Page 1

Page 2

Page 3

PCL 5 Color Technical Reference Manual

Page 4

Notice

The information contained in

this document is subject to

change without notice.

Copyright and

License

Copyright © 1999

Hewlett-Packard Company.

All rights are reserved. This

document contains proprietary

information which is protected

by copyright. Except as allowed

by copyright laws or herein,

reproduction, adaptation, or

translation without prior written

permission is prohibited.

Trademarks

Adobe, PostScript, and the

PostScript logo are trademarks

of Adobe Systems Incorporated

which may be registered in

certain jurisdictions. AppleTalk

is a registered trademark of

Apple Computer, Inc. PCL and

Resolution Enhancement are

registered trademarks of

Hewlett-Packard Compan y. IBM

is a registered trademark of

International Business

Machines Corporation.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Inside This Manual

What You Can Learn From This Manual

This manual describes the PCL 5 commands used to print color on

the HP Color LaserJet printer family and the other Hewlett-Packard

PCL 5 color printers. Some of the main topics include an overview of

the color printing process, using palettes, choosing color modes,

adjusting output color to meet your requirements, printing color raster

graphics, and HP-GL/2 vector graphics. Examples are provided which

demonstrate the use of the PCL 5 color commands.

Note All commands described in this manual are not necessarily supported

by all printers. See the PCL 5 Comparison Guide for feature support

information for each printer.

This manual is written primarily for users that are already familiar with

PCL 5 printer features. For information on using PCL 5, see the

PCL 5 Printer Language Technical Reference Manual.

iii

Page 6

Manual Organization

This manual contains seven chapters and four appendices. Chapters

2 through 4 describe command usage for the HP Color LaserJet 4500

and 8500 printers. Appendices A through D describe how these

functions are achieved on the HP Color LaserJet, Color LaserJet 5,

5M, and the DeskJet 1200C and 1600C printers. Chapters 5 through

7 pertain to all the color printers described in this manual. A brief

description of each chapter is provided below.

Chapter 1. Color Printing Overview

This chapter explains background information about printing color

documents using PCL 5. Topics include palettes, color selection, pixel

encoding, color modes, and color matching.

Chapter 2. Using Color Modes

Chapter 2 defines the color modes and describes how to use them,

including descriptions of sending color raster data using different pixel

encoding modes and color spaces.

Chapter 3. Using Palettes

This chapter describes the palettes associated with the color modes

and explains how palettes are created, saved, and modified.

Chapter 4. Modifying Output Color

This chapter explains the options for modifying the output color: the

Render Algorithm command, the Monochrome Print Mode command,

Driver Configuration command, and Finish Mode command.

Chapter 5. The PCL Print Model

Chapter 5 describes the print model and how it determines the

printed outcome when various patterns, colors, and images are

applied together on a page. This chapter discusses the role that

logical operations and transparency modes have on this process.

Chapter 6. Raster Graphics

This chapter describes the raster graphics commands and also

compressing raster graphics images using various compression

methods.

iv

Page 7

Chapter 7. Color Vector Graphics (HP-GL/2)

This chapter discusses printing color pages using HP-GL/2, the

vector graphics language included on all PCL 5 printers. The chapter

describes new and/or modified HP-GL/2 commands and how they are

used to print with HP color print ers.

Appendix A. Color Printing Overview (Color LaserJet,

5, 5M, DeskJet)

Appendix A explains background information about printing color

documents using PCL 5. Topics include palettes, device-dependent

vs. device-independent color, color selection, pixel encoding, color

modes, and color matching.

Appendix B. Using Color Modes (Color LaserJet, 5,

5M, DeskJet)

Appendix B defines the color modes for the HP Color LaserJet, Color

LaserJet 5, 5M, and the DeskJet 1200C and 1600C printers, and

describes how to use them. It includes descriptions of sending color

raster data using different pixel encoding modes and color spaces.

Appendix C. Using Palettes (Color LaserJet, 5, 5M,

DeskJet)

Appendix C describes the use of palettes for the HP Color LaserJet,

5, and 5M, and DeskJet 1200C and 1600C printers. It explains the

palettes associated with the color modes and explains how palettes

are created, saved, and modified.

Appendix D. Modifying Output Color (Color LaserJet,

5, 5M, DeskJet)

Appendix D describes how to modify output color for the HP Color

LaserJet, Color LaserJet 5, 5M, and the DeskJet 1200C and 1600C

printers. This chapter explains how color can be optimized by

compensating for different conditions, such as variations in color due

to light sources, limitations of the original artwork and variations in

viewing monitors. The chapter details the use of halftone rendering

algorithms, color lookup tables, gamma correction, and viewing

illuminant commands. These commands are provided so that users

can request and receive color output that matches their expectations.

Index

An index offers quick access to PCL command information.

v

Page 8

Related Documents

The following documents provide related information about

Hewlett-Packard PCL 5 printers.

PCL 5 Printer Language Technical Reference Manual

The PCL 5 Printer Language Technical Reference Manual provides a

description of the printer command language that controls PCL 5

printers. The manual provides explanations of each PCL command,

and has examples demonstrating how the commands are used to

manipulate the printer. A large portion of the manual is devoted to

HP-GL/2, the vector-based graphics language in PCL 5 printers.

PCL 5 Comparison Guide

This document provides printer-specific information on paper

handling, internal fonts, PCL command support, and control panel

information. It identifies feature differences between the various

PCL 5 printers, and how the printers implement the commands

described in the PCL 5 Printer Language Technical Reference

Manual.

Printer Job Language Technical Reference Manual

This manual describes PJL, the HP printer job language used on

many of the Hewlett-Packard printers. PJL is used for switching

printer languages, requesting status information, changing display

messages, inquiring about feature settings, and other job-level

functions.

PCL/PJL Technical Quick Reference Guide

This booklet is designed to provide quick access to the syntax of each

PCL and PJL command. The commands are grouped by their

function so that those familiar with PCL and/or PJL can find the

syntax of a specific command without opening the manual.

vi

Page 9

Contents

PCL 5 Color T e c hnic al Re ference Manual

Inside This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

. . .

. . .

. . .

Chapter 1 Color Printing Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Working with color documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

PCL 5 Color Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Color Specifications and Color Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Color Management and the Standard Red, Green, Blue Color Space. . . . . . . .1-4

Palettes and Color Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

PCL 5 Color Graphics Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

PCL 5 Color Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

PCL 5 Raster Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Pixels and Pixel Encoding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Well-Behaved Raster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Chapter 2 Using Color Modes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Simple Color Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

PCL Imaging Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Configure Image Data (CID) Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

HP-GL/2 Imaging Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Chapter 3 Using Palettes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Saving the Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Push/Pop Palette Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Palette Management by ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Select Palette Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Palette Control ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Palette Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Simple Color Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

EN Contents vii

Page 10

CID Color Palettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Device RGB and sRGB Palettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Device CMY Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

HP-GL/2 Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Foreground Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Foreground Color Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Programming Color Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Chapter 4 Modifying Output Color

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Halftone Render Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Render Algorithm Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Monochrome Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Monochrome Print Mode Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Driver Configuration Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Finish Mode Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Chapter 5 The PCL Print Model

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Command Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Source Transparency Mode Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Pattern Transparency Mode Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Logical Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Logical Operations and Transparency Interactions. . . . . . . . . . . . . . . . . . . . . .5-12

Logical Operation Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

ROPs in the RGB Color Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

ROPs in the CMY Color Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Using a ROP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Table of Logical Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Pixel Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Pixel Placement Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

Filling with Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Pattern ID (Area Fill ID) Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-29

Select Current Pattern Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

User-Defined Pattern Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

Using User-Defined Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

How the Printer Tiles a Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Pattern Reference Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Download Pattern Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

User-defined Pattern Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Set Pattern Reference Point Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-43

Pattern Control Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-44

Rectangular Area Fills (Rules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

Pattern Transparency for Rectangular Area Fill. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-50

Contents viii EN

Page 11

Rectangular Fill Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Solid Fill (Black/White) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Shaded Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

Chapter 6 Raster Graphics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

PCL 5 Color Raster Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Raster Graphics Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Raster Graphics Resolution Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Raster Graphics Presentation Mode Command . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Source Raster Height Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Source Raster Width Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Start Raster Graphics Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Raster Y Offset Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Set Compression Method Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Unencoded (Method 0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Run-length Encoding (Method 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Tagged Image File Format Encoding (Method 2) . . . . . . . . . . . . . . . . . . . . . . .6-21

Delta Row Compression (Method 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Adaptive Compression (Method 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Transfer Raster Data Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

Transfer Raster Data by Plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Transfer Raster Data By Row/Block Command . . . . . . . . . . . . . . . . . . . . . . . .6-33

End Raster Graphics Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Raster Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

Raster Graphics Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

Color Raster Graphics Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-42

Chapter 7 Color Vector Graphics (HP-GL/2)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Enter HP-GL/2 Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

MC (Merge Control). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

PC (Pen Color) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

NP (Number of Pens) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

CR (Color Range) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

PP (Pixel Placement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

EN Contents ix

Page 12

Appendix A Color Printing Overview (Color LaserJet, 5, 5M,

DeskJet)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Color Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Palettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Raster Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Raster Color vs. Non-Raster Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Device-Dependent vs. Device-Independent Color . . . . . . . . . . . . . . . . . . . . . . A-4

Black and White References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Color Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Pixel Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Encoding by Plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Color Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Device-Dependent Color Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Device-Independent Color Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Device-Independent Color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Device-Dependent Color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Device-Independent Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Color Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Processing Color Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Non-Raster Color vs. Raster Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Color Raster Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Appendix B Using Color Modes (Color LaserJet, 5, 5M, DeskJet)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Simple Color Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

PCL Imaging Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Configure Image Data (CID) Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Short Form of CID Command (Configure Image Data) . . . . . . . . . . . . . . . . . B-15

Long Form of CID Command (Configure Image Data) . . . . . . . . . . . . . . . . . . B-17

HP-GL/2 Imaging Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-28

Appendix C Using Palettes (Color LaserJet, 5, 5M, DeskJet)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Saving the Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Push/Pop Palette Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Palette Management by ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Palette Control ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Palette Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Simple Color Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

CID Color Palettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

HP-GL/2 Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Foreground Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-18

Contents x EN

Page 13

Programming Color Palettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-20

Color Component One . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-20

Color Component Two . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-20

Color Component Three . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-21

Assign Color Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-21

Appendix D Modifying Output Color (Color LaserJet, 5, 5M,

DeskJet)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Halftone Render Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Render Algorithm Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

User-Defined Dithers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Download Dither Matrix Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Multiple Dither Matrices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Color Lookup Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13

Gamma Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-17

Viewing Illuminant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-18

Monochrome Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20

Driver Configuration Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Index

EN Contents xi

Page 14

Contents xii EN

Page 15

Color Printing

1

Ov erview

Introduction

This chapter provides an overview of color printing with

Hewlett-Packard printers. A primary goal for HP color printers has

always been WYSIWYG (What You See Is What You Get) color,

where the color displayed on the screen while creating a document is

the same as the color in the printed document. However, this goal has

been very difficult to realize due to a number of factors such as:

• Some colors that can be shown on a computer display cannot

be reproduced by a printer.

• The Cyan, Magenta, and Yellow colors used to create the

colors specified in a document can differ in hue and quality

from printer to printer, even printers from the same

manufacturer. Furthermore, the colors produced by a given

printer can change over time, due to internal changes as well

as temperature and humidity.

Until recently, these and other problems have led HP to approach

color matching by presenting a PCL 5 color command set giving

users the ability to make both major and minor color print quality

adjustments.

However, the emergence of sRGB (standard Red Green Blue) as an

international color data standard and the growing sophistication of

Hewlett-Packard printers has allowed HP to provide high quality

WYSIWYG color documents with a much simpler PCL color

command set. Therefore, this manual has two main parts: Chapters 1

through 7 present the latest, simplified PCL 5 color command set, and

the appendices describe the command set described in Chapters 1

through 4 as they are supported by the Color LaserJet, Color

LaserJet 5, DeskJet 1200C, and DeskJet 1600C printers.

Chapters 5 – 7 pertain to both sets of printers.

EN Color Printing Overview 1-1

Page 16

Working with color documents

A document can be thought of as a series of text characters, vector

graphics objects and images. The parts of a document either have

color specifications in them, as do color images, or have color

specifications applied to them, as do color vectors or text. For color

images, the PCL 5 command set provides a way to specify the color

format so that the image data can be interpreted correctly. For vector

graphics and text, the PCL 5 color commands support the application

of a color from a palette of colors.

Each color printed is synthesized from a combination of three colors:

Cyan, Magenta, and Y ellow . The wa y the three colors are combined to

produce the desired color is called a half-tone, and the PCL 5 color

command, Render Algorithm, specifies which half-tone to use for a

color. Advances in Hewlett-Packard printers have allowed HP to

reduce the number of render algorithms to Best, High, and Low. While

the actual implementation of each of these algorithms may vary from

printer to printer, HP has determined that the three algorithms are

sufficient to produce high quality color documents containing text and

graphics.

The colors that appear on a page also have one of two color

treatments applied to them:

1 Screen Match (sRGB), which provides the best WYSIWYG color.

This is the default color treatment.

2 The Vivid color treatment, which provides access to the entire

device gamut (range of colors the printer can produce). However ,

these colors are less correlated to those shown on a monitor than

colors that have had the Screen Match treatment applied.

The following factors form the heart of the PCL color graphics state:

• The palette of colors to be used in a document

• The render algorithm to print the colors

• The color treatment to be applied to each color

Palettes of colors can be referenced by an ID, and so can PCL color

graphic states. At any given time there is an active palette to apply

colors from, along with a render algorithm and color treatment to be

applied to the colors. Palettes and their associated render algorithm

and color treatment can be stored and retrieved using a palette ID.

When a palette is retrieved and made the active palette, the render

algorithm and color treatment stored with the palette are set as the

current render algorithm and color treatment.

1-2 Color Printing Overview EN

Page 17

The PCL language also allows users to use patterns in combination

with colors. These patterns and colors can be combined with text,

vector graphics, and images to create new, complex graphics objects.

The PCL Print Model determines the logical operations (known as

ROPs, Raster Operations) used to combine each part of the graphic

object.

PCL 5 Color Concepts

This section describes some of the concepts and terminology of color

science related to the PCL 5 color commands.

Color

Color is a combination of human physiological and psychological

responses to a relatively narrow band of frequencies in the

electromagnetic spectrum. The frequencies visible to the human eye

are called the visible spectrum. It’s useful to understand that color

comes both from direct light and indirect light that has reflected from a

surface. Reflected light absorbs all but the reflected frequency. The

colors seen on a color monitor are combinations of different-colored

lights traveling directly to the eye. They are called additive colors

since the different colors combine to form the resulting color. The

colors seen on a printed material such as paper are reflected from the

paper surface, which absorbs some of the light. Colors seen under

these conditions depend on the viewing conditions, the amount and

color of ambient light, as well as the amount and color of the reflected

light.

Color Specifications and Color Spaces

A given color can be described as particular amounts of three light

frequencies (red, green, and blue light). For example, equal amounts

of red, green, and blue light are perceived as white light. The absence

of all three primary light colors is black.

EN Color Printing Overview 1-3

Page 18

Color can be described in ways other than amounts of red, green, and

blue light. Generally, these color specification systems are known as

color spaces. For example, The Cyan, Magenta, Yellow (CMY) color

space is us ed to descri be color s that ar e printed b y dep ositin g varyin g

amounts of these three ink pigments (Cyan, Magenta, Yellow). The

absence of pigment is considered to be white, and the presence of all

three is black. The CMYK color space is similar to the CMY color

space, but black pigment is used in place of 100% C, M, Y since

imperfections in the hues of the C, M, Y pigments yield a dark brown

rather than black.

A color specification, then, depends on the color space as well as the

values used to describe a given color. Black in the RGB color space is

described using the three numbers (0, 0, 0), but in the CMY color

space it is described as (100, 100, 100), where the values are

percentages of each color.

Color Management and the Standard Red, Green, Blue Color Space

For color to be reproduced in a predictable manner across different

devices and materials, it has to be described in a way that is

independent of the specific mechanisms and materials used to

produce it. For instance, color displays and color printers use very

different mechanisms for producing color. Traditionally, operating

systems have supported color by declaring support for a particular

color space (RGB in most cases). However , since the interpretation of

RGB values varies between devices, color was not reliably

reproduc ed across different devices.

The needs of the very high-end publishing sector could not be met by

the traditional means of color support, so the various computer

operating systems added support for using International Color

Consortium (ICC) profiles to characterize device-dependent colors in

a device-independent way. They used the profiles of the input device

that created an image, and the output device that displayed or printed

the image, to create a transform that moved the image from the color

space of the input device to that of the output device. This resulted in

very accurate color and access to the entire color gamut of both

devices. However, it also involved the overhead of transporting the

profile of the input device with the image and running the image

through the transform.

1-4 Color Printing Overview EN

Page 19

Note HP’s ICC profiles are available through normal HP software

distribution channels. For those who want the additional control

available through building their own ICC profiles, there are several

vendors of profiling tools available. To provide access to the printer's

pure primaries and entire available printer gamut, the Vivid mode may

be used when profiling the printer, and subsequently when using the

ICC workflow.

However, there are a broad range of users that do not require this

level of flexibility and control in an embedded color profile

mechanism. Instead it is possible to define a single, standard default

color space for exchange and interpretation of color data. Additionally ,

most existing file formats do not support color profile embedding, and

may never do so. There is also a broad range of uses that actually

discourages people from appending any extra data to their files. The

sRGB color space addresses these issues.

The sRGB color space maintains the advantage of a clear

relationship with ICC color management systems while minimizing

software processes and support requirements. Since the image is in

a known color space and the profile for that color space is included

within the operating system and display application, this enables

end-users to enjoy the benefits of color management without the

overhead of larger files. Application developers and users who do not

want the overhead of embedding profiles in documents or images

should convert them to sRGB. While it may be that profiles buy

slightly higher color accuracy, the benefits of using a standard color

space far outweigh the drawbacks for a wide range of users. The

migration of devices to support the standard color space (sRGB)

natively will further enhance the speed and quality of the user

experience.

The international standard color space sRGB (IEC 61966-2-1) is

designed to complement current color management strategies by

enabling a simple, robust method of handling color in the operating

systems, device drivers and the Internet. This solution provides good

quality and backward compatibility with minimum transmission and

system overhead. Based on a calibrated colorimetric RGB color

space well suited to cathode ray tube (CRT) displays, flat panel

displays, television, scanners, digital cameras, and printing systems,

the sRGB color space can be supported with minimum cost to

software and hardware vendors. The four major technical

components of the sRGB color space are the standard CRT primaries

(HDTV P22 phosphors); the simple gamma value of 2.2, a D65 white

point, and its well-defined viewing conditions.

EN Color Printing Overview 1-5

Page 20

Palettes and Color Selection

The PCL 5 language allows the user to define a palette of colors.

Each color is specified by three quantities or values which are

interpreted depending on the color space. For example, the color

white in an RGB palette is (1, 1, 1) while this set of values in a CMY

palette defines the color black. Each color in the palette is accessed

using an index number, starting with 0 as the first color in the palette.

The largest palette holds 256 colors, which is approximately the

largest set of distinct colors the human eye can distinguish under

normal viewing co ndi tio ns.

A color from a palette can be applied to either text or vector graphics

using the Foreground Color command. Once the command is invoked

the selected color will be applied to all text and vector graphics page

marking primitives, and to a certain extent to raster images.

Palettes can be identified with a Palette ID and then stored and

recalled as needed. A palette stack mechanism is also supported for

the convenience of applications that work well with a graphics stack.

PCL 5 Color Graphics Context

The Palette acts as the focal point of the PCL 5 color graphics

context. The color space, render algorithm, color treatment, and pixel

encoding mode are stored along with the palette. Therefore, selecting

or restoring a palette also restores these values.

PCL 5 Color Mode

The PCL language has four modes or ways of specifying and using

color:

• Black-and-White (monochrome) mode is the default mode so

that backward compatibility with previous printers is

maintained. When the printer is turned on it has a 2-entry

palette containing the color white at index 0 and black at

index 1. When the printer is reset with an

mode.

• Simple Color mode is entered with the Simple Color

command, which creates one of three fixed color palettes:

z A monochrome, two-entry palette with white at index 0 and

black at index 1.

1-6 Color Printing Overview EN

?E it reverts to this

Page 21

z An RGB, eight-entry palette with the following colors

starting at index 0: black, red, green, yellow, blue,

magenta, cyan, and white.

z A CMY, eight-entry palette with the following colors

starting at index 0: white, cyan, magenta, blue, yellow,

green, red and black.

• PCL Imaging mode is entered with the Configure Image Data

command that creates a programmable palette of a

programmed size. This palette can be programmed using the

color component and set index commands.

• HP-GL/2 Imaging mode is entered when HP GL/2 mode is

entered and the initialize command IN creates a

programmable palette that is shared between PCL and

HP-GL/2.

Any and all of the modes can be used on a page. For example, you

could enter the Simple Color mode to print a headline and bar chart,

PCL imaging mode to print a photographic image, and

Black-and-White mode for the text on the page. Each mode is

described in more detail in Chapter 2. “Using Color Modes.”

PCL 5 Raster Images

Monochrome PCL 5 raster images are made up of a series of zeros

and ones. A one indicates that a black dot should be deposited, a

zero indicates no dot, letting the white background show through. A

one-inch wide image with a resolution of 600 dots per inch (DPI) has

600 consecutive zeros and/or ones, which represent a horizontal slice

through the image starting at the left edge of the image. This slice is

known as a raster row. For an image one inch high and one inch wide,

at 600 dpi there are 600 hundred rows of 600 zeros and/or ones.

Color raster images follow the same conventions with this major

exception: the representation of a dot is changed from a single zero

or one to a color specification (a pixel).

Pixels and Pixel Encoding

Raster images can be thought of as being composed of a series of

pixels (picture elements). In the case of monochrome raster images,

a pixel is a single bit which takes on a value of zero or one. In color

images a pixel is essentially a color specification. However, there are

several ways of specifying a color, and how the color is specified is

called the Pixel Encoding Mode (PEM).

EN Color Printing Overview 1-7

Page 22

The PCL 5 color command set supports several Pixel Encoding

Modes. The PEMs are categorized first by whether the pixel is an

index into a palette, or a color specification. The other PEM

categorization is whether the pixel data is divided into planes and

transferred one plane at a time or is transferred in sequential order.

There are four supported Pixel Encoding modes:

1 Indexed by Plane

2 Indexed by Pixel

3 Direct by Plane

4 Direct by Pixel (also known as 24-bit direct).

For example, the format known as direct by plane, uses a 3-bit pixel

where the first bit indicates the presence or absence of a red dot, the

second a green dot and the third a blue dot. The data is still arranged

in rows, but all the red data is sent, then the green and finally all the

blue. The example below represents the commands to transfer an

image with the direct by plane PEM. The underlined bits, while

transferred separately, are logically from the same pixel.

?*b#V row 1 plane 1 (red) b1 b1 b1 b1 b1 b1...

?*b#V plane 2 (green) b2 b2 b2 b2 b2 b2...

?*b#W plane 3 (blue) b3 b3 b3 b3 b3 b3...

?*b#V row 2 plane 1 (red) b1 b1 b1 b1 b1 b1...

The direct by pixel PEM uses only the row transfer command. Each

pixel is composed of three bytes, one byte per component of the color

specification. All the bytes of a given pixel are transferred before the

next one is transferred.

?*b#W row x b1 b2 b3 b1 b2 b3 b1...

The indexed by pixel PEM is similar to the direct pixel PEM but the

pixel occupies at most one byte and is an index into the current

palette.

The indexed by plane PEM is similar to the direct by plane PEM

except the pixel's value is an index into the current palette. The use of

this mode is discouraged due to the extra processing required to

combine the bits from each plane into a single number, which is then

used as an index into the current palette.

1-8 Color Printing Overview EN

Page 23

Well-Behaved Raster

PCL raster images are processed most efficiently when the height

and width of the image are specified before the Raster Start

command begins an image data transfer. Furthermore, the entire

image should be transferred before using the End Raster command to

end the image. If the image is broken into pieces, certain print

artifacts such as lines or squares can appear in the image. These can

occur when “nearest neighbor operations” are applied to pixels that

appear to be at the edge of an image, but are really inside an image

that has been artificially broken up into smaller images.

EN Color Printing Overview 1-9

Page 24

1-10 Color Printing Overview EN

Page 25

2

Using Color Modes

Introduction

The PCL printer language has four color modes:

• Black-and-White

•Simple Color

• PCL Imaging

• HP-GL/2 Imaging

PCL allows you to use any mode or combination of modes to

accomplish your printing objectives most efficiently.

All four of the color modes create a palette. The palette for each mode

is discussed in the section describing that mode, and also in

Chapter 3 (“Using Palettes”).

Black-and-White Mode (Default)

Black-and-White Mode is the default color mode. PCL devices power

up in this mode and revert back to it whenever the printer receives an

?E reset. Black-and-White mode is also selectable using the Simple

Color command (

2-pen palette, with white at index 0 and black at index 1 (compatible

with existing monochrome PCL 5 printers).

Simple Color Mode

Simple Color Mode, entered by the Simple Color command (?*r#U),

creates a fixed-size, fixed-color, unmodifiable palette. Depending on

the value field,

an 8-pen RGB palette, or an 8-pen CMY palette. When using the

Simple Color mode, the pixel encoding mode is always indexed

planar.

EN Using Color Modes 2-1

?*r1U). This mode creates an unmodifiable, default

?*r#U can create a 2-pen Black-and-White palette,

Page 26

PCL Imaging Mode

PCL Imaging Mode, enabled by the Configure Image Data command

(

?*v#W), allows a maximum of 24 bits per pixel for color

specification. Therefore, more colors may be specified than are

obtainable in Simple Color Mode. In the PCL Imaging Mode, pixel

encoding mode, bits per pixel, bits per primary, and the color palette

are all programmable.

HP-GL/2 Imaging Mode

In HP-GL/2, the Initialize (IN) command starts color imaging and

performs the following:

• Sets the pixel encoding mode to index by plane.

• Sets bits per index to 3.

• Creates an 8-pen palette that is reprogrammable in either PCL

or HP-GL/2 contexts (see Chapter 3, “Using Palettes,” for more

information).

Although default HP-GL/2 palettes are different than default PCL

palettes, an HP-GL/2 palette is modifiable in either PCL or HP-GL/2

(using the Assign Color Index [

respectively). Likewise, a PCL palette created by the Configure Image

Data command (

using the same commands.

?*v#W) is modifiable in both PCL and HP-GL/2

?*v#I] or Pen Color [PC] commands,

The active palette is always transferred between HP-GL/2 and PCL

contexts. Since only one palette at a time can be active, a new palette

created in either context overwrites the current palette.

2-2 Using Color Modes EN

Page 27

Simple Color Mode

The Simple Color command (?*r#U) specifies color selection from a

fixed palette. RGB or CMY raster data must be sent by plane

(

?*b#V) as well as by row (?*b#W). The last plane in each row is

sent using the

?*b#V command. In Simple Color mode, the pixel encoding mode is

always indexed planar.

Simple Color Command

The Simple Color command creates a fixed-size palette, whose color

specification cannot be modified.

?*r#U

# = –3 - 3 planes, device CMY palette

1 - Single plane K (Black) palette

3 - 3 planes, device RGB palette

Default =1

Range =–3, 1, 3

?*b#W command; all other planes are sent using the

This command destroys the active palette and creates a new palette,

which becomes the active palette. When the Simple Color mode is

active, PCL and HP-GL/2 commands that modify the palette are

locked out (NP, PC,

Color palette is popped from the stack (

modified, and the pixel encoding mode reverts to indexed planar.

• A value field of 1 creates a 2-entry Black-and-White default

palette.

• A value field of 3 creates an 8-entry Device RGB palette

(compatible with a PCL Imaging Mode palette, but not an

HP-GL/2 default (IN) palette).

• A value field of –3 creates an 8-entry palette in Device CMY

color space.

EN Using Color Modes 2-3

?*v#A, ?*v#B, ?*v#C, ?*v#I). When a Simple

?*p#P), it cannot be

Page 28

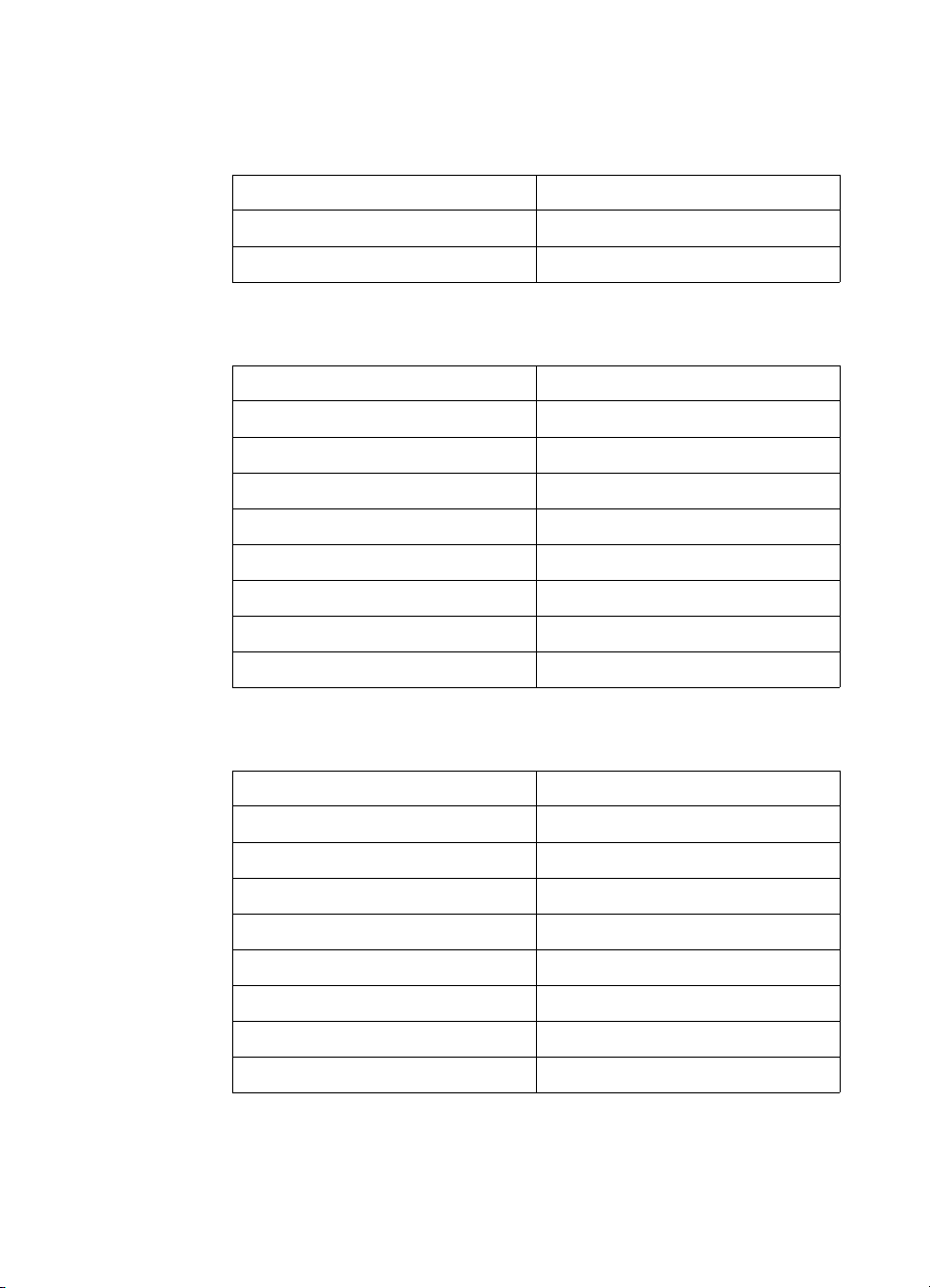

The Simple Color palettes are structured as follows:

Single Plane (value = 1)

Index Color

0White

1Black

3-Plane RGB (value = 3)

Index Color

0Black

1Red

2Green

3Yellow

4Blue

5 Magenta

6Cyan

7White

3-Plane CMY (value = –3 )

Index Color

0White

1Cyan

2 Magenta

3Blue

4Yellow

5Green

6Red

7Black

2-4 Using Color Modes EN

Page 29

PCL Imaging Mode

The PCL Imaging mode, entered using the Configure Image Data

(CID) command (

palette. It provides multiple color spaces, pixel encoding modes, and

reprogrammable palettes.

Configure Image Data (CID) Command

The CID command provides configuration information for creating

palettes and transmitting raster data. The CID command performs the

following:

• Designates the color space for the newly created palette

• Designates the size of the palette

• Designates the Pixel Encoding Mode, the format of the raster

data

• Designates, in certain circumstances, the size, in bits, of the

three components of the color specifications. However, this

information is rarely useful since it applies only to the

direct-by-pixel PEM, where the format must be eight bits per

component for 24-bit direct color, and the direct-by-plane,

where there is one bit per component.

?*v6W b0 b1 b2 b3 b4 b5

?*v#W), creates a variable-sized programmable

Where:

6 = The number of bytes following the “W”

b0 = byte 0 The color space

b1 = byte 1 The Pixel Encoding Mode

b2 = byte 2 The number of bits per index which implies the

size of the palette

b3 = byte 3 The number of bits in color component

(primary) #1

b4 = byte 4 The number of bits in color component

(primary) #2

b5 = byte 5 The number of bits in color component

(primary) #3

EN Using Color Modes 2-5

Page 30

The bytes are ordered as follows and are unsigned bytes:

Byte 15 (MSB) 8 7 0 (LSB) Byte

0 Color space Pixel encoding mode 1

2 Bits/index Bits/primary #1 3

4 Bits/primary #2 Bits/primary #3 5

Invalid configurations of the CID command are ignored and the data

discarded. A minus or a plus sign in the value field (-6 or 6) is ignored

The data fields in the command, bytes zero to five, must contain

byte-aligned binary data, not ASCII data.

Byte 0 (Color Space)

This byte specifies the color space. The range of values is 0 through

2. All other values are ignored.

Byte Value Color Space

0 Device Dependent RGB (default)

1 Device Dependent CMY

2 Standard RGB (sRGB)

Color space 2, sRGB, was the designation for Colorimetric RGB in

the Color LaserJet an d C ol or L aserJet 5 print er s. The v alu e 2 i s us ed

to represent sRGB since it is analogous to a standardized

Colorimetric RGB and the intent of the two color spaces is the same.

2-6 Using Color Modes EN

Page 31

Byte 1 (Pixel Encoding Mode)

This byte designates the format of any subsequent raster images.

The range of the value is zero to three. All other values for this field

are ignored.

V alue Pixel Encoding

Restrictions

Mode

0 Indexed by Plane Bits/Index can only be 1, 2, 3, 4, 5, 6,

7, or 8. Bit/Components 1, 2, and 3

are ignored

1 Indexed by Pixel Bits/Index can only be 1, 2, 4, or 8.

Bit/Components 1, 2, and 3 are

ignored

2 Direct by Plane Bits/Components 1, 2, and 3 must

be 1

3 Direct by Pixel Bits/Components 1, 2, and 3 must

be 8

The number of bits per index determines the size of the palette

created by this command. In the case of the Indexed by Plane mode

the number of planes needed to represent the index is also

determined by the number of bits per index. Therefore, if a 256 entry

palette is needed, then the bits per index is set to eight since

8

2

= 256. If the Indexed by Plane mode is chosen, at most eight

planes are needed to represent each row of data.

The recommended pixel encoding mode is Direct by Pixel, since this

gives the most efficient raster processing. However, using this mode

means that delta row compression should be used since it exploits

redundancy between rows. Other PCL compression modes exploit

redundancy within a row. With Direct by Pixel the redundancy from

pixel to pixel in a row is masked by the differences at the byte level

within the pixel, that is, the differences between the red, green, and

blue bytes within the pixel.

Note Raster data in Index by Plane or Direct by Plane modes cannot be

compressed using raster compression mode 5.

You need one plane or one bit/pixel for each power of two colors in the

palette. For example, a 256-color palette requires 8 planes or

8

8bits/pixel (2

EN Using Color Modes 2-7

= 256).

Page 32

PEM 0: INDEXED BY PLANE

In Pixel Encoding Mode 0, successive planes of data are sent for

each raster row. A plane contains one bit for each pixel in a row. A

pixel is not fully defined until all the planes for that row have been

received, which is signaled by a transfer raster row command. The

planes in a row form index numbers into the current palette. For

example, assuming three bits per index, the underlined column of bits

in the figure below is the palette index for pixel three of the first row (i1

is the least significant bit, i3 is the most significant bit). Note that the

Transfer Raster Data by Plane command (

planes except the last plane of each row, which is sent using the

Transfer Raster Data by Row command (

?*b#V) is used for all

?*b#W).

?*b#V row 1 plane 1 i1 i1 i1 i1 i1 i1

?*b#V plane 2 i2 i2 i2 i2 i2 i2

?*b#W plane 3 i3 i3 i3 i3 i3 i3

?*b#V row 2 plane 1 i1 i1 i1 i1 i1 i1

Example:

In the example below, the row transfer commands are shown in

binary for clarity, even though the actual data would be byte-aligned

binary data. The example is for an eight-pixel-wide image.

?*v6W 00 00 03 08 08 08 Binary data for CID represented

in hex. This command sets the

color space to RGB, the PEM to

Indexed by Plane, the palette size

3

to 8 (2

ignored.

). The last 3 bytes are

?*r1A Start raster.

?*b1V10110000 Transfer plane 1 (the first bit for

each pixel in the first row).

?*b1V01110000 Transfer plane 2 (the second bit

for each pixel in the row).

?*b1W10101000 Transfer plane 3 (the third and

final bit for each pixel in the row)

and move to the next row. Note

that the

used to send the last plane of

each row.

2-8 Using Color Modes EN

?*b#W command is

Page 33

PEM 1: INDEXED BY PIXEL

In this mode, each pixel in a row is fully specified before any bits are

sent for the next pixel. The bits for each pixel form a palette index

number. Assuming four bits per index, the underlined block below is

the palette index for pixel two of row one (i1 is the least significant bit).

?*b#W row 1 i4 i3 i2 i1 i4 i3 i2 i1 . . .

?*b#W row 2 i4 i3 i2 i1 i4 i3 i2 i1 . . .

?*b#W row 3 i4 i3 i2 i1 i4 i3 i2 i1 . . .

Example:

In the example below the data in the row transfer commands are

shown as two-digit hexadecimal numbers for clarity, even though the

actual data would be byte-aligned binary data. The example is for a

two-pixel-wide image.

?*v6W 00 01 04 08 08 08 Binary Data for the CID

command represented in

hexadecimal. This command

sets the color space to RGB, the

PEM to Indexed by Pixel, the

palette size to 16 (2

three bytes are ignored.

4

). The last

?*r1A Start raster

?*b1W45 The most significant nibble

selects palette entry 4 for the

first pixel. The second pixel is set

to index 5. Move to next row.

?*b1W6A The first pixel is index 6, the

second pixel is index 10. Move to

the next row .

?*b1W03 The first pixel is index 0, the

second pixel is index 3.

EN Using Color Modes 2-9

Page 34

MODE 2: DIRECT BY PLANE

In this mode, a pixel is composed of three, one-bit components. The

data is transferred a plane at a time, one plane for each component.

Therefore, each bit in a plane represents one component of a pixel.

The underlined bits below show the components for a pixel.

?*b#V row 1 plane 1 (red) b1 b1 b1 b1 b1 b1

?*b#V plane 2 (green) b2 b2 b2 b2 b2 b2

?*b#W plane 3 (blue) b3 b3 b3 b3 b3 b3

?*b#V row 2 plane 1 (red) b1 b1 b1 b1 b1 b1

Example:

In the example below the data in the row transfer commands are

shown in binary for clarity, even though the actual data would be

byte-aligned binary data. The example is for an eight-pixel-wide

image.

?*v6W 00 02 01 01 01 01 Binary Data for the CID command

represented in hexadecimal. This

command sets th e co lo r sp ac e to

RGB, the PEM to Direct by Plane.

The palette size is ignored. The

last three bytes are always one

for this mode.

?*r1A Start raster

?*b1V10110000 Transfer plane 1 (the first bit for

each pixel in the first row). Each

bit controls the red primary.

?*b1V01110000 Transfer plane 2 (the second bit

for each pixel in the row). Each bit

controls the green primary.

?*b1W10101000 Transfer plane 3 (the third and

final bit for each pixel in the row)

and move to the next row. Each

bit controls the blue primary. Note

that the

used to send the last plane of

each row.

2-10 Using Color Modes EN

?*b#W command is

Page 35

MODE 3: DIRECT BY PIXEL

This mode specifies a pixel as three, eight-bit components, thus the

name 24-bit direct color. Assuming the RGB color space with the

mandatory eight bits per component, the underlined bytes below

define the first pixel of row two.

?*b#W row 1 r7–r0 g7–g0 b7–b0 . . .

?*b#W row 2 r7–r0 g7–g0 b7–b0 . . .

?*b#W row 3 r7–r0 g7–g0 b7–b0 . . .

Example:

In the example below the data in the row transfer commands are

shown as two-digit hexadecimal numbers for clarity, even though the

actual data would be byte-aligned binary data. The example is for a

one-pixel-wide image.

?*v6W 00 03 00 08 08 08 Binary Data for CID command

represented in hexadecimal.

This command sets the color

space to RGB, the PEM to

Direct by Pixel. The palette size

is ignored. The last three bytes

must be 8.

?*r1A Start raster

?*b3W 45 06 30 The three bytes specify a single

pixel. The first sets 45 as the red

component’s value, the second

sets the green value to 06, and

the third sets the blue value to

30.

Byte 2 (Number of Bits per Index)

This command creates a palette regardless of the PEM chosen. This

byte determines the size of the created palette. The palette size is two

raised to the power of n (2

• In the Indexed-by-Plane PEM, where the raster data is

interpreted as palette indices, this value determines the

number of planes required per row.

EN Using Color Modes 2-11

n

), where n is the bits per index.

Page 36

• In the Indexed-by-Pixel PEM, where the raster data is

interpreted as palette indices, this value determines how to

interpret the byte-ordered row transfers. The following list

shows ho w each byte is translated into indices:

Bits/Index Indices/Byte

18

24

42

81

• In the Direct-by-Plane and Direct-by-Pixel PEMs, byte 2 does

not apply to the raster format.

Bytes 3, 4, and 5 (No. of Bits for Components 1, 2,

and 3)

These bytes are ignored for the Indexed by Plane and Indexed Direct

PEMs. For the Direct by Plane PEM they must be set to one bit per

component. For the Direct by Pixel PEM, they must be set to eight bits

per component.

2-12 Using Color Modes EN

Page 37

HP-GL/2 Imaging Mode

The HP-GL/2 Imaging Mode provides a way of using vector

commands in printing documents. Although the default PCL and

HP-GL/2 palettes are not the same, when transferring from PCL to

HP-GL/2, active palette information does stay the same. You can

switch between PCL and HP-GL/2 and use the same palette, and you

can also modify palettes using either PCL or HP-GL/2.

Compared to monochrome printers, the HP Color LaserJet printer

family, DeskJet 1200C and 1600C color printers have some

commands that are new and/or modified for use with color printers.

Chapter 7 describes the new or modified HP-GL/2 commands.

If you are not familiar with using HP-GL/2, see the PCL 5 Printer

Language Technical Reference Manual. It provides a detailed

explanation of using HP-GL/2.

EN Using Color Modes 2-13

Page 38

2-14 Using Color Modes EN

Page 39

3

Using Palettes

Introduction

A palette is a collection of color specifications selected using index

numbers. The figure below illustrates a palette. Each palette entry

associates an index number with three primary color components. For

HP-GL/2 purposes only, a pen width is also associated with each

palette entry.

EN Using Palettes 3-1

Page 40

In non-raster mode, the current palette contains all the available

colors. In raster mode, indexed color selection uses the palette, but

direct selection does not.

Default palettes are created by all the PCL color modes (Black and

White, Simple Color, PCL Imaging, and HP-GL/2 Imaging). The active

palette may be modified when in the PCL Imaging or HP-GL/2

imaging modes, but not when in the Simple Color or Black and White

modes. When switching between PCL 5 and HP-GL/2 contexts, the

active palette is automatically transferred.

Multiple palettes can exist in the system via the Palette ID and Palette

Stack mechanism. However , only one palette at a time can be active.

A palette created in the PCL context remains active and unchanged

when switching to the HP-GL/2 context, and a palette created in the

HP-GL/2 context remains active and unchanged when switching to

the PCL context. Performing a reset or entering PJL overwrites the

active palette with the default black and white palette.

Whenever a new palette is created, the currently or previously active

palette is destroyed. A new palette is created by power-on and also by

the following commands:

• PCL Reset (

•Simple Color (

• Configure Image Data (

• HP-GL/2 Initialize (IN)

The active palette can be saved by pushing it onto the palette stack

with the Push/Pop Palette command (

the stack destroys the active palette—the popped palette becomes

the active palette.

?E)

?*r#U)

?*v#W)

?*p#P). Popping a palette from

3-2 Using Palettes EN

Page 41

Saving the Palette

The current palette is destroyed when a new palette is created. The

Push/Pop Palette command (

palette and then restore (pop) it.

Push/Pop Palette Command

This command pushes or pops the palette from the palette stack.

?*p#P

# = 0 - Push (save) palette

1 - Pop (res t o re) palette

Default =0

Range = 0, 1 (invalid values are ignored)

?*p#P) can save (push) the current

A value of 0 (

palette stack. When a palette is pushed, the active palette is not

affected.

A value of 1 (

destroys the active palette; the popped palette becomes the active

palette. As with any stack, the last item pushed is the first item

popped.

Pushing a palette saves the following parameters:

• Color definitions for each palette entry

• Pen widths (for HP-GL/2 use)

• Color space specification

• Number of bits per index

• Pixel encoding mode

• Number of bits per primary

• Color treatment

• Render algorithm

?*p0P) pushes a copy of the active palette onto the

?*p1P) pops the most recently pushed palette and

EN Using Palettes 3-3

Page 42

Pushing a palette does not save the following parameters.

• Foreground color

• Color components: 1st, 2nd, and 3rd

• Finish mode

• Monochrome print mode

The palette stack depth is limited by printer memory. Attempts to push

a palette with insufficient memory cause an out-of-memory error.

Attempts to pop from an empty stack are ignored.

Macros can push and pop palettes. A palette that was popped in an

executed macro remains in effect at the end of the macro (this is not

true for “called” or “overlaid” macros).

The PCL reset command (

empty the palette stack and overwrite the active palette with a

non-programmable black and white palette. The HP-GL/2 commands

IN and DF have no effect on the palette stack, but they do destroy the

active palette and replace it with the default HP-GL/2 palette.

?E) or an exit to PJL causes the printer to

3-4 Using Palettes EN

Page 43

Palette Management by ID

All palettes have a unique ID (identification number). The default

black and white palette created on power-up or

Palette management by ID lets applications have multiple palettes. As

shown below, multiple palettes can exist in two areas: the palette

stack and the palette store. The stack holds palettes that are pushed

via a Push/Pop Palette command; the store holds palettes having

palette IDs.

?E has an ID of 0.

Palettes on the stack may not be selected by ID, since only a copy of

a palette is pushed onto the stack; the original palette and ID remain

in the palette store. A palette popped from the stack goes into the

palette store, becomes the new active palette, and assumes the ID of

the previously active palette, which is overwritten. Only one palette at

a time may be active.

EN Using Palettes 3-5

Page 44

Management by ID allows applications to tag data, have multiple

raster configurations, and have palettes for different color spaces—all

without reconfiguring the active palette. For example, one palette can

be created for PCL text, one for HP-GL/2 prim iti ves, one for simple

raster, and one for 24-bit raster. The application can then switch

between palettes according to what is being sent to the printer.

Selecting a new active palette changes the PCL graphics state.

Besides the color entries, a palette also has the graphics state which

contains the color space, color treatment, and render algorithm. This

ensures that the same color specification in a given palette will always

produce the same printed color.

As described below, the Select Palette (

(

?&p#C), and Palette Control ID (?&p#I) commands implement the

three basic operations of management by ID.

• Selection of the active palette

• Deletion of palettes

• Copying of palettes

?&p#S), Palette Control

Select Palette Command

The Select Palette command selects a new active palette by

specifying an ID number. The previously active palette is unchanged.

?&p#S

# = Palette ID number

Default =0

Range = 0 to 32767 (command is ignored for out- of-range

values)

This command activates the designated palette in the palette store.

The command is ignored if the specified ID matches the active

palette's ID, or if no palette with that ID exists. The designated ID is

saved as the palette select ID for the duration of the print job, or until

another Select Palette command is received.

This command can be used to de-select the active palette and select

as the new active palette a palette created by the Palette Control

command (

of 44 and select the new palette to use or modify, send

?&p#C). For example, to copy the active palette to an ID

?&p44i6c44S.

3-6 Using Palettes EN

Page 45

When a palette creation command is received such as Configure

Image Data (

created palette overwrites the active palette and is assigned the

current palette select ID.

A palette popped from the stack overwrites the active palette, and is

assigned the current palette select ID.

?*v#W), Simple Color (?*r#U), or an HP-GL/2 IN, the

?E resets the palette select ID value to 0 and deletes all palettes in

the palette stack and palette store, including the active palette, which

is replaced by a default PCL fixed black and white palette with a

palette ID of 0.

Macros affect the palette select ID value as follows:

• Calling or Overlaying a macro—saves the ID value and a copy

of the active palette. Upon macro exit, the restored palette

again becomes the active palette with the restored ID. An

existing palette with this ID is deleted.

• Executing a macro—does not save the ID value or the active

palette; changes remain in effect.

EN Using Palettes 3-7

Page 46

Palette Control ID

The Palette Control ID command specifies the ID number to be used

by the Palette Control Command.

?&p#I

# = Palette ID number

Default =0

Range = 0 to 32767 (command is ignored for out-of-range

The ID number specified by this command is saved as the palette

control ID and is used by the Palette Control command (

?E or power-up resets the palette control ID to 0, which is then the

default black and white palette ID.

Macros affect the palette control ID value as follows:

• Calling a macro—saves the value and restores the value at

exit.

• Exec ut i ng a ma c ro— d o es no t save the value; cha n ge s rem a in

in effect at exit.

• Overlaying a macro—copies the value before resetting to 0,

and restores at exit.

values)

?&p#C).

3-8 Using Palettes EN

Page 47

Palette Control

The Palette Control command provides a mechanism for making and

deleting palettes.

?&p#C

# = 0 - Delete all palettes except those in the stack (active

1 - Delete all palettes in the stack (active palette is not

2 - D ele te pale tte (spe ci fie d by Palette Control ID)

6 - Copy active palette to ID specified by Palette Control ID

Default =0

Range = 0, 1, 2, 6 (command is ignored for unsupported values)

• A value of 0 deletes all palettes except those on the palette

stack. The active palette is replaced by the default black and

white palette (ID 0). The palette control ID is not used.

• A value of 1 clears the palette stack. The active palette is

unaffected, and the palette control ID is not used.

• A value of 2 deletes the palette with the specified palette

control ID if it exists; otherwise the command is ignored. For

example, to delete palette 53, send

palette's ID is specified the active palette is replaced by the

default black and white palette. This option does not change

the palette control ID value.

palette deleted)

affected)

?&p53i2C. If the active

Note When the active palette is replaced by the default black and white

palette, the graphics state associated with the previous palette is also

replaced.

• A value of 6 creates a copy of the active palette. The copy

receives the ID specified by the last Palette Control ID

command. For example, to copy the active palette to a palette

with an ID of 14, send

overwrites any palette that already has an ID equal to the

palette control ID. The copied palette does not become the

active palette. The command is ignored if a palette is to be

copied to its own ID.

EN Using Palettes 3-9

?&p14i6C. The copied palette

Page 48

The Palette Control command provides a way of managing system

memory by deleting palettes in either the stack or store that are no

longer in use.

Palette Control that is exercised during macros can have significant

impact on palettes that exist within the system. Deleting all palettes,

or those on the stack, or the current palette, or all those except on the

stack can have adverse effects when the macro is exited. The

adverse effect could be the deletion of the desired palette, and

replacement with a black and white non-programmable palette.

3-10 Using Palettes EN

Page 49

Simple Color Palettes

The Simple Color command (?*r#U) provides a quick way to select

colors from a fixed, non-programmable palette.

The Simple Color command overwrites the current palette with one of

the fixed palettes below. When the Simple Color command is in effect,

the PCL and HP-GL/2 commands that modify a palette entry (NP, PC,

?*v#A, ?*v#B, ?*v#C, ?*v*I, ?*t*I) are locked out. A popped

simple color palette cannot be modified and the pixel encoding mode

reverts to “index by plane”. Only the IN or the CID (

commands can create a modifiable palette.

?*v#W)

As shown below, a value field of 1 (

palette. A value of 3 creates an 8-pen palette in Device RGB color

space. A value of –3 creates an 8-pen palette in Device CMY color

space. All of these Simple Color palettes are fixed and

non-programmable.

?*r1U) creates a black and white

Single Plane (value = 1)

Index Color

0White

1Black

3-Plane RGB (value = 3)

Index Color

0Black

1Red

2Green

3Yellow

4Blue

5 Magenta

6Cyan

7White

EN Using Palettes 3-11

Page 50

3-Plane CMY (value = –3 )

Index Color

0White

1Cyan

2 Magenta

3Blue

4Yellow

5Green

6Red

7Black

3-12 Using Palettes EN

Page 51

CID Color Palettes

The Configure Image Data command, explained in detail in Chapter

2, creates a palette based upon the parameters in its data field.

CID-created palettes are programmable: any entry can be reassigned

a different color using PCL commands (

?*v*I) or HP-GL/2 commands (PC, NP). Default palettes vary by

color space.

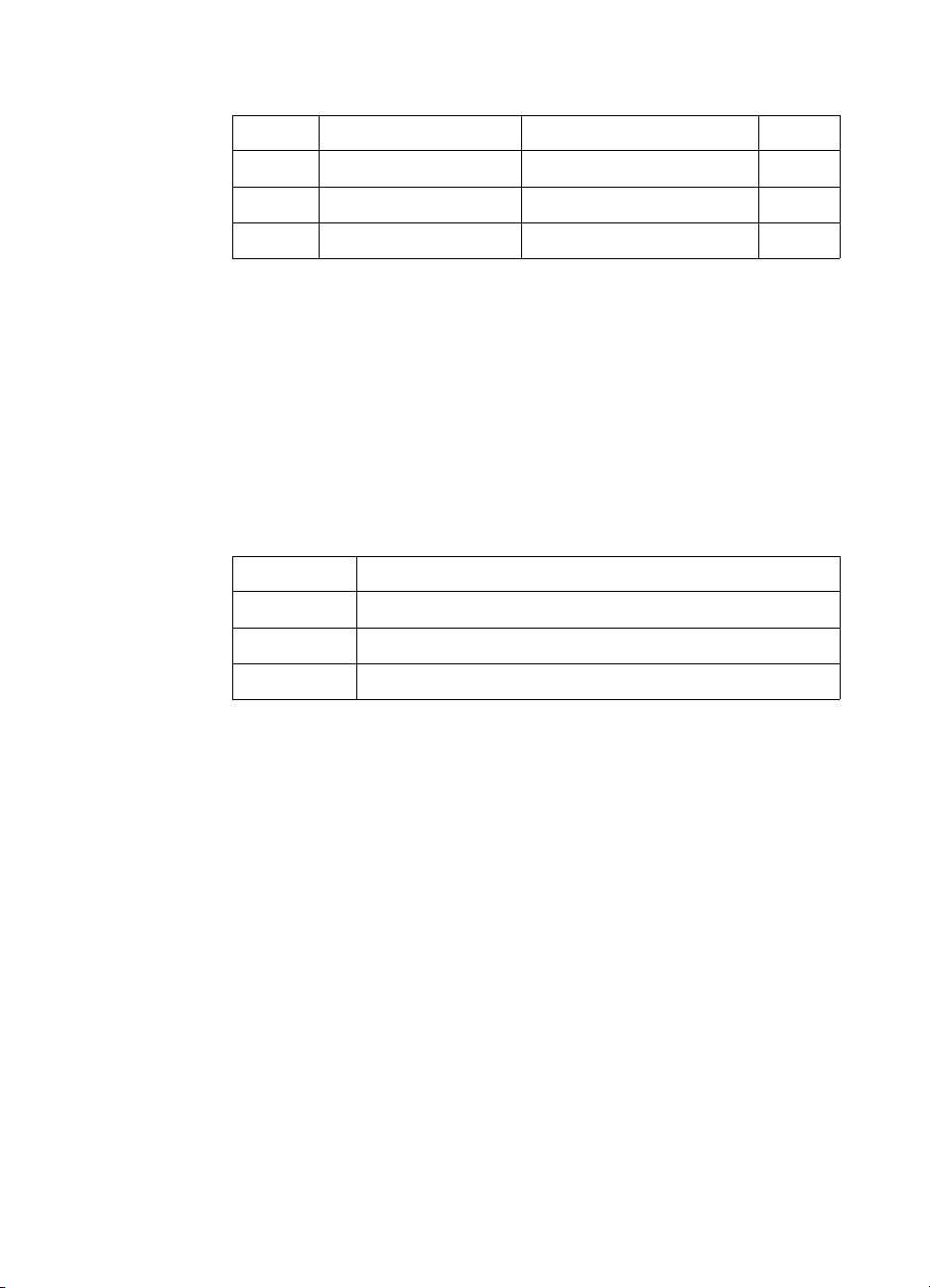

Device RGB and sRGB Palettes

Bits/Index = 1

Bits/Index = 2

?*v#A, ?*v#B, ?*v#C,

Index Color

0White

1Black

Index Color

0Black

1Red

2Green

3White

Bits/Index = 3 through 8

Index Color

0Black

1Red

2Green

3Yellow

4Blue

5 Magenta

6Cyan

7White

n > 7 Black

EN Using Palettes 3-13

Page 52

Device CMY Palettes

Bits/Index = 1

Index Color

0White

1Black

Bits/Index = 2

Index Color

0White

1Cyan

2 Magenta

3Black

Bits/Index = 3 through 8

Index Color

0White

1Cyan

2 Magenta

3Blue

4Yellow

5Green

6Red

7Black

n > 7 Black

3-14 Using Palettes EN

Page 53

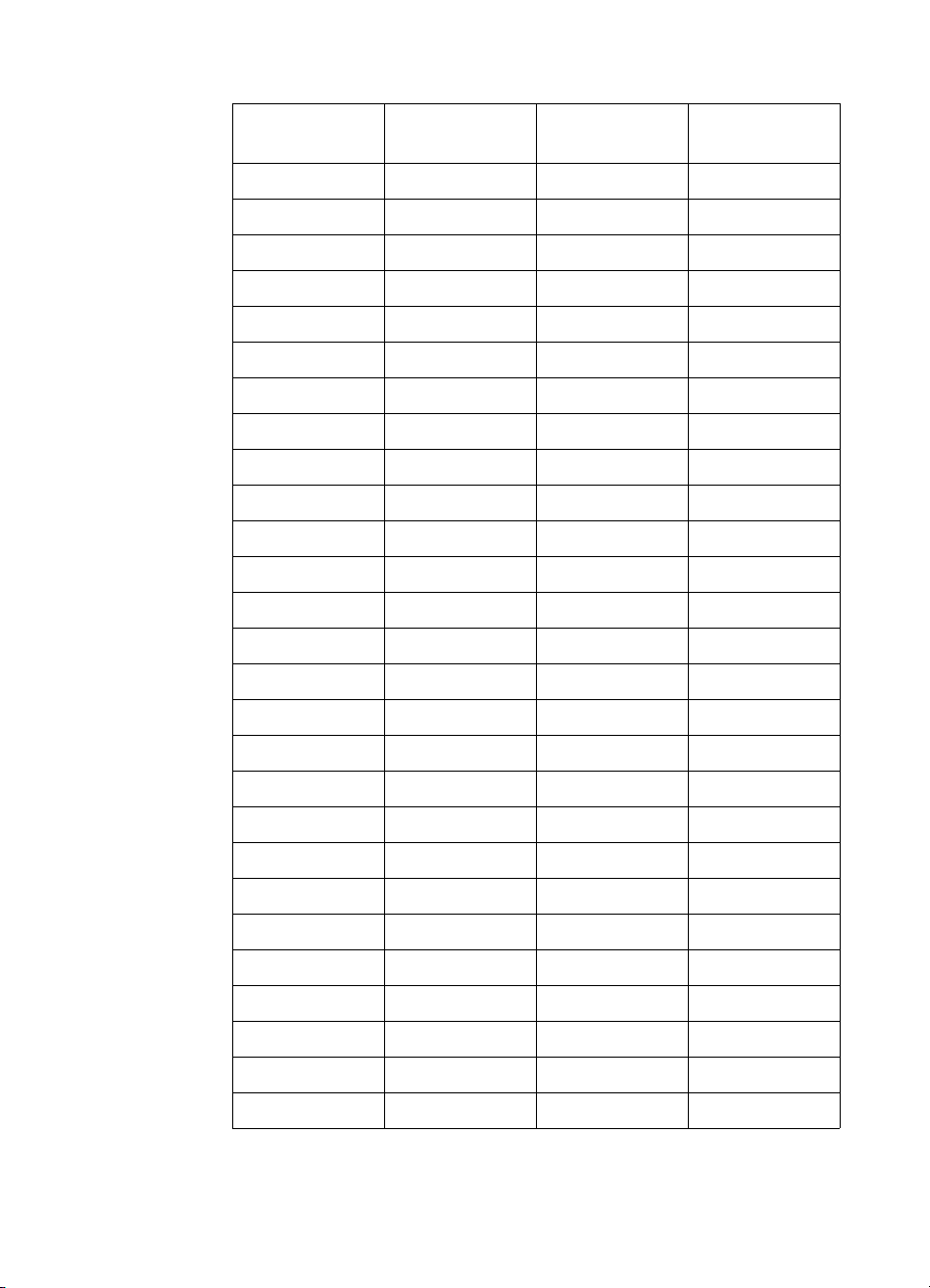

HP-GL/2 Palettes

Regardless of the color space, a default PCL palette is always

different than a default HP-GL/2 palette. The following table shows

the default palettes established in HP-GL/2. Like a default CID

palette, a default HP-GL/2 palette can be modified in either PCL or

HP-GL/2 contexts using the following commands:

PCL

• Color Components 1, 2, and 3 (?*v#A, ?*v#B, ?*v#C)

• Assign Color Index (

HP-GL/2

• Number of Pens (NP)

• Pen Color Assignment (PC)

Note The IN command always establishes the 8-pen palette.

T wo Pens

?*v#I)

Pen Number Color

0White

1Black

Four Pens