Page 1

Agilent N8480

Series Power Sensors

Operating and Service

Guide

Agilent Technologies

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2008-2012

No p art o f this manu al may be re produce d in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

N8481-90000

Edition

Fifth Edition, January 16, 2012

Printed in Malaysia

Agilent Technologies, Inc.

5301 Stevens Creek Blvd.

Santa Clara, CA 95051 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only those

rights customarily provided to end user customers. Agilent provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical

Data) and 12.212 (Computer Software) and,

for the Department of Defense, DFARS

252.227-7015 (Technical Data - Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer Software Documentation).

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

ii N8480 Series Power Sensors Operating and Service Guide

Page 3

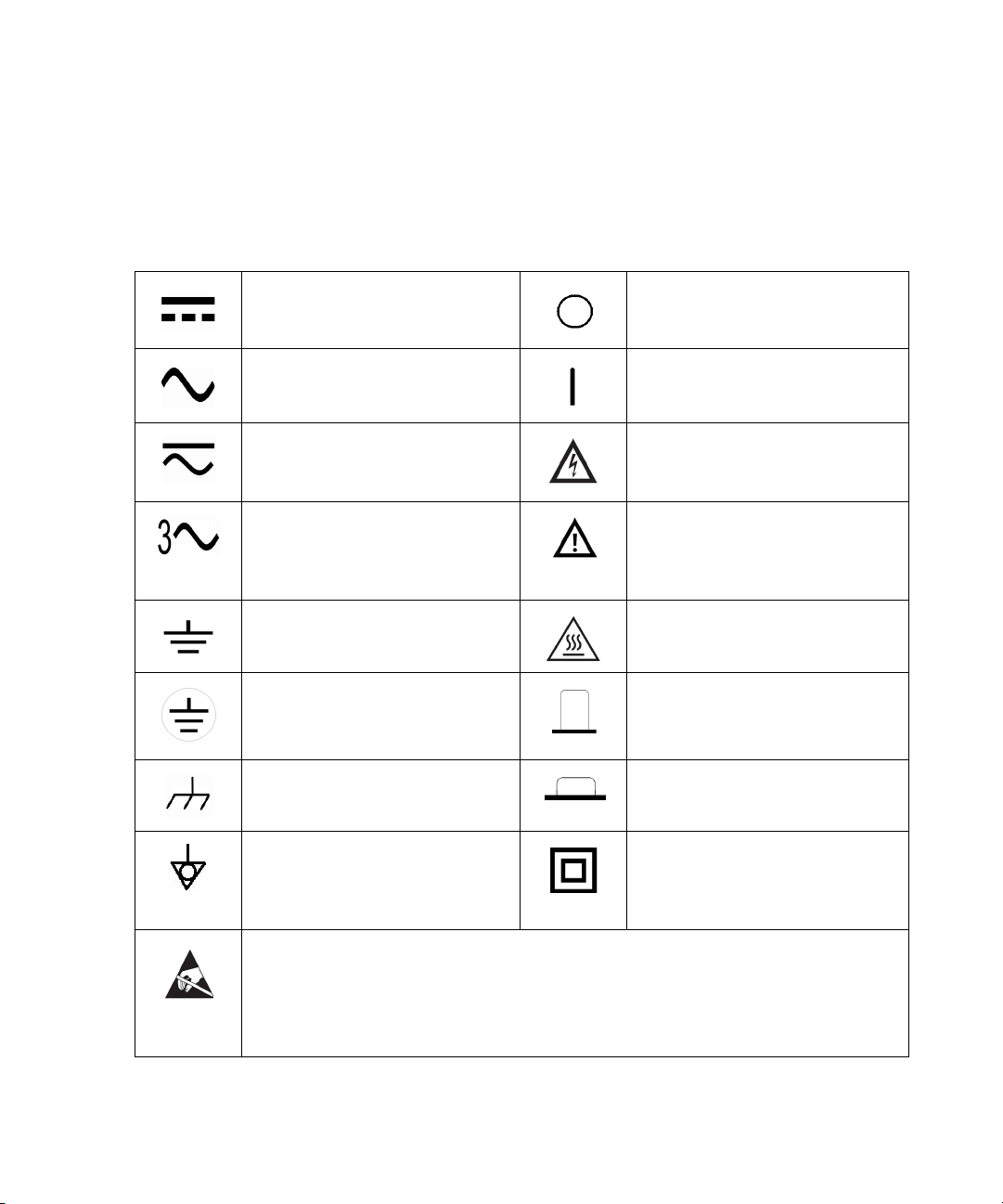

Safety Symbols

Direct current (DC) Off (supply)

Alternating current (AC) On (supply)

Both direct and alternating current Caution, risk of eletric shock

Three-phase alternating current Caution, risk of danger (refer to this

Earth (ground) terminal Caution, hot surface

Protective conductor terminal Out position of a bi-stable push control

The following symbol on the instrument and in the documentation

indicates precautions that must be taken to maintain safe operation of the

instrument.

manual for specific Warning or Caution

information)

Frame or chassis terminal In position of a bi-stable push control

Equipotentiality Equipment protected throughout by

double insulation or reinforced

insulation

This symbol indicates that a device, or part of a device, may be susceptible to electrostatic discharges

(ESD) which can result in damage to the product.

Observe ESD precautions given on the product, or its user documentation, when handling equipment

bearing this mark.

N8480 Series Power Sensors Operating and Service Guide iii

Page 4

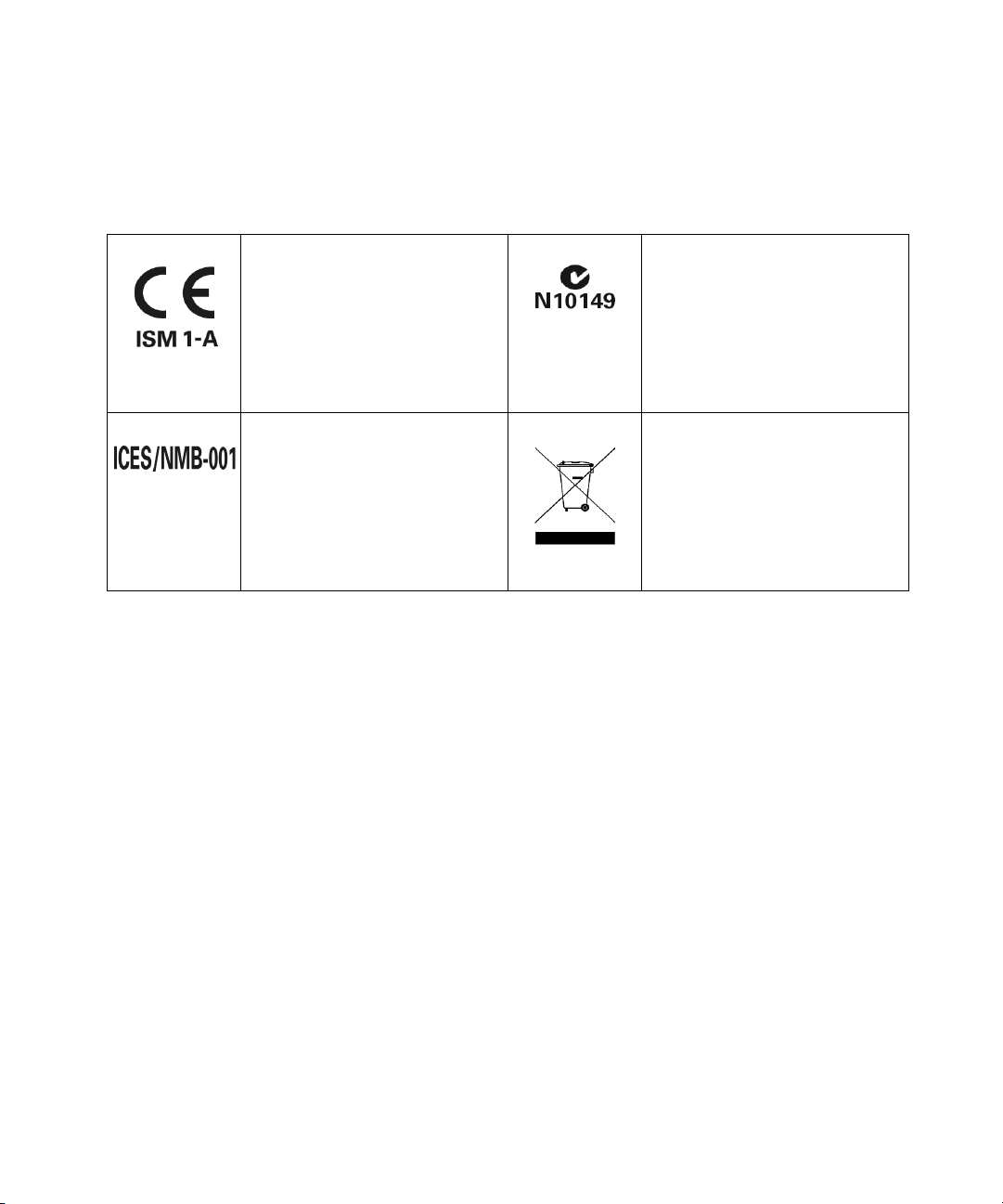

Regulatory Markings

The CE mark shows that the product

complies with all the relevant European legal Directives (if accompanied

by a year, it signifies when the design

was proven).

This ISM device complies with the

Canadian ICES-001,

Cet appareil ISM est conforme à la

norme NMB-001 du Canada.

The C-tick mark is a registered

trademark of the Spectrum

management Agency of Australia.

This signifies compliance with the

Australian EMC Framework

regulations under the terms of the

Radio Communications Act of 1992.

This product complies with the WEEE

Directive (2002/96/EC) marking

equipment. The affixed product label

indicates that you must not discard

this electrical/electronic product in

domestic household waste.

iv N8480 Series Power Sensors Operating and Service Guide

Page 5

General Safety Information

WARNING

CAUTION

The following general safety precautions must be observed during all

phases of operation, service, and repair of this instrument. Failure to

comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended

use of the instrument. Agilent Technologies assumes no liability for the

customer’s failure to comply with these requirements.

Before connecting the power sensor to other instruments ensure that all

instruments are connected to the protective (earth) ground. Any

interruption of the protective earth grounding will cause a potential

shock hazard that could result in personal injury.

• Use the instrument with the cables provided.

• Repair or service that is not covered in this manual should only be

performed by qualified personnels.

N8480 Series Power Sensors Operating and Service Guide v

Page 6

Waste Electrical and Electronic Equipment (WEEE) Directive

2002/96/EC

This instruction complies with the WEEE Directive (2002/96/EC) marking

requirement. This affixed product label indicates that you must not discard

this electrical/electronic product in domestic household waste.

Product Category:

With reference to the equipment types in the WEEE directive Annex 1, this

instrument is classified as a “Monitoring and Control Instrument” product.

The affixed product label is shown as below:

Do not dispose in domestic household waste

To return this unwanted instrument, contact your nearest Agilent office, or

visit

www.agilent.com/environment/product

for more information.

vi N8480 Series Power Sensors Operating and Service Guide

Page 7

Environmental Conditions

CAUTION

This instrument is designed for indoor use only. The table below shows

the general environmental requirements for the product.

Operating Environment

Environmental Conditions Requirements

Temperature 0 °C to 55 °C (Operating)

Humidity Maximum: 95% at 40 °C

Altitude Operating up to 4,600 metres (15,000 feet)

Storage Conditions

Environmental Conditions Requirements

Temperature –40 °C to 70 °C (Non-operating)

Humidity Non-operating up to 90% at 65 °C

Altitude Non-operating up to 7,620 metres (25,000 feet)

The N8480 Series power sensors complies with the following EMC

requirements:

• IEC 61326-1:2005/EN 61326-1:2006

• Canada: ICES/NMB-001:2004

• Australia/New Zealand: AS/NZS CISPR11:2004

Minimum: 15% at 40 °C

(Non-condensing)

N8480 Series Power Sensors Operating and Service Guide vii

Page 8

Declaration of Conformity (DoC)

NOTE

The Declaration of Conformity (DoC) for this instrument is available on the

Web site. You can search the DoC by its product model or description.

http://regulations.corporate.agilent.com/DoC/search.htm

If you are unable to search for the respective DoC, please contact your

local Agilent representative.

viii N8480 Series Power Sensors Operating and Service Guide

Page 9

In This Guide ...

1 Introduction Chapter 1 introduces the overview and operation of

the N8480 Series power sensors.

2 Specifications and Characteristics Chapter 2 describes the

specifications and characteristics of the N8480 Series power

sensors.

3Service Chapter 3 elaborates on the information about principle of

operations, troubleshooting, and repair of the N8480 Series power

sensors.

N8480 Series Power Sensors Operating and Service Guide ix

Page 10

x N8480 Series Power Sensors Operating and Service Guide

Page 11

Contents

Notices ii

Safety Symbols iii

Safety Symbols iii

Regulatory Markings iv

General Safety Information v

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC vi

Environmental Conditions vii

In This Guide ... ix

1 Introduction

General Information 2

Initial Inspections 3

Accessories Shipped with the Instrument 3

Original Packaging 3

Power Meter and Sensor Cable Requirements 4

Interconnection and Calibration 5

Recommended Calibration Interval 6

Temperature Sensitivity 6

Operating Instructions 7

Modulation Effect 8

To r q u e 8

Overview of the N8480 Series Power Sensors 9

N8485A Power Sensor 12

N8487A Power Sensor 12

N8488A Power Sensor 13

B-models and H-models Information 13

Waveguide-models Information 14

Options 15

Power Meter Firmware Compatibility 16

Power Meter Configuration Changes 17

Measurement Accuracy and Speed 18

Measurement Considerations 18

N8480 Series Power Sensors Operating and Service Guide xi

Page 12

2 Specifications and Characteristics

Specification Definitions 20

Warranted Specifications 20

Characteristic Specifications 20

Conditions 21

Specifications 22

Frequency and Dynamic Power Range 22

Damage Level 23

Maximum SWR 24

Power Linearity 31

Switching Point 35

Zero Set, Zero Drift and Measurement Noise 36

Settling Time 37

Calibration Factor and Reflection Coefficient 38

Calibration Factor Uncertainty 39

Supplemental Characteristics 43

Physical Characteristics 44

3 Service

Cleaning 46

Connector Care 46

Principle of Operations 47

Performance Test 48

Standing Wave Ratio (SWR) and Reflection Coefficient (Rho) Performance Test 48

Replaceable Parts 51

Troubleshooting 57

Repair 57

Diassembly/Reassembly Procedures 58

Diassembly Procedure 58

Reassembly Procedure 58

xii N8480 Series Power Sensors Operating and Service Guide

Page 13

List of Figures

Figure 1-1 N8480 Series power sensors 2

Figure 1-2 Connecting a sensor cable to power meter 5

Figure 1-3 Connecting waveguide flange to the N8486AQ power sensor 7

Figure 1-4 N8480 Series power sensor simplified block diagram 11

Figure 1-5 N8485A power sensor with adapter 12

Figure 1-6 N8487A power sensor with adapter 12

Figure 1-7 N8488A power sensor with adapter 13

Figure 1-8 Auto-averaging settings 17

Figure 2-1 Typical SWR, 10 MHz to 18 GHz (25 °C ±10 °C) for N8481A power sensor 25

Figure 2-2 Typical SWR, 100 kHz to 6 GHz (25 °C ±10 °C) for N8482A power sensor 26

Figure 2-3 Typical SWR, 10 MHz to 26.5 GHz (25 °C ±10 °C) for N8485A power sensor 26

Figure 2-4 Typical SWR, 50 MHz to 50 GHz (25 °C ±10 °C) for N8487A power sensor 27

Figure 2-5 Typical SWR, 10 MHz to 70 GHz (25 °C ±10 °C) for N8488A power sensor 27

Figure 2-6 Typical SWR, 33 MHz to 50 GHz (25 °C ±10 °C) for N8486AQ power sensor 28

Figure 2-7 Typical SWR, 26.5 GHz to 40 GHz (25 °C ±10 °C) for N8486AR power sensor 28

Figure 2-8 Typical SWR, 10 MHz to 18 GHz (25 °C ±10 °C) for N8481B power sensor 29

Figure 2-9 Typical SWR, 100 kHz to 6 GHz (25 °C ±10 °C) for N8482B power sensor 29

Figure 2-10 Typical SWR, 10 MHz to 18 GHz (25 °C ±10 °C) for N8481H power sensor 30

Figure 2-11 Typical SWR, 100 kHz to 6 GHz (25 °C ±10 °C) for N8482H power sensor 30

Figure 2-12 Typical N8481/2/5/7/8A and N8486AR/AQ power linearity at 25 °C, after

zero and calibration with associated measurement uncertainty 32

Figure 2-13 Typical N8481/2B power linearity at 25 °C, after zero and calibration with

associated measurement uncertainty 33

Figure 2-14 Typical N8481/2H power linearity at 25 °C, after zero and calibration with

associated measurement uncertainty 34

Figure 2-15 Autofilter, default resolution, 10 dB decreasing power step (not across the

switching point) 37

Figure 2-16 Typical cal factor and SWR vs. frequency 43

Figure 3-1 Illustrated Parts Breakdown 52

Figure 3-2 Removing power sensor shell 58

N8480 Series Power Sensors Operating and Service Guide xiii

Page 14

xiv N8480 Series Power Sensors Operating and Service Guide

Page 15

List of Tables

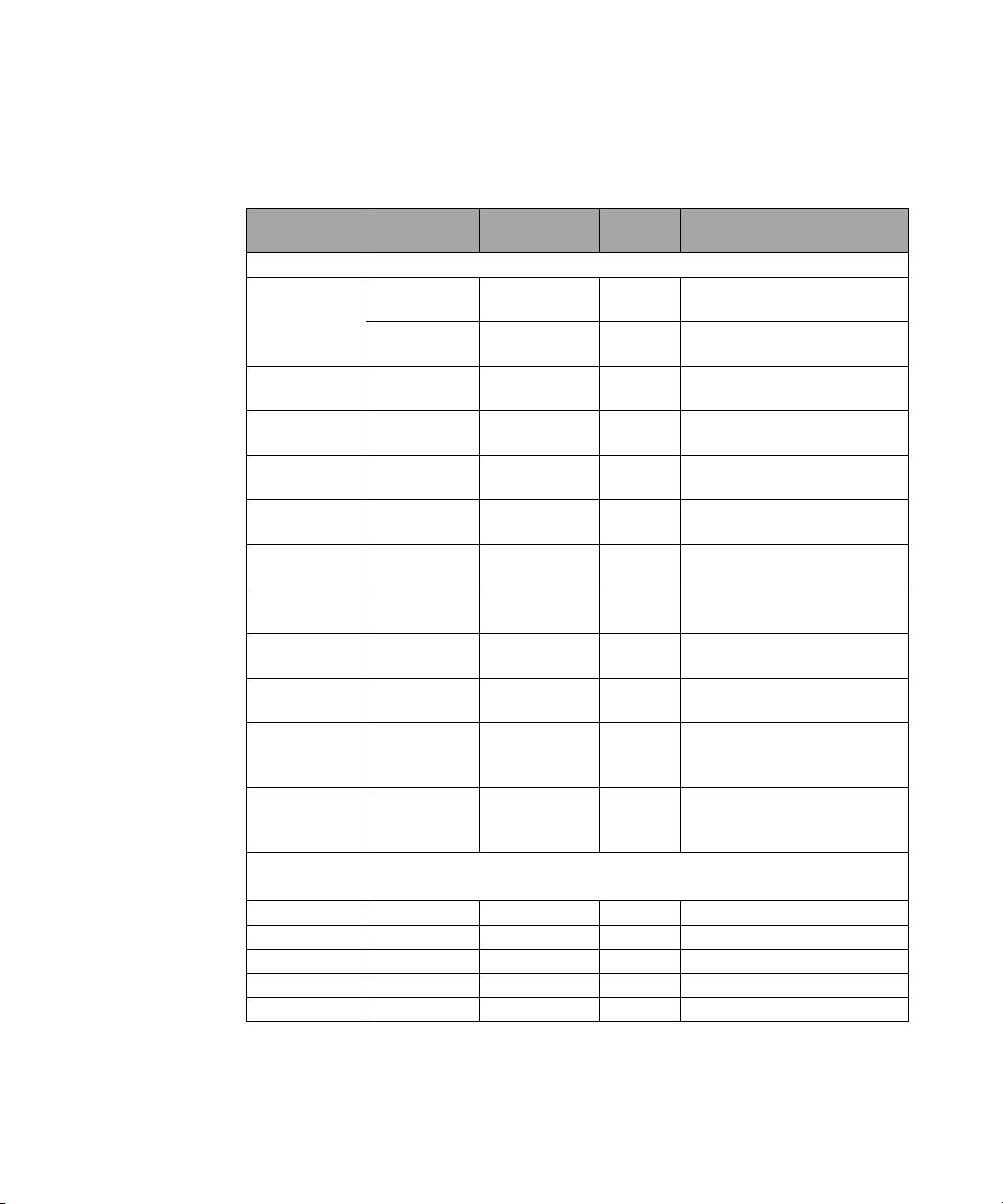

Ta b l e 1 - 1 Power sensor cable options 4

Ta b l e 1 - 2 RF connector type, wrench size, and torque values 8

Ta b l e 1 - 3 Power range in range setting 10

Ta b l e 1 - 4 Power meter firmware 16

Ta b l e 2 - 1 Frequency and dynamic power range 22

Ta b l e 2 - 2 Damage level at average and peak power 23

Ta b l e 2 - 3 Maximum SWR 24

Ta b l e 2 - 4 Power linearity 31

Ta b l e 2 - 5 Switching point hysteresis 35

Ta b l e 2 - 6 Zero set, zero drift and measurement noise 36

Ta b l e 2 - 7 Settling time in normal and x2 mode 37

Ta b l e 2 - 8 Calibration factor uncertainty at 25 ºC ± 3 ºC 39

Ta b l e 2 - 9 Calibration factor uncertainty at 25 ºC ± 10 ºC 40

Ta b l e 2 - 1 0 Calibration factor uncertainty at 0 ºC to 55 ºC 42

Ta b l e 2 - 1 1 Physical dimensions 44

Ta b l e 3 - 1 Reflection coefficient for N8480 Series power sensors (25 ºC ± 10 ºC) 49

Ta b l e 3 - 2 Replaceable parts list for standard N8480 Series power sensors 53

Ta b l e 3 - 3 Replaceable parts list for N8480 Series power sensors with Option CFT 55

N8480 Series Power Sensors Operating and Service Guide xv

Page 16

xvi N8480 Series Power Sensors Operating and Service Guide

Page 17

N8480 Series Power Sensors

Operating and Service Guide

1 Introduction

General Information 2

Initial Inspections 3

Accessories Shipped with the Instrument 3

Original Packaging 3

Power Meter and Sensor Cable Requirements 4

Interconnection and Calibration 5

Recommended Calibration Interval 6

Temperature Sensitivity 6

Operating Instructions 7

Modulation Effect 8

To r q u e 8

Overview of the N8480 Series Power Sensors 9

N8485A Power Sensor 12

N8487A Power Sensor 12

N8488A Power Sensor 13

B-models and H-models Information 13

Waveguide-models Information 14

Options 15

Power Meter Firmware Compatibility 16

Power Meter Configuration Changes 17

Measurement Accuracy and Speed 18

This chapter contains information about initial inspection and overview of the Agilent

N8480 Series power sensors.

Agilent Technologies

1

Page 18

1 Introduction

General Information

This guide contains information about the initial inspection, connections,

specifications, operation, and performance tests of the N8480 Series power

sensors. You can also find a copy of this guide on the EPM and EPM- P

Series Power Meter Documentation CD supplied with the power meter.

Figure 1-1 N8480 Series power sensors

2 N8480 Series Power Sensors Operating and Service Guide

Page 19

Introduction 1

NOTE

Initial Inspections

1 Inspect the shipping container for damage. Signs of damage may include

a dented or torn shipping container or cushioning material that shows

signs of unusual stress or compacting.

2 Carefully remove the contents from the shipping container and verify

that your order is complete.

• If the shipping container or packaging material is damaged, it should be kept until the

contents have been checked mechanically and electrically. If there is mechanical

damage, notify the nearest Agilent Technologies office. Keep the damaged shipping

materials (if any) for inspection by the carrier and Agilent representative. If required, you

can find a list of Agilent Sales and Service Offices on the last page of this guide.

• Ensure you have read and understand the preceding safety information before proceed.

Accessories Shipped with the Instrument

The following items are shipped with every purchase of N8480 Series

power sensor:

• Certificate of Calibration

• N8480 Series Power Sensors Operating and Service Guide

• Product Reference CD

Verify that any options ordered are included with the shipment by

checking the packing list included with the shipment.

Original Packaging

Containers and materials identical to those used in the factory packaging

are available through Agilent Technologies office. If the instrument is

being returned to Agilent Technologies for servicing, attach a tag

indicating the type of service required, return address, model number, and

serial number. Also mark the container FRAGILE to assure careful

handling. In any correspondence, refer to the instrument by model number

and serial number.

N8480 Series Power Sensors Operating and Service Guide 3

Page 20

1 Introduction

Power Meter and Sensor Cable Requirements

Table 1- 1 lists the length of cable option for the N8480 Series power

sensors.

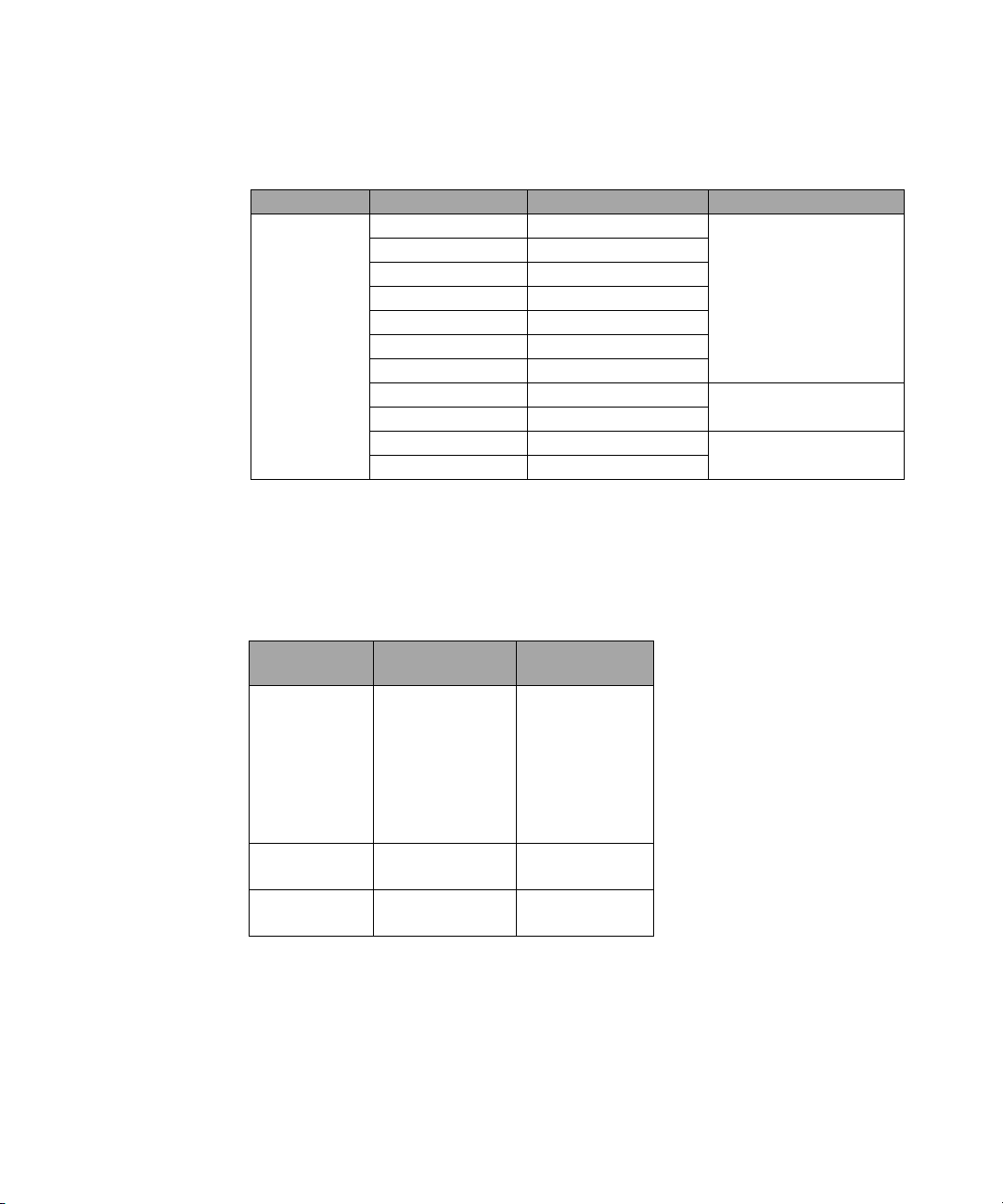

Tab l e 1 - 1 Power sensor cable options

Power Sensor Cable Option Description Supported Power Meter

11730 Family Sensor Cables (Grey)

11730A 1.5 m (5-ft) cable length

11730B 3 m (10-ft) cable length

11730C 6.1 m (20-ft) cable length

11730D 15.2 m (50-ft) cable length

11730E

1

11730F

E9288 Family Sensor Cables (Blue)

E9288A 1.5 m (5-ft) cable length

E9288B 3 m (10-ft) cable length

E9288C 10 m (31-ft) cable length

N1917 Family Sensor Cable Adapter

N1917A 1.5 m (5-ft) cable length

N1917B 3 m (10-ft) cable length

N1917C 10 m (31-ft) cable length

1

Only applicable for E4418B and E4419B power meters.

30.5 m (100-ft) cable

length

61 m (200-ft) cable length

(operate up to 45 °C)

EPM Series power meters

EPM Series power meters

EPM-P Series power

meters

P-Series power meters

1

4 N8480 Series Power Sensors Operating and Service Guide

Page 21

Introduction 1

NOTE

CAUTION

WARNING

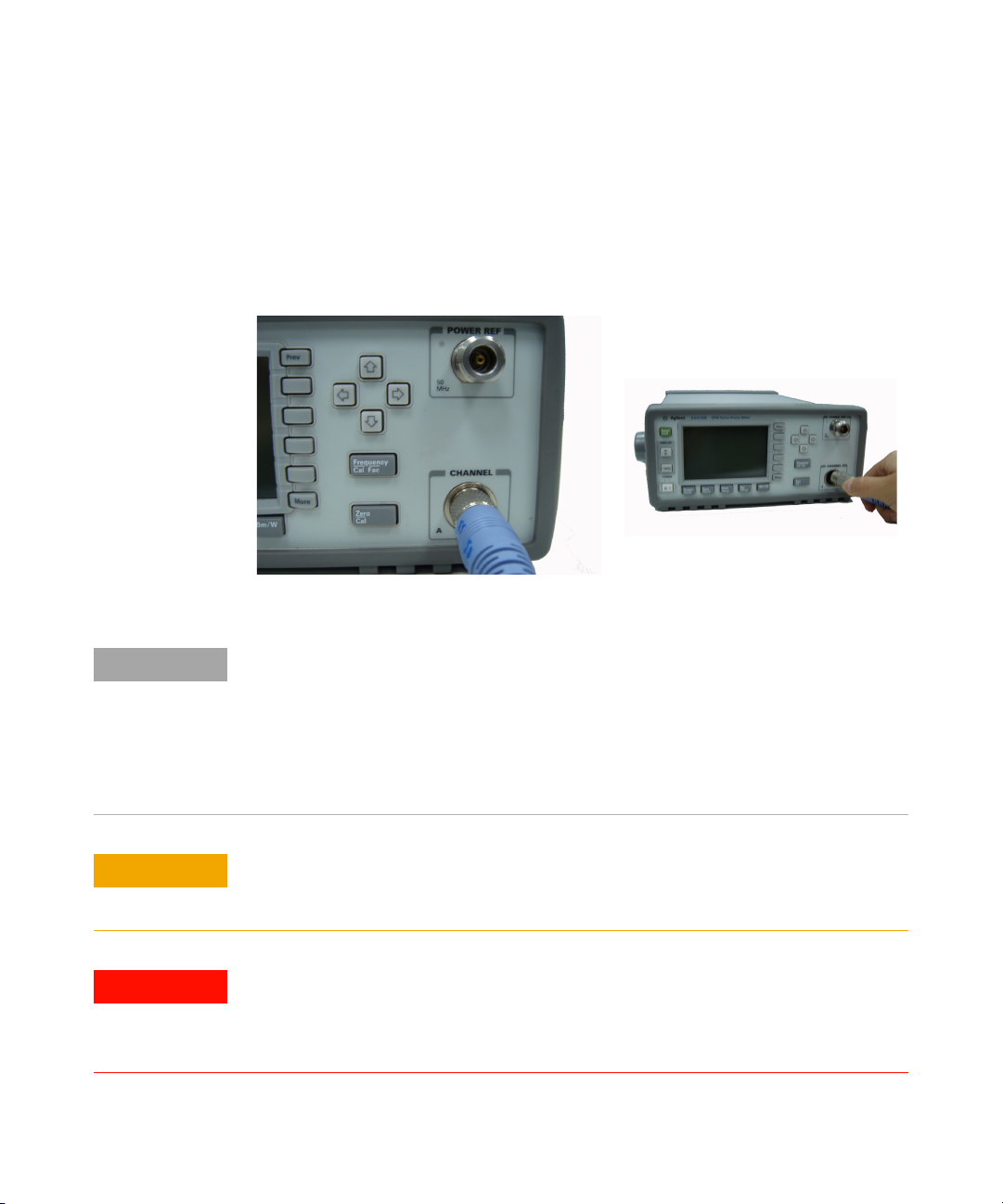

Interconnection and Calibration

Connect one end of the supported sensor cable to the N8480 Series power

sensor and connect the other end of the cable to the power meter’s

channel input. Allow approximately four seconds for the power meter to

download the data from the power sensor’s EEPROM.

Figure 1-2 Connecting a sensor cable to power meter

N8480 Series Power Sensors Operating and Service Guide 5

• For B-models power sensors, you must disconnect the attached attenuator before

connecting it to the power meter for zero and calibration.

• The waveguide-models power sensors have two inputs:

• Type-N connector — for a 50 MHz 1 mW calibration signal generated by the

power meter

• Waveguide flange — to be connected to the test port during actual measurement.

For power sensors with Type-N connector, connect the power sensor to the power

meter by turning the nut only. The power sensor can be damaged if the torque is

applied to the power sensor’s body.

Before connecting the power sensor to other instruments, ensure that all

instruments are connected to the protective (earth) ground. Any interruption of the

protective earth grounding will cause a potential shock hazard that could result in

personal injury.

Page 22

1 Introduction

To carry out a zero and calibration cycle required by the power meter,

refer to the respective power meter’s User’s Guide for details of the power

sensor’s zero and calibration procedures.

Recommended Calibration Interval

Agilent Technologies recommends a one year calibration cycle for the

N8480 Series power sensors.

Temperature Sensitivity

The sensitivity of the power sensor is influenced by ambient temperature.

The sensor should be recalibrated at each change in temperature to obtain

the most accurate results. The sensor has a built- in temperature

compensation that ensures the accuracy of measurement carried out

within 0 to 55 °C, refer to Table 2- 4 for details. For measurement below

–25 dBm, it is recommended to re- apply zero procedure when there has

been a temperature variation of more than ±5 °C since the last zeroing.

6 N8480 Series Power Sensors Operating and Service Guide

Page 23

Introduction 1

CAUTION

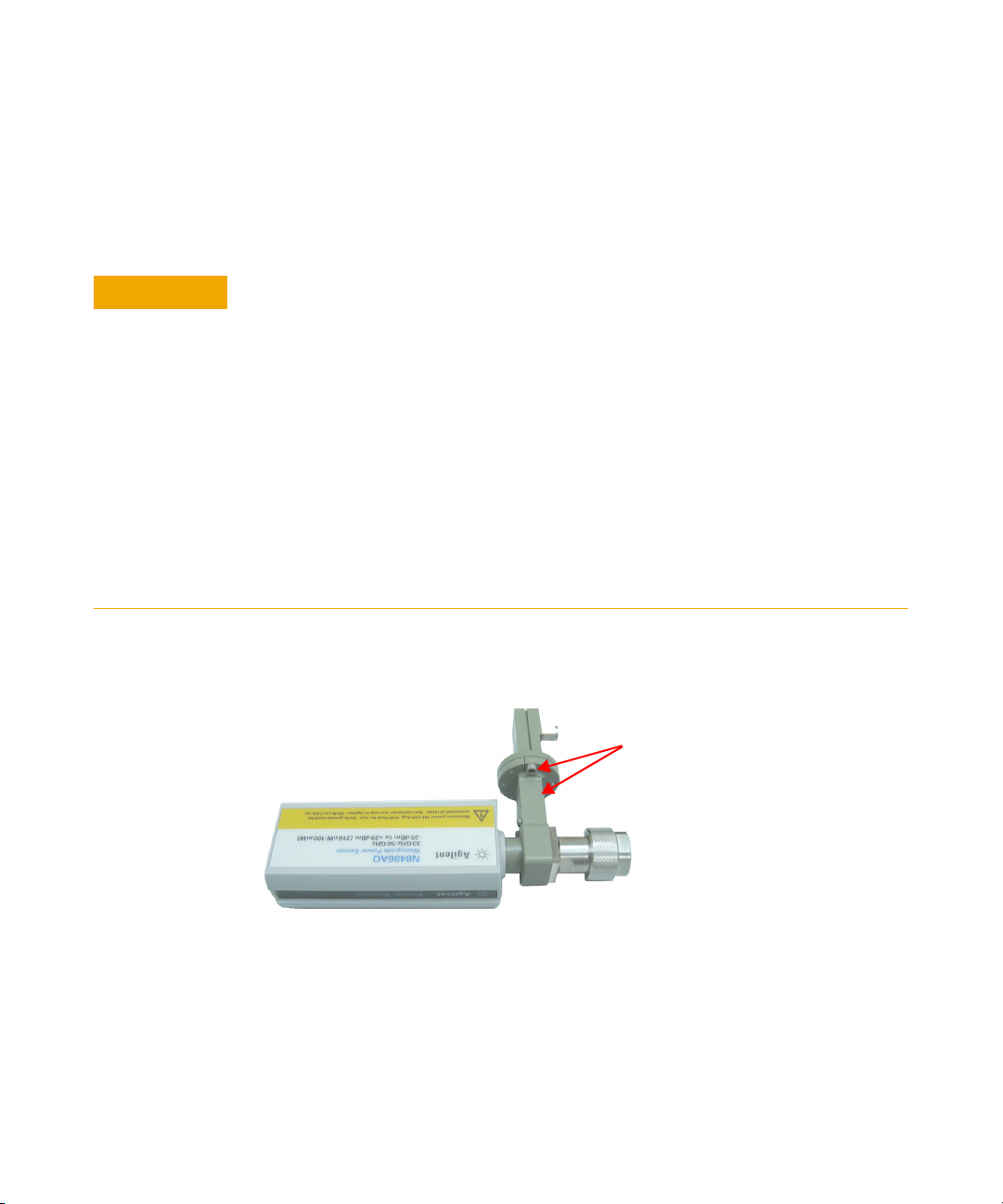

Insert this screw, and the

one opposite (hidden under

the instrument) as shown in

the diagram.

Operating Instructions

To operate the power sensors, refer to the operating instructions in the

respective power meter’s User’s Guide.

For N8486AQ power sensor only.

When connecting the waveguide flange to the power sensor, make sure you follow the

following procedures to avoid any damage to the precision waveguide flange:

1 Torque the waveguide flange’s screws to < 3.75 lb-in (maximum).

2 Insert the two screws as indicated in Figure 1-3 located at the side of the flange. Insert

the remaining two screws to either side of the flange. Tighten the four screws until

finger tight.

3 Tighten the flange using a calibrated torque wrench by going back and forth between

each screws that are opposite to each others. Tighten each screw with a small

incremental torque until the desired torque is achieved.

If you are using the hex ball driver, hold the driver with your thumb and forefinger to

avoid excess torque. You must extremely carefull not to over-torque when using the hex

ball driver, and do not fully torque one screw before tightening the others.

N8480 Series Power Sensors Operating and Service Guide 7

Figure 1-3 Connecting waveguide flange to the N8486AQ power sensor

Page 24

1 Introduction

Modulation Effect

When measuring RF or microwave sources that are modulated at the

chopper frequency (nominally 440 Hz), at the first or second harmonic or

submultiples of the chopper frequency, beat notes may occur. Unless these

beat notes are exactly the chopper frequency, they can usually be

eliminated by averaging (filtering) since the amplitudes are plus and

minus the actual power. These frequencies may also be avoided by

changing the modulation frequency slightly, if possible.

Refer to the respective power meter’s User’s Guide for information on

setting the averaging (filtering).

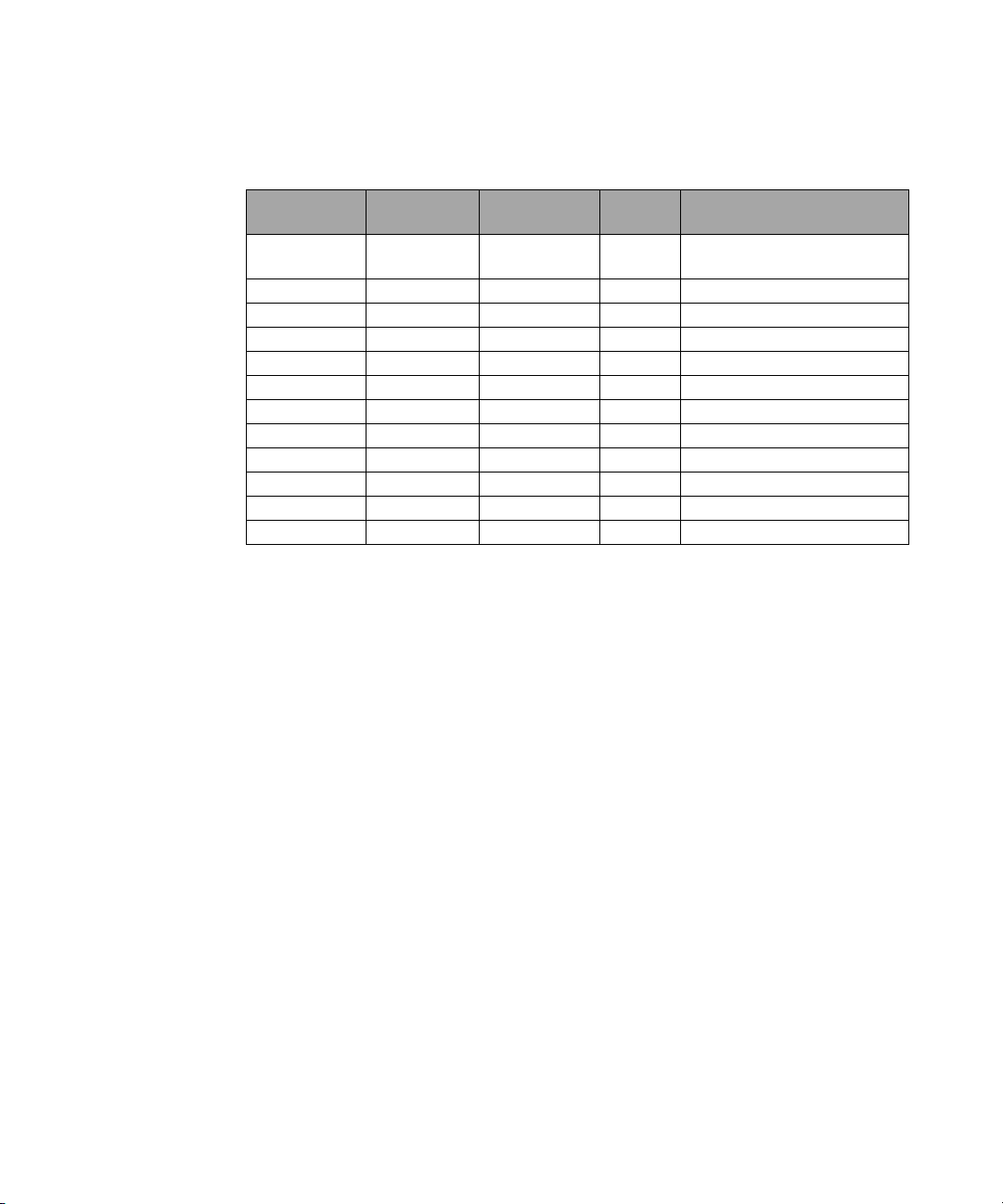

Torque

Table 1- 2 shows the connector type (for connection to DUT) for the power

sensor models. A torque wrench must be used to tighten these connectors.

Only use a wrench set to the correct torque value.

Tab l e 1 - 2 RF connector type, wrench size, and torque values

Model Option RF Connector Wrench Size Torque Value

N8481A

N8482A

N8481B N8481B-100

N8482B N8482B-100

N8481H N8481H-100

N8482H N8482H-100

N8485A

N8487A N8487A-100 2.4 mm (male) 5/16 inch open end 8 lb-in

N8488A N8488A-100 1.85 mm (male) 4/5 inch open end 8 lb-in

N8486AQ N8486AQ-100

N8486AR N8486AR-100

1

Balldriver is used to tighten the screws, instead of the connector.

N8481A-100 Type-N (male)

N8481A-200 APC-7

N8482A-100

Type-N (male)

3/4 inch open end 12 lb-in

N8485A-100 3.5 mm (male) 3/4 inch open end 8 lb-in

Waveguide Flange

UG-383/U

Waveguide flange

UG-599/U

3/32 inch

Balldriver-Hex

3/32 inch

Balldriver-Hex

1

1

3.75 lb-in

3.75 lb-in

8 N8480 Series Power Sensors Operating and Service Guide

Page 25

Overview of the N8480 Series Power Sensors

The N8480 Series power sensors are high accuracy thermocouple power

sensors that allow direct measurement of RF or microwave power through

the heating effect it has on a terminating load. All calibration data for the

N8480 Series power sensors is stored in EEPROM

the power meter when the sensor is connected. In terms of functionality

and performance, they

thermocouple power sensors.

The N8480 Series power sensors are used for measuring the average power

supplied by an RF or microwave source or a device-under-test (DUT). In

use, the power sensor is connected to the RF or microwave source and to

a compatible power meter. The N8480 Series power sensors are compatible

with the EPM Series power meters (E4418B, E4419B, N1913A, and

N1914A), EPM- P Series power meters (E4416A and E4417A), and P- Series

power meters (N1911A and N1912A) only. The N8480 Series power sensors

place a 50 W load on the RF or microwave source. The power meter

indicates the power dissipated in this load in mW or dBm.

The N8480 Series power sensors consist of four sensor model types with

respective power range:

• A- models (–35 dBm to +20 dBm)

• N8481A, N8482A, N8485A, N8487A, and N8488A

• B- models (–5 dBm to +44 dBm)

• N8481B and N8482B

• H- models (–15 dBm to +35 dBm)

• N8481H and N8482H

• Waveguide- models (–35 dBm to +20 dBm)

• N8486AQ and N8486AR

2

replace and surpass the popular 8480

Introduction 1

1

and is downloaded to

3

1

The calibration factor table stored in the EEPROM is not applicable for N8480 Series sensors with

Option CFT.

2

Except for N8488A power sensor. N8488A power sensor is a newly introduced high frequency

sensor. It is not meant to replace any of the the existing 8480 thermocouple power sensors.

3

Option CFT is not available for N8488A power sensor.

N8480 Series Power Sensors Operating and Service Guide 9

Page 26

1 Introduction

NOTE

For B-models power sensors, the calibration factor data is valid only when the sensor is

used with the supplied attenuator.

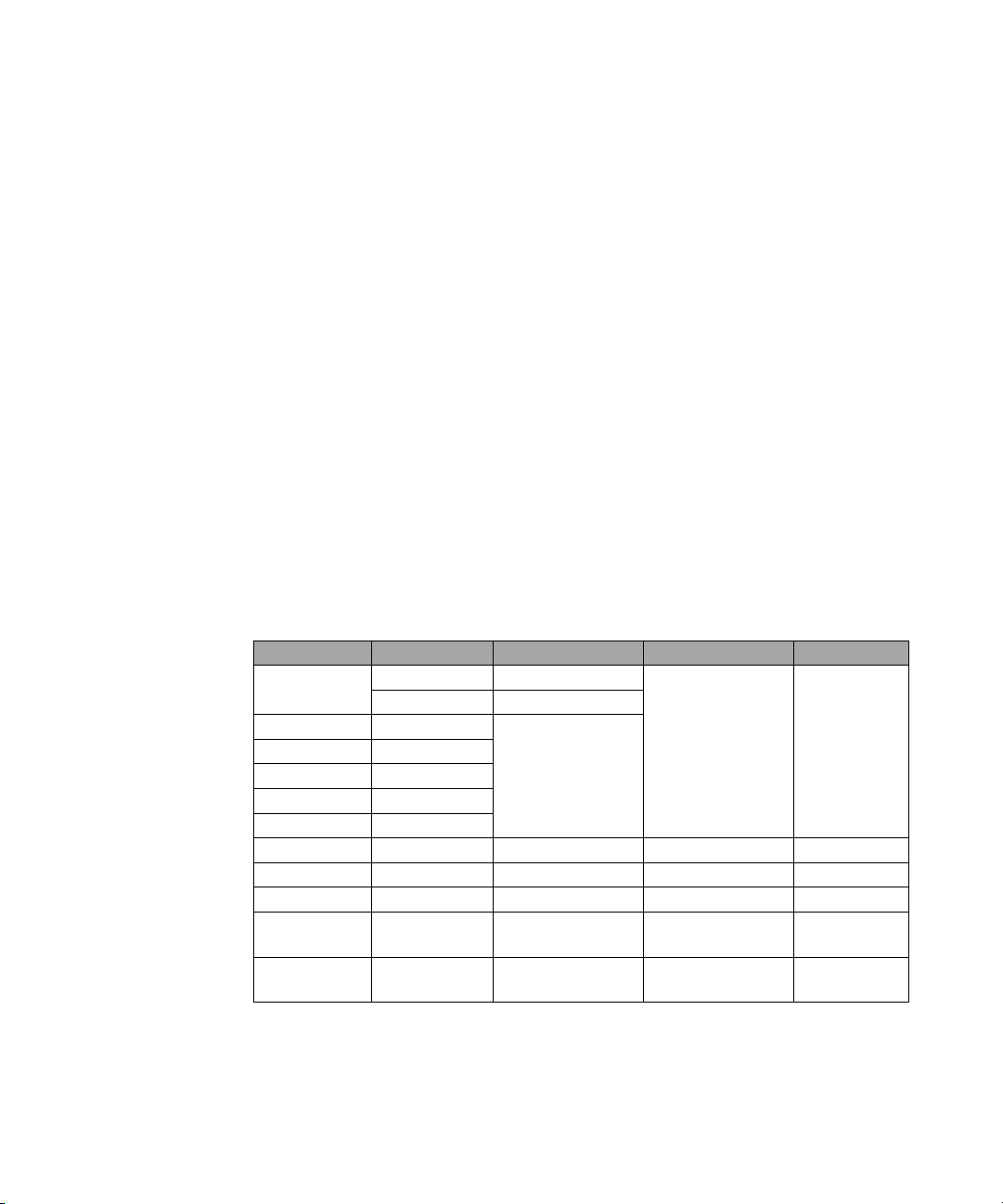

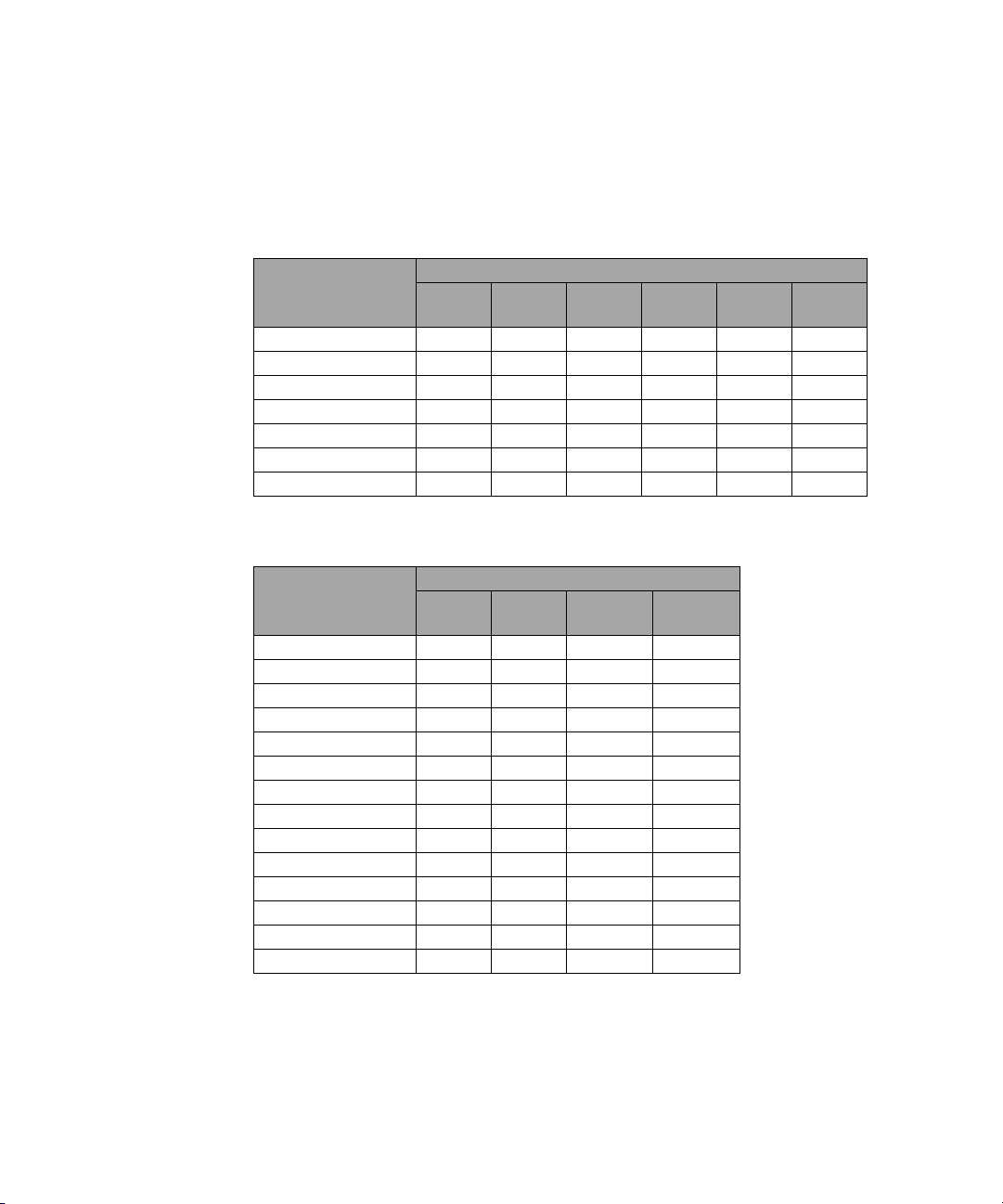

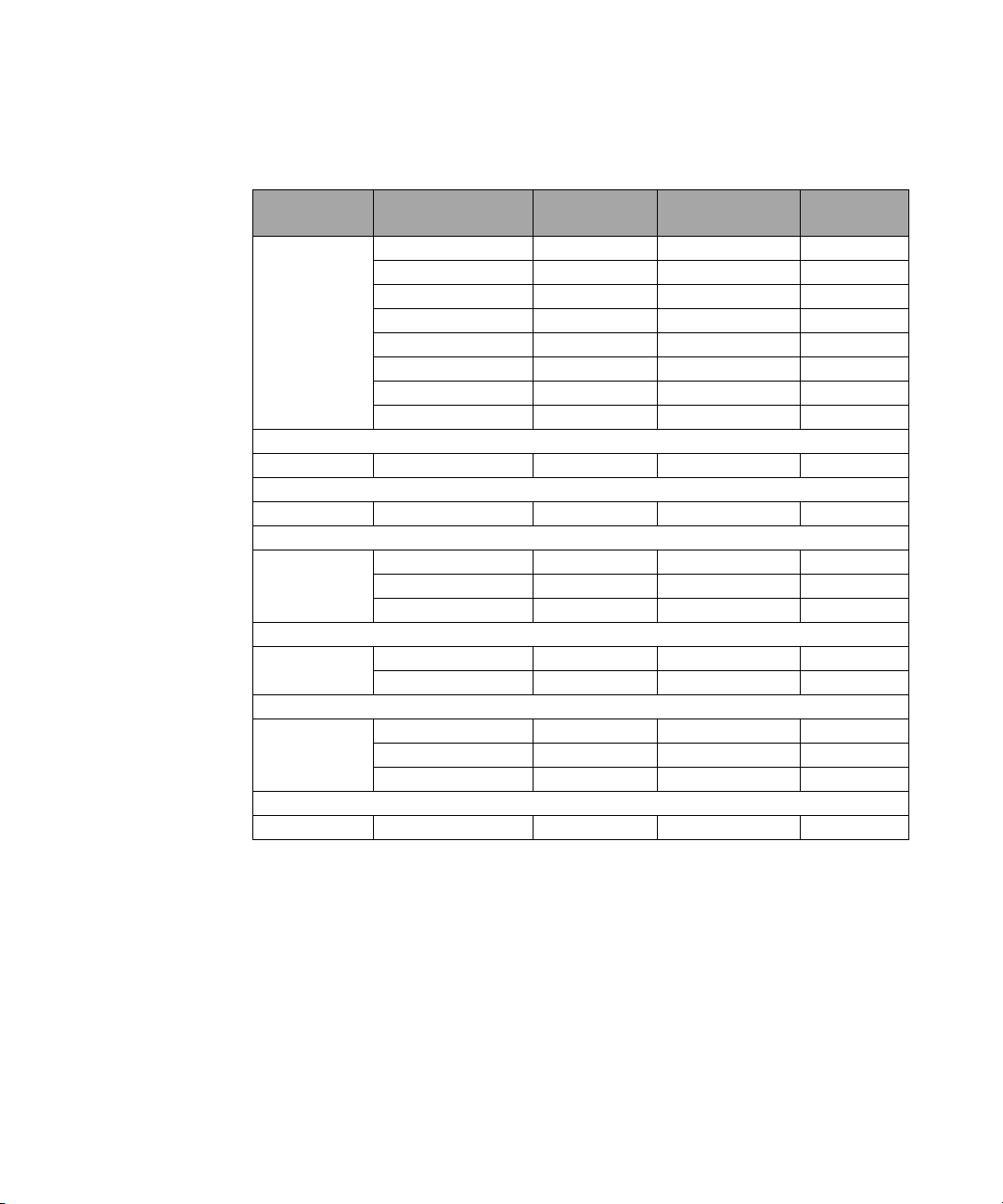

Tab l e 1 - 3 Power range in range setting

Sensor Range Setting Lower Range Upper Range

N8481/2/5/7/8A

and N8486AQ/AR

excluding Option

CFT

N8481/2B excluding

Option CFT

N8481/2H excluding

Option CFT

1

Recommended for pulse signals measurement with period of more than one second.

AUTO (Default) –35 dBm to –1 dBm

LOWER

1

UPPER

AUTO (Default) –5 dBm to +29 dBm

LOWER

1

UPPER

AUTO (Default) –15 dBm to +17 dBm

LOWER

1

UPPER

–35 dBm to –1 dBm

-

–5 dBm to +29 dBm

-

–15 dBm to +17 dBm

-

–1 dBm to +20 dBm

-

–30 dBm to +20 dBm

+29 dBm to +44 dBm

-

0 dBm to +44 dBm

+17 dBm to +35 dBm

-

–10 dBm to +35 dBm

The N8480 Series power sensors (excluding Option CFT) measure power

levels from –35 dBm to +44 dBm (316 nW to 25.1 W), at frequencies from

100 kHz to 67 GHz and have two independent power measurement range

(upper and lower range).

Meanwhile, the N8480 sensors with Option CFT (except for N8488A) only

measure power levels from –30 dBm to +44 dBm (1 µW to 25.1 W) in

single range. Similiar to the E- Series power sensors, the N8480 Series

power sensors are also equipped with EEPROM to store sensor’s

characteristics such as model number, serial number, linearity, temperature

compensation, calibration factor, and so forth.

This feature ensures the correct calibration data is applied by any

compatible power meter connected with N8480 Series power sensor, and

to ensure the accuracy of the measurements.

10 N8480 Series Power Sensors Operating and Service Guide

Page 27

Introduction 1

Thermocouple

Sensor

Thermistor

440 Hz

Gain-select

Circuit

Amplifier

Power Supply

I2C Remote I/O I2C Buffer Circuit

EEPROM

Chopper

RF Power

Pre-amplifier

To Power Meter via Power Sensor Cable

Reference Source

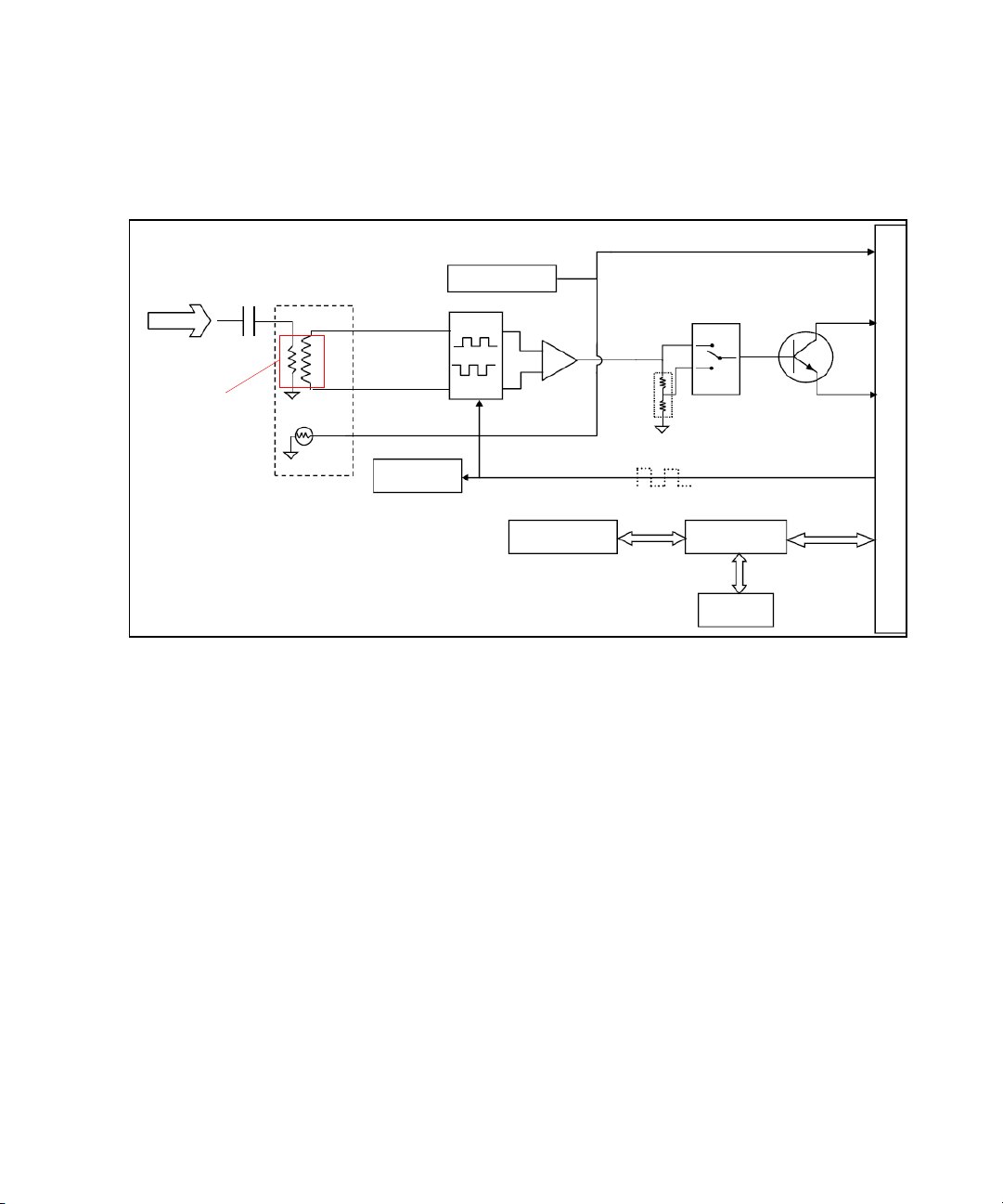

Figure 1-4 N8480 Series power sensor simplified block diagram

Figure 1- 4 illustrates a basic power sensor block diagram for

thermocouple power sensing elements. From the RF or microwave signal

input, the thermocouple detector mounts generate a very low voltage — in

the order of nV. As the DC voltage is very low, it requires amplification

before it can be transferred to the power meter on the standard cables.

The amplification is provided by an input amplifier assembly that consists

of a balanced chopper and an AC coupled low- noise amplifier. The DC

voltage is routed through gold wires to the chopper circuit, which converts

the low- level DC voltage to an AC voltage. To do this, the chopper is

controlled by a 440 Hz square- wave generated by the power meter (the

chop signal). The result is an AC output signal proportional to the DC

input. The AC signal is then amplified to a relatively high-level AC signal

that can be routed to the power meter by standard cables (Agilent 11730

Series cables are available up to 61 metres from –5 °C to 45 °C).

N8480 Series Power Sensors Operating and Service Guide 11

Page 28

1 Introduction

NOTE

NOTE

N8485A Power Sensor

The N8485A power sensor is fitted with 3.5 mm (m) connectors as

standard. To convert the 3.5 mm (m) connector for calibration, an adapter

(3.5 mm (f) to Type- N (m)) is included with the power sensor.

See Figure 1-5.

Figure 1-5 N8485A power sensor with adapter

The 3.5 mm to Type-N adapter is intended for the use of 1 mW, 50 MHz power reference of

the power meter only. Its function as a calibration reference may be compromised if it is

used for other purpose.

N8487A Power Sensor

The N8487A power sensor is fitted with 2.4 mm (m) connector as

standard. To convert the 2.4 mm (m) connector for calibration, an adapter

(2.4 mm (f) to Type- N (m)) is included with the power sensor.

See Figure 1-6.

Figure 1-6 N8487A power sensor with adapter

The 2.4 mm to Type-N adapter is intended for the use of 1 mW, 50 MHz power reference of

the power meter only. Its function as a calibration reference may be compromised if it is

used for other purpose.

12 N8480 Series Power Sensors Operating and Service Guide

Page 29

Introduction 1

NOTE

N8488A Power Sensor

The N8488A power sensor is calibrated to measure power levels in 10 MHz

to 67 GHz frequency range. This sensor is functional up to 70 GHz; with

typical specifications ranging from 67 GHz to 70 GHz.

The N8488A power sensor is fitted with 1.85 mm (m) connector as

standard. To convert the 1.85 mm (m) connector for calibration, an

adapter (2.4 mm (f) to Type- N (m)) is included with the power sensor.

See Figure 1-7.

Figure 1-7 N8488A power sensor with adapter

• The 2.4 mm to Type-N adapter is intended for the use of 1 mW, 50 MHz power reference

of the power meter only. Its function as a calibration reference may be compromised if it

is used for other purpose.

• According to IEEE Standard for Precision Coaxial 1.85 mm Slash Sheet, the 1.85 mm (m)

connector is compatible with the 2.4 mm (f) connector. Hence, the adapter (2.4 mm (f) to

Type-N (m)) can be used to convert the 1.85 mm (m) connector for calibration.

B-models and H-models Information

The B- models (with 30 dB removable attenuator) or H- models (with 20 dB

attenuator) power sensor is a calibrated combination of an attenuator

assembly and a sensor assembly.

The attenuator and sensor assemblies are calibrated as a set and must be

used together when a specified accuracies are to be obtained. These

combination is referred to as a power sensor.

N8480 Series Power Sensors Operating and Service Guide 13

Page 30

1 Introduction

NOTE

WARNING

For B-models power sensors only

• Removal of D-ring from the sensor assembly will void the warranty.

• The D-ring that is available on the input connector; located on the sensor is used to

prevent the sensor from being connected to a high power source when an attenuator is

not attached. The sensors must only be connected to the power meter for calibration or

to a high power attenuator for any RF measurements.

• For B-models power sensors only. The high power attenuator contains a substrate

of beryllium oxide. Beryllium oxide in powder form ia a hazardous material and

may be harmful to your health if inhaled. Do not perform any operation on the

beryllium oxide that might generate dust.

• Defective attenuator should be returned to Agilent Technologies for proper

disposal.

Waveguide-models Information

14 N8480 Series Power Sensors Operating and Service Guide

The waveguide power sensors (excluding Option CFT) measure power

levels from –35 dBm to +20 dBm at frequencies from 26.5 GHz to 50 GHz.

They consist of a multi- stepped coax which adapt the 50 W thermocouple

impedance to the desired waveguide impedance, and hence provide a very

low SWR up to 40 or 50 GHz.

Page 31

Introduction 1

NOTE

NOTE

Options

N8481A Option 200

The N8481A power sensor is fitted with Type- N (m) connector as

standard. Users can choose the sensor to be fitted with APC- 7 connector

by choosing the Option 200.

N8485A Option 033

The N8485A power sensor with Option 033 is calibrated to measure power

levels in the 10 MHz to 33 GHz frequency range.

The N8485A Option 033 power sensor is fitted with a 3.5 mm(m) connector.

N8480 Series power sensors with Option CFT

The N8480 Series power sensors with Option CFT covers –30 dBm to

+20 dBm in a single power range and allows users to use the calibration

factor in two methods:

• manually enter the calibration factor for a particular frequency prior to

make a measurement; or

• manually enter the sensors calibration factor table and select the

frequency of the signal to be measured

The calibration factor data is provided on the label attached to the power

sensor’s cover. This calibration factor is used to make frequency

dependent efficiency correction and it is unique to each sensors.

For Option CFT specifications and characteristics, see

Chapter 2, “Specifications and Characteristics.”

• The calibration factor table stored in the EEPROM is not applicable for N8480 Series power

sensors with Option CFT.

• Please refer to the respective power meter’s User’s Guide on how to make a measurement using

the calibration factor table.

N8480 Series Power Sensors Operating and Service Guide 15

Page 32

1 Introduction

NOTE

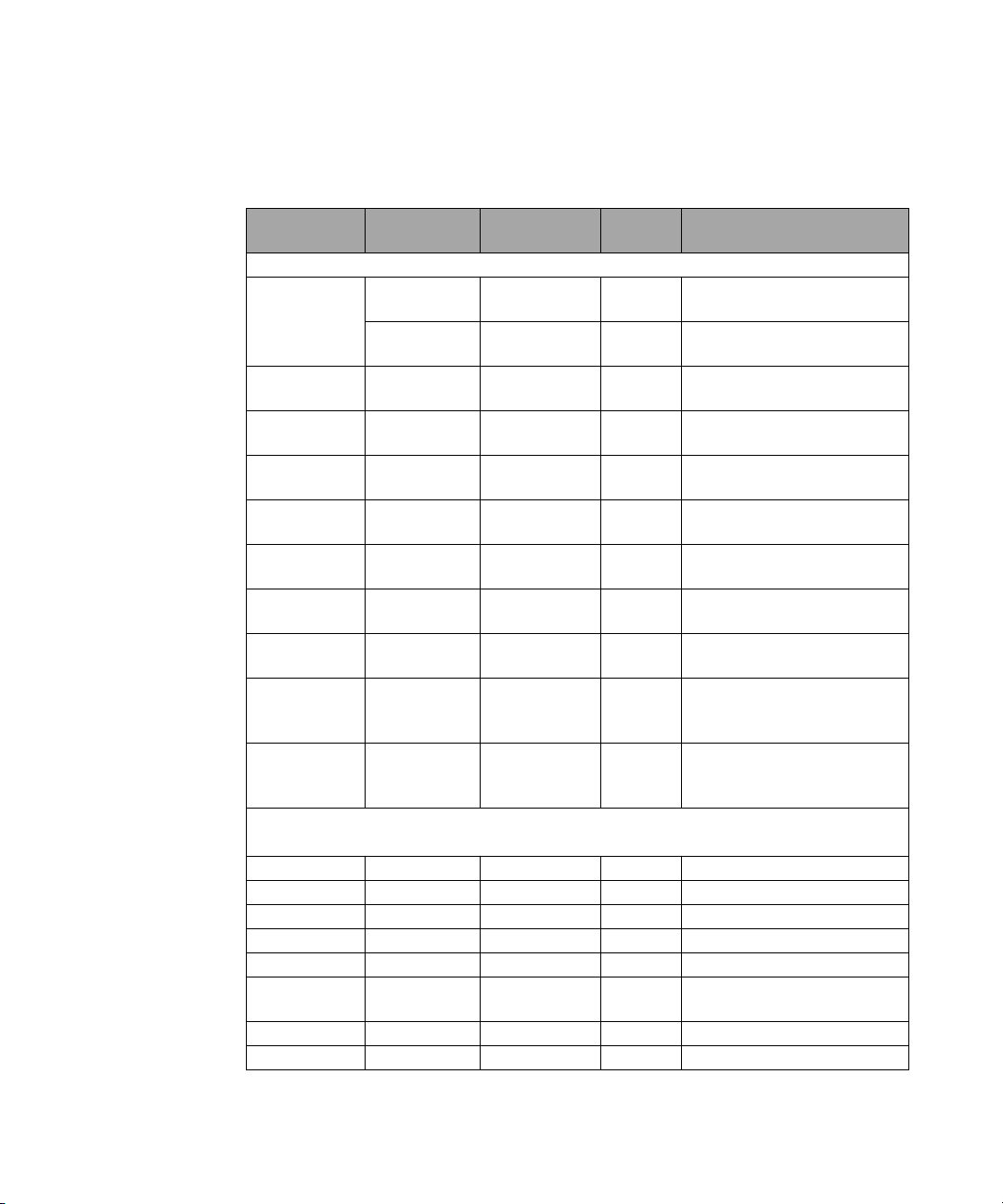

Power Meter Firmware Compatibility

Before using the N8480 Series power sensors, make sure the power meter

is using the latest firmware as shown in Table 1- 4. This is to ensure that

the power meter is compatible with N8480 Series power sensors.

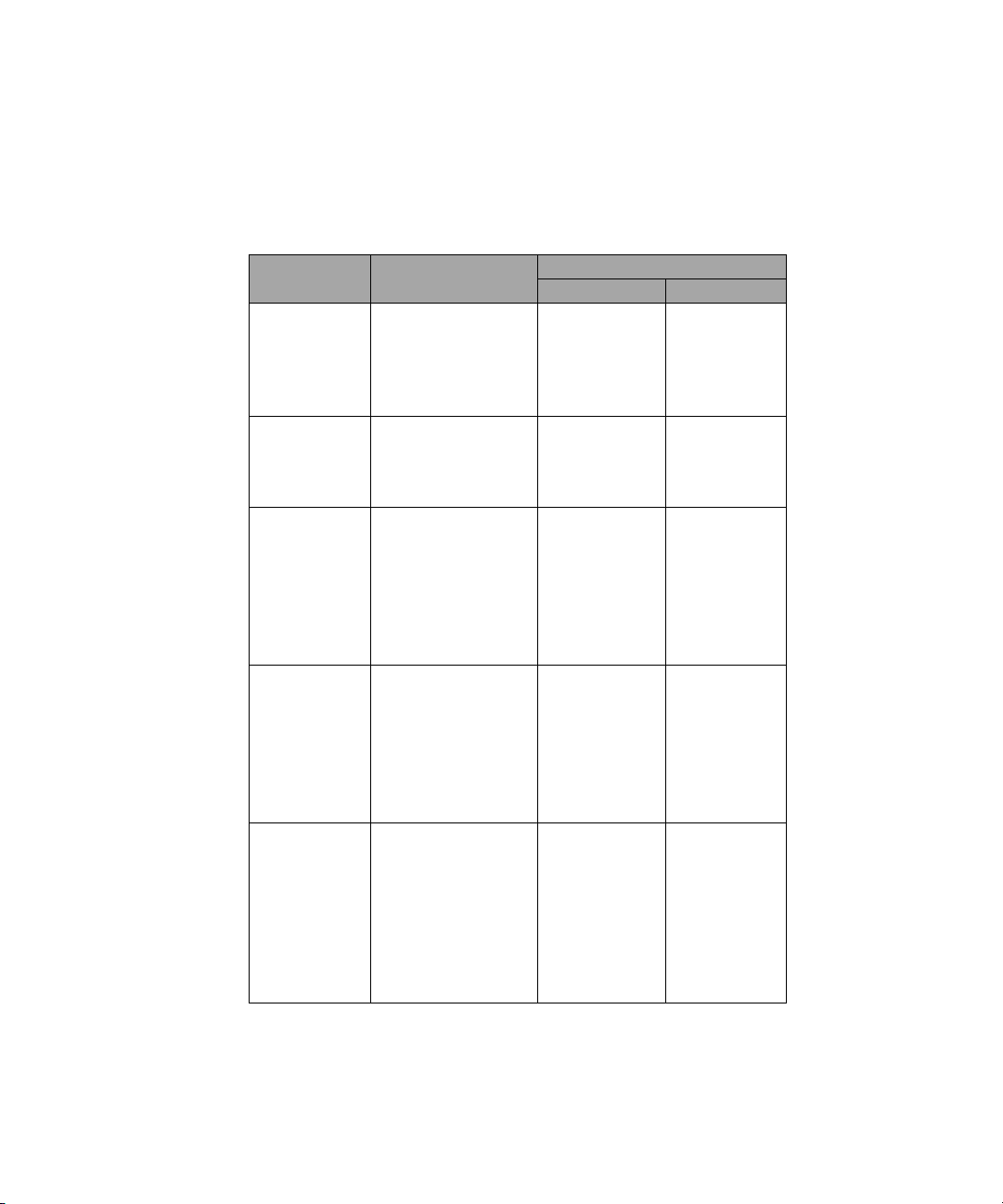

Tab l e 1 - 4 Power meter firmware

Power Meter

EPM Series power meters

EPM-P Series power meters

P-Series power meters

Model

Number

E4418B A1.09.01 and above

E4419B A2.09.01 and above

N1913A

N1914A

E4416A A1.05.01 and above

E4417A A2.05.01 and above

N1911A

N1912A

Compatible

Firmware Revision

A.01.00 and above

A.05.02 and above

For detailed information on the firmware installation, refer to the

respective power meter Web site located at www.agilent.com under

Technical Support > Drivers & Software > Firmware Update.

You can also find the compatible power meter’s firmware as well as the firmware upgrade

procedures in N8480 Series Power Sensors Product Reference CD.

16 N8480 Series Power Sensors Operating and Service Guide

Page 33

Power Meter Configuration Changes

Sensor Power

Minimum

Sensor Dynamic Range

1234

1128

Resolution Setting

Number of Averages

22432

2

4

32

2 2 16 256

2 8 128 128

Maximum

4 64 256 512

Upper Range

Lower Range

Sensor Power

0 dBm

–1 dBm

–30 dBm

–10 dBm

–20 dBm

2

20 dBm

17 dBm

–10 dBm

10 dBm

0 dBm

N8481/2H

30 dBm

29 dBm

0 dBm

20 dBm

10 dBm

N8481/2B

N8481/2/5/7/8A

N8486AQ/AR

NOTE

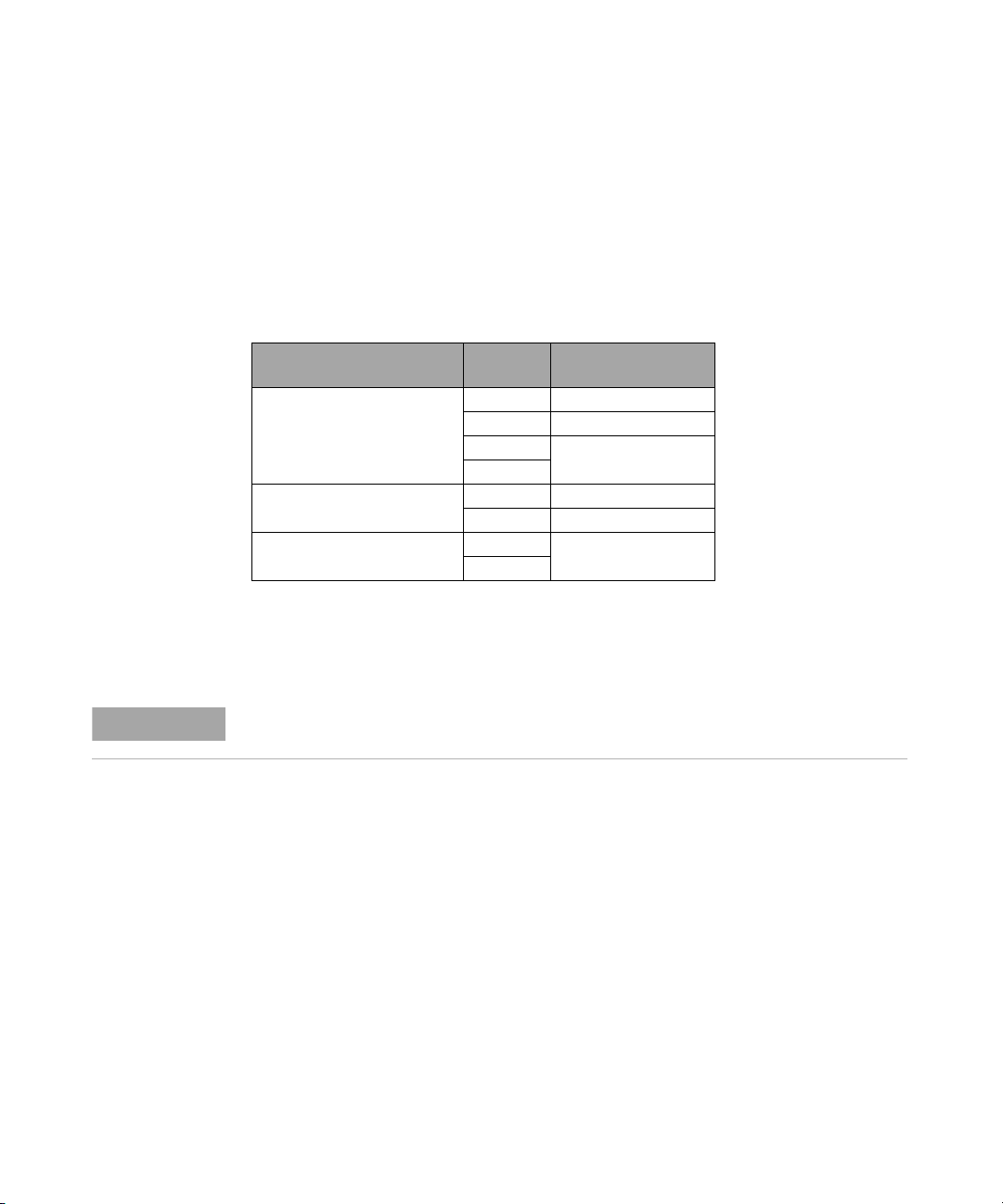

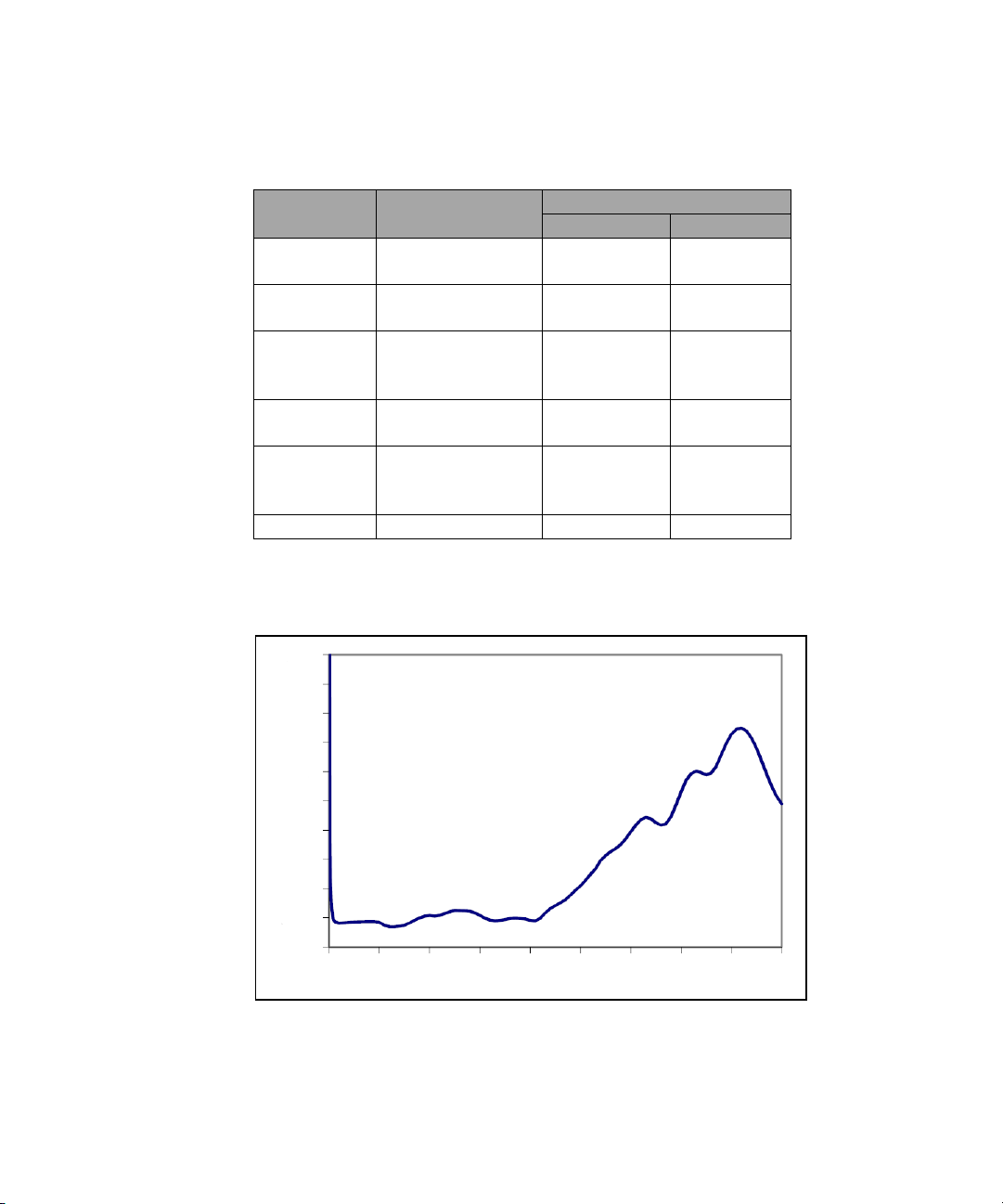

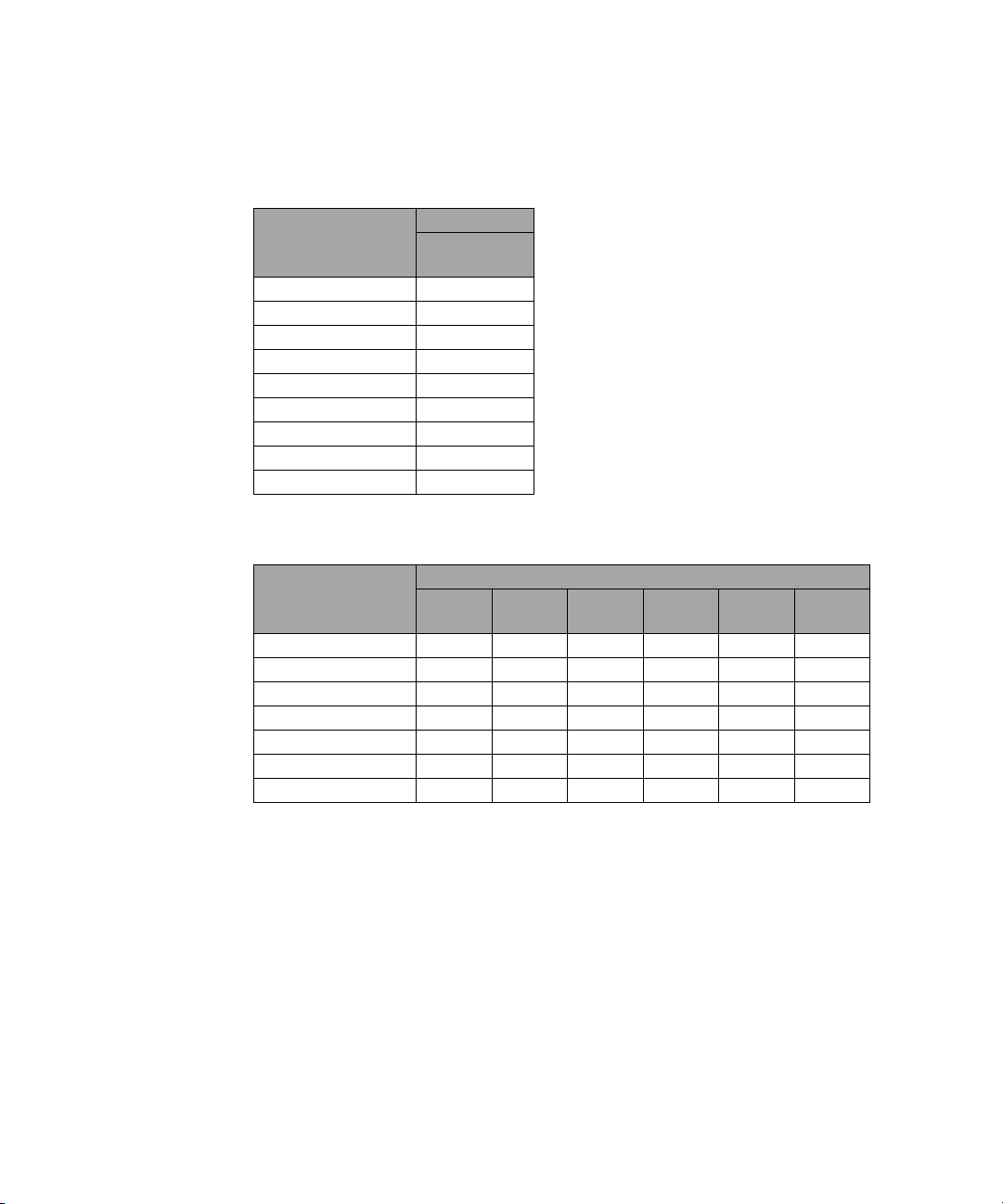

The Agilent EPM Series, EPM- P Series, or P- Series power meters recognize

the Agilent N8480 Series power sensor when it is connected. The N8480

Series power sensors (excluding Option CFT) calibration data is

automatically read by the power meter. In addition, the auto- averaging

settings shown in Figure 1-8 are also automatically configured.

Introduction 1

Figure 1-8 Auto-averaging settings

These values are valid only for the power meter channel connected to an Agilent N8480

N8480 Series Power Sensors Operating and Service Guide 17

Series power sensor. Averaging settings can also be manually configured. Refer to the

respective power meter’s User’s Guide for information on setting the averaging (filtering).

Page 34

1 Introduction

Measurement Accuracy and Speed

The power meter has no internal ranges. The only ranges you can set are

those of the Agilent N8480 Series power sensors and other Agilent

E- Series power sensors. With an Agilent N8480 Series power sensor

(excluding Option CFT) or E- Series power sensor, the range can be set

either automatically or manually. Use autoranging when you are not sure

of the power level you are about to measure.

Measurement Considerations

While autoranging is a good starting point, it is not ideal for all

measurements. Signal characteristics such as crest factor or duty cycle

may cause the power meter to select a range which is not the optimum

configuration for your specific measurement needs. Signals with average

power levels close to the range switch point require you to consider your

needs for measurement accuracy. When measuring pulse signals, you are

recommended to select manual filtering. This allows you to choose the

averaging to cover the many periods of the pulse signal instead of having

it determined by measurement noise. Selecting manual filtering also

changes the behaviour of the autoranging to help prevent frequency range

changes due to pulses. For a very long pulse periods (more than one

second), it may be better to select UPPER range as this will prevent any

possibility of range changes upsetting the measurement.

18 N8480 Series Power Sensors Operating and Service Guide

Page 35

N8480 Series Power Sensors

Operating and Service Guide

2 Specifications and Characteristics

Specification Definitions 20

Warranted Specifications 20

Characteristic Specifications 20

Conditions 21

Specifications 22

Frequency and Dynamic Power Range 22

Damage Level 23

Maximum SWR 24

Power Linearity 31

Switching Point 35

Zero Set, Zero Drift and Measurement Noise 36

Settling Time 37

Calibration Factor and Reflection Coefficient 38

Calibration Factor Uncertainty 39

Supplemental Characteristics 43

Physical Characteristics 44

This chapter contains information about specifications and characteristics of the Agilent

N8480 Series power sensors.

Agilent Technologies

19

Page 36

2 Specifications and Characteristics

Specification Definitions

There are two types of product specifications:

• warranted specifications

• characteristic specifications

Warranted Specifications

Warranted specifications are covered by the product warranty and apply

over 0 °C to 55 °C, unless otherwise noted. Warranted specifications

include measurement uncertainty calculated with 95% confidence.

Characteristic Specifications

Characteristic specifications are not warranted. They describe product

performance that is useful in the application of the power sensors by

giving typical, but non- warranted performance parameters. These

characteristics are shown in italics or denoted as “typical”, “nominal” or

“approximate”.

Characteristic information is representative of the product. In many

cases, it may also be supplemental to a warranted specification.

Characteristic specifications are not verified on all power sensors. The

types of characteristic specifications can be placed in two groups:

• The first group of characteristic types describes 'attributes' common to

all products of a given model or option.

Examples of characteristics that describe 'attributes' are product weight,

and 50 W input Type- N connector. In these examples product weight is

an approximate value and a 50 W input is nominal. These two terms

are most widely used when describing a product's 'attributes'.

20 N8480 Series Power Sensors Operating and Service Guide

Page 37

Specifications and Characteristics 2

• The second group of characteristic types describes 'statistically' the

aggregate performance of the population of products. These

characteristics describe the expected behavior of the population of

products. They do not guarantee the performance of any individual

product. No measurement uncertainty value is accounted for in the

specification. These specifications are referred to as typical.

Conditions

The power meter and power sensor meet its specifications when:

• Stored for a minimum of two hours at a stable temperature within the

operating temperature range, and turned on for at least 30 minutes.

• The power meter and power sensor are within their recommended

calibration periods.

• Used in accordance to the information provided in the power meter’s

User's Guide.

N8480 Series Power Sensors Operating and Service Guide 21

Page 38

2 Specifications and Characteristics

NOTE

Specifications

• Specifications stated in this chapter refer to all N8480 Series power sensors unless

otherwise stated.

• The term “standard” used in table under the Sensor Option column is refering to all

N8480 Series power sensors except Option CFT.

Frequency and Dynamic Power Range

Tab l e 2 - 1 Frequency and dynamic power range

Sensor Option Sensor Model Frequency Range Dynamic Power Range

Standard

N8481A 10 MHz to 18 GHz

N8482A 100 kHz to 6 GHz

N8485A 10 MHz to 26.5 GHz

N8485A Option 033 10 MHz to 33 GHz

N8487A 50 MHz to 50 GHz

N8488A

N8486AR 26.5 GHz to 40 GHz

N8486AQ 33 GHz to 50 GHz

N8481B 10 MHz to 18 GHz

N8482B 100 kHz to 6 GHz

N8481H 10 MHz to 18 GHz

N8482H 100 kHz to 6 GHz

10 MHz to 67 GHz

67 GHz to 70 GHz

–35 dBm to +20 dBm

–5 dBm to +44 dBm

–15 dBm to +35 dBm

22 N8480 Series Power Sensors Operating and Service Guide

Page 39

Specifications and Characteristics 2

Tab l e 2 -1 Frequency and dynamic power range

Sensor Option Sensor Model Frequency Range Dynamic Power Range

N8481A 10 MHz to 18 GHz

N8482A 100 kHz to 6 GHz

N8485A 10 MHz to 26.5 GHz

–30 dBm to +20 dBm

0 dBm to +44 dBm

–10 dBm to +35 dBm

Option CFT

N8485A Option 033 10 MHz to 33 GHz

N8487A 50 MHz to 50 GHz

N8486AR 26.5 GHz to 40 GHz

N8486AQ 33 GHz to 50 GHz

N8481B 10 MHz to 18 GHz

N8482B 100 kHz to 6 GHz

N8481H 10 MHz to 18 GHz

N8482H 100 kHz to 6 GHz

Damage Level

Tab l e 2 -2 Damage level at average and peak power

Sensor Model

N8481A

N8482A

N8485A

N8487A

N8488A

N8486AR

N8486AQ

N8481B

N8482B

N8481H

N8482H

Damage Level

(Average Power)

+25 dBm 15 W/2 µs

+49 dBm 500 W/1 µs

+40 dBm 100 W/1 µs

Damage Level

(Peak Power)

N8480 Series Power Sensors Operating and Service Guide 23

Page 40

2 Specifications and Characteristics

Maximum SWR

Tab l e 2 -3 Maximum SWR

Sensor Model Frequency Band

10 MHz to 30 MHz

30 MHz to 50 MHz

N8481A

N8482A

N8485A

N8487A

N8488A

50 MHz to 2 GHz

2 GHz to 12.4 GHz

12.4 GHz to 18 GHz

100 kHz to 300 kHz

300 kHz to 1 MHz

1 MHz to 2 GHz

2 GHz to 6 GHz

10 MHz to 50 MHz

50 MHz to 100 MHz

100 MHz to 2 GHz

2 GHz to 12.4 GHz

12.4 GHz to 18 GHz

18 GHz to 26.5 GHz

26.5 GHz to 33 GHz

50 MHz to 100 MHz

100 MHz to 2 GHz

2 GHz to 12.4 GHz

12.4 GHz to 18 GHz

18 GHz to 26.5 GHz

26.5 GHz to 40 GHz

40 GHz to 50 GHz

10 MHz to 100 MHz

100 MHz to 2.4 GHz

2.4 GHz to 12.4 GHz

12.4 GHz to 18 GHz

18 GHz to 26.5 GHz

26.5 GHz to 40 GHz

40 GHz to 67 GHz

67 GHz to 70 GHz

Maximum SWR

(25 °C ± 10 °C ) (0 °C to 55 °C )

1.37

1.14

1.08

1.16

1.23

1.54

1.17

1.06

1.07

1.33

1.08

1.05

1.14

1.19

1

1.26

1.32

1.08

1.05

1.10

1.16

1.22

1.30

1.34

1.08

1.08

1.10

1.12

1.21

1.30

1.46

1.48

1.57

1.16

1.11

1.16

1.25

1.57

1.17

1.06

1.08

1.53

1.11

1.07

1.14

1.20

1.28

1.36

1.10

1.07

1.10

1.16

1.22

1.30

1.33

1.08

1.08

1.10

1.14

1.23

1.31

1.47

1.50

24 N8480 Series Power Sensors Operating and Service Guide

Page 41

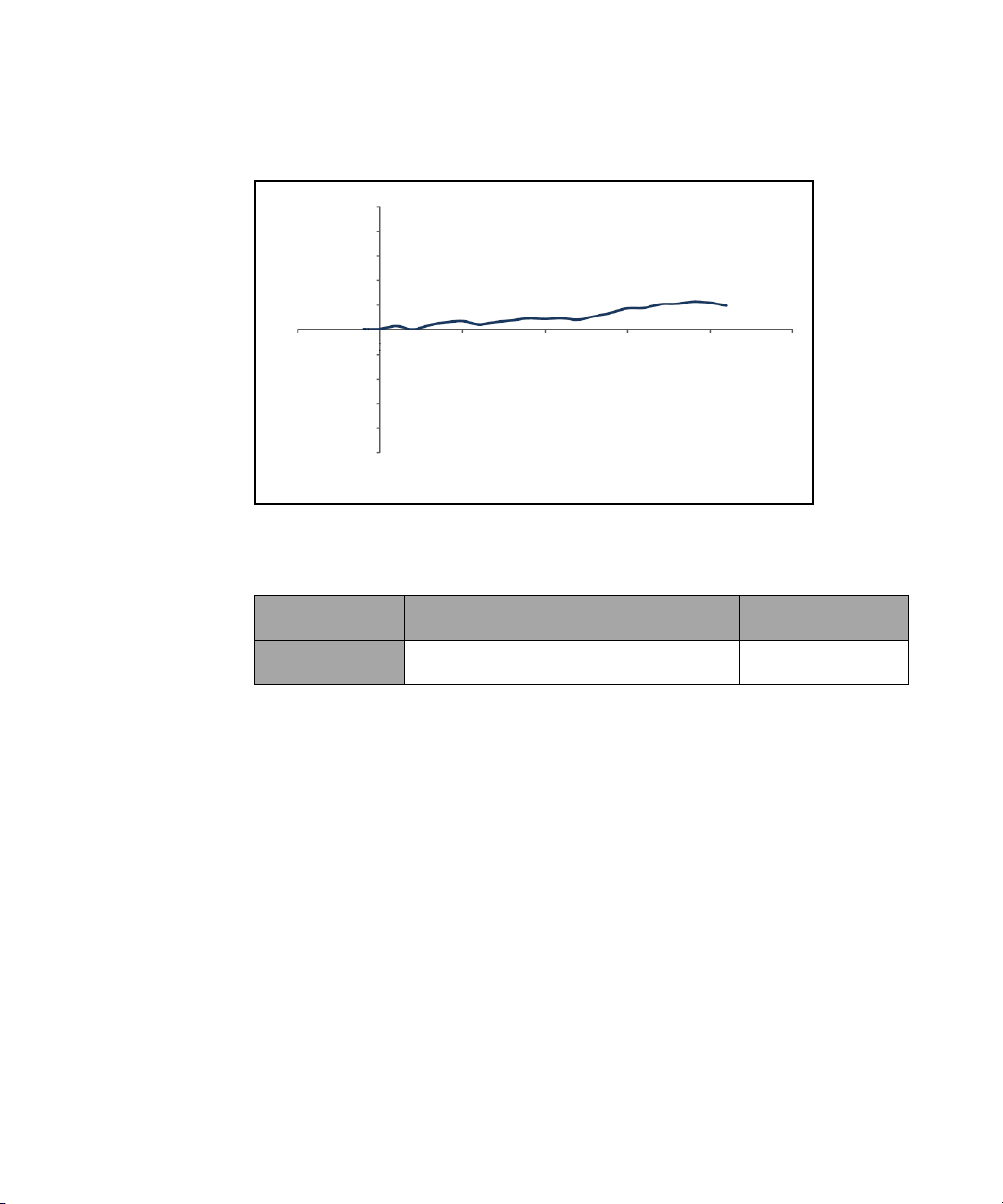

Tab l e 2 - 3 Maximum SWR

Frequency (GHz)

SWR

1

0

2

8

6

4

10

12

14

16

18

1.02

1.04

1.06

1.08

1.10

1.12

1.14

1.16

1.18

1.20

Specifications and Characteristics 2

Sensor Model Frequency Band

2

N8486AR

N8486AQ

50 MHz

26.5 GHz to 40 GHz

2

50 MHz

33 GHz to 50 GHz

10 MHz to 2 GHz

N8481B

2 GHz to 12.4 GHz

12.4 GHz to 18 GHz

N8482B

100 kHz to 2 GHz

2 GHz to 6 GHz

10 MHz to 8 GHz

N8481H

8 GHz to 12.4 GHz

12.4 GHz to 18 GHz

(25 °C ± 10 °C ) (0 °C to 55 °C )

Maximum SWR

1.17

1.40

1.17

1.50

1.09

1.14

1.23

1.08

1.16

1.16

1.22

1.32

1.20

1.40

1.20

1.50

1.10

1.18

1.28

1.10

1.18

1.16

1.22

1.41

N8482H 100 kHz to 6 GHz 1.13 1.14

1

Only applicable for N8485A Option 033.

2

SWR for 50 MHz calibration port . Type-N (m) coaxial connector is used in the 50 MHz calibration.

Figure 2-1 Typical SWR, 10 MHz to 18 GHz (25 °C ±10 °C) for N8481A power sensor

N8480 Series Power Sensors Operating and Service Guide 25

Page 42

2 Specifications and Characteristics

02

1

3

4

56

1

1.01

1.02

1.03

Frequency (GHz)

SWR

1.04

Frequency (GHz)

SWR

1

0

5

20

10

25

30

35

1.02

1.04

1.06

1.08

1.12

1.14

1.16

1.18

1.20

15

1.10

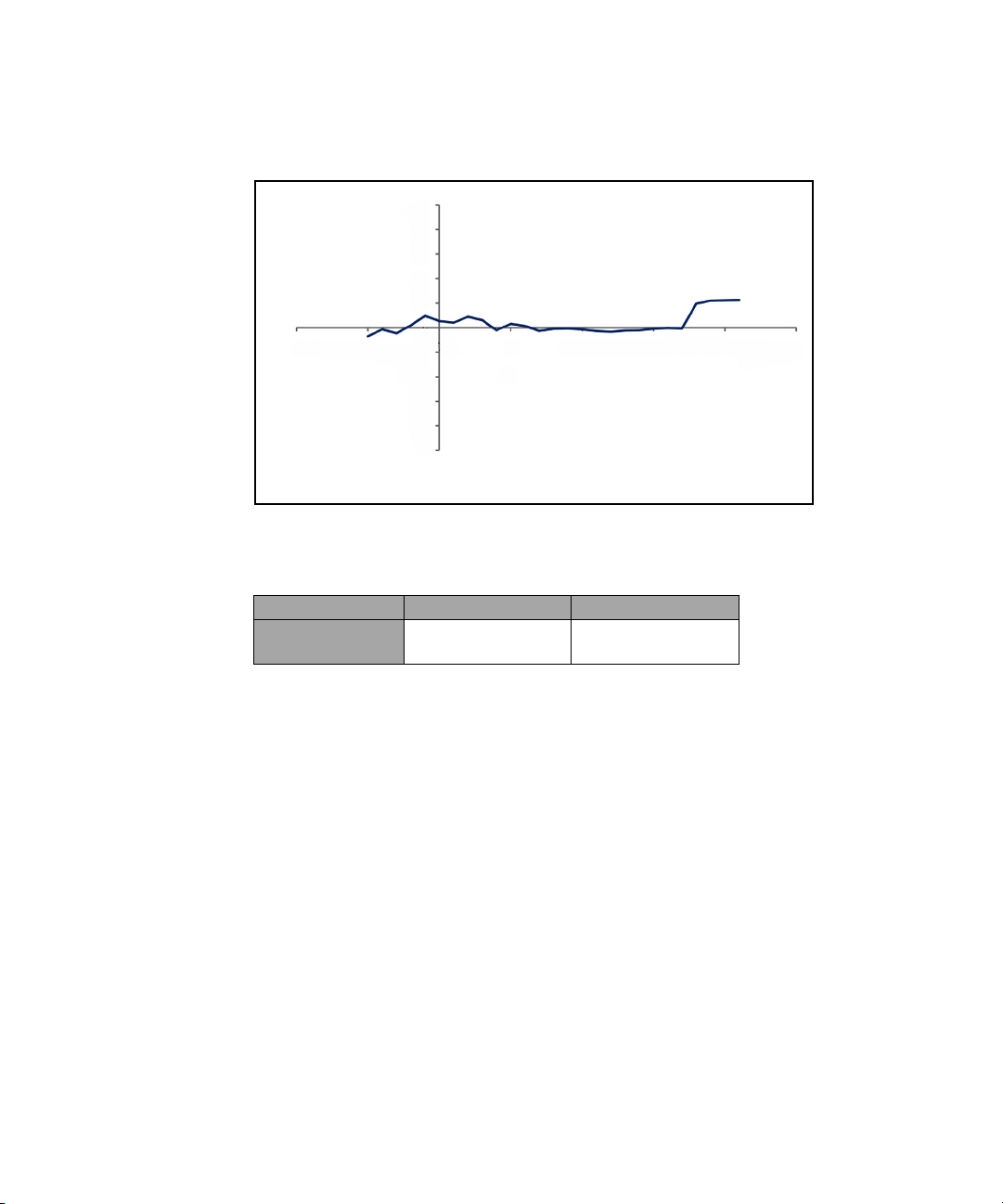

Figure 2-2 Typical SWR, 100 kHz to 6 GHz (25 °C ±10 °C) for N8482A power sensor

26 N8480 Series Power Sensors Operating and Service Guide

Figure 2-3 Typical SWR, 10 MHz to 26.5 GHz (25 °C ±10 °C) for N8485A power sensor

Page 43

Specifications and Characteristics 2

Frequency (GHz)

SWR

1

0

10

20

40

50

60

1.02

1.04

1.06

1.08

1.12

1.14

1.16

1.18

1.20

30

1.10

Frequency (GHz)

SWR

1

0

10

20

40

50

60

1.05

1.10

1.20

1.25

1.30

30

1.15

70

Figure 2-4 Typical SWR, 50 MHz to 50 GHz (25 °C ±10 °C) for N8487A power sensor

Figure 2-5 Typical SWR, 10 MHz to 70 GHz (25 °C ±10 °C) for N8488A power sensor

N8480 Series Power Sensors Operating and Service Guide 27

Page 44

2 Specifications and Characteristics

Frequency (GHz)

SWR

33

36

39

45

48

51

1.06

1.11

1.16

1.21

1.26

1.31

1.36

1.41

42

Frequency (GHz)

SWR

1.04

26.5

29

36.5

31.5

39

41.5

1.06

1.08

1.10

1.12

1.18

1.20

1.22

34

1.14

1.16

Figure 2-6 Typical SWR, 33 MHz to 50 GHz (25 °C ±10 °C) for N8486AQ power sensor

Figure 2-7 Typical SWR, 26.5 GHz to 40 GHz (25 °C ±10 °C) for N8486AR power sensor

28 N8480 Series Power Sensors Operating and Service Guide

Page 45

Specifications and Characteristics 2

Frequency (GHz)

SWR

1

0

2

8

4

10

12

14

1.01

1.02

1.03

1.04

1.06

1.07

1.08

6

1.05

16

18

20

Frequency (GHz)

SWR

1.01

0

1

4

2

5

6

7

1.012

1.014

1.016

1.018

1.022

1.024

1.026

1.028

3

1.020

Figure 2-8 Typical SWR, 10 MHz to 18 GHz (25 °C ±10 °C) for N8481B power sensor

Figure 2-9 Typical SWR, 100 kHz to 6 GHz (25 °C ±10 °C) for N8482B power sensor

N8480 Series Power Sensors Operating and Service Guide 29

Page 46

2 Specifications and Characteristics

Frequency (GHz)

SWR

0

2

8

4

10

12

14

6

16

18 20

1

1.02

1.04

1.06

1.08

1.20

1.22

1.24

1.18

1.16

1.14

1.12

1.10

Frequency (GHz)

SWR

1

1.01

1.02

1.03

1.04

1.06

1.07

1.08

1.09

1.05

0

1

4

2

5

6

3

7

Figure 2-10 Typical SWR, 10 MHz to 18 GHz (25 °C ±10 °C) for N8481H power sensor

Figure 2-11 Typical SWR, 100 kHz to 6 GHz (25 °C ±10 °C) for N8482H power sensor

30 N8480 Series Power Sensors Operating and Service Guide

Page 47

Specifications and Characteristics 2

NOTE

Power Linearity

After zero and calibration at ambient environment conditions.

The N8480 Series power sensors’ linearity is negligible except for the power range

specified in Ta b l e 2 - 4 .

Tab l e 2 - 4 Power linearity

Sensor Model Power Range

N8481A

N8482A

N8485A

N8487A

N8488A

N8486AR

N8486AQ

N8481B

N8482B

N8481H

N8482H

–1 dBm to +15 dBm ±0.52% ±0.80%

+15 dBm to +20 dBm ±0.80% ±1.90%

+29 dBm to +39 dBm ±0.52% ±0.80%

+39 dBm to +44 dBm ±1.66% ±2.75%

+17 dBm to +30 dBm ±0.77% ±1.05%

+30 dBm to +35 dBm ±2.84% ±3.93%

Linearity

(25°C ± 10 °C )

Linearity

(0 °C to 55 °C )

N8480 Series Power Sensors Operating and Service Guide 31

Page 48

2 Specifications and Characteristics

Input Power (dBm)

% Error

0

0.2

0.4

0.6

1.0

0.8

–1.0

–0.8

–0.6

–0.2

–0.4

–5

5

20

10

25

15

Figure 2-12 Typical N8481/2/5/7/8A and N8486AR/AQ power linearity at 25 °C, after

zero and calibration with associated measurement uncertainty

N8481/2/5/7/8A

and N8486AR/AQ

Measurement

Uncertainty (%)

32 N8480 Series Power Sensors Operating and Service Guide

–1 dBm to +10 dBm +10 dBm to +15 dBm +15 dBm to +20 dBm

±0.35 ±0.35 ±0.35

Page 49

Specifications and Characteristics 2

Input Power (dBm)

% Error

0.2

0.4

0.6

1.0

0.8

–1.0

–0.8

–0.6

–0.2

–0.4

5

0

10

20

25

15

Figure 2-13 Typical N8481/2B power linearity at 25 °C, after zero and calibration with

associated measurement uncertainty

N8481/2B +29 dBm to +40 dBm +40 dBm to +44 dBm

Measurement

Uncertainty (%)

±0.35 ±1.21

N8480 Series Power Sensors Operating and Service Guide 33

Page 50

2 Specifications and Characteristics

Input Power (dBm)

% Error

0

0.2

0.4

0.6

1.0

0.8

–1.0

–0.8

–0.6

–0.2

–0.4

–5

5

20

10

25

15

–10

Figure 2-14 Typical N8481/2H power linearity at 25 °C, after zero and calibration with

associated measurement uncertainty

N8481/2H +17 dBm to +30 dBm +30 dBm to +35 dBm

Measurement

Uncertainty (%)

±0.60 ±2.39

34 N8480 Series Power Sensors Operating and Service Guide

Page 51

Specifications and Characteristics 2

NOTE

Switching Point

Switching point is applicable for standard N8480 Series power sensors only.

The N8480 Series power sensors have two power measurement ranges; a

lower range and upper range. The power meter automatically selects the

proper power range. To avoid unnecessary switching when the power level

is near switching point, a Switching Point Hysteresis has been added.

Tab l e 2 - 5 Switching point hysteresis

Switching point hysteresis 0.5 dB

N8481/2/5/7/8A and N8486AQ/AR power sensors

This hysteresis causes the lower range to remain selected until

approximately –0.5 dBm as the power level is increased, above this power

the upper range is selected.

The upper range remains selected until approximately –1.5 dBm as the

signal level decreases, below this power the lower range is selected.

N8481/2B power sensors

This hysteresis causes the lower range to remain selected until

approximately 29.5 dBm as the power level is increased, above this power

the upper range is selected.

The upper range remains selected until approximately 28.5 dBm as the

signal level decreases, below this power the lower range is selected.

N8481/2H power sensors

This hysteresis causes the lower range to remain selected until

approximately 17.5 dBm as the power level is increased, above this power

the upper range is selected.

The upper range remains selected until approximately 16.5 dBm as the

signal level decreases, below this power the lower range is selected.

N8480 Series Power Sensors Operating and Service Guide 35

Page 52

2 Specifications and Characteristics

Zero Set, Zero Drift and Measurement Noise

Tab l e 2 - 6 Zero set, zero drift and measurement noise

Sensor

Model

N8481A

N8482A

N8485A

N8486AR

N8486AQ

N8487A

N8488A

N8481B

N8482B

N8481H

N8482H

Sensor Option Range

Upper 20% to 70% ±63 nW < ±7 nW < 114 nW

Standard

Lower 20% to 70% ±25 nW < ±3 nW < 80 nW

Option CFT N/A

Upper 20% to 70% ±63 nW < ±7 nW < 114 nW

Standard

Lower 20% to 70% ±25 nW < ±3 nW < 80 nW

Option CFT N/A

Upper 20% to 70% ±63 µW < ±7 µW < 114 µW

Standard

Lower 20% to 70% ±25 µW < ±3 µW < 80 µW

Option CFT N/A

Upper 20% to 70% ±6.3 µW < ±0.7 µW < 11.4 µW

Standard

Lower 20% to 70% ±2.5 µW < ±0.3 µW < 8 µW

Option CFT N/A

Conditions

1

(RH)

5

5

5

5

20% to 70% ±63 nW < ±7 nW < 114 nW

5

N/A

20% to 70% ±63 µW < ±7 µW < 114 µW

20% to 70% ±6.3 µW < ±0.7 µW < 11.4 µW

Zero Set

N/A

4

Zero Drift

5

N/A

5

2, 4

Measurement

Noise

N/A

3, 4

5

1. RH is the abbreviation for relative humidity.

2. Within one hour after zero set, at a constant temperature, after a 24 hour warm-up of the power meter with sensor connected.

3. The number of averages at 16 for normal mode and 32 for x2 mode, at a constant temperature,

measured over one minute interval and two standard deviations.

4. The zero set, zero drift, and measurement noise specifications are tested at 50 MHz.

5. N/A is the abbreviation for “not applicable”.

36 N8480 Series Power Sensors Operating and Service Guide

Page 53

Specifications and Characteristics 2

x2 Mode

Maximum sensor power

Sensor

Dynamic

Range

180 ms

Minimum sensor power

400 ms

3.6 s

150 ms

Ty p i c a l

Settling

Times

10 dB

10 dB

10 dB

20 dB

6.6 s

5 dB

Normal Mode

Maximum sensor power

Sensor

Dynamic

Range

200 ms

Minimum sensor power

1 s

6.6 s

150 ms

Ty p i c a l

Settling

Times

10 dB

10 dB

10 dB

20 dB

13.5 s

5 dB

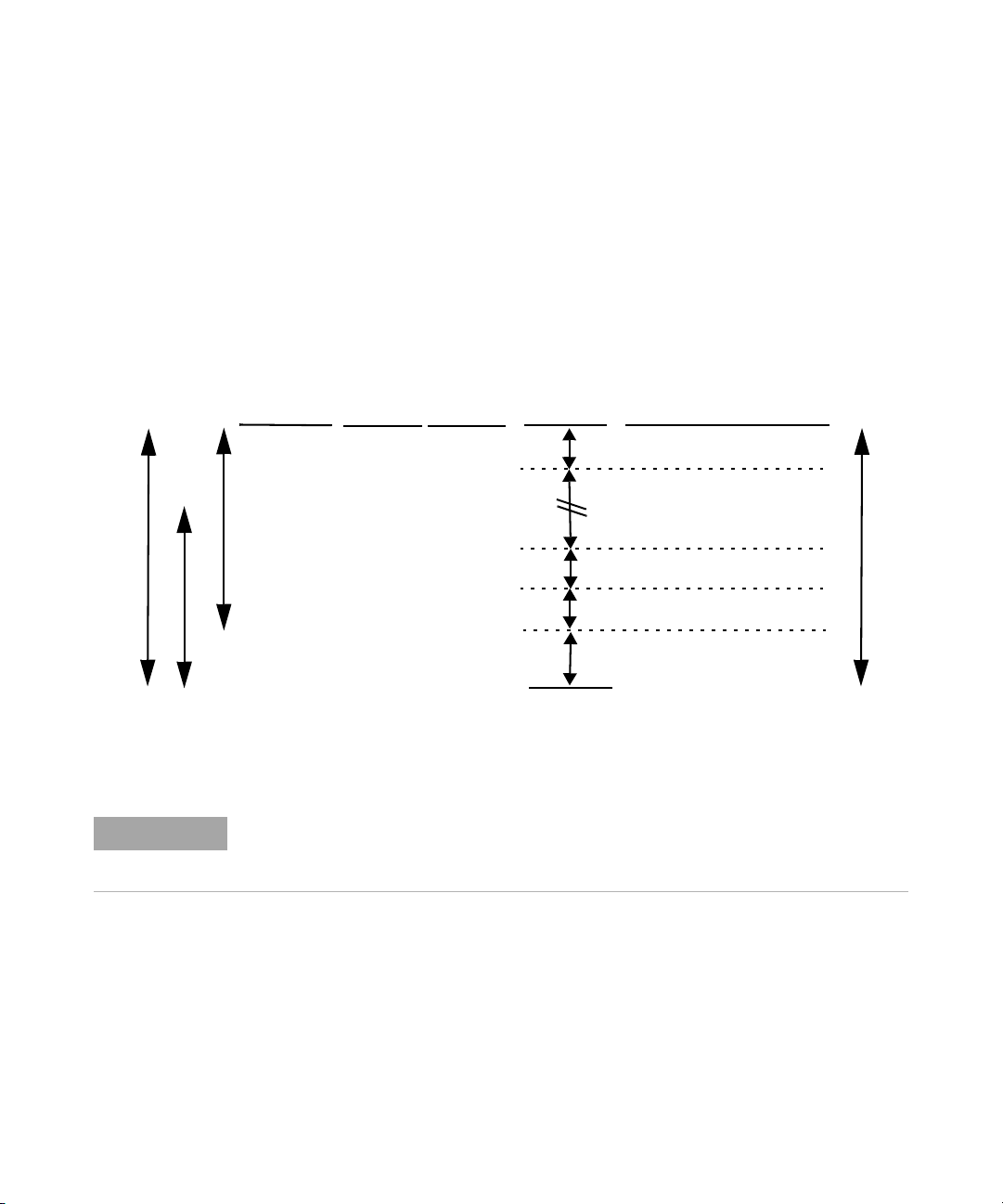

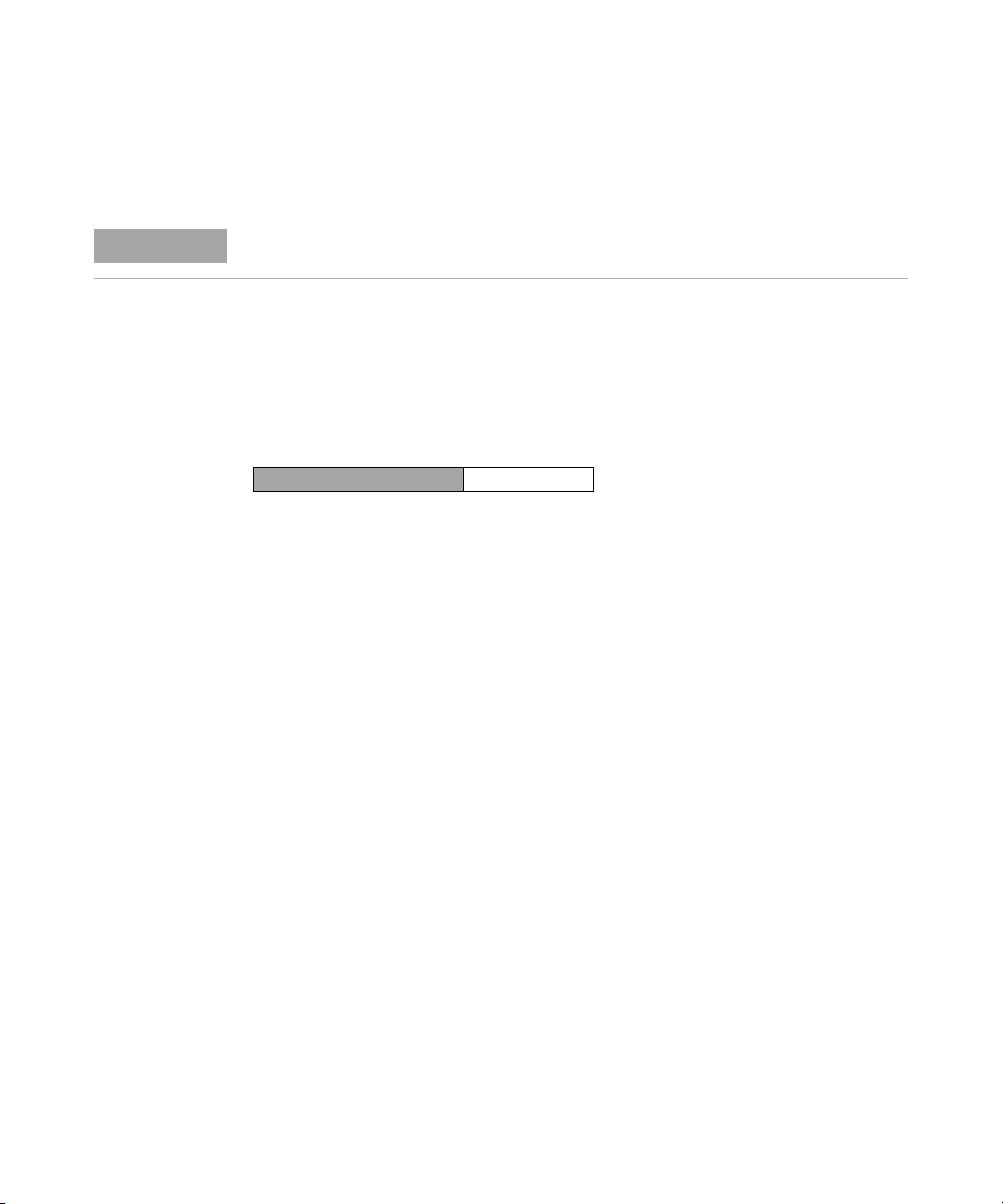

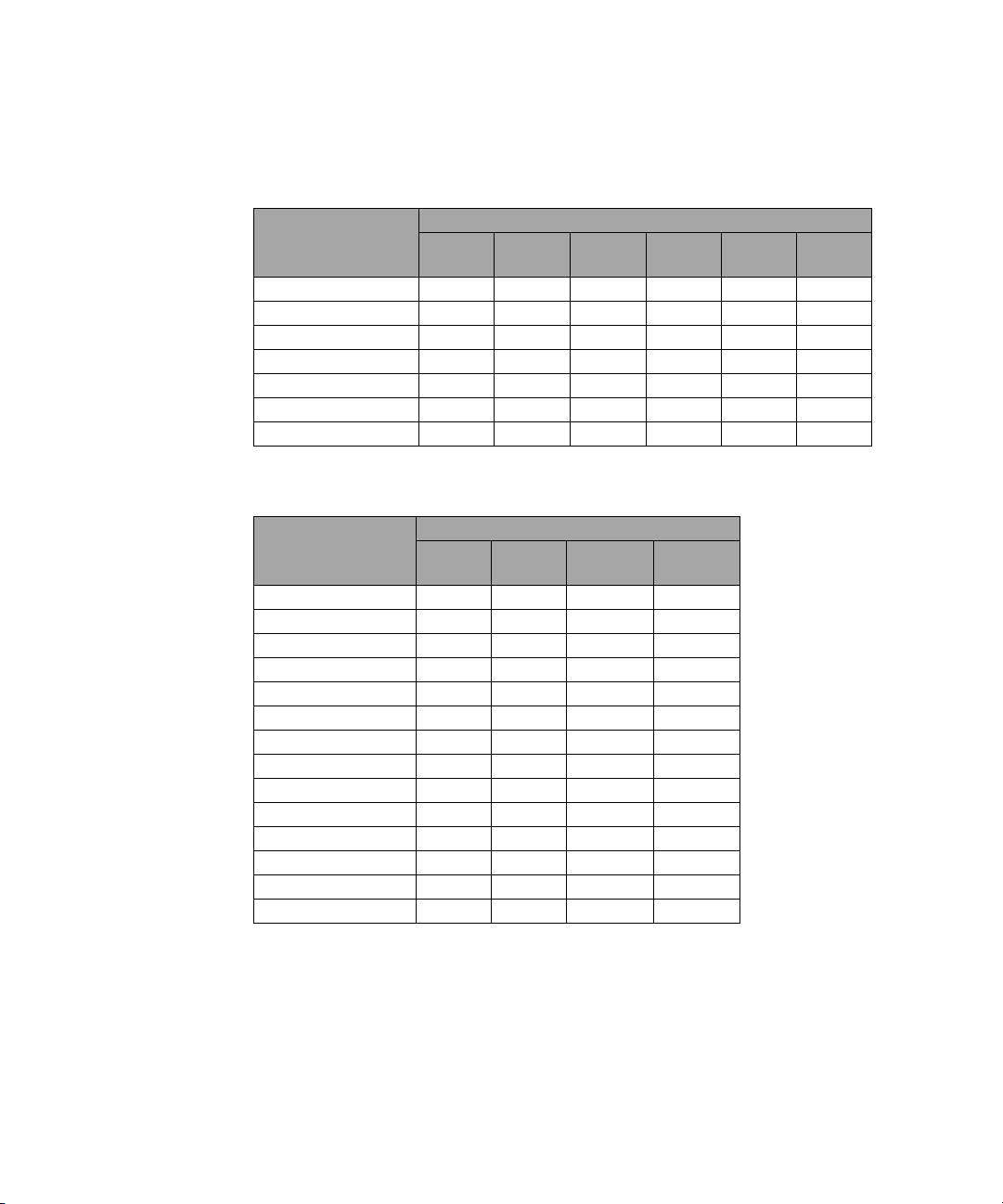

Settling Time

In normal and x2 mode, manual filter, 10 dB decreasing power step (not

across the switching point), the settling time is shown in Table 2- 7.

Tab l e 2 - 7 Settling time in normal and x2 mode

Number of

Averages

Settling Time (s)

(Normal mode)

Response Time

(s) (x2 mode)

1 2 4 8 16 32 64 128 256 512 1024

0.15 0.2 0.3 0.5 1.1 1.9 3.4 6.6 13 27 57

0.15 0.18 0.22 0.35 0.55 1.1 1.9 3.5 6.9 14.5 33

Figure 2-15 Autofilter, default resolution, 10 dB decreasing power step (not across the

switching point)

N8480 Series Power Sensors Operating and Service Guide 37

Page 54

2 Specifications and Characteristics

1 +

r

1 –

r

SWR =

NOTE

Calibration Factor and Reflection Coefficient

Calibration Factor (CF) and Reflection Coefficient (Rho) data are provided

on a data sheet included with the power sensor. This data is unique to

each power sensor. If you have more than one power sensor, match the

serial number on the data sheet with the serial number on the power

sensor you are using. The CF corrects for the frequency response of the

power sensor. The Agilent EPM Series, EPM- P Series, or P- Series power

meters automatically read the CF data stored in the power sensor’s

EEPROM and use it to make the corrections.

Reflection Coefficient (Rho, or

following formula:

Typical measurement uncertainties of the Calibration Factor (CF) are

listed in the following tables. There is only one set of CF data used for

both high and low range of each power sensors. Therefore, there is only

one set of measurement uncertainty data available. The typical

measurement uncertainty data listed in this guide is meant to help users

on the measurement uncertainty estimation. These values are only a

guideline and are not to be used in any accurate uncertainty calculations.

For accurate measurement uncertainty values, please refer to the

measurement report

Do not assume the typical measurement uncertainty listed in this guide as the maximum

calibration factor measurement uncertainty.

1

of the specific power sensor.

r

) relates to the SWR according to the

38 N8480 Series Power Sensors Operating and Service Guide

1

Only applicable with the purchase of Option 1A7 or Option A6J.

Page 55

Specifications and Characteristics 2

Calibration Factor Uncertainty

Tab l e 2 - 8 Calibration factor uncertainty at 25 ºC ± 3 ºC

25 ºC ± 3 ºC

Frequency

100 kHz to 10 MHz - - - 0.91 1.48 0.89

10 MHz to 30 MHz 0.82 1.42 0.77 0.78 1.43 0.79

30 MHz to 500 MHz 0.77 1.48 0.89 0.77 1.49 0.89

500 MHz to 1.2 GHz 0.78 1.48 0.89 0.78 1.49 0.89

1.2 GHz to 6 GHz 0.91 1.58 1.06 0.89 1.56 1.02

6 GHz to 14 GHz 1.26 1.77 1.46 - - -

14 GHz to 18 GHz 1.59 1.92 1.73 - - -

Tab l e 2 - 8 Calibration factor uncertainty at 25 ºC ± 3 ºC (continued)

Frequency

N8481A N8481B N8481H N8482A N8482B N8482H

25 ºC ± 3 ºC

N8485A N8487A N8486AR N8486AQ

100 kHz to 10 MHz - - - -

10 MHz to 30 MHz 0.82 - - 30 MHz to 500 MHz 1.24 1.33 - 500 MHz to 1.2 GHz 1.26 1.35 - -

1.2 GHz to 6 GHz 1.35 1.41 - 6 GHz to 14 GHz 1.66 1.61 - -

14 GHz to 18 GHz 1.83 1.73 - -

18 GHz to 26.5 GHz 2.67 2.26 - -

26.5 GHz to 33 GHz 3.32 2.58 2.68 33 GHz to 34 GHz - 2.80 3.19 3.14

34 GHz to 35 GHz - 2.80 3.19 3.40

35 GHz to 40 GHz - 2.80 3.19 3.14

40 GHz to 45 GHz - 3.66 - 3.19

45 GHz to 50 GHz - 4.23 - 3.26

N8480 Series Power Sensors Operating and Service Guide 39

Page 56

2 Specifications and Characteristics

Tab l e 2 - 8 Calibration factor uncertainty at

25 ºC ± 3 ºC

Frequency

100 kHz to 50 MHz 1.70

50 MHz to 100 MHz 1.60

100 MHz to 2 GHz 1.58

2 GHz to 12.4 GHz 1.75

12.4 GHz to 18 GHz 1.92

18 GHz to 26.5 GHz 2.43

16.5 GHz to 50 GHz 4.56

50 GHz to 67 GHz 5.30

67 GHz to 70 GHz 5.81

N8488A

25 ºC ± 3 ºC (continued)

Tab l e 2 - 9 Calibration factor uncertainty at 25 ºC ± 10 ºC

25 ºC ± 10 ºC

Frequency

100 kHz to 10 MHz - - - 1.28 2.40 0.99

10 MHz to 30 MHz1.471.981.391.031.840.86

30 MHz to 500 MHz1.031.911.101.031.830.98

500 MHz to 1.2 GHz0.971.911.151.081.941.00

1.2 GHz to 6 GHz 1.231.971.421.812.681.19

6 GHz to 14 GHz 1.85 2.69 3.87 - - -

14 GHz to 18 GHz 2.17 3.20 7.01 - - -

N8481A N8481B N8481H N8482A N8482B N8482H

40 N8480 Series Power Sensors Operating and Service Guide

Page 57

Specifications and Characteristics 2

Tab l e 2 - 9 Calibration factor uncertainty at

Frequency

100 kHz to 10 MHz - - - -

10 MHz to 30 MHz 0.94 - - 30 MHz to 500 MHz 1.43 1.84 - 500 MHz to 1.2 GHz 1.52 2.10 - -

1.2 GHz to 6 GHz 1.68 2.36 - 6 GHz to 14 GHz 2.26 2.87 - -

14 GHz to 18 GHz 2.47 3.14 - -

18 GHz to 26.5 GHz 3.75 3.77 - -

26.5 GHz to 33 GHz 4.79 4.17 3.48 33 GHz to 34 GHz - 4.55 4.07 5.02

34 GHz to 35 GHz - 4.55 4.07 4.99

35 GHz to 40 GHz - 4.55 4.07 5.02

40 GHz to 45 GHz - 5.40 - 5.17

45 GHz to 50 GHz - 6.02 - 5.20

N8485A N8487A N8486AR N8486AQ

25 ºC ± 10 ºC (continued)

25 ºC ± 10 ºC

Tab l e 2 - 9 Calibration factor uncertainty at 25 ºC ± 10 ºC (continued)

25 ºC ± 3 ºC

Frequency

N8488A

100 kHz to 50 MHz 2.83

50 MHz to 100 MHz 1.98

100 MHz to 2 GHz 1.84

2 GHz to 12.4 GHz 2.45

12.4 GHz to 18 GHz 2.89

18 GHz to 26.5 GHz 3.52

16.5 GHz to 50 GHz 4.99

50 GHz to 67 GHz 6.46

67 GHz to 70 GHz 7.29

N8480 Series Power Sensors Operating and Service Guide 41

Page 58

2 Specifications and Characteristics

Tab l e 2 - 10 Calibration factor uncertainty at

Frequency

100 kHz to 10 MHz - - - 1.59 2.67 1.41

10 MHz to 30 MHz 4.46 3.64 2.83 0.91 1.73 0.86

30 MHz to 500 MHz 1.57 2.22 1.44 1.16 1.77 1.03

500 MHz to 1.2 GHz 1.65 2.49 1.60 1.54 2.12 1.07

1.2 GHz to 6 GHz 2.04 2.85 1.96 1.99 3.91 1.40

6 GHz to 14 GHz 2.62 3.81 4.81 - - -

14 GHz to 18 GHz 3.27 4.30 9.74 - - -

N8481A N8481B N8481H N8482A N8482B N8482H

0 ºC to 55 ºC

0 ºC to 55 ºC

Tab l e 2 - 10 Calibration factor uncertainty at 0 ºC to 55 ºC (continued)

0 ºC to 55 ºC

Frequency

100 kHz to 10 MHz - - - -

10 MHz to 30 MHz 1.25 - - 30 MHz to 500 MHz 1.98 2.14 - 500 MHz to 1.2 GHz 2.07 2.45 - -

1.2 GHz to 6 GHz 2.40 2.65 - 6 GHz to 14 GHz 2.99 3.17 - -

14 GHz to 18 GHz 3.35 3.41 - -

18 GHz to 26.5 GHz 4.70 4.04 - -

26.5 GHz to 33 GHz 6.41 4.43 3.76 33 GHz to 34 GHz - 4.84 4.25 6.04

34 GHz to 35 GHz - 4.84 4.25 6.04

35 GHz to 40 GHz - 4.84 4.25 6.04

40 GHz to 45 GHz - 5.70 - 5.86

45 GHz to 50 GHz - 6.19 - 6.59

N8485A N8487A N8486AR N8486AQ

42 N8480 Series Power Sensors Operating and Service Guide

Page 59

Specifications and Characteristics 2

92

0.9

0.95

1

1.05

1.1

1.15

Ty p ic al CF

Ty p ic al SW R

Cal Factor

SWR

Typical CF and SWR vs. Frequency

91

0.05

1

12

8

4

15

19

93

94

95

96

97

98

99

100

1

1.2

1.25

Frequency (GHz)

23

27

Tab l e 2 - 10 Calibration factor uncertainty at

0 ºC to 55 ºC (continued)

25 ºC ± 3 ºC

Frequency

N8488A

100 kHz to 50 MHz 3.69

50 MHz to 100 MHz 2.63

100 MHz to 2 GHz 2.40

2 GHz to 12.4 GHz 2.61

12.4 GHz to 18 GHz 3.15

18 GHz to 26.5 GHz 4.50

16.5 GHz to 50 GHz 5.67

50 GHz to 67 GHz 7.18

67 GHz to 70 GHz 8.69

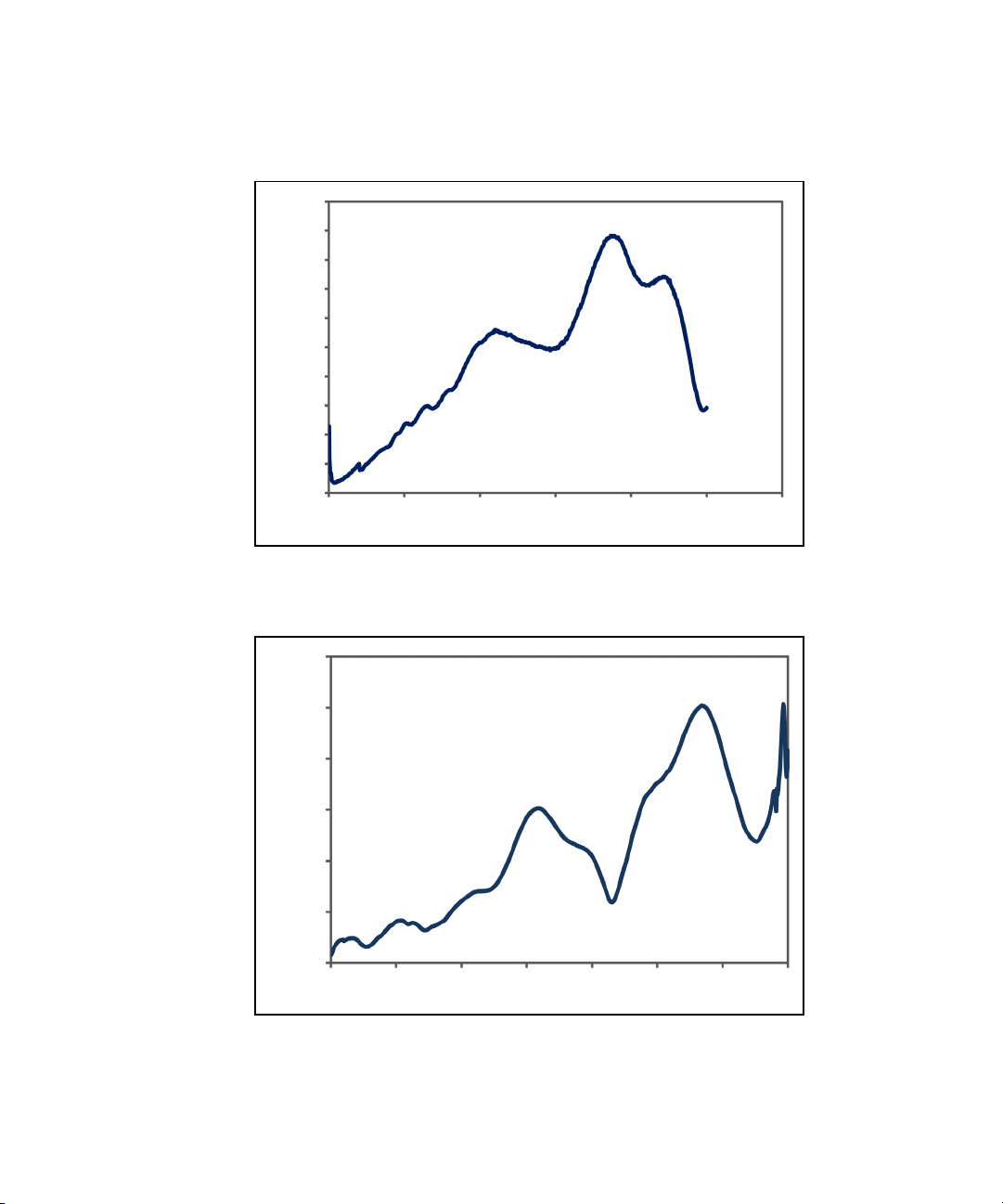

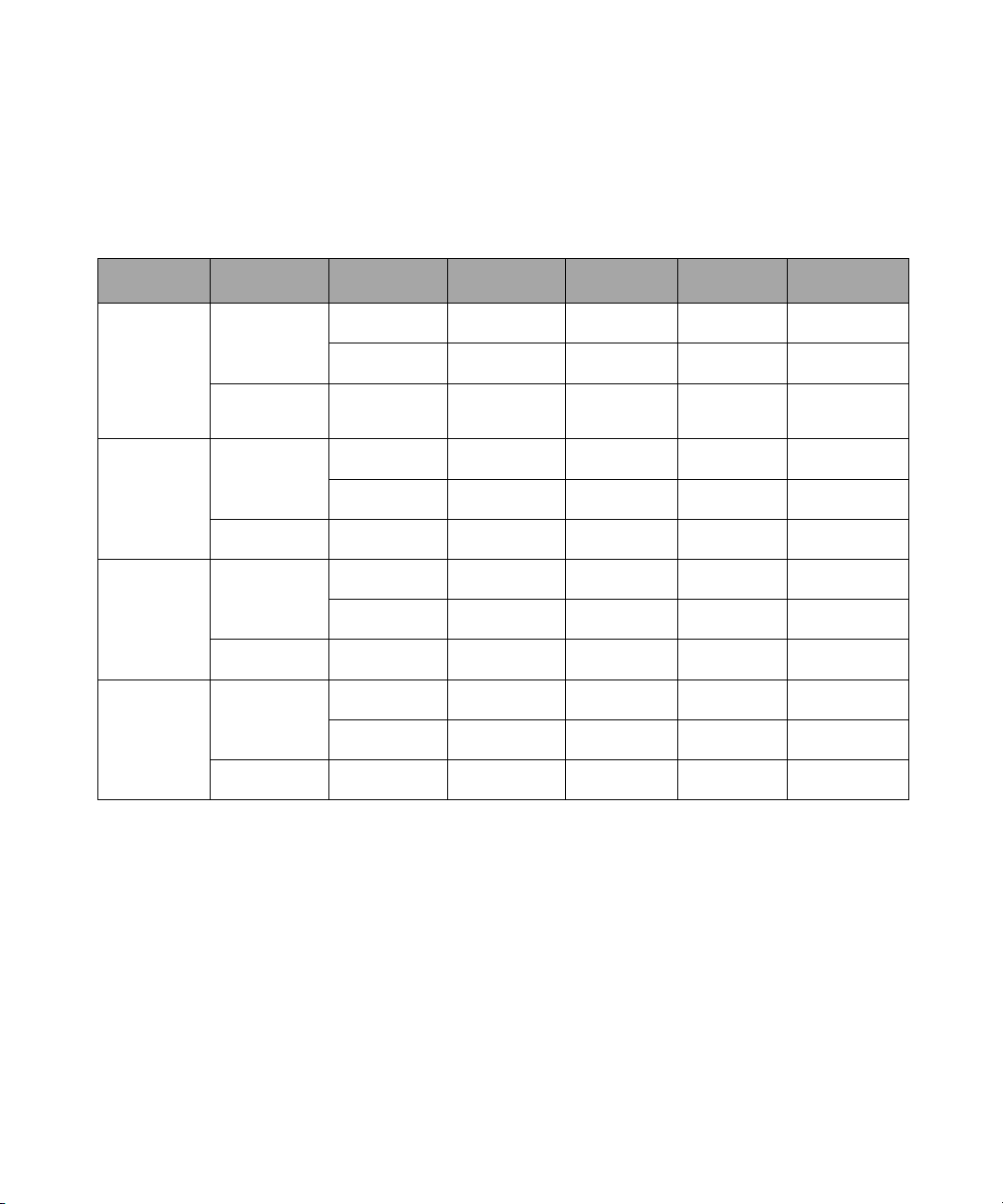

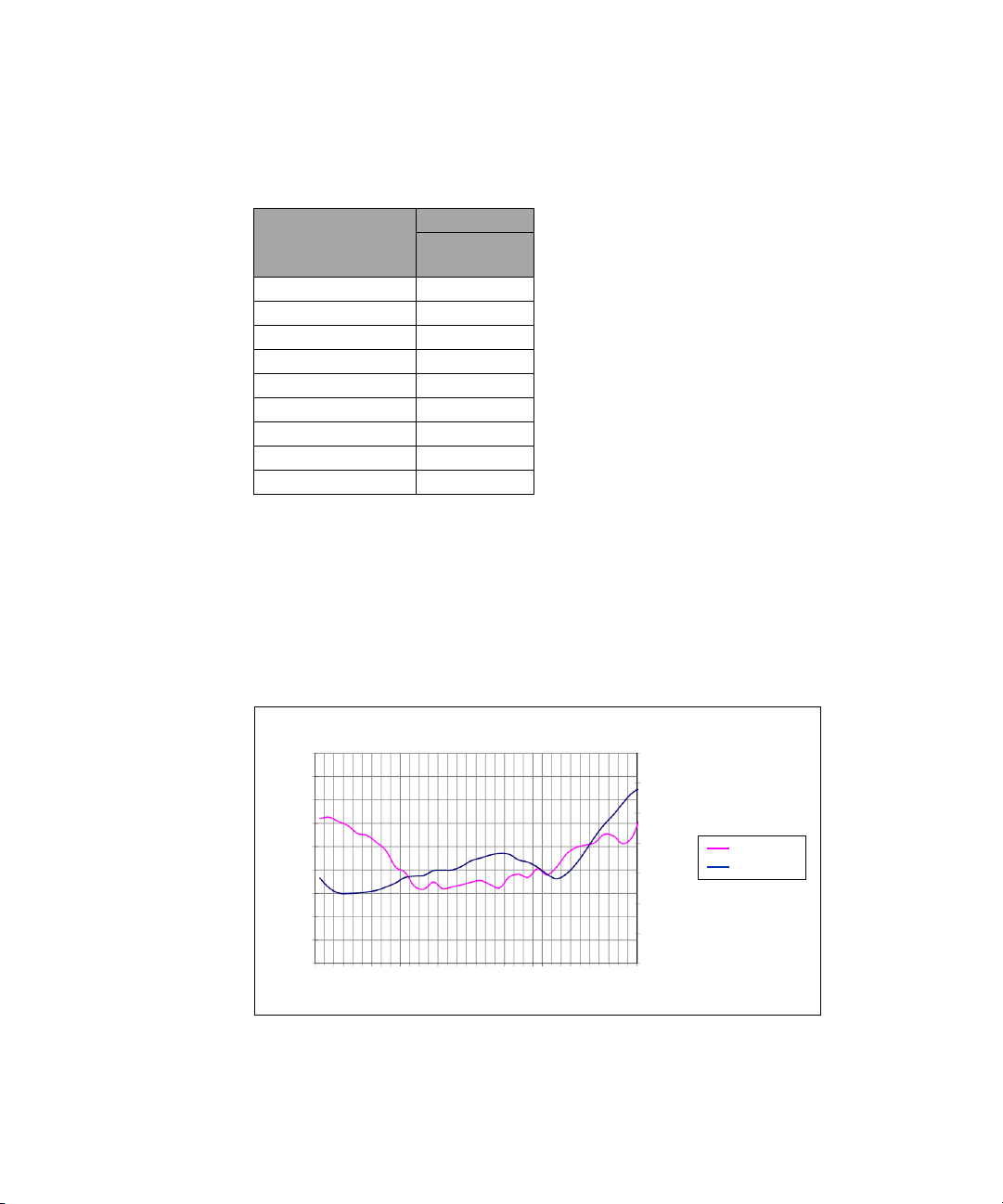

Supplemental Characteristics

Supplemental characteristics are intended to provide additional

information, useful in applying the power sensor by giving a typical but

not warranted performance parameters.

N8480 Series Power Sensors Operating and Service Guide 43

Figure 2-16 Typical cal factor and SWR vs. frequency

Page 60

2 Specifications and Characteristics

Width (W)

Height (H)

Length (L)

Physical Characteristics

Tab l e 2 - 11 Physical dimensions

Sensor Model Dimensions Weight

N8481A

N8482A

N8485A

38 mm W x 30 mm H x 121 mm L

N8487A 38 mm W x 30 mm H x 121 mm L

N8488A

N8486AR 38 mm W x 62 mm H x 152 mm L

N8486AQ 38 mm W x 62 mm H x 152 mm L

N8481B

N8482B

N8481H

N8482H

38 mm W x 30 mm H x 130 mm L

(1.5 in X 1.2 in X 5.1 in)

(1.5 in X 1.2 in X 4.75 in)

(1.5 in X 1.2 in X 4.75 in)

38 mm W x 30 mm H x 115 mm L

(1.5 in X 1.2 in X 4.5 in)

(1.5 in X 2.4 in X 6.0 in)

(1.5 in X 2.4 in X 6.0 in)

83 mm W x 114 mm H x 283 mm L

(3.2 in X 4.5 in X 11.1 in)

38 mm W x 30 mm H x 174 mm L

(1.5 in X 1.2 in X 6.8 in)

Net: 0.181 kg (0.40 lb)

Shipping: 0.90 kg (1.98 lb)

Net: 0.183 kg (0.40 lb)

Shipping: 0.90 kg (1.98 lb)

Net: 0.154 kg (0.34 lb)

Shipping: 0.874 kg (1.92 lb)

Net: 0.162 kg (0.36 lb)

Shipping: 0.881 kg (1.94 lb)

Net: 0.202 kg (0.45 lb)

Shipping: 0.922 kg (2.03 lb)

Net: 0.204 kg (0.45 lb)

Shipping: 0.924 kg (2.03 lb)

Net: 0.684 kg (1.51 lb)

Shipping: 1.404 kg (3.09 lb)

Net: 0.234 kg (0.52 lb)

Shipping: 0.954 kg (2.10 lb)

44 N8480 Series Power Sensors Operating and Service Guide

Page 61

N8480 Series Power Sensors

Operating and Service Guide

3 Service

Cleaning 46

Connector Care 46

Principle of Operations 47

Performance Test 48

Replaceable Parts 51

Troubleshooting 57

Repair 57

Diassembly/Reassembly Procedures 58

Diassembly Procedure 58

Reassembly Procedure 58

This chapter contains information about principle of operations, troubleshooting, and repair

of the Agilent N8480 Series power sensors.

Agilent Technologies

45

Page 62

3Service

CAUTION

Cleaning

Use a clean, damp cloth to clean the body of the N8480 Series power

sensors.

Connector Care

A solution of pure isopropyl or ethyl alchohol can be used to clean

connectors but make sure to keep in mind on its flammable nature.

• The RF connector bead deteriorates when contacted with any chlorinated or

aromatic hydrocarbon such as acetone, thrichlorethane, carbon tetrachloride,

and benzene.

• Do not attempt to clean connectors with anything metallic such as pins or

paper clips.

46 N8480 Series Power Sensors Operating and Service Guide

Clean the connector only at a static free workstation. Electrostatic

discharge to the center pin of the connector will render the power

sensor inoperative.

Clean the connector face by first using a blast of compressed air. If the

compressed air fails to remove contaminants, use a cotton swab dipped in

isopropyl or ethyl alcohol. If the swab is too big, use a round wooden

toothpick wrapped in a lint free cloth dipped in isopropyl or ethyl alcohol.

Page 63

Principle of Operations

The A1 module assembly (refer to Figure 3- 1) on the Agilent N8480 Series

power sensors provides a 50 W load to the RF signal applied to the power

sensor. A thermocouple assembly in the bulkhead converts the applied RF

to produce DC voltages which vary with the RF power across the

50 W load.

The low- level DC voltages from the bulkhead assembly are amplified

before they are transferred on standard cables to the power meter. The

amplification is provided by an input amplifier assembly which consists of

a chopper (sampling gate) and an input amplifier. The chopper circuit

converts the DC voltages to AC voltages. The chopper is controlled by a

440 Hz square wave generated by the power meter. The amplitude of the

sampling gate output is a 440 Hz square wave which varies with the RF

power input. The 440 Hz AC output is applied to an amplifier which

provides the input to the power meter.

The Agilent EPM Series, EPM- P Series, or P- Series power meters

automatically detects the power sensor when an Agilent N8480 Series

power sensor is connected and downloads the correction data from the

sensor’s EEPROM. The auto- averaging settings are also configured

automatically for use with Agilent N8480 Series power sensors. This

configures the power meter to operate over the range with that particular

sensor’s unique correction data applied.

Service 3

N8480 Series Power Sensors Operating and Service Guide 47

Page 64

3Service

NOTE

Performance Test

Standing Wave Ratio (SWR) and Reflection Coefficient (Rho) Performance Test

This section does not establish preset SWR test procedures since there are

several test methods and different equipment available for testing the SWR

or reflection coefficient. Therefore, the actual accuracy of the test

equipment must be accounted for when measuring against instrument

specifications to determine a pass or fail condition. The test system used

must not exceed the system Rho uncertainties shown in Table 3- 1 when

testing the N8480 Series power sensors.

To check the calibration factor, the power sensor should be compared with

another recently calibrated power sensor. The source should be leveled

with a reference coupler that has low SWR and high directivity to monitor

or level the incident power.

For calibration factor and error analysis, refer to Agilent Application Note

AN1449- 1 to AN1449- 4 (Part 1 to Part 4), “Fundamentals of RF and

Microwave Power Measurement”.

Waveguide power sensors only (N8486AR and N8486AQ)

• While the flange of the N8486AR is similar to the one described in MIL F-3922/54C-003,

the N8486AQ is modified to mate with the greater precision of MIL-3922/67B-006

flanges. The true position of the holes relative to each other are held to a diameter

tolerance of 0.0254 mm (0.001 in). The holes are held to 1.664 mm (0.0655 in) minimum

diameter while the pins are held to 1.61 mm (0.0634 in) maximum diameter.

48 N8480 Series Power Sensors Operating and Service Guide

Page 65

Service 3

Tab l e 3 - 1 Reflection coefficient for N8480 Series power sensors (25 ºC ± 10 ºC)

Sensor Model Frequency

10 MHz to 30 MHz ±0.007 0.157

30 MHz to 50 MHz ±0.005 0.067

N8481A

N8482A

N8485A

N8487A

50 MHz to 2 GHz ±0.005 0.040

2 GHz to 12.4 GHz ±0.012 0.073

12.4 GHz to 18 GHz ±0.013 0.105

100 kHz to 300 kHz ±0.007 0.212

300 kHz to 1 MHz ±0.005 0.077

1 MHz to 2 GHz ±0.008 0.030

2 GHz to 6 GHz ±0.009 0.035

10 MHz to 50 MHz ±0.011 0.143

50 MHz to 100 MHz ±0.006 0.038

100 MHz to 2 GHz ±0.005 0.025

2 GHz to 12.4 GHz ±0.009 0.064

12.4 GHz to 18 GHz ±0.011 0.085

18 GHz to 26.5 GHz ±0.014 0.114

26.5 GHz to 33 GHz ±0.020 0.139

50 MHz to 100 MHz ±0.013 0.038

100 MHz to 2 GHz ±0.011 0.026

2 GHz to 12.4 GHz ±0.011 0.049

12.4 GHz to 18 GHz ±0.014 0.072

18 GHz to 26.5 GHz ±0.022 0.099

26.5 GHz to 40 GHz ±0.039 0.130

40 GHz to 50 GHz ±0.055 0.144

System Rho

Uncertainty

Actual

Measurement

Maximum

Rho

N8480 Series Power Sensors Operating and Service Guide 49

Page 66

3Service

Tab l e 3 - 1 Reflection coefficient for N8480 Series power sensors (25 ºC ± 10 ºC)

Sensor Model Frequency

10 MHz to 100 MHz ±0.005 0.016

100 MHz to 2.4 GHz ±0.004 0.018

2.4 GHz to 12.4 GHz ±0.004 0.043

N8488A

N8486AR 26.5 GHz to 40 GHz ±0.021 0.168

N8486AQ 33 GHz to 50 GHz ±0.054 0.200

N8481B

N8482B

N8481H

12.4 GHz to 18 GHz ±0.005 0.056

18 GHz to 26.5 GHz ±0.007 0.099

26.5 GHz to 40 GHz ±0.011 0.133

40 GHz to 67 GHz ±0.022 0.190

67 GHz to 70 GHz ±0.026 0.200

10 MHz to 2 GHz ±0.007 0.042

2 GHz to 12.4 GHz ±0.018 0.066

12.4 GHz to 18 GHz ±0.023 0.102

100 kHz to 2 GHz ±0.011 0.041

2 GHz to 6 GHz ±0.013 0.074

10 MHz to 8 GHz ±0.015 0.075

8 GHz to 12.4 GHz ±0.021 0.099

12.4 GHz to 18 GHz ±0.046 0.140

System Rho

Uncertainty

Actual

Measurement

Maximum

Rho

N8482H 100 kHz to 6 GHz ±0.012 0.063

50 N8480 Series Power Sensors Operating and Service Guide

Page 67

Replaceable Parts

NOTE

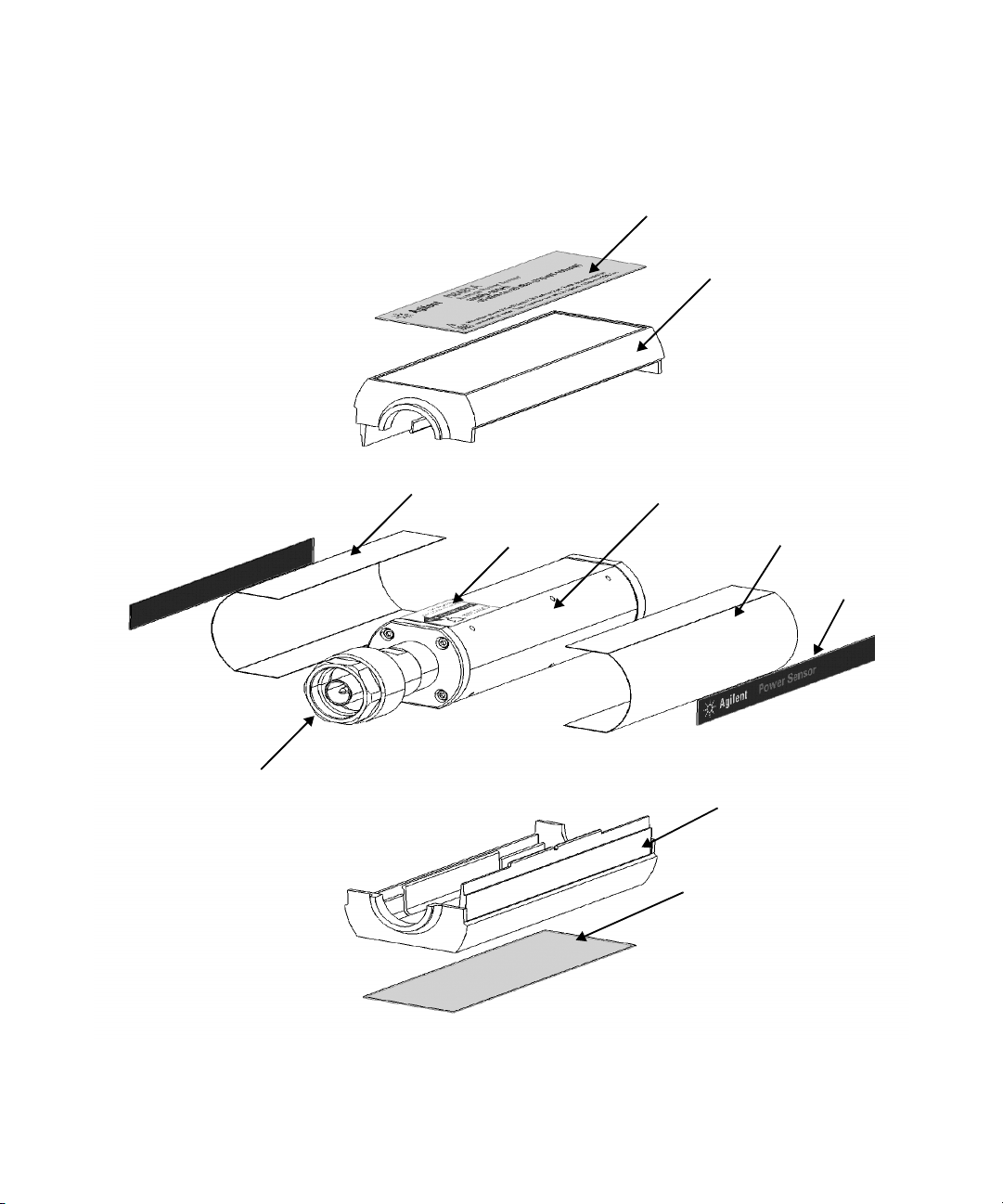

Figure 3- 1 illustrates the parts breakdown of the N8480 Series power

sensors that identifies all the replaceable parts. If you want to order a

part, quote the Agilent part number, specify the quantity required, and

address the order to the nearest Agilent office.

If you are located within United States, you are adviced to order directly from the Agilent

Parts Center in Roseville, California.

Ask your nearest Agilent office for ordering information and forms for the “Direct Mail

Order System”. Information such as toll free telephone number will be provided.

Service 3

N8480 Series Power Sensors Operating and Service Guide 51

Page 68

3Service

MP5

MP1

MP 4

MP2

MP6

MP4

MP1

MP3

A1

MP2

Figure 3-1 Illustrated Parts Breakdown

52 N8480 Series Power Sensors Operating and Service Guide

Page 69

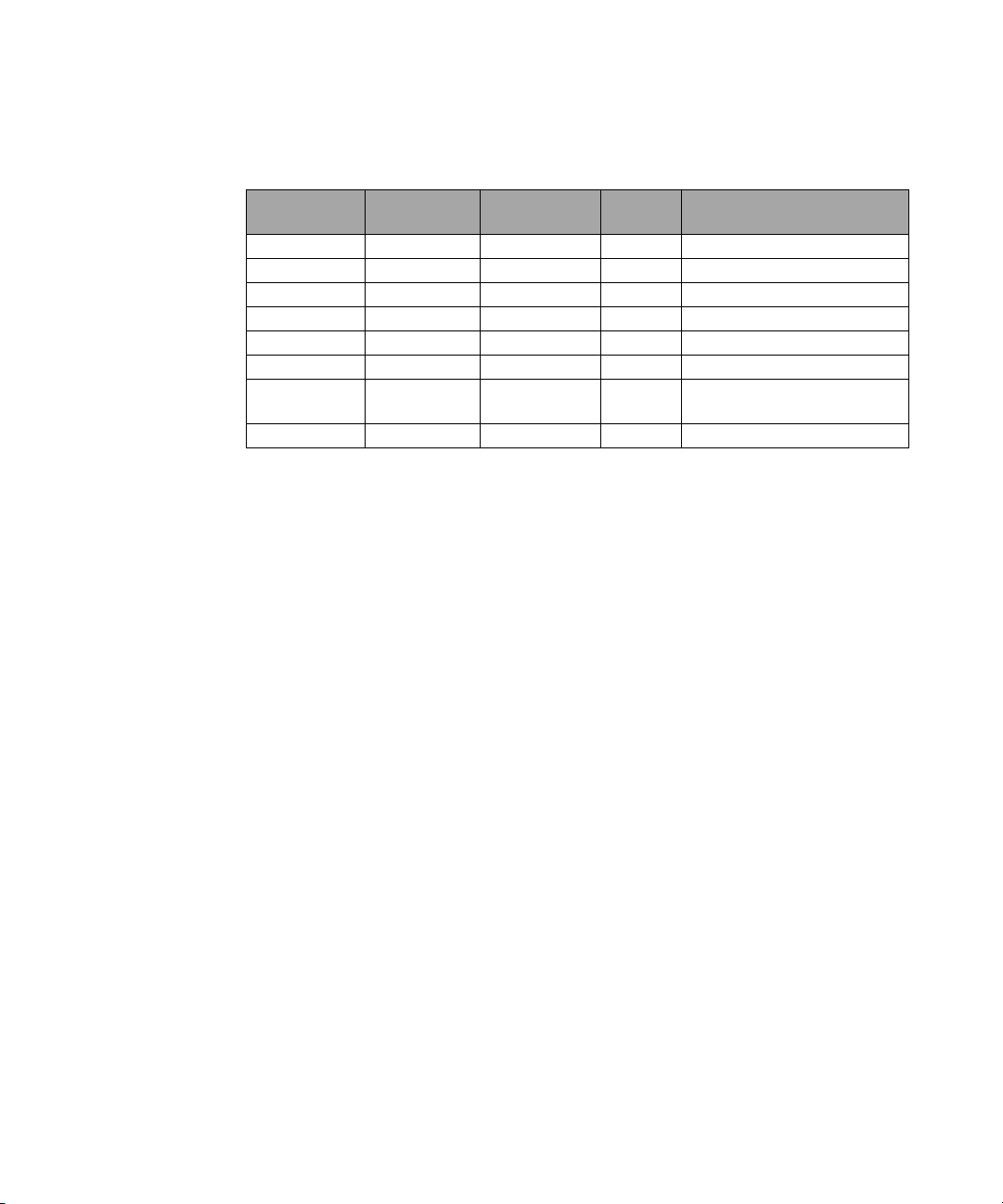

Tab l e 3 - 2 Replaceable parts list for standard N8480 Series power sensors

Service 3

Reference

Designaton

A1

N8481A

N8482A N8482A-100 N8482-60002 1

N8485A N8485A-100 N8485-60002 1

N8487A N8487A-100 N8487-60005 1

N8488A N8488A-100 N8488-60006 1

N8481B N8181B-100 N8481-60012 1

N8482B N8482B-100 N8482-60008 1

N8481H N8481H-100 N8481-60014 1

N8482H N8482H-100 N8482-60010 1

N8486AR N8486AR-100 N8486-60010 1

N8486AQ N8486AQ-100 N8486-60008 1

Option Part Number Quantity Description

N8481A-100 N8481-60007 1

N8481A-200 N8481-60008 1