics of

good envelope construction.

l You may need to acclimate the

envelope to your environment to

diminish differences in heat and

moisture. See "Conditioning print

media".

42 Envelope problems

Page 44

Technical specification tables

U.S. paper grades

The U.S. paper grading system has evolved from custom and usage,

resulting in similar papers having differently stated weig ht s. Fo r

example, a 24-lb bond paper is exactly the same weight as a 60-lb

book paper, or a 60-lb text, or a 33-lb cover. This is because basis

weight is defined as the weight of 500 sheets of paper cut to basic

size. The basic size for bond, book/text, cover, index, bristol, and tag

are all different, so the given weights for these paper grades can be

different although the physical weight is virtually identical. The tables

in this section help clarify these differences. Note the difference in

basic size for each grade, which affects the weight of 50 0 sheets of

that grade.

– Technical specification tables 43

Page 45

Common paper grades and basis weights

The following table helps clarify differences in weights among paper

grades. Note the difference in basic size for each grade, which affects

the weight of 500 sheets of that grade.

Note The specifications in the following table are general and may not be

optimal for your HP LaserJet printer. Refer to the documentation that

came with your HP LaserJet printer.

Paper grade Basic size Basic area Factor

Bond 432 by 559 mm

Text 635 by 965 mm

Book (coated or

uncoated)

Cover 508 by 660 mm

Bristol 571 by 724 mm

Index 648 by 775 mm

Tag 610 by 910 mm

Metric weight none none 3.76 90 g/m

(17 by 22 in)

(25 by 38 in)

635 by 965 mm

(25 by 38 in)

(20 by 26 in)

(22.5 by 28.5 in)

(25.5 by 30.5 in)

(24 by 36 in)

2

.241 m

(374.0 sq. in)

2

.613 m

(950.0 sq. in)

2

.613 m

(950.0 sq. in)

2

.335 m

(520.0 sq. in)

2

.414 m

(641.25 sq. in)

2

.502 m

(777.75 sq. in)

2

.557 m

(864.0 sq. in)

1.00 24# bond

2.54 61# text

2.54 61# book

1.39 33# cover

1.71 41# bristol

2.08 50# index

2.31 55# tag

Equivalent basis

weights (example)

2

44 U.S. paper grades

Page 46

Weight equivalence table

The following table shows equivalent weights for different grades of

paper. A bolded value indicates a commonly available standard

weight for that grade.

Note Text and book grades marked with an asterisk (*) actually calcu late to

51, 61, 71, and 81 but are rounded to standard book/text weights of

50, 60, 70 and, 80.

Bond wt.

(17 x 22 in)

16# 41# 22# 27# 33# 37# 60 g/m

17# 43# 24# 29# 35# 39# 64 g/m

20# 50# * 28# 34# 42# 46# 75 g/m

21# 54# 30# 36# 44# 49# 80 g/m

24# 60# * 33# 41# 50# 55# 90 g/m

27# 68# 37# 45# 55# 61# 100 g/m

28# 70# * 39# 49# 58# 65# 105 g/m

29# 74# 41# 50# 61# 68# 110 g/m

32# 80# * 44# 55# 67# 74# 120 g/m

36# 90# 50# 62# 75# 83# 135 g/m

39# 100# 55# 67# 82# 91# 148 g/m

40# 101# 55# 68# 83# 92# 150 g/m

43# 110# 60# 74# 90# 100# 163 g/m

45# 115# 63# 77# 94# 104# 170 g/m

47# 119# 65# 80# 97# 108# 176 g/m

51# 128# 70# 86# 105# 117# 190 g/m

53# 134# 74# 90# 110# 122# 199 g/m

54# 137# 75# 93# 113# 125# 203 g/m

58# 146# 80# 98# 120# 133# 216 g/m

65# 165# 90# 111# 135# 150# 244 g/m

66# 169# 92# 114# 138# 154# 250 g/m

67# 171# 94# 115# 140# 155# 253 g/m

70# 178# 98# 120# 146# 162# 264 g/m

72# 183# 100# 123# 150# 166# 271 g/m

Text/Book wt.

(25 x 38 in)

Cover wt.

(20 x 26 in)

Bristol wt.

(22.5 x

28.5 in)

Index wt.

(25.5 x

30.5 in)

Tag wt.

(24 x 36 in)

Metric

wt.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

– Technical specification tables 45

Page 47

Print media specifications

This section contains specifications for the following types of print

media:

l Paper

l Envelopes

l Adhesive labels

l Overhead tranparencies

Some of the specifications are explained in the "What the

specifications mean" section.

What the specifications mean

The following specifications are defined in this section:

l Paper weight l Surface roughness

l Electrical properties l Composition (furnish)

l Moisture content l Curl

l Caliper l Finish (smoothness)

l Grain l Felt side vs. wire side

l Stiffness

Paper weight

Paper weight is the weight of paper for a given area. Grammage is

the weight in grams of one square meter of a paper. Basis weight is

typically used in the U.S. and can sometimes be confusing because

the measurement for areas change depending on the paper grade.

Heavy paper becomes stiffer and harder to pick up and transport

through the paper path and can also increase w ea r of roller s an d

guides and degrade print quality and toner adhesion. Very light paper

can bend too easily and tend to feed multiple sheets or jam inside th e

paper path. See the "Paper" specifications section.

CAUTION Avoid using extremely heavy or light paper. Use paper that falls within

your printer’s specified basis weight, as shown in the user

documentation that came with your printer.

Electrical properties

The electrical resistivity of the paper is one of the most important

properties for photocopy and laser papers. If resistance is too high,

problems caused by static buildup can occur with paper hand ling and

46 Print media specifications

Page 48

print quality. If electrical resistivity is too low, poor image transfer and

low density can result. Generally, paper has very high resistance, so

paper manufacturers add salts or other materials to lower the

resistivity.

Moisture content

Paper is hygroscopic; that is, it will absorb or give up moisture

depending on the humidity in the air around it. The moisture content

of paper has a great effect on its resistivity. Paper will absorb

moisture in a high-humidity environment and lose moisture in a low

humidity environment. Small increases in moisture content greatly

reduce resistivity while small decreases in moisture content greatly

increase resistivity.

Moisture content can also affect other paper properties such as curl,

stiffness, and dimensional size. Higher moisture content can make

paper prone to curl and wrinkling during printing, make a sheet limp,

and increase the dimensions of a cut sheet. Paper performance can

change significantly with seasonal or weather changes, which affect

the humidity in the printing environment.

Caliper

Caliper is the thickness of a sheet of paper or other print media. It is

typically specified in mils (one-thousandth of an inch) or millimeters. It

is closely associated with paper weight but not directly, because

some papers have more bulk (less density) than others.

Grain

Grain is the orientation of paper fibers in paper. Fibers tend to align

themselves in the process direction of the paper machine. Papers are

stiffer in the grain direction. Most cut sheet papers are cut long grain,

that is, with the grain direction parallel with the long edge of the sheet.

For heavier weight papers (>135 gsm) Hewlett-Packard

recommends using short-grain paper, if available, to impro ve fe edin g

and reduce wear to the paper path.

Stiffness

A minimum stiffness is required for paper to separate from the

transfer and fuser rollers. Most long-grain papers greater than 60 g sm

will have adequate stiffness to transport through the printer.

Generally, stiffness increases with paper weight.

– Technical specification tables 47

Page 49

Surface roughness

Surface roughness of papers can affect print quality, feeding, and

fusing (toner adhesion). If paper is very smooth, backgrou nd particles

are more easily seen and sheets tend to stick together and create

multiple feeds. Very rough papers can degrade transfer of toner onto

the page, causing jagged edges or toner scatter. Fusing (toner

adhesion) can also be drastically reduced on very rough papers.

Roughness is usually measured using an air leak method such as the

Sheffield method. Typical Sheffield values for different paper sur faces

are:

l around 120 to 150 for xerographic grades (wove or regular

finishes)

l around 40 to 60 for very smooth laser or coated gra d es

l around 250 to 300 for cockle finishes

l greater than 350 for traditional linen and laid finishes

Composition (furnish)

Composition (furnish) is the mixture of various materials, such as

fiber, filler, sizing materials, and other additives, used to make the

paper stock. Fillers such as calcium carbonate, clay, or talc are

added to paper to fill in the spaces between fibers.

For optimum performance of your HP LaserJet printer, use paper

made from 100% chemical wood pulp and/or cotton fiber. Recycled

paper, made with no more than 5% groundwood, is also acceptable.

To ensure that paper of a special fiber composition will work correctly

in your printer, test it before purchasing large quantities.

Note Avoid using print media containing materials tha t melt, vaporize, offset,

discolor, or release undesirable emissions when exposed to 205° C

(401° F) for 0.1 second (0.2 second for HP Color LaserJet printers).

Curl

Curl is curvature or wave in a sheet of paper before or after printing.

Sheets might curl before printing if they are exposed to humid

conditions or very dry conditions. Residual stresses in the sheet or

high moisture content can also affect the level of curl after printing.

Good process control by the paper manufacturer and proper paper

storage and handling will minimize curl problems.

48 Print media specifications

Page 50

Curl is typically measured by laying the sheet of paper on a flat

surface and measuring the height of the corners. There ar e two types

of curl:

l In-ream curl is the amount of curl in a sheet of paper before

printing. In-ream curl results from the paper-manufacturing

process or from exposure to the environment. Paper with

excessive in-ream curl might lead to feeding and print-quality

problems.

l Post-image curl is the amount of curl in a sheet of paper after

printing. Post-image curl results from exposure to the fusing

process and the paper path in the printer. Paper with excessive

post-image curl can be difficult to handle or to use in

automatic-feed photocopiers.

Finish (smoothness)

Paper for laser printers should not have a heavy texture or a glossy

smoothness unless the paper is specifically designed to work with

your HP LaserJet printer. Printed output on textured paper might

have broken character edges and show poor toner adhesion. On the

HP Color LaserJet printers, textured paper will cause inconsistent or

blotchy colors and can wrinkle in the fuser. Glossy-smooth paper

tends to highlight defects such as stray toner particles, and might no t

hold toner. If a glossy paper is desired for the HP Color LaserJet

printer, try HP’s Soft Gloss paper (see "Purchasing HP print media").

For sharp resolution or detail, use a smooth pape r.

Paper finish is typically measured using air-leak methods. We

recommend a range for smoothness using the Sheffield method.

Equivalent values for other methods can be found in "Comparisons of

paper smoothness".

Avoid using paper with embossed or raised surfaces, because spotty

printing and misfeeding can occur. It is possible to print satisfactorily

on paper that has embossed areas in the leading edge, trailing edge,

or areas where print will not appear on the paper; however,

misfeeding or jamming can occur.

Felt side vs. wire side

Some methods of manufacturing paper result in two-sided paper

properties. Along with other process variations, these properties can

make one side of the paper the preferred sid e on which to pr int. The

“top” side of the paper sheet, as it is formed, is known as t he felt side.

The “bottom” side is known as the wire side. Most manufacturers

indicate the preferred printing side on the package. See "Reading a

ream label".

– Technical specification tables 49

Page 51

Paper

The table below summarizes the paper specifications that provide the

best performance.

Note The specifications listed in this section generally apply to all HP

LaserJet printers but check the user documentatio n that came with your

printer for product specific information.

Property Specifications

Basis weight 64 gsm to 105 gsm (17 lb to 28 lb) typical.

See the user documentation that came with your printer for

specific printer and input limits.

Caliper 0.09 mm to 0.17 mm (3.5 mil to 6.5 mil) typical.

See the user documentation that came with your printer for

specific printer and input limits.

Minimum stiffness 1.2 minimum (Taber) machine direction;

0.8 minimum (Taber) cross direction.

Grain portrait feeding: long grain up to 36#;

short grain >36# landscape feeding: long grain.

Electrical surface resistivity 109 to 1013 ohms/square.

Electrical volume resistivity 109 to 1014 ohms - cm.

Surface roughness 100 to 190 Sheffield optimal;

30 to 350 Sheffield extended (fusing or feeding performance can

be degraded at outer ranges).

Fusing compatibility Must not scorch, melt, ignite, offset materials, or release

undesirable emissions when heated to 205° C (401° F) for

0.1 second (0.2 se cond for HP Color LaserJet printers).

Furnish (composition) 100% chemical pulp and/or cotton content;

recycled paper with up to 5% groundwood can be used.

Dimensional accuracy Cut sheet within ±0.80 mm (±0.03 in) of nominal.

Cut edge quality Cuts must be smooth and clean with no fray or edge roll.

Curl Must lie flat within 5 mm (0.2 in).

Moisture content 4% to 6% by weight.

Packaging Moisture-proof ream wrap.

Wax pick 12 minimum (Dennison).

50 Print media specifications

Page 52

Envelopes

The table below summarizes the envelope specifications that provide

the best performance.

Note The specifications listed in this section generally apply to all HP

LaserJet printers but check the user documentatio n that came with your

printer for product specific information.

Property Specifications

Basis weight 64 gsm to 105 gsm (17 lb to 28 lb) typical.

See the user documentation that came with your printer for

specific printer and input limits.

Caliper 0.09 mm to 0.14 mm (3.6 mil to 5.5 mil) typical single-layer

thickness.

Surface roughness 100 to 200 Sheffield.

Fusing compatibility All inks, adhesives, and other materials used in the envelope

construction must be compatible with the heat and pressure of

the fusing process. Materials must not scorch, melt, ignite, offset

materials, or release undesirable emissions when heated to

205° C (401° F) for 0.1 second (0.2 second for HP Color

LaserJet printers).

Dimensional accuracy and

construction quality

Curl Envelopes must lie flat, with no more than 6 mm (0.25 in) curl

Adhesive flap curl Envelope flap should be flat, with 1.5 mm (0.059 in) over width

Moisture content 4% to 6% by weight.

Grain Different envelope constructions might require different grain

Packaging Protective box to prevent edge damage and maintain flatness.

Envelopes must be folded within ±1.01 mm (±0.04 in) of nominal

size with no more than two thickness of paper anywhere along

the leading edge;

all folds must be sharply creased and construction must be tight

(not baggy) to avoid wrinkling;

envelopes must not be stuck together from excess seam

adhesive (blocking);

flap must be flat within 1.5 mm (0.059 in) over the width where

adhesive is applied.

across the entire surface.

where adhesive is applied.

orientations for best performance, which is left to the discretion

of the converter.

– Technical specification tables 51

Page 53

Adhesive labels

The table below summarizes the adhesive label specifications that

provide the best performance.

Note The specifications listed in this section generally apply to all HP

LaserJet printers but check the user documentatio n that came with your

printer for product specific information.

CAUTION Not all HP Color LaserJet printer support printing on labels. Please

refer to your user guide to determine if your printer supports labels.

Property Specifications

Adhesive Must not be on any external surfaces of the label before, during,

or after printing. Label construction, adhesive release strength,

and die-cutting must not allow labels to peel of during printing.

Caliper Must not exceed 0.23 mm (9.0 mils).

Fusing compatibility All inks, adhesives, and other materials used in the label

construction must be compatible with the heat and pressure of

the fusing process. Materials must not scorch, melt, ignite, offset

materials, or release undesirable emissions when heated to

205° C (401° F) for 0.1 second (0.2 second for HP Color LaserJet

printers).

Packaging Moisture-proof wrap to preserve properties.

Shelf life One year minimum, stored at 23° C (73° F) and 50% RH.

52 Print media specifications

Page 54

Overhead tranparencies

The table below summarizes the overhead tranparen cy specifications

that provide the best performance.

Note The specifications listed in this section generally apply to all HP

LaserJet printers but check the user documentatio n that came with your

printer for product specific information.

Property Specifications

Caliper 0.12 mm to 0.13 mm (4.8 mils to 5.2 mils) for HP Color LaserJet

printers.

0.10 mm to 0.11 mm (4.0 mils to 4.4 mils) for HP black and white

printers.

10

Electrical surface resistivity 2.0 to 15 by 10

Fusing compatibility Overhead transparency materials must be compatible with the

heat and pressure of the fusing process. Materials must not

discolor, melt, offset, or release undesirable emissions when

heated to 205° C (401° F) for 0.1 second (0.4 second for

HP Color LaserJet printers).

ohms/square.

– Technical specification tables 53

Page 55

Standard media sizes used in laser printers

This section lists the English and Metric dimensions of the most

commonly used paper, envelope, and card stock sizes. See the user

documentation that came with your printer for specific information

about the media supported by your HP LaserJet printer. Use only

media that is supported by your printer.

Paper

Size English dimension Metric dimension

Letter 8.5 by 11.0 in 216 by 279 mm

Legal 8.5 by 14.0 in 215.9 by 355.6 mm

Executive 7.25 by 10.50 in 184 by 267 mm